Patents

Literature

64results about How to "Rigorous workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength magnesium alloy and preparation method thereof

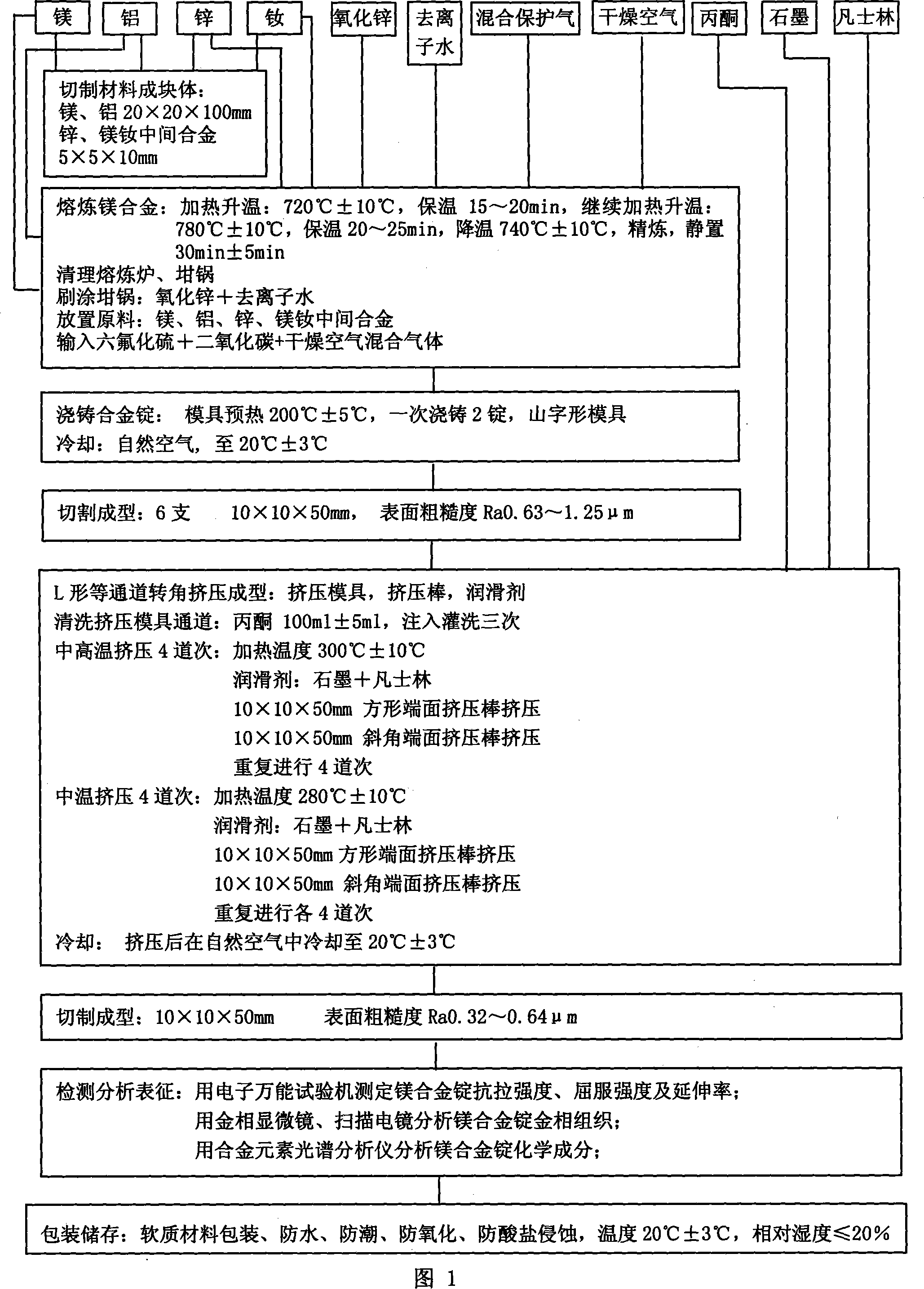

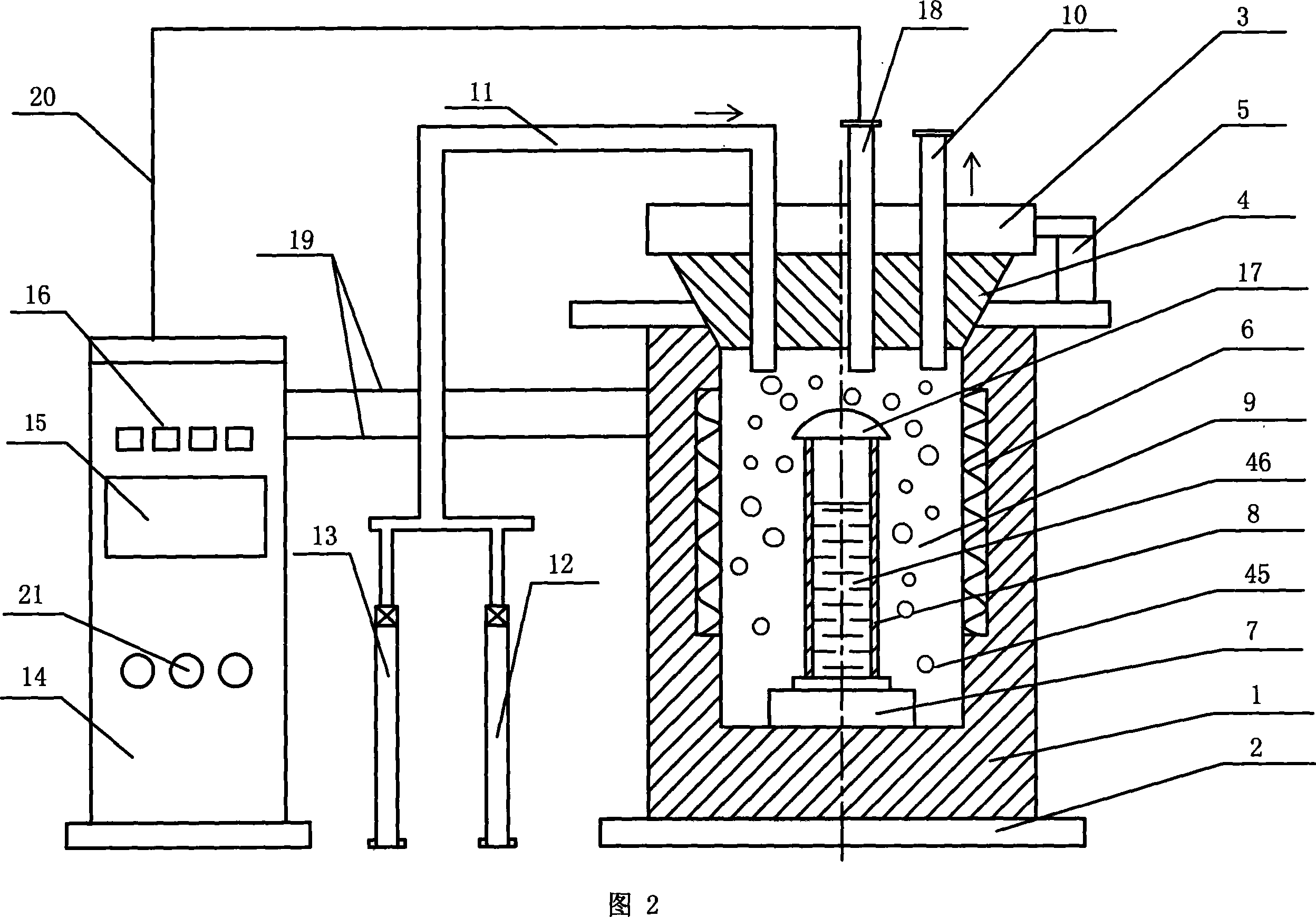

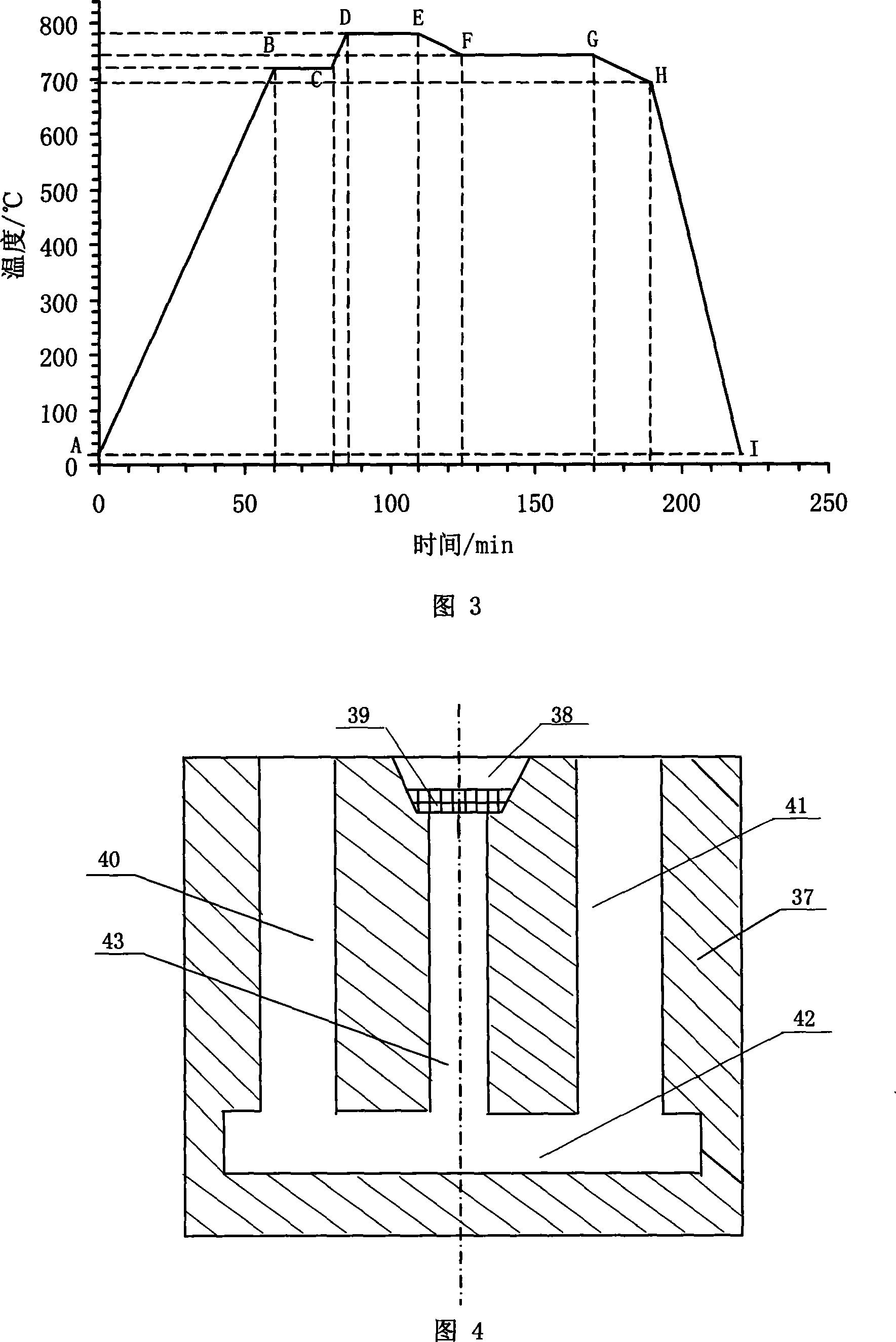

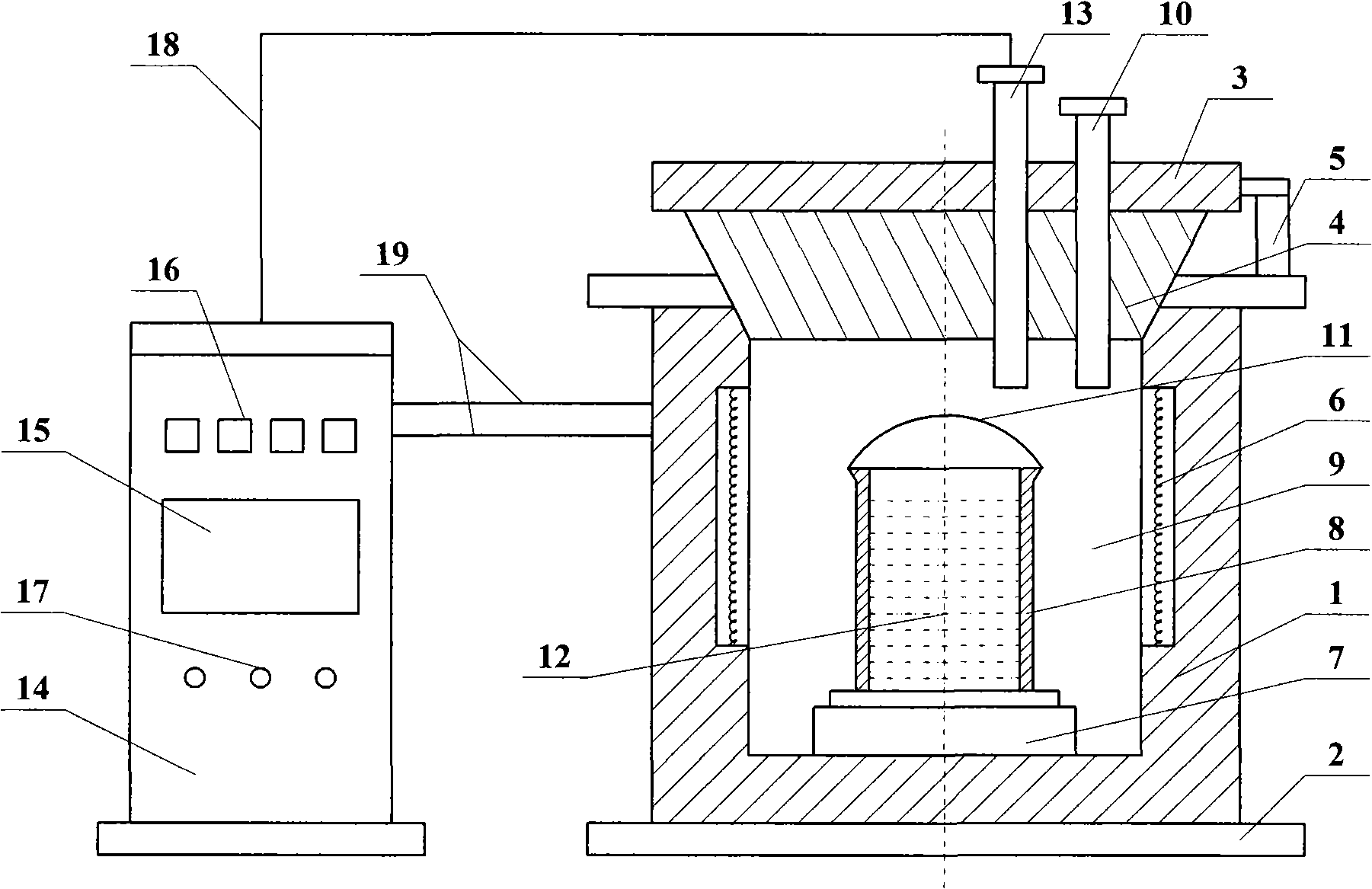

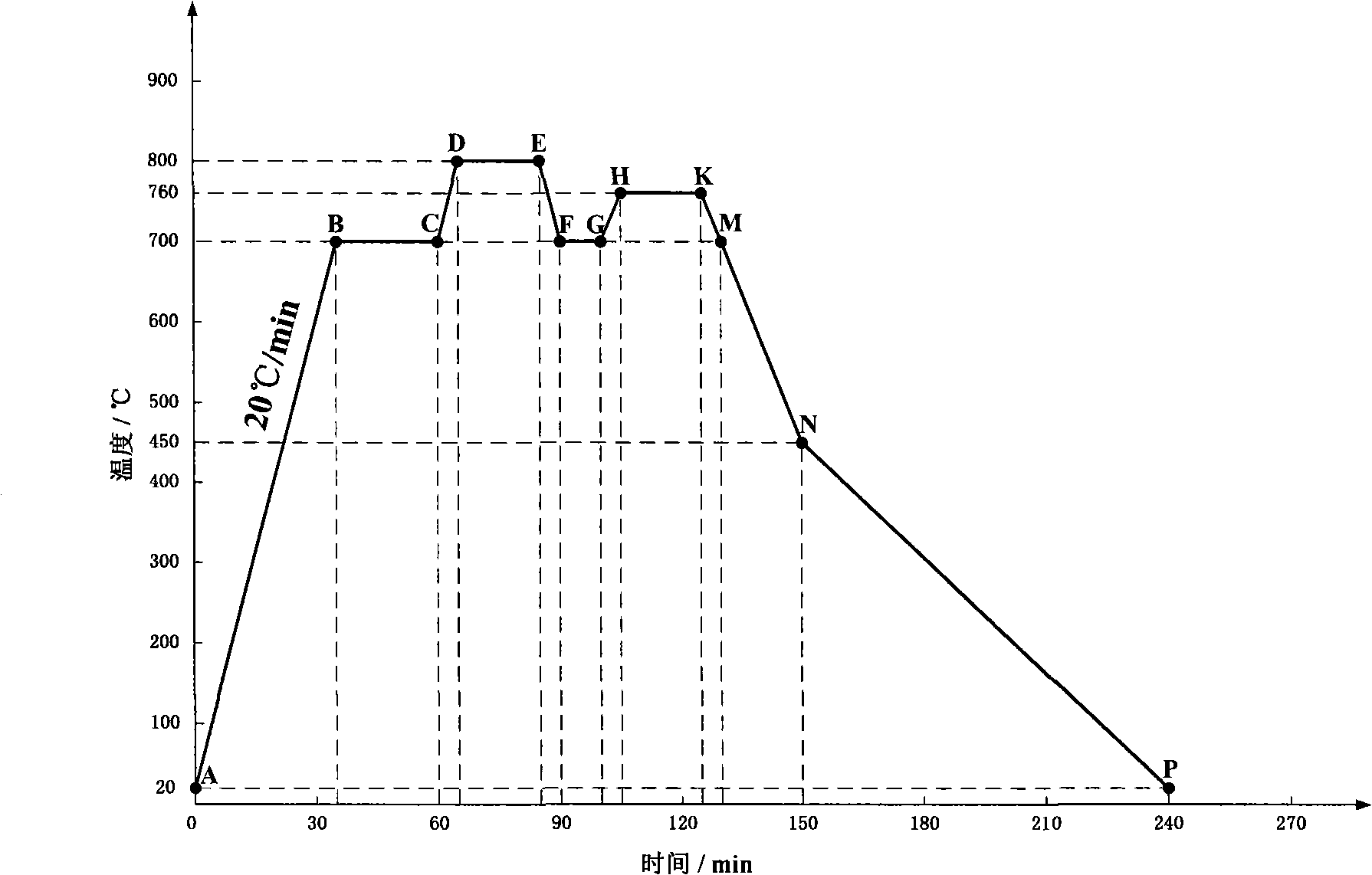

The present invention relates to a high intensity magnesium alloy and the preparation method. Magnesium, aluminum, zinc and neodymium are adopted as raw materials, which are melted in a melting furnace, under the protection of the mixed gases, and are melted down at the temperature of 720 plus or minus 10 degrees Celsius system, magnesium- neodymium alloy is added at the temperature of 780 plus or minus 10 degrees Celsius system, refined and the heat is preserved at the temperature of 740 plus or minus 10 degrees Celsius system and then the magnesium-aluminum-zinc-neodymium melt is obtained. When the temperature is lowered to 680-700 degrees Celsius system, the magnesium-aluminum-zinc-neodymium melt is discharged and cut into shapes after being moulded and cooled and then made into high intensity aluminum-magnesium alloy ingots after an 8-channel equal channel rotor angle pinch. The raw material mixture ratio of magnesium, aluminum, zinc and neodymium is 82 to 15 to 2 to 1 and aluminum makes up 15 percent. The aluminum material is abundant in resource, low in price and more economical and the lanthanon neodymium can change the metallurgical structure and mechanical property. The method has a short process flow and a slight pollution to the environment. The tensile strength, yield strength and elongation of the magnesium alloy ingots can be increased by 147.4 percent, 210.6 percent and 448.3 percent respectively. The metallurgical structure is compact and even and the average crystal grain size is less than or equal to 2 micrometers.

