Patents

Literature

174results about How to "High blocking rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

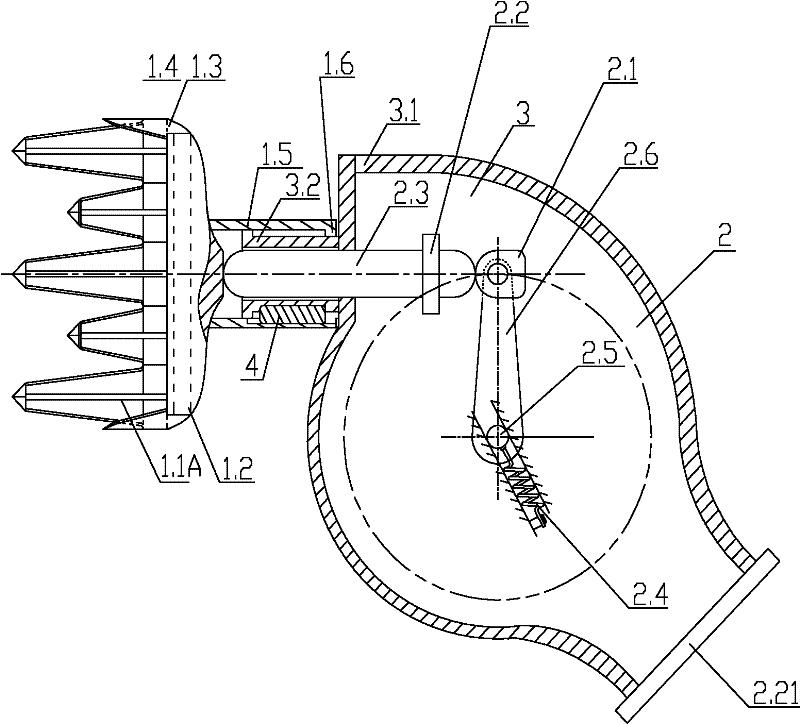

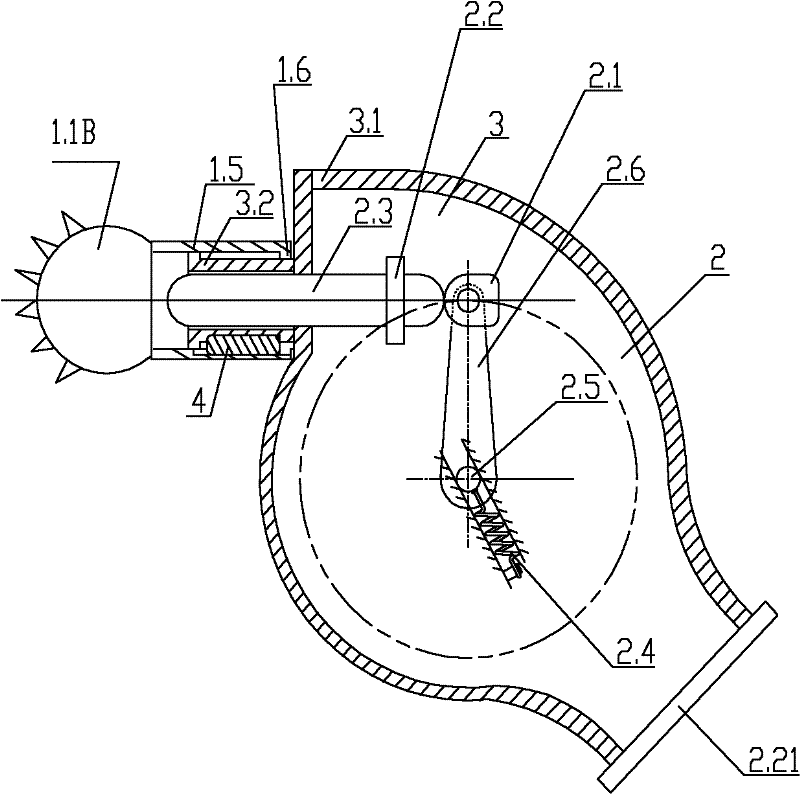

High-efficiency blocking coal shovel

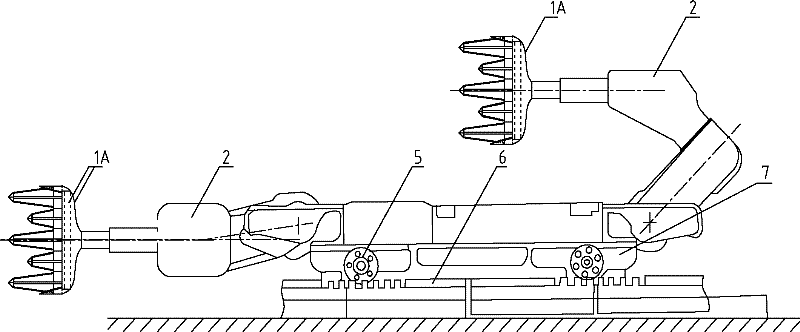

The invention relates to coal mining equipment and specially, relates to a high-efficiency blocking coal shovel. The high-efficiency blocking coal shovel comprises a shovel body. The shovel body comprises a frame. The high-efficiency blocking coal shovel also comprises an impulsion shovel mechanism. The impulsion shovel mechanism comprises a shovel head and an impulsion device. The shovel head comprises shovel teeth and a fixing part. The shovel teeth are installed on the fixing part. A rear part of the fixing part is provided with an impulsion stroke guiding mechanism. The impulsion stroke guiding mechanism is sildingly connected to a guiding sleeve. The guiding sleeve is arranged on the impulsion device and / or the frame. The impulsion device impacts the impulsion stroke guiding mechanism. Only through one impulsion process, the shovel head can complete both coal falling and surface cleaning. The impulsion shovel mechanism is arranged on the shovel body. The shovel body drives the whole high-efficiency blocking coal shovel to walk. Coal mined by the high-efficiency blocking coal shovel is not broken fully. The high-efficiency blocking coal shovel has a high blocking rate and low power consumption, produces a small quantity of coal dust, provides a good work environment, realizes continuous coal mining, synchronously completes both coal falling and surface cleaning, and saves a mass of energy.

Owner:刘素华

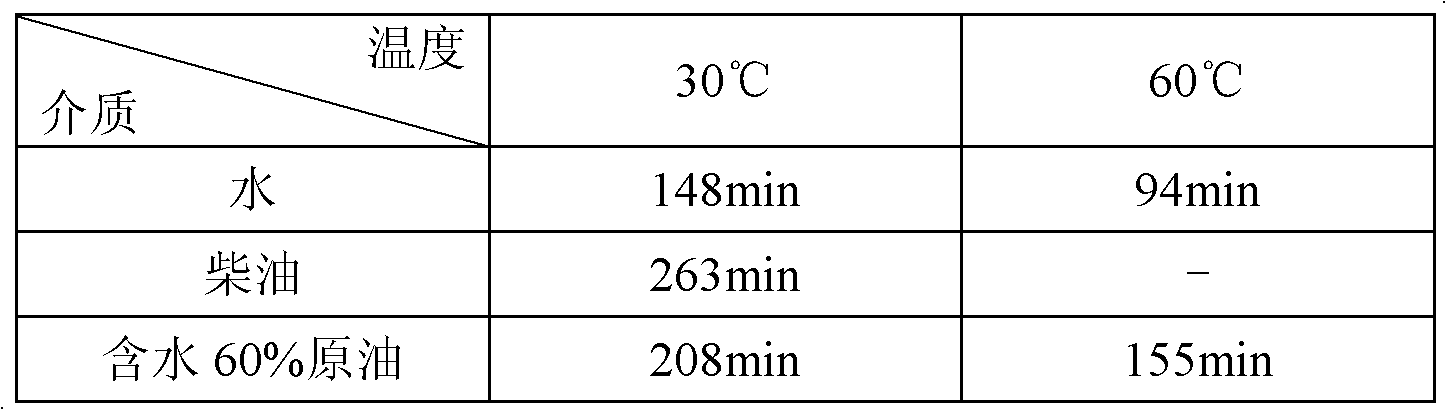

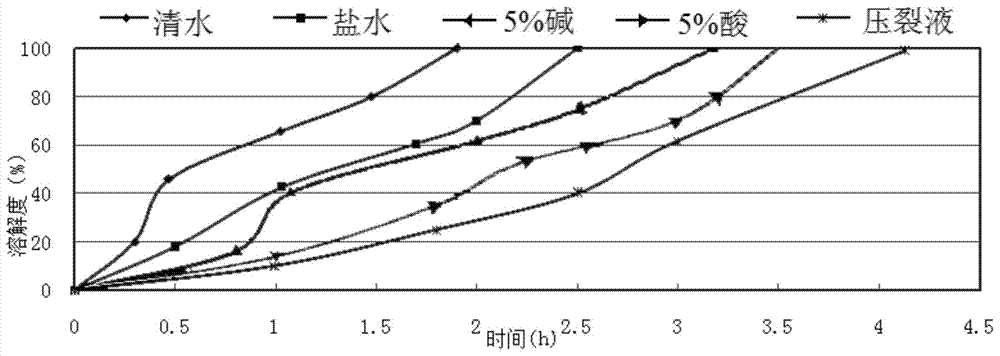

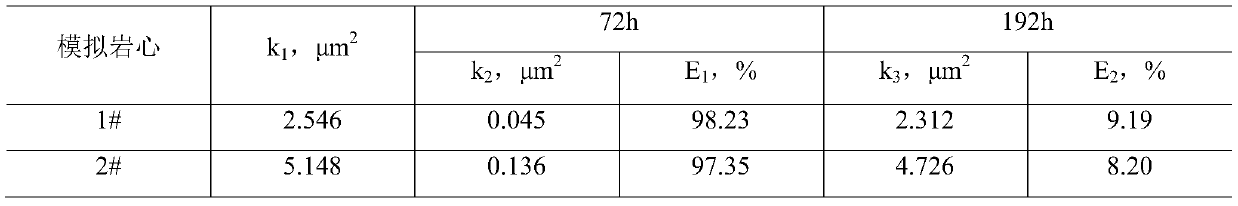

Temporary plugging diversion agent for refracturing of oil-water well and preparation method thereof

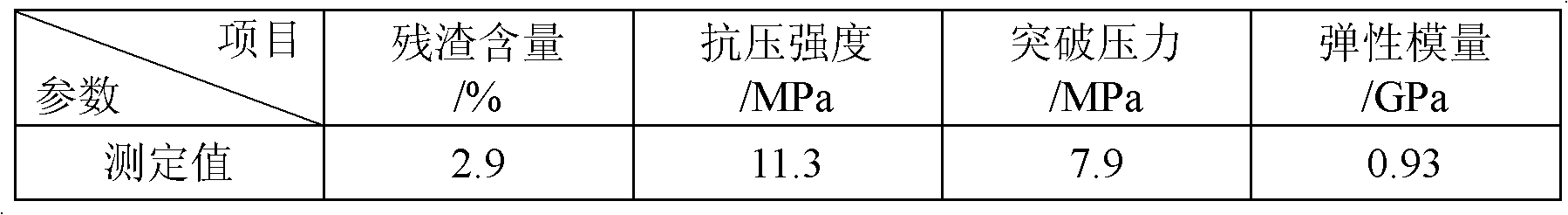

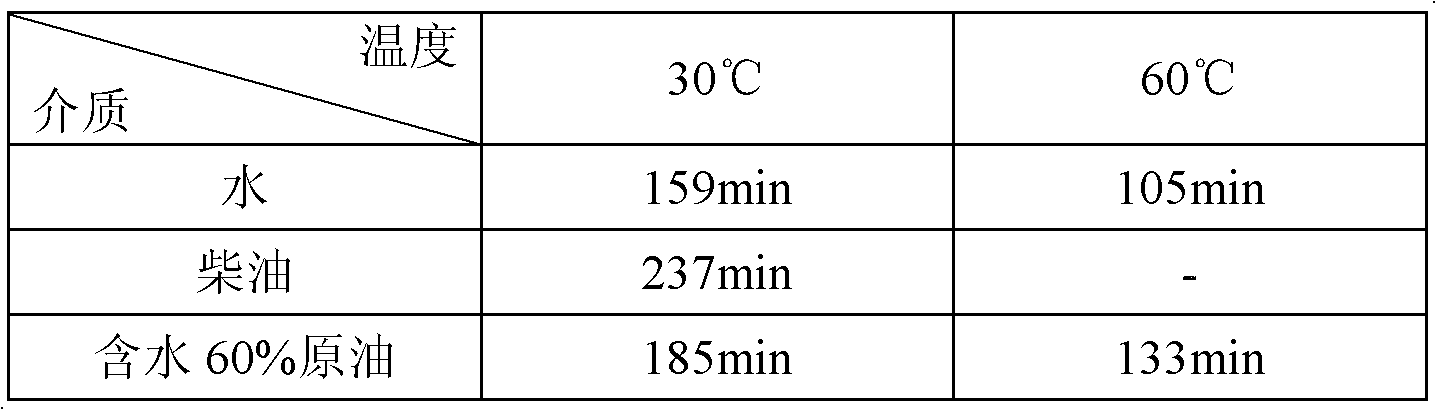

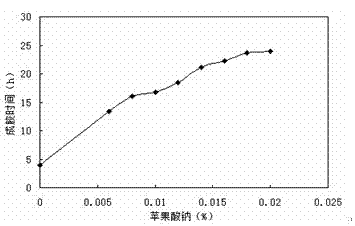

The invention relates to a temporary plugging diversion agent for refracturing of an oil-water well and a preparation method thereof. The temporary plugging diversion agent comprises the following raw materials: adhesive bonding agent 35-65%, plasticizer 15-25%, thickening agent 10-20%, and dispersant 10-20% calculated by the total weight of the temporary plugging diversion agent. The invention also provides the preparation method of the temporary plugging diversion agent, which comprises the following steps: preparing partial thickening agent into a thickening agent water solution; dissolving the adhesive bonding agent into the thickening agent water solution; holding constant temperature in a 25-35 DEG C water bath for 2-5 hours, and after the adhesive bonding agent is swollen completely, increasing the temperature to 45-55 DEG, and continuing holding constant temperature for 0.5-2 hours; after the adhesive bonding agent is completely dissolved, adding dispersant and stirring to be homogenous, and adding the plasticizer and the rest thickening agent while stirring to obtain viscous paste; and cutting the viscous paste to granules of side length 3-6 mm, and drying to obtain the temporary plugging diversion agent. The temporary plugging diversion agent provided by the invention has the advantages of good oil solubility and water solubility, low residue content, good elasticity, and on the like.

