Patents

Literature

85 results about "Virtual production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

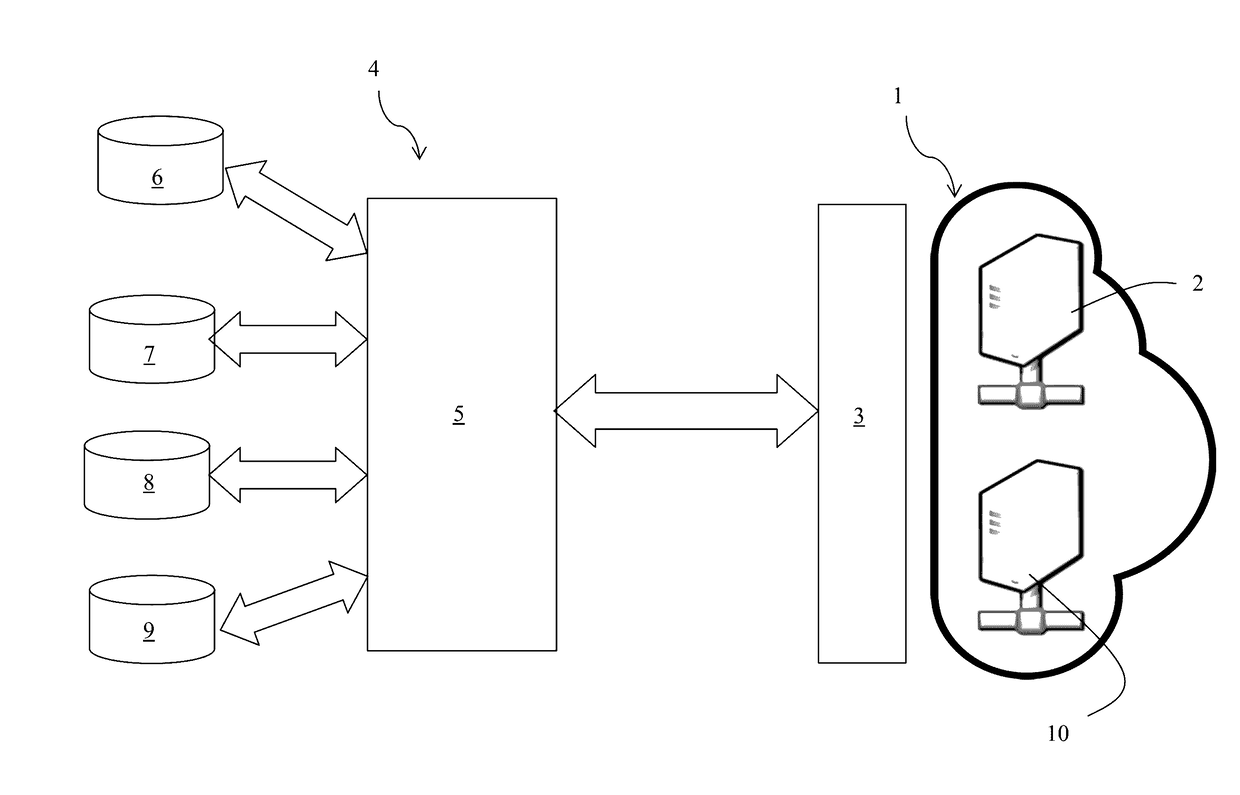

Digital twin system of an intelligent production line

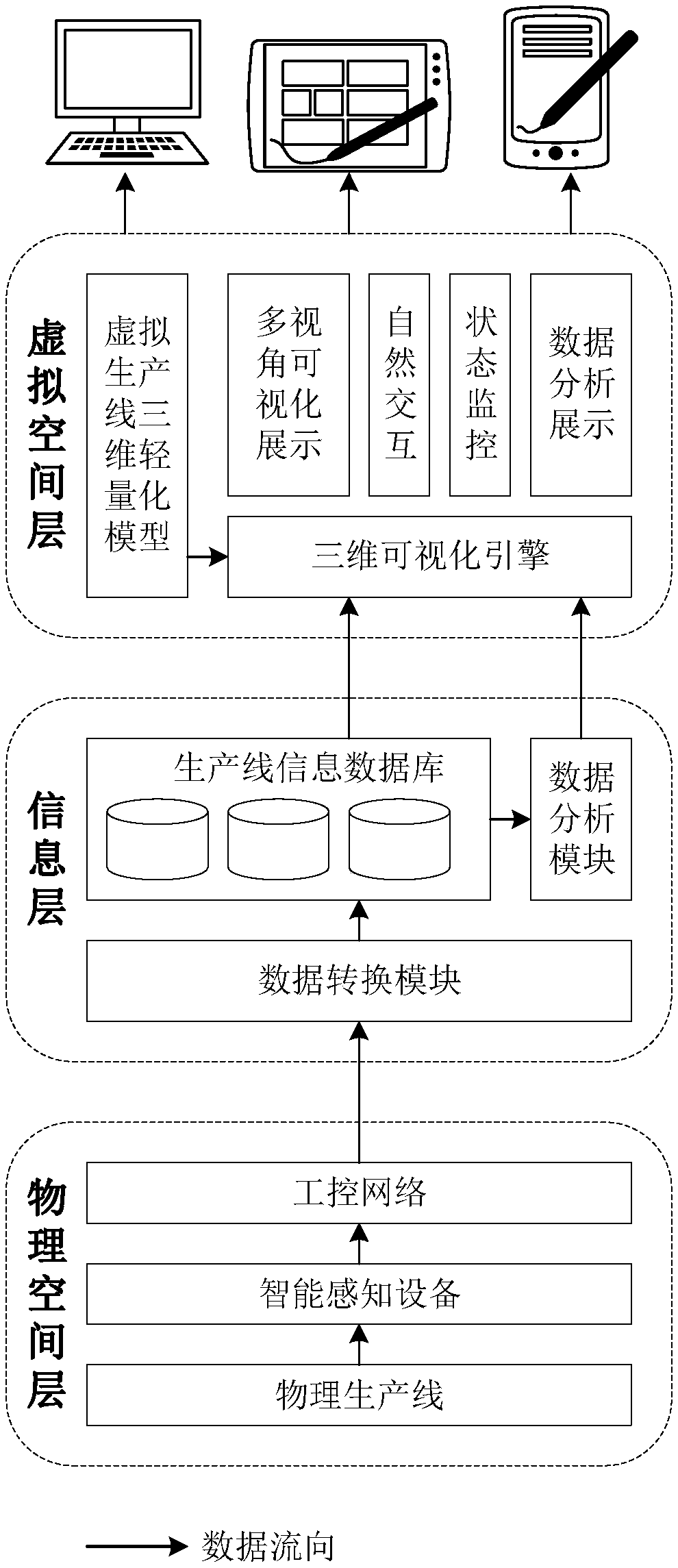

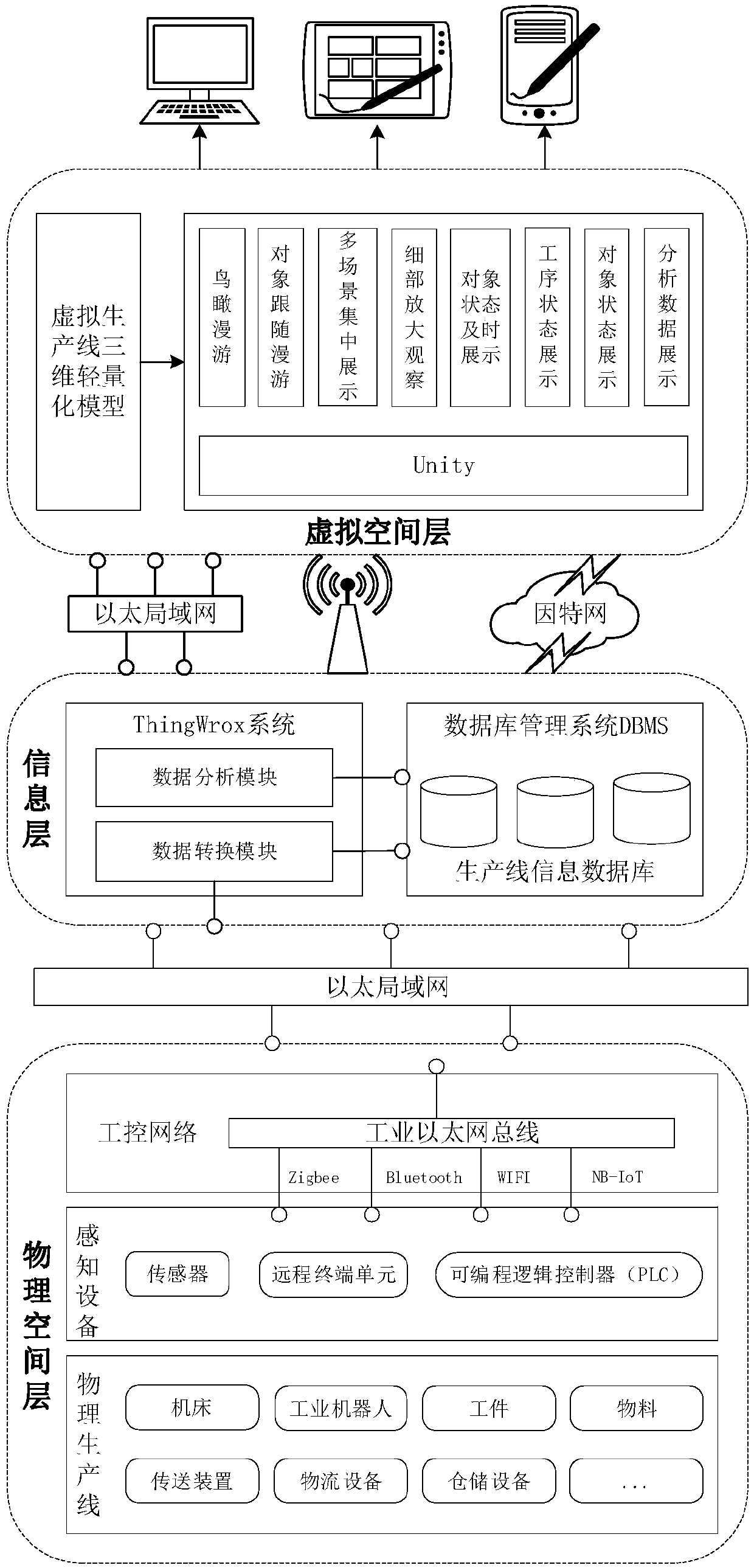

InactiveCN109613895AImplement twin mirroringData processing applicationsTotal factory controlTime informationInformation layer

The invention relates to a digital twin system of an intelligent production line, which comprises a physical space layer, an information layer and a virtual space layer. The physical space layer is composed of a physical production line, intelligent sensing devices and an industrial control network. The information layer includes a data conversion module, a data analysis module and a production line information database. The virtual space layer can adapt to a variety of platforms and environments including personal computers and handheld devices, is used for generating a virtual production line consistent with the physical production line by a 3D visual engine through online real-time and offline non-real-time rendering under the driving of the production line information database of the information layer, and has the functions of multi-angle of view visual display, natural interaction, state monitoring and so on. The real-time state information of the physical production line is collected by various intelligent sensing devices, and based on the information, a three-dimensional visual engine is driven to generate a virtual production line model consistent with the physical production line through rendering, thereby realizing the twin mirror image of the virtual production line and the physical production line.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

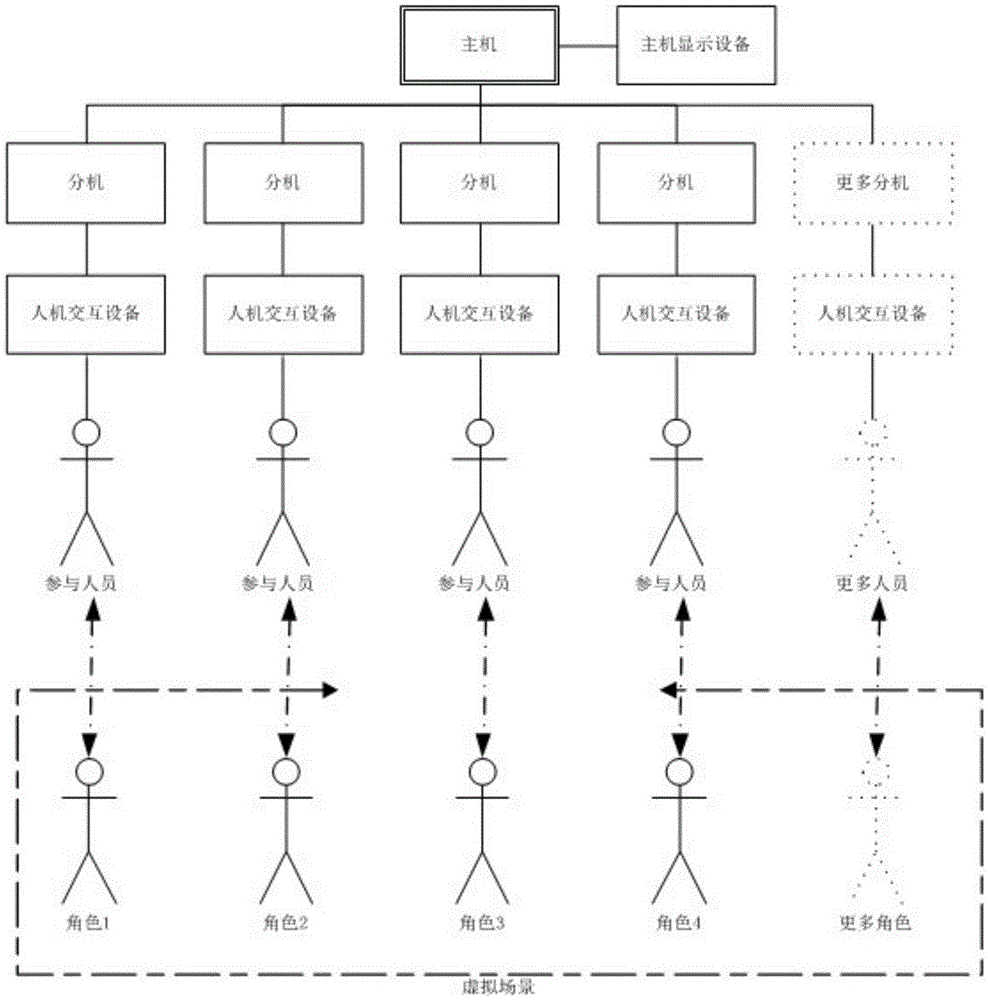

Multi-user immersive full-interactive virtual reality engineering training system

InactiveCN105425955ASolve fit problemsSolving Field ExperimentsInput/output for user-computer interactionCosmonautic condition simulationsExtension setField experiment

The invention discloses a multi-user immersive full-interactive virtual reality engineering training system, and belongs to a virtual reality engineering training system. A participant of the training system is endowed with a specific role of the virtual system; the participant is interacting with a virtual scene through a man-machine interactive device; each extension set is connected with a host computer through the network, and the communication between the host computer and the extension set is realized; and a host computer operator monitors, evaluates and guides the virtual scenes and roles through a host computer display device and the man-machine interactive device. A virtual reality technology applied to the engineering training is realized; the training system is applied to the man-machine interaction and provided with the characteristics of experience, sense of immersion and sense of participation; by the combination of online operation, cooperation of types of works and virtual production scenes, the problems of difficulty in implementation, high cost and dangers existing in field experimentation, practical teaching and security training of the engineering fields are well solved; the training system has the advantages that the time-space limitation is broken through by using the virtual reality technology; the study and participation interest of the participant is improved; and in addition, the training system can be updated and perfected in real time with the development of science and technology and with the scene changes.

