Patents

Literature

438results about How to "Relieve stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

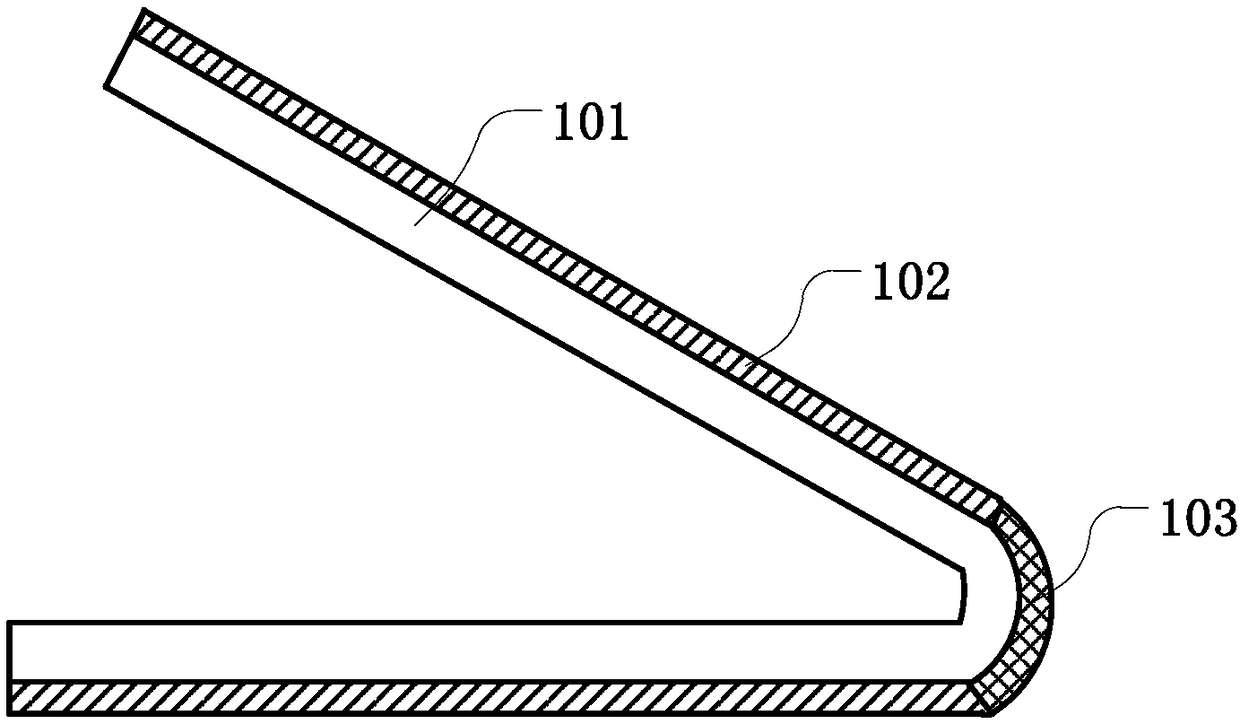

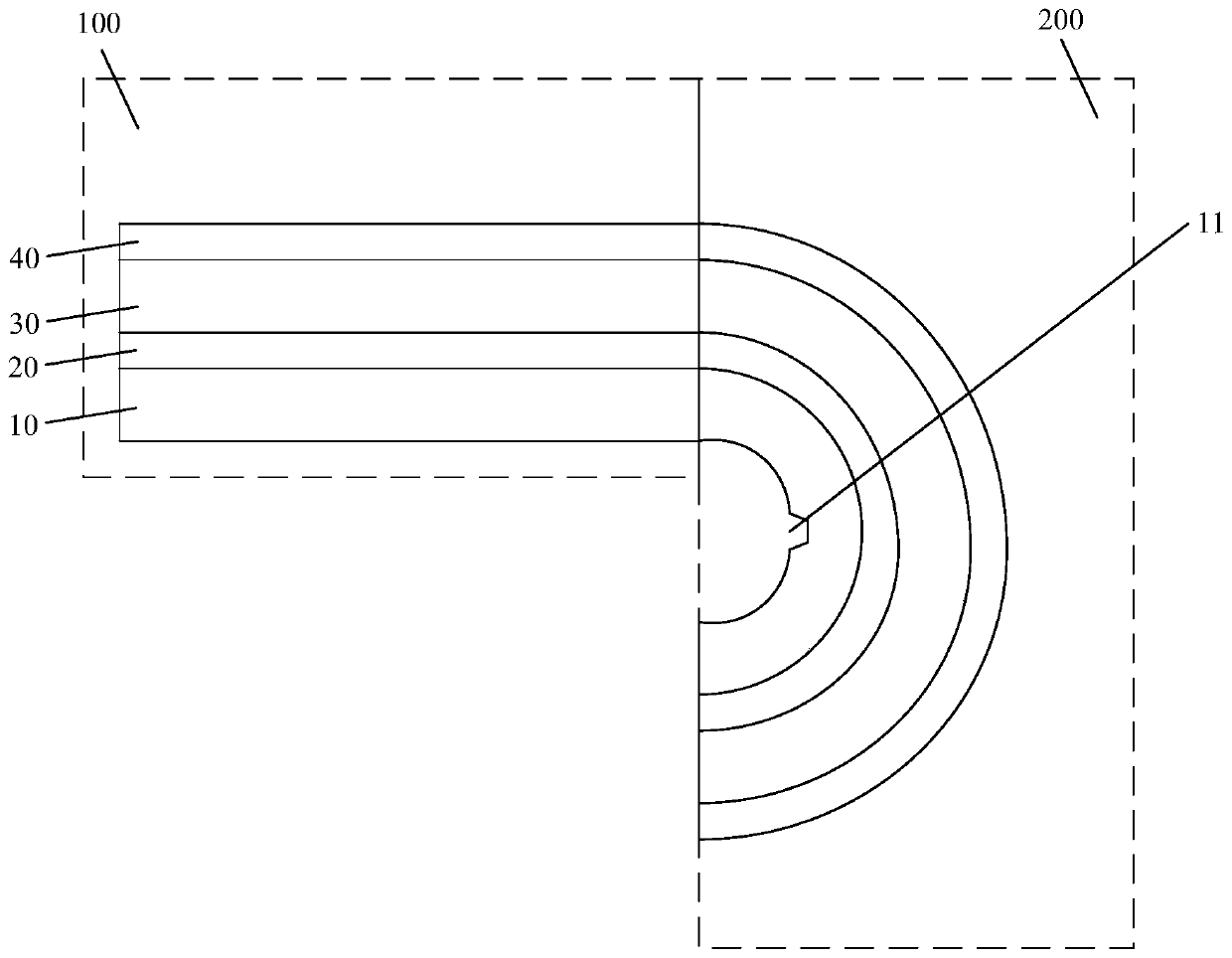

Flexible display screen and display device

The invention discloses a flexible display screen and a display device. The flexible display screen comprises a display panel, a backboard and a bent area, wherein the backboard attaches to the back side of the display panel; the backboard at least is of a hollow structure at the bent area. For the flexible display screen and the display device provided by the embodiment of the invention, the stress generated by the backboard of the flexible display screen during bending can be effectively alleviated, thus the breakage of the backboard can be avoided, and the property of the flexible display screen is further optimized.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Flexible display screen

InactiveCN108155218AImprove reliabilityReduce bending stressSolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationEngineering

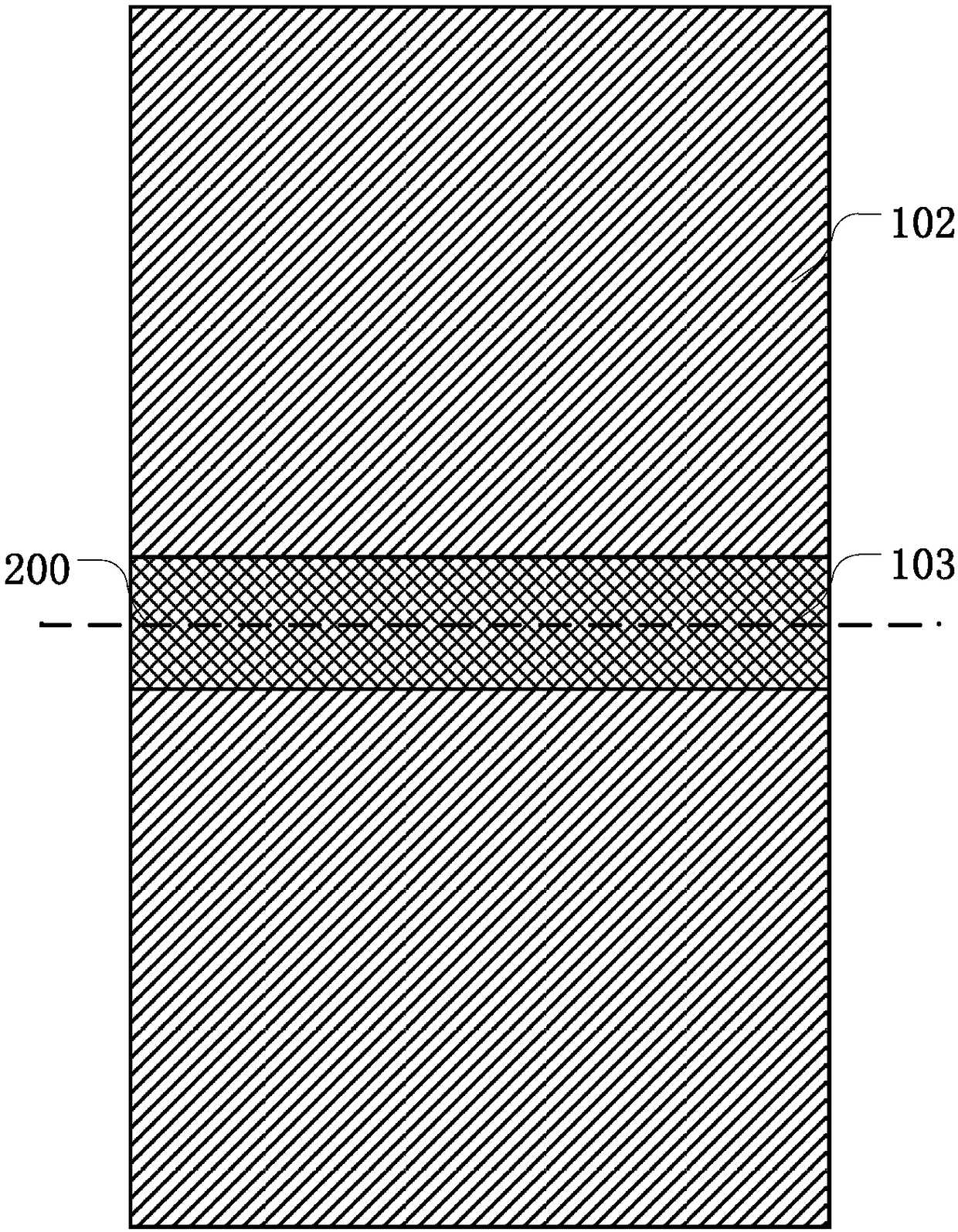

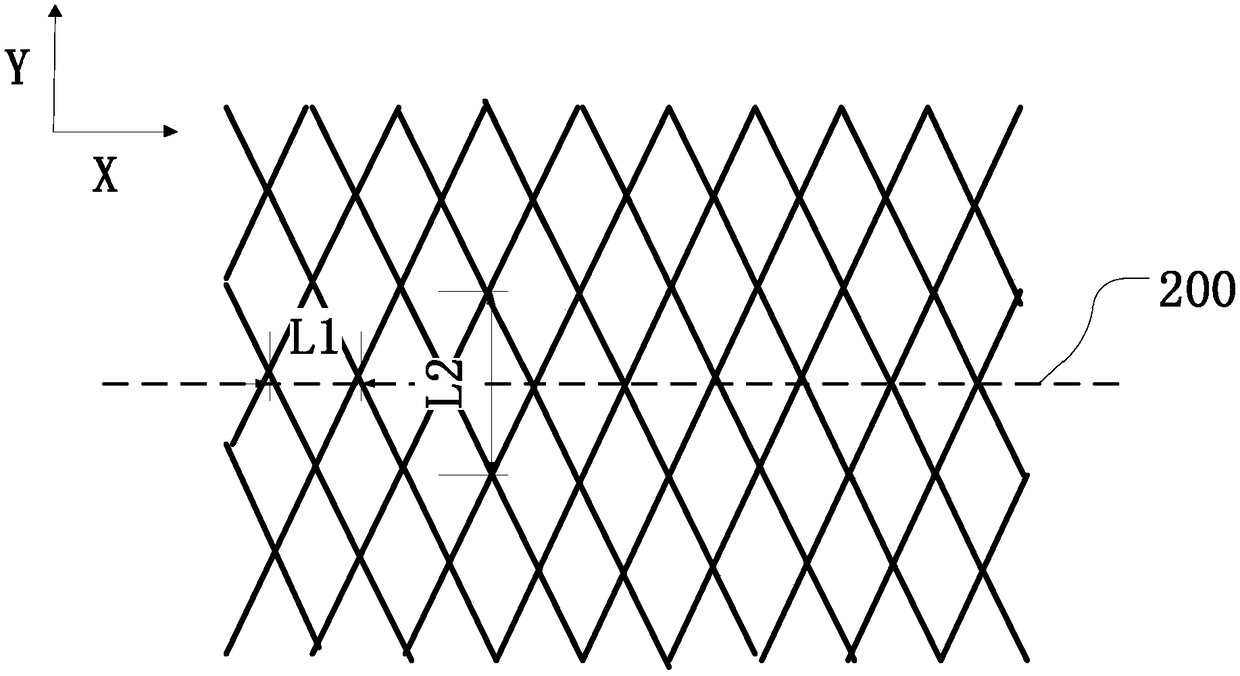

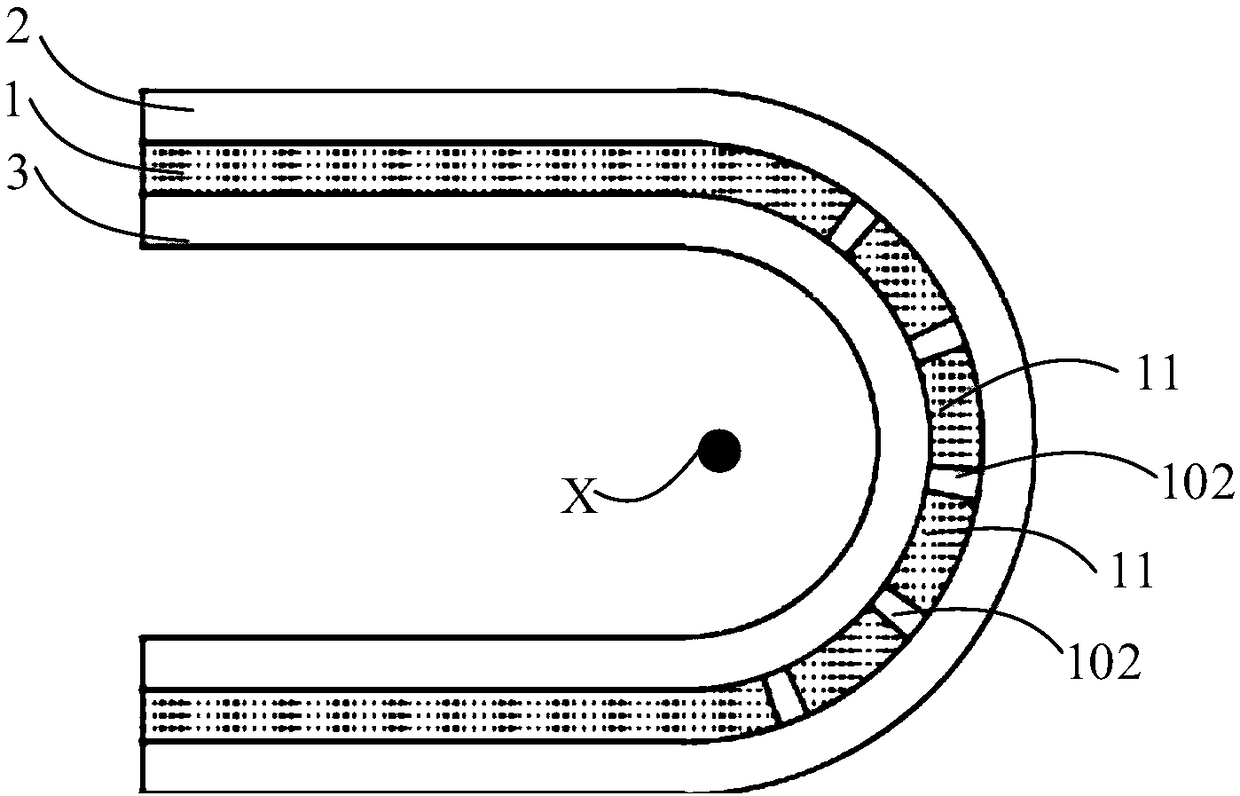

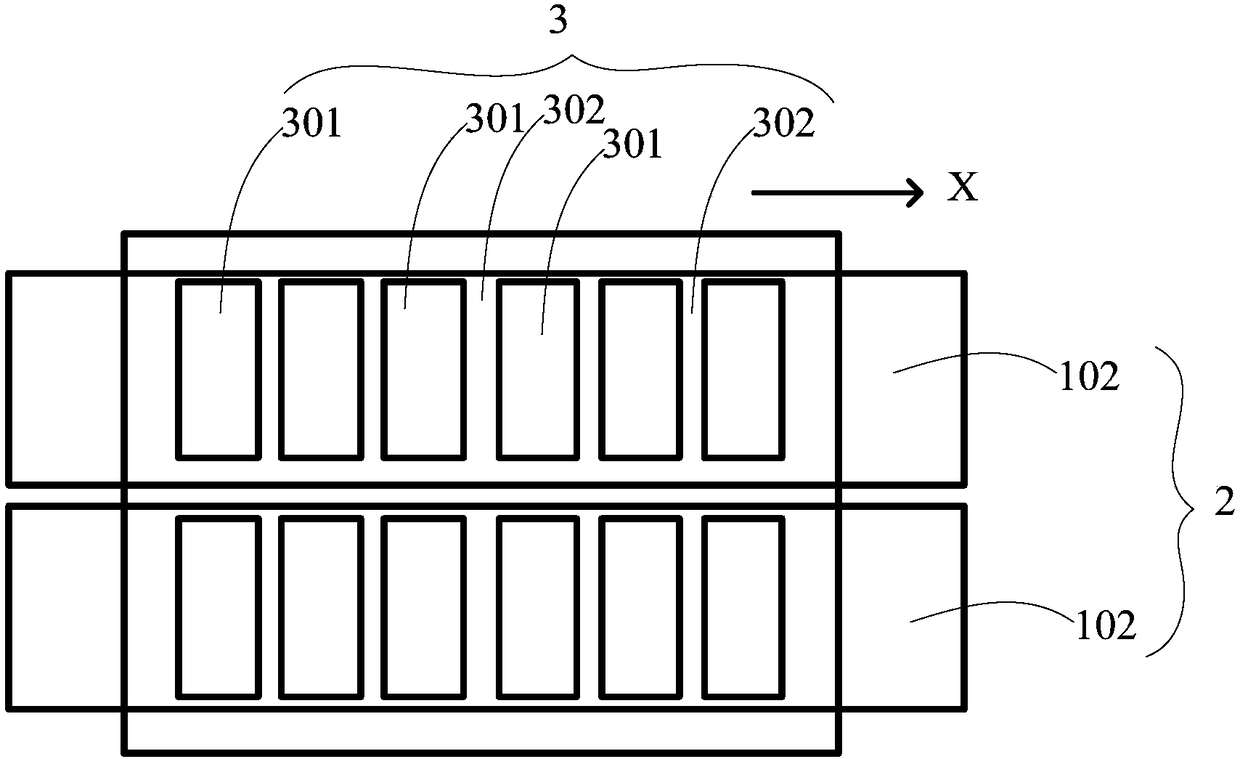

The embodiment of the invention provides a flexible display screen. The screen comprises multiple functional film layers which are sequentially overlapped, wherein at least one functional film layer of the functional film layers comprises multiple sections of module material, clearances or grooves are formed in the positions between two adjacent sections of the module material, and elastic materials fill the clearances or the grooves. The contact area between the functional layer where the module material is located and the adjacent functional layer can be reduced by the grooves or the clearances, so that when the flexible display screen is bent, bending stress on the adjacent functional layer generated by the functional layer where the module material is located is reduced, and thereforeseparation or fracture between the adjacent functional layers is prevented. Moreover, the elastic materials fill the clearances or the grooves, concentration of the stress of the functional layers where the clearances or the grooves are located can be relieved when the flexible display screen is bent, and the bending stress is released to improve reliable performance of the flexible display screen.

Owner:YUNGU GUAN TECH CO LTD

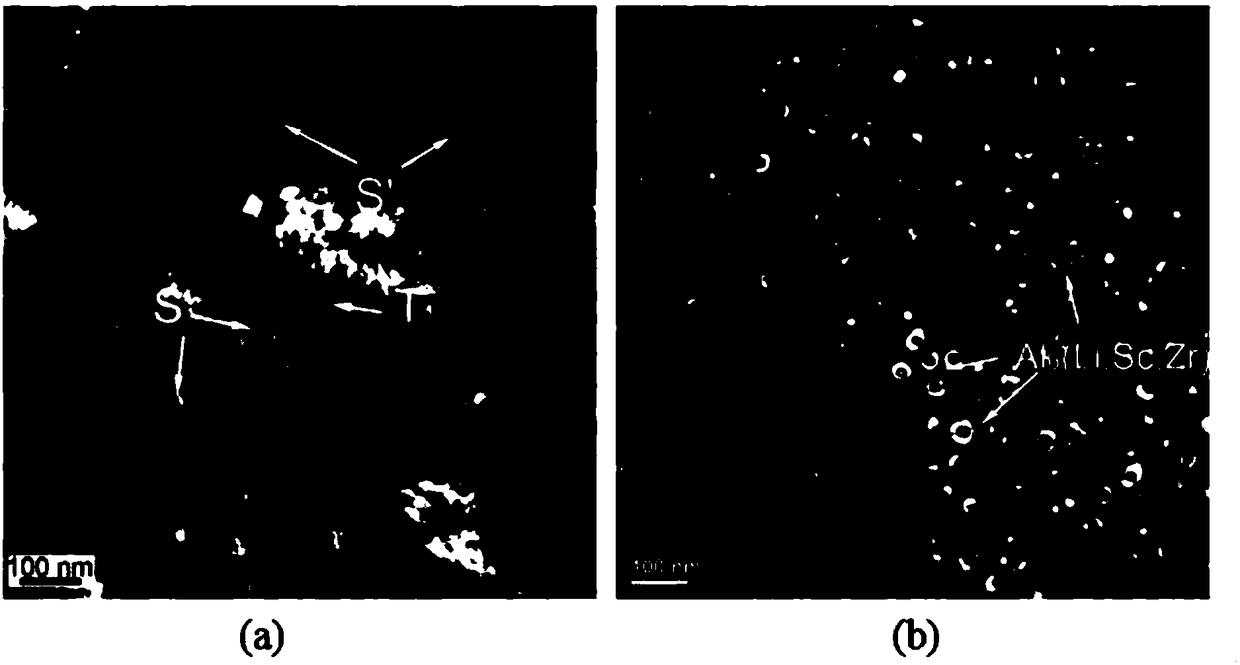

Authigenic quasicrystal reinforced high plastic deformation magnesium alloy

The high molding distortion magnesium alloy with the autogeny allowing the crystal wnganced belongs to the metal technical domain. The invention team and the weight percent: 2-10% Zn, 0.5-6%Gd, 0-1.0%Zr, the impurity element Fe is below 0.005%, the rest is Mg. the invention alloy contains the allowing crystal phase, it is formed into the casting group as the formation of the branch crystal, the allowing crystal phase crushed to distribute along the distorting direction through the extrusion or the rolling hot distorting technology, at the same time, the dispersion distributing twice allowing crystal phase is separated out on the inner group body and the edge of the crystal during the extrusion and the rolling to improve the capability of the alloy. The allowing crystal and the group body has the good interface connecting function, it can harmonize distortion and delay the stress concentrate. So the mold distortional capability of the magnesium alloy can be improved highly. It can be used to produce the magnesium alloy distortional material with the higher distortional capability to resisting the extrusion, the rolling and the pressing. The alloy has the upper model ability and matched with the middling intensity; the resisting intension under the room temperature: 260MPa-320MPa; the extending percent: 20%-26%.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

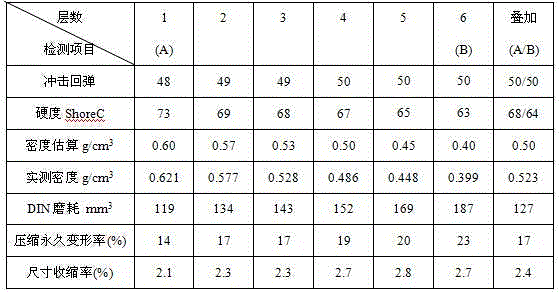

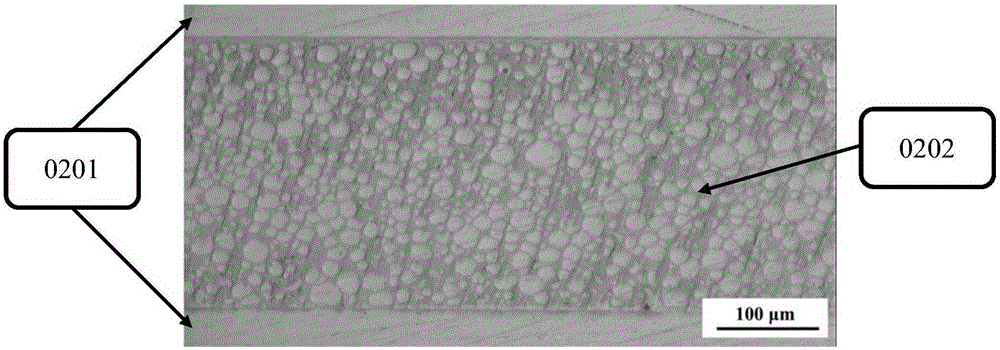

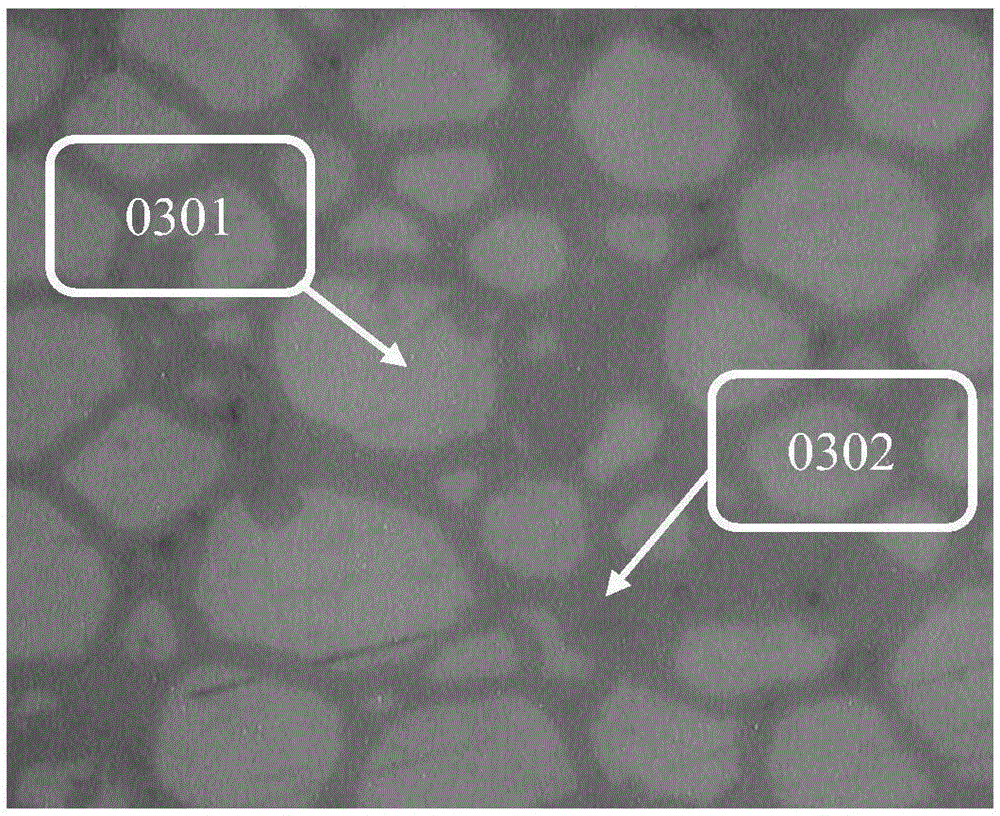

Lightweight wear-resistant density-gradient foamed sole material and preparation method thereof

