Overwater Floating bridge and erection method

A floating bridge and floating board technology, applied in the direction of floating bridges, bridge construction, bridges, etc., can solve the problems of long-term use, troublesome operation, etc., and achieve the effects of convenient operation and installation, low water absorption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

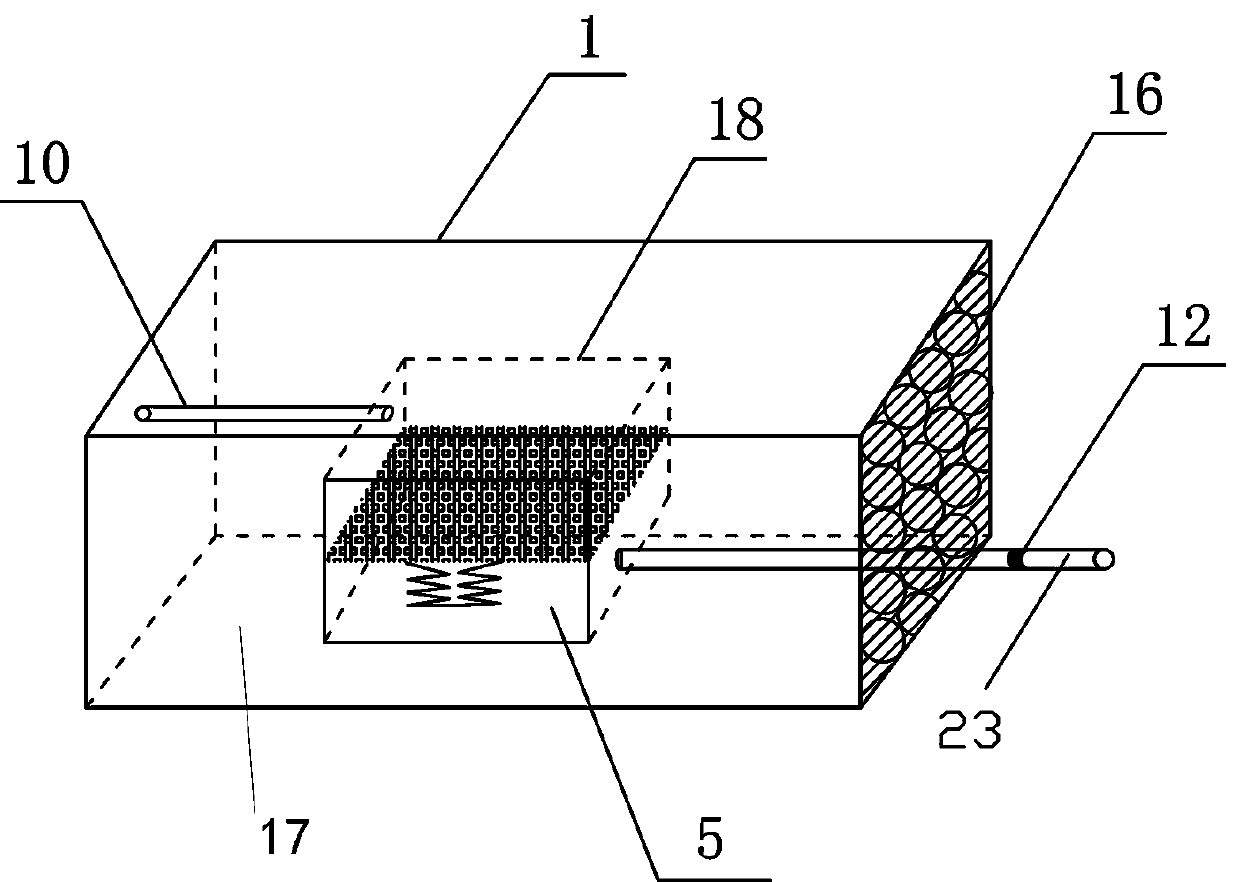

[0044] Such as Figure 2-Figure 2 As shown, a floating board unit includes a ceramsite board 1. The ceramsite board 1 includes a plate body frame 17 made of a flexible mesh body. The plate body frame 17 is filled with a filling body composed of N layers of ceramsite 16 and lightweight concrete. , N≥1;

[0045] A groove 18 is provided in the ceramsite board 1, and a water storage lifting device 5 is placed in the groove;

[0046] The outer surface of each side of the board frame 17 is provided with an inclusion 3, the inclusion 3 is wrapped with an outer mesh body 14, and the space between the outer mesh body 14 and the inclusion 3 is filled with lightweight concrete.

