Patents

Literature

353 results about "Lithium tantalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium tantalate (LiTaO₃) is a perovskite which possesses unique optical, piezoelectric and pyroelectric properties which make it valuable for nonlinear optics, passive infrared sensors such as motion detectors, terahertz generation and detection, surface acoustic wave applications, cell phones and possibly pyroelectric nuclear fusion. Considerable information is available from commercial sources about this salt.

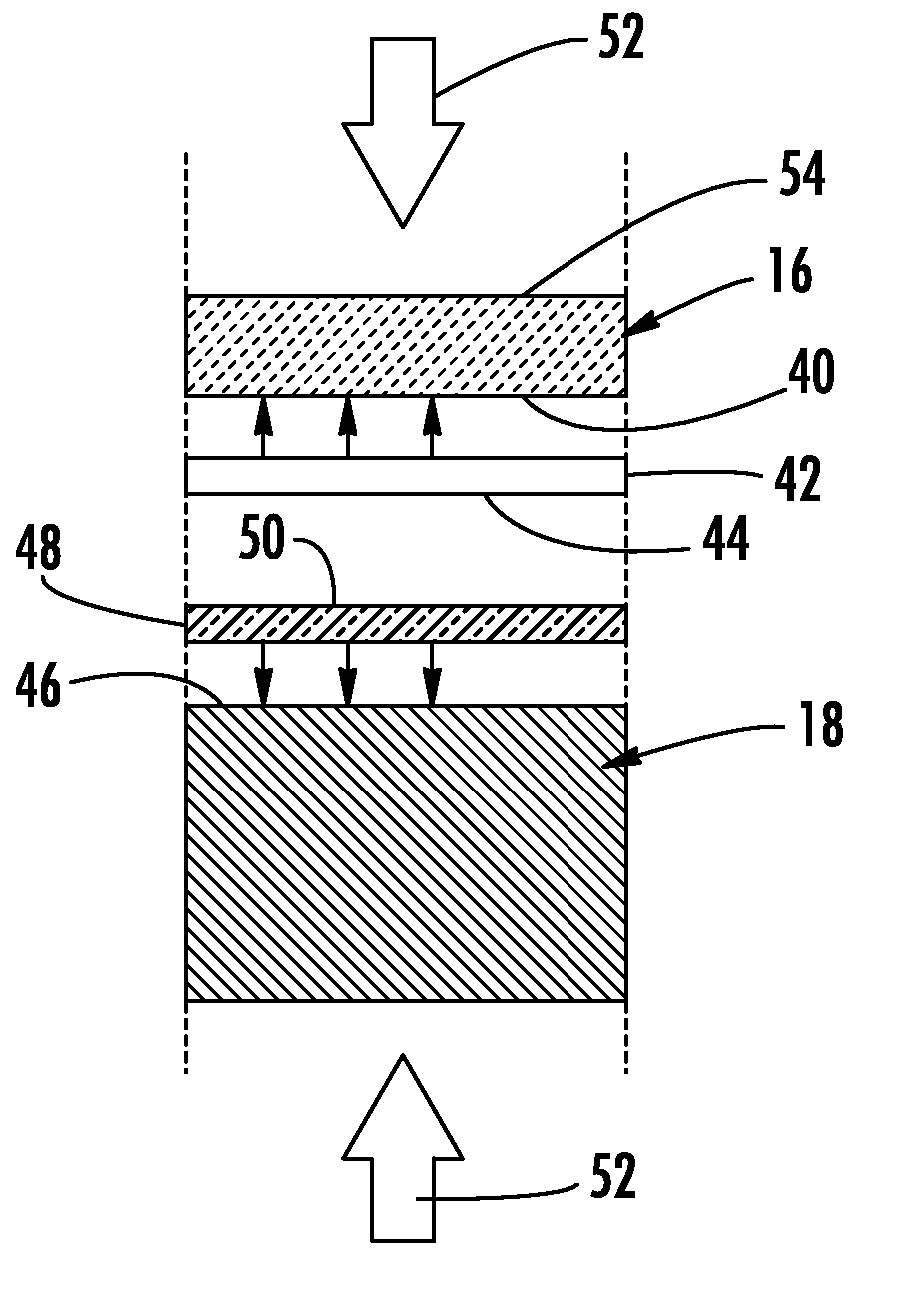

Saw filter device and method employing normal temperature bonding for producing desirable filter production and performance characteristics

ActiveUS7105980B2Improve reliabilityReduce heat sensitivityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLength waveSilicon

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

Method of forming a surface acoustic wave (SAW) filter device

InactiveUS7213314B2Improve reliabilityReduce heat sensitivityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveLength wave

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

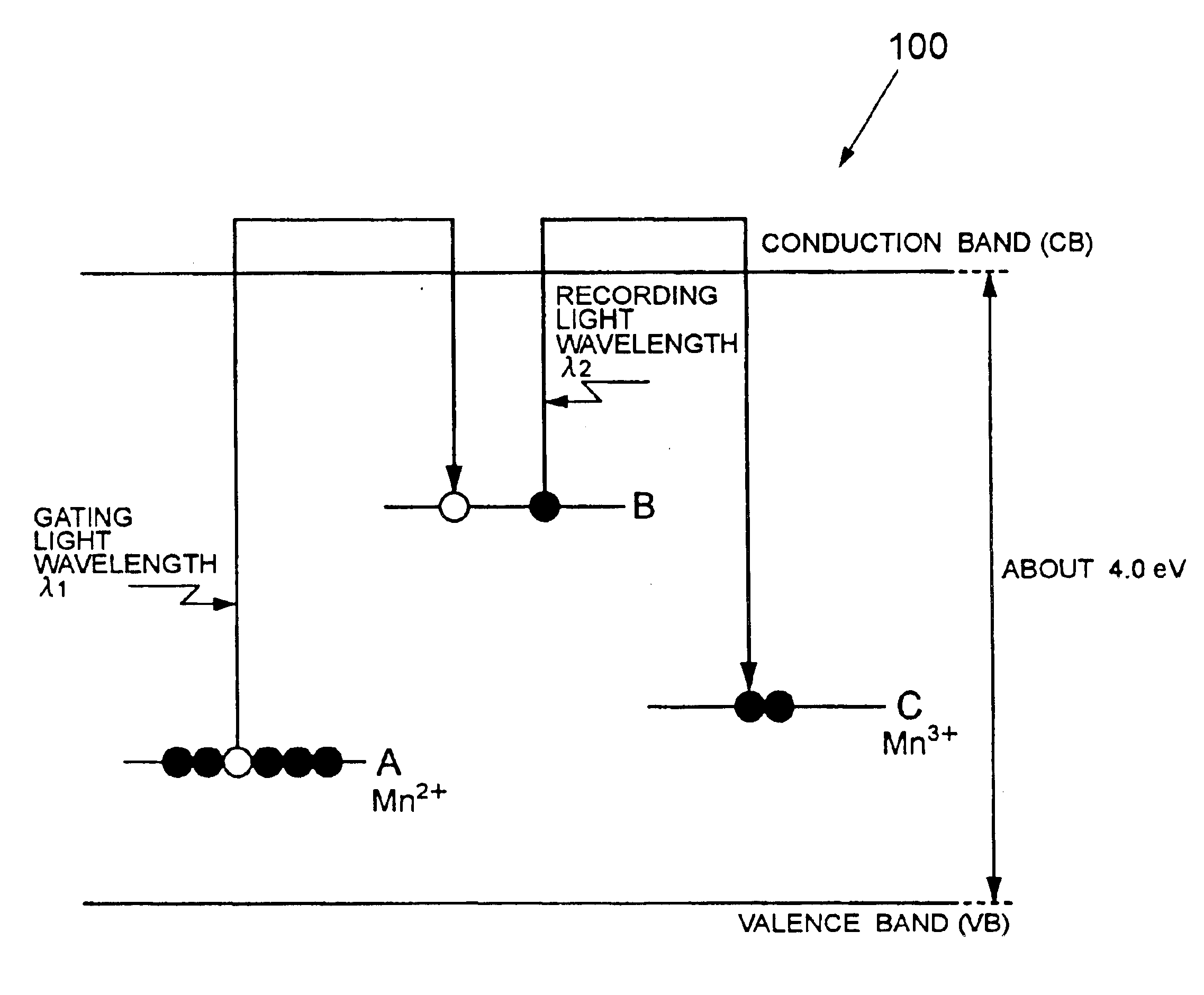

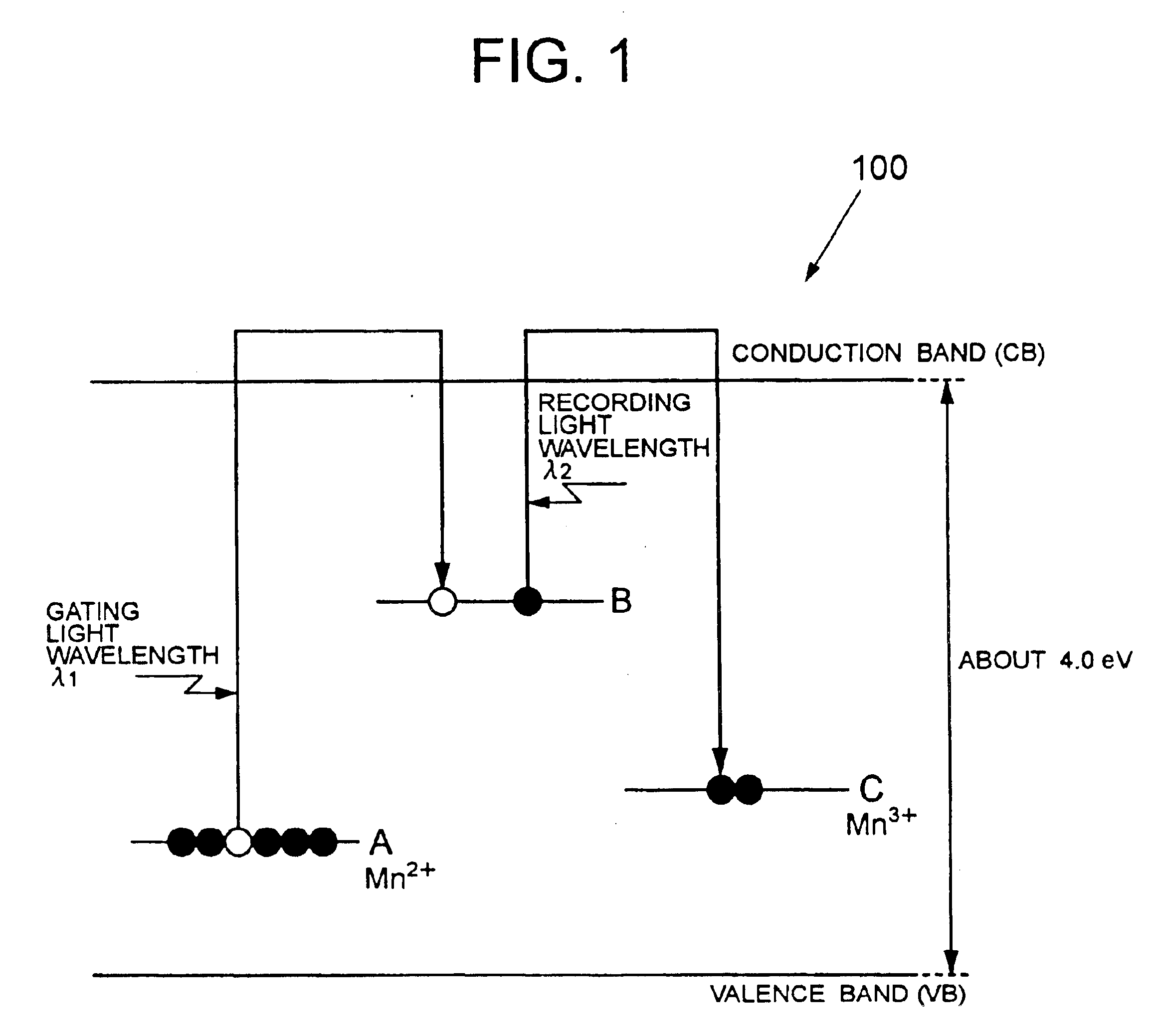

Holographic recording medium and holographic recording/reproducing apparatus using the same

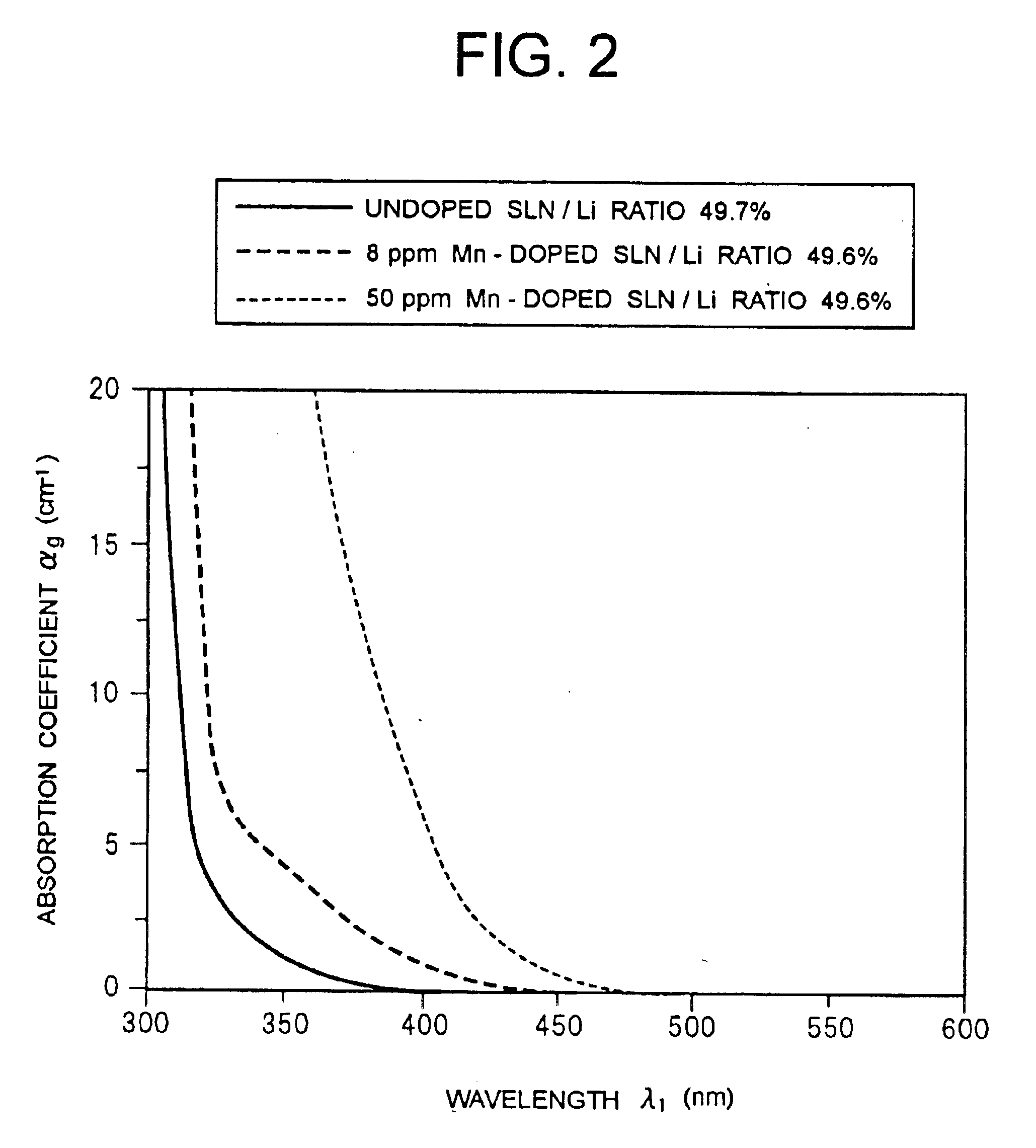

InactiveUS6856433B2High sensitivityMitigating optical damageRecord carriers used with machinesRecording/reproducing/erasing using optical interference patternsDopantReduction treatment

A holographic recording medium exhibiting a high recording sensitivity without execution of reduction treatment. A system records information on the holographic recording medium by using a gating light within a wavelength band causing less optical damage to the holographic recording medium. The holographic recording medium includes a single crystal of lithium niobate (LiNbO3) or lithium tantalate (LiTaO3) containing Mn as a dopant.

Owner:NAT INST FOR MATERIALS SCI +1

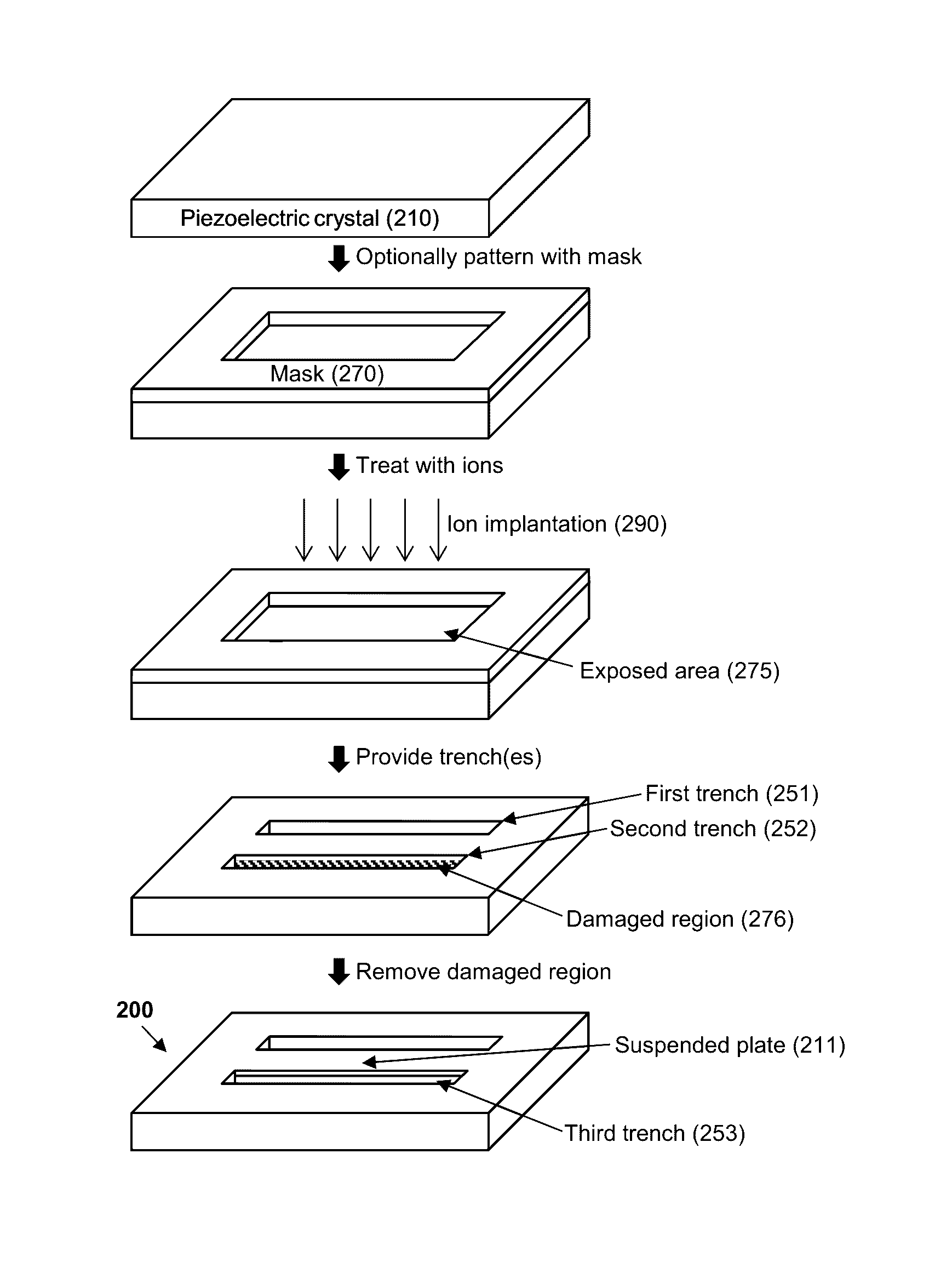

Single crystal micromechanical resonator and fabrication methods thereof

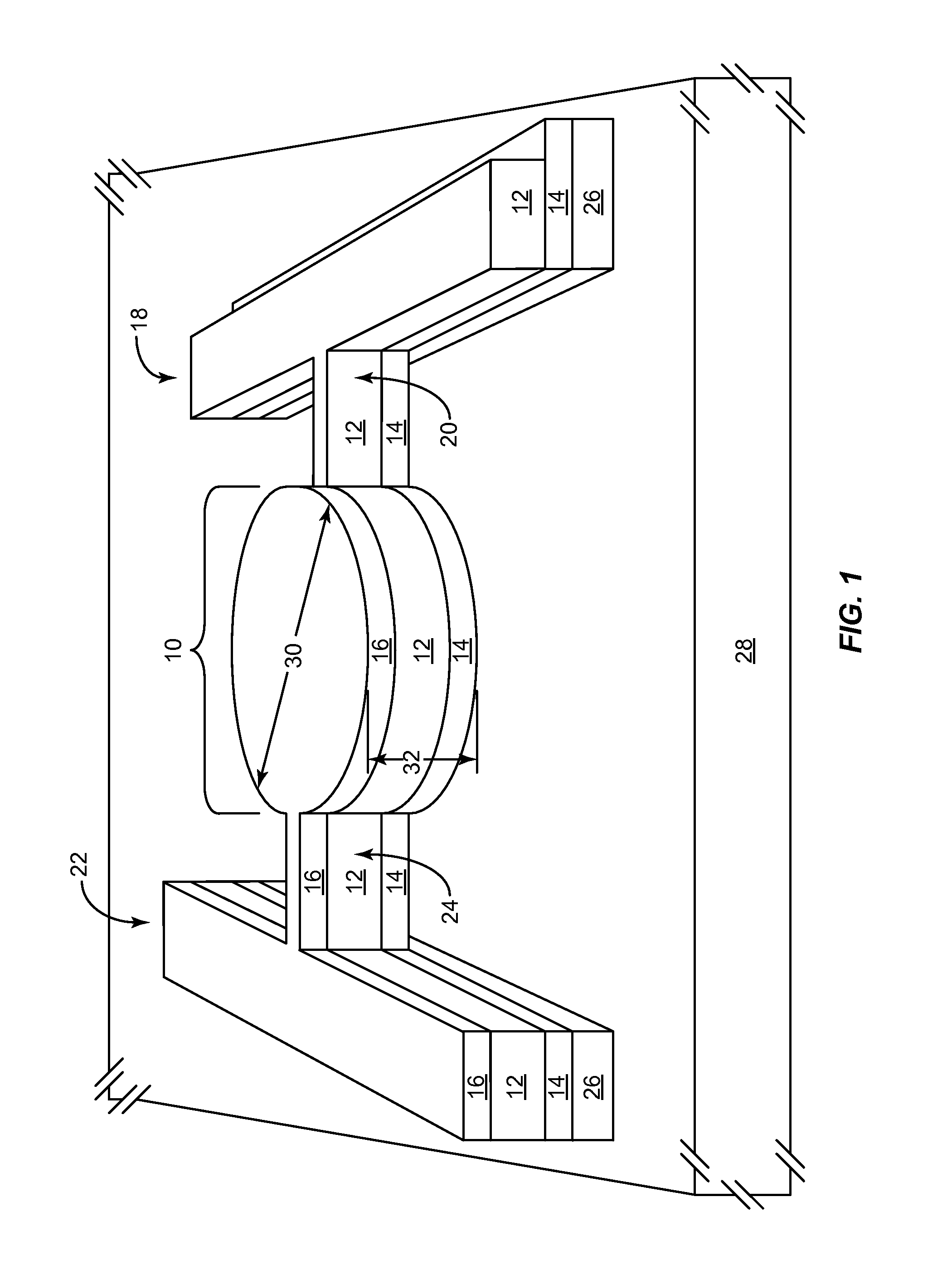

The present invention relates to a single crystal micromechanical resonator. In particular, the resonator includes a lithium niobate or lithium tantalate suspended plate. Also provided are improved microfabrication methods of making resonators, which does not rely on complicated wafer bonding, layer fracturing, and mechanical polishing steps. Rather, the methods allow the resonator and its components to be formed from a single crystal.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

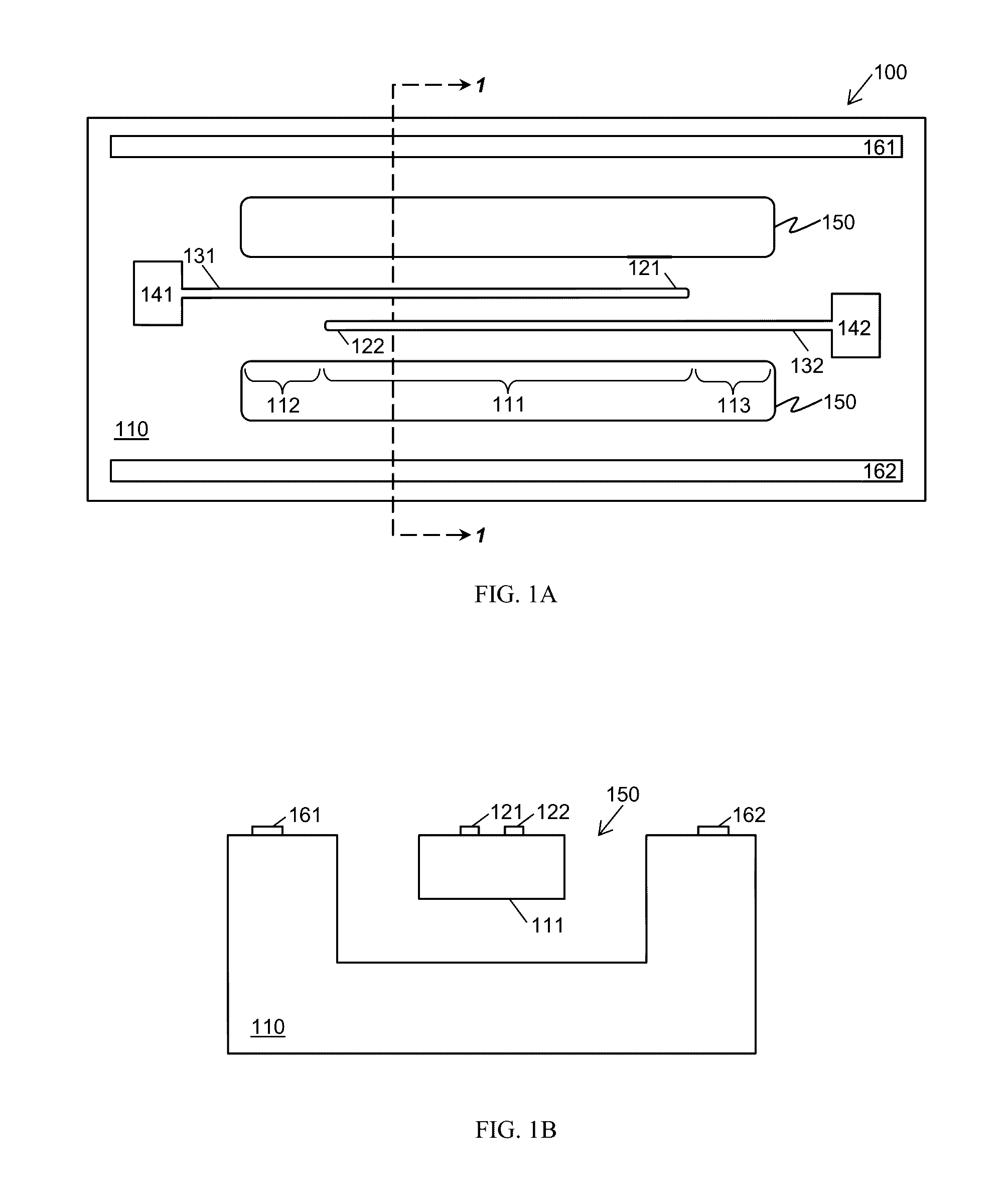

Method for manufacturing a vibrating MEMS circuit

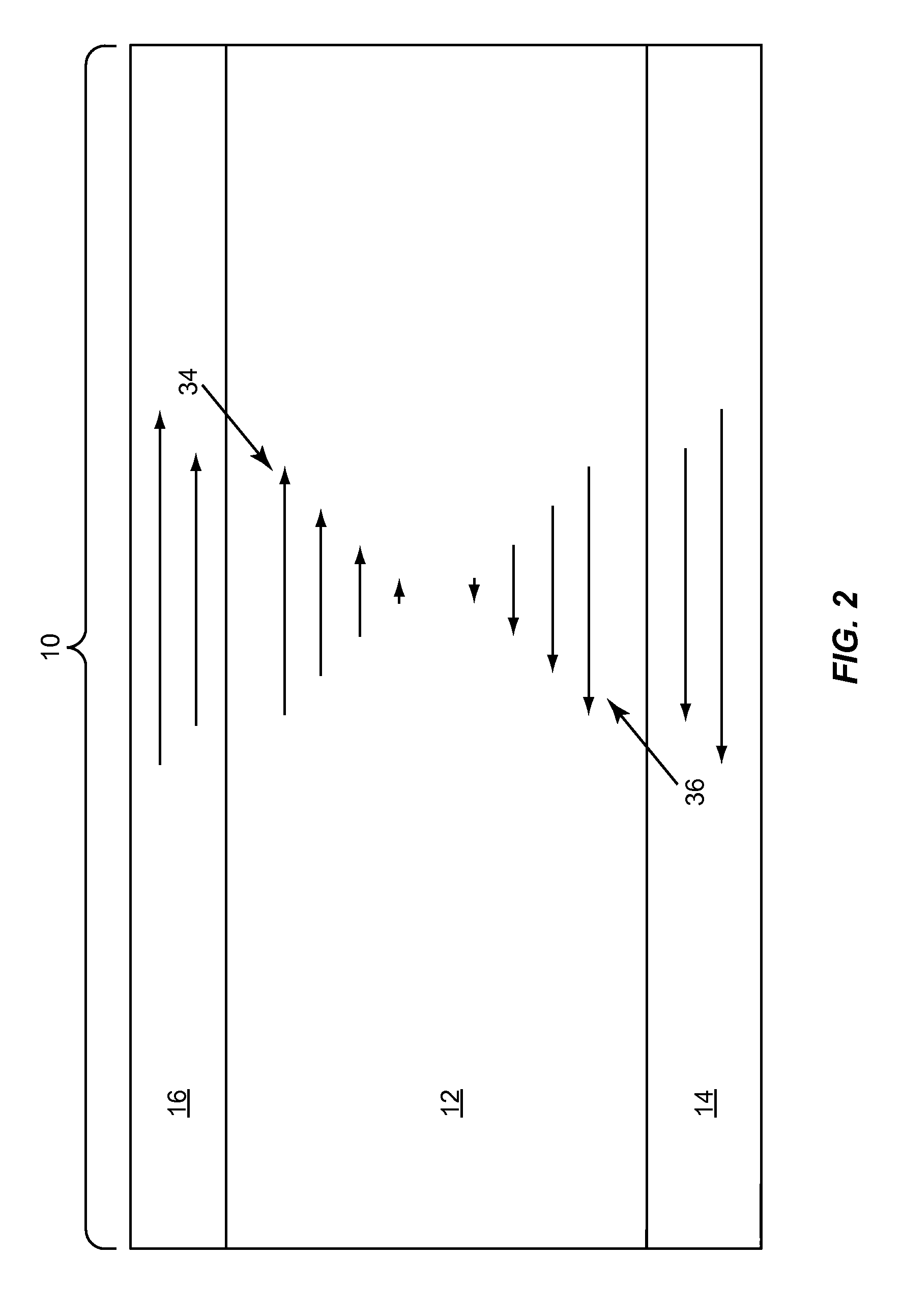

ActiveUS9369105B1Low temperature coefficientAccurate shapePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectromechanical coupling coefficientCrystal orientation

A method for making a micro-electro-mechanical systems (MEMS) vibrating structure is disclosed. The MEMS is supported by a MEMS anchor system and includes a single-crystal piezoelectric thin-film layer that has a specific non-standard crystal orientation, which may be selected to increase an electromechanical coupling coefficient, decrease a temperature coefficient of frequency, or both. The MEMS vibrating structure may have dominant lateral vibrations or dominant thickness vibrations. The single-crystal piezoelectric thin-film layer may include Lithium Tantalate or Lithium Niobate, and may provide MEMS vibrating structures with precise sizes and shapes, which may provide high accuracy and enable fabrication of multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

