Patents

Literature

76results about How to "Rigorous process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

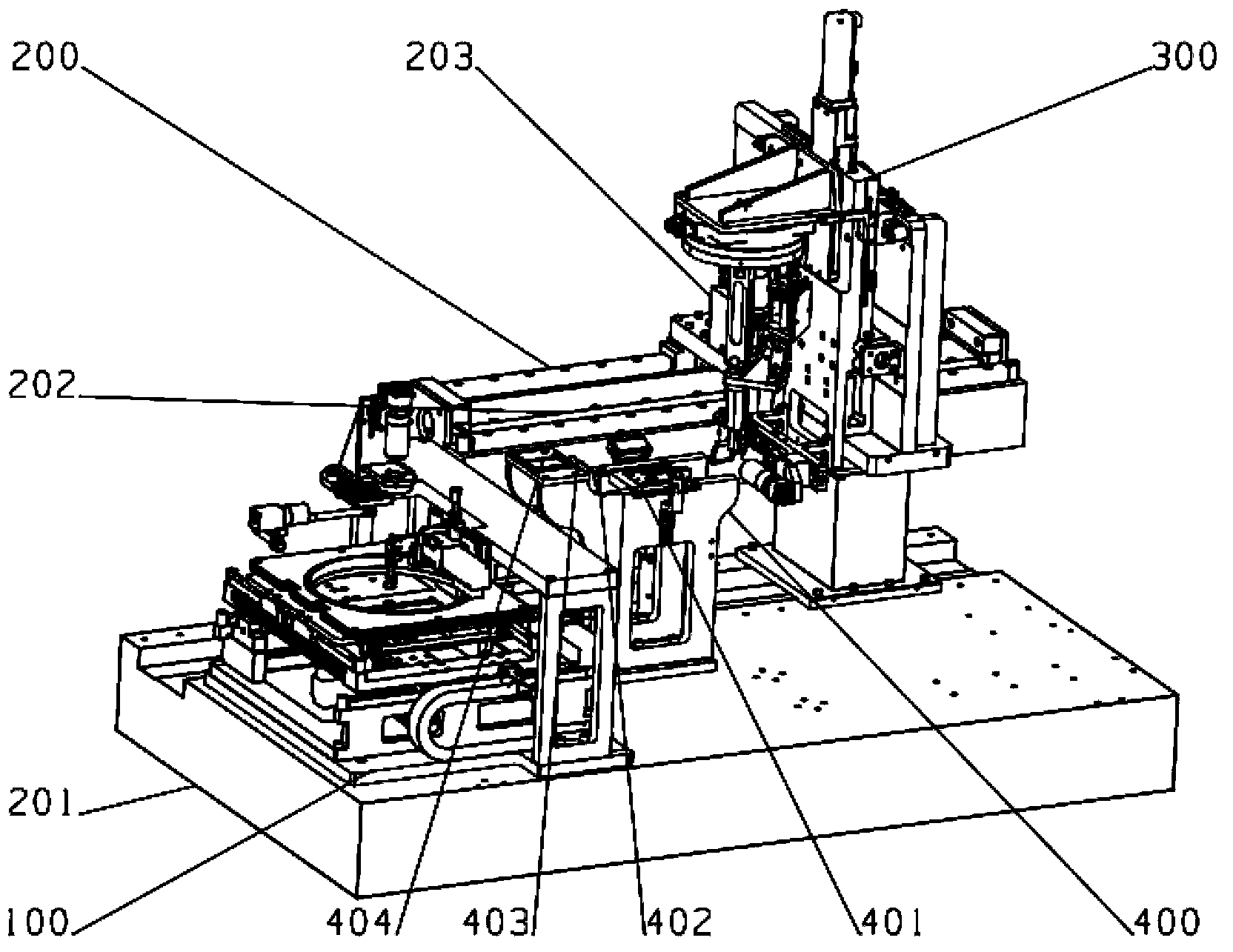

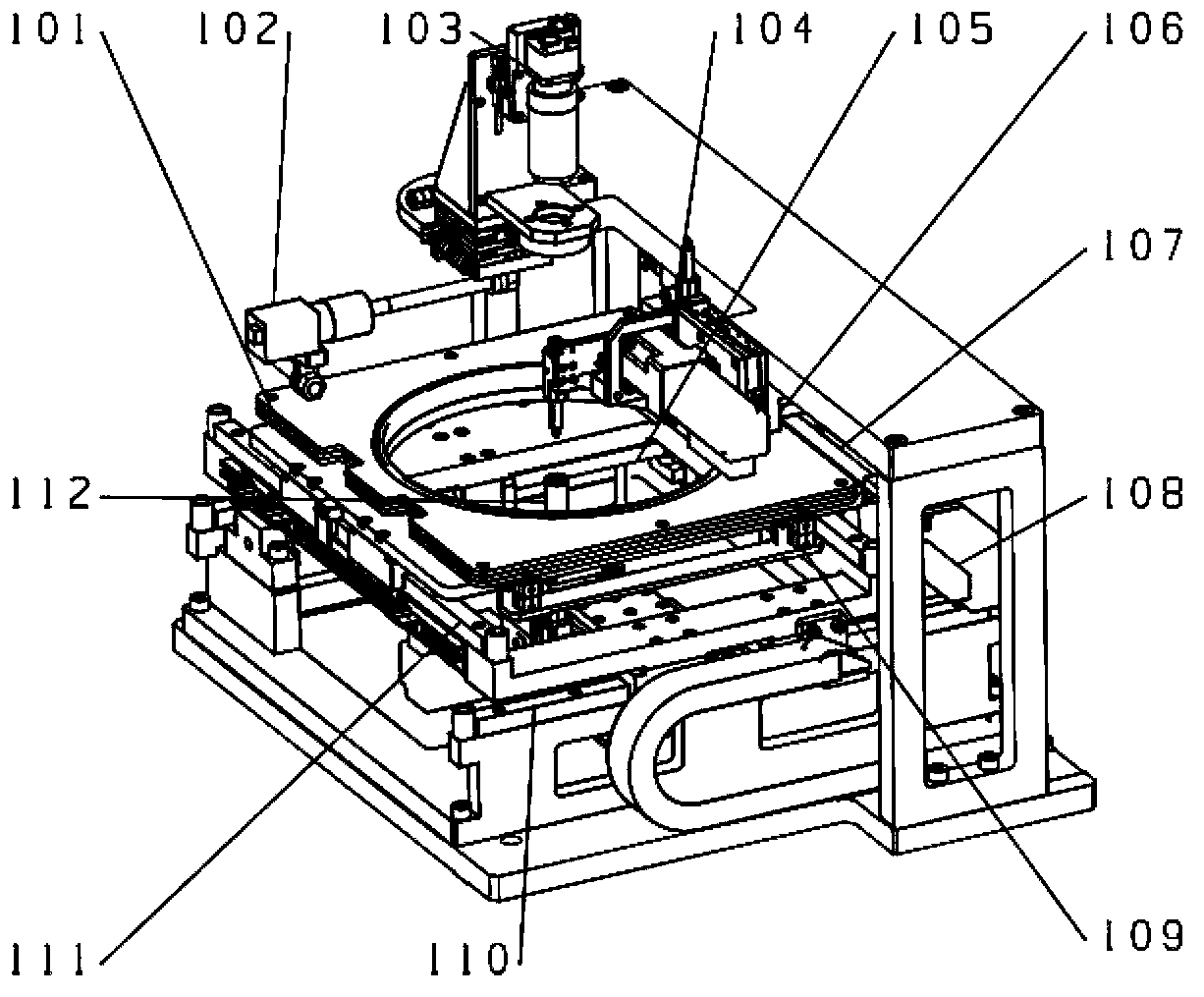

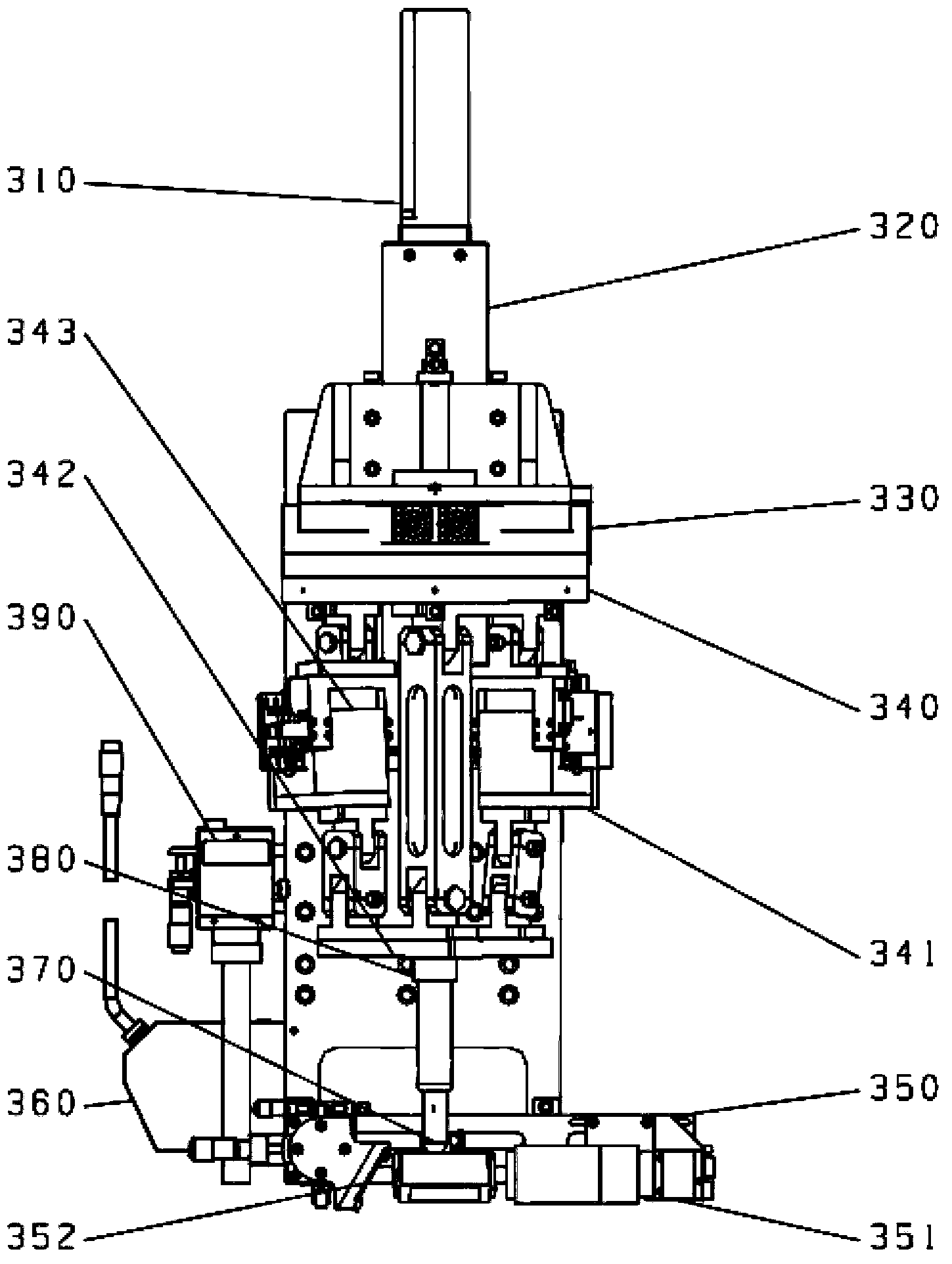

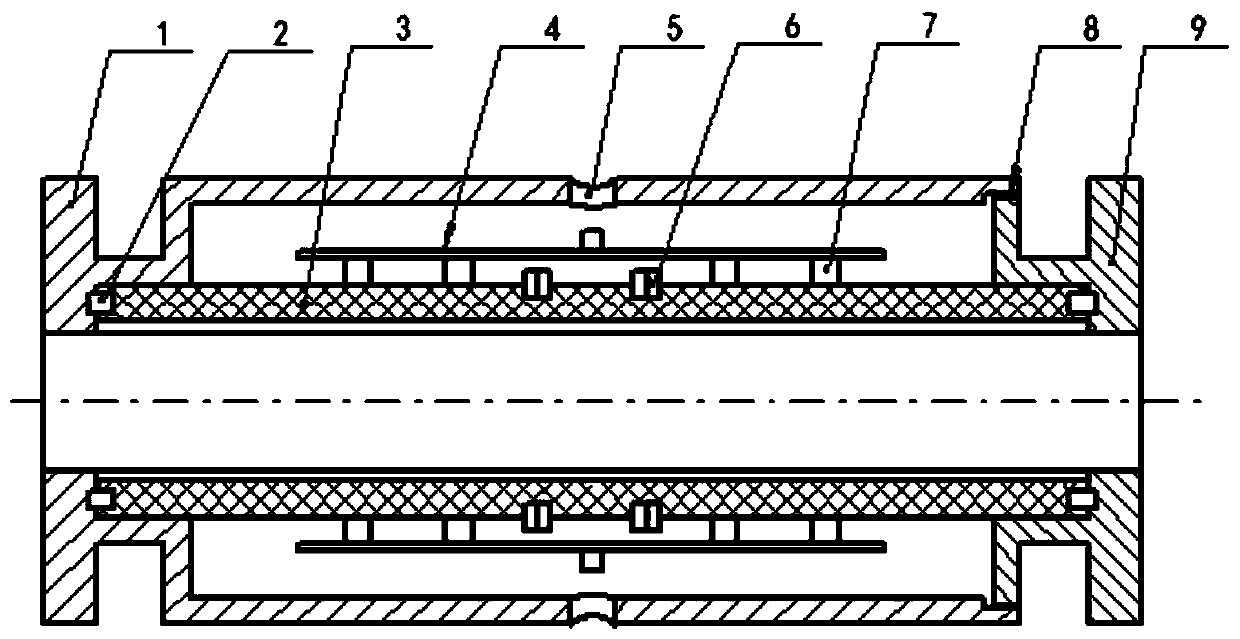

Back bonding platform for superchip

ActiveCN103367208ARigorous processHigh precisionSemiconductor/solid-state device manufacturingCircular discMicrometer

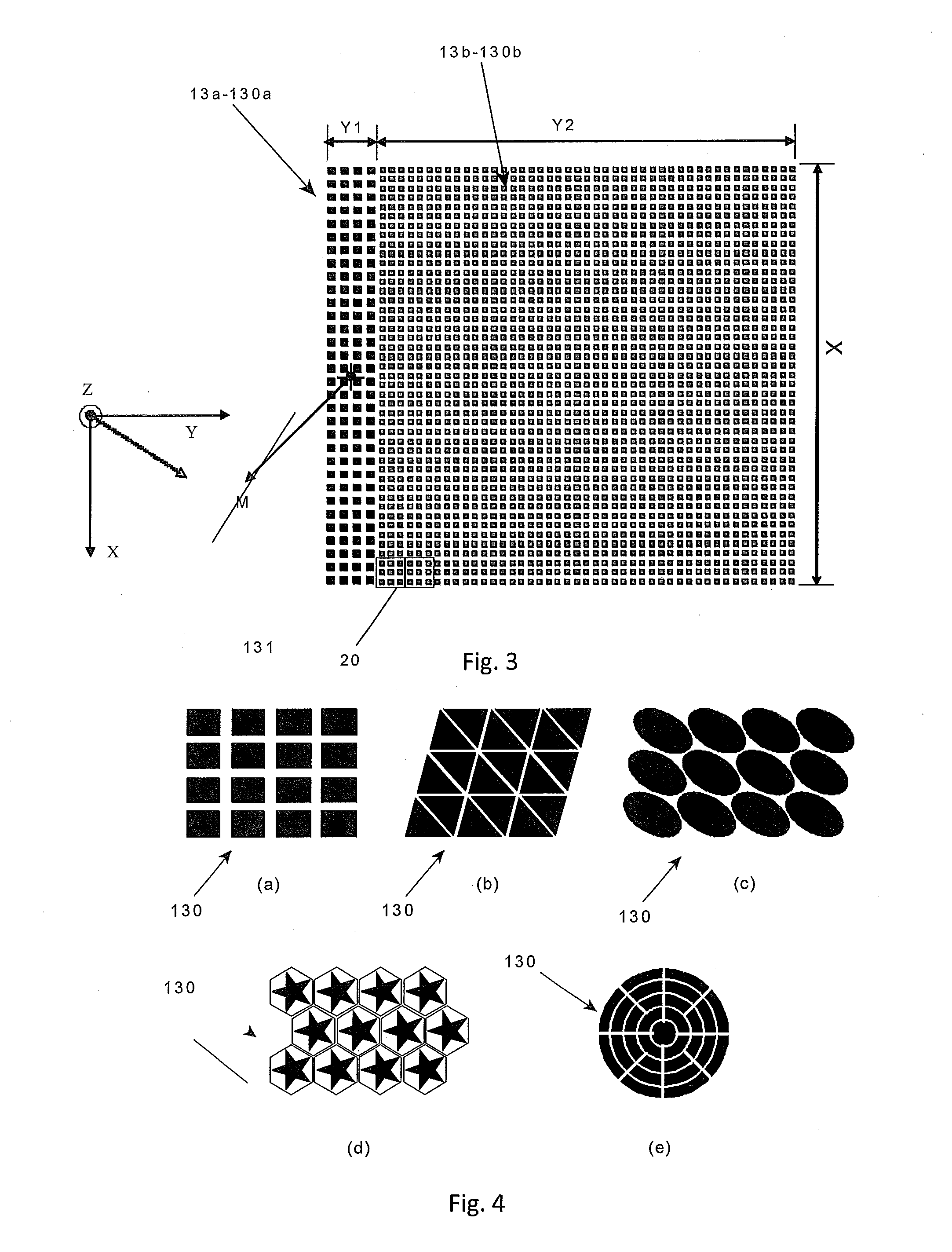

The invention discloses a back bonding platform for a superchip. The back bonding platform comprises a substrate, a chip peeling and overturning unit, an X-Y direction movement unit, a multi-degree of freedom bonding head and a mounting platform unit, wherein the chip peeling and overturning unit is used for respectively peeling and overturning a chip on a wafer disk and sending the chip to a to-be-picked position; the multi-degree of freedom bonding head is arranged on a supporting guide rail of the X-Y direction movement unit in a cantilever mode, and has functions of automatically levelling and aligning; the mounting platform unit is used for adsorbing the substrate and matched with the bonding head, so that the chip and the substrate are mutually positioned. In addition, in order to ensure the high-precision movement or matching of units, a plurality of vision positioning systems are configured in the back bonding platform. The back bonding platform can reach micrometer-level alignment accuracy, has the parallel adjusting accuracy of higher than 0.01 degree, and has the advantages of compact structure, convenience for operation and the like, so that the back bonding platform is particularly suitable for back bonding of the superchip.