Owner:CHINA UNIV OF MINING & TECH

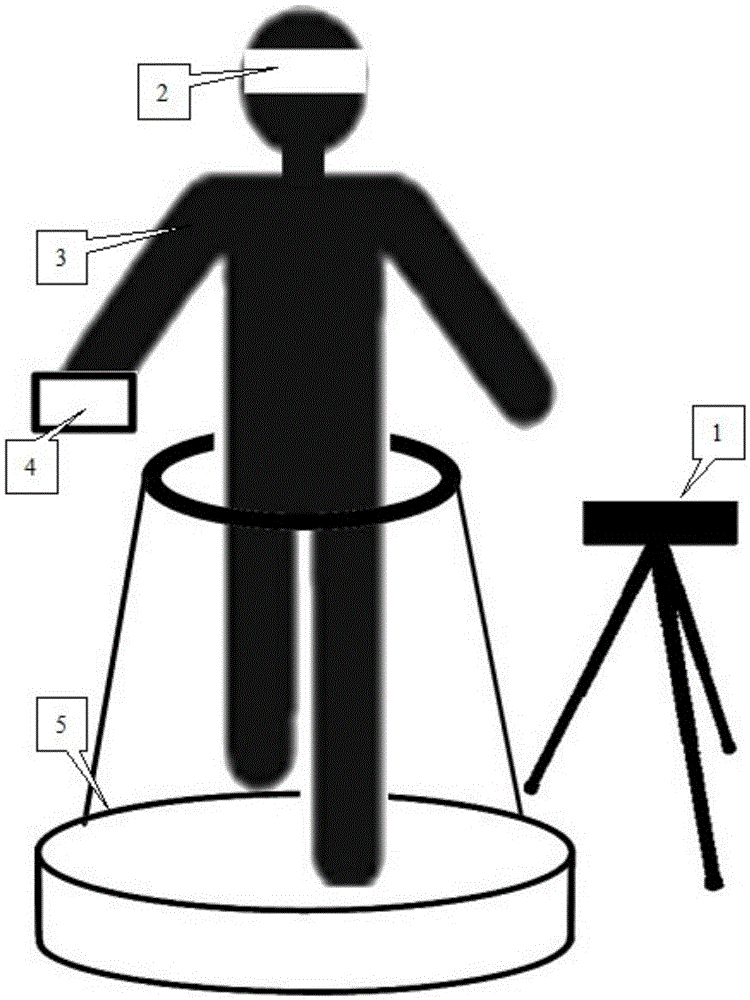

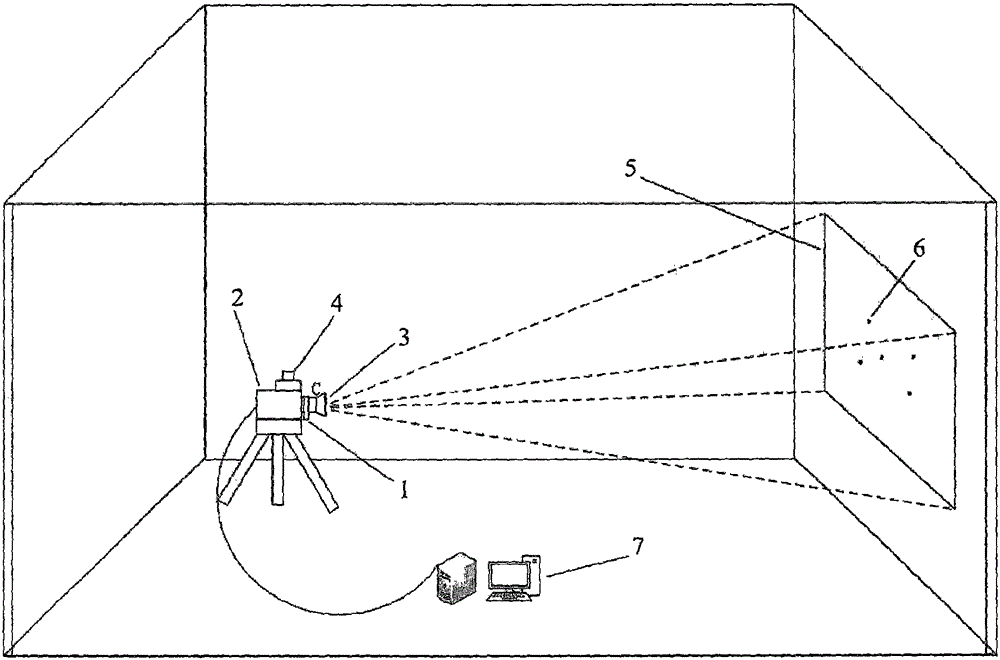

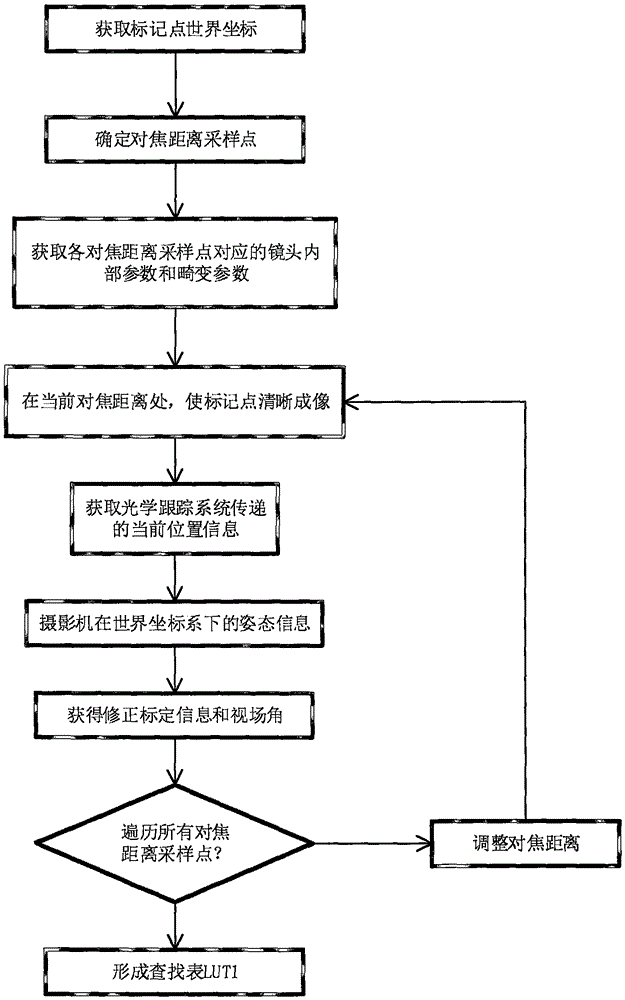

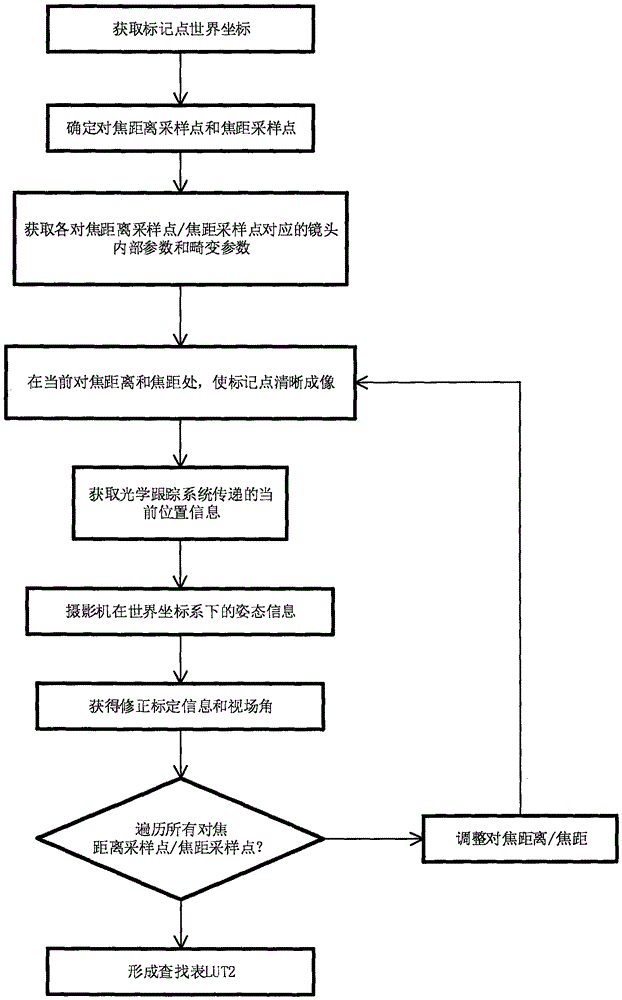

Camera positioning correction calibration method and system

ActiveCN105118055AFully automatedReal-time computingImage enhancementImage analysisCamera lensOptical tracking

The present invention discloses a camera positioning correction calibration method and a system for realizing the method, belonging to the technical field of image virtual production. Through the intrinsic relationship among a lens parameter, an imaging surface and an optical tracking device, by using the world coordinate and image point coordinate of N mark points on a background screen and the internal parameter and lens distortion parameter of a camera lens, the rotation matrix between a camera coordinate system and a world coordinate system and the translation vector of a camera perspective center in the world coordinate system are obtained, combined with the current position information given by a camera posture external tracking device in a current state, camera correction calibration information and viewing angle are obtained, the lookup table with a focusing distance and a focus length relationship is established, thus when a camera position, a lens focal distance and a focusing distance change, the position of the virtual camera of the virtual production system is fully automatically positioned and corrected, and thus a real video frame picture and a virtual frame image generated by a computer can be matched perfectly.

Owner:BEIJING FILM ACAD

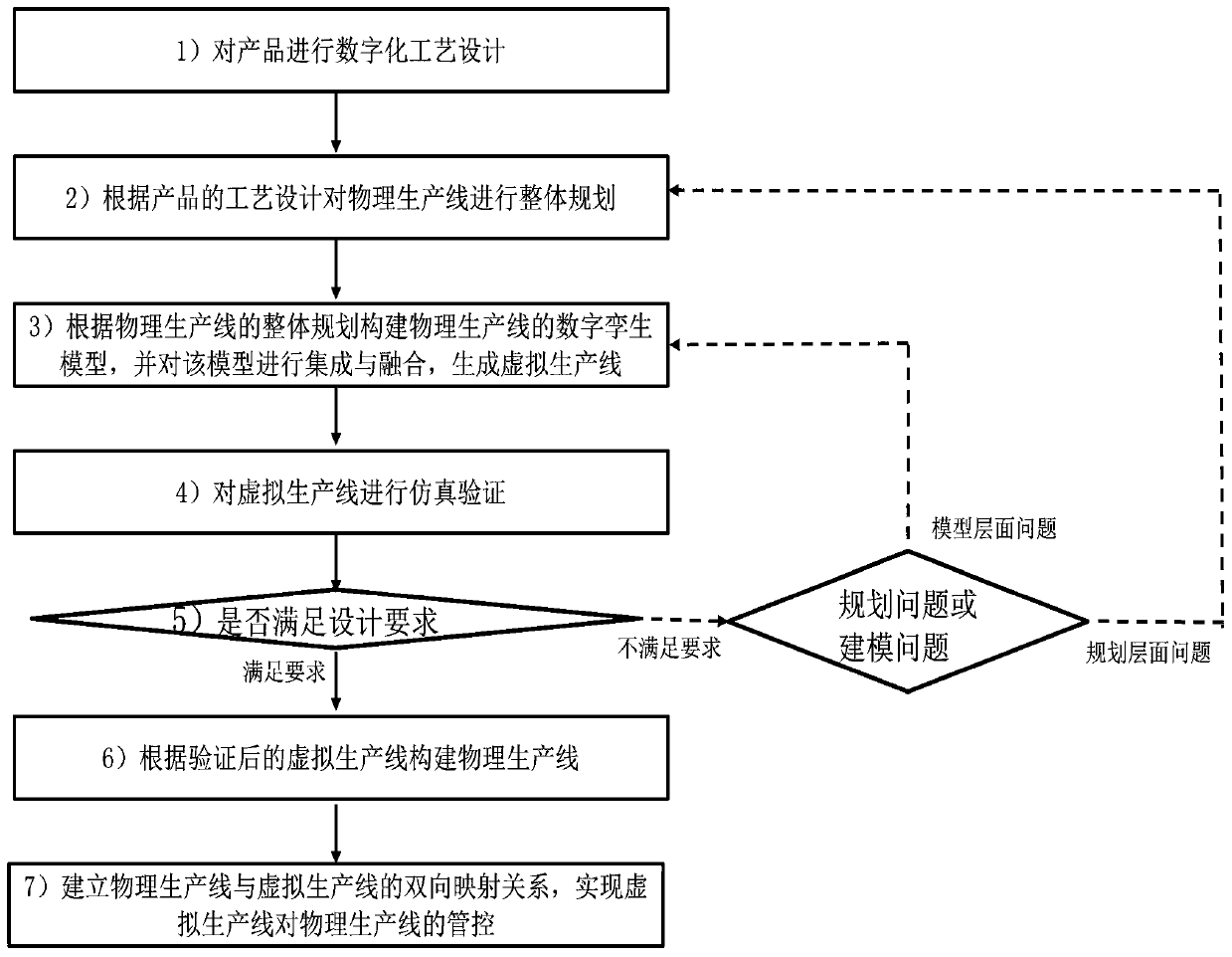

Production line design and optimization method based on digital twinning

PendingCN111061232AEasy to controlHave assessmentForecastingTotal factory controlProduction lineStatistical analysis

The invention relates to a production line design and optimization method based on digital twinning. The production line design and optimization method comprises the following steps: performing digital process design on a product, integrally planning a production line, constructing and integrating a digital twinning model of the production line, performing simulation verification on a virtual production line, constructing and implementing a physical production line, and performing virtual-real mapping and optimization on the production lines. According to the invention, the digital twinning model is constructed according to three levels of elements, behaviors and rules, and has production line evaluation, evolution and reasoning capabilities; a virtual production line model is established,virtual debugging and simulation operation of the virtual production line are achieved, the production line does not need to be constructed firstly, design risks are avoided, and debugging time is saved; and a virtual-real mapping relationship and an interaction mechanism between the virtual production line and the physical production line are established, statistical analysis is performed on theoperation data of the virtual production line, and optimization and management and control on the physical production line are realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

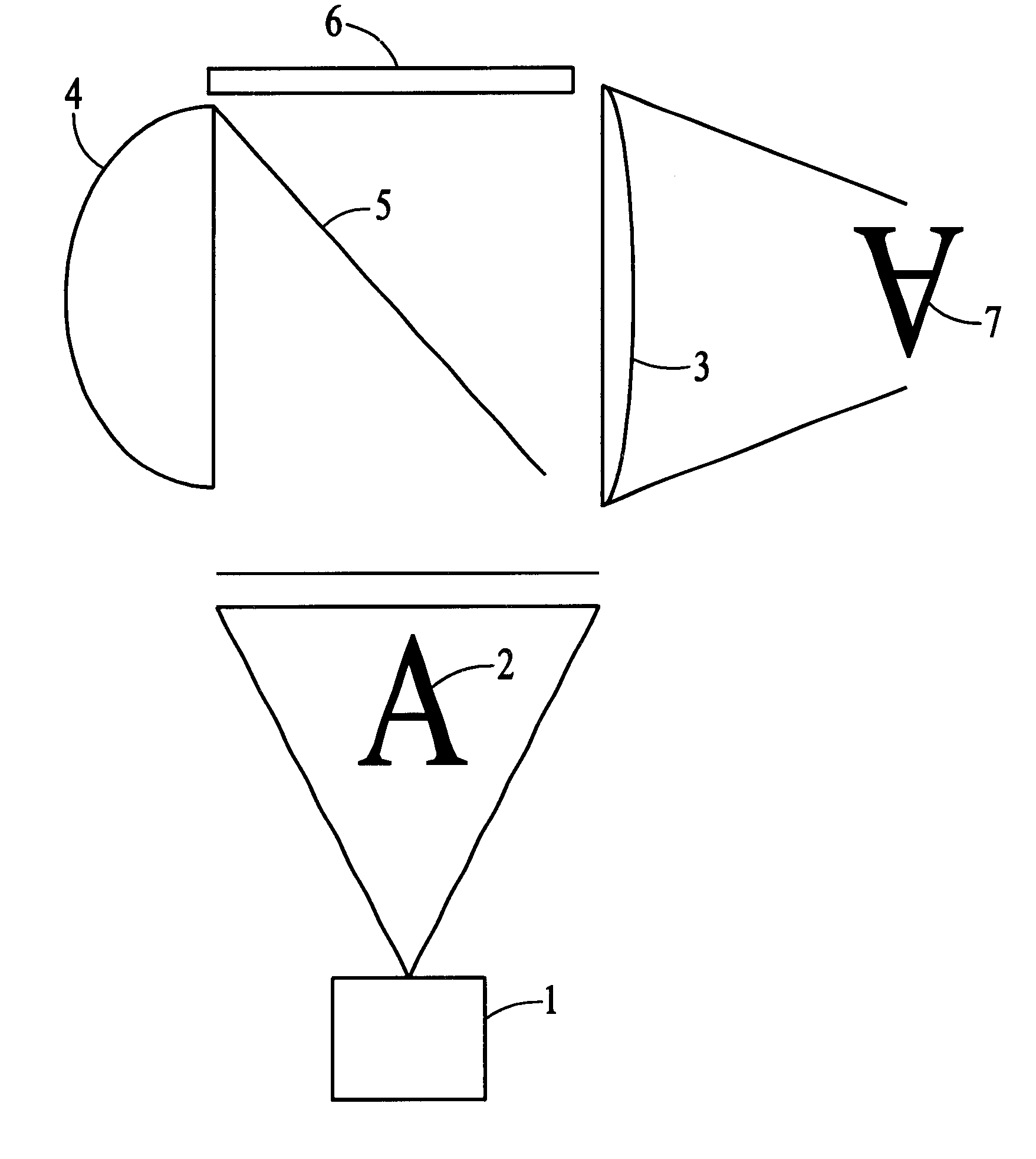

Virtual image projection device

InactiveUS6364490B1Improve viewing angleWiden perspectiveProjectorsOptical elementsFresnel lensOptic system

The invention relates to a device for the virtual production of an image, with a housing, an image projection device, which produces an image to be displayed. The housing has an observation opening in a wall of the housing with a fresnel lens arranged therein. Imaging optics arranged in the housing for depicting the object onto the fresnel lens. In order to ensure a large range of applications for this device, provision is made that the imaging optics have a concave mirror arranged in the path of light rays between the image projection device and the fresnel lens. The concave mirror lies opposite the fresnel lens and a ray divider is provided therebetween. To increase the illusion effect, a partially translucent mirror (spy mirror) is additionally arranged on the observation side of the fresnel lens.