Owner:PETROCHINA CO LTD

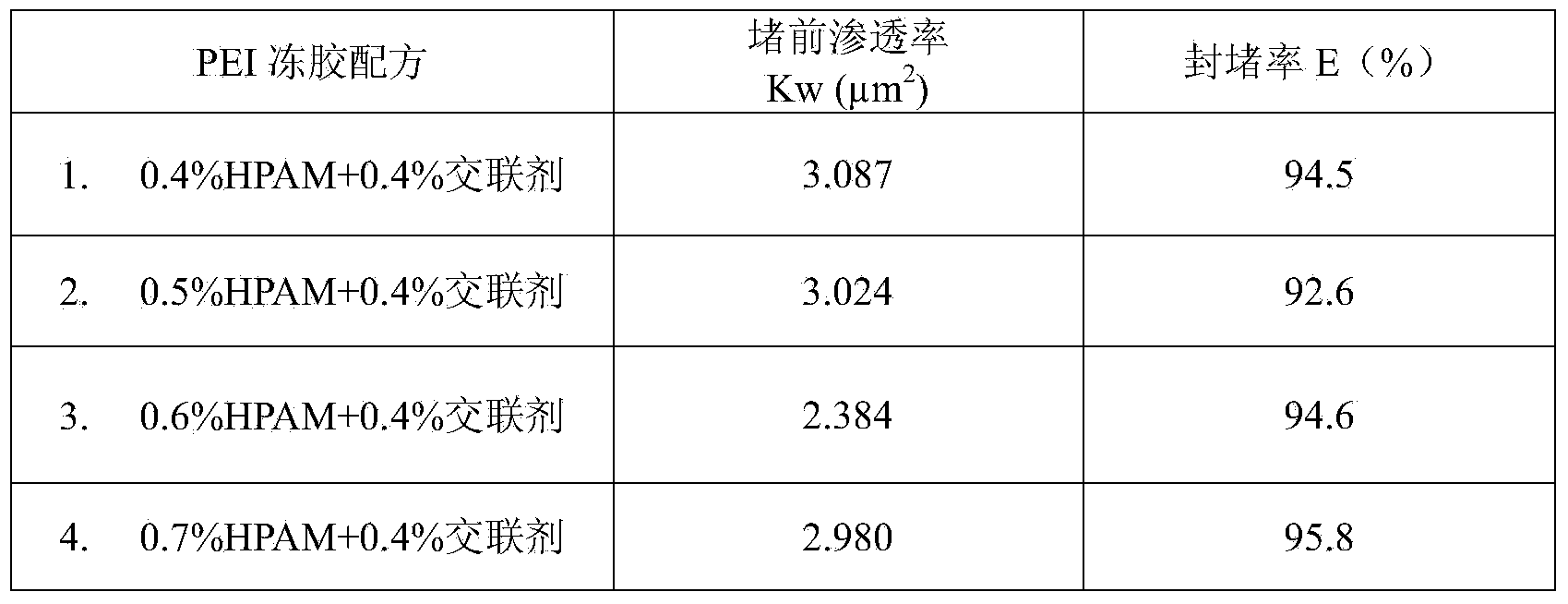

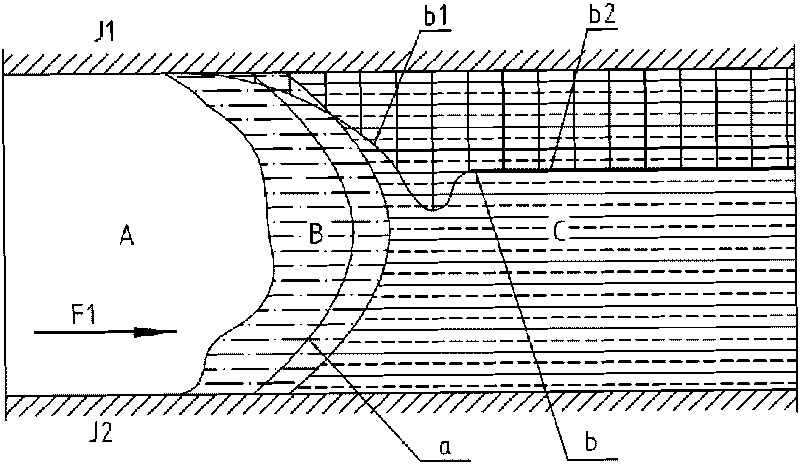

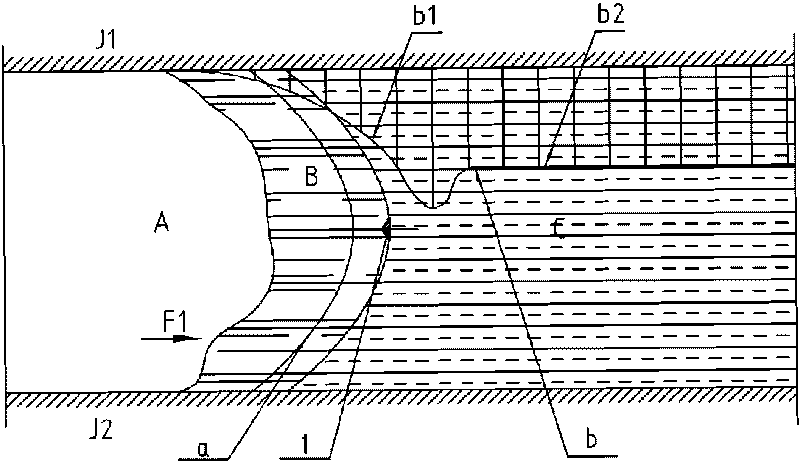

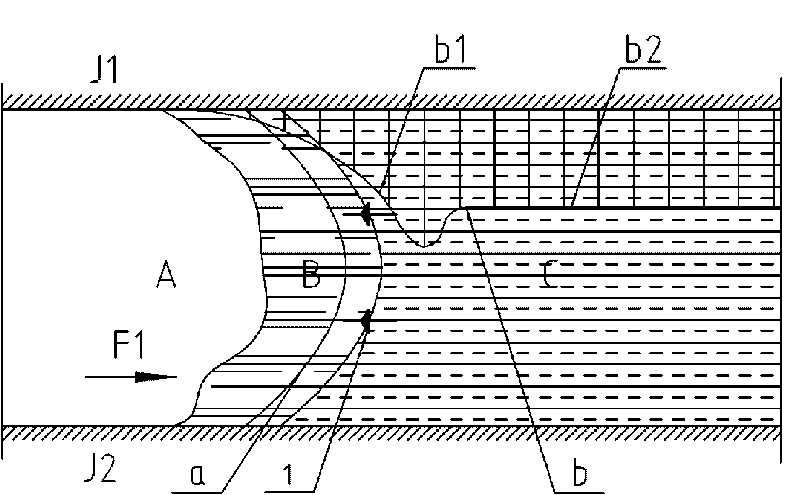

Polyethyleneimine jelly profile-control water-blocking agent

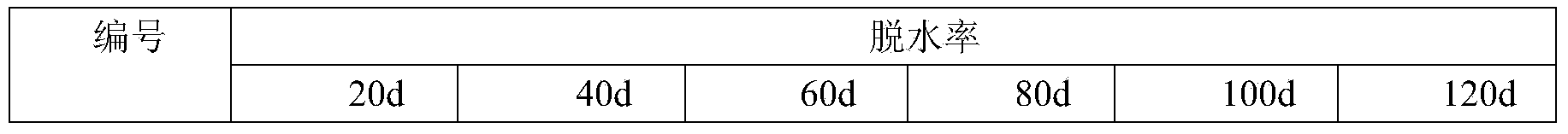

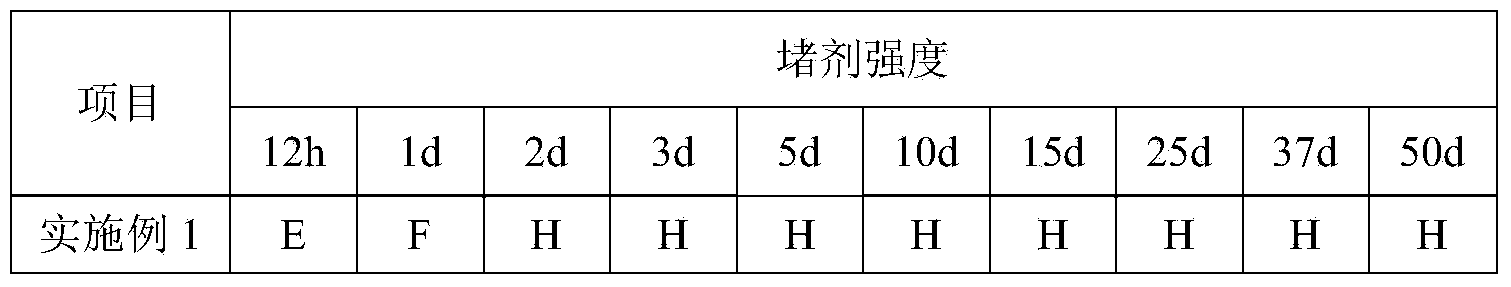

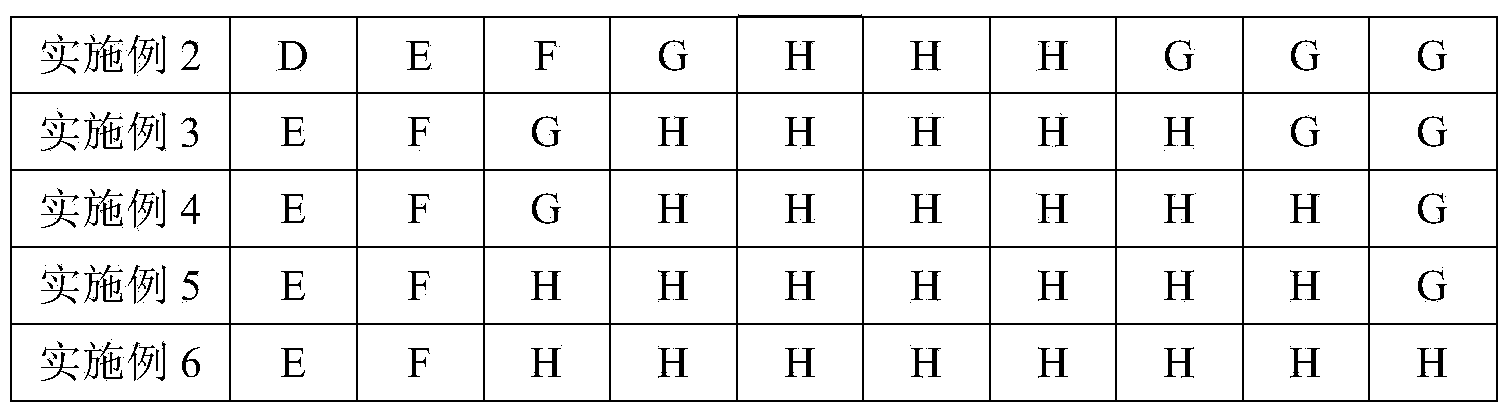

The invention provides a polyethyleneimine jelly profile-control water-blocking agent. The profile-control water-blocking agent is prepared by reacting partially-hydrolyzed polyacrylamide and a cross-linking agent polyethyleneimine. The profile-control water-blocking agent comprises following components by weight: 0.3-0.8% of the partially-hydrolyzed polyacrylamide, 0.2-0.5% of the cross-linking agent polyethyleneimine and 0.3-0.8% of an additive, with the balance being water, wherein the partially-hydrolyzed polyacrylamide adopts anionic polyacrylamide, and the additive is one compound selected from a group of sodium sulfite, sodium bisulfate, and sodium hyposulfite or thiourea, or is a mixture of several compounds selected from the group. The jelly forming time of the profile-control water-blocking agent is adjustable and the jelly has high strength. The profile-control water-blocking agent can block underground water having a temperature lower than 110 DEG C and a NaCl mineralization degree of 50000 mg / L. The profile-control water-blocking agent has good temperature toleration and cannot be dehydrated for 120 days.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

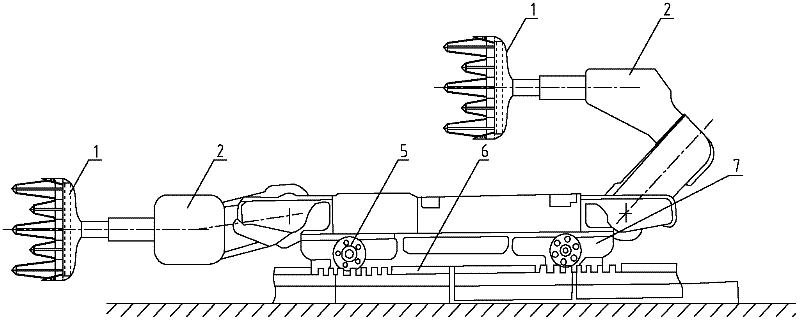

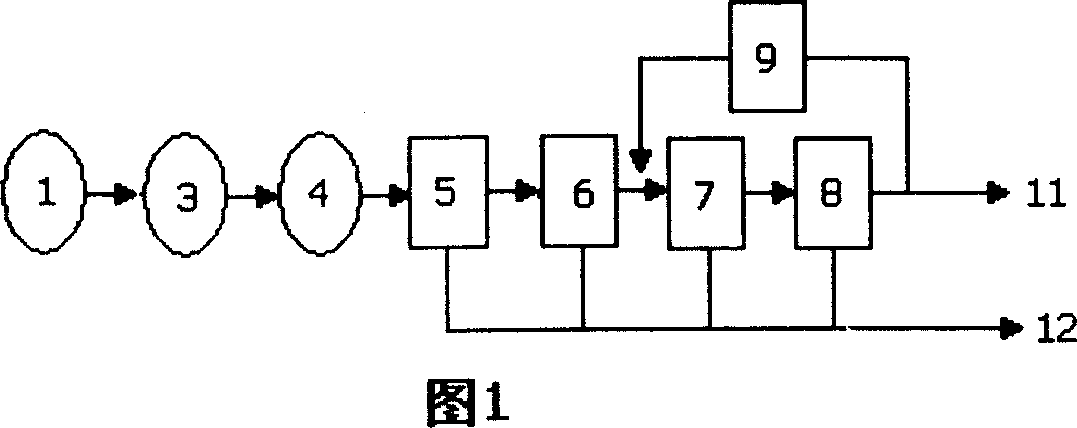

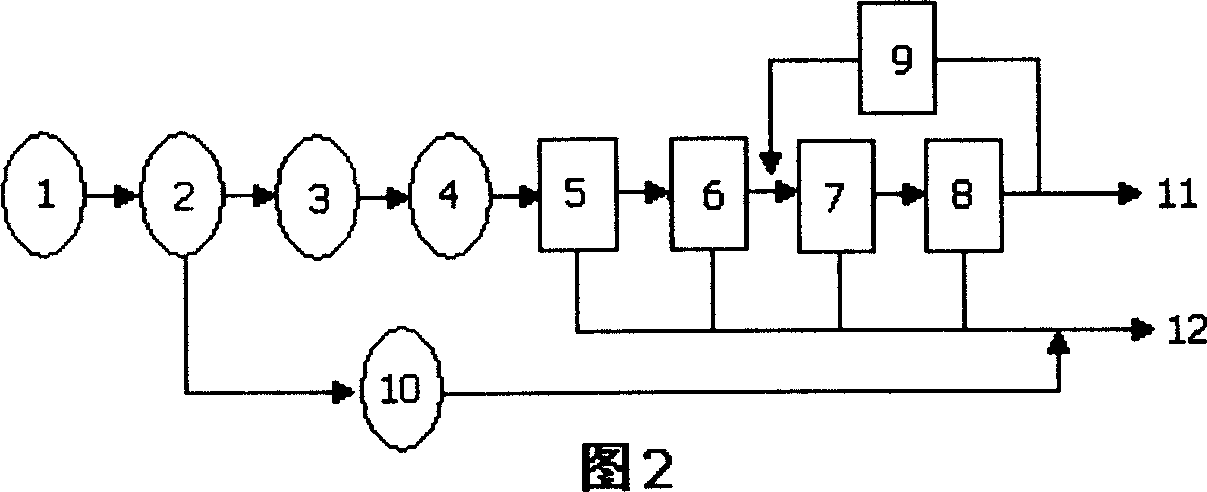

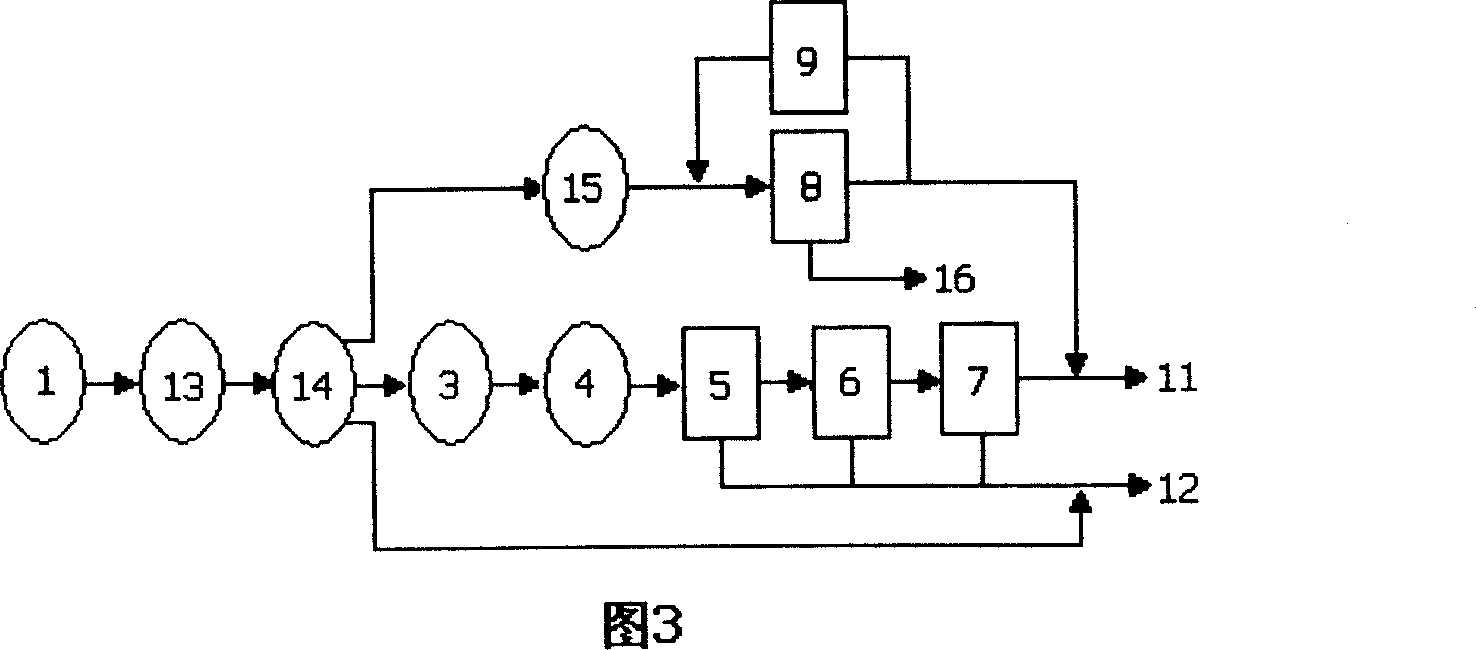

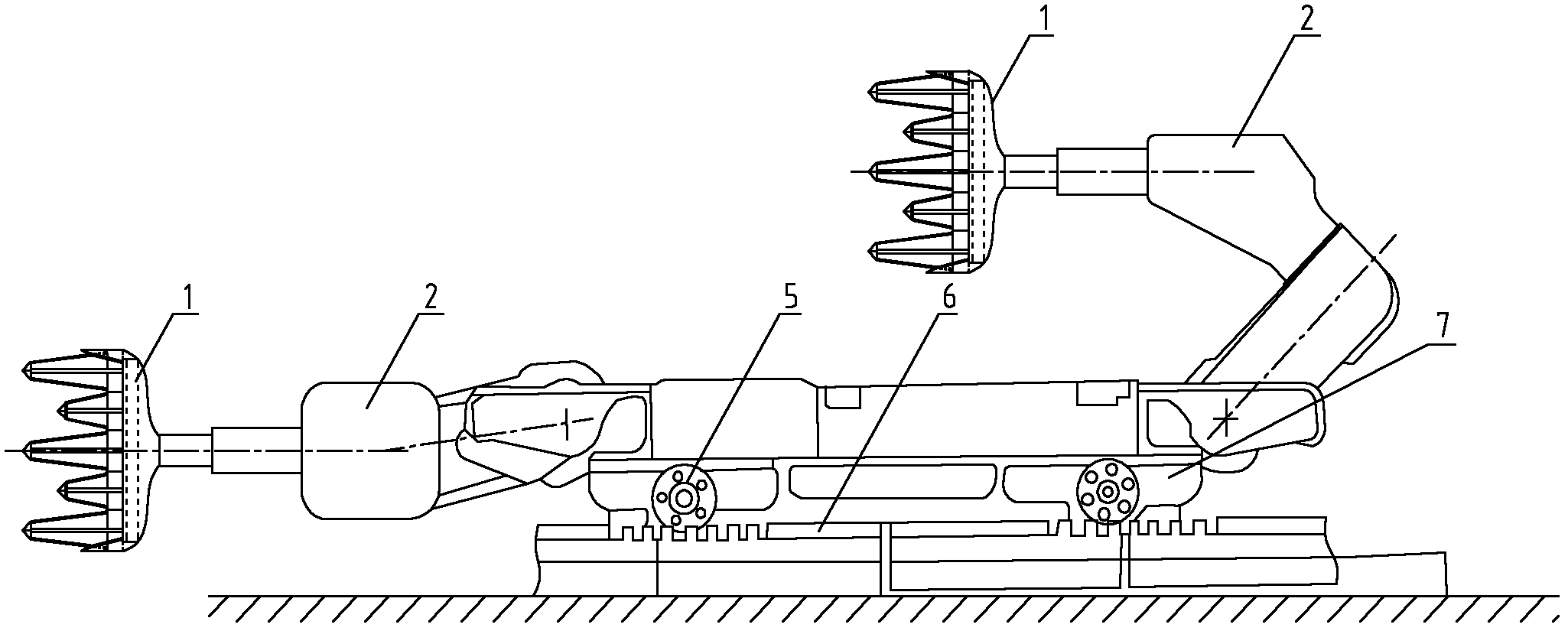

Coal mining method and coal mining apparatus implementing same

InactiveCN101725347AReduce lossImprove coal mining efficiencyDisloding machinesMining engineeringMechanical engineering

The invention relates to a coal mining method and a coal mining apparatus. The coal mining method comprises the following steps of: directly inserting a wedge-shaped body into a coal layer on the coal layer parallel to a goaf surface; continuously advancing the wedge-shaped body forwards; continuously cracking and collapsing coal bodies outside the wedge-shaped body and facing the direction of the goaf surface; continuously clearing a top plate, a bottom plate and dropped coals after the coal bodies are collapsed in the front; and continuously conveying the collapsed coal bodies and the cleared dropped coals by a conveyor to complete a continuous coal mining process. The apparatus implementing the coal mining method comprises a coal mining head and an auxiliary mechanism, wherein the coal mining head comprises the wedge-shaped body, a support and a plough-shaped plate; the wedge-shaped body and the plough-shaped plate are arranged on the support; the top plate and the bottom plate at the front end of the plough-shaped plate are respectively fixed with a top plate clearing mechanism and a bottom plate clearing mechanism; and the wedge-shaped body is arranged at the front end of the coal mining head. Compared with the prior art, the coal mining method and a coal mining apparatus have the advantages of high production efficiency, low energy loss and high block rate.