Owner:TAIYUAN UNIV OF TECH

Method for manufacturing high-strength magnesium alloy solder wire

InactiveCN101269449AImprove toughnessImprove solderabilityWelding/cutting media/materialsSoldering mediaRare-earth elementManganese

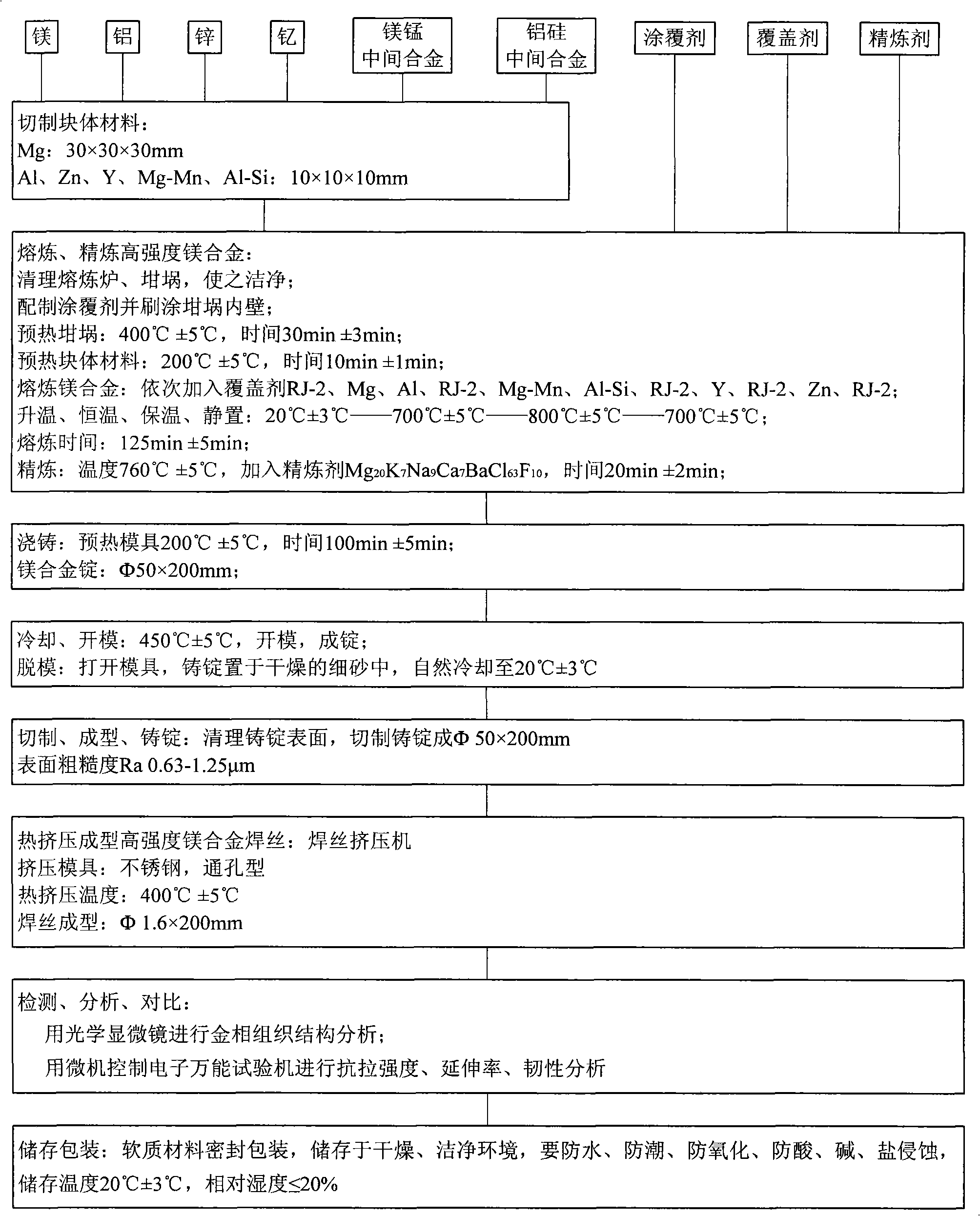

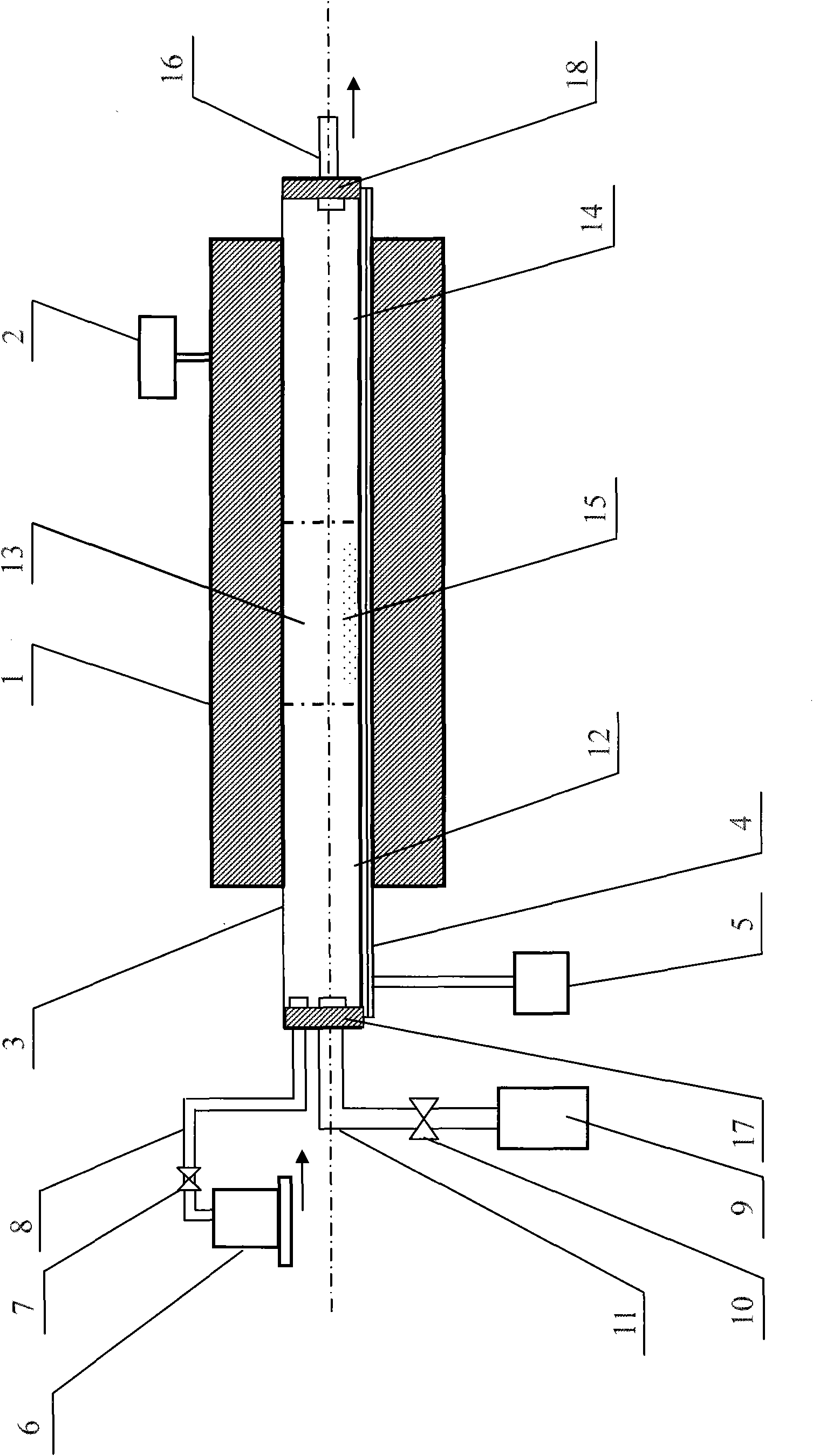

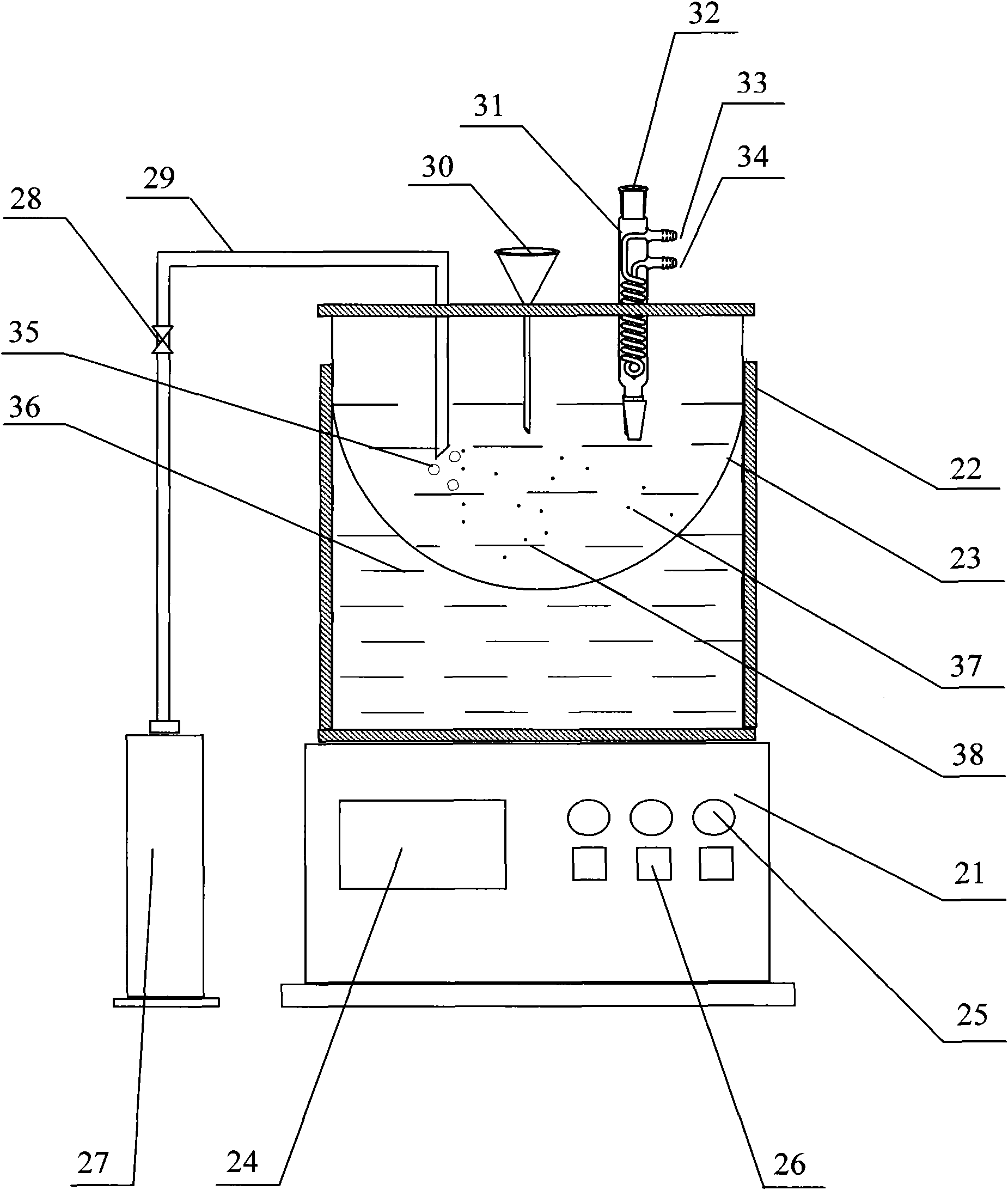

The invention relates to a preparation method of a high-intensity magnesium alloy soldering wire, which adopts alloy agent magnesium, aluminum, zinc, yttrium, magnesium-manganese intermediate alloy and aluminium-silicon intermediate alloy as raw materials. In a vertical melting furnace, through being melted at 700 DEG C, rare-earth element yttrium is added at 800 DEG C and is refined at 760 DEG C, with a covering agent and a refine agent being added, through constant temperature, thermal retardation and stewing, then magnesium alloy molten liquid is made; through casting a mould, magnesium alloy ingot is made; through cooling, cutting and forming, and then thermoplastic extruding, in the end, the high-intensity magnesium alloy soldering wire is made; the yttrium element, the magnesium-manganese intermediate alloy and aluminium-silicon intermediate alloy can greatly improve the intensity, the malleability and the solderability of the magnesium alloy soldering wire; the preparation technology is refined, the mixture ratio is reasonable, the environment pollution does not exist; the outcome of a magnesium alloy soldering wire metallic phase has uniform structure and good compactability, the average grain size is 25microns, the tensile strength can reach 330MPa, the elongation percentage can reach 25 percent and can be improved by 18 to 28 percent compared with the prior art, and the solderability is good.

Owner:TAIYUAN UNIV OF TECH

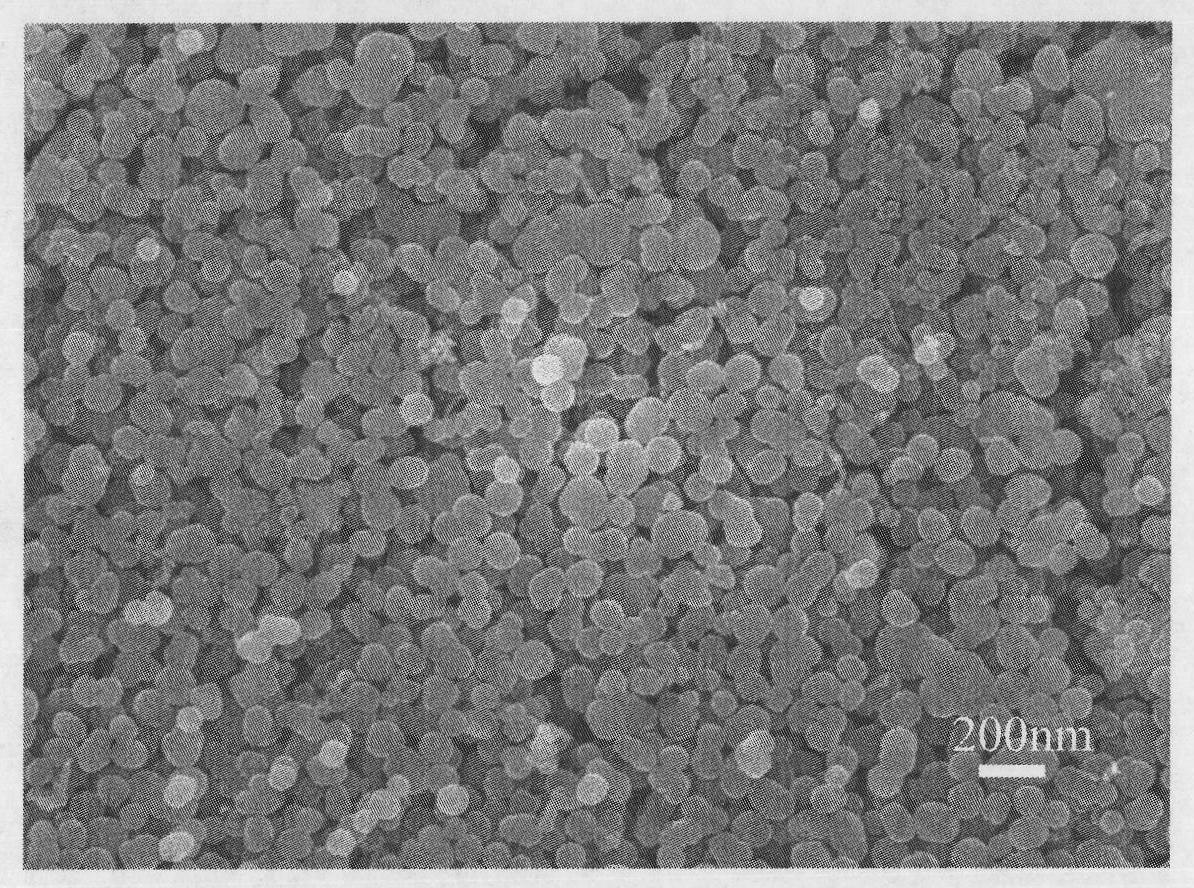

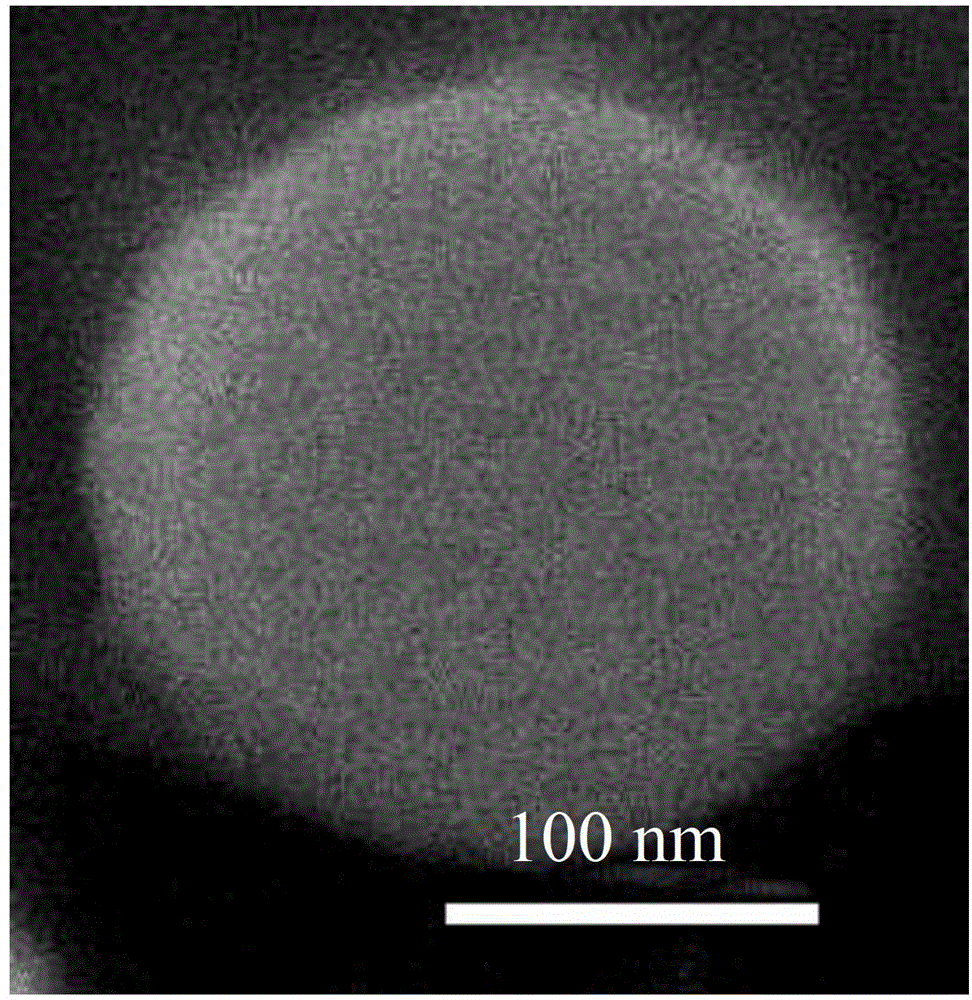

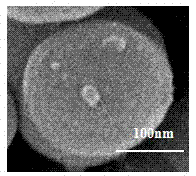

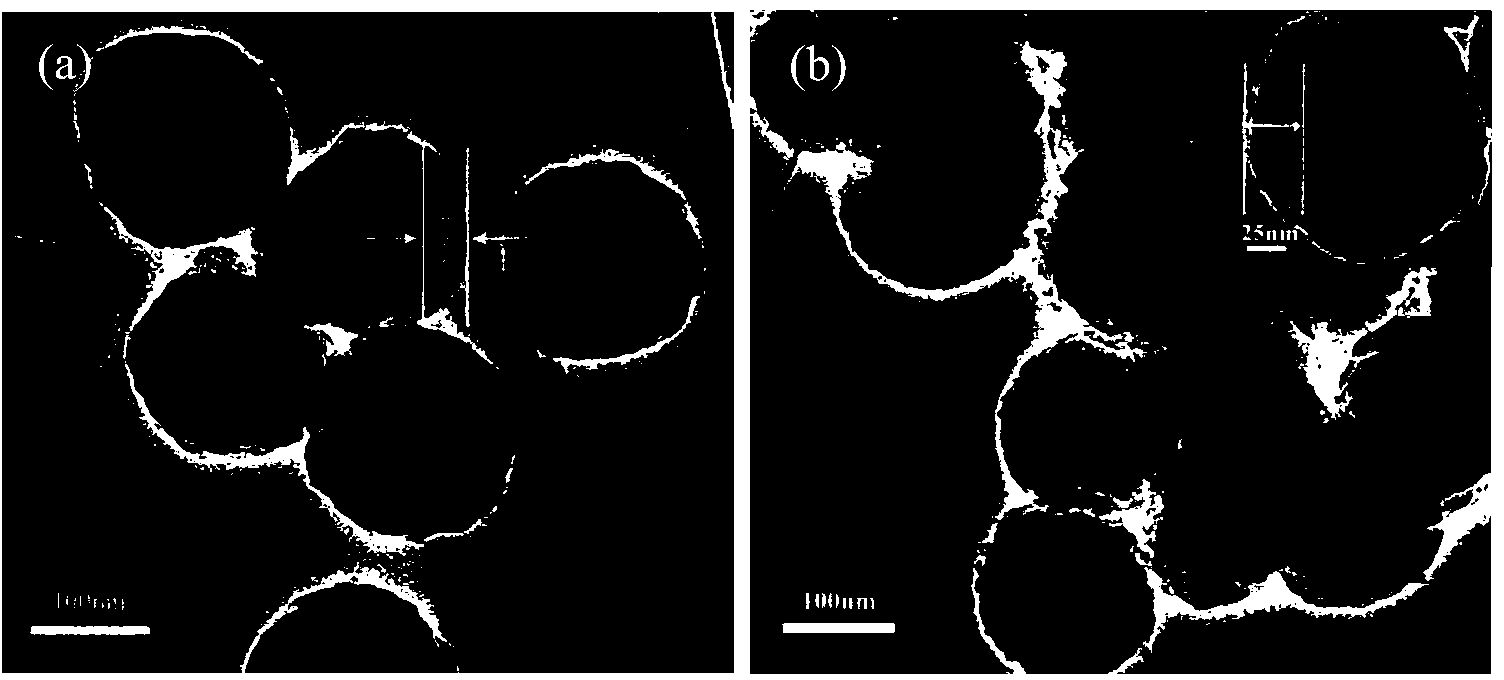

Method for preparing molecular imprinted polymer on surface of carbon microspheres

InactiveCN101845125AGood lookingHigh purityOther chemical processesAlkali metal oxides/hydroxidesWater bathsMicrosphere

The invention relates to a method for preparing a molecular imprinted polymer on the surface of carbon microspheres, which comprises the following steps of: preparing the carbon microspheres by using acetylene gas; and preparing imprinted carbon microspheres on a three-neck flask, a water bath and an electrothermal stirring vessel, namely performing oxidation treatment on the carbon microspheres and then performing surface modification on the oxidized carbon microspheres to prepare the imprinted carbon microspheres and form irregular hole prints on the surface of the carbon microspheres. The preparation method has the advantages of advanced and reasonable process, short process flow, less environmental pollution, attractive appearance of a product, high purity of 99 percent and high product yield of 91 percent; the imprinted carbon microspheres are black and round particles with the particle diameter of 100 to 200nm and can be matched with various chemical substances; the method is an ideal method for preparing the imprinted carbon microspheres; and the product can be applied to the fields of pharmacy and various industries.

Process for manufacturing multi-layer solid wood composite floor

InactiveCN101704263AQuality improvementRigorous workmanshipDomestic articlesFlooringSolid woodLacquer

The invention relates to a process for manufacturing a composite floor, in particular to a process for manufacturing a multi-layer solid wood composite floor. The process comprises twelve procedures of selecting a log, rotatably cutting and drying the log, sorting a solid wood core board, hot pressing and gluing the core board, fixing thickness and polishing a base material, sorting and preserving the base material, selecting solid wood skin, molding a floor blank, preserving the floor blank, cutting and slotting the floor, painting and drying for molding. The invention has strict process, good quality of the produced floor, smooth and flexible paint surface, no cracking, long service life and easy processing.