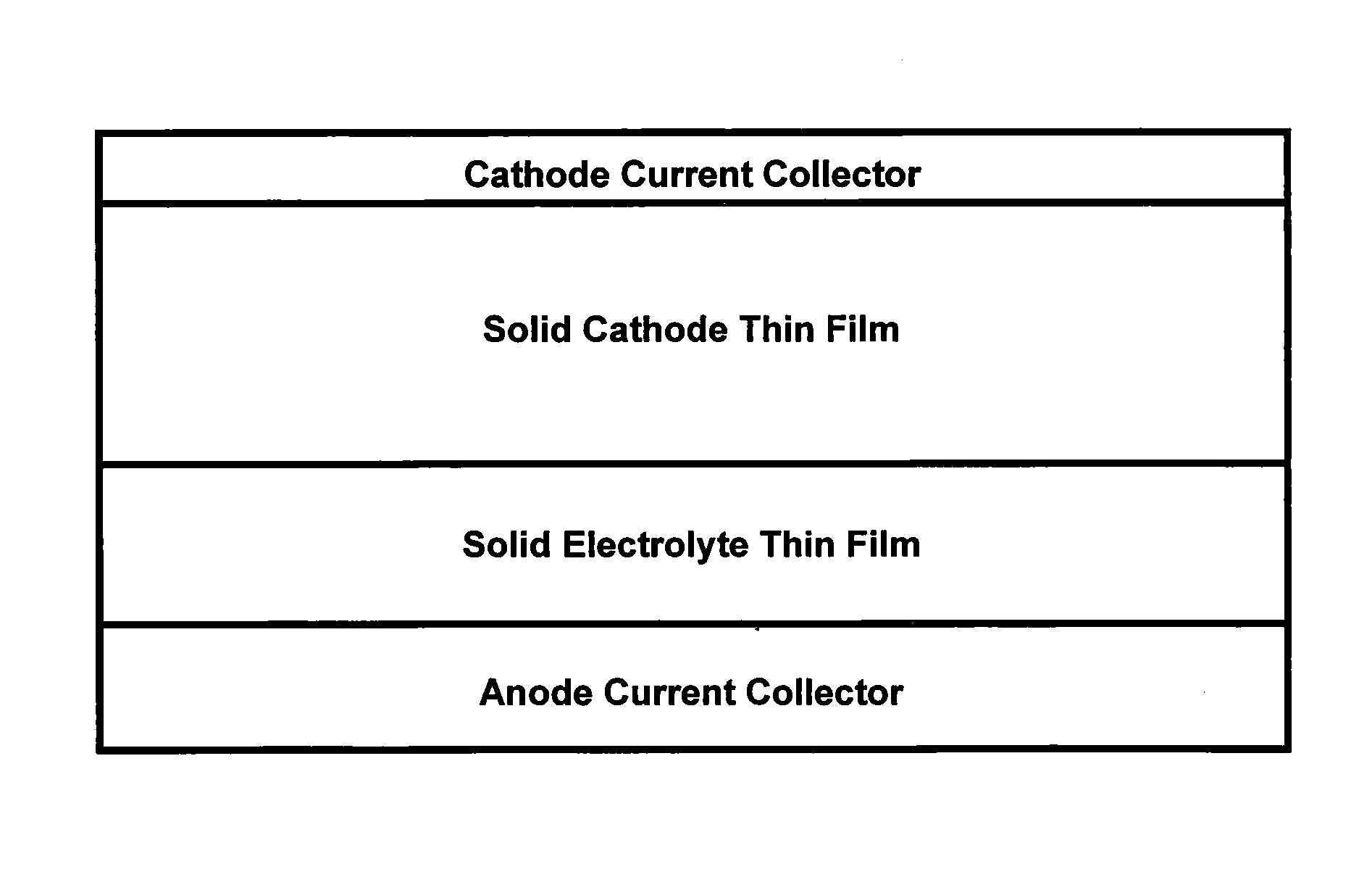

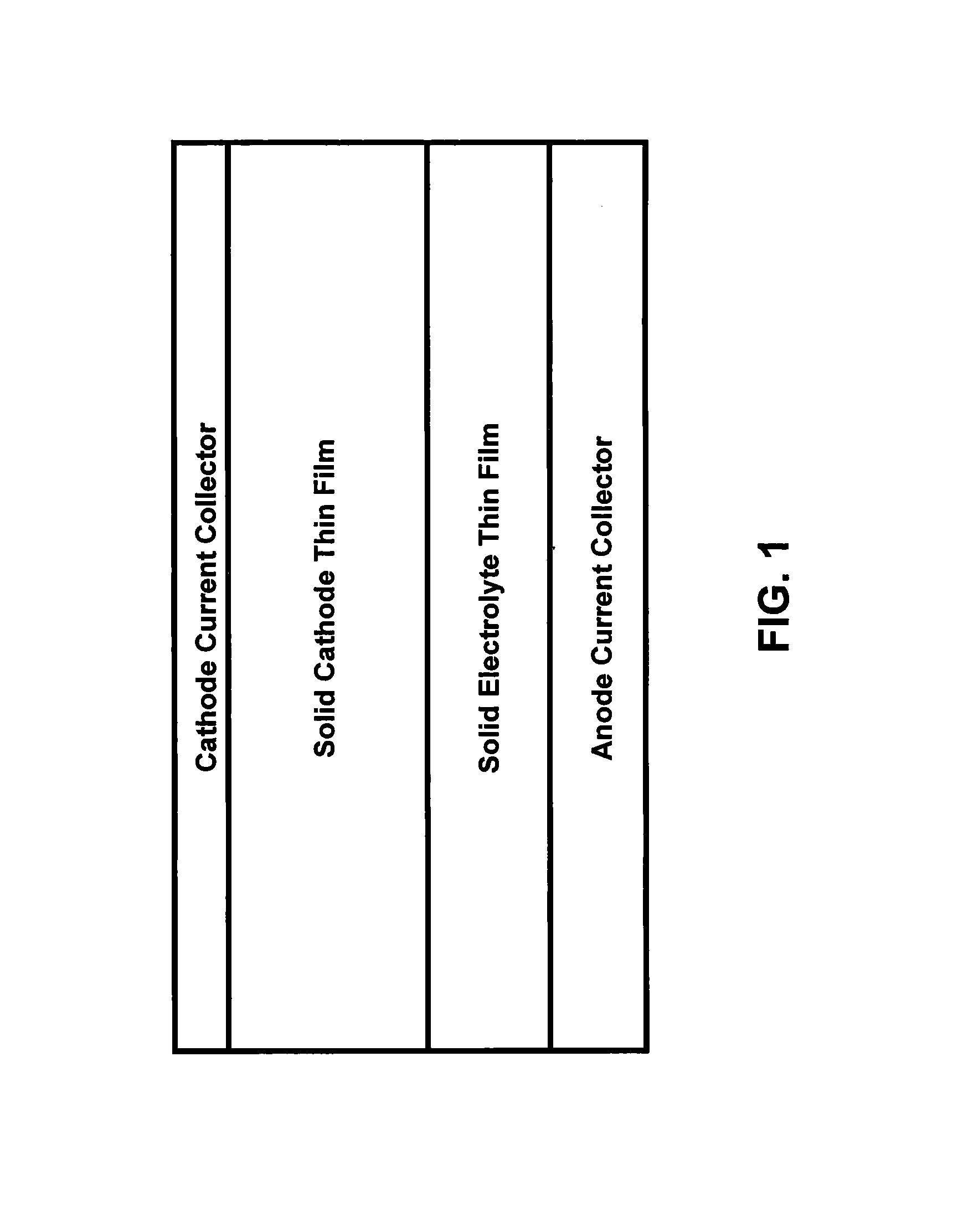

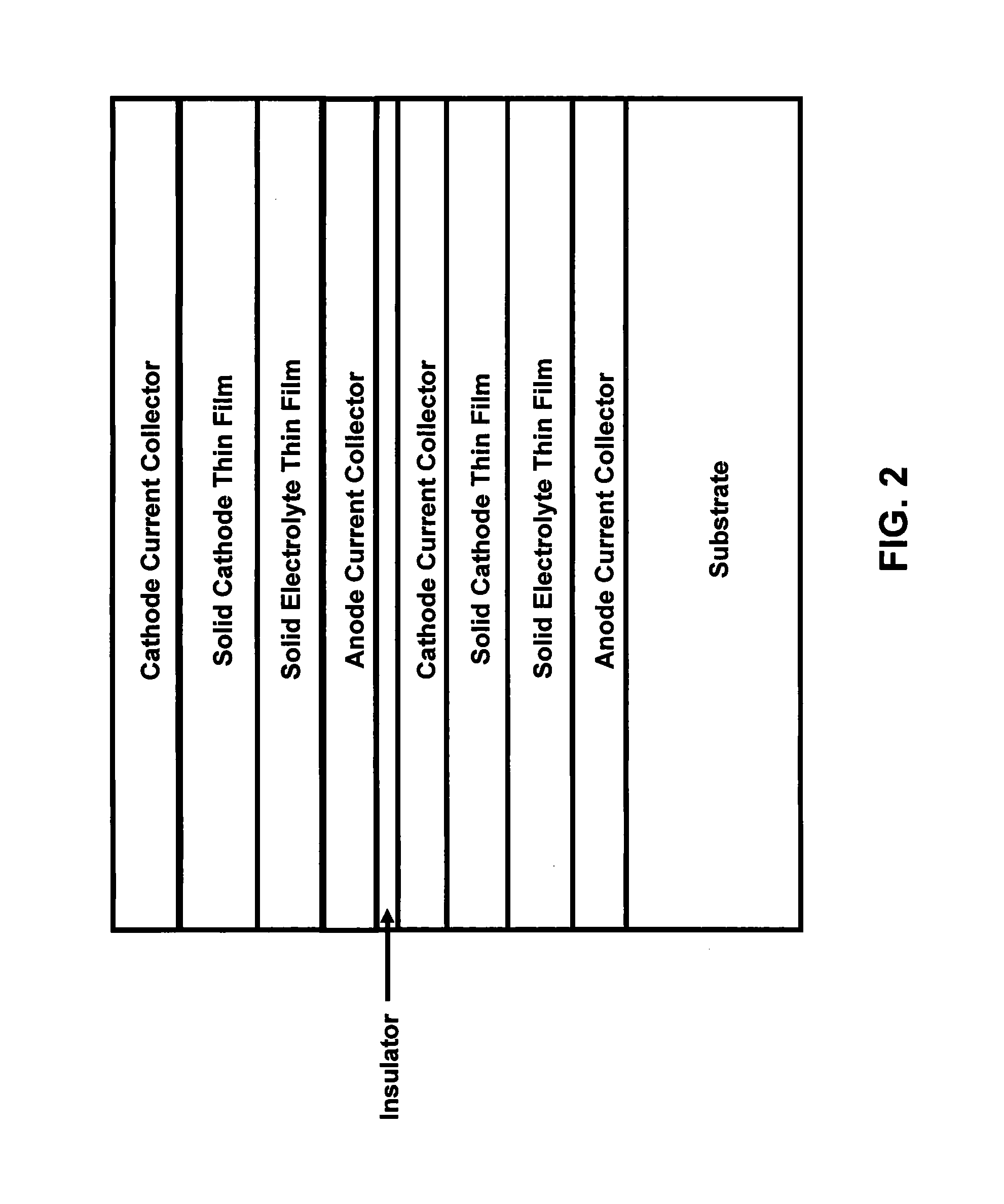

Solid-state lithium battery

ActiveUS8877388B1Low form factor requirementsIncrease powerTantalum compoundsPrinted batteriesLanthanumLithium.free

The present invention is directed to a higher power, thin film lithium-ion electrolyte on a metallic substrate, enabling mass-produced solid-state lithium batteries. High-temperature thermodynamic equilibrium processing enables co-firing of oxides and base metals, providing a means to integrate the crystalline, lithium-stable, fast lithium-ion conductor lanthanum lithium tantalate (La1 / 3-xLi3xTaO3) directly with a thin metal foil current collector appropriate for a lithium-free solid-state battery.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

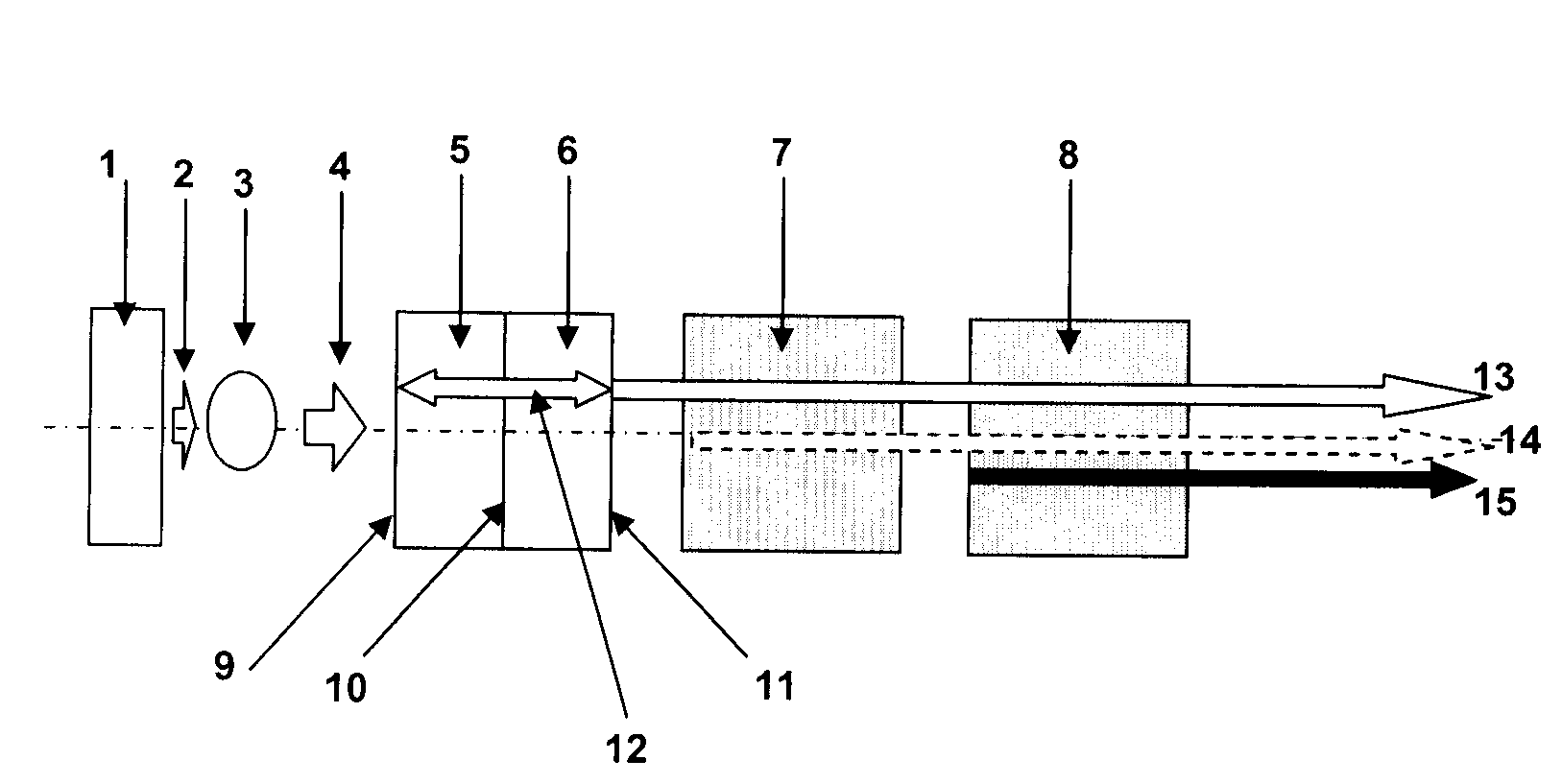

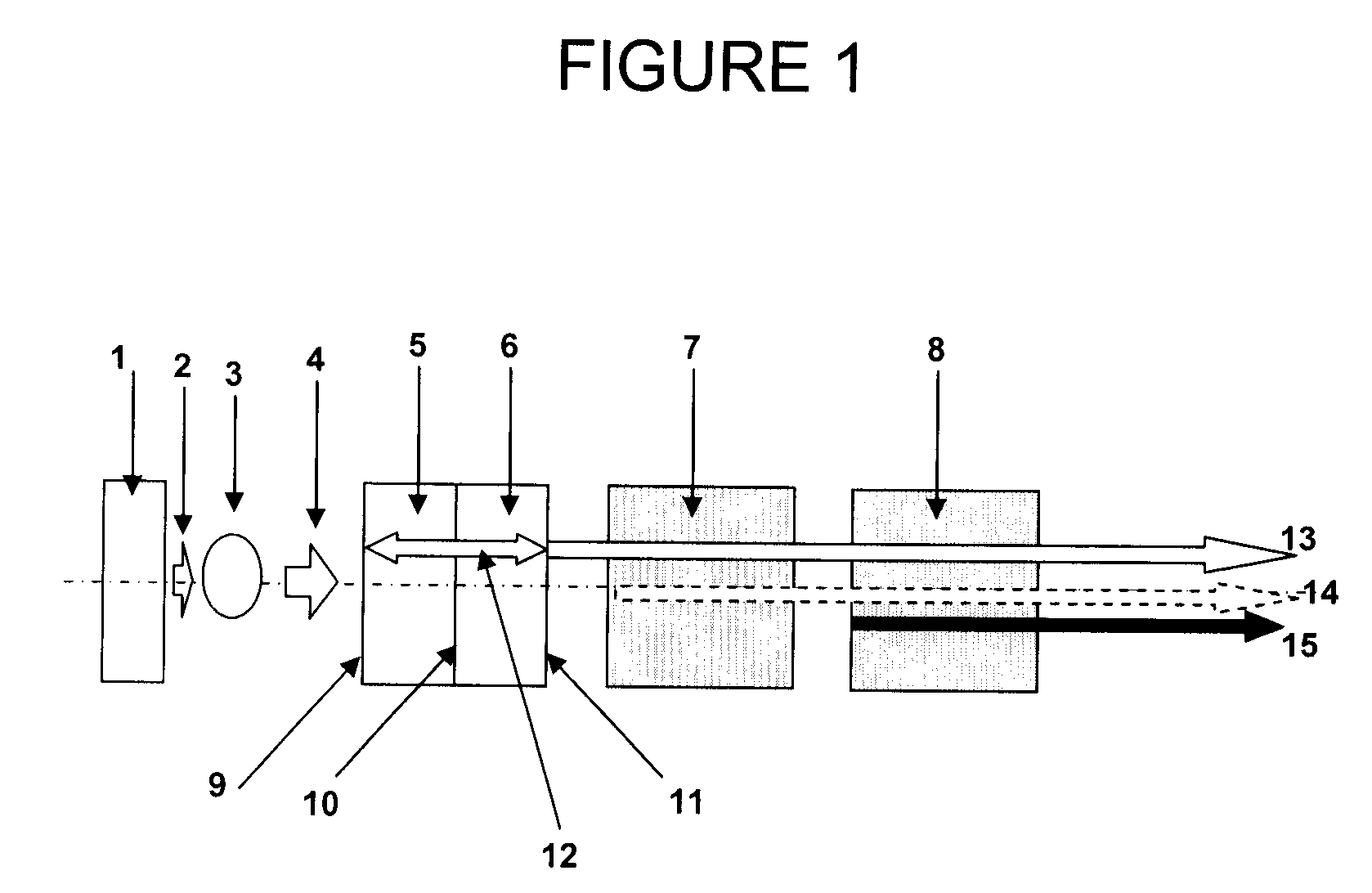

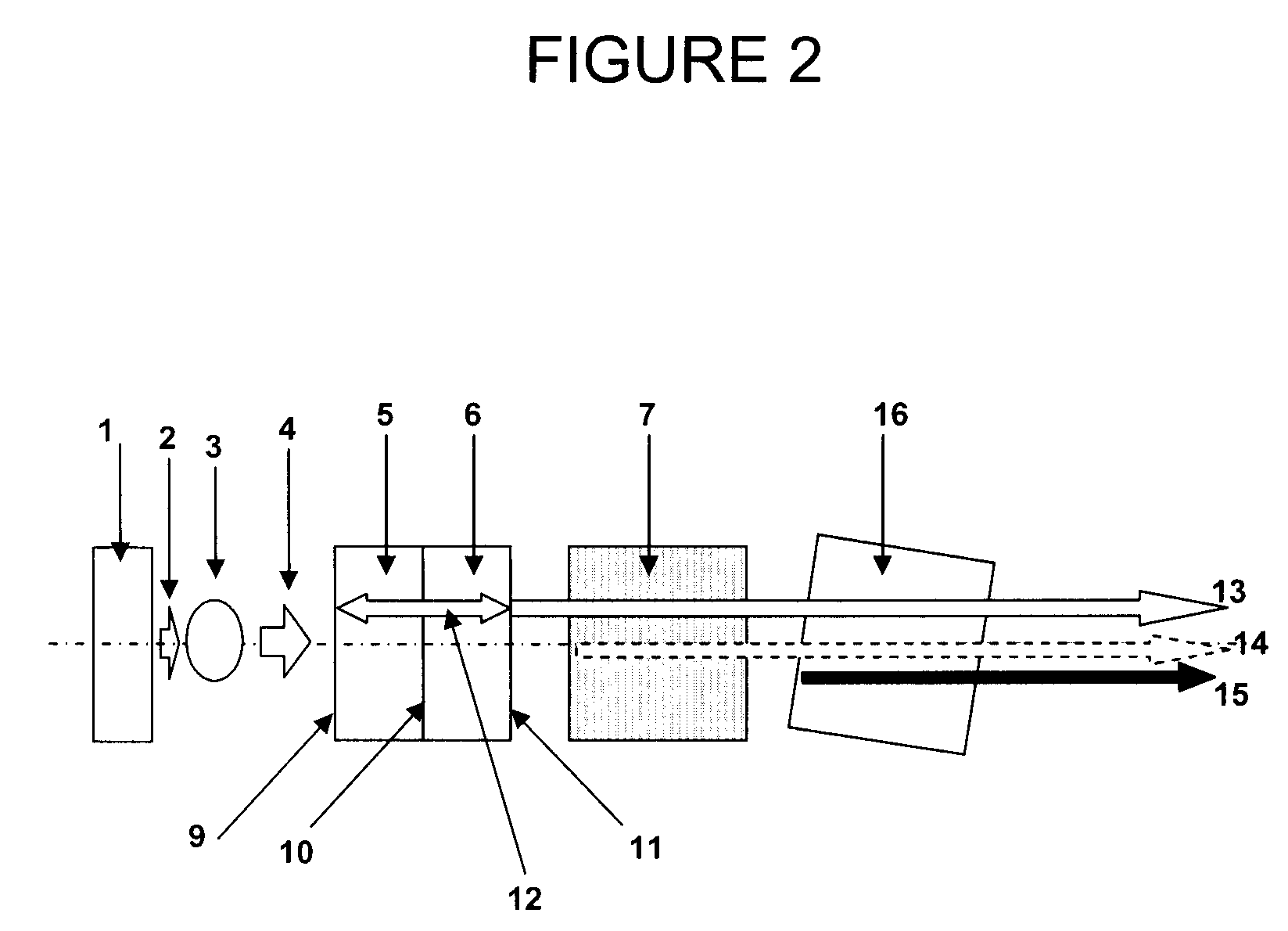

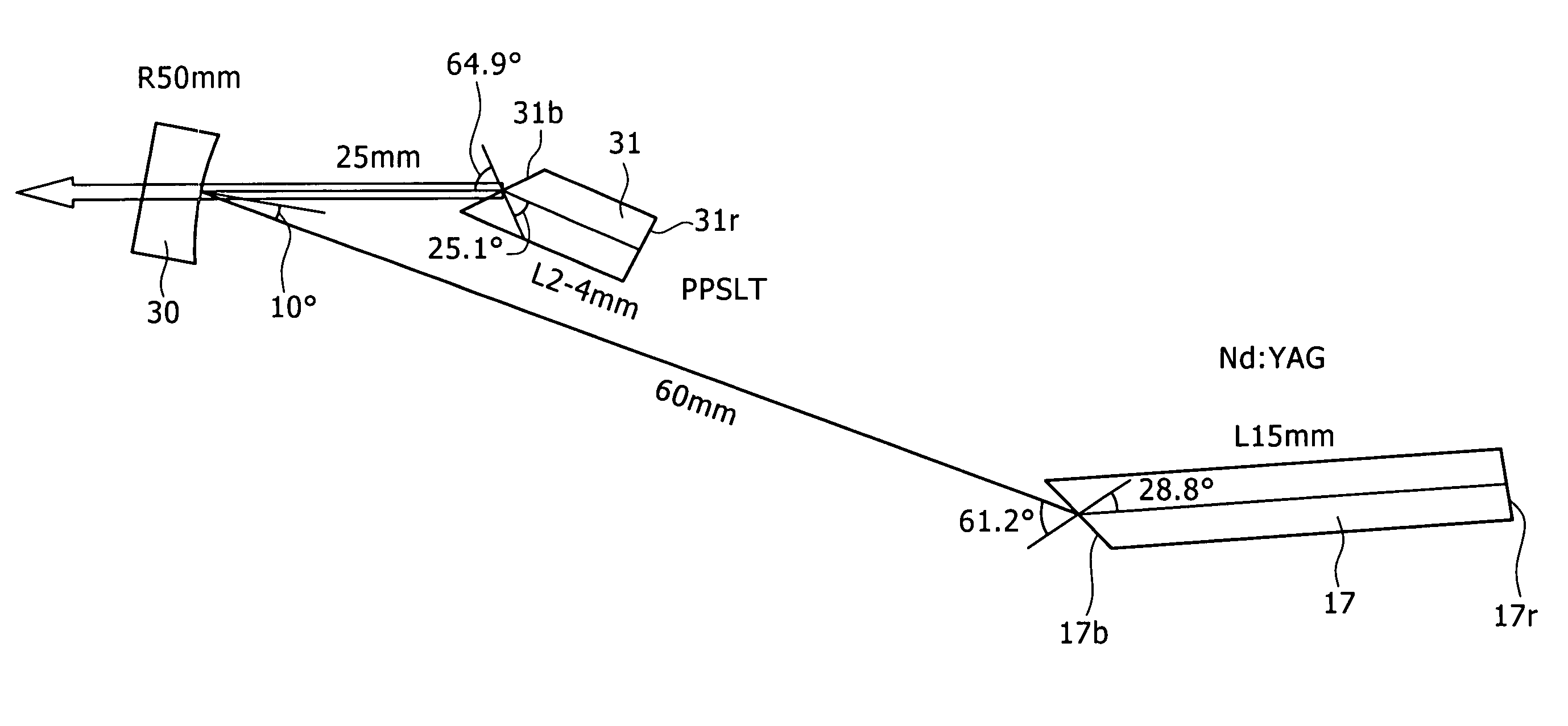

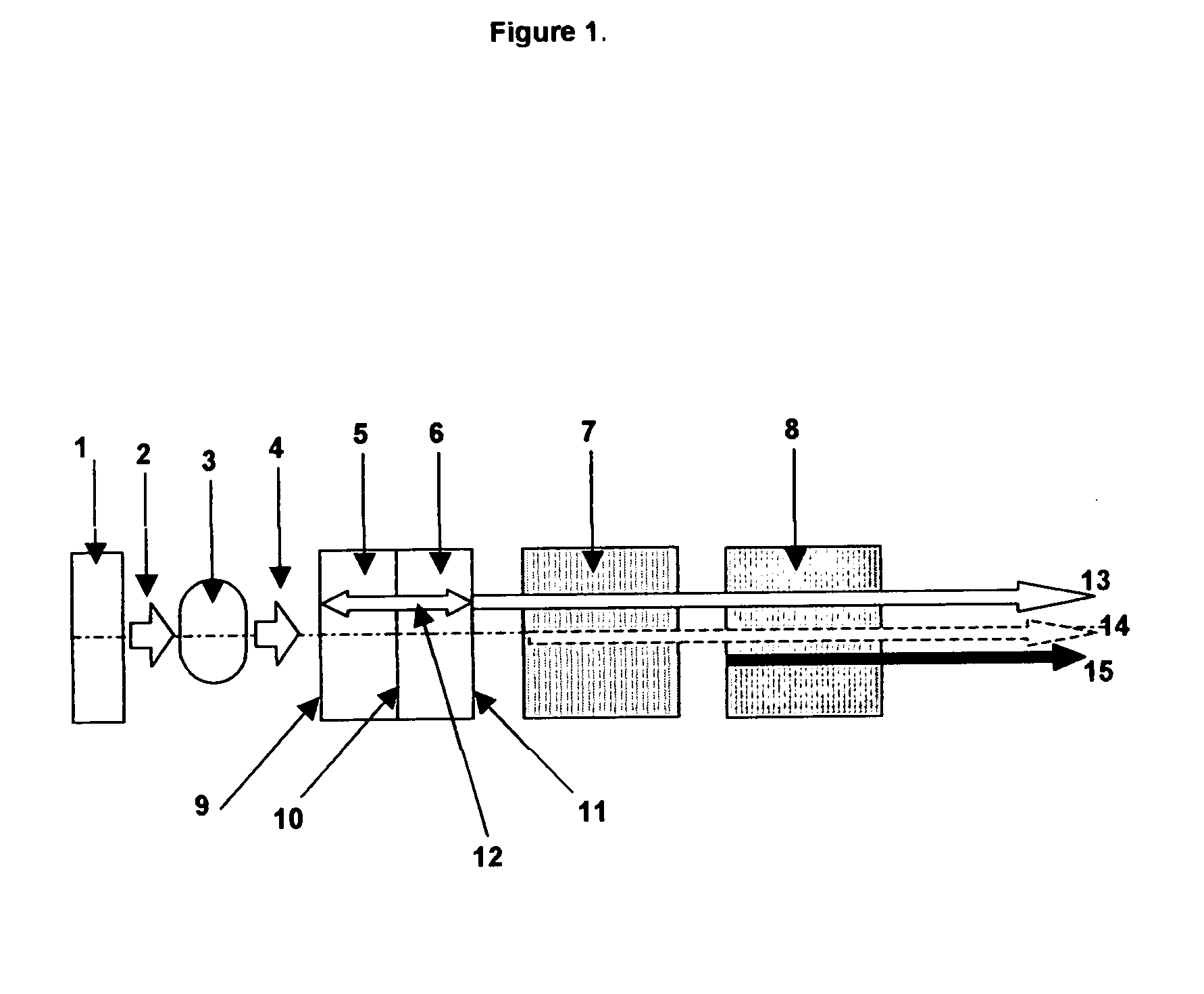

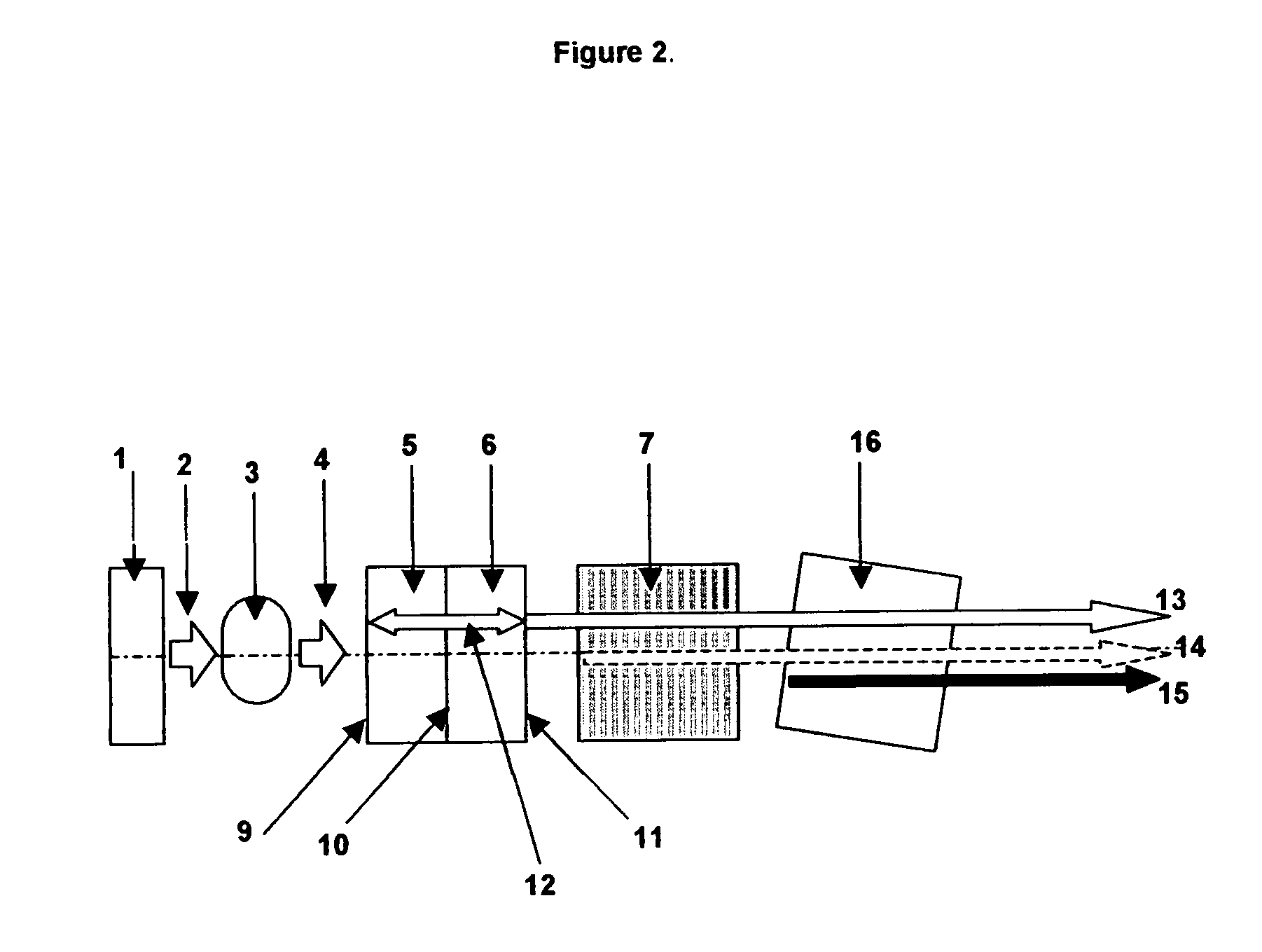

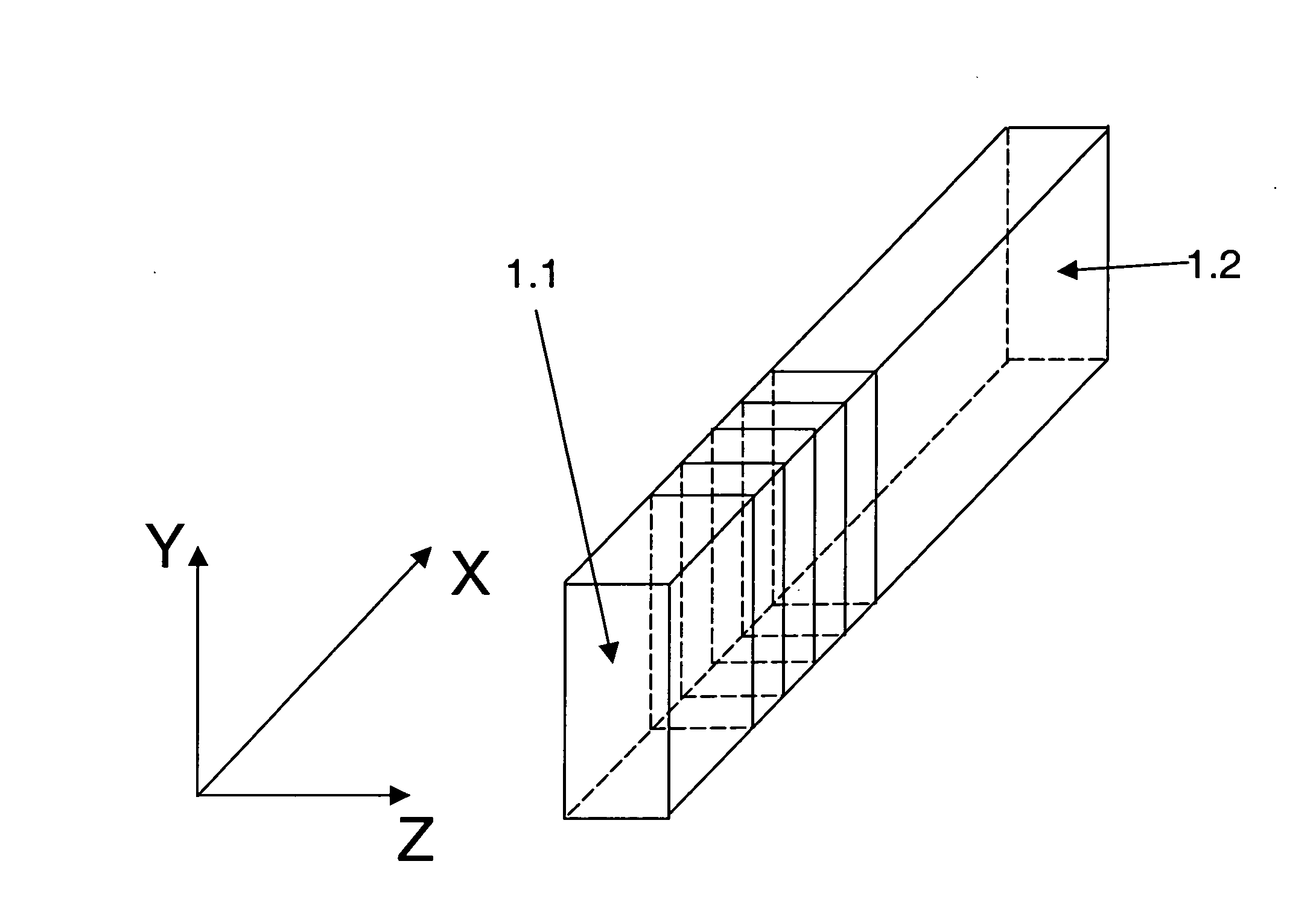

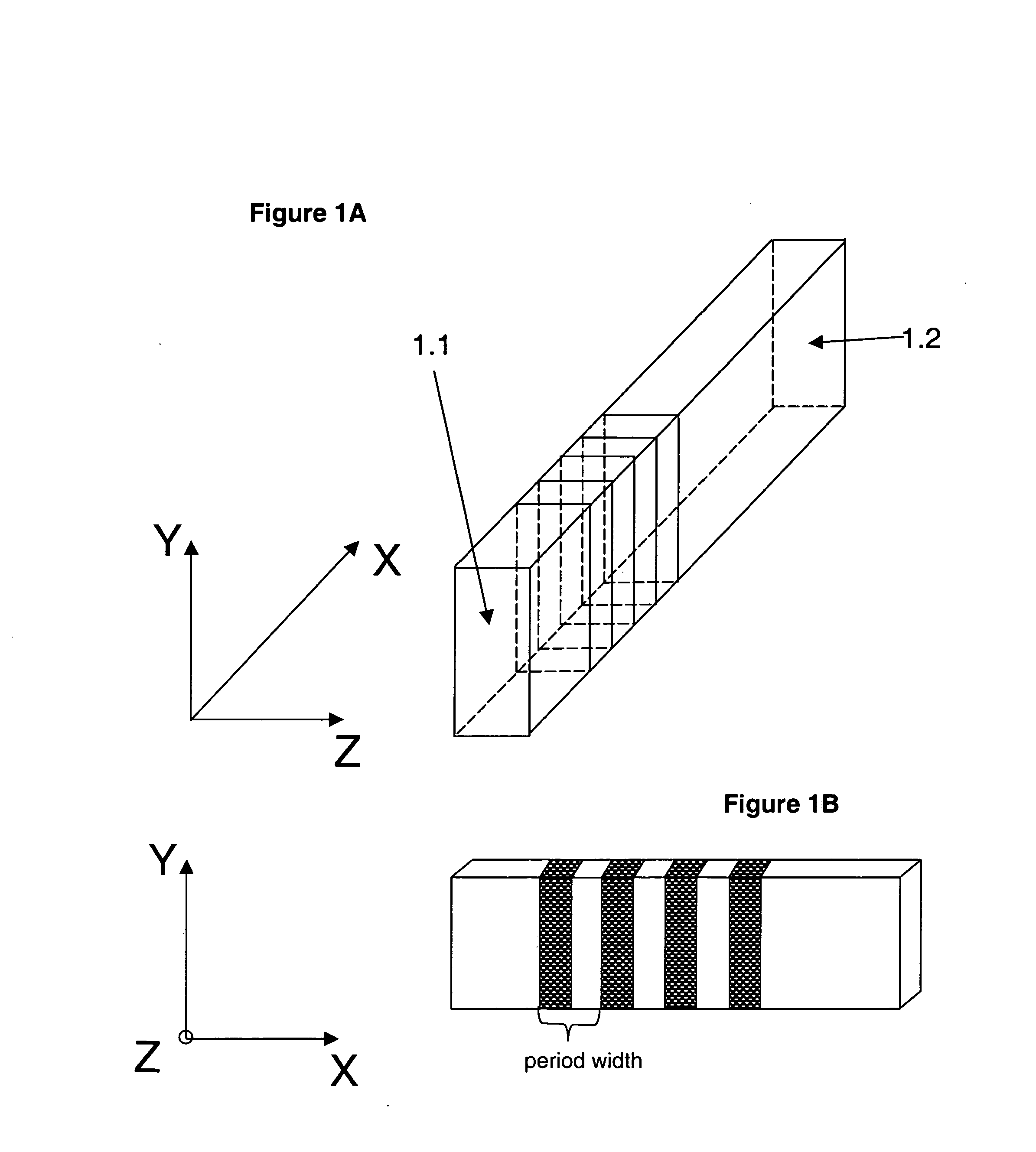

Compact efficient and robust ultraviolet solid-state laser sources based on nonlinear frequency conversion in periodically poled materials

InactiveUS7570676B2Low costHigh peak powerOptical devices for laserNon-linear opticsNonlinear crystalsLight source

A compact and efficient ultraviolet laser source based on a optically-pumped solid-state or fiber laser that produces near-infrared output light suitable for nonlinear frequency conversion. The infrared laser output is frequency tripled or quadrupled to produce light in the ultraviolet wavelength range (200 nm to 400 nm). The novel technology is the use of highly efficient periodically poled nonlinear crystals, such as stoichiometric and MgO-doped lithium tantalate and lithium niobate. As opposed to conventional frequency-converted UV laser sources, which have high power consumption, high cost, and low efficiency, the laser sources of this invention utilize high efficiency nonlinear conversion provided by periodically poled materials and allow lower-cost architectures without additional focusing lenses, high power pump diodes, etc.