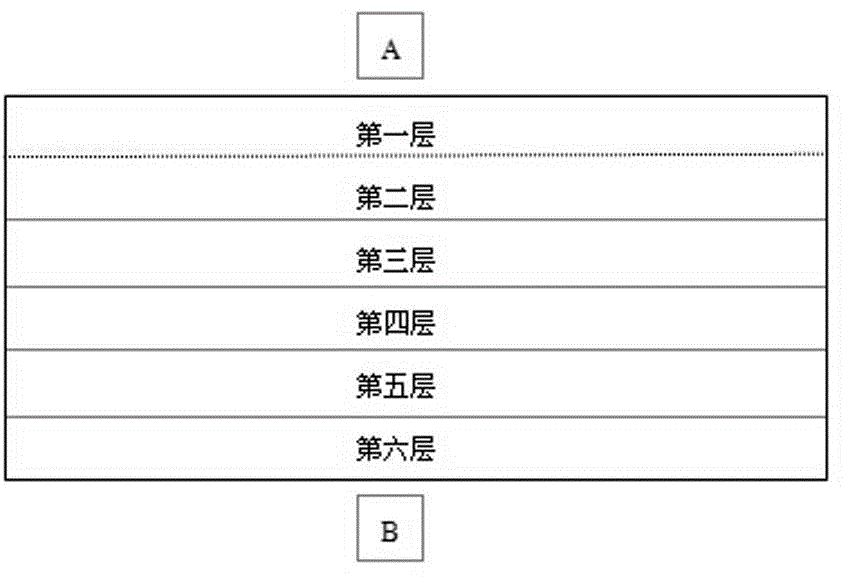

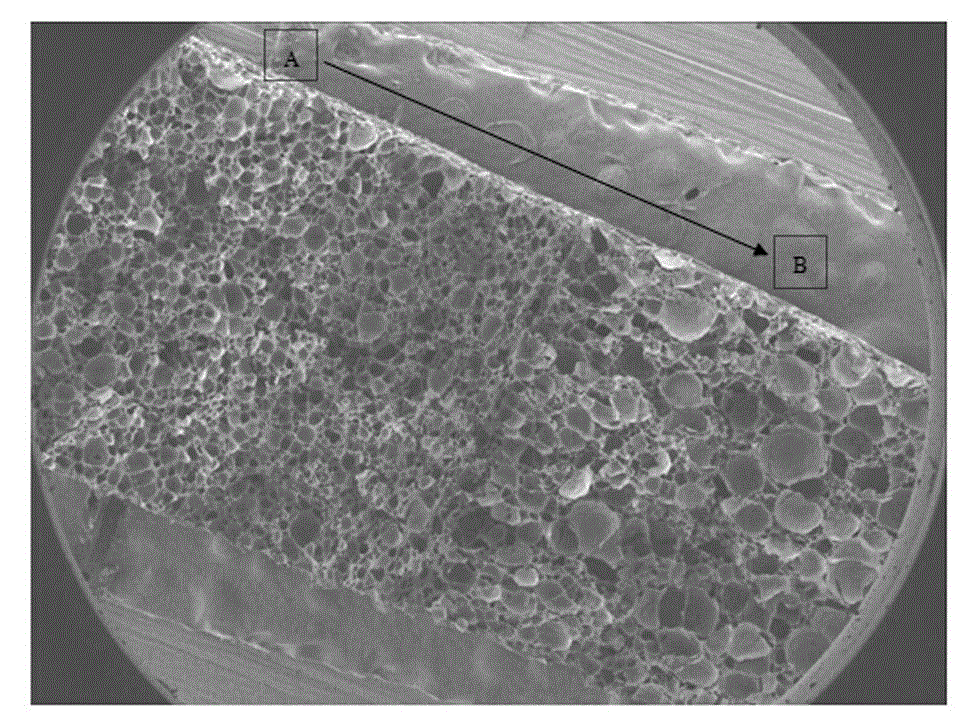

The invention relates to a lightweight wear-resistant density-gradient foamed sole material and a preparation method thereof. The lightweight wear-resistant density-gradient foamed sole material is mainly composed of EPDM, ethylene-octene copolymer, low density polyethylene, a cross-linking agent, a filling material, a foaming agent and a foaming promoter. On the basis of foaming of EPDM, POE and LDPE and through control of a foaming ratio and density difference values of each layer of materials, a heterogeneous expandable rubber compound composed of a plurality of layers and having quasi-continuously changing performances in the thickness direction of the materials are subjected to one-shot mould pressing, foaming and moulding so as to prepare the foamed sole material, and function gradient differences of density, hardness and wear resistance are realized. Due to gradual change of density, stress concentration is mitigated, and the prepared foamed sole material does not warp. The foamed material has low density at one side close to the vola while the foamed material has high density at one side close to the outer sole, so the foamed sole material has good wear resistance, reduces the weight of the sole and has improved wearing comfortableness.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

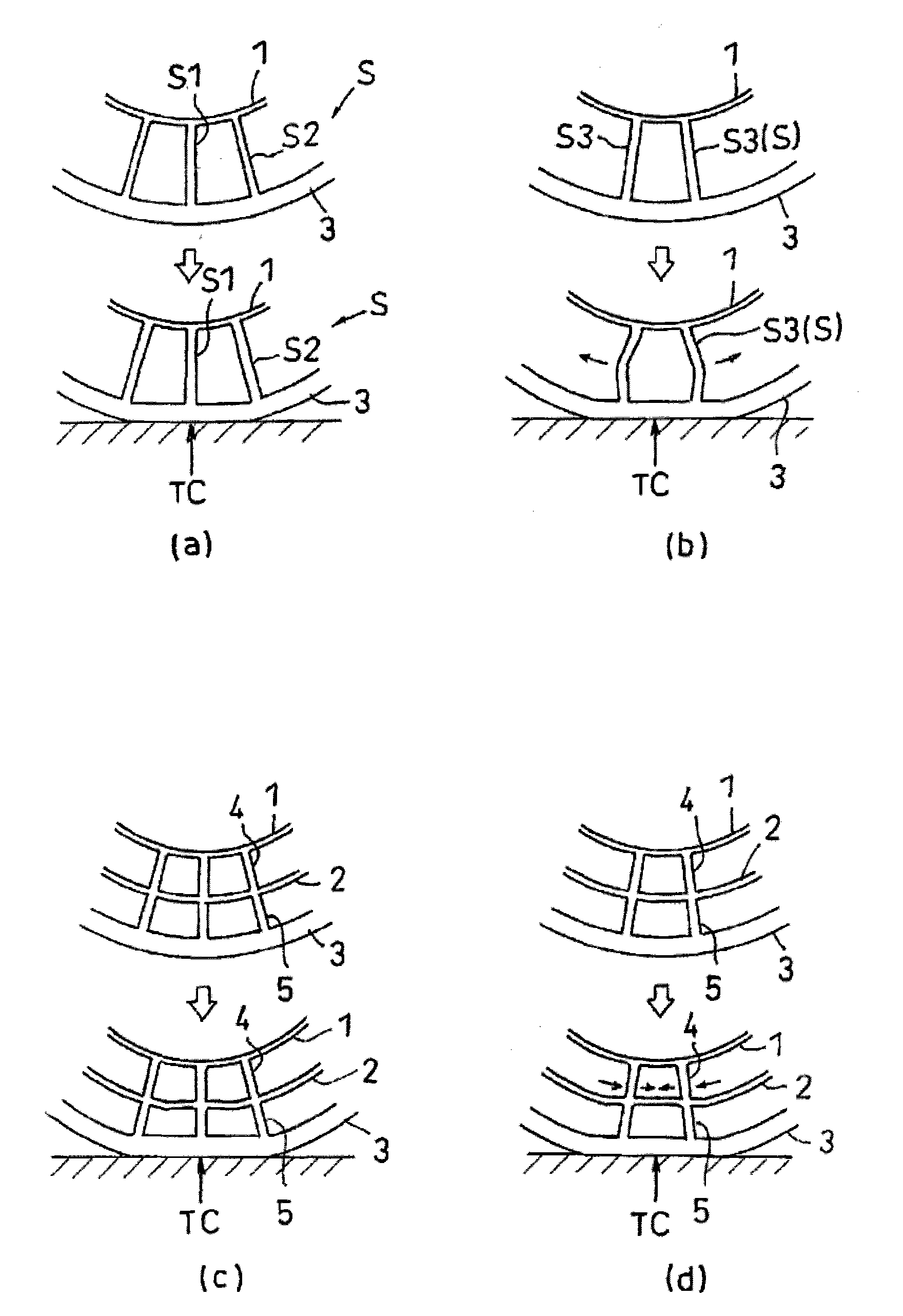

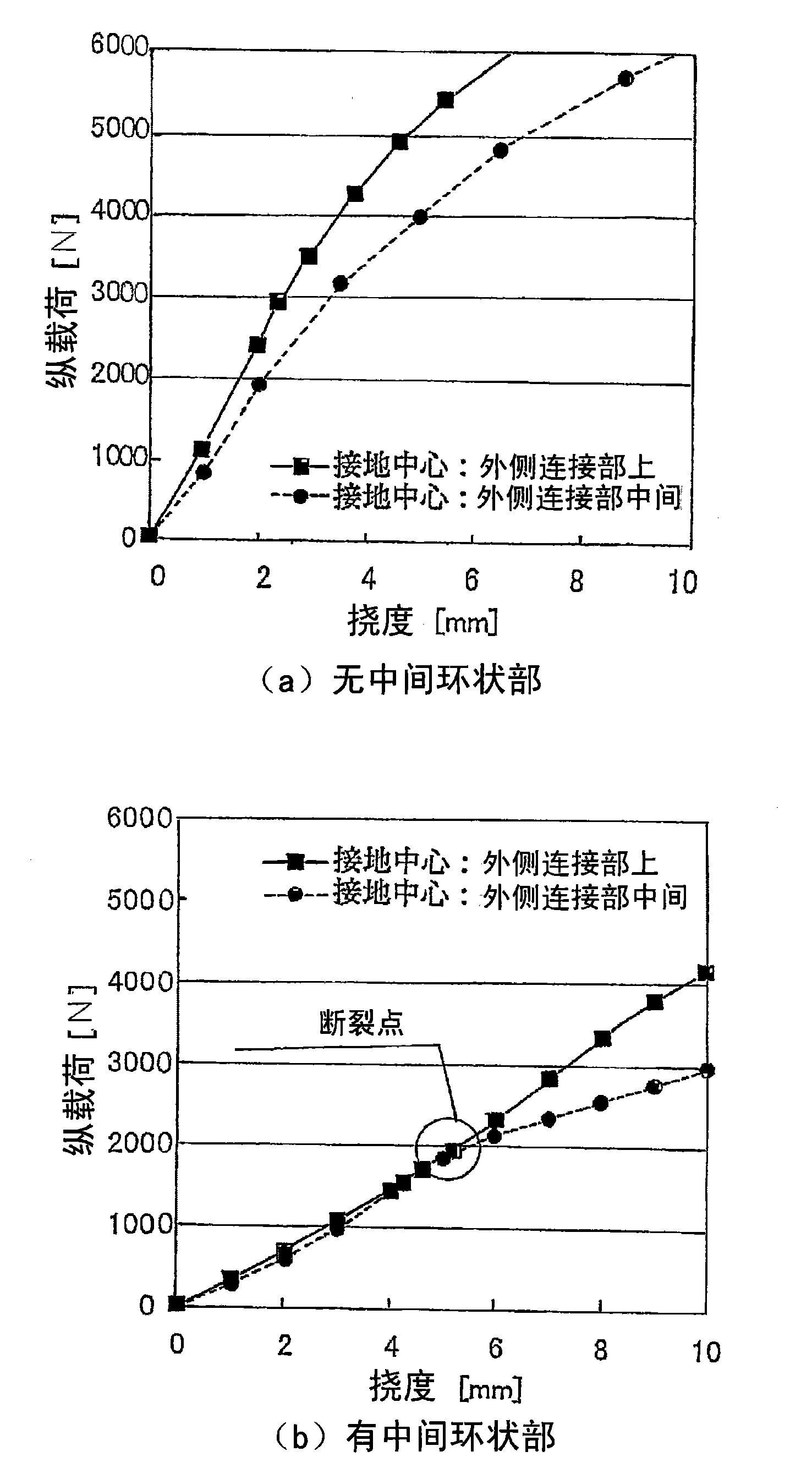

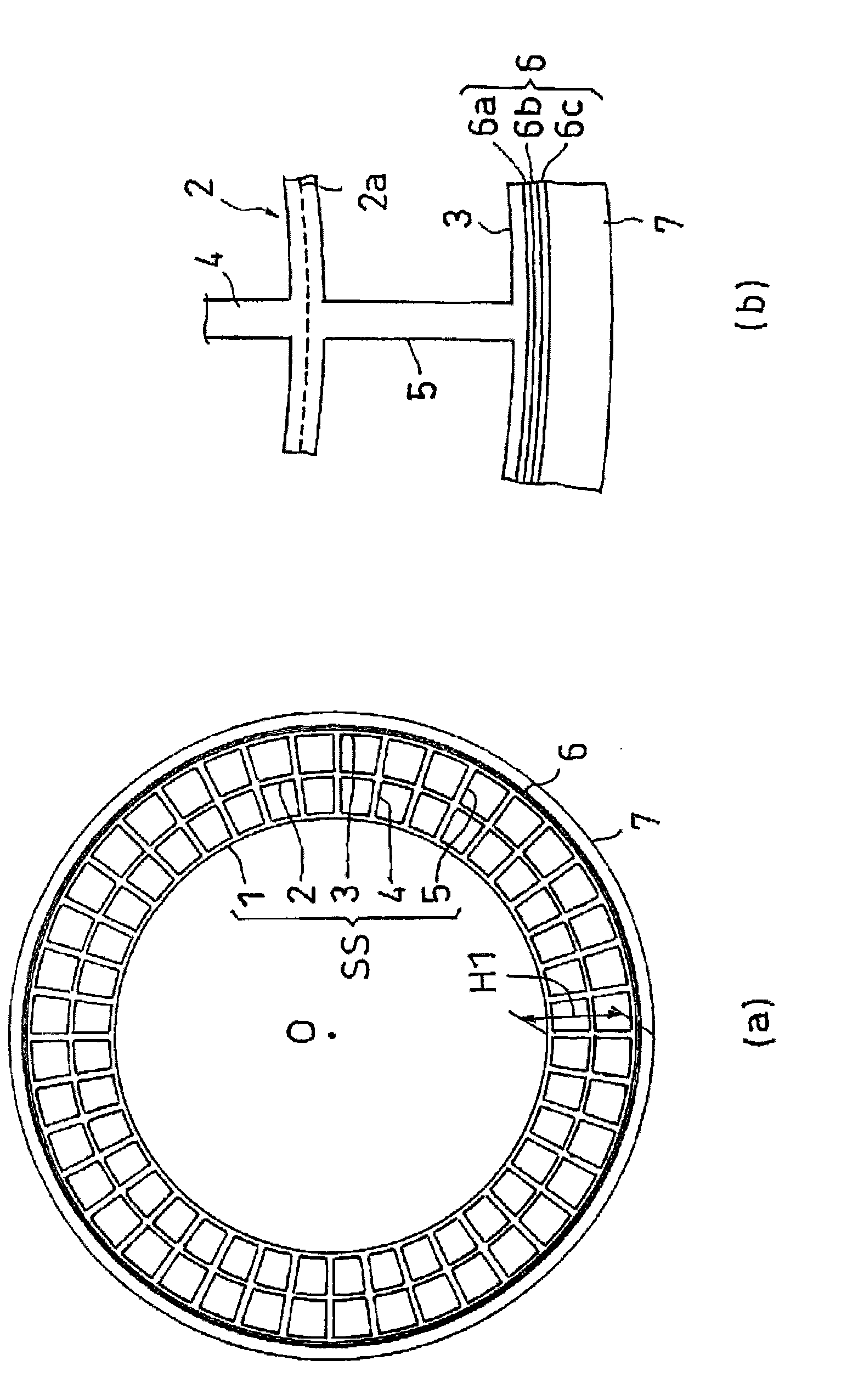

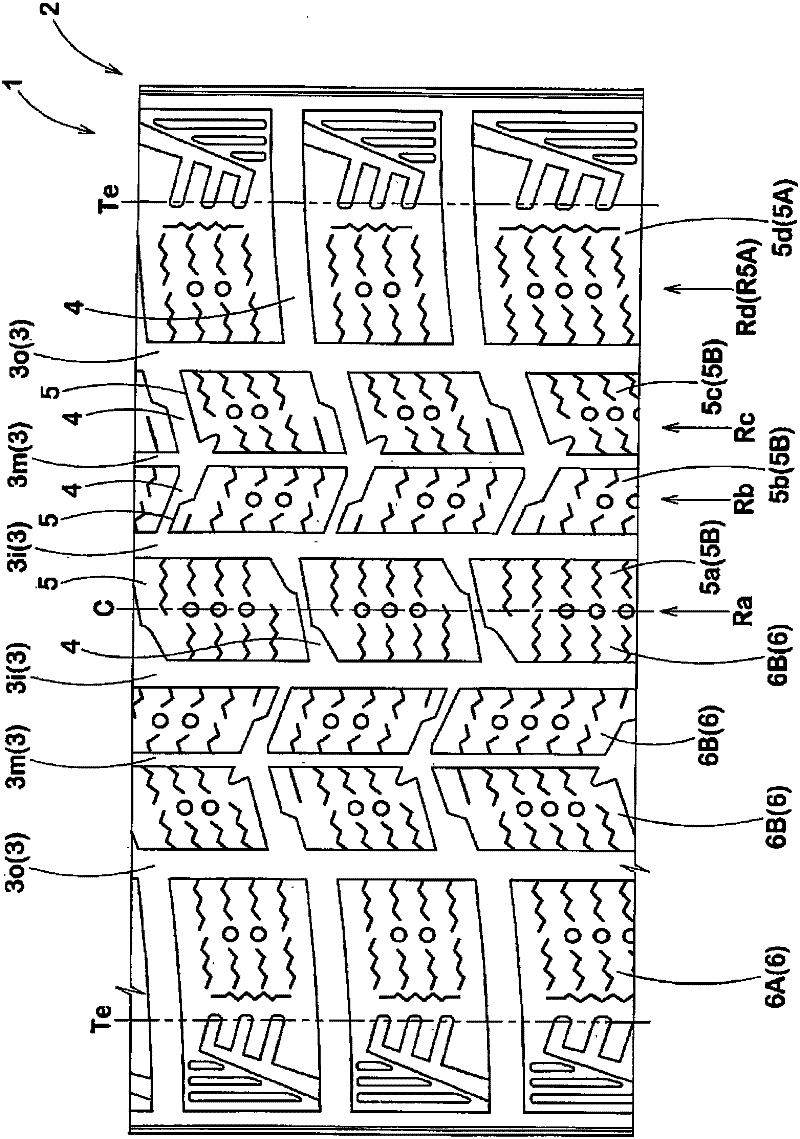

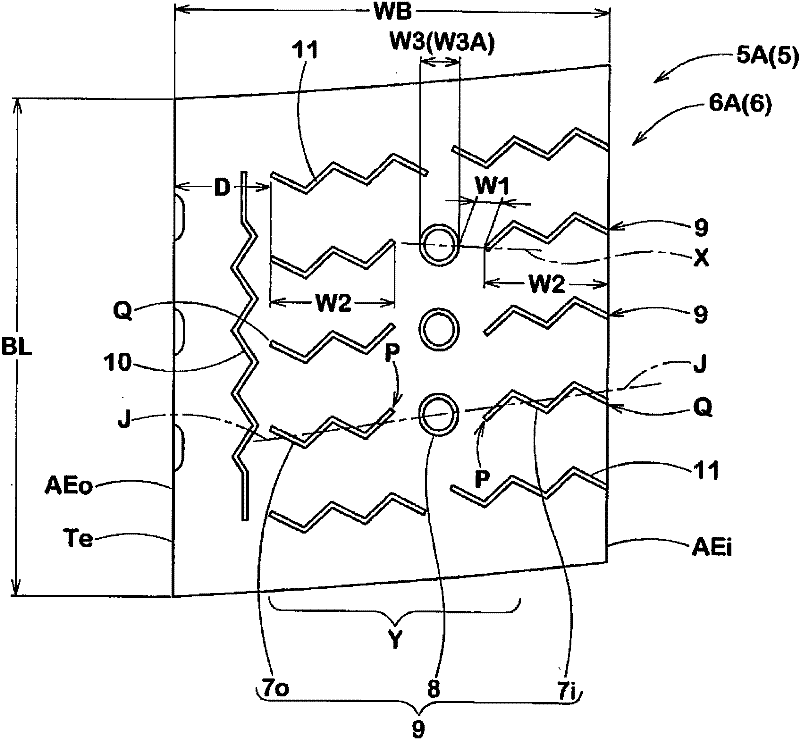

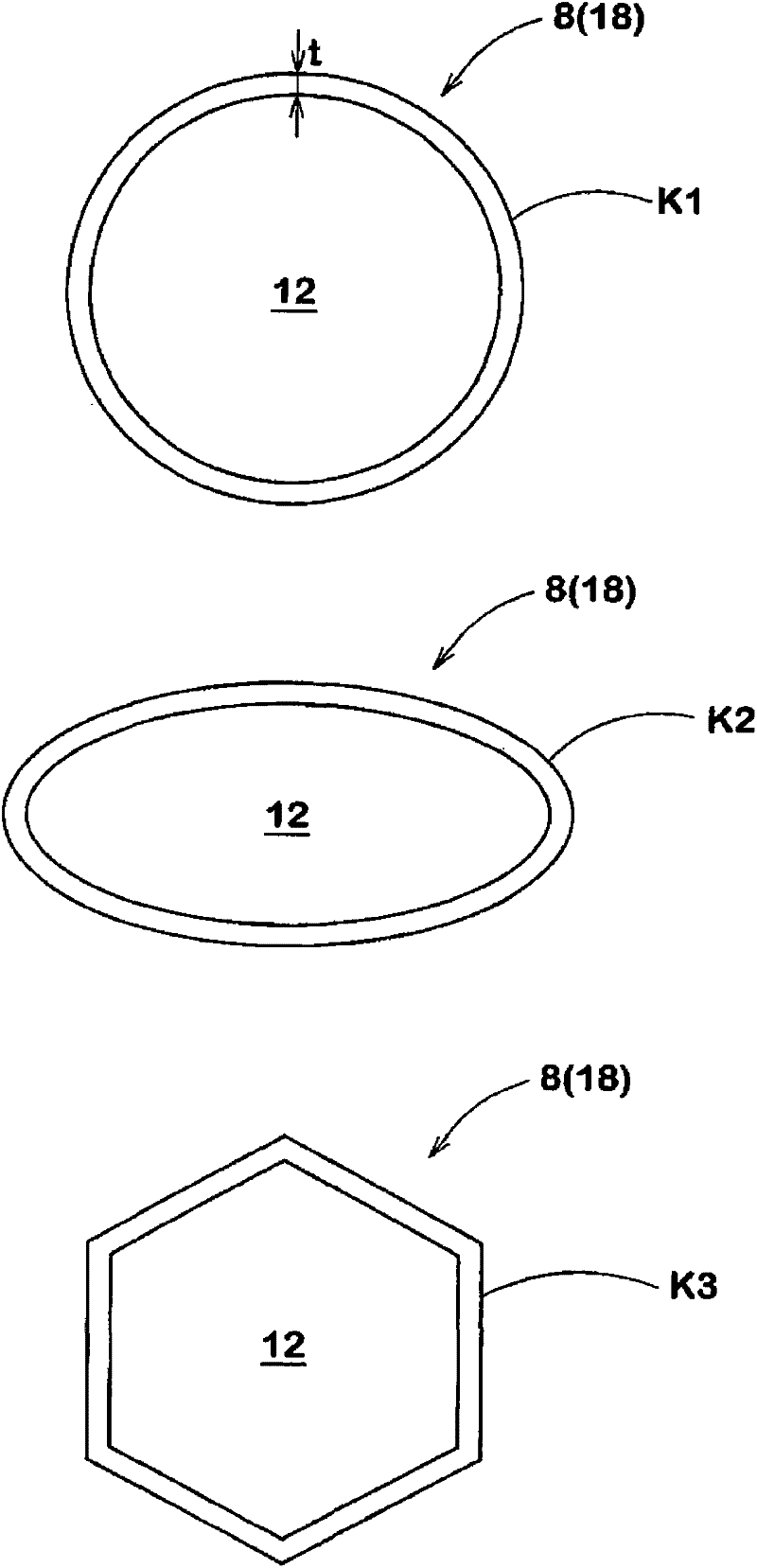

Non-pneumatic tire, and its manufacturing method

InactiveCN101668646AEnsure deflectionEasy to transformNon-inflatable tyresEngineeringMechanical engineering

Owner:TOYO TIRE & RUBBER CO LTD

CO2 gas protection welding process of 800 MPa high-strength steel

InactiveCN102179601AUniform strengthUniform hardnessArc welding apparatusWelding/cutting media/materialsThumb oppositionOperability

The invention discloses a CO2 gas protection welding process of 800 MPa high-strength steel. The CO2 protection welding process is characterized by comprising the following steps of: (1) machining a joint: machining an X-shaped groove on the joint; (2) using a solid welding wire with the diameter of 1.2 mm and the tensile strength of 800 MPa, wherein the solid welding wire comprises the following chemical components in percentage by weight: 0.04-0.10% of C, 0.30-0.80% of Si, 1.30-2.0% of Mn, 0.40-1.0% of Ni, 0.20-0.50% of Cr, 0.20-0.60% of Mo, 0.30-0.80% of Cu, 0.05-0.20% of Ti, 0.002-0.010% of B, less than and equal to 0.020% of P, less than and equal to 0.015% of S, less than and equal to 0.03% of Als, and the balance of Fe and inevitable impurities; (3) setting a welding mode: adopting CO2 gas protection welding and a DC power supply opposition method; and (4) welding: carrying out one-side welding with back formation on a first welding line, and then carrying out multilayer multipass welding, wherein interlayer temperature is less than and equal to 160 DEG C. The invention has the advantages of simple process, high operability and low welding energy consumption and welding cost and can be widely used for the technical fields of the gas protection welding of the high-strength steel.

