Dispenser for dispensing fluid

一种分配器、流体的技术,应用在单个的手持设备、喷射装置等方向,能够解决元件没有补偿系统、不能补充产品体积等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

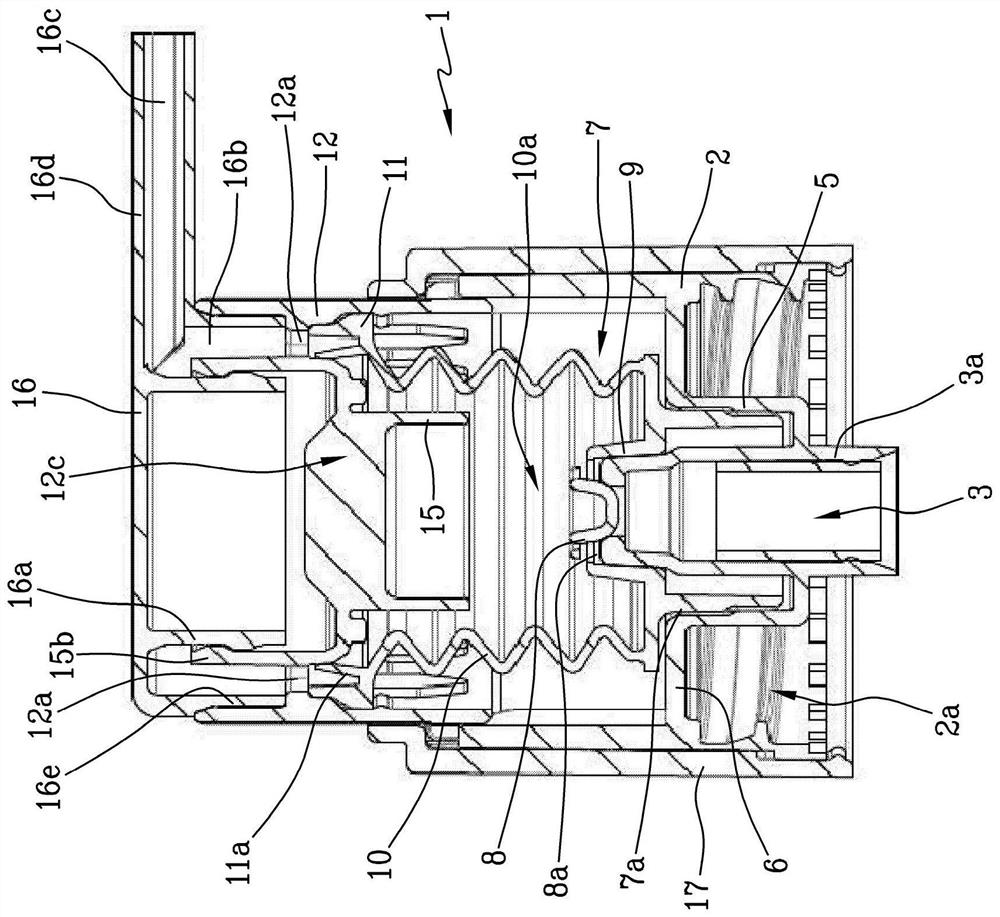

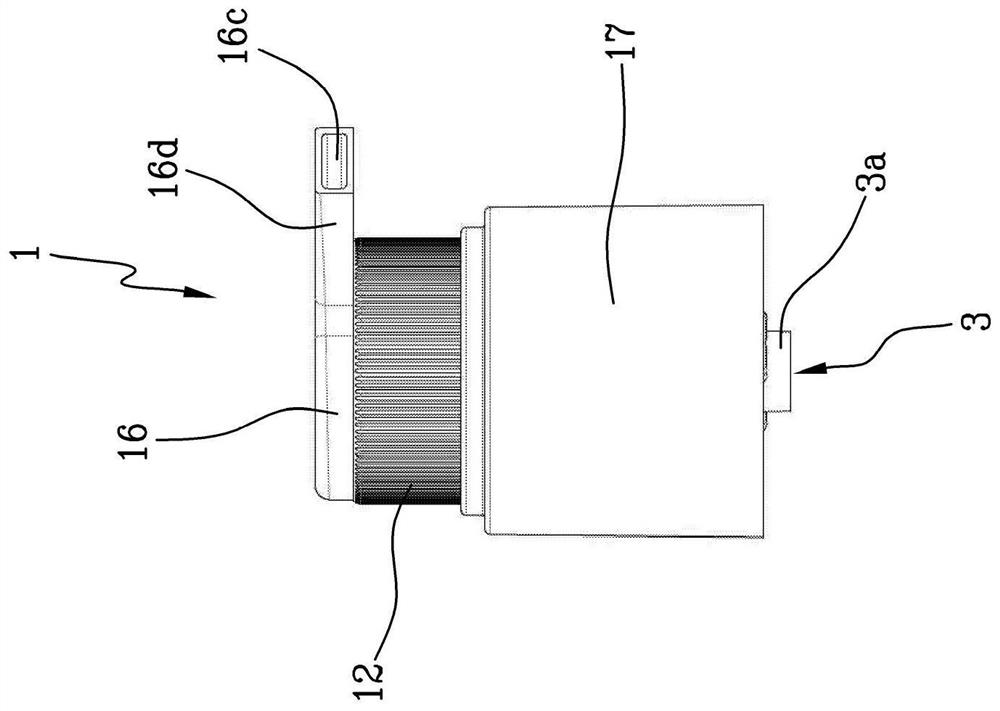

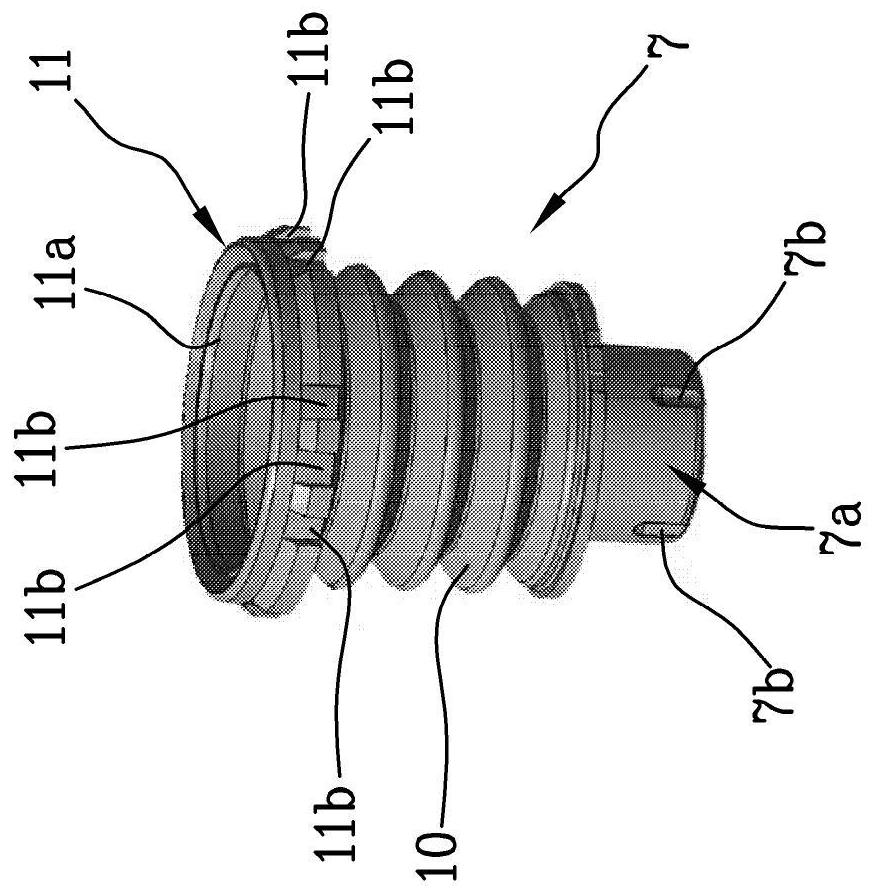

[0026] Referring to the drawings, reference numeral 1 generally denotes a dispenser for dispensing fluid, which is hereinafter referred to as dispenser 1 for simplicity of description.

[0027] The dispenser 1 is made of plastic material to simplify recycling. Preferably, the dispenser 1 is made of polyethylene. Even better, the plastic material is a bioplastic produced from non-fossil sources. In other words, the parts from which the dispenser 1 is made are dimensioned so as to be made of a single plastic family, eg polyethylene, so that it can also be recycled with the bottle, also made of polyethylene when it is opaque. Advantageously, in the polyvinyl family there are the above-mentioned bioplastics (made from non-fossil sources), which are particularly recyclable and / or biodegradable.

[0028] The dispenser 1 comprises a ring nut 2 which can be screwed onto the neck of a bottle (not shown). The ring nut 2 is equipped with a preferably threaded coupling system. The fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com