Owner:HUAZHONG UNIV OF SCI & TECH

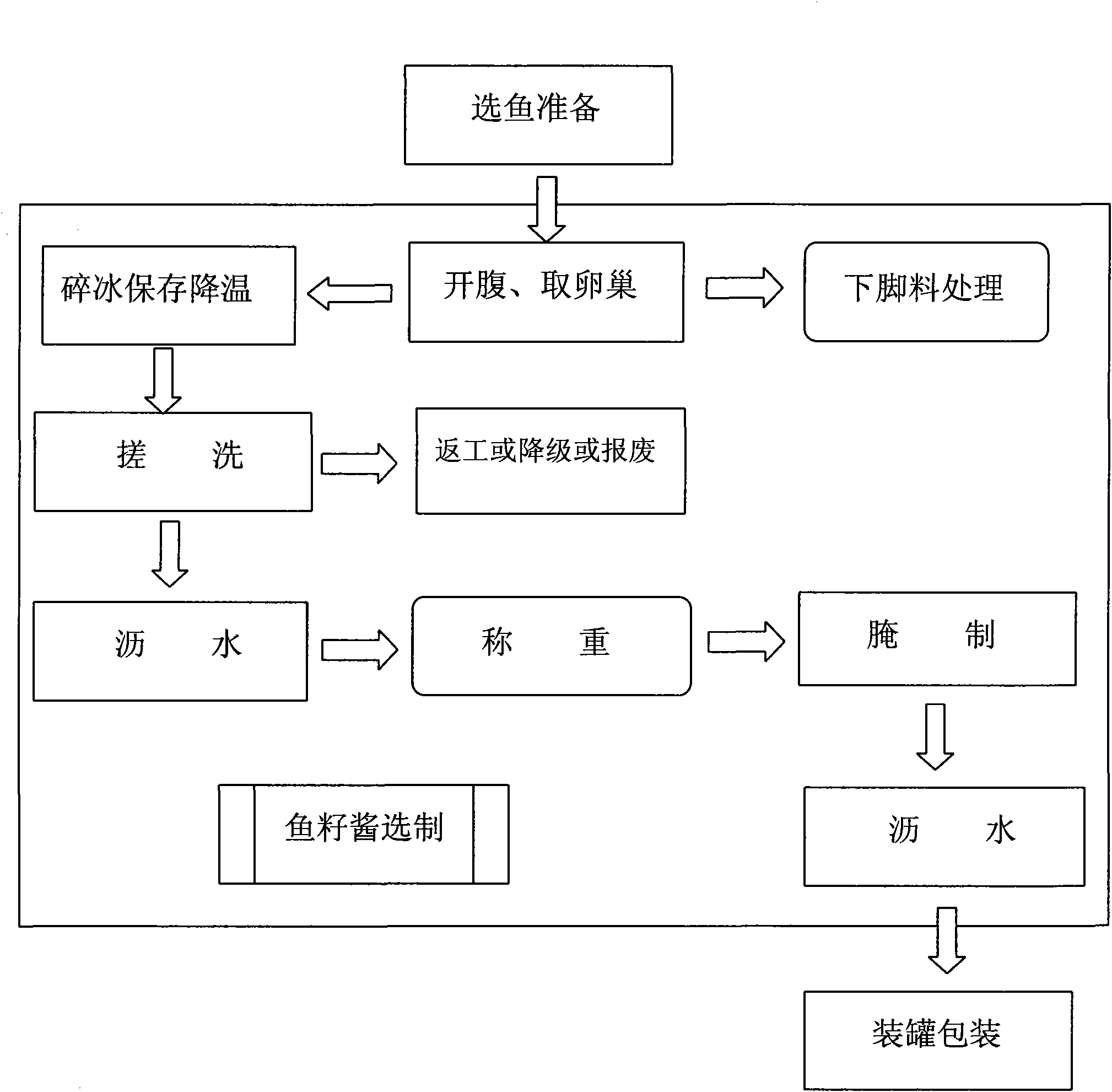

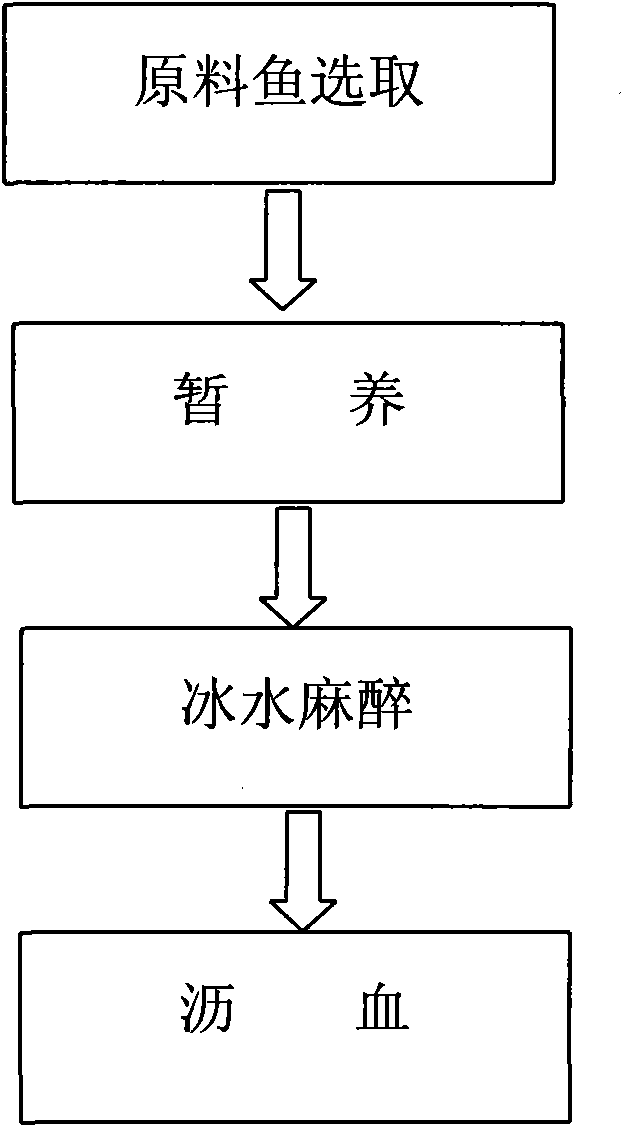

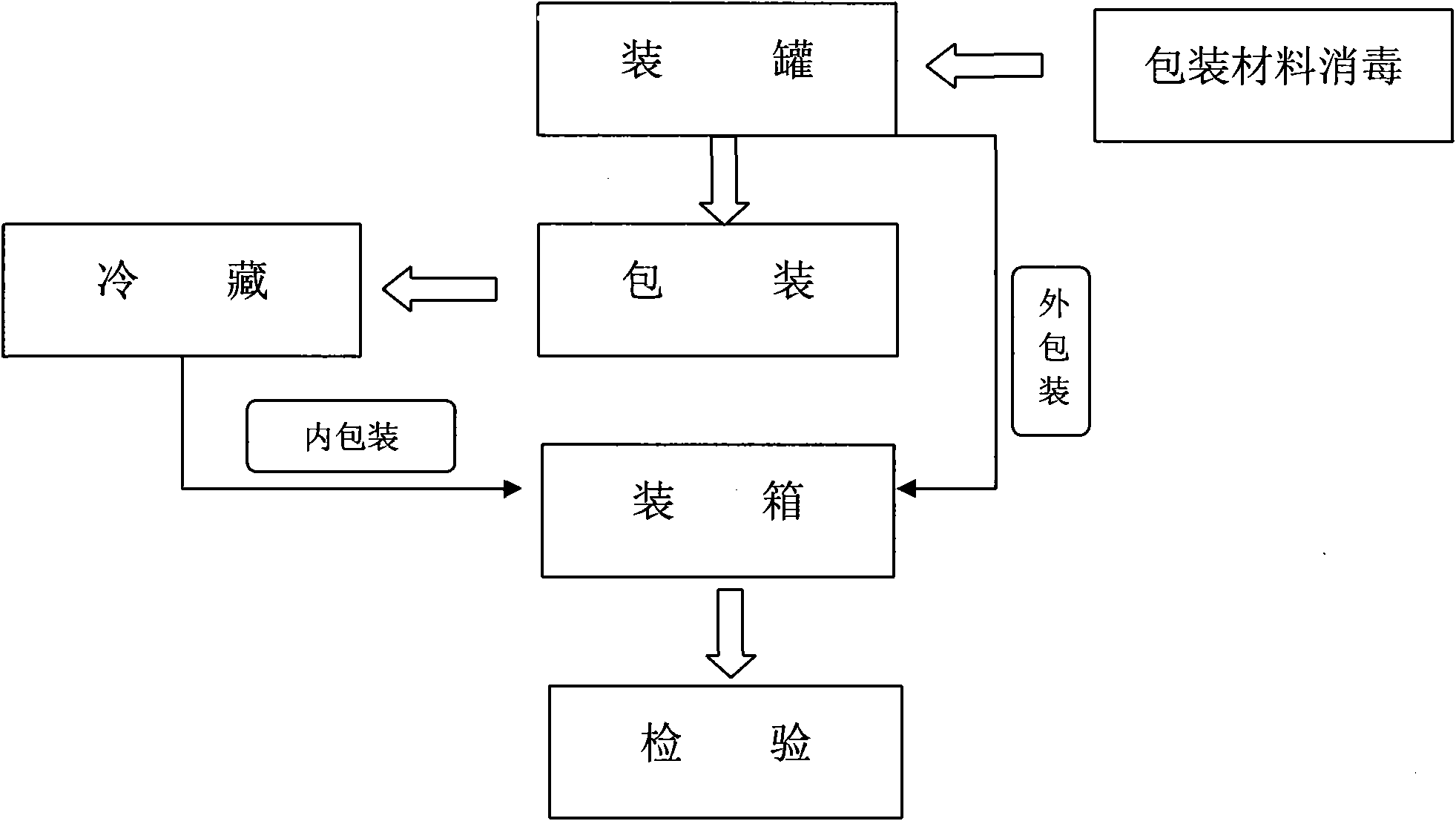

Technology for processing caviar

ActiveCN101647582AProcess safetyReasonable workmanship standardsFood preparationCaviar preparationSturgeon

The invention relates to food processing technology, in particular to technology for processing sturgeon caviar, which comprises steps of: fish selection for standby, caviar preparation and packagingby canning, wherein the caviar preparation process comprises strict processing processes such as opening belly and taking ovary, preserving and reducing temperature with broken ice, scrubbing, weighing and salting, leaching water and the like. The invention provides a scientific processing means for selecting fish and preparing roe, in particular the technology for processing the caviar which cankeep pure taste of the caviar and is aseptic, safe and reliable.

Owner:HANGZHOU QIANDAOHU XUNLONG SCI TECH

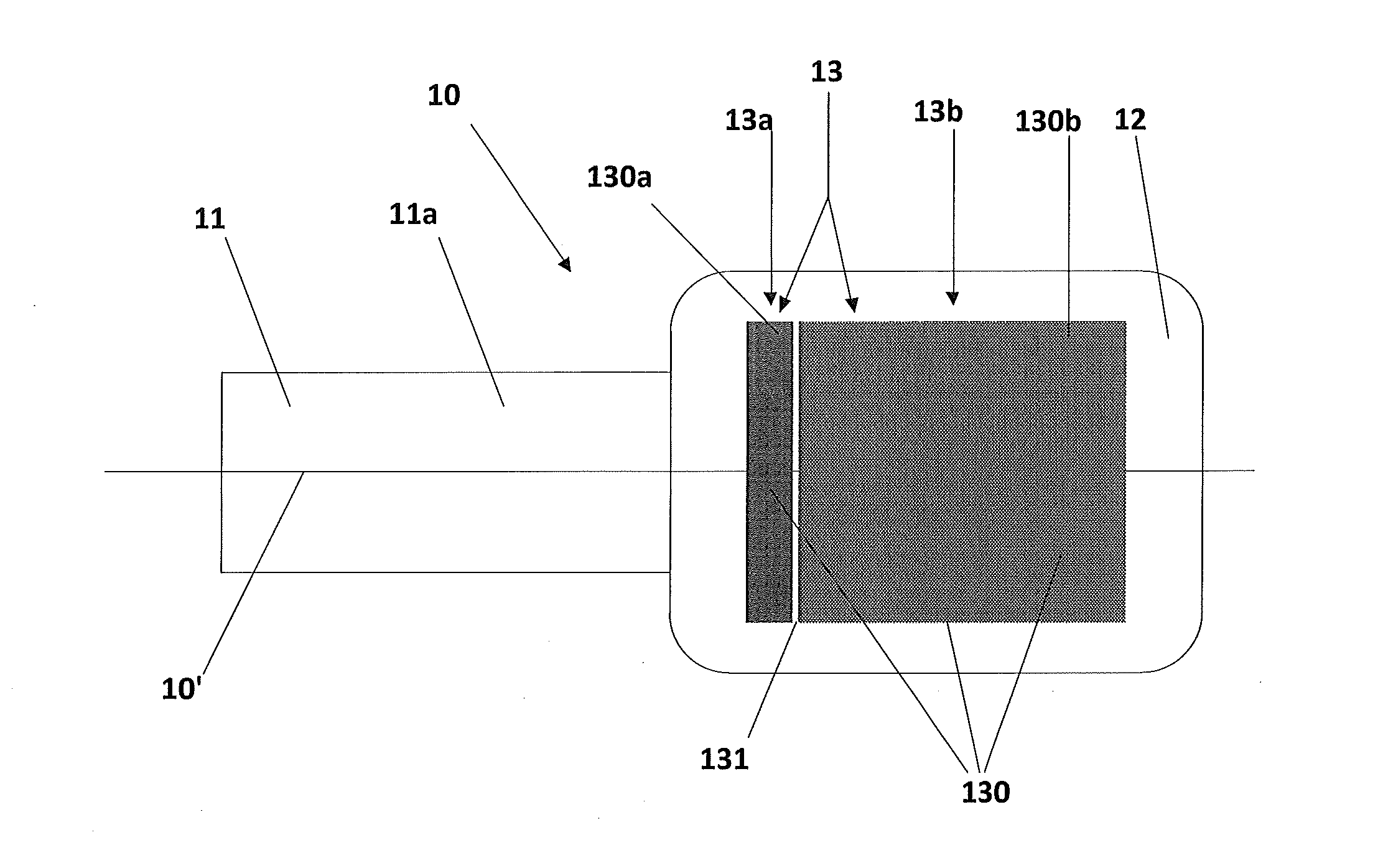

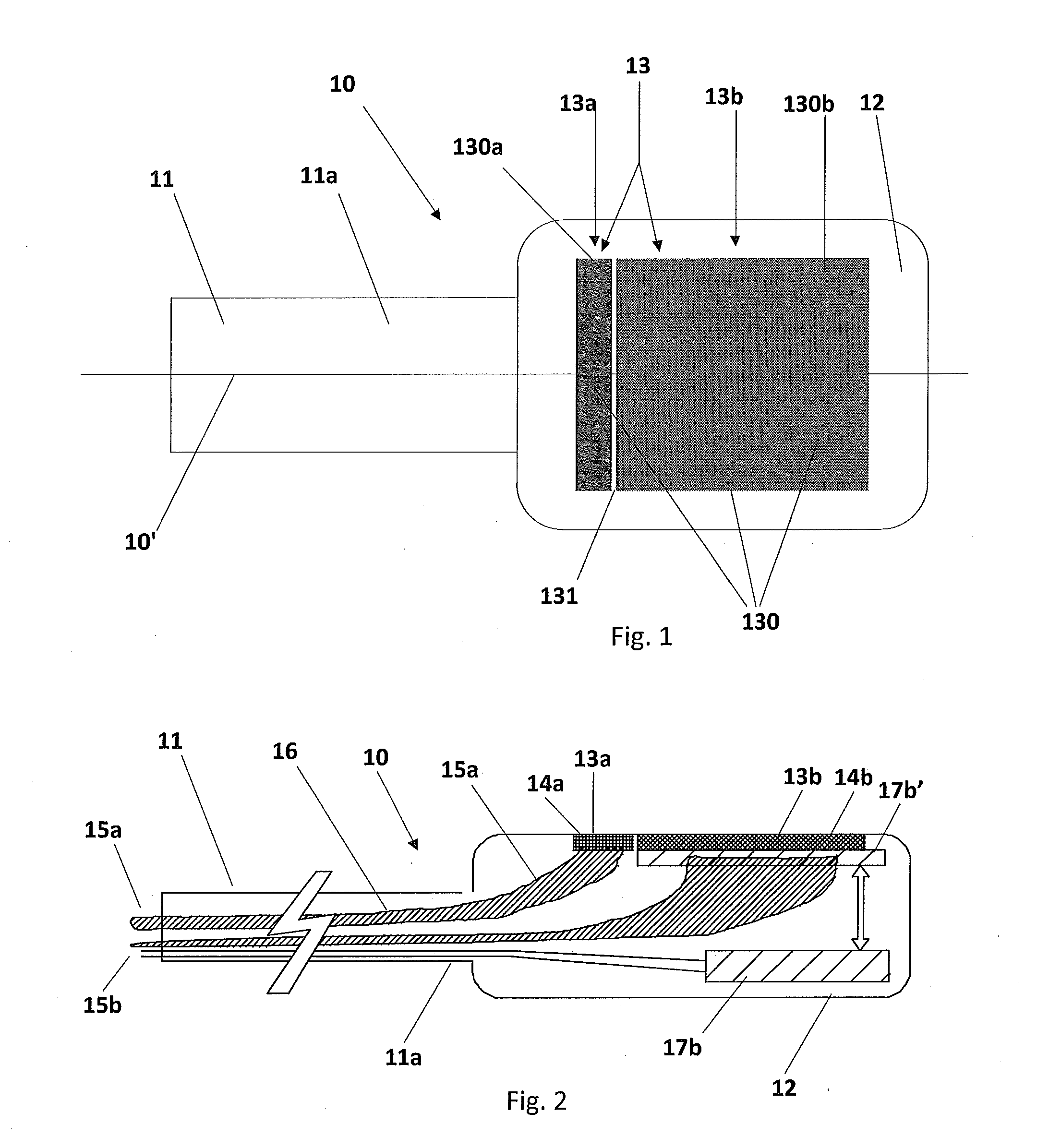

Method of manufacturing an ultrasound transducer and devices including an ultrasound transducer

ActiveUS20130245450A1Increase acoustic propertyMore tolerantUltrasonic/sonic/infrasonic diagnosticsSemiconductor/solid-state device manufacturingTransducerUltrasonic sensor

A method of manufacturing an ultrasound transducer for an ultrasound imaging device including a plurality of transducer elements arranged in a two dimensional array on a single carrier of semi-conductor material including the step of providing a buffer layer between the carrier and a layer including piezo electrical material, the buffer layer having a thickness arranged for dicing each of the plurality of transducer elements on the carrier.

Owner:OLDELFT

Preparation method for low-temperature sintered tin-doped nano-silver soldering paste

InactiveCN107175433ARigorous processRigorous implementationWelding/cutting media/materialsSoldering mediaRosinUltimate tensile strength

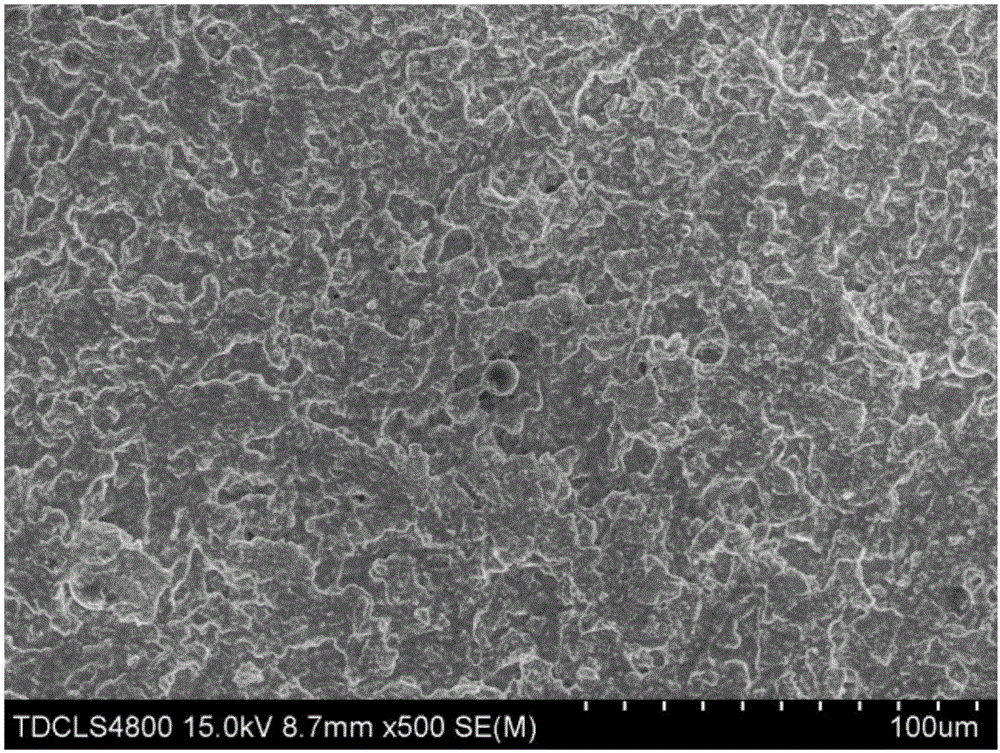

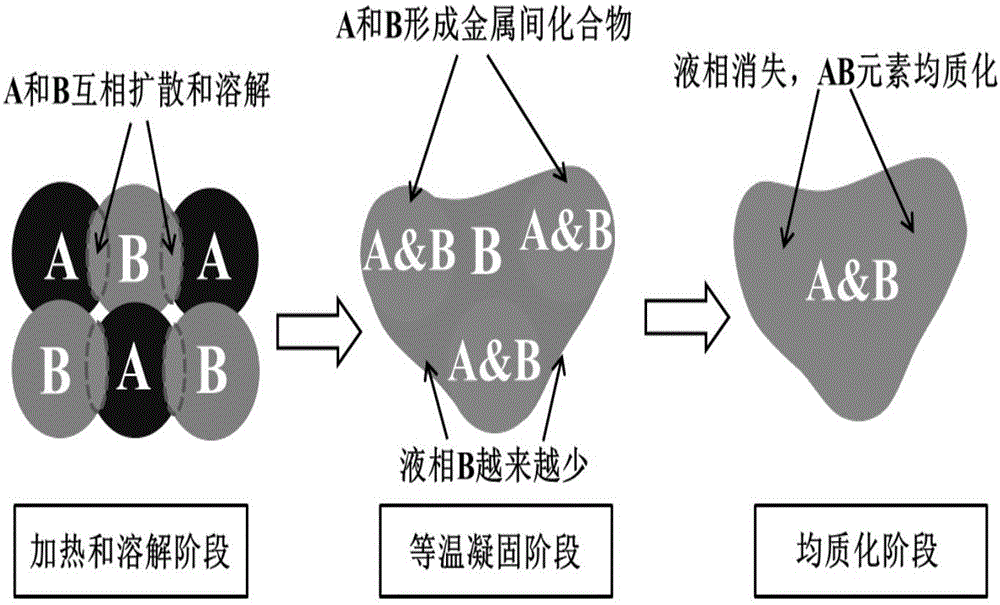

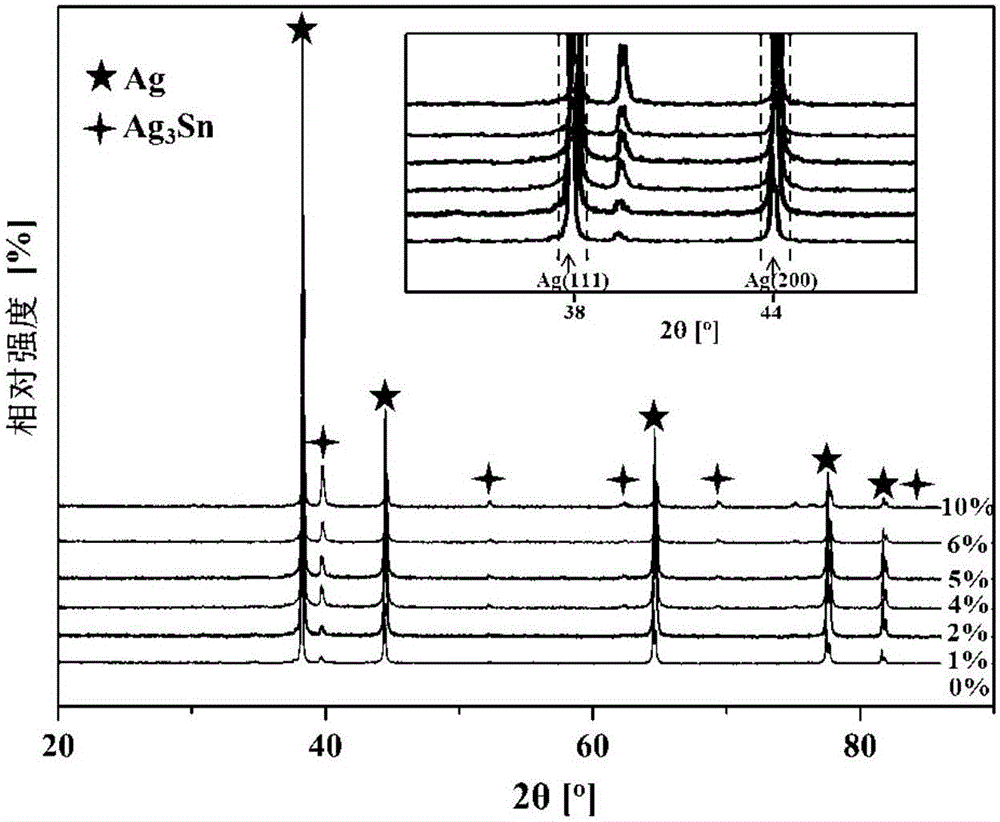

The invention relates to a preparation method for low-temperature sintered tin-doped nano-silver soldering paste. According to the mass ratio of tin powder to a soldering flux, 90% of powder and 10% of the rosin soldering flux are prepared, wherein raw material of the powder is Sn element. A micron solder paste is prepared through stirring, the silver mass fraction is 90-99%, and the tin mass fraction is 1-10%; a nano-silver soldering paste and the micron solder paste are weighed and added with terpilenol to be dissolved, firstly mechanical oscillation is conducted by using a spiral oscillator, then ultrasonic oscillation is conducted by using an ultrasonic cleaner, and a mixture is obtained; and constant temperature bath and volatilization are conducted on the mixture at the temperature of 70 DEG C till the mixture is in a paste shape. Pressure is not added in the sintering process of the tin-doped nano-silver soldering paste, protection of inert gases is not needed, and the maximum sintering temperature is 235 DEG C. According to the preparation method for the low-temperature sintered tin-doped nano-silver soldering paste, the process procedure is well-conceived, and implementation is strict; and the sintering temperature of the low-temperature sintered tin-doped nano-silver soldering paste is lower than the sintering temperature of a traditional silver soldering paste, and compared with a pure nano-silver soldering paste, under the same sintering process, the connection strength of the low-temperature sintered tin-doped nano-silver soldering paste after being sintered is double of the connection strength of the pure nano-silver soldering paste.

