Environment-friendly crosslinking and gelling retarding profile control agent and preparation method thereof

A technology of cross-linked gel and profile control agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems affecting the injection performance of gel profile control agent and the performance of deep water control and displacement, and the gelation time of gel Short and other problems, to achieve the effect of large dose injection, expansion of injection water sweep volume, good temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

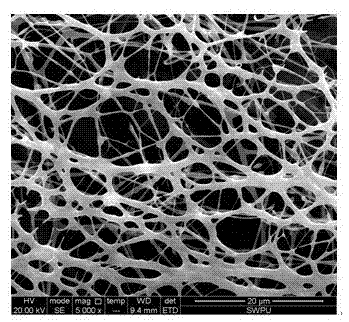

[0026] Embodiment 1: the microstructure of environment-friendly delayed crosslinking gel profile control agent under scanning electron microscope

[0027] Use prepared water (see Table 1 for the ion content of the prepared water) to prepare 0.5% hydrophobic association polymer mother liquor, stir and dissolve fully and let it stand for 24 hours; use distilled water to prepare 1.0% aluminum citrate, 1.0% sodium sulfite and 1.0% sodium malate respectively solution; add 0.5% hydrophobic association polymer mother liquor 60ml, 1.0% aluminum citrate 1.5ml, 1.0% sodium sulfite 2.0ml, 1.0% sodium malate 1.6ml and 34.9ml prepared water into a 200ml jar, The bottle was placed on a magnetic stirrer and stirred for 30 minutes to prepare an environmentally friendly delayed crosslinking gel profile control agent; then the jar was placed in a thermostat set at 65°C to form a gel; The microstructure of the glue profile control agent, the experimental results are as follows figure 1 It is sh...

Embodiment 2

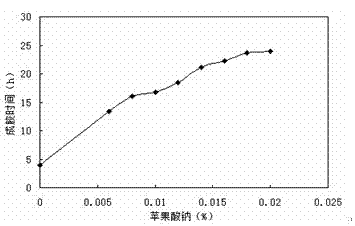

[0030] Embodiment 2: The impact of retarder dosage on the gelation time of environmental protection delayed cross-linked gel profile control agent

[0031] According to the method of preparing the environment-friendly delayed cross-linking gel profile control agent in Example 1, the added amount of the hydrophobic association polymer (0.3%), the cross-linking agent aluminum citrate (0.015%), and the antioxidant sodium sulfite (0.020%) were fixed , change the dosage of retarder sodium malate (0.006%, 0.008%, 0.010%, 0.012%, 0.014%, 0.016%, 0.018%, 0.020%), and prepare different dosage of retarder sodium malate Environmentally friendly delayed cross-linking gel profile control agent. Put the wide-mouth bottle containing the environmentally friendly delayed cross-linking gel profile control agent in an incubator set at 65°C to form a gel, and regularly use a Brookfield DV-III rotational viscometer (temperature 65°C, shear rate 7.34s -1 ) Determination of the gelation time of the...

Embodiment 3

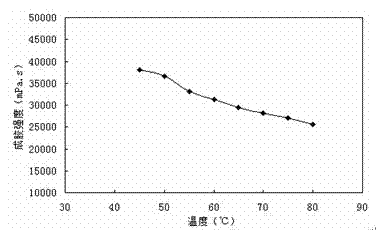

[0032] Embodiment 3: the temperature resistance of environmental protection delay cross-linked gel profile control agent

[0033] According to the method for preparing the environmental protection delayed cross-linking gel profile control agent in Example 1, the preparation of the environmental protection delayed cross-linked gel profile control agent is packed into 8 jars respectively; In constant temperature boxes at different temperatures (45°C, 50°C, 55°C, 60°C, 65°C, 70°C, 75°C and 80°C), the Brookfield DV-III rotational viscometer (temperature at 65°C, shear rate 7.34s -1 ) to determine the gelling strength of the environmentally friendly delayed cross-linking gel profile control agent. Experimental results such as image 3 As shown, as the temperature rises, the gel strength of the environmentally friendly delayed cross-linking gel profile control agent weakens, but at 80°C, the gel strength is still 25600mPa.s, indicating that the profile control agent has better res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com