Method for preparing transparent photoelectric ceramic-base tunable wave filter

A technology for tuning filters and optoelectronic ceramics, used in instruments, optics, nonlinear optics, etc., can solve the problems of lack of breakthrough in growth technology and short service life of single crystals, and achieve low production costs, good light transmittance, and freedom. The effect of wide spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

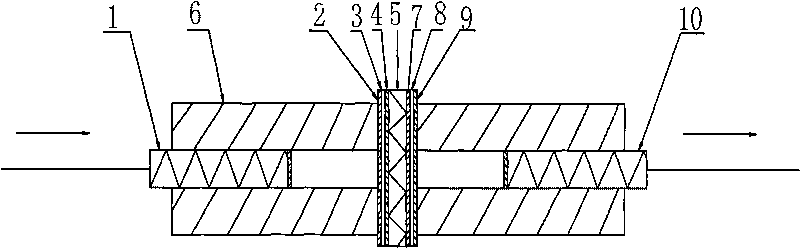

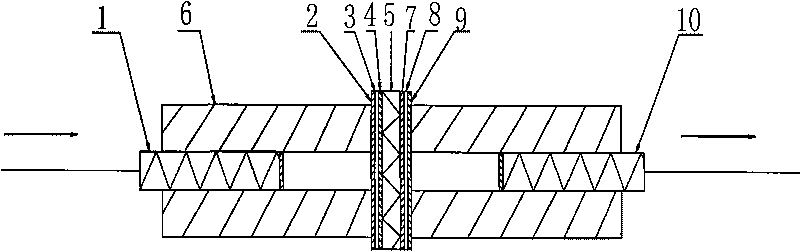

[0019] The following is attached figure 1 The technical solution of the present invention is further described.

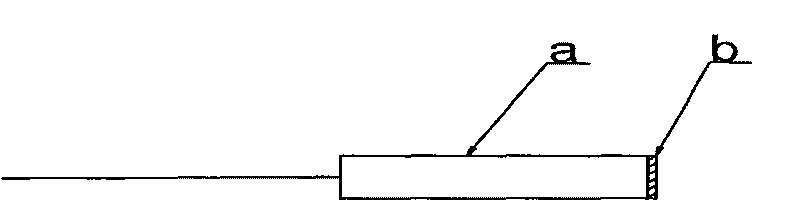

[0020] Concrete preparation method of the present invention is: first, as figure 2 Shown: one end face of the collimator lens a is coated with an anti-reflection film b with a transmittance above 99.9%, forming a collimator, (front collimator and rear collimator).

[0021] Another example figure 1 Shown: be 2mm in length, be 1mm in width, and be 0.1-0.2mm in thickness lead magnesium niobate-lead titanate PMN-PT photoelectric transparent ceramic 5 two ends respectively plate front transparent electrode 4 and back transparent electrode 7 (by Made of ITO material); on the outer surface of the front transparent electrode 4 and the rear transparent electrode 7, the front high reflection film 3 and the rear high reflection film 8 are plated respectively, and the reflectivity is more than 99.0% on the front high reflection film 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com