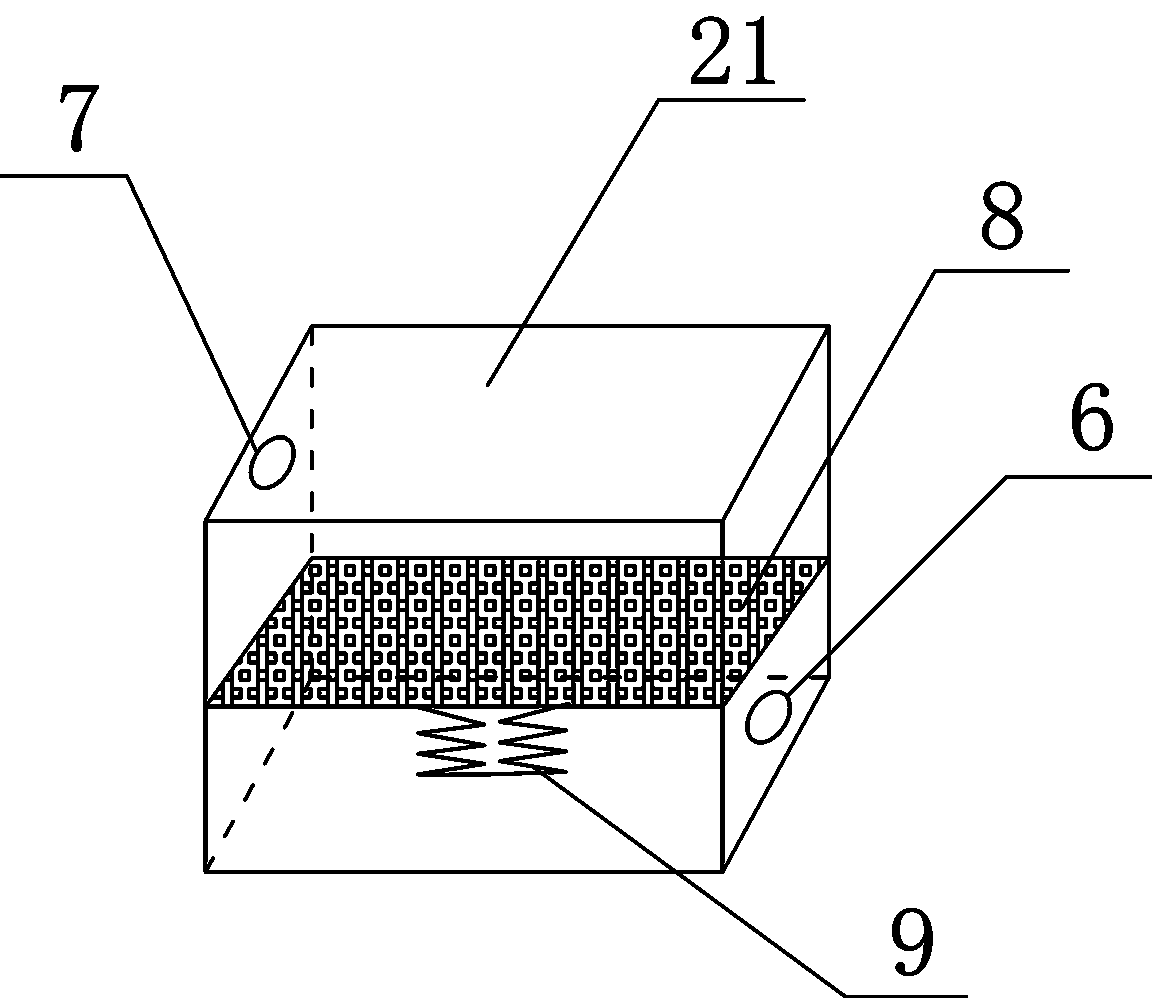

[0047] The water storage lifting device 5 includes a hollow closed container body 21. The internal space of the closed container body 21 is divided into a water outlet space and a water inlet space by a piston 8. The piston 8 and the bottom surface of the closed container body 21 are connected by a lifter 9, and the in...

