High-temperature brazing filler metal preparing method based on foamed silver filled with metal tin

A technology of high-temperature solder and foamed silver, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as inability to play a connection role, achieve excellent thermal cycle reliability, good compatibility, and reduce heat damage effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Implementation example 1, refer to figure 1 and 2 :

[0040] A method for preparing high-temperature solder based on metal tin filling foam silver, the method specifically includes the following steps (making metal tin fill foam silver into a solder sheet by printing solder paste and then reflowing it, and finally making it High temperature solder joints as an example):

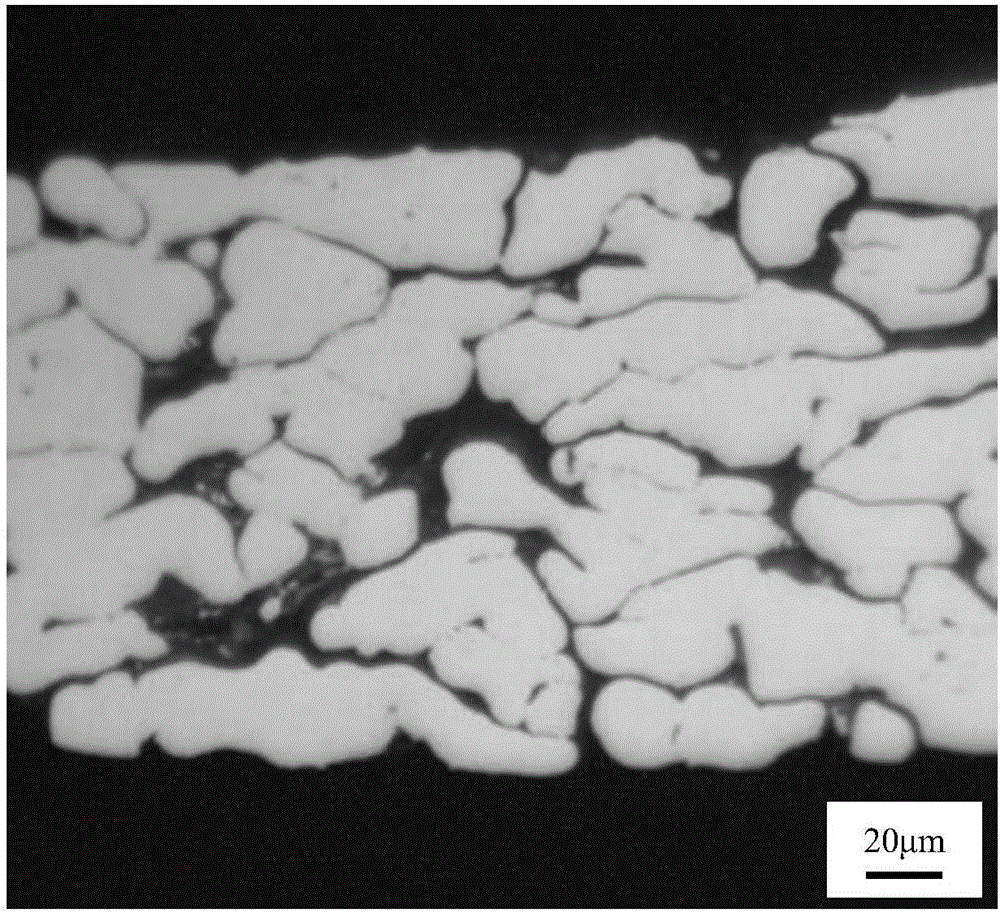

[0041] (1) Cut out a silver foam sheet with a length of 10mm*width of 10mm*thickness of 0.6mm, and its pore size is generally less than 20μm;

[0042] (2) Step (1) gained foam silver sheet is placed in the solution containing thiourea, citric acid, salt of wormwood (mass ratio, thiourea: citric acid: potassium carbonate: deionized water=1:3:1: 25), and finally wash the copper powder 3 times with deionized water, and dry it for later use;

[0043] (3) Print Sn1Ag0.5Cu solder with a length of 10mm*width of 10mm*thickness of 0.5mm on the silver foam sheet by screen printing, and reflow at 250°C for 30...