Owner:TIANJIN UNIV

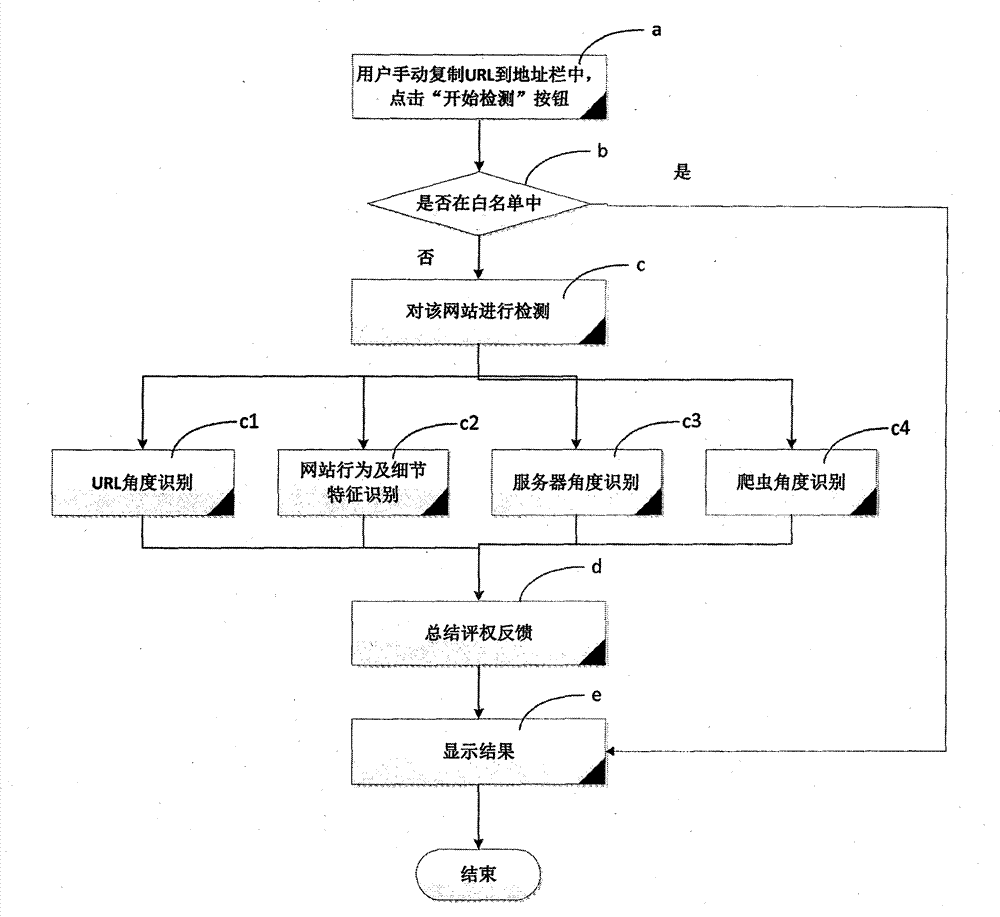

Anti-phishing method based on multi-factor comprehensive assessment method

InactiveCN104202291AConsider comprehensivelyImprove accuracyTransmissionSpecial data processing applicationsAssessment methodsWeight value

The invention relates to an anti-phishing method based on a multi-factor comprehensive assessment method. The method comprises the following steps: step a, establishing a blacklist and whitelist library of URL (uniform resource locator), and processing a target URL, judging whether the processed URL is in the blacklist / whitelist, if so, executing the step d, directly feeding back a result to the user; otherwise, executing the step b, subsequently detecting the website; step b, detecting four aspects of the website: URL angle recognition, website behavior and detail feature recognition, server angle recognition and crawler angle recognition; step c, summarizing and affirming the feedback result; and step d, displaying a result. The method provided by the invention can be used for assessing in many ways with strict procedure; the consideration is comprehensive and the accuracy is high; the hit suspects and corresponding weight value, searched webpage link, website file and judgment criterion are displayed in a graphical interface in a simple and clear mode , the result is available for related professional for examining while being fed back to the user.

Owner:XIDIAN UNIV

Sugariness dried oyster with iodine-containing tea flavor

ActiveCN101120799APrevent decline in male sexual functionRigorous workmanshipFood preparationHerbal preparationsAdditive ingredient

The present invention discloses a sweet dried oyster with iodine-tea taste, which belongs to instant dried food ingredients and the making method. The main raw material of the present invention is fresh oyster, and the supplemental materials are slat, white sugar, malt sugar, honey, edible oil and so on. The product is made after the materials being treated, cooked, immersed, dried, fried, roasted (for dehydration), coated with instant black tea powder, baked, cooled, packed, disinfected with microwave and stored in case, and processed cold storage process or procedure. The produced instant dried oyster has original flavor and taste, and has taste of Chinese herbal preparation honey-peppery oil tea camellia. The present invention has oyster and Chinese herbal preparation, and so the dried oyster has the function of enhancing the male reproductive system, preventing male sexual function from decreasing and prostatic hypertrophy. The present invention also can protect heart and liver, benefit for gallbladder, adjust blood lipid, make the skin soft, improve appearance, and is good for mental and brain, and so on.

Owner:漳州市美丽家香食品股份有限公司

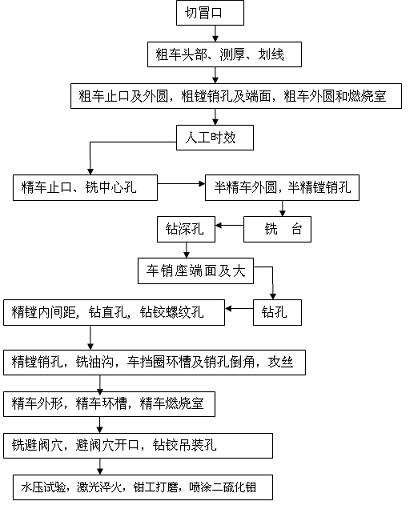

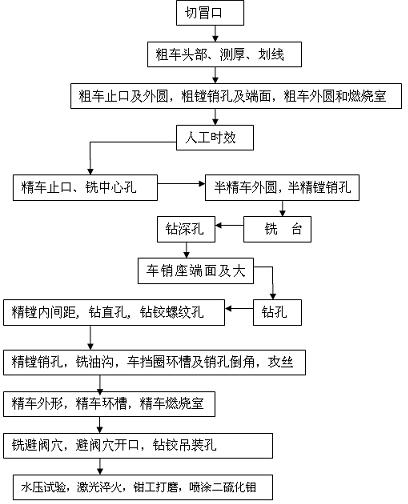

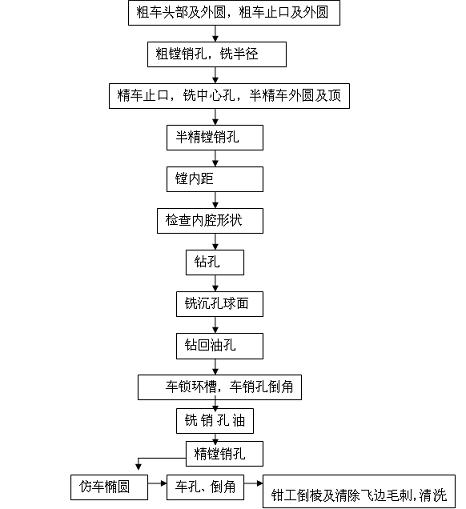

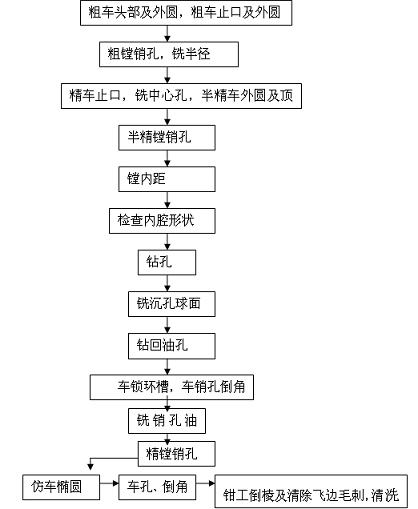

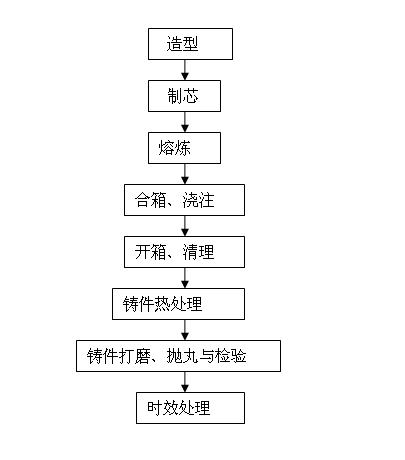

Processing technology for whole spherical iron piston

InactiveCN102213313AImprove machining accuracyRigorous processPlungersTrunk pistonsCombustion chamberLaser quenching

The invention discloses a processing technology for whole spherical iron piston, and the method comprises the following steps: step a, cutting a riser; step b, carrying out rough turning on a head, measuring the thickness and marking off; step c, carrying out rough turning on a spigot and an excircle, carrying out heavy boring on a pin hole and an end face, and carrying out rough turning on the excircle and a combustion chamber; step d, carrying out precipitation heat treatment; step e, carrying out finish turning on the spigot and milling a center hole; step f, carrying out semi-finish turning on the excircle, and carrying out semi-finish boring on the pin hole; step g, milling a table face; step h, drilling a deep hole; step i, turning a seat end face and turning a macropore; step j, drilling a hole; step k, carrying out finish boring on an internal space, drilling a straight hole and drilling a hinge screwed hole; step l, carrying out finish boring on the pin hole, milling an oil gallery, chamfering an vehicle shield ring groove and the pin hole, and tapping; step m, carrying out finish turning on appearance, carrying out finish turning on the ring groove and carrying out finish turning on the combustor chamber; step n, milling an avoided valve hole, opening the avoided valve hole, and drilling a hinge hoisting hole; step o, carrying out a hydrostatic test, laser quenching and fitter polishing, and spraying molybdenum disulfide. The processing technology for the whole spherical iron piston in the invention has the advantages of high process precision, rigorous process flow and superior processed product quality.

Owner:DALIAN BINCHENG PISTON MFG

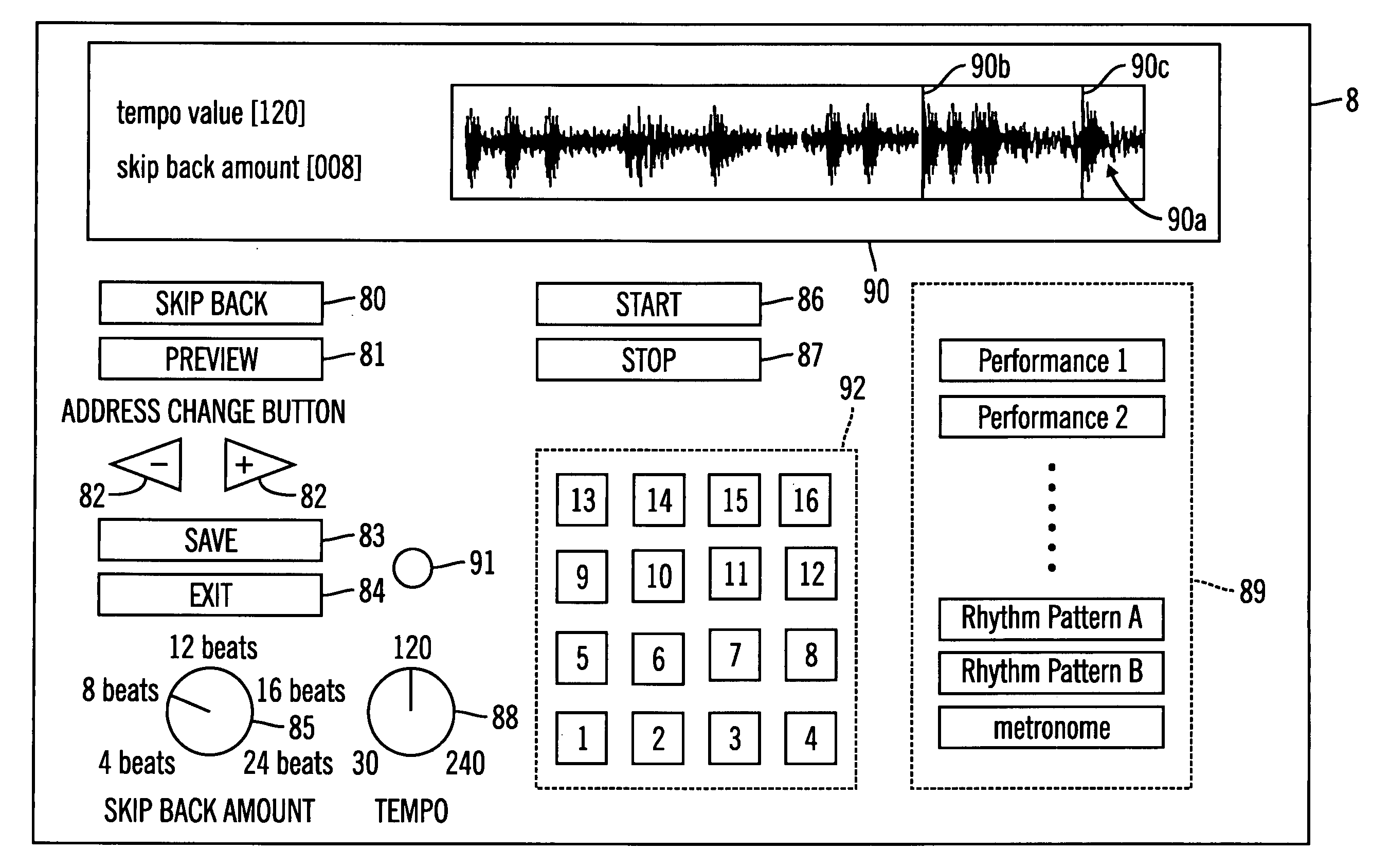

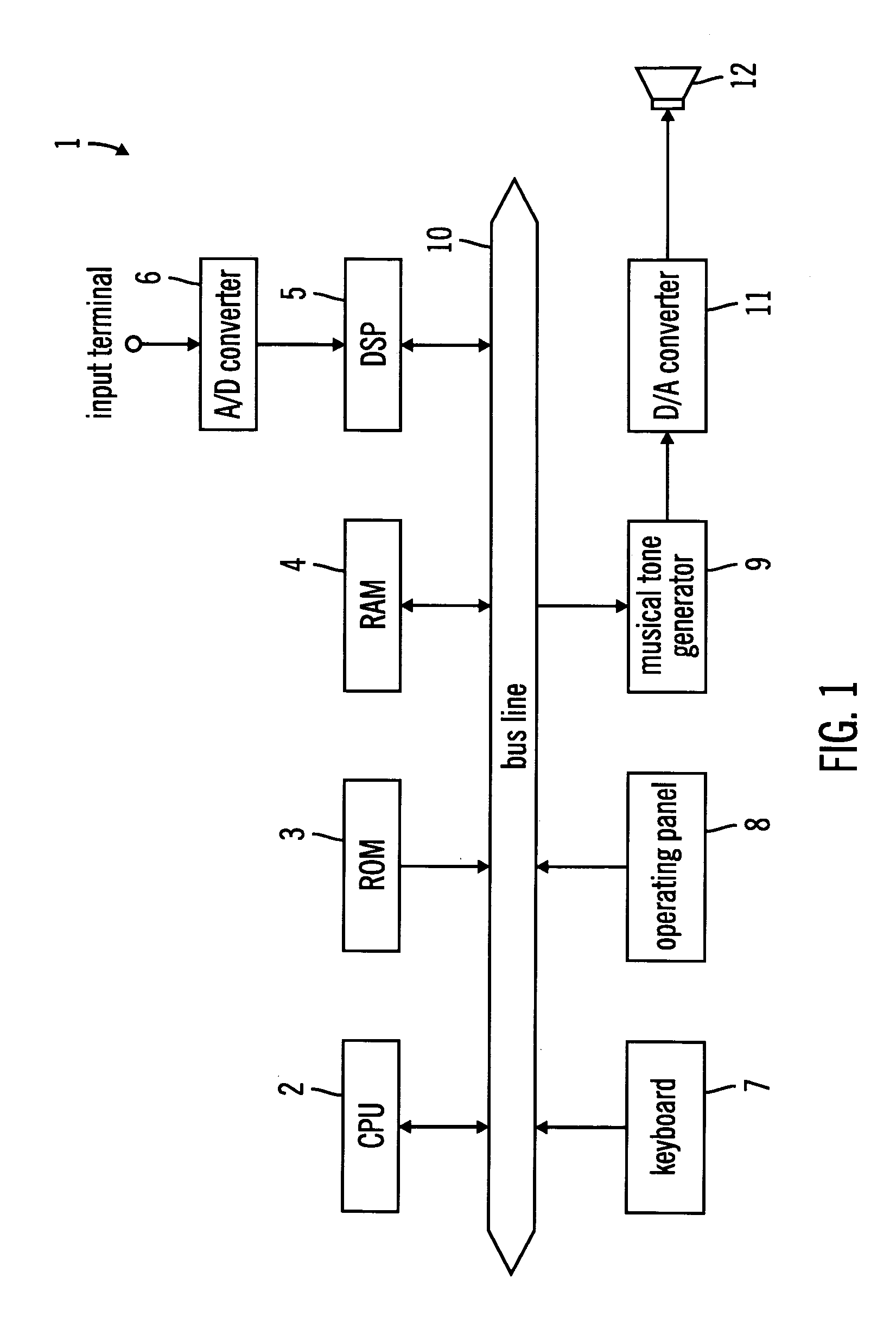

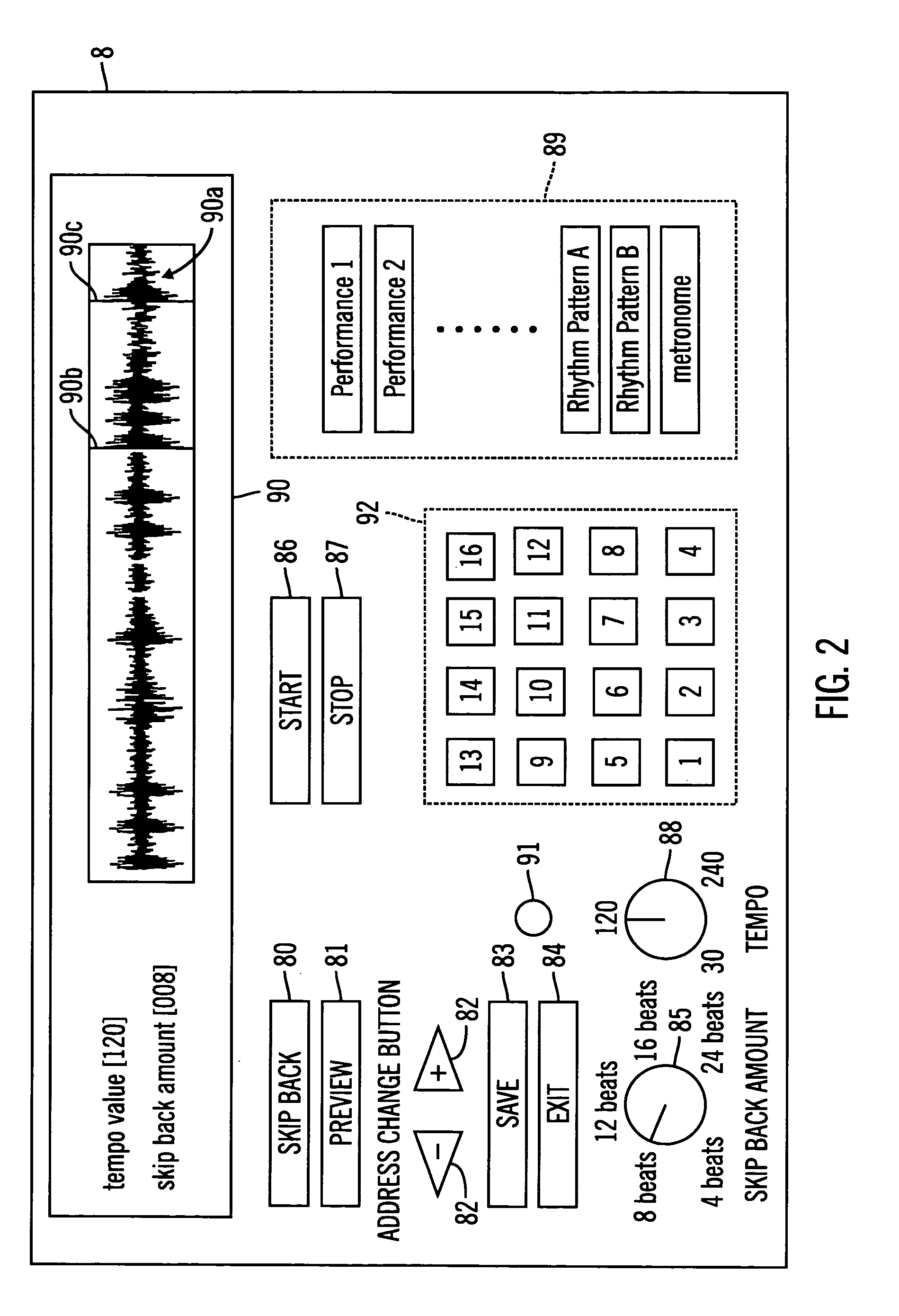

Electronic musical instrument

An electronic musical instrument with which, without difficulty to a user, it is possible to reproduce and save and the like the musical tones that the user has performed and to carry this out in units having musically satisfactory breaks. For each count of one beat by a beat counter, the time information for the musical tone data that are stored at that timing is stored in a beat time information table. When a skip-back button is operated during the recording, an address having a musically satisfactory break is acquired by computation based on the time information and the storage address of the operation timing, the time information of said table, and the sampling period. Therefore, even in those cases where optimization processing of the memory has been done during the recording, there is no need to update the storage address at that time. In addition, it is possible to carry out the reproduction and saving of beat units having musically satisfactory breaks by carrying out the reproduction and the saving at the storage address units that have been acquired.