Owner:武钢集团有限公司

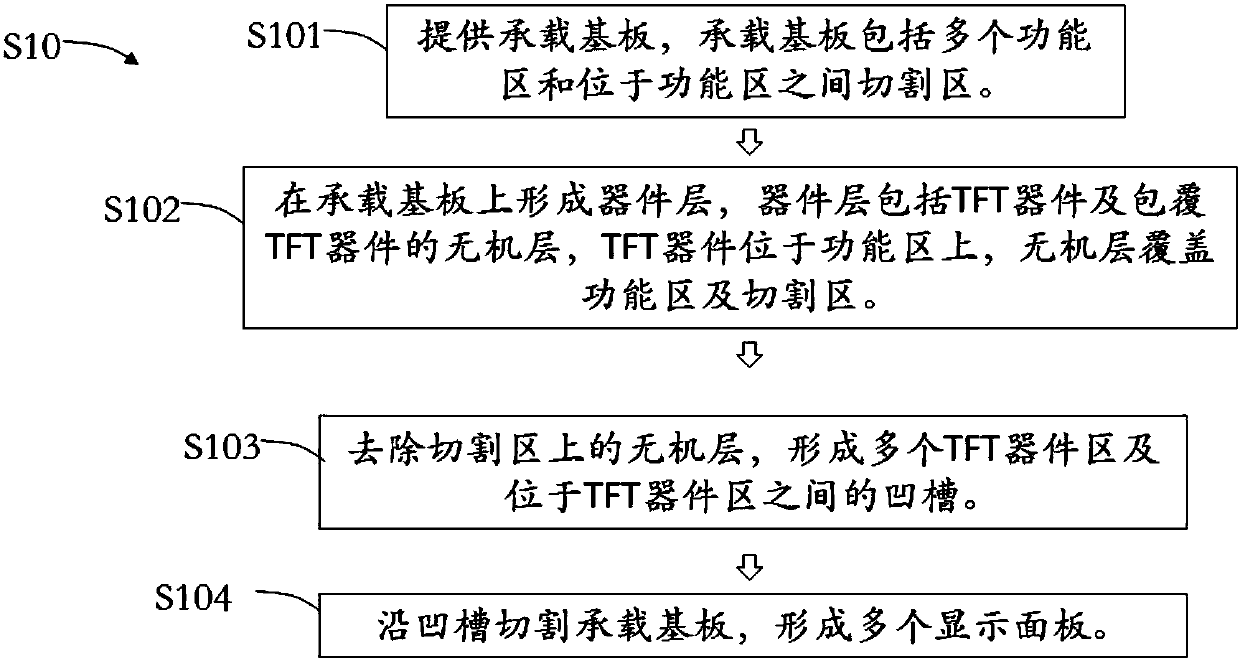

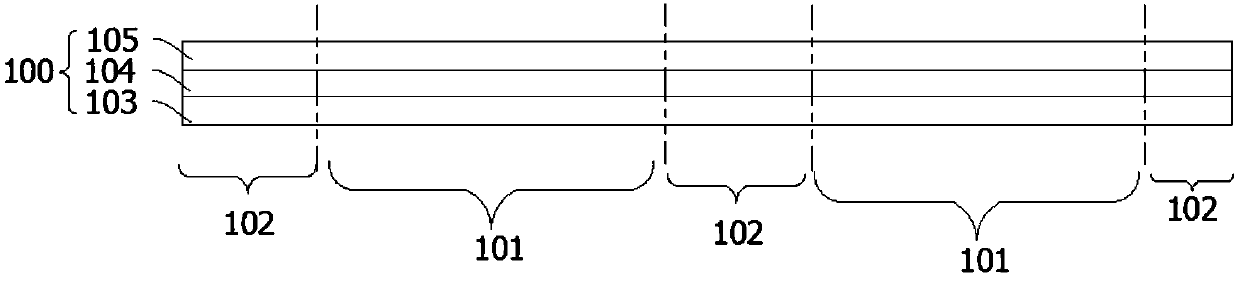

Display panel and production method thereof

InactiveCN108022878AImprove production yieldImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringInorganic layer

The invention provides a production method of a display panel. The production method comprises the following steps of providing a bearing substrate, wherein the bearing substrate comprises a pluralityof functional areas and cutting areas located between the functional areas; forming a device layer on the bearing substrate, wherein the device layer comprises a TFT device and an inorganic layer coating the TFT device; the TFT device is located on the functional areas; and the inorganic layer covers the functional areas and the cutting areas; removing the inorganic layer on the functional areasand forming a plurality of TFT device areas and grooves located between the TFT device areas; and cutting the bearing substrate along the grooves and forming a plurality of display panels. The invention further provides the display panel. The production yield of the display panel can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

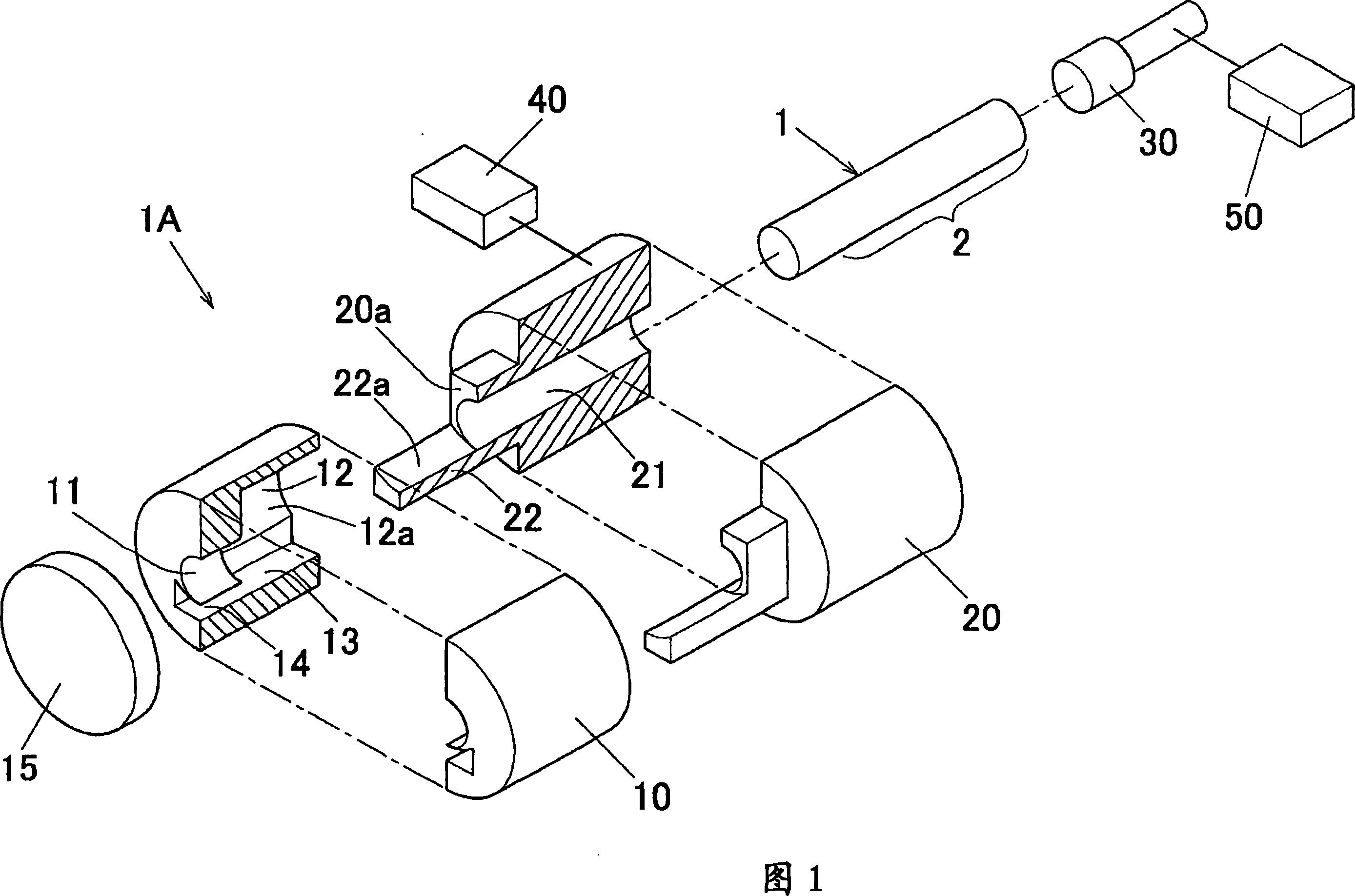

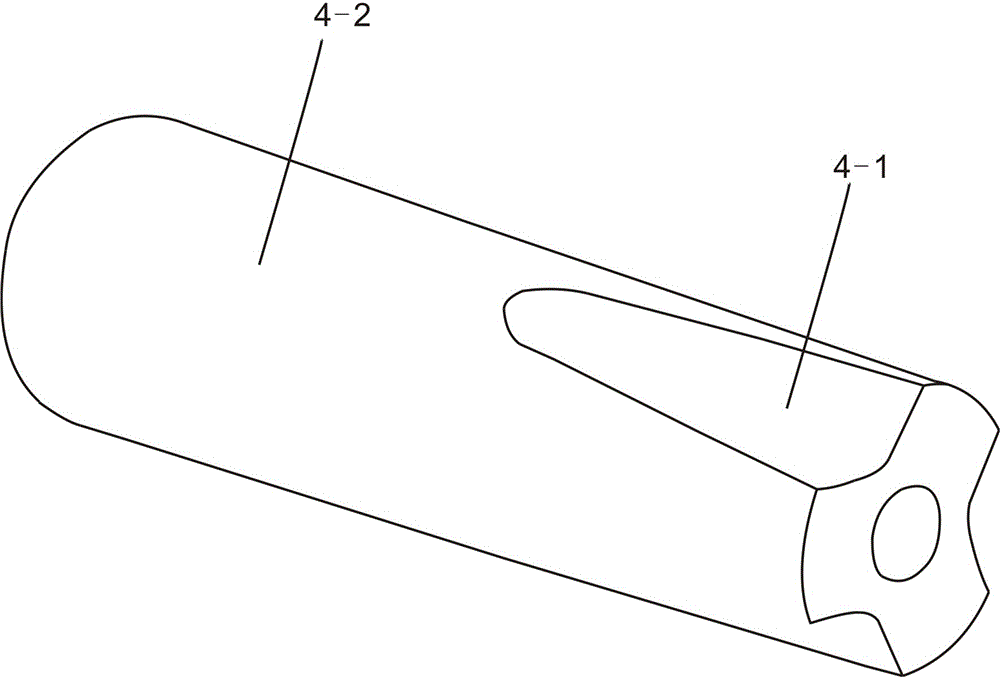

Upsetting method and upsetting apparatus

InactiveCN101111329AEfficient preparationReliable shapeMetal-working apparatusEngine componentsDistal portionBiomedical engineering

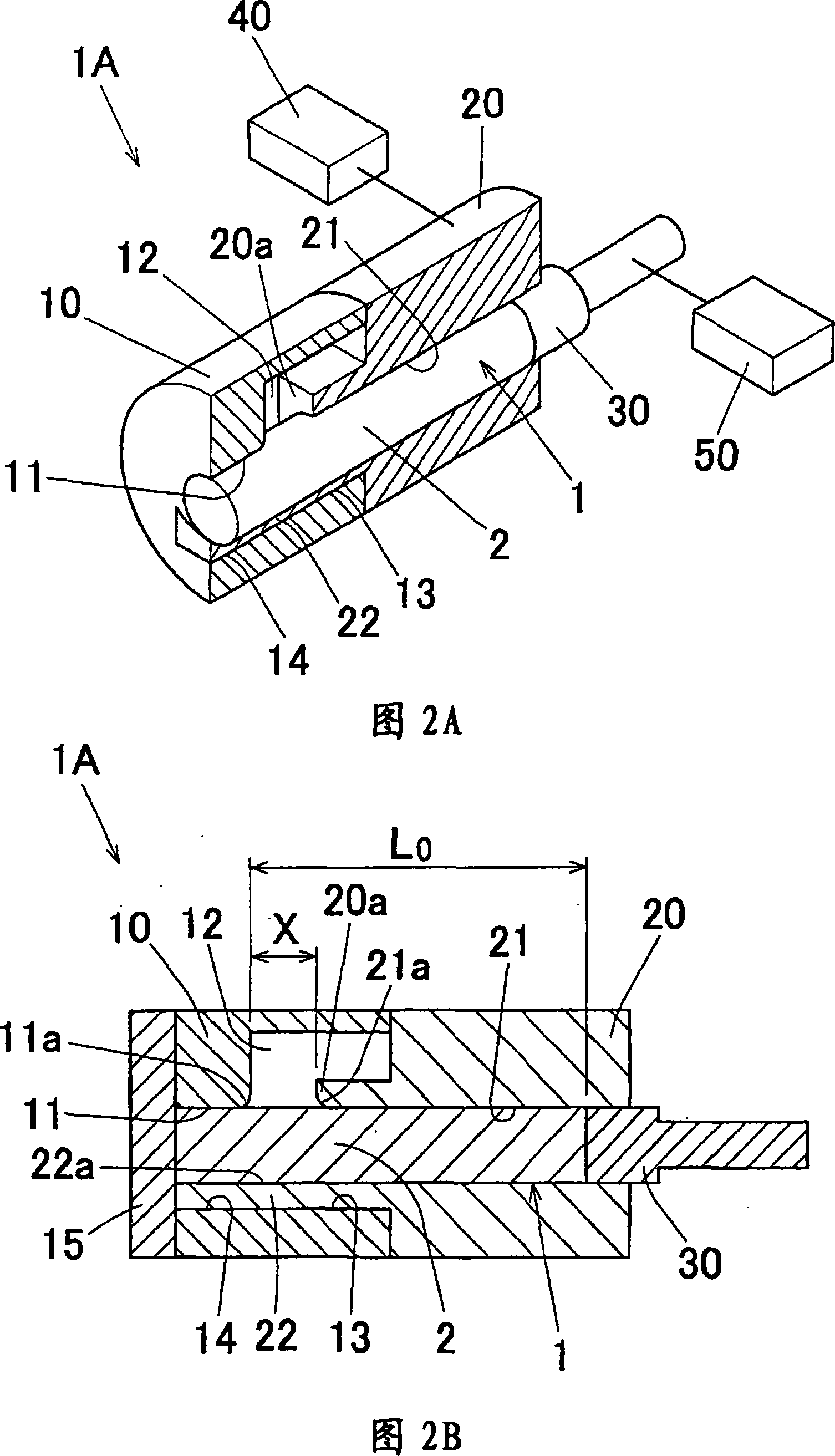

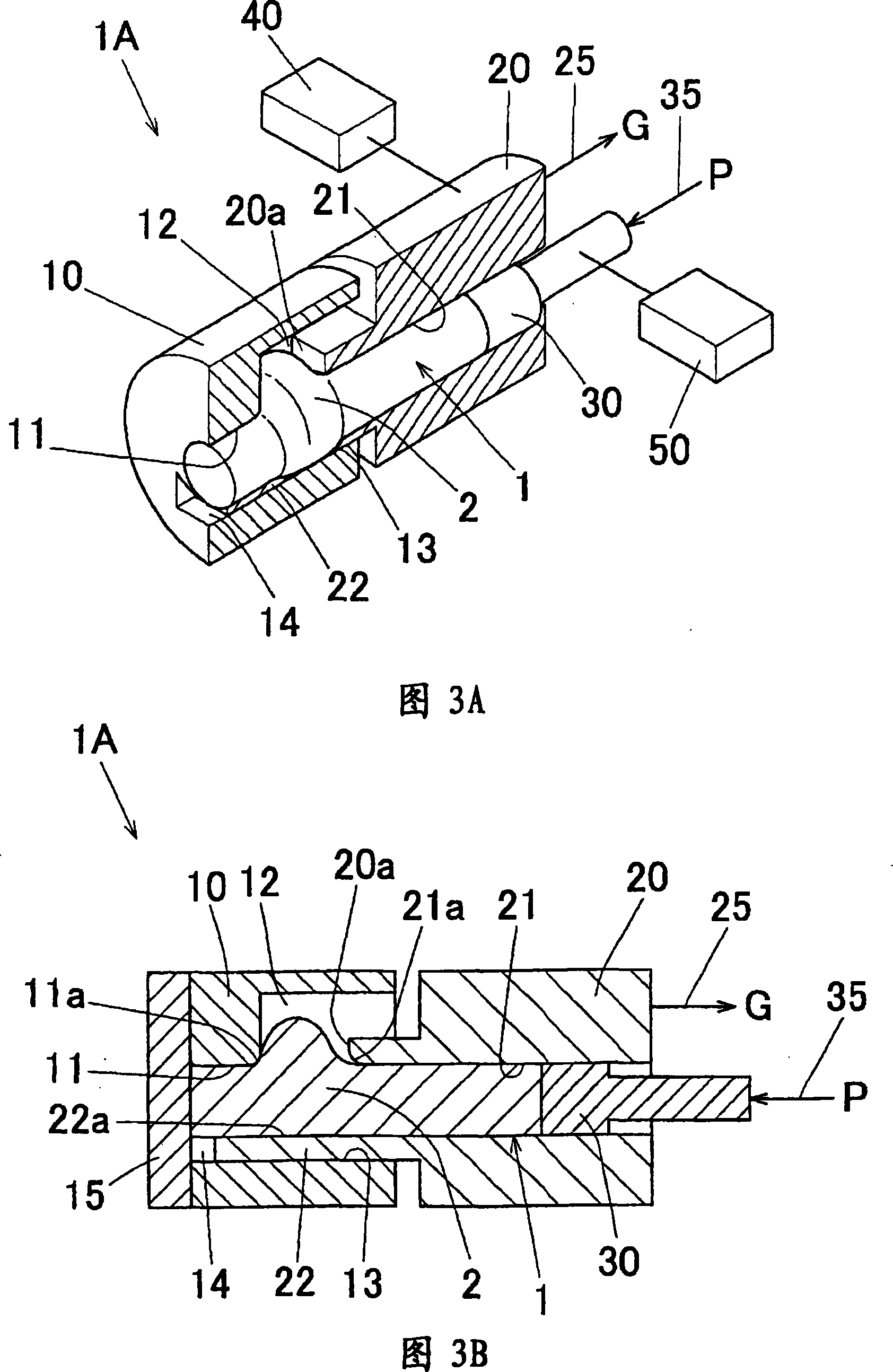

The present invention provides an upsetting method capable of unevenly expanding the diameter of a portion to be expanded in the circumferential direction of a blank. A guide body (20) having an insertion hole (21) through which the planned diameter expansion portion (2) of the holding blank (1) is inserted in a vertical bending preventing state is prepared. A protruding piece portion (22) for suppressing diameter expansion that protrudes in the axial direction of the guide body (20) is integrally provided on a part of the front end portion (20a) of the guide body (20). The predetermined diameter expansion portion (2) of the blank (1) fixed in the stationary mold (10) is inserted and held in the insertion hole (21) of the guide body (20). Next, while moving the punch (30) and pressing the portion (2) of the blank (1) to be enlarged by the punch (30) in the axial direction, the guide body (20) is directed toward the punch (30) is moved in the opposite direction of the moving direction, whereby the planned diameter expansion portion (2) of the blank (1) exposed between the front end portion (20a) of the guide body (20) and the fixed mold (10), The diameter expansion is performed in a state where the diameter expansion is suppressed for the contact portion of the planned diameter expansion portion (2) with the protruding piece portion (22).

Owner:SHOWA DENKO KK

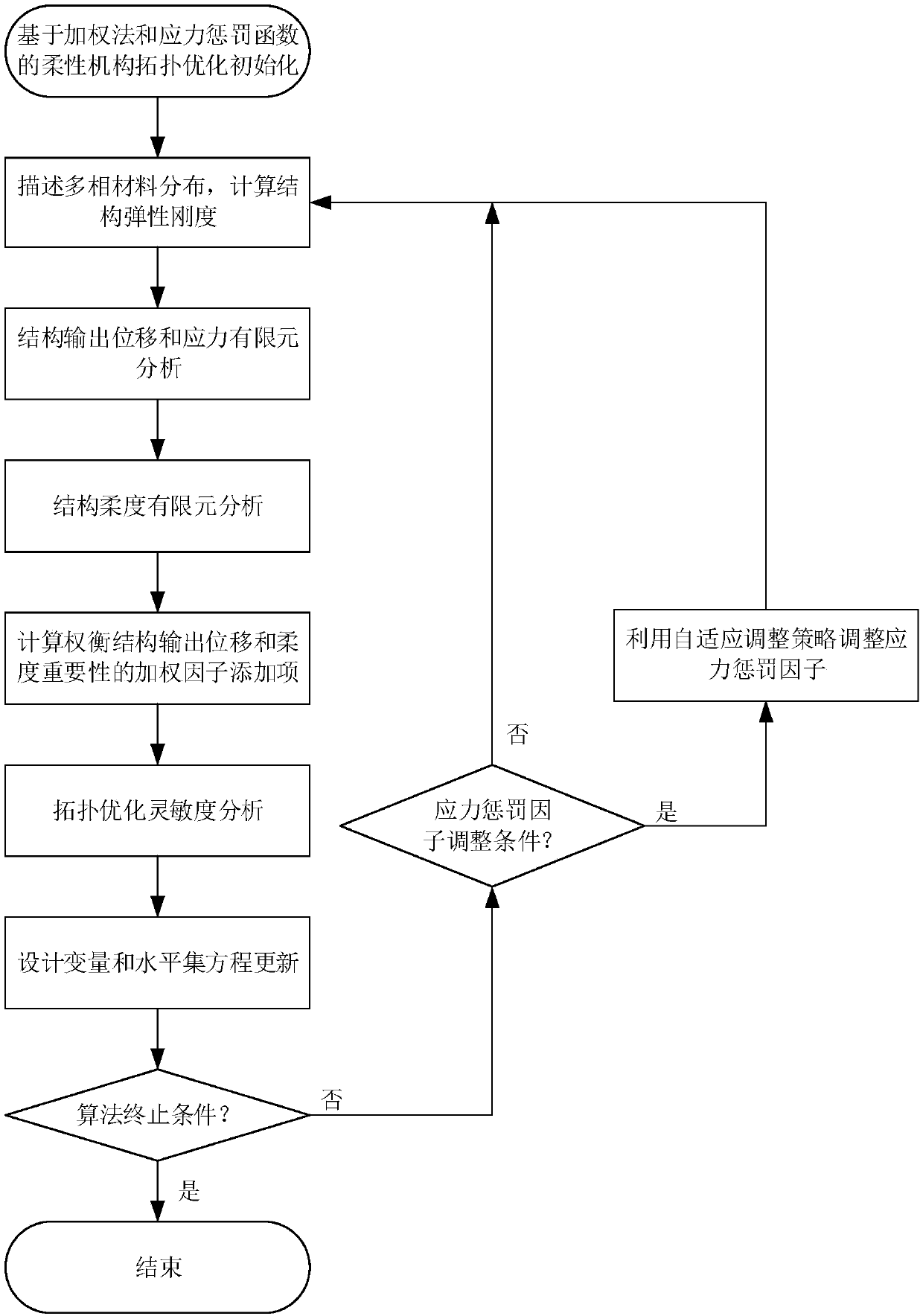

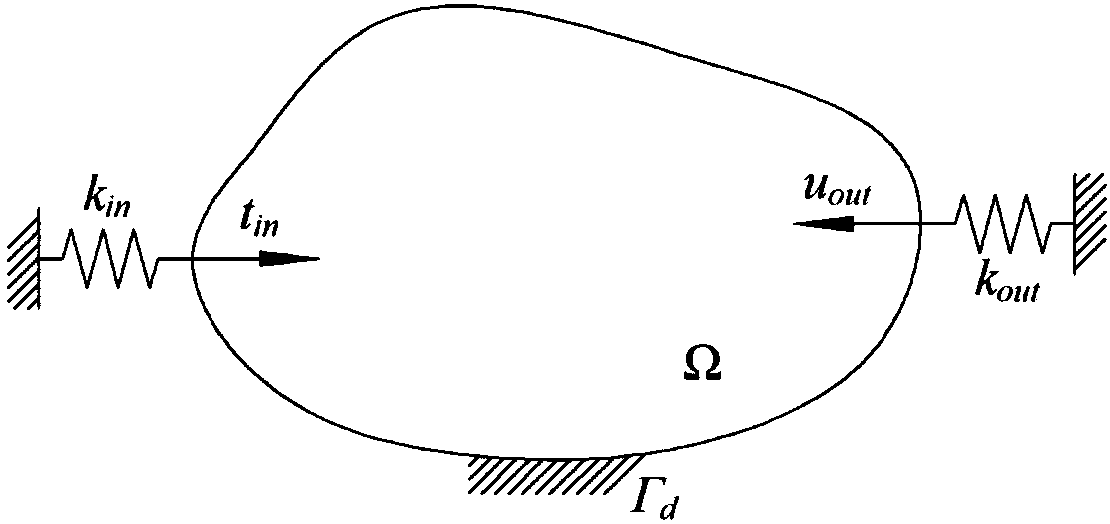

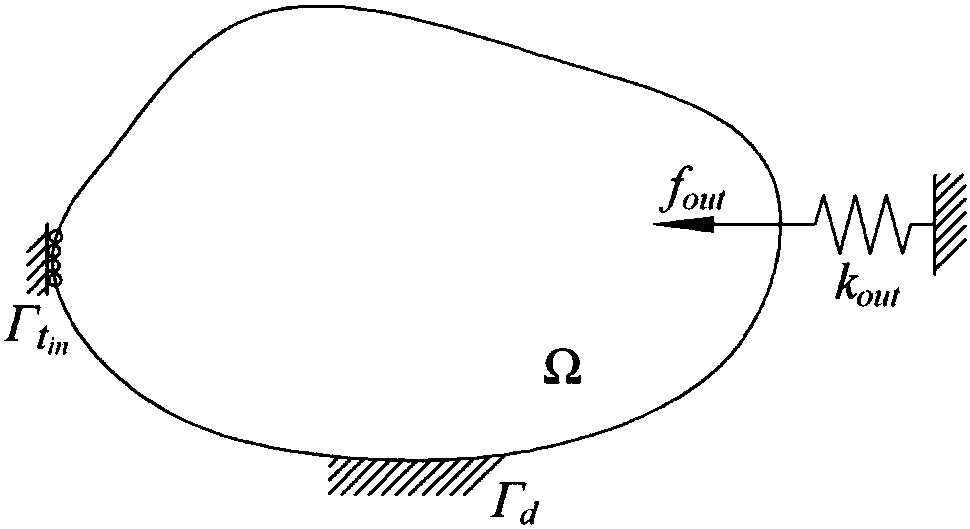

Method for topological optimization of multiphase material flexible mechanisms under stress constraints

ActiveCN107491599AGuaranteed accuracyImprove solution efficiencyGeometric CADSpecial data processing applicationsStress concentrationFlexible Mechanisms

The invention belongs to related technical field of optimum structural design, discloses a method for topological optimization of multiphase material flexible mechanisms under stress constraints, and aims at optimizing structures of the multiphase material flexible mechanisms. The method comprises the following steps of: (1) constructing a multiphase material level set topological description model to describe distribution of a multiphase material structure; (2) constructing a rigidity interpolation model and a separable stress interpolation model to respectively calculate elastic rigidity and stress of the multiphase material structure; and (3) constructing a weighing method and stress punishment-based multiphase material flexible mechanism parameterized level set topological optimization model, optimizing output displacement and flexibility of a flexible mechanism, and controlling local stress of the multiphase material structure. The method is applied to topological optimization design of multiphase material flexible mechanisms under stress constraints, the optimized multiphase material flexible mechanisms have the advantages of being high in flexibility and high in rigidity, flexible knot parts of the multiphase material flexible mechanisms do not have single point hinge phenomenon, the structural strength requirements are satisfied, and the stress concentration problems are eased.

