Patents

Literature

70 results about "Lead magnesium niobate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead Magnesium Niobate is a piezoelectric polycrystalline ceramic material with applications in optoelectronics and acousto-optics.

Amorphous dielectric capacitors on silicon

InactiveUS6255122B1Improve conformityReduce leakage currentTransistorSemiconductor/solid-state device manufacturingLead zirconate titanateMaterials science

High-capacity capacitors and gate insulators exhibiting moderately high dielectric constants with surprisingly low leakage using amorphous or low temperature films of perovskite type oxides including a titanate system material such as barium titanate, strontium titanate, barium strontium titanate (BST), lead titanate, lead zirconate titanate, lead lanthanum zirconate titanate, barium lanthanum titanate, a niobate, aluminate or tantalate system material such as lead magnesium niobate, lithium niobate lithium tantalate, potassium niobate and potassium tantalum niobate, a tungsten-bronze system material such as barium strontium niobate, lead barium niobate, barium titanium niobate, and Bi-layered perovskite system material such as strontium bismuth tantalate, bismuth titanate deposited directly on a silicon surface at temperatures about 450° C. or less.

Owner:GLOBALFOUNDRIES INC

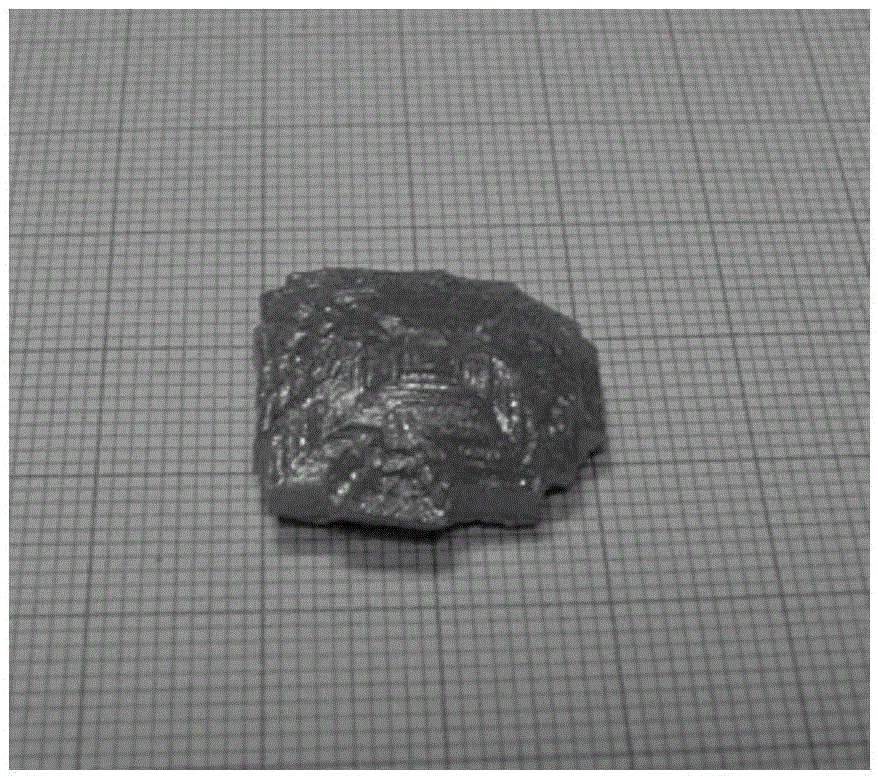

Novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate

InactiveCN102051685APolycrystalline material growthFrom melt solutionsCrystal rotationSingle crystal

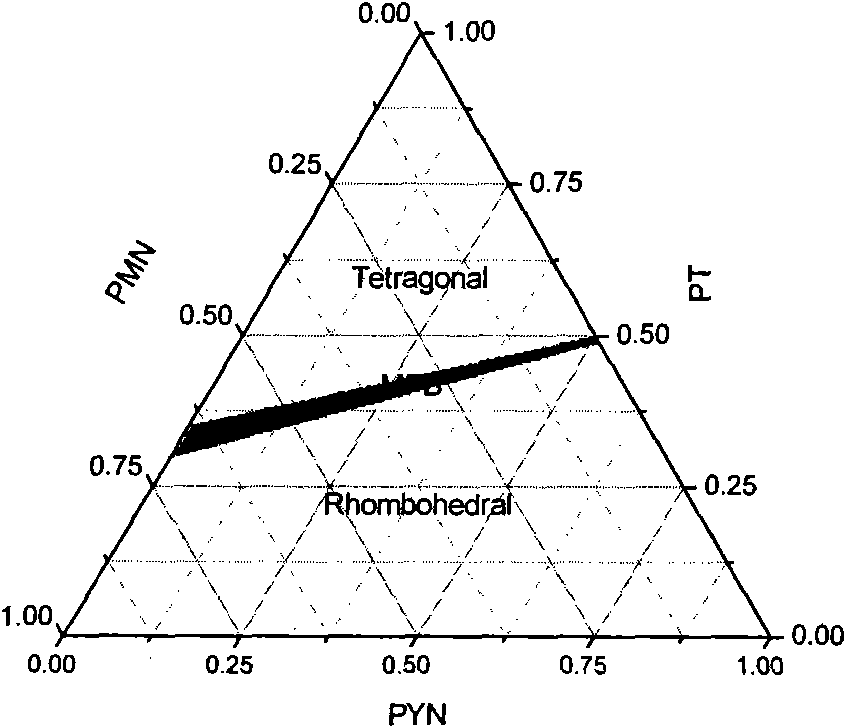

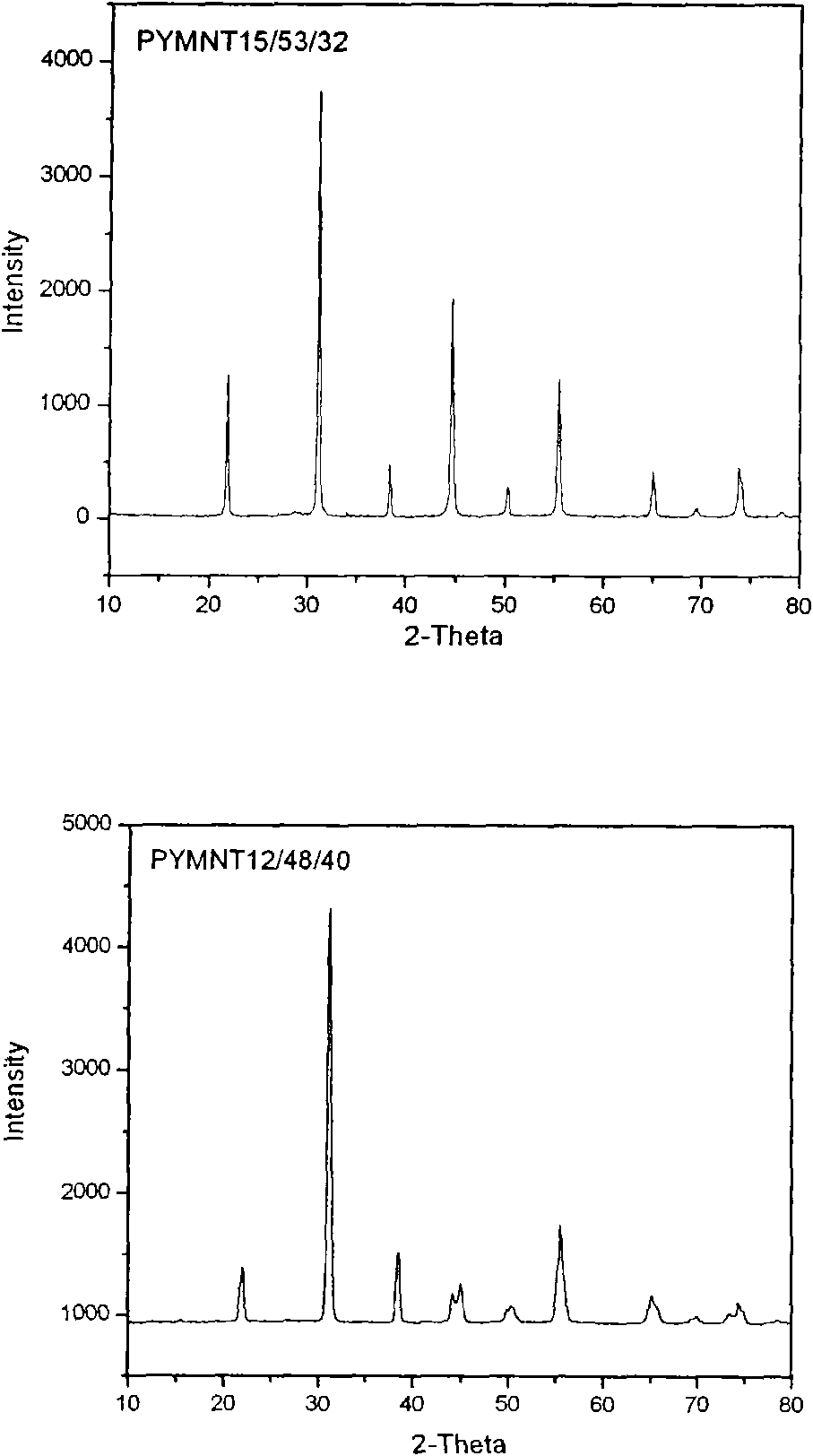

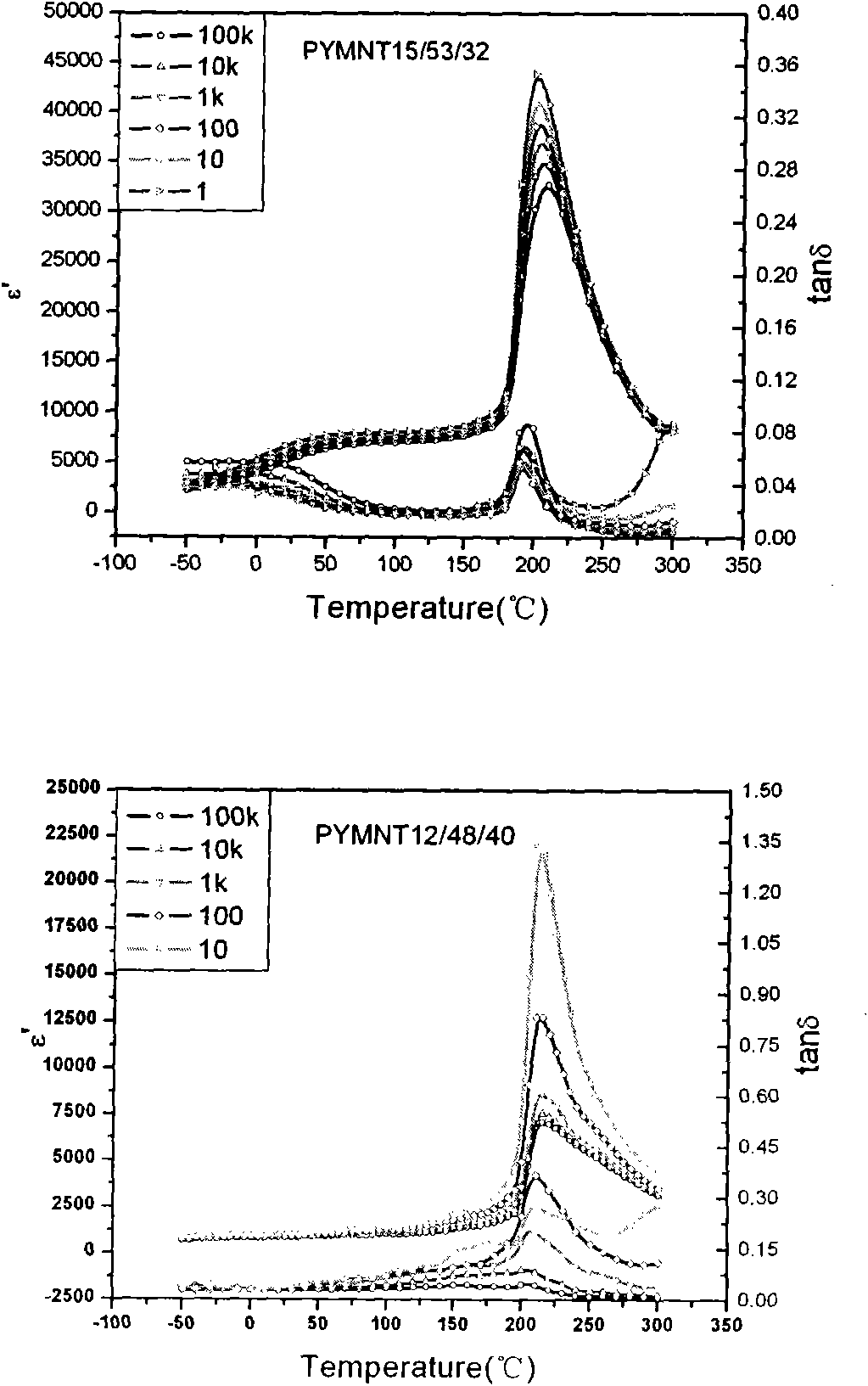

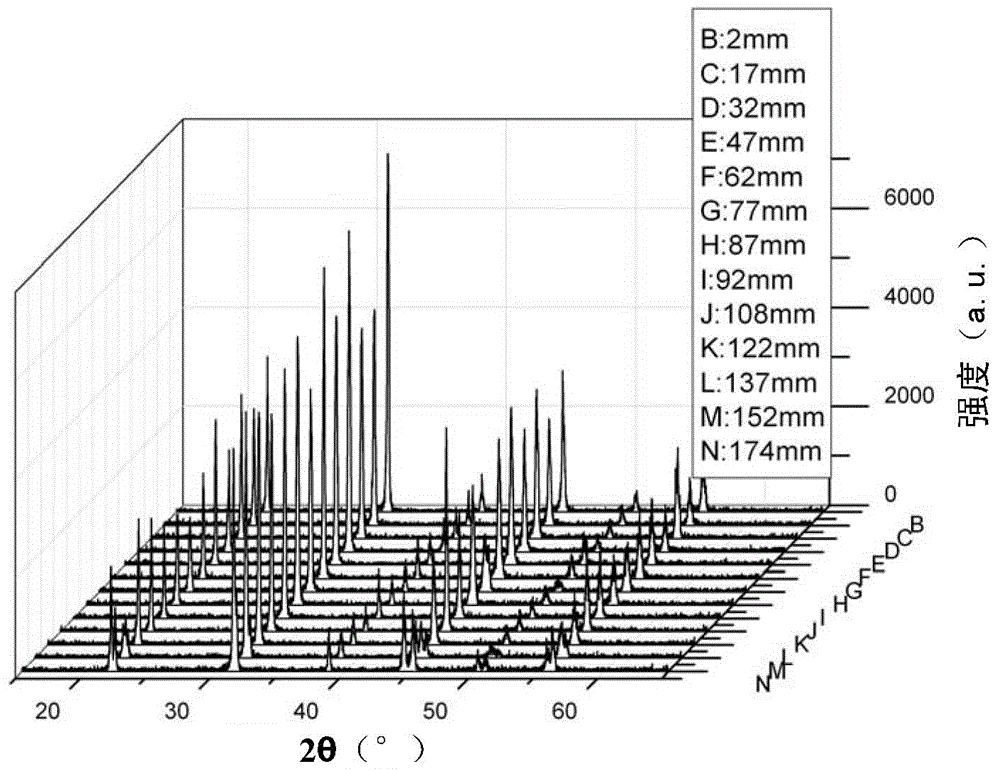

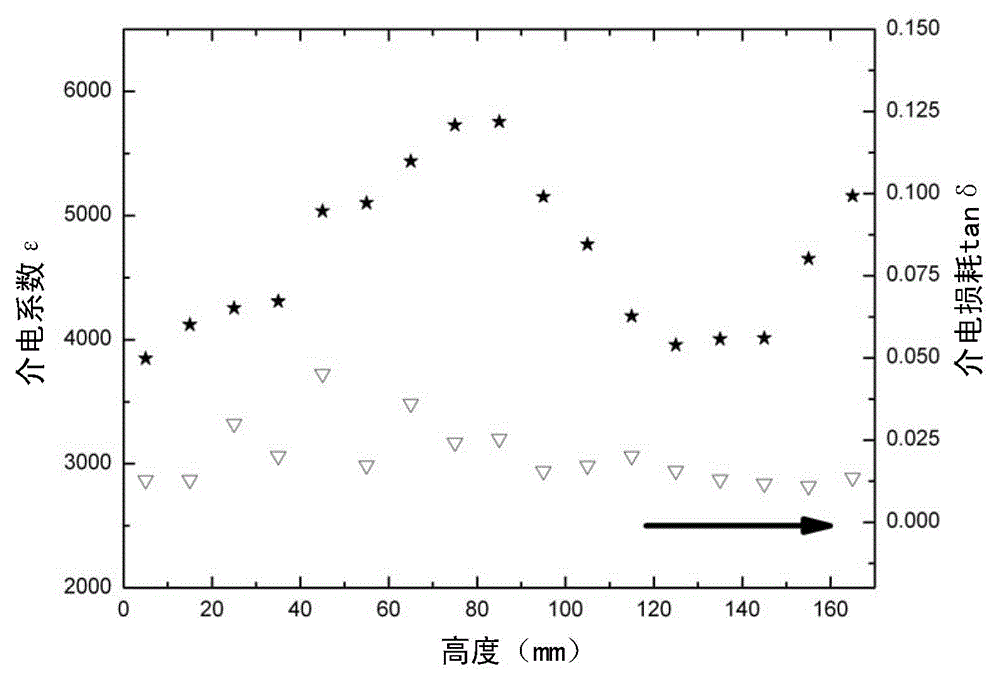

The invention relates to the growth, the structures and the properties of novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate. The crystal belongs to a perovskite structure, has an MPB region and has a chemical formula of (1-x-y)Pb(Yb1 / 2Nb1 / 2)O3-xPb(Mg1 / 3Nb2 / 3)O3-yPbTiO3 which is short for PYMNT or PYN-PMN-PT. By adopting a top crystal-seeded method, the crystal with large size and high quality can grow under the conditions that the growth temperature of the crystal is 950-1100 DEG C, the crystal rotation speed is 5-30rpm, and the cooling speed is 0.2-5 DEG C / day, and the grown crystal exposes a 001 natural growth surface. Through X-ray powder diffraction, the system is confirmed as the perovskite structure; and through ferroelectric, dielectric and piezoelectric measurement, the ferroelectricity, the dielectric property and the piezoelectricity of the crystal are analyzed. The crystal has high Curie temperature and trigonal-tetragonal phase transition temperature, large piezoelectric constant and electromechanical coupling factor, high dielectric constant and low dielectric loss and better heat stability. The crystal can be widely applied to devices in the piezoelectric fields of ultrasonically medical imaging, sonar probes, actuators, ultrasonic motors, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Piezoelectric Single Crystal and Piezoelectric Single-Crystal Device and Method for Manufacturing the Same

InactiveUS20070267947A1Stable growthHigh mechanical quality factorPolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyIndiumSingle crystal

An inexpensive piezoelectric single-crystal device being excellent in the piezoelectric characteristics and having a complex perovskite structure can be provided by adding a specific additive to a lead magnesium niobate-lead titanate (PMN-PT) single crystal or a lead zinc niobate-lead titanate (PZN-PT or PZNT) single crystal. Specifically, the piezoelectric single crystal has a complex perovskite structure and is formed of a composition containing 35 to 98 mol % lead magnesium niobate [Pb(Mg1 / 3Nb2 / 3)O3] or lead zinc niobate [Pb(Zn1 / 3Nb2 / 3)O3], 0.1 to 64.9 mol % lead titanate [PbTiO3], and 0.05 to 30 mol % lead indium niobate [Pb(In1 / 2Nb1 / 2)O3] wherein calcium is substituted for 0.05 to 10 mol % lead in the composition.

Owner:KAWATETABU MINING

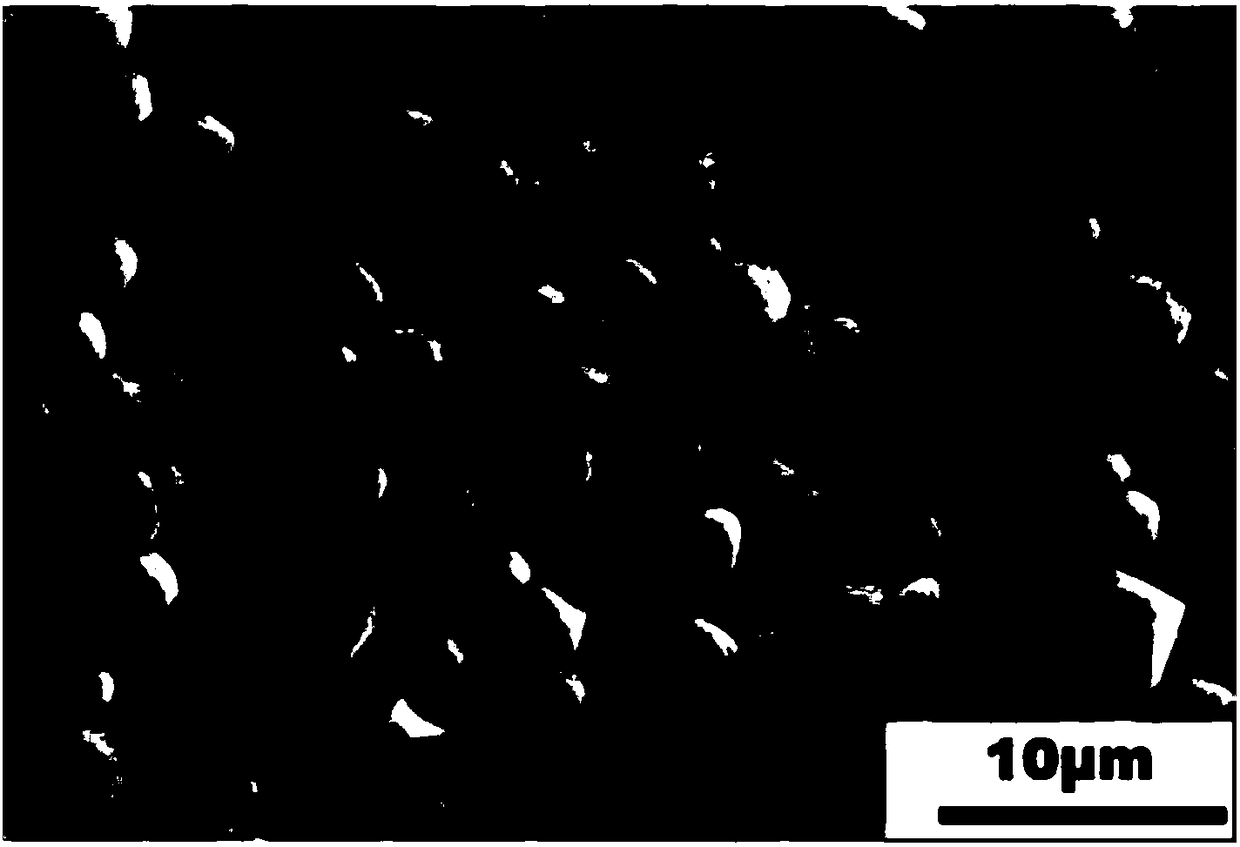

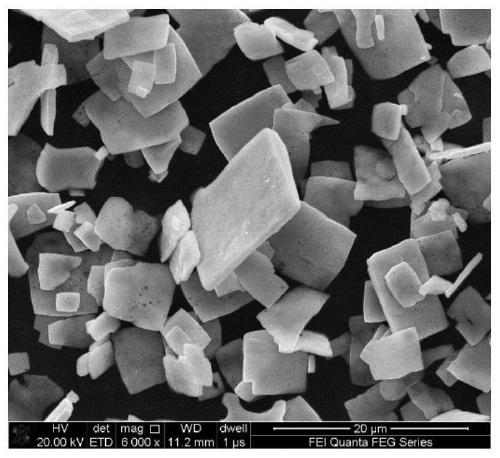

Lead indium niobate-lead magnesium niobate-lead titanate relaxor ferroelectric textured ceramic with high electrical properties and preparation method and application of textured ceramic