Owner:ROLAND CORP

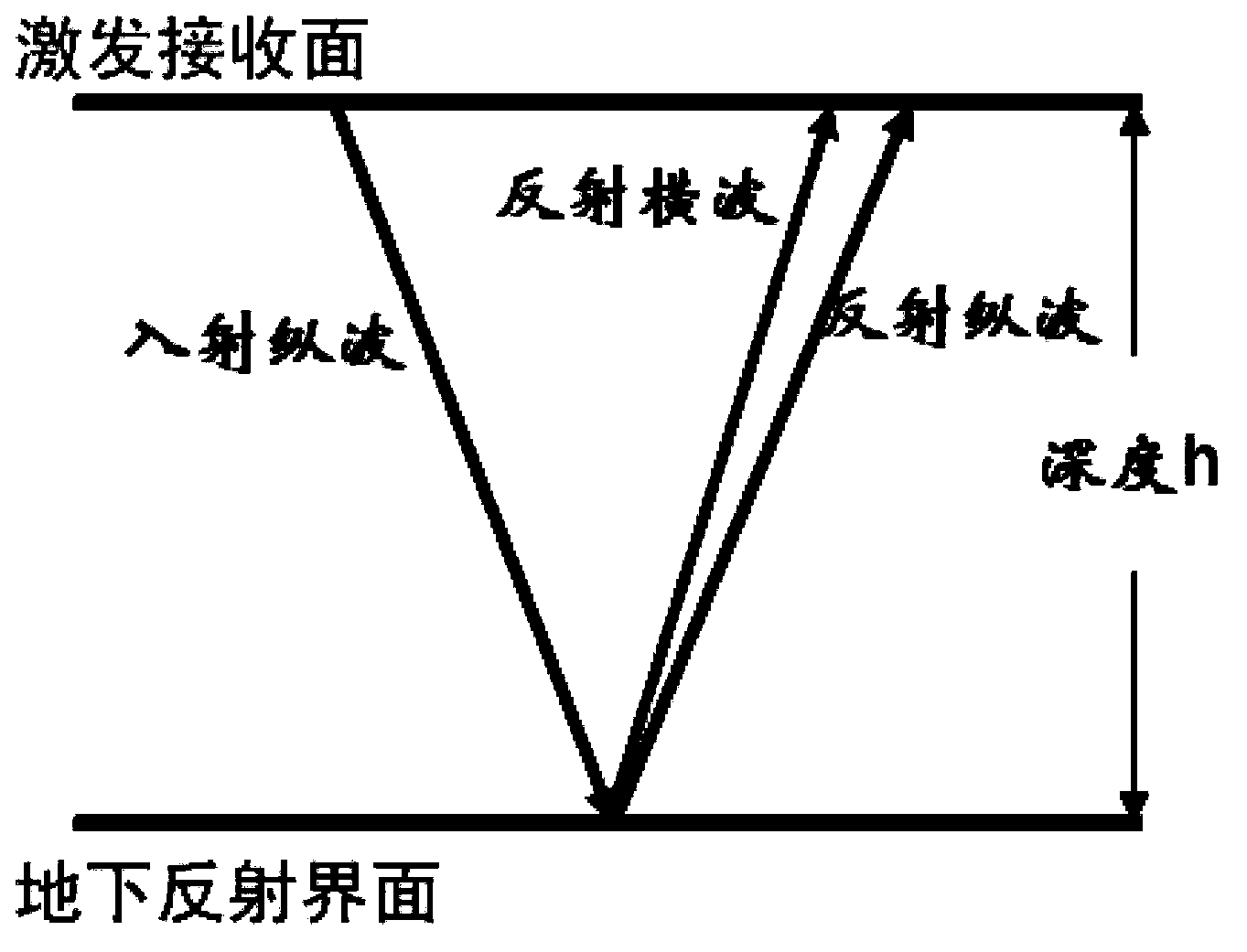

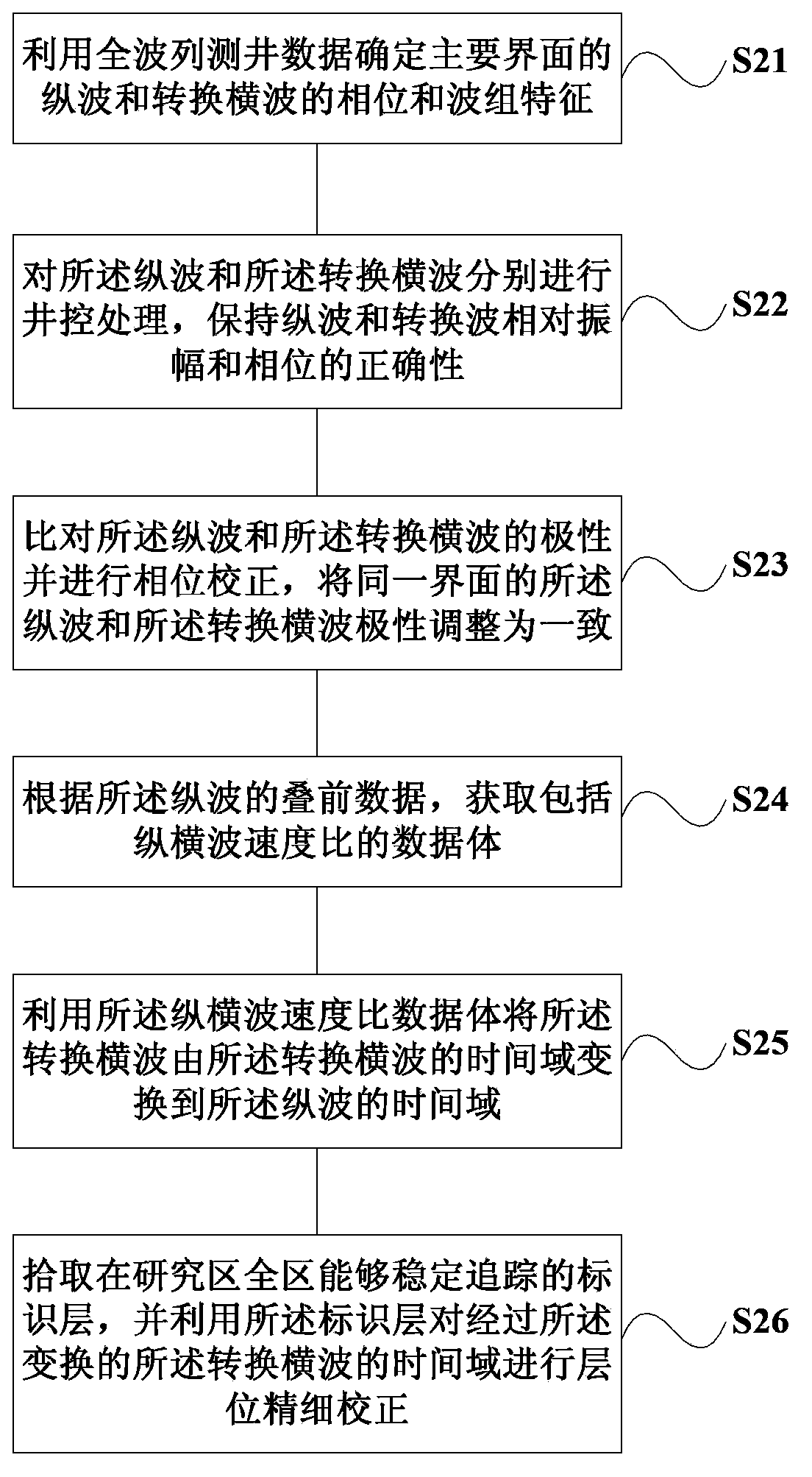

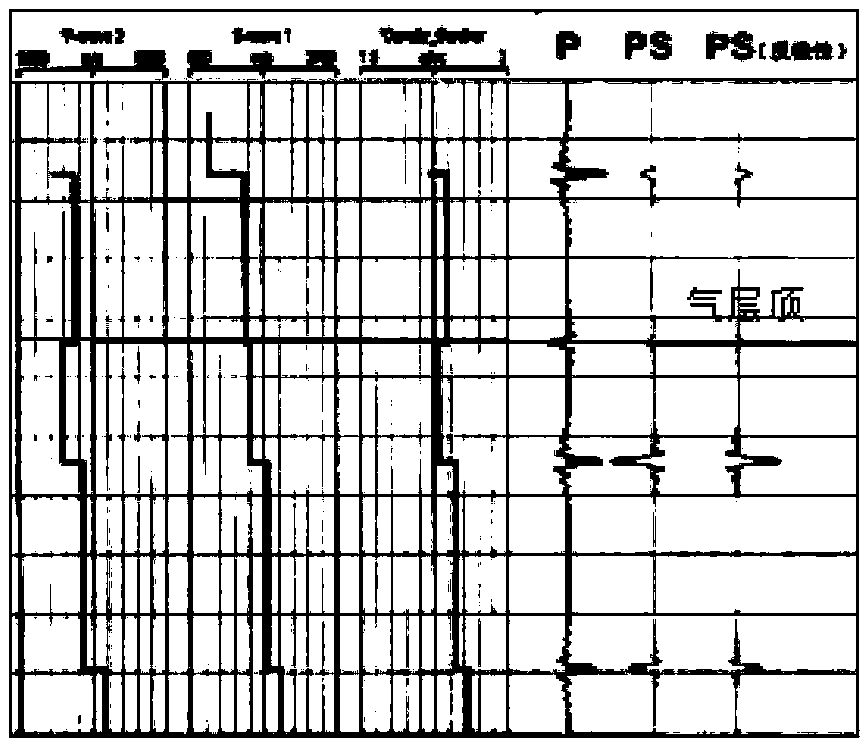

Method for matching longitudinal waves with transverse waves for geophysical exploration

The embodiment of the invention provides a method and device for matching longitudinal waves with transverse waves for geophysical exploration. The method includes the steps that full wave train well logging data are utilized to determine phase and wave group characteristics of the longitudinal waves and converted transverse waves in a main interface; well control processing is respectively conducted on the longitudinal waves and the converted transverse waves; the polarity of the longitudinal waves and the polarity of the converted transverse waves are compared and phase correction is conducted; a data body including the speed ratio of the longitudinal waves to the transverse waves is acquired according to prestack data of the longitudinal waves; the data body is utilized to convert the converted transverse waves from the time domain of the converted transverse waves to the time domain of the longitudinal waves; identification layers which can stably track in whole research area are picked up and utilized to conduct fine horizon correction on the converted time domain of the converted transverse waves. The method and device are combined with seismic data processing, forward modeling, inversion and other measures, so that the method and device are reliable in theory and rigorous in process, and the longitudinal waves and the transverse waves can be well matched.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

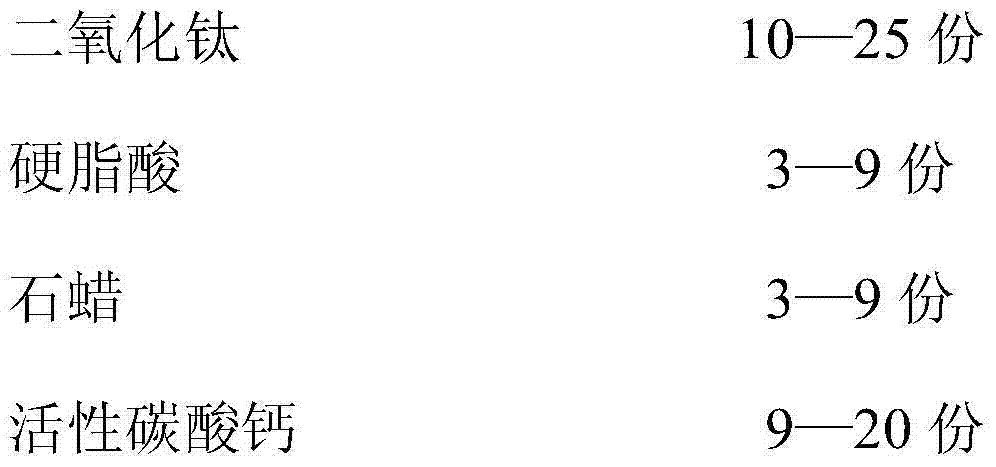

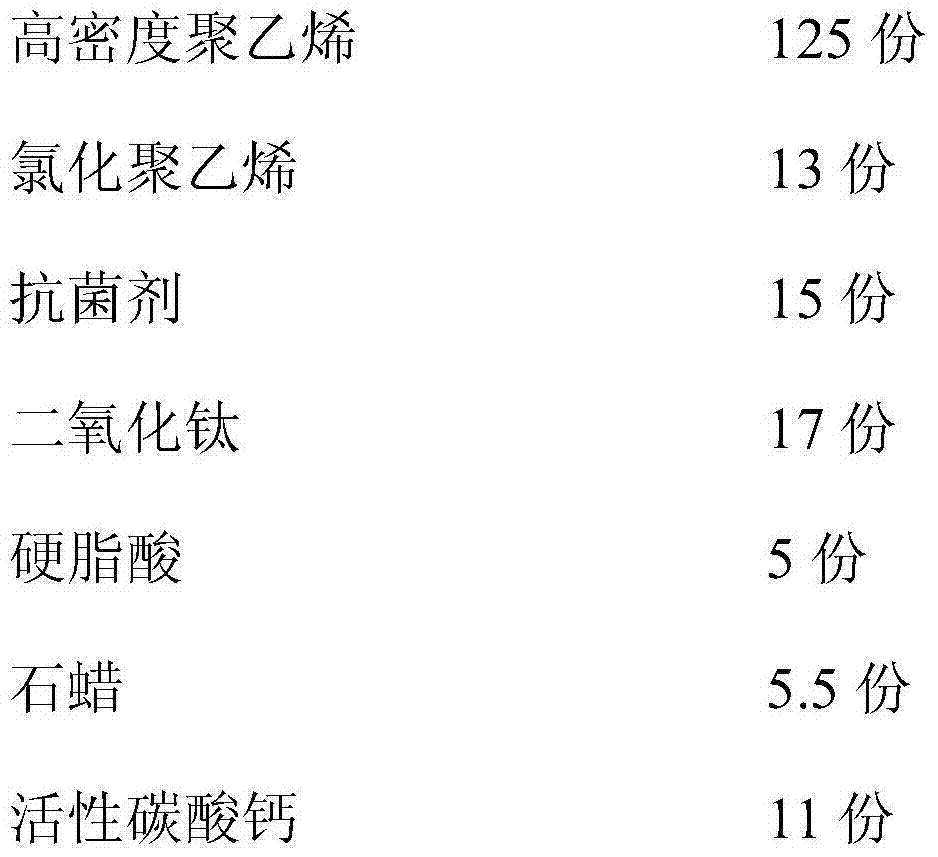

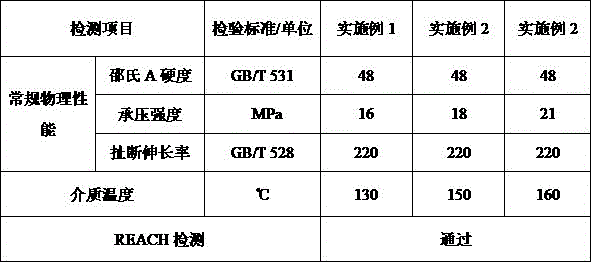

Antibacterial pipe material and preparation method thereof

InactiveCN103694536AImprove antibacterial propertiesImprove product qualityAntibacterial agentMaterials science

The invention discloses an antibacterial pipe material and a preparation method thereof. By using a special antibacterial agent, the antibacterial effect of a polyethylene pipe material can be greatly improved by three different types of nano-antibacterial powder. The preparation method disclosed by the invention adopts an improved formula and a process, and the pipe material produced by using the method has an excellent antibacterial effect and can effectively improve the using effects of a product and ensure the quality of drinking water. The invention provides the antibacterial pipe material and the preparation method thereof, the preparation method has the advantages of perfection in operation and rigorous process, and the production quality of an enterprise can be greatly improved.

Owner:江苏金波新材料科技有限公司

Tin-bismuth jet printing soldering paste modified by silver powder particles and preparation method thereof

ActiveCN107825001AImprove printing effectRigorous processWelding/cutting media/materialsSoldering mediaAdhesiveDiluent

The invention discloses tin-bismuth jet printing soldering paste modified by silver powder particles. The tin-bismuth jet printing soldering paste modified by the silver powder particles comprises, byweight, 50 wt%-80 wt% of SnBi soldering paste and 20 wt%-50 wt% of conductive silver adhesive. The conductive silver adhesive comprises, by mass, 65 %-67% of Ag and 33%-35% of assistant. The assistant comprises bisphenol-A epoxy resin, a curing agent, a coupling agent, a diluent, an accelerant and a defoaming agent. The invention further provides a preparation method of the tin-bismuth jet printing soldering paste modified by the silver powder particles. According to the preparation method, the SnBi soldering paste and the conductive silver adhesive are respectively prepared; the prepared soldering paste and the conductive silver adhesive are evenly mixed at a corresponding ratio, and the tin-bismuth jet printing soldering paste modified by the silver powder particles are obtained. By theadoption of the technical scheme, the modified soldering paste mixed with the silver particles has good jet printing performance, the prepared jet printing soldering paste modified by the silver powder particles is free of lead and halogen, when used, the prepared jet printing soldering paste modified by the silver powder particles is environmentally friendly, harmless and good in wetting performance; and during jet printing, the spot diameters are uniform, the heights are identical, welding spots are smooth and full, and the mechanical performance is excellent.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST +1

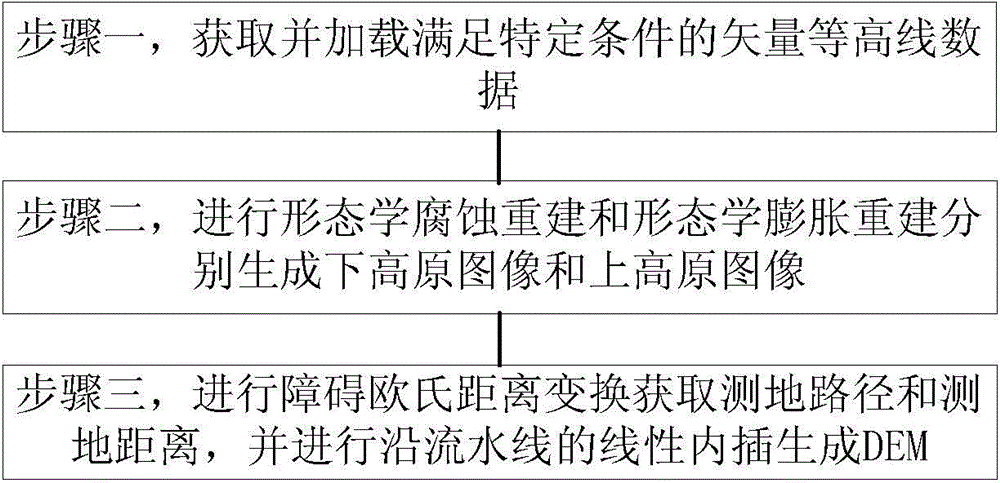

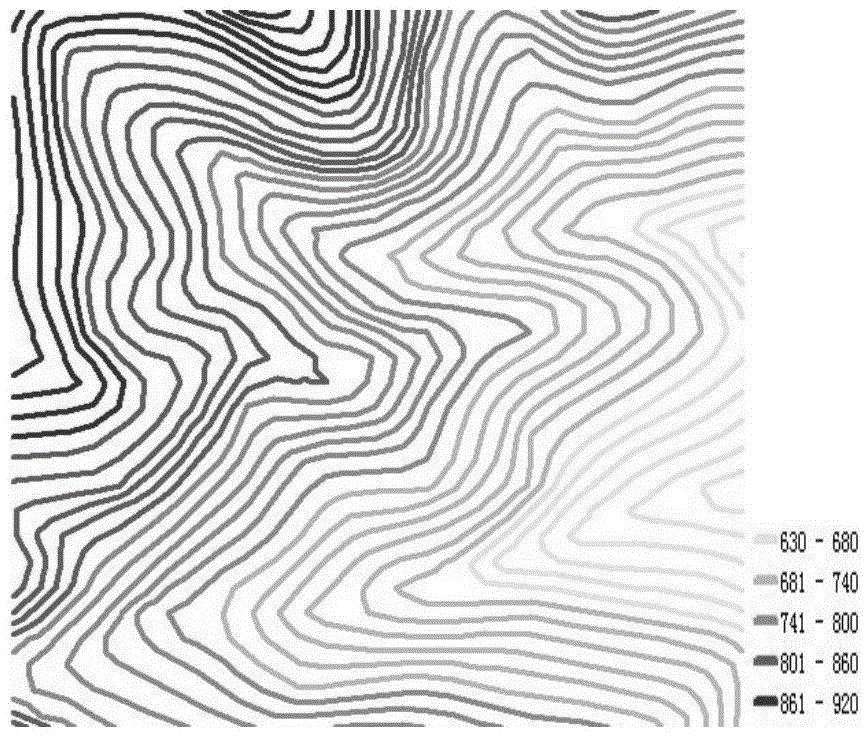

Interpolation method for DEM (Digital Elevation Model) generated by contour lines

The invention discloses an interpolation method for a DEM (Digital Elevation Model) generated by contour lines. The interpolation method comprises the following steps: 1, acquiring and loading vector contour line data meeting specific conditions, wherein the specific conditions are: each contour line is spatially and continuously distributed and cannot be interrupted, and odd contour lines and even contour lines exist at intervals; 2, performing morphological corrosion reconstruction and morphological expansion reconstruction to generate a lower plateau image and an upper plateau image respectively; 3, performing obstacle Euclidean distance conversion to acquire a geodesic path and a geodesic distance, and performing pipelined linear interpolation to generate the DEM. The generated DEM has the characteristics of high accuracy and high fidelity and is generated by using the linear interpolation method, the DEM accuracy obtained under the condition that only contour line data are used is equal to or higher than the DEM accuracy obtained by using a map algebra method, manual intervention is not needed, the DEM is not limited by iterations, an adaptive algorithm is truly achieved, and the interpolation method can be applied to various industries.