Owner:周广龙

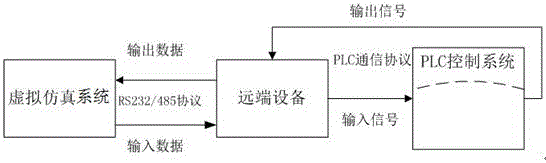

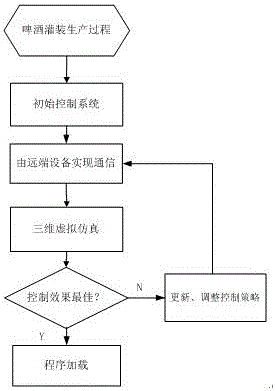

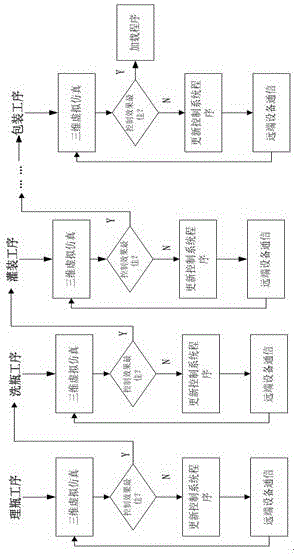

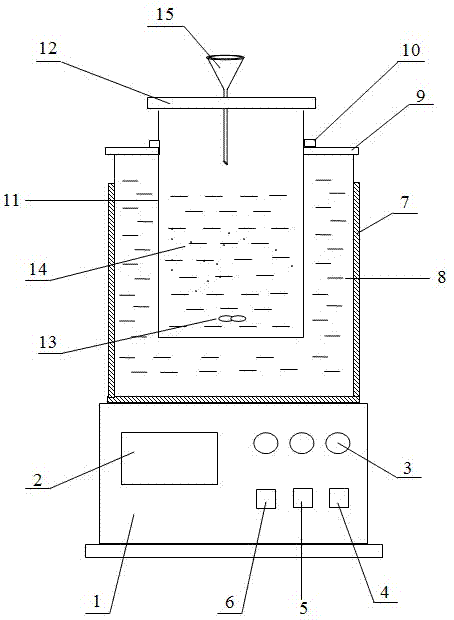

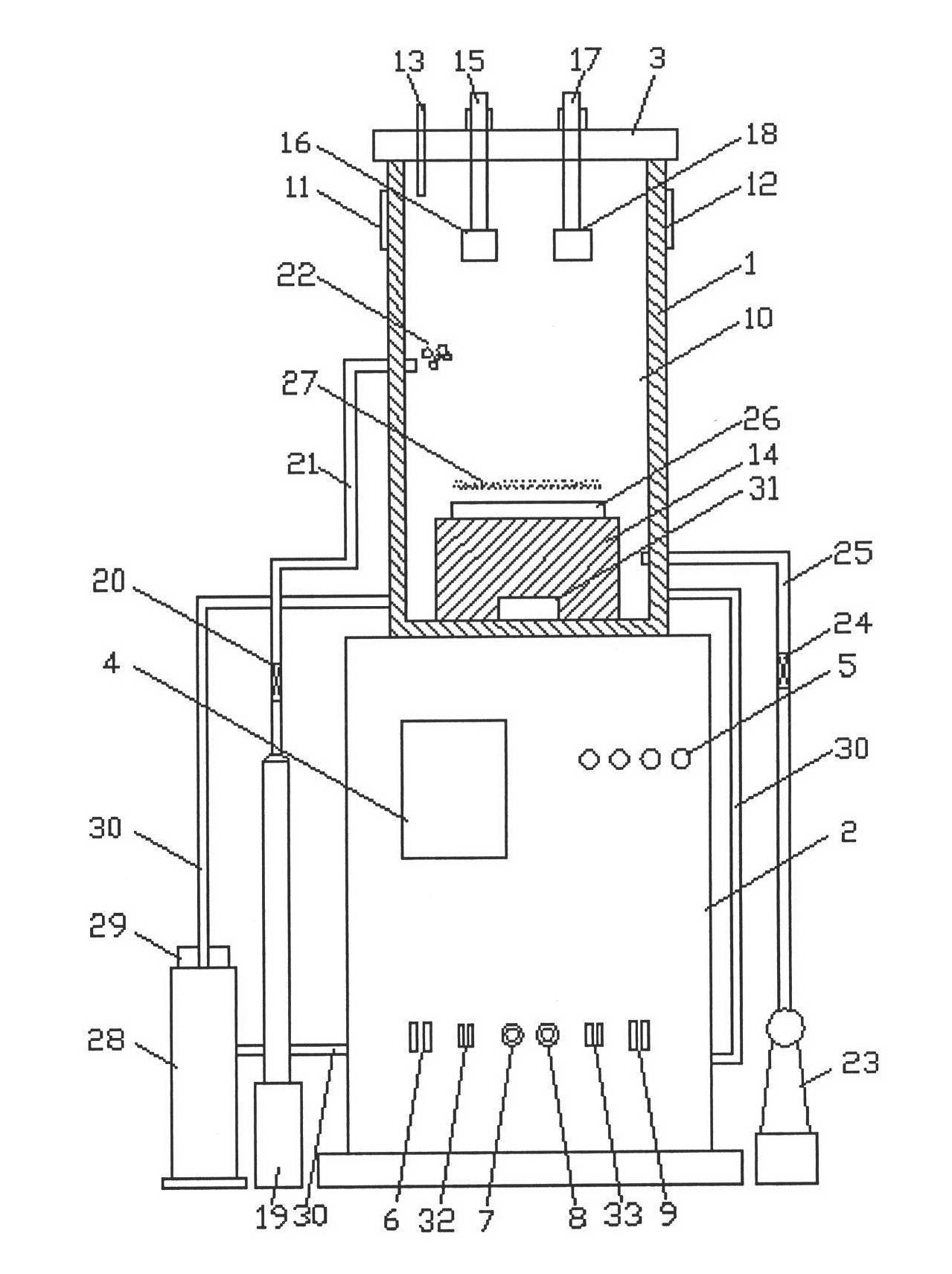

Filling production line control system based on virtual-reality technology and implementation method of filling production line control system

PendingCN106444616AAvoid time consumingAvoid security issuesProgramme control in sequence/logic controllersControl systemAnimation

The invention discloses a filling production line control system based on the virtual-reality technology. The filling production line control system comprises a virtual simulation system, remote equipment and a PLC control system, wherein the virtual simulation system is bidirectionally connected with the remote equipment, and the remote equipment is bidirectionally connected with the PLC control system. The beer filling production line control system based on the virtual-reality technology has the advantages that animated simulation of a beer production line filling process can be performed, a control strategy can be applied to each process or object in a virtual environment through the interaction module of the virtual environment and an entity PLC so as to intervene and control a virtual production line, animated demonstration is updated in real time after the control measure is applied, the optimal control strategy and scheme of the production line can be determined fast, the filling process is fast and stable, the process is strict, and the system is promising in market prospect.

Owner:启东威艾信息技术有限公司

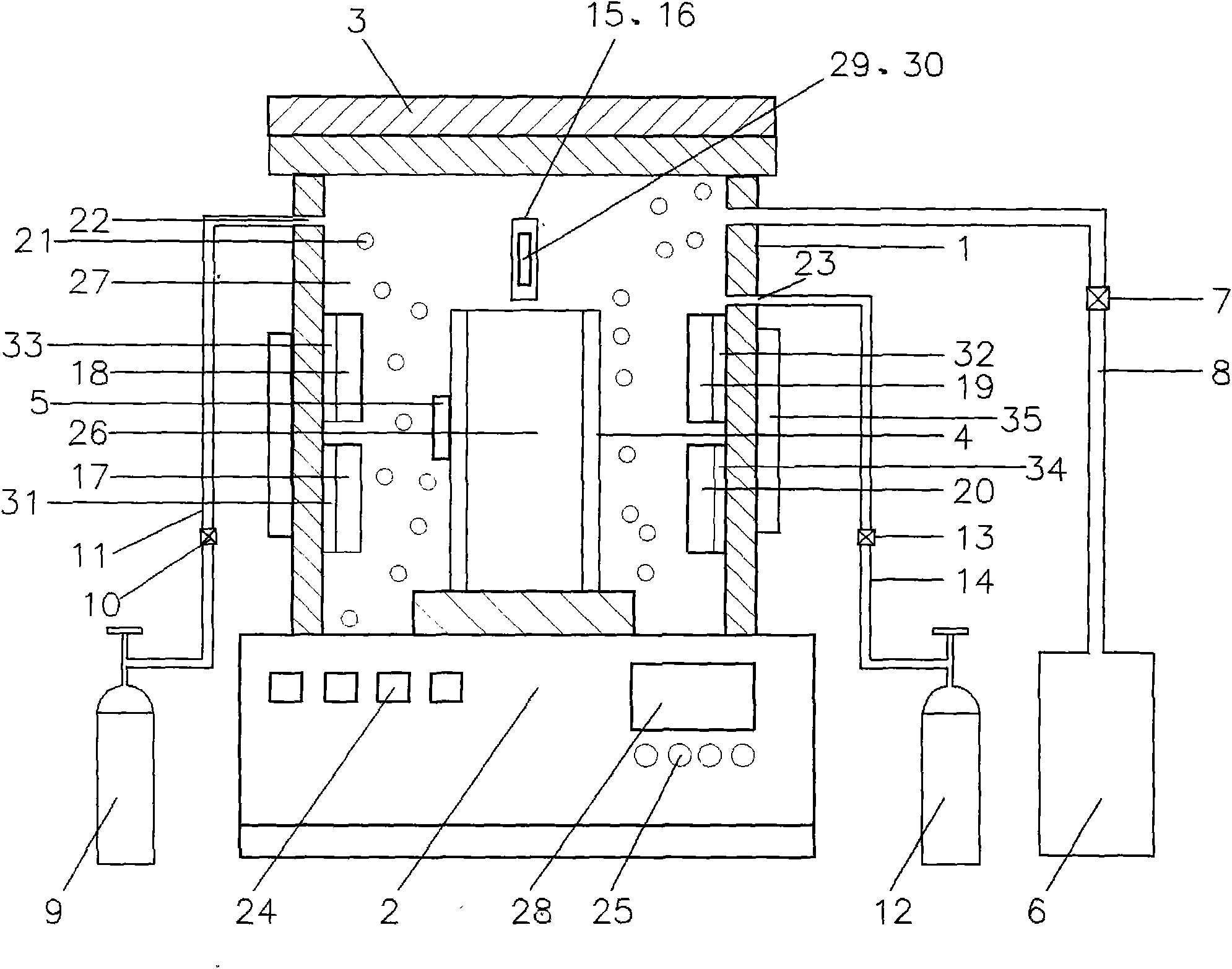

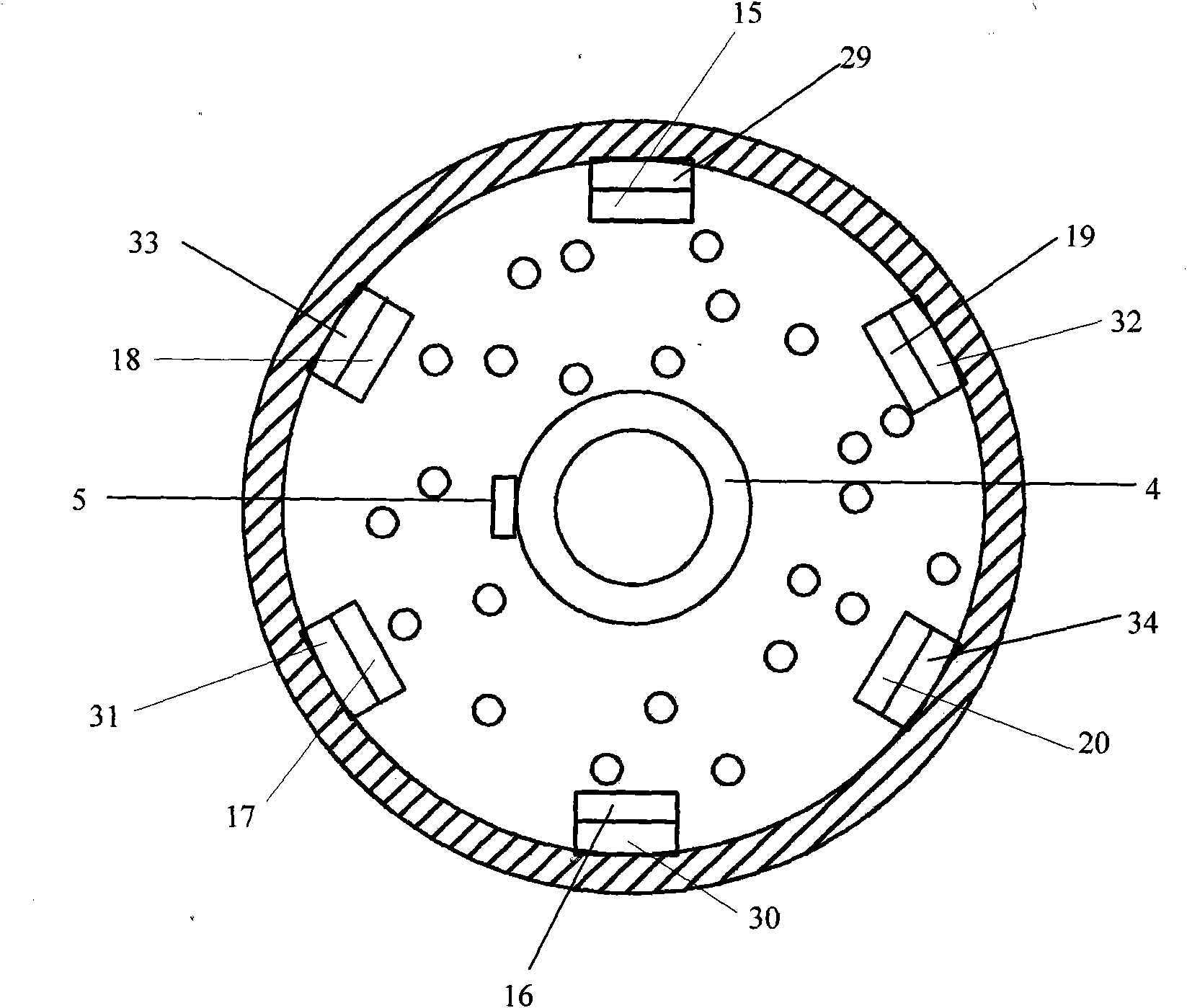

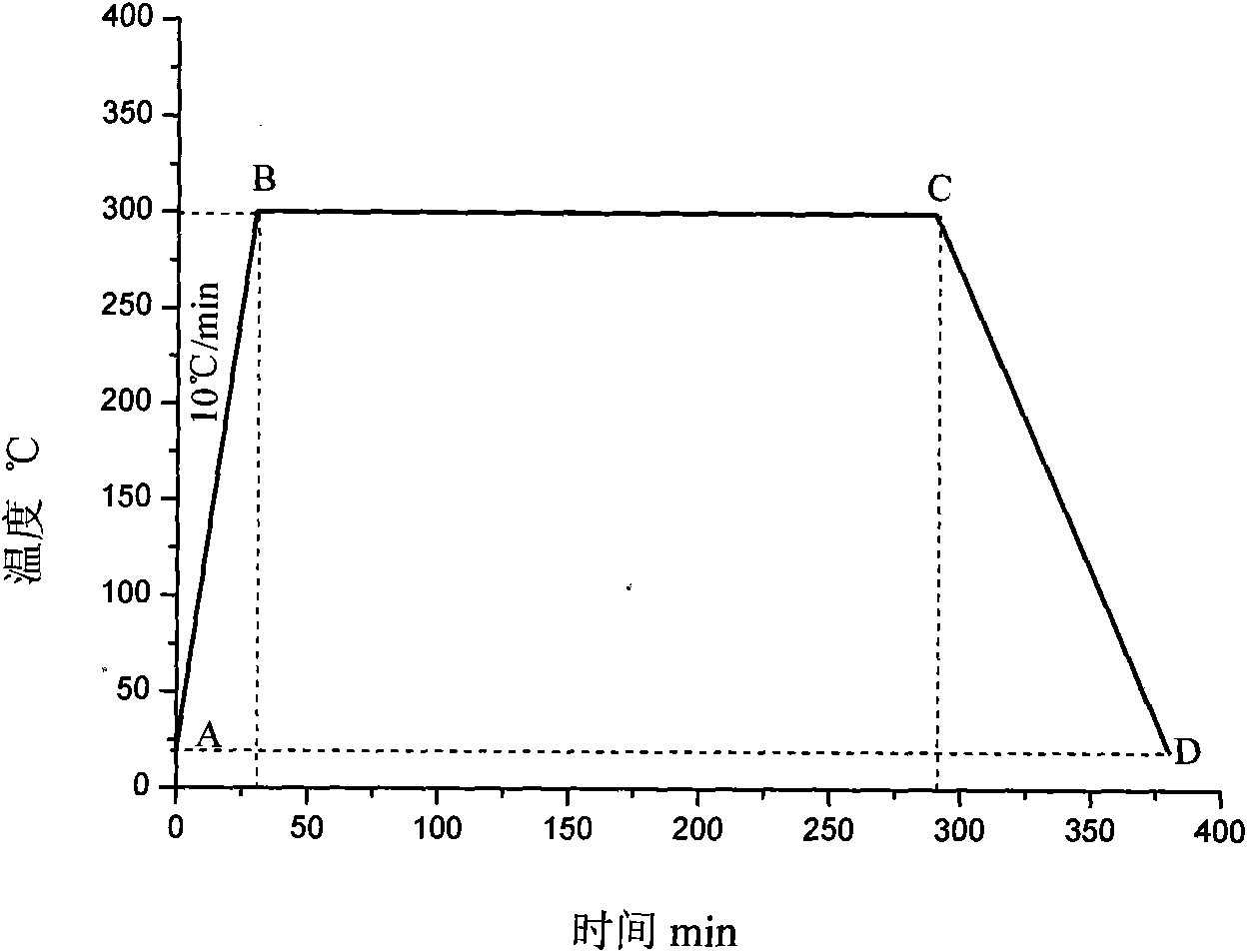

Preparation method of chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering

InactiveCN101575696AImprove mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingAluminum IonShielding gas

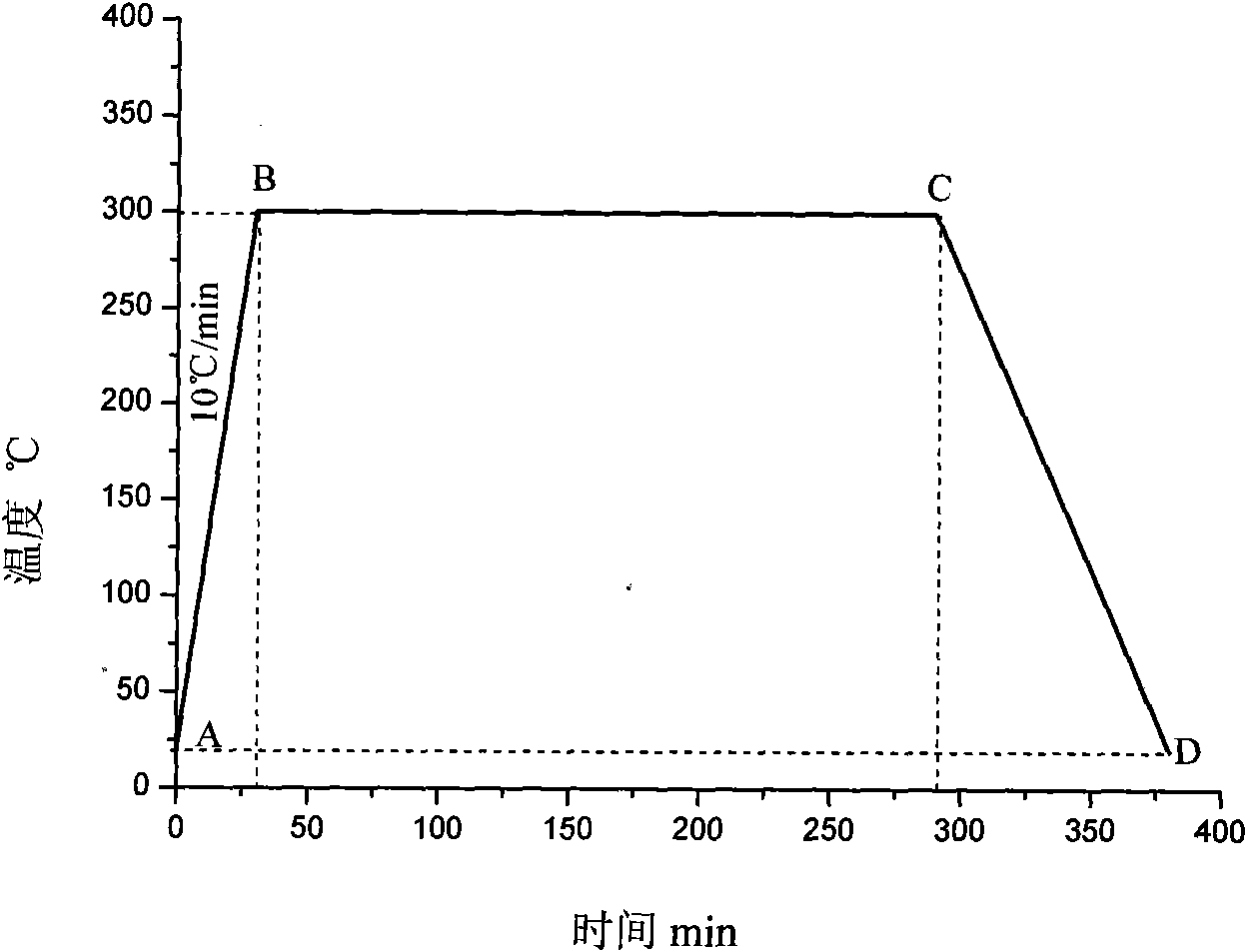

The invention relates to a preparation method of a chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering, which comprises the following steps: a chromium-tungsten-manganese steel plate is taken as a basal body, chromium and aluminum as a target source of metal ion, nitrogen gas as reactant gas, and argon gas as ion bombardment gas and protection gas; in a vacuum sputtering furnace, in a closed magnetic field state, in the argon gas and at the temperature of 300 DEG C, the surface of the chromium-tungsten-manganese steel plate is sputtered with chromium ion, aluminum ion and nitrogen ion and the chromium-aluminum-nitrogen hard film is formed on the surface of the steel plate, and then the low temperature tempering and alloying solid solution are conducted, thus greatly improving mechanical property, hardness, intensity, abrasive resistance and erosion resistance of the surface of the chromium-tungsten-manganese steel plate. The mechanical property of the chromium-tungsten-manganese steel plate can be improved by 466% compared with that of hardened steel plates. The preparation method has short process flow, precise technique, accurate and detailed measurement values, the film with thickness of 4,600nm, and the alloy layer with good solid solution effect and being not easy to peel off, thus being the ideal treatment method for strengthening and hardening the surface of alloy tool steel.