Owner:山东华智科技有限公司

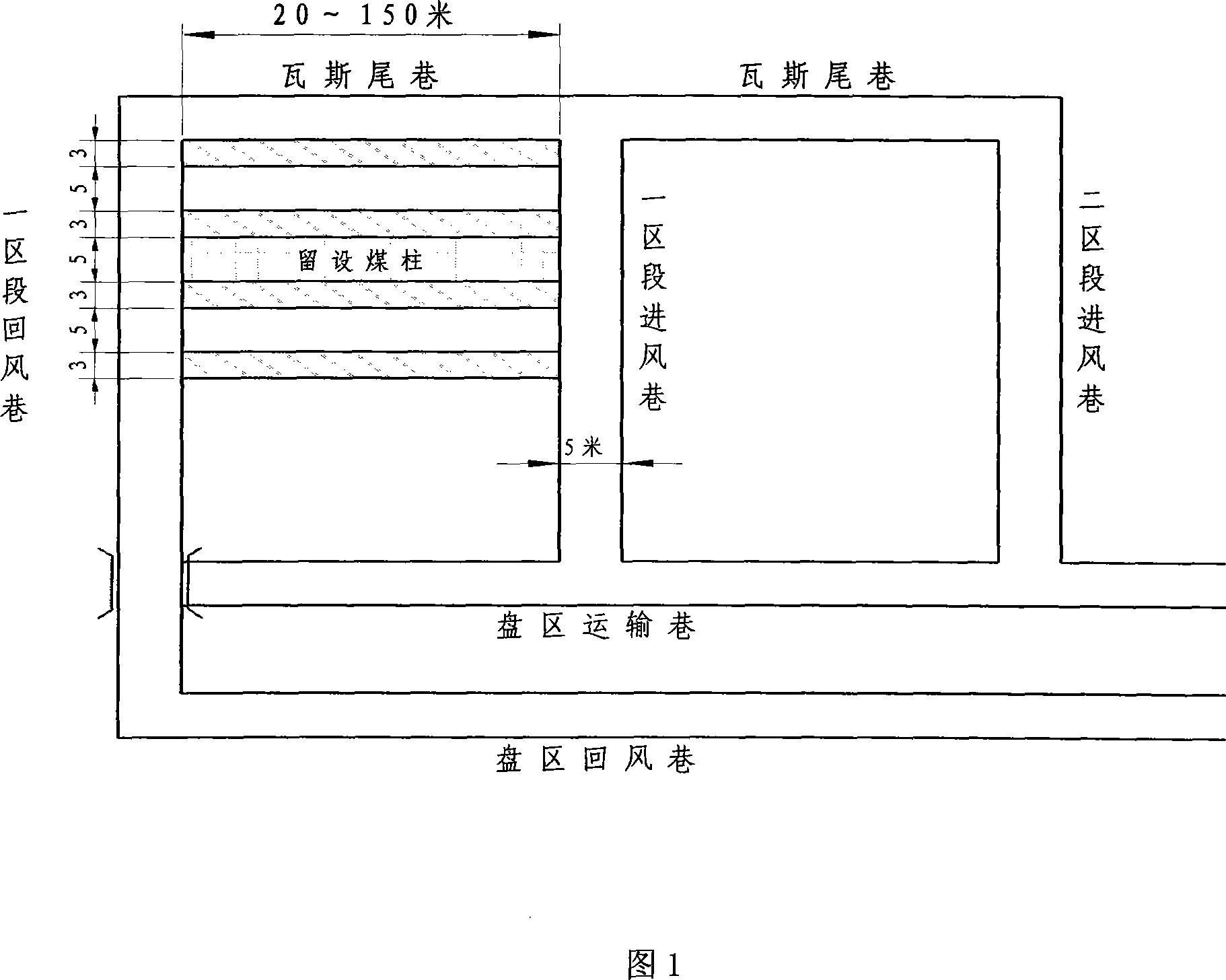

Method for coal mine downhole reproduction and back production

InactiveCN101025085AReduce equipment investmentShort construction periodUnderground miningBlastingResource depletionCoal pillar

The invention provides a coal mine underground coal remining and extracting method, comprising: laneway disposing, mining, coal dropping, and adopting the processes of coal loading, coal conveying and timbering by a coal loading, coal conveying and anchor rod timbering mechanical integrated device and recovering from two wings, where the laneway disposing divides several segments in a mining section and disposes two preparing laneways in each segment, one as air inlet lane and the other as air return lane, after all coal in the previous segment has been mined, the air inlet lane of the previous segment can act as an air return lane for the next segment, and the next segment is made with only one air return lane, it disposes a strip house pillar in the middle of the two preparing laneways, arranges mining house, mining pillar and remains coal pillars, and determines the sizes of the mining house and mining pillar according to the characteristics of the top plate, and implements mine underground mechanical mining, makes medium-sized and small-sized mines whose 'resources have dried up' implement remining, and makes coal pillars and corner coal recovered in large-sized and medium-sized mines and makes the coal extraction ratio up to 50%-70%.

Owner:闫振东

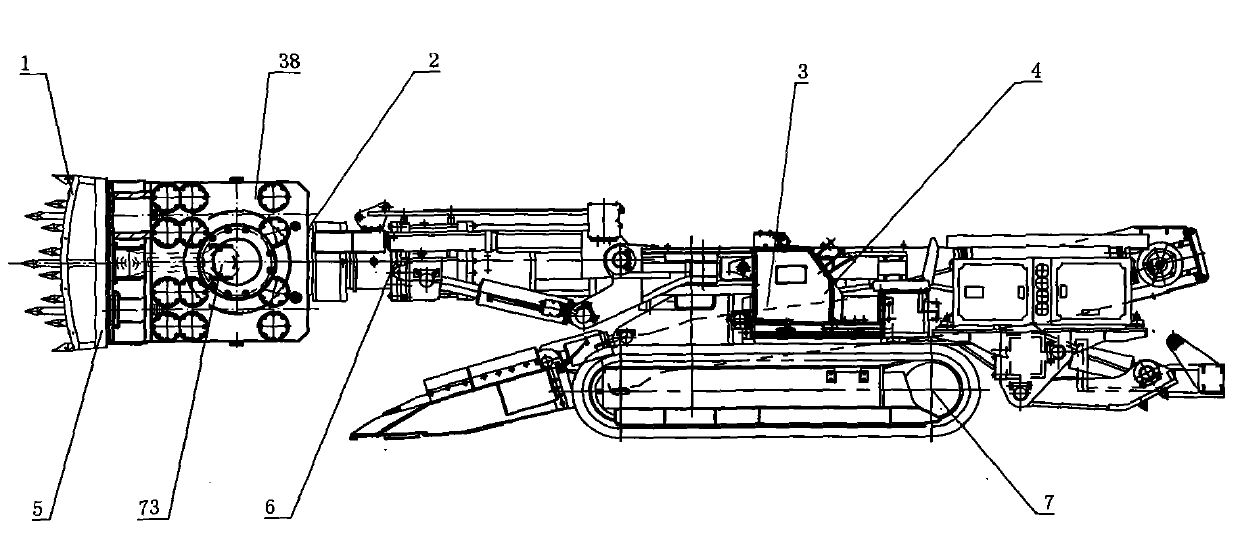

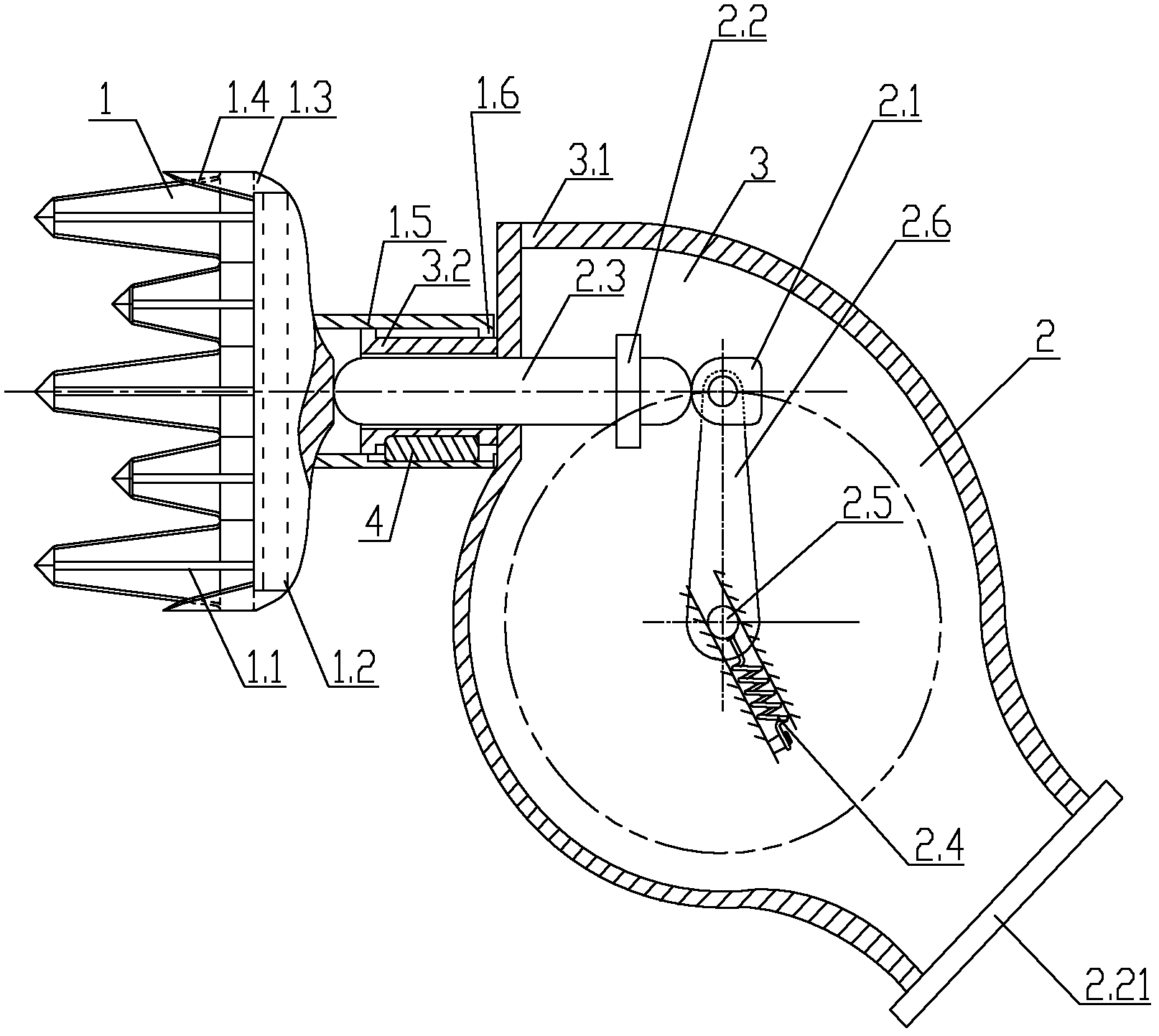

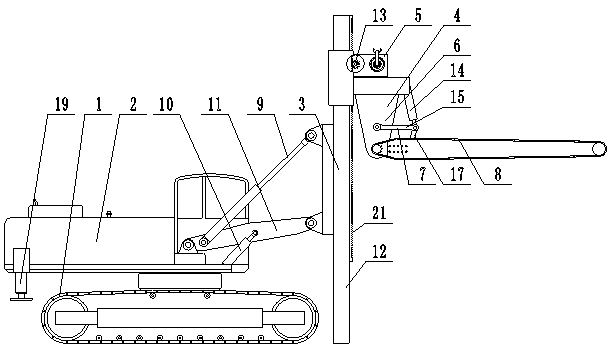

Method and apparatus for converting rotary motion into reciprocating impact motion

ActiveCN103498673APass smoothlySmooth nestingDriving meansPercussion drillingDrive shaftReciprocating motion

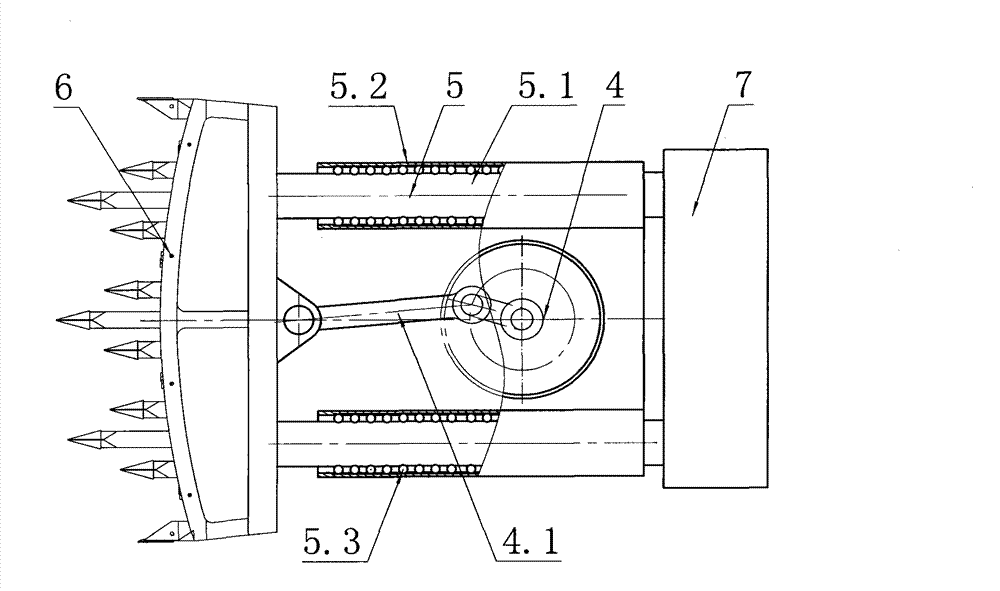

A method and device for converting rotary motion to reciprocating percussion motion. The device comprises a machine body (4), a travel portion (7), and a reciprocating percussion portion (5). The reciprocating percussion portion (5) comprises a percussion drive mechanism (2), a rocker arm (6), and a percussion head (1). The percussion drive mechanism (2) comprises a percussion power source member (11), a transmission component, and a crankshaft (10). The percussion power source member (11) comprises a motor, and the motor comprises a power output shaft (14). The transmission component comprises a power gear (13) and a transmission gear (12). The power gear (13) is mounted on the power output shaft (14). The transmission gear (12) drives the crankshaft (10). The transmission component comprises a transmission shaft. The power output shaft (14) is perpendicular to the rocker arm (6), and is parallel to the transmission shaft and the crankshaft (10) so that the transmission gear (12) drives the crankshaft (10) to convert rotary motion to reciprocating motion; or the power output shaft (14) is parallel to the rocker arm (6), the crankshaft (10) is driven to convert rotary motion to reciprocating motion after the power direction is changed by a power bevel gear and a transmission bevel gear. The crankshaft (10) drives the percussion head (1) to perform reciprocating percussion. The travel portion (7) drives the machine body to travel. The machine body (4) drives the reciprocating percussion portion (5) to move and work continuously. The device applies to the mining field or mechanical engineering field, and has advantages such as strong structural strength and a small amount of maintenance.