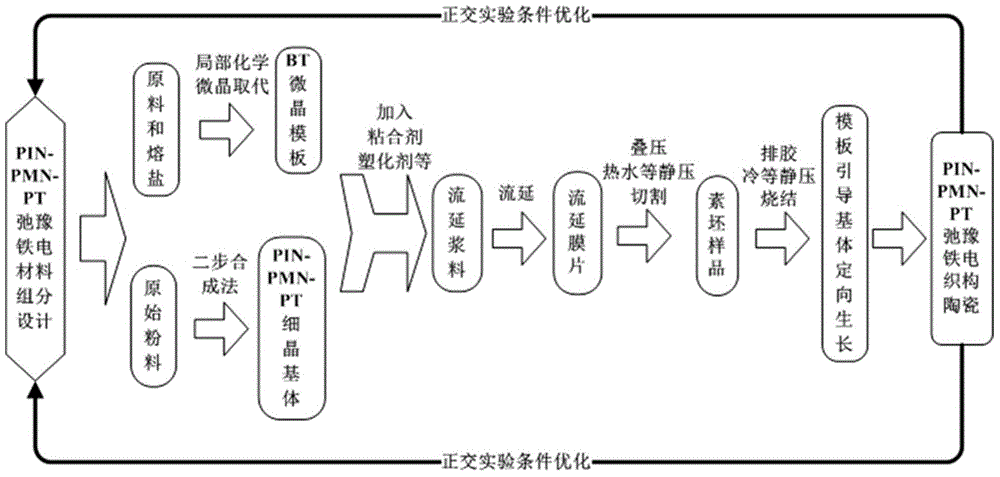

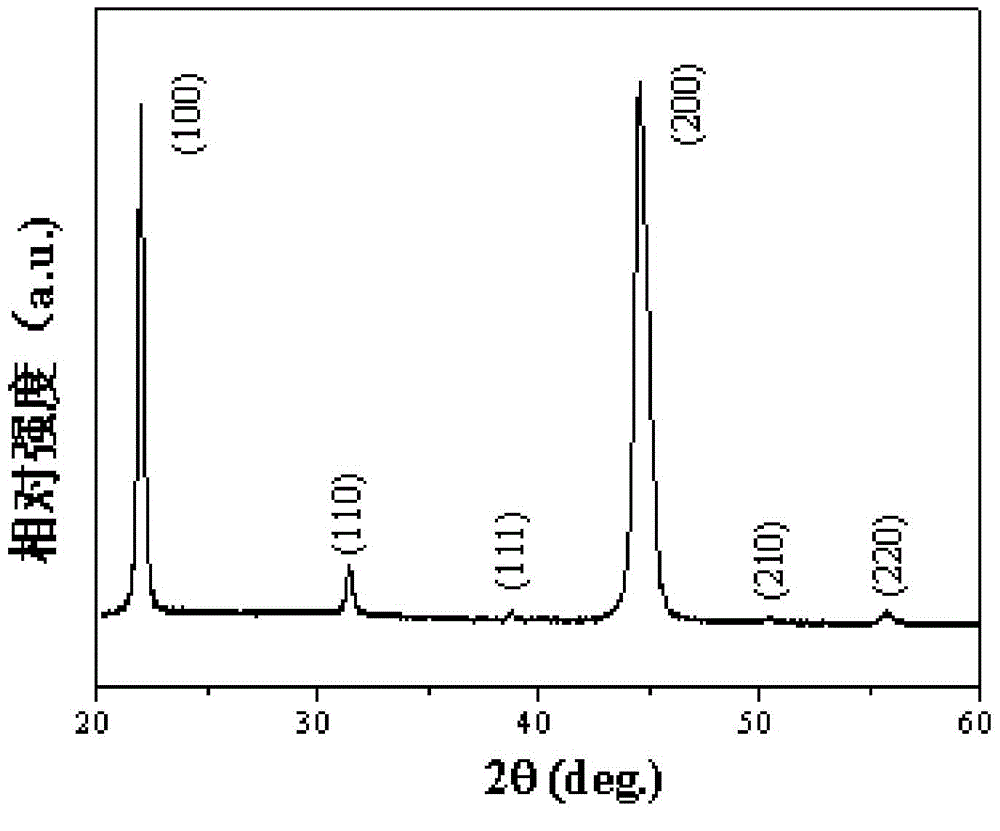

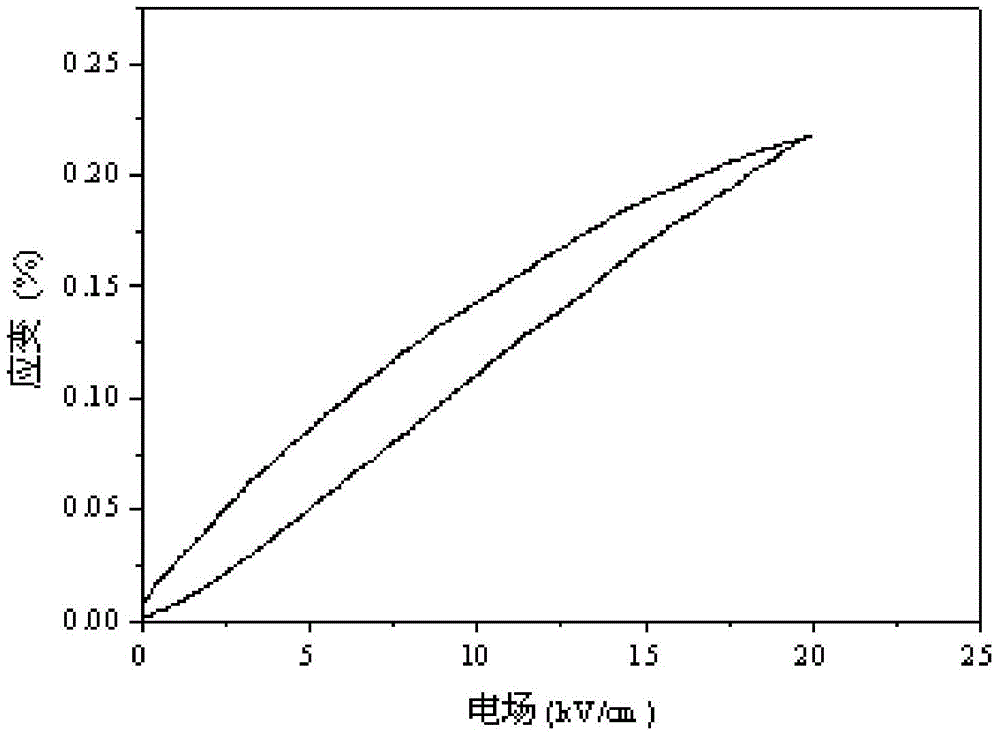

The invention discloses a lead indium niobate-lead magnesium niobate-lead titanate relaxor ferroelectric textured ceramic with high electrical properties and a preparation method and application of the textured ceramic and relates to the field of piezoelectric and ferroelectric materials. The invention aims to solve the problem that an existing PIN-PMN-PT single crystal component is segregated, the available size is limited, the mechanical property is poor, and the PIN-PMN-PT ceramic is low in electric property. The chemical formula is xPb(In<1 / 2>Nb<1 / 2>)O<3>-(1-x-y)Pb(Mg<1 / 3>Nb<2 / 3>)O<3>-yPbTiO<3>-avol.%BaTiO<3>. The method comprises the steps: preparing PIN-PMN-PT fine crystal matrix powder by a two-step synthetic method; preparing a BaTiO<3> sheet micro-crystal template by virtue of a local chemical micro-crystal substitution method; and preparing the PIN-PMN-PT-based ternary relaxor ferroelectric textured ceramic orientated along [001] height by adopting a template grain orientated growth technology. The ceramic is applied to the field of ultrasonic transducers, piezoelectric drivers and piezoelectric sensors.

Owner:HARBIN INST OF TECH

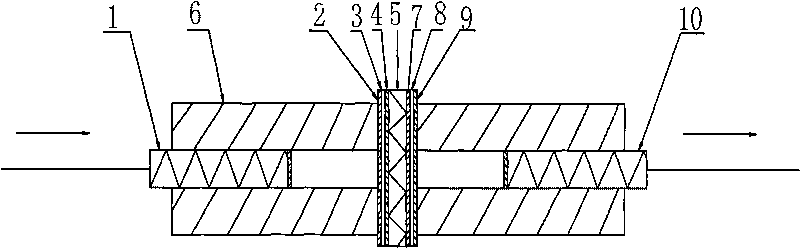

Focusing ultrasonic transducer and producing method thereof

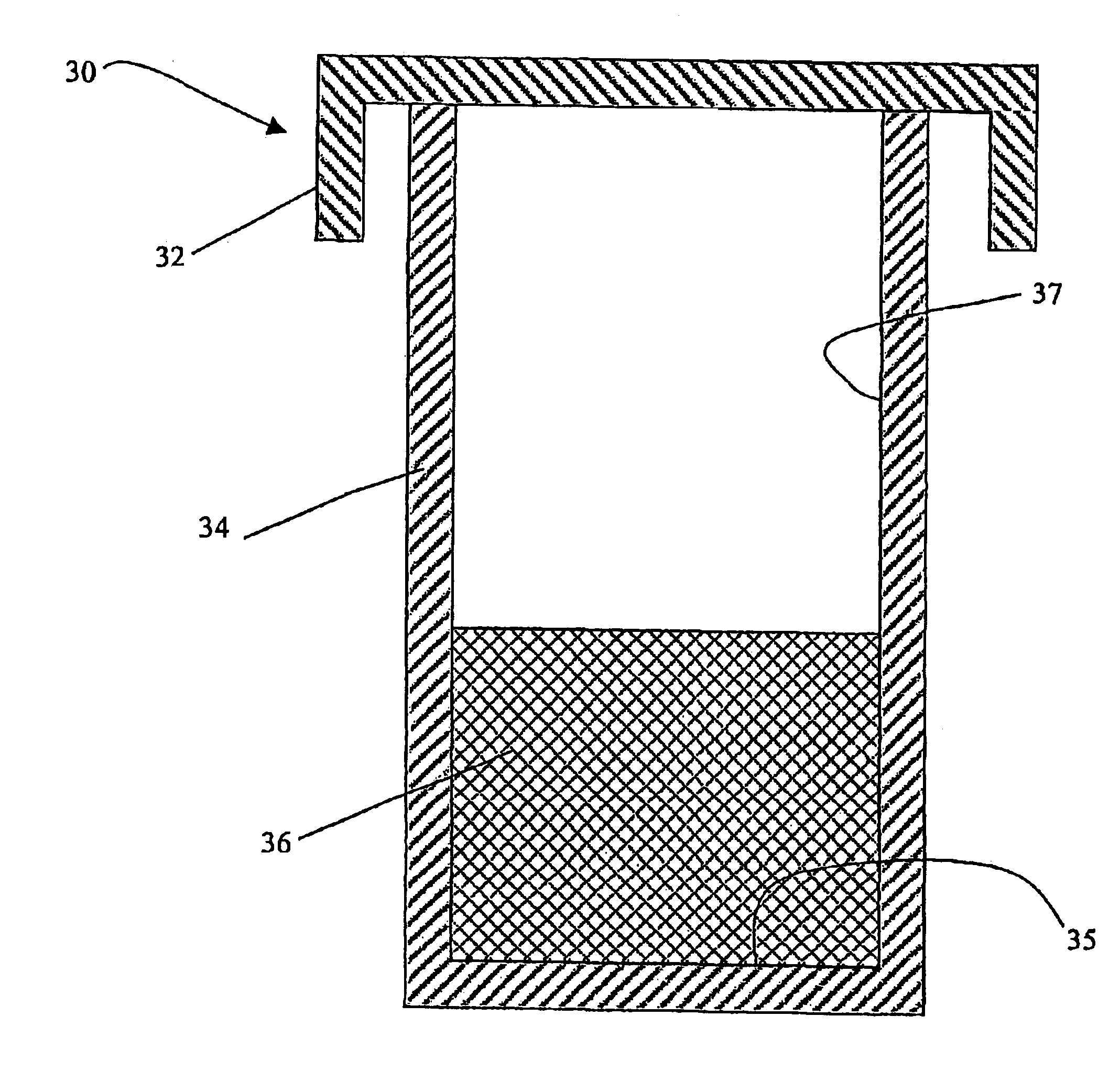

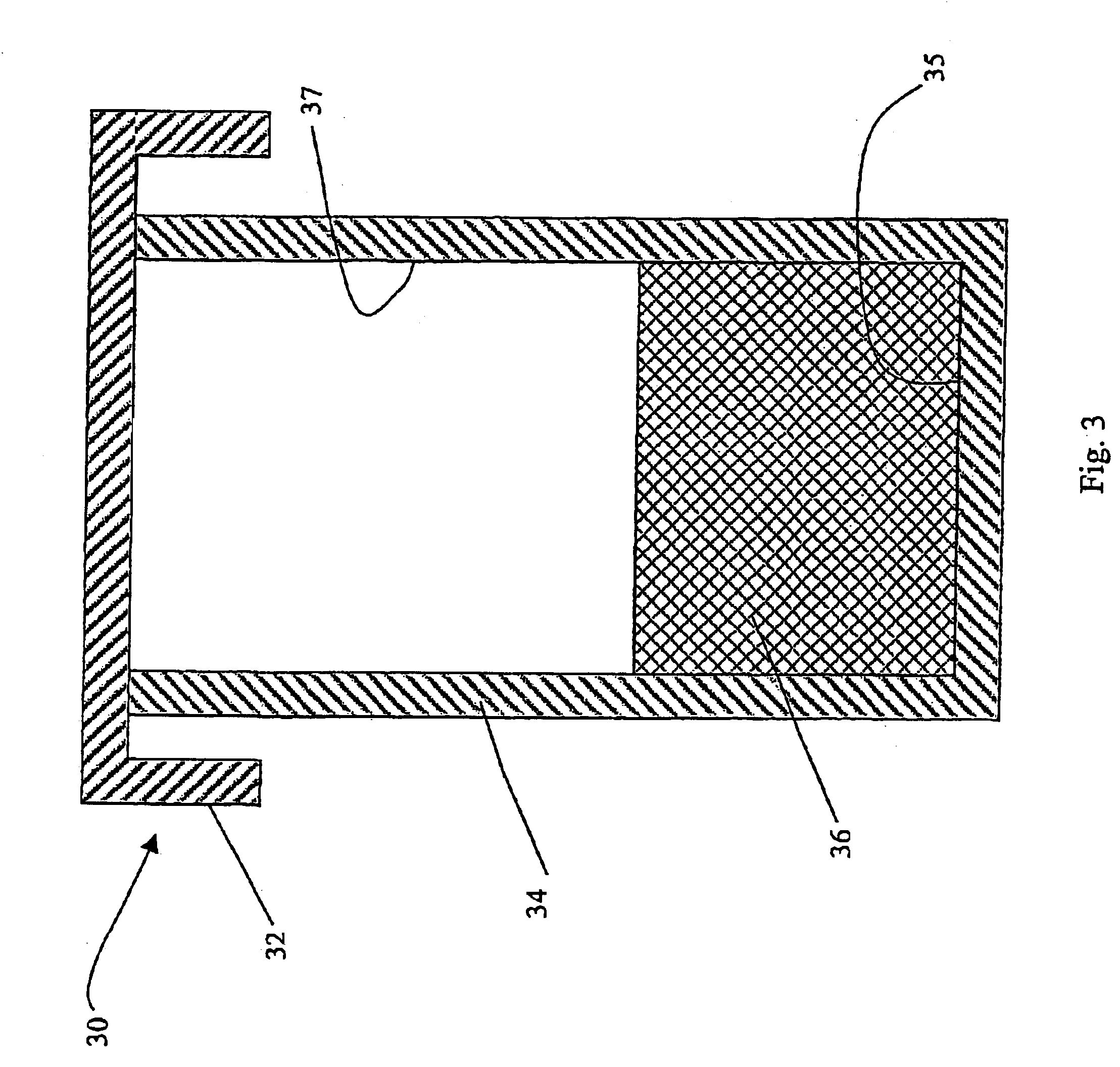

InactiveCN103041978ASimple structureEasy to manufactureMechanical vibrations separationUltrasonographyIndium

The invention discloses a focusing ultrasonic transducer which sequentially comprises a matching layer, a piezoelectric vibrator layer and a backing block. The piezoelectric vibrator layer is made of a piezoelectric single crystal / polymer 1-3 composite material; the piezoelectric single crystal is lead magnesium niobate-lead titanate with a chemical composition of (1-x) Pb (mg1 / 3Nb2 / 3) O3-xPbTiO3, the crystallographic direction is the (001) direction; or a lead indium niobate-lead magnesium niobate-lead titanate with a chemical composition of xPb (In1 / 2Nb1 / 2) O3-yPb (Mg1 / 3Nb2 / 3) O3- (1-x-y) PbTiO3, the crystallographic direction is the (001) direction; wherein 0<x<1, 0<y<1, and 0<x+y<1. The focusing ultrasonic transducer is simple in structure, convenient to prepare and low in manufacturing cost, can obtain high sensitivity, bandwidth and resolution ratio, and has a broad application prospect in the technical fields of medical ultrasonic imaging and industrial nondestructive testing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of lead magnesio-niobate-lead titanate ceramic

The invention discloses a preparation method of lead magnesio-niobate-lead titanate ceramic for solving the technical problem that dielectric loss of the lead magnesio-niobate-lead titanate ceramic prepared by the conventional method is large. The technical scheme is that: weighing and dosing analytically pure MgO (magnesium oxide), Nb2O5 (niobium oxide), PbO (lead oxide) and TiO2 (titanium dioxide) according to the chemical metering ratio (1-x)Pb(Mgl / 3Nb2 / 3)O3-xPbTiO3 (x is smaller than or equal to 0.07 and greater than or equal to 0.01); drying and pressing the materials into blocks after ball-milling, crushing the materials to obtain MgNb2O6 (magnesium niobium oxide) powder; adding TiO2 and PbO to MgNb2O6 powder and then ball-milling, and obtaining PMN-PT (lead magnesium niobate) powder by pressing and burning the material into large blocks; sieving and pre-pressing the PMN-PT powder into wafer, and carrying out isostatic pressing pressure molding; and carrying out heat preservation for 1-4 hours on the molded wafer at 1175-1250 DEG C, and then sintering the molded wafer into ceramic. Two systems are composited together, so that the prepared lead magnesio-niobate-lead titanate ceramic has combination properties of two different systems of lead magnesio and niobate-lead titanate, and has high dielectric constant under the condition that the temperature is 300K same as that of a background technology, meanwhile, lower dielectric loss and higher dielectric tenability are respectively kept at 0.007-0.011 and 63-87% at the same time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Lead lutetioniobate-lead magnesioniobate-lead titanate ternary-system relaxation ferroelectric monocrystal and preparation method thereof

InactiveCN102817080AExcellent piezoelectric propertiesGood electric field stabilityPolycrystalline material growthFrom frozen solutionsMass growthSingle crystal

The invention discloses a lead lutetioniobate-lead magnesioniobate-lead titanate ternary-system relaxation ferroelectric monocrystal and a preparation method thereof. The chemical general formula of the monocrystal is xPb(Lu1 / 2Nb1 / 2)O3-yPb(Mg1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein 0.1<=x<=0.4, 0.2<=y<=0.6, but 1-x-y is not equal to 0. The PLMNT monocrystal is prepared by a crucible descent method. The invention effectively overcomes the defect of overlow Curie temperature in the PMNT monocrystal and the defects of difficulties in crystallization and mass growth in the PLNT monocrystal in the prior art. The PLMNT monocrystal disclosed by the invention has great application potential at room temperature, is very applicable to high-temperature devices, has wide application temperature range, and can completely satisfy the application requirements in high technologies, such as ultrasonic imaging, ultrasonic motors and the like, thereby having very wide application prospects.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

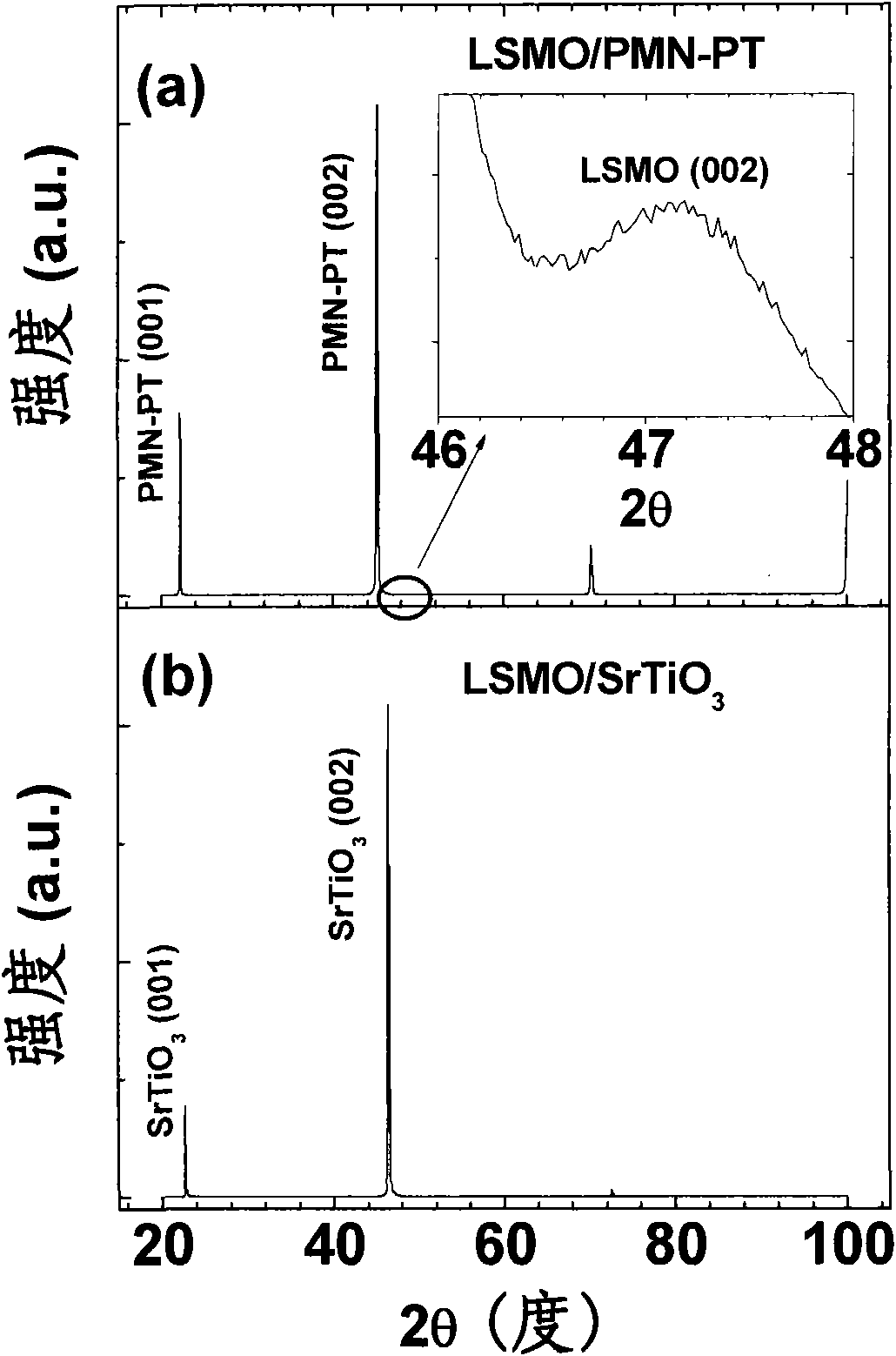

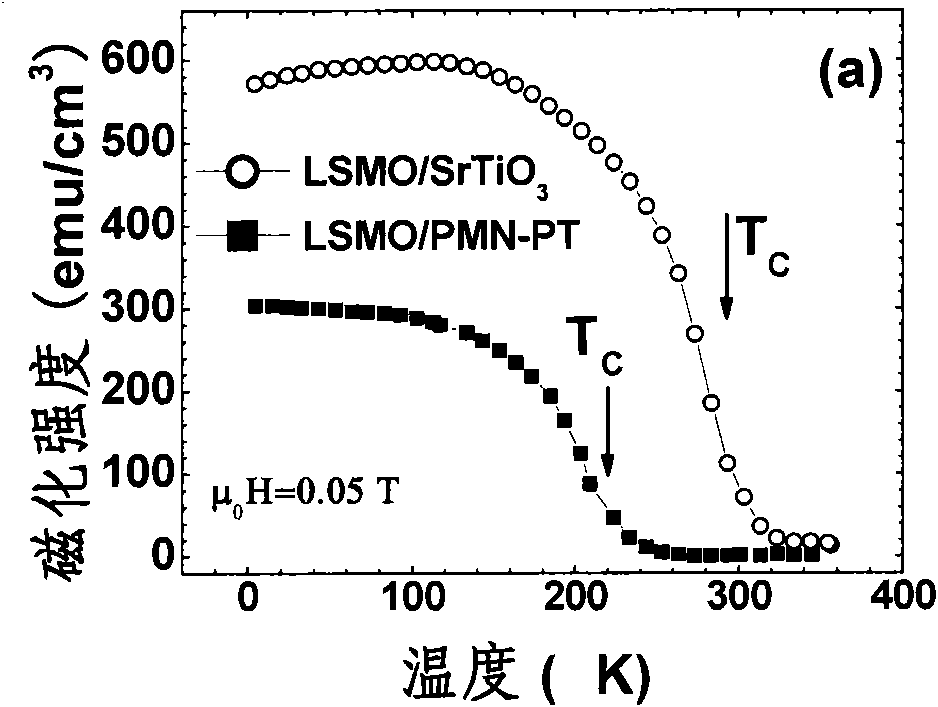

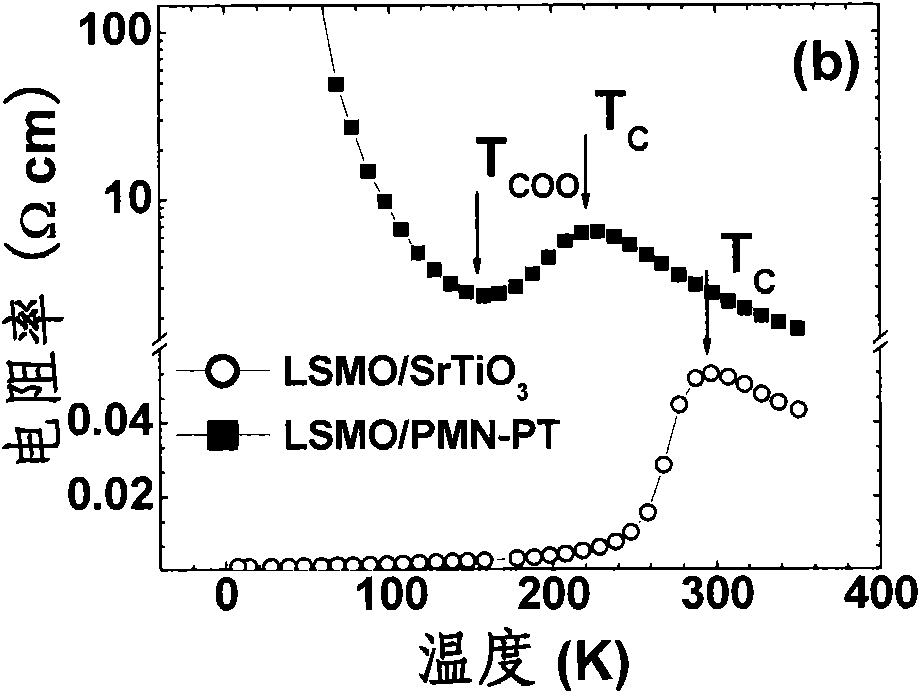

Manganese oxide thin film with adjustable charge-orbital ordering characteristic

ActiveCN102101793ASimple processGood repeatabilityVacuum evaporation coatingSputtering coatingIn planeTensile strain

The invention discloses a new method for realizing adjustable charge-orbital ordering characteristic in a (001) oriented perovskite manganese oxide thin film and use thereof. In the method, (001) oriented lead magnesium niobate-lead titanate (PMN-PT) with high reverse piezoelectric performance is used as a substrate, the lattice mismatch of the substrate and the perovskite manganese oxide is controlled to be 1 to 3 percent to ensure that the thin film has a large in-plane tensile strain during epitaxial growth, and thus, the charge-orbital ordered transformation is induced. The chemical general formula of the thin film is Re1-xAexMnO3, wherein x ranges from 0 to 1; Re is one or more than two of La, Ce, Pr, Eu, Ho, Nd and Sm; and Ae is one or more than two of Ca, Sr, Ba, Ce, Sn, Y and Hf. Furthermore, the state of the charge-orbital ordered phase in the thin film can be adjusted by applying a bias electric field onto the substrate, and thus, the magnetoresistance of the thin film can be controlled.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