Owner:HUAZHONG UNIV OF SCI & TECH

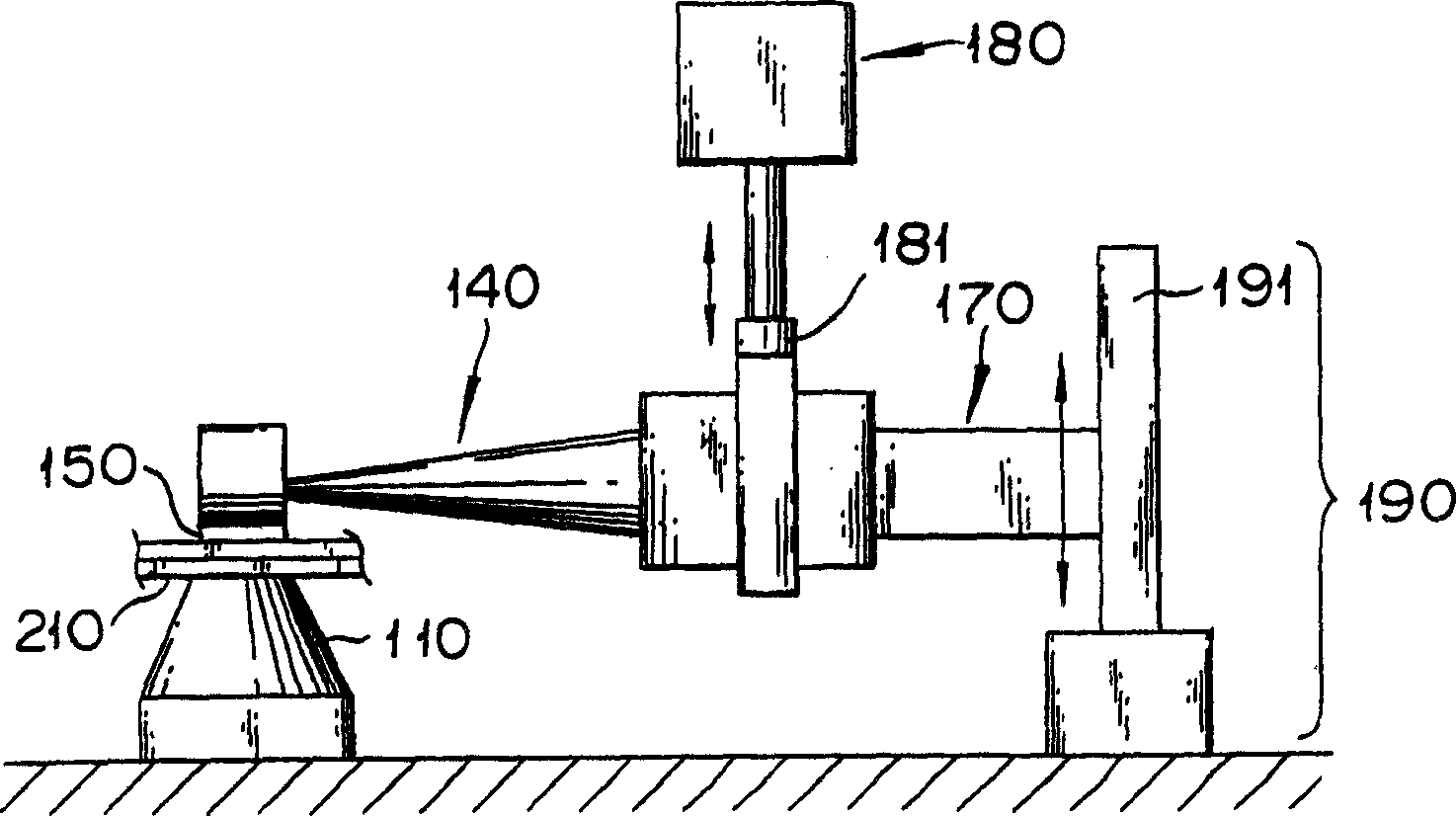

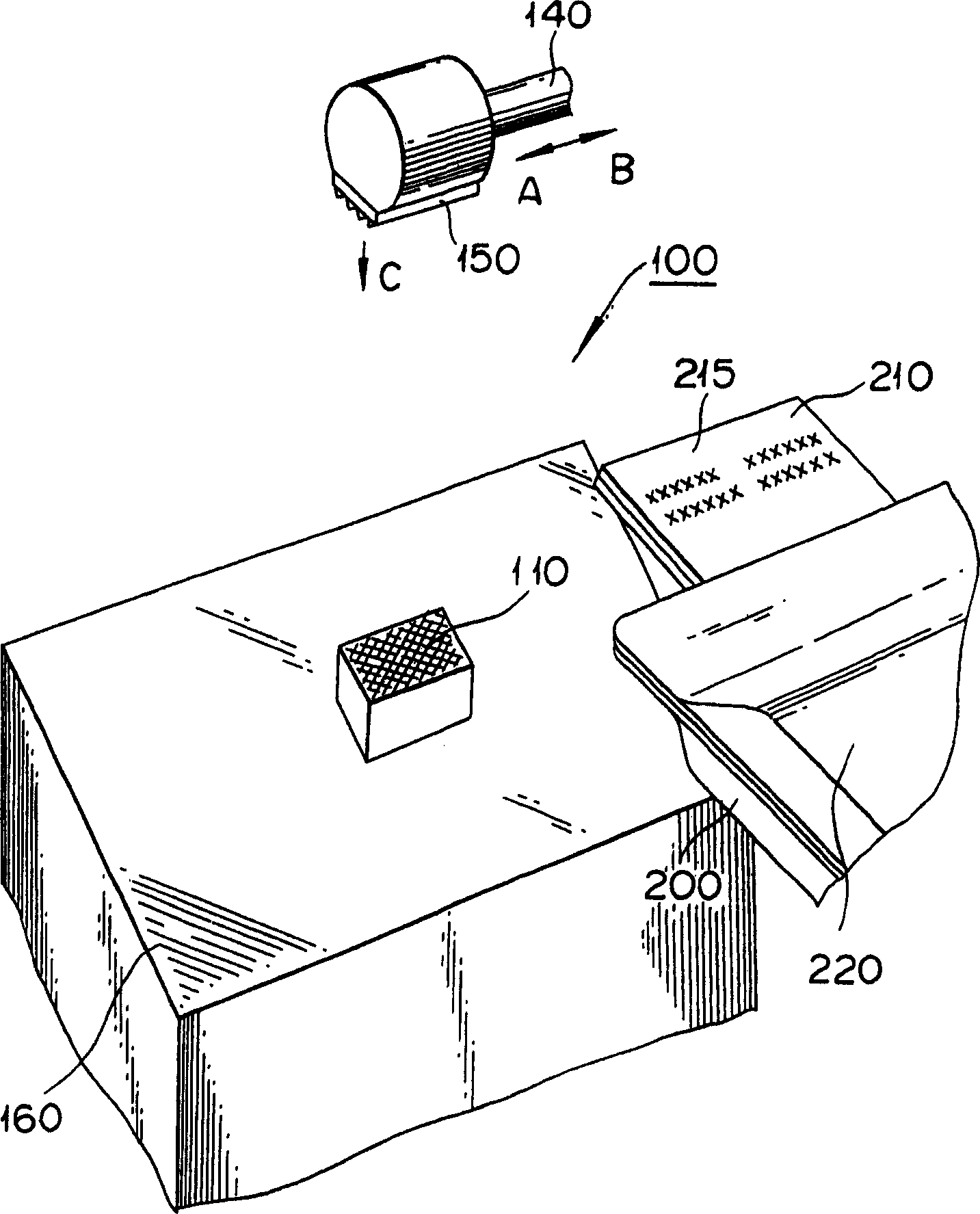

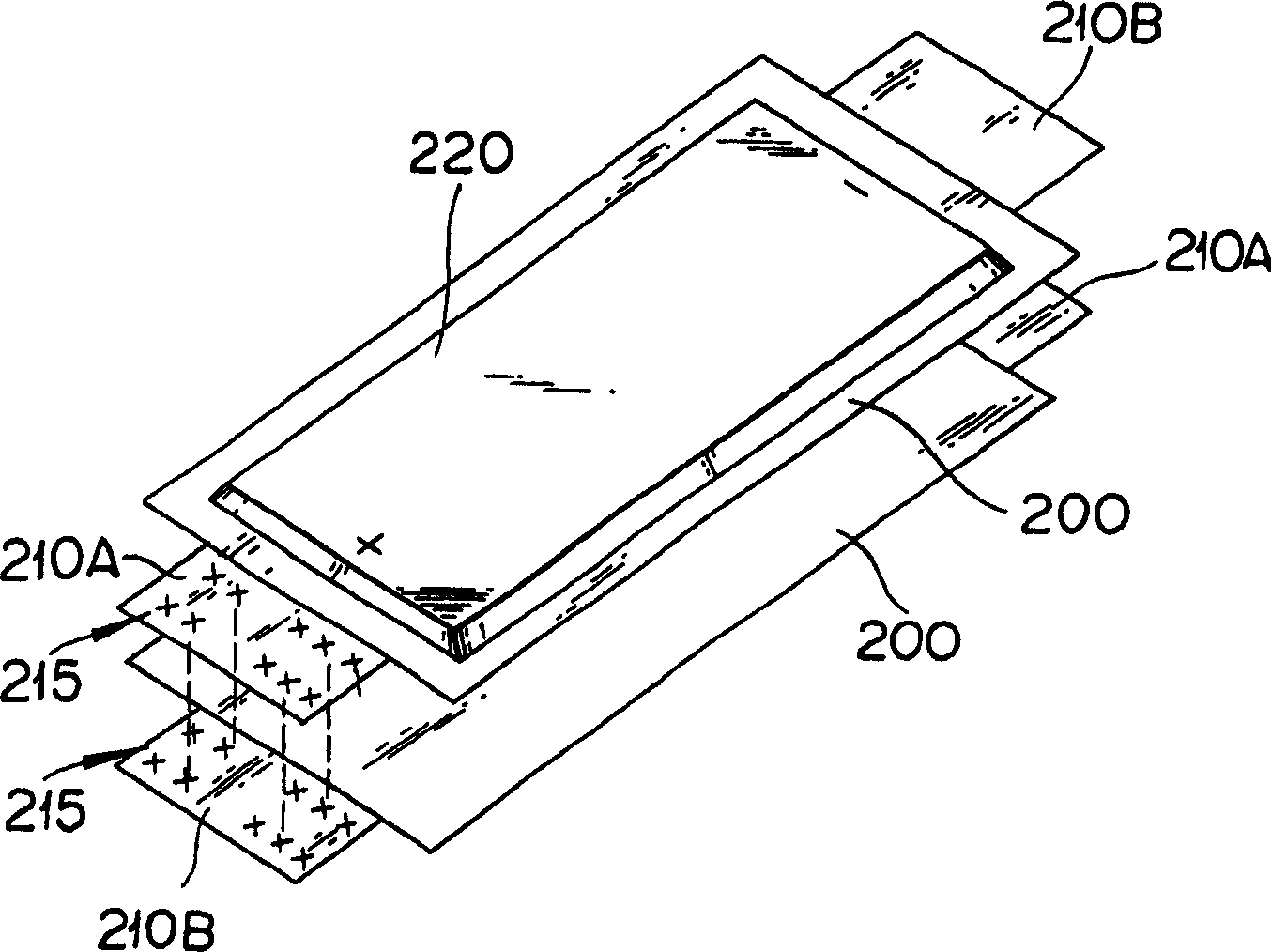

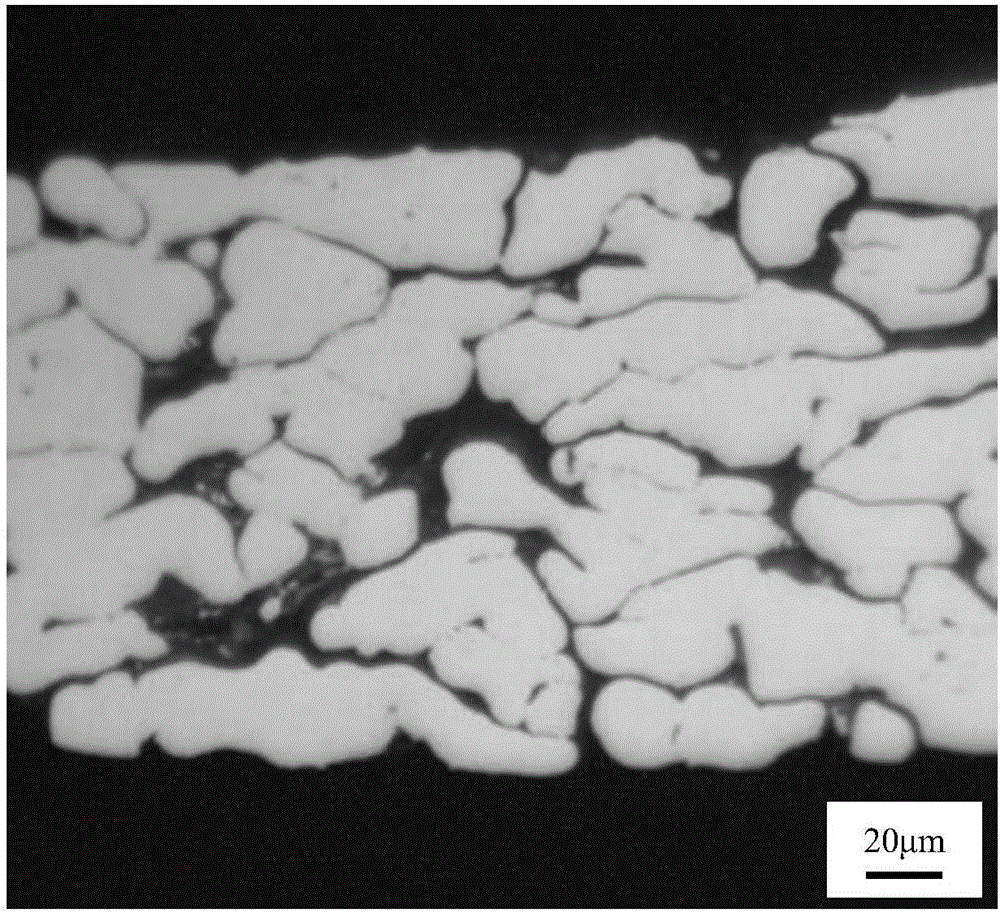

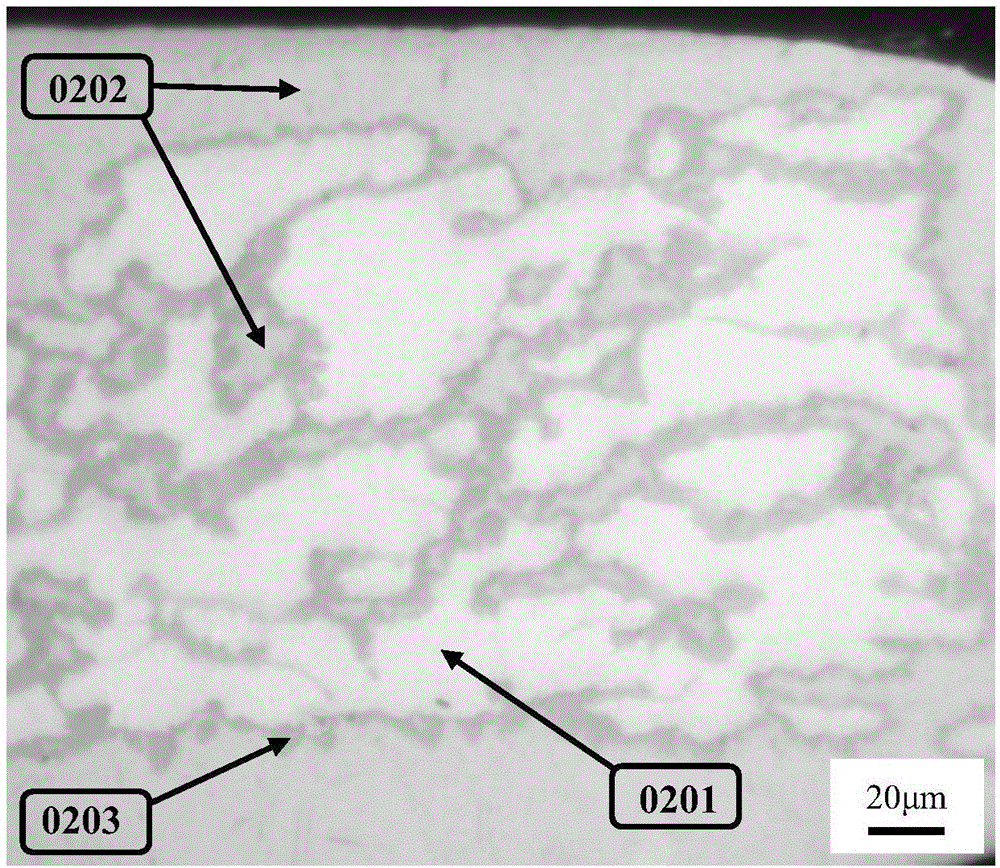

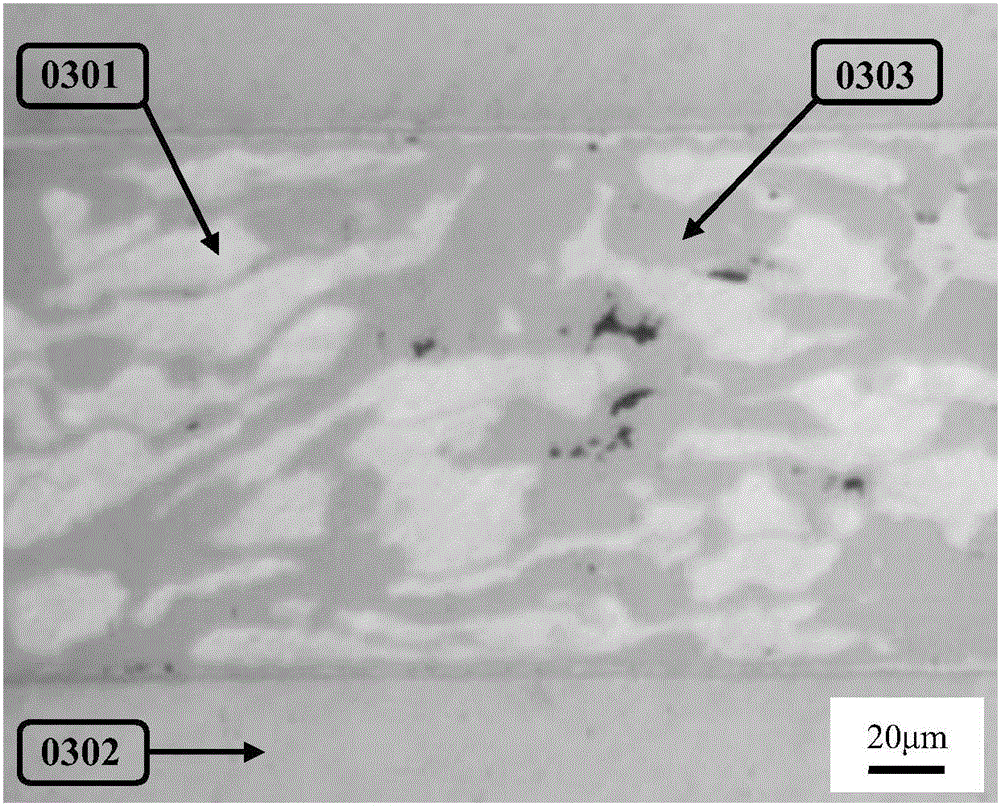

Ultrasonic bonding equipment and resulting bonding structure

ActiveCN1814388AReduce intrusionHigh breaking strengthCell electrodesDomestic articlesGrip forceUltrasonic bonding

The invention provides an ultrasonic bonding equipment and a bonding construction body to increase the strength of a joined part of a work after the ultrasonic bonding is completed. An ultrasonic bonding equipment has an anvil 110 and a horn 140 arranged facing the anvil, and performs the ultrasonic bonding of the work to be bonded by pressurizing and oscillating electrode tabs 210 as a plurality of works overlapped and set on the anvil by the horn. Gripping force on the outer side part is set to be smaller than the gripping force on the inner side part in a gripping area to the works by the anvil and the horn.

Owner:ENVISION AESC JAPAN LTD

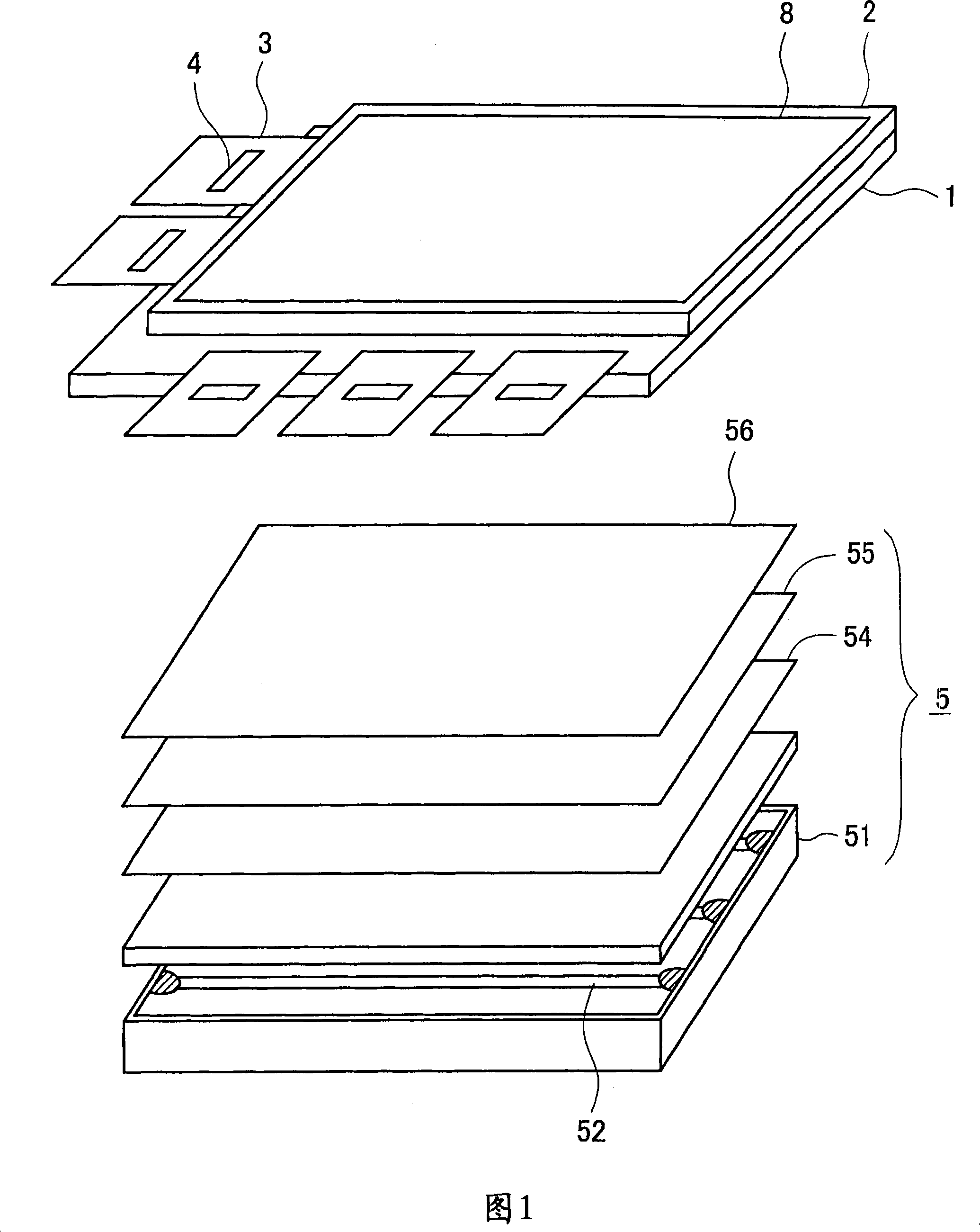

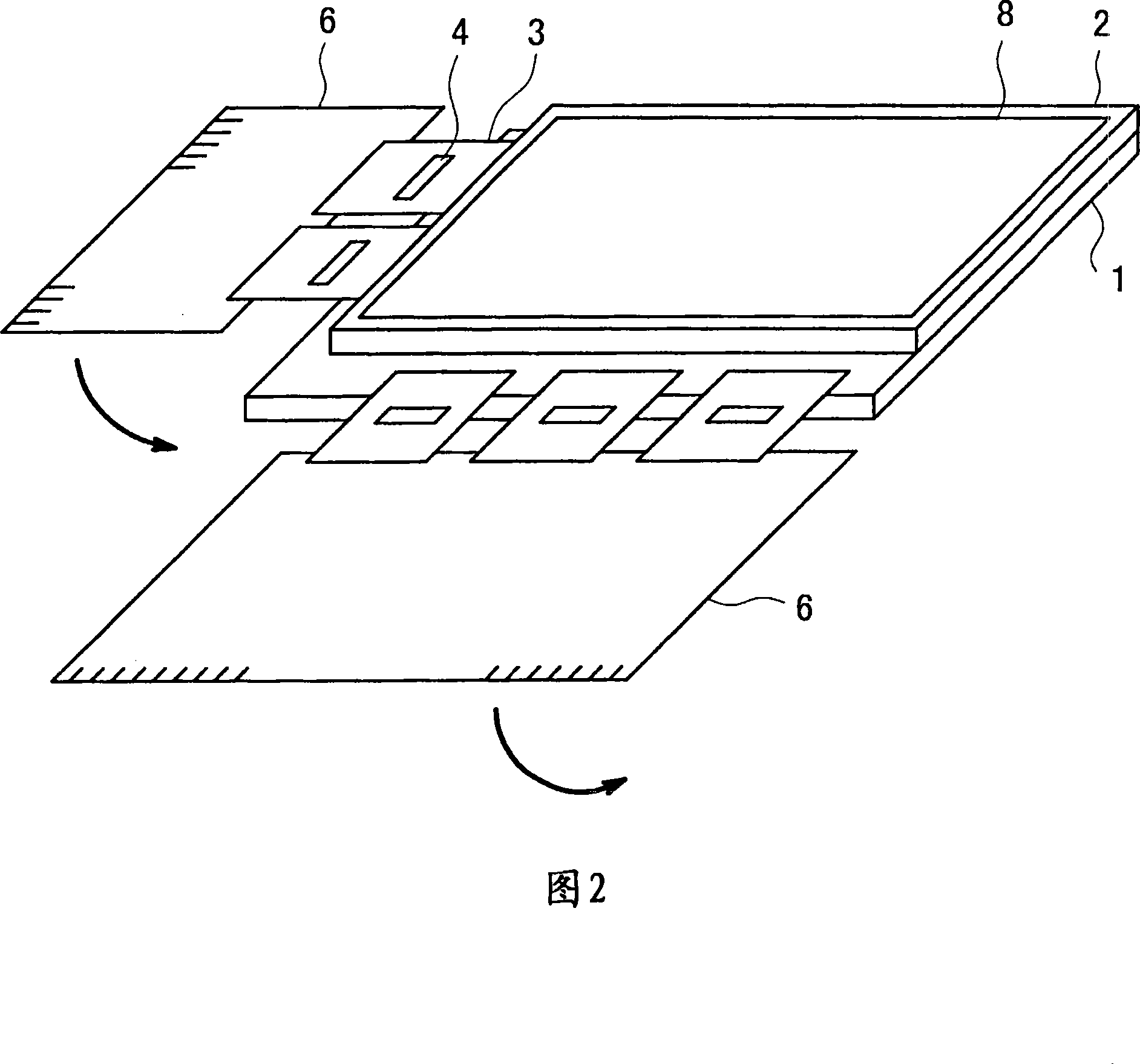

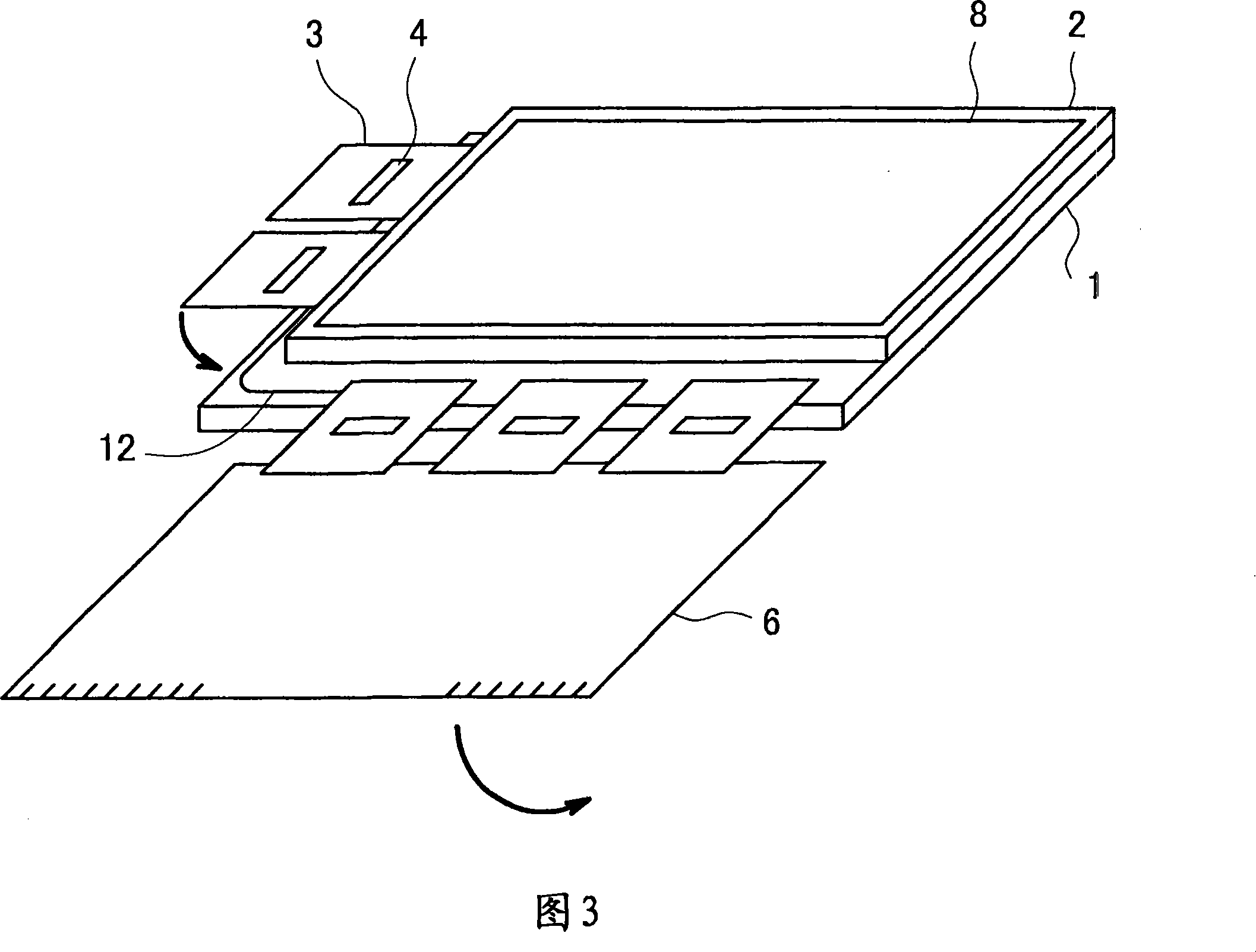

Display device and flat display device

ActiveCN101187735AAvoid disconnectionImprove reliabilitySemiconductor/solid-state device detailsElectroluminescent light sourcesDisplay deviceExternal circuit

The present invention prevents, when a COF which is connected with an external circuit is bent in a flat display device, the disconnection of lines on the COF. At a position where a line of the COF is connected to terminal portions of a TFT, and the line having a large width is branched into lines having a small width T 1 to T 3 or T 4 to T 6. By displacing line branching positions from each other as indicated by an arrow A and an arrow B, when the COF is bent or deformed, stress applied to the line branching positions can be dispersed thus preventing the disconnection of lines.

