Polishing method for lithium tantalate substrate

A lithium tantalate and substrate technology, which is applied in the field of semiconductor materials, can solve the problems of poor roughness and flatness, deterioration of polishing quality, non-uniform wear of polishing, etc., to achieve small roughness, improve the quality of filter components, and reduce processing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a) Grind the cut lithium tantalate wafer with an abrasive with a particle size of 6um so that the roughness of the lithium tantalate wafer is less than 300nm and the flatness is less than 10um, and then ultrasonically cleaned to obtain a lithium tantalate grinding surface with a rough structure piece;

[0028] b) The lithium tantalate grinding piece is directly chemically etched in a closed container containing a mixed acid of nitric acid and hydrofluoric acid, the etching temperature is 25°C, and the etching time is 4 hours, so that the roughness of the lithium tantalate wafer is <200nm, The flatness is less than 5um, and ultrasonic cleaning is performed to obtain lithium tantalate corrosion sheets with random and disordered pit structures on the surface;

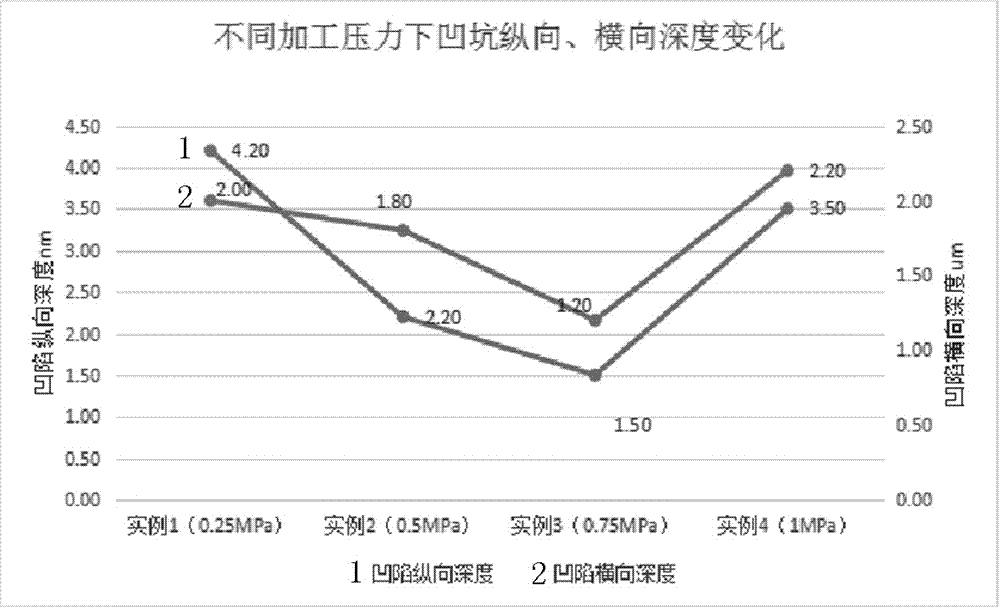

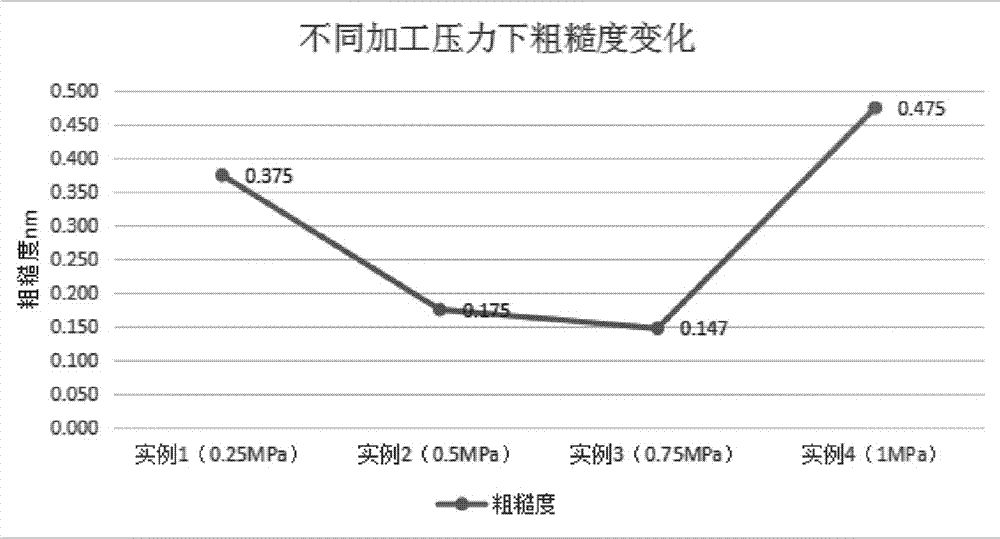

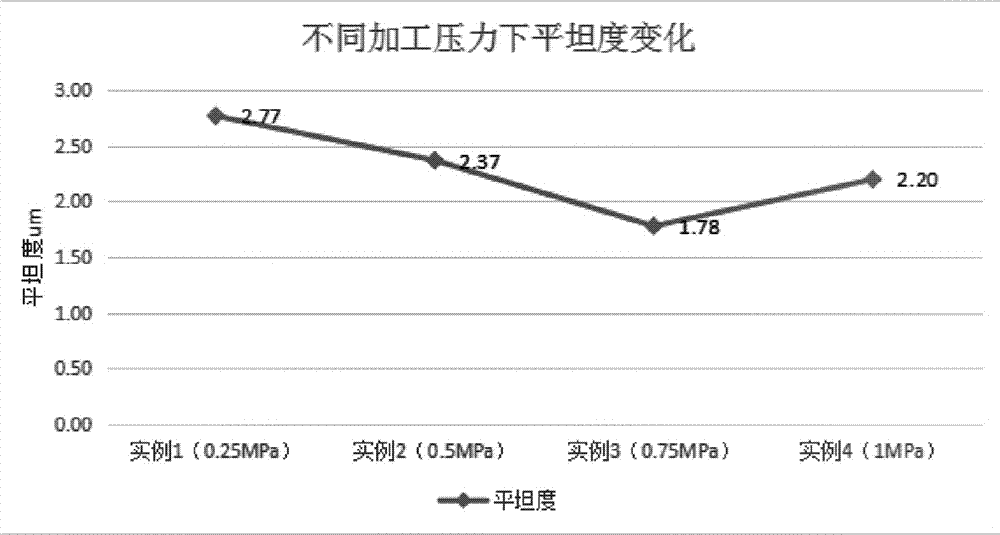

[0029] c) Polish the lithium tantalate wafer on one side with a single polishing machine and polishing liquid, the polishing pressure is 0.25MPa, and the polishing temperature is 30°C, so that the roughness of the l...

Embodiment 2

[0031] a) Grind the cut lithium tantalate wafer with an abrasive with a particle size of 6um so that the roughness of the lithium tantalate wafer is less than 300nm and the flatness is less than 10um, and then ultrasonically cleaned to obtain a lithium tantalate grinding surface with a rough structure piece;