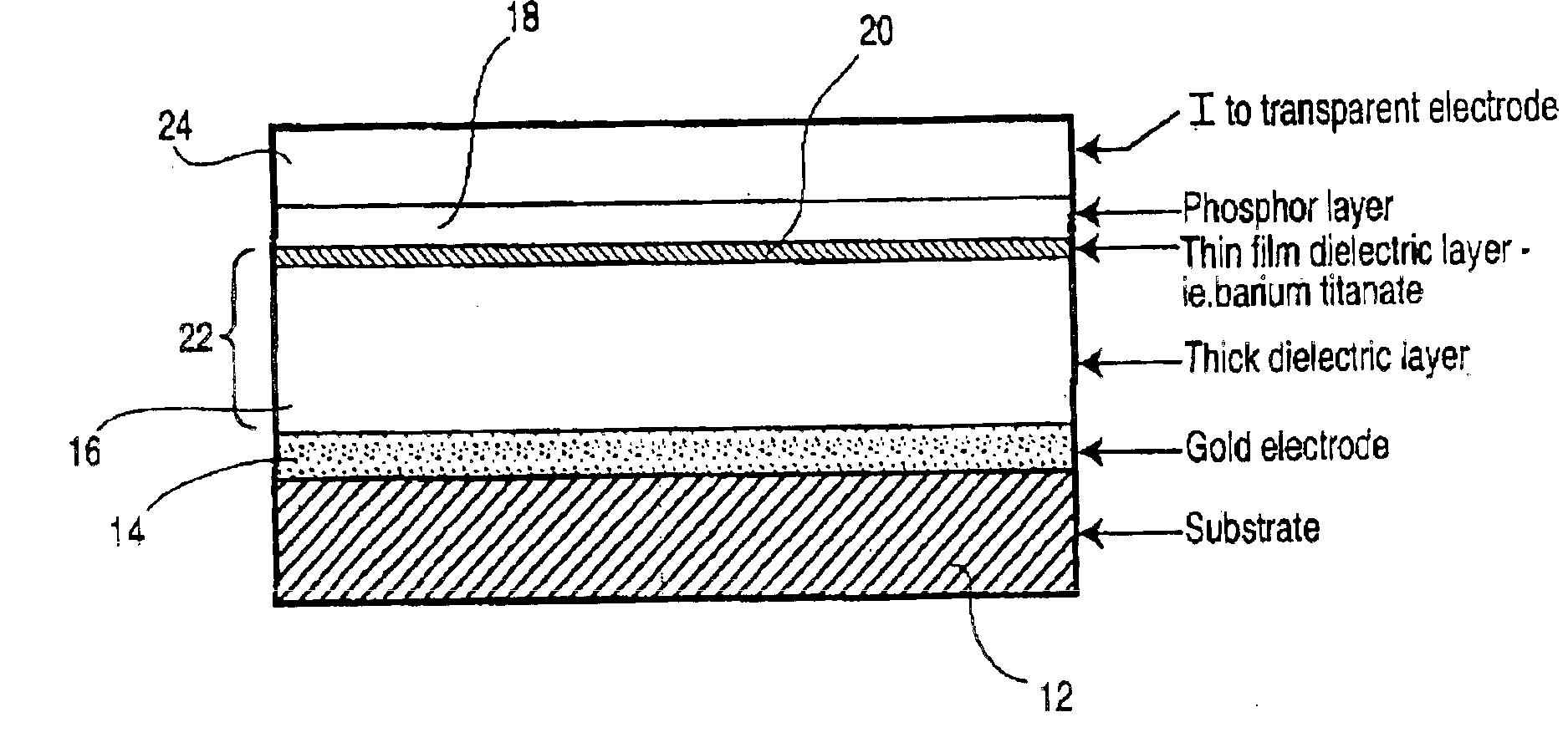

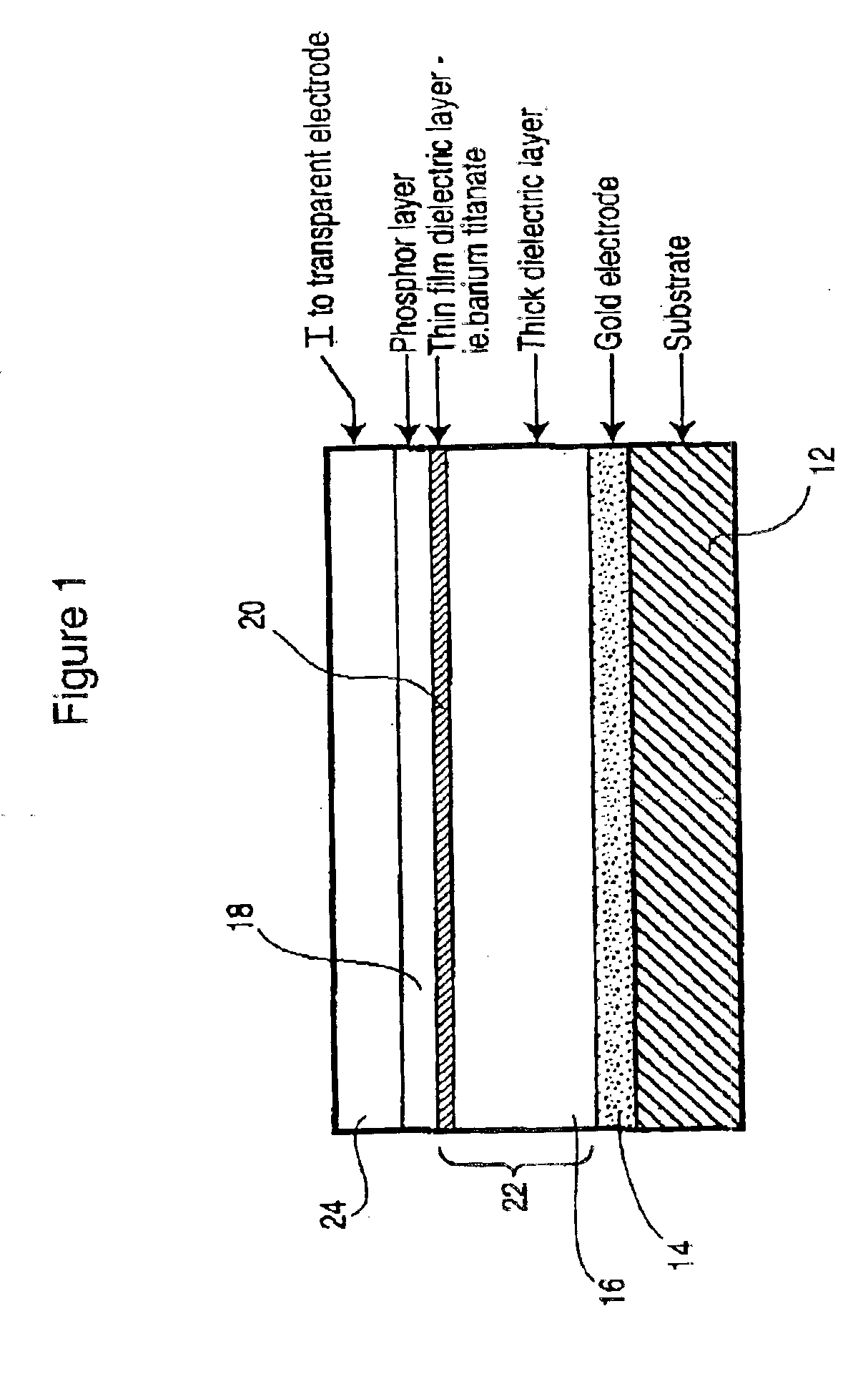

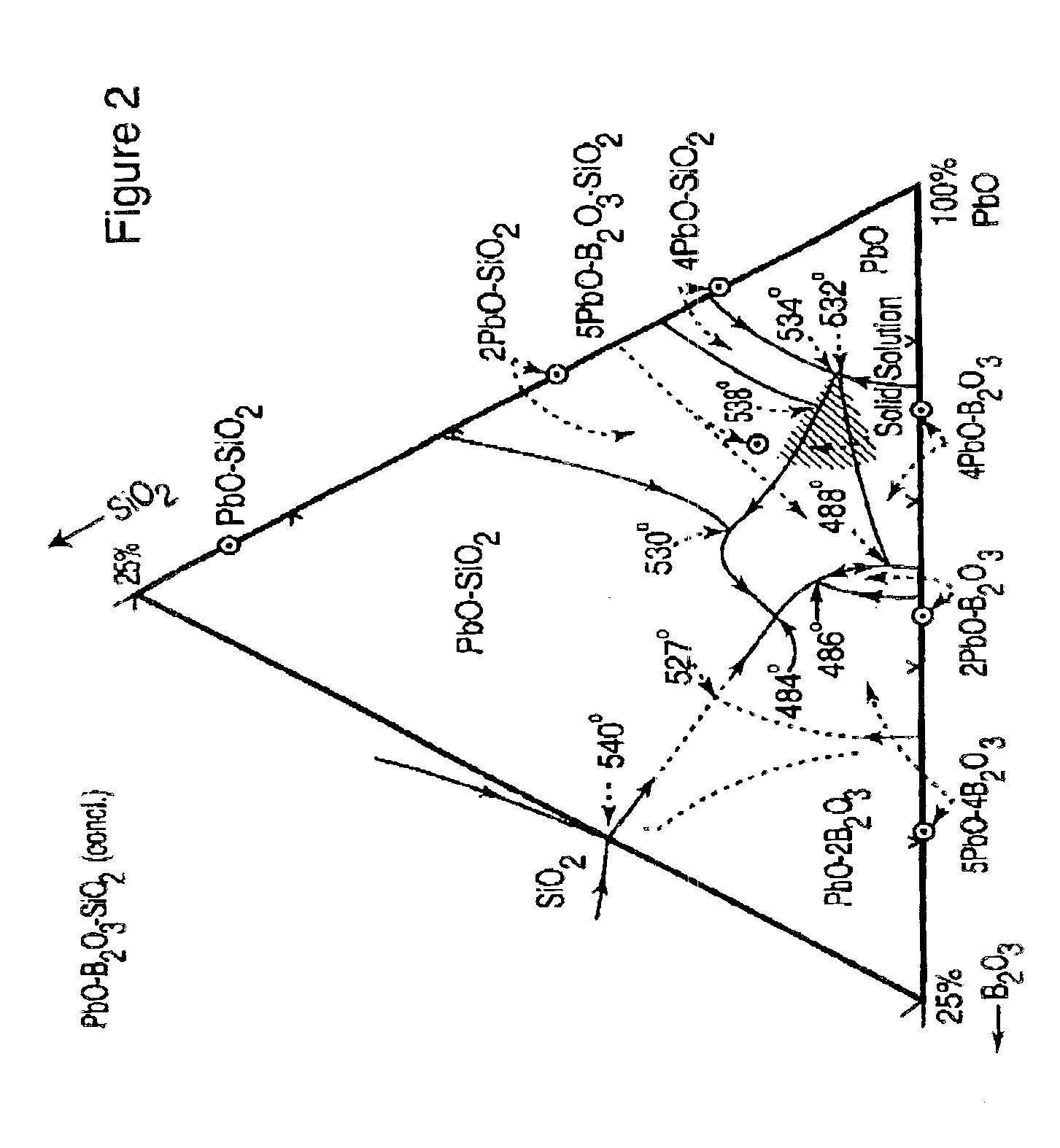

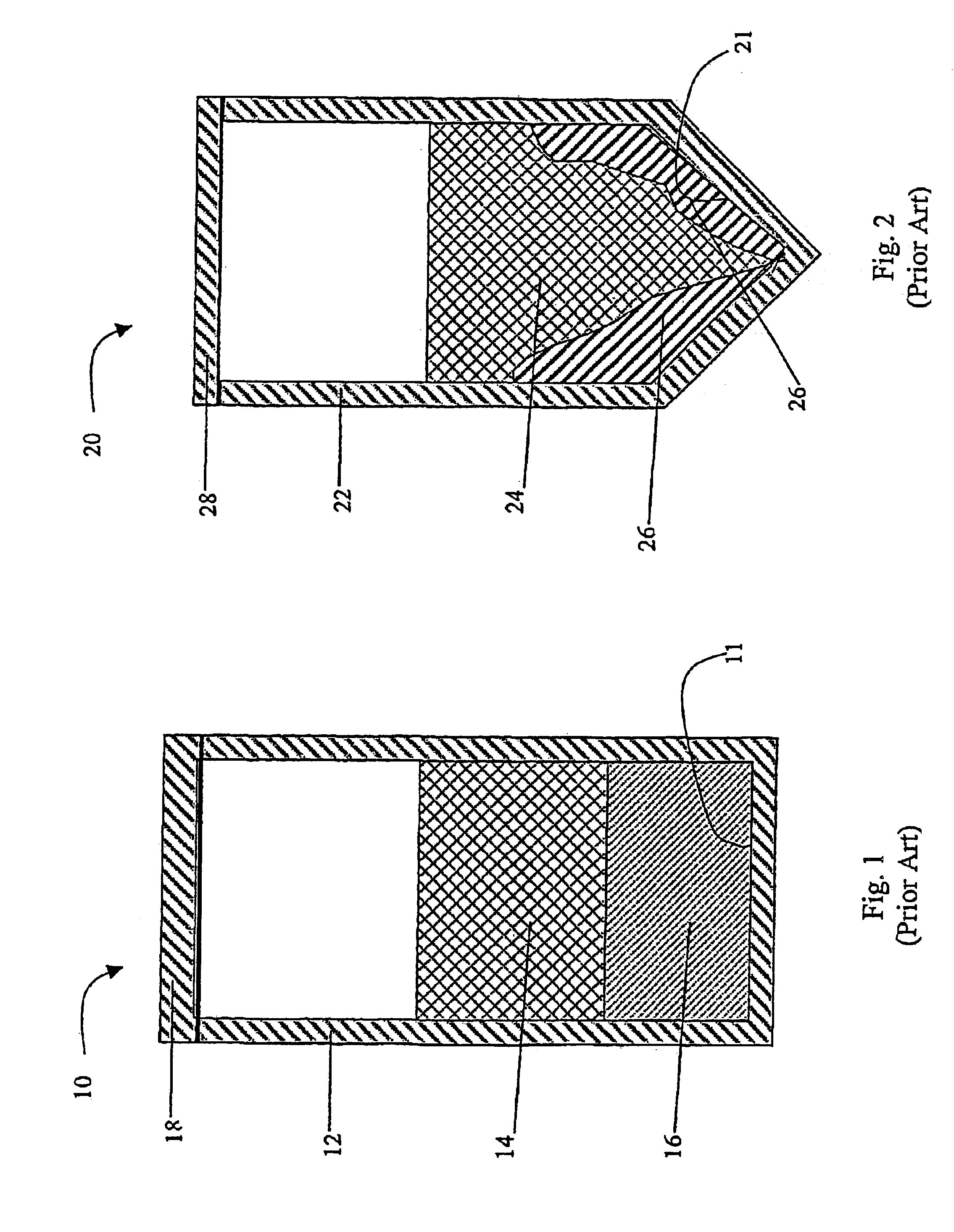

Low firing temperature thick film dielectric layer for electroluminescent display

InactiveUS6919126B2Increasing residual porosityEasy to useElectroluminescent light sourcesPretreated surfacesLead zirconate titanateBarium titanate

The present invention is a low firing temperature, composite thick film dielectric layer for an electroluminescent display. The composite thick film dielectric layer comprises;(a) a lower zone layer of a thick film composition comprising;one or more of lead magnesium niobate (PMN), lead magnesium niobate-titanate (PMN-PT), lead titanate, barium titanate and lead oxide; anda glass frit composition comprising lead oxide, boron oxide and silicon dioxide;(b) an upper zone comprising at least one layer of lead zirconate titanate (PZT) and / or barium titanate; and(c) an intermediate composite zone comprising a composite of (a) and (b).

Owner:IFIRE IP CORP

Lead magnesio-niobate-lead titanate binary system high-heat electricity-release ceramic material and preparation technique thereof

This invention discloses a binary system high pyroelectric ceramic materials of lead-niobate-magnesate and lead titanate. The basic components of this inventive single-component linear pyroelectric ceramic material and multicomponent nonlinear pyroelectric ceramic material are as below: xPb(Mg1 / 3Nb2 / 3)O3+(1-x)PbTiO3, i.e. xPMN+(1-x)PT, wherein x=0.2-0.48. The above-mentioned components involve doped elements. The pyroelectric coefficient of this inventive product is higher than that of prior art product. The dielectric coefficient of said product can be regulated between 1000-8000, the products can be matched with infrared focal plane devices. Compared with prior art gelatin moulding method, this inventive method has advantages of: simple operation, easy treatment of raw materials, low cost.

Owner:SHANGHAI NORMAL UNIVERSITY

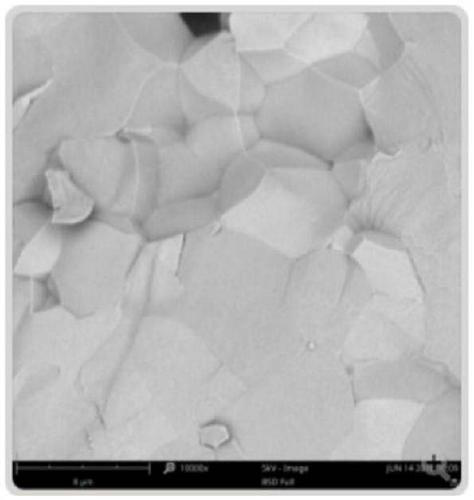

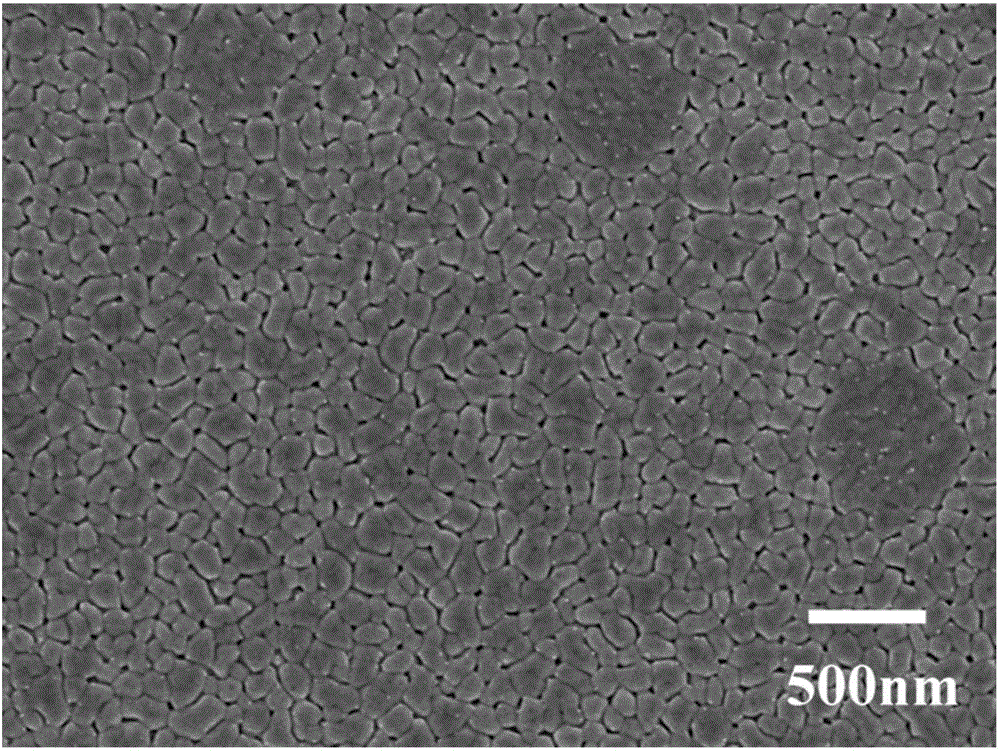

Sm-modified lead magnesium niobate-lead titanate-based piezoelectric and ferroelectric thick film material and preparation method thereof

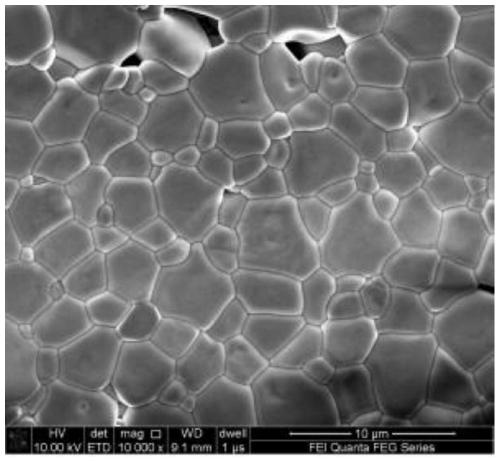

The invention belongs to the technical field of ferroelectric and piezoelectric functional materials, and discloses a Sm-modified lead magnesium niobate-lead titanate-based piezoelectric and ferroelectric thick film material. The molecular formula of the Sm-modified lead magnesium niobate-lead titanate-based piezoelectric and ferroelectric thick film material is [Sm<x>-Pb<(1-1.5x)>][(Mg<1 / 3>Nb<2 / 3>)<(1-Y)>Ti<y>]O3, wherein 0<X<=0.1,0.25<Y<=0.32, the preparation method comprises the steps that S1, raw materials areweighed according to stoichiometric ratio; S2, a two-step solid-phase reaction method is adopted to prepare and obtain Sm-modified lead magnesium niobite-lead titanate powder body ofperovskite phase; S3, the powder body is mixed with a dispersing agent and a binder to obtain a slurry; S4,the slurry is subjected to tape casting, drying, cutting, and lamination to obtain a green tape in a desired shape; S5, the green tape is adhered and sintered to obtain the piezoelectric and ferroelectric thick film material. Thepiezoelectric and ferroelectric thick film material is of a perovskite phase structure, microstructure is compact, piezoelectric performanceis excellent, sinteringcan be conducted at a low temperature, preparation technology is simple, the cost is low, industrial production is advantageous, and the piezoelectric and ferroelectric thick film material is expected to be used for piezoelectric ultrasonic transducer and high frequency piezoelectric ultrasonic transducer arrays, piezoelectric actuators, and sensors.

Owner:GUANGDONG JC TECHNOLOGICAL INNOVATION ELECTRONICS CO LTD +1

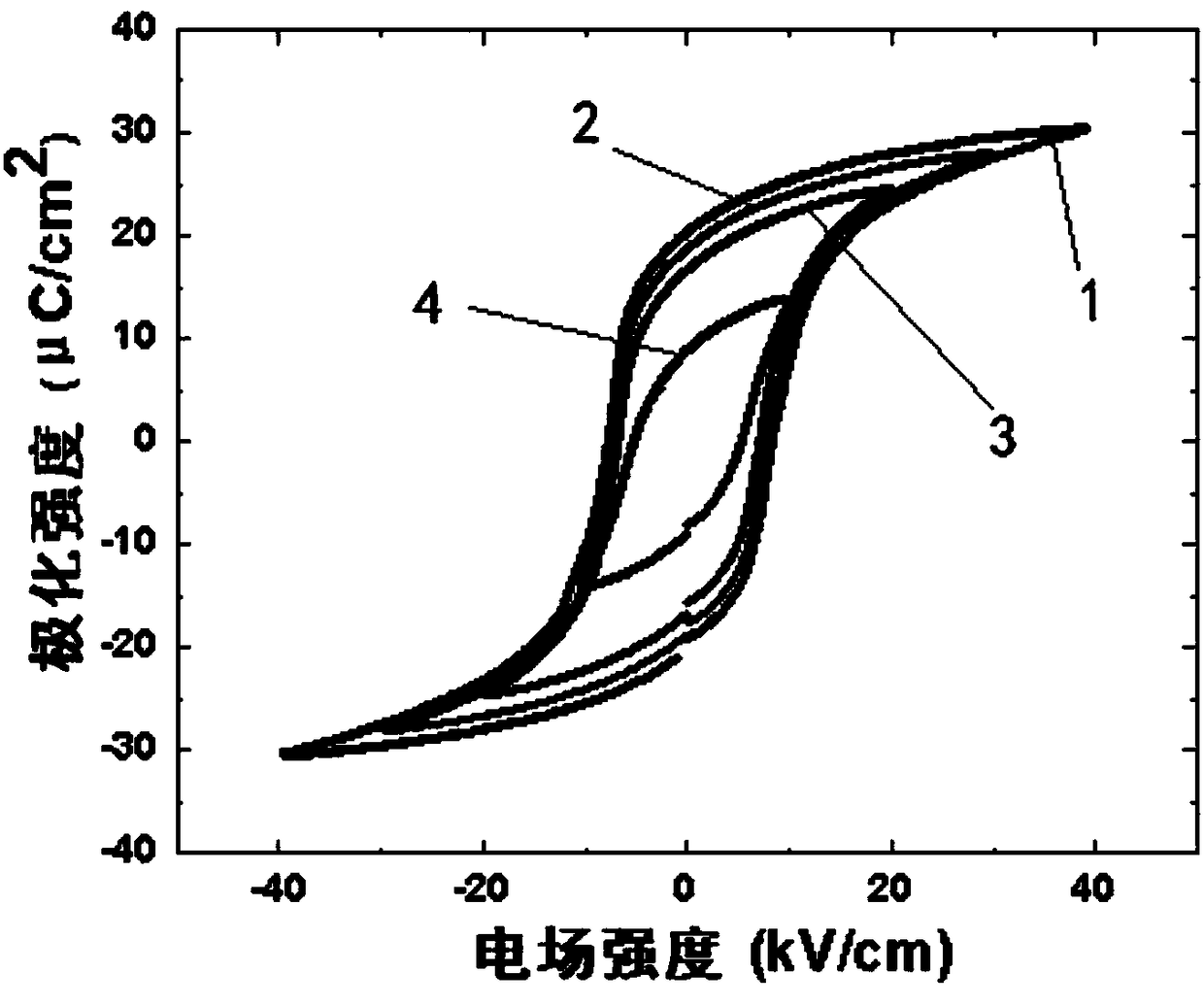

Lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material and preparation method thereof

InactiveCN107500764AHigh strengthImprove magnetic propertiesInorganic material magnetismComposite ceramicRoom temperature

The invention discloses a lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material and a preparation method thereof. The lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material comprises a novel ferroelectric and ferromagnetic composite ceramic material formed by adding bismuth ferrite into lead magnesium niobate (PMN)-lead titanate (PT) serving as a matrix. The material comprises the chemical components: (1-x)[(1-y)Pb(Mg1 / 3Nb2 / 3)O3+yPbTiO3]+xBiFeO3, x is equal to 0.01-0.05, and y is equal to 0.30-0.39. The lead magnesium niobate-lead titanate-bismuth ferrite multiferroic ceramic material is simple in process and low in cost, and the spontaneous polarization intensity and magnetic property of the material can be improved by regulation. The multiferroic ceramic material is relatively low in raw material cost, simple in preparation process and easy to store and use; and the multiferroic magnetoelectric composite can be widely applied to aspects such as sensors, energy converters, filters, oscillators and storages due to a remarkable magnetoelectric effect at room temperature.