Embodiment 2

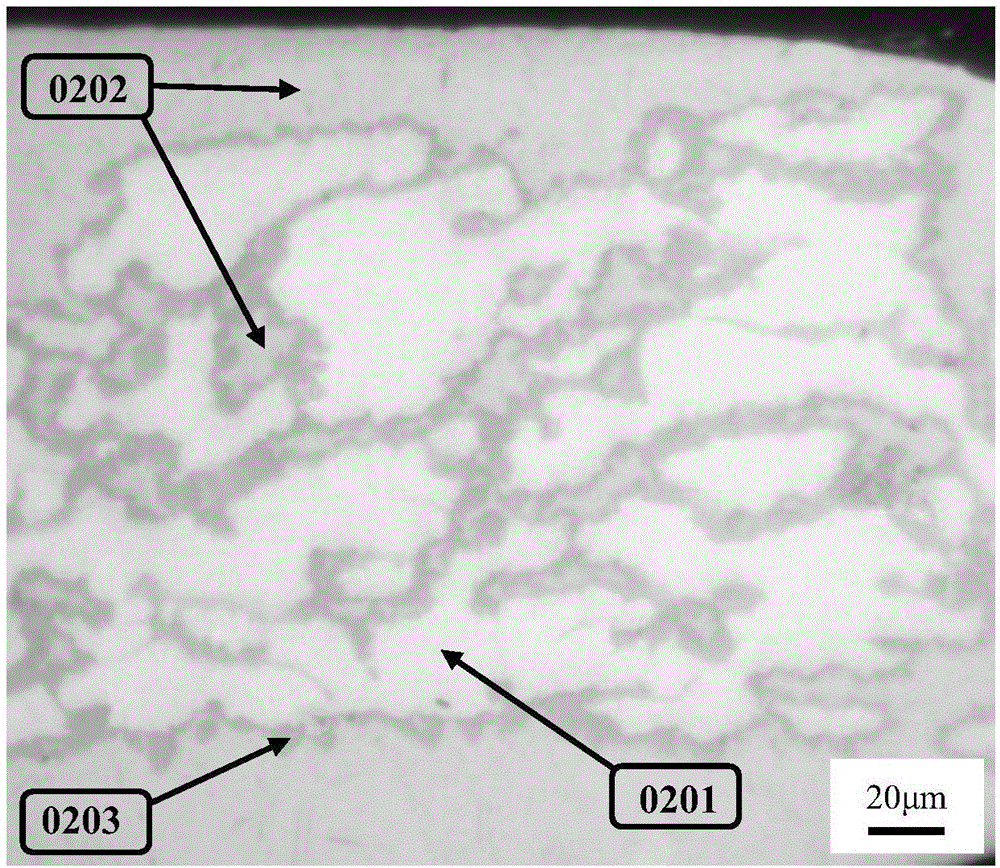

[0044] Implementation example 2, refer to figure 1 and 2 :

[0045] A method for preparing high-temperature solder based on metal tin filling foam silver, the method specifically includes the following steps (making metal tin fill foam silver into a solder sheet by printing solder paste and then reflowing it, and finally making it High temperature solder joints as an example):

[0046] (1) Cut out a silver foam sheet with a length of 10mm*width of 10mm*thickness of 0.6mm, and its pore size is generally less than 20μm;

[0047] (2) Step (1) gained foam silver sheet is placed in the solution containing thiourea, citric acid, salt of wormwood (mass ratio, thiourea: citric acid: potassium carbonate: deionized water=1:3:1: 25), and finally wash the copper powder 3 times with deionized water, and dry it for later use;

[0048] (3) The foamed silver sheet is first impregnated with flux (the flux is purchased from the market and conforms to the electronic industry standard SJ / T112...

Embodiment 3

[0049] Embodiment 3 metal welding

[0050] Use the high-temperature solder sheet obtained in the above steps of Example 1 to carry out welding, the welding temperature is selected as 250 ° C, and the heat preservation is 3 minutes. After testing, the weld seam finally formed is composed of remaining foamed silver and Ag 3 Composition of Sn. The welding seam can realize low-temperature (250°C) welding, and the obtained solder joints can withstand high-temperature (480°C) service.

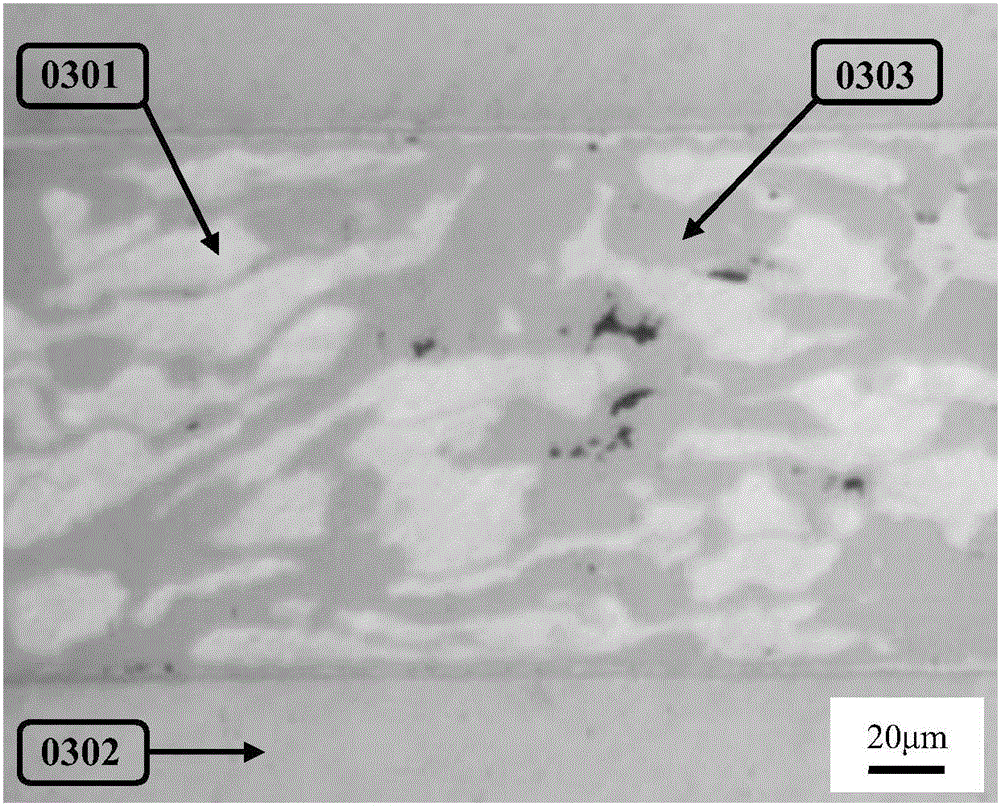

[0051] The obtained weld structure is as image 3 Shown:

[0052] It has been verified by a large number of experiments that the resistivity of this weld is 5.18μΩ·cm, and its conductivity is far superior to that of traditional tin-based solder (11.5μΩ·cm) and the solder made entirely of silver-tin compounds made by the traditional TLP process. Pure IMC solder joints are in the same order of magnitude (2.5-10μΩ·cm) as the welds after nano-silver sintering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com