Owner:SHANDONG LINYI TOBACCO

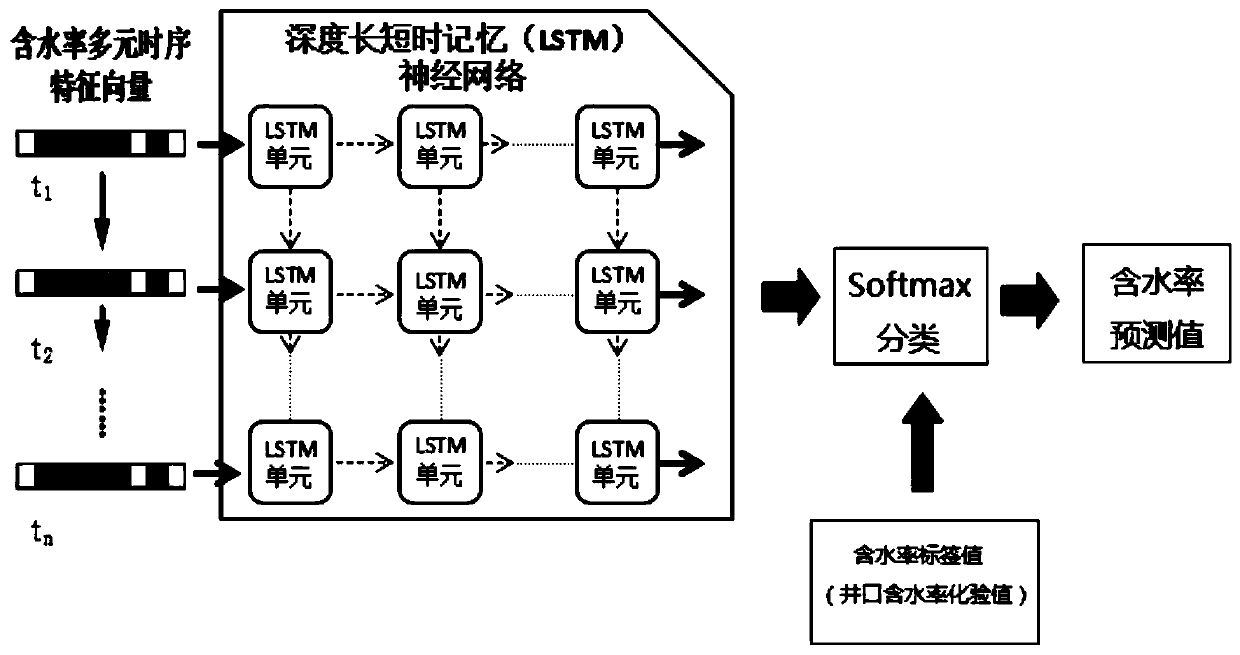

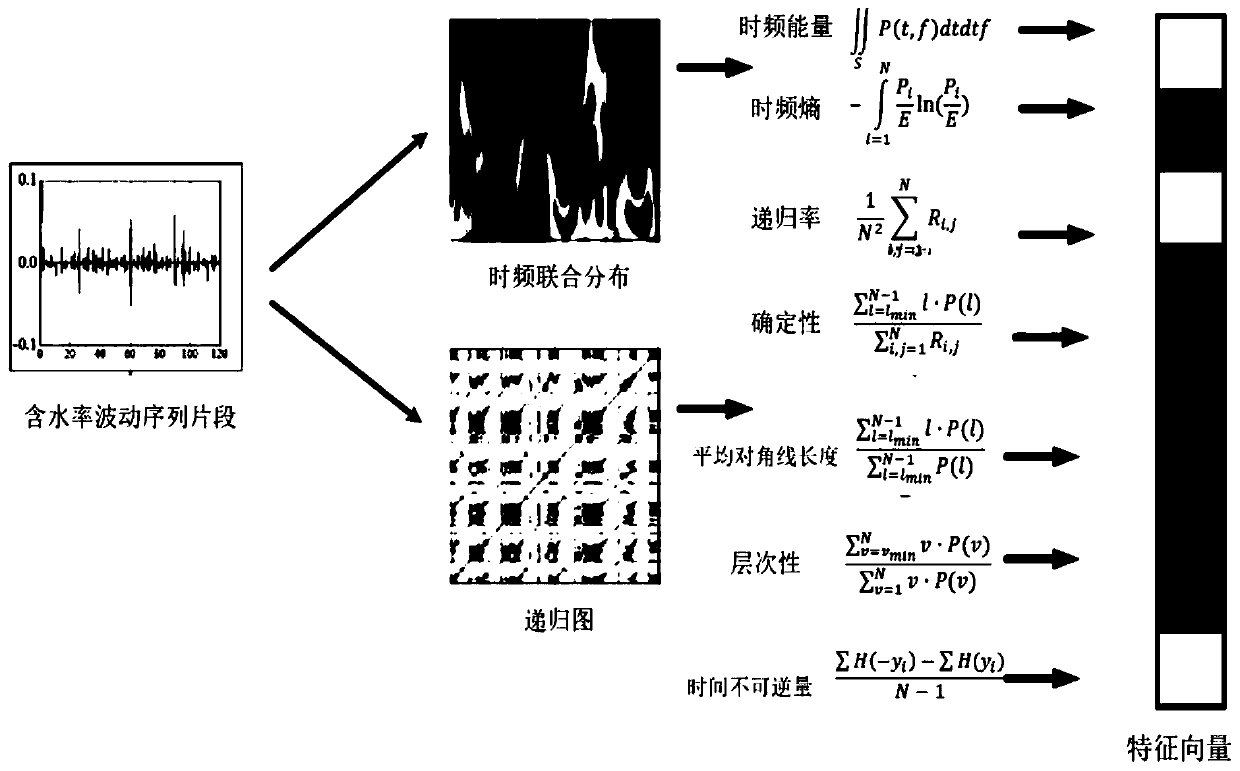

System and method for predicting wellhead water content of low gas yield oil wells based on deep long-term and short-term memory networks

ActiveCN110630256AEasy accessAccurately obtainedConstructionsForecastingShort-term memoryWater content

The invention relates to a system and a method for predicting the wellhead water content of low gas yield oil wells based on deep long-term and short-term memory networks. By a high-frequency double-loop capacitance sensor, the water content fluctuation information of a wellhead mixed fluid is measured, by performing windowing processing on the collected fluctuation time series of the water content, the collected fluctuation time series of the water content is divided into multiple time series-varying time segments, the time-frequency characteristics, non-linear characteristics, and time irreversible characteristics of each time-series segment are extracted to form characteristic vectors, thereby forming the wellhead water content characteristic vector time series. Afterwards, the extracted characteristic vector time series of the water content is used as the input of the deep long-term and short-term memory networks, and a model for predicting the water content based on the deep long-term and short-term memory networks and multiple characteristics is established. By adopting the model, the test value of the water content of the wellhead produced fluid is used as the water contentlabel for training, and finally the predicted value of the water content is obtained. Since the characteristic time series of the water content fluctuation signal is an accurate description of the wellhead produced fluid characteristics, such method can effectively eliminate the influence of a small amount of gas content at the wellhead on the measurement, and further improve the measurement accuracy of the water content of the wellhead produced fluid.

Owner:吴晓南

Steel roof aluminum skirt piston machining process

The invention discloses a steel roof aluminum skirt piston machining process, which comprises the following steps of: a, performing rough turning on a head and an excircle, and performing rough turning on a seam allowance and the excircle; b, roughly boring a pin hole, and milling the radius; c, performing finish turning on the seam allowance, milling a central hole, and performing semi-finish turning on the excircle and a top surface; d, performing semi-finish boring on the pin hole; e, boring the inner distance; f, checking the shape of an inner cavity; g, drilling; h, milling a spherical surface of a counter bore; i, drilling an oil return hole; j, turning a lock groove, and turning chamfering of the pin hole; k, milling an oil groove of the pin hole; l, performing finish boring on the pin hole; m, imitating an ellipse; n, turning holes and chamfering; and o, forming fitter chamfering, removing burr and flashing, and cleaning. By the steel roof aluminum skirt piston machining process, the machining accuracy is high, the process flow is precise and the quality of the machined product is high.

Owner:DALIAN BINCHENG PISTON MFG

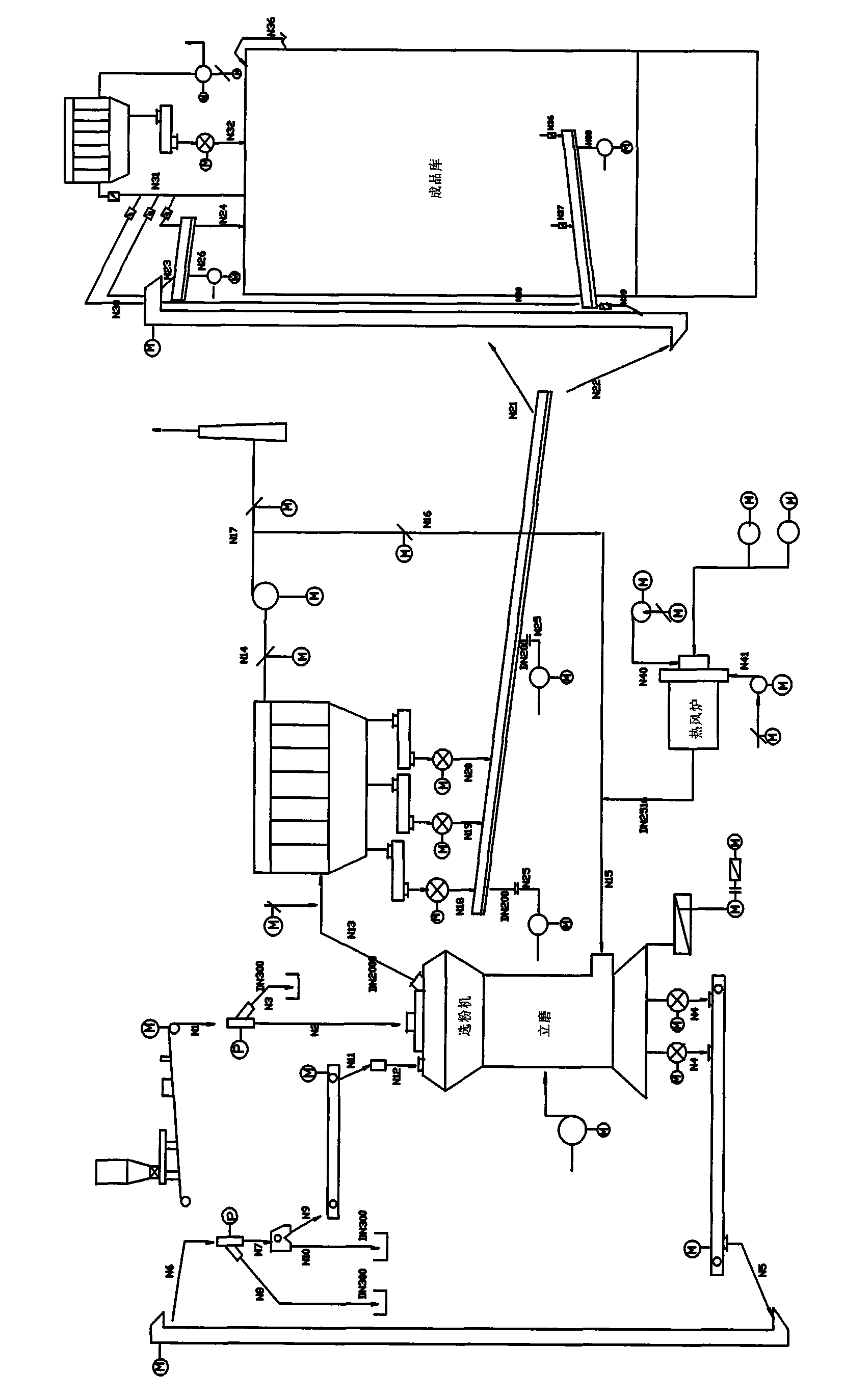

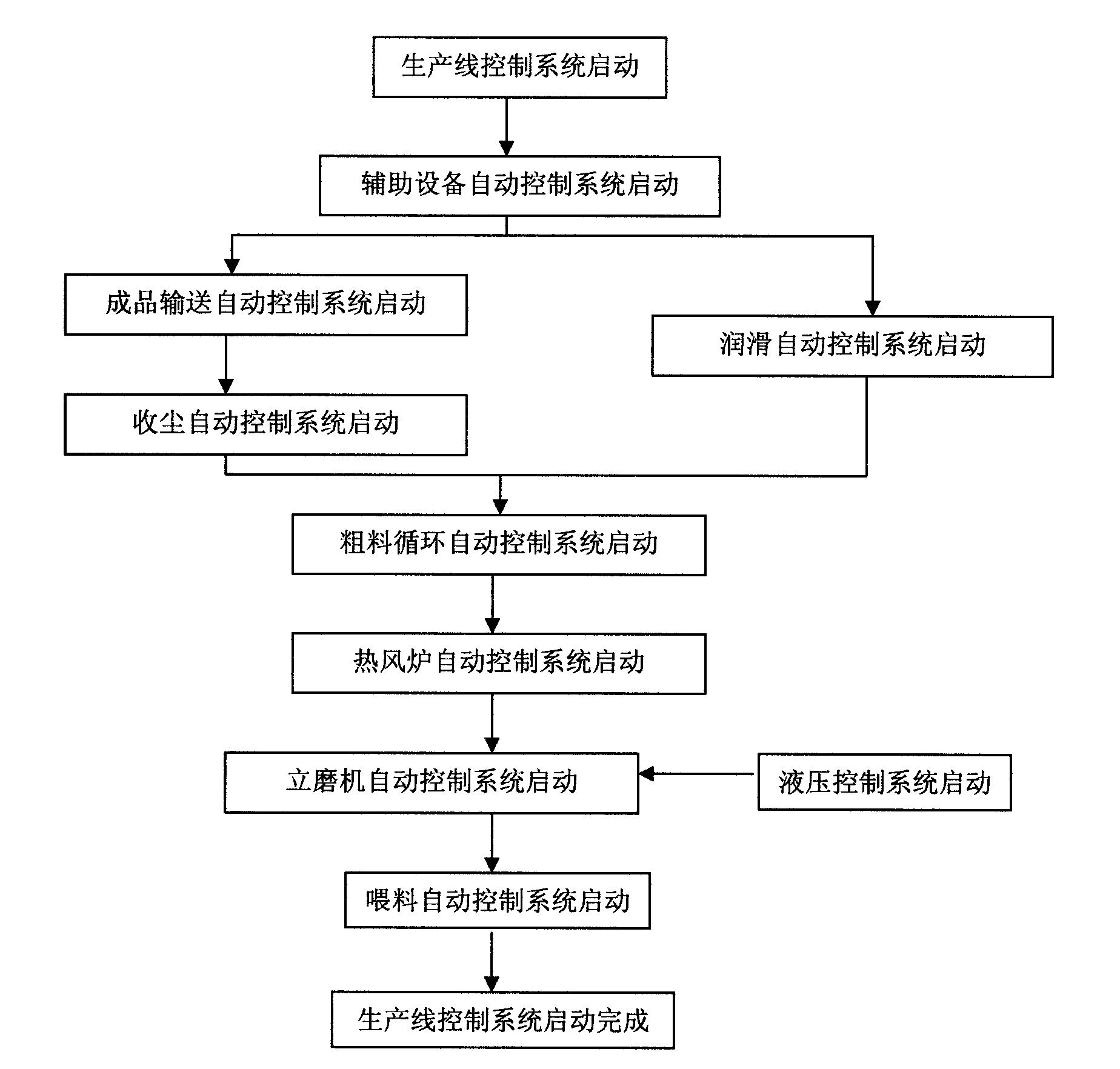

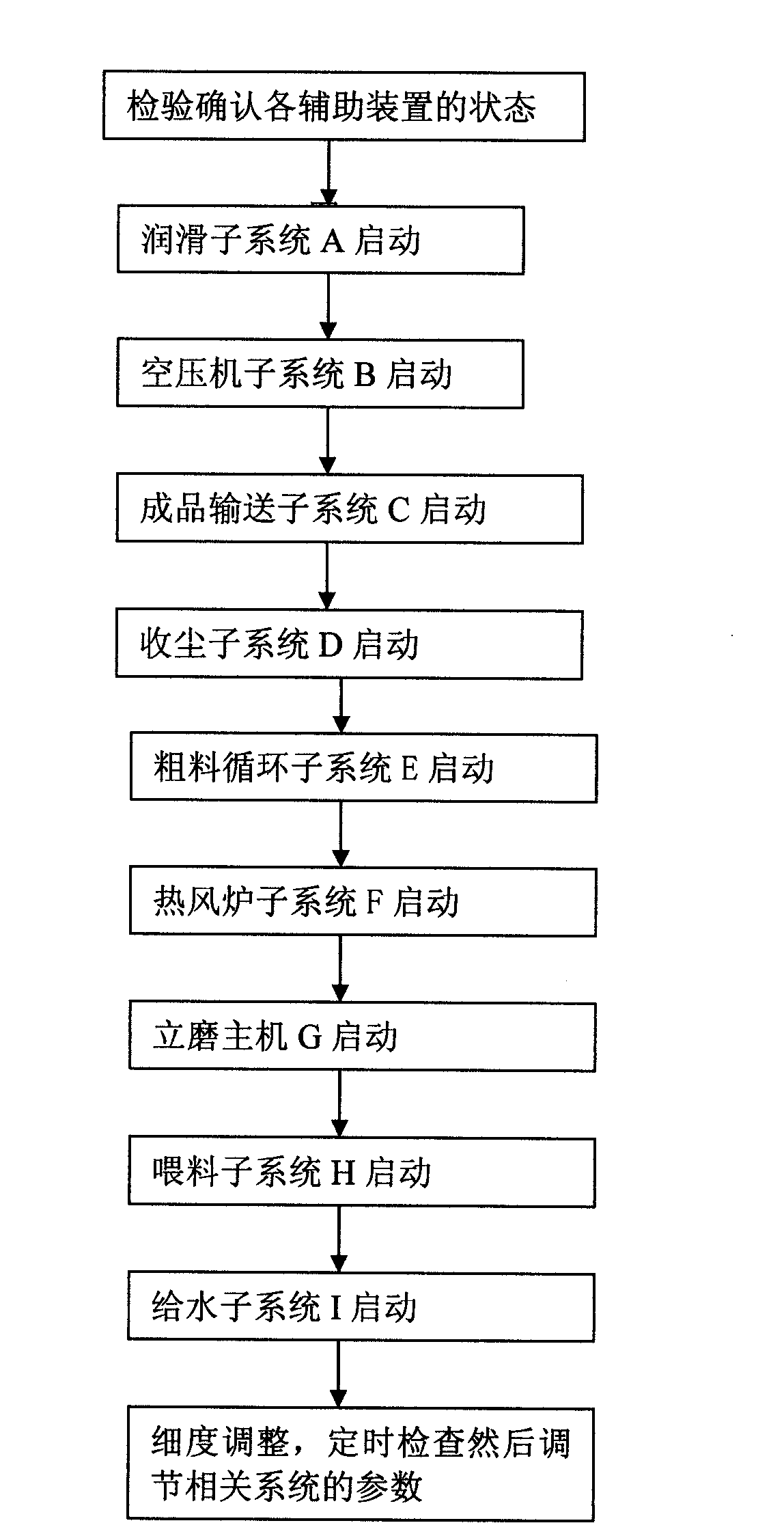

Start control process for COREX slag grinding production control system

ActiveCN101930226AEasy to operateImprove stabilityGrain treatmentsTotal factory controlSlagControl system

The invention relates to a start control process for a COREX slag grinding production control system. The control system comprises a vertical grinding host machine (G), and a lubricating sub-system (A), an air compressor sub-system (B), a finished product conveying sub-system (C), a dust collection sub-system (D), a crude material circulation sub-system (E) and a hot air furnace sub-system (F) serving as assistance, as well as a feeding sub-system (H) and a water supply sub-system (I). The start control process comprises the following concrete steps: (1) checking and confirming the state of each assisted device; (2) implementing start on each sub-system based on the sequence of A-I; and (3) adjusting fineness, regular checking, and adjusting parameters of related systems. The process recombines the sub-systems of the conventional process, strictly starts according to a certain sequence with rigorous procedure, and is advantageous to production operation and production stability; a related hydraulic unit is firstly started so as to contribute to normal operation of subsequent equipment and improve the service life of the equipment.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Production method of conditioned beef steak dish

The invention belongs to the field of food processing and relates to a production method of a conditioned beef steak dish. The production method comprises the following steps: (1) selecting materialsand unfreezing, (2) slicing raw materials, (3) calendering and tendering, (4) rolling, kneading and pickling, (5) packaging and shaping and (6) quickly freezing and packaging. According to the production method, the operability is strong, the procedure is strict, the production of beef steak products can be well guided, the standardized production of beef steak can be well controlled, the steps are optimized, the production process is not tedious, and the problem that the raw materials have relatively hard mouth feel can be solved; and furthermore, the convenient conditioned dish can be obtained by virtue of the production method, so that the cooking in a family and a dining room is facilitated, delicious food can be cooked by an operator with a poor cooking skill, and the application problem of a production product of a cucumber strip raw material is well solved.