Owner:OOO SPECTRALUS

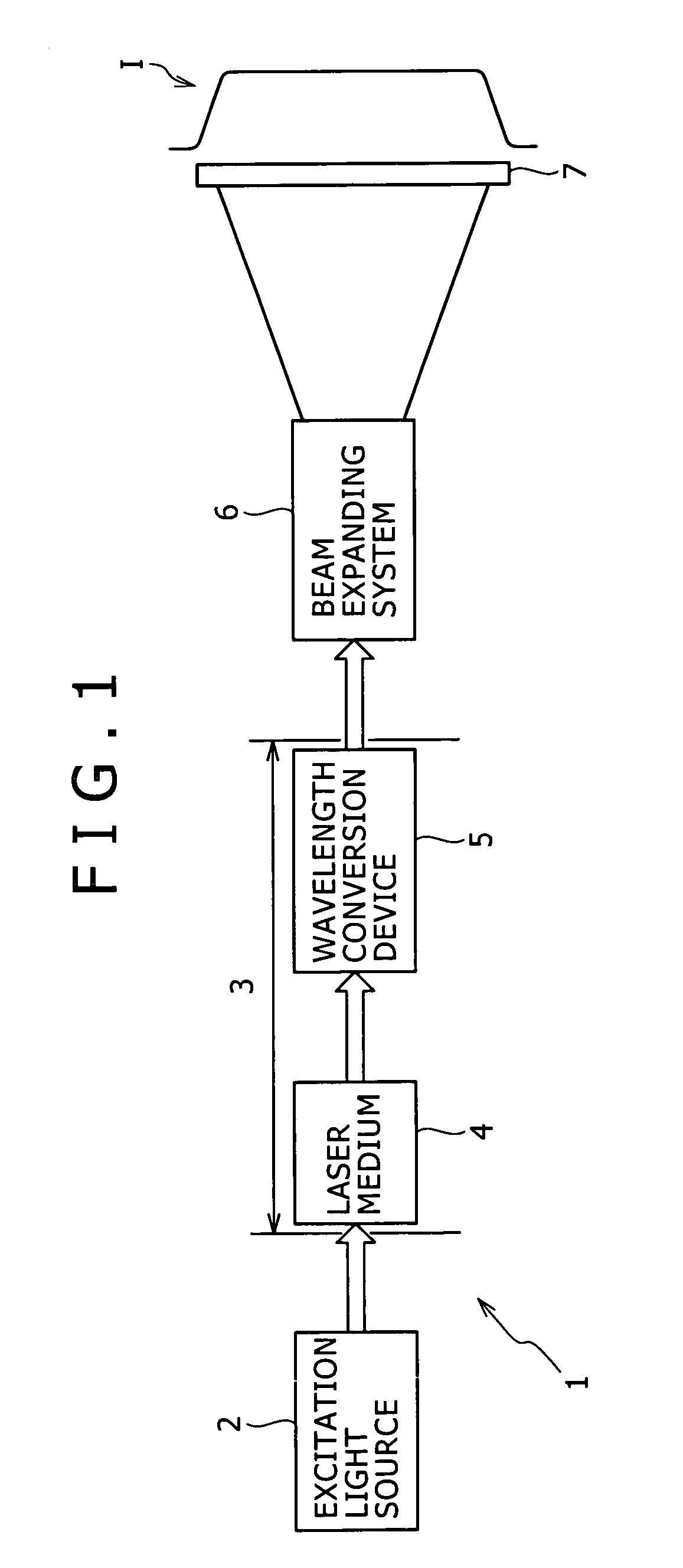

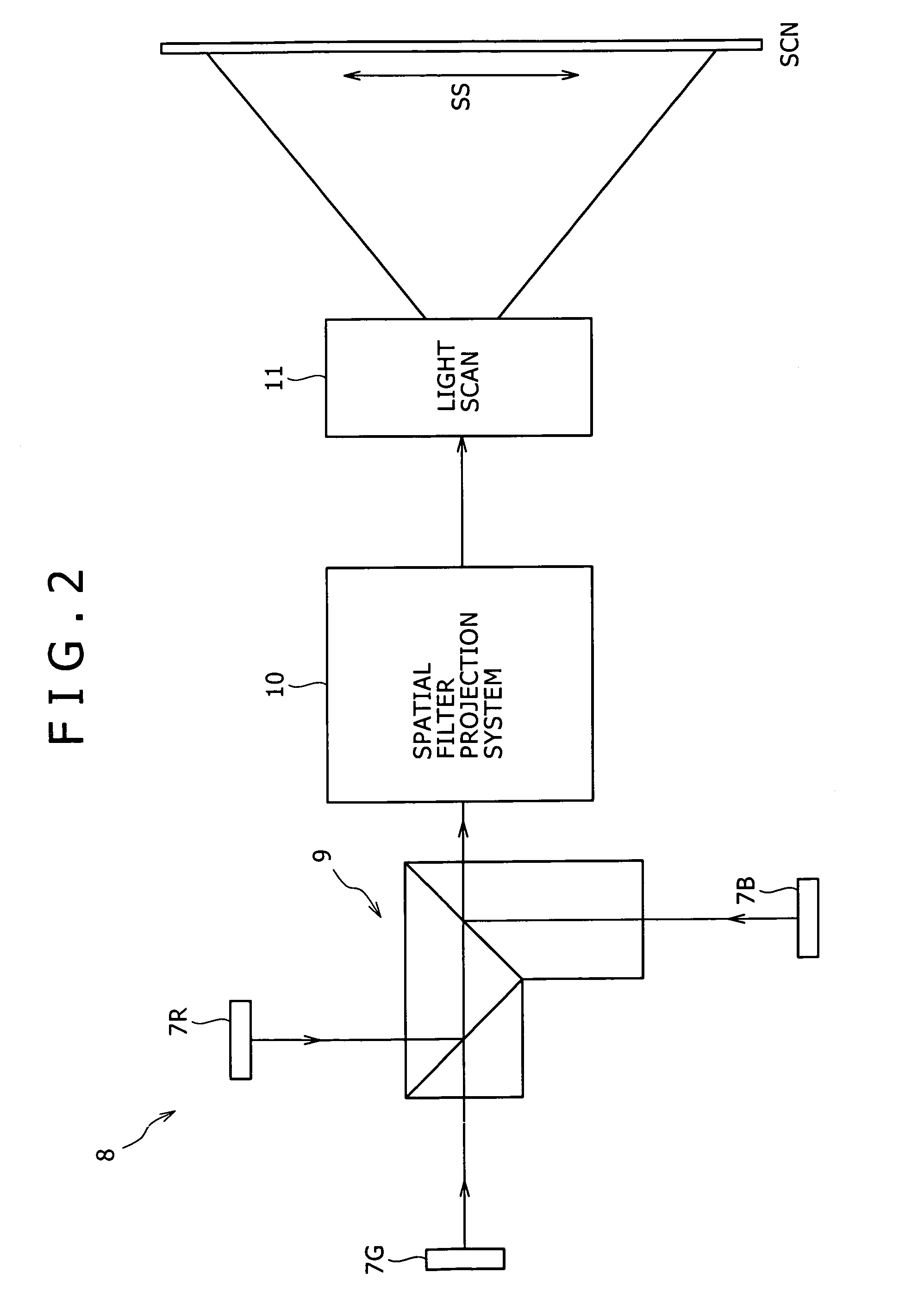

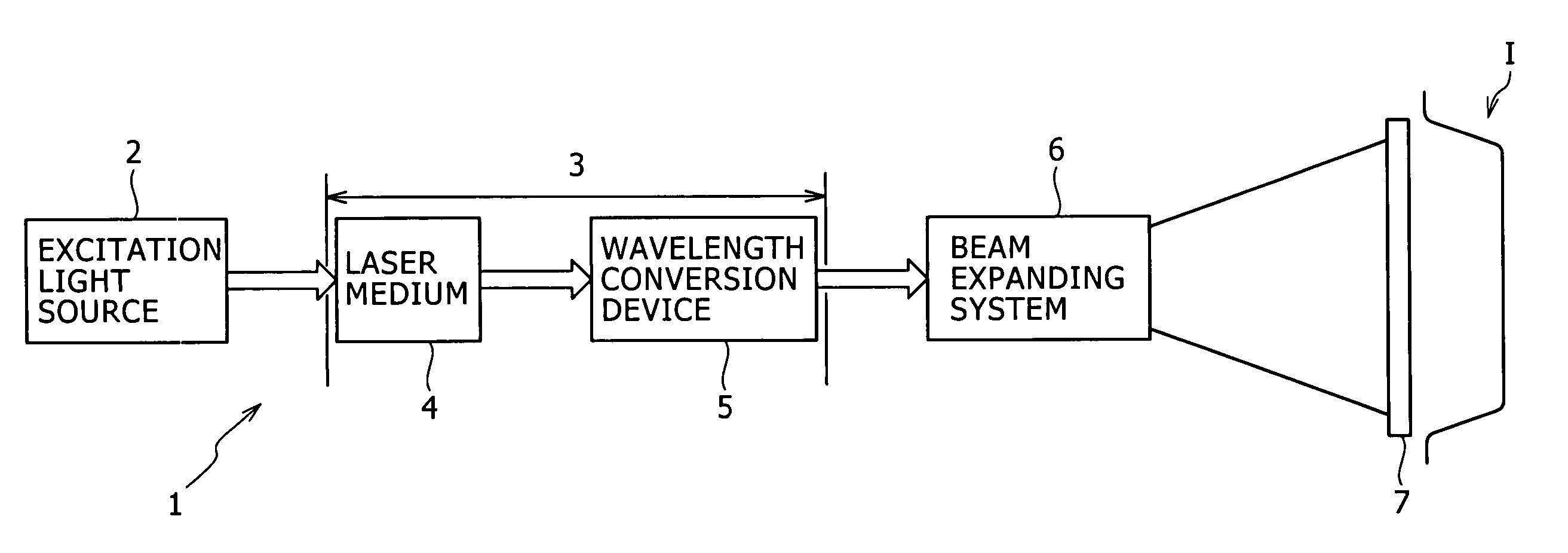

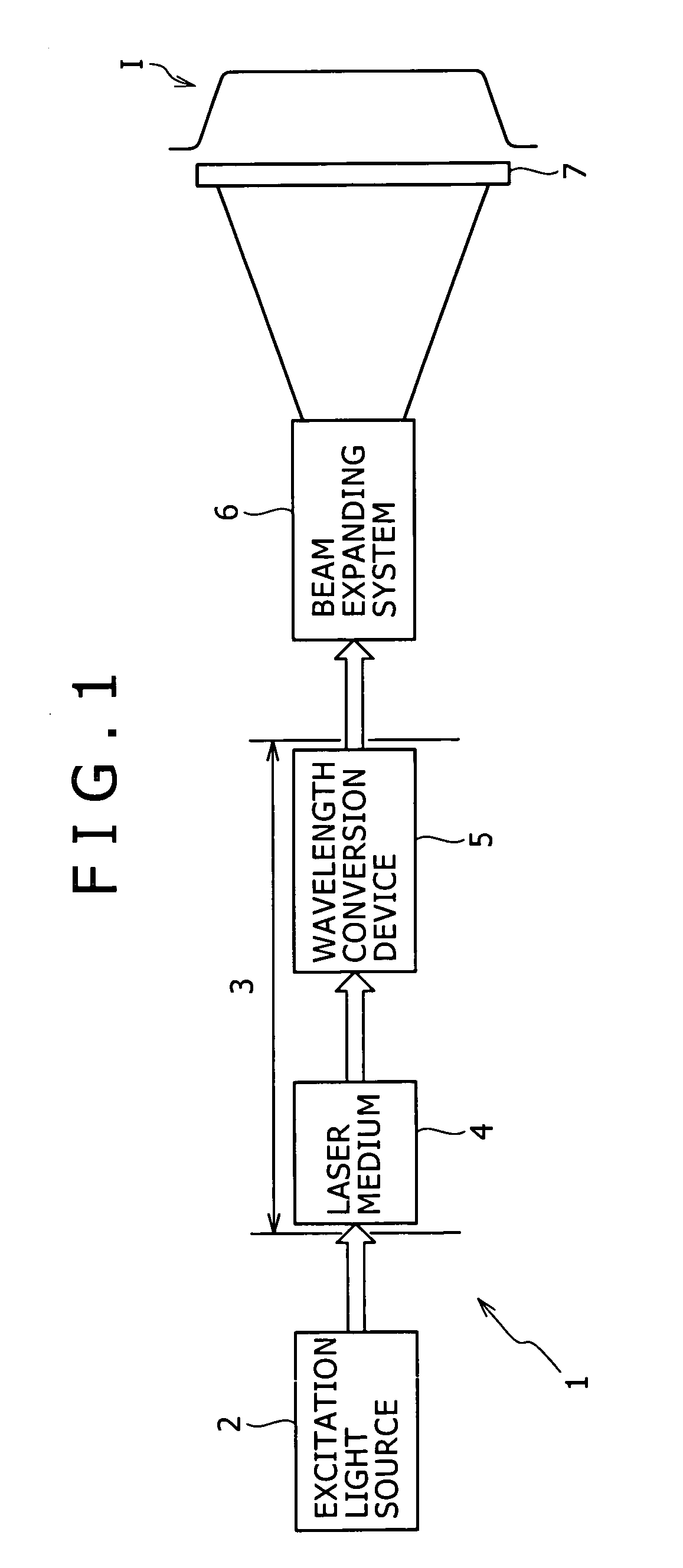

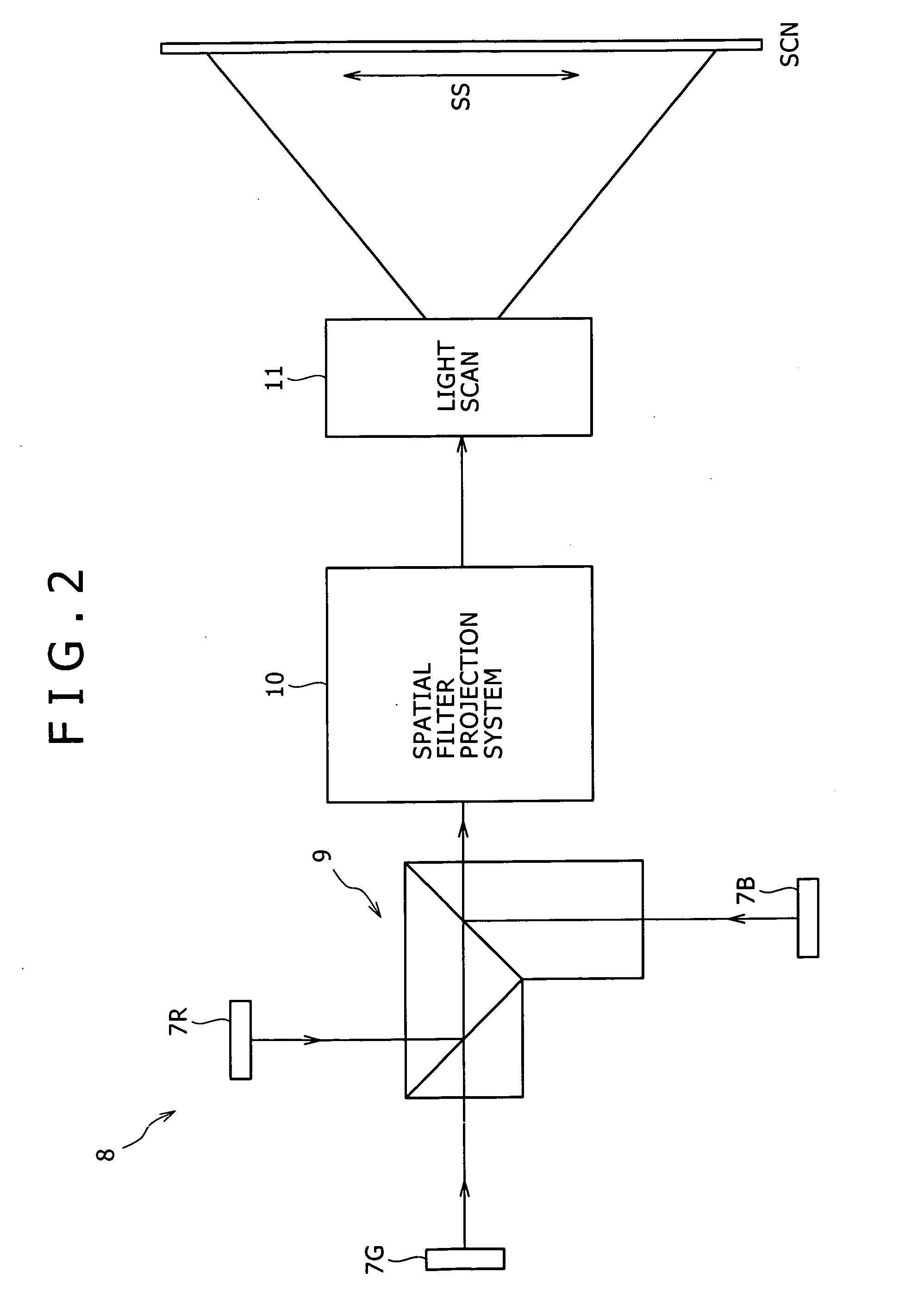

One-dimensional illumination apparatus and imaging apparatus

InactiveUS7545837B2High in output and efficiencyReduce speckle noiseSemiconductor laser arrangementsPicture reproducers using projection devicesNonlinear optical crystalLight equipment

Owner:SONY CORP

Amorphous dielectric capacitors on silicon

InactiveUS6255122B1Improve conformityReduce leakage currentTransistorSemiconductor/solid-state device manufacturingLead zirconate titanateMaterials science

High-capacity capacitors and gate insulators exhibiting moderately high dielectric constants with surprisingly low leakage using amorphous or low temperature films of perovskite type oxides including a titanate system material such as barium titanate, strontium titanate, barium strontium titanate (BST), lead titanate, lead zirconate titanate, lead lanthanum zirconate titanate, barium lanthanum titanate, a niobate, aluminate or tantalate system material such as lead magnesium niobate, lithium niobate lithium tantalate, potassium niobate and potassium tantalum niobate, a tungsten-bronze system material such as barium strontium niobate, lead barium niobate, barium titanium niobate, and Bi-layered perovskite system material such as strontium bismuth tantalate, bismuth titanate deposited directly on a silicon surface at temperatures about 450° C. or less.

Owner:GLOBALFOUNDRIES INC

Compact efficient and robust ultraviolet

InactiveUS20070263693A1Low costHigh peak powerOptical devices for laserNon-linear opticsUltravioletLaser source

A compact and efficient ultraviolet laser source based on a optically-pumped solid-state or fiber laser that produces near-infrared output light suitable for nonlinear frequency conversion. The infrared laser output is frequency tripled or quadrupled to produce light in the ultraviolet wavelength range (200 nm to 400 nm). The novel technology is the use of highly efficient periodically poled nonlinear crystals, such as stoichiometric and MgO-doped lithium tantalate and lithium niobate. As opposed to conventional frequency-converted UV laser sources, which have high power consumption, high cost, and low efficiency, the laser sources of this invention utilize high efficiency nonlinear conversion provided by periodically poled materials and allow lower-cost architectures without additional focusing lenses, high power pump diodes, etc.

Owner:OOO SPECTRALUS

MEMS vibrating structure using a single-crystal piezoelectric thin-film layer having domain inversions

ActiveUS7898158B1Accurate shapeSmall sizePiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectricitySingle crystal

The present invention relates to a micro-electro-mechanical systems (MEMS) vibrating structure supported by a MEMS anchor system, and includes a single-crystal piezoelectric thin-film layer having domain inversions, which determine certain vibrational characteristics of the MEMS vibrating structure. The MEMS vibrating structure may have dominant lateral vibrations or dominant thickness vibrations. The single-crystal piezoelectric thin-film layer may include Lithium Tantalate or Lithium Niobate, and may provide MEMS vibrating structures with precise sizes and shapes, which may provide high accuracy and enable fabrication of multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

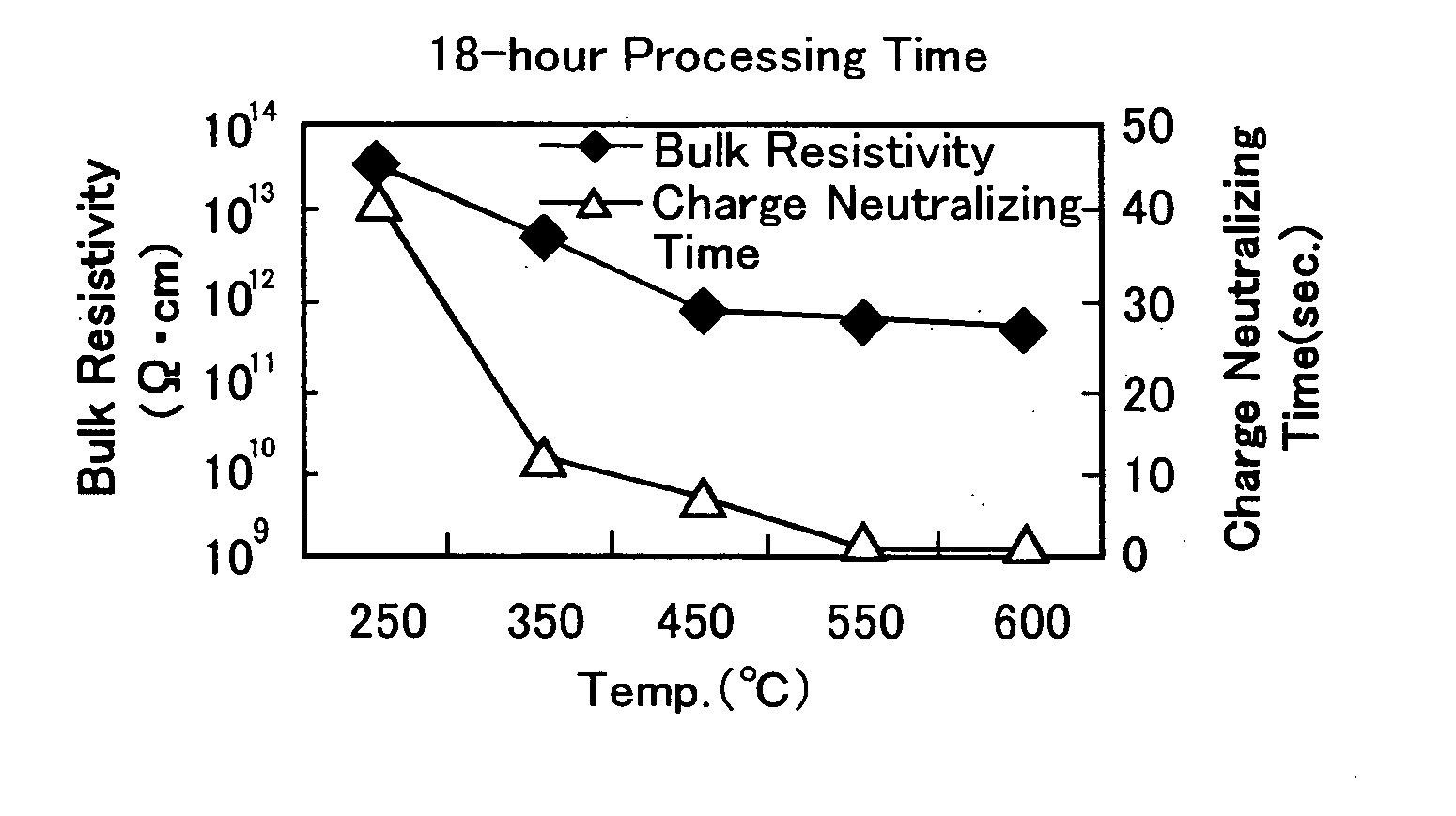

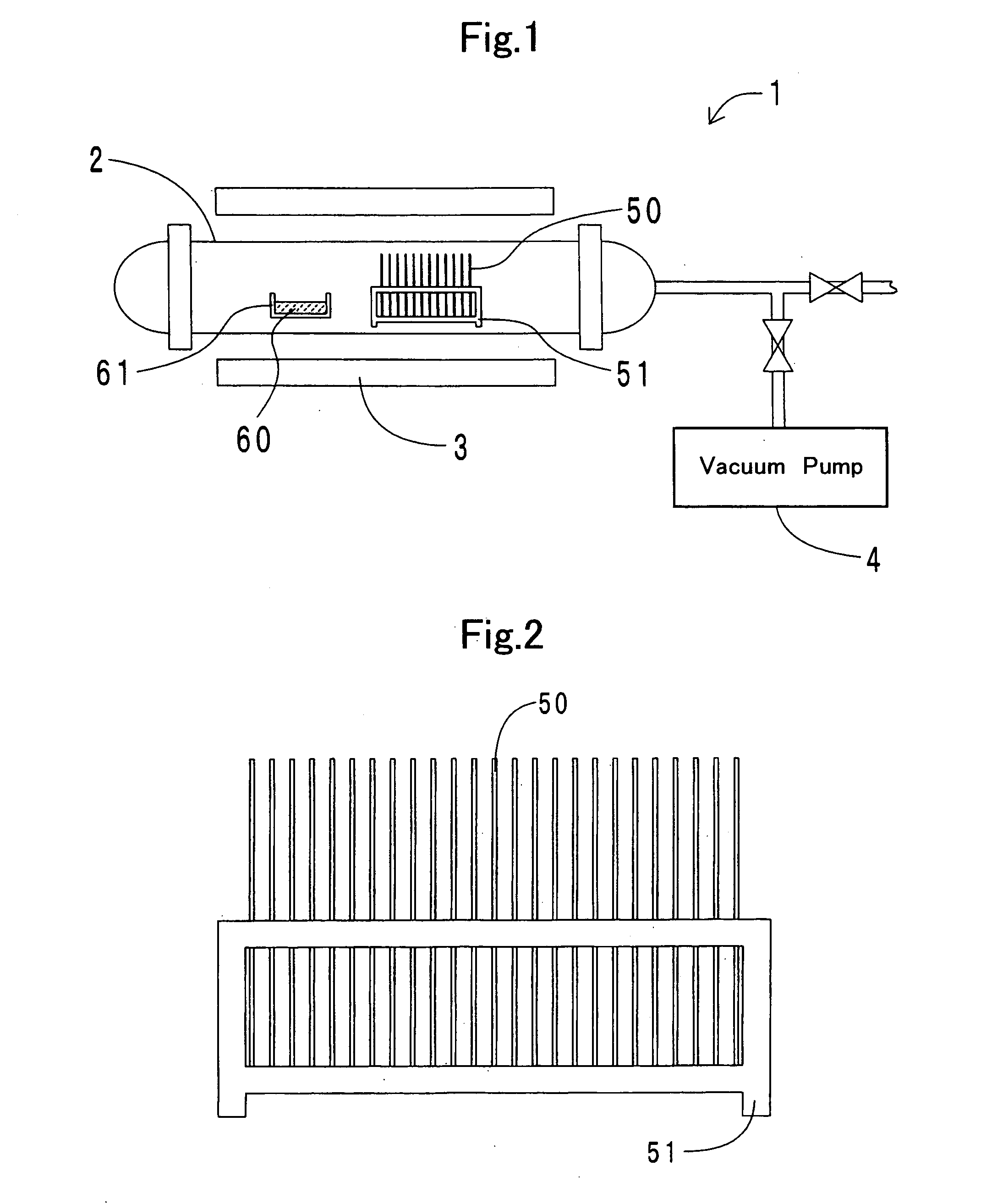

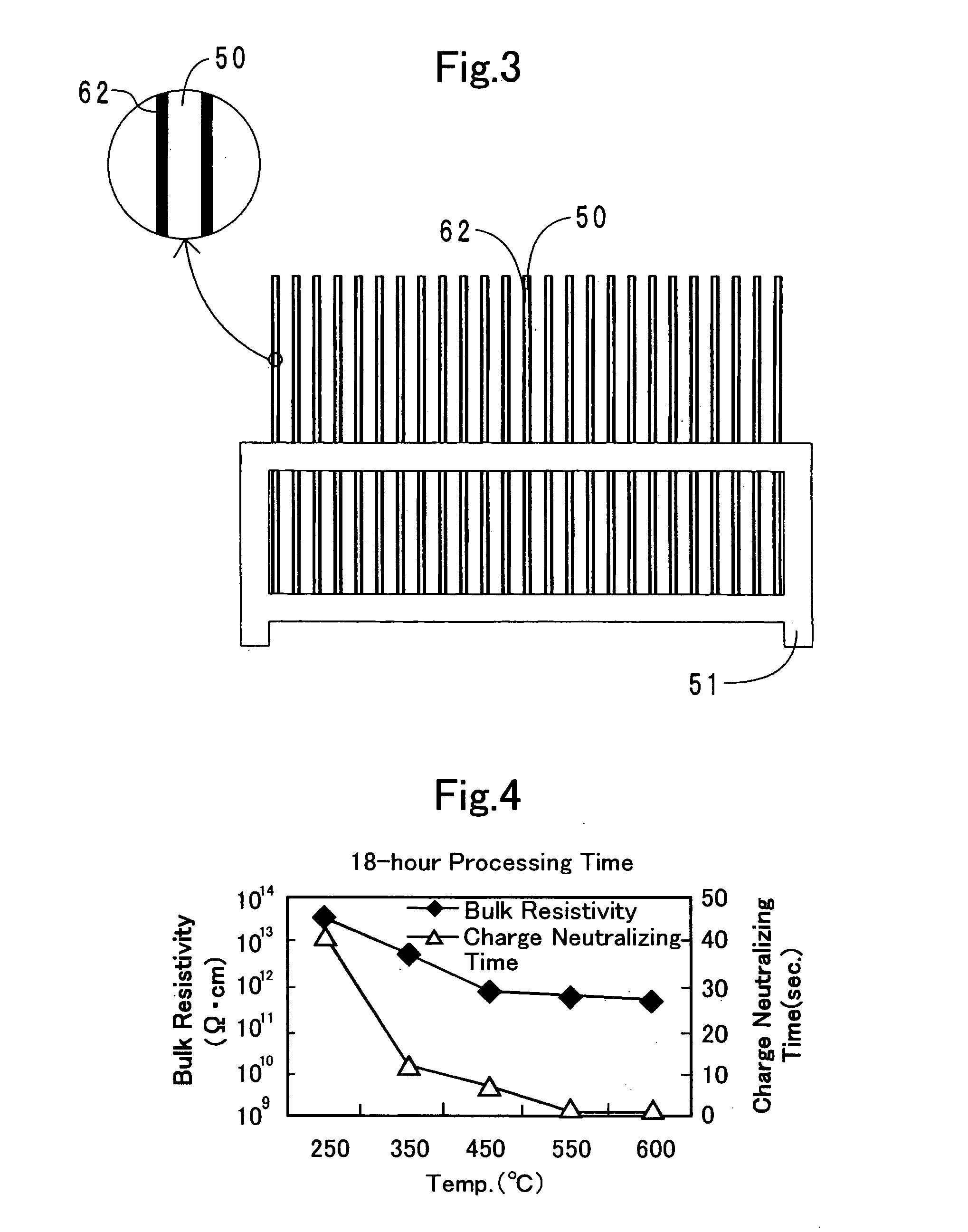

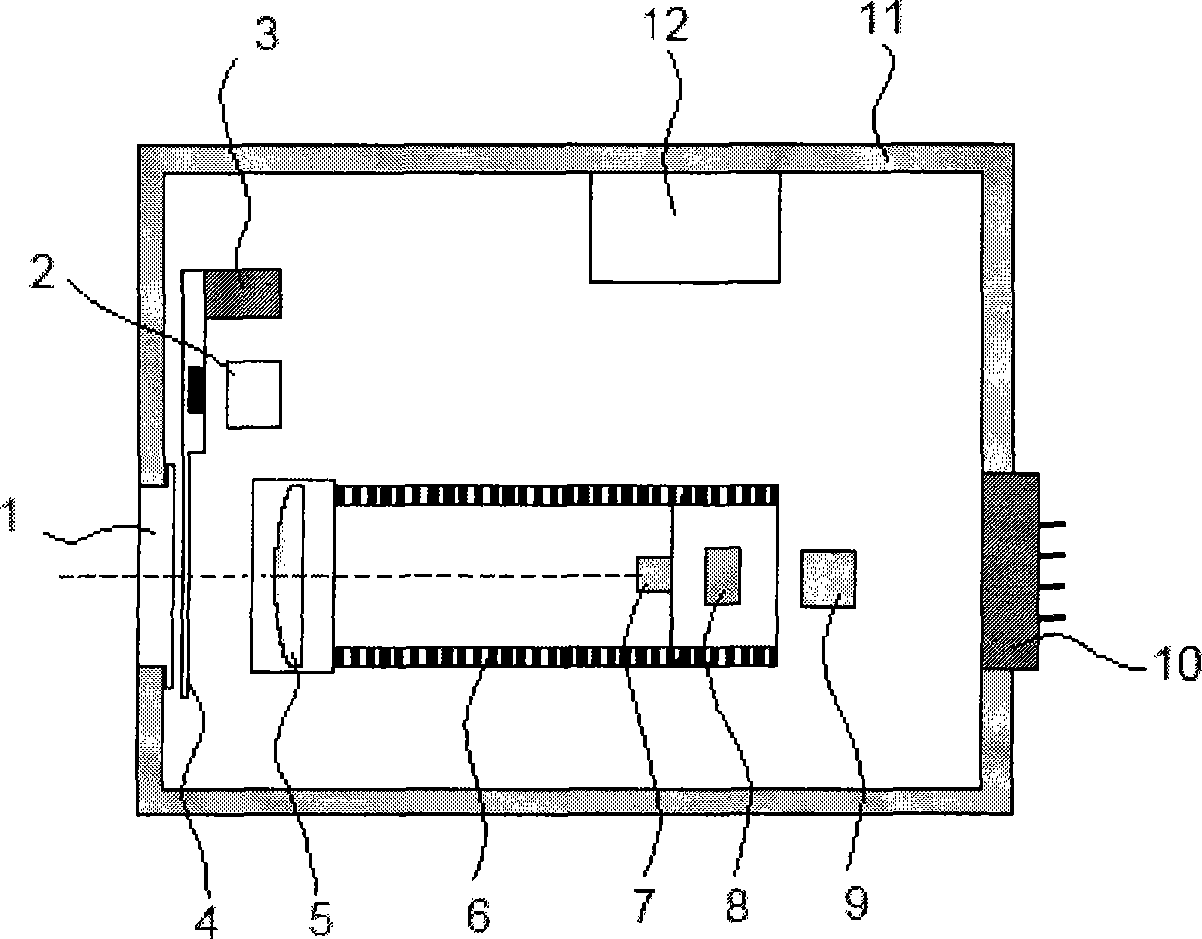

Charge restrained wafer of piezoelectric oxide single crystal, and charge restraining method and apparatus for piezoelectric oxide single crystal

InactiveUS20050284359A1Improve securityAvoid chargingPolycrystalline material growthAfter-treatment detailsSingle crystalCurie temperature

To provide a wafer, made from a lithium tantalate single crystal or a lithium niobate single crystal, wafer which is charge restrained without impairing the piezoelectricity. Moreover, to provide a processing method and a processing apparatus therefor. It is characterized in that a wafer 50, made from a lithium tantalate single crystal or a lithium niobate single crystal, and a reducing agent 60, including an alkali metal or an alkali metal compound, are accommodated in a processing tank 2, and the inside of the processing tank 2 is held at a temperature of from 200° C. or more to less than a Curie temperature of the single crystal under decompression, thereby reducing the wafer 50.