Owner:TAIYUAN UNIV OF TECH

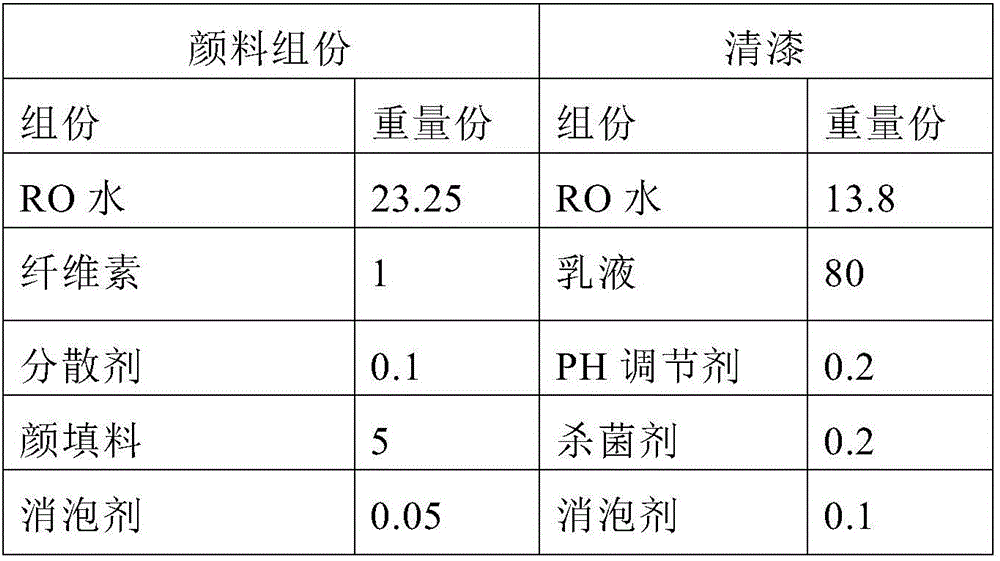

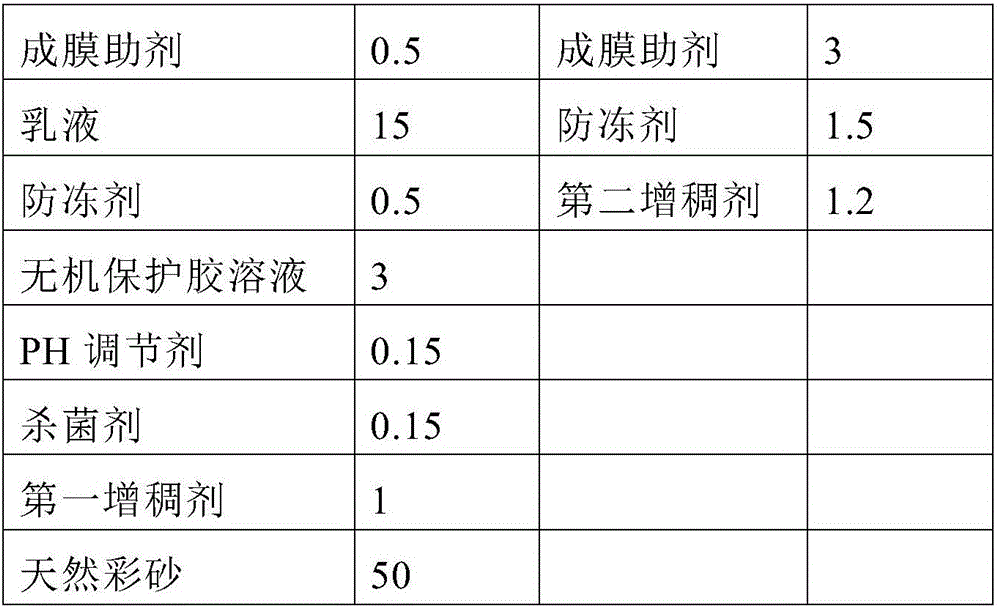

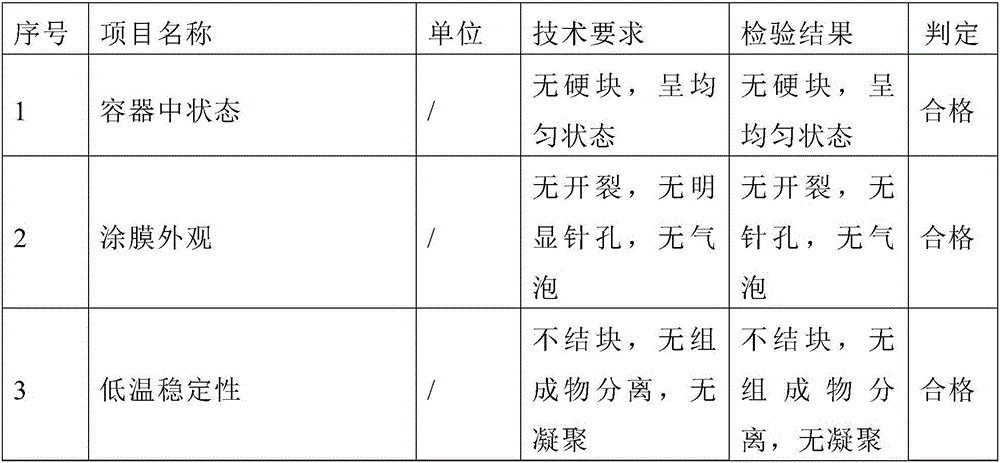

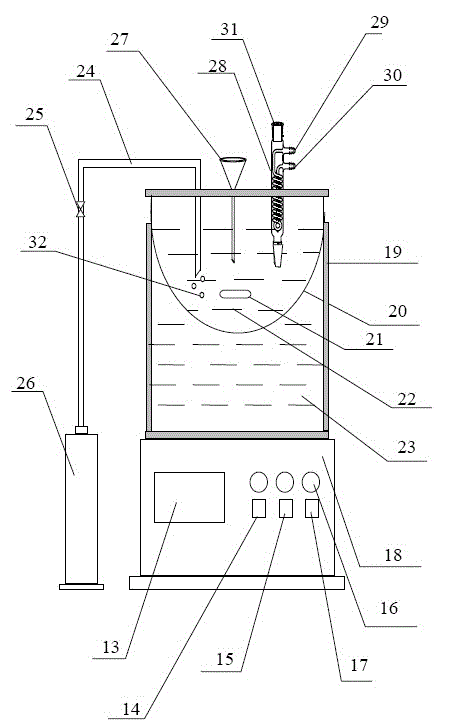

Sand-containing colorful environment-friendly coating and preparation method of same

ActiveCN106366814AGood storage stabilityGood construction stabilityMulticolor effect coatingsAdhesion forceClear Layer

The invention relates to a sand-containing colorful environment-friendly coating and a preparation method of the same. The coating is composed of a pigment component, a dispersion medium and varnish; the pigment component includes RO water, cellulose, a dispersant, pigments and fillers, a defoamer, a film forming additive, an emulsion, an anti-freeze agent, an inorganic protective glue solution, a pH regulator, a sterilizing agent, a first thickener, and natural colorful sands; the dispersion medium includes RO water, the film forming additive, a rheological agent, the emulsion, an organic protective glue solution, the defoamer and a coupling agent; and the varnish includes RO water, the emulsion, the pH regulator, the sterilizing agent, the defoamer, the film forming additive, the anti-freeze agent, and a second thickener. Compared with the prior art, the sand-containing colorful environment-friendly coating has good storage and construction stability, wherein a dried film of the coating is excellent in adhesion force and water resistant performance. The coating, when being used, has a good rough sense and has clear layer sense, thereby representing a texture effect of natural stone materials better.

Owner:上海磐彩环保科技股份有限公司

Porous imprinting carbon nano-sphere preparation method

The present invention relates to a porous imprinting carbon nano-sphere preparation method, which comprises adopting a glucose solution to carry out hydrothermal synthesis of carbon nano-spheres, and carrying out surface modification, sintering carbonization, and grafting modification on the porous carbon nano-spheres to finally prepare the porous imprinting carbon nano-spheres. The preparation method has characteristics of rigorous process, advancement, reasonability, and accurate and detailed data. The product has the following characteristics that: a morphology is good, the product is black round particles, a particle diameter is less than or equal to 180 nm, a porous imprinting effect is significant, the product can be matched with a plurality of chemical substances, product purity is good and achieves 99%, and a yield is high and achieves 91%. In addition, the preparation method is an ideal porous imprinting carbon nano-sphere preparation method.

Owner:TAIYUAN UNIV OF TECH

Machining method for three-dimensional flow impeller

The invention discloses a machining method for a three-dimensional flow impeller. An original whole forging of a wheel cover is changed into a panel, the wheel cover is formed through a die and spliced with an inlet ring in a welding manner, then, the wheel cover and blades manufactured in advance are spliced and formed, finally, a wheel disc and the wheel cover are welded and formed, and finish turning is carried out after thermal treatment. An impeller and the blades are independently manufactured and spliced together through spliced welding. Compared with the traditional technology, by means of the whole forging forming, the integral strength cannot be changed, the consumption of raw materials is greatly reduced through the new technology, the machining difficulty is lowered, and the machining efficiency is improved.

Owner:湖北双剑鼓风机股份有限公司

Sugariness dried oyster with iodine-containing tea flavor

ActiveCN101120799APrevent decline in male sexual functionRigorous workmanshipFood preparationHerbal preparationsAdditive ingredient

The present invention discloses a sweet dried oyster with iodine-tea taste, which belongs to instant dried food ingredients and the making method. The main raw material of the present invention is fresh oyster, and the supplemental materials are slat, white sugar, malt sugar, honey, edible oil and so on. The product is made after the materials being treated, cooked, immersed, dried, fried, roasted (for dehydration), coated with instant black tea powder, baked, cooled, packed, disinfected with microwave and stored in case, and processed cold storage process or procedure. The produced instant dried oyster has original flavor and taste, and has taste of Chinese herbal preparation honey-peppery oil tea camellia. The present invention has oyster and Chinese herbal preparation, and so the dried oyster has the function of enhancing the male reproductive system, preventing male sexual function from decreasing and prostatic hypertrophy. The present invention also can protect heart and liver, benefit for gallbladder, adjust blood lipid, make the skin soft, improve appearance, and is good for mental and brain, and so on.

Owner:漳州市美丽家香食品股份有限公司

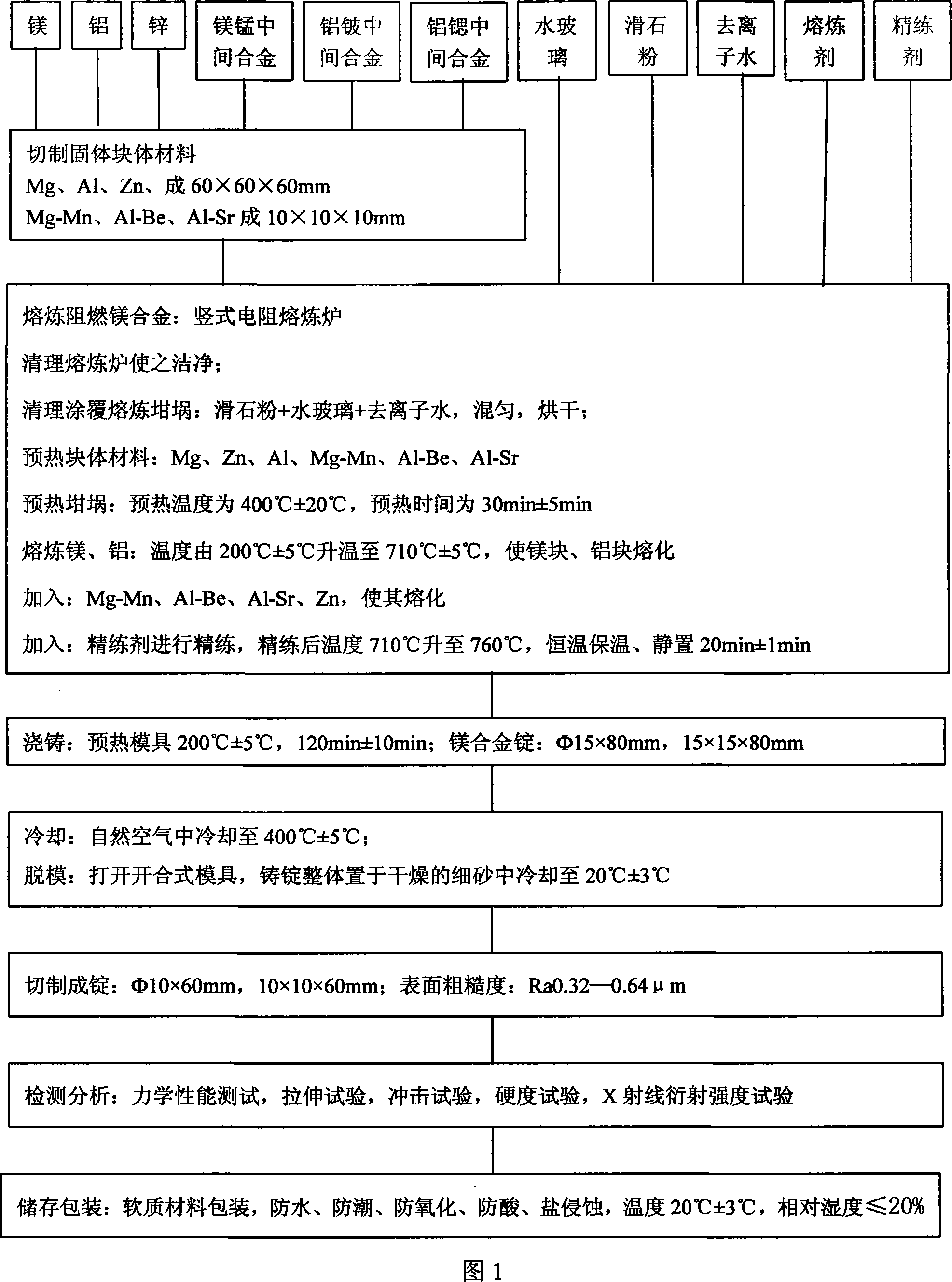

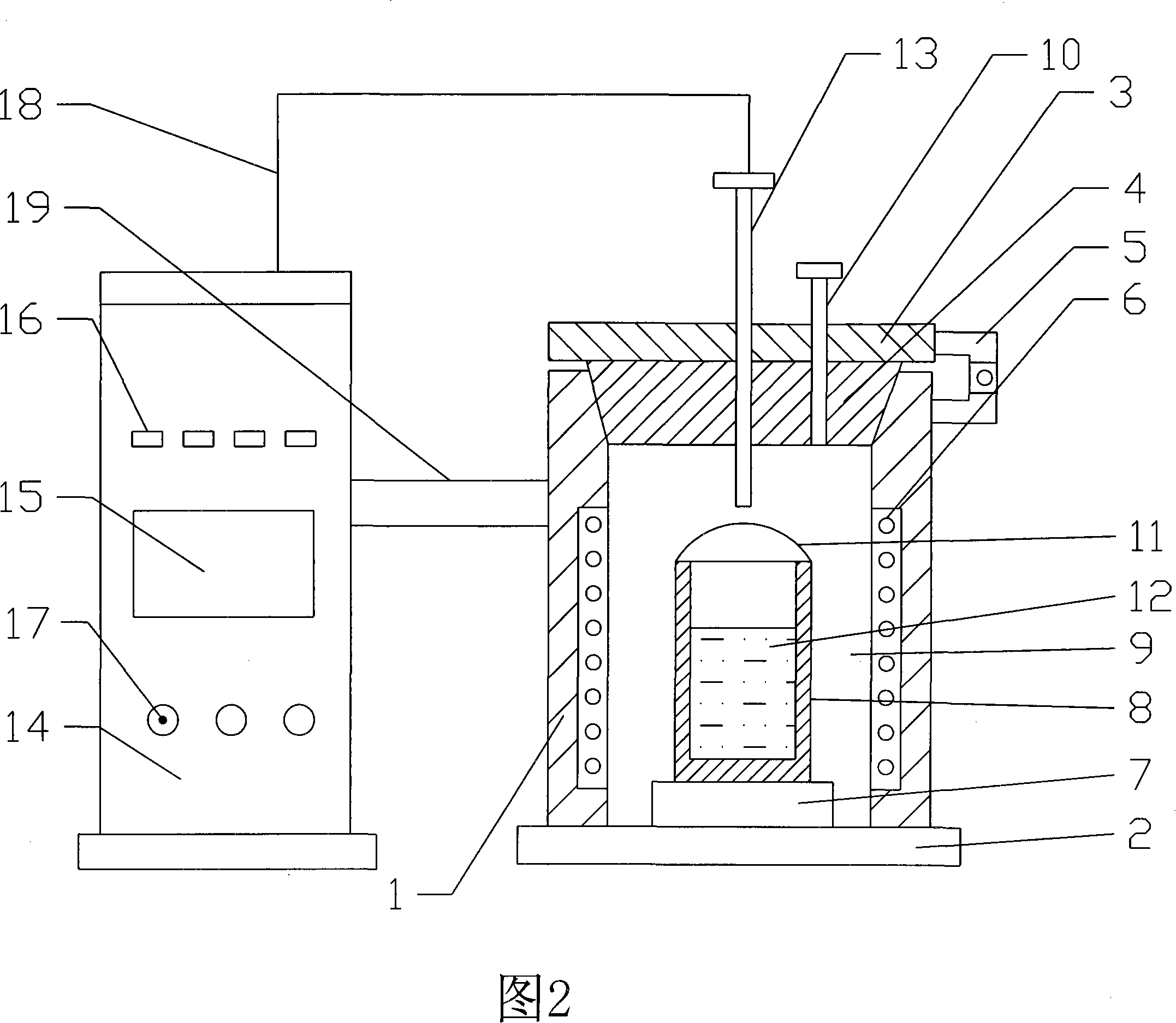

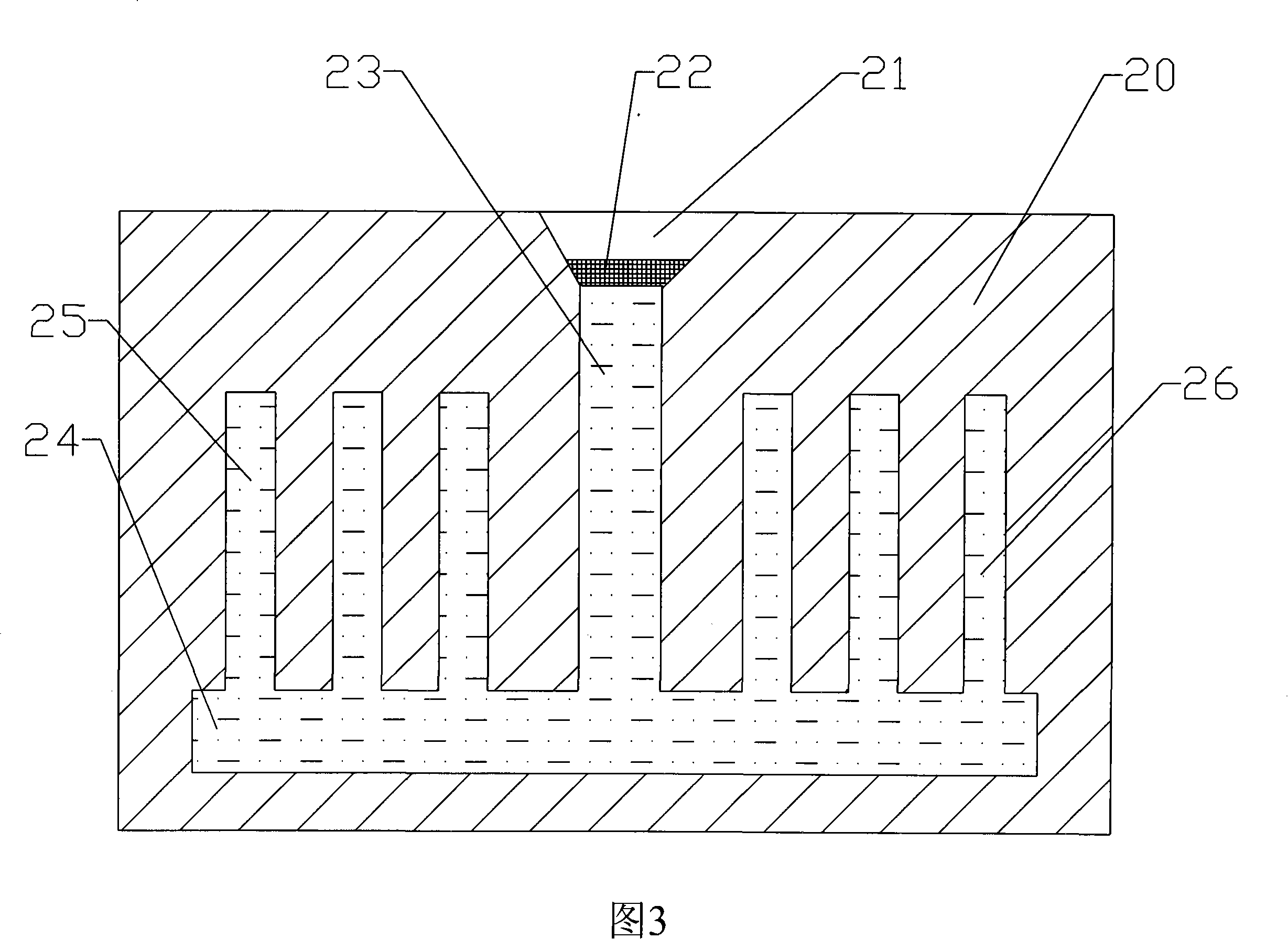

Flame-proof magnesium alloy added with beryllium and strontium and preparation method thereof

The invention relates to a flame-retardant Mg alloy doped with Gl and Sr and a preparation method thereof. The alloy is made from Mg, Al, Zn, and Mg-Mn intermediate alloy as raw materials, Al-Gl intermediate alloy and Al-Sr intermediate alloy as fire retardants and Al-Sr intermediate alloy as an agent for enhancing mechanical property of the alloy. The preparation method is carried out in a vertical smelting furnace, and comprises smelting at 710 plus or minus 5 DEG C, refining at 760 plus or minus 5 DEG C, standing, casting at 700 plus or minus 5 DEG C, adding smelting and refining agents, incubating at a constant temperature, standing to obtain a molten liquid of flame-retardant Mg alloy, casting in a die, cooling, cutting and shaping to obtain flame-retardant Mg alloy ingot. During the smelting process, the addition of Al-Gl intermediate alloy and Al-Sr intermediate alloy can efficiently prevent the combustion and oxidation of Mg alloy and simultaneously improve the mechanical property of Mg alloy. This method has the advantages of rigor process, reasonable formation, short process flow, less environmental pollution, and good compactness and uniformity of metallurgical structure of Mg alloy ingot product. The average crystal grain of the product is less than or equal to 90 micron, the tensile strength reaches 200 MPa, and the impact ductility reaches 15J / cm<2>.