Owner:郑州中技联创环境技术有限公司

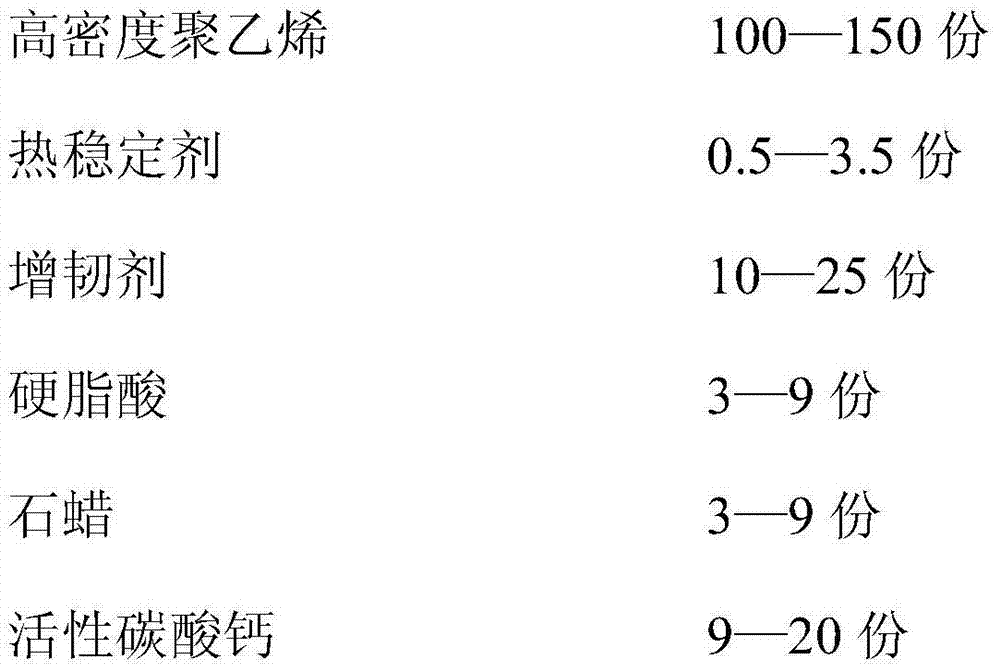

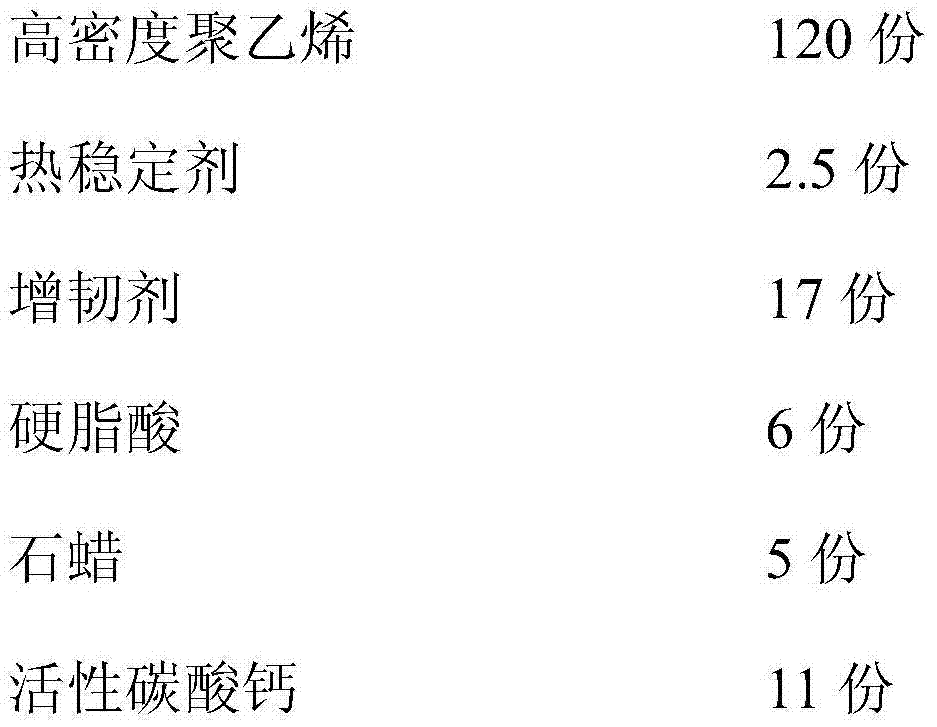

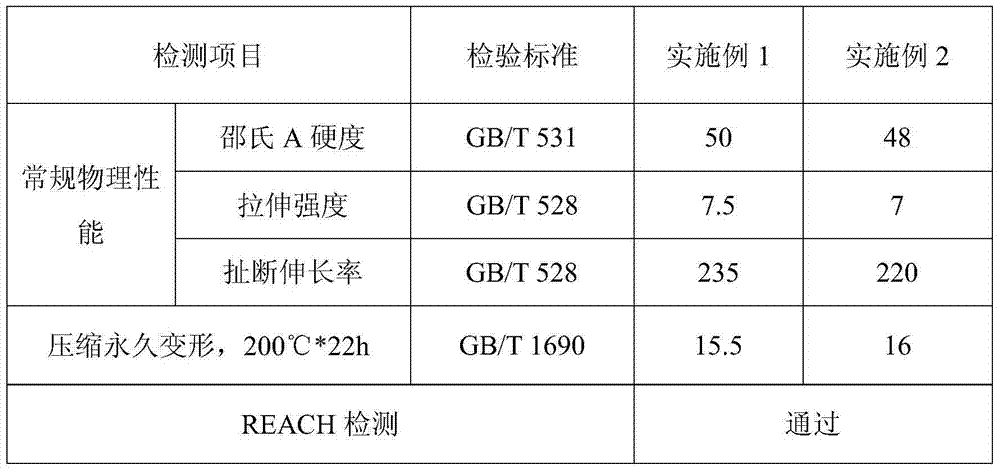

Pressure-tolerant polyethylene tubular product and preparation method thereof

The invention discloses a pressure-tolerant polyethylene tubular product and a preparation method thereof. By adopting improved formula and technology, the tubular product prepared by the method has wonderful pressure-tolerant effect, the using effect of the tubular product can be effectively improved, and the serviceable range of the tubular product can be enlarged. The preparation method for the pressure-tolerant polyethylene tubular product has complete and strict operation steps, and greatly improves the production quality of enterprises.

Owner:江苏金波新材料科技有限公司

Process for processing cylinder sleeve of diesel engine

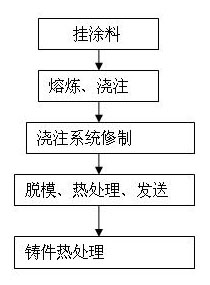

InactiveCN102198496AImprove machining accuracyRigorous processFoundry mouldsFoundry coresPeeningProcessing accuracy

The invention discloses a process for processing a cylinder sleeve of a diesel engine. The process comprises the following steps of: a, coating paint, wherein a metal die and a baffle are prepared, and the paint is prepared; b, smelting and pouring, wherein the smelt process controls the carbon and silicon equivalent C to be between 3.7 and 3.9, the silicon carbon ratio Si / C to be between 0.6 and 0.73, and the pouring requirement is as the specification; c, repairing a pouring system, repairing the inner wall of a quantitative pouring packet with refractory bricks and water glass sands, introducing CO to harden the inner wall of the quantitative pouring packet, coating the paint and drying; d, demolding, thermally treating and delivering, wherein, in cast demolding, a metal die pin, front and rear baffles can be removed after 8 hours, the cast is impacted by a hammer by moving from the small end to the big end; and e, thermally treating the cast, wherein the cast is subject to shot blasting treatment and aging treatment. The process for processing the cylinder sleeve of the diesel engine has the advantages of high processing accuracy, precise process procedure and high quality of processed products.

Owner:DALIAN BINCHENG PISTON MFG

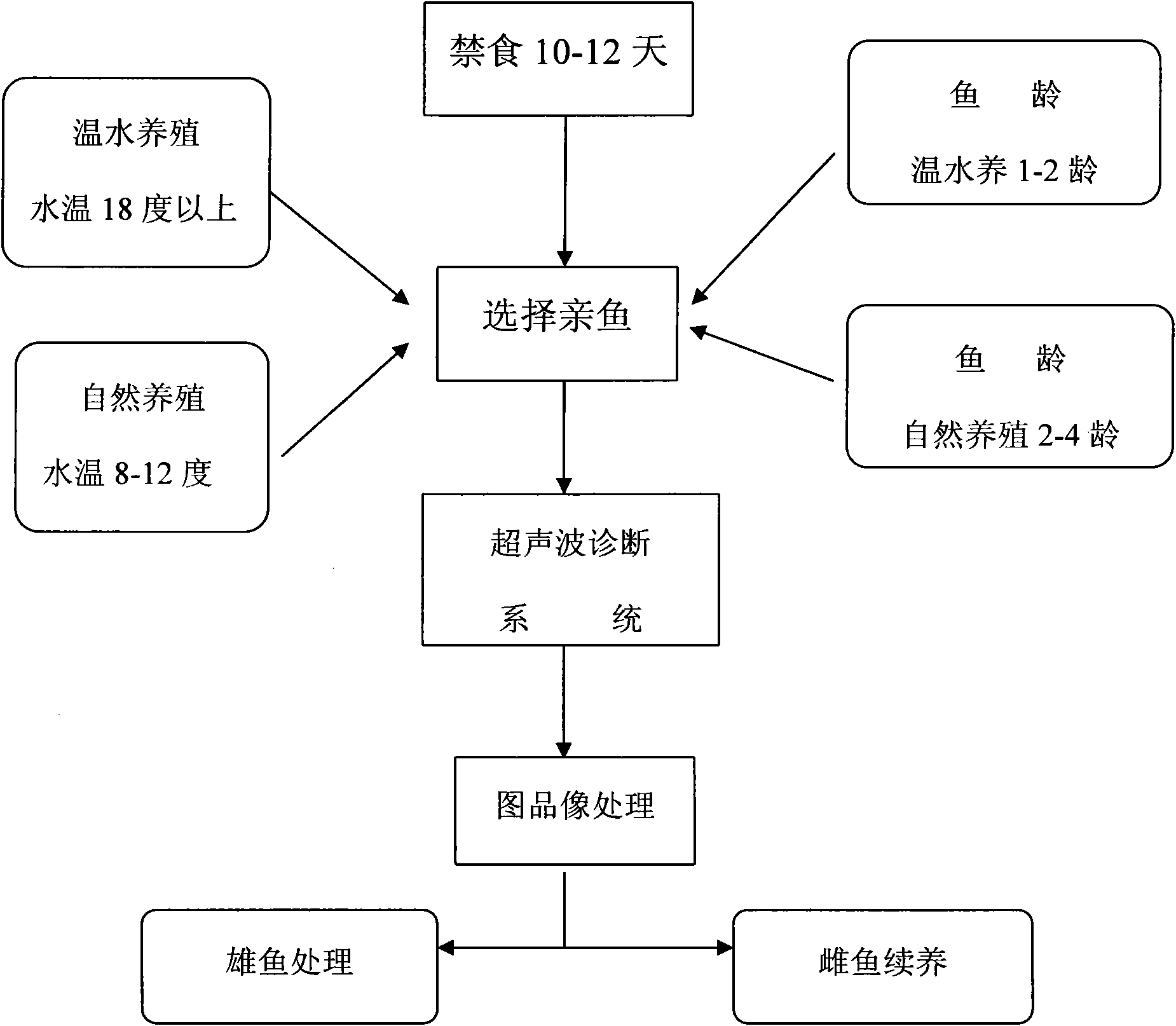

Method for identifying male and female sturgeons by ultrasonic waves

ActiveCN101647718AThe technological means are scientific and reasonableRigorous processTomographyAcoustic wave reradiationClassification methodsSturgeon

The invention relates to a method for classifying males and females of a fish, in particular to a method for examining early sexual glands of sturgeons by using physical functions of ultrasonic waves,and identifying male and female sturgeons according to an echogram generated in the process of examining the sturgeons by the ultrasonic waves. The method not only causes no injuries to the fishes but also can observe dynamic pictures, has the advantages of reasonable process means, precise processes and high diagnostic accuracy, and is a safe and reliable method for identifying the male and thefemale sturgeons by the ultrasonic waves.

Owner:HANGZHOU QIANDAOHU XUNLONG SCI TECH

Method for preparing natural 5-hydroxy tryptamine hydrochloride by utilizing banana peel

5-hydroxytryptamine is an indole derivative and can participate in various central nervous activities, so that people generate cheerful mood. The invention discloses a method for preparing natural 5-hydroxy tryptamine hydrochloride by utilizing banana peel. The method comprises the following preparation procedures: cleaning the banana peel, drying and crushing the banana peel; carrying out ultrasonic auxiliary water bath extraction; carrying out column chromatography separation; concentrating an extracting solution; leaching by ethanol; and crystallizing. The method disclosed by the invention is simple and feasible in process, scientific and rational in procedure, rigorous in working procedure, low in cost, easy to implement, small in energy consumption, high in extracting rate and high in product purity. According to the invention, only alcohol and ultrasonic auxiliary water are used for refining, so the pollution of an organic solvent is avoided; a source of natural 5-hydroxy tryptamine hydrochloride is provided, and the method can be widely applied to the field of food processing, so market requirements are met; and a new way is provided for comprehensive utilization of the banana peel, and the method has wide market development prospect.

Owner:杨公明

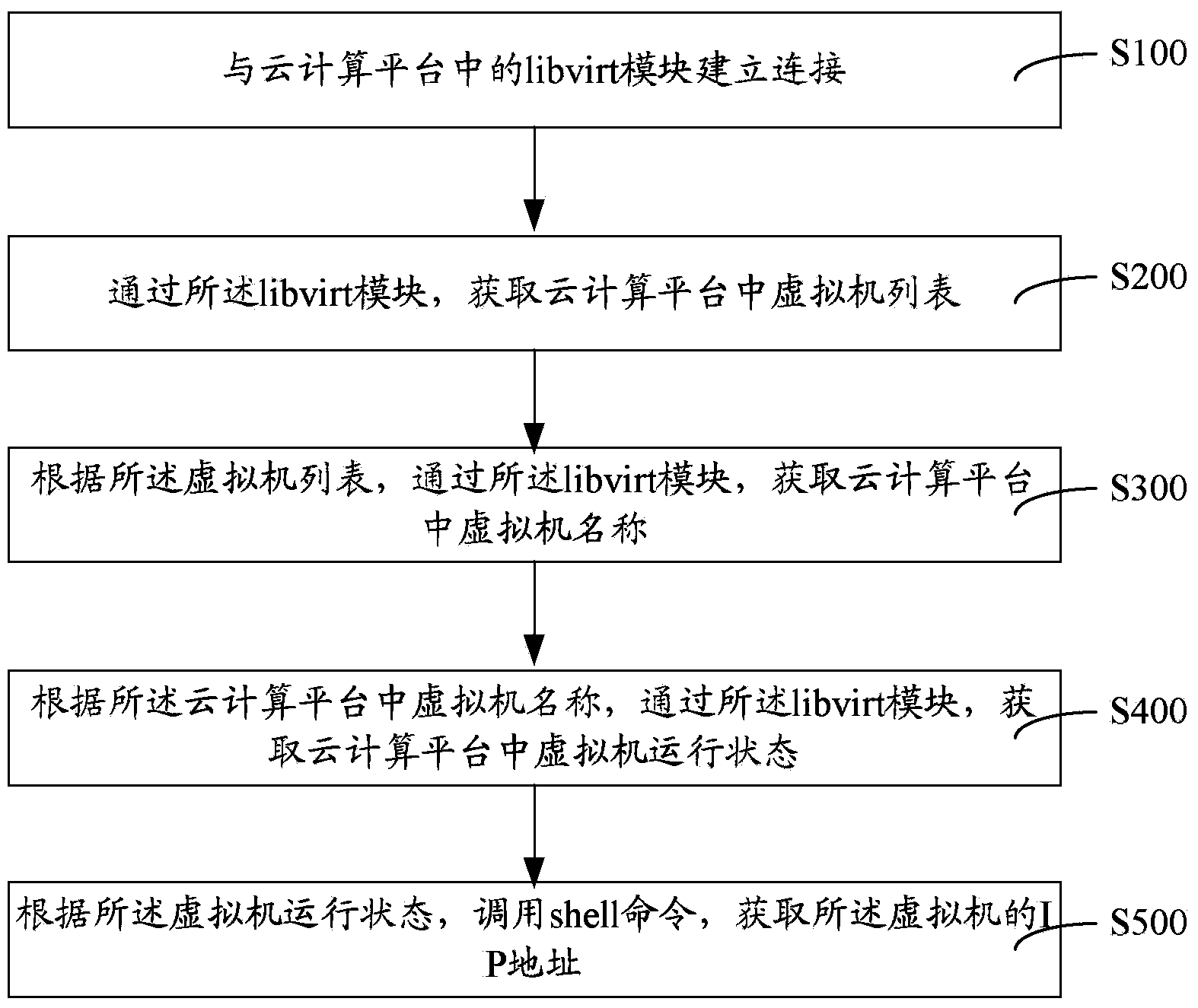

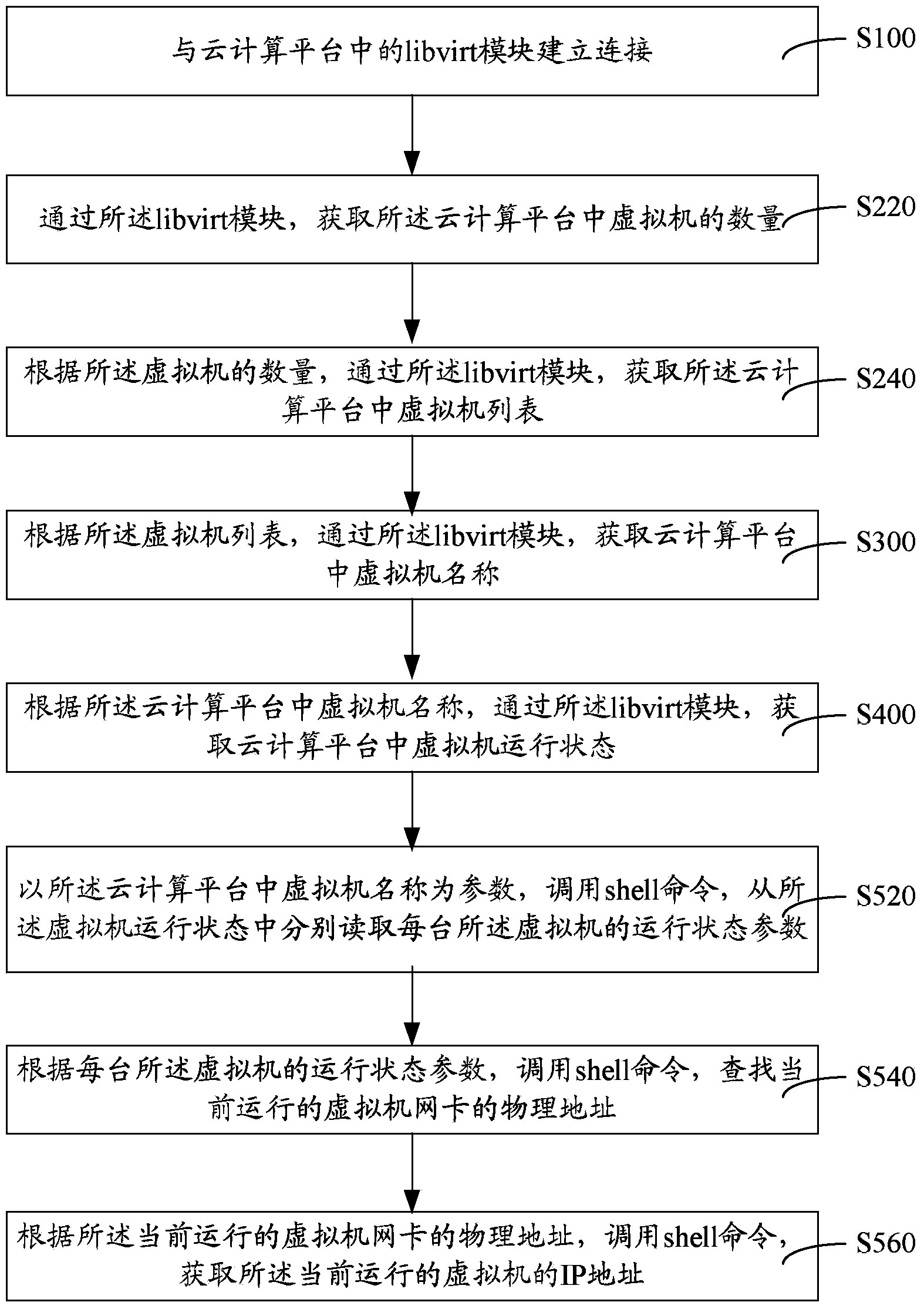

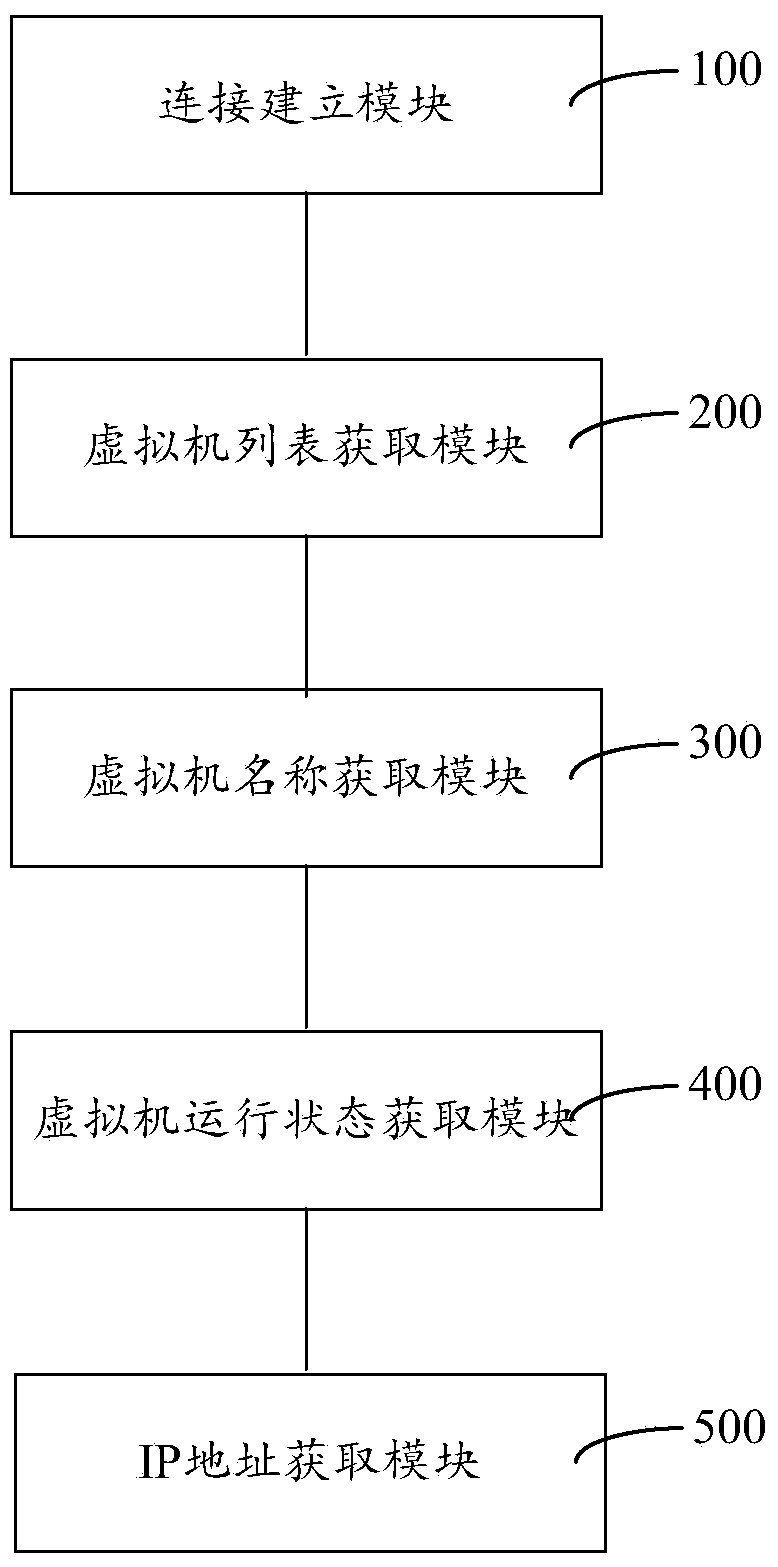

Method and system for obtaining IP (Internet Protocol) address of virtual machine in cloud computing platform

InactiveCN104111862AImprove efficiencyEasy to controlTransmissionSoftware simulation/interpretation/emulationIp addressCloud computing

The invention provides a method and system for obtaining an IP address of a virtual machine in a cloud computing platform. The method for obtaining the IP address of the virtual machine in the cloud computing platform comprises establishing connection with a libvirt module in the cloud computing platform, obtaining a virtual machine list in the cloud computing platform through the libvirt module in the cloud computing platform, obtaining virtual machine names in the cloud computing platform through the libvirt module, obtaining running status of virtual machines in the cloud computing platform, and finally calling a shell command according to the running status of the virtual machines to obtain the IP address of the virtual machine. In the whole process, the virtual machine list, names and running status are sequentially obtained through the libvirt module and the IP address of the virtual machine can be obtained according to the shell command built in the cloud computing platform, the IP address of the virtual machine can be automatically obtained efficiently and accurately through a simple and strict processing process, efficiency during data interaction of the virtual machine with other devices can be improved and background control of the cloud computing platform can be facilitated.