Owner:JAPAN DISPLAY INC +1

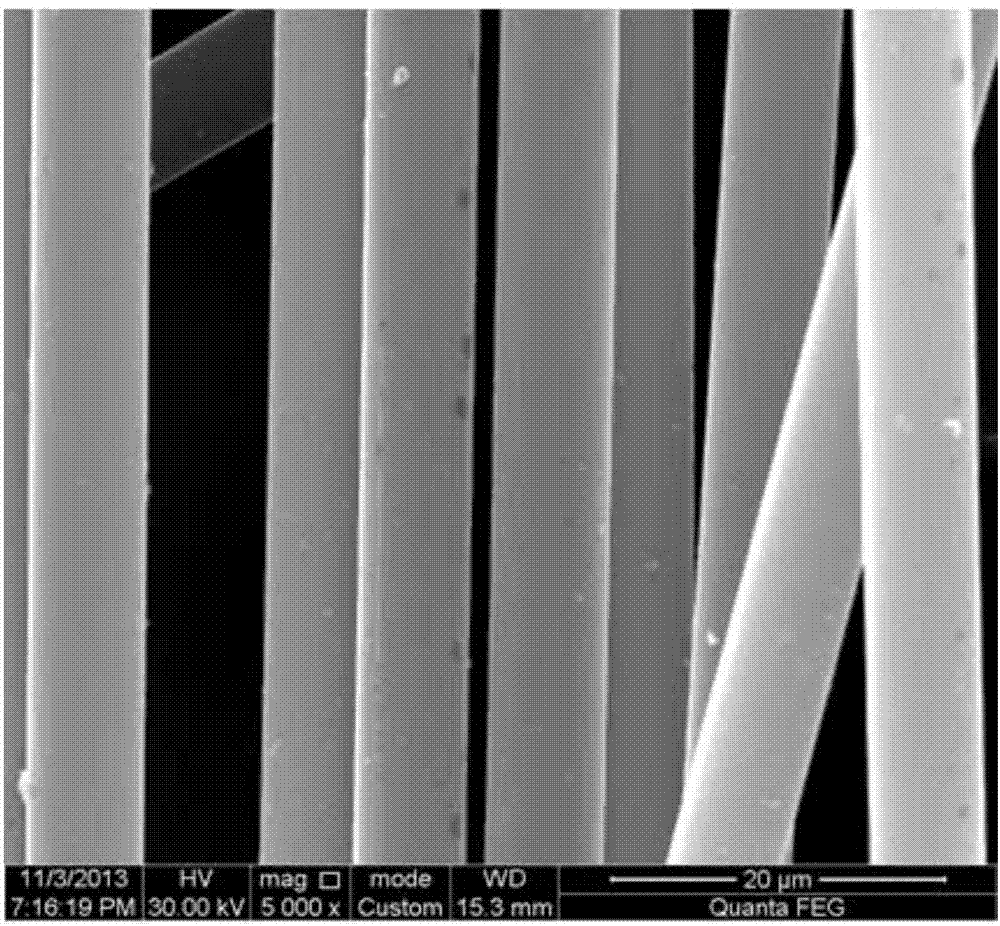

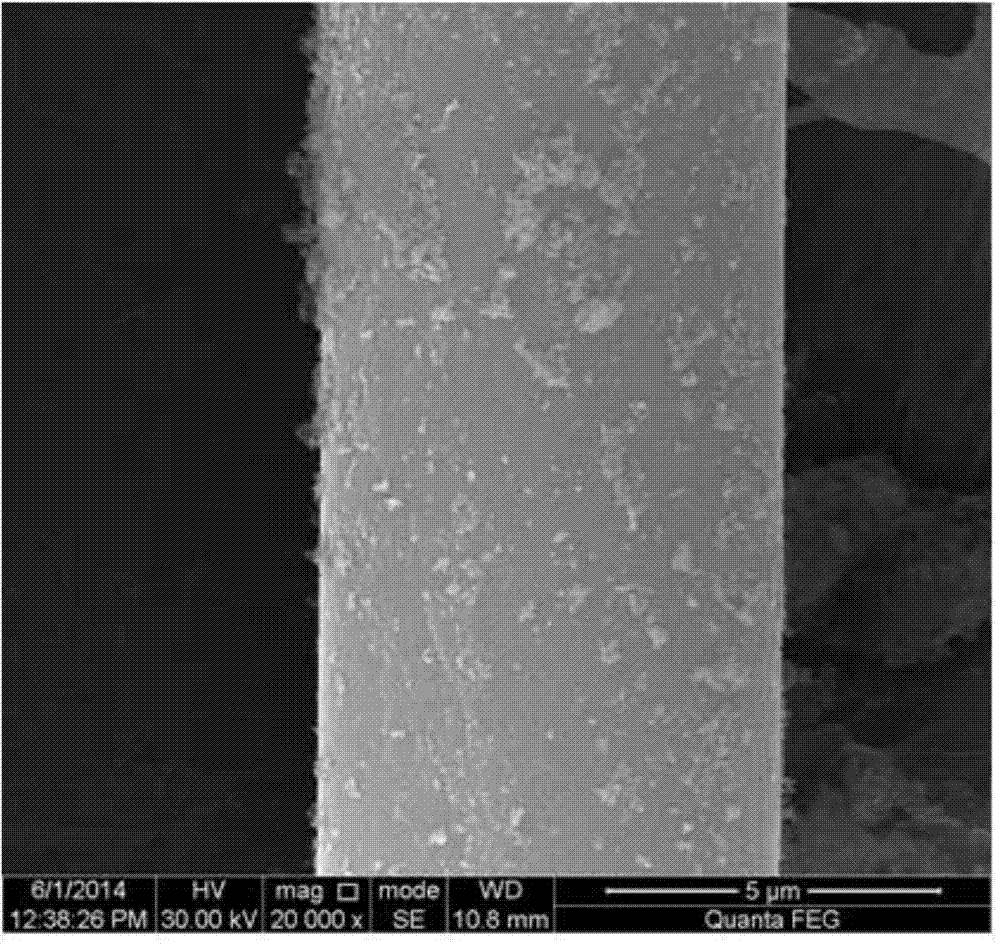

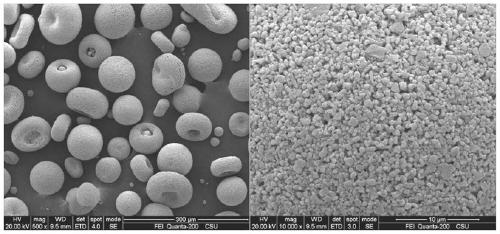

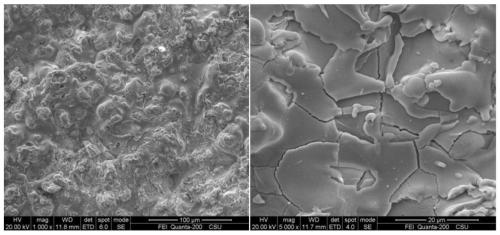

Surface modification method for carbon fibers by nano silicon dioxide

ActiveCN104499270AImprove thermal stabilityImprove wettabilityCarbon fibresFiberStress concentration

The invention provides a surface modification method for carbon fibers by nano silicon dioxide and relates to a method for carrying out surface modification on the carbon fibers, aiming at solving the problems that the mechanical property and the thermal property of current carbon fibers are worse. The method comprises the following steps: 1. carrying out surface halogenation on the nano silicon dioxide to obtain a product; 2. carrying out nano silicon dioxide surface azidation treatment; 3. carrying out oxidization treatment on the carbon fibers; 4. carrying out carbon fiber surface modification alkynylation treatment; and 5. grafting the nano silicon dioxide on the surfaces of the carbon fibers. After the nano silicon dioxide is modified, the surface wettability of the carbon fibers is remarkably improved, and the roughness is obviously increased; and a transferring effect between a base body and an interface in a composite material can be easily enhanced, the stress concentration can be effectively alleviated, and the damages to the material are prevented, so that the mechanical property of the composite material is improved. The thermal stability of the carbon fibers is remarkably improved through the surface modification of the nano silicon dioxide. The surface modification method is used for modifying the carbon fibers.

Owner:HARBIN INST OF TECH

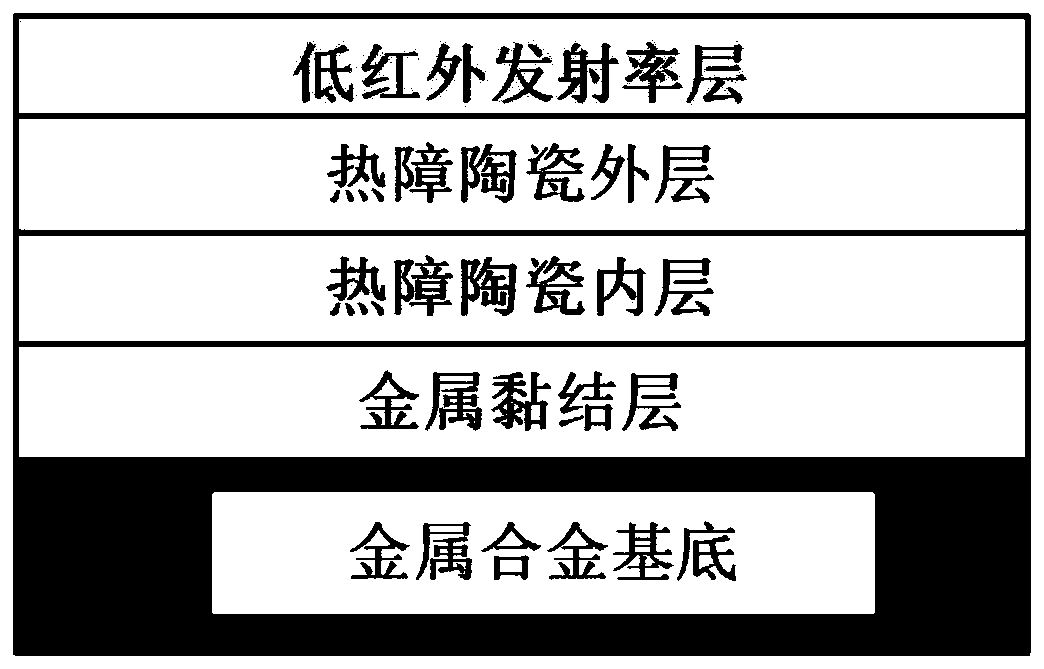

Double-layer thermal barrier/high-temperature low-infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110055486AGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityAlloy

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating which is of a multilayer superposition structure. The multilayer superposition structure sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a thermal barrier ceramic outer layer and a low-infrared emissivity layer from inside to outside, and the thermal barrier ceramic inner layer is La2Zr2O7-8YSZ mixture layer, wherein the mass fraction of La2Zr2O7 powder in the mixture is not more than 45%, the thermal barrier ceramic outer layer is a rare earthzirconate layer, and the low-infrared emissivity layer is a Bi2O3-Al2O3-ZrO2-CaO-SiO2 glass coating comprising conductive phase AuPt alloy powder. The invention also provides a metal composite material with the coating and a preparation method thereof. The integrated coating has the characteristics of heat insulation performance, high-temperature low infrared emissivity, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

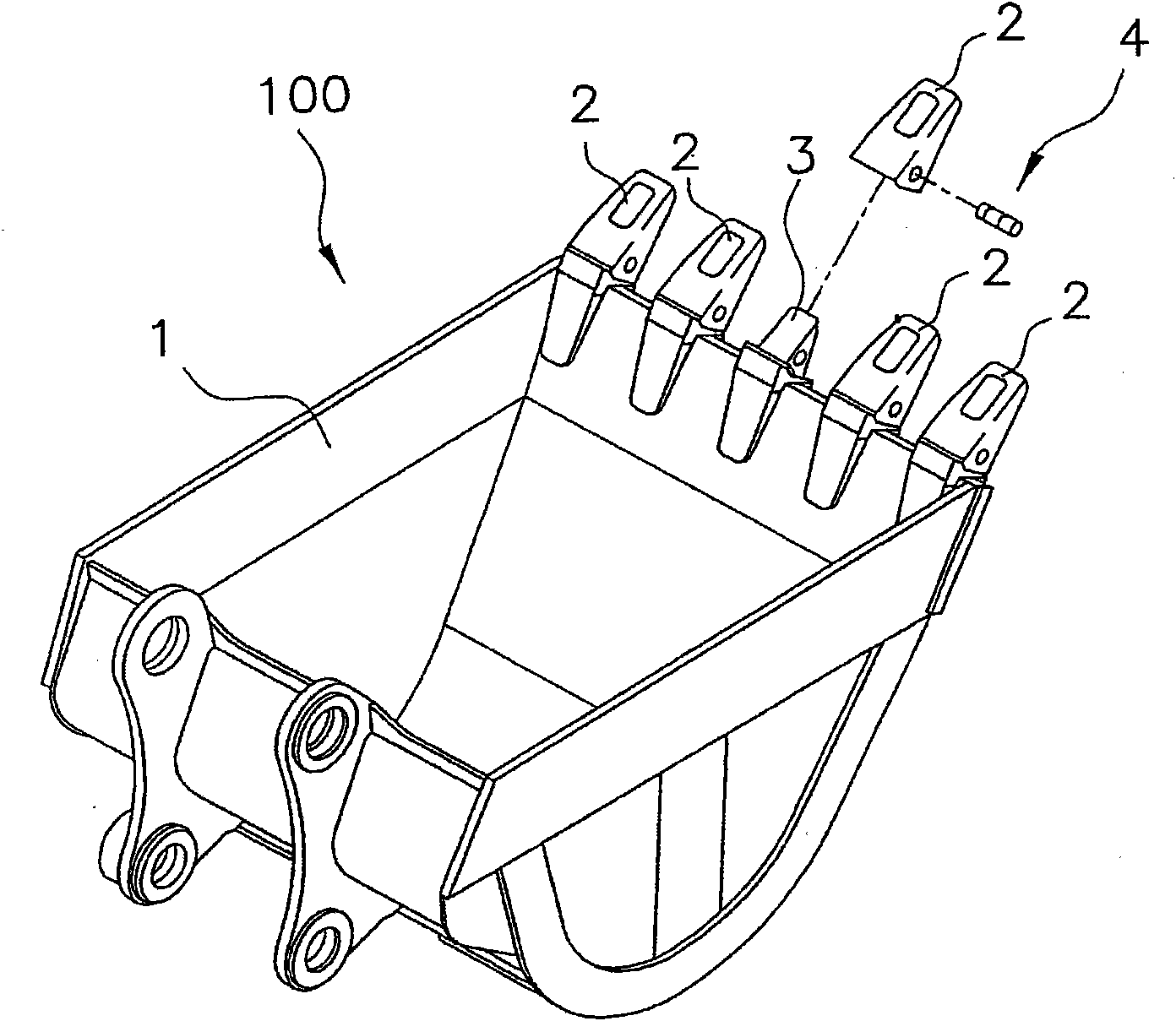

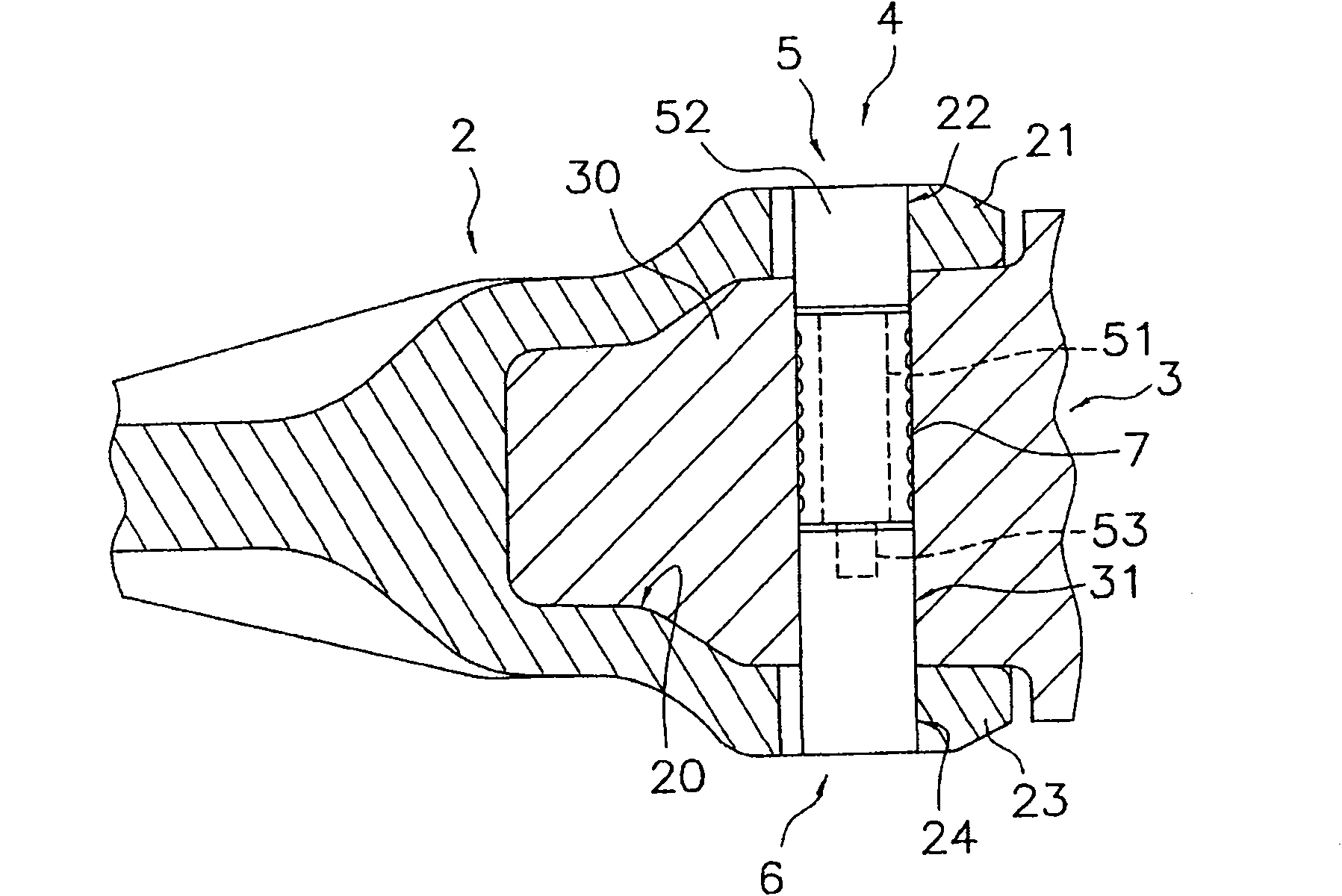

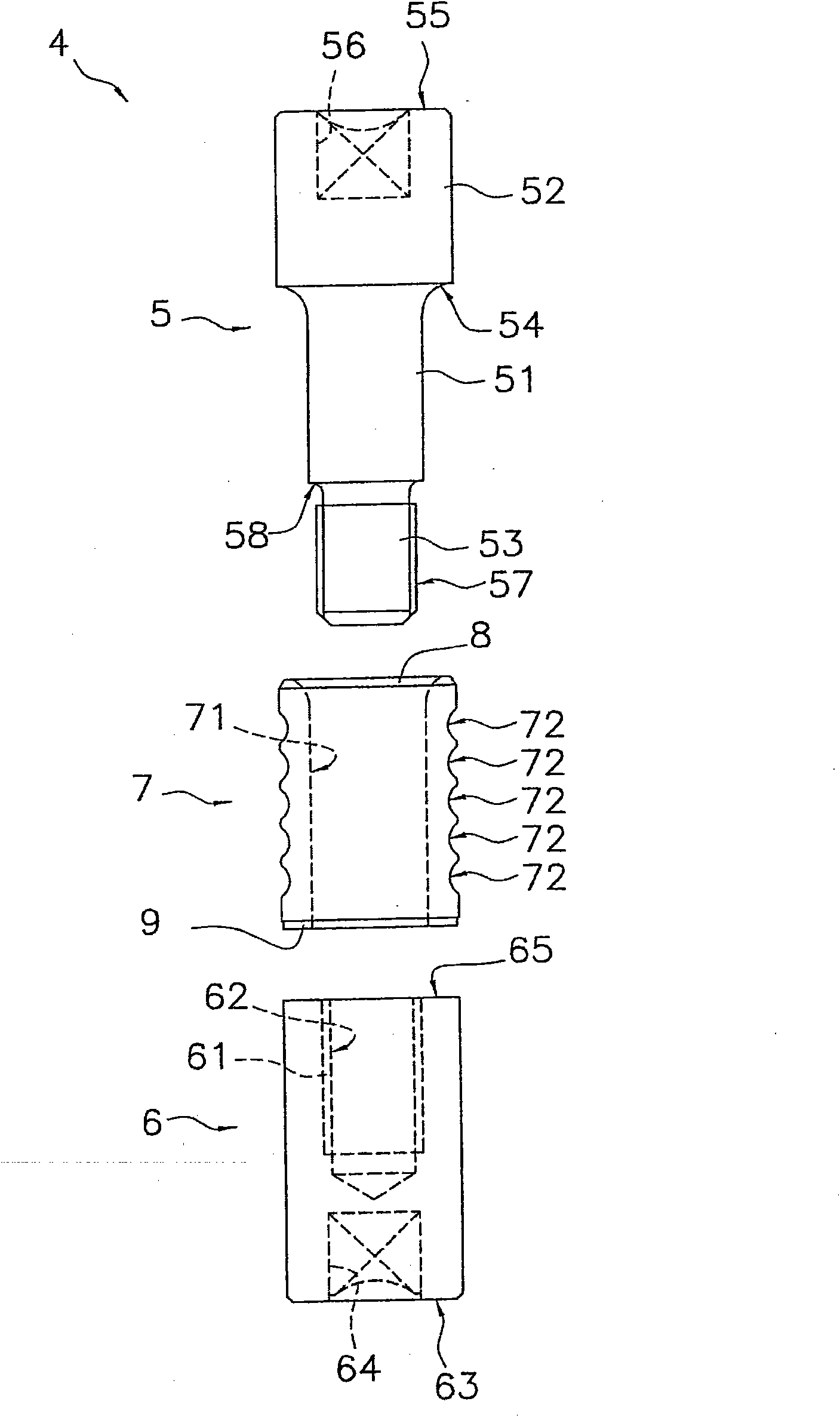

Bucket tooth mounting structure and mounting pin assemble

InactiveCN101821458ARelieve stress concentrationSoil-shifting machines/dredgersEngineeringMechanical engineering

The invention provides a bucket tooth mounting structure and a mounting pin assemble. The bucket tooth mounting structure is enabled to increase a fixing force between a tooth and an adapter by an easily manufacturable constitution. In the bucket tooth mounting structure, an elastic member (7) is inserted into a hole (31) of an adapter (3). As a first mounting pin (5) and a second mounting pin (6) have their male thread and female thread engaging each other, the elastic member (7) is axially compressed between and radially expanded by the first mounting pin (5) and the second mounting pin (6) so that it comes into close contact with the inner wall face of the hole (31). Moreover, that portion of the hole (31) of the adapter (3), which confronts the elastic member (7), is diametrically equal to the remaining portion of the hole (31), and the elastic member (7) has a recess extended along the circumferential direction in the outer circumference of at least the axially intermediate portion.