Owner:SHANGHAI NORMAL UNIVERSITY

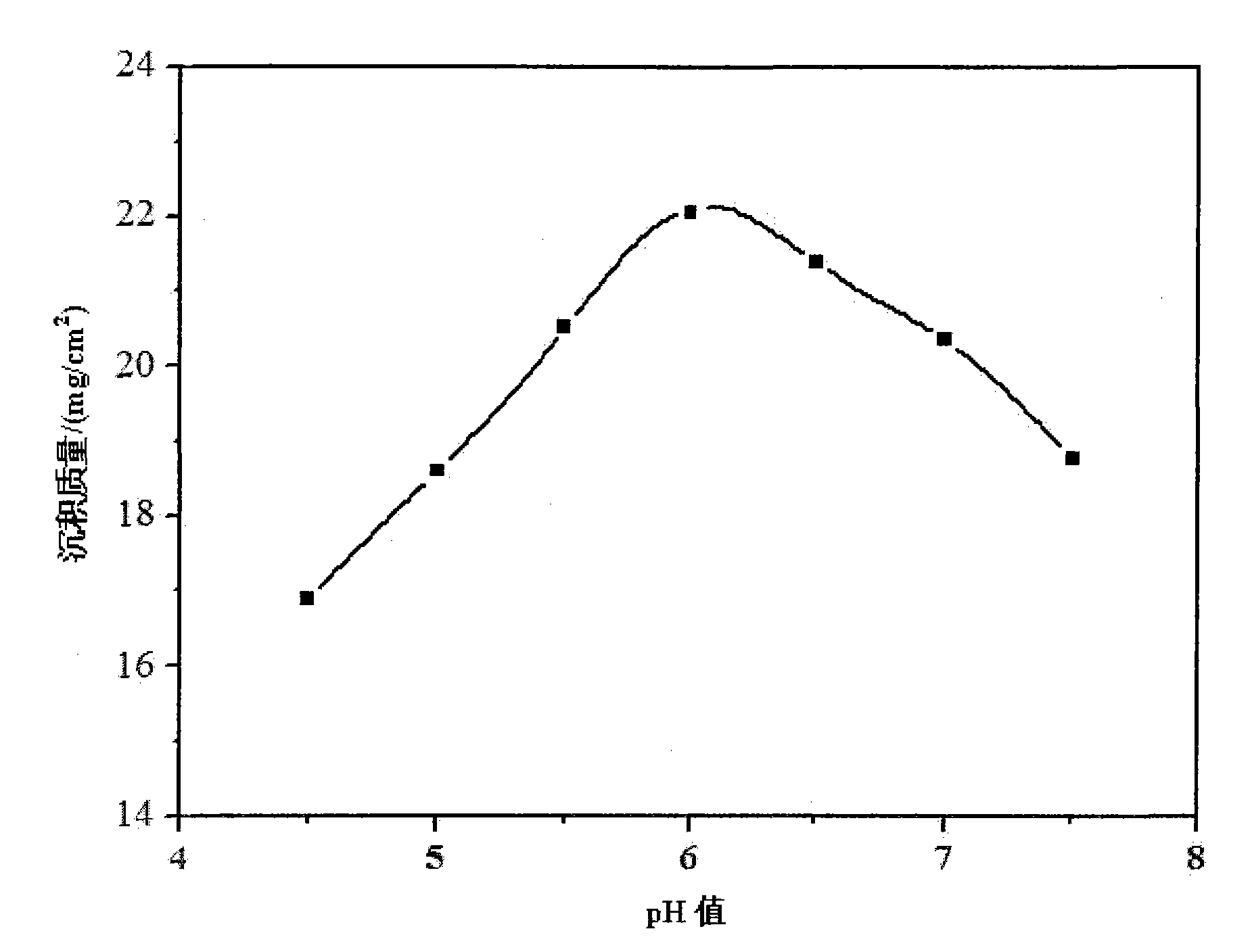

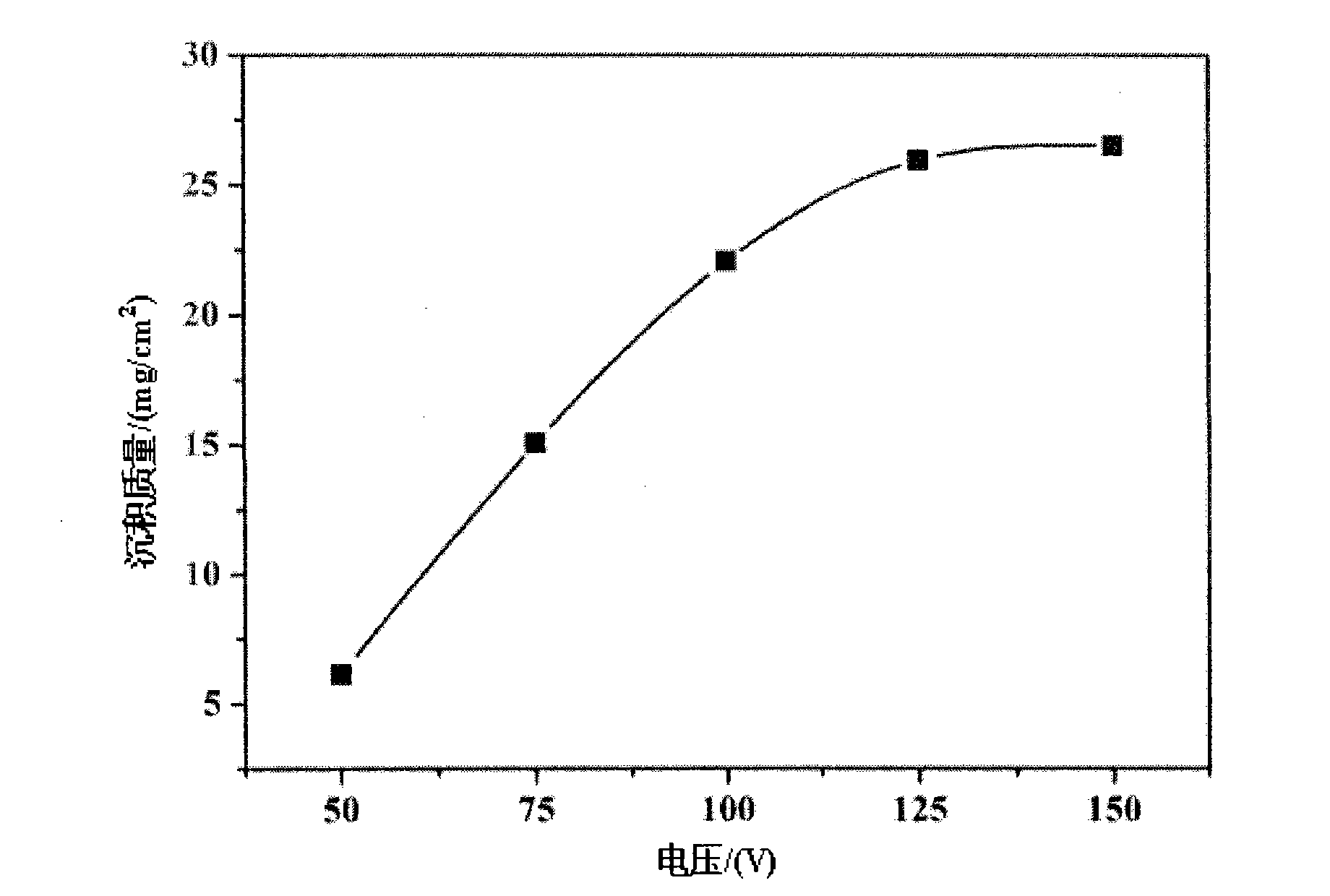

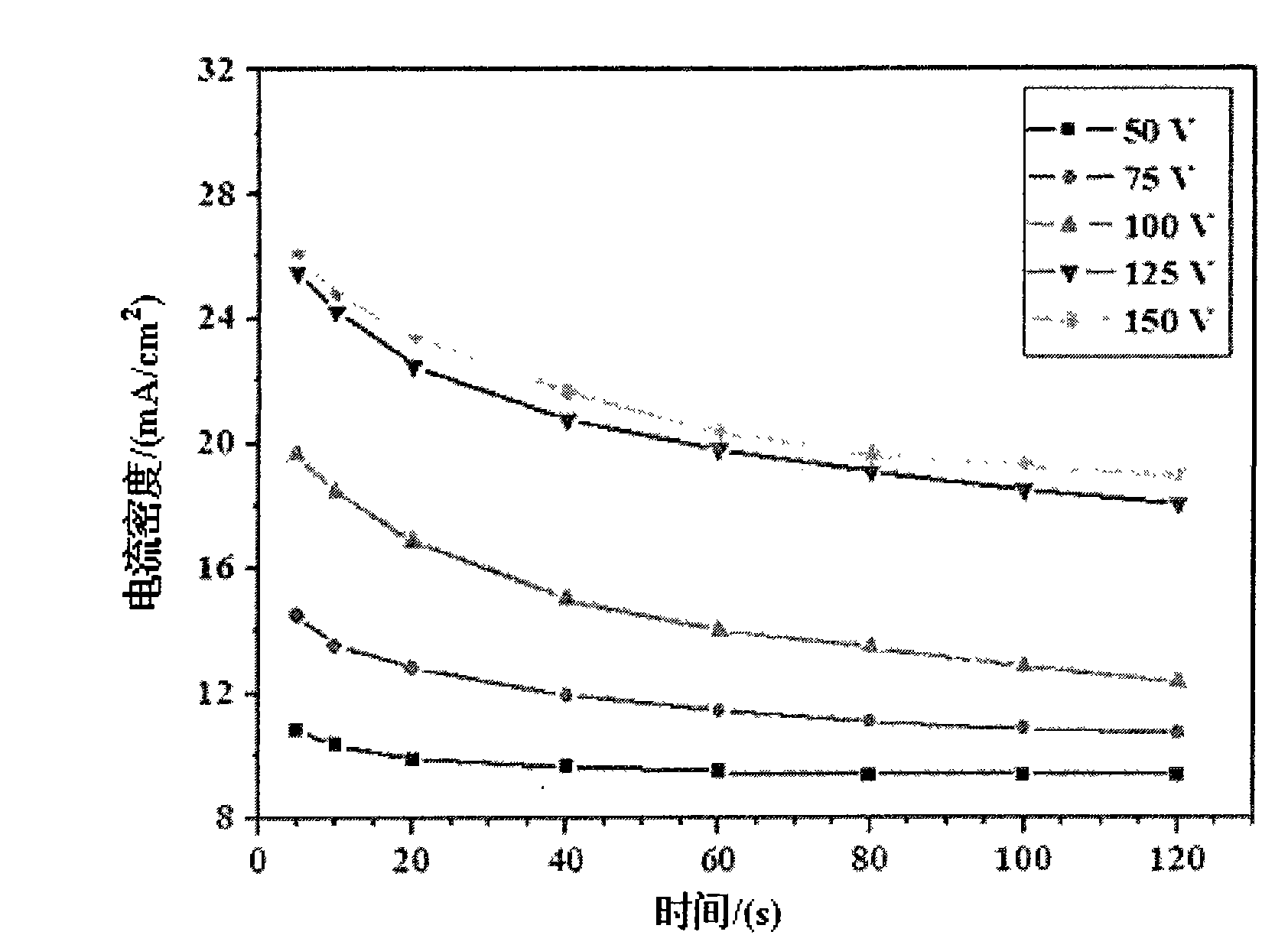

Method for preparing lead magnesium niobate-lead titanate thick film

The invention discloses a method for preparing a lead magnesium niobate-lead titanate thick film to solve the technical problem of poor surface compactness of the lead magnesium niobate-lead titanate thick film prepared by the preparation method in the prior art. The invention adopts a technical scheme that: the method comprises the following steps: blending materials according to (1-x)Pb(Mg1 / 3Nb2 / 3)O3-xPbTiO3 to prepare (1-x)Pb(Mg1 / 3Nb2 / 3)O3-xPbTiO3 powder; after the thick film is prepared from the powder through electrophoretic deposition, naturally drying the thick film; and preparing a layer of lead oxide surface sol-gel film by using a spinning method, or sintering at high temperature in lead-rich atmosphere after cold isostatic pressing treatment so as to obtain the lead magnesium niobate-lead titanate thick film. Because the lead magnesium niobate-lead titanate thick film is prepared by adopting the electrophoretic deposition method, the surface compactness of Si3O4-SiO2 duplex ceramic is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of perovskite-structure relaxor ferroelectric single crystal lead indium niobate-lead magnesium niobate-lead titanate

ActiveCN104419984AInhibit component segregationLow costPolycrystalline material growthFrom frozen solutionsIndiumChemical composition

The invention relates to a preparation method of perovskite-structure relaxor ferroelectric single crystal lead indium niobate-lead magnesium niobate-lead titanate. The chemical composition of the perovskite-structure relaxor ferroelectric single crystal lead indium niobate-lead magnesium niobate-lead titanate is (1-x-y)Pb(In1 / 2Nb1 / 2)O3-yPb(Mg1 / 3Nb2 / 3)O3-xPbTiO3, wherein x is equal to 0.20-0.45 and y is equal to 0.15-0.70. The preparation method comprises the following steps: (1) preparing a primary crystal growth raw material; (2) primarily growing crystals; (3) preparing secondary crystal growth raw material; and (4) secondarily growing the crystals. According to the preparation method disclosed by the invention, a crucible descending multi-growth method is adopted, the component segregation of wafers can be obviously suppressed, the high-performance areas of the crystals can be expanded, and relaxor ferroelectric single crystal material PIMNT with large dimensions, large high-performance intervals and high quality can be grown effectively with regard to the optimally-orientated wafers for different applications, thus the utilization rate of the crystals is increased, and the difficulties of batch growth and applications of single crystals can be overcome.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

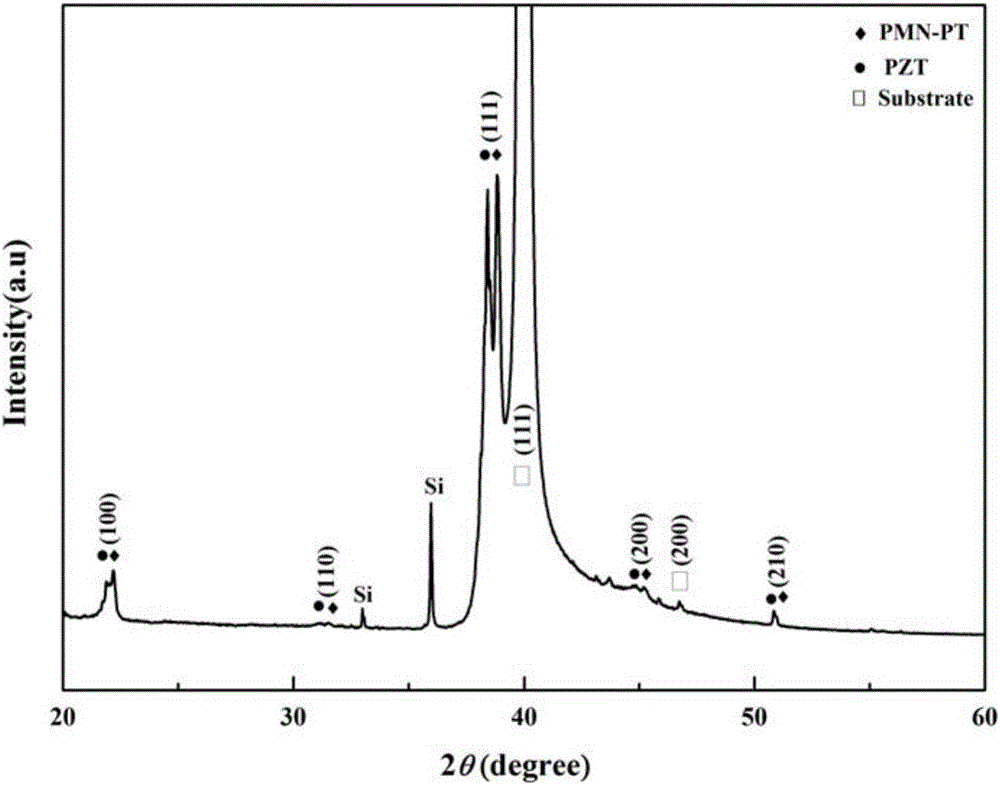

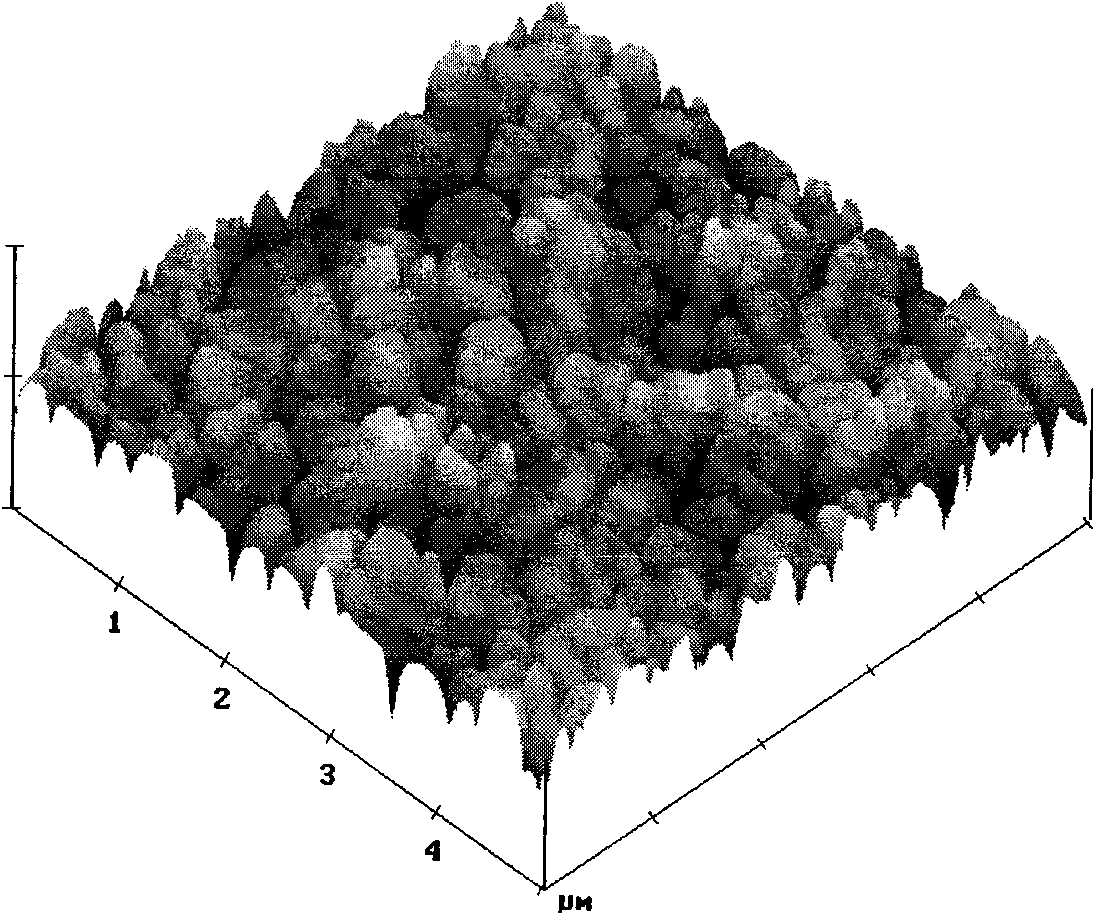

Method for preparing lead-titanate-lead-magnesium niobate films by pulsed laser deposition assisted by oxygen plasmas

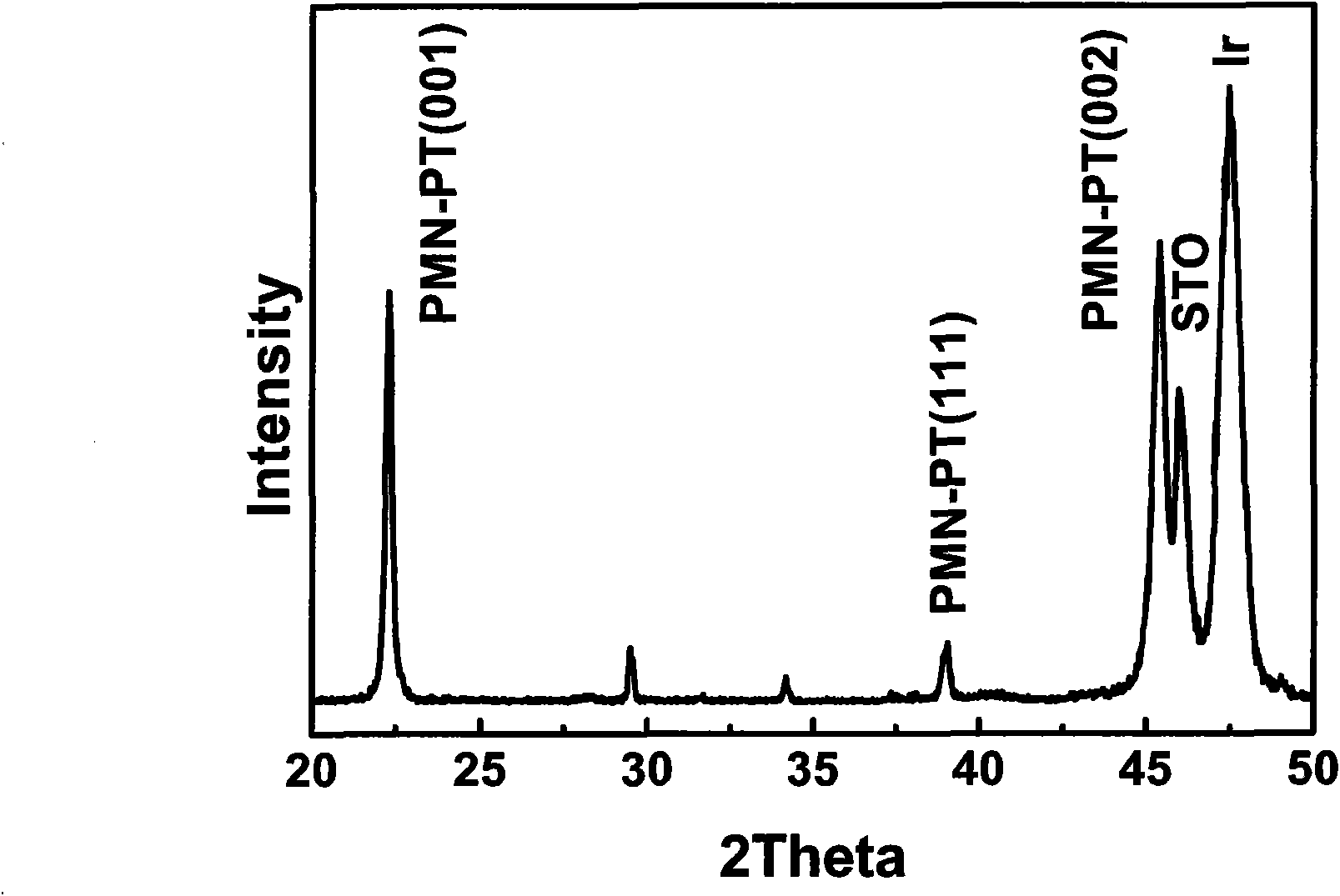

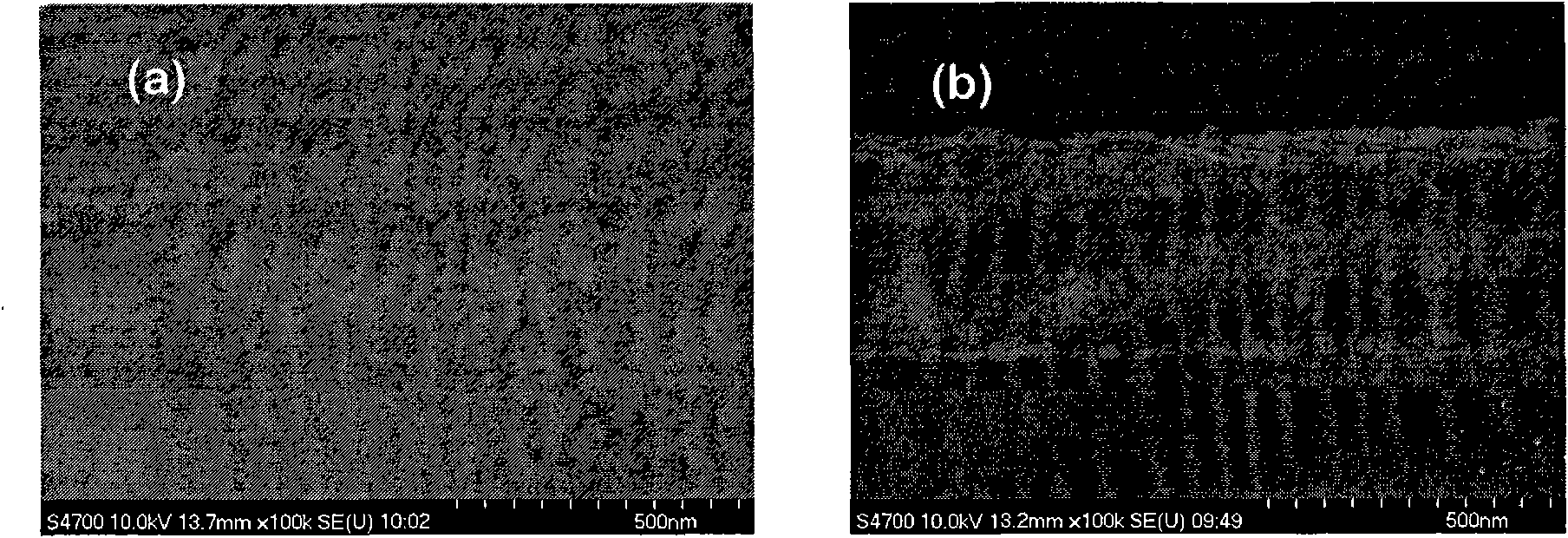

ActiveCN101892522AOptimizing Deposition Growth ConditionsCompact structurePolycrystalline material growthFrom condensed vaporsHigh energyCrystallinity

The invention provides a method for preparing lead-titanate-lead-magnesium niobate films by pulsed laser deposition assisted by oxygen plasmas, which is characterized by introducing high-activity oxygen plasmas to the process of preparing lead titanium-magnesium niobate films by pulsed laser deposition and improving the crystallinity and topography of the oxygen plasmas, thus obtaining the high-quality lead titanium-magnesium niobate films. The specific process is as follows: placing the lead-titanate-lead-magnesium niobate target and the substrate into a vacuum chamber; vacuumizing the vacuum chamber and heating the substrate to certain temperature; then pumping certain amount of high-purity oxygen and ionizing the oxygen by using a gas ionization system to apply high pressure to form the high-activity oxygen plasmas; ensuring the oxygen plasmas between the lead-titanate-lead-magnesium niobate target and the substrate; and using the high energy pulse laser to bombard the lead-titanate-lead-magnesium niobate target to generate the high energy plasmas and depositing the lead-titanate-lead-magnesium niobate films on the substrate. The films prepared by the invention have good crystallization quality, compact structure and excellent dielectric and ferroelectric properties.