Owner:YAMAJIYU CERAMICS

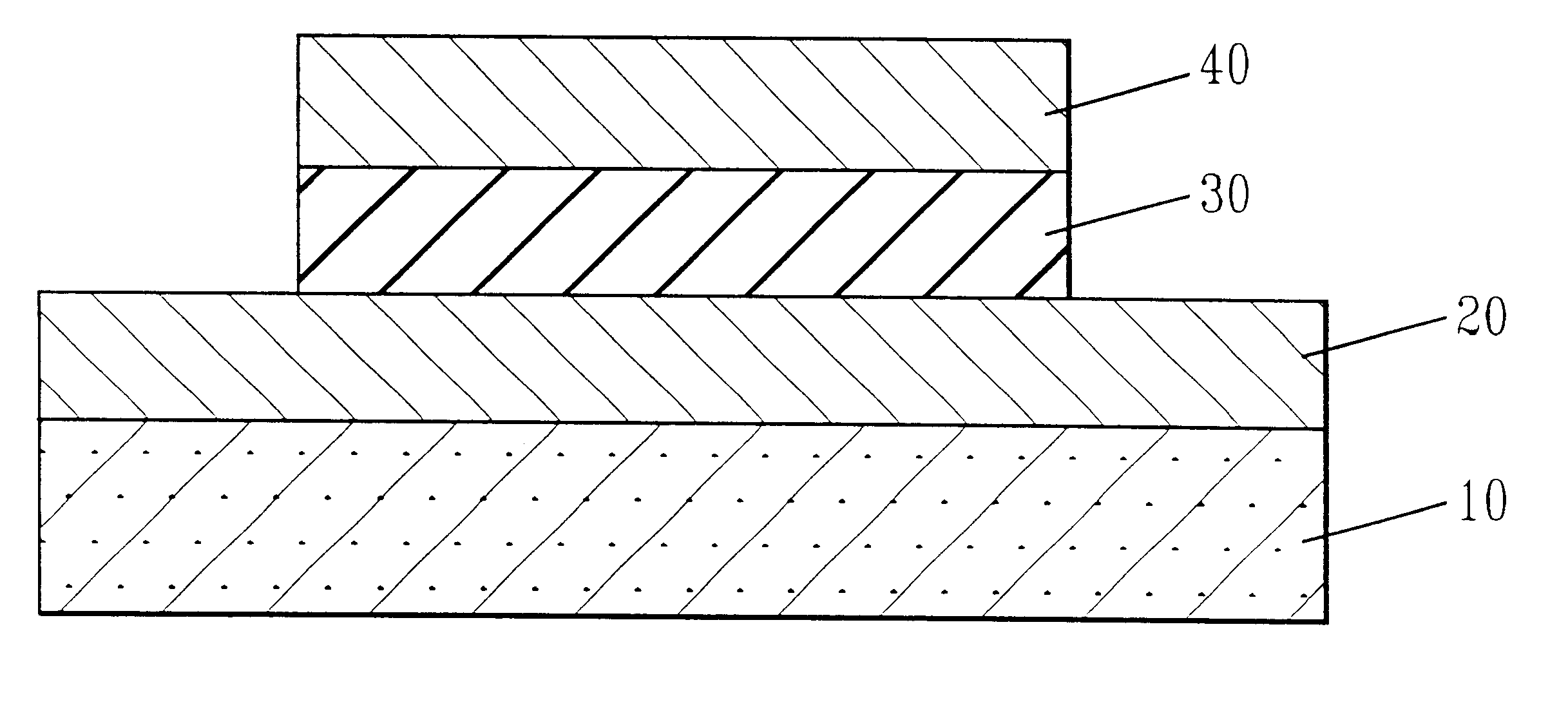

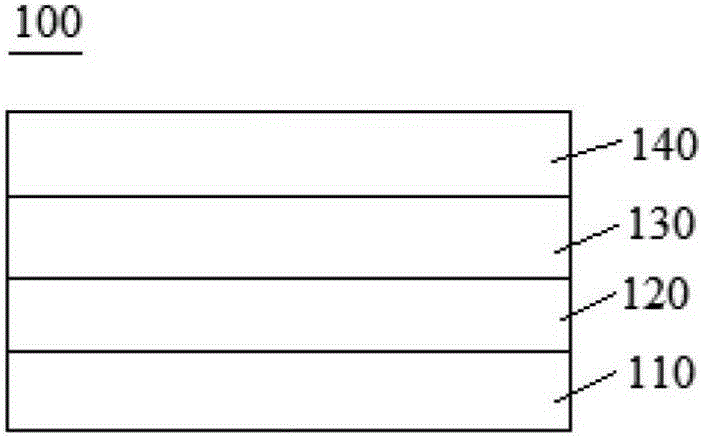

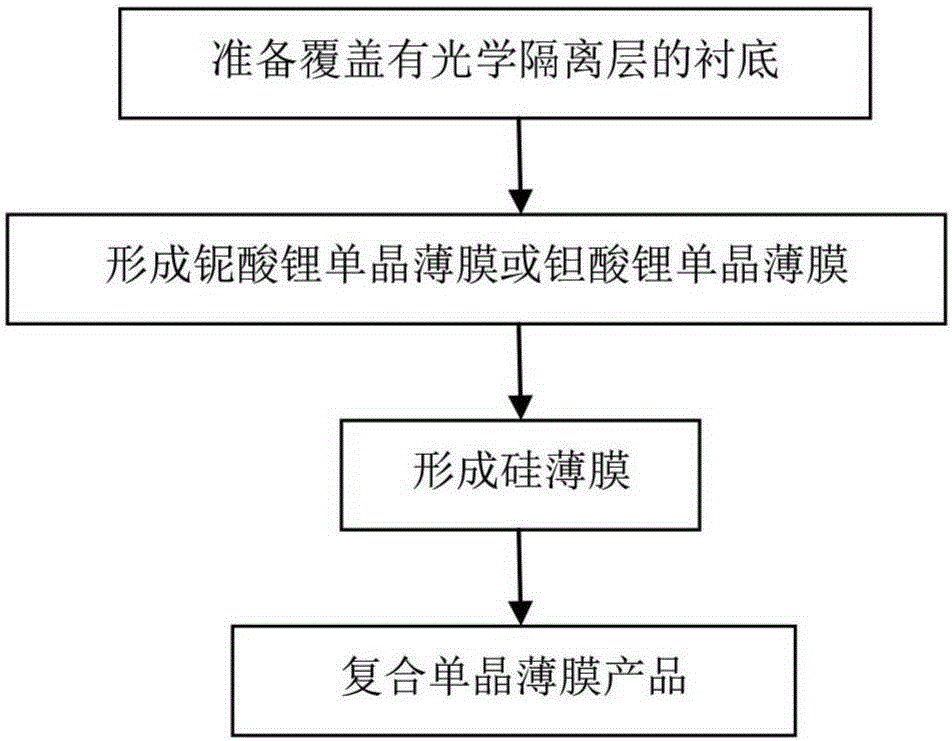

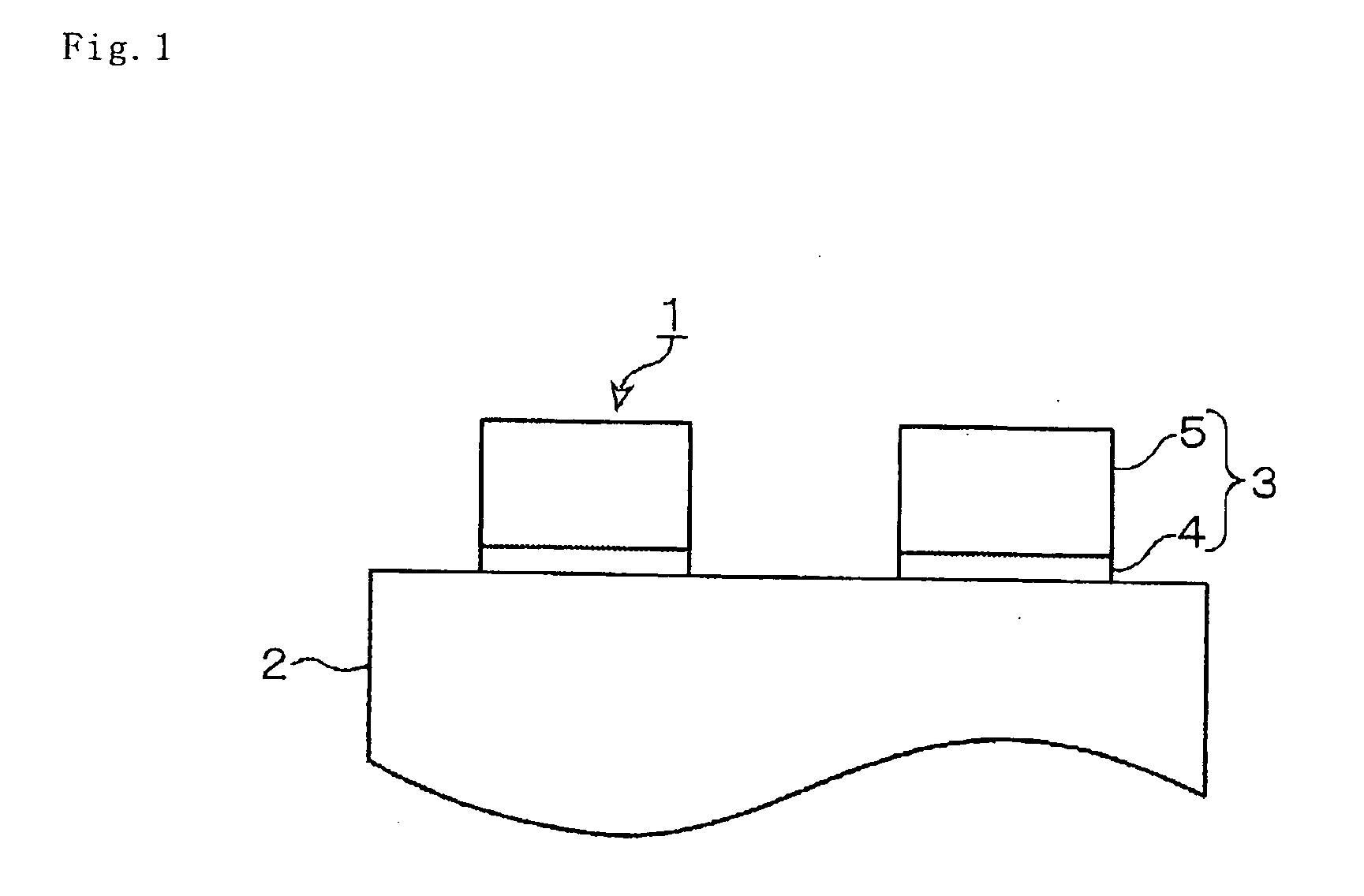

Composite single crystal thin film and method for manufacturing composite single crystal thin film

InactiveCN105321806APerfectly compatibleGood nonlinear opticsFinal product manufactureSemiconductor/solid-state device manufacturingIsolation layerSingle crystal

The invention discloses a composite single crystal thin film and a method for manufacturing the composite single crystal thin film. The composite single crystal thin film comprises a substrate, an optical isolation layer, a lithium niobate single crystal thin film or a lithium tantalate single crystal thin film and a silicon thin film, wherein the optical isolation layer is located on a substrate; the lithium niobate single crystal thin film or the lithium tantalate single crystal thin film is located on the optical isolation layer; and the silicon thin film is located on the lithium niobate single crystal thin film or the lithium tantalate single crystal thin film. The composite single crystal thin film disclosed by the invention has good nonlinear optical effect, acousto-optical effect, electro-optic effect and the like of a lithium niobate or lithium tantalite material, and simultaneously has the characteristic of a mature processing technology of a silicon material, so that the composite single crystal thin film disclosed by the invention can achieve relatively good compatibility with an existing IC production technology and has a broad industrial prospect. In addition, stable and effective industrial production can be achieved according to the method for manufacturing the composite single crystal thin film disclosed by the invention.