Owner:VANTAGE LIGHTING

Method used for planning production line and apparatus thereof

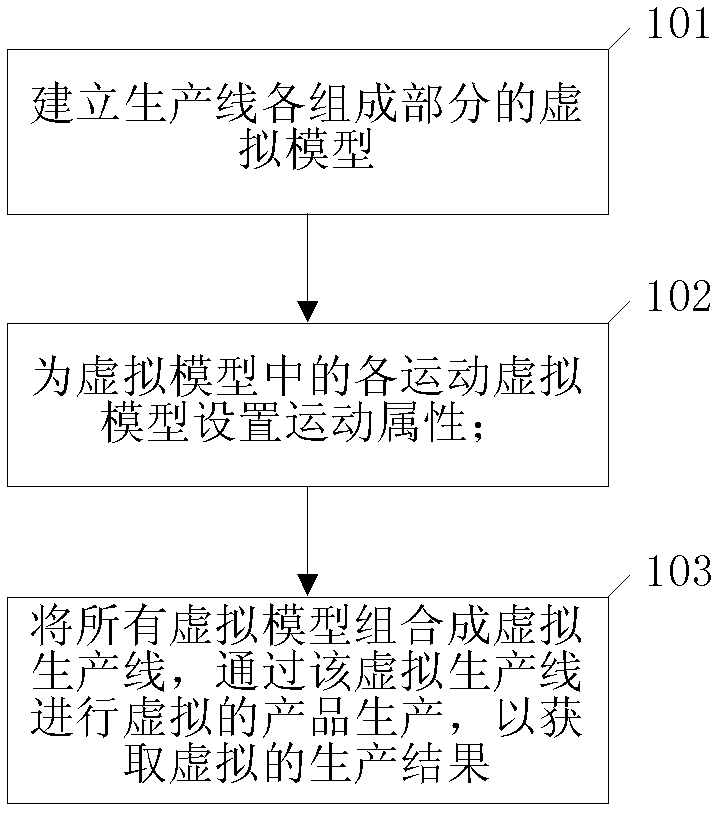

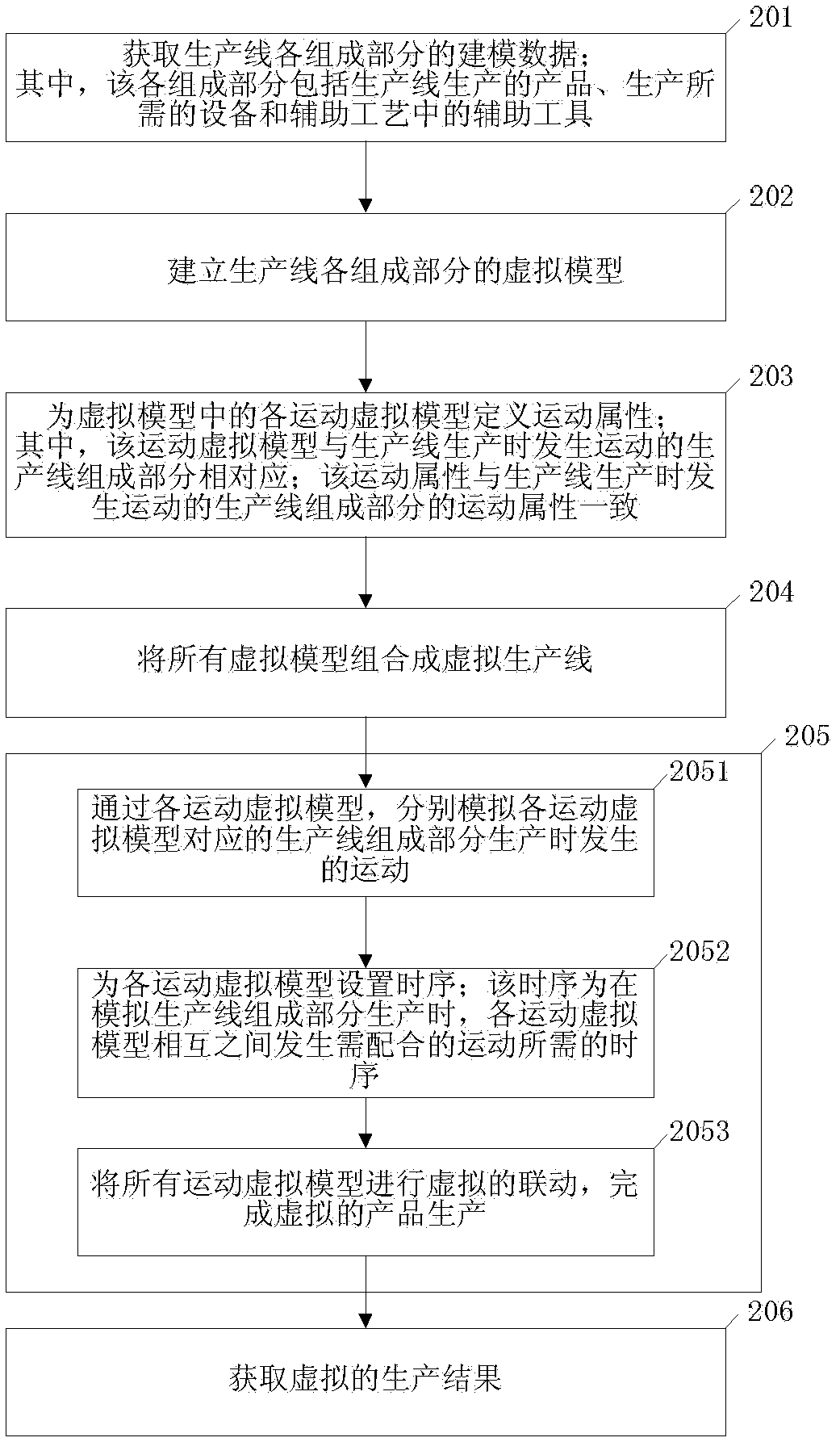

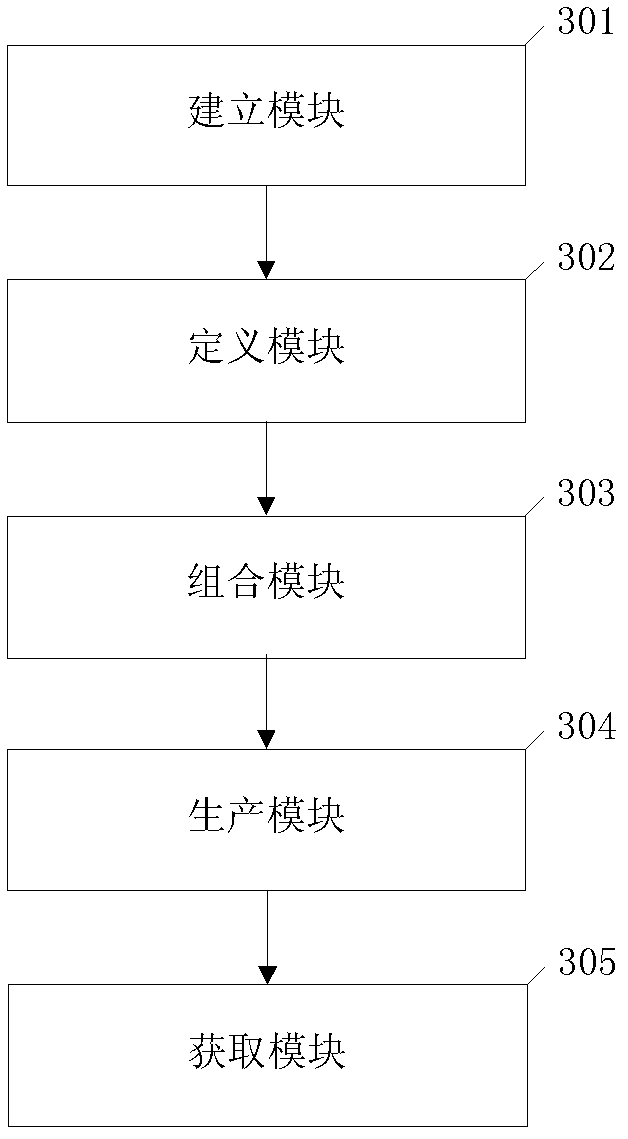

ActiveCN102436236AMeet the process requirementsReduced commissioning timeTotal factory controlProgramme total factory controlProduction lineComputer module

The invention, which belongs to the automation manufacturing field, discloses a method used for planning a production line and an apparatus thereof. The method comprises the following steps: establishing a virtual model of each component in the production line; defining a motion attribute for each moving virtual model in the virtual models, wherein the moving virtual model corresponds with the production line component which moves during production on the production line and the motion attribute corresponds with the motion attribute of the production line component which moves during production on the production line; combining all the virtual models into a virtual production line; carrying out virtual product production through the virtual production line so as to acquire a virtual production result. The apparatus comprises: an establishment module, a definition module, a combination module, a production module and an obtaining module. By using the method and the apparatus of the invention, a motion which is consistent with the motion in on-site production on the production line can be output in a virtual environment. A technology requirement of the on-site production on the production line can be satisfied and a scheme which is suitable for the production site and is used to plan the production line can be acquired.

Owner:CHERY AUTOMOBILE CO LTD

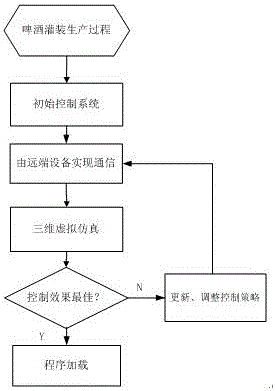

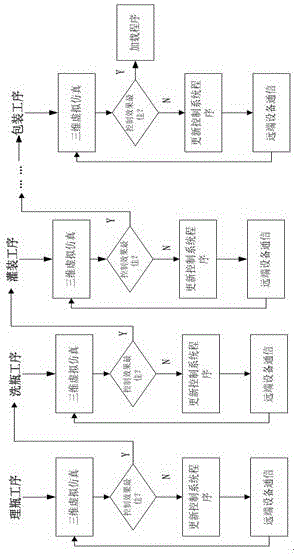

Filling production line control system based on virtual-reality technology and implementation method of filling production line control system

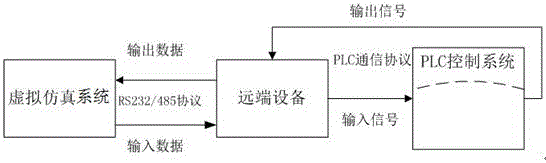

PendingCN106444616AAvoid time consumingAvoid security issuesProgramme control in sequence/logic controllersControl systemAnimation

The invention discloses a filling production line control system based on the virtual-reality technology. The filling production line control system comprises a virtual simulation system, remote equipment and a PLC control system, wherein the virtual simulation system is bidirectionally connected with the remote equipment, and the remote equipment is bidirectionally connected with the PLC control system. The beer filling production line control system based on the virtual-reality technology has the advantages that animated simulation of a beer production line filling process can be performed, a control strategy can be applied to each process or object in a virtual environment through the interaction module of the virtual environment and an entity PLC so as to intervene and control a virtual production line, animated demonstration is updated in real time after the control measure is applied, the optimal control strategy and scheme of the production line can be determined fast, the filling process is fast and stable, the process is strict, and the system is promising in market prospect.