Owner:中国科学院上海硅酸盐研究所苏州研究院

Lead magnesium niobate-lead titanate and lead zirconate titanate alloplasmic structure film and preparing method of film

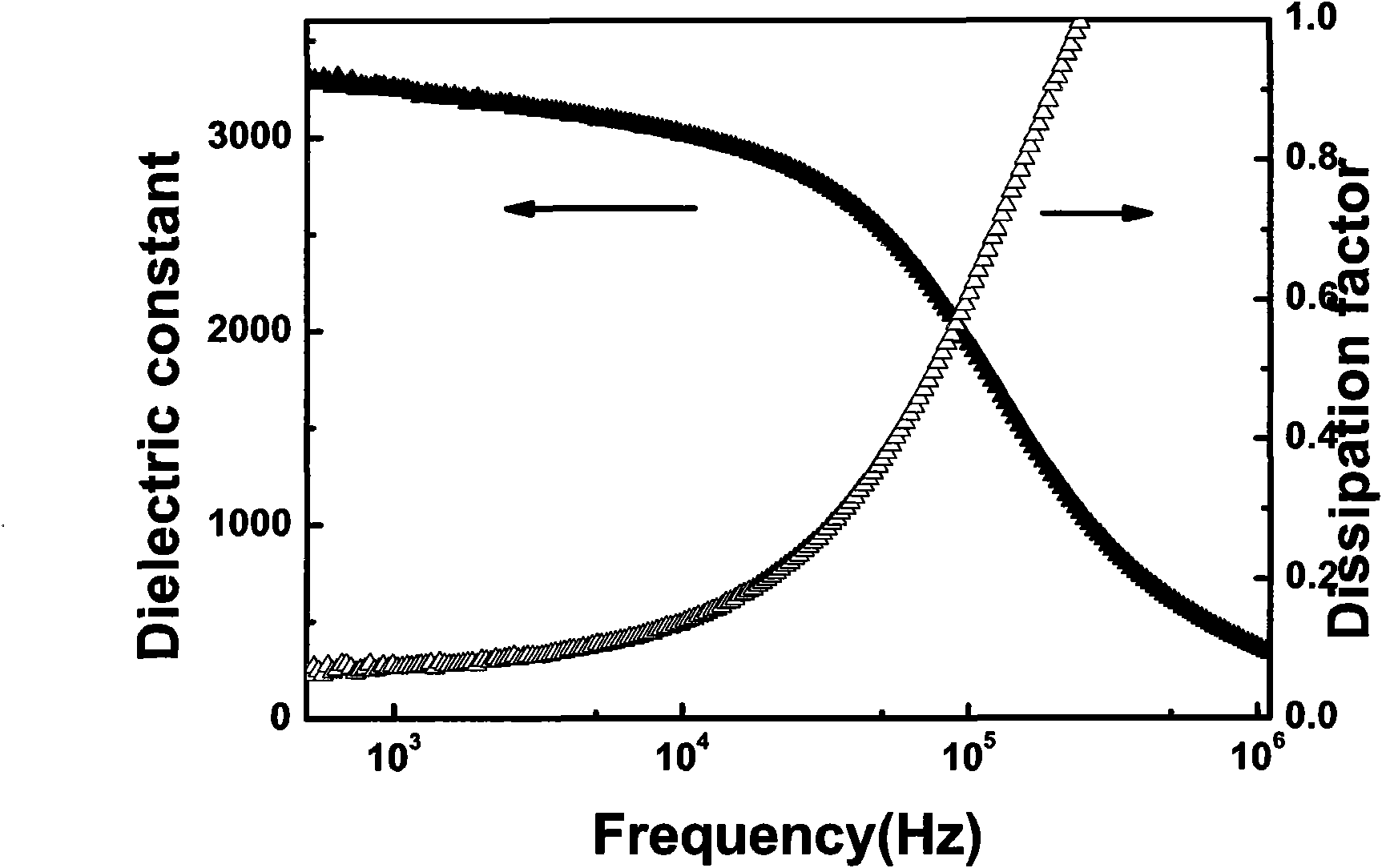

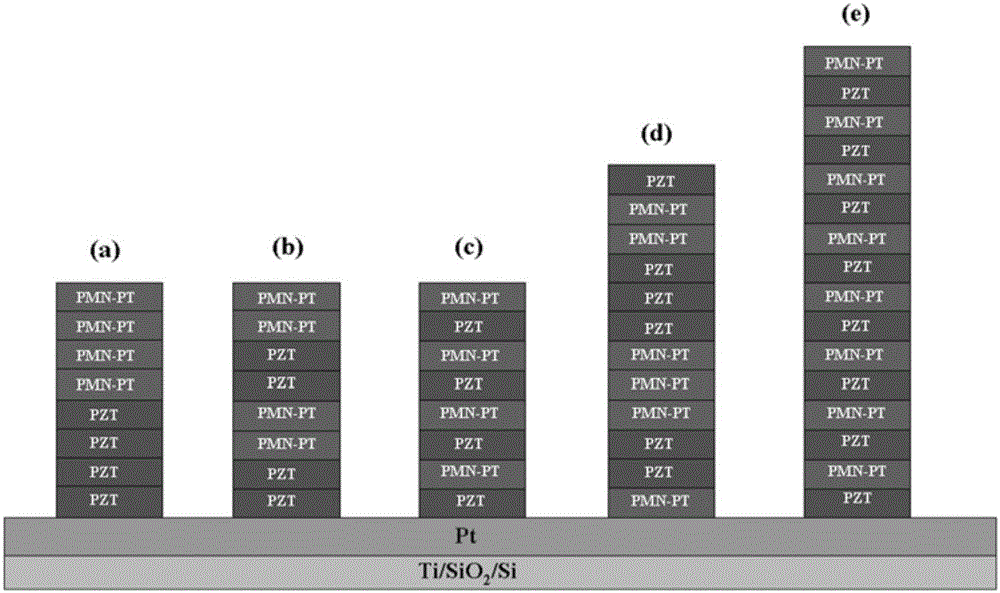

ActiveCN106835080AApplicable temperature rangeIncrease wideningLiquid/solution decomposition chemical coatingCapacitanceLead zirconate titanate

The invention relates to a lead magnesium niobate-lead titanate and lead zirconate titanate alloplasmic structure film and a preparing method thereof. Lead magnesium niobate-lead titanate and lead zirconate titanate alloplasmic thin films form the multilayer alloplasmic structure film in different sequences. The temperature coefficient of capacitance is reduced, the dielectric peak widening is improved, and the application field of the film is widened; the dielectric property of the film is effectively improved, and the electric conductance of the film is reduced; meanwhile, the interface effect in the alloplasmic structure can effectively obstruct electronic and hole transmission, the leaked current is reduced, and the ferroelectric properties are improved.

Owner:WUHAN UNIV OF TECH +1

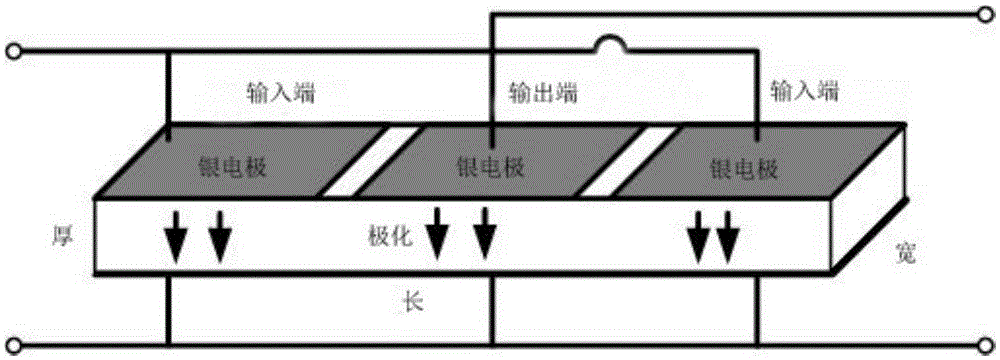

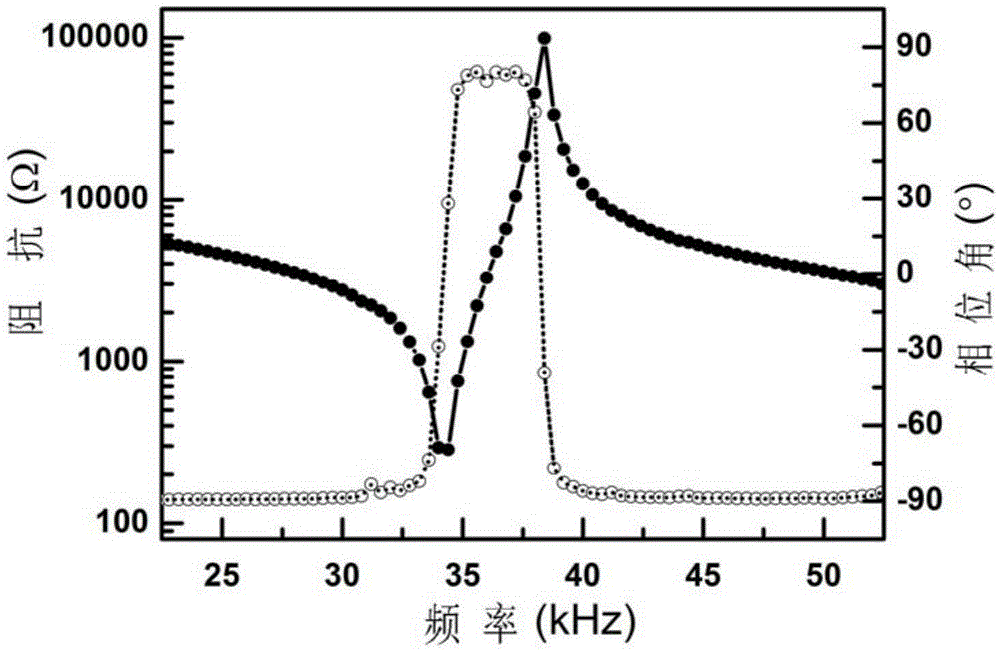

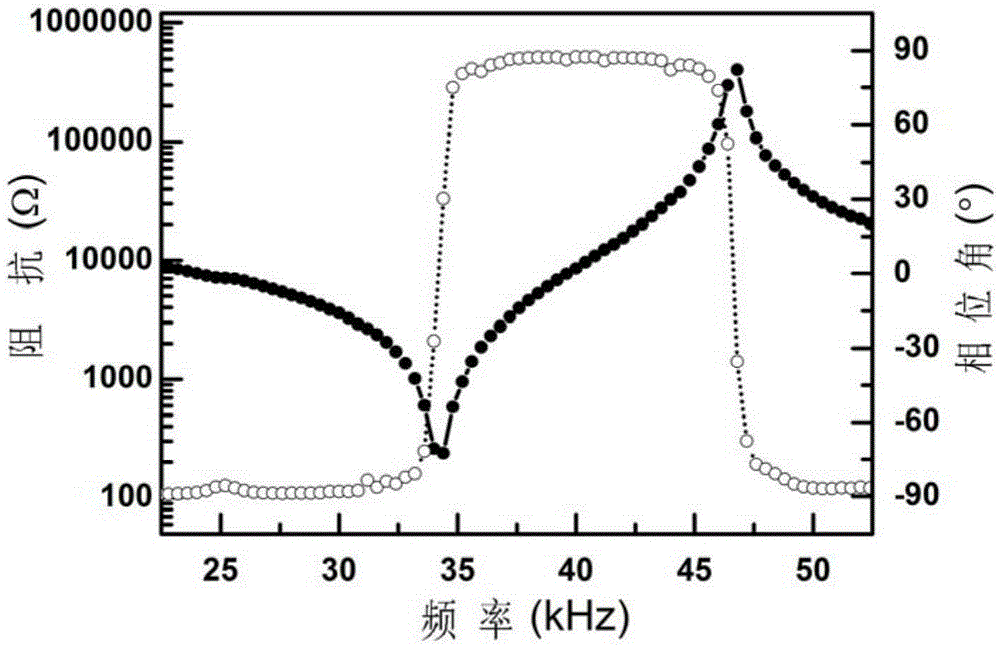

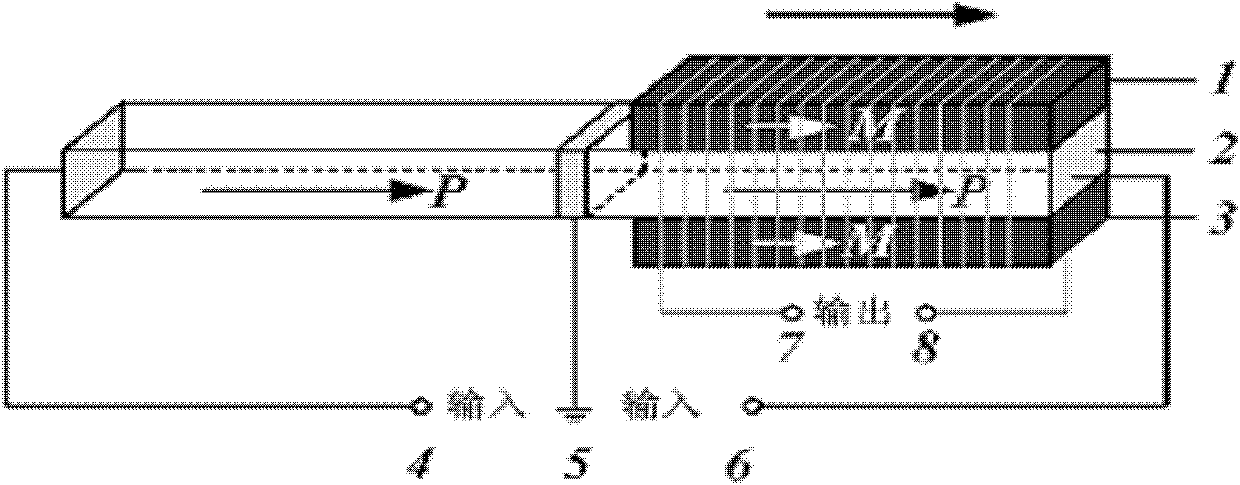

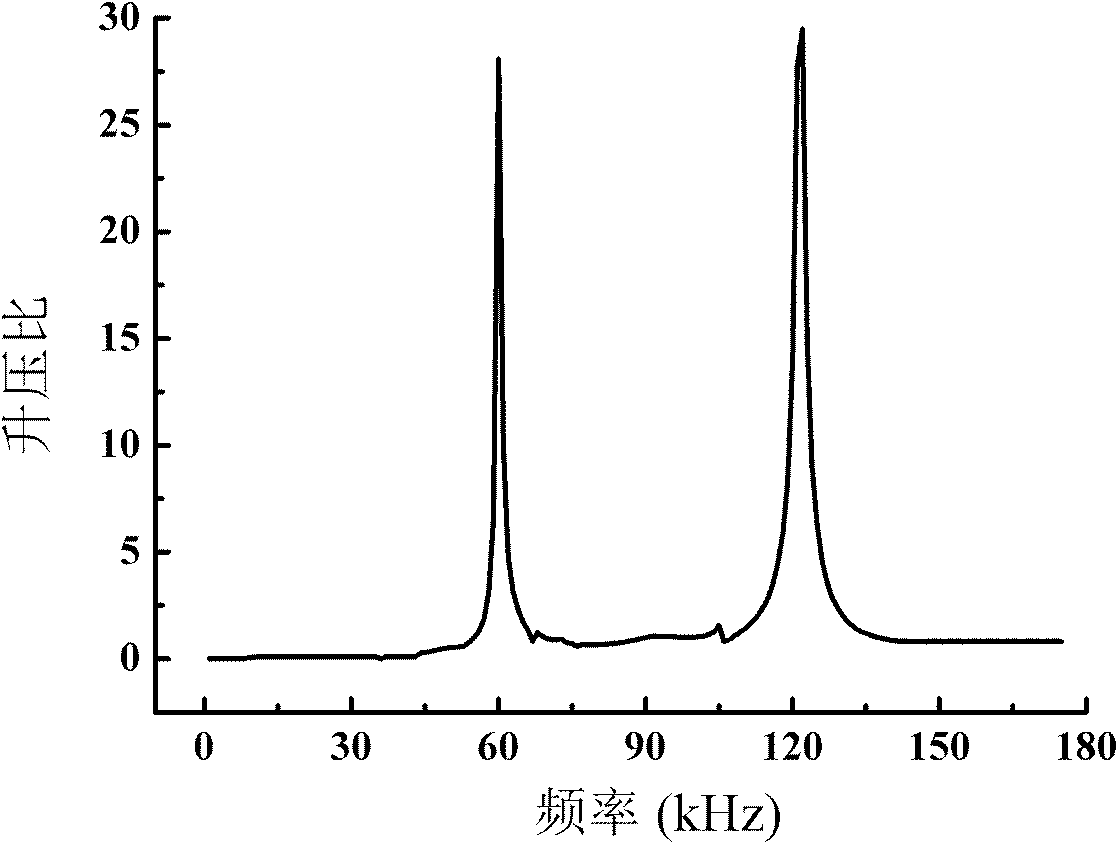

Ternary system relaxation ferroelectric monocrystal piezoelectric transformer having high power density

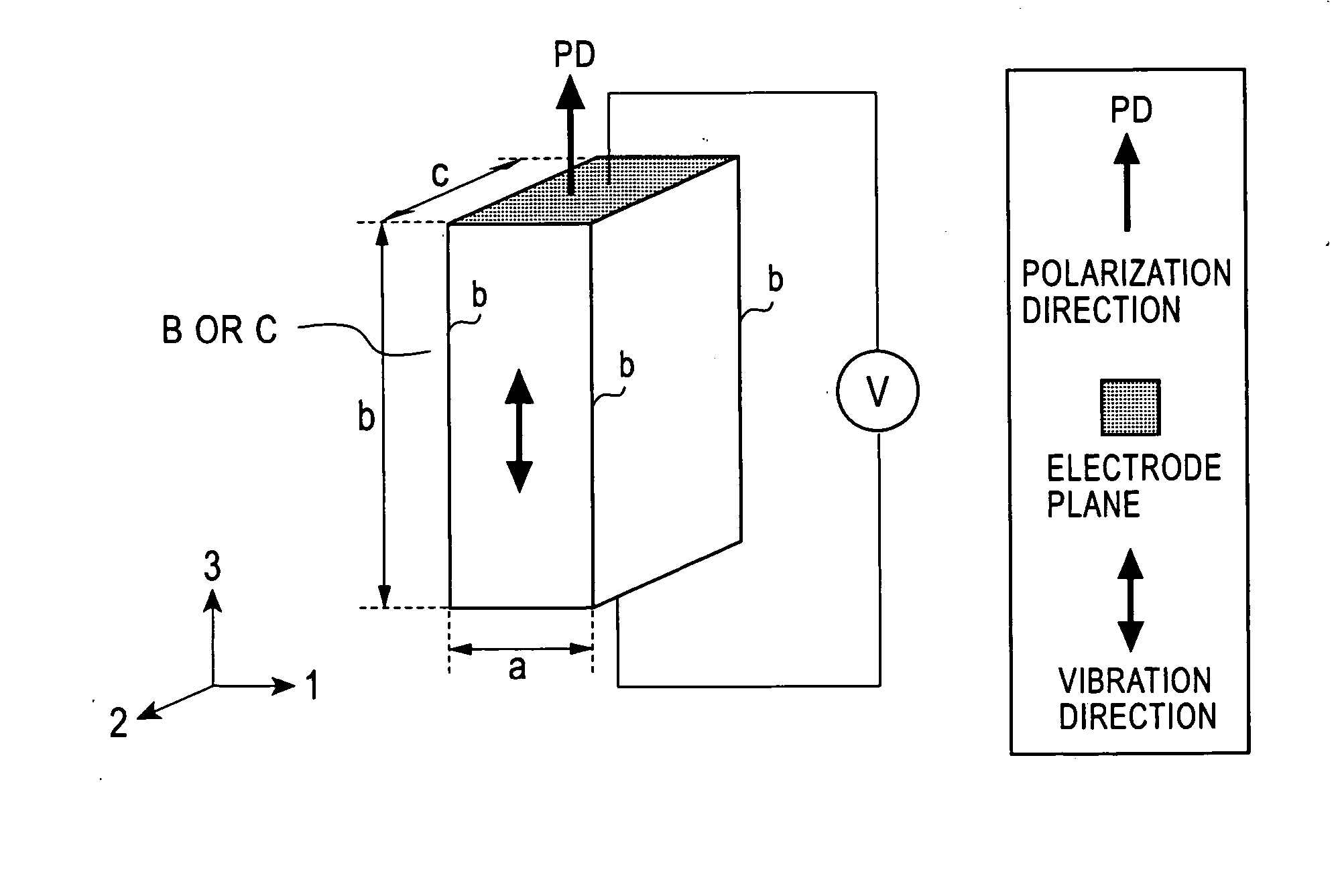

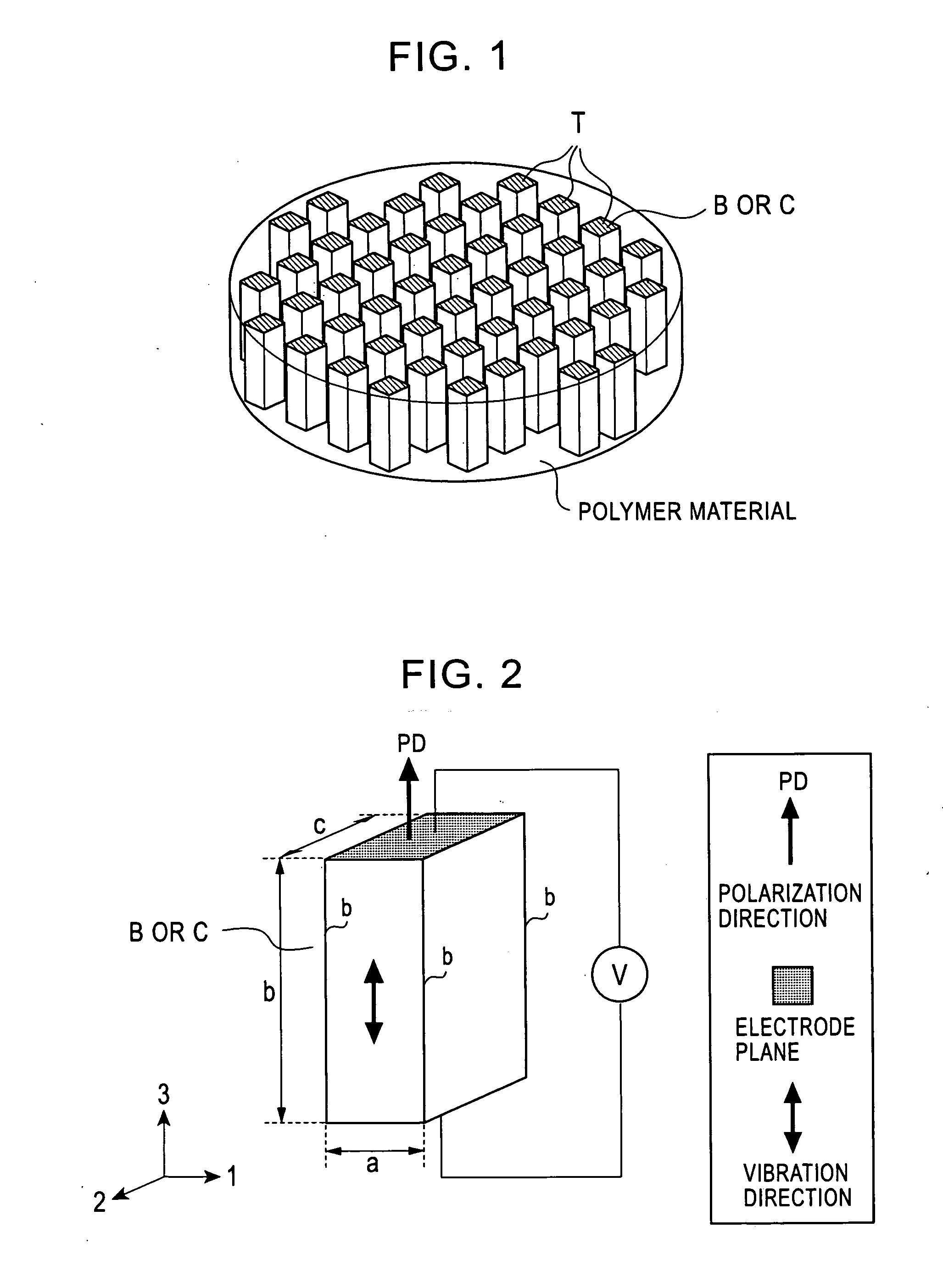

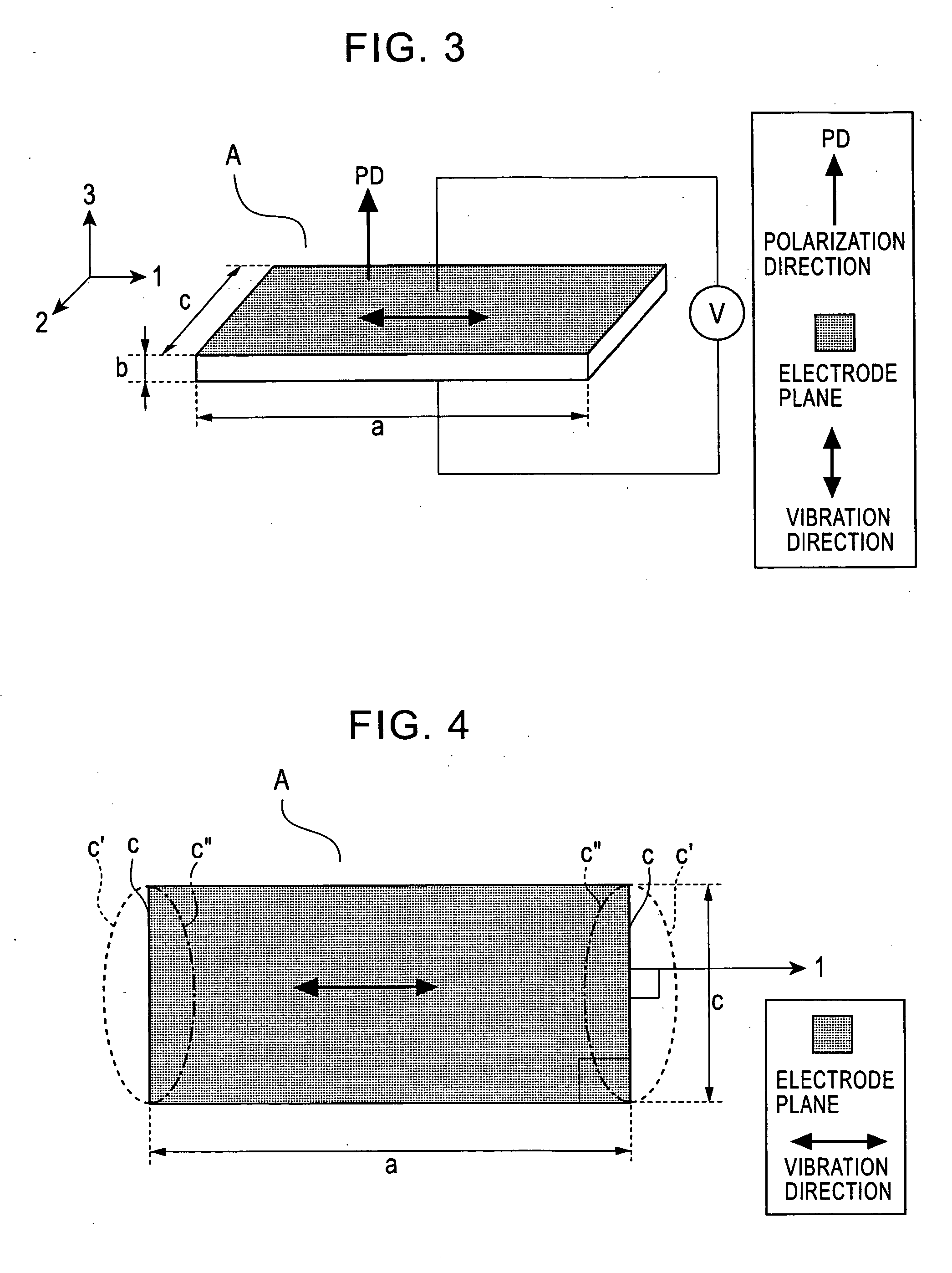

ActiveCN105405959AReduce volumeLight in massPiezoelectric/electrostrictive/magnetostrictive devicesInformation processingElectricity

The invention provides a ternary system relaxation ferroelectric monocrystal piezoelectric transformer having the high power density, the monocrystal piezoelectric transformer comprises a piezoelectric element, and a material of the piezoelectric element is lead magnesium niobate-lead indium niobate-lead titanate monocrystalline. The ternary system relaxation ferroelectric monocrystal piezoelectric transformer provided in the invention has the advantages of the small volume, the light weight and simple manufacture; the power density of a current piezoelectric transformer can be obviously improved, and requirements of micromation and integration of related information processing equipment are met; and the ternary system relaxation ferroelectric monocrystal piezoelectric transformer is a power device having simple structure and excellent comprehensive performance.