Owner:JINAN JINGZHENG ELECTRONICS

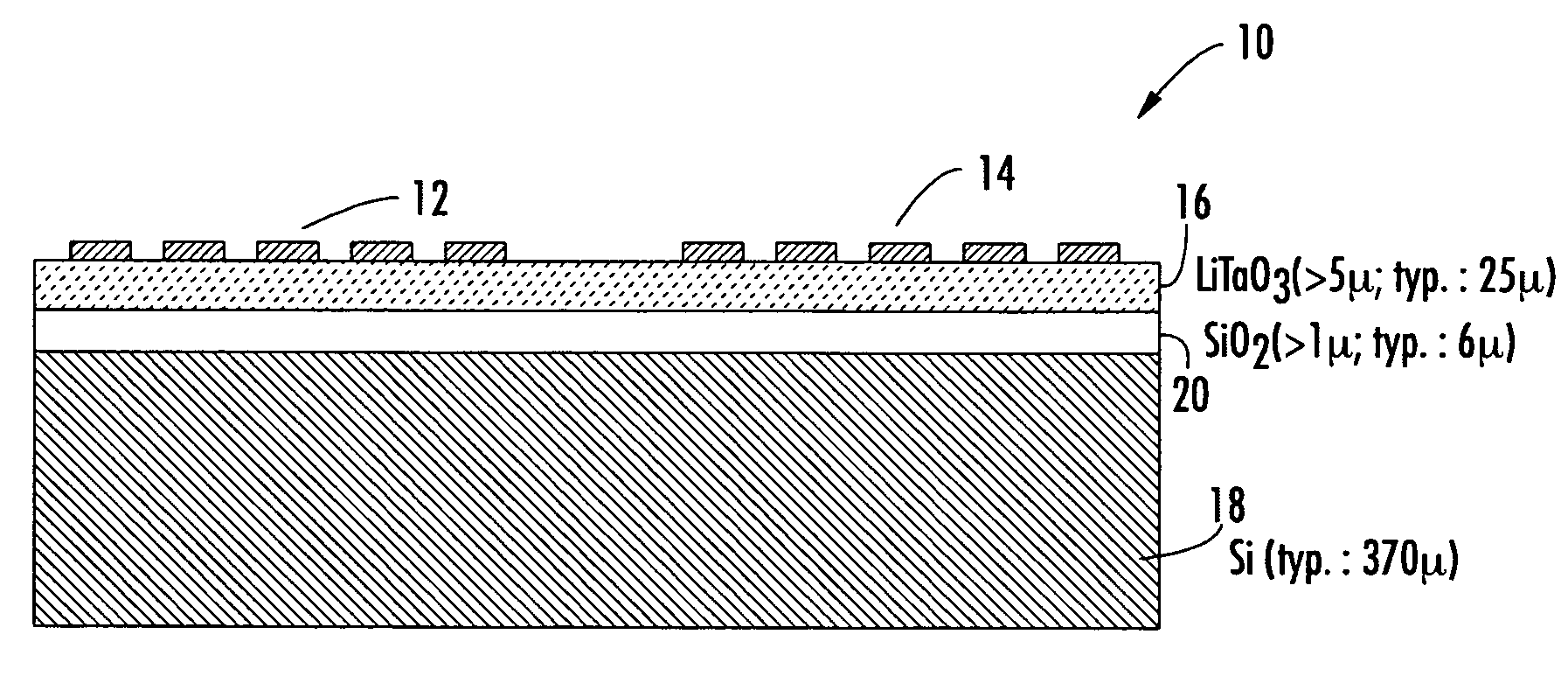

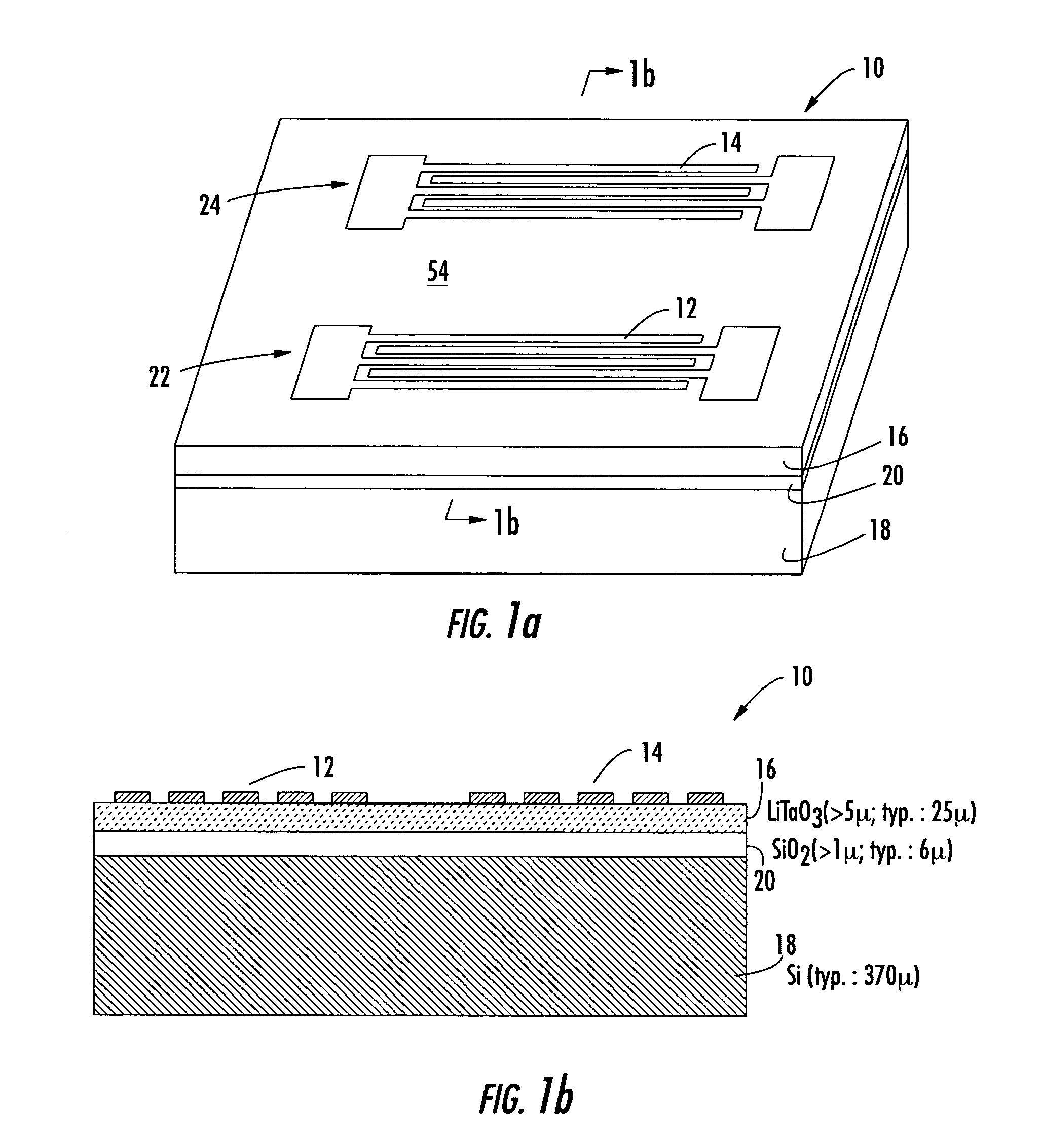

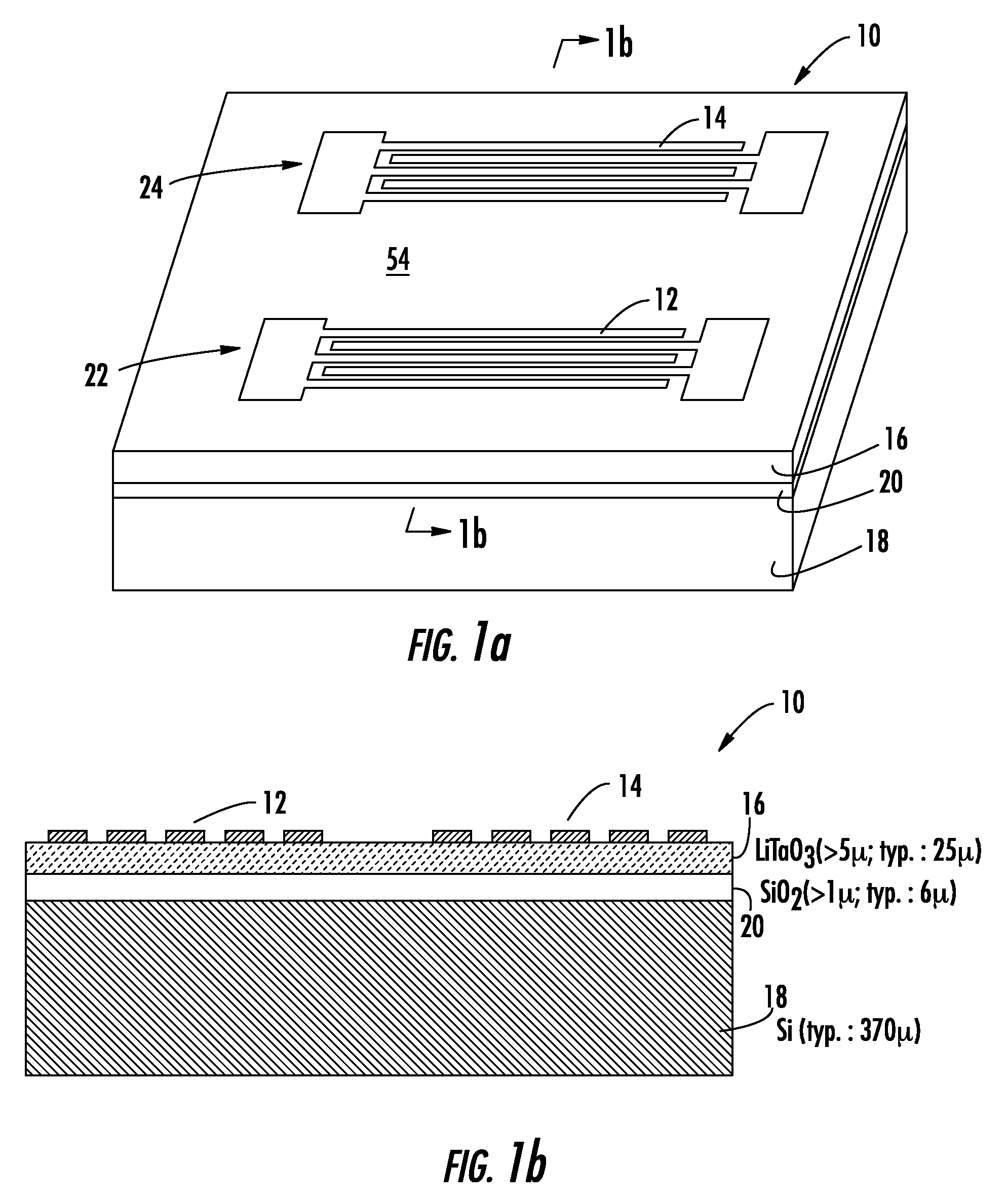

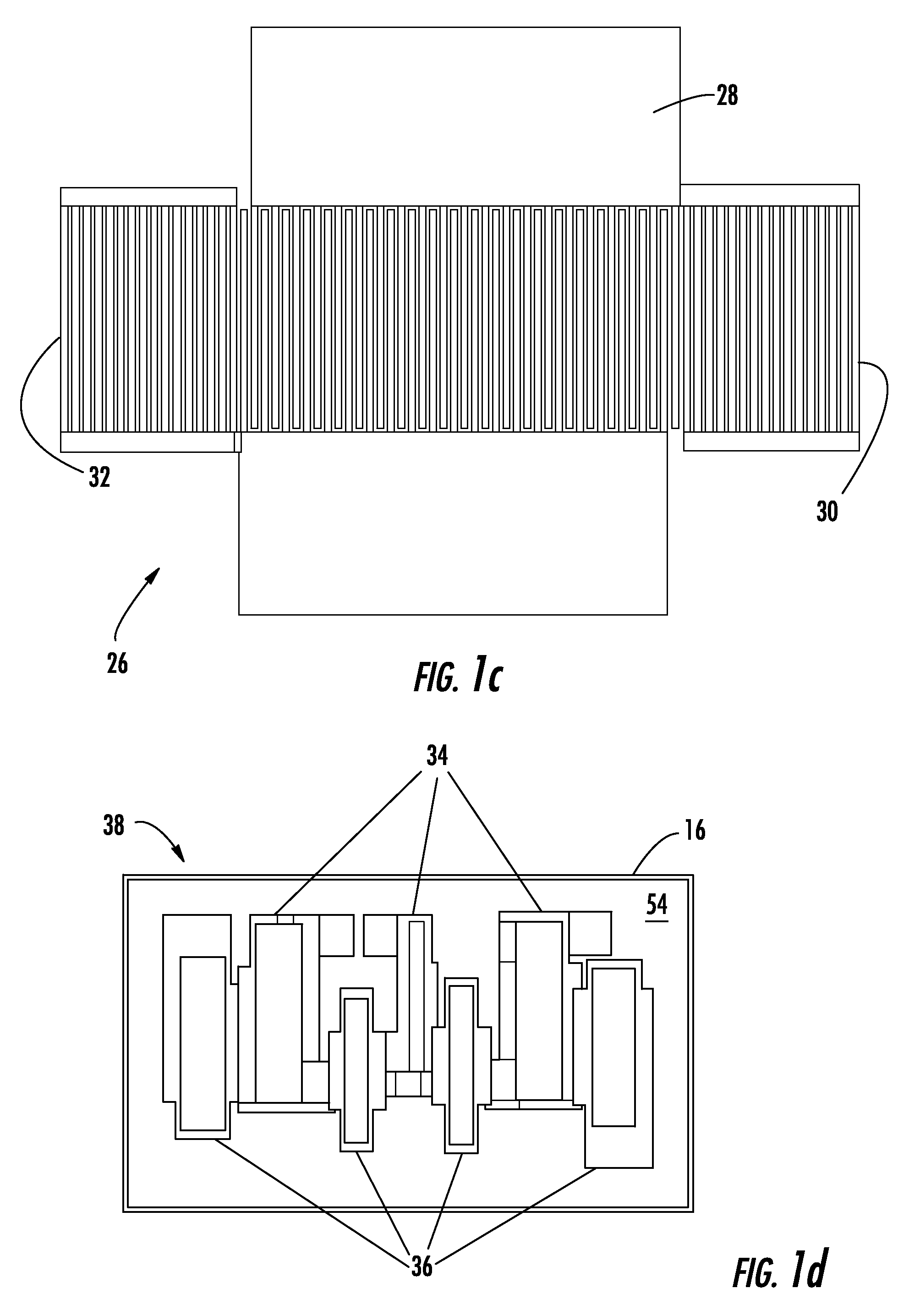

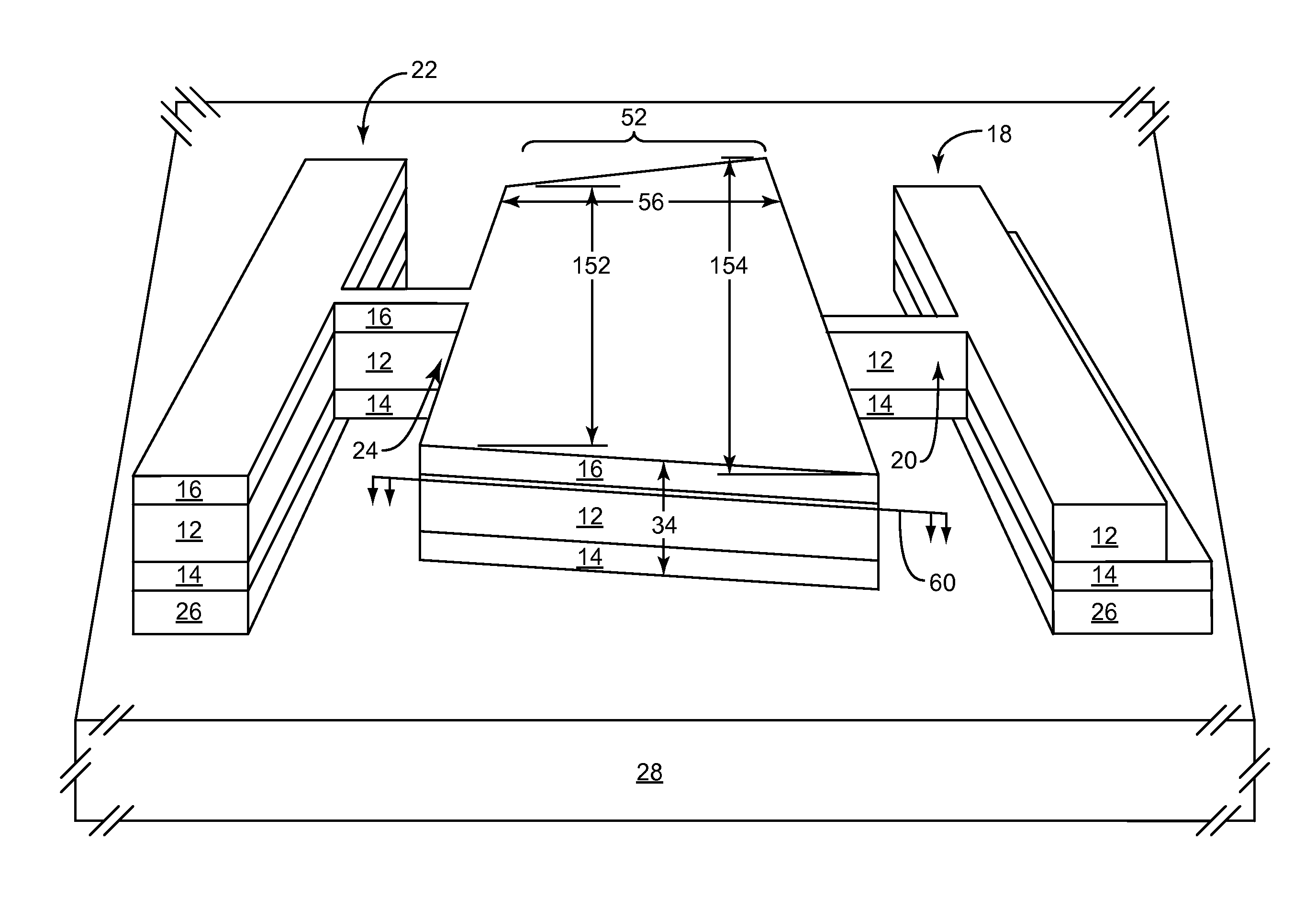

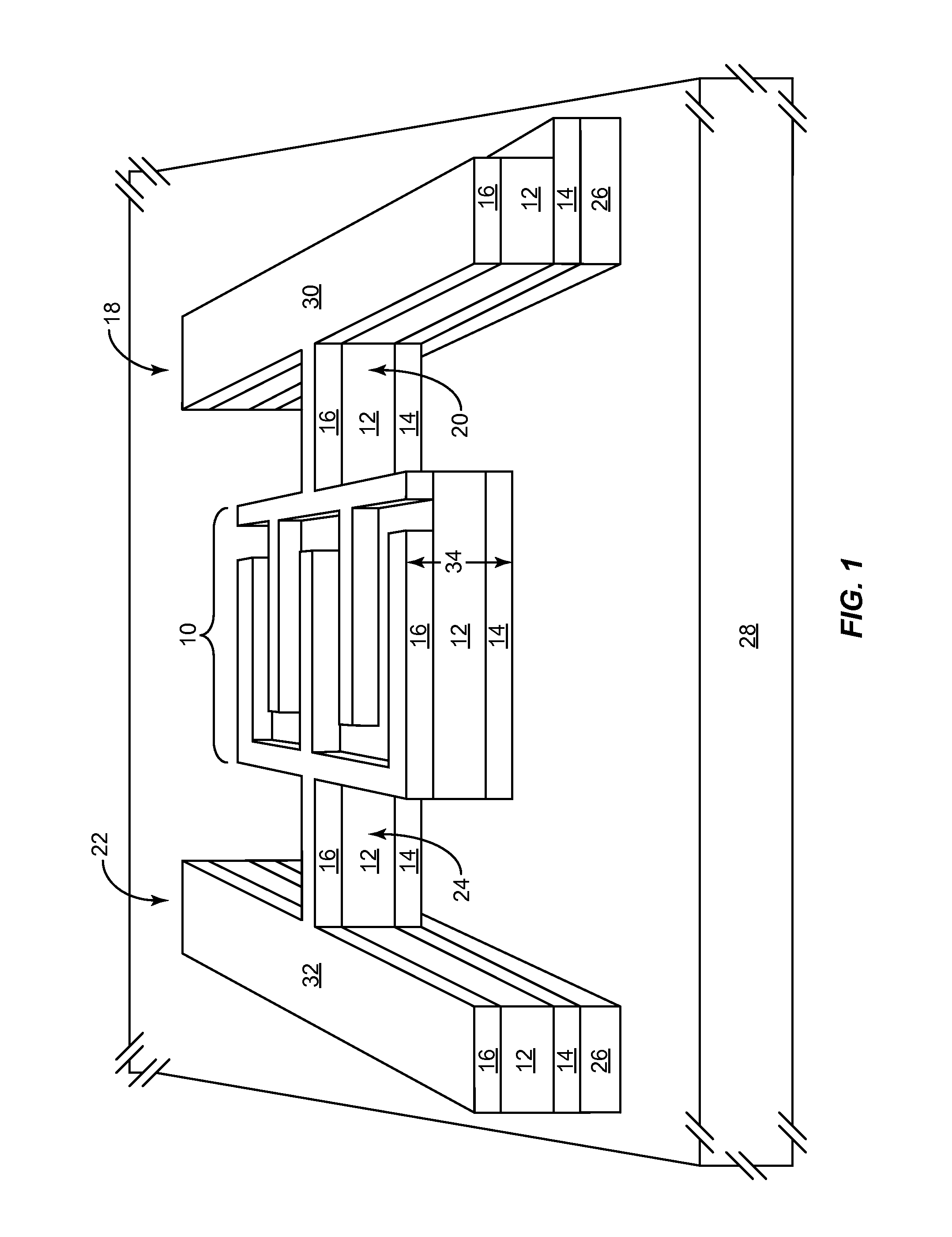

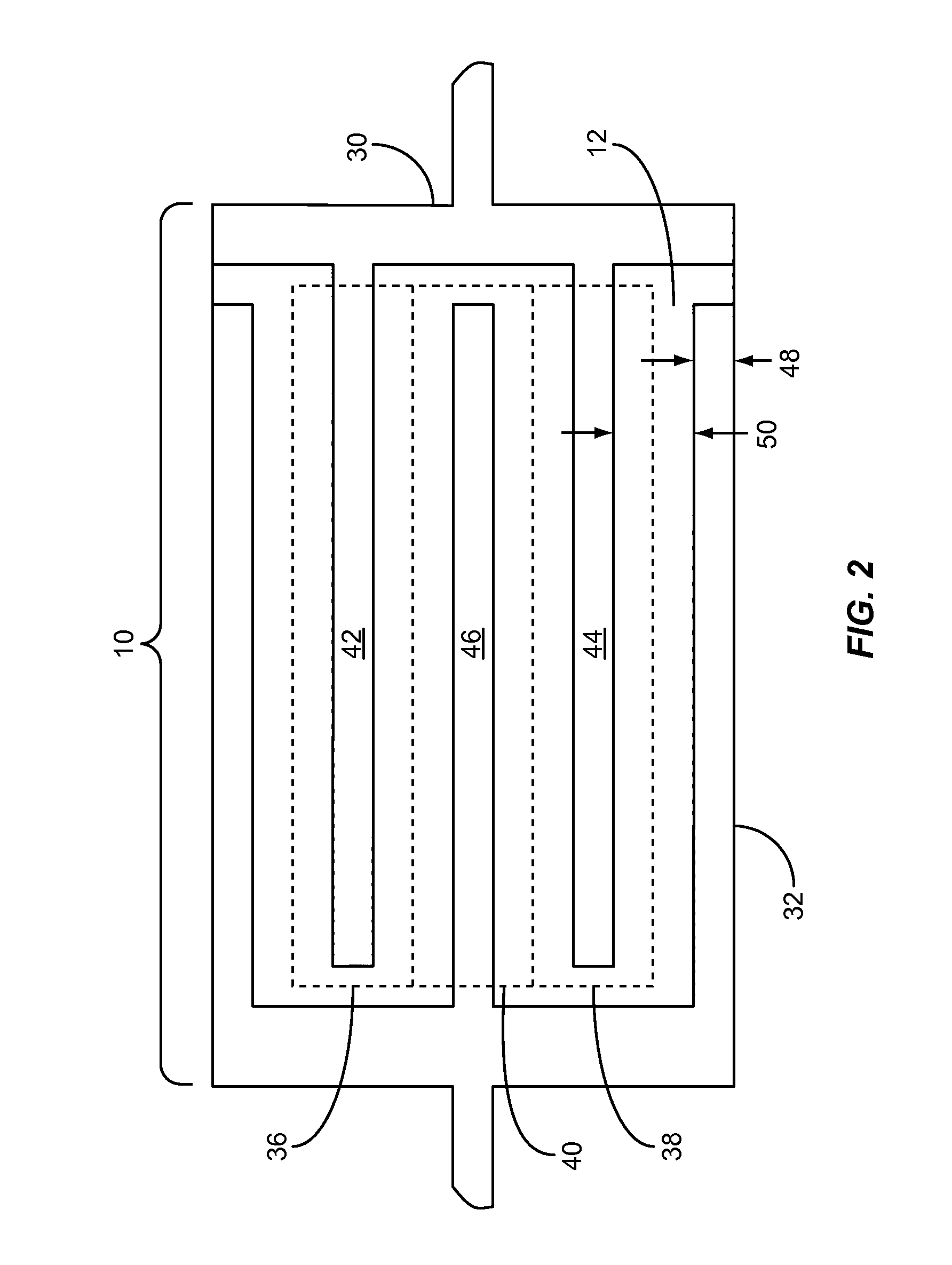

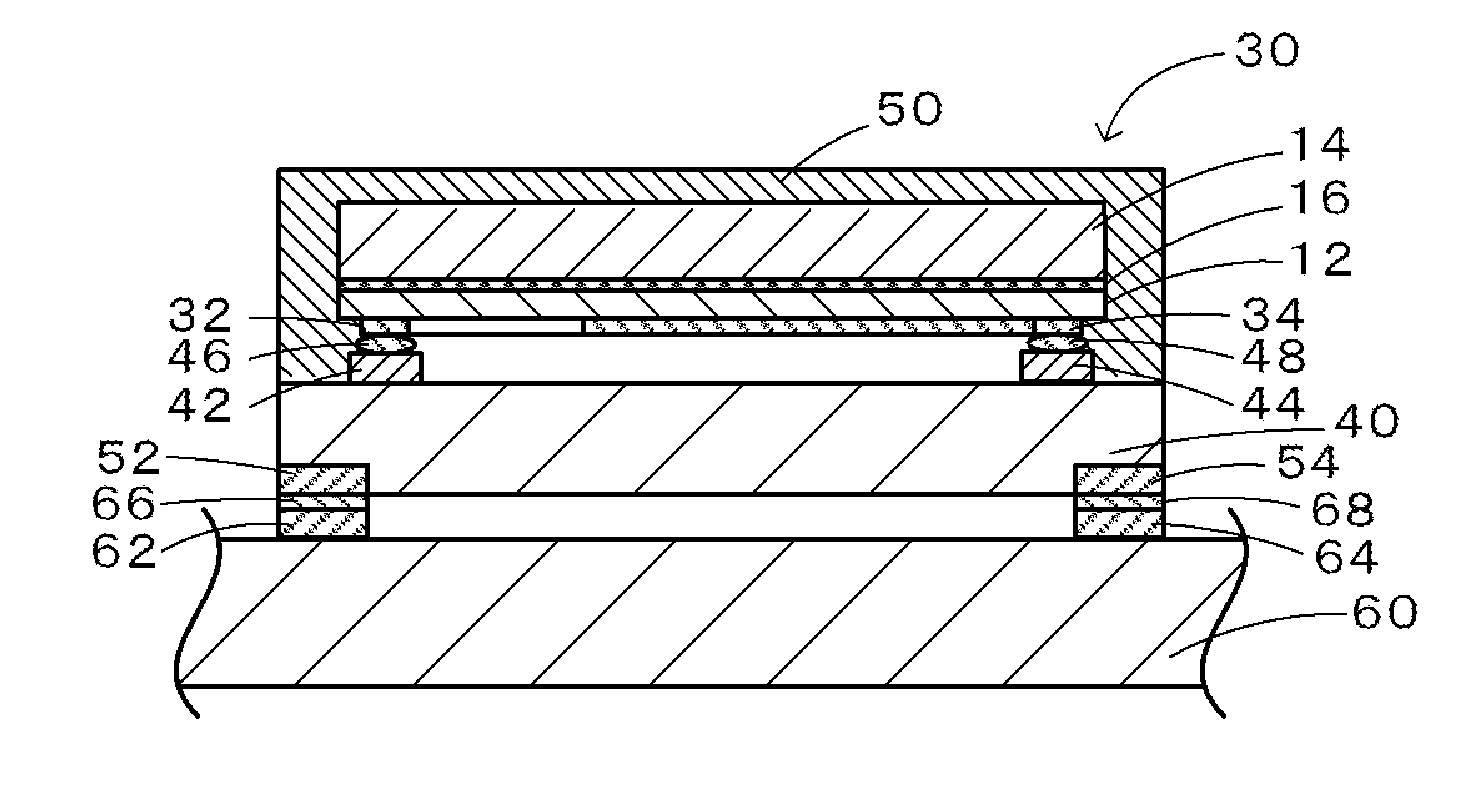

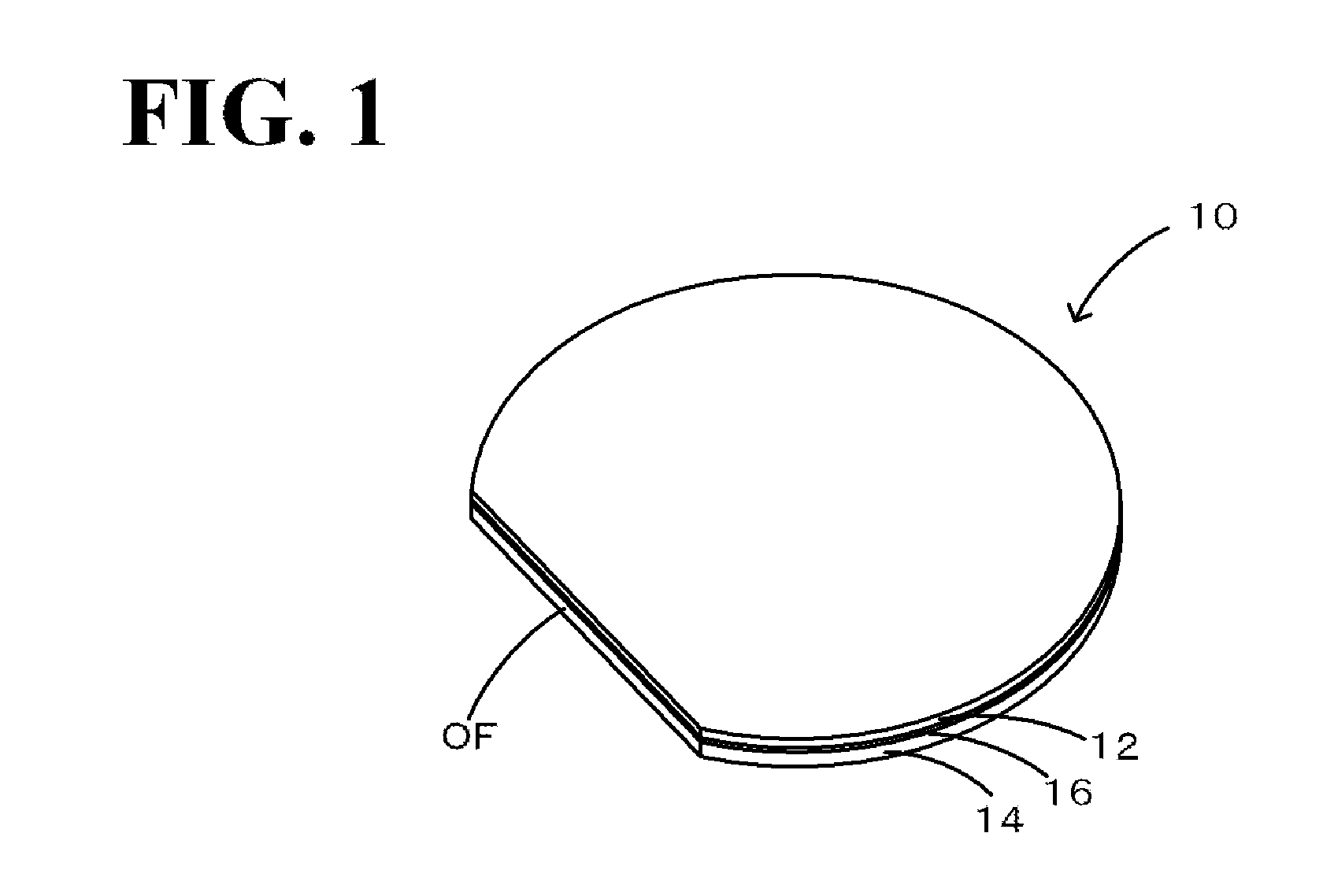

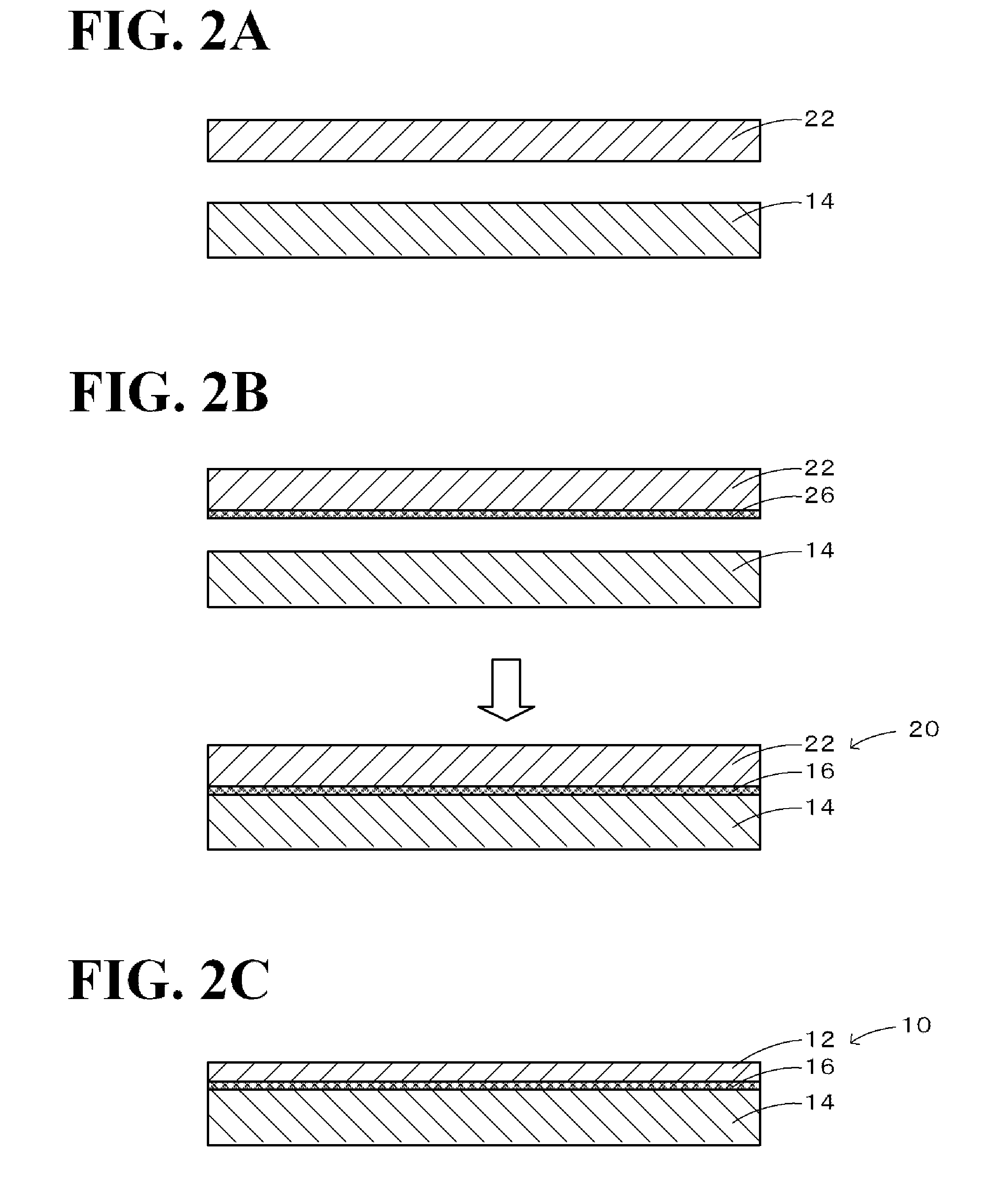

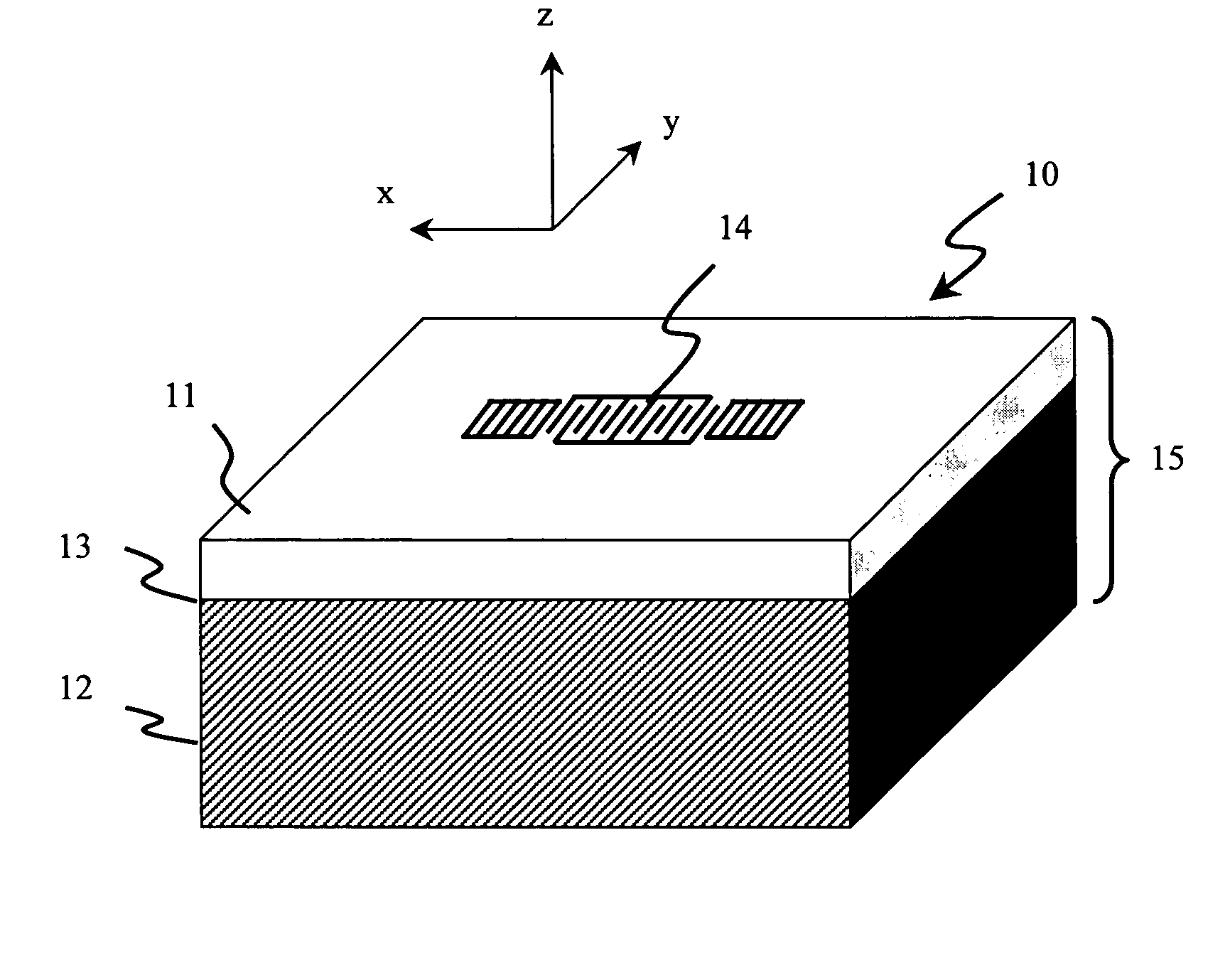

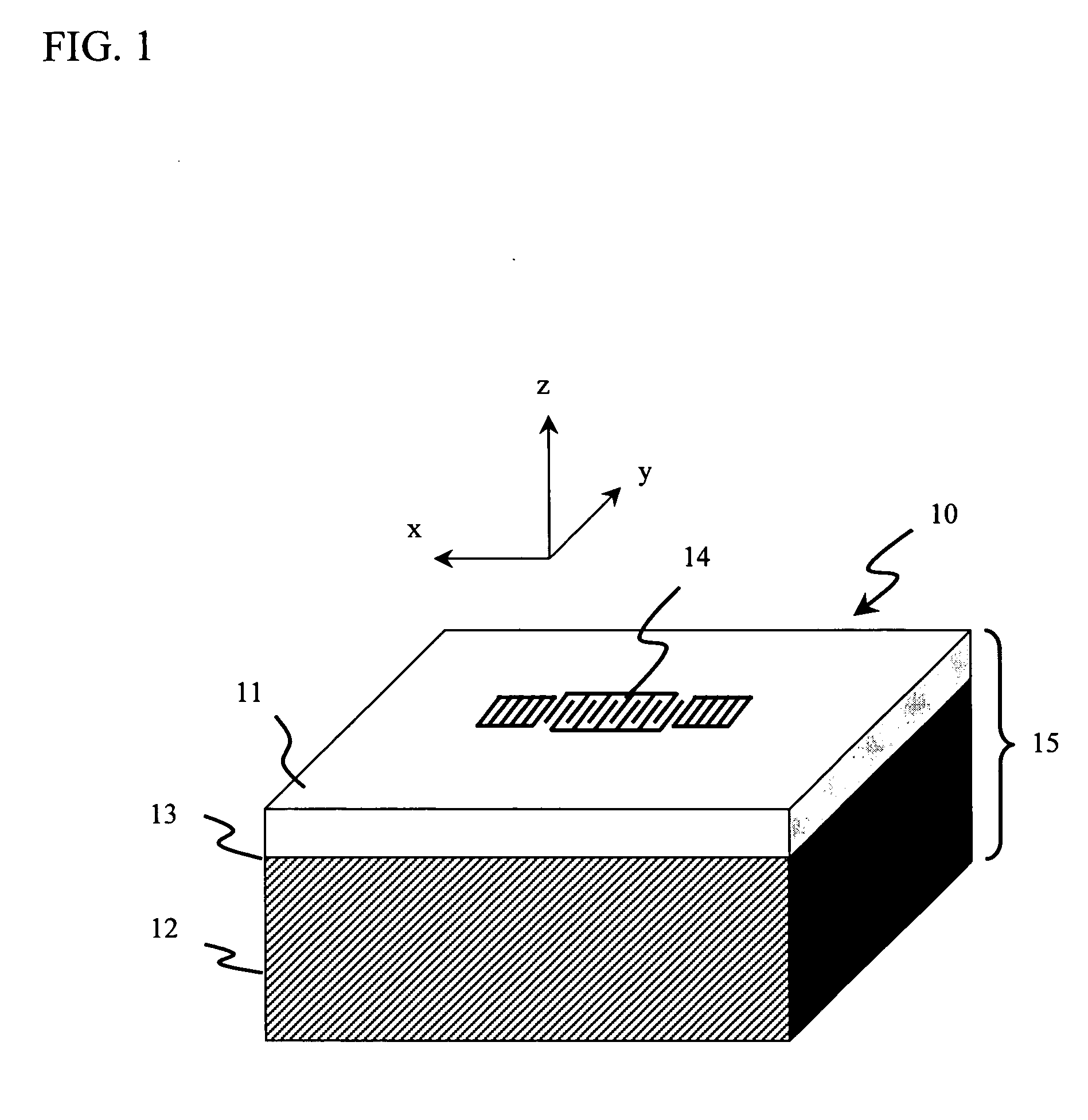

Composite substrate and elastic wave device using the same

ActiveUS20100182101A1Improve heat resistanceSmall componentImpedence networksPiezoelectric/electrostriction/magnetostriction machinesComposite substrateSilicon

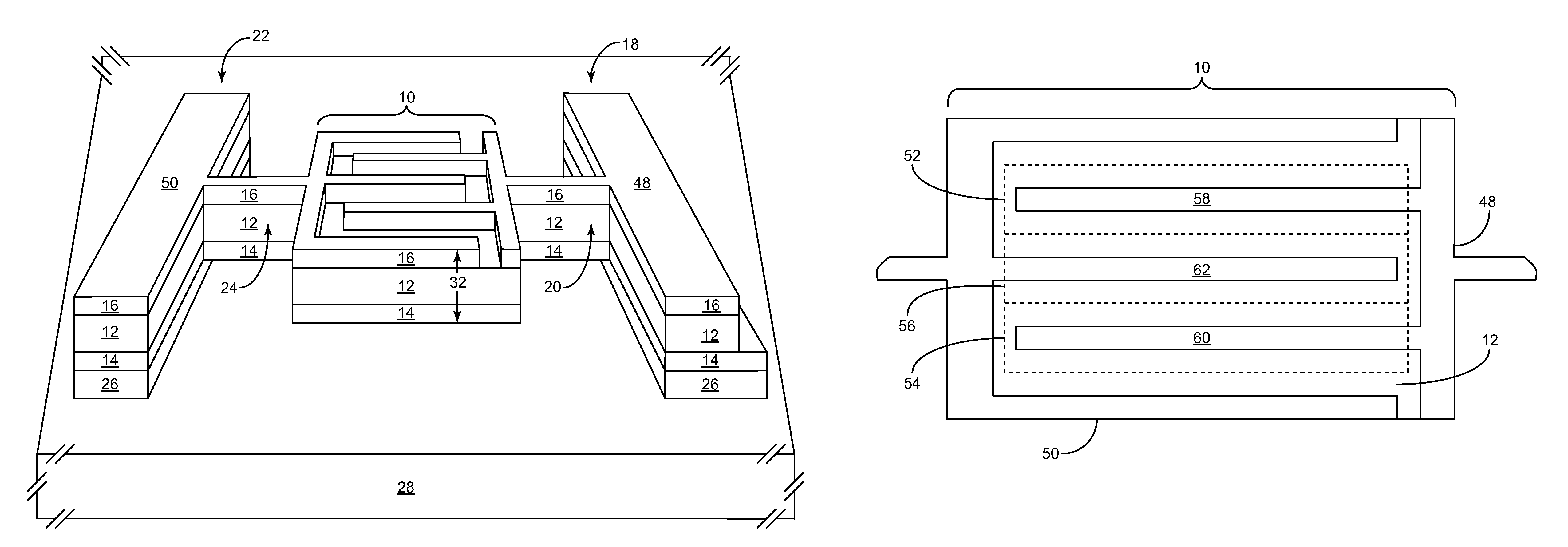

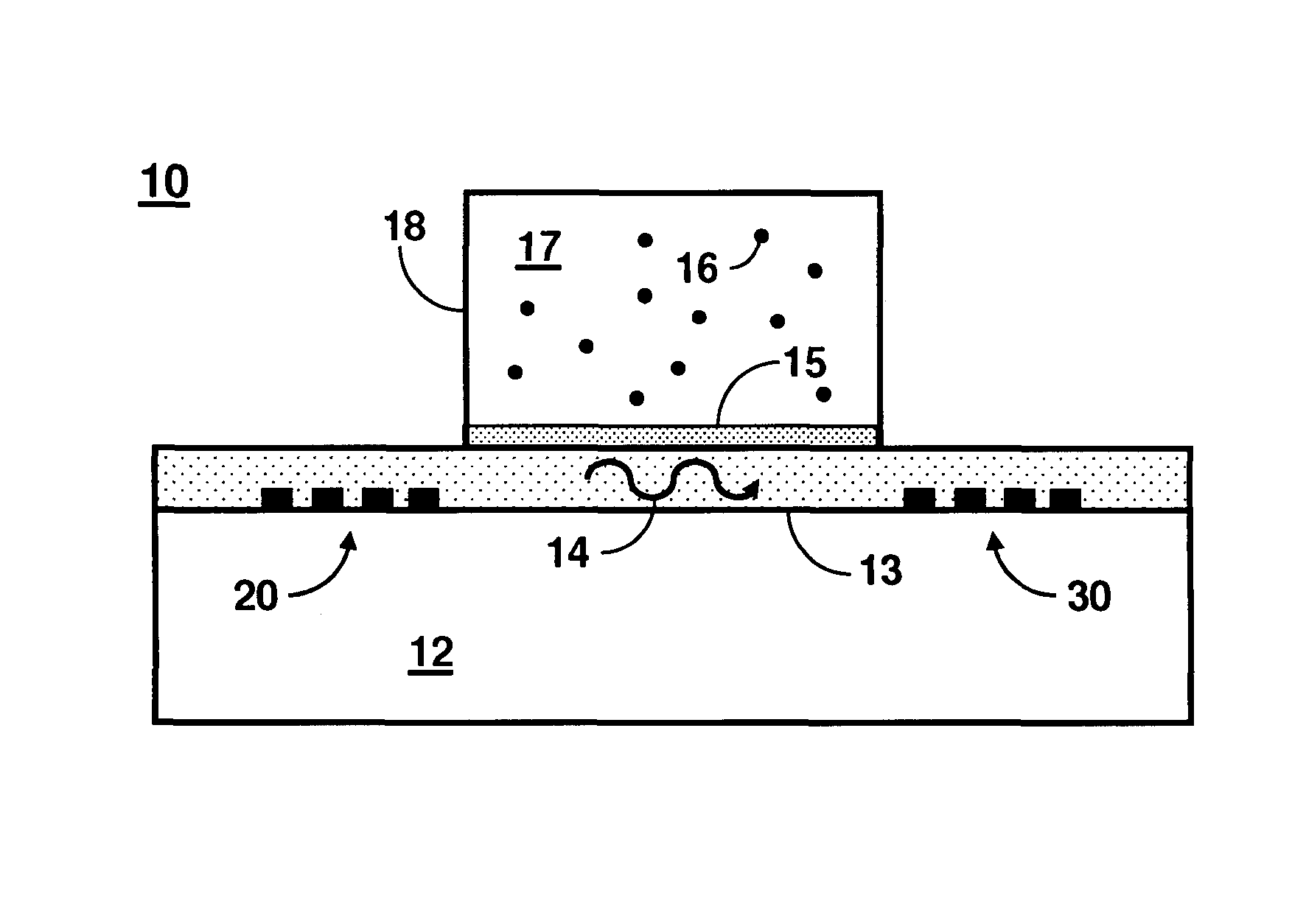

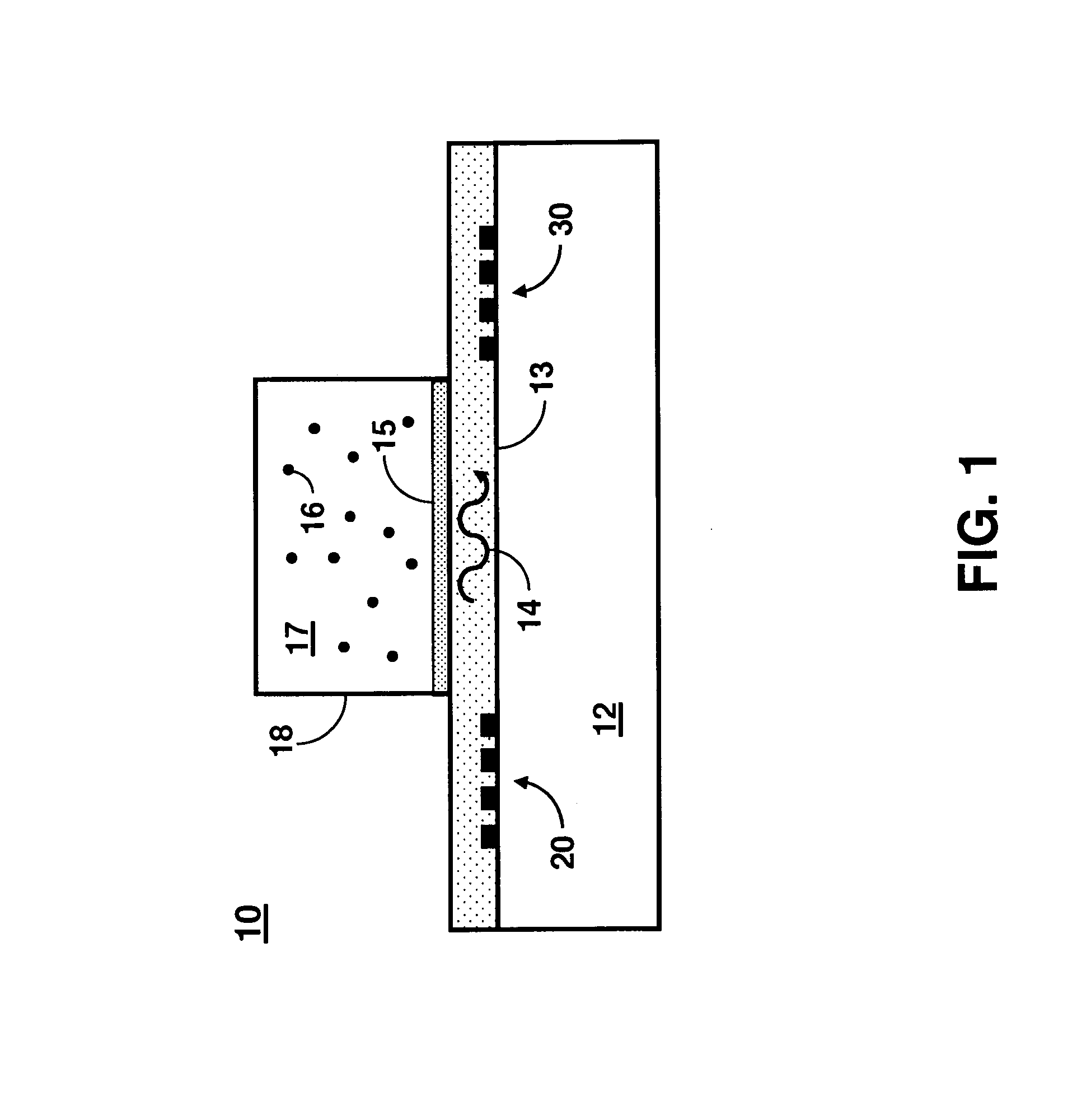

A composite substrate 10 includes: a piezoelectric substrate 12 capable of transmitting an elastic wave and composed of lithium tantalate (LT); a silicon support substrate 14 that is bonded to the rear surface of the piezoelectric substrate in the (111) plane; and an adhesive layer 16 bonding the substrates 12 and 14 to each other.