Owner:KOMATSU LTD

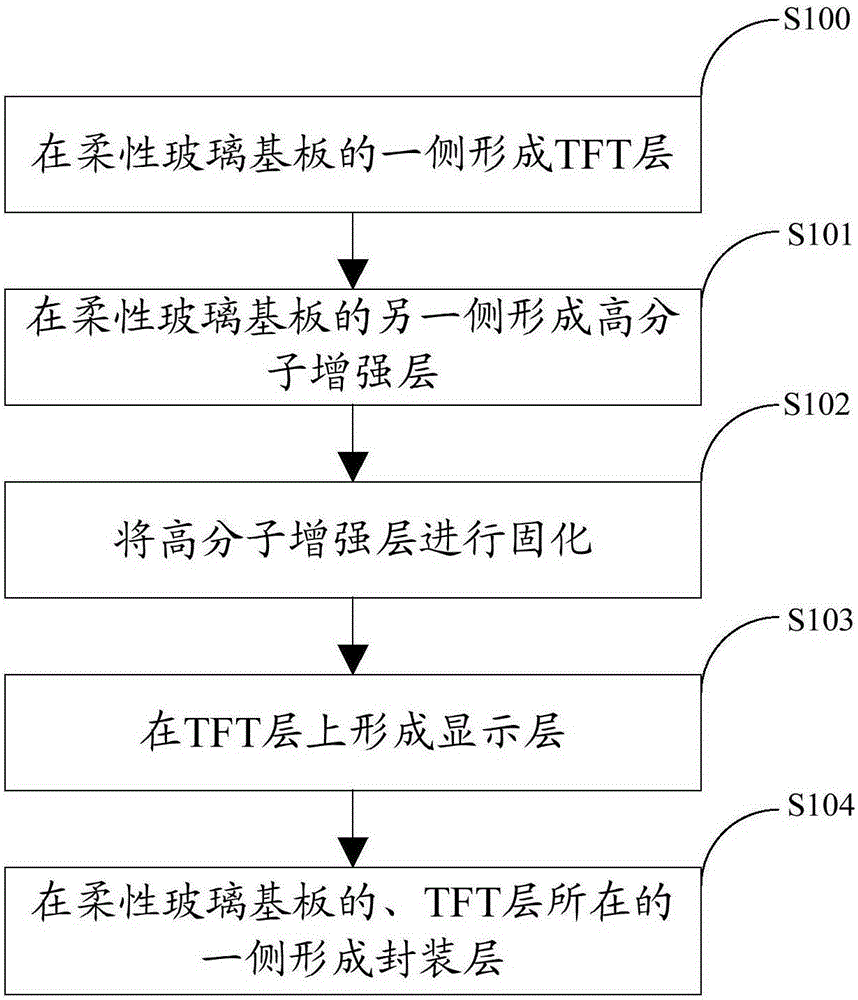

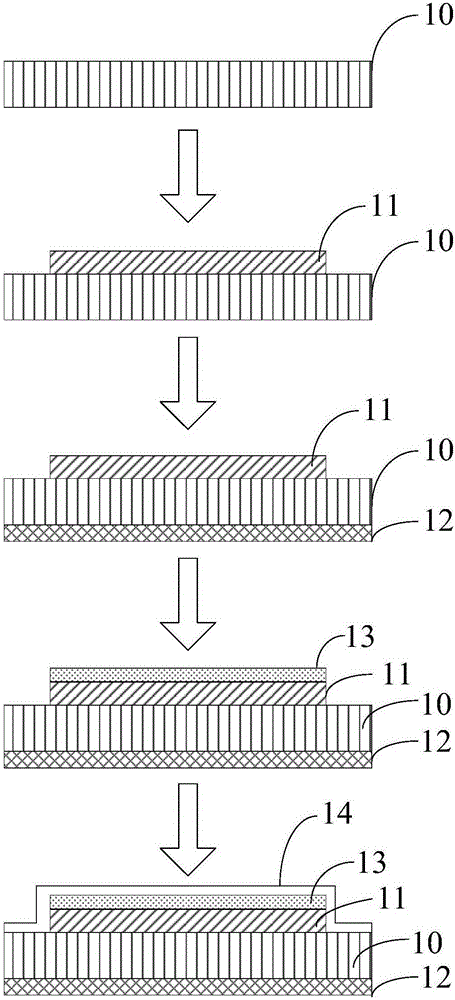

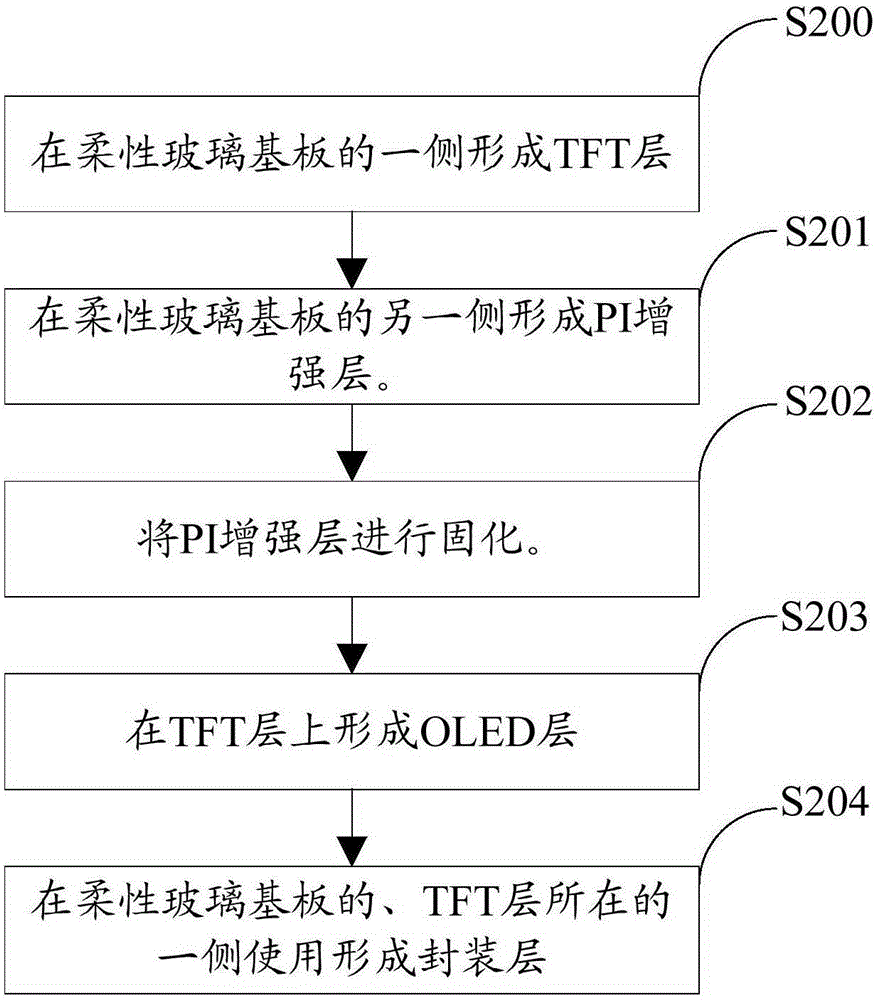

Manufacturing method of flexible display screen, flexible glass substrate and flexible display screen

ActiveCN105185809AHigh compressive strengthPolymer enhanced compressive strengthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCompressive strength

The invention provides a manufacturing method of a flexible display screen, a flexible glass substrate and a flexible display screen. The manufacturing method comprises the following steps: forming a TFT layer at one side of a flexible glass substrate; forming a high-molecular enhancement layer at the other side of the flexible glass substrate; solidifying the high-molecular enhancement layer; forming a display layer on the TFT layer; and forming a packaging layer on the flexible glass substrate at one side of the TF layer. The high-molecular enhancement layer is arranged at one side of the flexible glass substrate. The flexible display screen consists of a flexible glass substrate, a TFT layer, a high-molecular enhancement layer, a display layer, and a packaging layer. According to the invention, a defect of frangibility of the flexible glass substrate is overcome and the compressive strength of the flexible glass substrate is enhanced, thereby improving the product quality.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method of heat-insulating ceramic phenolic resin-based gradient composite material

The invention discloses a preparation method of a heat-insulating ceramic phenolic resin-based gradient composite material. Fiber cloth is used as a reinforcing phase, and the fiber cloth is respectively dipped in different gum dipping solutions with the phenolic resin as a matrix and contents of ceramic components and hollow microbeads in gradient distribution to prepare a prepreg; laminating, die pressing and thermal curing molding at 150-200 DEG C to obtain the gradient composite material comprising a heat-proof layer, a gradient transition layer and a heat-insulating layer. When the temperature of the gradient composite material is as high as 1000 DEG C, the heat-proof layer can be converted into a ceramic phase with higher strength and can resist heat flow erosion; the gradient transition layer can relieve stress concentration and reduce stress; and hollow microspheres are added to guarantee that the heat-insulating layer has good thermal matching performance.

Owner:WUHAN UNIV OF TECH

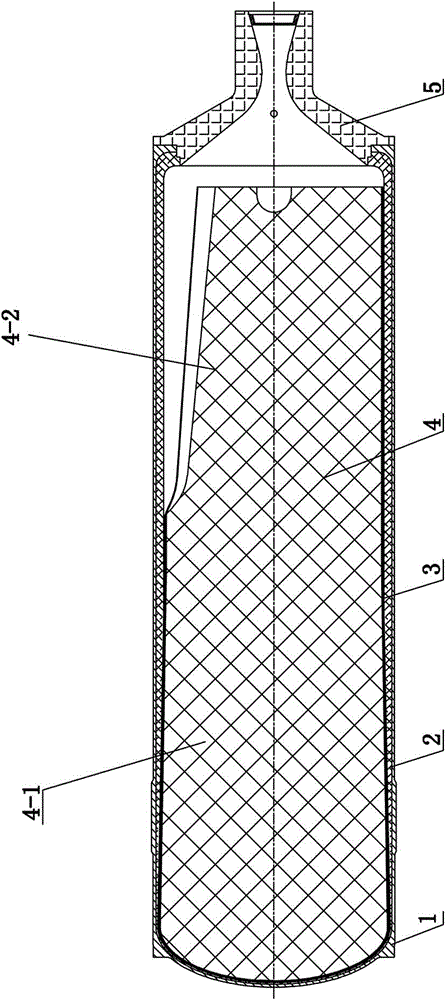

Solid rocket engine with high thrust ratio and manufacturing method thereof

ActiveCN105003355AImprove bonding qualityRelieve stress concentrationRocket engine plantsPhysicsCombustion chamber

A solid rocket engine with a high thrust ratio comprises a combustion chamber shell. A heat insulated layer is pasted to the inner surface of the combustion chamber shell. A heat insulated sleeve is bonded to the outer surface of a grain and forms a whole with the grain. The grain with the heat insulated sleeve is arranged in the combustion chamber shell with the heat insulated layer in a free-filling mode. A spray pipe is arranged at the outlet end of the combustion chamber shell. The grain comprises a booster-stage three-arm type grain body and a cruising-stage end-burning grain body which are connected in series to form the integrated grain. The booster-stage three-arm type grain body and the cruising-stage end-burning grain body are grain bodies for four-component hydroxy-terminated polyb propellants of the same formula. By means of the solid rocket engine with the high thrust ratio and a manufacturing method thereof, the problem of a small thrust ratio can be solved, the high thrust ratio can be provided, working is table, and the structure and performance are reliable.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

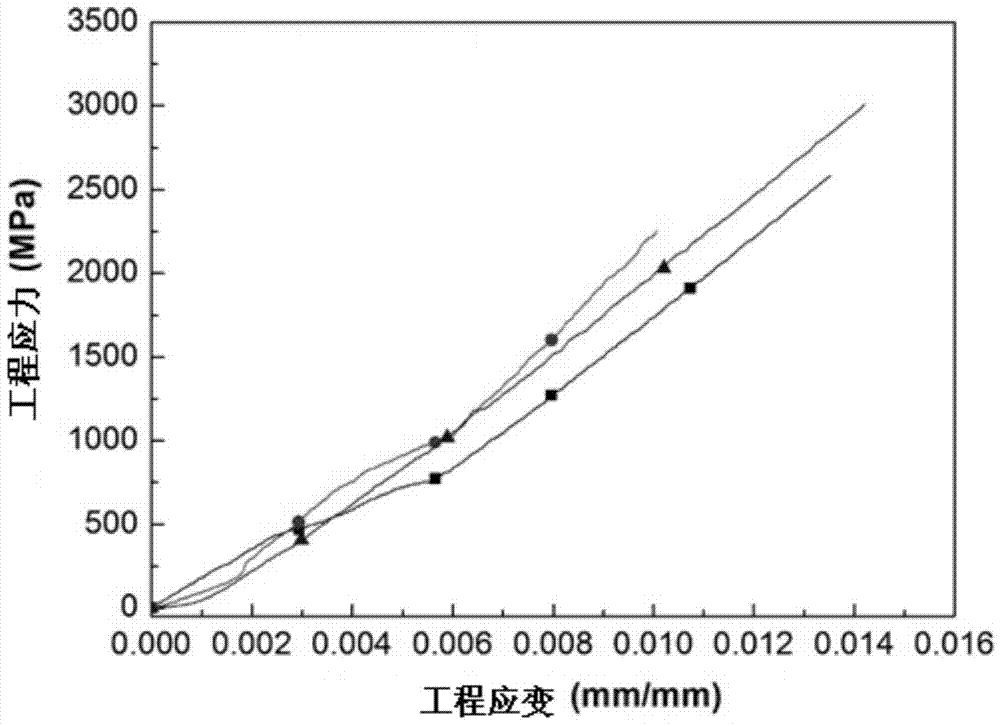

Non-preheating strength gradient matched welding technology for low-alloy high-strength steel with yield strength of 800MPa

The invention provides a non-preheating strength gradient matched welding technology for low-alloy high-strength steel with the yield strength of 800MPa, which belongs to the field of the non-preheating welding technology for the low-alloy high-strength steel. The welding technology mainly adopts welding wires with the tensile strength of 500MPa for backing welding and welding wires with the tensile strength of 800MPa for padding and cosmetic welding. The technology mainly solves the technical problem that in the background art, as backing welded joints in a high restraint-intensity welding structure have higher tensile strength, cracks can not be thoroughly eliminated under a non-preheating condition. The technology is used for the non-preheating high-quality welding for the low-alloy high-strength steel with the yield strength of 800MPa.

Owner:HARBIN WELDING INST LTD

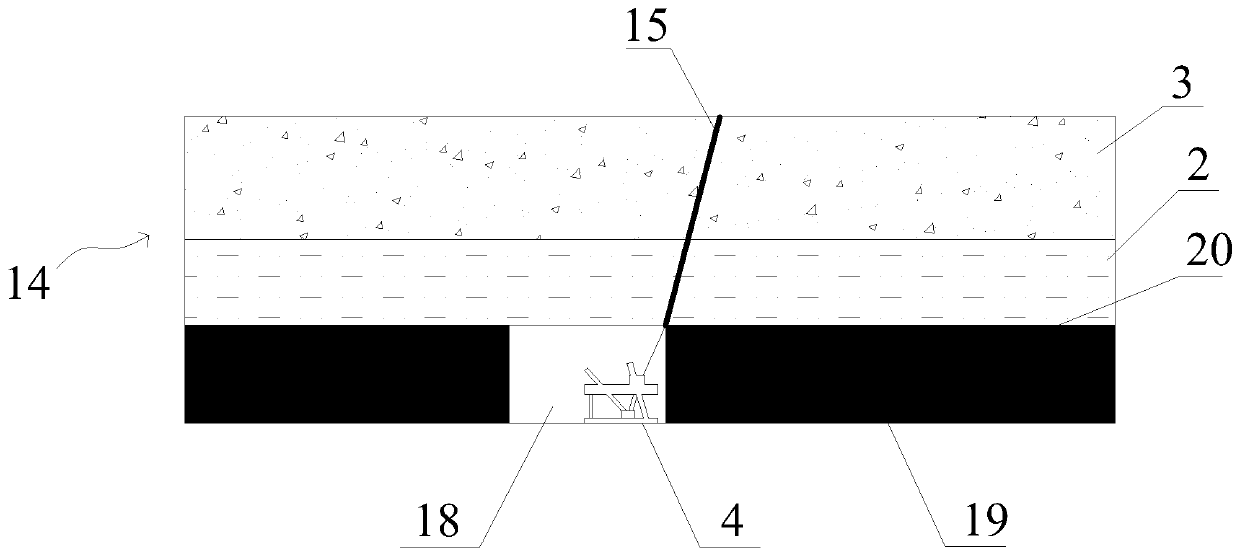

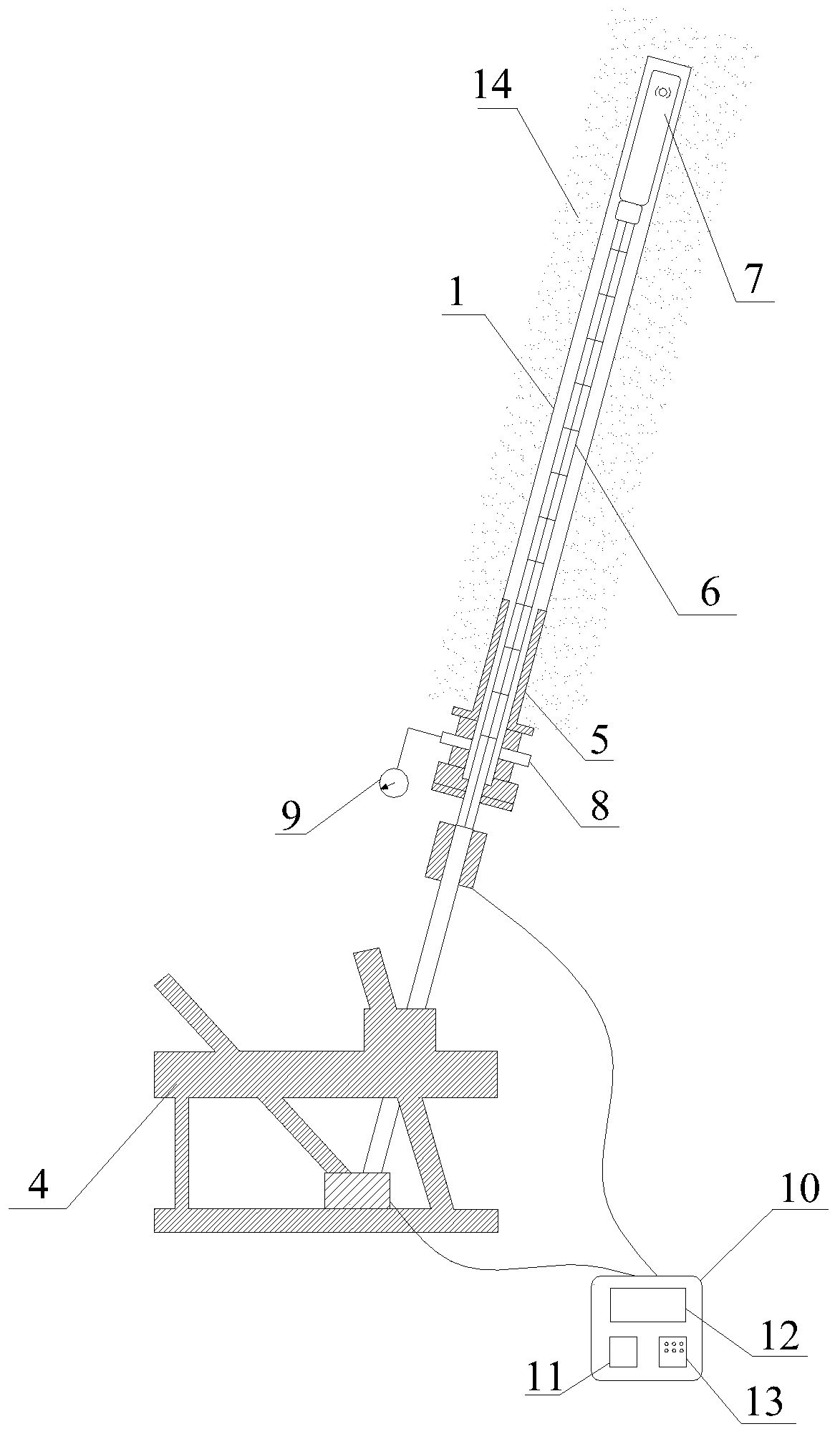

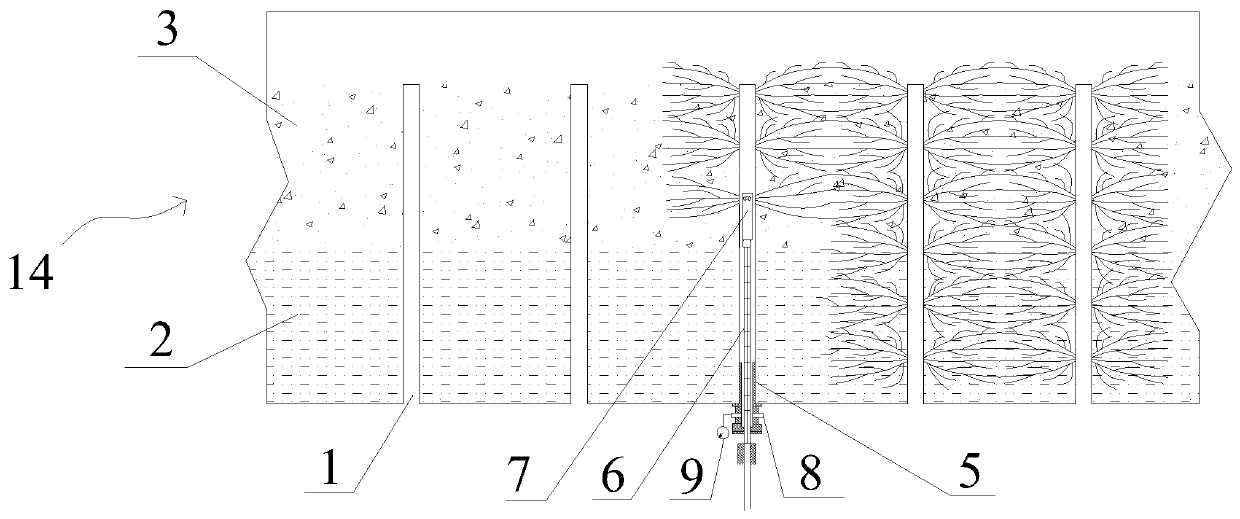

Operation-controllable roof-cutting pressure-relief gob-side entry retaining method

ActiveCN111022049AShorten the lengthRelieve stress concentrationDisloding machinesUnderground miningSingle supportMining engineering

The invention provides an operation-controllable roof-cutting pressure-relief gob-side entry retaining method which comprises the steps that a plurality of drill holes are formed in an advance workingface in the extending direction of a roadway, and the drill holes obliquely extend into a basic roof; a shock wave device is installed below the drill holes, a shock wave generator is sent to the bottom of the drill holes, and a hole packer is in sealing fit with a hole opening; injecting water into the drill holes from a water injection port, and starting the shock wave generator after the drillholes are filled with water to enable shock waves to impact along the roadway extension direction; the shock wave generator is repeatedly loaded at the bottom of the drill holes to break the rock stratum to a certain range, and then the push rod is contracted to carry out the next-stage operation until the push rod is contracted to the hole opening to finish the first drilling operation; performing the next drilling operation until all the drilling operation is completed; the rock stratum is sheared and broken at a pre-splitting kerf formed by penetration of the drill holes; and after the working face is pushed, single supports are arranged for temporary supporting. The method is controllable in roof cutting, easy to operate and good in safety performance, operation can be completed quickly, and safe and efficient production of a coal mine is guaranteed.

Owner:CHINA UNIV OF MINING & TECH

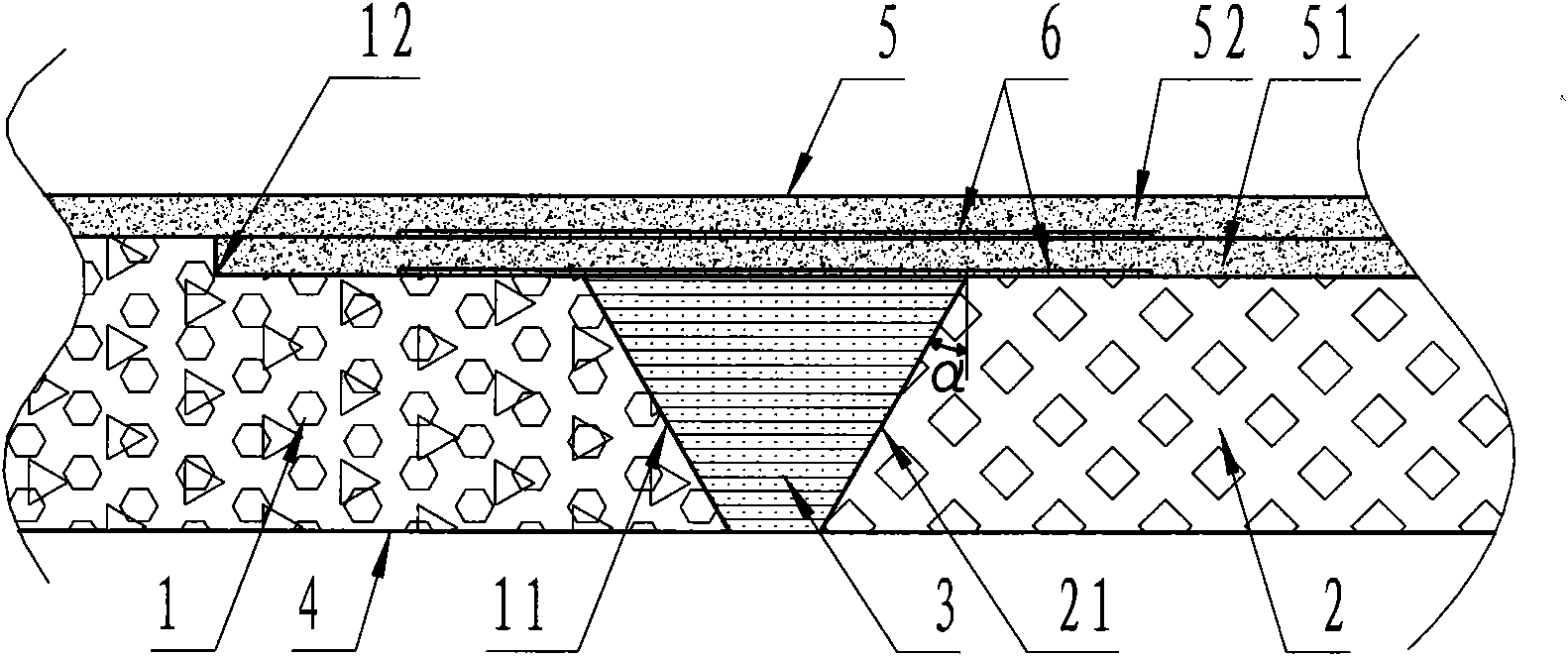

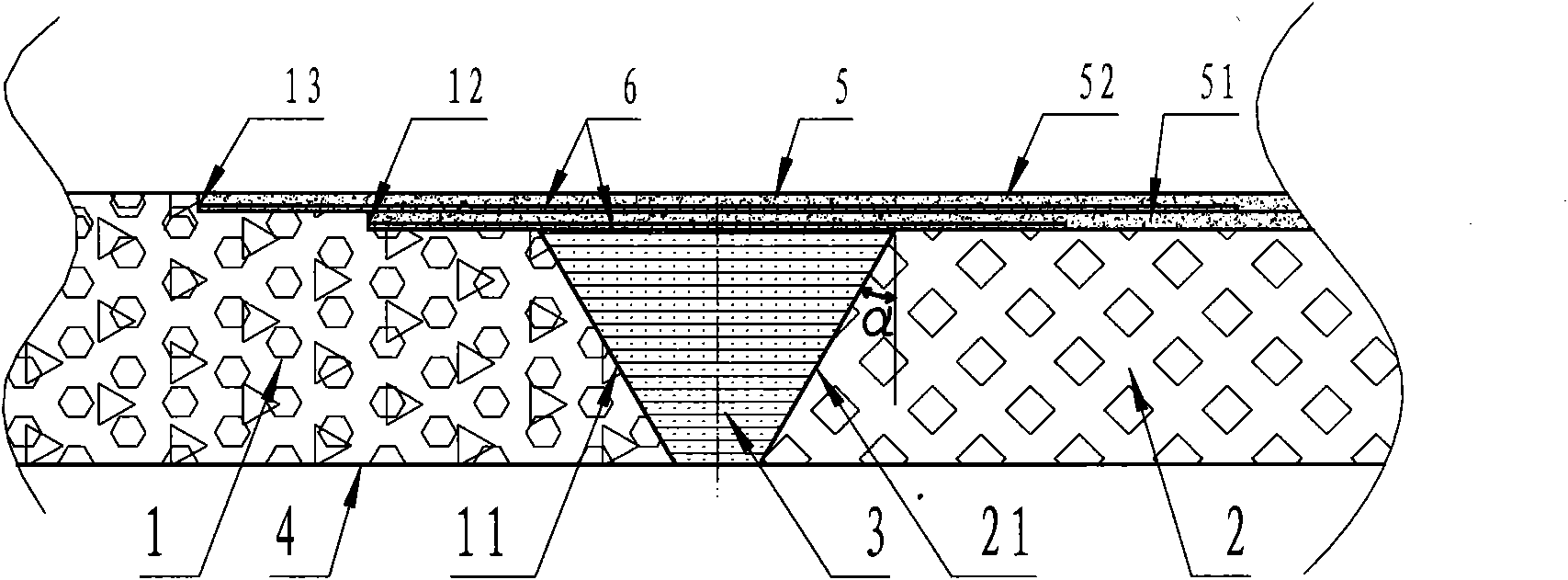

Stress absorption band and construction method thereof

ActiveCN101591882AStrong compression resistanceAvoid Longitudinal CracksPaving detailsCrushed stoneEngineering