Owner:刘素华

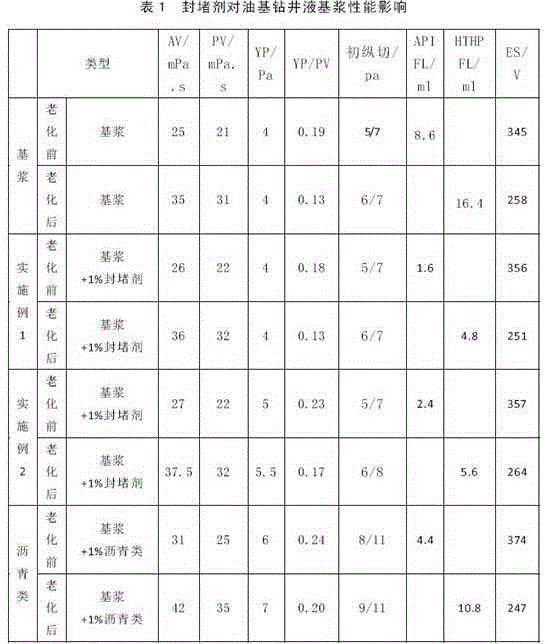

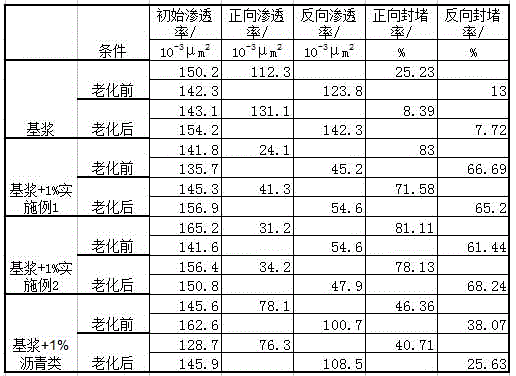

Resin type nanoparticle latex blocking agent for drilling fluids and preparation method of blocking agent

ActiveCN105462568AHigh blocking rateWide particle size distributionDrilling compositionBenzeneNanoparticle

The invention discloses a resin type nanoparticle latex blocking agent for drilling fluids. The blocking agent comprises raw materials in parts by weight as follows: 20 parts of alkenyl benzene, 15 parts of acrylate, 1 part of acrylates and 10 parts of hard inorganic materials, wherein the mass ratio of short-chain monomers to long-chain monomers in acrylate monomers is 3:1. The blocking agent is a composite product of the inorganic materials and organic materials, combines the hard materials with soft materials, has a higher blocking rate and is wide in particle size distribution and wider in application range; the rheological property of the drilling fluids are seldom influenced after the blocking agent is added to the drilling fluids, the blocking capacity of the drilling fluids can be remarkably improved, and the filter loss of the drilling fluids is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Leak protection plugging agent used during drilling for remarkably enhancing plugging effect

InactiveCN102093853AGood plugging effectHigh blocking rateDrilling compositionCross-linkWell drilling

The invention discloses a leak protection plugging agent used during drilling for remarkably enhancing plugging effect. The plugging agent comprises the following components in percentage by weight: 16.0 to 17.0 percent of 2-methyl-2-acrylamidopropanesulfonic acid, acrylic acid and acrylamide, 80.0 to 82.0 percent of water and the balance of initiator and cross linking agent. The effect of plugging along with drilling and leakage can be achieved, the plugging agent has high plugging rate and high loading capacity, and the plugging effect of well drilling is remarkably enhanced.