Owner:启东威艾信息技术有限公司

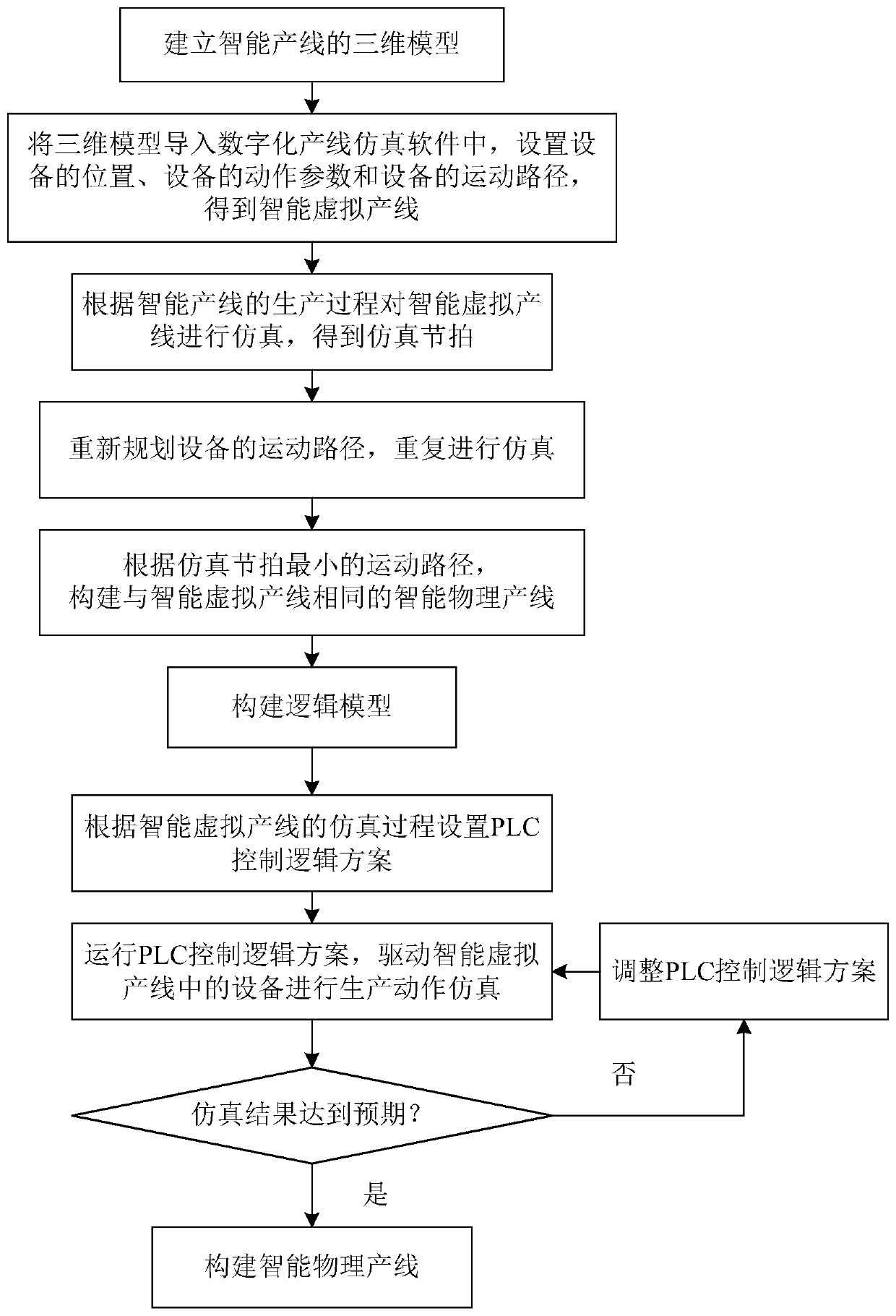

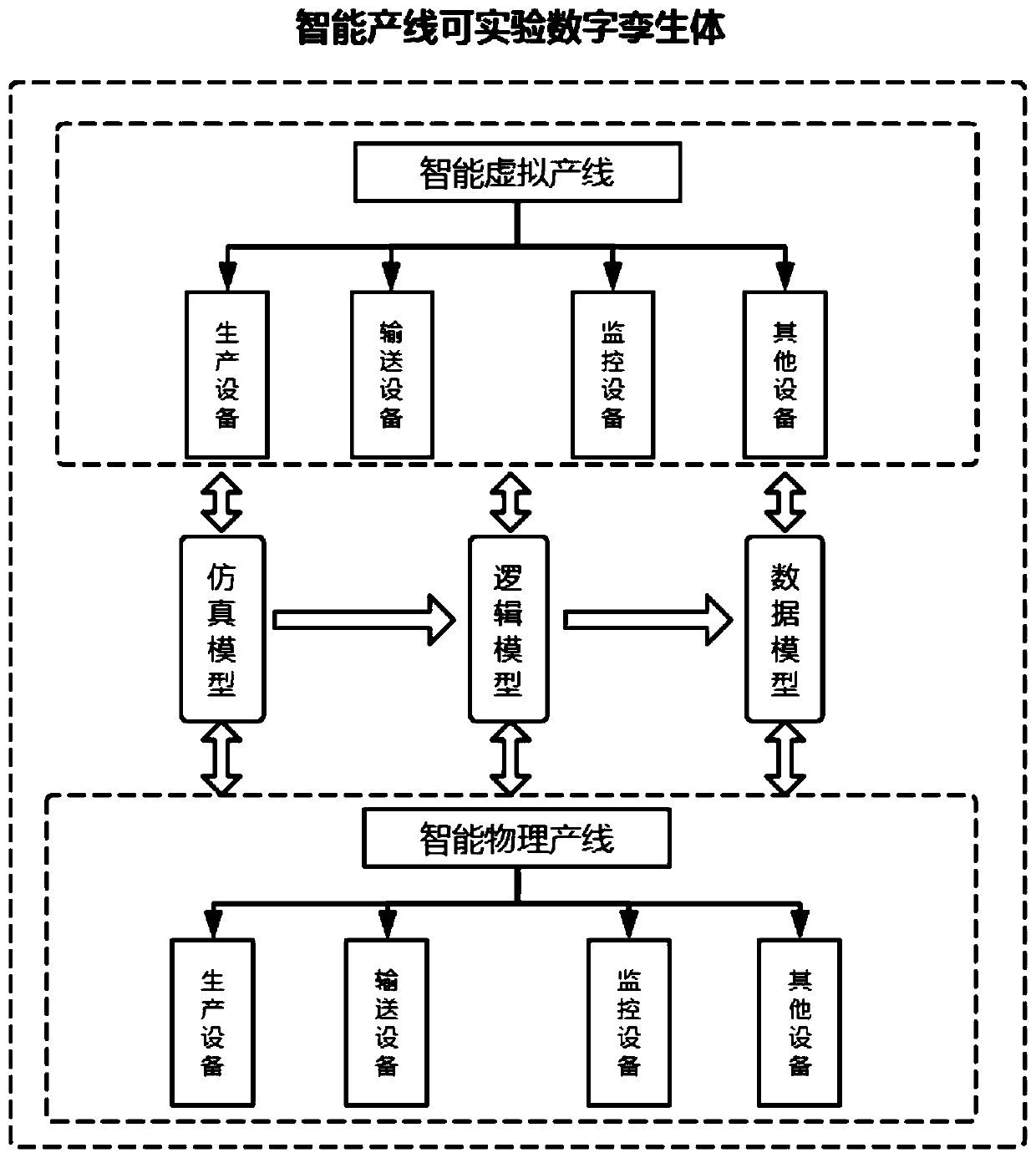

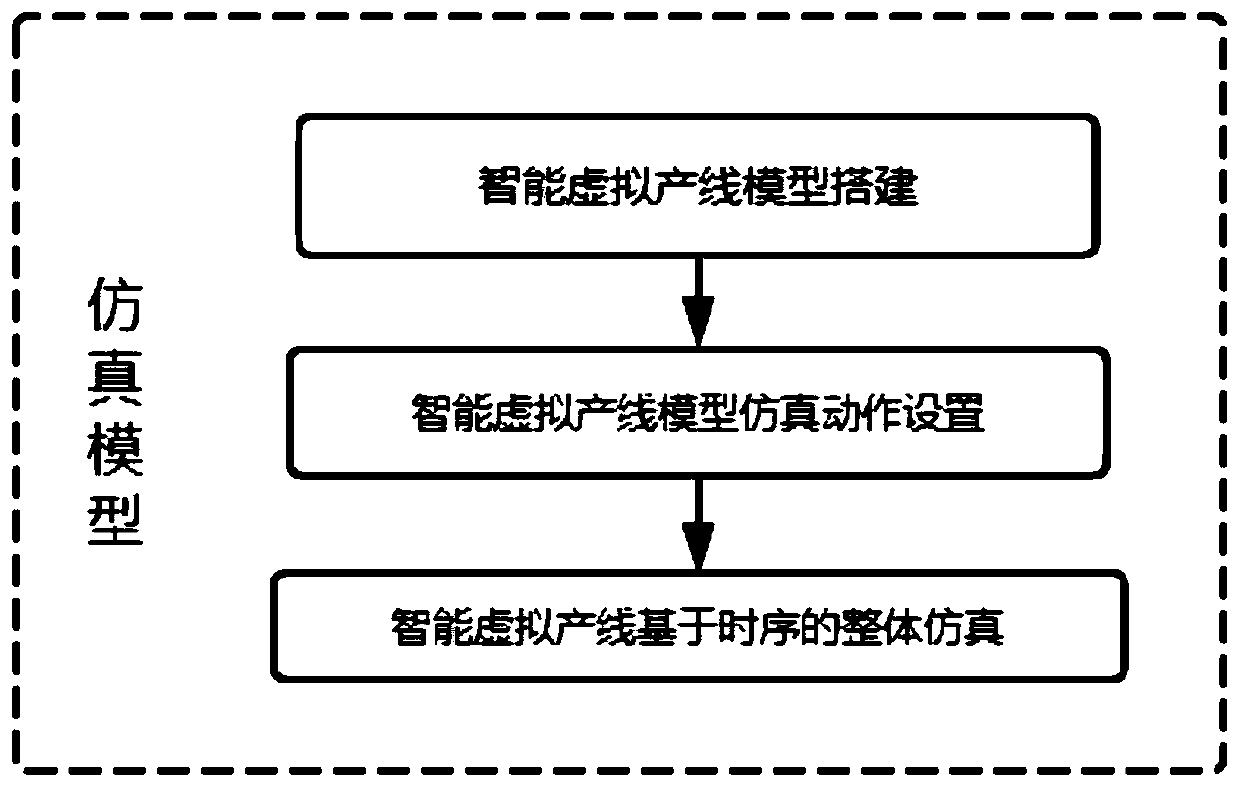

Testable digital twinning body modeling method for intelligent production line

ActiveCN111046589AReduce build timeReduced commissioning timeDesign optimisation/simulation3D modellingProduction lineModelSim

The invention provides a testable digital twinning body modeling method for an intelligent production line, and the method comprises the steps: firstly building a three-dimensional model of equipmentin the intelligent production line through digitalized modeling software, and importing the three-dimensional model into digitalized production line simulation software to obtain an intelligent virtual production line; secondly, planning motion paths of the equipment, simulating the intelligent virtual production line to obtain simulation beats until all the motion paths are traversed, and exporting the motion path with the smallest simulation beat to construct an intelligent physical production line which is the same as the intelligent virtual production line; and finally, setting a PLC control logic scheme according to the simulation process of the intelligent virtual production line so as to drive equipment of the intelligent virtual production line to perform production action simulation, so that the production actions of the intelligent physical production line and the intelligent virtual production line are kept consistent, and the construction of the testable digital twinning body of the intelligent production line is completed. Key information and operation data of the intelligent physical production line can be reflected in real time by operating the intelligent virtual production line, the production line building and debugging time is shortened, the project period is shortened, and the project cost is reduced.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

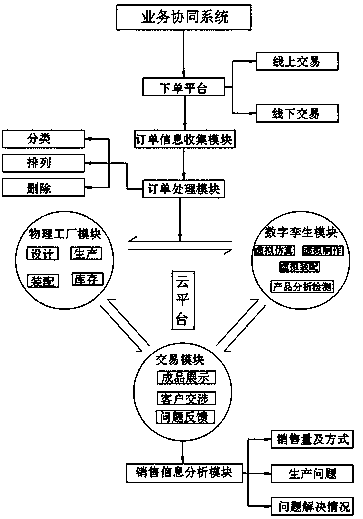

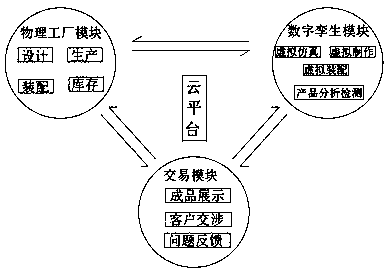

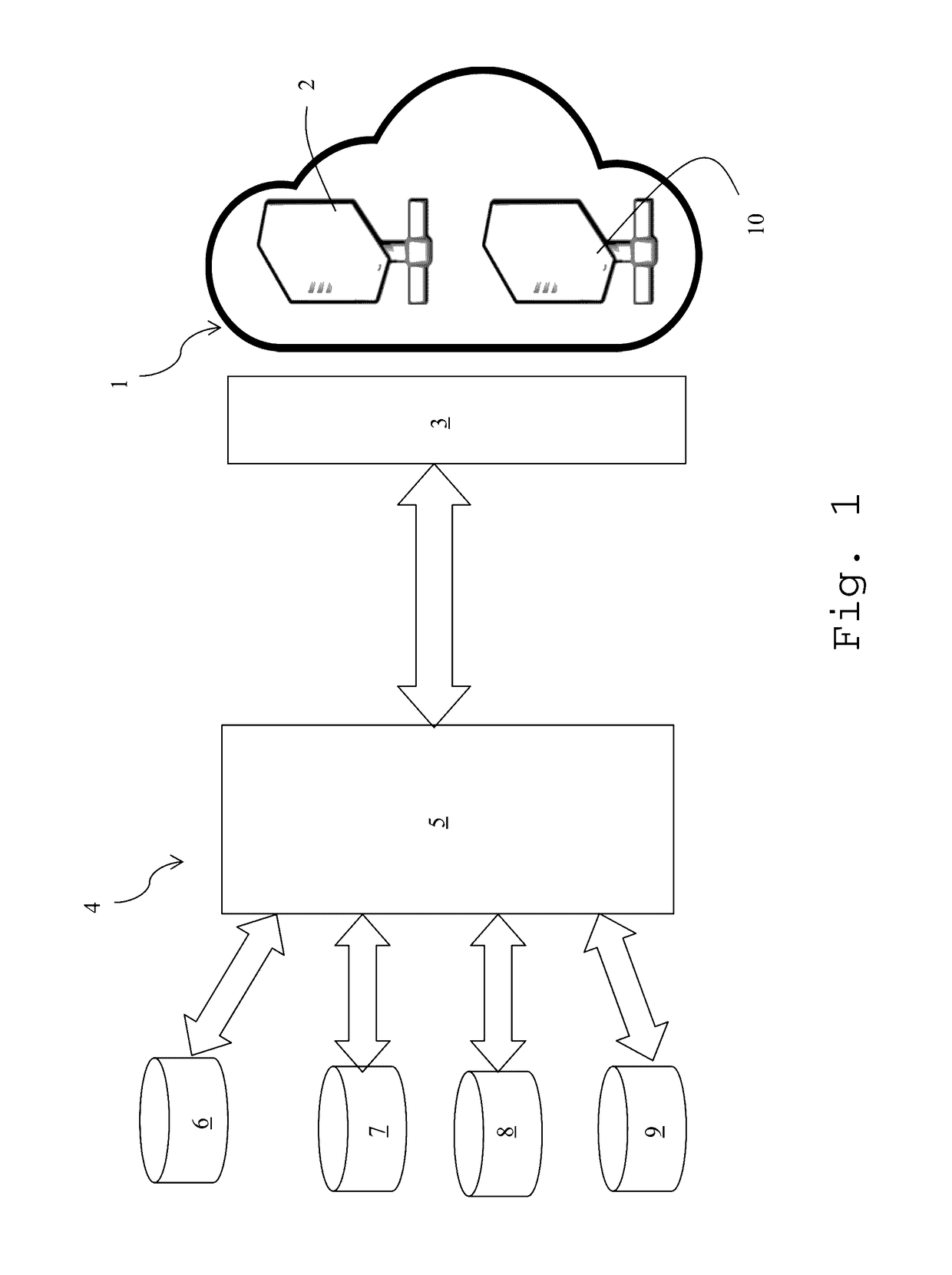

A virtual factory service collaboration system based on a digital twinning technology

InactiveCN109559039AAchieve synergyEasy to useResourcesManufacturing computing systemsVirtual productionClosed loop

The invention discloses a virtual factory service collaboration system based on a digital twinning technology. The system includes a physical plant module, a digital twinning module and a transactionmodule., The system is scientific and reasonable, safe and convenient in use, and is provided with a physical plant module, a digital twinning module and a transaction module, the cloud platform is used for carrying out real-time mutual communication on information among the three parts; the digital twinning module is sued for making systematic planning on different aspects including to-be-manufactured products, manufacturing modes, resources and locations; all the aspects are associated; collaboration of design personnel and manufacturing personnel is realized; the physical plant module, thedigital twin module and the transaction module build a closed loop for planning and execution, the digital twin module is used for combining a virtual production world and a real production world, thedigital twin module is used for generating detailed operation instructions to associate with the whole process of the physical factory module design and transaction module, and the production efficiency is improved.