Owner:SHANGHAI NORMAL UNIVERSITY

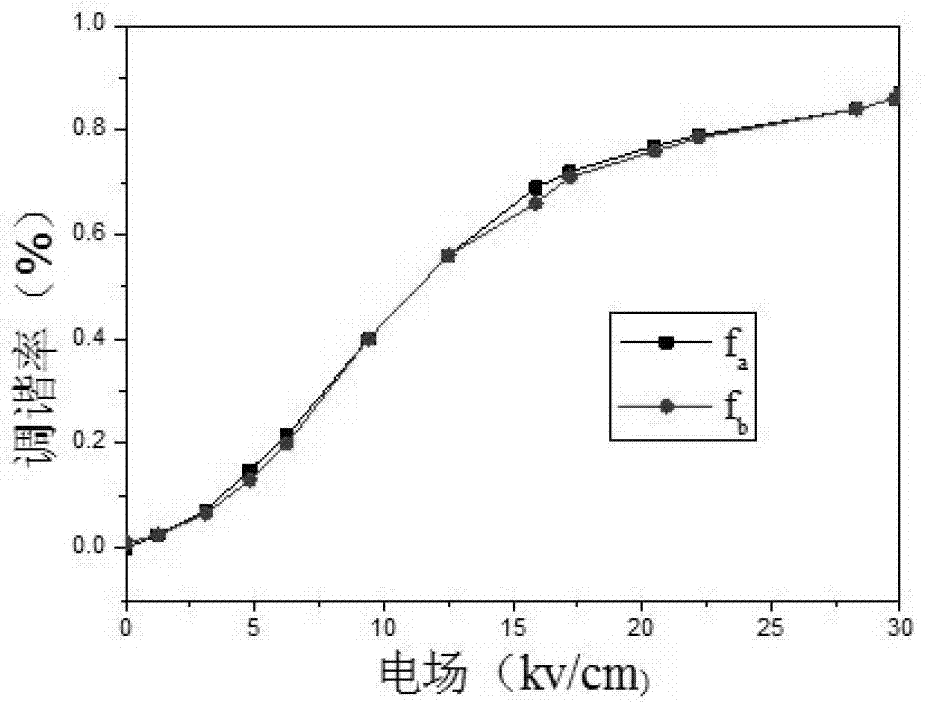

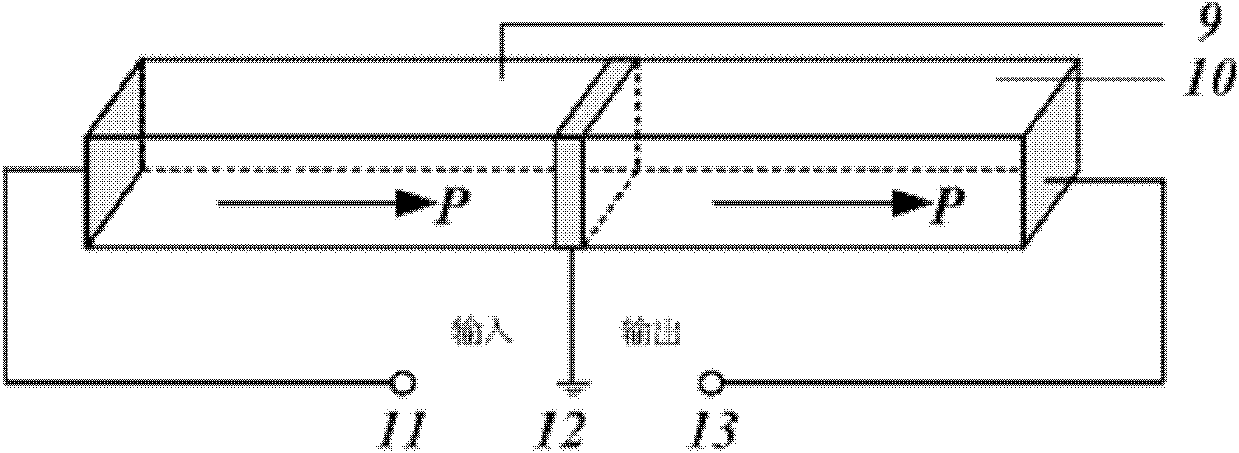

Method for preparing transparent photoelectric ceramic-base tunable wave filter

The invention discloses a method for preparing a transparent photoelectric ceramic-base tunable Fabry-Perot cavity wave filter. The tunable Fabry-Perot cavity wave filter comprises a collimator composed of a self-focusing lens and a tail fiber, novel plumbum magnesio niobate-plumbum titanate (PMN-PT) photoelectric transparent ceramics and a cylindrical metal cavity, wherein the end surface of the collimator is coated with an antireflection film; the novel plumbum magnesio niobate-plumbum titanate (PMN-PT) photoelectric transparent ceramics are coated with an antireflection film, a high reflective film and a transparent electrode; and the novel plumbum magnesio niobate-plumbum titanate (PMN-PT) photoelectric transparent ceramic block, both ends of which are respectively coated with a high reflective film, forms the Fabry-Perot cavity. The birefringent effect which is generated from the optical waves in the cavity when the voltage changes, and the multipass interference effect formed along with the reflection are utilized to carry out the tunable filtering. The wave filter has the advantages of low requirement for rear end equipment, small volume and stable performance, is suitable for mass production and can be widely used in optical fiber sensing systems.

Owner:WUHAN UNIV OF TECH

Preparation method for relaxor ferroelectric single crystal raw material

The invention discloses a preparation method for a relaxor ferroelectric single crystal raw material. The relaxor ferroelectric single crystal raw material comprises lead magnesium niobate-lead titanate (PMN-PT), lead zinc niobate-lead titanate (PZN-PT), lead indium niobate-lead titanate (PIN-PT), lead indium niobate-lead magnesium niobate-lead titanate (PIN-PMN-PT) as well as PMN-PT, PZN-PT, PIN-PT and PIN-PMN-PT which are subjected to doping modification. The preparation method comprises the following steps: adopting basic magnesium carbonate containing crystal water, rutile titanium dioxide, high-purity niobium pentoxide, high-purity indium sesquioxide, high-purity zinc oxide and high-purity lead oxide as raw materials, performing step sintering to finally synthesize a single crystal raw material of required chemical composition, performing processes of secondary ball milling, drying, granulating, forming, adhesive removal, ceramic firing and the like on the synthesized single crystal raw material to prepare a ceramic raw material matched with a growth crucible in shape, and filling the growth crucible with the ceramic raw material. According to the preparation method, the quality of finished crystals can be remarkably improved and the seepage risk of the crucible can be reduced.

Owner:XI AN JIAOTONG UNIV

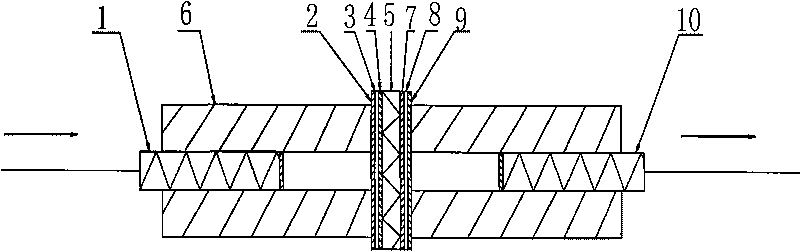

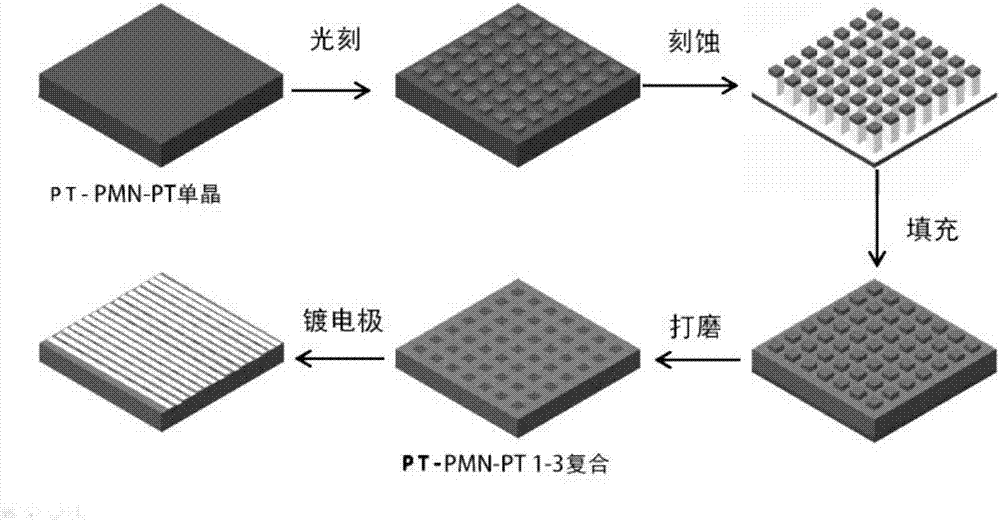

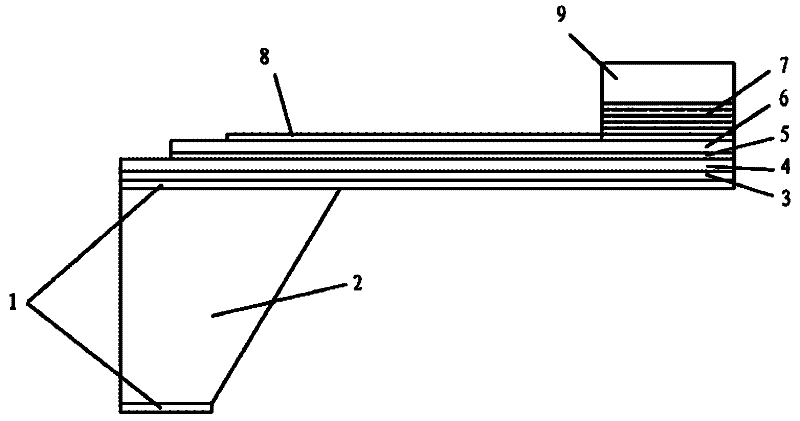

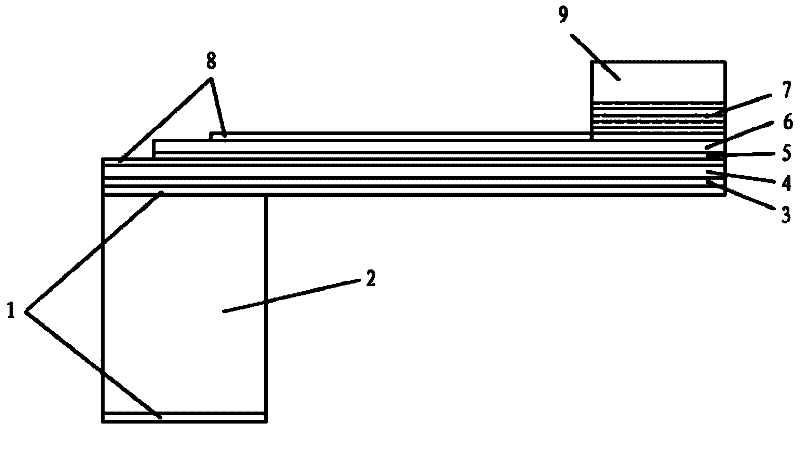

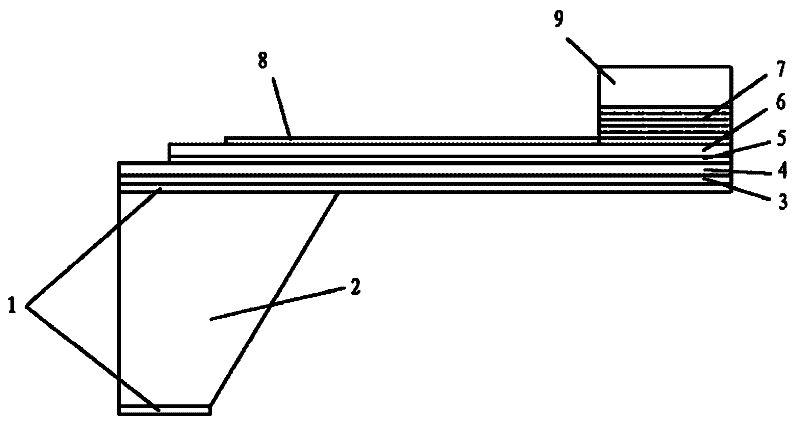

One dimensional ultrasound phased array probe based on PIN-PMN-PT (lead indium niobate-lead magnesium niobate-lead titanate) ternary system piezoelectric monocrystalline and preparing method

InactiveCN106890783AImprove performanceHigh curie temperatureMechanical vibrations separationIndiumFlexible circuits

The invention discloses a one dimensional ultrasound phased array probe based on a PIN-PMN-PT (lead indium niobate-lead magnesium niobate-lead titanate) ternary system piezoelectric monocrystalline and a preparing method thereof. The phased array probe comprises a lower electrode, a 1-3 composite PIN-PMN-PT piezoelectric monocrystalline array, an upper electrode array and a flexible circuit board which are laminated from bottom to top in sequence; array elements of the upper electrode array and the array elements of the piezoelectric monocrystalline array correspond one to one, and print circuit passages on the flexible circuit board correspond to the array elements on the upper electrode array; a preparing method comprises adopting a photoetching and etching method for grooving to form the 1-3 composite PIN-PMN-PT piezoelectric monocrystalline array, and forming the lower electrode on a piezoelectric plate of the lower bottom surface of the PIN-PMN-PT piezoelectric monocrystalline array through a sputtering process, forming upper electrodes on the upper surface of the piezoelectric monocrystalline array and adopting the flexible circuit board to provide a lead for the electrodes to be connected to an external circuit. The one dimensional ultrasound phased array probe can bear higher working temperature and electric field.

Owner:HUAZHONG UNIV OF SCI & TECH

MEMS (Micro-electromechanical Systems) wideband frequency vibration energy collector based on PMNT (Lead Magnesium Niobate-Lead Titanate) piezoelectric mono-crystal, and preparation method

InactiveCN102544349AImprove output characteristicsChange natural frequencyPiezoelectric/electrostrictive device manufacture/assemblyDecorative surface effectsMechanical energySingle crystal

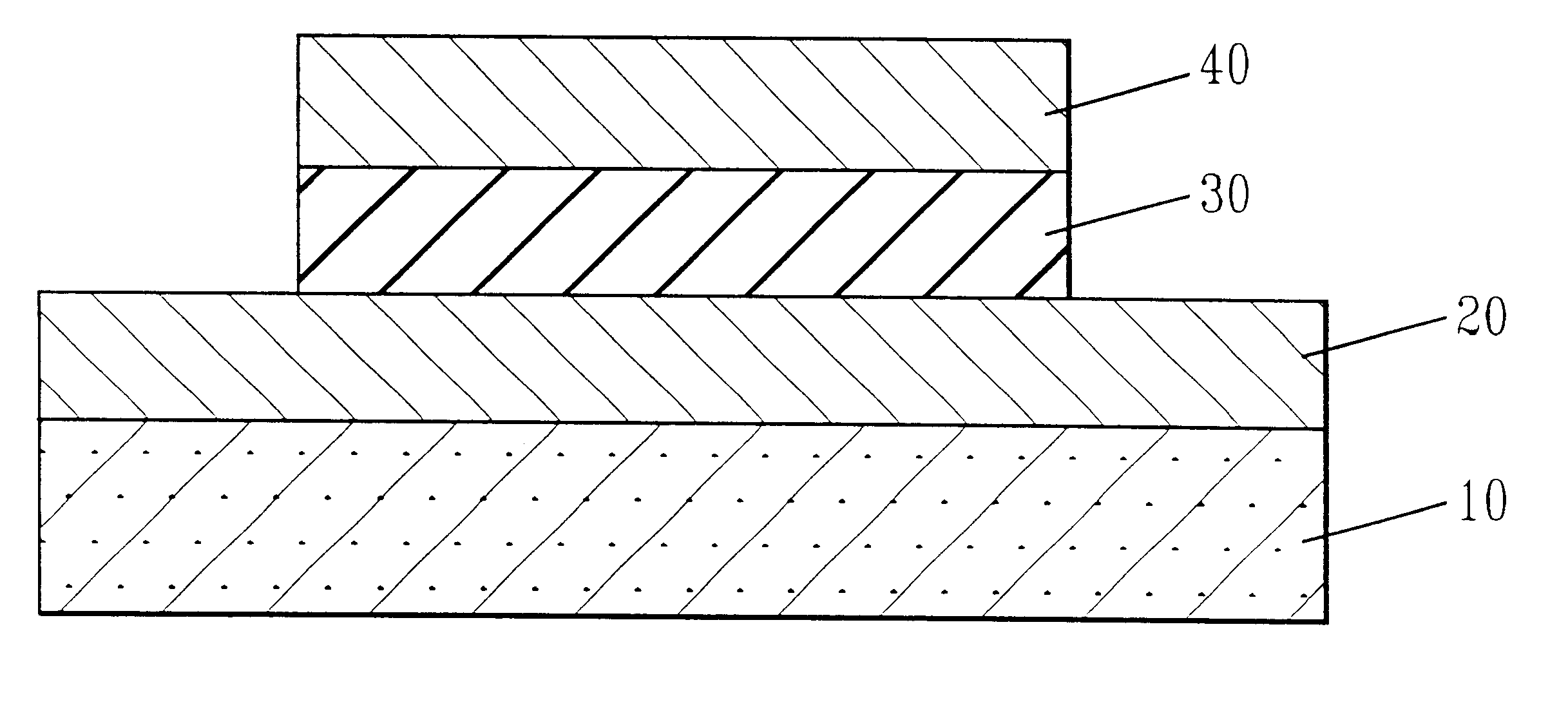

The invention provides an MEMS (Micro-electromechanical Systems) wideband frequency vibration energy collector based on PMNT (Lead Magnesium Niobate-Lead Titanate) piezoelectric mono-crystal. The device is a piezoelectric device which converts mechanical energy of flexural vibration into electric energy and comprises a silicon fixing seat, a support layer, a PMNT piezoelectric film layer and a mass block, wherein the silicon fixing seat, the support layer and the PMNT piezoelectric film layer are adhered sequentially to form a multilayer structure; one end of the multilayer structure is suspended; and the mass block is fixed on a free end of the multiplayer structure. According to the invention, PMNT mono-crystal which has better piezoelectric performance is adopted as piezoelectric material, and PMNT piezoelectric films having high performance are manufactured with a bonding and thinning method, such that the output property of the device can be improved effectively, and the conversion efficiency is increased; at the same time, a micro-container which is fixed at the end part of a cantilever and is full of liquid is adopted, such that inherent frequency of the device under a vibration condition can be changed effectively in real time, and the vibration frequency of the environment is matched better, and the device can obtain stable output in the vibration environment within a relatively wide frequency scope.