Owner:武侯区巅峰机电科技研发中心

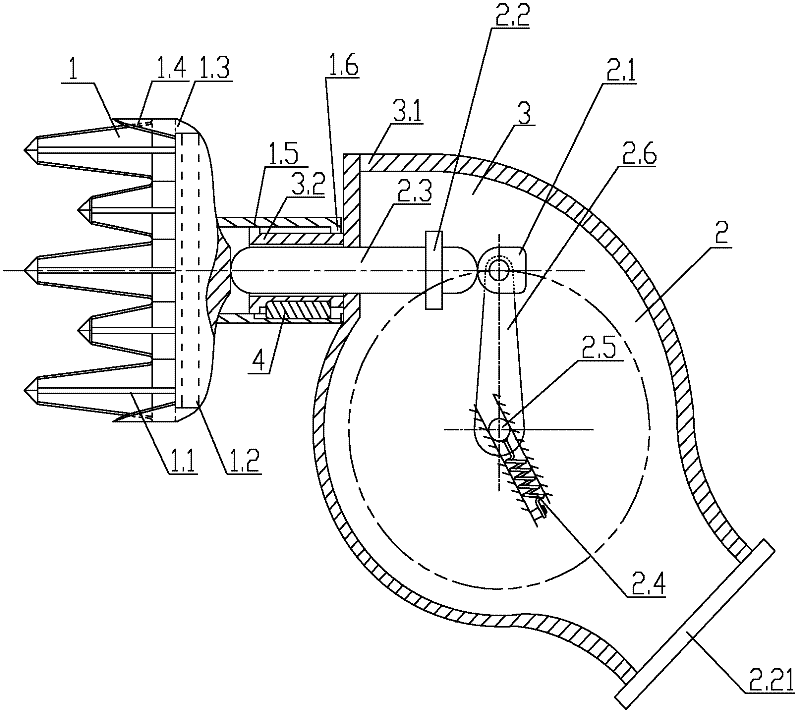

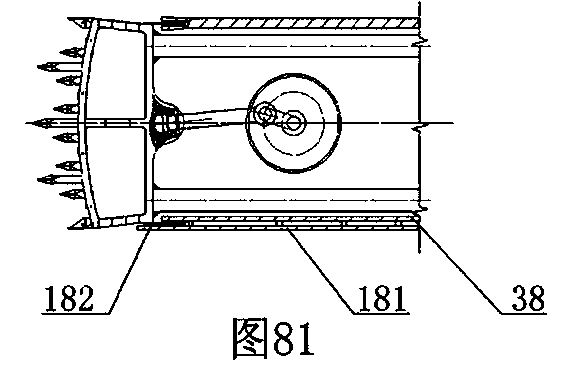

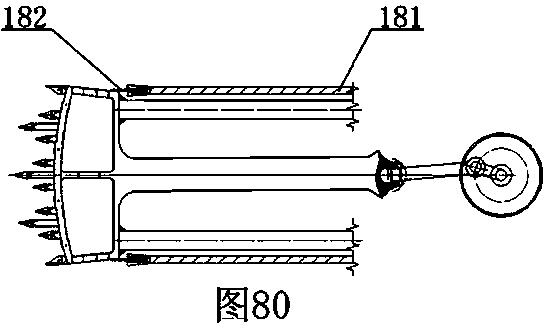

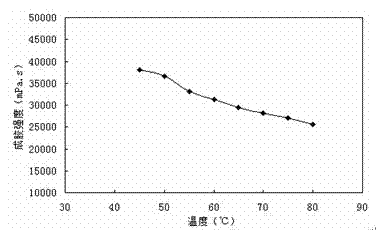

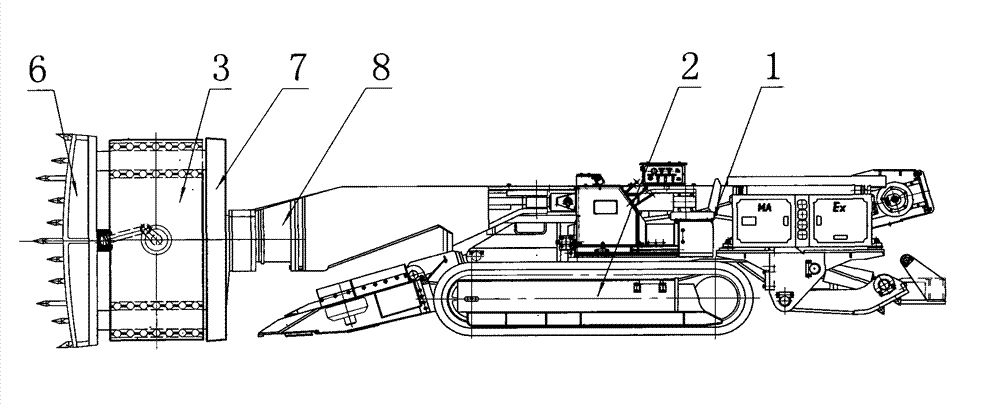

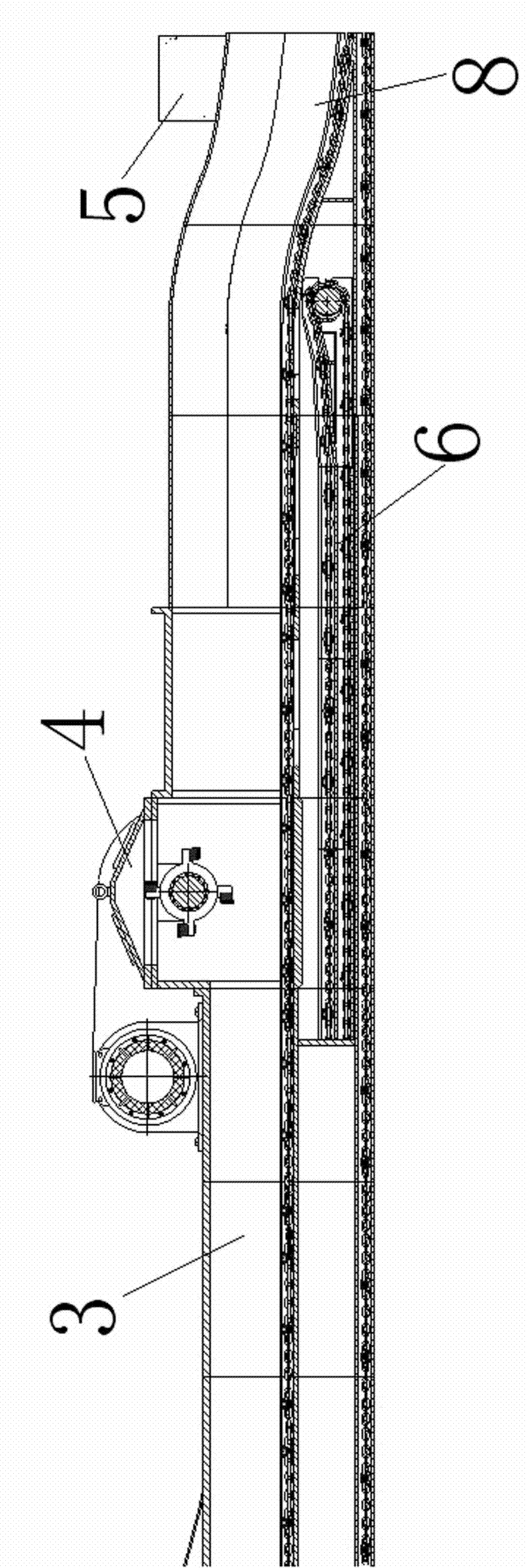

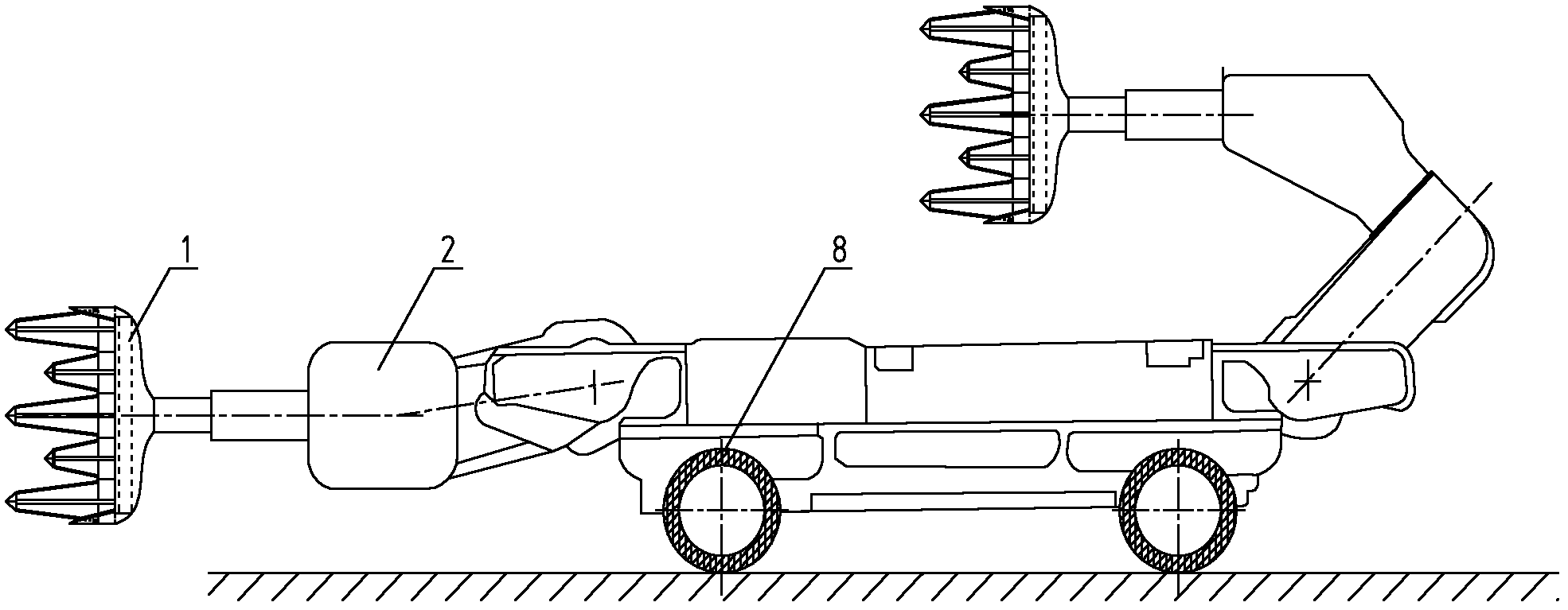

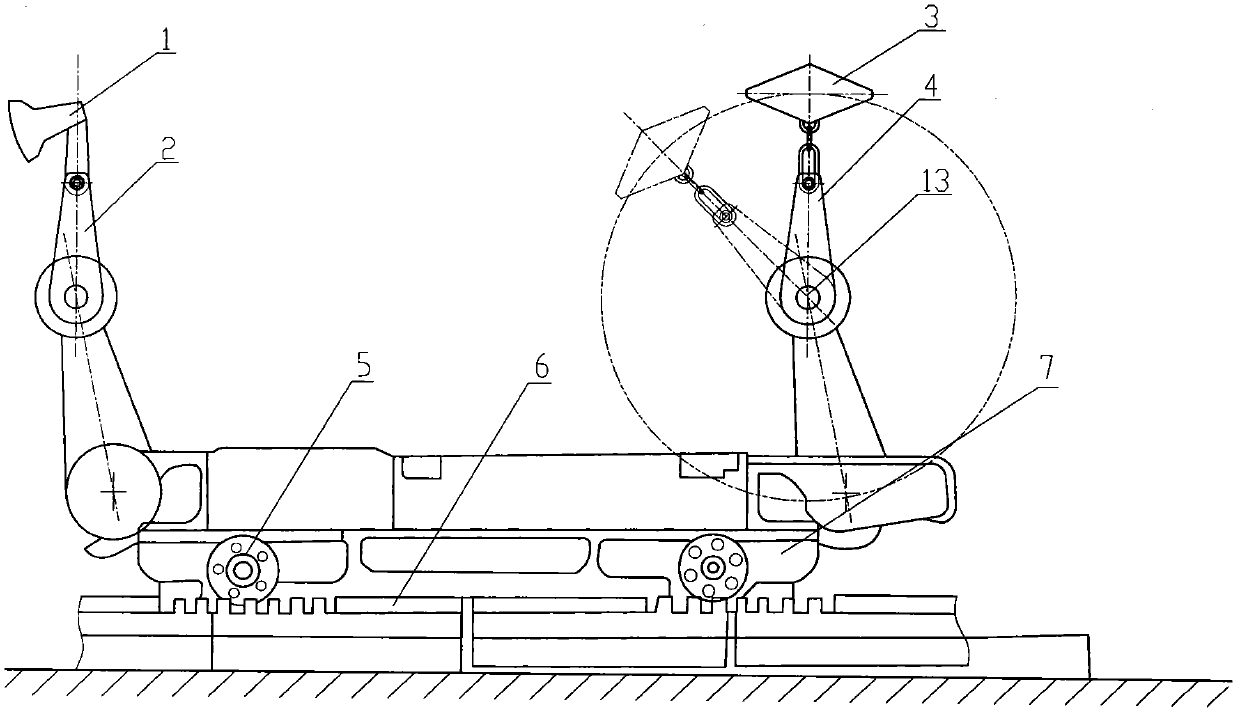

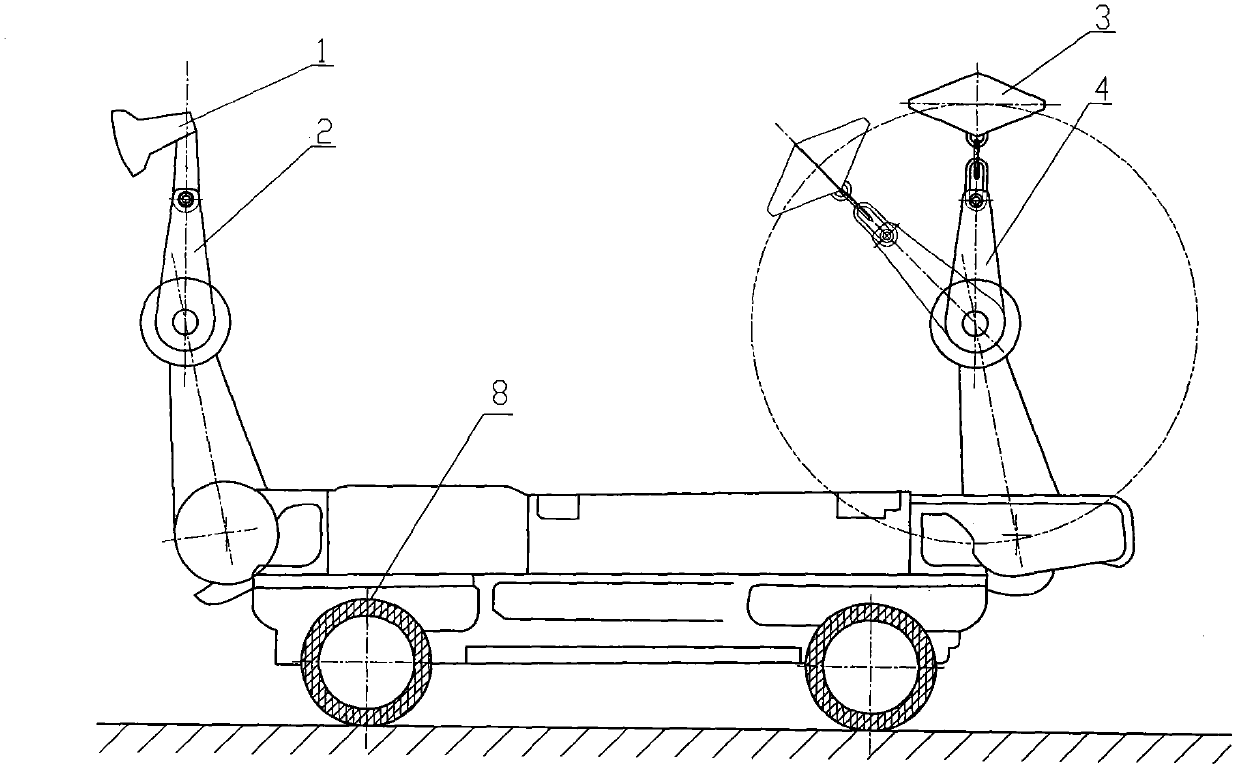

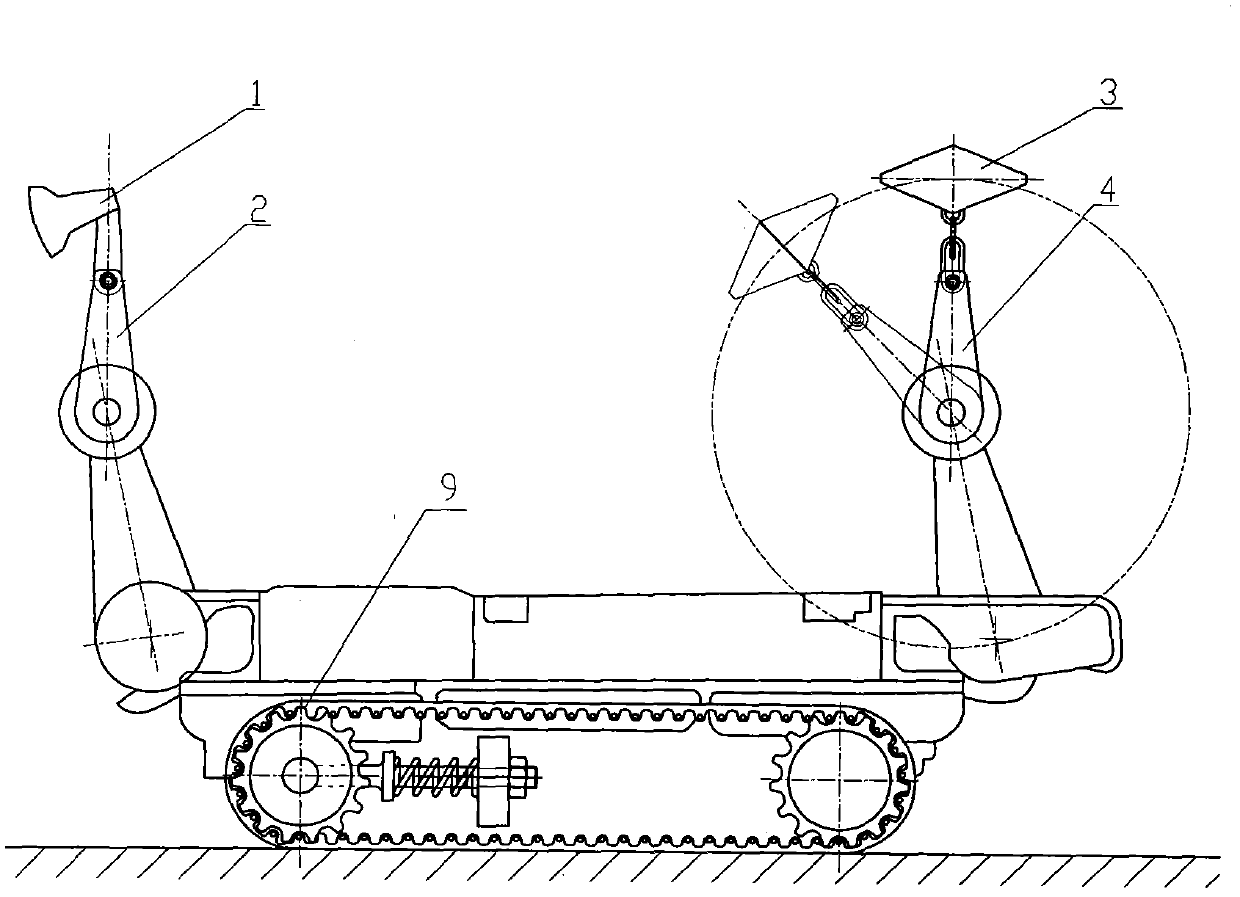

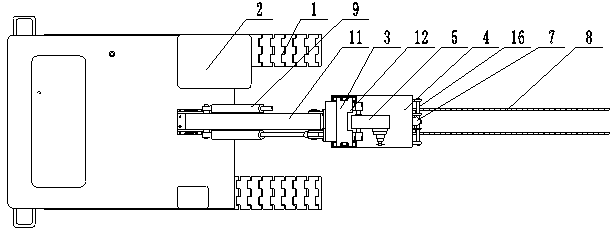

Efficient block mining machine

ActiveCN102654053AHigh blocking rateReduce power consumptionSlitting machinesChiselAgricultural engineering

The invention relates to coal-mining tunneling equipment for mines and particularly relates to an efficient block mining machine. The mining machine comprises a machine body, wherein the machine body comprises a machine frame, a guide device and a travelling device. The efficient block mining machine further comprises an impact blanking mechanism, wherein the impact blanking mechanism comprises a shovel head or a chisel head; the impact blanking mechanism further comprises an impact stroke device and an impacting device; the impact stroke device is in slide connection with the guide device; the guide device is arranged on the impacting device and / or the machine frame; the impact stroke device slides forwards and backwards along the guide device; the shovel head or the chisel head is arranged at the front part of the impact travelling device; the impacting device impacts the impact stroke device and the shovel head or the chisel head; the impact blanking mechanism is arranged on the machine body; and the travelling device drives the machine body to travel.

Owner:刘素华

Pretreatment process for tobacco threshing and redrying

InactiveCN101077213AHigh purityStrong targetingTobacco preparationTobacco treatmentEngineeringPre treatment

The present invention relates to tobacco pre-treatment, and is especially sectional tobacco thrashing and redrying pre-treatment process. The tobacco pre-treatment process includes the following steps: spreading the vacuum dampened tobacco leaf; cutting tobacco leaf into three sections including leaf stem, leaf base and leaf tip; moistening the leaf stem and separating in a leaf stem returning device into tobacco leaf stem and inferior tobacco leaf; and sieving leaf base to eliminate sand, moistening and multi-stage separating to obtain tobacco leaf stem and tobacco leaf. The tobacco pre-treatment process has high product quality.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Double-medium decoupling fracture damage blasting control method and auget

InactiveCN101363701AHighlight substantive featuresHigh static pressure resultant forceBlasting cartridgesBlastingEngineeringExplosive power

The invention relates to a method for controlling blasting by double-medium decoupling fracture and damage and a blasting cartridge thereof. The method adopts cylindrical explosive, detonator or primacord to explode a hole on a blasted rock body. The method is characterized in that water and air are simultaneously used in the hole to separate explosive, wherein, the water medium is aligned to the side of a free surface, while the air medium is aligned to the side of a reserved surface; the uniform distributing state of explosive energy can be changed by using the characteristics that the two media have different efficiencies of transmitting energy, thereby achieving the function of completely destroying one side and protecting the reserved surface during blasting, and forming a flat fracture surface. The blasting cartridge consists of an outer tube, an inner tube and a separating wall, wherein, the separating wall separates a cavity formed between the outer tube and the inner tube into a medium chamber for containing the water medium and a medium chamber for containing the air medium; and an explosive chamber for placing the cylindrical explosive is arranged in the inner tube. The invention has the advantages of easily operating, improving explosive power and agglomerating rate, protecting stability of wall rock, reducing harm of dust and noise, and the like, and can be widely applied to smooth blasting projects such as tunnels, side slopes, water conservancies, mining, and the like.

Owner:TAIYUAN UNIV OF TECH

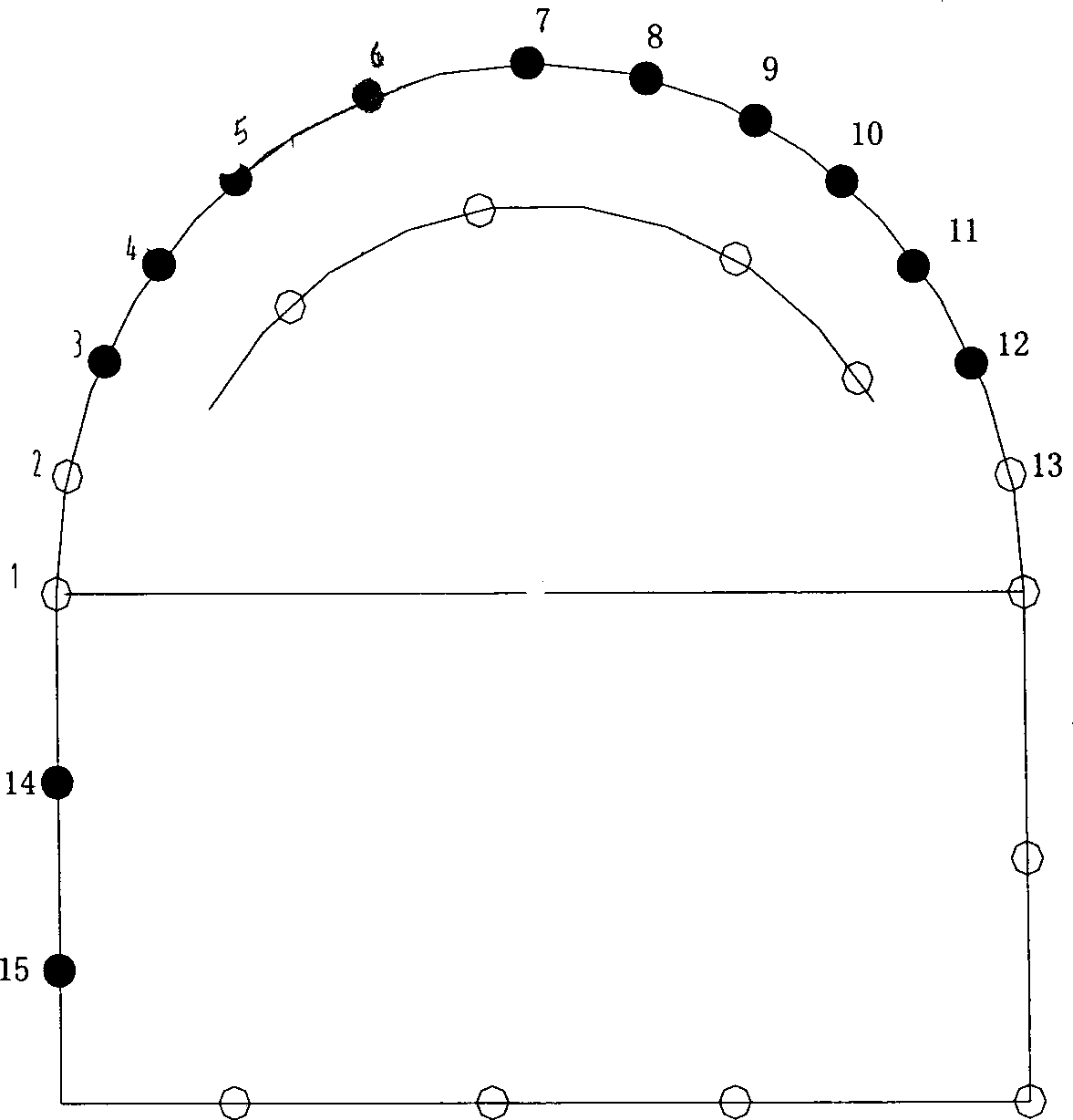

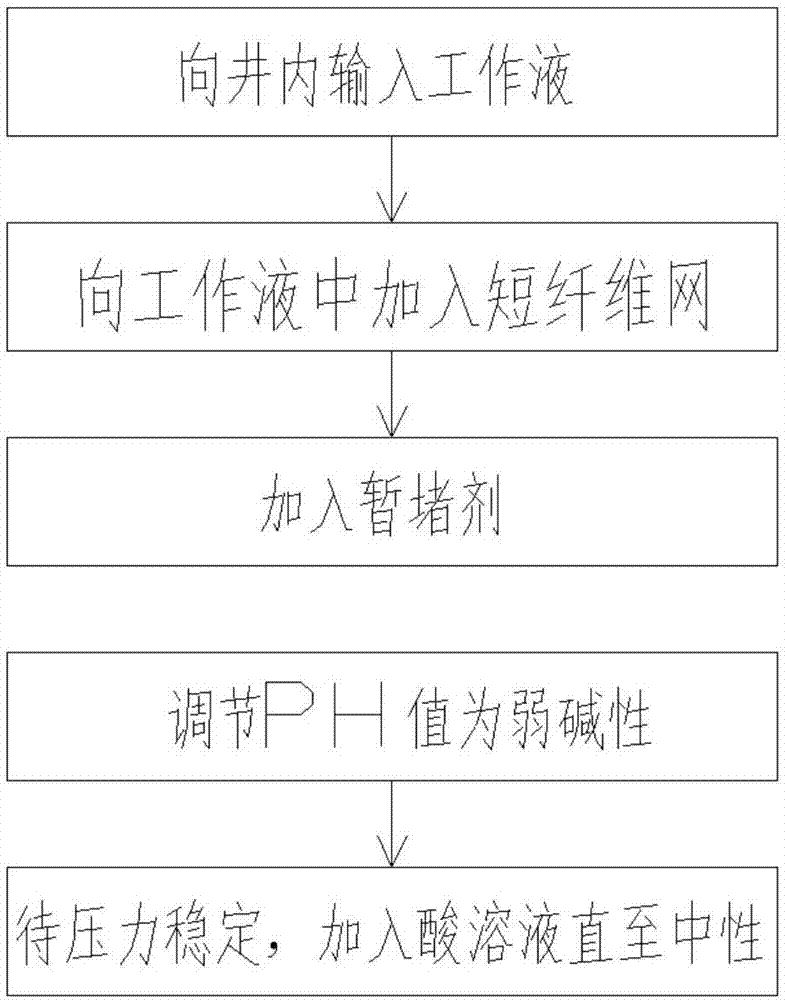

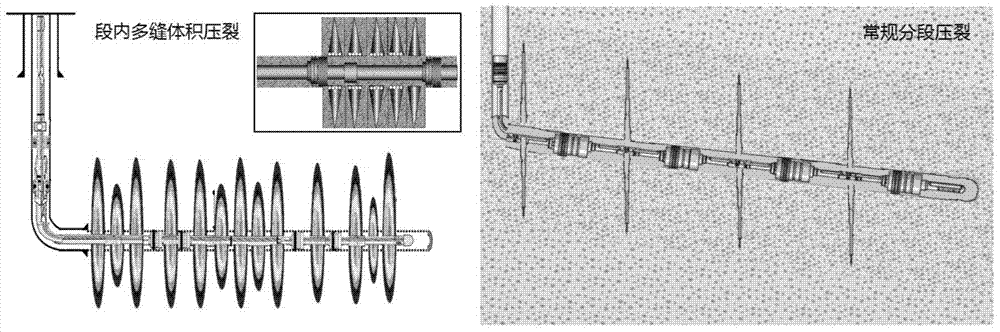

Temporary plugging turnaround fracture method

ActiveCN107100607AWide temperature rangeHigh blocking rateFluid removalDrilling compositionFiberSodium hydroxide

The invention provides a temporary plugging turnaround fracture method. The temporary plugging turnaround fracture method comprises the following steps that firstly, working liquid comprising fracturing liquid is input into a well; secondly, when the liquid level of the working liquid rises rapidly, a short fiber mesh is added into the working liquid; thirdly, temporary plugging agents comprising the large-particle temporary plugging agent and the powder temporary plugging agent are added into the working liquid; fourthly, the PH value of the lower-layer working liquid is measured, if the PH value of the lower-layer working liquid is neutral or acidic, a sodium hydroxide solution is added, and the PH value is adjusted to be weakly alkaline; and fifthly, after the pressure is stable, an acid solution is added till the PH value of the lower-layer working liquid is neutral. The temporary plugging turnaround fracture method has the advantages that by injecting the high-strength temporary plugging agents comprising the large-particle temporary plugging agent and the powder temporary plugging agent into a stratum in a pumping mode, former cracks are plugged, a fluid is forced to turn around, new cracks are opened in a pressed mode to enable crack forms to be complicated, and accordingly the single well yield and the controlled reserve are increased.

Owner:大庆中联信实石油科技开发有限公司

High-temperature resistant secondary cross-linked gel profile control agent and preparation method thereof

InactiveCN104357032AImprove gelationImprove seal strengthDrilling compositionCross-linkSalt resistance

The invention discloses a high-temperature resistant secondary cross-linked gel profile control agent and a preparation method thereof, and belongs to the technical field of oilfield chemistry. The profile control agent has good gelling property and high plugging strength and can resist high temperature of 150 DEG C, and the gelling strength and the gelling time can be adjusted. The high-temperature resistant secondary cross-linked gel profile control agent is mainly characterized by the secondary composite crosslinking process, that is, a plugging agent reacts with a first crosslinking agent under the ground condition to form flowable gel similar to weak gel so as to reduce filter loss of the plugging agent in oil deposit during the construction process and reduce the risk of blocking a low-permeability oil flow channel by the plugging agent; and a second crosslinking agent has a second crosslinking reaction under the high-temperature condition of an oil layer to form high-strength gel so as to effectively plug a high-permeability steam flowing channel, and accordingly, steam suction is controlled, and the sweep efficiency is improved. Gelling of the high-temperature resistant secondary cross-linked gel profile control agent is characterized in that micromolecules are inserted into organic macromolecular materials HPAM, and micromolecules and macromolecules mutually permeate, so that a gel system easily performs sizing; and meanwhile, temperature resistance, salt resistance, shear resistance and ageing resistance are enhanced, and the system performance can be well played.