Owner:HUNAN SHENGYUN TECH

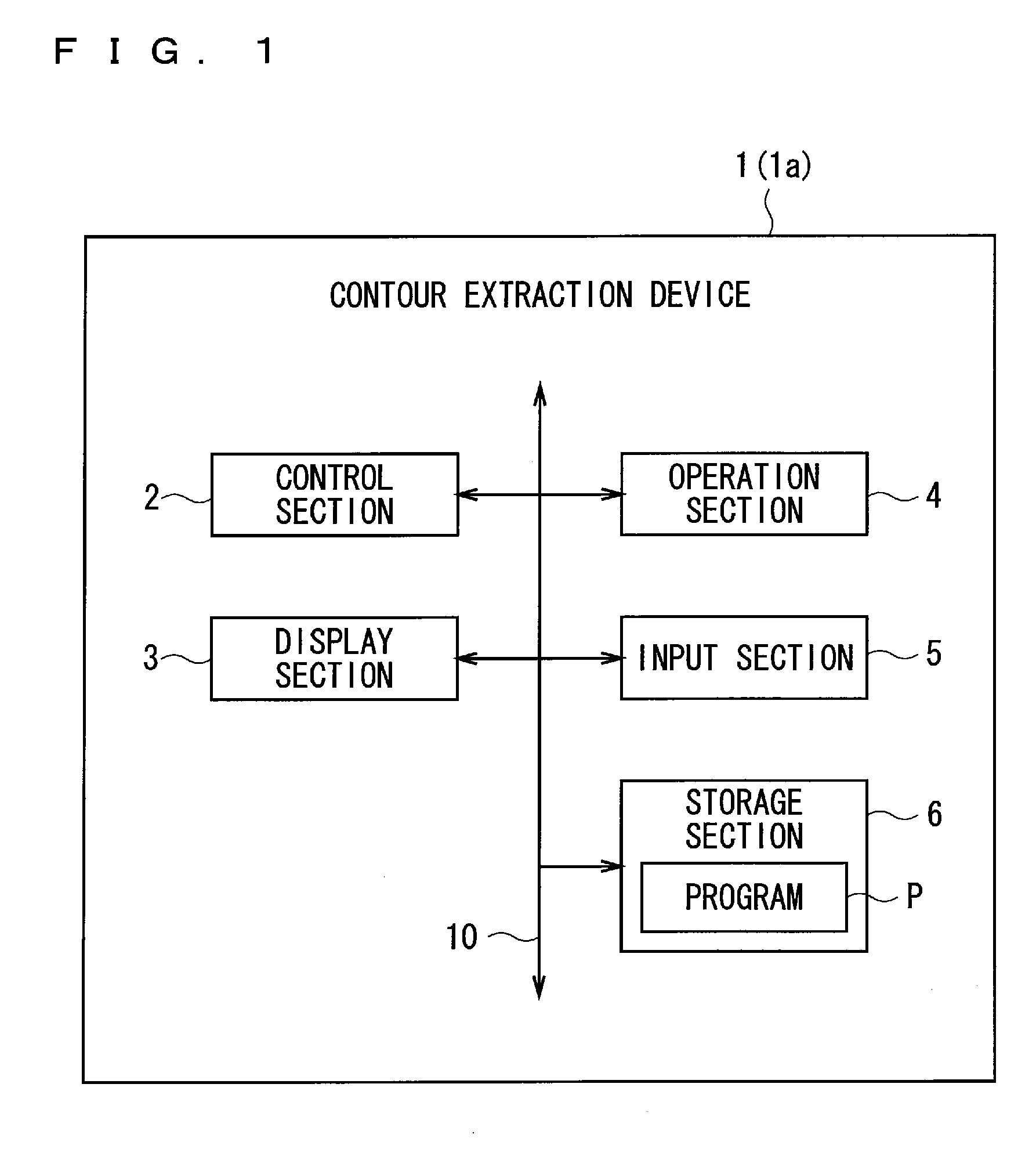

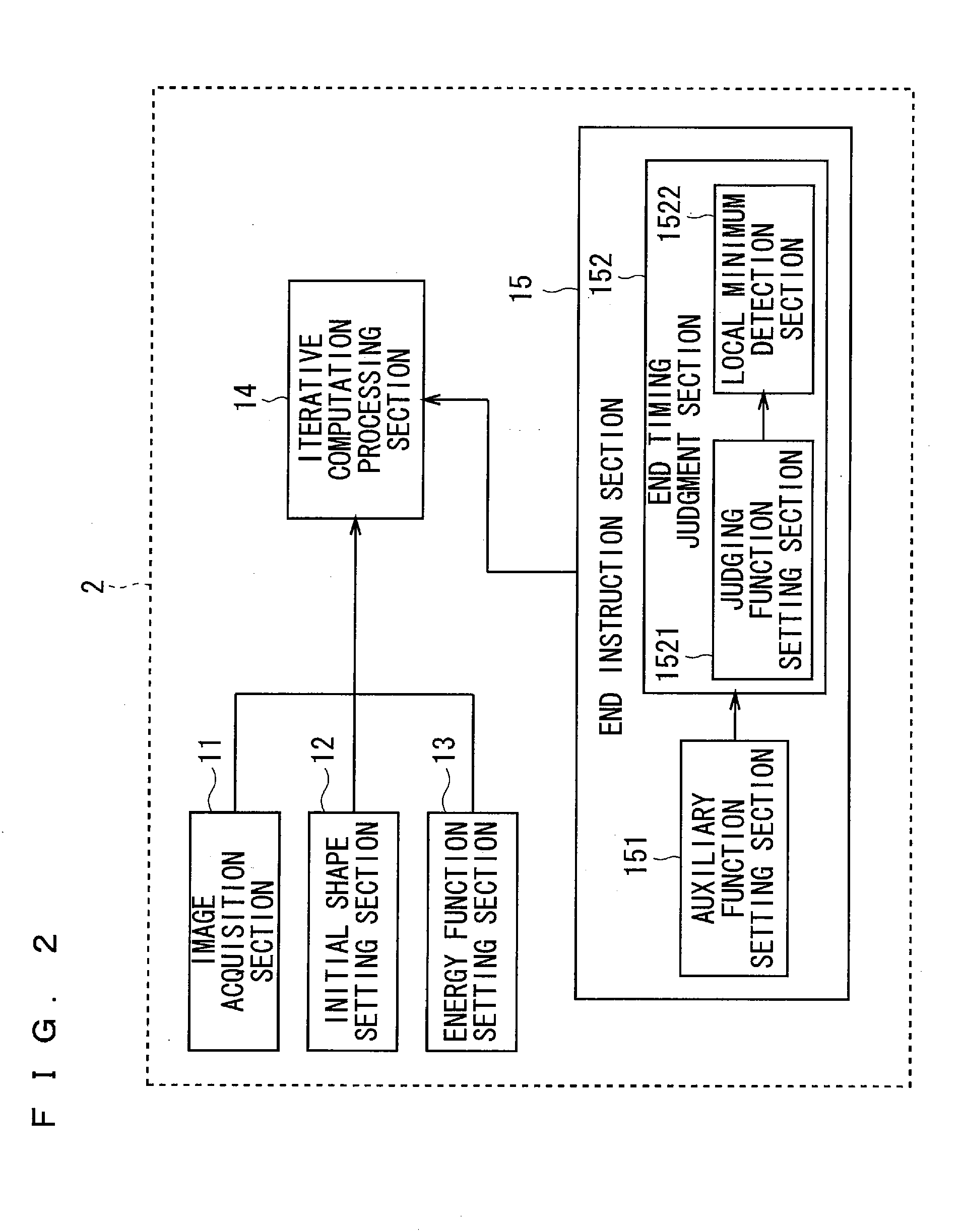

Contour extraction device and program

InactiveUS20120099799A1Rigorous processAppropriate balanceImage enhancementImage analysisEnergy function minimizationComputation process

An object of the present invention is to provide the technology capable of appropriately balancing the preciseness of contour extraction and calculation cost. In order to achieve this object, an energy function setting section sets an energy function that is expressed by a weighted linear sum of a plurality of kinds of energy terms defined correspondingly to a state of an active curve and is formulated so as to have a smaller value as approaching a shape of the contour to be extracted, and an iterative computation processing section minimizes the energy function by an iterative computation. An end instruction section sets an auxiliary function formulated so as to monotonously increase in accordance with the number of iteration times of iterative computation and sets a judging function expressed by a linear sum of the auxiliary function and the energy function. Then, a point of time when a local minimum appears in the judging function in the course of the iterative computation is judged as the end timing of iterative computing.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

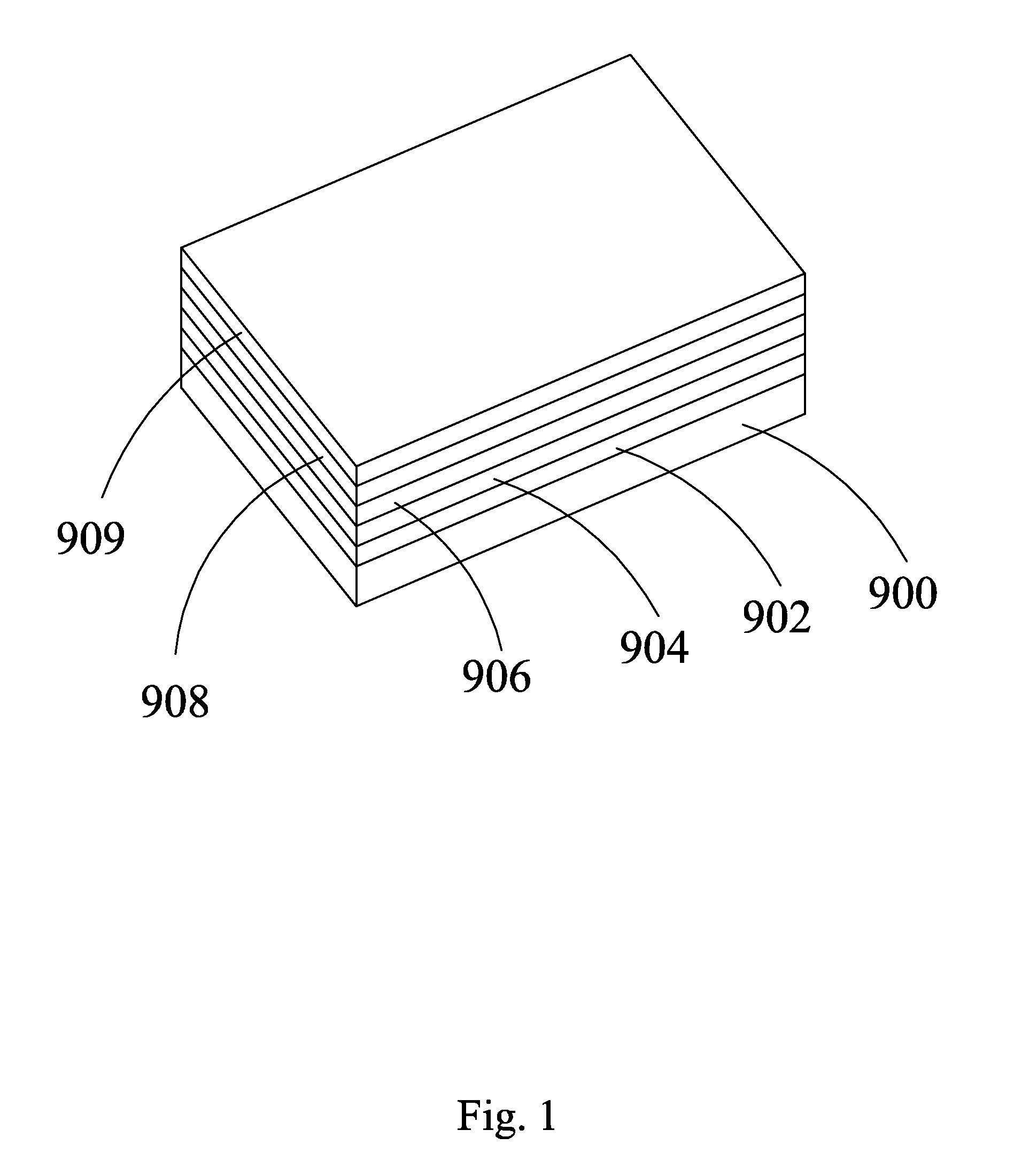

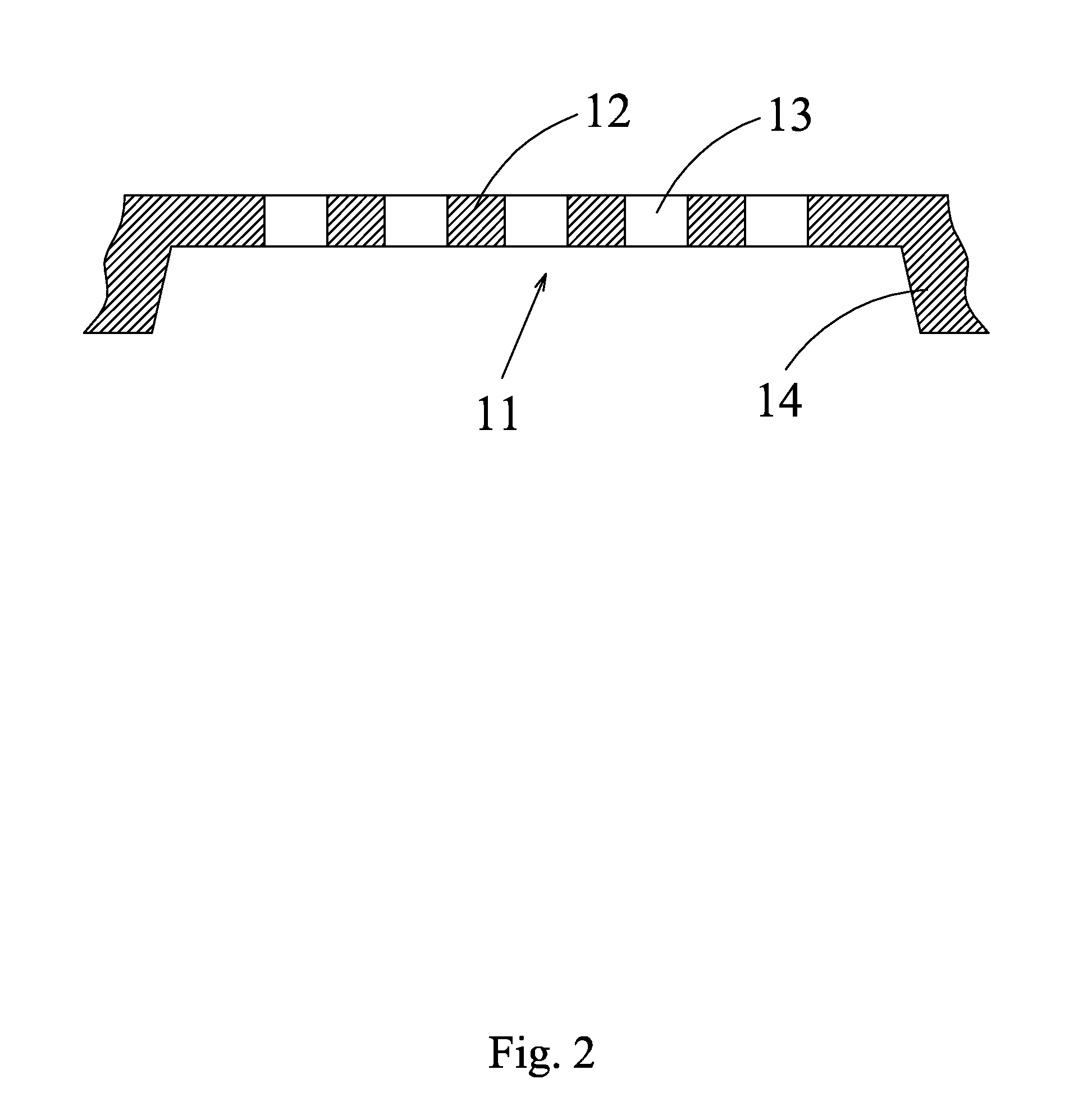

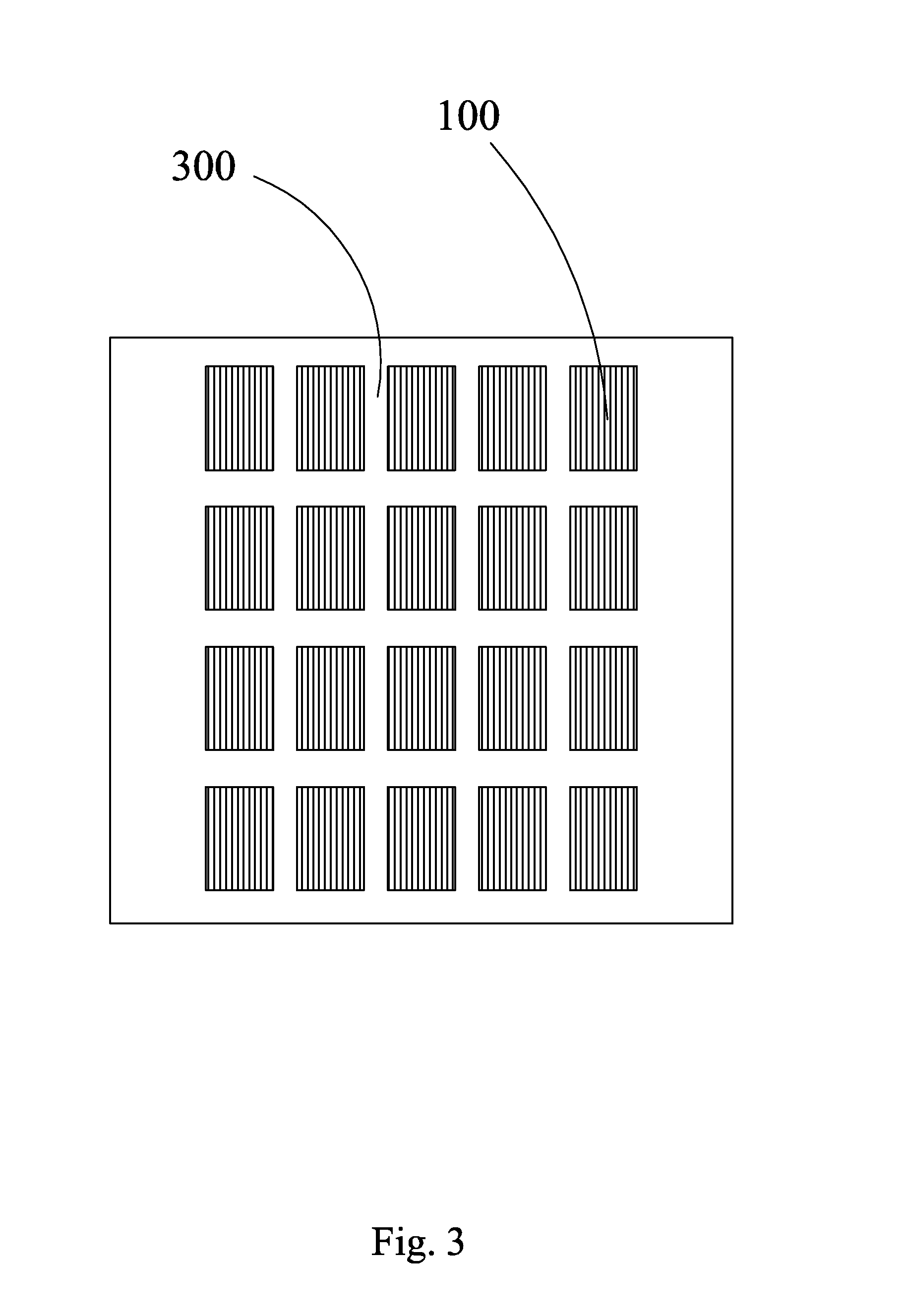

Method for manufacturing photo mask and photo mask manufactured with same

ActiveUS20160011504A1Reduce mass differenceEliminate the problemOriginals for photomechanical treatmentEngineeringPhotomask

Disclosed are a method for manufacturing a photo mask and a photo mask manufactured with the method. The method includes (1) providing a partially finished photo mask, which has effective open areas and ineffective areas located around the effective open areas and (2) applying a half-etching process to form recesses in the ineffective areas. With the recesses formed through a half-etching process in the ineffective areas located around the effective open areas, a mass difference between the effective open areas and the ineffective areas is reduced so that in the process of attracting the photo mask, inconsistent sequence of attraction caused by a great mass difference between the effective open areas and the ineffective areas can be eliminated to thereby ensure that the effective open areas of the photo mask can be laid completely flat on a substrate at predetermined locations and thus ensure the preciseness of a deposited pattern.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

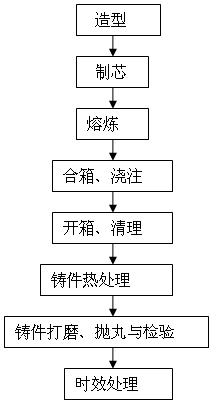

Process for machining piston skirt

InactiveCN102213312AImprove machining accuracyRigorous processPlungersTrunk pistonsPistonThermal treatment

The invention discloses a process for machining a piston skirt. The process comprises the following steps of: a, shaping: checking the completeness of a die and a chilling block of the die before production; b, manufacturing a core which consists of a body core and a side binding core; c, smelting: when the temperature of a furnace is raised to 1,250 DEG C, sampling and testing, and adjusting components in the furnace; and when the temperature of the furnace is up to 1,520+ / -10 DEG C, cutting off power and standing for preparation; d, closing a box and pouring: closing the box, fastening a box clamp, placing a pouring cup, pouring by using quantitative pouring ladles and preparing to lead air out during pouring, wherein the pouring speed is 7 to 9S and the pouring temperature is 1,430 to 1,400 DEG C; e, opening the box and cleaning: tapping a casting by using a hammer, taking a sand core out, removing a water gap and a dead head, and shoveling fins, flying edges and burrs of the casting; f, performing thermal treatment, normalizing treatment and tempering treatment on the casting; g, polishing the casting, and performing shot blasting and inspection; and h, performing aging treatment. The process for machining the piston skirt is high in machining precision, strict in process flows and higher in machined product quality.