Owner:TAIYUAN UNIV OF TECH

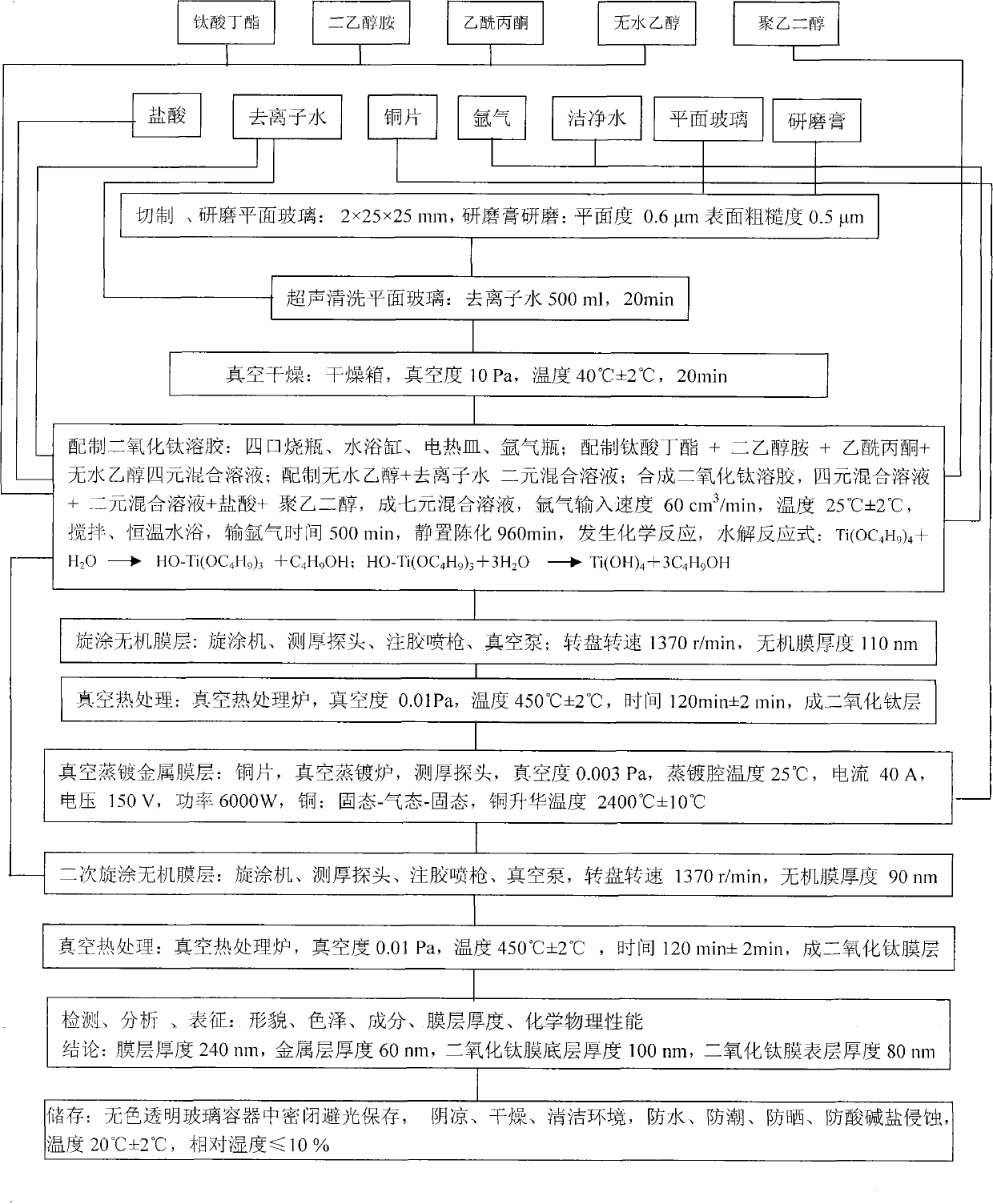

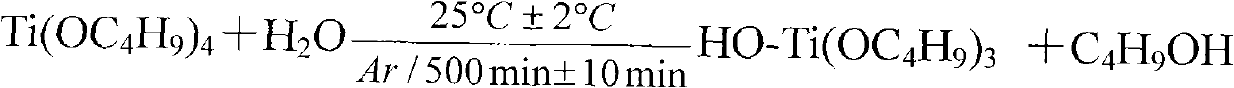

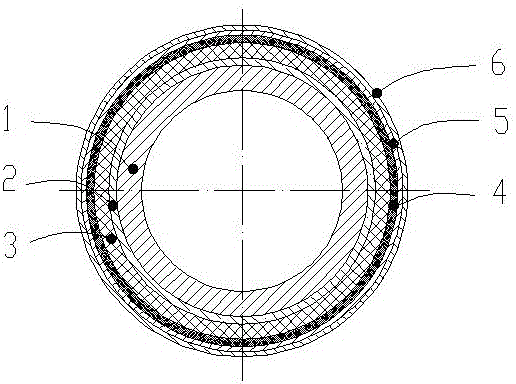

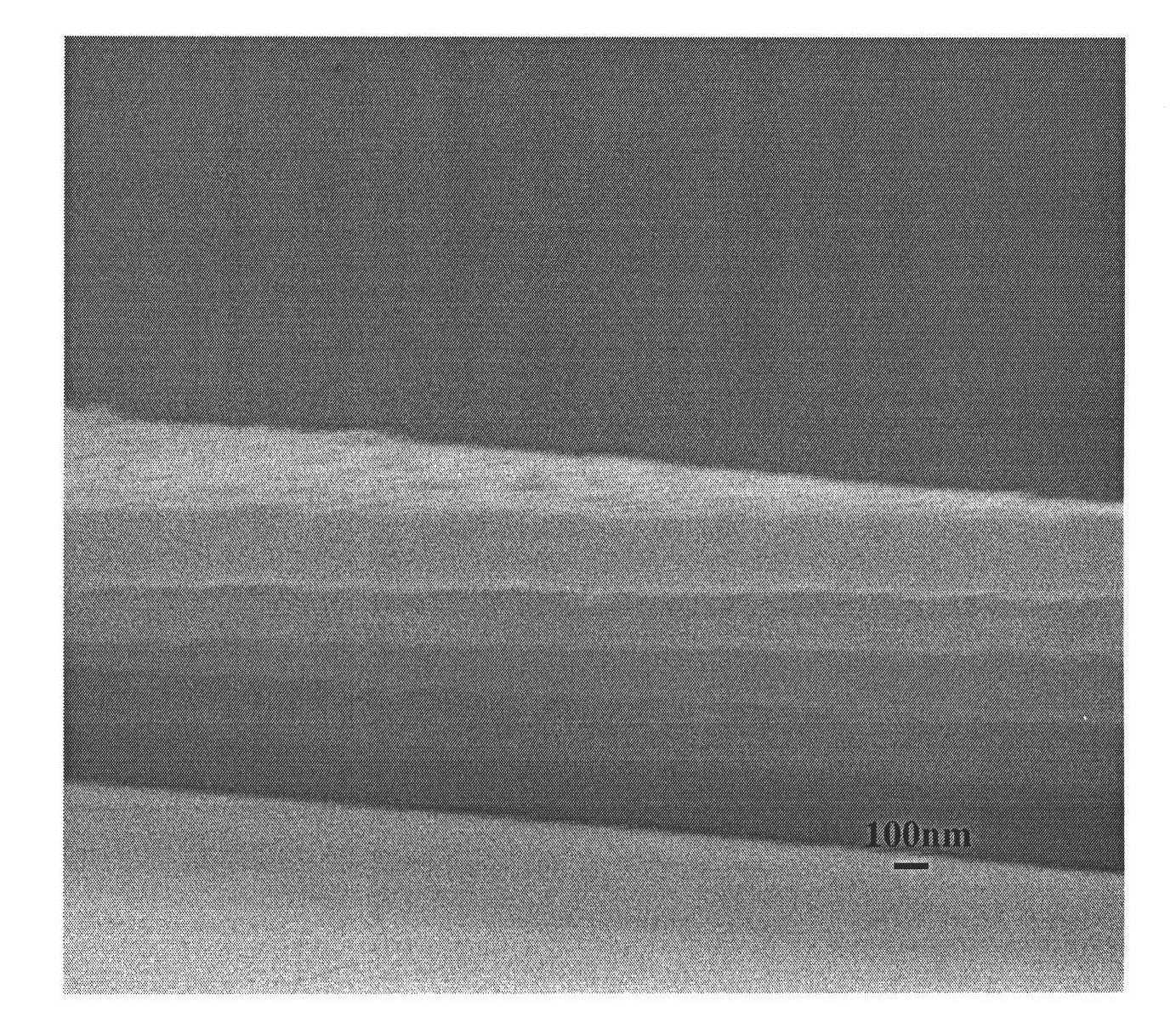

Method for preparing nano titanium dioxide heterogeneous composite membrane

InactiveCN101792271AHigh purityReasonable and tight structureMetal/metal-oxides/metal-hydroxide catalystsFlat glassCopper

The invention relates to a method for preparing a nano titanium dioxide heterogeneous composite membrane. In the invention, strict process flow is adopted, and precision and purity of chemical materials are controlled. The method comprises the following steps: cutting, grinding, cleaning and drying flat glass; preparing titanium dioxide seven-element mixed sol; performing spin coating on titanium dioxide inorganic membrane in a layered manner; and carrying out vacuum evaporation of metallic copper membrane layer and vacuum heat treatment to obtain the nano titanium dioxide heterogeneous composite membrane, wherein the thicknesses of inorganic titanium dioxide membrane layer are 100nm and 80nm, the thickness of metallic copper membrane layer is 60nm, and the thickness of the total membrane layer is 240nm. The product prepared by the invention has the advantages of advanced technology, reasonable and strict membrane structure, high purity, and good photochemical catalysis performance under the sun. The membrane purity is up to 99.5%. The method is an ideal method for preparing nano titanium dioxide heterogeneous composite membrane.

Owner:TAIYUAN UNIV OF TECH

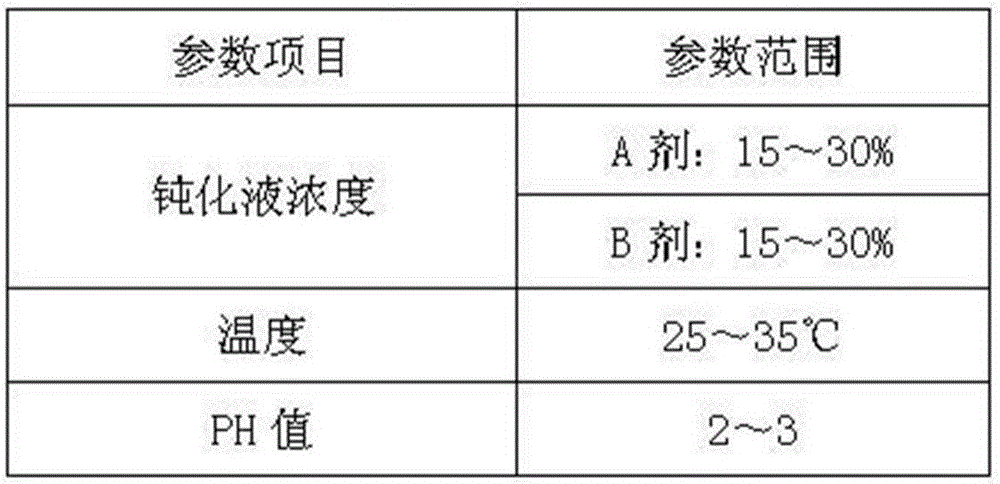

Composite galvanized army green steel pipe for refrigeration and manufacturing method of composite galvanized army green steel pipe

InactiveCN106544490AUniform thicknessImprove bindingHot-dipping/immersion processesFurnace typesZincWear resistance

The invention discloses a composite galvanized army green steel pipe for refrigeration and a manufacturing method of the composite galvanized army green steel pipe. The composite galvanized army green steel pipe comprises a steel pipe positioned on the innermost layer and is characterized in that a zinc-iron alloy layer is arranged on the outer surface of the steel pipe; a pure zinc layer is arranged on the outer surface of the zinc-iron alloy layer; an army green passivation layer is arranged on the outer surface of the pure zinc layer; a first closing layer and a second closing layer are separately arranged outside the army green passivation layer; and a product is obtained by the steps of carrying out deoiling, thermal treatment, composite galvanization, preheating, burnishing, washing with water, colored passivation, drying, closing for two time and drying. The composite galvanized army green steel pipe has a good binding force; a passivation bonding force among layers is high and weather fastness of the passivation layer is high; a finished product of the steel pipe has excellent wear resistance; the composite galvanized army green steel pipe has the advantages of good bright line, smoothness, anti-tarnishing property, rigorous process and high stability of the finished product; and when a condenser and a dew removable tube are manufactured, a protective heat shrink tube does not need to be added, so the working procedure is simple.

Owner:ZHEJIANG KANGSHENG CO LTD

Preparation method of imprinted carbon microspheres

The invention relates to a preparation method of imprinted carbon microspheres. The imprinted carbon microspheres are prepared by a three-neck flask, an ultrasonic dispersion instrument, a water bath tub, an electric heating stirring utensil and an ultraviolet light mercury lamp, and the preparation method comprises the following steps of: firstly performing oxidation treatment on the carbon microspheres, then performing surface modification and further grafting a polymer on the surfaces of the carbon microspheres to finally prepare the imprinted carbon microspheres, wherein irregular cavity imprints are formed on the surfaces of the carbon microspheres. The preparation method has the advantages of advanced and reasonable process, short process flow, low environmental pollution, good product morphology, high purity which can be up to 99% and high product yield which can be up to 93%, the imprinted carbon microspheres are black and circular particles, the diameter of the particles is 100-200nm, and the imprinted carbon microspheres can be matched with a variety of chemical substances, so that the preparation method is a very ideal method for preparing the imprinted carbon microspheres, and products can be applied to a variety of industrial fields, such as pharmacy, fine chemicals and the like.

Owner:TAIYUAN UNIV OF TECH

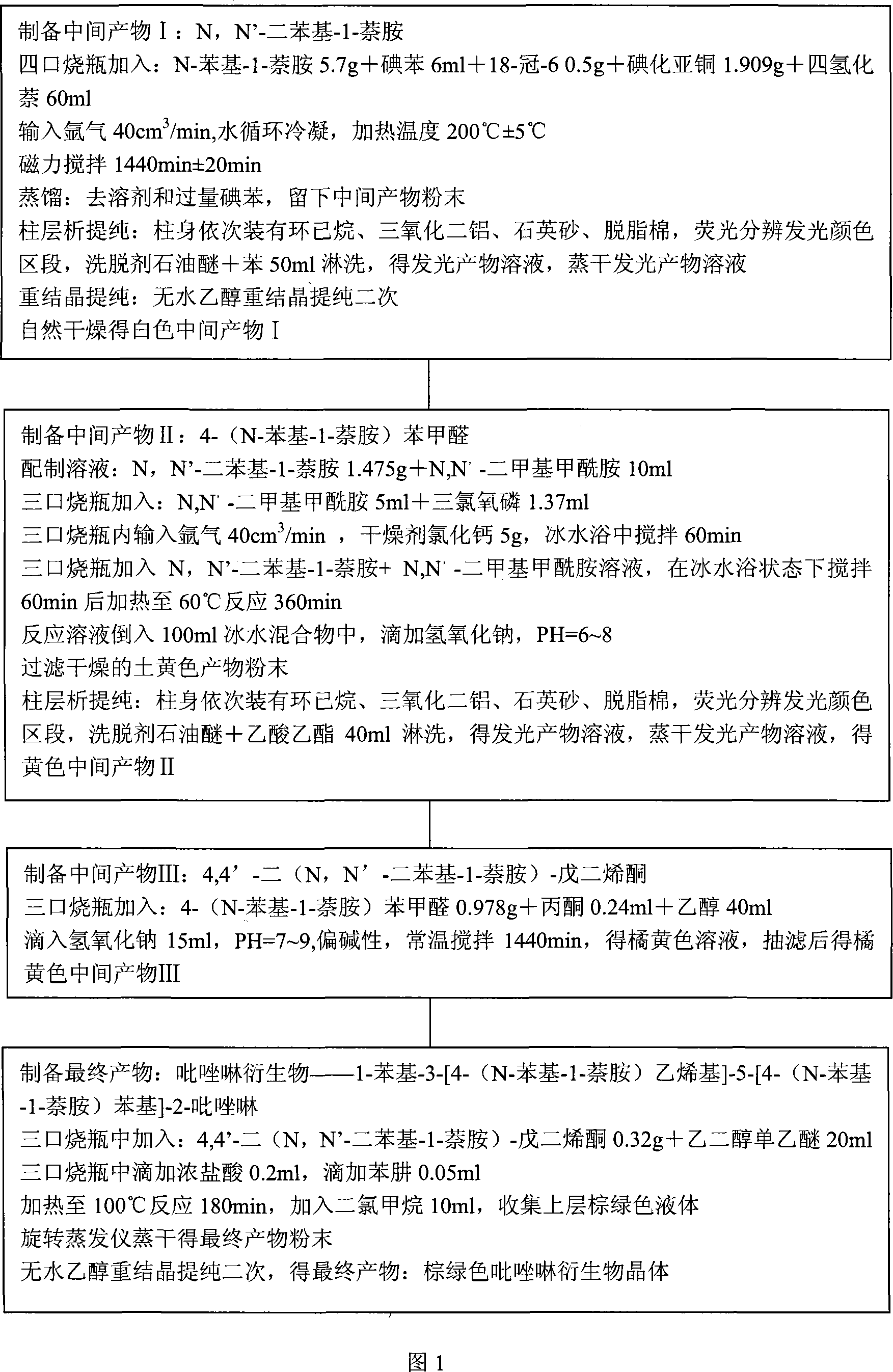

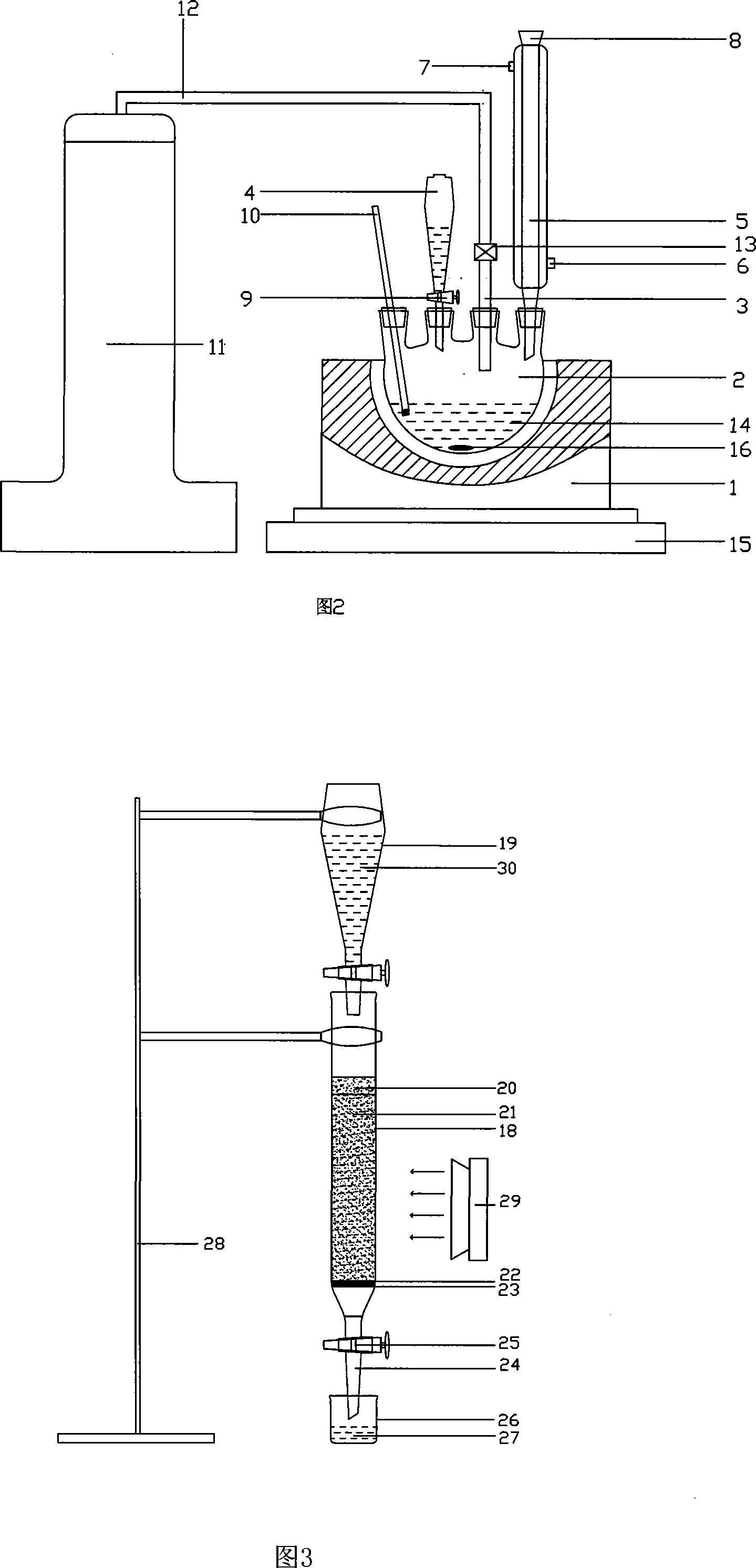

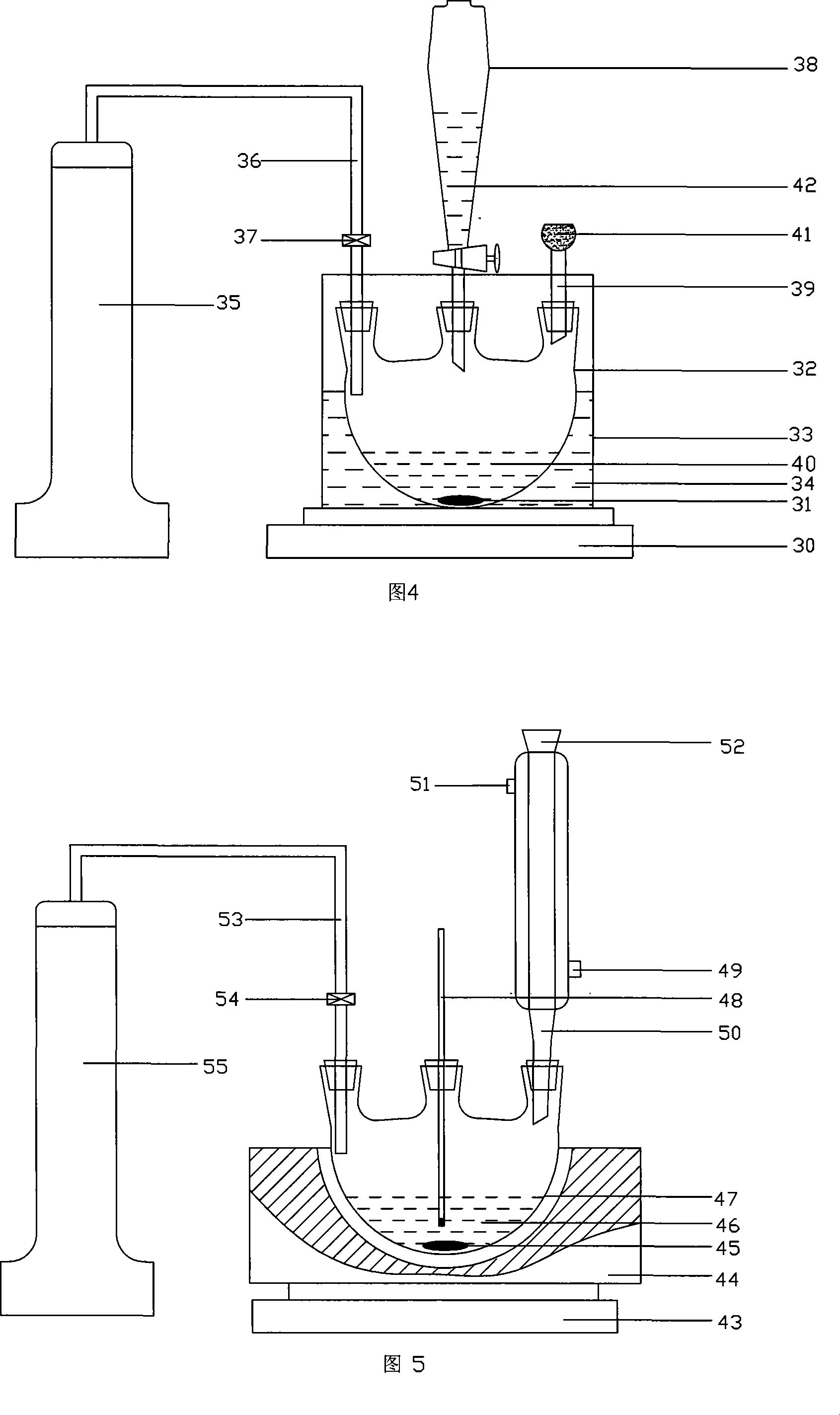

Method for synthesizing pyrazoline derivatives capable of irradiating yellow green light