Owner:CHINA PETROLEUM & CHEM CORP +1

Expansion and solidification type plugging agent

The invention relates to an expansion and solidification type plugging agent which comprises the following components in parts by weight: 0.5-2 parts of a calcium sulphoaluminate expanding agent, 1-4 parts of polypropylene fibers, 0.1-1 part of a water adsorption expansion type polymer, 1-5 parts of super absorbent resin SAP, 2-6 parts of puffed starch, 2-6 parts of salt-resistant clay, 20-40 parts of calcium carbonate and 0.1-0.5 part of high viscosity polyanionic cellulose PAC-HV. The preparation method comprises the following steps: sequentially adding the components in parts by weight to a kneading machine by a conventional preparation method under normal temperature and pressure; uniformly mixing and stirring; and crushing to a particle product with the grain size of 0.01-0.5mm till being dried. The plugging agent provided by the invention has the characteristics of high expansion rate, viscous flow capacity, plugging capacity, strong salt-resistance, flowability, pumpability, good coagulability, simple process, safe and quick construction, long coagulability, wide source of raw materials, high plugging success rate and the like, and is widely applied to plugging processes of large pore paths, subterranean rivers and great Karst cave leakage strata in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

High-strength temporary blocking agent for oil and gas wells and preparation method and application thereof

ActiveCN103788936AHigh strengthGood blocking rateDrilling compositionSealing/packingSolubilityAdhesive

The invention relates to a high-strength temporary blocking agent for oil and gas wells and a preparation method and application thereof. The temporary blocking agent for oil and gas wells is prepared from the following ingredients through crosslinking reaction: thickening agent, dispersing agent, adhesive and a temperature resistant material with mass ratio of (2.5-3):(1.3-2):(2.8-3):(1.7-2), preferentially, 3:2:3:2. The temporary blocking agent for oil and gas wells has the advantages of high strength, filter cake formation, good solubility and controllable time, flowback is facilitated and the method is simple to operate.

Owner:ORIENT BAOLIN TECH DEV BEIJING

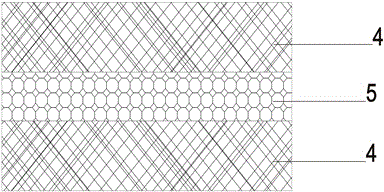

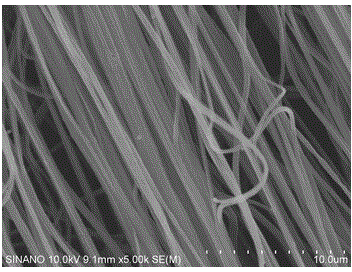

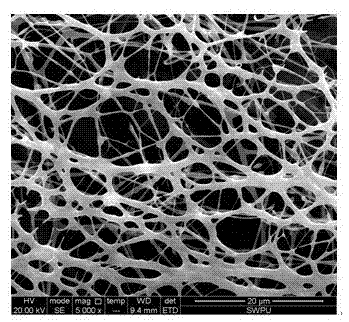

Nano window screen

InactiveCN104405271ALarge specific surface areaSmall particlesDispersed particle filtrationInsect protectionActivated carbonHazardous substance

The invention discloses a nano window screen which comprises a frame and gauze embedded on the frame. The gauze comprises a non-woven fabric overlaid layer formed by two layers of non-woven fabrics and at least one layer of nanofiber film arranged between the two layers of non-woven fabrics; each nanofiber film is formed by nanofibers in a crossed manner; pores with an aperture range of 0.1mu m to 0.5mu m are formed between the nanofibers. According to the nano window screen, the nanofibers which are special superfine fibers are used; the surfaces of the superfine fibers are provided with activated carbon particles with an adsorption effect. The superfine fibers have large specific surface areas and have more contact probability with particles and micromolecular harmful substances in air. The pores formed by the fibers in the crossed manner also show a nano-scale distribution range, and commonly, each nanofiber film with a thickness of 10mu m has the aperture range of 0.05mu m to 0.5mu m, and thus, the window screen can block particles with the particle size of being no less than 0.5mu m and the blockage rate is improved a lot. The thickness of each nanofiber film can be controlled to change the aperture range so as to implement filtering on smaller particles in the air.

Owner:南通百博丝纳米科技有限公司

Method for preparing cow dung charcoal for inhibiting nitrogenous fertilizer leaching loss

InactiveCN104030862AExpanding the Utilization Ways of Cow Dung Biomass ResourcesGood economic benefitsClimate change adaptationAgriculture gas emission reductionWater contentMuffle furnace

The invention discloses a method for preparing cow dung charcoal for inhibiting nitrogenous fertilizer leaching loss, and relates to a charcoal preparation method. The method comprises the following steps of pretreating cow dung, namely, collecting and drying cow dung so as to reduce the water content of cow dung to be 10-20%; preparing the charcoal, namely, preheating to keep the water content of cow dung to be about 5-8%; splitting the charcoal, namely, performing pyrolysis for 2-3 hours under anoxic condition; finally turning off a power supply control switch of a muffle furnace; cooling to be less than 80 DEG C under the condition that the door of the muffle furnace is closed; taking out a crucible utensil from the muffle furnace; putting into a drier for being cooled for later use; crushing the charcoal, namely, putting the cow dung charcoal prepared from splitting into a crushing machine for crushing, screening, and taking the cow dung charcoal of 20-40 meshes. Due to adoption of the method of applying the cow dung charcoal soil improver, the resource utilization ways of cow dung are widened, the utilization efficiency of a nitrogenous fertilizer is improved, and the environment pollution caused by nitrogenous fertilizer leaching loss is reduced.

Owner:SHENYANG UNIV

Environment-friendly crosslinking and gelling retarding profile control agent and preparation method thereof

InactiveCN102965088ADo no harmImprove water injection development effectDrilling compositionSulfite saltAntioxidant

The invention discloses an environment-friendly crosslinking and gelling retarding profile control agent and a preparation method thereof and belongs to the field of enhanced oil recovery technologies for oilfields. The profile control agent comprises a primary agent, i.e. hydrophobic association, a crosslinking agent, i.e. aluminum citrate, an antioxidant, i.e. sodium sulfite, and a retarding agent, i.e. sodium malate, and contains all the ingredients in percentage by weight: 0.1-0.4% of hydrophobic association, 0.01-0.02% of aluminum citrate, 0.015-0.025% of sodium sulfite, 0.005-0.020% of sodium malate and the balance of water. The profile control agent disclosed by the invention has the characteristics that the profile control agent is environment-friendly and is free of damage / injury to environments / human bodies; the crosslinking is retarded, and the gelling time is prolonged, thereby being beneficial to high-dose injection and deep profile control; the plugging rate is high; and the profile control agent has certain temperature-resistant and salt-tolerant performance and scouring resistance. The profile control agent can be used for adjusting a water absorption profile of a water-flood well and improving the water-flood development effect of oilfields.

Owner:SOUTHWEST PETROLEUM UNIV

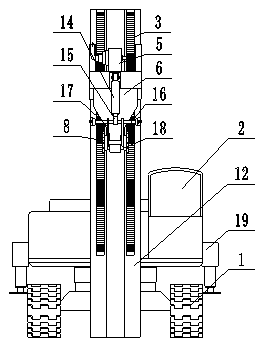

Rolling friction or suspension friction impact excavating method and antiabrasion impact excavator for implementing the same

ActiveCN103291291AEliminate farewellAvoid damageDriving meansTunnelsRolling resistanceReciprocating motion

The invention relates to a rolling friction or suspension friction impact excavating method and an antiabrasion impact excavator for implementing the same. The antiabrasion impact excavator includes a reciprocating impact part, which consists of an impact drive device, a rolling reciprocating device and an impact head. The rolling reciprocating device comprises a friction body, a friction body support, an impact guide element and a limit structure. The friction body is arranged between the friction body support and the impact guide element and is disposed at the limit structure to form a rolling guide. The impact drive device is equipped with an anti-breakoff mechanism. The excavator is also provided with a rotary power buffering device and a structure buffering device, so that the impact head can make rolling friction or suspension friction reciprocating motion under support of the impact guide element, the damage caused by an anti-breakoff force to a power drive device and a rolling path guiding device can be prevented, and the influence of a reciprocating impact part's impact shock on the excavator body and other parts can be avoided. Therefore, stability of the whole excavator can be improved, and the service life can be prolonged.

Owner:刘素华

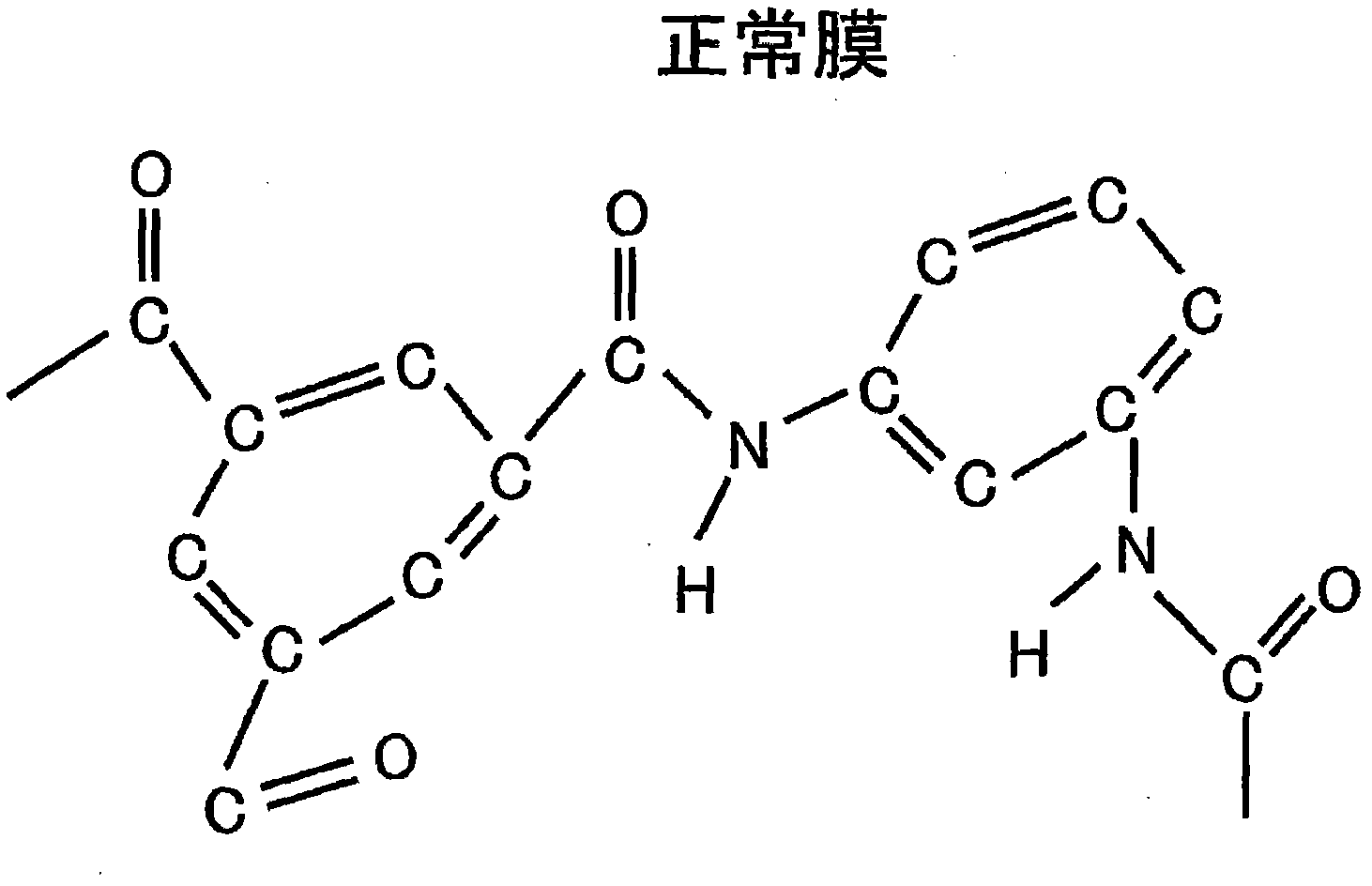

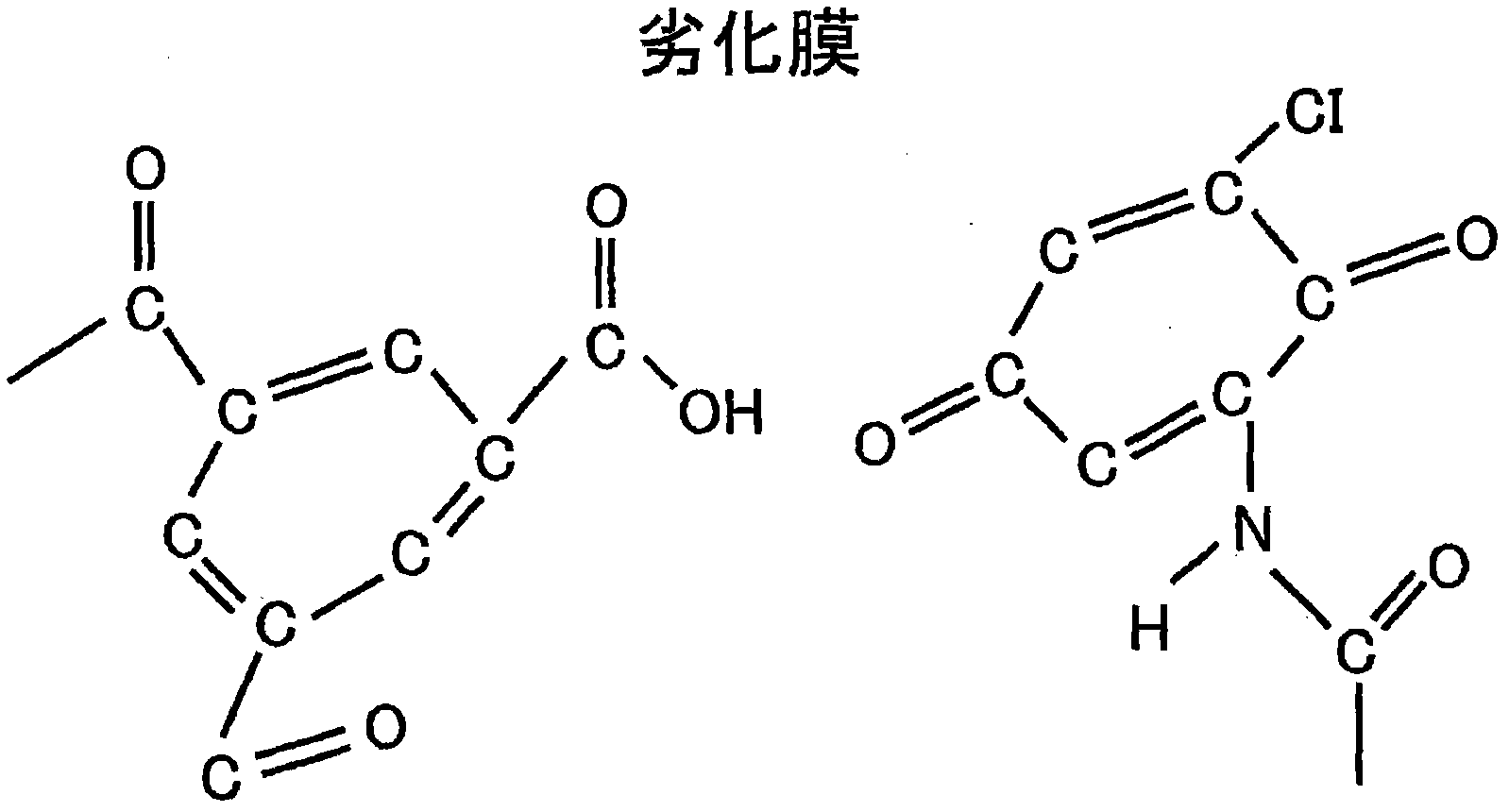

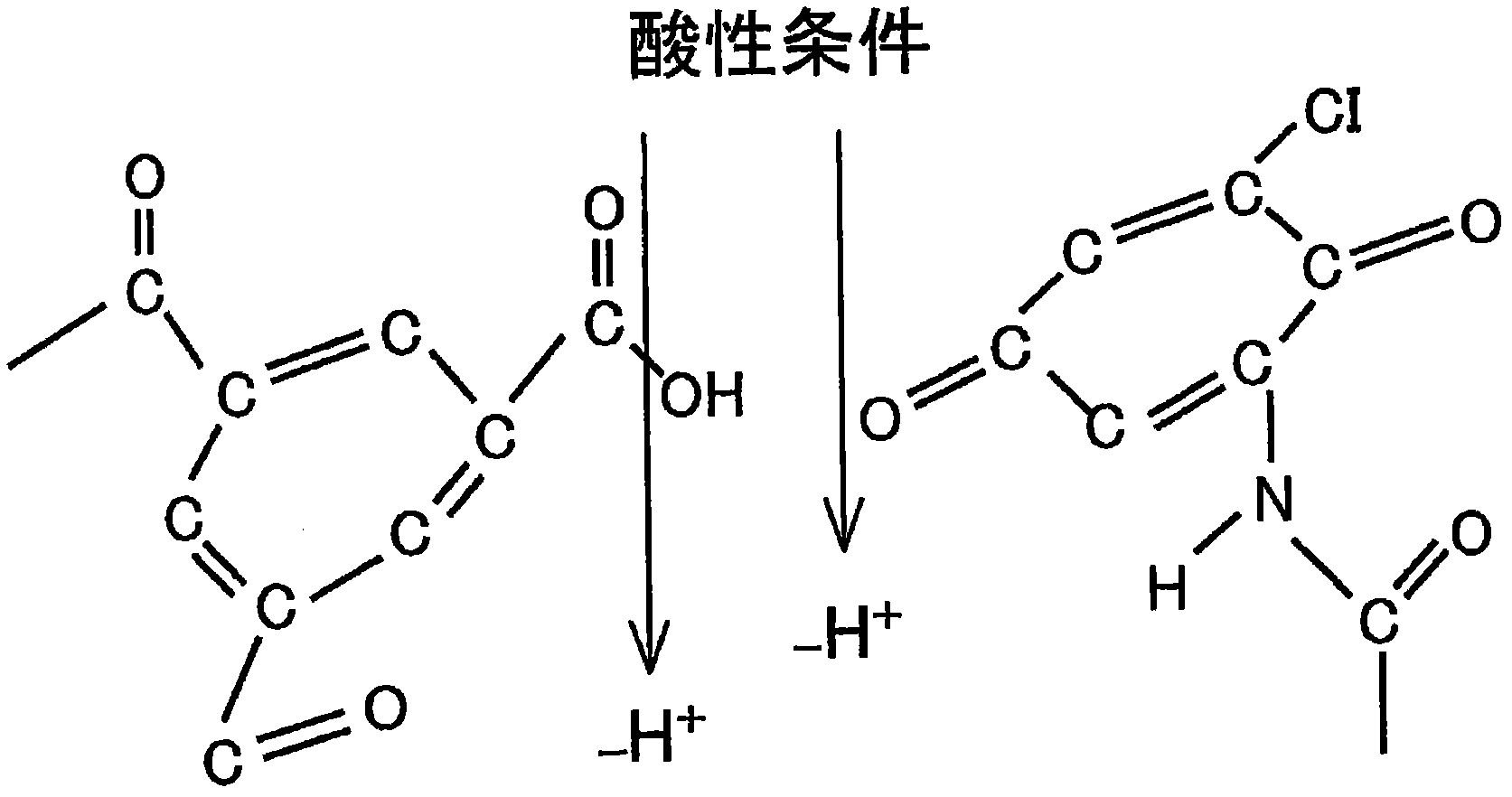

Method for improving rejection of permeable membrane and permeable membrane

ActiveCN102695555APermeation flux dropBlock rate recoveryWater/sewage treatment by irradiationTreatment involving filtrationTreatments waterAmmonia

A method is provided with which it is possible to effectively improve the rejection of a membrane without considerably lowering the permeation flux, even when the membrane has significantly deteriorated. The method for improving the rejection of a permeable membrane includes a step (amino treatment step) in which an aqueous solution that contains a compound having an amino group and having a molecular weight of 1,000 or lower and has a pH of 7 or lower (amino treatment water) is passed through the permeable membrane. After this amino treatment step, water having a higher pH than the amino treatment water is passed through the permeable membrane. Thus, by passing the low-molecular amino compound, the part of the membrane which has deteriorated can be repaired without considerably lowering the permeation flux of this permeable membrane, and the rejection can be effectively improved.