Owner:贵州航天云网科技有限公司

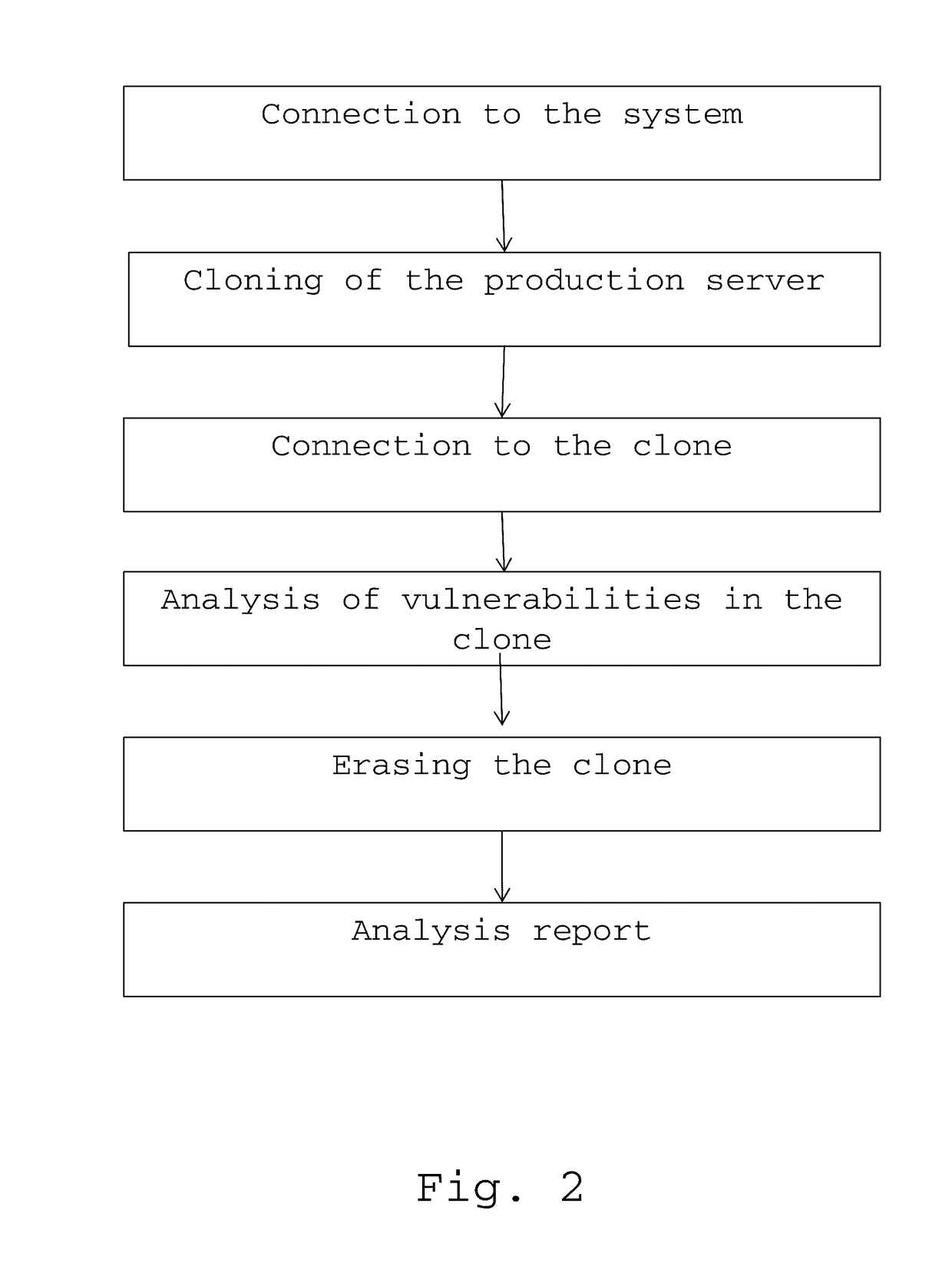

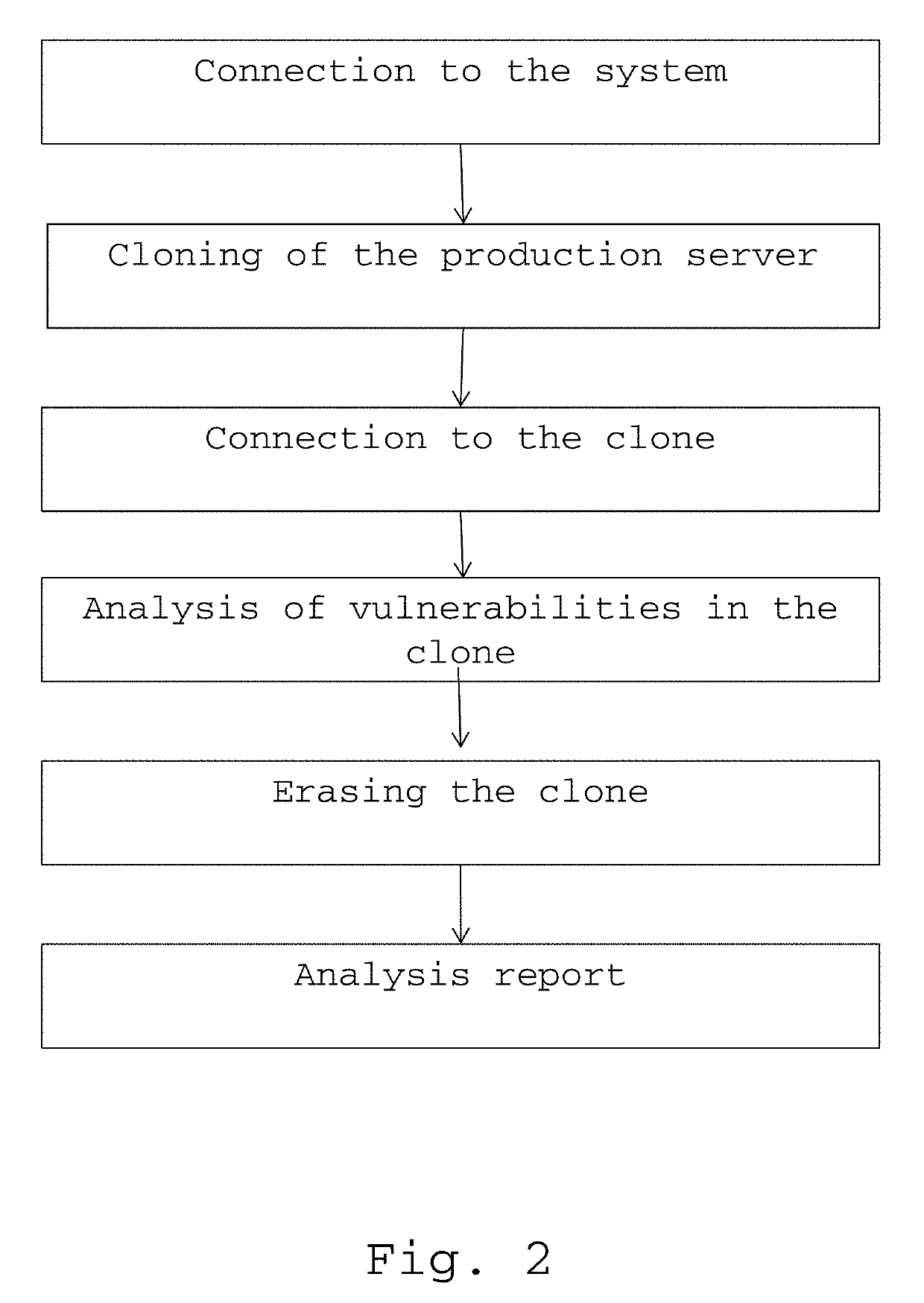

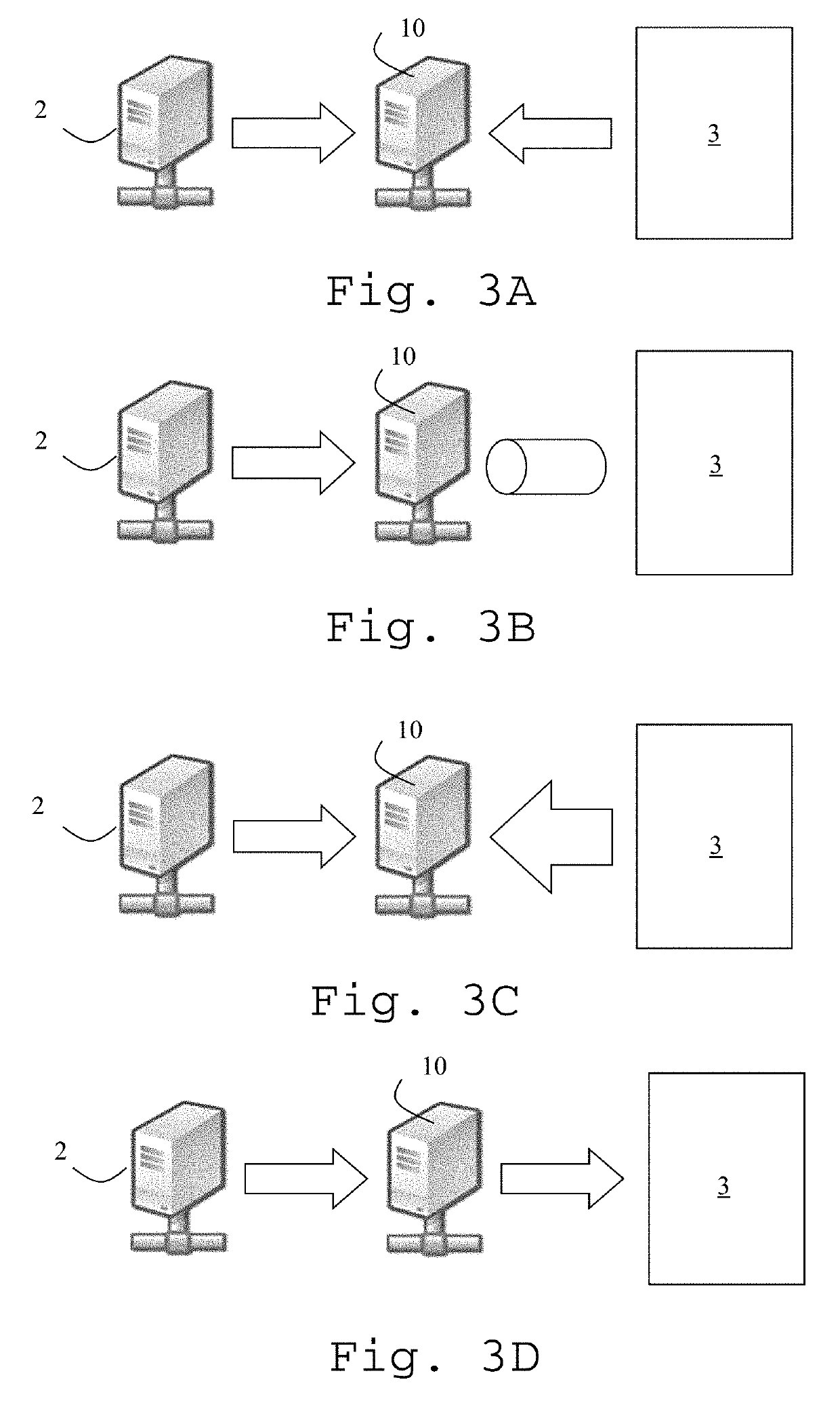

Method for detecting vulnerabilities in a virtual production server of a virtual or cloud computer system

ActiveUS20170111384A1Low costComputer security arrangementsTransmissionSystems analysisVirtual production

The invention relates to a method for detecting vulnerabilities in a virtual production server of a virtual or cloud computer system, said system comprising one or more virtual servers. The invention comprises the following steps: a system for analyzing vulnerabilities in the virtual production servers is provided; the system for analyzing vulnerabilities connects to the virtual or cloud computer system; the system for analyzing vulnerabilities requests the cloning of the virtual production server in order to obtain a clone or a disk copy of the virtual production server; the clone or the disk copy is created in the virtual or cloud computer system; the system for analyzing vulnerabilities connects to the clone or to the disk copy; the system for analyzing vulnerabilities analyzes the vulnerabilities of the clone or of the disk copy; the clone or the disk copy is erased; a report analyzing the vulnerabilities of the clone or of the disk copy is generated.