Owner:NGK INSULATORS LTD

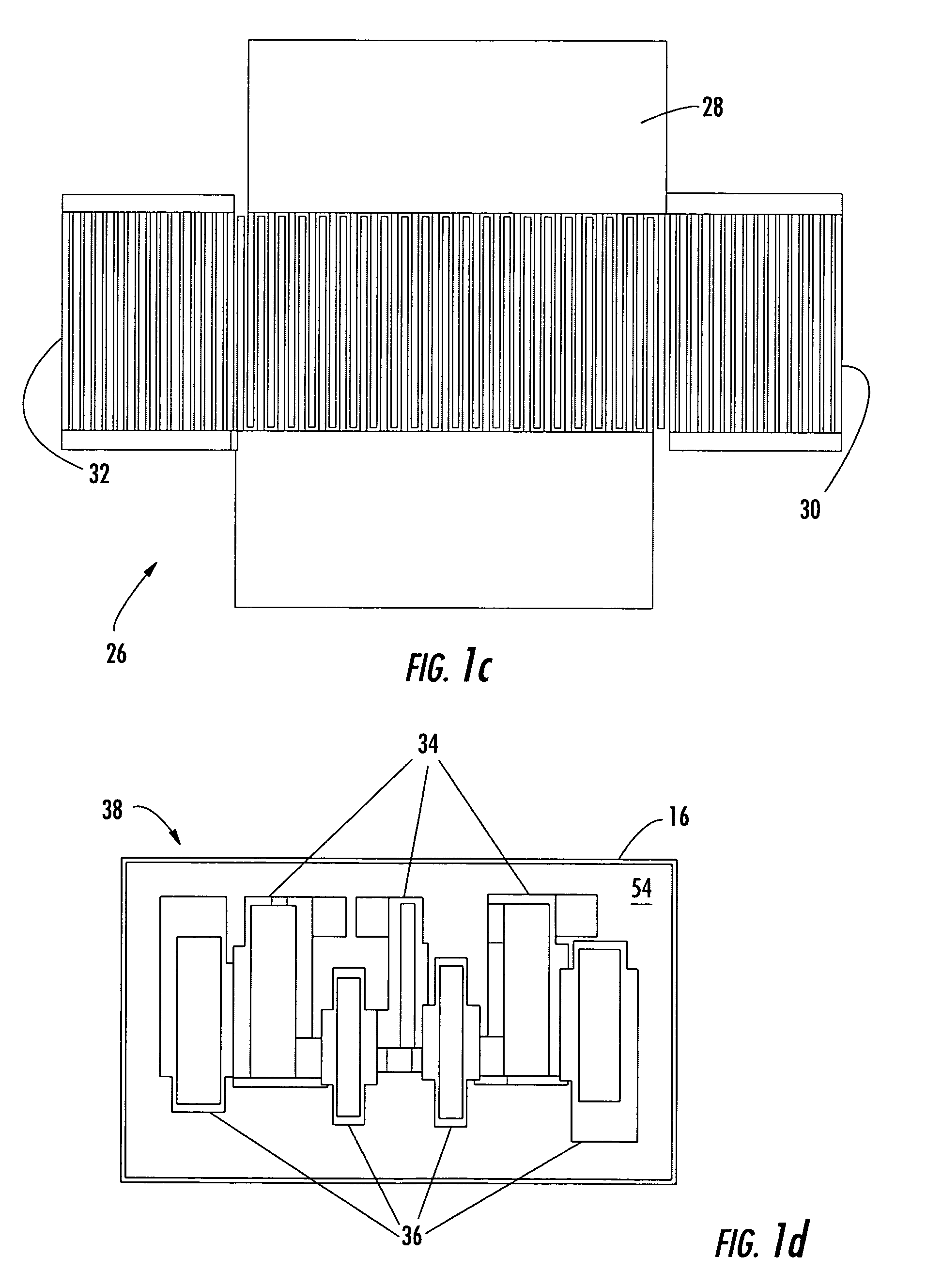

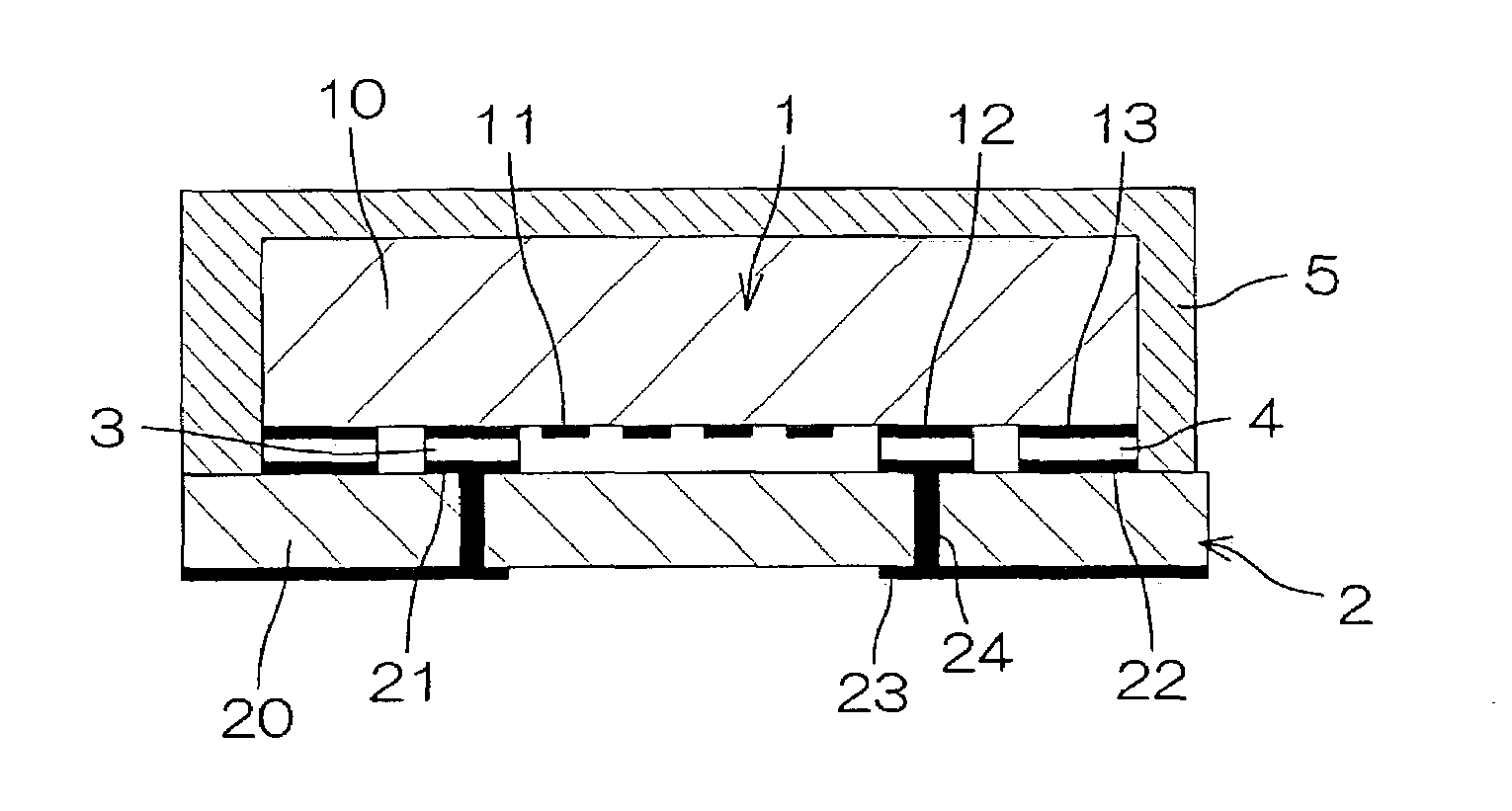

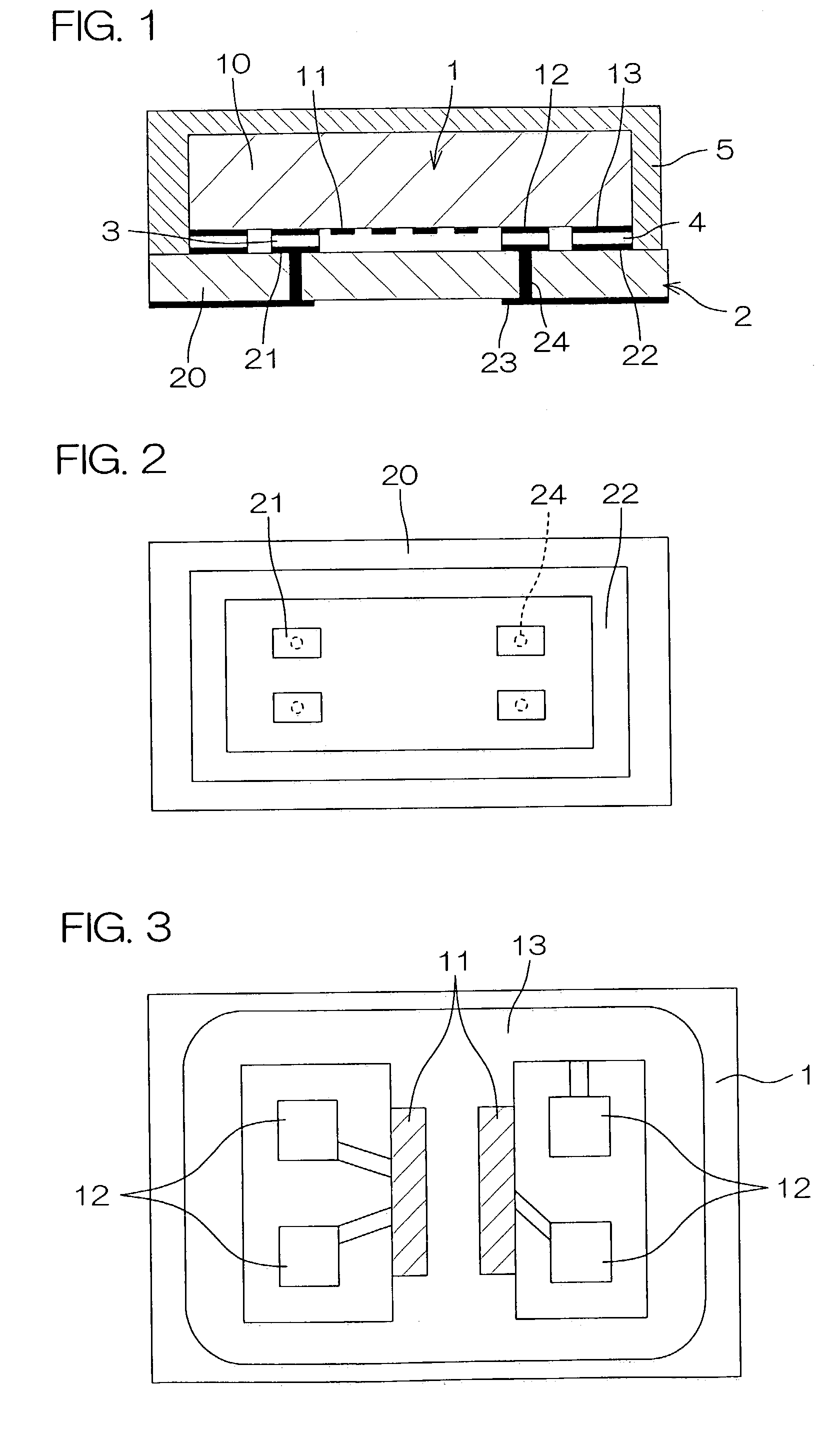

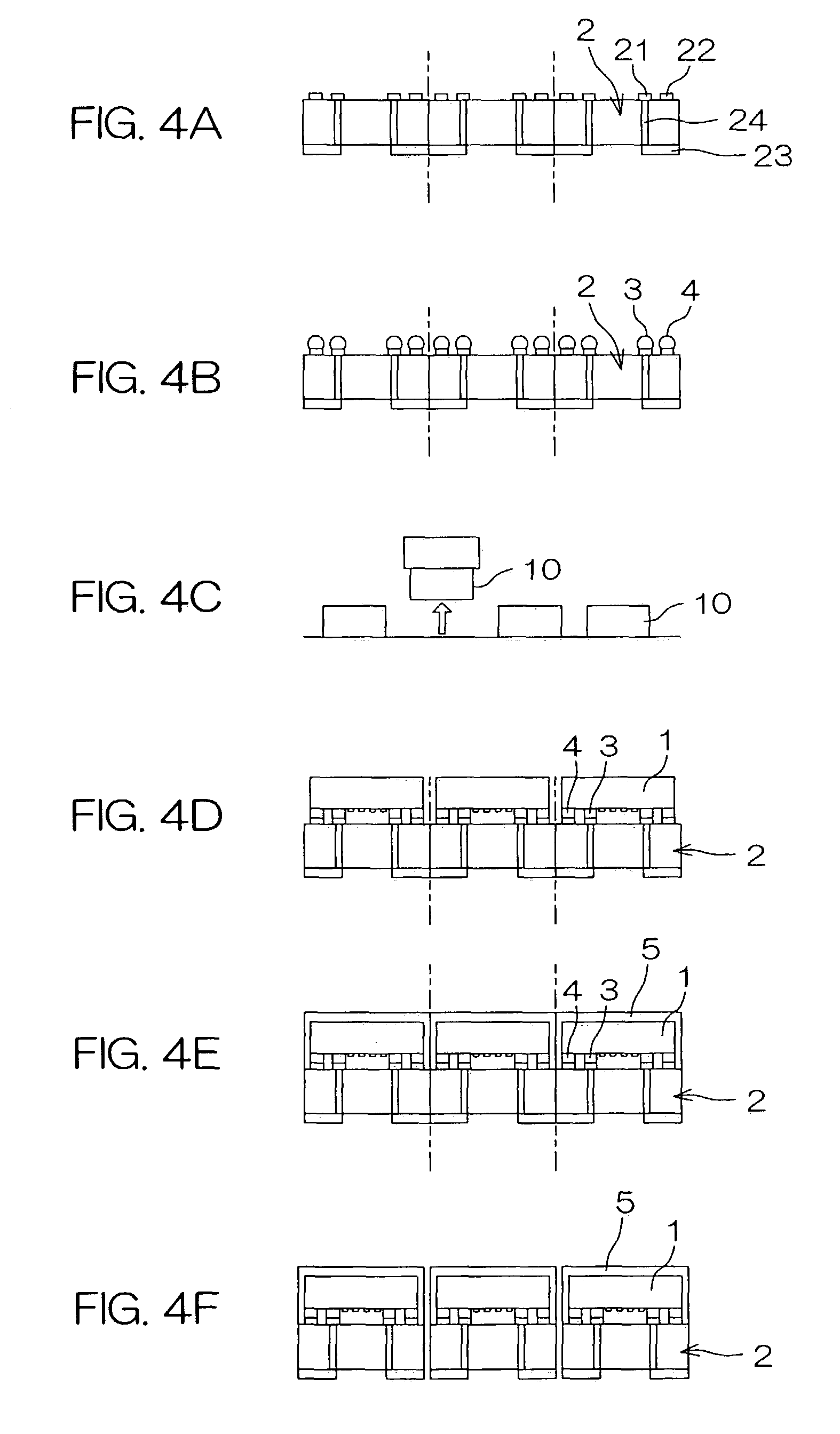

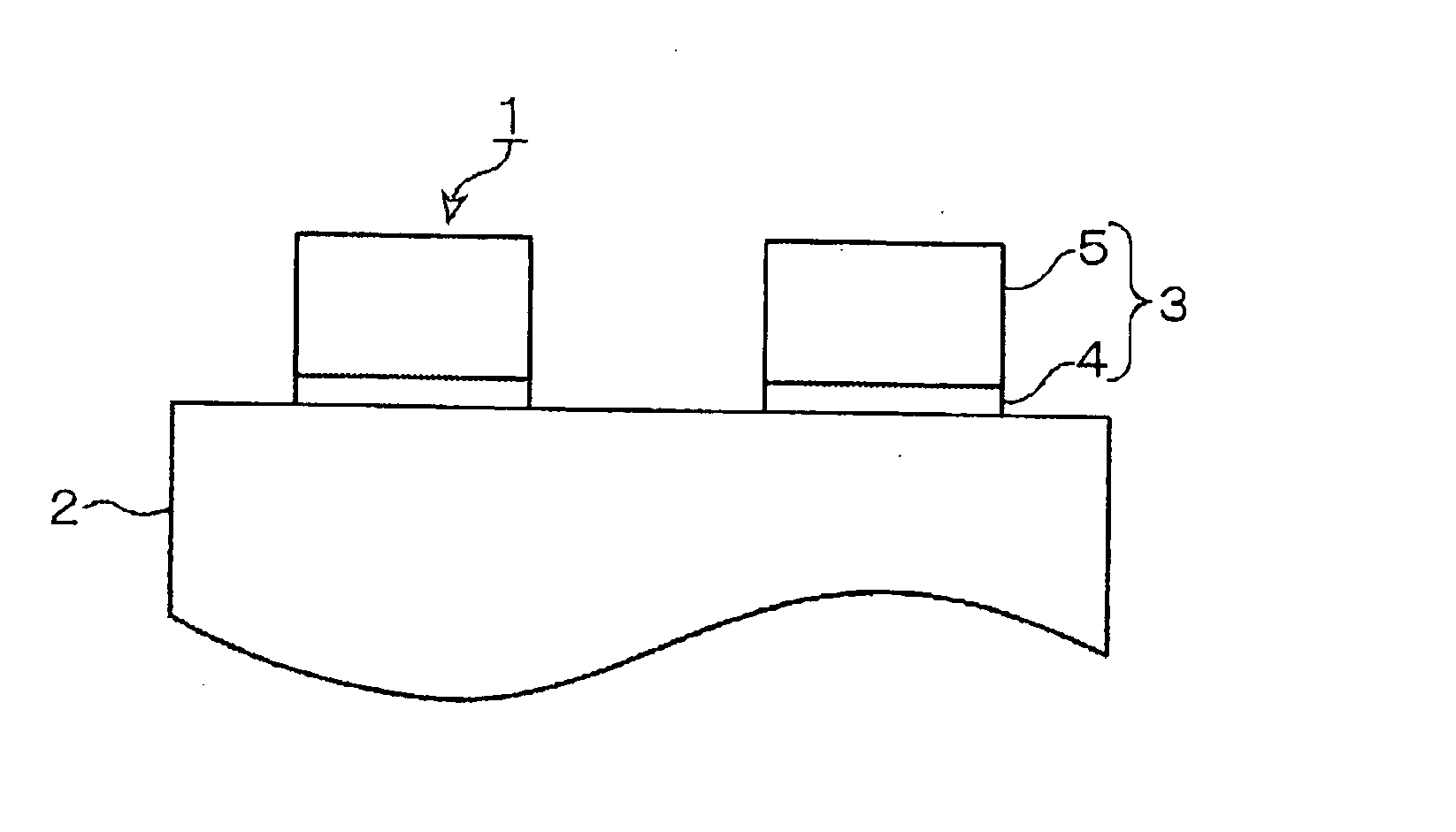

Surface acoustic wave device and method for manufacturing same

ActiveUS7154206B2Firmly connectedImprove production efficiencyVibration measurement in fluidPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustic wave

A surface acoustic wave device is disclosed, which comprises a surface acoustic wave element including a lithium tantalate piezoelectric substrate 10 with one principal surface thereof formed with an IDT electrode 11, a connector electrode 12 and a periphery sealing electrode 13, and a base substrate 2 formed with an electrode 21 for connection to the element connected to the connector electrode 12 through a solder bump component 3 and a periphery sealing conductor film 22 joined to the periphery sealing electrode 13 thorough a solder sealing component 4. For the solder bump component 3 and the solder sealing component 4, a Sn—Sb based or Sn—Ag based lead-free solder containing 90% or more Sn is used, and the thermal expansion coefficient of the base substrate 2 is set in the range of 9–20 pm / ° C. The joining is accomplished with high stability resisting thermal stress due to a difference in thermal expansion coefficient, so that a surface acoustic wave device that can maintain stable connection for a long duration of time can be provided.

Owner:KYOCERA CORP

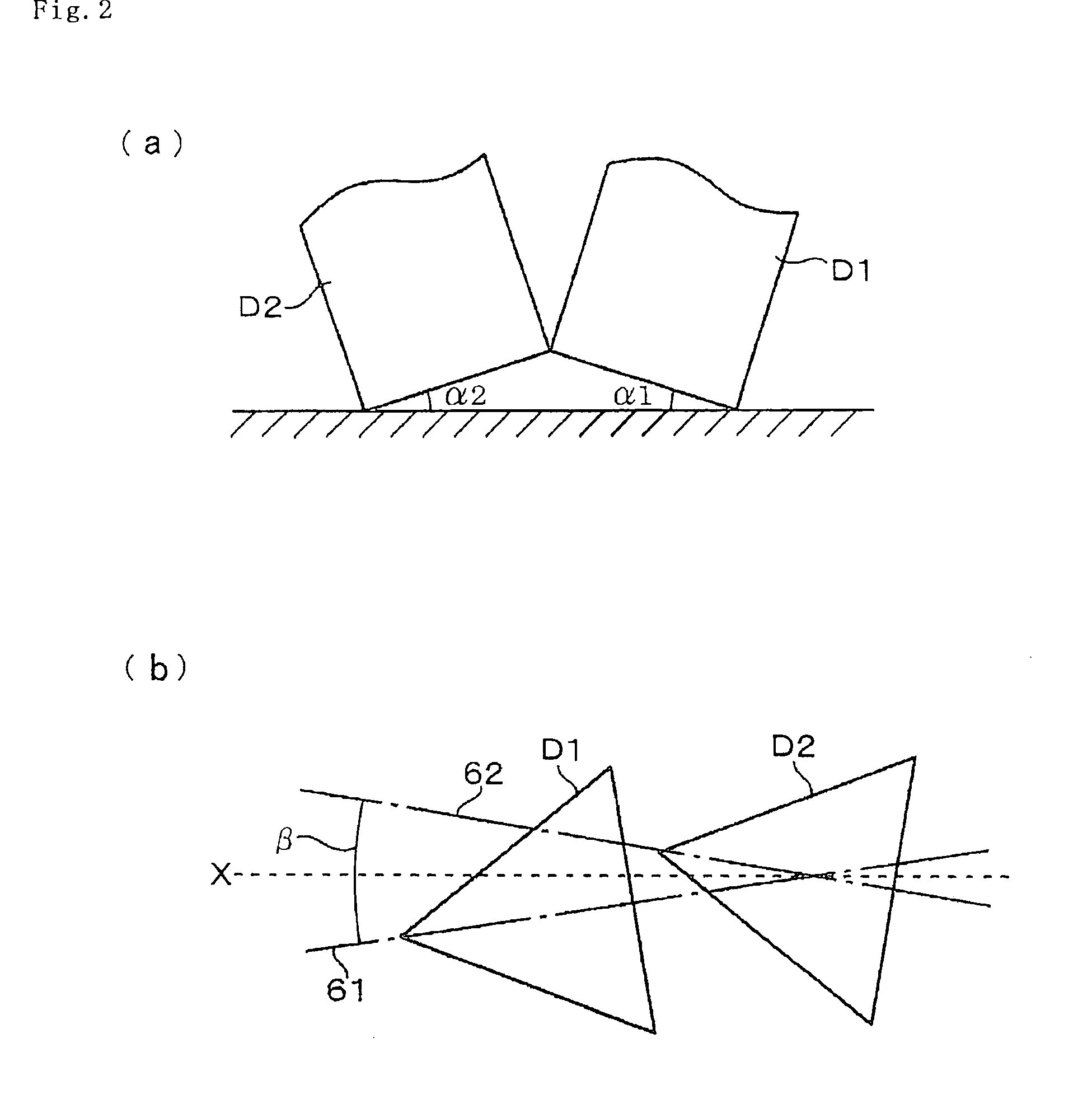

Surface acoustic wave device and method of manufacturing the same

ActiveUS20070103038A1Excellent power durabilityGood reproducibilityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksOptoelectronicsSingle crystal

In order to provide a surface acoustic wave device provided with a pseudo-single crystal aluminum electrode film, having excellent power durability, easy to manufacture, and possible to grow with good reproducibility, a titanium buffer film 4 and an electrode film composed of an aluminum film or an aluminum alloy film are formed on a piezoelectric substrate 2 composed of lithium tantalate or lithium niobate. The electrode film 5 comprises a pseudo-single crystal film composed of two (111) domains. Each of the <111> directions of two (111) domains tilts in the range of 0 to 10 degrees to the substrate surface, and the <11-2> directions in the respective (111) domain planes are 1 to 15 degrees apart.

Owner:NDK SAW DEVICES CO LTD

One-dimensional illumination apparatus and imaging apparatus

InactiveUS20050238071A1High in output and efficiencyReduce speckle noiseSemiconductor laser arrangementsPicture reproducers using projection devicesNonlinear optical crystalLight equipment

A one-dimensional transverse multiple mode laser is used for a one-dimensional illumination apparatus. A pumping light source, and a laser medium and a wavelength conversion device (nonlinear optical crystal or a nonlinear optical device) which are disposed in a resonator, are provided, and the nonlinear optical crystal or a nonlinear optical device is irradiated with a line beam obtained by exciting the laser medium in an elliptic transverse mode pattern. Then, a one-dimensional light modulation device is irradiated with the wavelength-converted line beam, and scanning with the beam modulated by the modulation device is conducted to produce a two-dimensional image. For example, in a green illumination optical system, in the case where the nonlinear optical device for obtaining visible rays through second harmonic generation from IR rays oscillated by a solid state laser medium has a periodical poling structure, stoichiometric composition periodical poling lithium tantalate having been subjected to vapor transport equilibration is used, whereby reliability is enhanced and a reduction in cost can be achieved through mass production.

Owner:SONY CORP

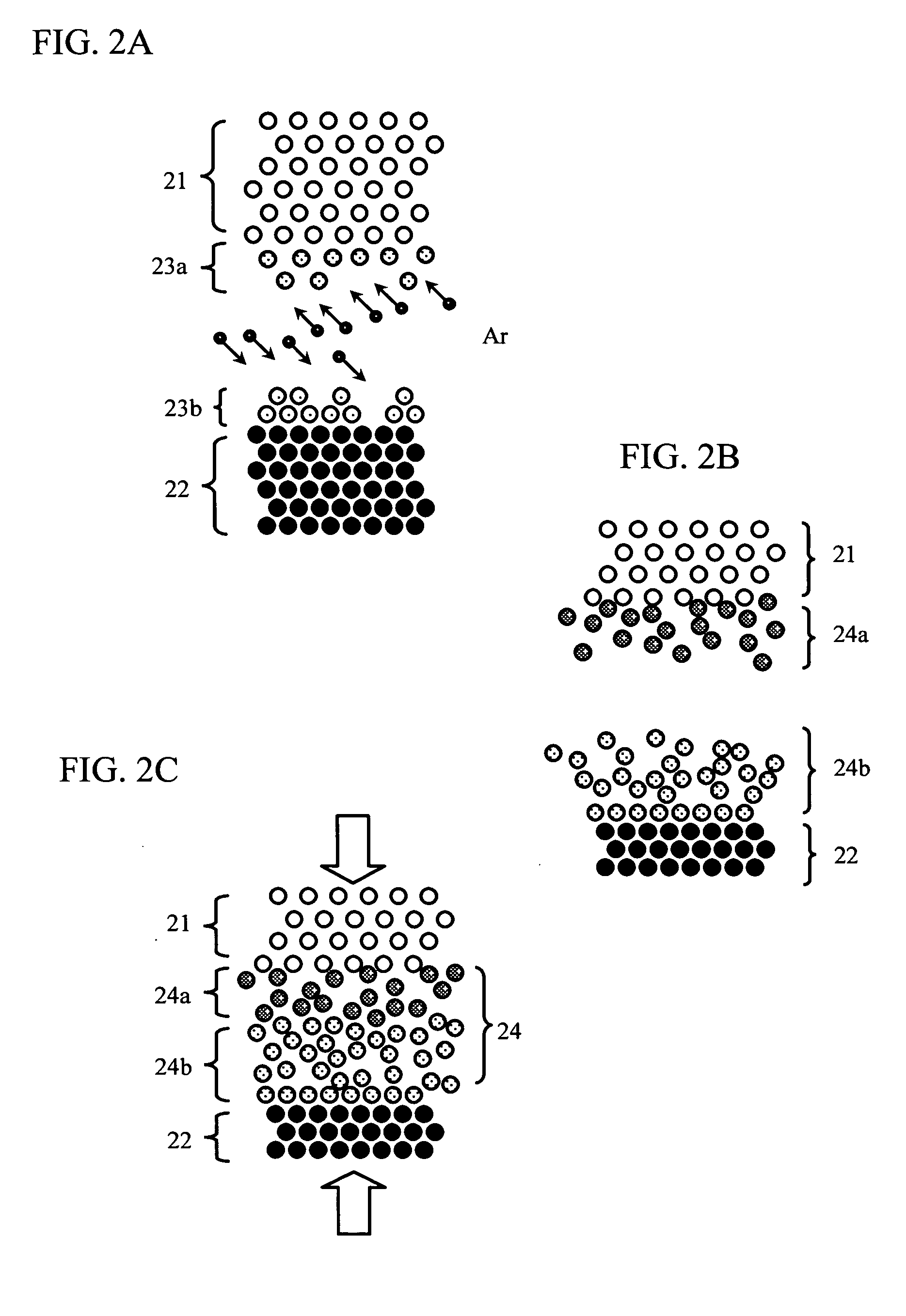

Bonded substrate, surface acoustic wave chip, and surface acoustic wave device

ActiveUS20050194864A1High bonding strengthSmall distortionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesBond interfaceOxygen

A bonded substrate includes a lithium tantalate substrate and a sapphire substrate to which the lithium tantalate substrate is bonded, a bonded interface of the lithium tantalate and the sapphire substrate includes a bonded region in an amorphous state having a thickness of 0.3 nm to 2.5 nm. The bonded region in the amorphous state is formed by activating at least one of the lithium tantalate substrate and the sapphire substrate in the bonded interface with neutralized atom beams, ion beams or plasma of inert gas or oxygen. It is possible to bond the piezoelectric substrate to the supporting substrate having different lattice constants without the high-temperature thermal treatment and realize the bonded substrate having an excellent bonding strength and being less warped.

Owner:TAIYO YUDEN KK

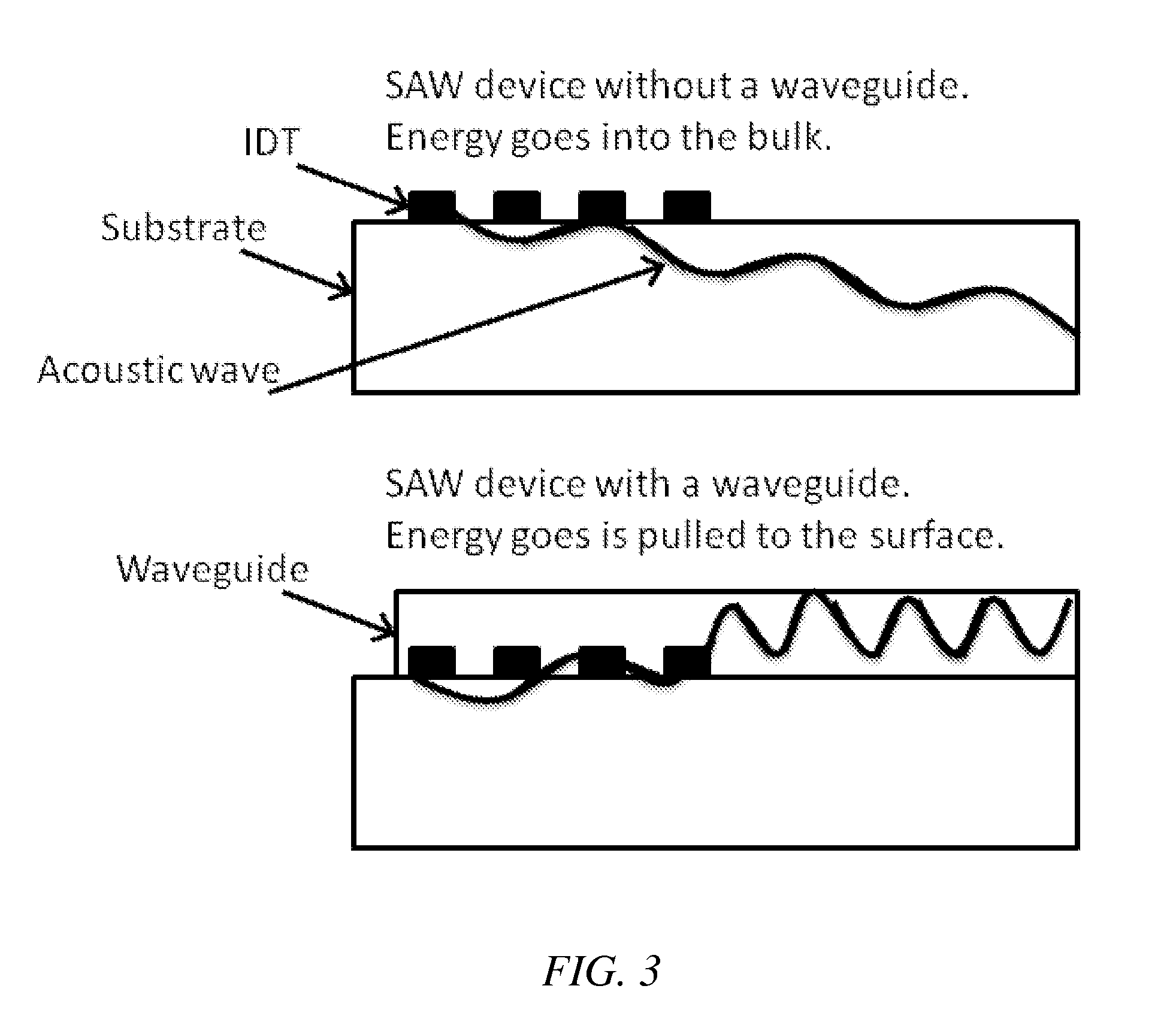

High-frequency shear-horizontal surface acoustic wave sensor

ActiveUS8436509B1Material analysis using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesMulti analyteImpedance matching

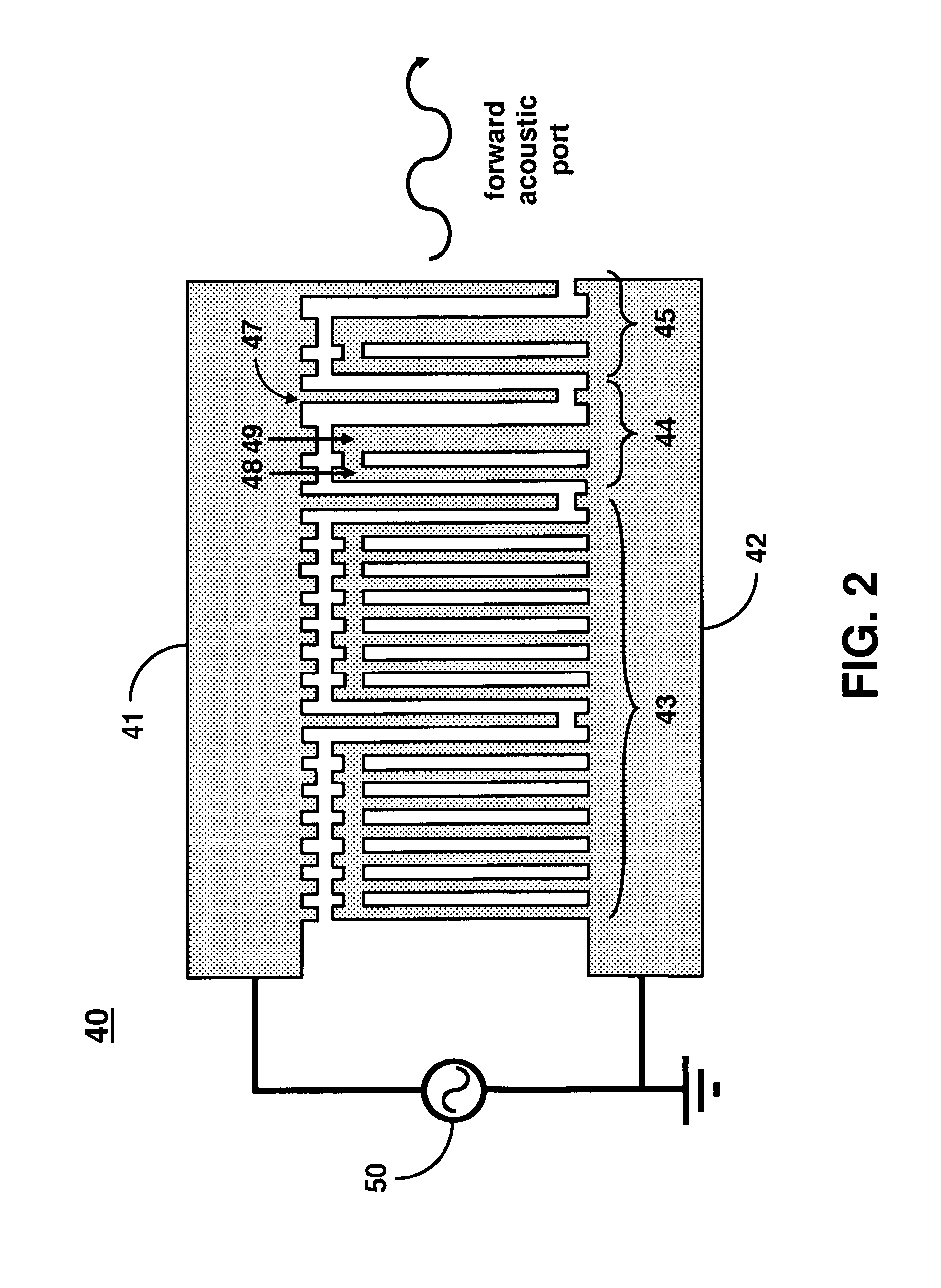

A Love wave sensor uses a single-phase unidirectional interdigital transducer (IDT) on a piezoelectric substrate for leaky surface acoustic wave generation. The IDT design minimizes propagation losses, bulk wave interferences, provides a highly linear phase response, and eliminates the need for impedance matching. As an example, a high frequency (˜300-400 MHz) surface acoustic wave (SAW) transducer enables efficient excitation of shear-horizontal waves on 36° Y-cut lithium tantalate (LTO) giving a highly linear phase response (2.8° P-P). The sensor has the ability to detect at the pg / mm2 level and can perform multi-analyte detection in real-time. The sensor can be used for rapid autonomous detection of pathogenic microorganisms and bioagents by field deployable platforms.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