Owner:KURITA WATER INDUSTRIES LTD

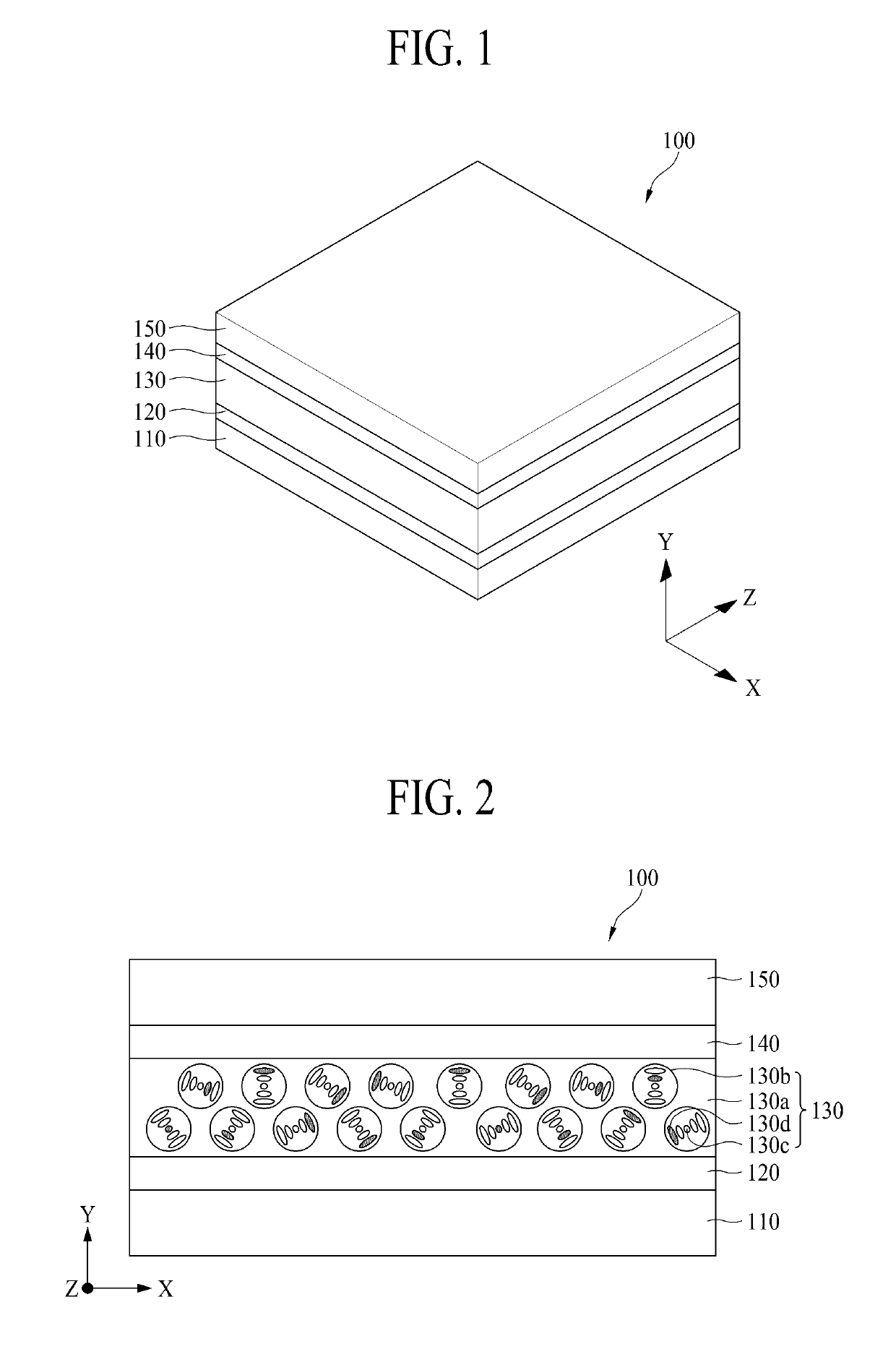

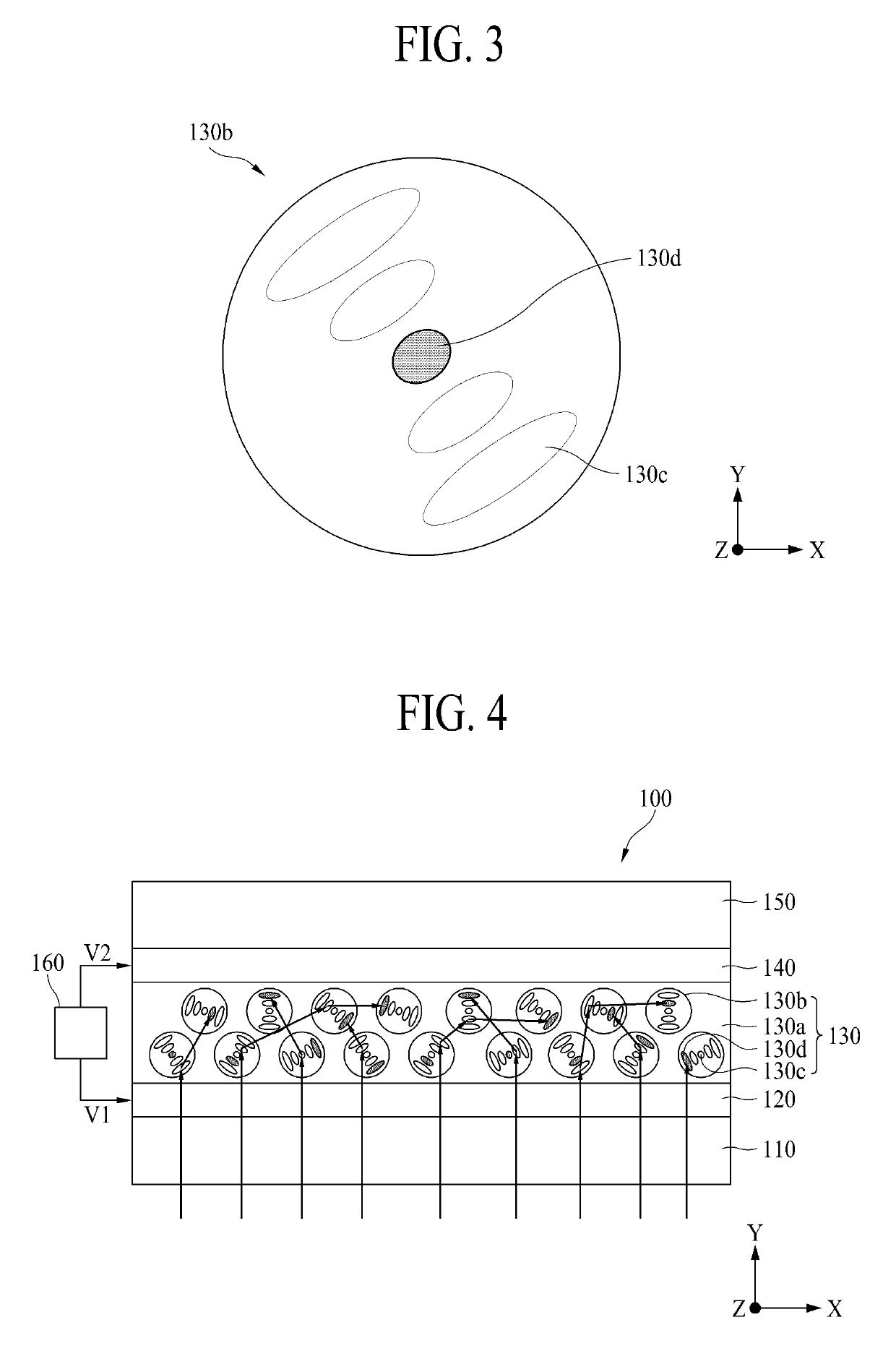

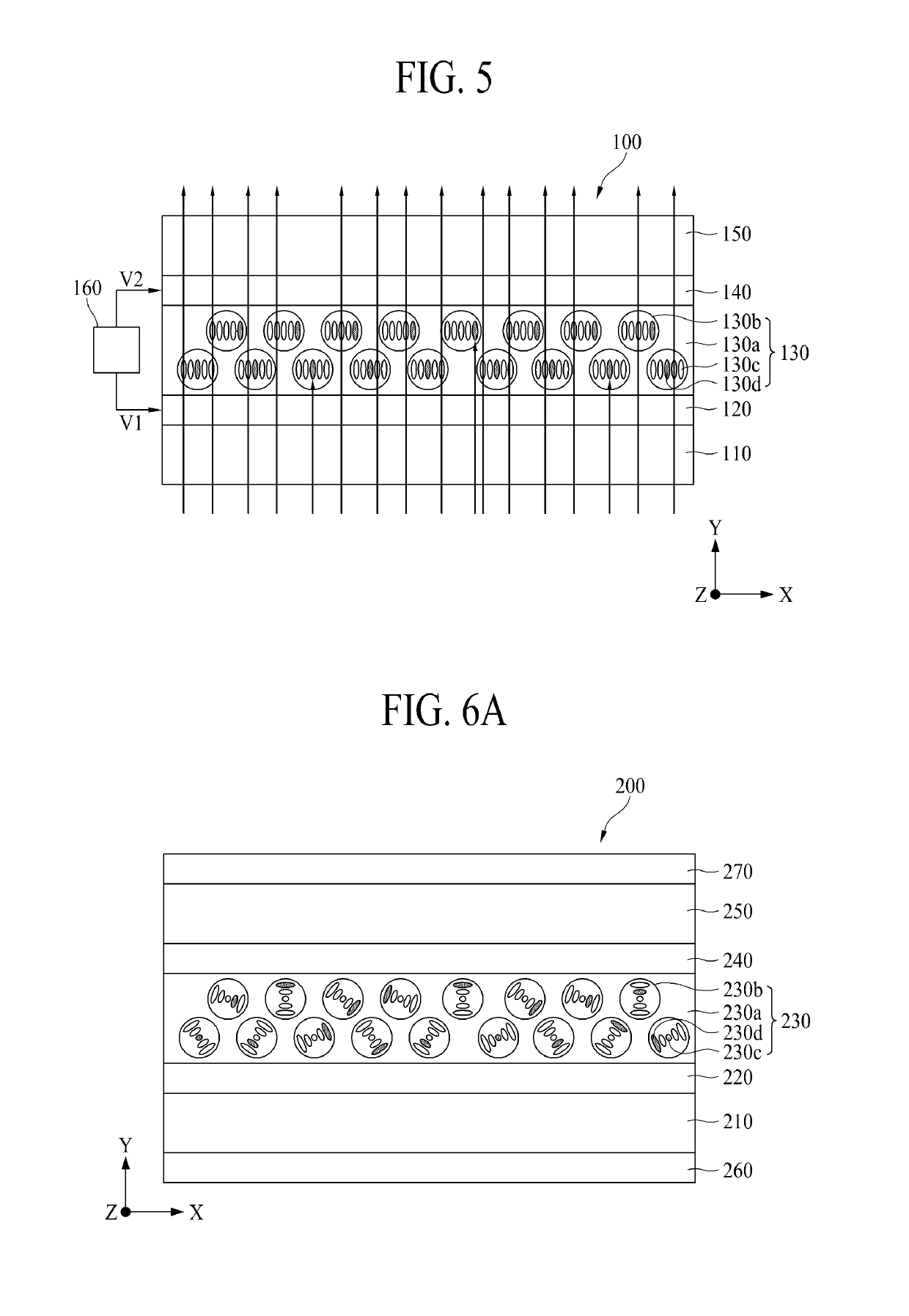

Light blocking device, method of manufacturing the same, and transparent display device including the same

ActiveUS10394070B2High blocking rateHigh light transmittanceStatic indicating devicesSolid-state devicesDichroic dyeLiquid crystal

Owner:LG DISPLAY CO LTD

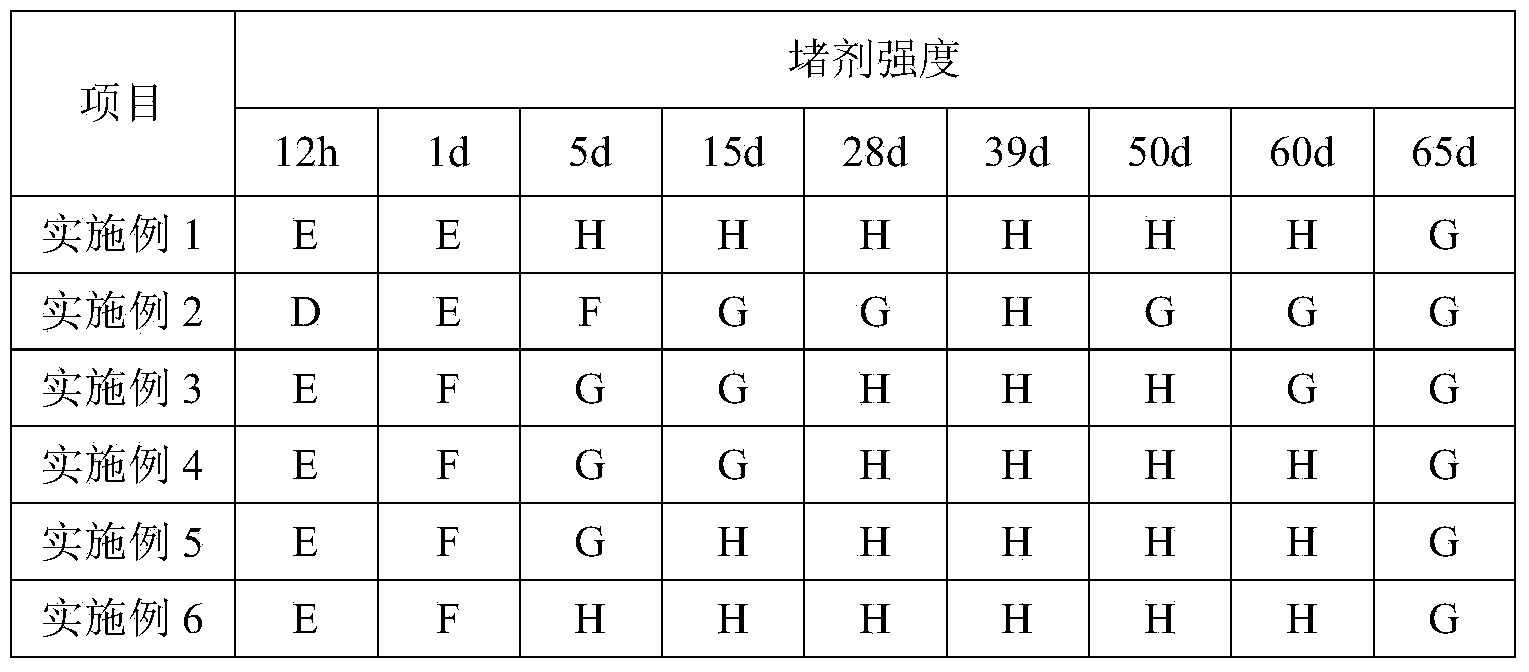

A technology and equipment for increasing coal lump rate

ActiveCN102269012AFree from secondary breakage into foamHigh blocking rateEarth drilling and miningUnderground transportProcess engineeringCrusher

The invention relates to a process and equipment for coal mine production, in particular to a process and equipment for increasing block coal rate. The technical problem of reduced block coal rate resulted from the disadvantages of fully mechanized coal mining equipment, in particular the process matched design of a crusher and an elevating conveyor, in the coal mine underground mining process is solved. The process is characterized by comprising the following steps: a coal block and slack coal mixture body obtained by cutting through a coal mining machine is sorted through a screening device; the block coal not less than 200 mm is sorted and delivered out of the rear section of the screening device and is conveyed away by bypassing the crusher; large block coal to be crushed is fed to the crusher to be crushed and then is conveyed to a main conveying belt through the elevating conveyor; the sorted mixed coal less than 200 mm is conveyed to the outlet of the crusher through a sorting conveying section by bypassing the crusher, fed to the front section of the elevating conveyor, delivered to the main conveying belt, and then conveyed to a place aboveground; and the whole process of sorting, crushing and conveying is completed. The block rate of the coal with the diameter of 13-200 mm is comprehensively increased by 5-6%.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