The invention discloses a stress absorption band and a construction method thereof. The stress absorption band (3) is arranged at the joint part of a new road (2) and an old road (1), namely from the top surface of a roadbed to the underside of a newly paved oil surface, the stress absorption band (3) is arranged into an inverse trapezoid or an inverse triangular groove, and the groove is filled with asphalt macadam or modified asphalt macadam. The invention also discloses the construction method for the stress absorption band. The stress absorption band (3) is arranged at the joint part of the new road and the old road, can absorb and reduce stress, and prevent road surface diseases caused by the stress at the joint part of the new road and the old road.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

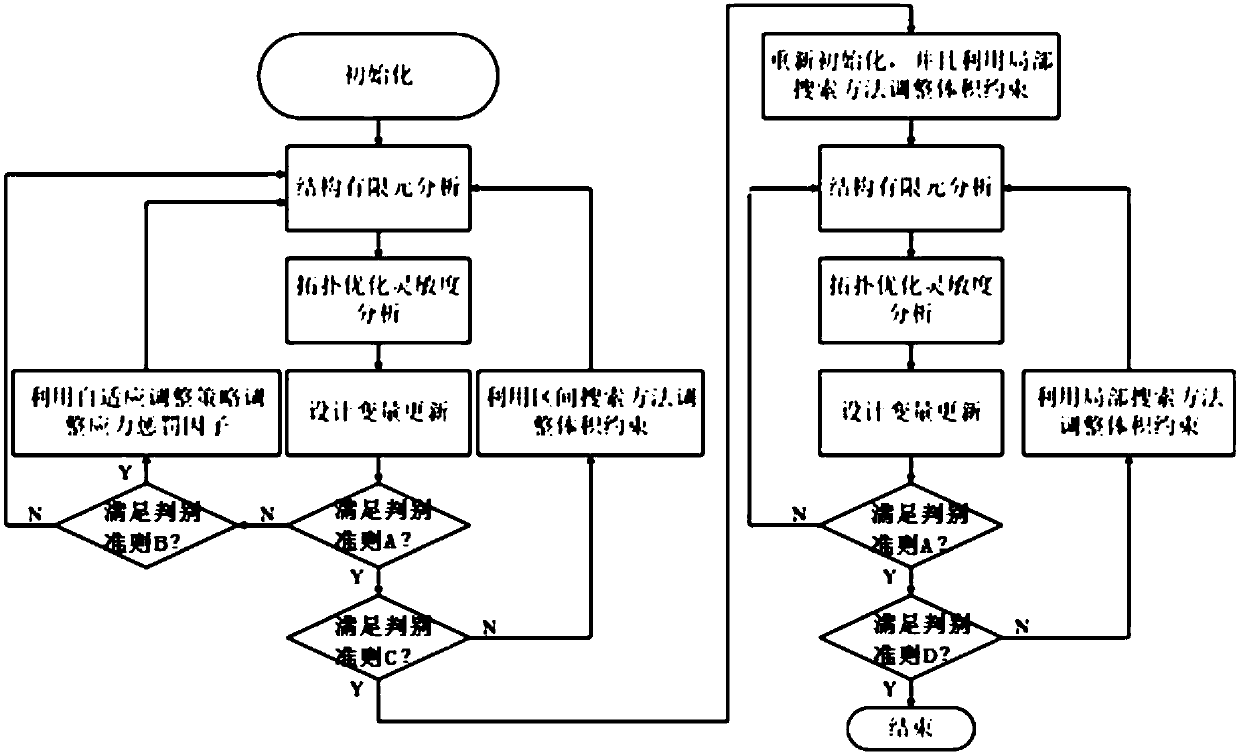

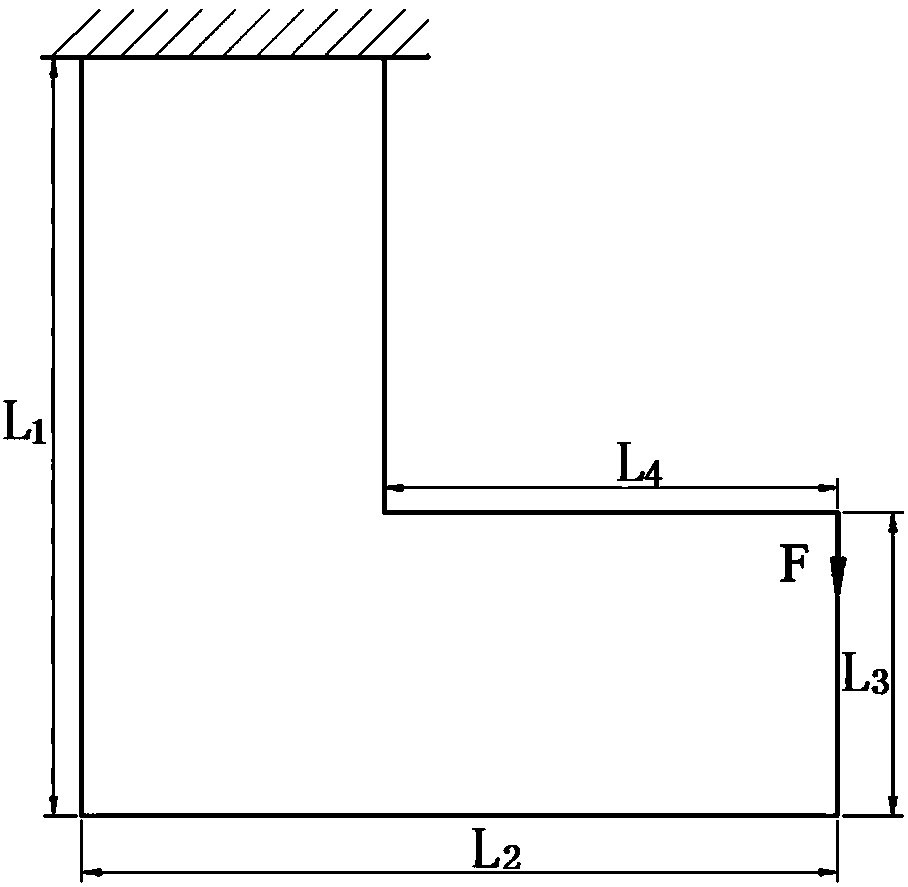

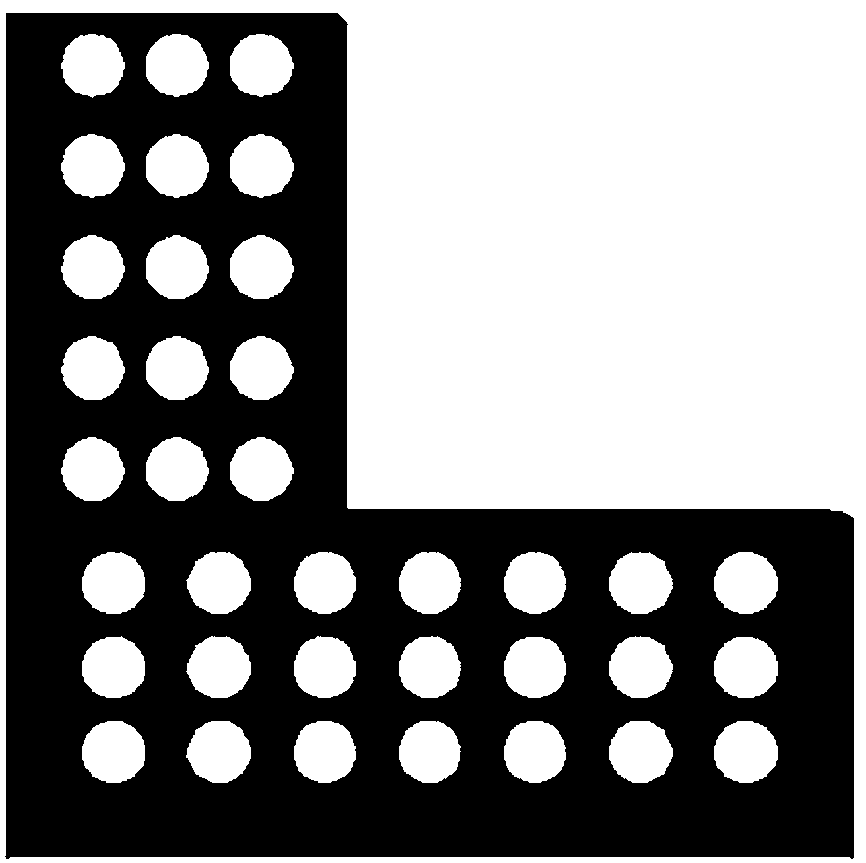

Structural topology optimization design method based on stress punishment and self-adaptive volume

ActiveCN107273613ASimplify the solution processClear and smooth borderDesign optimisation/simulationSpecial data processing applicationsSelf adaptiveBody volume index

The invention belongs to the related technical field of structural optimization design and discloses a structural topology optimization design method based on stress punishment and self-adaptive volume. The structural topology optimization design method is suitable for structural optimization considering stress constraints, rigidity maximization and volume fraction minimization and comprises the following steps that an optimization model based on stress punishment and a parameterized level set method is utilized to solve flexibility minimized structural optimization based on stress under volume constraints, and an interval searching method is utilized to adjust the volume constraints so as to narrow the searching range of structural optimized volume fractions and obtain the volume fraction upper limit value of an optimum structure; a local searching method is utilized to further adjust the volume constraints so as to obtain the volume fraction of the optimum structure and output the optimum structure. According to the structural topology optimization design method, solution is performed in a cycle applying mode, and the shortcoming that the structural volume minimization serves as an optimization target or the shortcoming brought by man-made selection of the volume constraints is directly avoided. The optimized structure has the advantages of high rigidity and light weight, and the strength of the optimized structure meets the design requirements.

Owner:HUAZHONG UNIV OF SCI & TECH

High-temperature brazing filler metal preparing method based on foamed silver filled with metal tin

InactiveCN106216873AImprove mechanical propertiesImprove plasticityWelding/cutting media/materialsSoldering mediaMetal sheetLiquid metal

The invention provides a high-temperature brazing filler metal preparing method based on foamed silver filled with metal tin. High-temperature brazing filler metal is a metal sheet formed by the foamed silver with micro and nanoscale pores filled with the metal tin, the foamed silver is filled with liquid metal tin through the capillary action, and preparing of the brazing filler metal is achieved. When the brazing filler metal is used for welding, a finally-formed welding line is composed of an intermetallic compound and remaining foamed silver, low-temperature welding can be achieved, an obtained welding point can be subject to high-temperature service, welding point reliability and welding line stability are greatly improved, and the method can be widely applied to various high-temperature welding fields.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

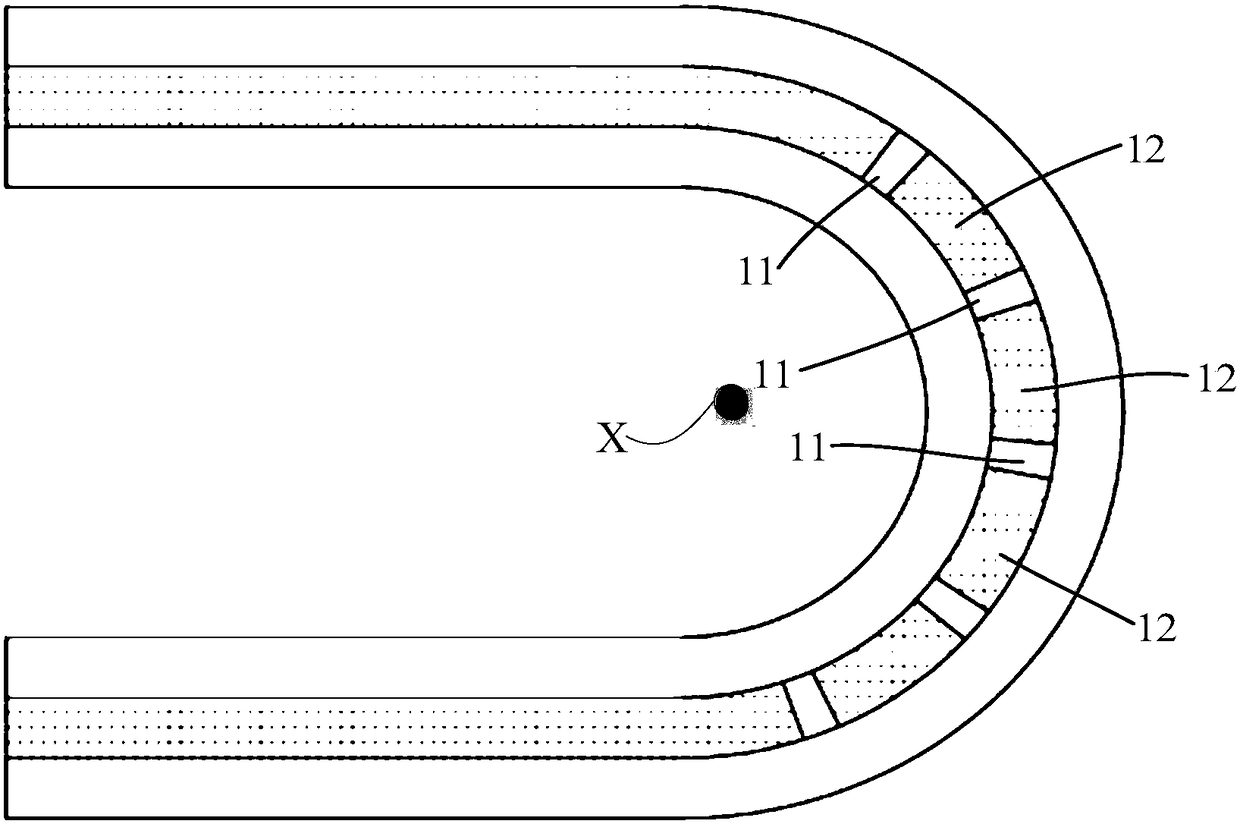

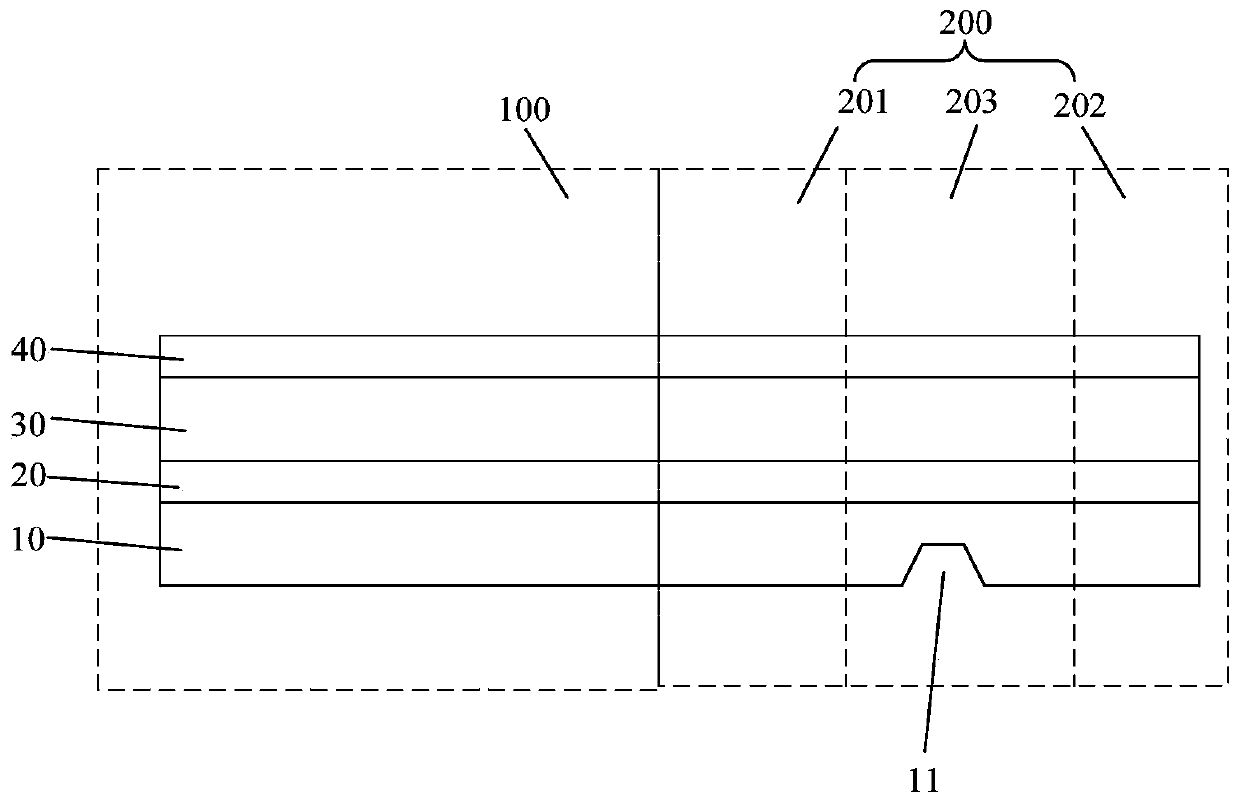

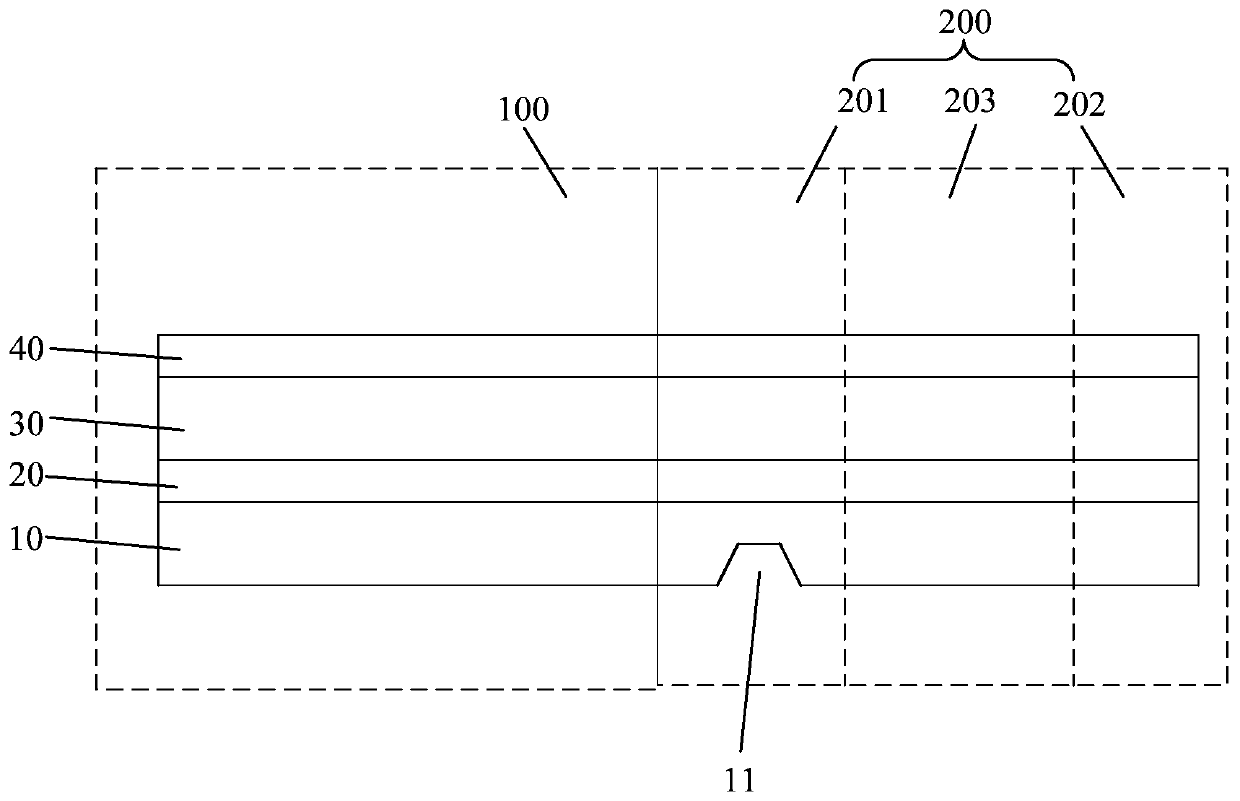

Display panel and display panel manufacturing method

InactiveCN110428731ARelieve stress concentrationMitigation of Fractured Technical IssuesIdentification meansEngineeringSurface plate

The present invention provides a display panel and a display panel manufacturing method. The display panel comprises a planar area and a bending area connected with the planar area, and the display panel further comprises a flexible substrate and a driving circuit layer; the flexible substrate comprises at least a first flexible layer, a barrier layer formed on one side of the first flexible layerand a second flexible layer formed on the side, away from the first flexible layer, of the barrier layer; the driving circuit layer is formed on the side, away from the barrier layer, of the second flexible layer; and in the bending area, a groove is formed on the side, away from the barrier layer, of the first flexible layer. According to the technical scheme of the present invention, by settingthe groove in the first flexible layer in the bending area, the thickness of the first flexible layer in the bending area can be reduced, and a stress neutral layer in the bending area can approach the metal trace area of the driving circuit layer, so that the technical problems of stress concentration and metal trace breakage in the bending area can be alleviated.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

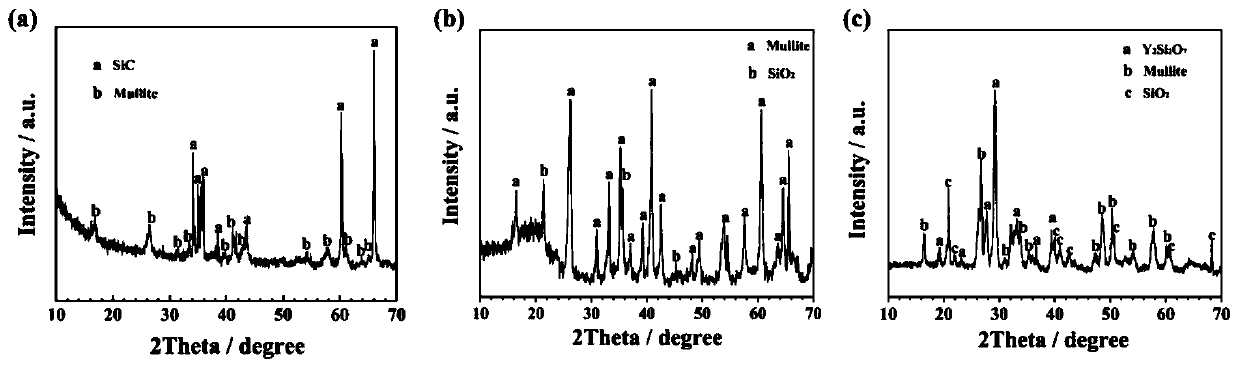

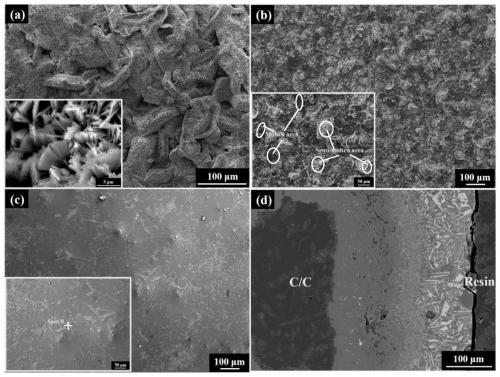

Carbon/carbon composite material surface mullite whisker-mullite/yttrium alumina silicate compound anti-oxidation coating and preparation method

The invention relates to a carbon / carbon composite material surface mullite whisker-mullite / yttrium alumina silicate compound anti-oxidation coating and a preparation method. According to the preparation method, firstly, an in-situ molten-salt growth method is adopted for preparing a porous mullite whisker layer on the surface of a SiC coating. On one hand, the mullite whisker layer can improve the wettability of SiC and a middle mullite layer; on the other hand, the mullite whisker can improve the inherent brittleness of a mullite ceramic coating. A yttrium alumina silicate glass ceramic coating with good wettability in the presence of the mullite, good inoxidizability and chemical durability at the high temperature is selected for conducting hole sealing treatment on the mullite coatingprepared through supersonic plasma spraying to reduce the porosity of the carbon / carbon composite material surface mullite whisker-mullite / yttrium alumina silicate compound anti-oxidation coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

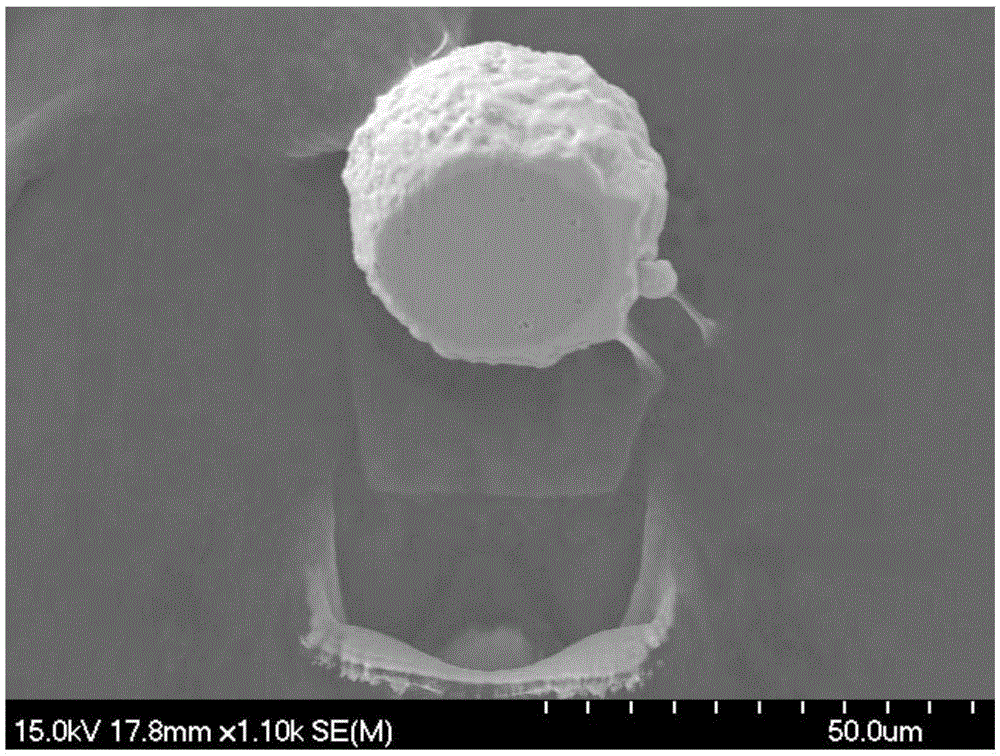

Method for cladding surface of micro-nano-copper ball with thick tin layer with weldable thickness

ActiveCN105290418ABroad prospects for promotion and applicationImprove compatibilityCoatingsMicro nanoSolderability

The invention provides a method for a cladding surface of a micro-nano-copper ball with thick tin layer with weldable thickness. According to the method, bimetallic powder clad with the thick tin layer based on a Cu@Sn core-shell structure is obtained. A presetting piece formed by pressing a bimetallic powder material is used for welding, so that low-temperature (250DEG C) welding can be realized. The obtained welding spot can be served at high temperature (676DEG C), and the reliability of the welding spot and the stability of weld joints are greatly improved. The method can be widely applied to various high temperature welding fields.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Pneumatic tire

InactiveCN102328556AReduce rigidityInhibition of reduced gripTyre tread bands/patternsEngineeringMechanical engineering

The invention provides a pneumatic tire, which can inhibit a crack generated at the inner side terminal of a blade groove pattern. The decrease of the edge length can prevent an opening. A plurality of pattern areas are provided on the surface of the pneumatic tire. The pattern areas at least include the following: a pattern area with an annular blade groove possessing a blade groove assembly, the blade groove assembly includes a pair of blade groove pattern plates, which are extended respectively from the two-side pattern blocks at the pattern area width direction inward; and annular blade groove patterns which are arranged between the inner sides.