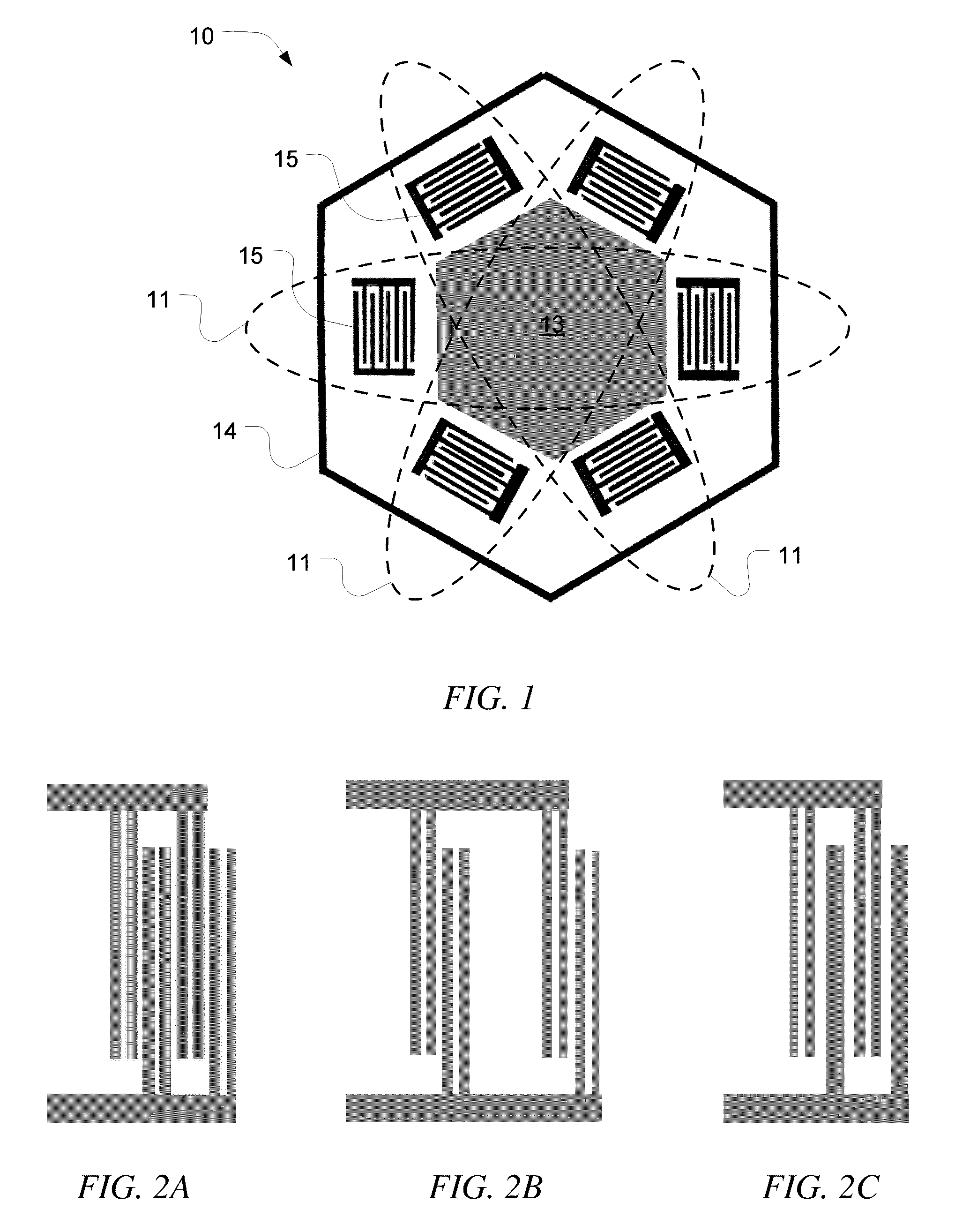

Simultaneous sample manipulation and sensing using surface acoustic waves

ActiveUS7878063B1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectricityWhite blood cell

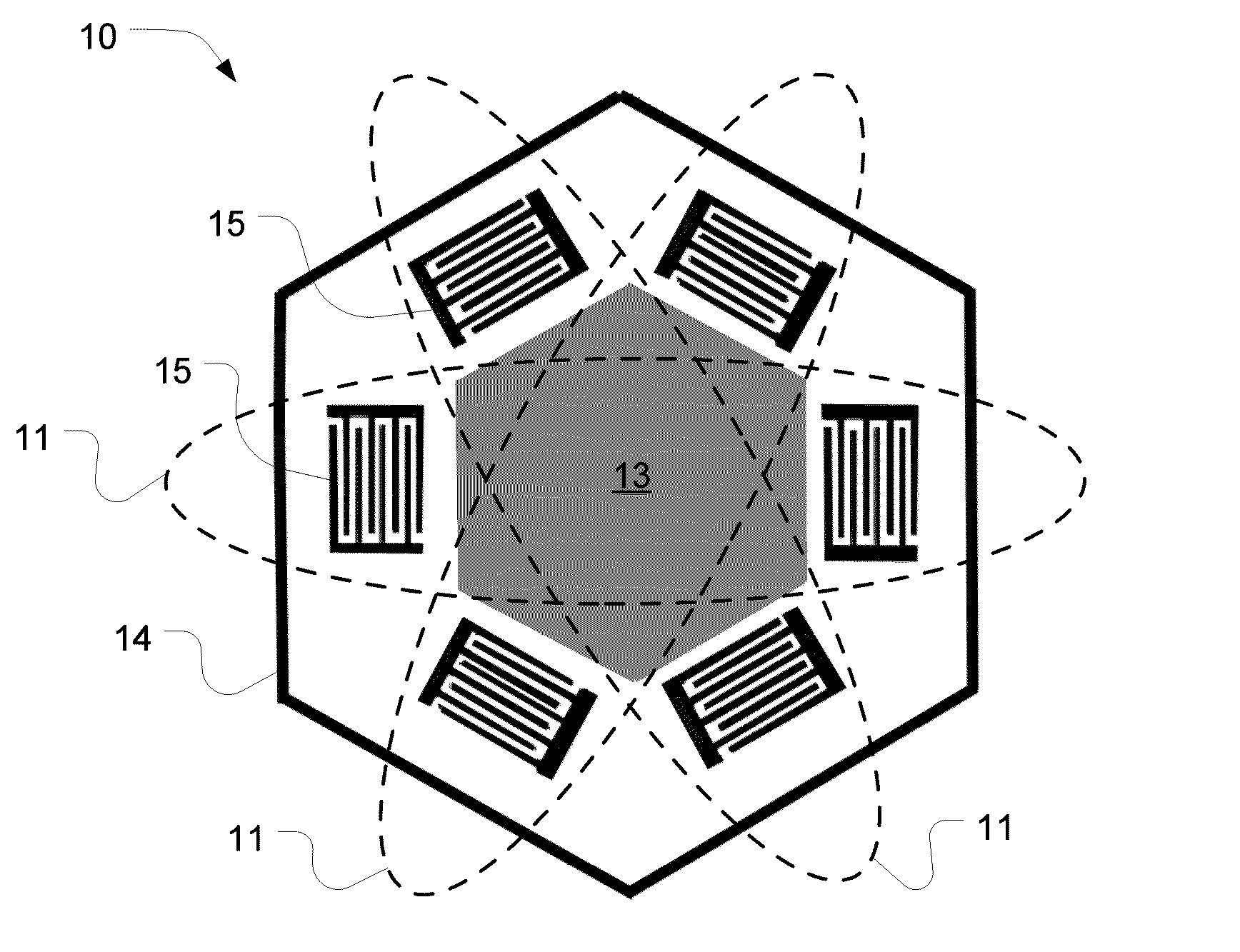

The present invention provides a hexagonal, delay line surface acoustic wave device fabricated on a a piezoelectric substrate, such as lithium tantalate, coated with an insulating waveguide on to which a sensing film, such as an anti-human Interleukin-6 biosensor film, is physically absorbed. The acoustic waves that propagate along the delay lines of the SAW device provide for detection of biological species along one delay line and simultaneously provide for removal of non-specifically bound protein along the remaining delay lines.

Owner:UNIV OF SOUTH FLORIDA +1

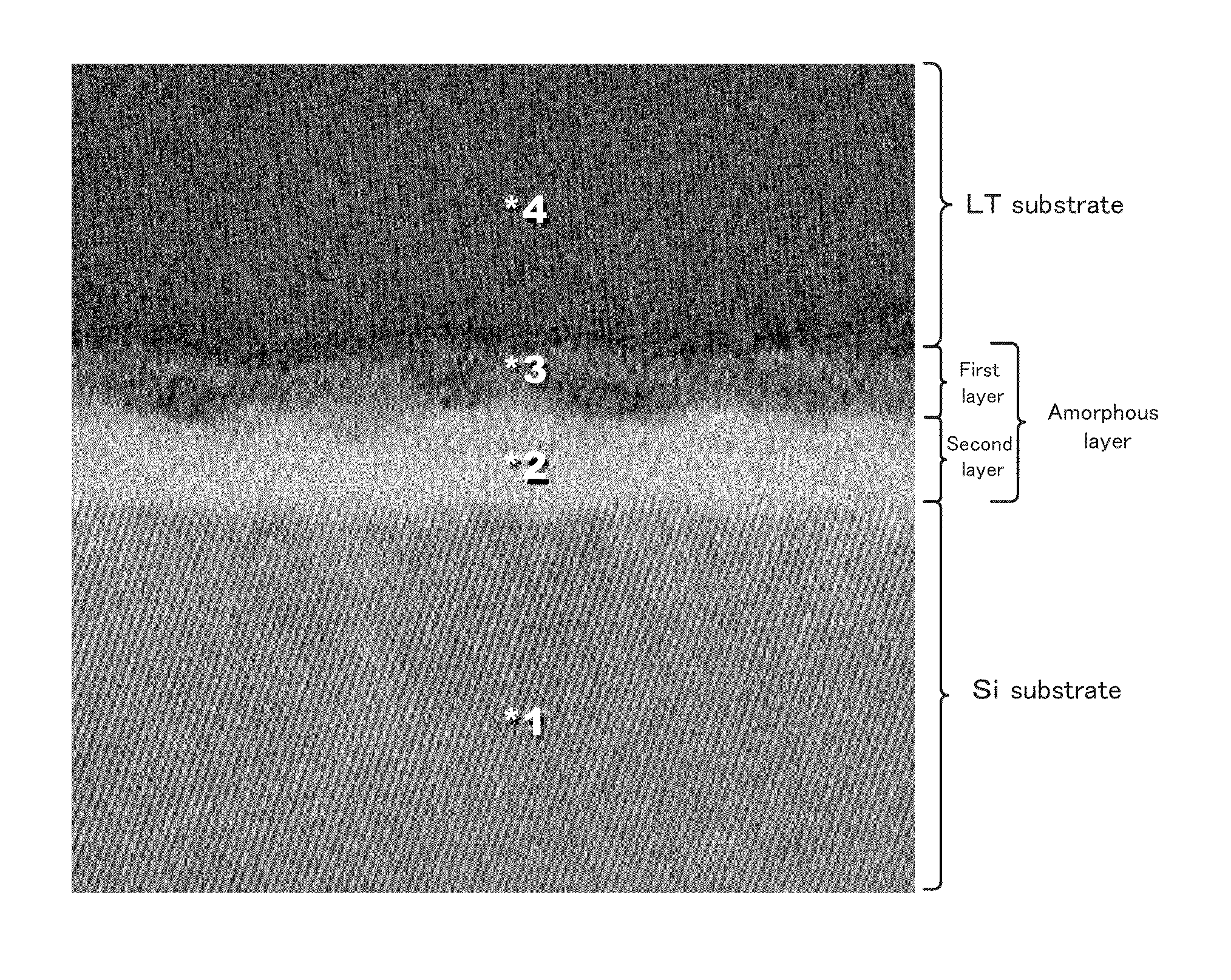

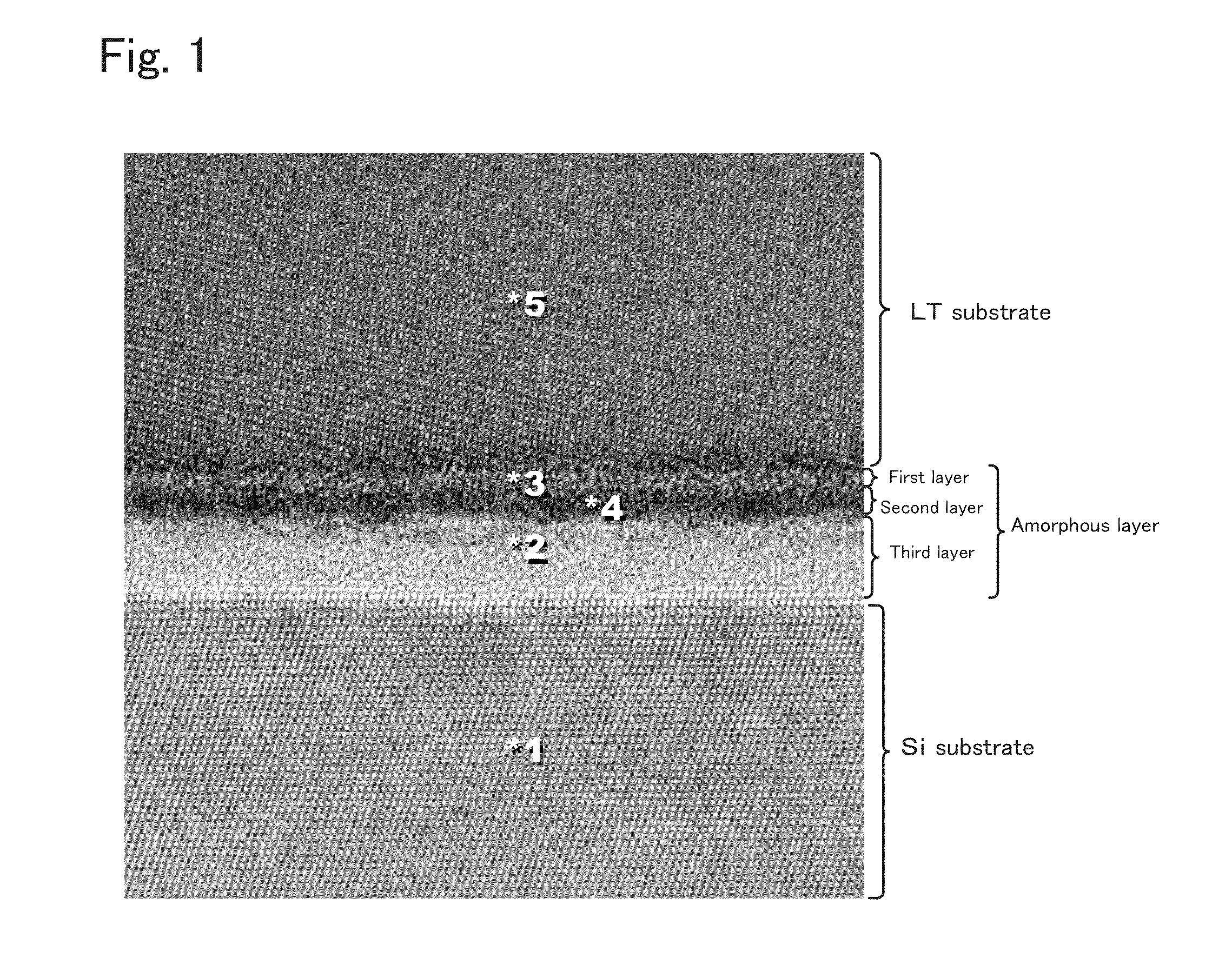

Composite Substrate

ActiveUS20140210317A1Reduce thermal stressHigh bonding strengthPiezoelectric/electrostriction/magnetostriction machinesImpedence networksComposite substrateSingle crystal

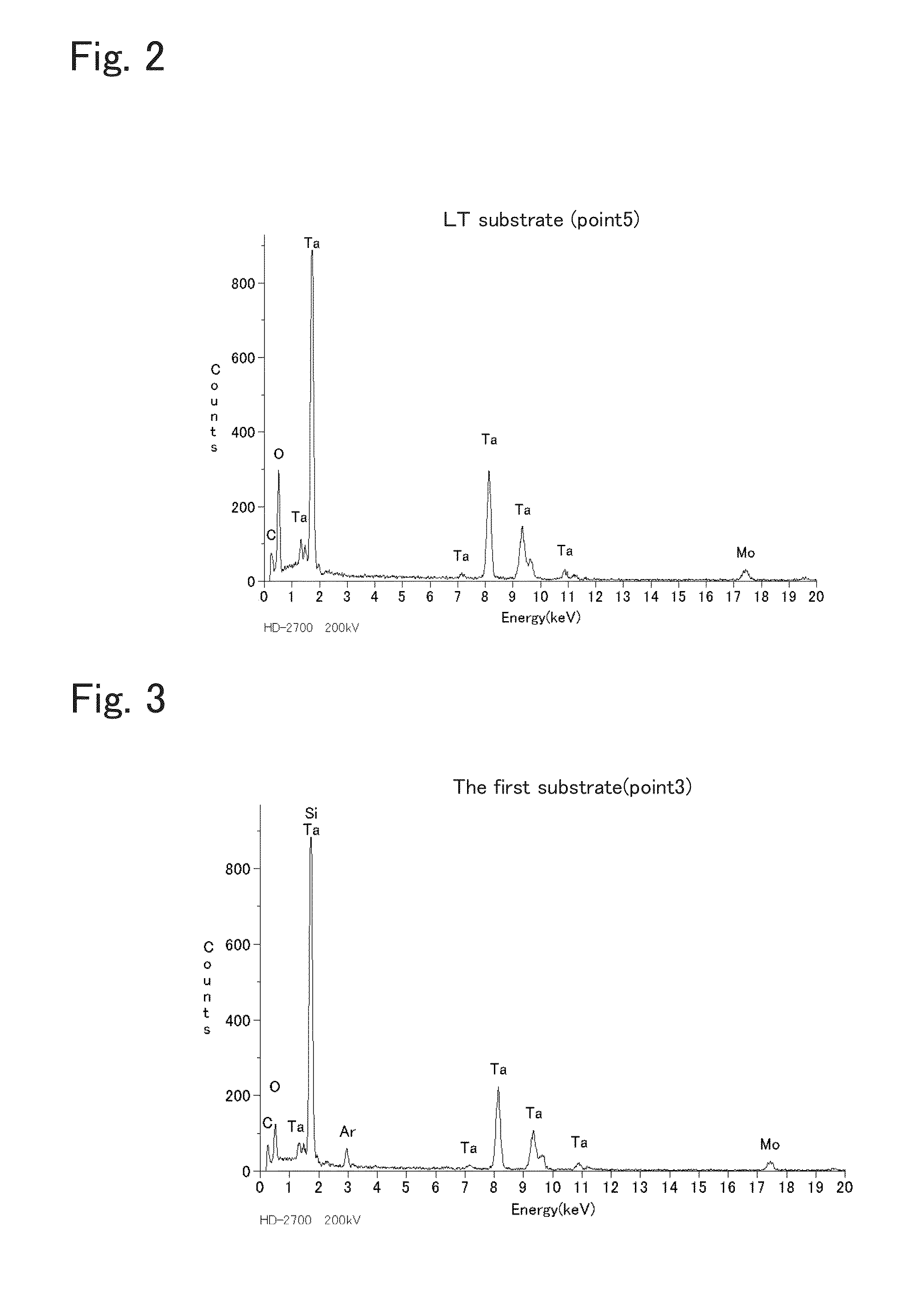

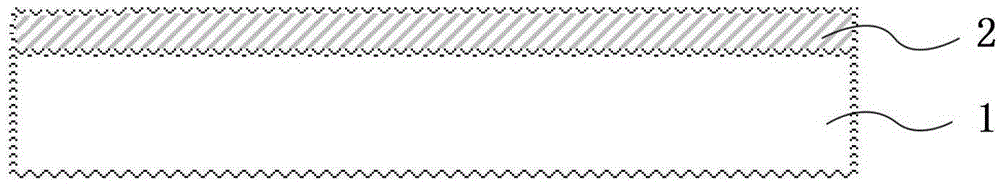

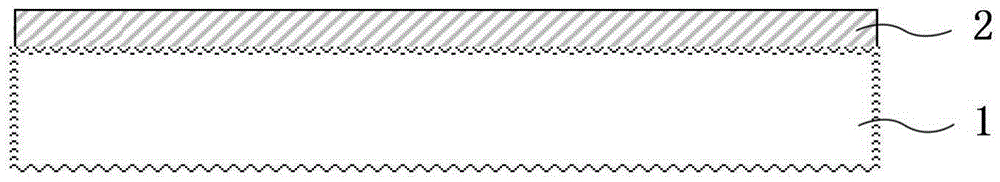

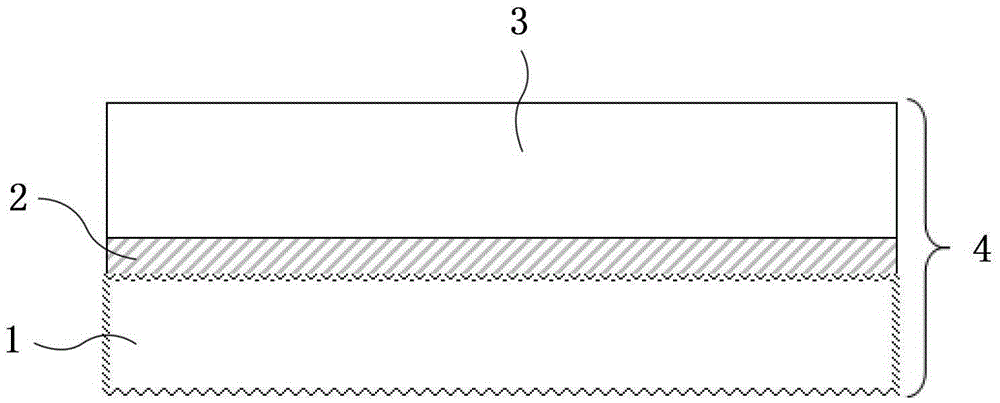

A composite substrate according to the present invention includes a piezoelectric substrate that is a single-crystal lithium tantalate or lithium niobate substrate, a support substrate that is a single-crystal silicon substrate, and an amorphous layer joining together the piezoelectric substrate and the support substrate. The amorphous layer contains 3 to 14 atomic percent of argon. The amorphous layer includes, in order from the piezoelectric substrate toward the composite substrate, a first layer, a second layer, and a third layer. The first layer contains a larger amount of a constituent element (such as tantalum) of the piezoelectric substrate than the second and third layers. The third layer contains a larger amount of a constituent element (silicon) of the support substrate than the first and second layers. The second layer contains a larger amount of argon than the first and third layers.

Owner:NGK INSULATORS LTD

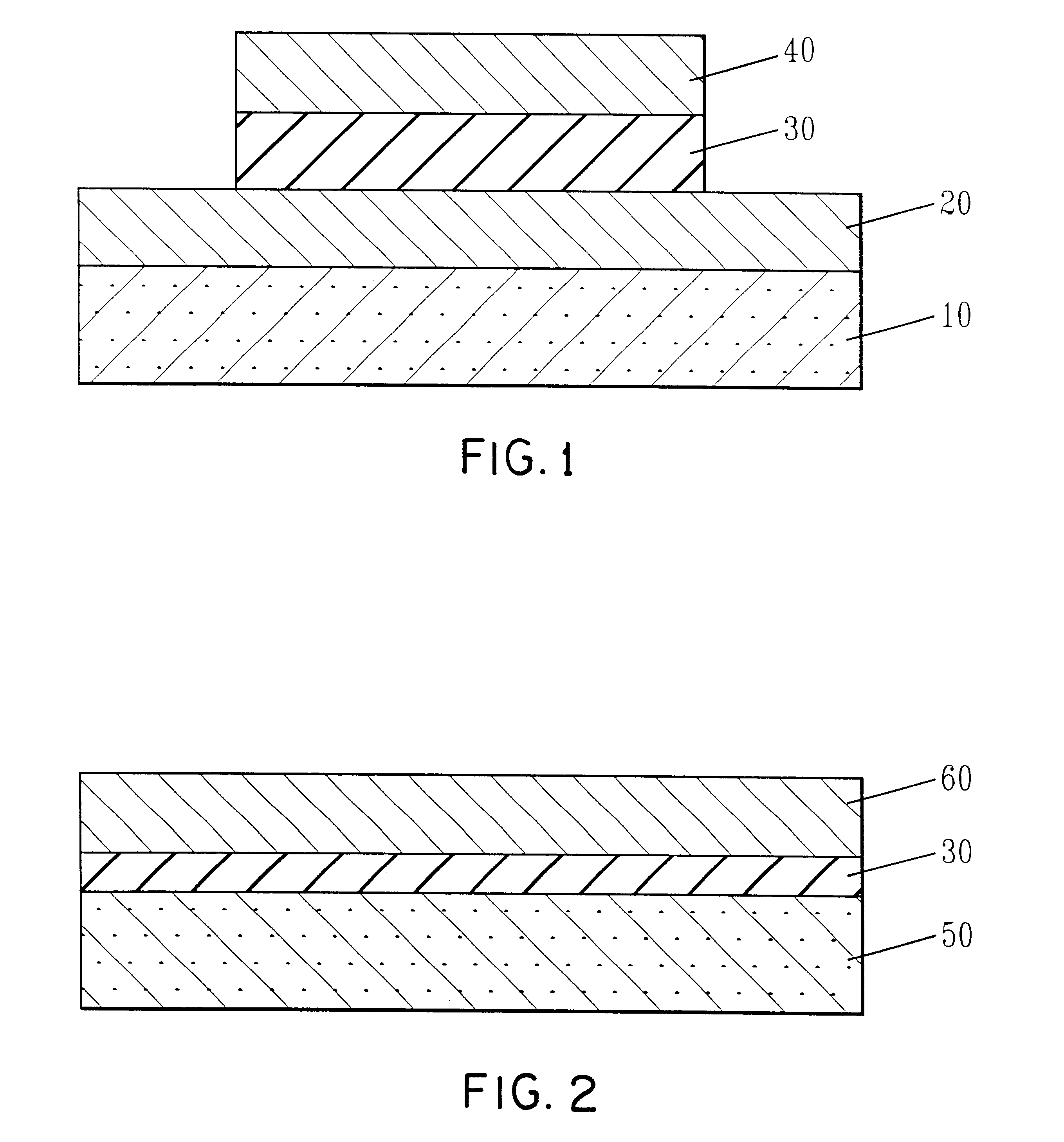

Single-crystal film bonding body and manufacturing method thereof

InactiveCN105420674AReduce direct reflectionReduce or even eliminate reflectionVacuum evaporation coatingSputtering coatingThin membraneSingle crystal

The invention provides a single-crystal film bonding body and a method for manufacturing the single-crystal film bonding body. The single-crystal film bonding body comprises a silicon substrate, a lithium niobate single-crystal film or lithium tantalate single-crystal film and a silicon-based film located between the silicon substrate and the lithium niobate single-crystal film or lithium tantalate single-crystal film. The silicon-based film is formed on the lithium niobate single-crystal film or lithium tantalate single-crystal film through deposition and is bonded with the silicon substrate through a direct bonding method, and the silicon-based film is a silicon film or a silicon dioxide film or a silicon nitride film. By means of the single-crystal film bonding body of the three-layer structure, the reflection effect of interfaces between the lithium niobate or lithium tantalate single-crystal film and the silicon substrate on optical waves and sound waves can be effectively reduced and even eliminated, and the interference caused by the reflection effect between the interfaces to optical or sound wave signals is reduced.

Owner:JINAN JINGZHENG ELECTRONICS

Method for processing lithium niobate or lithium tantalate wafer

ActiveCN101608342ANo depolarizationLow resistivityPolycrystalline material growthAfter-treatment detailsIron powderLithium carbonate

The invention discloses a method for processing a lithium niobate or lithium tantalate wafer, which comprises the following steps: respectively placing the lithium niobate or lithium tantalate wafer to be processed into a crucible; adding iron powder and lithium carbonate powder evenly mixed in advance according to mass proportion to completely cover the wafer; placing a corundum crucible into a thermal treatment furnace; performing thermal treatment for 3-20 hours at 450-550 DEG C under the nitrogen atmosphere with the flow rate of 0.5-1L / min to prepare a finished product of the lithium niobate or lithium tantalate wafer. The wafer resistivity is at the magnitude order of between 10 and 10, compared with the conventional non-processed wafer, the resistivity is greatly reduced, the method can effectively prepare a wafer needed for a SAW device through the thermal treatment in a short time, and increase a finished product ratio in the manufacture process of an element, therefore, the method for processing lithium niobate or lithium tantalite wafer becomes an industrialized optimizing method.

Owner:CETC DEQING HUAYING ELECTRONICS +1

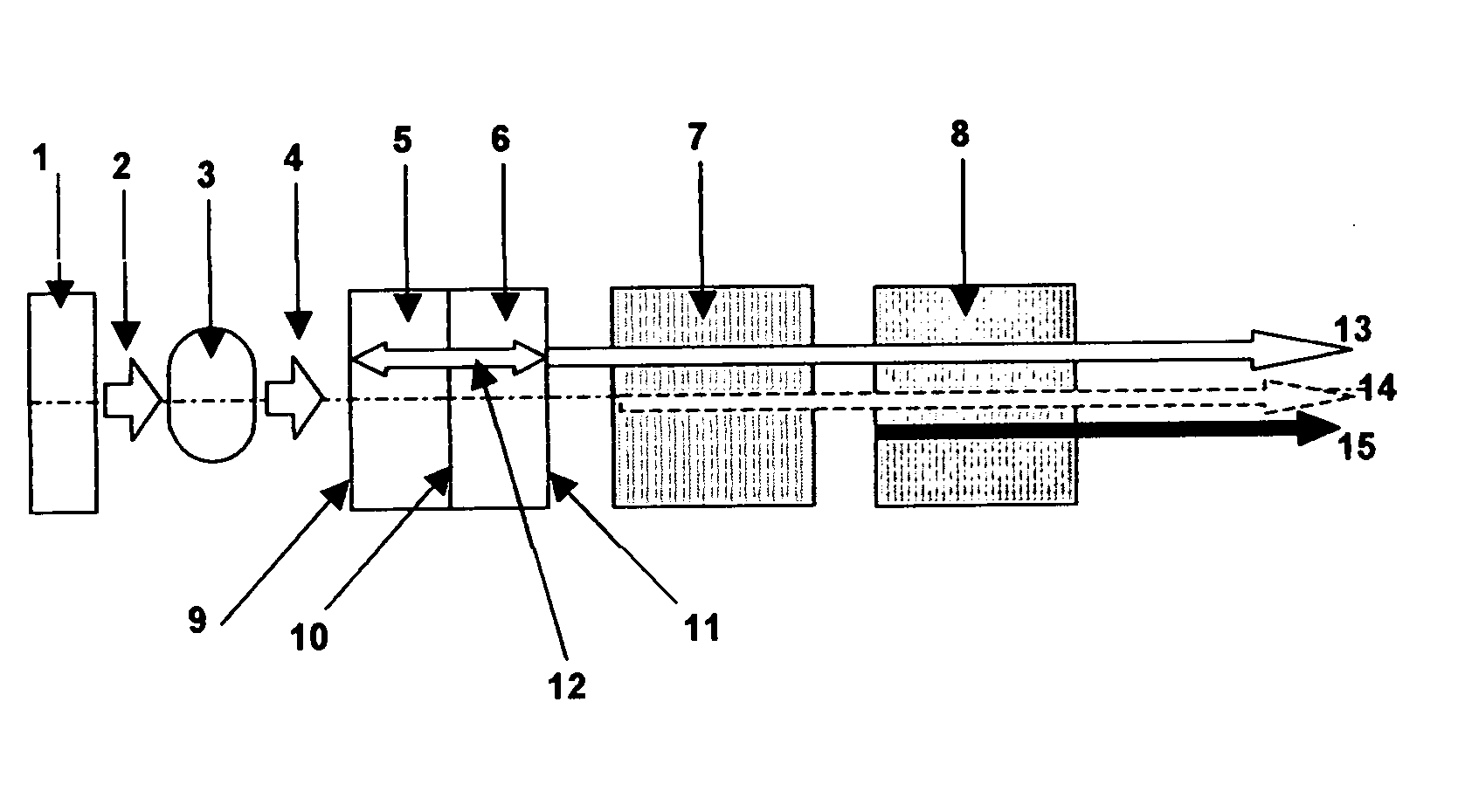

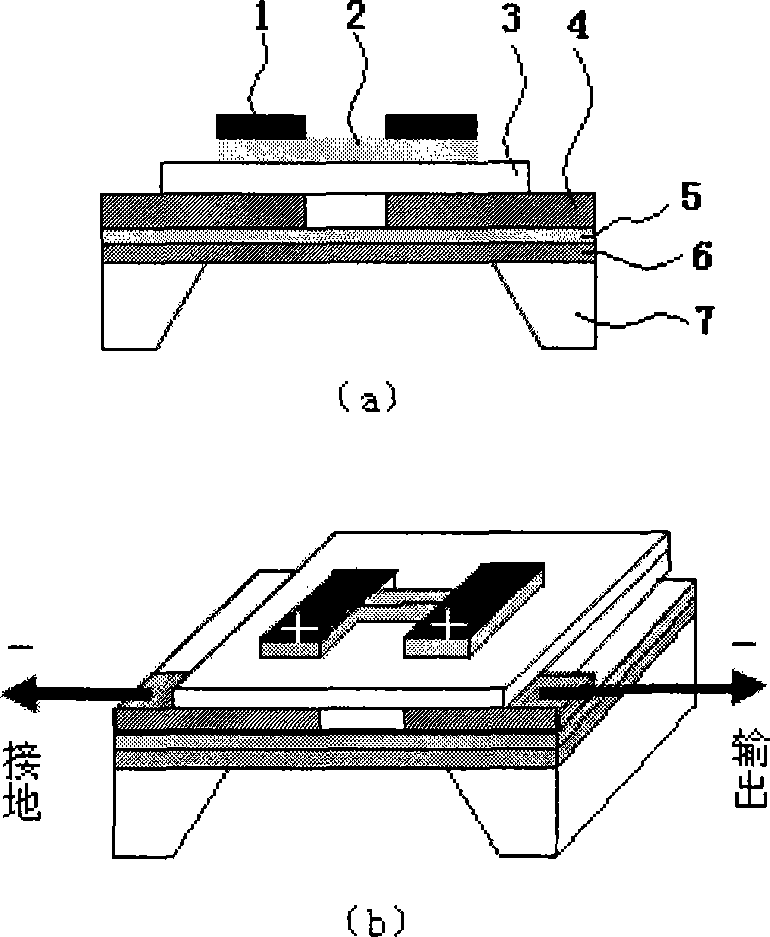

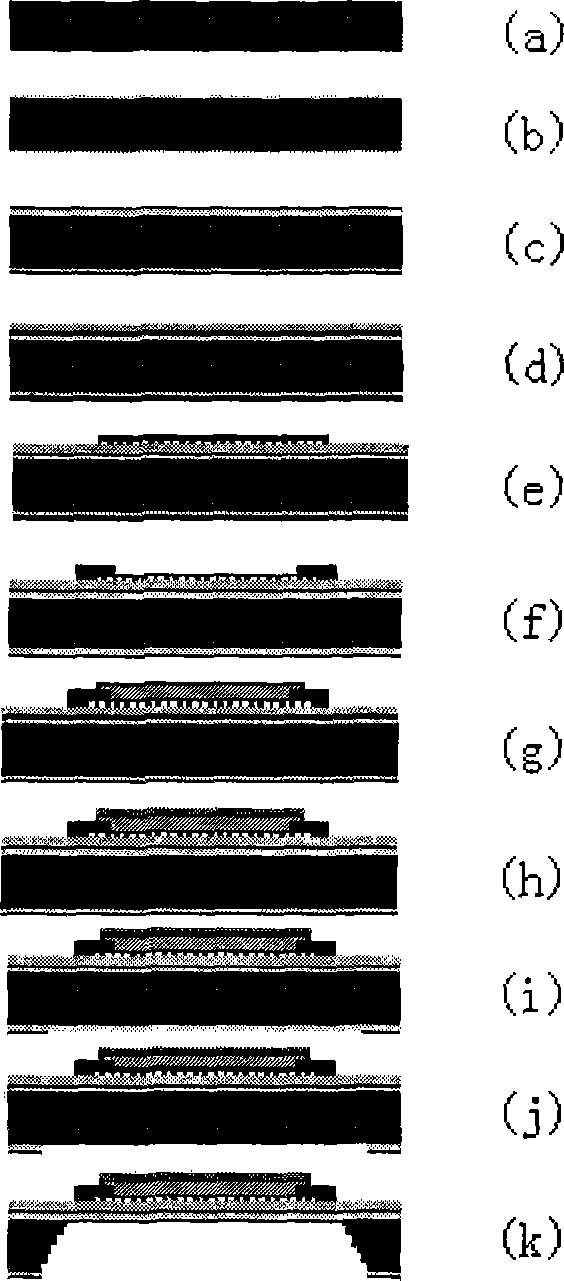

Lithium tantalate thin film infrared detector and manufacturing method

InactiveCN101246055AAchieve Impedance MatchingAchieve modulationRadiation pyrometryLow-pass filterOptoelectronics

The present invention relates to a lithium tantalate film infrared detector and the preparing method thereof. The invention comprises the following components: an infrared filtering window, a resonance chopped wave modulator, a focusing lens, a pyroelectric lithium tantalate film infrared measuring probe, a heat sink cavity, a preamplifier, a low-pass filter, an electric power and signal output interface, a casing and an environment temperature detecting filter. The method for preparing the detector comprises the following steps: selecting a substrate, growing a SiO2 layer on the front and back surface, depositing Si3N4 layer on the front surface in sequence, sputtering a Ti layer, sputtering a photoetching Pt electrode layer, producing a lithium tantalate film layer, depositing a phototeching Al electrode layer, growing a photoetching SiNX antireflection layer and sputtering a black layer to complete the double unit structure infrared probe. The focusing lens is coated with an anti-reflection film. The infrared window is pasted with a narrowband filtering film. The preamplifier is built with a JFET tube or operational amplifier. The low-pass filter is built with an operational amplifier. The resonance chopped wave modulator is driven by piezoelectricity or electromagnet, and the resonance frequency is 1Hz-1000Hz.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Blackening method for lithium tantalate or lithium niobate crystal substrate

ActiveCN106048735AReduce manufacturing costWeakened pyroelectric propertiesAfter-treatment detailsScreen printingReduction treatment

The invention relates to a blackening method for a lithium tantalate or lithium niobate crystal substrate. The method comprises the following steps: preparing a mixed system from an elemental material with deoxidation ability and a mixture of a glue and a certain proportion of lithium carbonate powder; uniformly coating both sides of a to-be-treated lithium tantalate or lithium niobate crystal substrate by using a screen printing method; and placing the substrate in a stainless steel container, then putting the container into a heat treatment furnace, and carrying out reduction treatment on the to-be-treated lithium tantalate or lithium niobate crystal substrate in a nitrogen atmosphere with a flow of 6 L / min to 10 L / min under and at a temperature below the Curie temperature of the to-be-treated lithium tantalate or niobate crystal substrate. In the mixed system, organic silicone glue is used as glue; and the elemental material with deoxidation ability is Zn powder which accounts for 35% or less of the mass of the mixed system. According to the invention, reduced blackening treatment of the lithium tantalate or lithium niobate crystal substrate is carried out under Curie temperature conditions; and through blackening treatment, the pyroelectric properties of the substrate is reduced, and thus, manufacturing cost for a SAW filter is lowered and the production efficiency of the SAW filter is improved.