Owner:OUTPOST 24 FRANCE

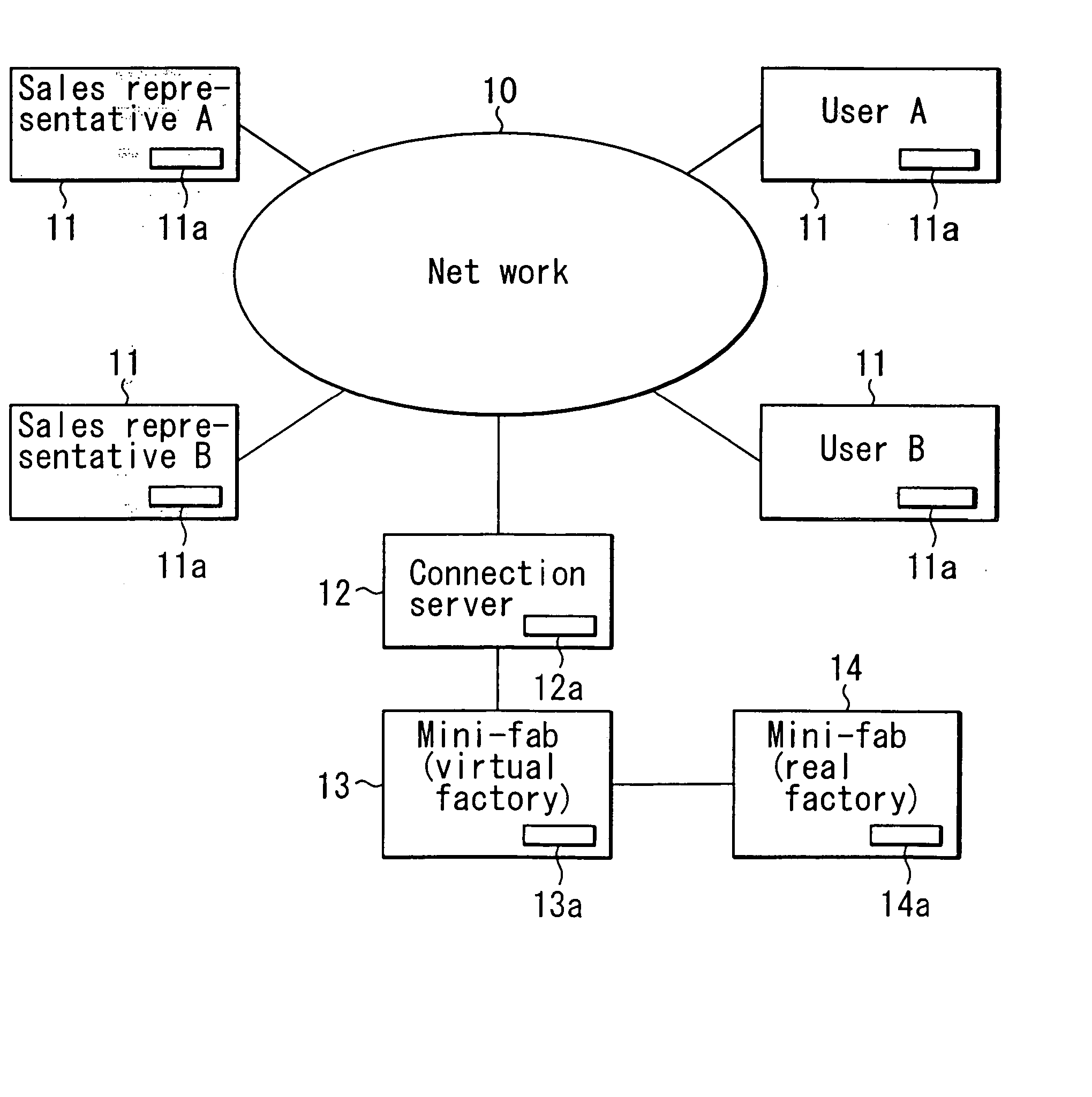

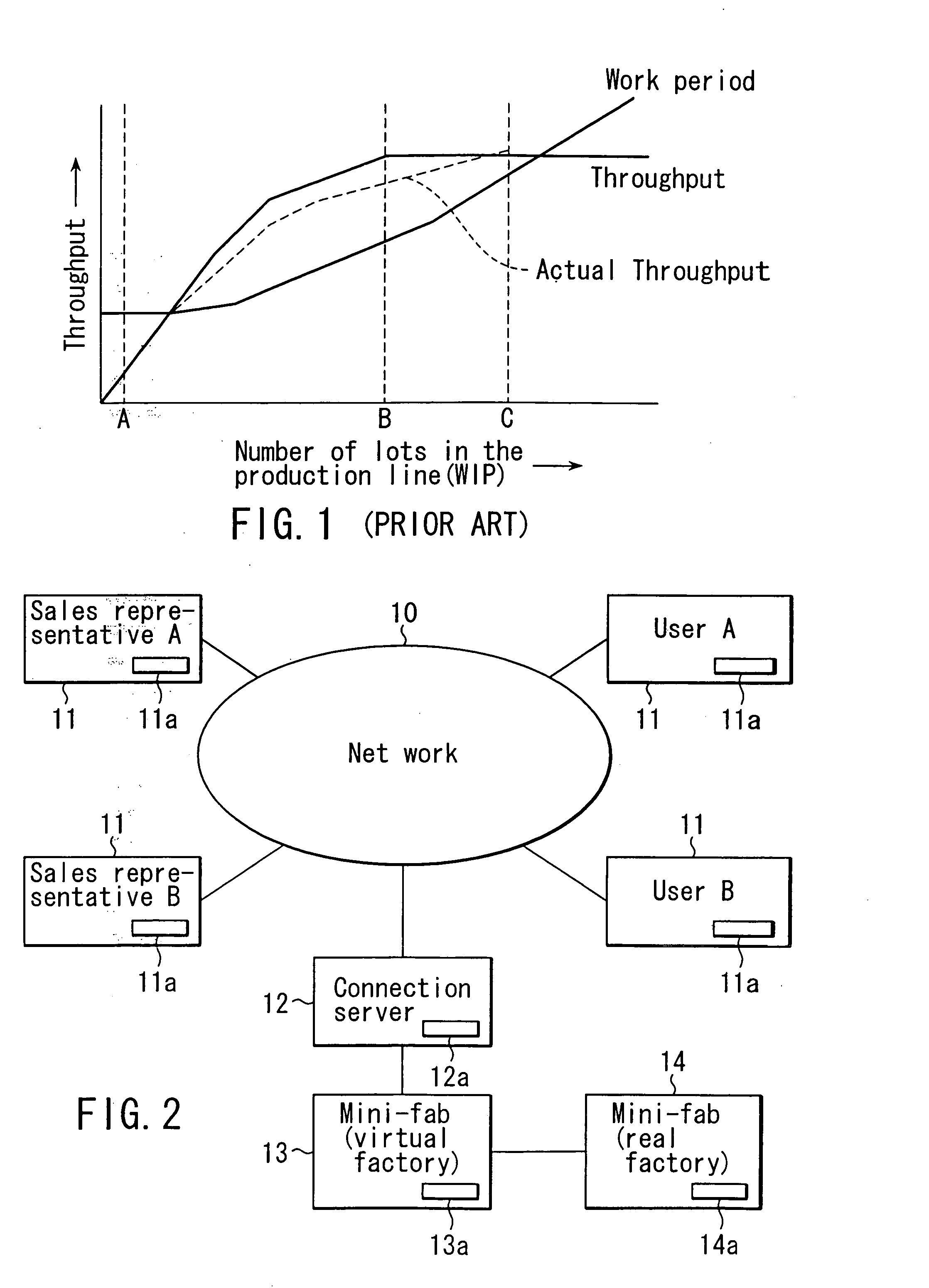

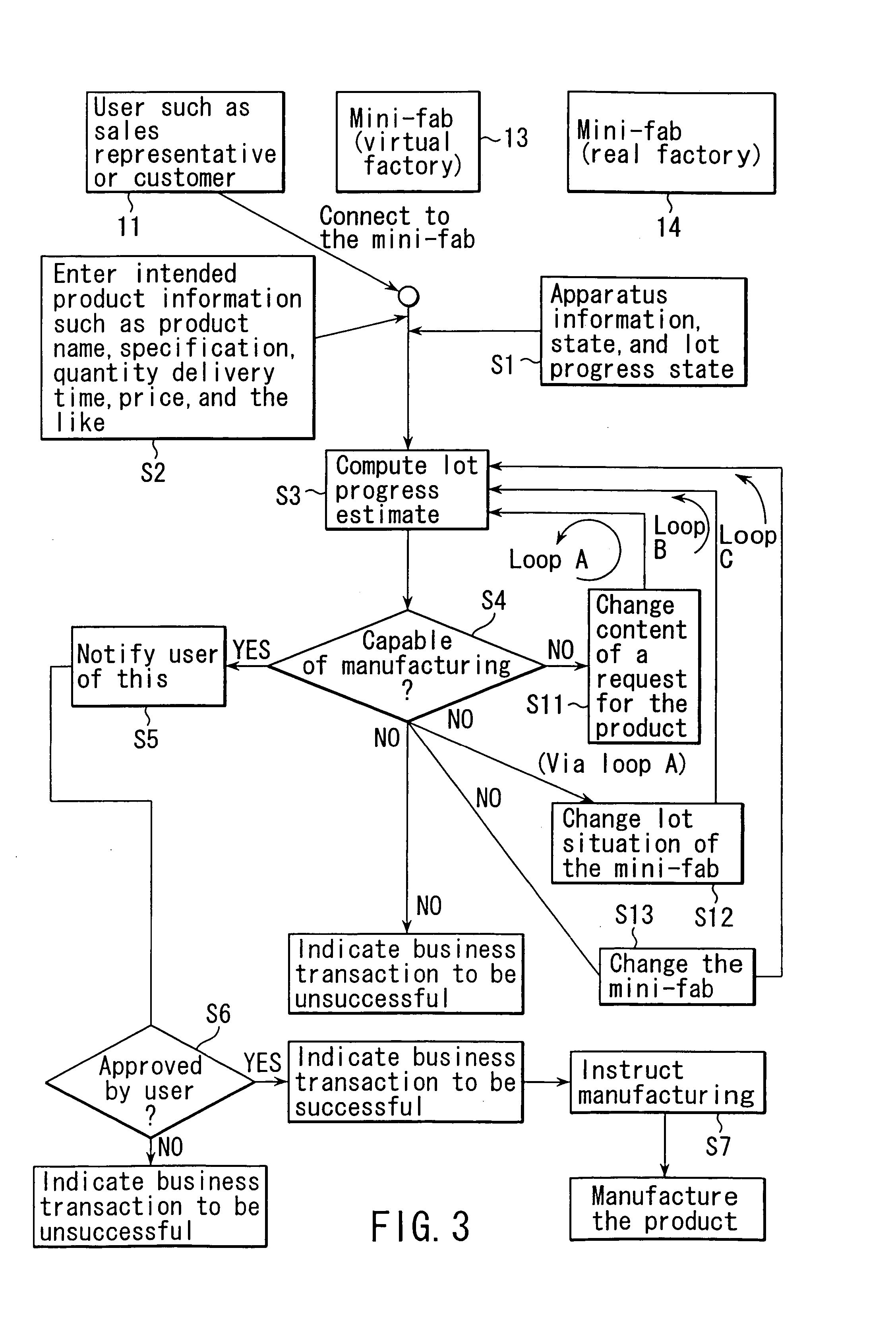

Electronic commerce method for semiconductor products, electronic commerce thereof, production system, production method, production equipment design system, production equipment design method, and production equipment manufacturing method

InactiveUS20050010492A1Increase business opportunitiesBuying/selling/leasing transactionsResourcesProduction lineE-commerce