[0032] b) The lithium tantalate grinding piece is directly chemically etched in a closed container containing a mixed acid of nitric acid and hydrofluoric acid, the etching temperature is 25°C, and the etching time is 8 hours, so that the roughness of the lithium tantalate wafer is <200nm, The flatness is less than 5um, and ultrasonic cleaning is performed to obtain lithium tantalate corrosion sheets with random and disordered pit structures on the surface;

[0033] c) Polish the lithium tantalate wafer on one side with a single polishing machine and polishing solution, the polishing pressure is 0.50MPa, and the polishing temperature is 30°C, so that the roughness of the...

Embodiment 3

[0035] a) Grind the cut lithium tantalate wafer with an abrasive with a particle size of 6um so that the roughness of the lithium tantalate wafer is less than 300nm and the flatness is less than 10um, and then ultrasonically cleaned to obtain a lithium tantalate grinding surface with a rough structure piece;

[0036] b) The lithium tantalate grinding piece is directly chemically etched in a closed container containing a mixed acid of nitric acid and hydrofluoric acid, the etching temperature is 25°C, and the etching time is 8 hours, so that the roughness of the lithium tantalate wafer is <200nm, The flatness is less than 5um, and ultrasonic cleaning is performed to obtain lithium tantalate corrosion sheets with random and disordered pit structures on the surface;

[0037] c) Polish the lithium tantalate wafer on one side with a single polishing machine and polishing liquid, the polishing pressure is 0.75MPa, and the polishing temperature is 30°C, so that the roughness of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com