Owner:SHANGHAI JIAO TONG UNIV

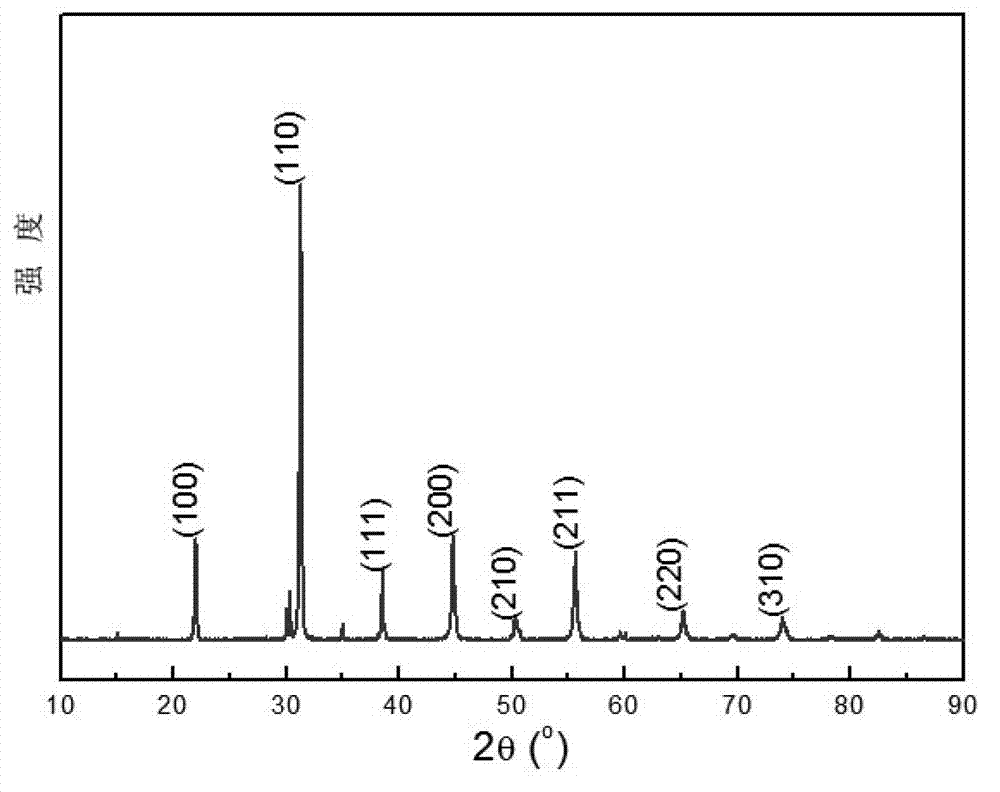

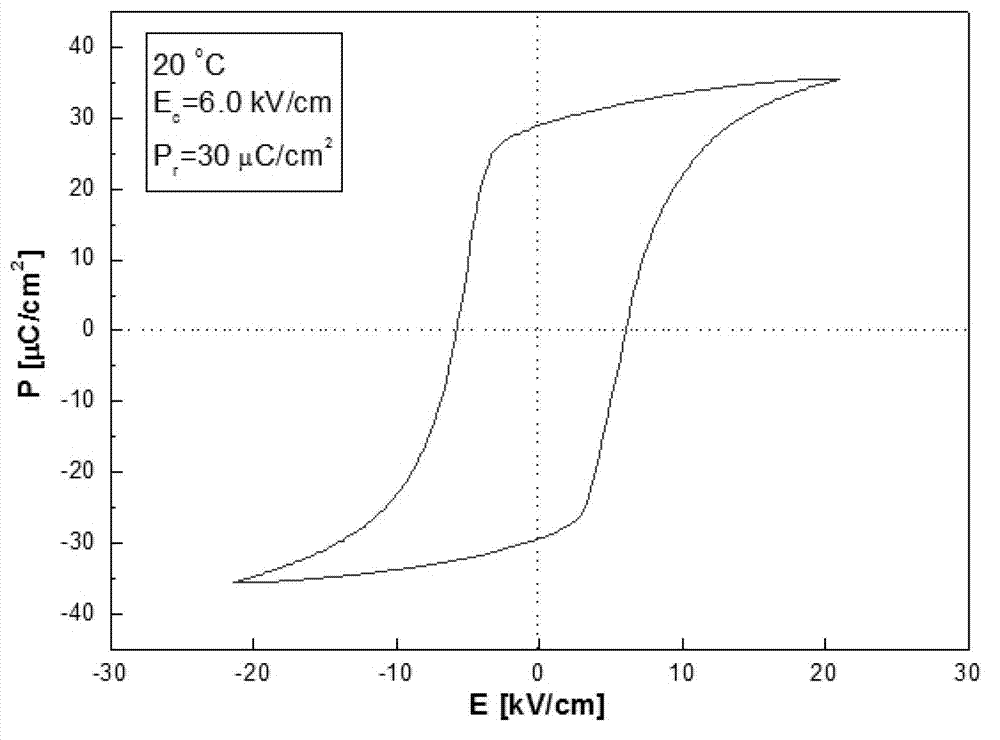

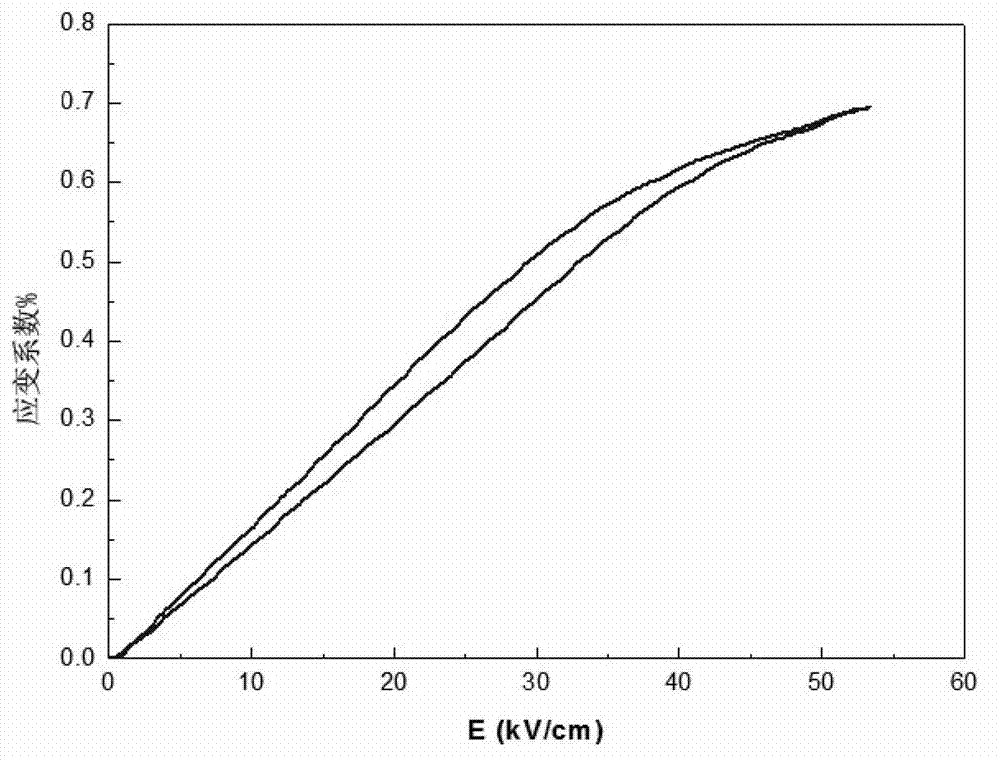

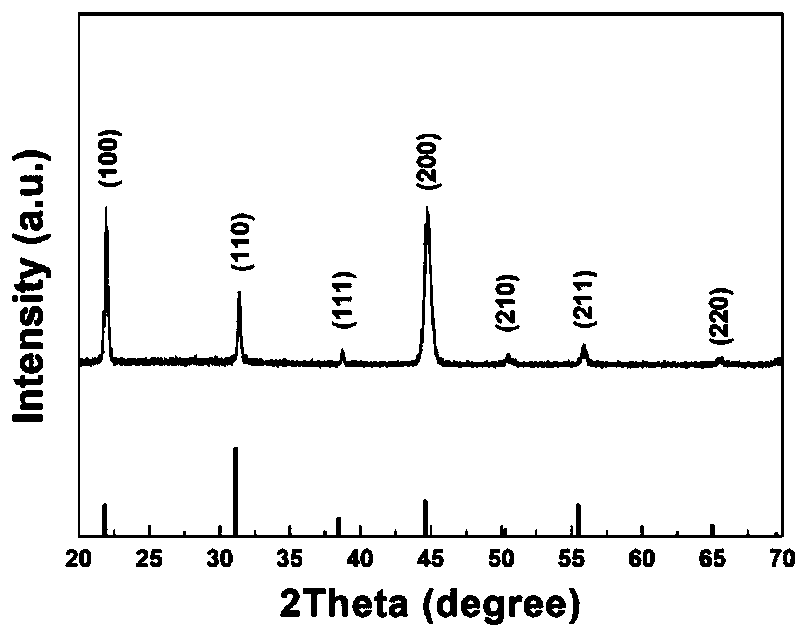

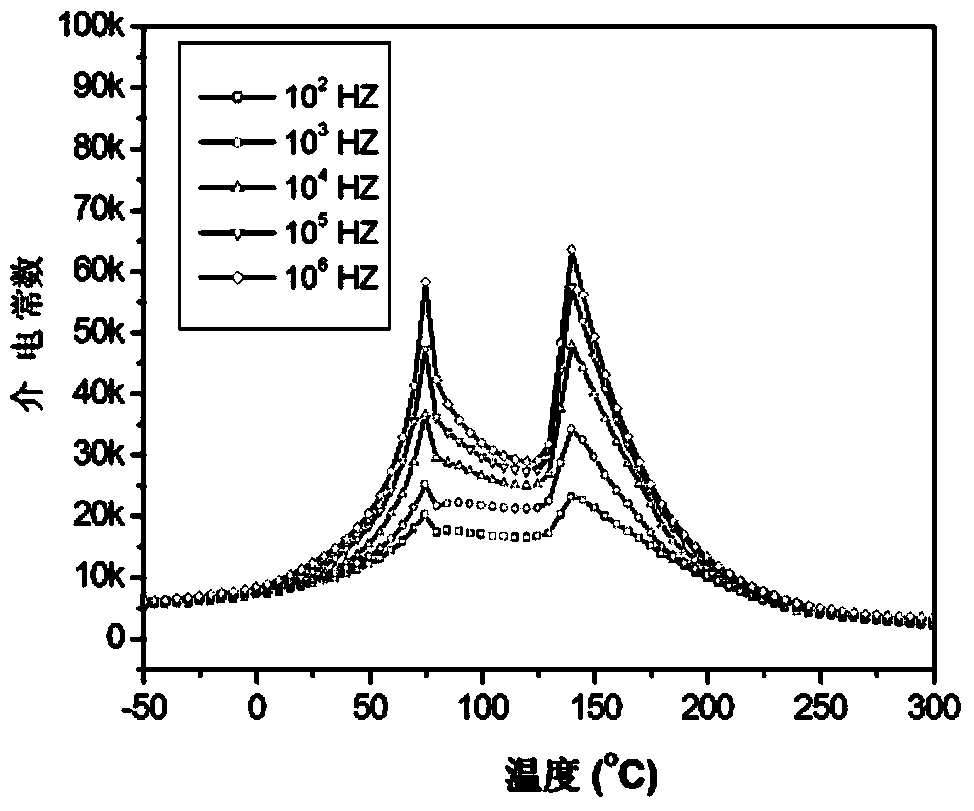

Ternary ferroelectric solid solution lead lutecium niobate-lead magnesium niobate-lead titanate

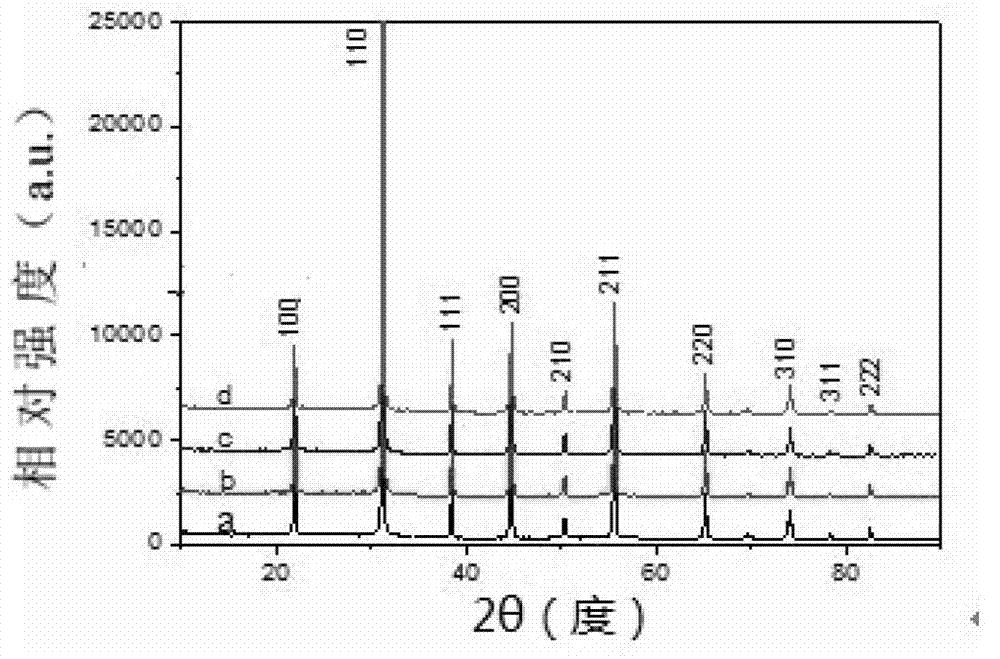

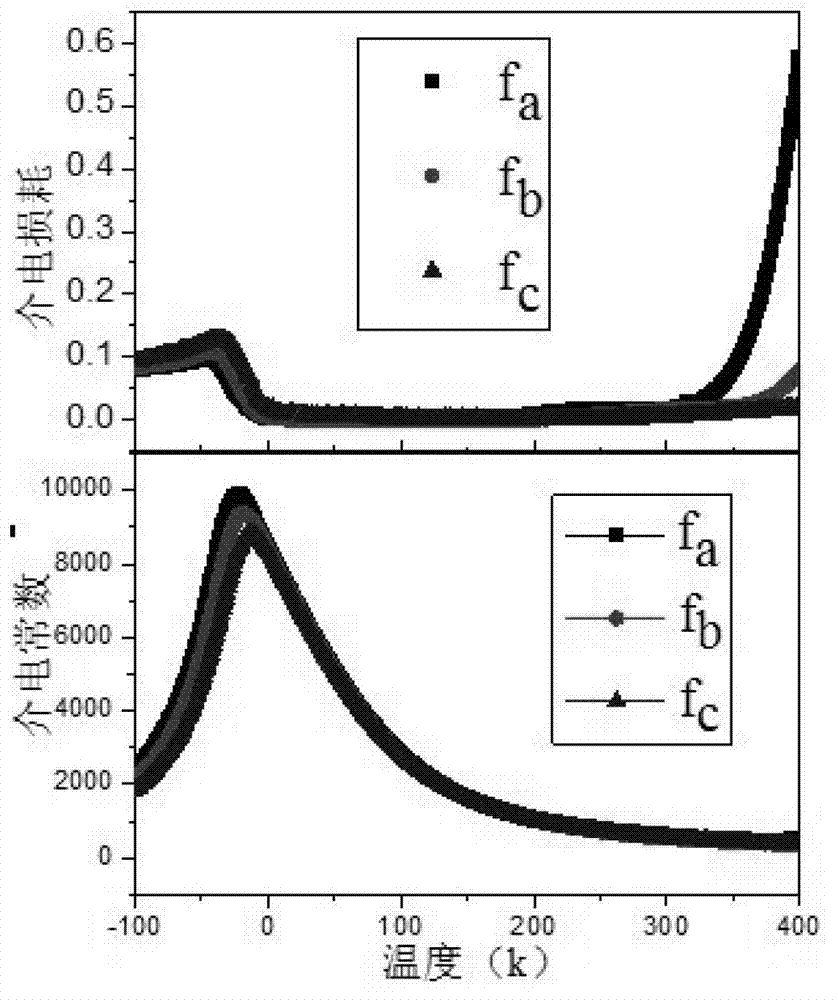

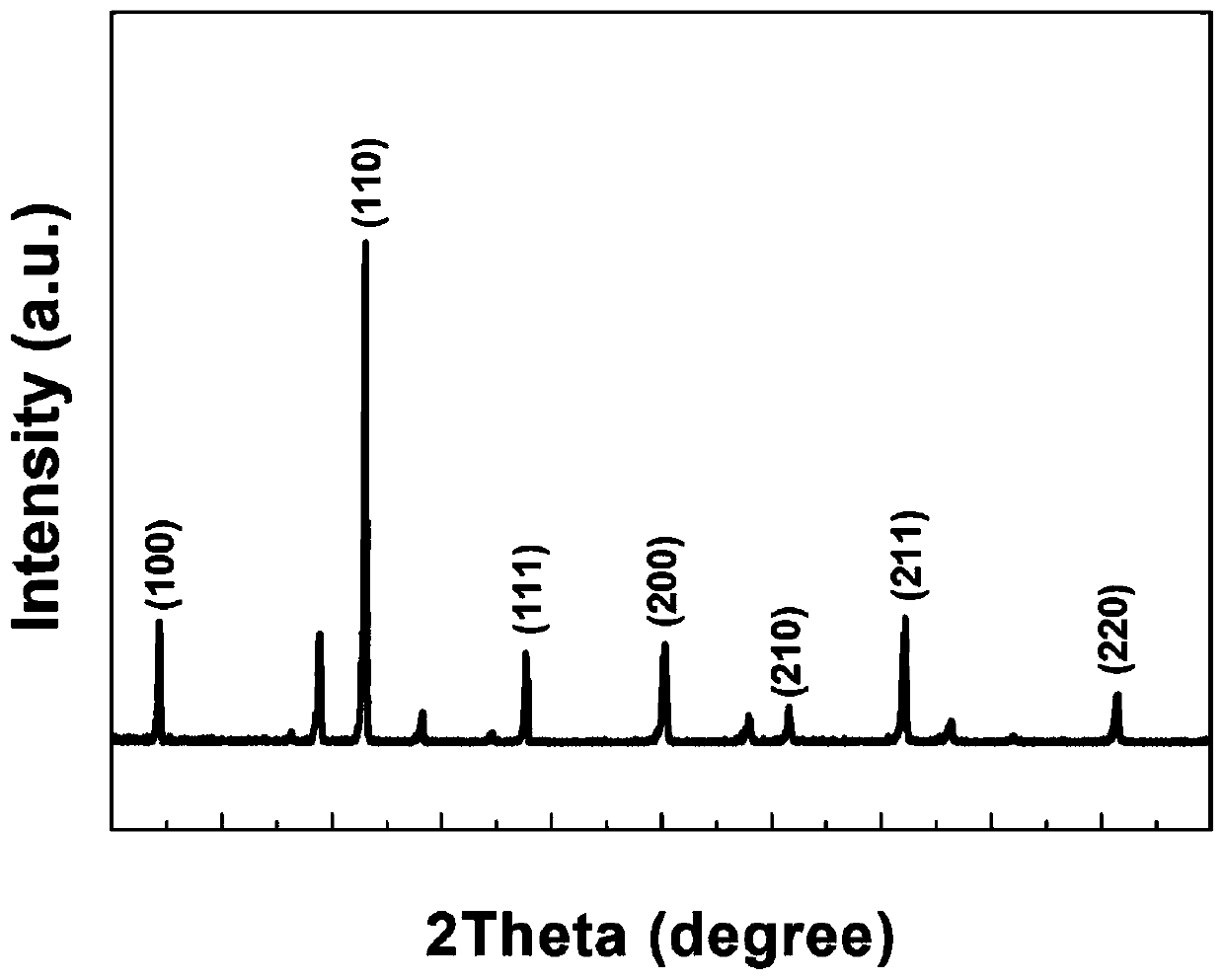

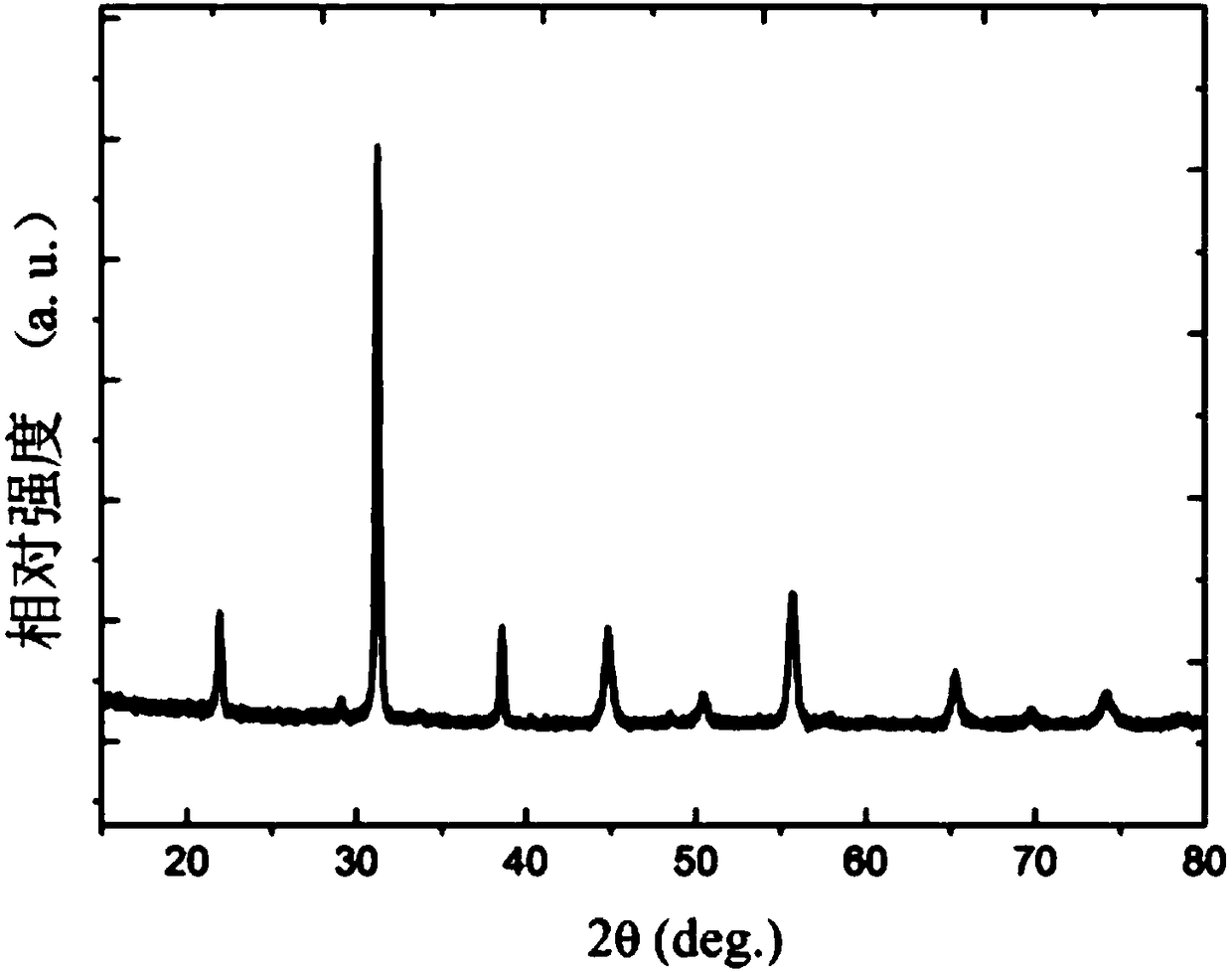

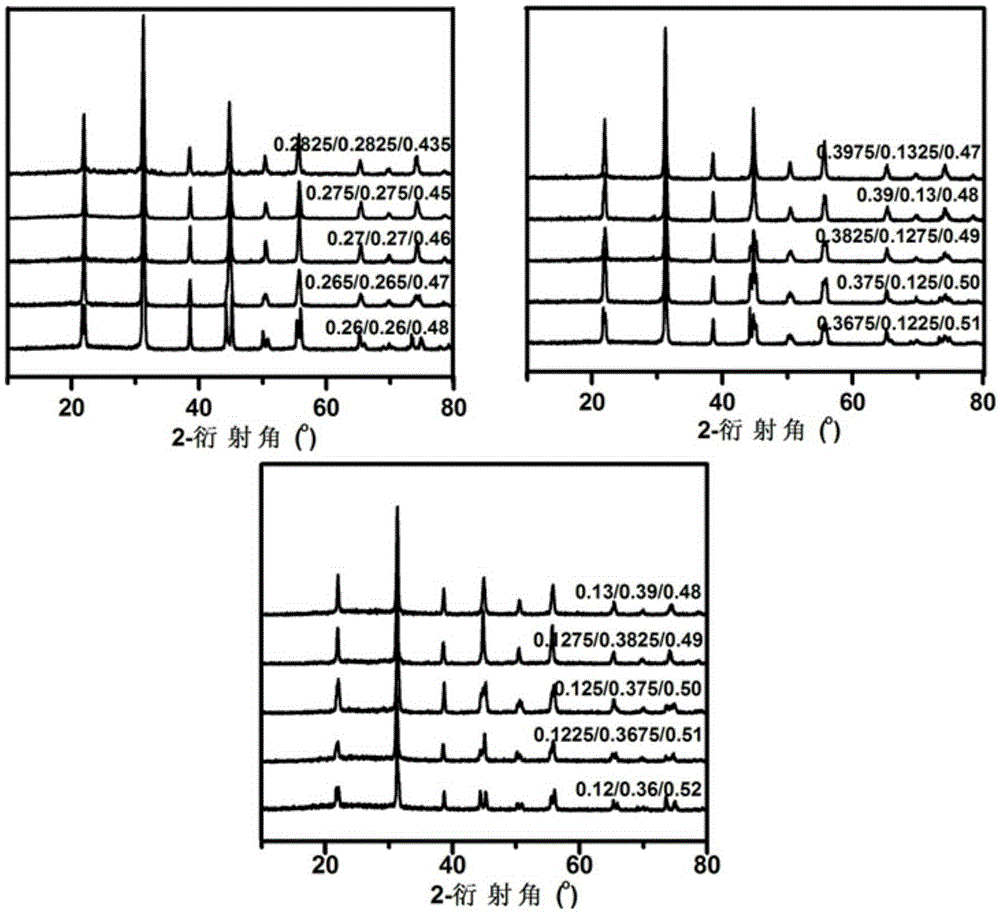

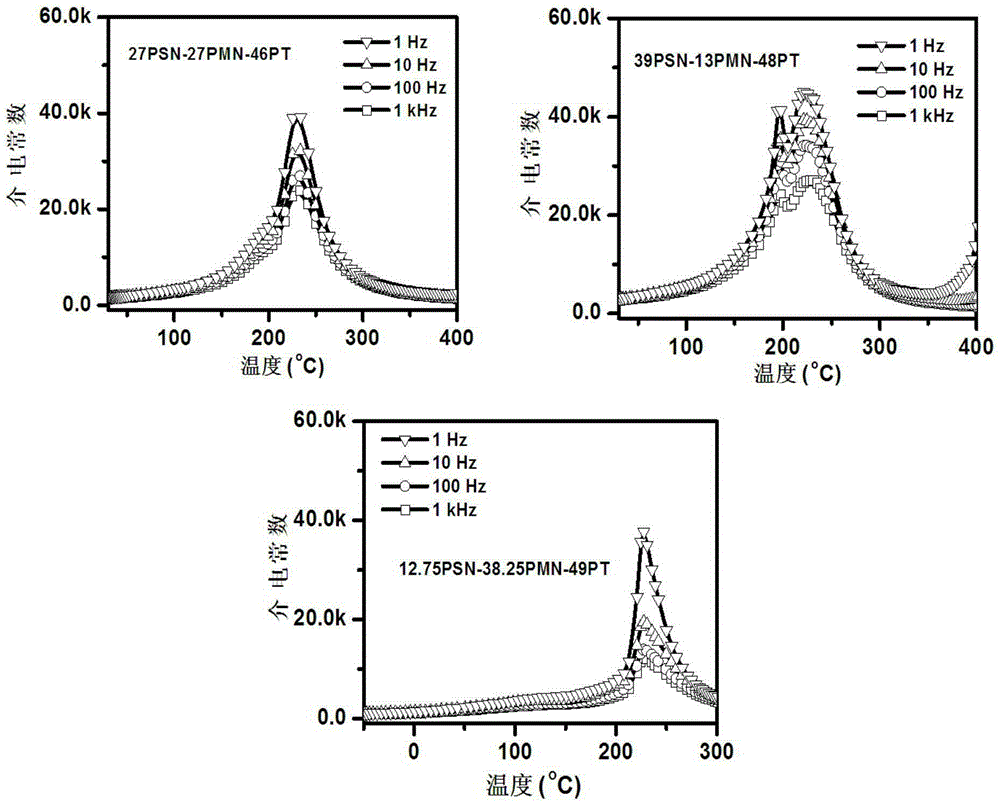

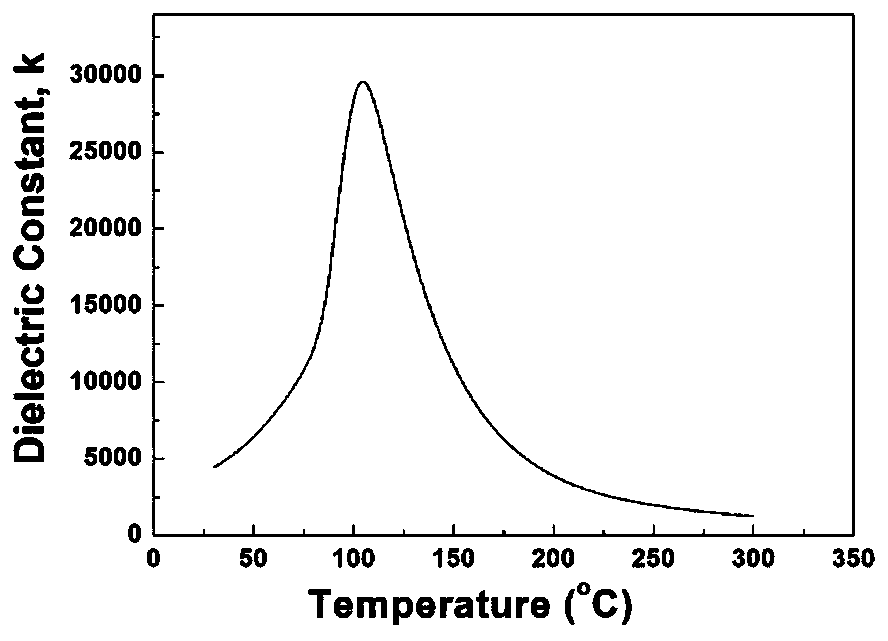

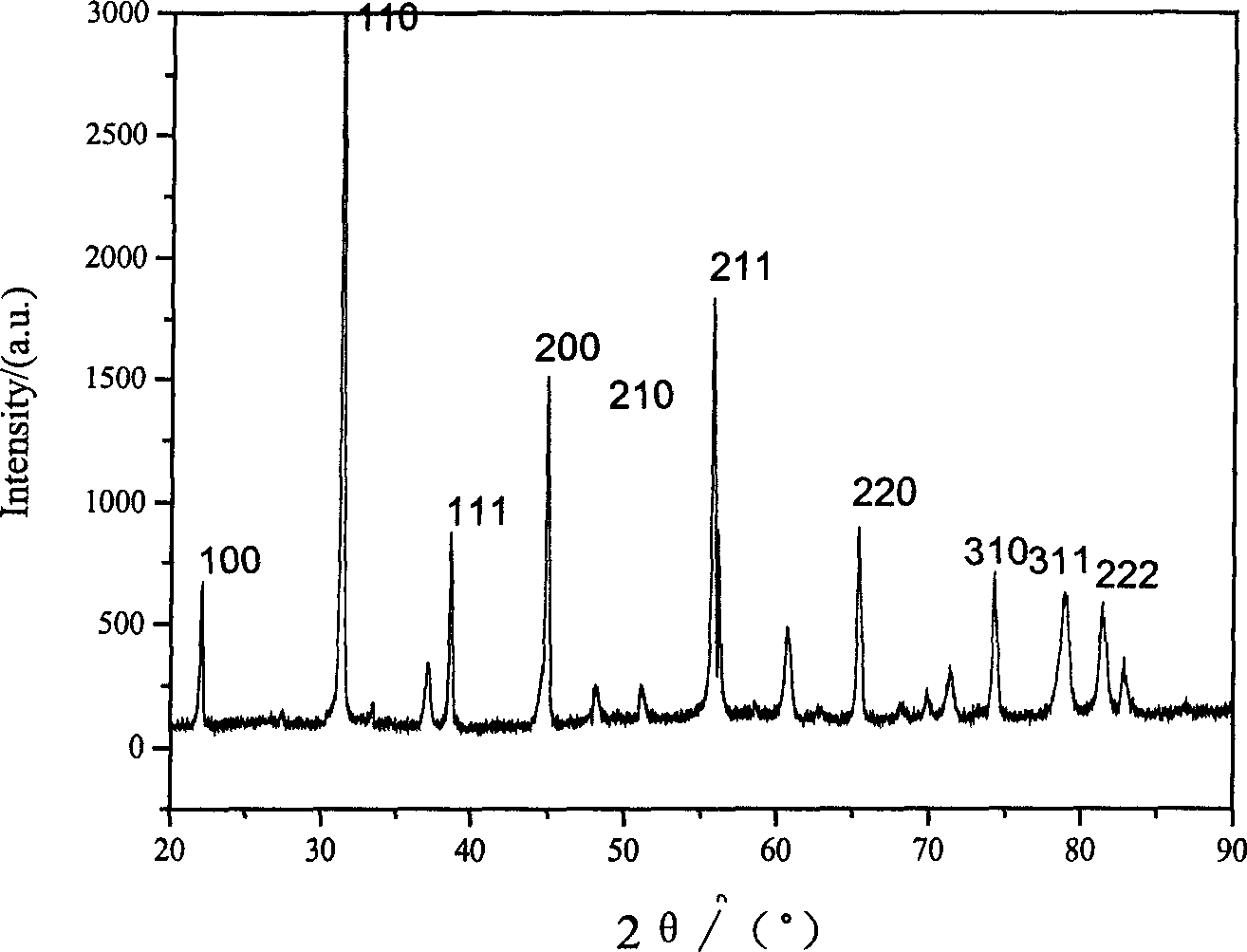

ActiveCN103011815AExcellent piezoelectric propertiesImprove thermal stabilityPiezoelectric/electrostrictive/magnetostrictive devicesElectricityX-ray

The invention relates to a ferroelectric solid solution lead lutecium niobate-lead magnesium niobate-lead titanate and a preparation method and application thereof. Such a solid solution system is determined to be a perovskite structure through X-ray powder diffraction, and ferroelectricity, dielectricity and piezo-electricity of the solid solution system are analyzed by using ferroelectric, dielectric and piezoelectric measurement. Based on measurement and analysis of the structure and dielectricity of the solid solution system, MPB composition of the ternary ferroelectric solid solution system is obtained. The system has good piezoelectric and electromechanical properties, a high Curie temperature, good thermal stability and wide application prospects.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Praseodymium-doped indium lead magnesium niobate-lead titanate luminescent piezoelectric ceramic as well as preparation method and application thereof

ActiveCN108585852AImprove electromechanical performanceImprove luminous performancePiezoelectric/electrostrictive device material selectionRare-earth elementIndium

The invention discloses praseodymium-doped indium lead magnesium niobate-lead titanate luminescent piezoelectric ceramic as well as a preparation method and application thereof, belongs to the field of functional ceramic materials and particularly relates to the praseodymium-doped indium lead magnesium niobate-lead titanate luminescent piezoelectric ceramic as well as the preparation method and the application thereof. The invention aims at solving the problem of extremely-low electromechanical properties of existing rare earth element doped piezoelectric ceramic. A chemical formula of the piezoelectric ceramic is 0.24Pb(In1 / 2Nb1 / 2)O3-0.42Pb(Mg1 / 3Nb2 / 3)O3-0.34PbTiO3:xPr<3+>, wherein x is mole fraction and is greater than 0 and is smaller than or equal to 0.02. The preparation method comprises the following steps: firstly, synthesizing an InNbO4 and MgNb2O6 precursor; secondly, preparing by taking InNbO4, MgNb2O6, PbO, TiO2 and Pr6O11 as raw materials; thirdly, carrying out gold platingon an electrode and polarization treatment to obtain the piezoelectric ceramic. The praseodymium-doped indium lead magnesium niobate-lead titanate luminescent piezoelectric ceramic disclosed by the invention is used for high-sensitivity temperature sensing and electro-optical control.