Owner:MITSUTAKE KUNIHIRO +1

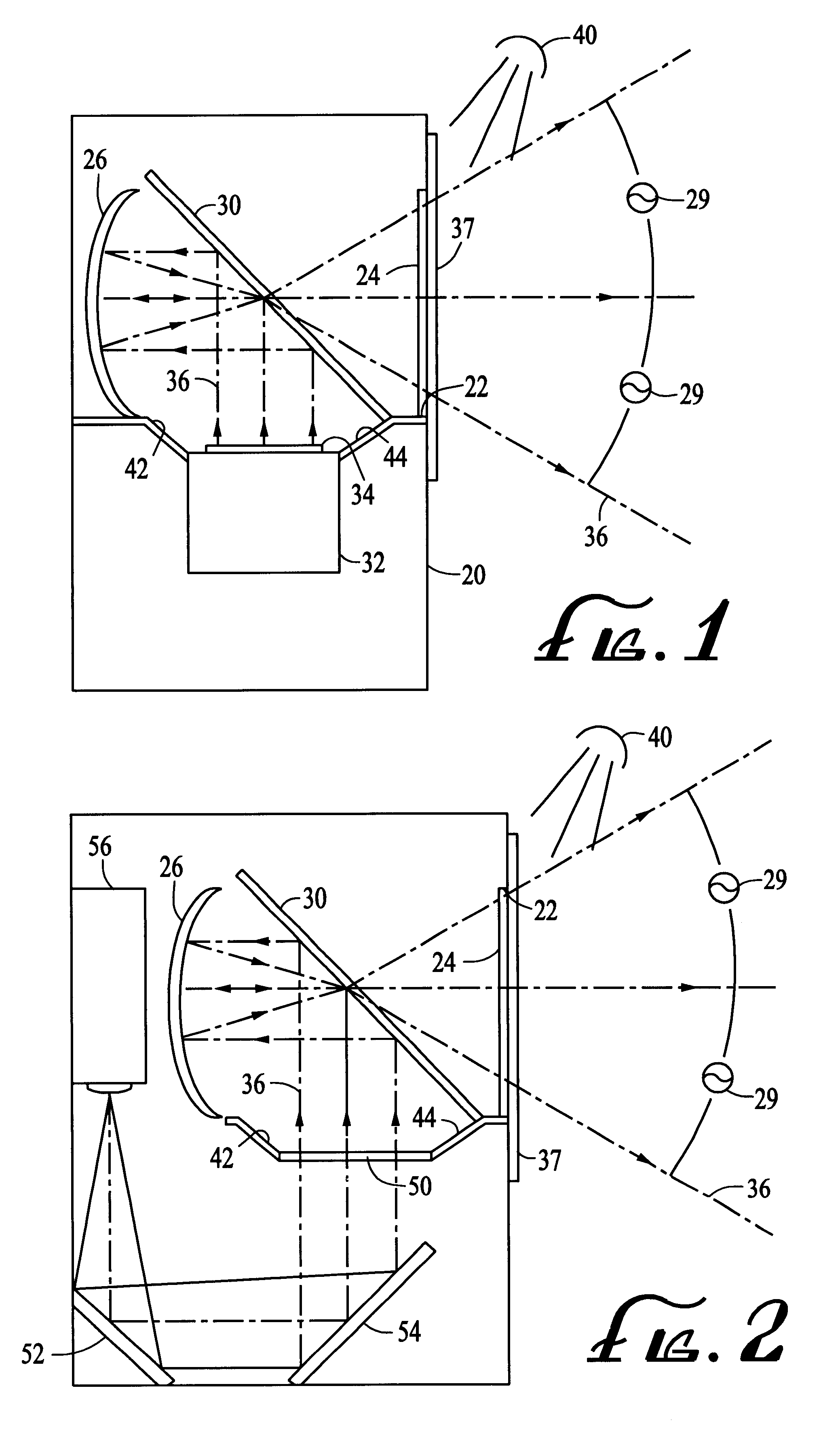

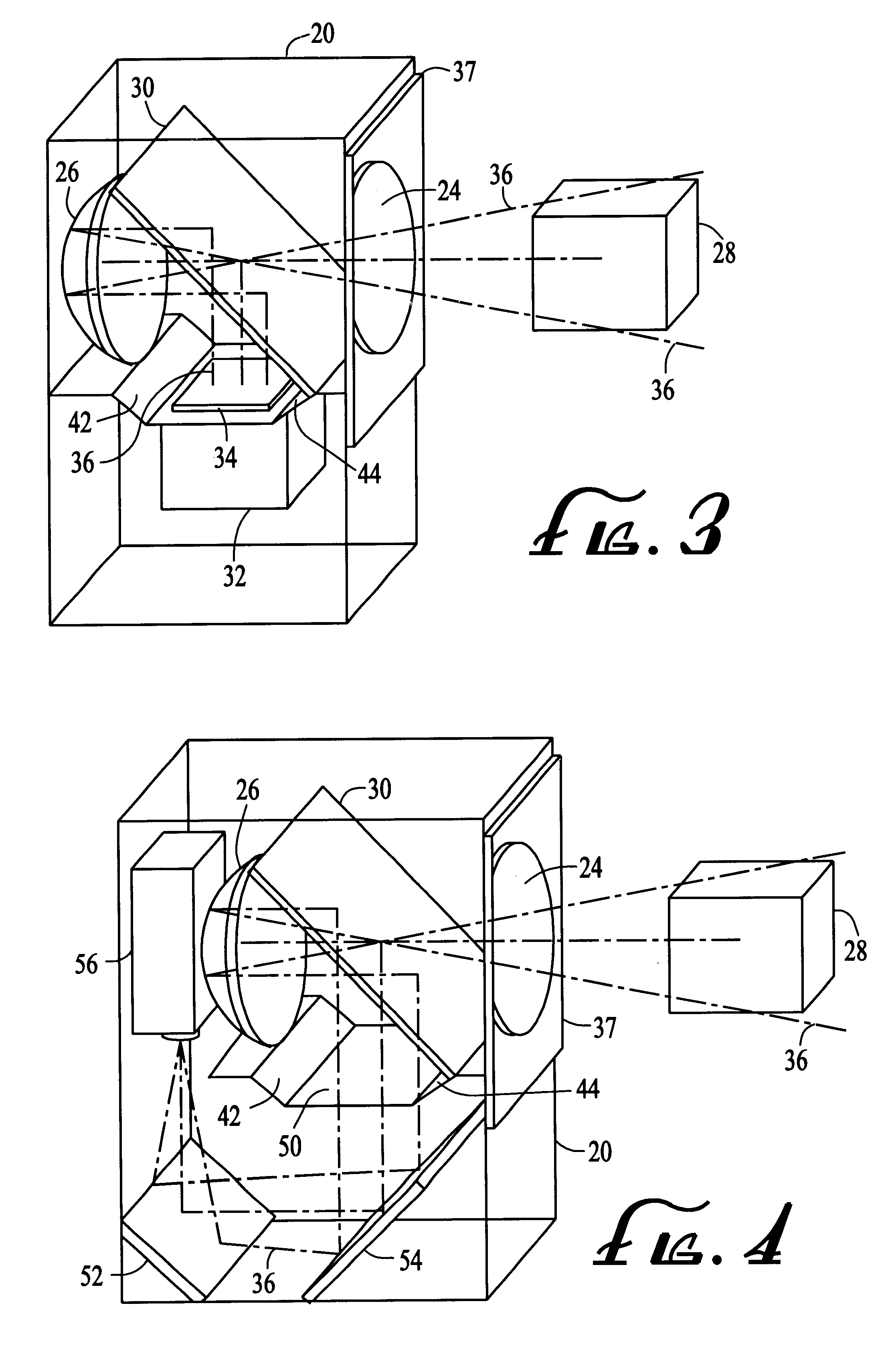

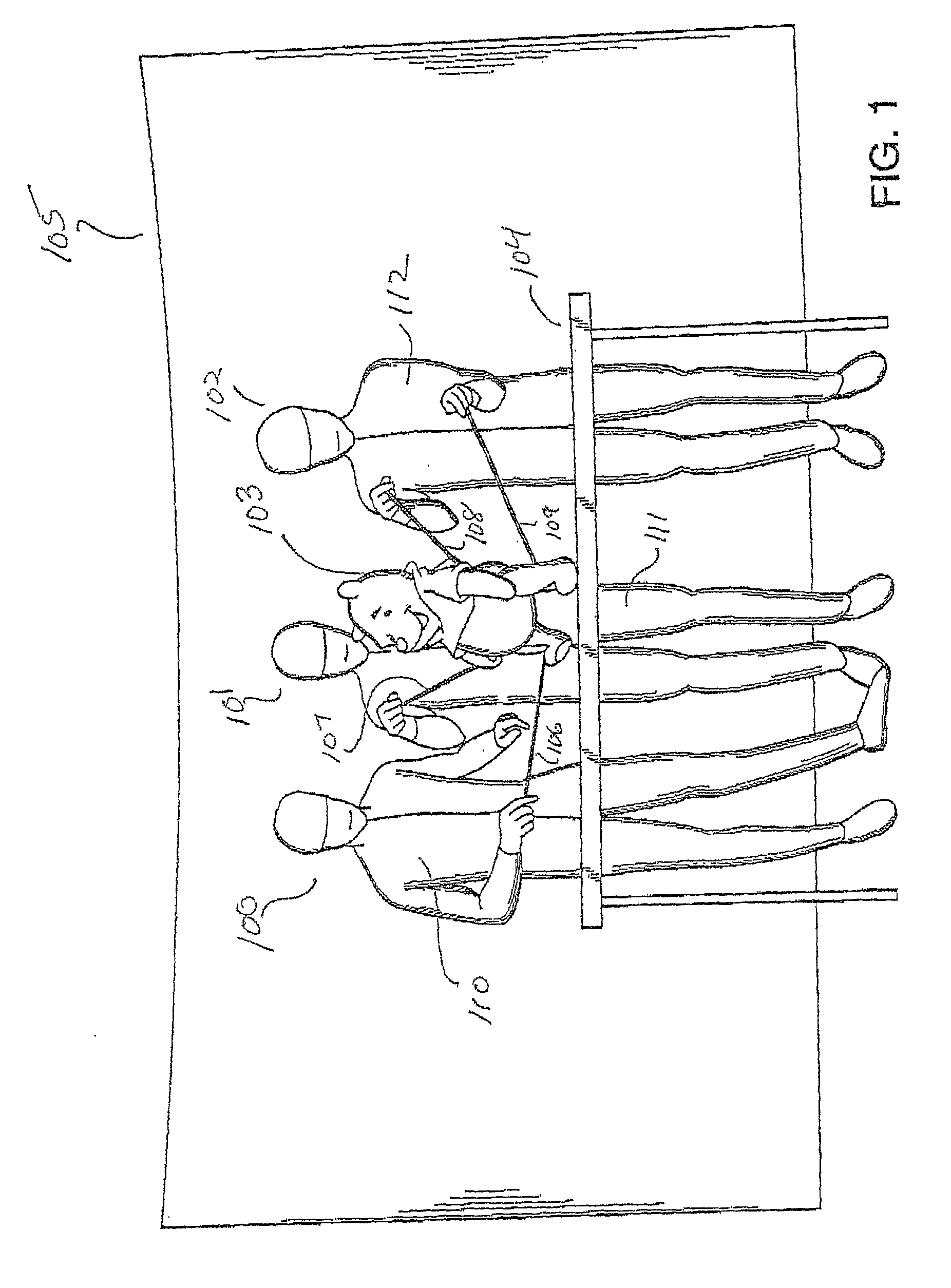

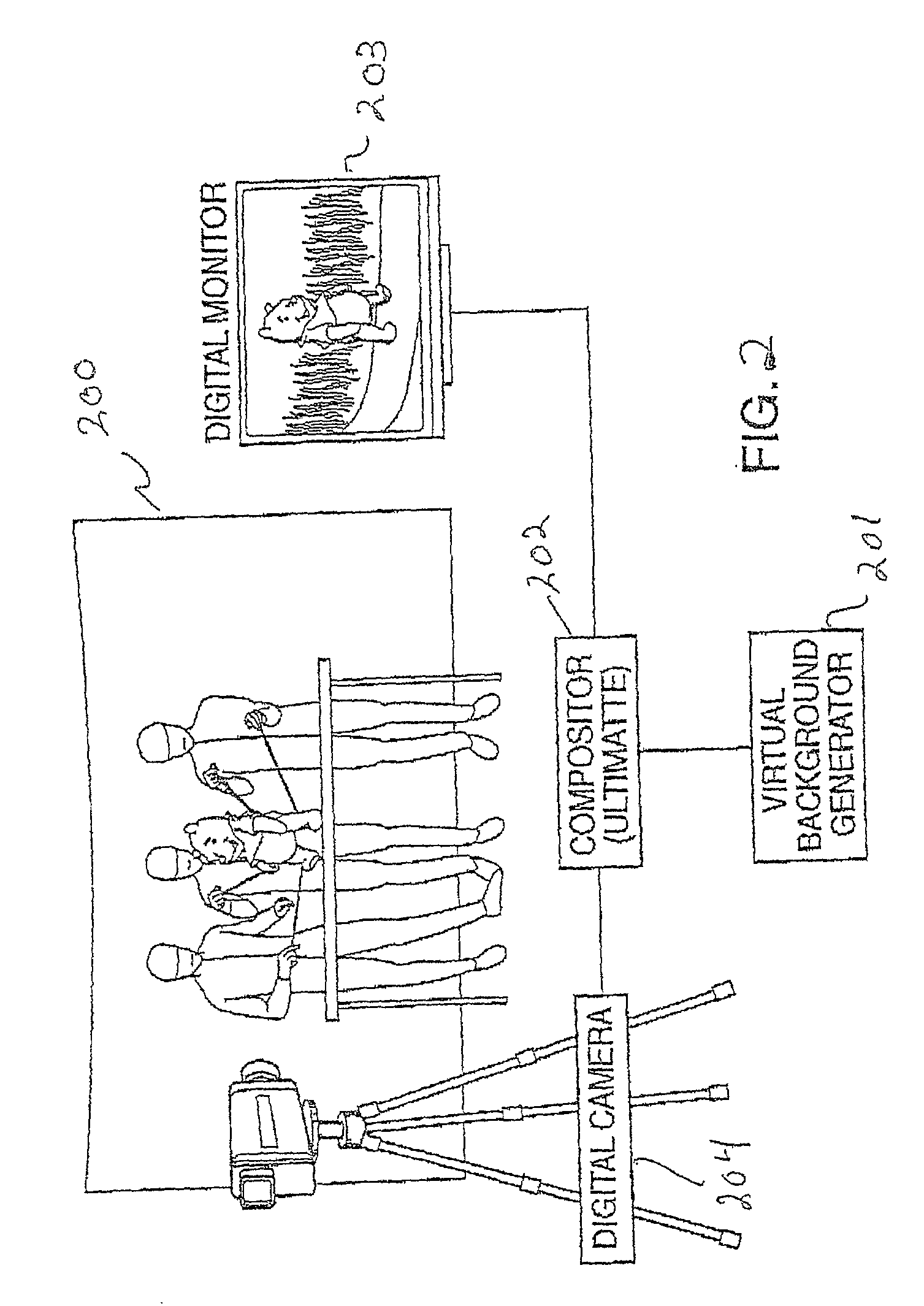

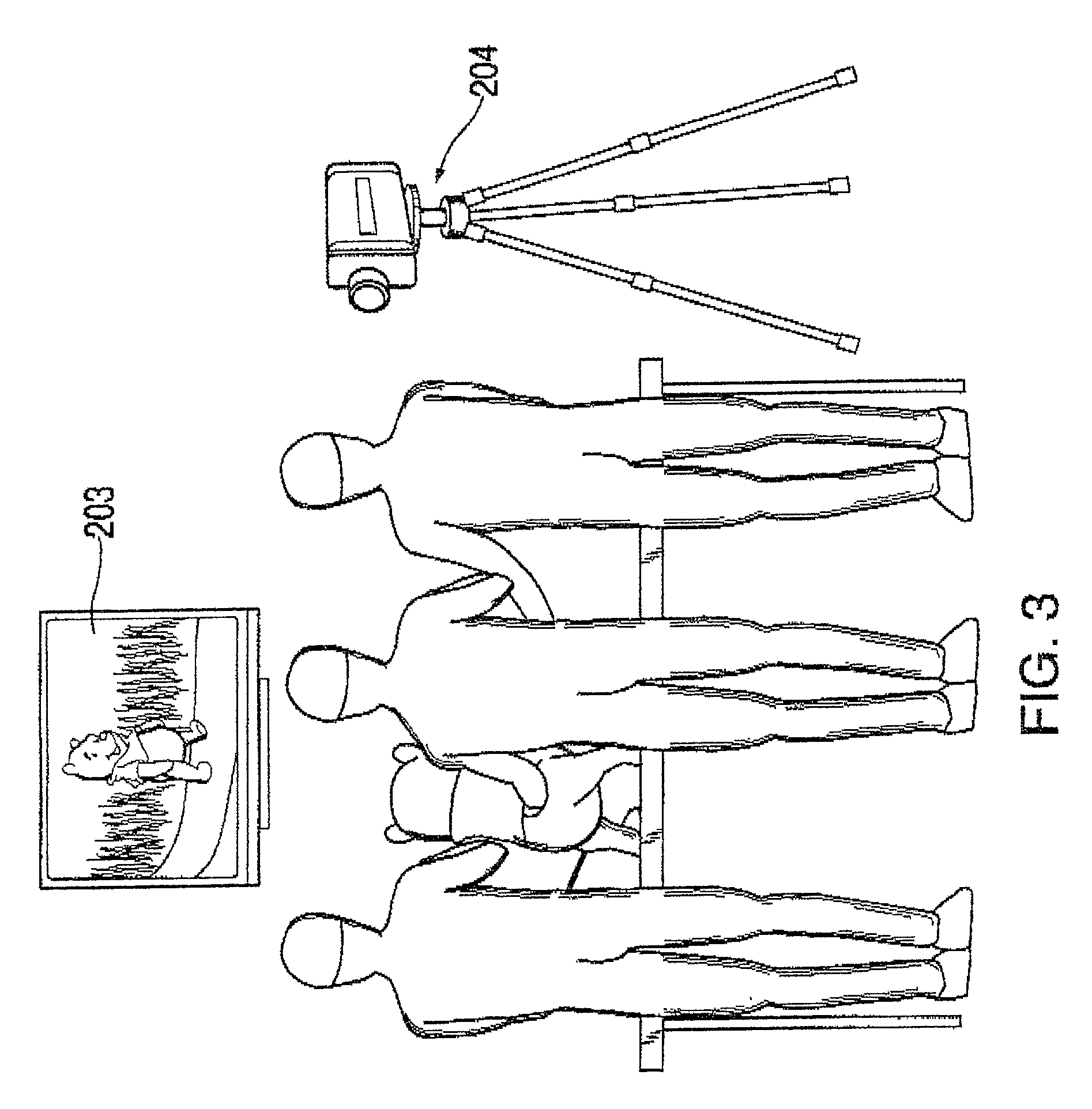

System & method for compositing of real and virtual images in a cinematographic puppetry production

InactiveUS20010024533A1Permit useEffective on-the-fly changeTelevision system detailsColor signal processing circuitsAnimationVideo production

An improved cinematographic system for creation of a film and / or video productions wherein the action figures are puppets controlled by rods, manipulated by puppeteers, on a virtual production set. In the system and method of this invention, one or more production set props are positioned within the studio set between the puppeteers and the puppet. In order to avoid puppeteer cross of the set props while manipulation of the puppet, one or more real production set props, or components of real production set props, are key-colored to a background screen of the virtual production set, and thereby initially eliminated from the cinematographic reproduction of the real / action images of the action figures on the set. Thereafter, the real / action image is composited with at least one virtual image (virtual image of the production set prop and a virtual image of a background scene of the real / action image) to complete the cinematographic composition.