Owner:TDG HLDG CO LTD

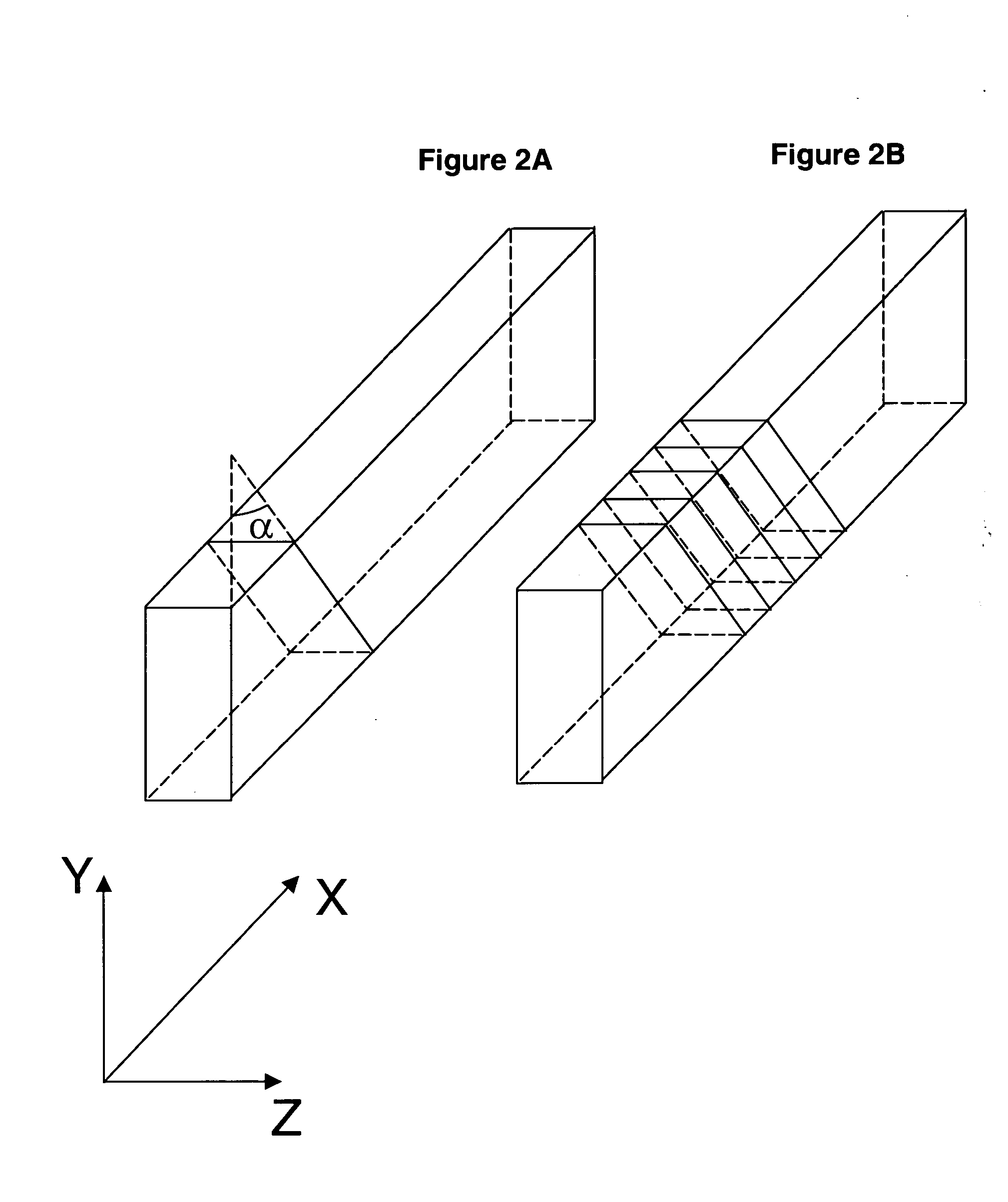

Frequency doubling crystal and frequency doubled external cavity laser

InactiveUS20060233206A1Preserve collinearityMaximize conversion efficiencyLaser detailsNon-linear opticsExternal cavity laserHarmonic

A periodically poled second harmonic generating crystal having a long axis, said crystal comprising Magnesium Oxide doped Congruent Lithium Niobate, Magnesium Oxide doped Stoichiometric Lithium Niobate, Stoichiometric Lithium Tantalate or Potassium Titanyl Phosphate wherein the poling planes of said periodically poled crystal are canted relative to said axis and a doubled, external cavity laser utilizing said crystal, comprising an external cavity pump laser section and an extra-cavity frequency doubling section.

Owner:NEWPORT CORP

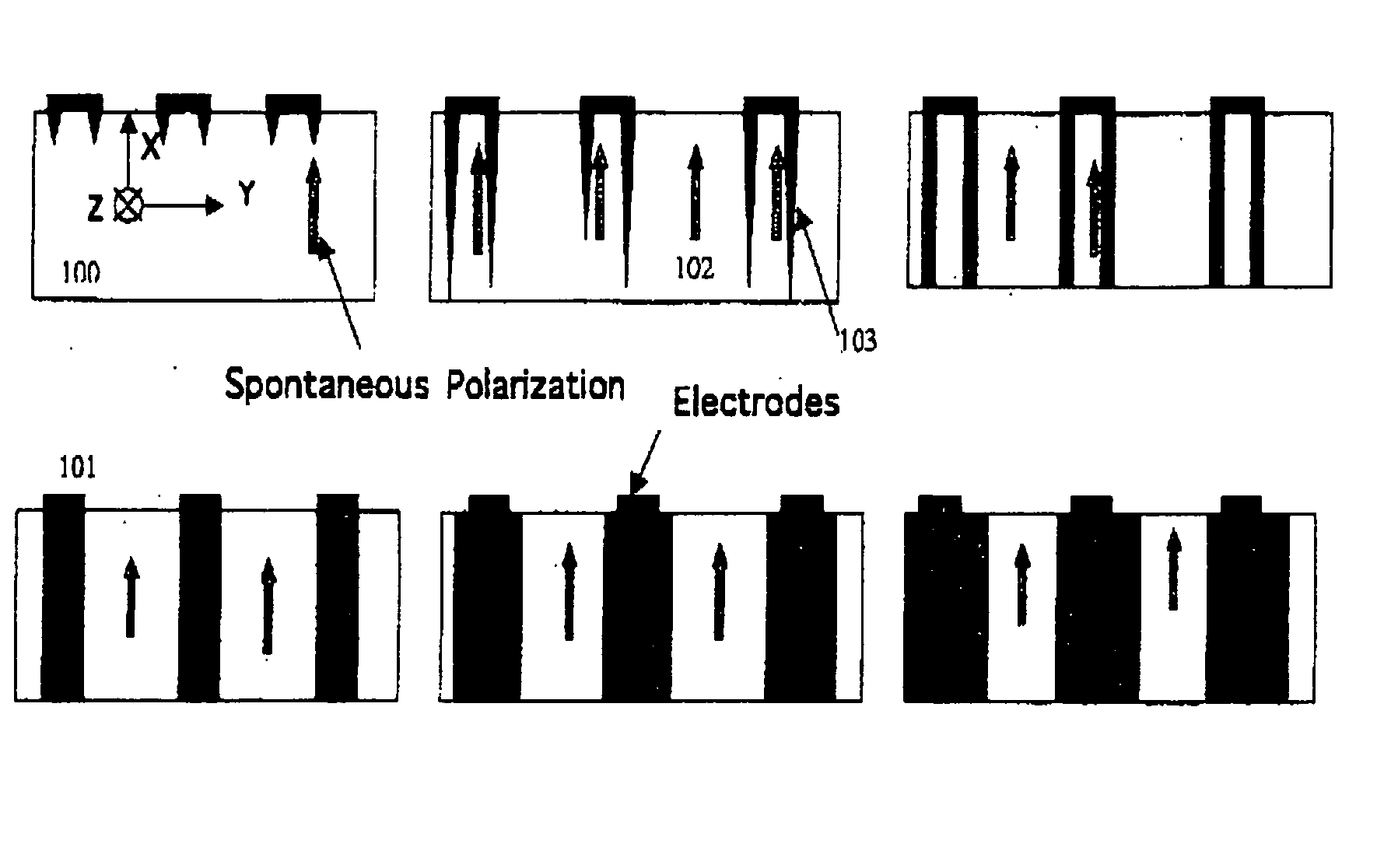

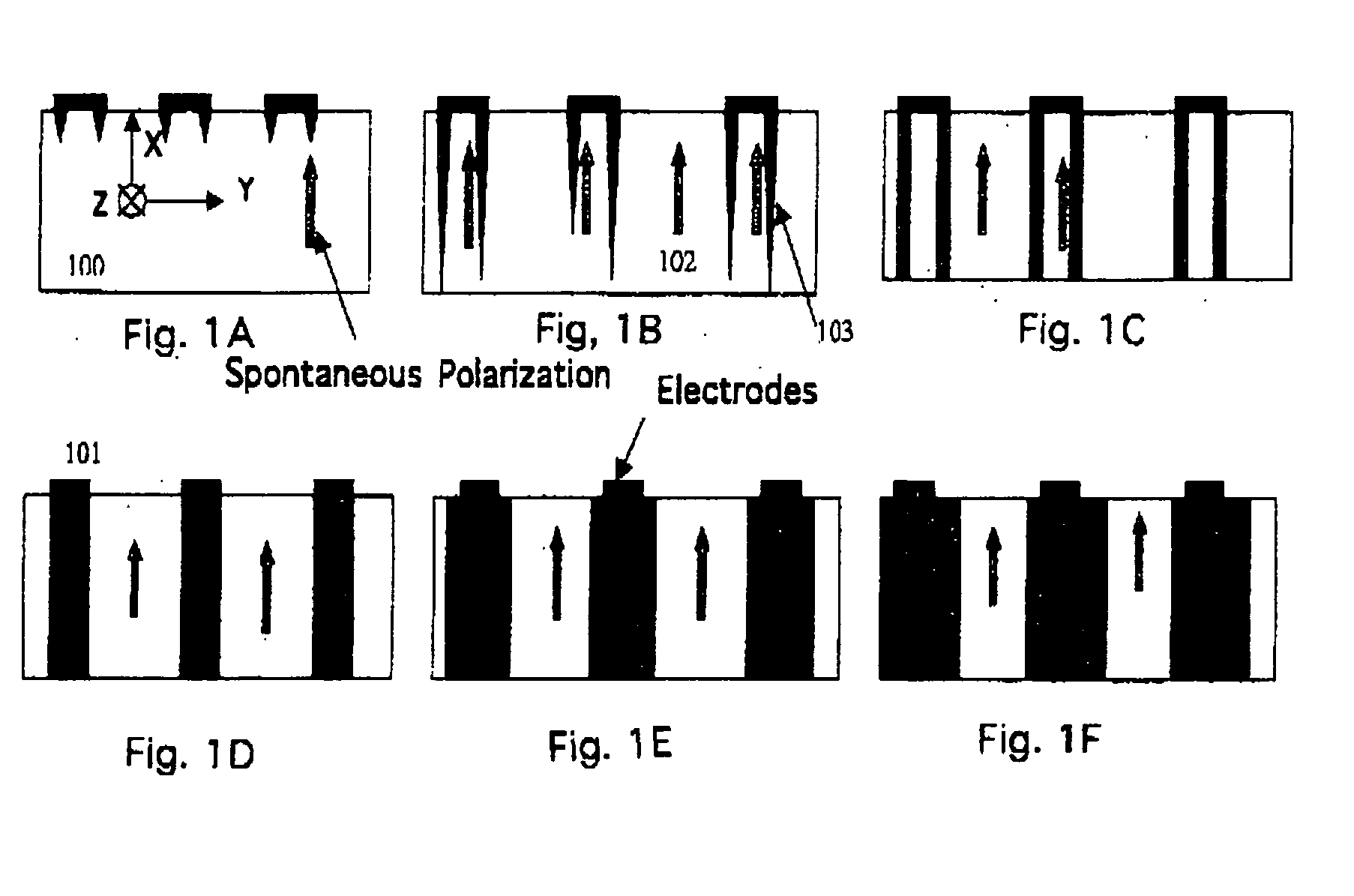

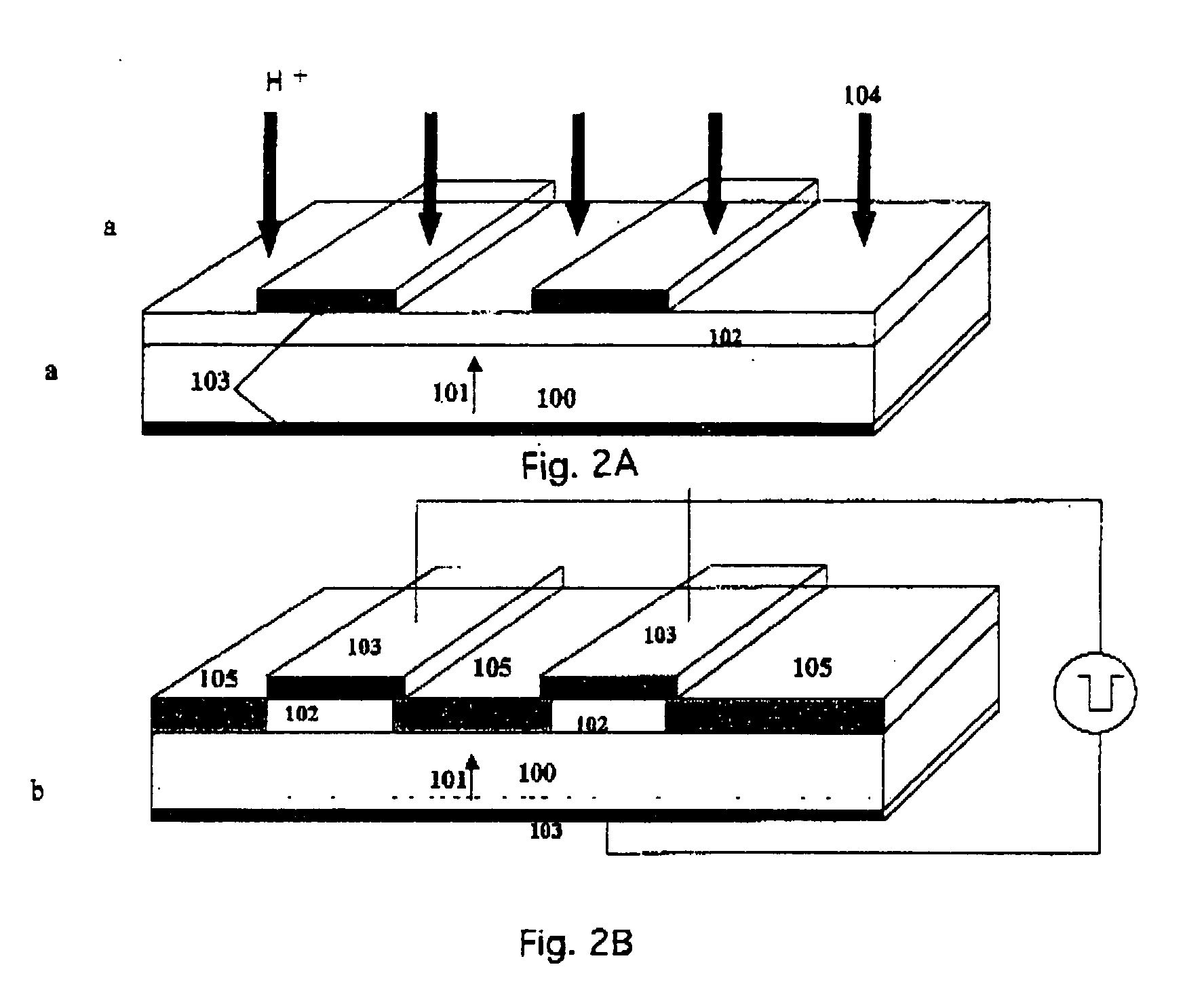

Method for the fabrication of periodically poled Lithium Niobate and Lithium Tantalate nonlinear optical components

ActiveUS20050133477A1Slows domain growthReduce the impactLaser detailsLiquid surface applicatorsThin layerGreen-light

A process for reducing the poling field of congruent grown LiNbO3 and LiTaO3 crystal-based nonlinear optical devices and for the production of domain structures with precise reproducibility of the main parameters by depositing a thin layer of a stechiometric LiNbO3 film on the Z-face of a congruent LiNbO3 or LiTaO3 wafer. A new domain nucleation, evolution and stabilization process is provided to afford a uniform, short period domain superstructure for the conversion of near infra-red light to near ultraviolet, blue and green light

Owner:OOO SPECTRALUS +1

Method for producing lithium tantalate crystal

ActiveUS20060169196A1Improve conductivityEasy to produceTantalum compoundsSemiconductor/solid-state device manufacturingLithiumReducing atmosphere

A method of producing a lithium-tantalate crystal, wherein at least a first material containing lithium tantalate, lithium niobate or hydrogen storage alloy storing hydrogen that is subjected to a heat treatment at a temperature of T1′ that is Curie temperature or higher in a reducing atmosphere is superposed on a single-polarized lithium-tantalate crystal, and then the crystal is subjected to a heat treatment at a temperature of T2′ that is lower than Curie temperature in a reducing atmosphere, thereby an electric conductivity of the single-polarized lithium-tantalate crystal is increased. There can be provided a method of producing a lithium-tantalate crystal wherein the surface charge generated by applying a temperature change to the lithium-tantalate crystal can be decayed quickly without accumulating by increasing the electric conductivity, and an effective piezoelectric property is exhibited by maintaining the single polarized structure.

Owner:SHIN ETSU CHEM IND CO LTD

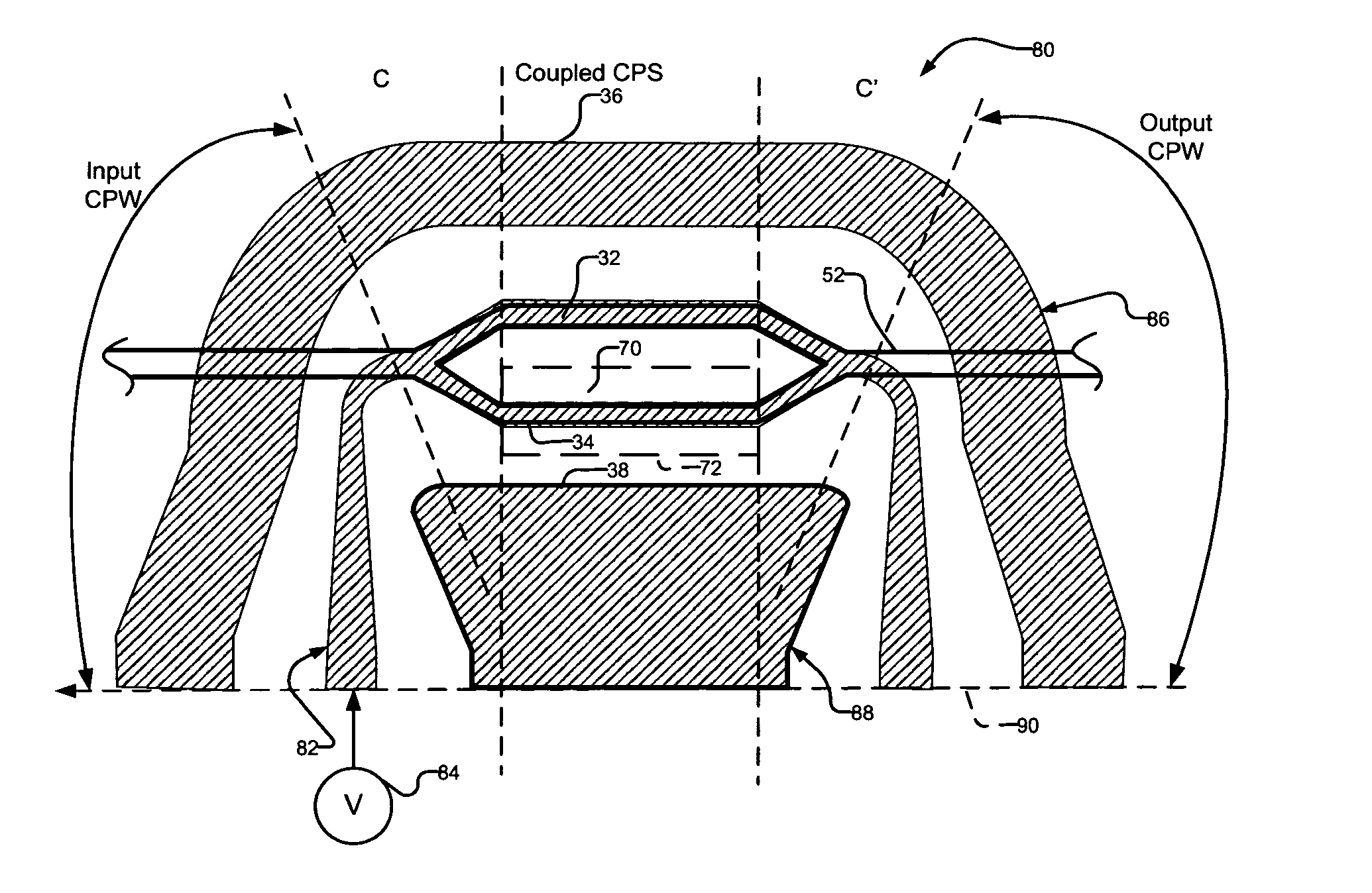

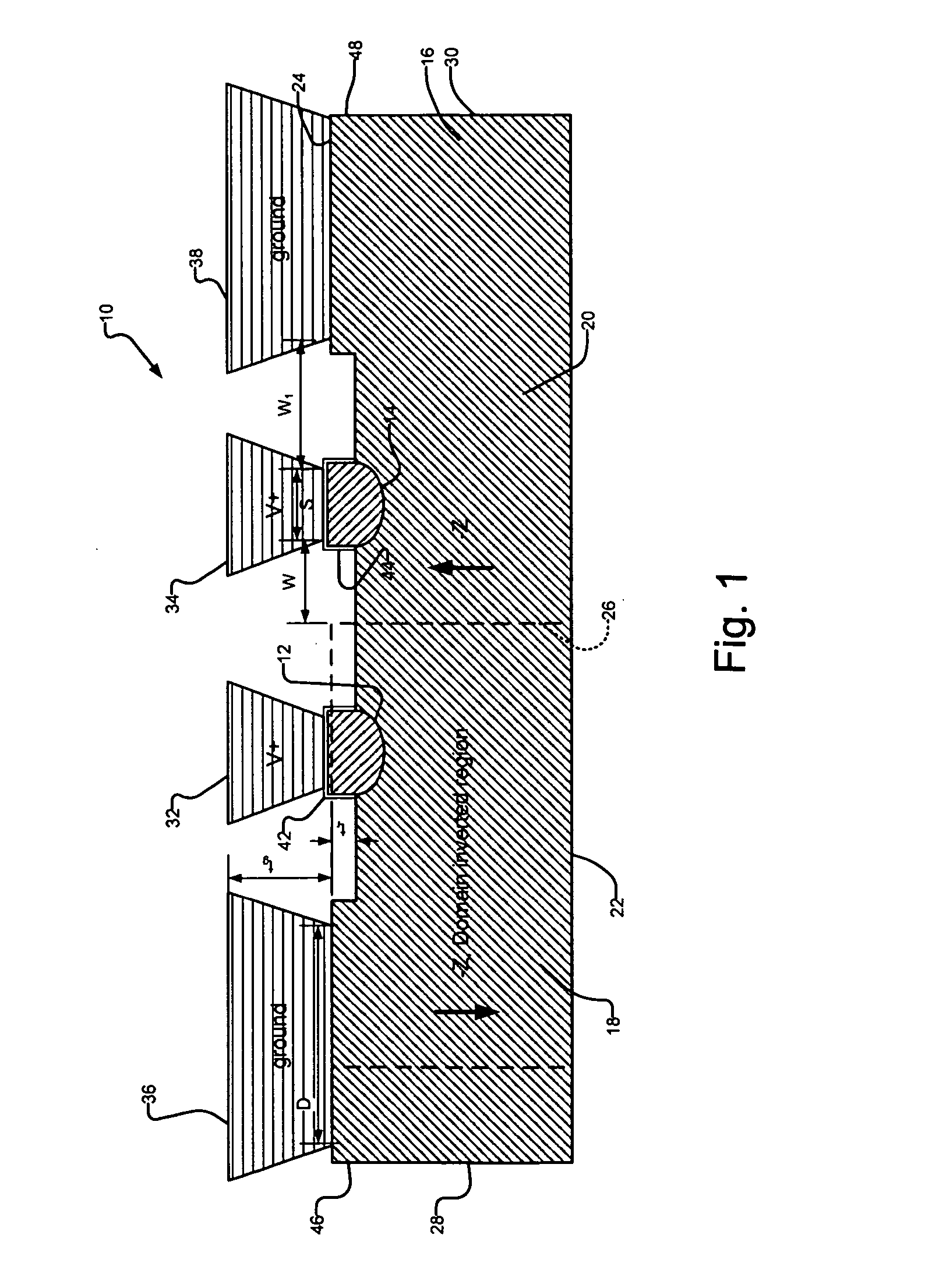

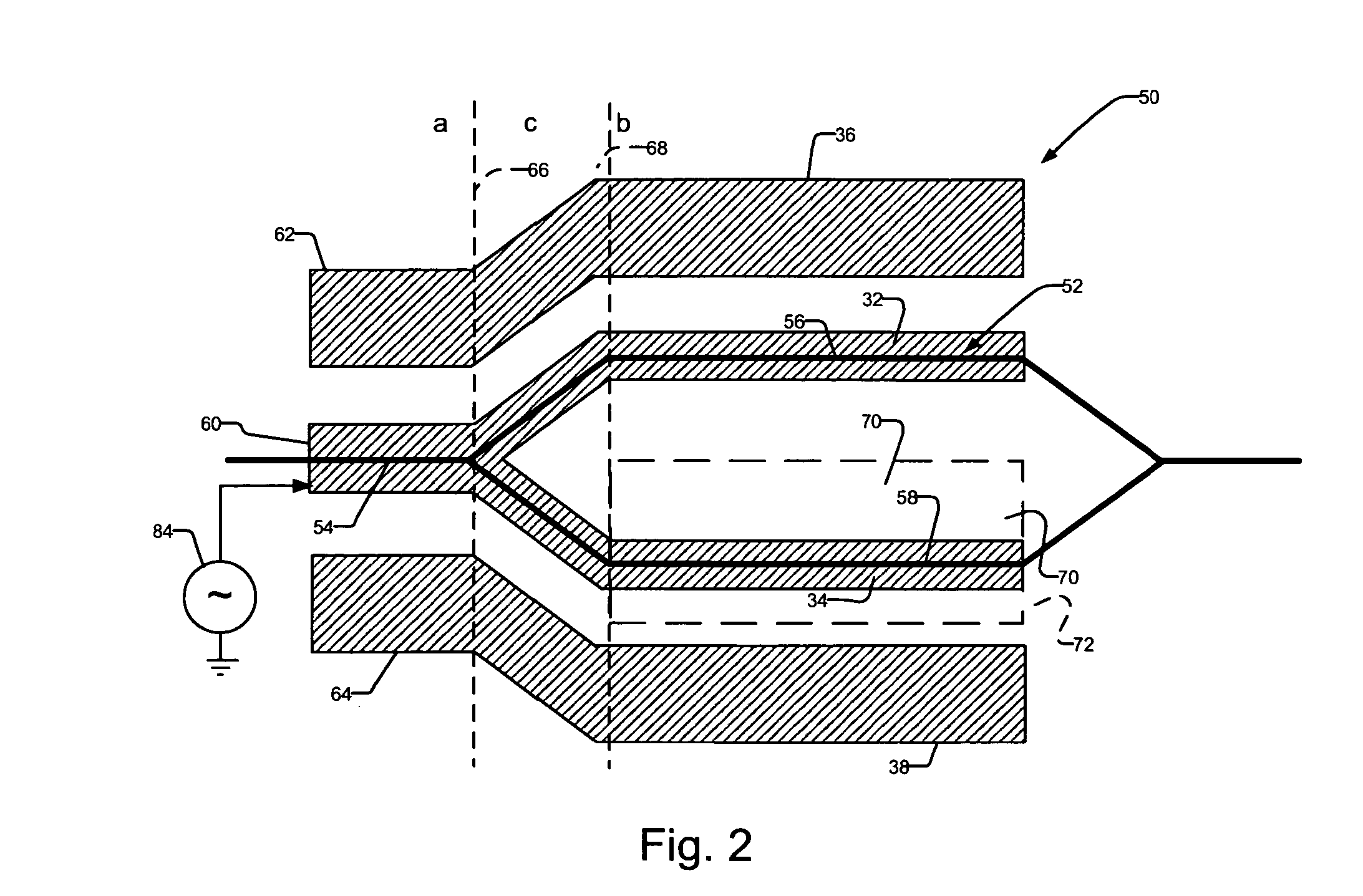

Optical modulator with coupled coplanar strip electrode and domain inversion

InactiveUS20060228065A1Reduced voltage-length productModest reduction in line impedanceCoupling light guidesNon-linear opticsA domainOptical modulator

A modulator includes an interferometer waveguide structure formed on an electro-optical substrate, preferably a Z-cut lithium niobate or a Z-cut lithium tantalate. The substrate includes a domain inversion between a region near the first arm and a region near the second arm of the interferometer waveguide structure. In one example, two coplanar strip electrode structures, each extending near at least a portion of the first arm and the second arm, respectively, are electrically coupled to each other.

Owner:PHOTONICSYST

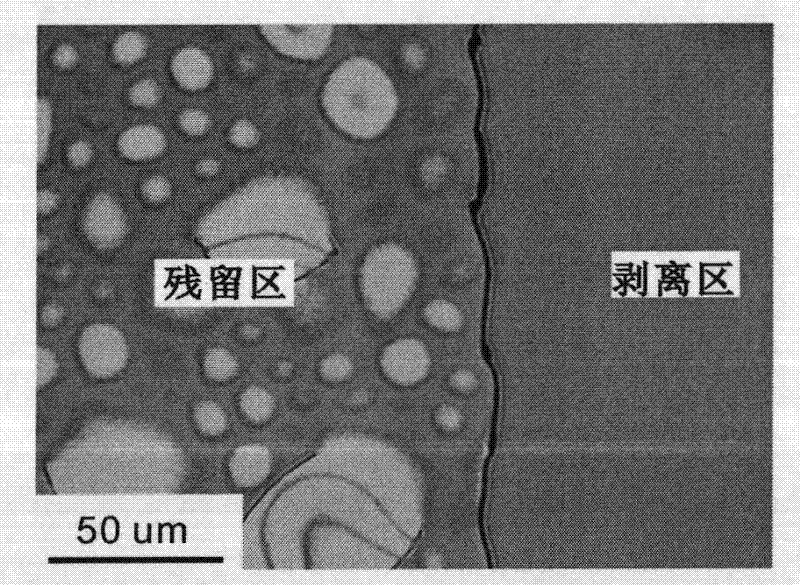

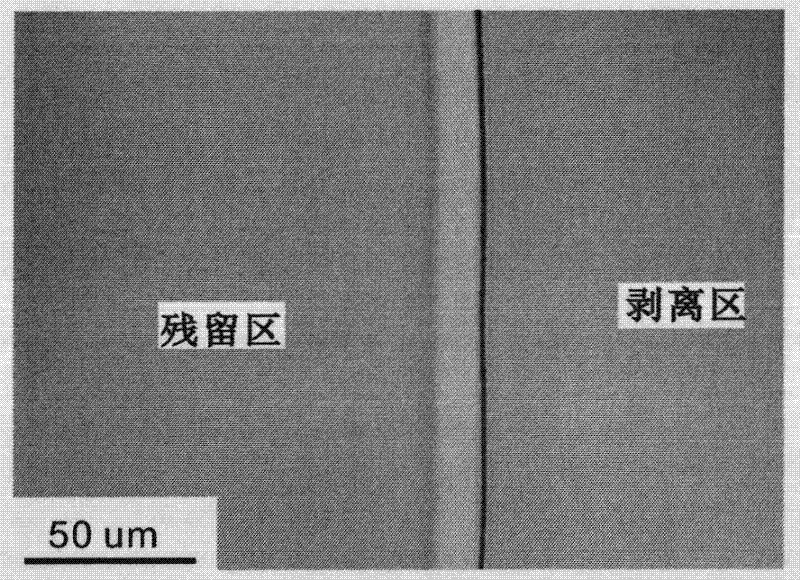

Stripping method of thin-film material

ActiveCN102443851ASmall doseQuality improvementPolycrystalline material growthAfter-treatment detailsOptoelectronicsThermal expansion

A technical process for manufacturing a monocrystal lithium niobate thin film or a monocrystal lithium tantalate thin-film material. After bonding of wafers, reduction of crystal lattice intensity of a damage layer caused by ion implantation and differences of thermal expansion coefficients between a silicon dioxide layer and a lithium niobate (lithium tantalate) crystal are utilized to select an appropriate heat treatment process and form stress in wafer set, so as to strip the film. The process can substantially reduce ion implantation dosage, thereby reducing production cost and increasing film quality.

Owner:JINAN JINGZHENG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com