Owner:SUMITOMO RUBBER IND LTD

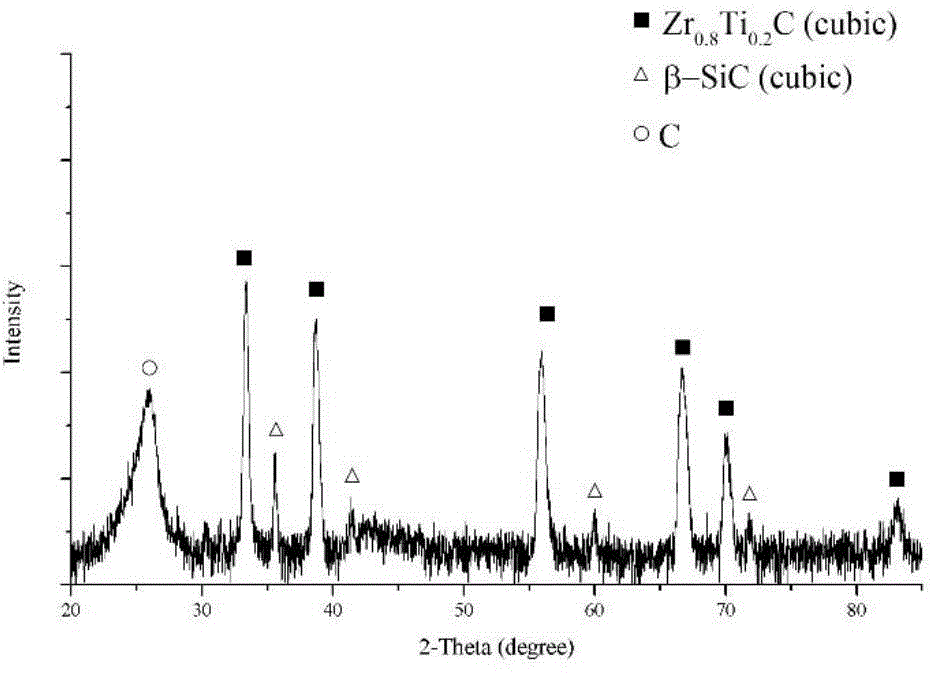

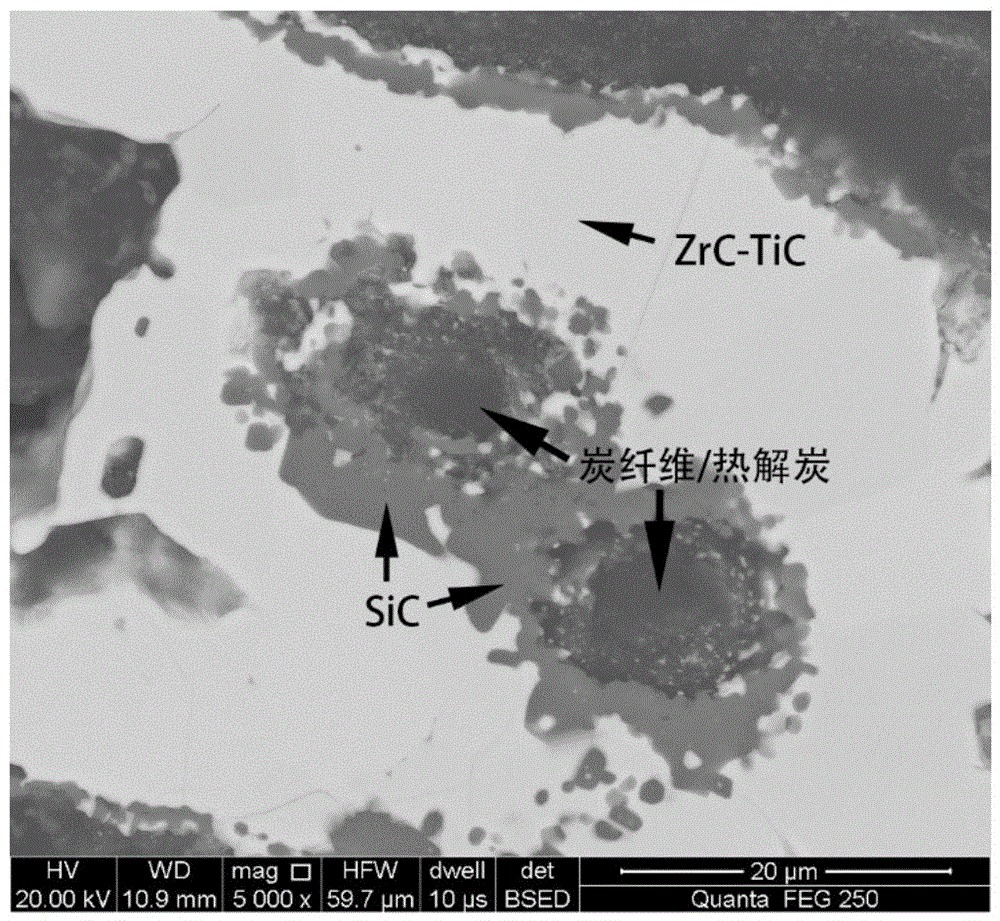

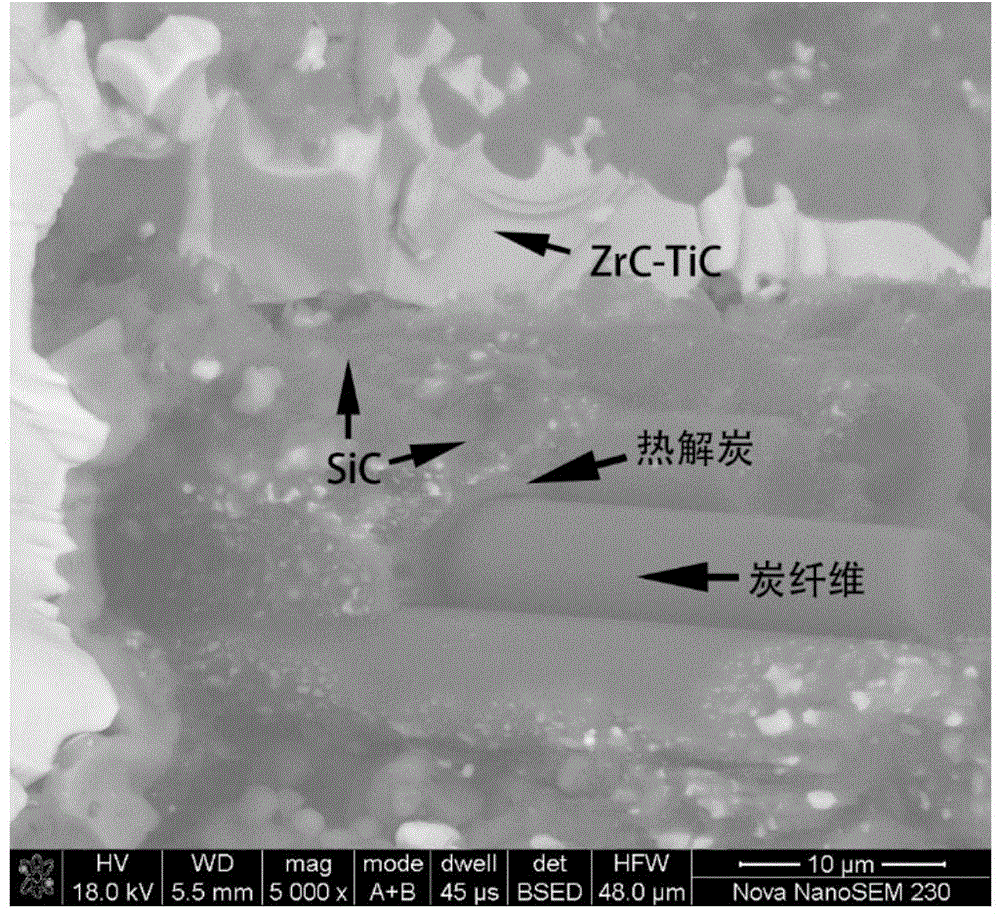

C/C-SiC-ZrC-TiC composite material and preparation method thereof

ActiveCN104671814AReduce thermal mismatchRelieve stress concentrationInterface layerPyrolytic carbon

The invention discloses a C / C-SiC-ZrC-TiC composite material and a preparation method thereof. The composite material is composed of a carbon fibre, a pyrolytic carbon, a main matrix phase ZrC-TiC and a sub matrix phase SiC. The composite material is characterized in that the SiC is used as an interface layer for separating the pyrolytic carbon from the ZrC-TiC. The preparation method comprises the following steps: melting the mixed powder of Zr, Ti and Si, permeating into the inside of the low-density C / C composite material through a capillary action, forming a ceramic phase in a hole through an in situ reaction to obtain the C / C-SiC-ZrC-TiC composite material. The preparation method is rapid and effective and low in cost; the prepared composite material has excellent super-high temperature ablation resistance performance and simultaneously has excellent strength, breaking tenacity and thermal shock resistance.

Owner:深圳金羽先进材料有限公司

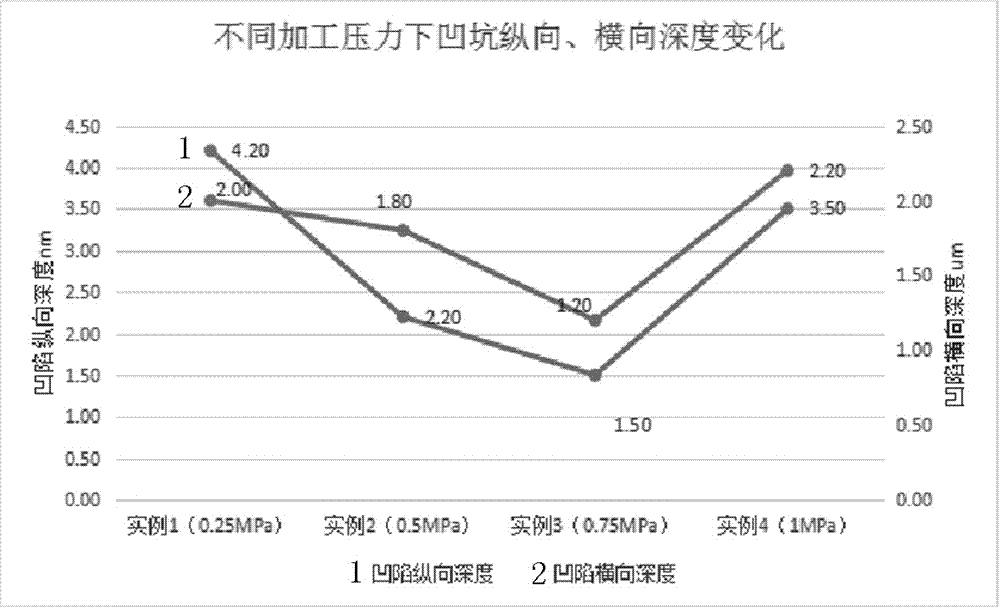

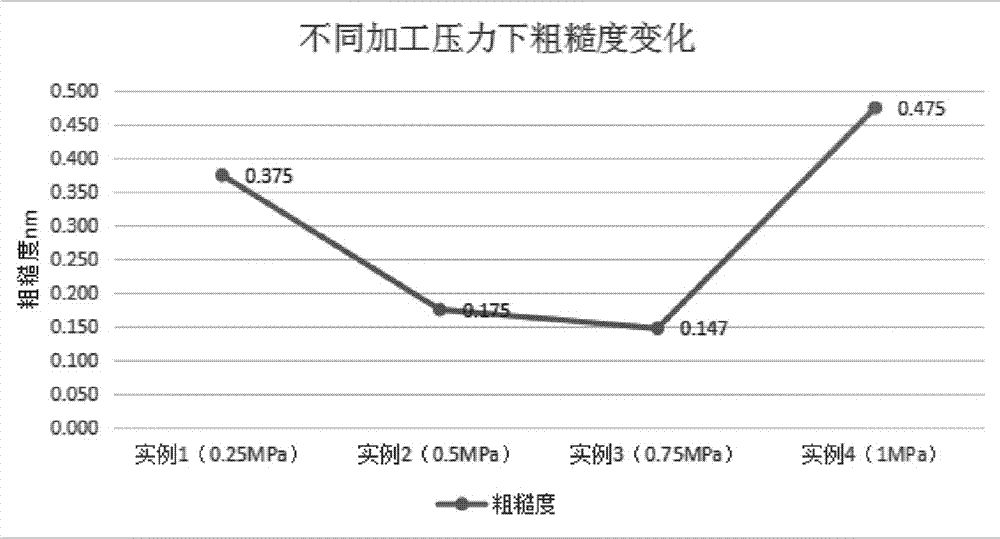

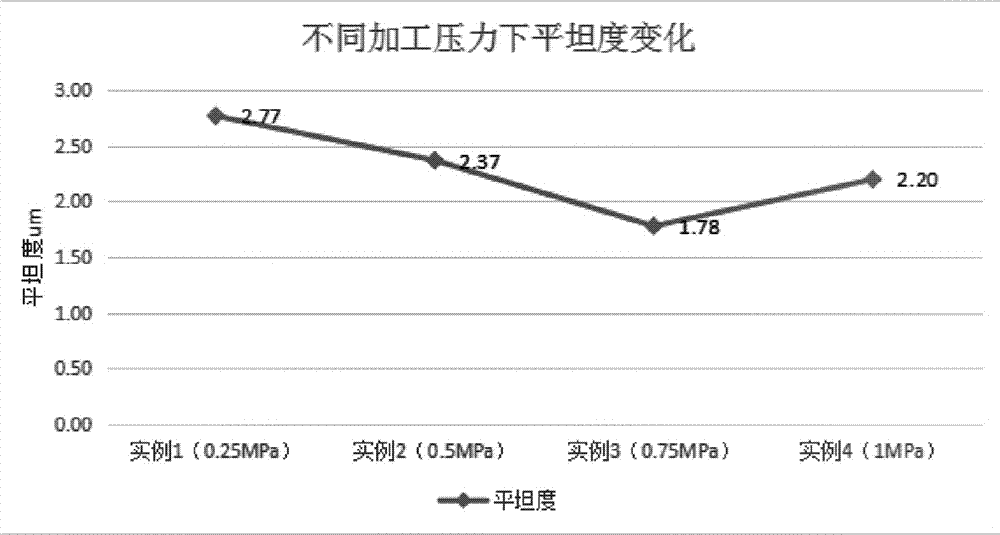

Polishing method for lithium tantalate substrate

The invention discloses a polishing method for a lithium tantalate substrate. The method includes the steps of 1, grinding a cut tantalate lithium wafer with an abrasive material with the particle size of 5-20 microns, and obtaining a lithium tantalate grinding sheet with the surface of a rough structure; 2, directly conducting chemical corrosion on the lithium tantalate grinding sheet in a sealed container filled with the mixed acid of nitric acid and hydrofluoric acid, wherein the roughness of the tantalate lithium wafer is smaller than 200 nm, and the flatness is smaller than 5 microns; obtaining a lithium tantalate corrosion sheet with the surface of a random disordered pit structure; 3, conducting single-side polishing on the lithium tantalate corrosion sheet with a single-polishing machine and a polishing liquid, wherein the polishing pressure is 0.005-1 MPa, the roughness of the tantalate lithium wafer is smaller than 0.5 nm, and the flatness is smaller than 3 microns; obtaining a lithium tantalite polishing sheet. The polishing method has the advantages of one-time polishing, batch production and high polishing efficiency, and the produced lithium tantalate substrate has high surface flatness which determines that the lithium tantalate substrate is not easily broken in the application of devices; the material utilization is high, and the processing yield is high.

Owner:TDG HLDG CO LTD

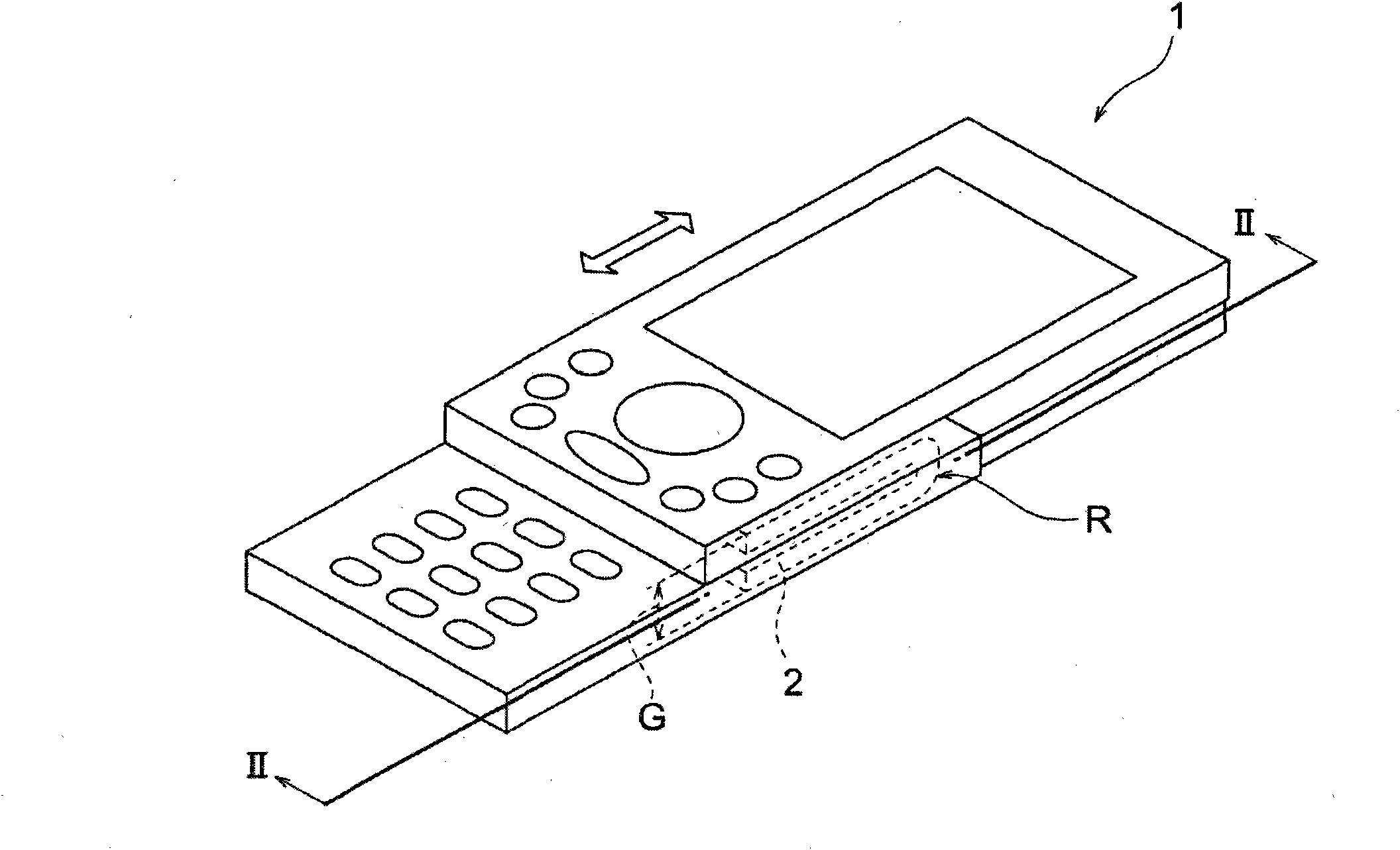

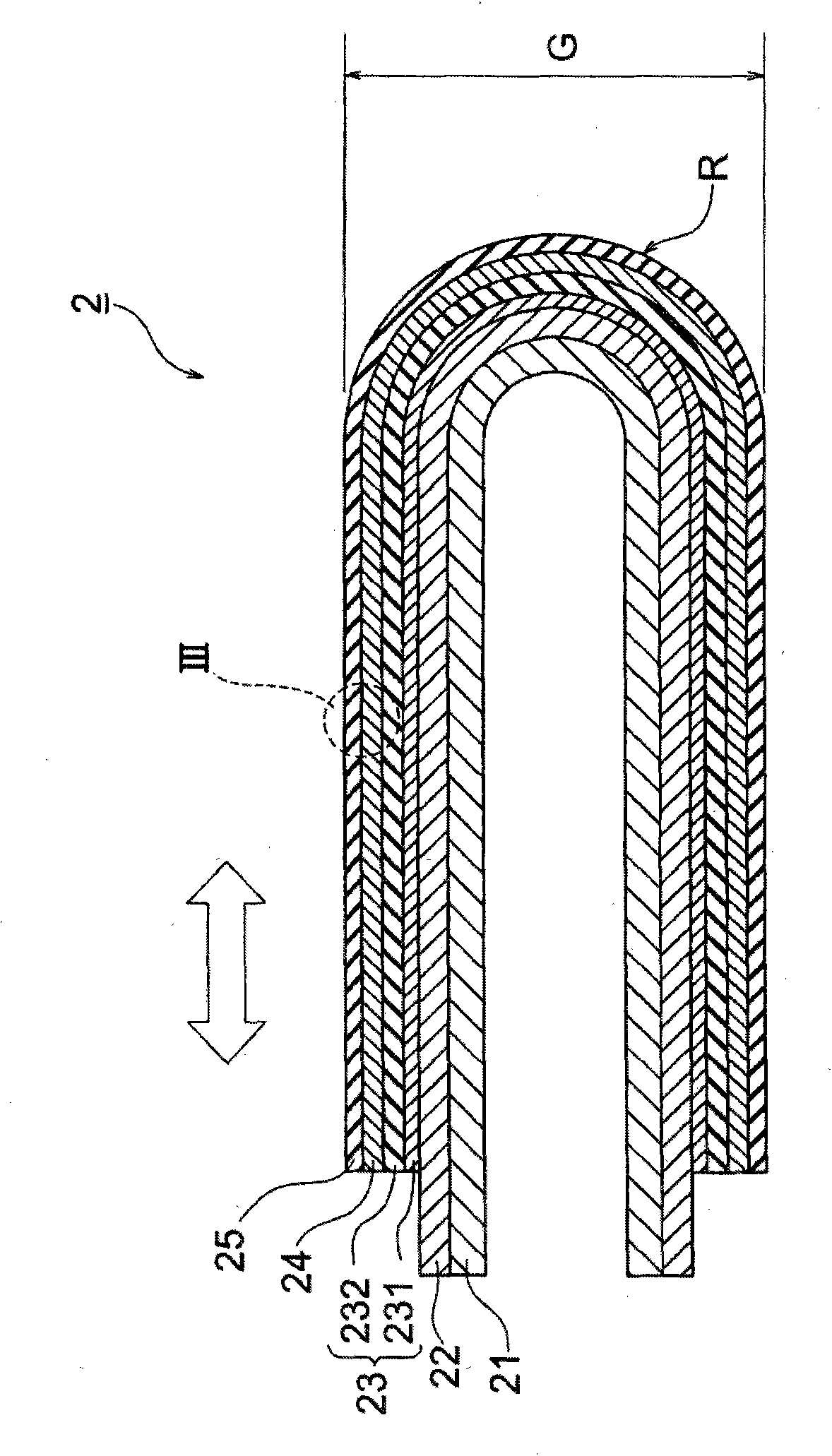

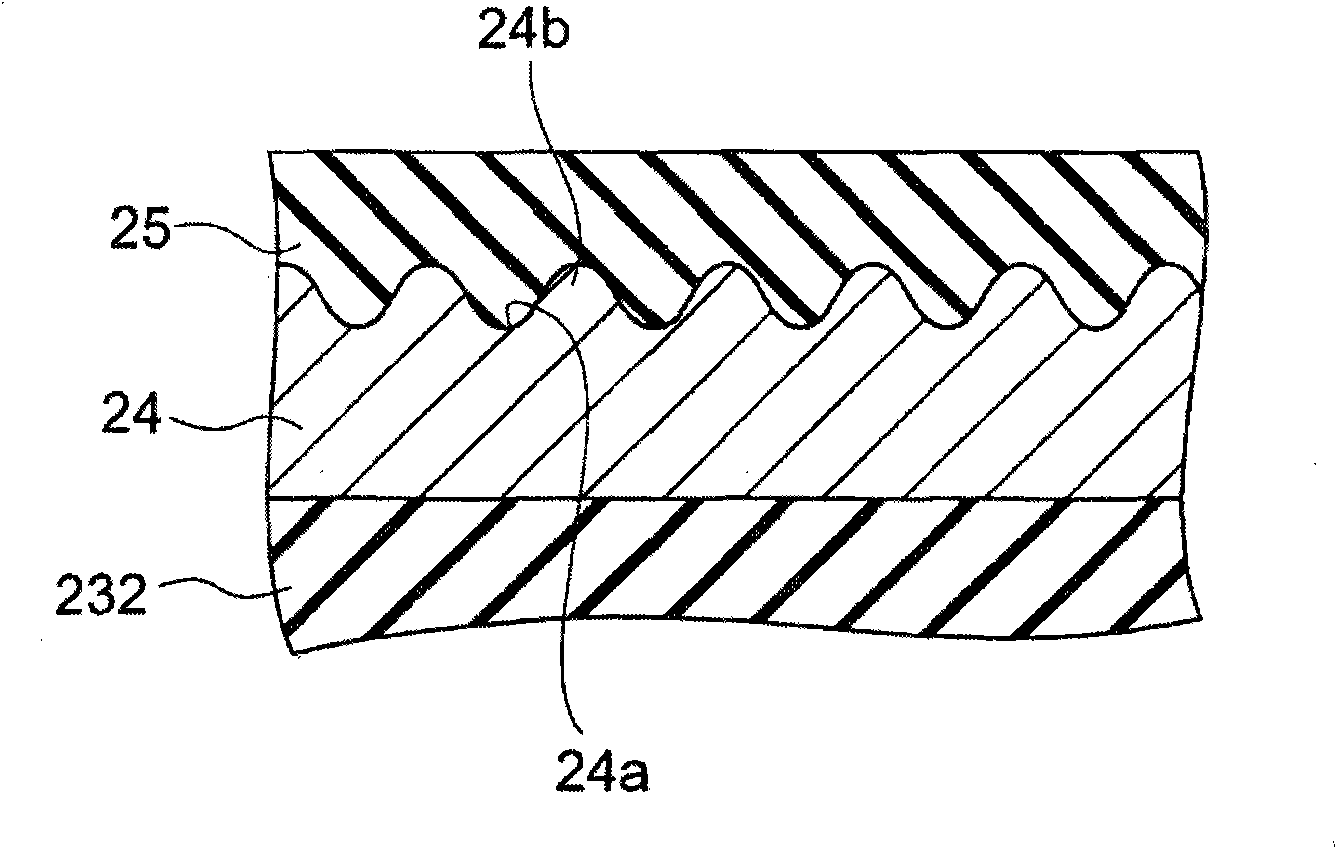

Flexible printed board and method of manufacturing same

ActiveCN102215630AImprove bending performanceRelieve stress concentrationCross-talk/noise/interference reductionPrinted circuit aspectsPrinted circuit boardElastic modulus

The invention provides a flexible printed board improved in bendability and a method of manufacturing the same. The flexible printed board 2 comprises: an insulating substrate 21; a circuit wiring 22 laid on the insulating substrate 21; a circuit protection layer 23 laid on the circuit wiring 22; a shield conductive layer 24 laid on the circuit protection layer 23; and a shield insulating layer 25 laid on the shield conductive layer 24, and is characterized by meeting the following Expression (1). 0.75<=E2 / E1<=1.29... Expression (1) Note that E1 denotes the tensile elastic modulus of the shield conductive layer 24 and E2 denotes the tensile elastic modulus of the shield insulating layer 25.

Owner:FUJIKURA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com