Owner:DALIAN BINCHENG PISTON MFG

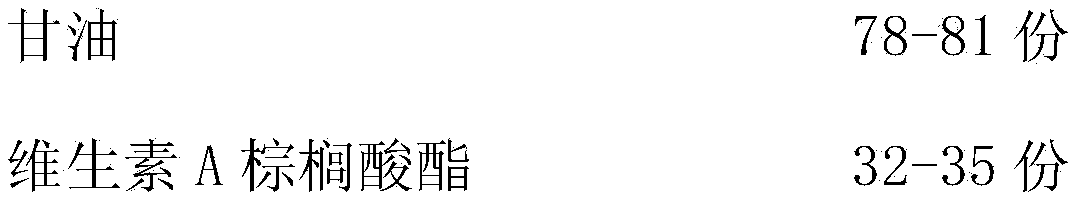

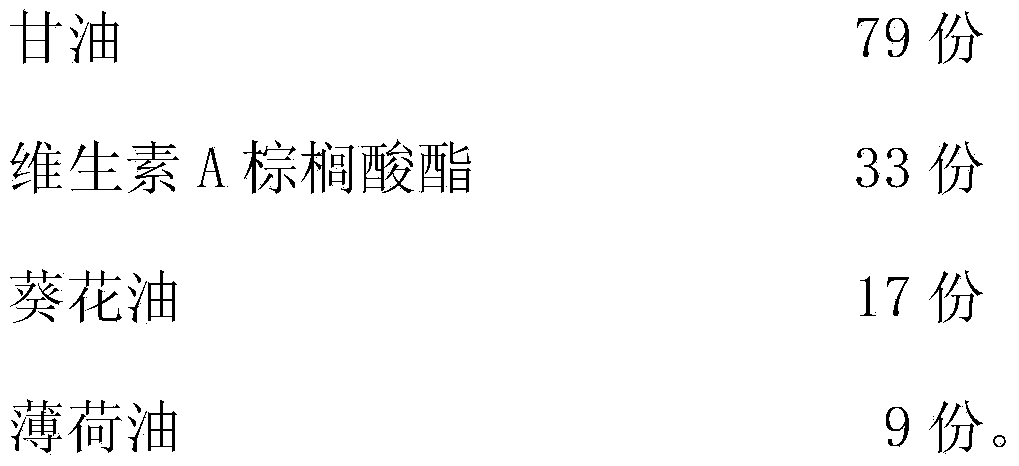

Rubber gloves with skin moisturizing function and manufacturing method thereof

InactiveCN103535935AEasy to useOperation diversificationCoatingsProtective garmentBiochemical engineeringProduction quality

The invention discloses rubber gloves with a skin moisturizing function. By means of an improved formula and an improved technology, the rubber gloves manufactured through the method have a good skin moisturizing function on the hands especially in autumn and winter, and a use effect of the rubber gloves is greatly improved. The manufacturing method is perfect in operation and strict in process and greatly improves production quality of enterprises.

Owner:ZHENJIANG SUHUI LATEX PROD

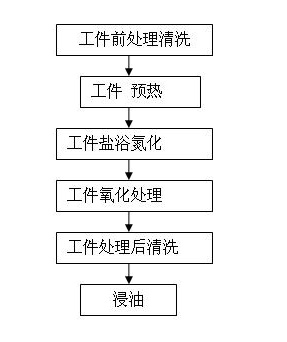

Cylinder sleeve salt bath nitridation process

InactiveCN102162081ARigorous processFine processSolid state diffusion coatingMetallurgyOxidative treatment

The invention discloses a cylinder sleeve salt bath nitridation process, which comprises the following steps of: a, workpiece pretreatment and cleaning, namely putting a workpiece to be cleaned into a cleaning tank and cleaning the workpiece by using cleaning solution; b, workpiece preheating at the temperature of between 300 and 400 DEG C; c, workpiece salt bath nitridation, namely putting the workpiece into a salt bath furnace and performing salt bath nitridation treatment; d, workpiece oxidation treatment, namely putting the workpiece into an oxidation furnace and performing oxidation treatment; e, cleaning of the treated workpiece; and f, oil immersion. The cylinder sleeve salt bath nitridation process has strict and elaborate process flows and good salt bath nitridation effect.

Owner:DALIAN BINCHENG PISTON MFG

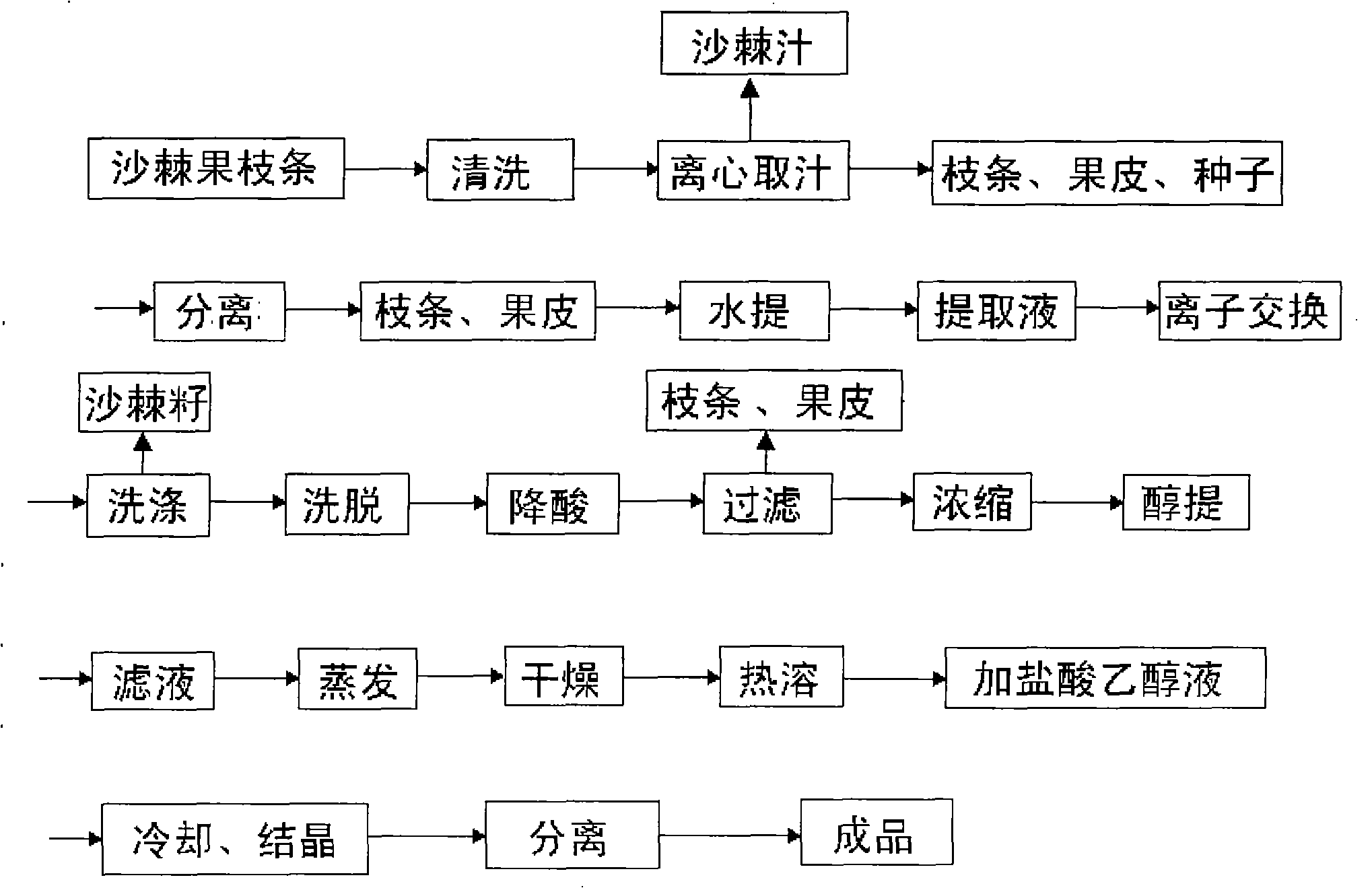

Method for preparing 5-hydroxytryptamine from hippophae rhamnoides

InactiveCN101337921BReduce production extraction costsHigh purityOrganic chemistryFiltrationIon exchange

The invention relates to a method for preparing natural active substance mixture from tresses, pomaces and peels of a plant, in particular to a method for preparing 5-hydroxytryptamine from sea buckthorn. The method for preparing 5-hydroxytryptamine from sea buckthorn comprises the following steps: (1) the tresses of a sea buckthorn fruit is collected and washed; (2) juice is extracted; (3) separation is performed; (4) water extraction is performed; (5) filtration is performed; (6) ion exchange is performed; (7) washing and elution are performed; (8) acid reduction is performed; (9) concentration is performed; (10) extraction is performed by ethanol; (11) the product is obtained through crystallization. The method for extracting 5-hydroxytryptamine from the tresses, the pomaces and the peels of sea buckthorn, and the waste can be reused; 5-hydroxytryptamine has high content and can be used as raw material for waste utilization, and the manufacturing extraction cost of 5-hydroxytryptamine is lowered. The method for preparing 5-hydroxytryptamine from sea buckthorn has simple and easy technology, scientific and reasonable processes, precise working procedure, low cost, and high product purity.

Owner:QINGHAI TSINGHUA BIOTRY BIO TECH

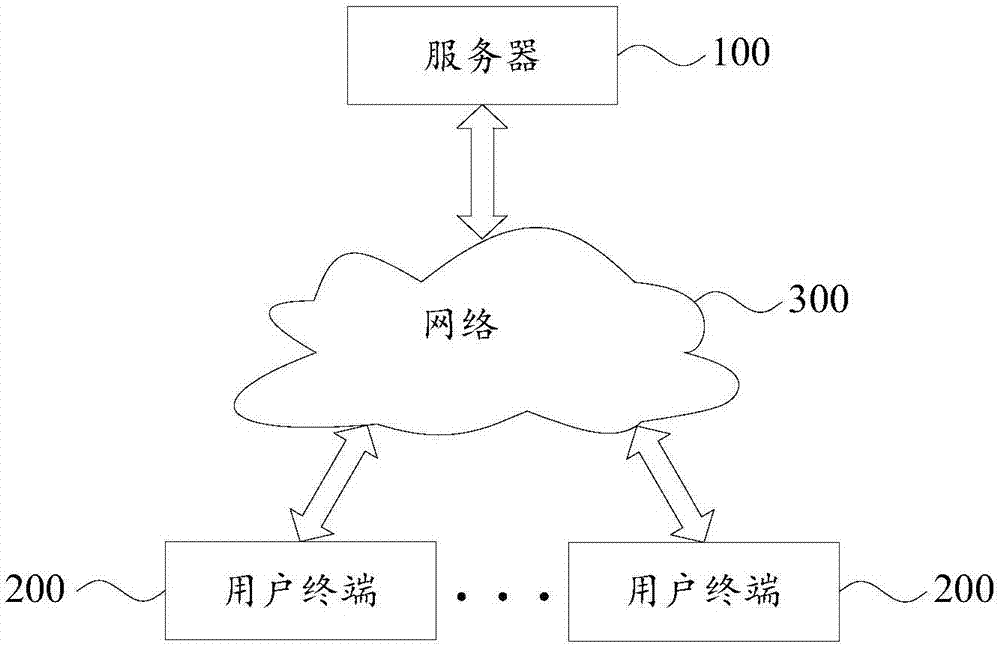

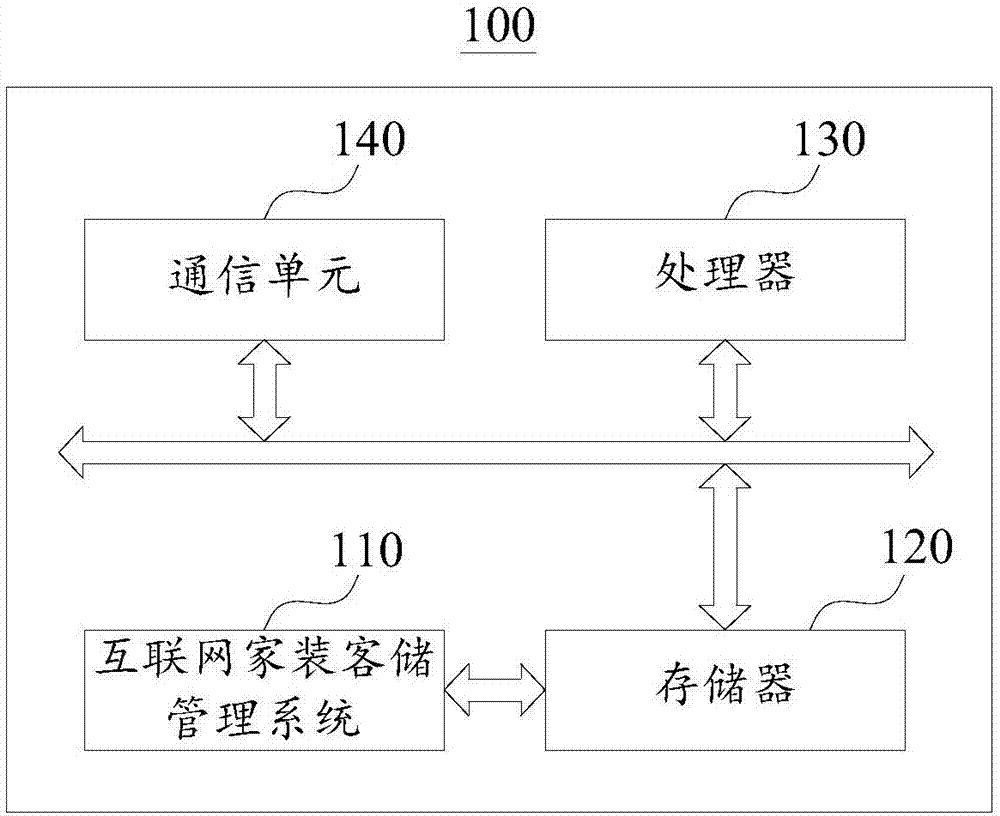

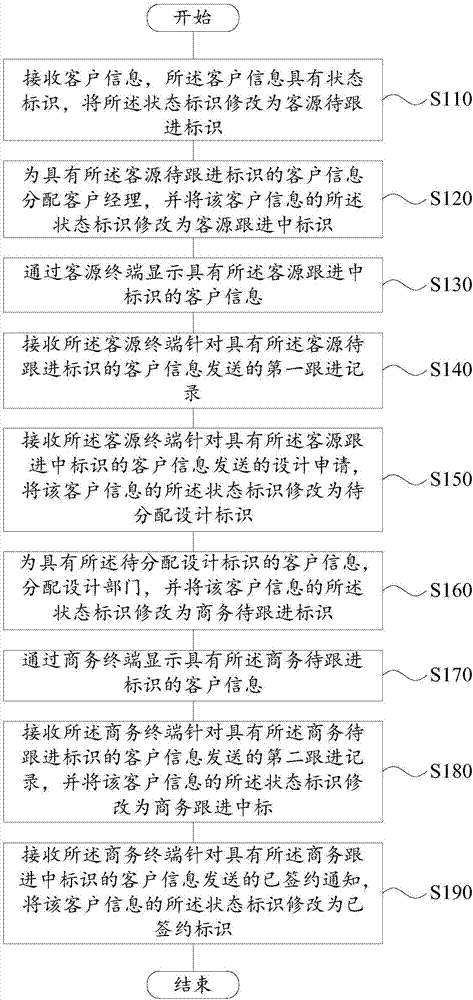

Internet home decoration customer information storage management method and system

ActiveCN107993002AEasy to manageEasy to operateCustomer relationshipOffice automationThe InternetComputer terminal

The invention provides an internet home decoration customer information storage management method and system. The method comprises the steps of receiving customer information, and modifying a state identification to a customer source identification to be followed up; allocating the customer information to a customer manager, and modifying the state identification of the customer information to a customer source follow-up identification; displaying the customer information with the customer source follow-up identification through a customer source terminal; receiving a design application sent by the customer source terminal, and modifying the state identification of the customer information to a design identification to be allocated; allocating the customer information to a design department, and modifying the state identification of the customer information to a business identification to be followed up; displaying the customer information with the business identification to be followed up through a business terminal; receiving a signed notification sent by the business terminal, and modifying the state information of the customer information to a signed identification. The customer information is identified at different circulation stages, the management of the customer information is facilitated, the operation is simple, the configuration is flexible, and the process is rigorous.

Owner:DONG YI RI SHENG HOME DECORATION GRP

Composite polyethylene alloy pipe material and preparation method thereof

ActiveCN106523806AImprove bearing strengthImprove product qualityRigid pipesAlloyUltimate tensile strength

The invention discloses a composite polyethylene alloy pipe material. The composite polyethylene alloy pipe material adopts a three-layer composite structure which comprises a high-temperature-resistant polyethylene pipe layer, a fiber winding reinforced layer and an anti-oxidation polyethylene protective layer sequentially from inside to outside. By adoption of a novel formula and a preparation process, the prepared composite polyethylene alloy pipe material has excellent bearing strength, high use temperature and low production cost, and can effectively improve the use effect of products and enlarge the use range of the products.

Owner:江苏金波新材料科技有限公司

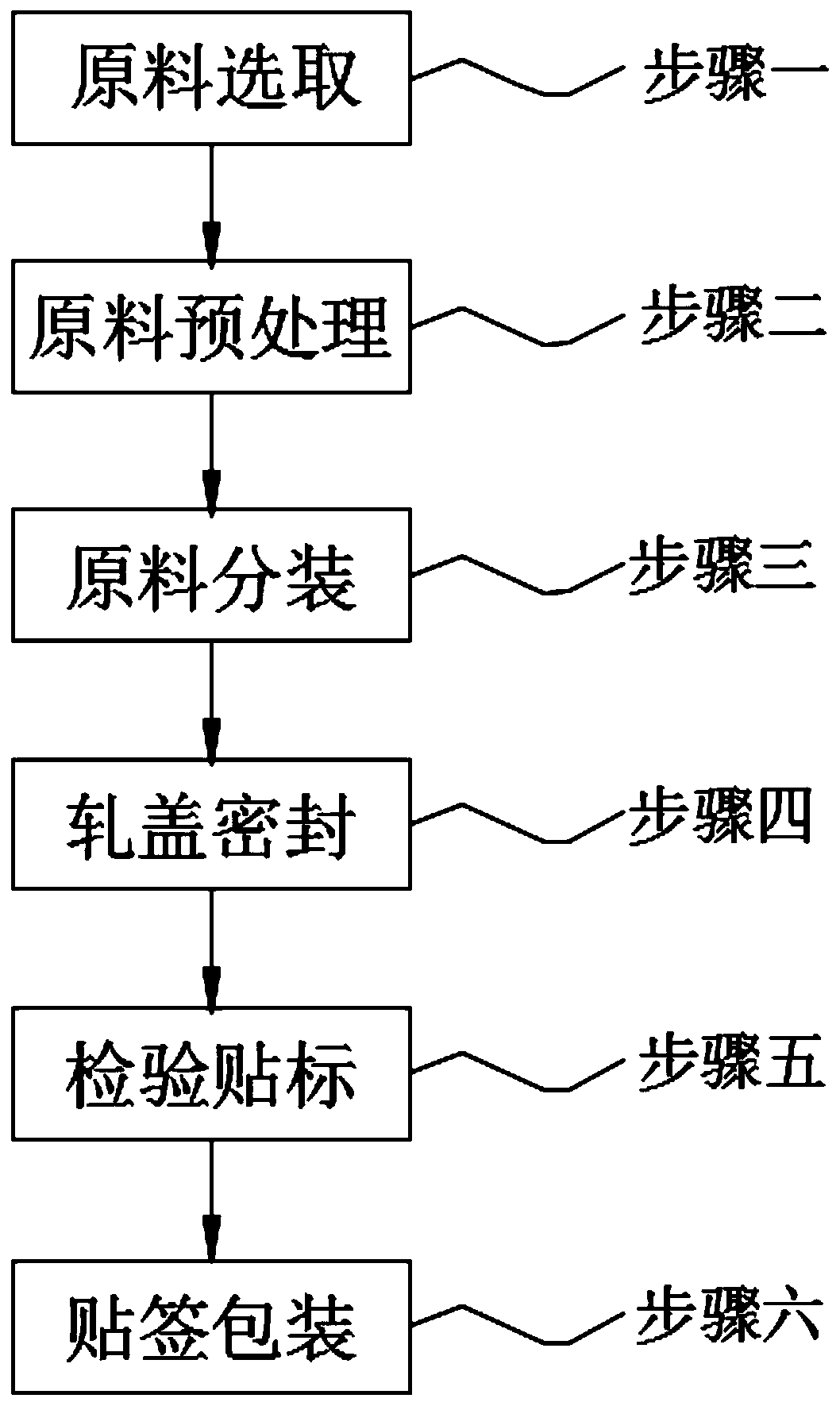

Cefodizime sodium for injection and preparation method of cefodizime sodium

InactiveCN110384704AThe production process is cleanImprove sanitationAntibacterial agentsPowder deliveryCefodizime SodiumPre treatment

The invention discloses cefodizime sodium for injection and a preparation method of the cefodizime sodium. A dispensation comprises the cefodizime sodium, the cefodizime sodium is contained in a glassbottle, a rubber plug is plugged at the bottle opening of the glass bottle, an aluminum-plastic cover is arranged at the top of the rubber plug, and the aluminum-plastic cover is capped at the bottomopening of the glass bottle. The preparation method of the cefodizime sodium for injection comprises the following steps that 1, a raw material is selected; 2, the raw material is preprocessed; 3, the raw material is subpackaged; 4, capping and sealing are conducted; 5, detecting and marking are conducted; and 6, labelling and packing are conducted, and a raw material drug, a glass bottle, a rubber plug and a plurality of aluminum-plastic covers are selected for standby application. According to the cefodizime sodium for injection and the preparation method of the cefodizime sodium, the wholemanufacturing process is clean, the hygienic conditions are good, the manufacturing process is smooth, seamless transition is achieved, the pharmacy efficiency can be greatly improved, the process isprecise, detection is strict, the quality of products can be effectively guaranteed, meanwhile the cost is controlled, waste is less, and generalization is convenient.

Owner:汕头金石粉针剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com