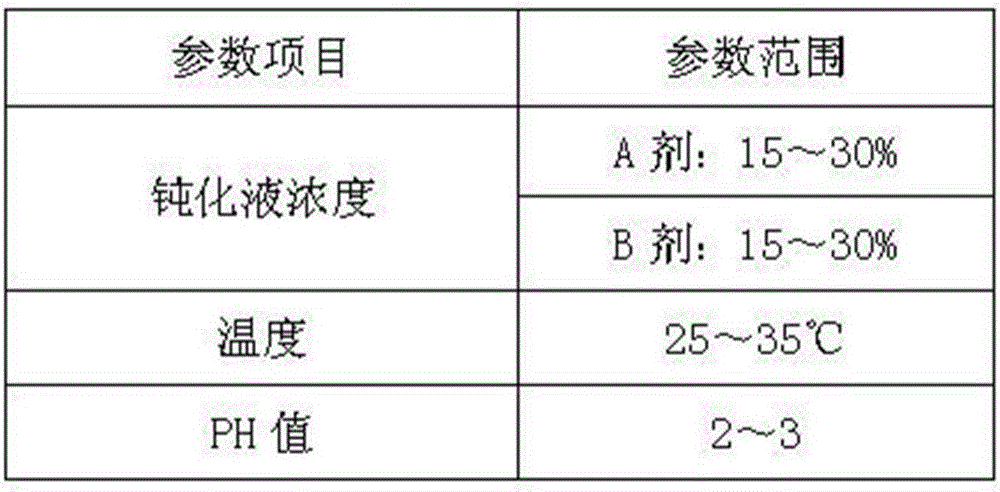

InactiveCN101239949AHigh purityPure colorOrganic chemistryLuminescent compositionsIce waterFull width at half maximum

Disclosed is a synthesis method of pyrazoline derivatives emitting olivine light, in which the pyrazoline derivative, 1-phenyl-3-[4-(N-phenyl-1-naphthylamine)ethylene]-5-[4-(N-phenyl-1-naphthylamine)phenyl]-2-pyrazoline brown-green crystals are finally prepared through three-times intermediates, by selecting material, preparing sollution, chemical combination reaction, heating, mixing, water-circulation condensation, ice water washing, argon protection, column chromatography purification, recrystallization purification, vacuum filtering, evaporation and drying, the products are grain diamond-shaped, the color coordinate is that x=0.3257, y=0.5452, the maximal emission wavelength of photoluminescence spectrum is 523 nm and the full width at half maximum is 96 nm. The products have high purity, pure color, excellent irradiance performance, high irradiance intensity and high lighteness, the products are also capable of improving the stability, reliability and life time of organic electroluminescent devices, being used in the fields of advance electronic display and irradiance illumination technology, the method of the invention is strictness and reasonable.

Owner:TAIYUAN UNIV OF TECH

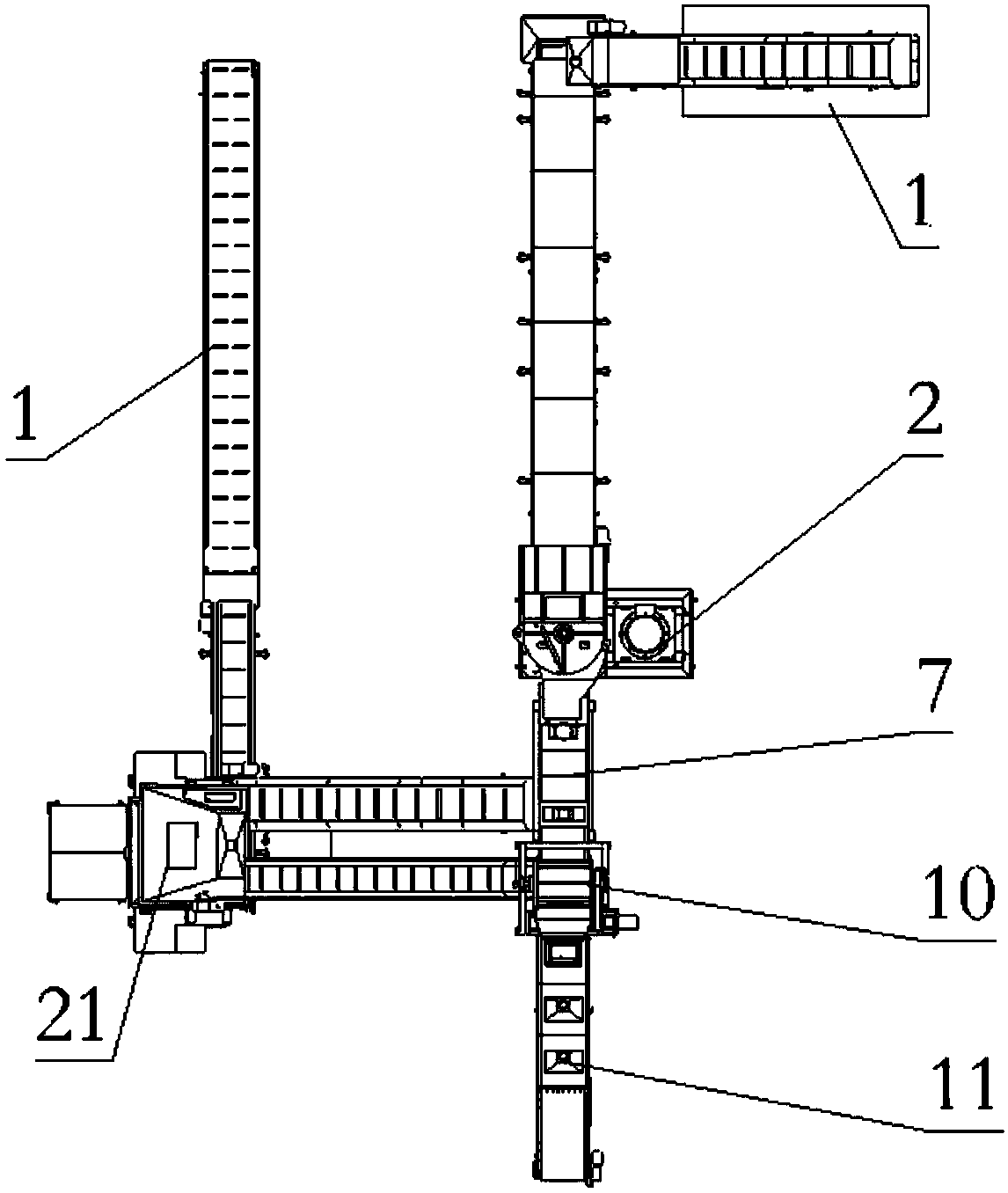

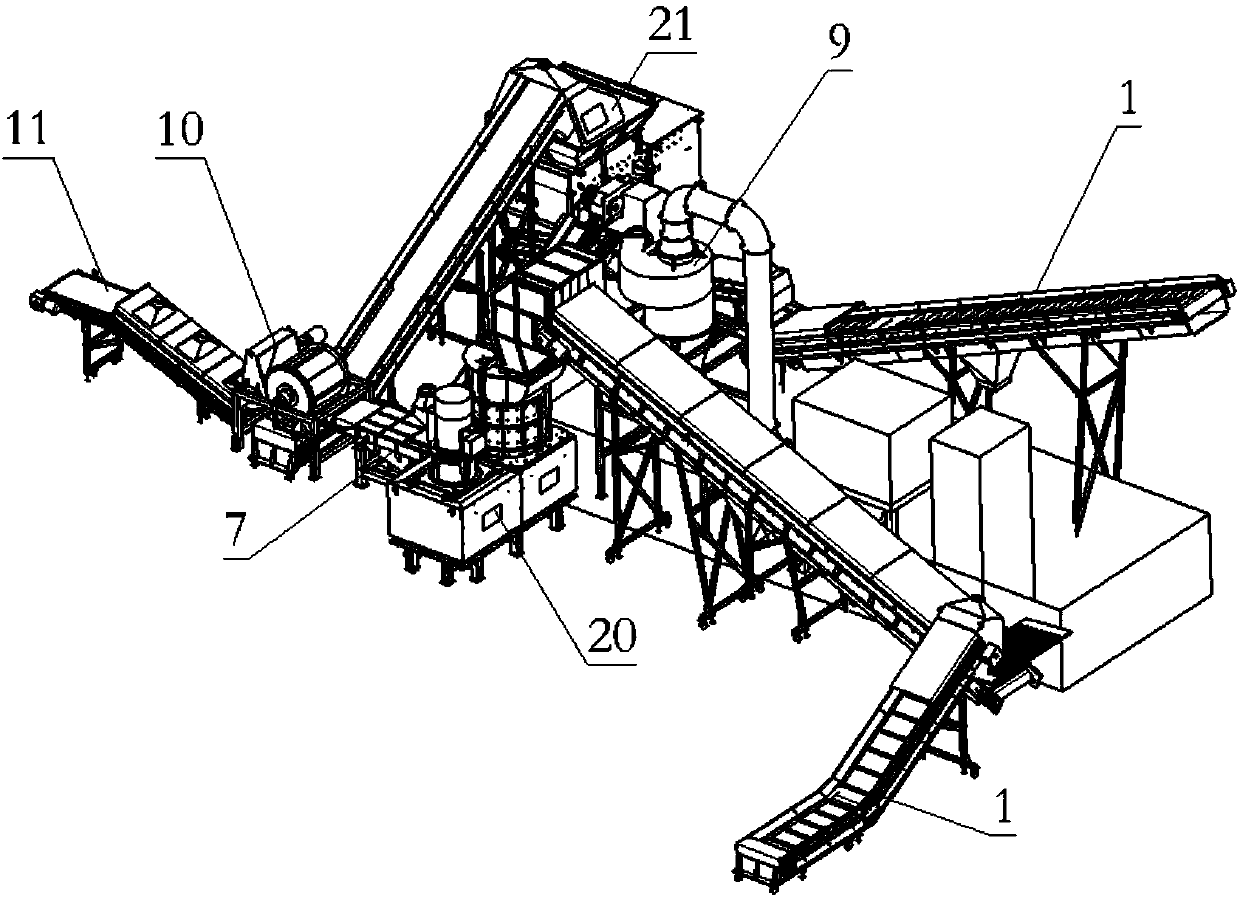

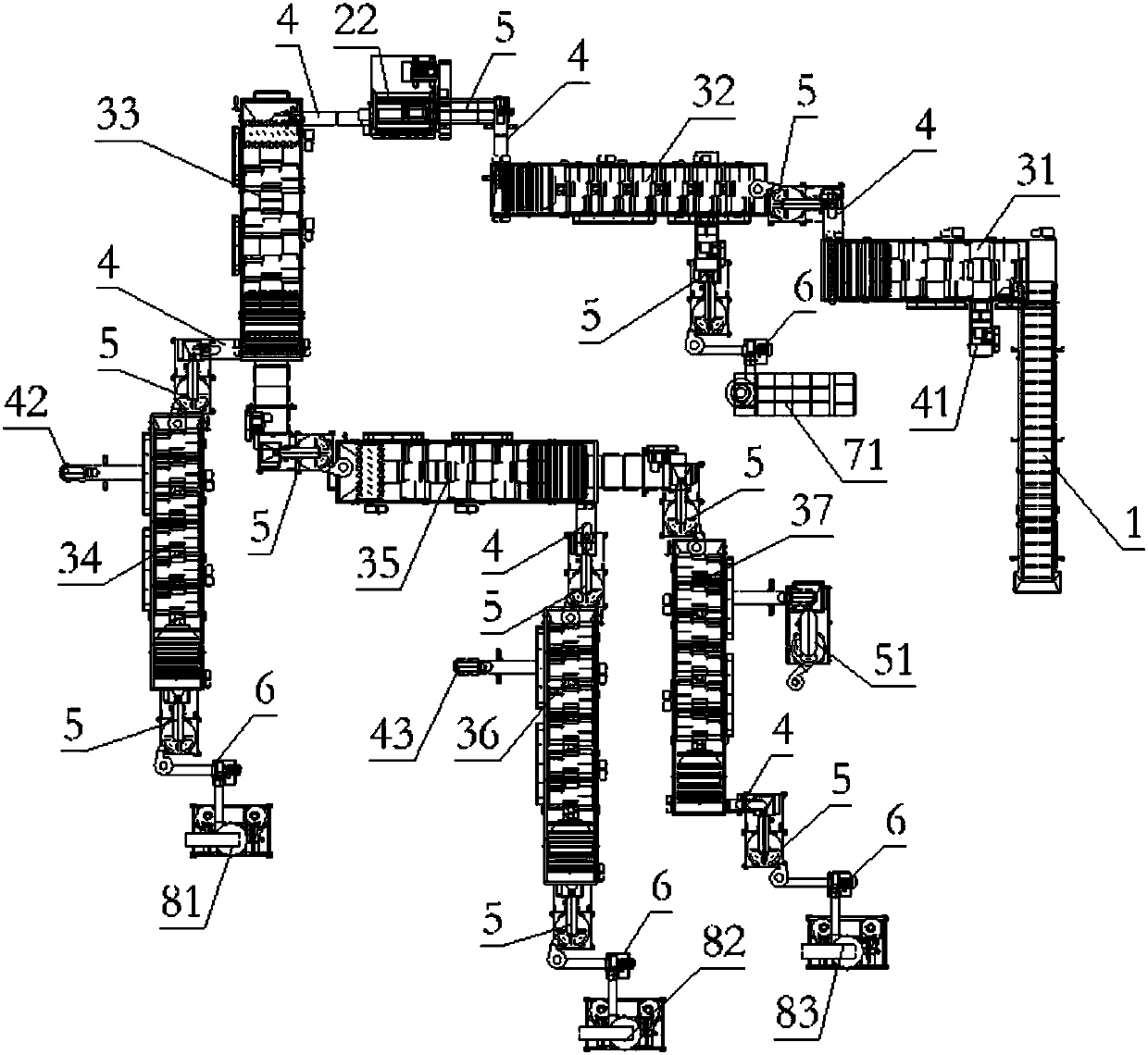

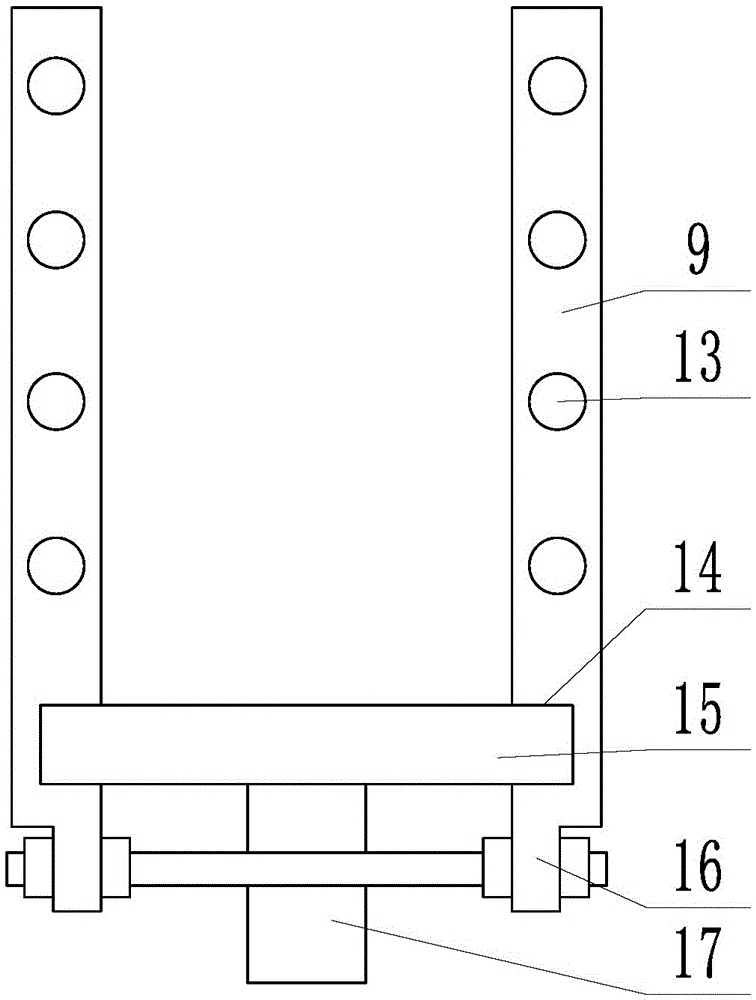

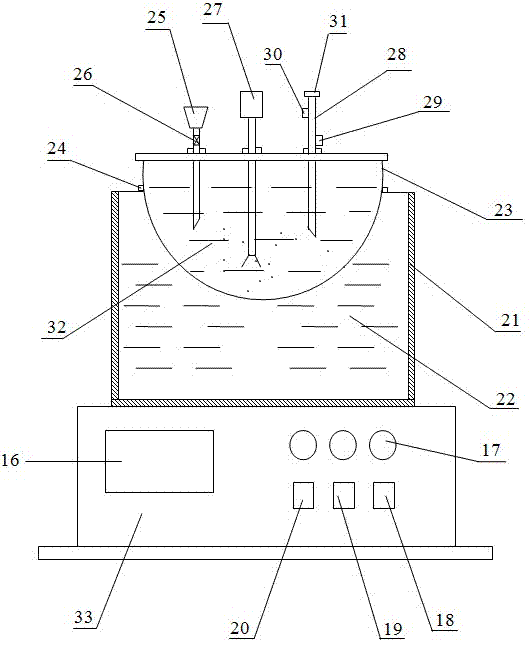

Plastic recycling process and plastic recycling system

PendingCN107639765AReasonable designRigorous workmanshipPlastic recyclingMechanical material recoveryMagnetic separatorMetal impurities

The invention provides a plastic recycling system which comprises a screening and cleaning preorder system and a screening and cleaning system. The screening and cleaning preorder system is used for crushing initial materials and filtering metal impurities, the screening and cleaning system is used for screening and cleaning plastic particles in the materials, the screening and cleaning preorder system comprises a conveying belt, a crusher and a magnetic separator, and the screening and cleaning system comprises a conveying belt, a crusher and a separation and precipitation tank. The inventionfurther relates to a plastic recycling process. By the aid of separating media with different densities, repeated dewatering separation is performed to obtain plastic recycling particles with different materials. The plastic recycling system is reasonable in design, rigorous in process, high in recycling rate, safe and efficient, the recycled materials are rapidly crushed, screened and separated,and modernized advanced manufacture standards are met.