Owner:HARBIN INST OF TECH

An infinitely mixable and meltable ferroelectric solid solution monocrystalline lead scandium niobate-lead magnesium niobate-lead titanate and a preparing method thereof

ActiveCN106637405AMeet stability requirementsFulfil requirementsPolycrystalline material growthFrom frozen solutionsCurie temperatureSolid solution

The invention relates to ferroelectric solid solution monocrystalline lead scandium niobate-lead magnesium niobate-lead titanate and a preparing method thereof. A top seed crystal growth process is adopted to perform growth. The process is simple, and the prepared crystal has excellent performance. The ferroelectric solid solution monocrystalline lead scandium niobate-lead magnesium niobate-lead titanate has excellent piezoelectric performance and a high Curie temperature, can meet requirements of medicine and military application having very high requirements on material stability, and has good research and application value.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Textured rare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic material and preparation method thereof

InactiveCN110372381AImprove piezoelectric performanceGood value for moneyUltrasonic sensorRare earth

The invention provides a textured rare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic material and a preparation method thereof. The composition of the textured rare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic material is expressed by a following formula of [R<x>-Pb<1- 1.5x>][(Mg<1 / 3>Nb<2 / 3>)<1-y>Ti<y>]O3-avol.%BaTiO3, wherein <x> is greater than 0 and less than or equal to 0.03, <y> is greater than or equal to 0.29 and less than or equal to 0.325, a is greater than or equal to 0.01 and less than or equal to 0.1, <x> and <y> are mole numbers, and a is the volume percentage; R<x> is one of Sm<3+> or Dy<3+>; first higher piezoelectric activity is achieved in a matrix material through rare earth modification; then, ceramic crystal grains are subjected to oriented growth in a certain direction through texturing to further improve the piezoelectric property of the ceramic material; the texturedrare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic material prepared has a degree of texturing of 40-90% in the [001] direction, and the piezoelectric coefficient d<33> is 40%-80% higher than that of unmodified non-textured ceramic; the dielectric constant at a room temperature under the frequency of 1 kHz is about 1.8-2 times higher than that of theunmodified non-textured ceramic; the textured rare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic material can be applied to piezoelectric devices suchas ultrasonic transducers, drives and sensors; and the piezoelectric ceramic material is low in cost and simple in preparation process and is conducive to industrial production.

Owner:XI AN JIAOTONG UNIV +1

Process for preparing superfine powder of lead magnesium niobate-lead titanate solid solution

The preparation process of superfine lead magnesate niobate-lead titanate solid solution powder, unlike conventional superfine powder preparing process, adopts capillary with peristaltic pump to add sol slowly into alkali solution for controlling the powder producing condition and thus has short powder preparing period and lowered sintering temperature. During the powder drying stage, the cleaning with organic solvent and the vacuum freeze drying are combined to raise the dispersivity of prepared powder. The powder of the present invention has the feature of low sintering temperature, and, TEM, EDS and XRD test and analysis shows, has precise components, fine and homogeneous granularity, high dispersivity and complete perovskite phase structure.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

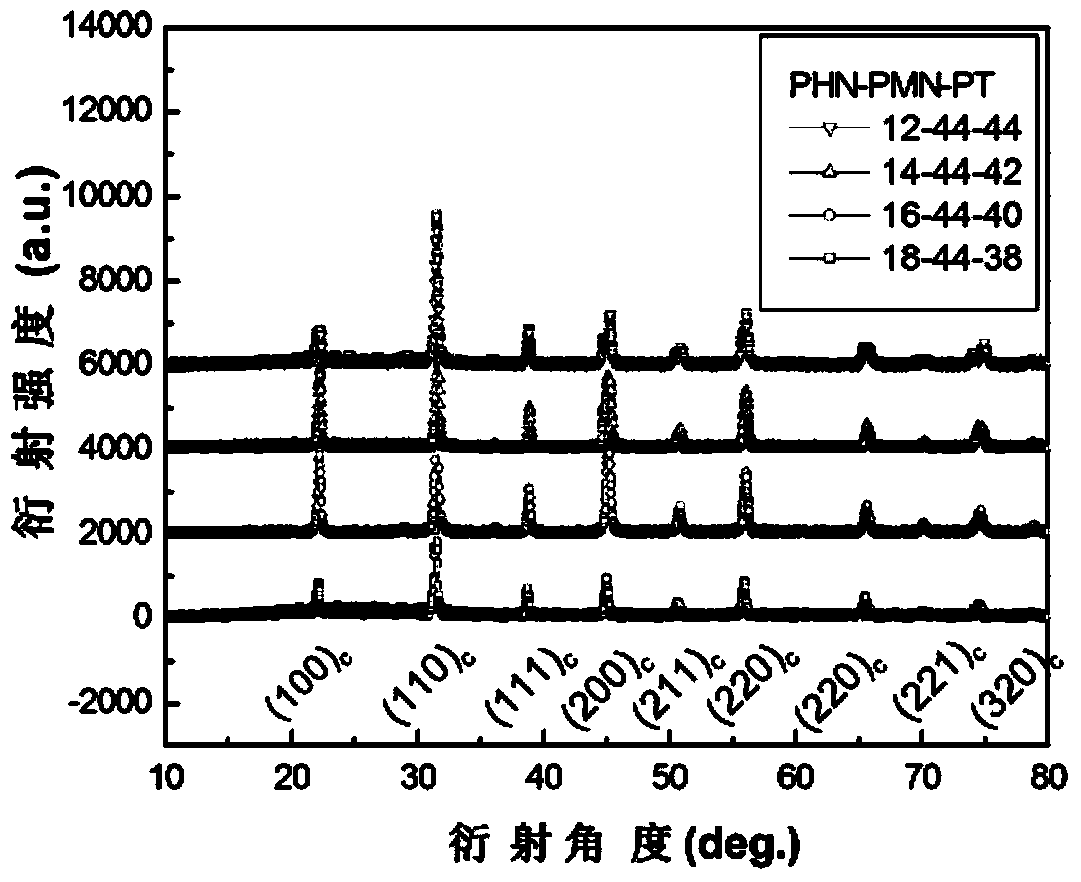

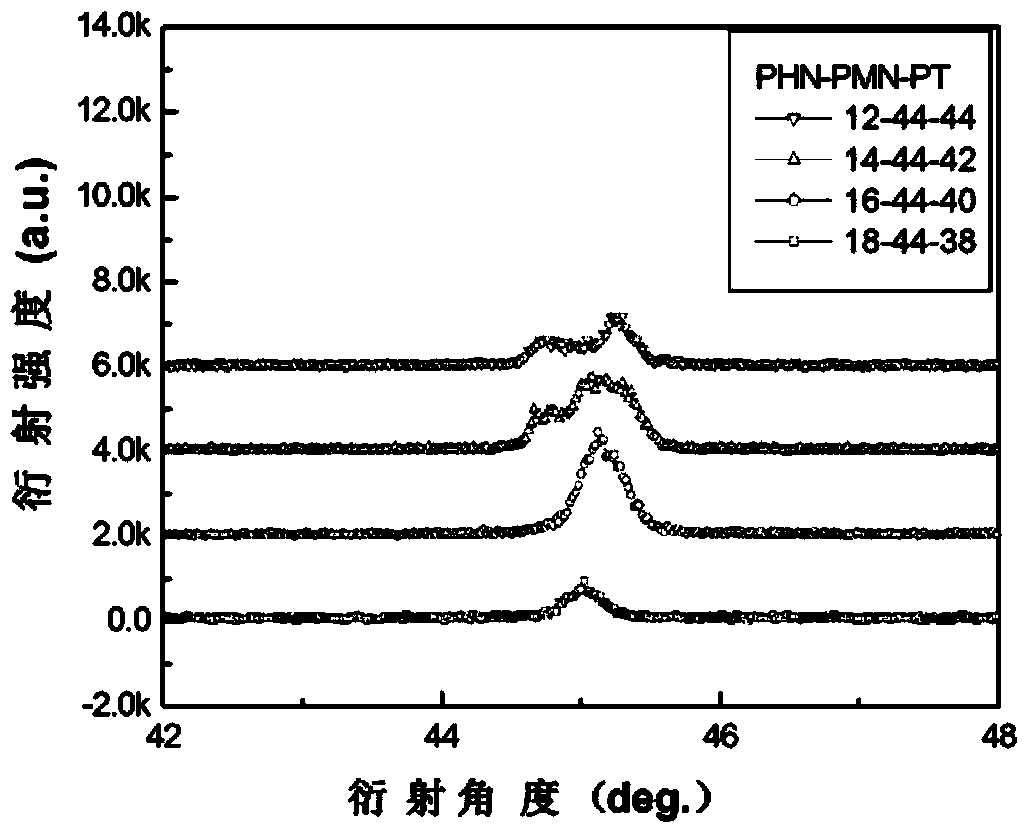

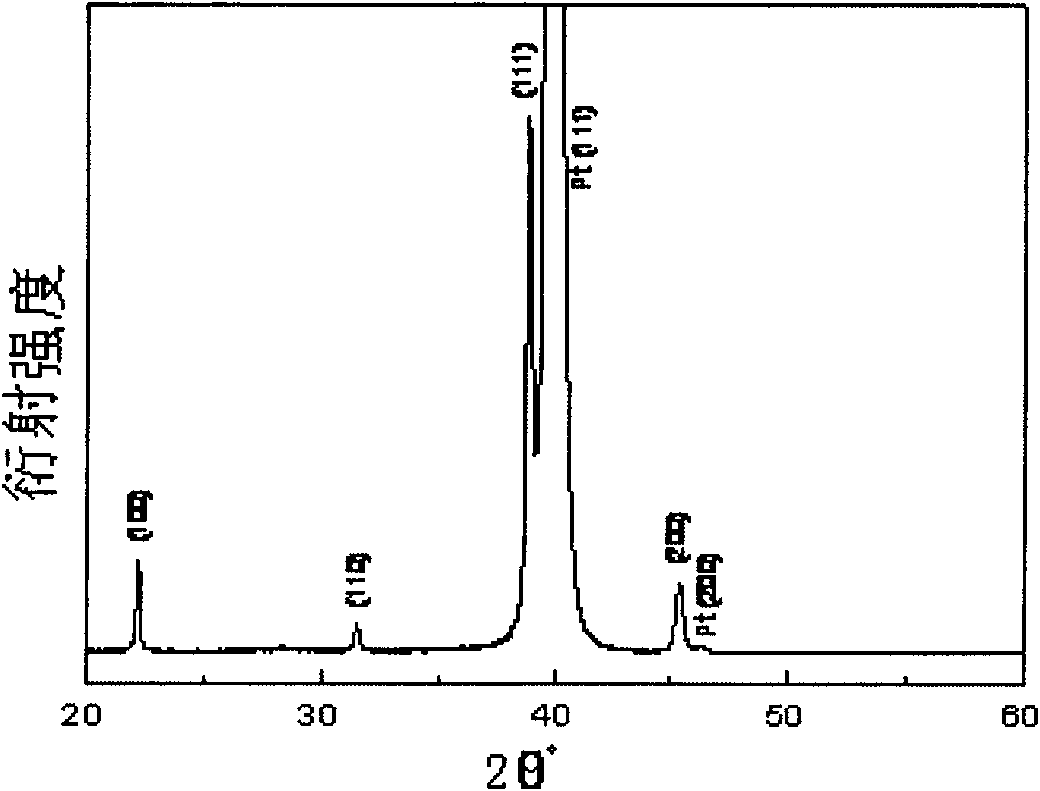

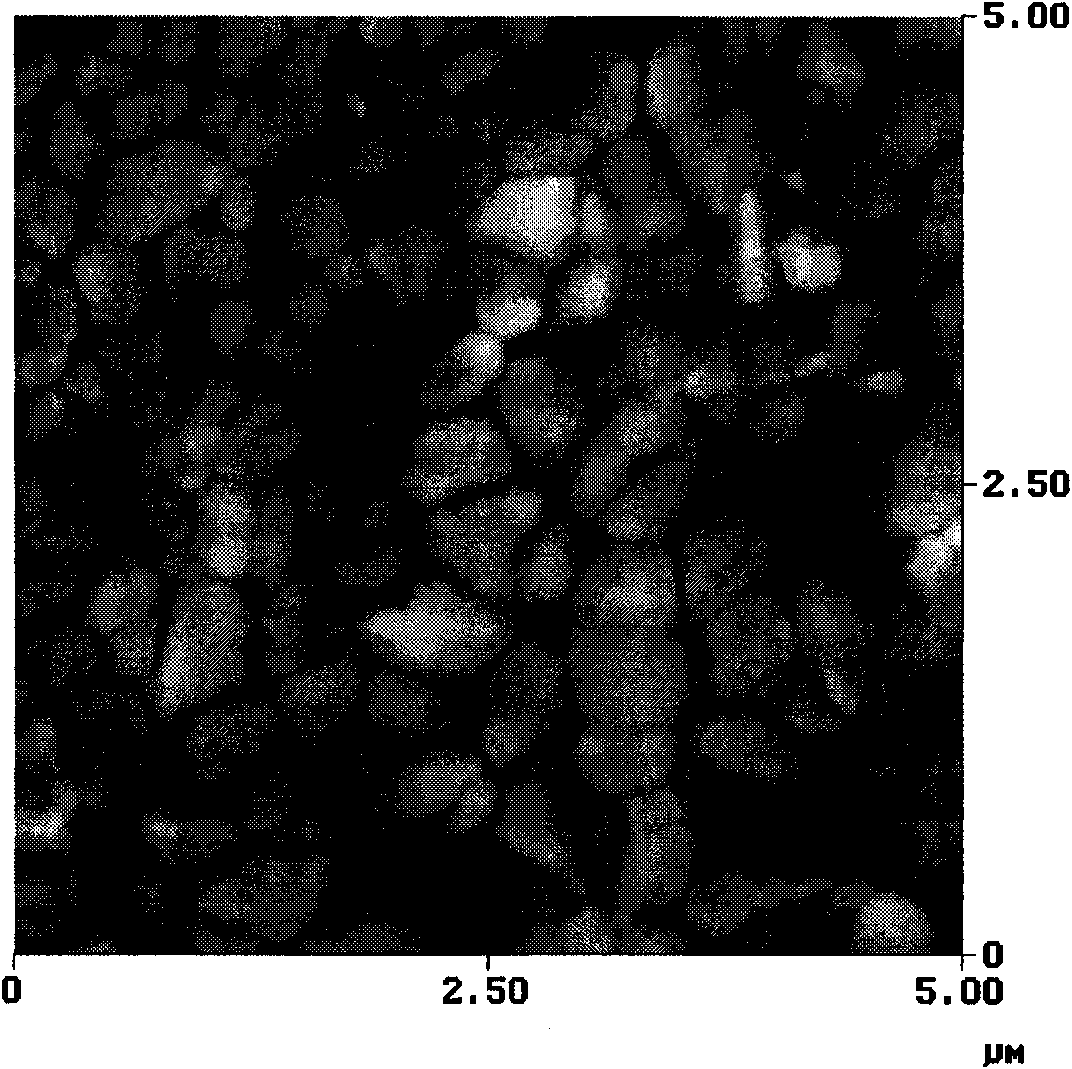

Ferroelectric piezoelectric single crystal lead holmium niobate-lead magnesium niobate-lead titanate as well as preparation and application thereof

InactiveCN103710754APolycrystalline material growthBy pulling from meltCurie temperatureSingle crystal

The invention relates to ferroelectric piezoelectric single crystal lead holmium niobate-lead magnesium niobate-lead titanate as well as preparation and application of the ferroelectric piezoelectric single crystal lead holmium niobate-lead magnesium niobate-lead titanate. The crystal material is prepared by top seeded solution growth, belongs to a perovskite structure, has the following chemical formula: (1-x-y)Pb(Ho1 / 2Nb1 / 2)O3-xPb(Mg1 / 3Nb2 / 3)O3-yPbTiO3, simply recorded as PHN-PMN-PT or PHMNT. When the morphotropic phase boundary (MPB) area of the PHN-PMN-PT solid solution single crystal is in the range that x greater than 0 and less than 0.8, y is greater than 0.20 and less than 0.50, the curie temperature (Tc) of the PHN-PMN-PT crystal in MPB area and near the MPB area is 110-170 DEG C, triangle-square phase transition temperature (TRT) is 70-110 DEG C, coercive field (Ec) is (2.5-5kV / cm), piezoelectric coefficient d33 is (1100-3915pC / N), and the electromechanical coupling factor k33 reaches maximum 94.4%.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for preparing lead magnesium niobate-lead titanate ferroelectric thin film

InactiveCN101550027AImprove ferroelectric propertiesStrong electro-optical propertiesHigh densityFerroelectric thin films

A method for preparing lead magnesium niobate-lead titanate ferroelectric thin film relates to a method for preparing ferroelectric thin film. The method of the invention settles the problems of inferior performance, inferior electrooptic performance, low purity, low density and high sintering temperature in preparing process in the lead magnesium niobate-lead titanate ferroelectric thin film prepared by the prior method. The method comprises the following steps: 1. weighting the raw material; 2. preparing a solution A; 3. preparing a solution B; 4. preparing a solution C; 5, preparing (1-x)Pb(Mg1 / 3Nb12 / 3-xPbTiO3 sol; 6. preprocessing substrate; 7. coating the sol on the substrate with a spin coater and drying for preparing a film D; and 8. calcining the film D in a fast heat treatment furnace, and then cooling to room temperature for obtaining the PMN-PT ferroelectric thin film. The ferroelectric thin film prepared according to the method has excellent ferroelectric performance and electrooptic performance, high purity, high density and lower crystallization temperature. The method of the invention has the advantages of simple technique, simple device, short preparing period, low cost of raw material and excellent availability on market.

Owner:HARBIN INST OF TECH

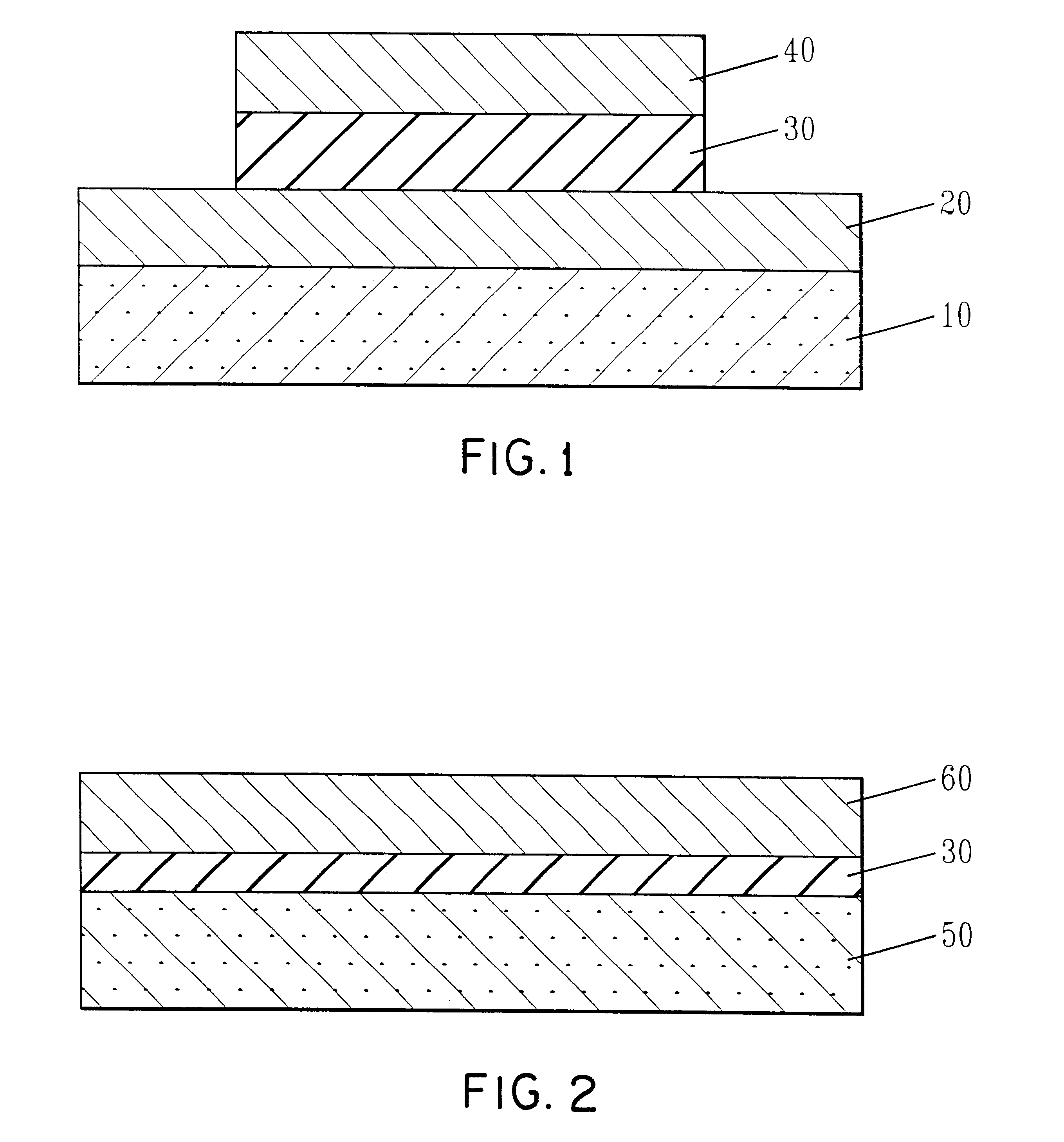

A laminated composite material used for magnetoelectricity storage unit

InactiveCN102169952ASimple structureReduce volumePiezoelectric/electrostrictive/magnetostrictive devicesLead titanateChemical composition

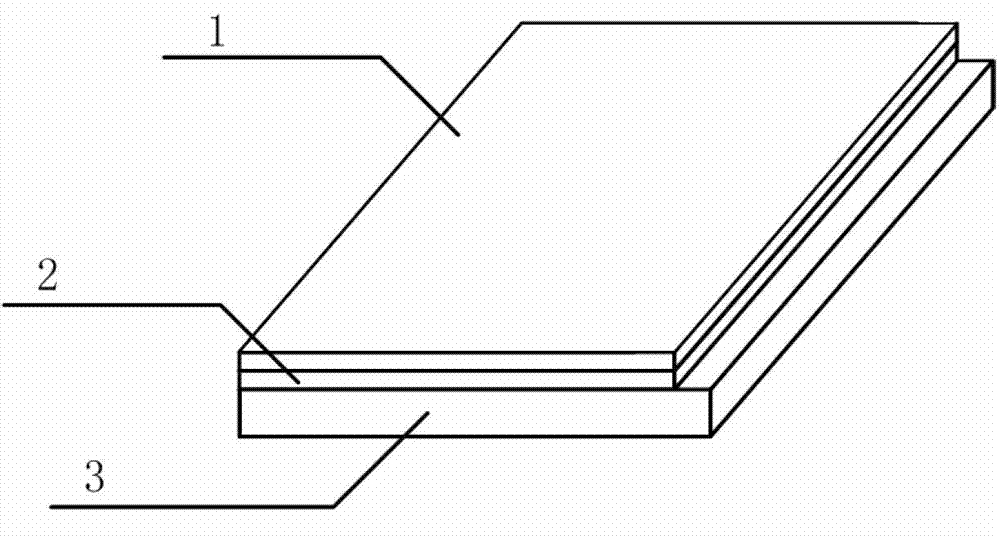

The invention relates to piezoelectric material, especially to a laminated composite material used for a magnetoelectricity storage unit. In the prior art, materials with comparatively high anti-magnetoelectricity coefficient are rare, thereby limiting the application of piezoelectric material. In the invention, an upper magnetostrictive material(1), a middle piezoelectric material (2) and a lower upper magnetostrictive material(3) are bonded with insulation paste, wherein the thickness ratio of the three layers of materials is 1:0.6-1:1; the piezoelectric material is lead magnesio niobate-lead titanate monocrystaline material. The chemical composition of the lead magnesio niobate-lead titanate monocrystaline material is (1-x)Pb (Mg1 / 3Nb2 / 303)-xPbTiO3 (PMN-PT), wherein the optimal component range of x is between 0.28 and 0.33; the crystallographic orientation is longthwise (001) direction. The material in the invention has advantages of multi-input, high anti-magnetoelectricity coefficient, simple structure, small volume, convenient preparation, quick response, easy tuning and low power dissipation.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com