Embodiment 2

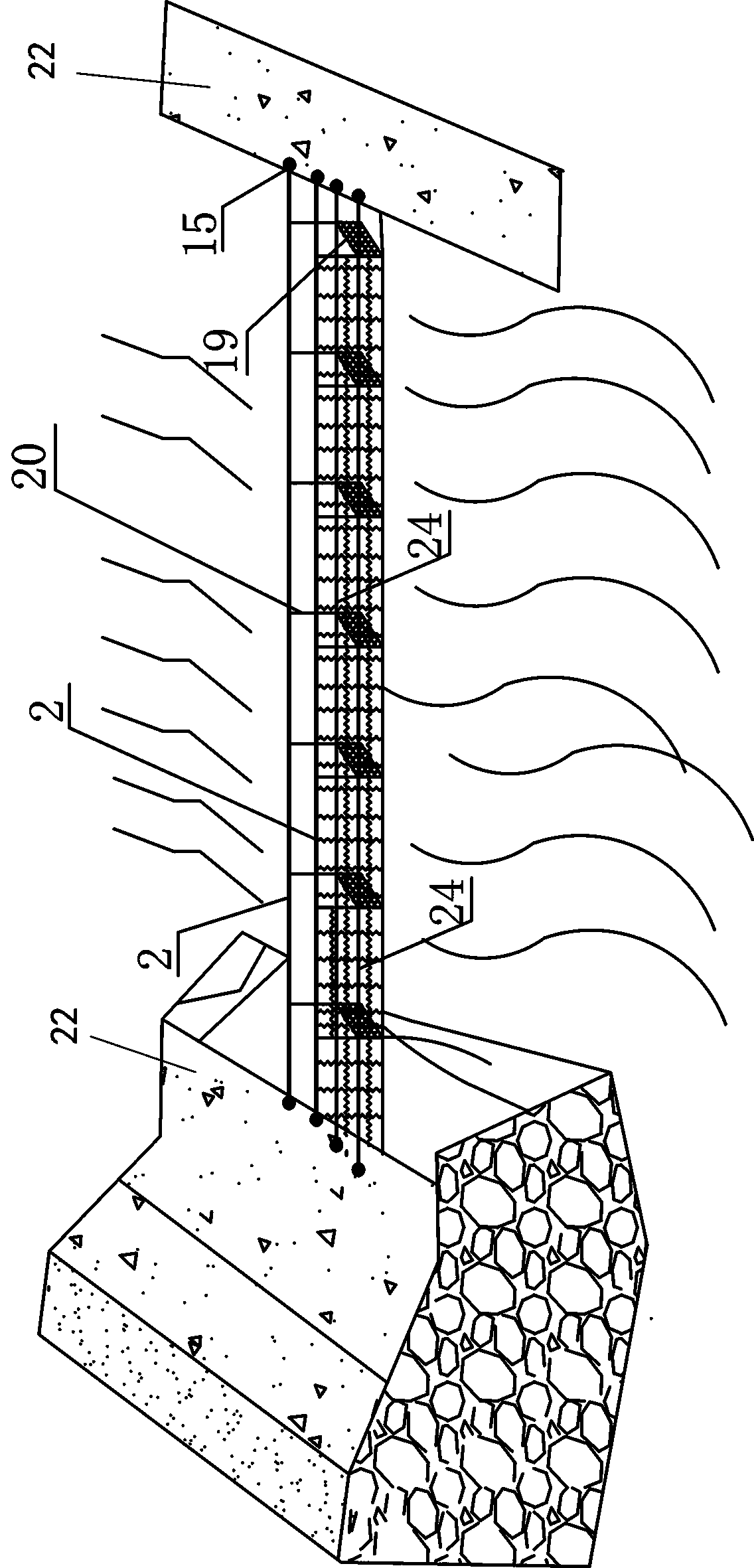

[0050] Such as figure 1 , Figure 4-Figure 6 As shown, a floating bridge is provided with two rows of steel cables 2 on the foundation 22 of the two river banks. It is characterized in that: multiple floating board units 19 are connected to the steel cables 2 through suspension cables 20 and spliced to form a whole floating bridge ;

[0051] The steel cable 2 is set on the foundation 22 on the banks of the two rivers through an anchor 15.

[0052] The four top corners of the floating board unit 19 are respectively installed with shackles 4, one end of the suspension cable 20 is fixed on the shackle 4 of the floating board unit 19, and the other end of the suspension cable 20 is fixedly connected with the steel cable 2. Each floating board unit A double-layer flexible net 11 is arranged between the two suspension cables 20 on the same side.

[0053] The two adjacent floating board units 19 are connected by a hook.

[0054] The ceramsite 16 adopts shale ceramsite, fly ash ceramsite,...

Embodiment 3

[0057] Such as figure 1 , Figure 4-Figure 6 As shown, a method for erecting the above-mentioned floating pontoon includes the following steps:

[0058] Step 1: Manufacturing floating plate unit 19:

[0059] Step 1-1: Manufacturing the ceramsite board 1: Place the water storage lifting device 5 in the middle of the ceramsite board structure model, and connect the PVC pipes to the water inlet 6 and the water outlet 7 of the water storage lifting device 5 respectively The inlet pipe 23 and the outlet pipe 10 are formed; a layer of flexible mesh is laid on the bottom of the ceramsite plate structure model, and N layers of ceramsite 16 are laid on the flexible mesh body, N≥1, and another layer is arranged on the N layer of ceramsite 16 Layer flexible nets, and use iron wires to sew the two flexible nets together to form a plate frame 17, wrap the water storage lifting device 5 in the middle of the plate frame 17, and then pour lightweight concrete into the plate frame 17, , The ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com