Owner:GENOX RECYCLING TECH

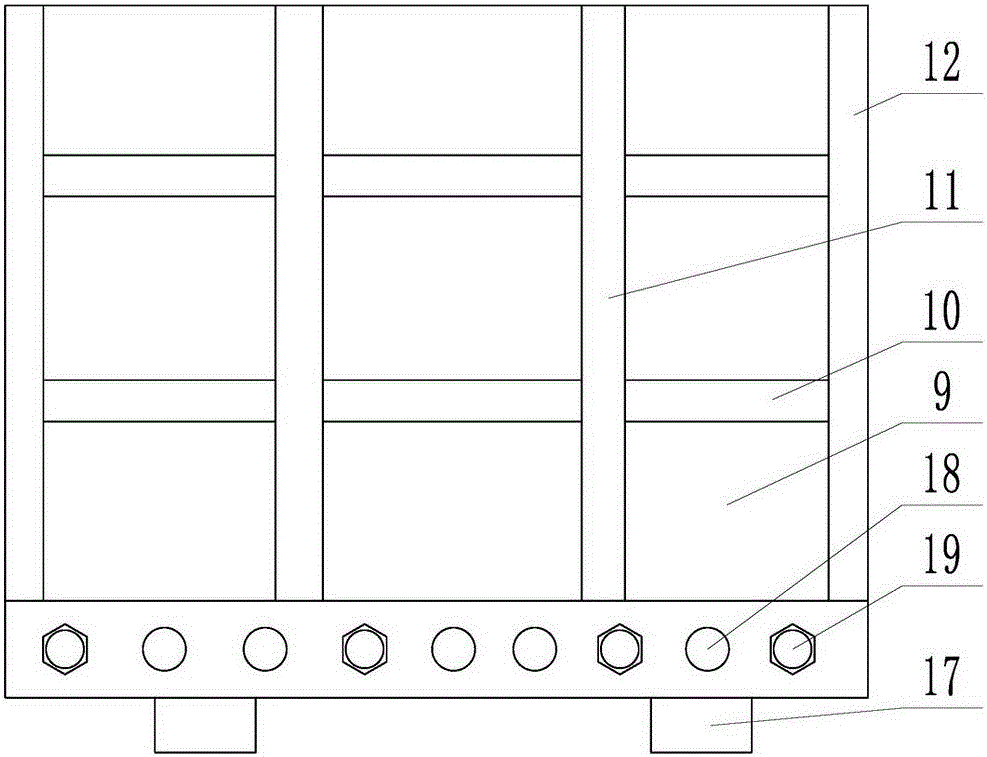

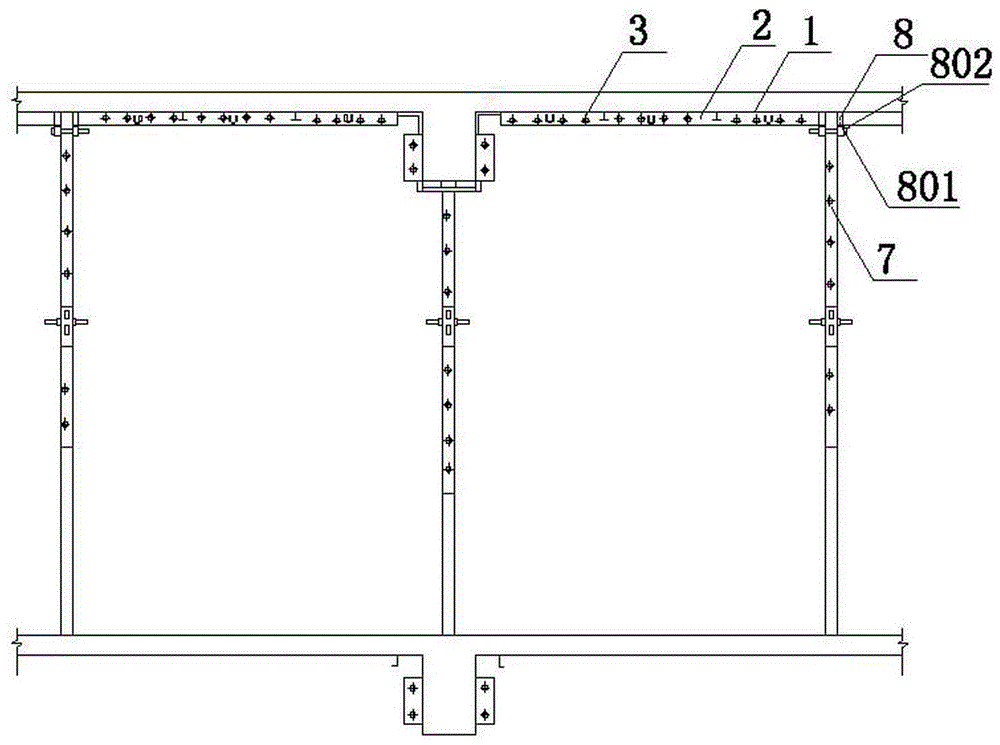

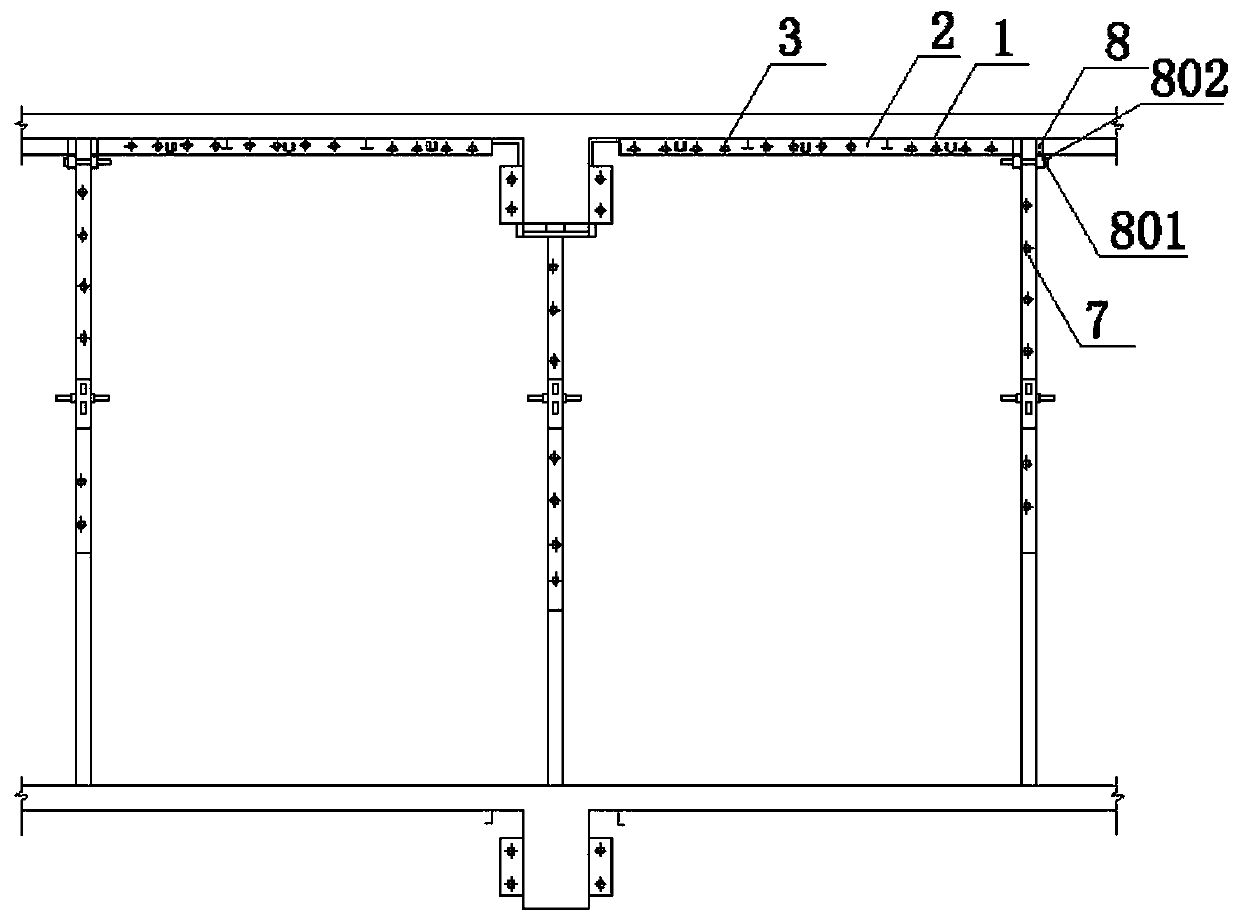

Aluminum alloy template construction technology and method

ActiveCN106351439ARigorous workmanshipImprove construction progressForms/shuttering/falseworksForming/stuttering elementsTemplate designAluminium alloy

The invention discloses an aluminum alloy template construction technology and an aluminum alloy template construction method. By the technology and the method, a problem that the current template has the construction difficulty, complex operation, low construction cost and protection difficulty can be effectively solved; the technical solution solved by the technology and the method is implemented by the following steps: 1, determining the aluminum alloy template design solution; 2, configuring aluminum alloy template resources; 3, measuring method; 4, constructing sequence; 5, installing the aluminum alloy template; 6, removing the aluminum alloy template; the technology is strict, in comparison with a traditional technology, the aluminum alloy template construction solution implemented according to the technology has a great improvement, a disadvantage during construction is reduced, and the operating efficiency is increased.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Sugariness dried oyster with iodine-containing tea flavor

ActiveCN101120799BPrevent decline in male sexual functionRigorous workmanshipFood preparationEccentric hypertrophyHerbal preparations

The present invention discloses a sweet dried oyster with iodine-tea taste, which belongs to instant dried food ingredients and the making method. The main raw material of the present invention is fresh oyster, and the supplemental materials are slat, white sugar, malt sugar, honey, edible oil and so on. The product is made after the materials being treated, cooked, immersed, dried, fried, roasted (for dehydration), coated with instant black tea powder, baked, cooled, packed, disinfected with microwave and stored in case, and processed cold storage process or procedure. The produced instant dried oyster has original flavor and taste, and has taste of Chinese herbal preparation honey-peppery oil tea camellia. The present invention has oyster and Chinese herbal preparation, and so the driedoyster has the function of enhancing the male reproductive system, preventing male sexual function from decreasing and prostatic hypertrophy. The present invention also can protect heart and liver, benefit for gallbladder, adjust blood lipid, make the skin soft, improve appearance, and is good for mental and brain, and so on.

Owner:漳州市美丽家香食品股份有限公司

Preparation method of blotted carbon microsphere for adsorbing dibenzothiophene

ActiveCN102827334AObvious blotBlot reasonableOther chemical processesBy adsorptionMicrosphereCompound (substance)

The invention relates to a preparation method of blotted carbon microspheres for adsorbing dibenzothiophene, which comprises the following steps: performing oxidation treatment of carbon microspheres, then performing silanization reaction, surface modification, and polymerization elution to obtain the blotted carbon microspheres; irregular hole blots are formed on microsphere surfaces; the preparation method is advanced and reasonable in technology, short in process flow, detailed and accurate in data, and good in product morphology; the product purity is as high as 99%; the product yield is as high as 91%; the blotted carbon microspheres are black round particles with a particle diameter of 100-200 nm, can be matched with various chemical substances; the method of the invention is a quite ideal method for preparing blotted carbon microspheres; and the product is applicable to pharmacy and fine chemical engineering.

Owner:TAIYUAN UNIV OF TECH

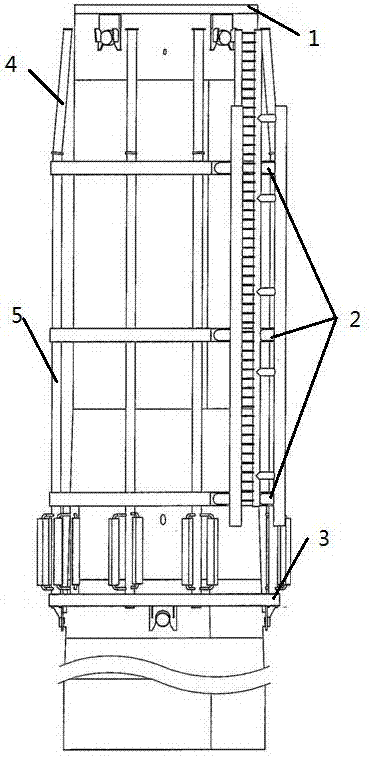

High-power draught fan single pile sleeve cage assembly process

ActiveCN107268664AReduce welding distortionSmall size deviationFoundation engineeringRear quarterEngineering

The invention discloses a high-power draught fan single pile sleeve cage assembly process. The high-power draught fan single pile sleeve cage assembly process comprises the steps that ring beam pairing, welding and trepanning are carried out, wherein cross-shaped center lines are marked, a circle center is fixed, the positions of an inner side plate and an outer side plate of a ring beam are marked, the positions of swallow tail buckles are determined, paired ring beams are folded and welded, lines are marked at the position of the cross-shaped center lines of the ring beams for labeling, and a hole penetrating a supporting pipe is formed; and an overall sleeve cage is folded, paired and welded, wherein a working table is adjusted, the cross-shaped center lines are marked, the circle center is fixed, the ring beams are placed, the position of the supporting pipe is corrected so as to be vertical to a working platform, the ring beams are subject to tack-welding at the supporting pipe position where labeling is made, and the supporting pipe and the lower surface of the ring beams are subject to spot welding fixing. The high-power draught fan single pile sleeve cage assembly process has the beneficial effects that disconnected and jumped type symmetrical welding is carried out, and welding deformation is reduced; and strictly according to the drawing requirement, the position accuracy of the eight swallow tail buckles is guaranteed to meet the requirement, and the sleeve cage marine installation risk is reduced.

Owner:江苏海力海上风电装备制造有限公司

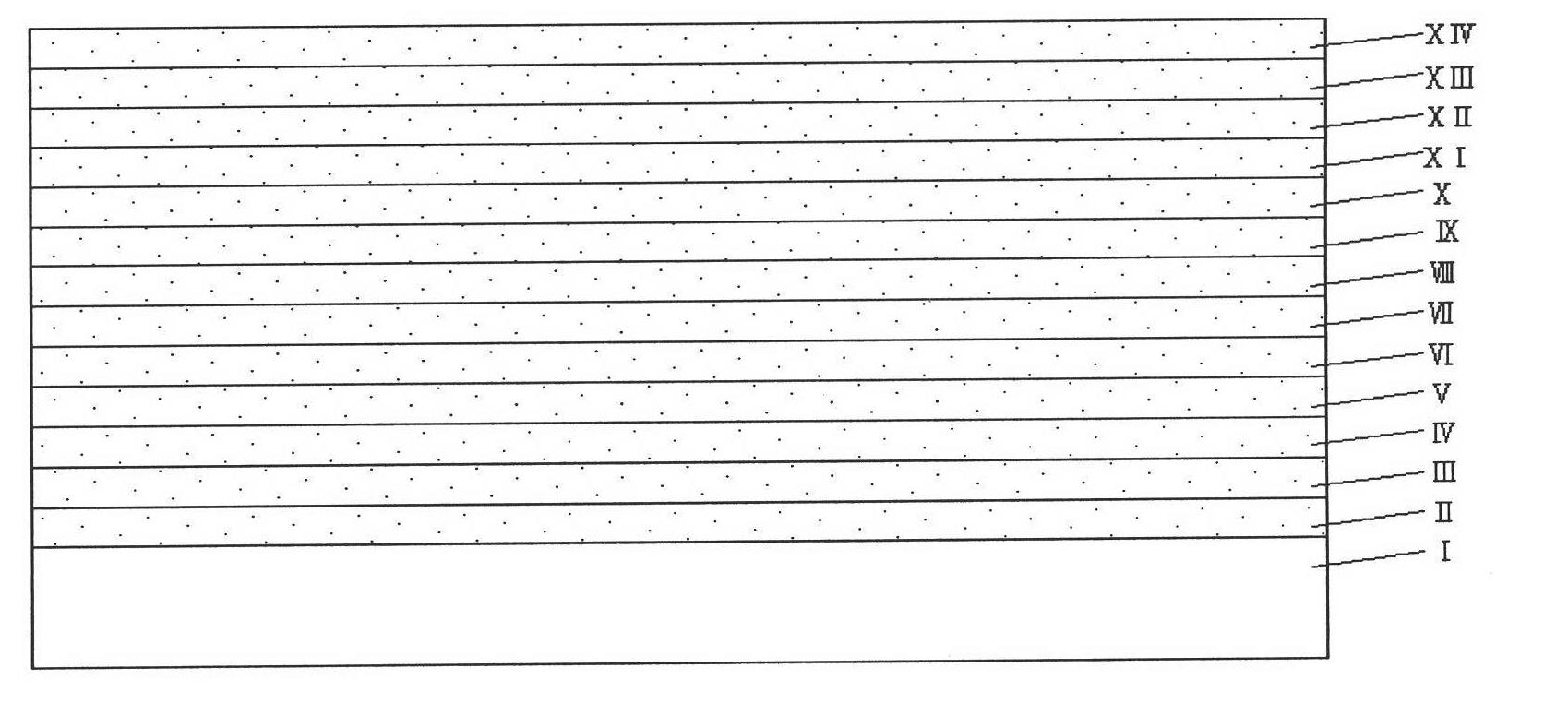

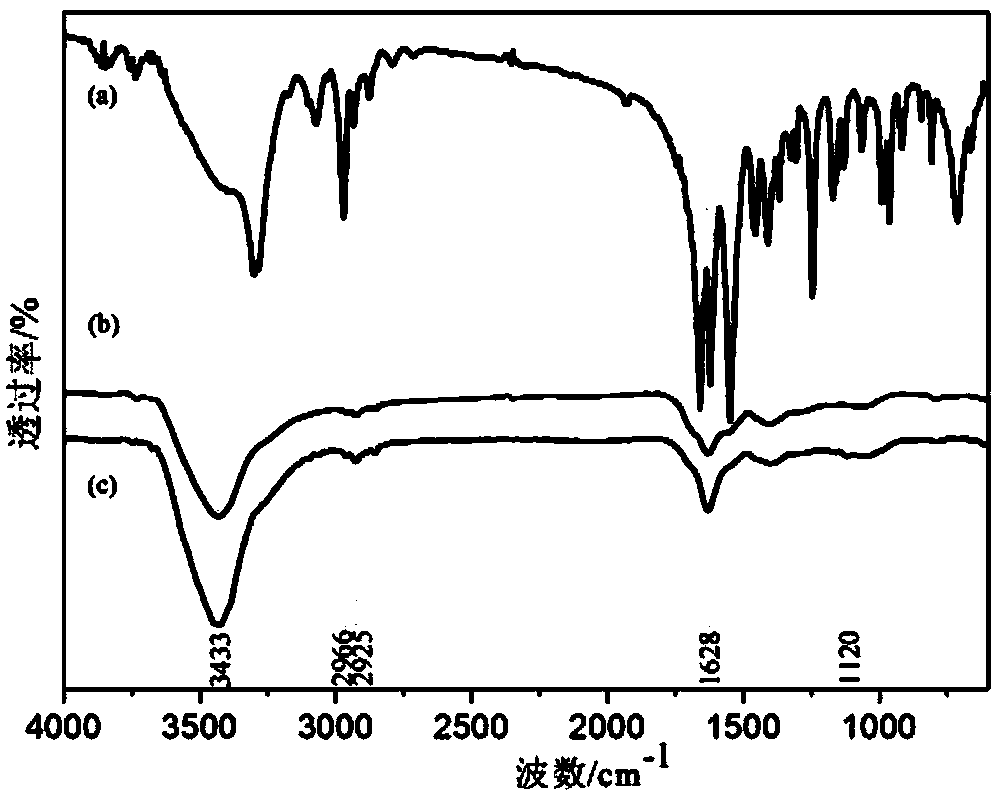

Preparation method of photonic crystal multilayer film

InactiveCN102358936AImprove chemical and physical propertiesImprove mechanical propertiesVacuum evaporation coatingSputtering coatingFilm structureElectrically conductive

The invention relates to a preparation method of a photonic crystal multilayer film. Aiming at application state of the photonic crystal to optical materials, an electrically conductive glass is used as a substrate, and titanium oxide and copper are used as films; TiO2 films and Cu films are sputtered on the substrate through magnetron sputtering; the TiO2 film and the Cu film alternatively arranged form a 14-layer multilayer film structure; then the multilayer film are treated with low temperature tempering to increase physical properties and mechanical properties of the multilayer film. Thepreparation method employs an advanced and rigorous technology with detailed and accurate technical parameters; the product has good quality, high purity and good optical performance; therefore, provided is an ideal preparation method of the photonic crystal multilayer film.

Owner:TAIYUAN UNIV OF TECH

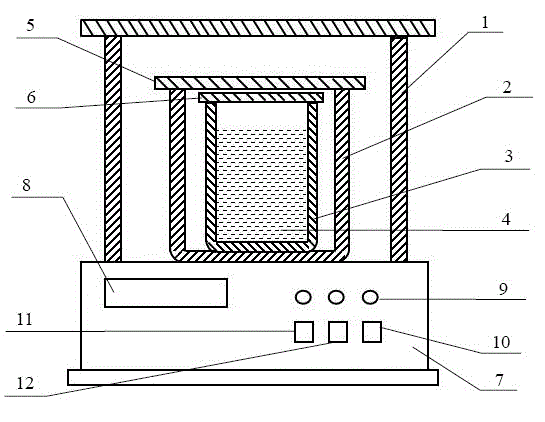

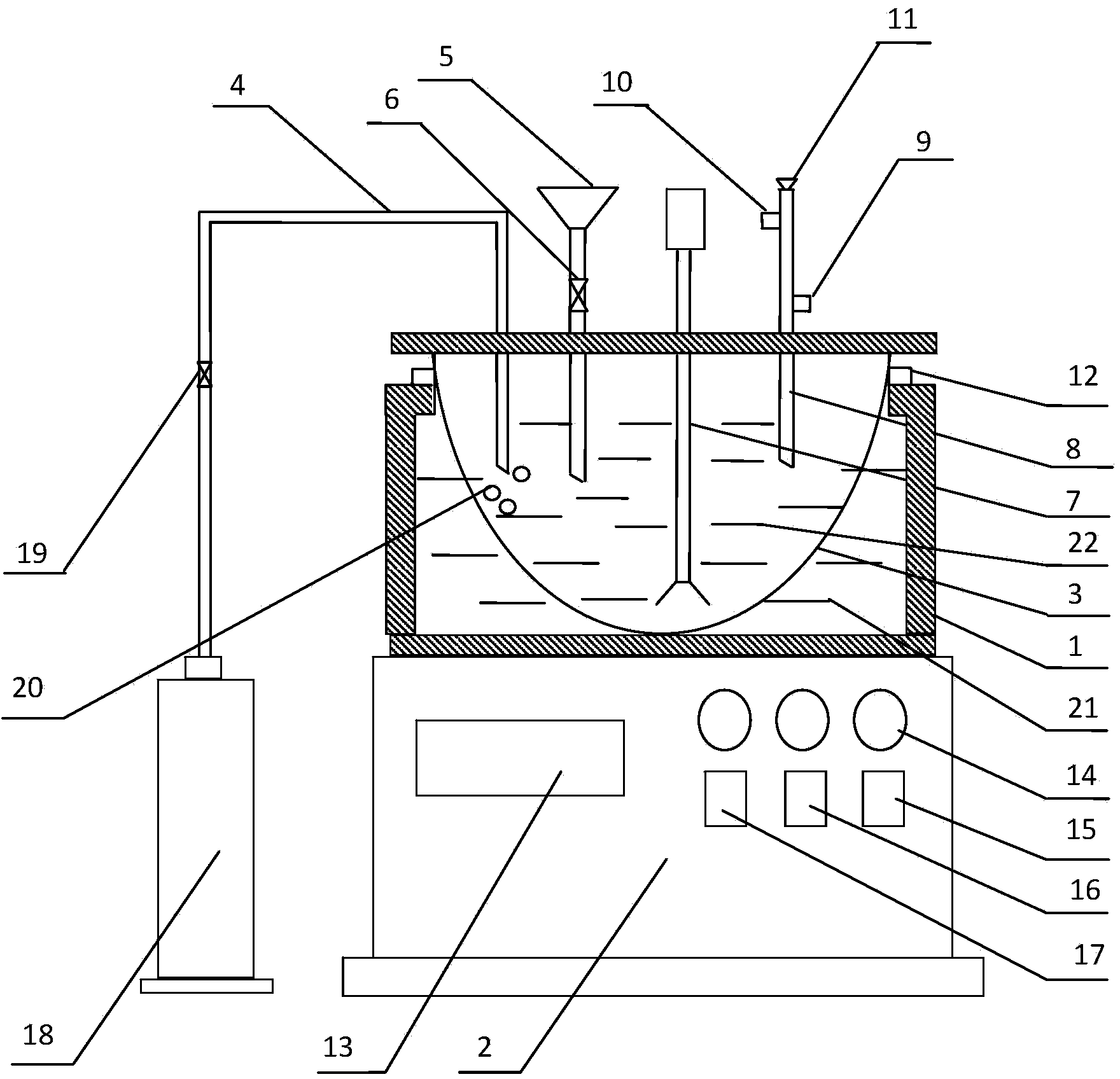

Preparation method of magnetic temperature-sensitive nanoparticles

ActiveCN103772630AGood superparamagneticObvious thermosensitive effectMagnetite NanoparticlesSuperparamagnetism

The invention relates to a preparation method of magnetic temperature-sensitive nanoparticles. Aiming at the deficiencies of magnetic nanoparticles, the magnetic temperature-sensitive nanoparticles are prepared by the following steps: firstly, silylanizing the magnetic nanoparticles; and then carrying out graft polymerization, ultrasonic dispersion, washing and extraction, and vacuum drying. The preparation method is strict in process, advanced and reasonable, full and accurate in data and good in shape of products which are ash black powder particles, wherein the particle diameter of the powder is less than or equal to 220nm. The magnetic nanoparticles have remarkable superparamagnetism and a carbon wrapping layer is arranged on the surface to prevent mutual attraction among the nanoparticles in the application process to lead to coagulation. The product is remarkable in temperature-sensitive effect, high in purity which reaches 99% and high in yield which reaches 97.5%. The preparation method is a very ideal method for preparing the magnetic temperature-sensitive nanoparticles. The product can be applied to the fields such as medicines, bioengineering and various industries.