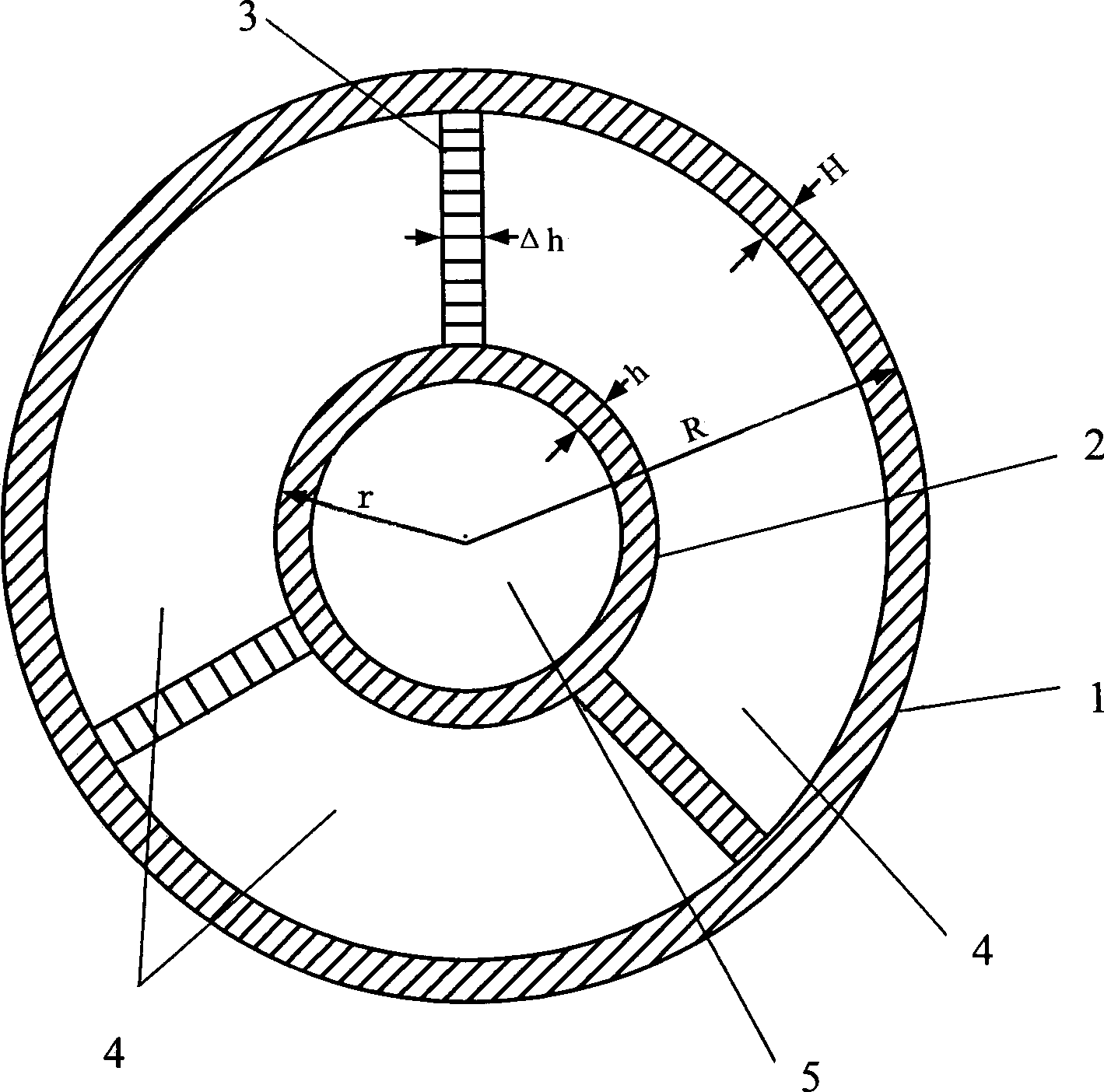

Efficient blocking coal shoveling device

ActiveCN102678111AImprove efficiencyExtended service lifePropulsionSurface cleaningWorking environment

The invention relates to mine coal extraction equipment and specifically relates to an efficient blocking coal shoveling device. The coal shoveling device comprises a device body and an impact shovel mechanism, wherein the device body comprises a rack, the impact shovel mechanism comprises a shovel head and an impacting device, the shovel head includes shovel teeth and a fixing part, the shovel teeth are installed on the fixing part, an impact stroke guide rod is arranged on the rear portion of the fixing part and is in a sliding connection with a guide sleeve, the guide sleeve is arranged on the impacting device and / or the rack, the impacting device can impact the impact stroke guide rod, an impacting action enables the shovel head to have a one-time completion of a coal blanking and a surface cleaning, and the impact shovel mechanism is arranged on the device body which drive a whole device to move. By means of the efficient blocking coal shoveling device, extracted coals are not subjected to a sufficient crushing, so that blocking material rate is high, power consumption and coal dusts are small, work environment is good, a continuous coal extraction and the one-time completion of the coal blanking and the surface cleaning are achieved, and a large amount of energy is saved.

Owner:刘素华

Outside casing channeling-blocking agent

The invention discloses an outside casing channeling-blocking agent which is applicable to the blocking of the outside casing channeling of an oil-water well casing on an oil field. The outside casing channeling-blocking agent is composed of 0.5-2% of nano zinc oxide, 1-3% of nano titanium oxide, 15-30% of silicon micro powder, 0.5-2% of glass fiber, 30-45% of ultra-fine cement, 1-1.5% of complex iron salt, 0.5-2% of retarder and 35-45% of water. Because of the addition of the part of the nano materials, the channeling-blocking agent has good slurry fluidity and high thixotropy, ensures high intensity and non-shrinking volume after being cured, produces no micro crack and has high blocking rate. Besides, the channeling-blocking agent can effectively solve the outside casing channeling problem caused by poor high pressure water injection quality of a water injection well, poor well cementing quality of an oil well or other reasons, and can be also used for secondary well cementing above the top of the cement.

Owner:CHINA PETROLEUM & CHEM CORP +1

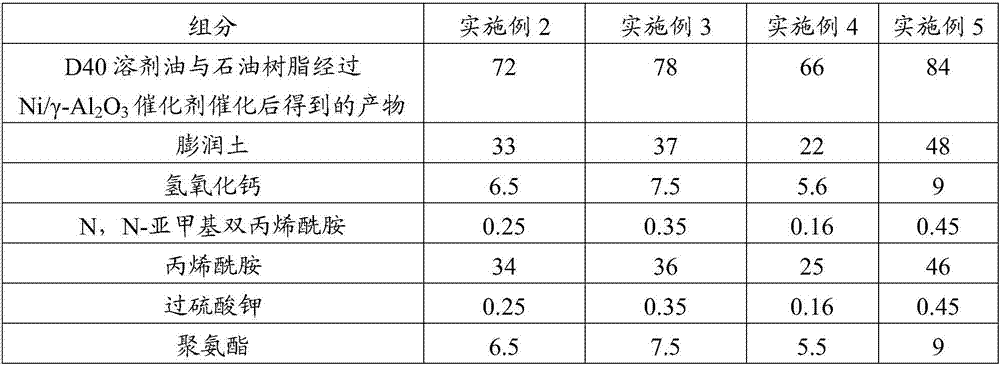

Temperature-resistant salt-resistant filled flow regulation particle and preparation method thereof

The invention relates to a temperature-resistant salt-resistant filled flow regulation particle which comprises the following components in parts by weight: 65-85 parts of a product prepared by catalyzing solvent oil and petroleum resin through a catalyst Ni / gamma-Al2O3, 20-50 parts of bentonite, 5-10 parts of calcium hydroxide, 0.1-0.5 part of N,N-methylenebis acrylamide, 20-50 parts of acrylamide, 0.1-0.5 part of potassium persulfate, 5-10 parts of polyurethane and 30-50 parts of water. The product has the advantages of simple construction, high efficiency, low cost, low density, high strength, low water swelling rate, excellent heat resistance and the like, is capable of realizing fixed-point storage of deep petroleum reservoir and is suitable for fractured-vuggy reservoir.

Owner:CHINA PETROLEUM & CHEM CORP

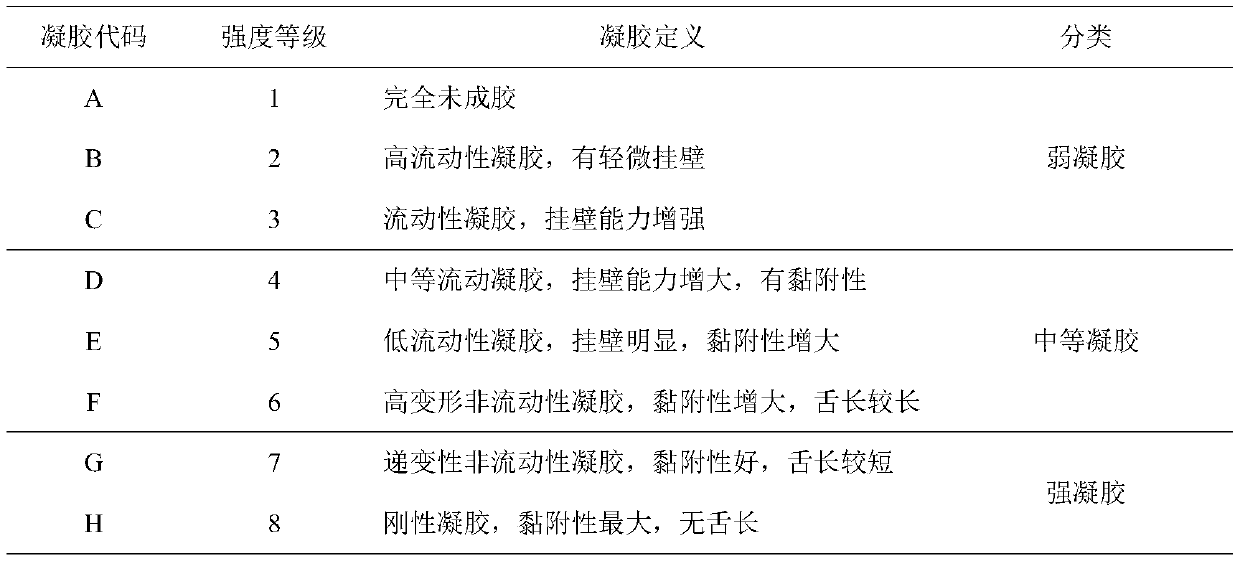

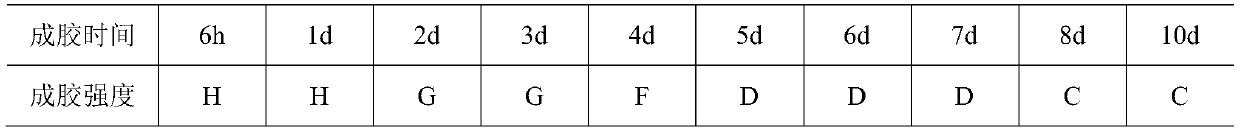

Medium-high temperature oil reservoir phenolic gel self-degradation temporary plugging agent and preparation method thereof

The invention relates to a medium-high temperature oil reservoir phenolic gel self-degradation temporary plugging agent and a preparation method thereof. The temporary plugging agent is prepared fromthe following components in percentage by mass: 2 to 2.5 percent of low molecular weight polymer, 0.2 to 0.25 percent of phenolic cross-linking agent, 0.2 to 0.6 percent of aldehyde cross-linking agent, 0.05 percent of stabilizer, 0.1 percent of catalyst, 0.5 to 2 percent of gel breaker and the balance of water, wherein the sum of the mass percent of all the components is 100 percent. The gel temporary plugging agent provided by the invention can meet the requirements that the oil reservoir temperature is 60-100 DEG C, the plugging time is adjustable within 120-168h, and the gel breaking timeis adjustable within 168-240h; the plugging rate of a rock core reaches 98% or above, the permeability damage rate after gel breaking is 10% or below, a high-permeability layer of a target stratum canbe effectively plugged, flowback is easy after automatic gel breaking, damage to the stratum is extremely small, and the plugging agent can be suitable for most conventional oil reservoirs and has good field application value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Leak plugging agent applied to exploration and development of petroleum and natural gas

InactiveCN102093858AImprove water absorptionHigh expansion rateDrilling compositionCross-linkMass ratio

The invention discloses a leak plugging agent applied to the exploration and development of petroleum and natural gas. The leak plugging agent comprises the following components in percentage by weight: 2.0 percent of 2-methyl-2-acrylamidopropanesulfonic acid, 4.0 percent of acrylic acid, 14.0 percent of acrylamide, 78.0 percent of water and 2.0 percent of initiator and cross-linking agent in a mass ratio of 1:1-1:3. The reaction time is short; the water absorbency and the expansion rate of the leak plugging agent are improved; the plugging rate is high; the loading capacity is high; and the leak plugging effect in the exploration and development process of the petroleum and the natural gas is obviously improved.

Owner:武侯区巅峰机电科技研发中心

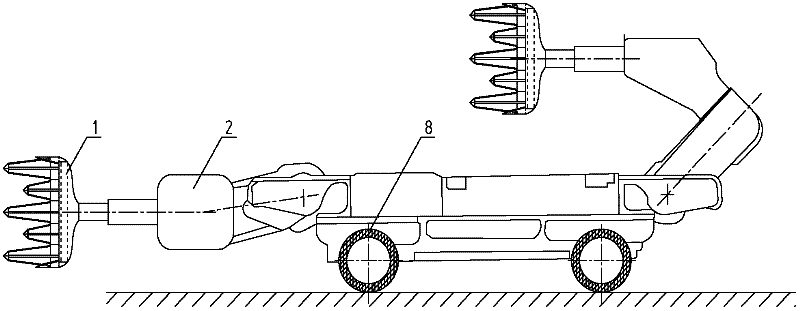

Spinning coal mining machine

InactiveCN102168557AImprove work efficiencyReduce energy consumptionDriving meansPropulsionSurface cleaningEngineering

The invention relates to mining equipment, particular to a spinning coal mining machine and a method which are used for mining large-sized coal according to the brittle feature of coal by using a spinning mechanism to impact, vibrate and cut coal layers in a rotating way. The spinning coal mining machine comprises a spinning mechanism, a driving mechanism, a machine body and the like, wherein the spinning mechanism is mounted on the machine body; the driving mechanism drives the spinning mechanism to rotate; the spinning mechanism impacts and cuts coal layers; the walking process of the machine body progresses in the match with the depth that the spinning mechanism impacts and cuts the coal layers. If a rotation bush hammer of the spinning mechanism has impact overload during a complete impacting process, by the bending, shifting and the like of a chaining part, a coupling part and an axial buffer part of a rotation arm, the rotation bush hammer can pass smoothly and continuously spins quickly to impact and cut the coal layers to continue coal mining. By the equipment, coal spinning and surface cleaning can be completed synchronously. And the spinning coal mining machine has the advantages of high block material rate, low power consumption, simple structure, stable performance, large mining height range, safety and reliability and the like.

Owner:刘素华

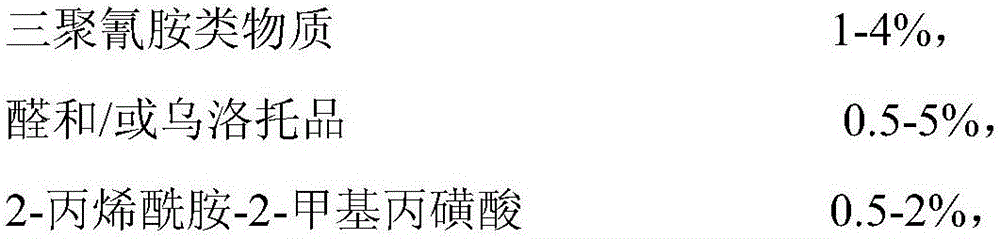

Steam-displacement ultrahigh-temperature channeling sealing agent, and preparation method and application thereof

The invention provides a steam-displacement ultrahigh-temperature channeling sealing agent, and a preparation method and application thereof. The steam-displacement ultrahigh-temperature channeling sealing agent comprises the following components in percentage by weight: 1-4% of melamine substance, 0.5-5% of aldehyde and / or urotropine, 0.5-2% of 2-acrylamido-methylpropylsulfonic acid, 0.05-0.2% of plasticizer, 0.05-0.2% of persulfate and the balance of water. The steam-displacement ultrahigh-temperature channeling sealing agent has the characteristics of favorable pumpability, favorable temperature resistance, long-term effectiveness, simple preparation process, low cost and the like, has the advantages of adjustable gelling time and high sealing, plugging capacity and wide oil reservoir variety applicability, can not easily pollute the stratum, can enter the deep stratum, and effectively solves the production problems of nonuniform steam suction cross section, steam channeling among wells and the like in the steam-displacement oil reservoir.

Owner:PETROCHINA CO LTD

Self-propelled coal sawing machine for longitudinally cutting coal bed into block coal and cutting method for cutting coal bed by using machine

InactiveCN103470265AHigh blocking rateHigh economic valueOpen-pit miningCutting machinesMechanical engineeringCoal mining

The invention discloses a self-propelled coal sawing machine for longitudinally cutting a coal bed into block coal and a cutting method for cutting the coal bed by using the machine, belonging to the technical field of coal-mining of opencast coal mines. In order to overcome defects in the prior art, the invention provides a self-propelled coal sawing machine for longitudinally cutting a coal bed into block coal and a cutting method for cutting the coal bed by using the machine, which are capable of greatly improving a block forming rate, mining efficiency as well as economic value of the coal mining, and a cutting method thereof. In order to solve the technical problems, According to the technical scheme adopted by the invention, the self-propelled coal sawing machine for longitudinally cutting the coal bed into block coal is characterized in that an operating mechanism is arranged on a travelling mechanism; the operating mechanism can rotate on the traveling mechanism by 360 degrees in a reciprocating manner; a guide mechanism is hinged on the operating mechanism; the guide mechanism can be stretched out or withdrawn according to a condition that whether the guide mechanism is worked or not; an executing mechanism is movably arranged on the guide mechanism; the executing mechanism can move up and down along the guide mechanism in the reciprocating manner. The method for cutting the coal bed by using the machine is also provided. The self-propelled coal sawing machine for longitudinally cutting the coal bed into block coal and the cutting method for cutting the coal bed by using the machine, disclosed by the invention, are mainly used for cutting an opencast coal bed.

Owner:马爱民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com