Owner:TAIYUAN UNIV OF TECH

Manufacturing method for aluminum alloy plate for freight train carriage

The invention relates to a manufacturing method for an aluminum alloy plate for a freight train carriage. The manufacturing method for the aluminum alloy plate for the freight train carriage comprises steps of smelting, refining and degassing, casting, saw cutting and milling, heating, hot rolling, roller type straightening and transecting and precise saw cutting. The manufacturing method for the aluminum alloy plate for the freight train carriage has the advantages of being preciseness in technology, corrosion resistant in prepared product, good in product performance, good in uniformity and stable in product performance.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

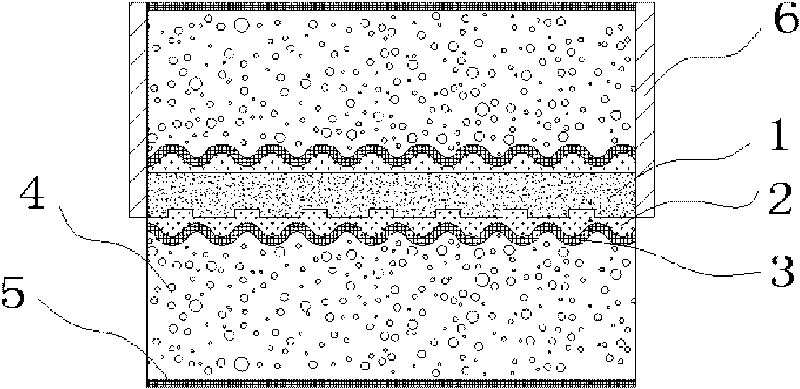

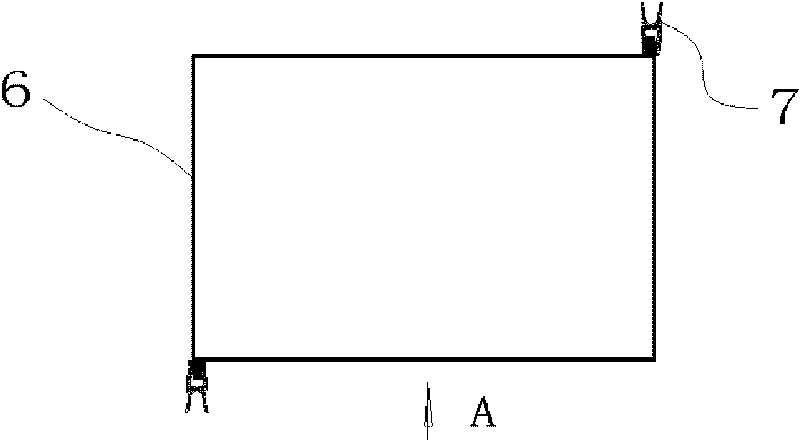

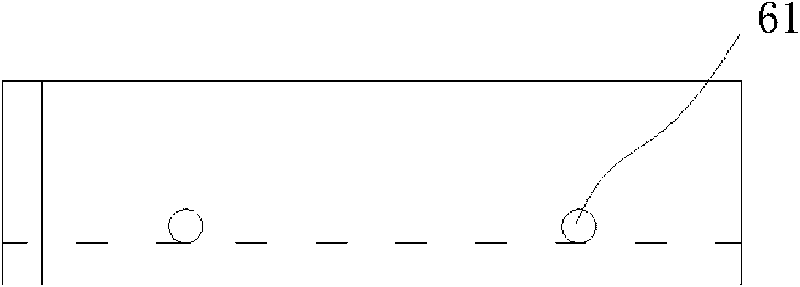

Method for fabricating compound heat preservation stone and dedicated die therefor

InactiveCN101722576AReasonable structural designBeautiful textureMould separation apparatusMouldsSlurryNatural stone

The invention relates to the technical field of construction material, in particular to a method for fabricating compound heat preservation stone and a dedicated die therefor. A layer of natural stone and a light heat preservation material glued into a whole with the natural stone are provided. The fabrication method comprises the following steps: carrying out polishing, glueing, setting of electric heat galvanized steel net in the dedicated die to pour light heat preservation layer size; pouring the light heat preservation layer size for the second time after the size is maintained and cured so as to obtain two-fold compound heat preservation stone; then splitting the natural stone into two halves, thus obtaining two compound heat preservation stone. The dedicated die of the invention features reasonable design, low comprehensive cost, textural quality and beautiful appearance, natural stone texture, stringent technological processes and high fabrication efficiency.

Owner:浙江奥灵格建材系统有限公司

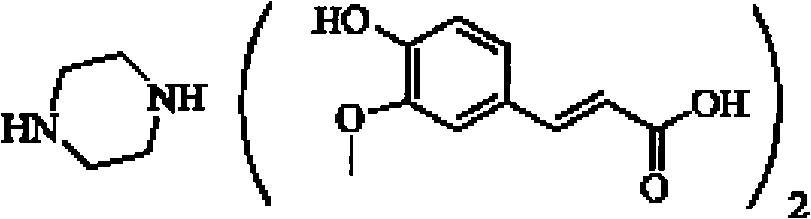

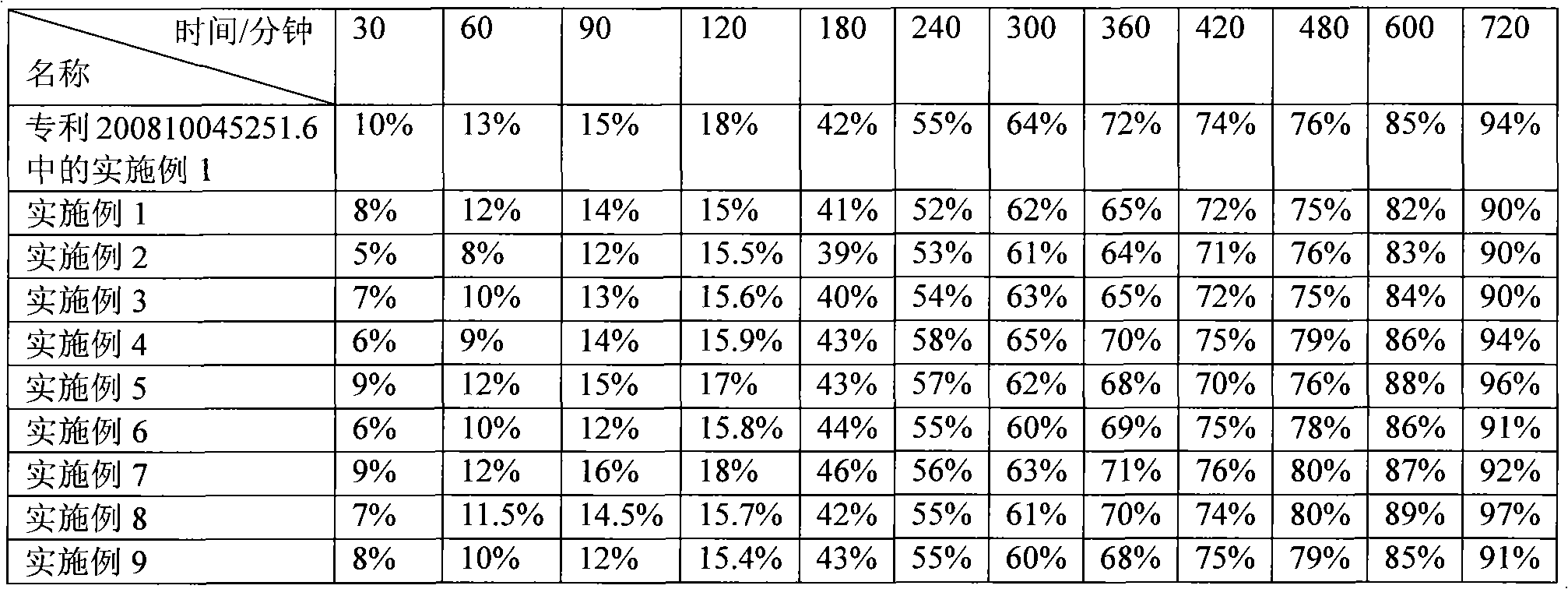

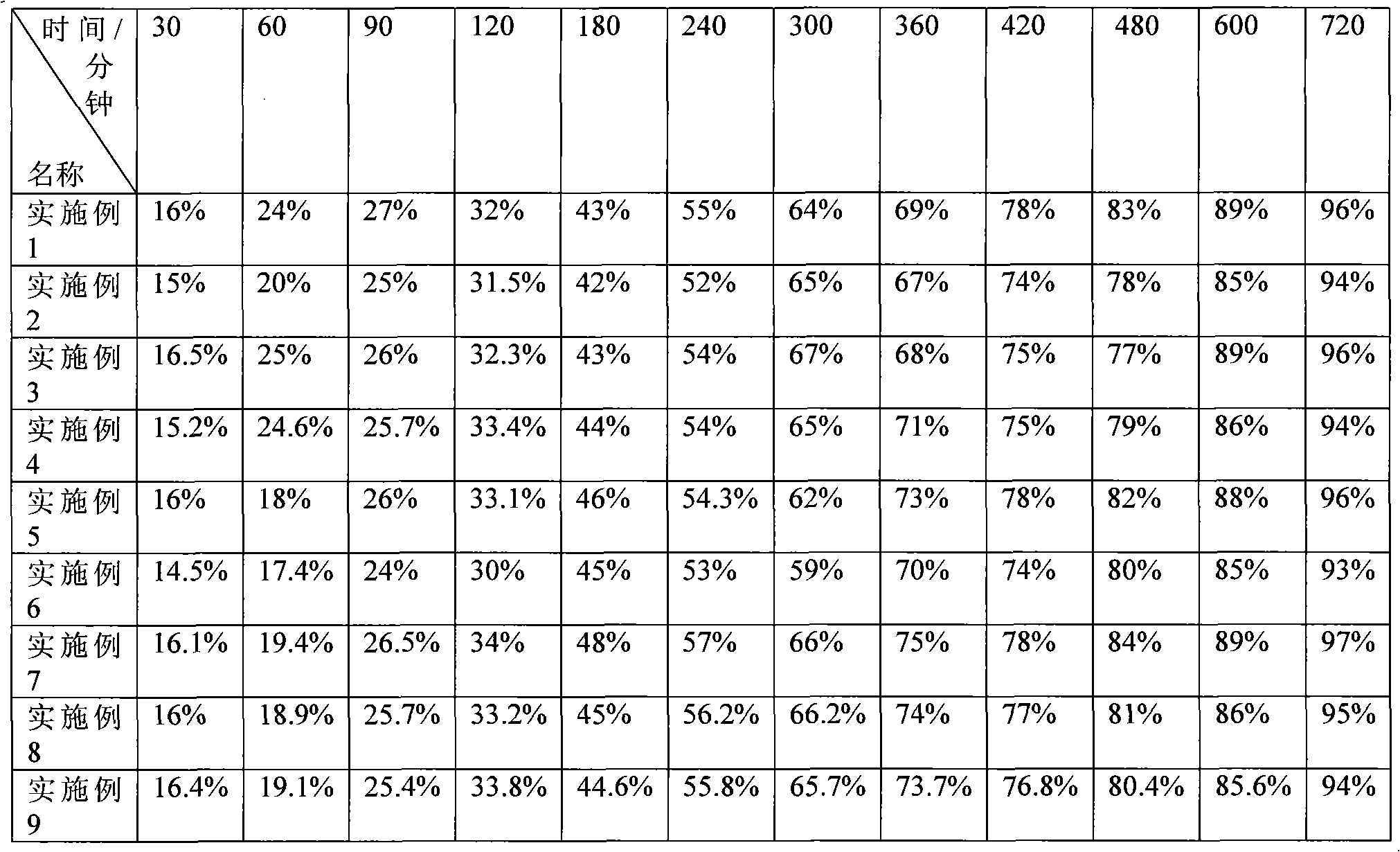

Piperazine ferulate sustained-release tablet and its preparation method

ActiveCN102335153AImprove release resultsImprove liquidityOrganic active ingredientsPharmaceutical delivery mechanismAdhesiveDissolution

The invention describes a piperazine ferulate sustained-release tablet and its preparation method. The piperazine ferulate sustained-release tablet consists of piperazine ferulate, a framework material, a diluent, a lubricant, an adhesive, and optionally a coating material. In the invention, starch1500 (shanda in Chinese) is added into the diluent to improve the release of the sustained-release preparations. Meanwhile, a strict preparation process is employed so as to make the tablet of the invention reach a release result approximate to human in vivo release. With simple analysis of dissolution and release, the tablet and its preparation method are suitable for large scale production. According to a rotating basket method for in vitro drug release of sustained-release preparations in the 2010 edition of Chinese pharmacopoeia, in 900ml of water, the release rate of the tablet in the invention can be 25-35% accumulatively in 2h, 45-60% in 4h, 60-75% in 6h, and over 90% in 12h. A detailed study of the in vitro release result of the tablet indicates that the piperazine ferulate sustained-release tablet reaches good sustained-release effects and can have delayed release within 12h, so that the medicine taking time can be reduced.

Owner:浙江四维医药科技有限公司

Preparation method of chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering

InactiveCN101575696BImprove mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingAluminum IonShielding gas

The invention relates to a preparation method of a chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering, which comprises the following steps: a chromium-tungsten-manganese steel plate is taken as a basal body, chromium and aluminum as a target source of metal ion, nitrogen gas as reactant gas, and argon gas as ion bombardment gas and protection gas; in a vacuum sputtering furnace, in a closed magnetic field state, in the argon gas and at the temperature of 300 DEG C, the surface of the chromium-tungsten-manganese steel plate is sputtered with chromium ion, aluminum ion and nitrogen ion and the chromium-aluminum-nitrogen hard film is formed on the surface of the steel plate, and then the low temperature tempering and alloying solid solution are conducted, thus greatly improving mechanical property, hardness, intensity, abrasive resistance and erosion resistance of the surface of the chromium-tungsten-manganese steel plate. The mechanical property of the chromium-tungsten-manganese steel plate can be improved by 466% compared with that of hardened steel plates. The preparation method has short process flow, precise technique, accurate and detailed measurement values, the film with thickness of 4,600nm, and the alloy layer with good solid solution effect and being not easy to peel off, thus being the ideal treatment method for strengthening and hardeningthe surface of alloy tool steel.

Owner:TAIYUAN UNIV OF TECH

Aluminum formwork construction technology

ActiveCN106351439BRigorous workmanshipImprove construction progressForms/shuttering/falseworksForming/stuttering elementsTemplate designAluminium alloy

The invention discloses an aluminum alloy template construction technology and an aluminum alloy template construction method. By the technology and the method, a problem that the current template has the construction difficulty, complex operation, low construction cost and protection difficulty can be effectively solved; the technical solution solved by the technology and the method is implemented by the following steps: 1, determining the aluminum alloy template design solution; 2, configuring aluminum alloy template resources; 3, measuring method; 4, constructing sequence; 5, installing the aluminum alloy template; 6, removing the aluminum alloy template; the technology is strict, in comparison with a traditional technology, the aluminum alloy template construction solution implemented according to the technology has a great improvement, a disadvantage during construction is reduced, and the operating efficiency is increased.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Propolis shower gel with function of moisturizing skin

InactiveCN106667890APromote absorptionFormulation ScienceCosmetic preparationsToilet preparationsPropolisRadix Astragali seu Hedysari

The invention discloses propolis shower gel with a function of moisturizing skin. The propolis shower gel is prepared from the following raw materials in parts by weight: 13-18 parts of propolis, 15-25 parts of radix astragali seu hedysari, 15-25 parts of Chinese angelica, 4-9 parts of pearl powder, 6-12 parts of glycerol, 1-3 parts of rose essential oil, 0.2-0.8 part of a foaming agent and 0.01-0.03 part of a PH regulator. The propolis shower gel with the function of moisturizing skin provided by the invention is scientific in formula, pure natural in raw materials, safe and non-toxic, and precise in technology; the obtained shower gel is faintly acid, thus not causing any irritation to the skin; the propolis shower gel is aromatic in smell, fine and mild in foams and easy to wash, and not only has good effects of cleaning, relieving itching, resisting inflammations and inhibiting bacteria, but also has the advantages of being good in permeability and easy to absorb; the propolis shower gel can effectively moisturize the skin and has good effects of whiting the skin, preserving moisture, exfoliating and tendering the skin, thus being worth popularization.

Owner:FUJIAN SHENFENG SCI & TECH DEV

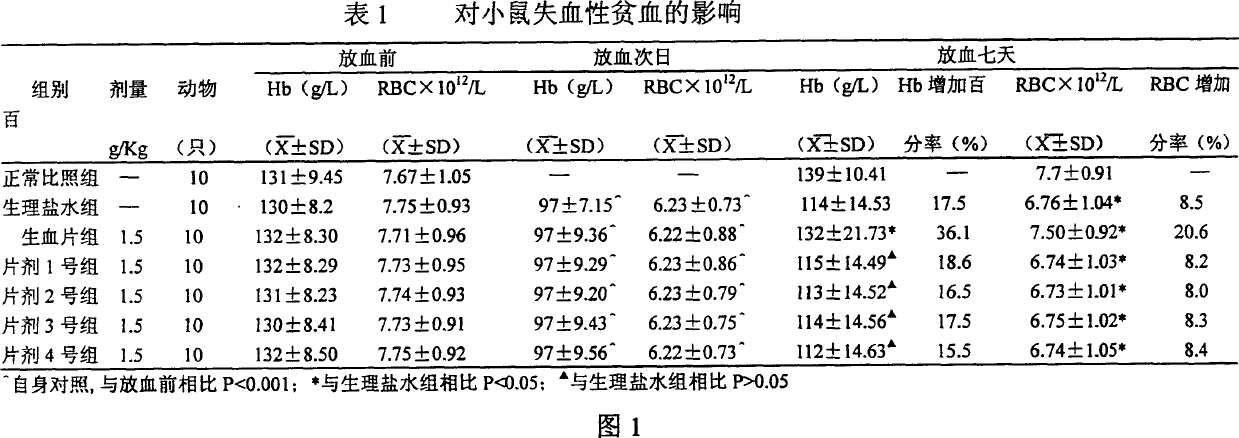

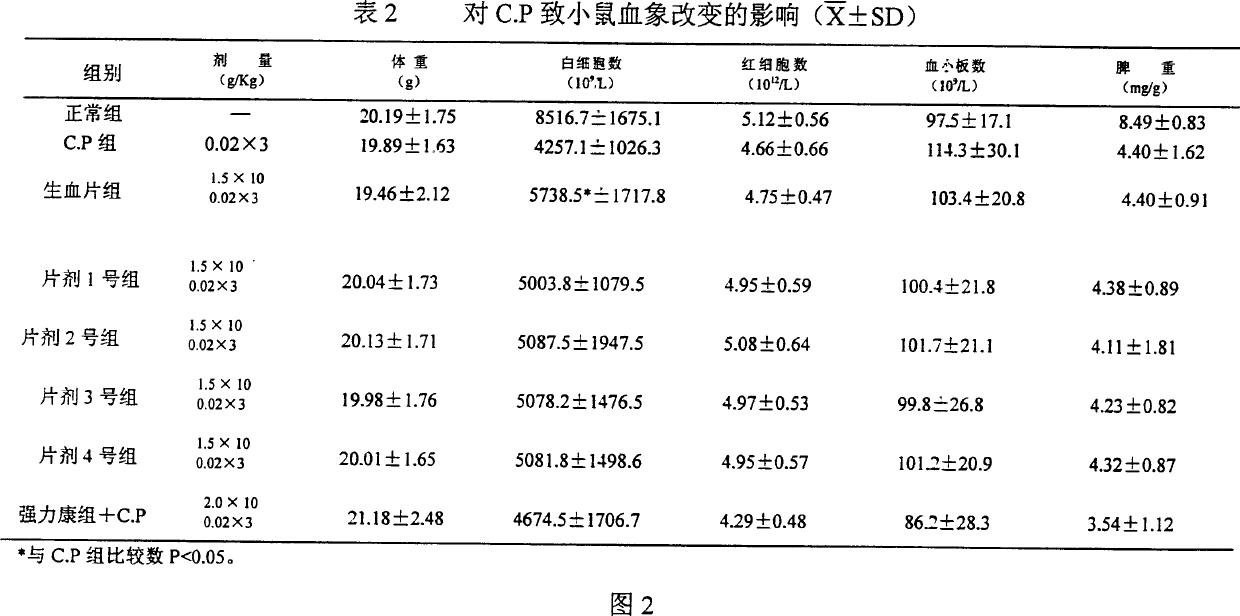

Composite Chinese medicine for nourishing qi, restoring yang, replenishing vital essence and generating blood and its production

ActiveCN1583013ARigorous workmanshipPromote hematopoiesisMammal material medical ingredientsBlood disorderCuttlefishRed blood cell

A Chinese medicine for reinforcing vital energy and vital function, promoting hematopoietic function and treating the oligocythemia and thrombocytopenia caused by radiotherapy is prepared from 5 Chinese-medicinal materials including human placenta, donkey-hide gelatin, cinammon bark, cuttlefish bone, etc.

Owner:辽宁中医学院药业有限公司

High-temperature heated flocked silk banner and production process thereof

ActiveCN102737562BImprove quality requirementsRigorous production requirementsFlags/bannersEngravingGlass fiberLaser engraving

The invention relates to a high-temperature heated flocked silk banner and a production process thereof, which belongs to the field of the production of artware. The silk banner adopts the most delicate thickened flannel fabric, falls naturally and has no fold marks, needed character content can be engraved by a laser engraving machine, through the high-temperature heating of a machine, the thickened flannel fabric characters are adhered onto the fabric at high temperature to be hot pressed, different from traditional lettering technology, the silk banner has texture and a stereoscopic impression and is more fashionable; tassels of the silk banner are made of latest fashionable material which is an artificial silk, the tassels are well made and durable, and the tradition can be broken through; a cross bar on the silk banner abandons a wooden material but utilizes glass fiber rod with better quality, the head of the silk banner adopts the latest design and is formed by an acrylic technical injection method, and the head of the silk banner is crystal like an amber and is more attractive. A set of completely new design technique is adopted, so that the silk banner is more fashionable, the traditional silk banner form is broken through, and a novel culture of the silk banner is created.

Owner:于国军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com