Owner:KRIEGMAN MITCHELL

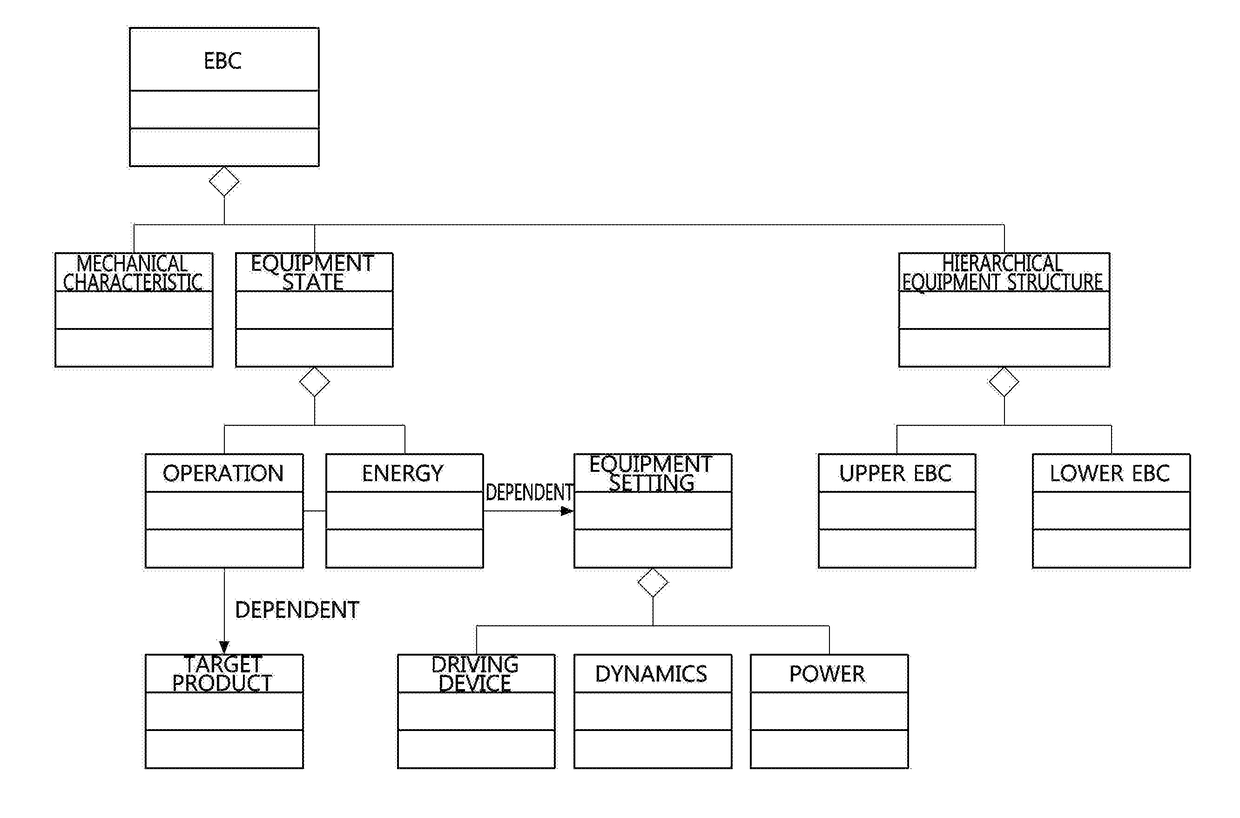

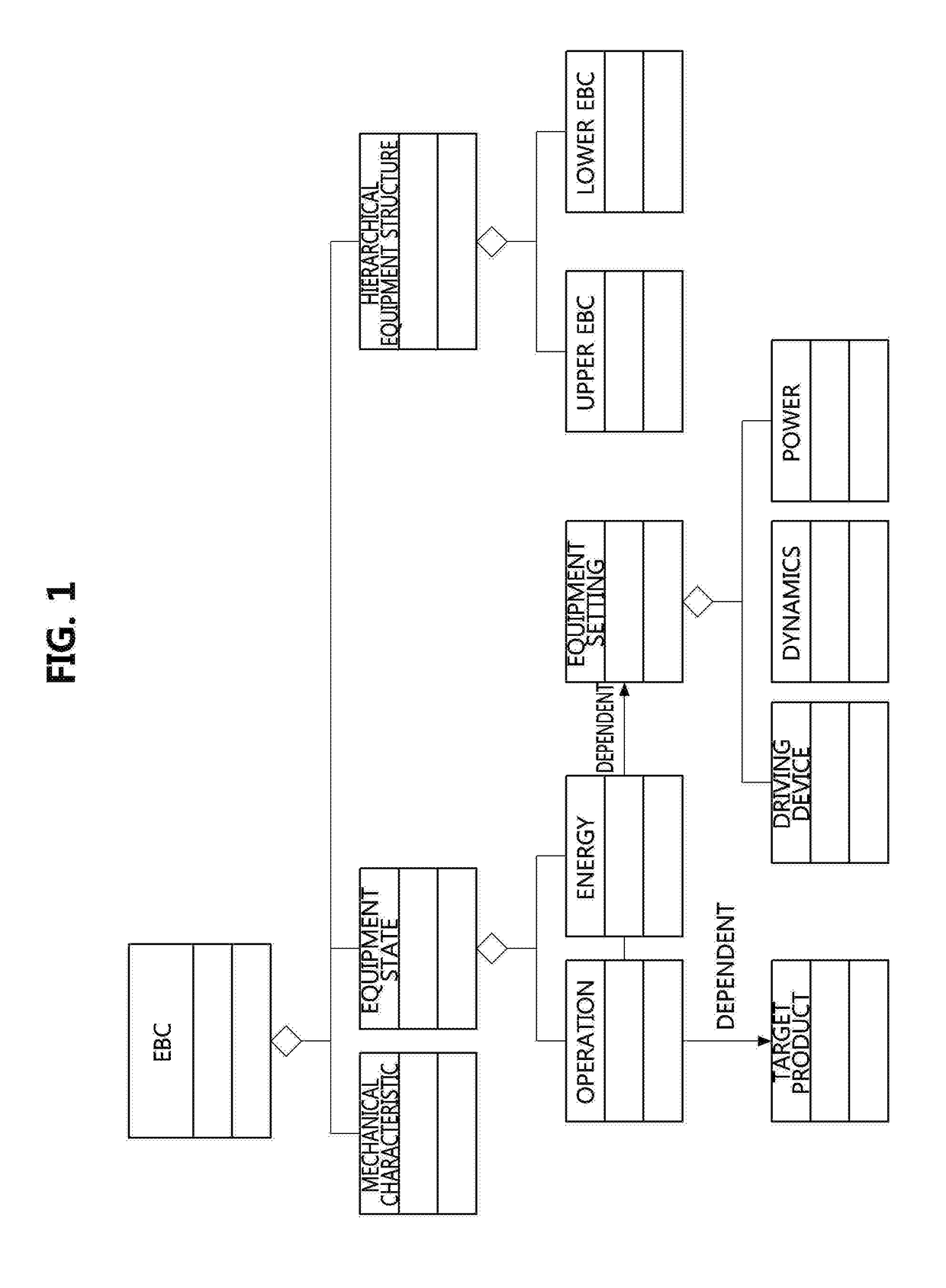

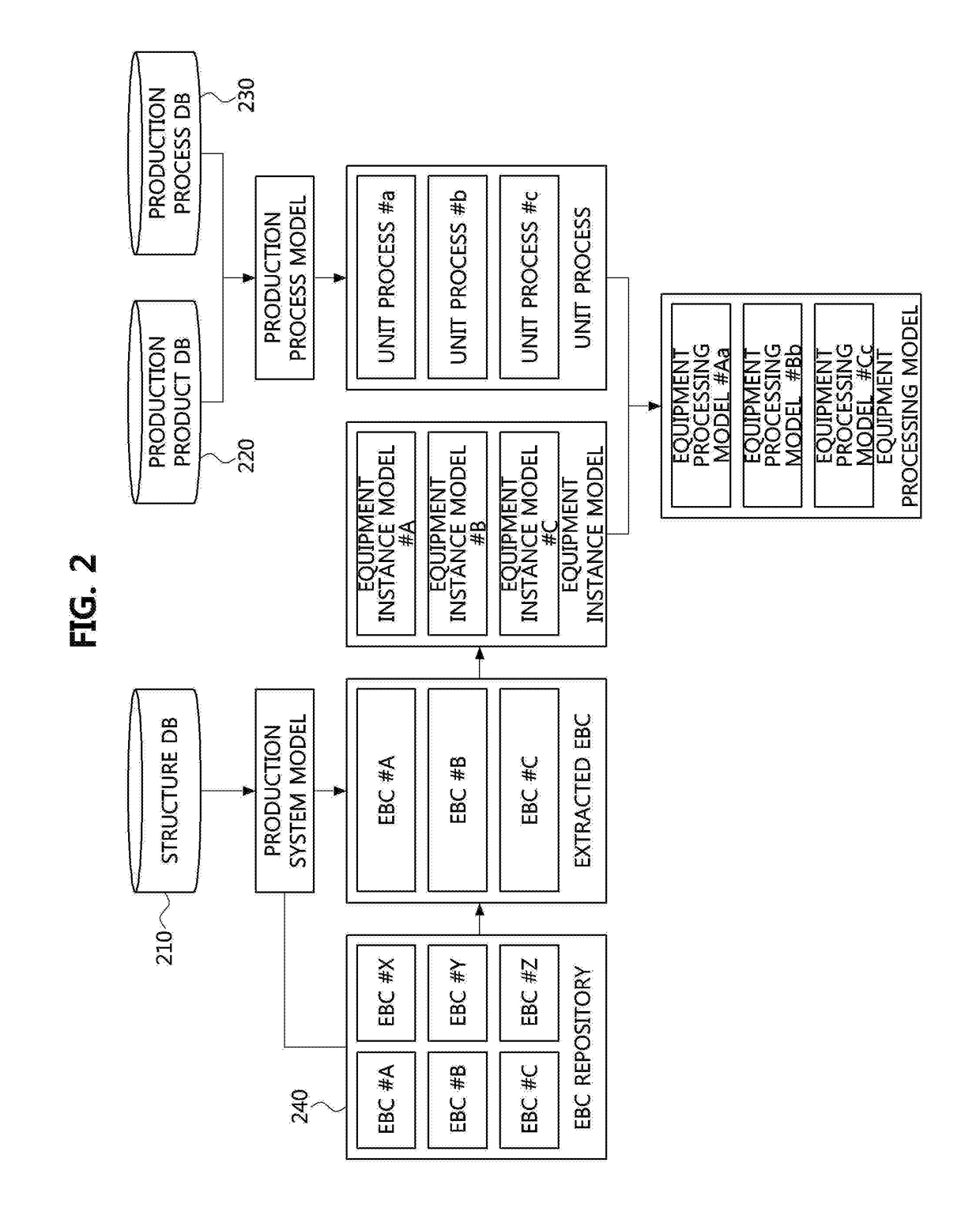

Method and apparatus for registering virtual equipment for virtual production system

InactiveUS20180239342A1Accurate predictionProvide convenienceDatabase distribution/replicationDesign optimisation/simulationVirtual plantVirtual device

A method of registering virtual equipment for a virtual production system includes generating a production system model and a production process model of a virtual factory on the basis of a structure database (DB), a production DB, and an operation DB, extracting a plurality of equipment behavior catalogs (EBCs) regarding a plurality of pieces of virtual equipment used in the virtual factory from an EBC repository on the basis of the production system model, generating and simulating a plurality of equipment processing models on the basis of the plurality of EBCs and the production process model, and generating an EBC set on the basis of the plurality of EBCs when a result of the simulation satisfies a predetermined criterion.

Owner:ELECTRONICS & TELECOMM RES INST

Method for detecting vulnerabilities in a virtual production server of a virtual or cloud computer system

ActiveUS10412109B2Low costPlatform integrity maintainanceTransmissionVirtual productionVirtual servers

The method for detecting vulnerabilities in a virtual production server of a virtual or cloud computer system of one or more virtual servers includes analyzing vulnerabilities in the virtual production servers by connecting to the virtual or cloud computer system; requesting the cloning of the virtual production server in order to obtain a clone or a disk copy of the virtual production server, which is created in the virtual or cloud computer system; connecting to the clone or to the disk copy; analyzing the vulnerabilities of the clone or of the disk copy; erasing the clone or the disk copy; and generating a report analyzing the vulnerabilities of the clone or of the disk copy.

Owner:OUTPOST 24 FRANCE

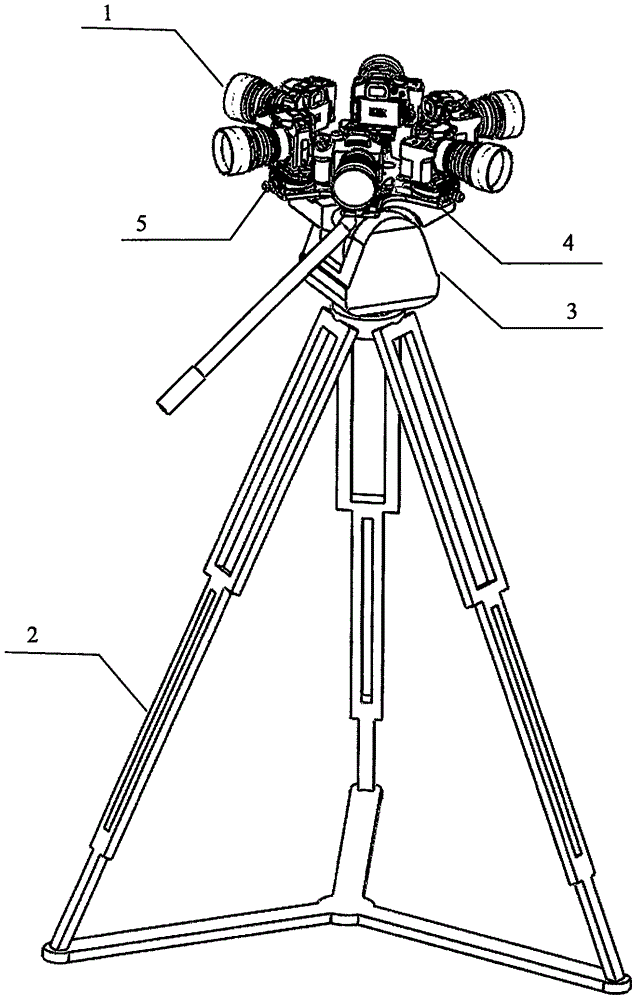

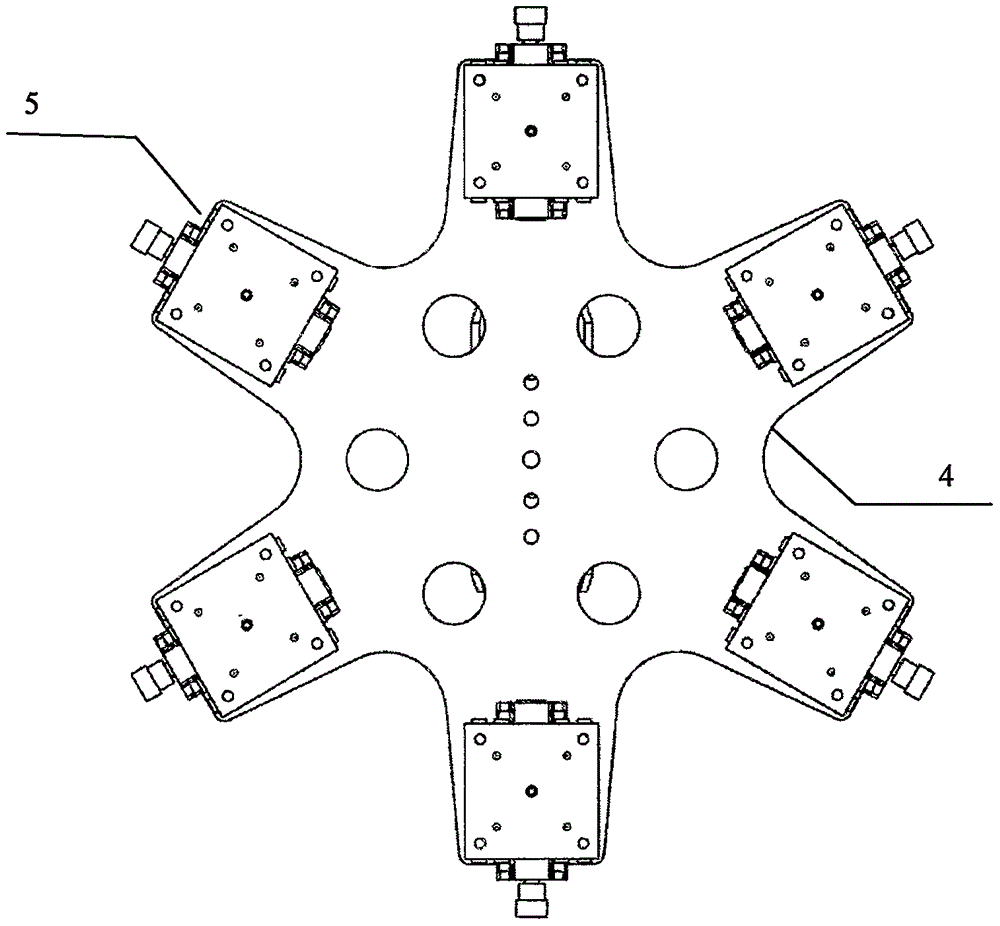

Controllable pitch angle panoramic photography system used for film virtual production

InactiveCN105681638AMeet different shooting needsReduce post-calculationTelevision system detailsColor television detailsCamera controlMulti machine

The invention discloses a controllable pitch angle panoramic photography system used for film virtual production, belonging to the camera control technical field, and comprises a plurality of cameras and a panoramic photography system support. The panoramic photography system support comprises a foot rest, a holder, a multi-machine supporting plate, camera pitching adjusting components and camera fast-assembling components. The multi-machine supporting plate is fixed at the top end of the holder; the cameras, the fast-assembling components and the camera pitching adjusting components are successively in connection; the bottom of each set of camera pitching adjusting components is fixed on the multi-machine supporting plate; the pitching shooting angle of each camera is adjustable under the condition of not increasing system total resolution; the pitching shooting angle of each camera can be accurately and flexibly controlled according to camera positions, shooting scenes, etc., and thereby wider dynamic vertical visual angles can be obtained.

Owner:BEIJING FILM ACAD

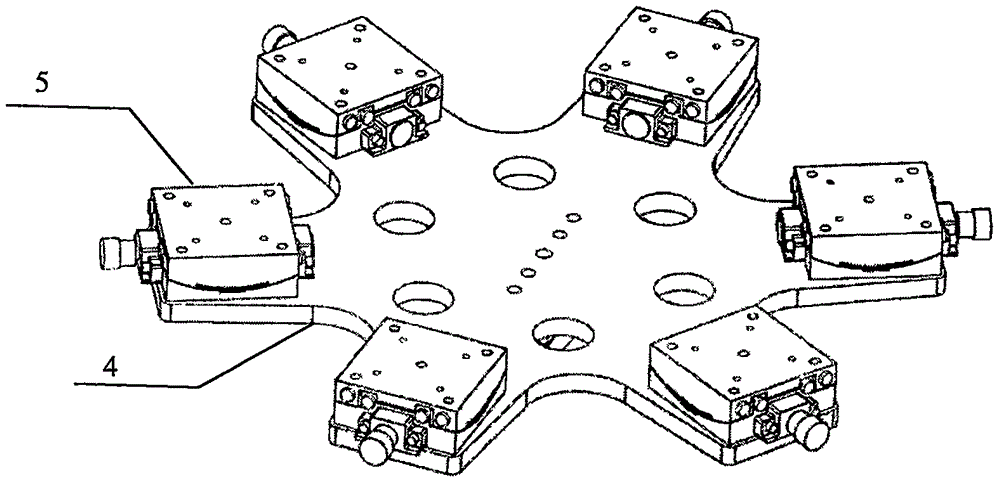

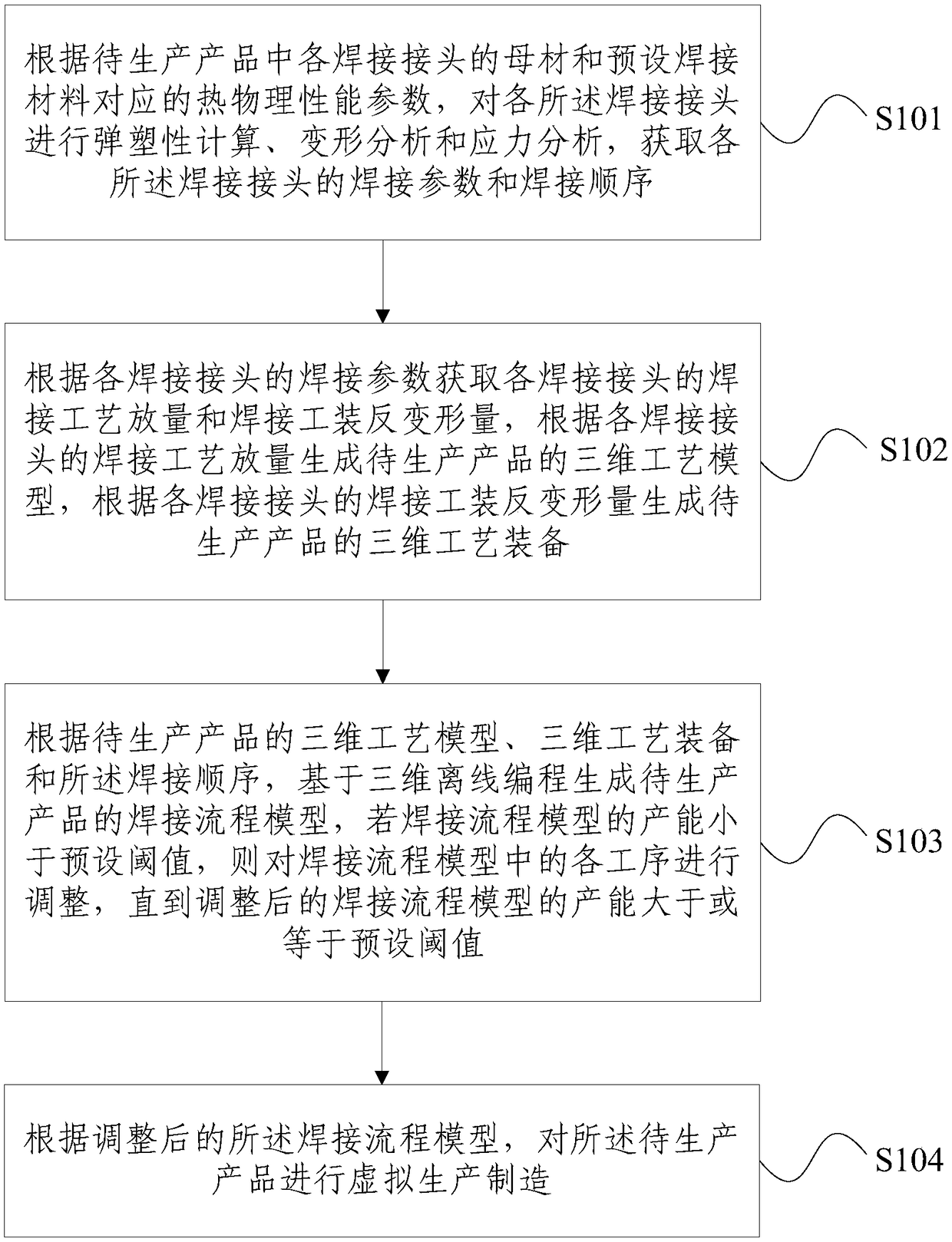

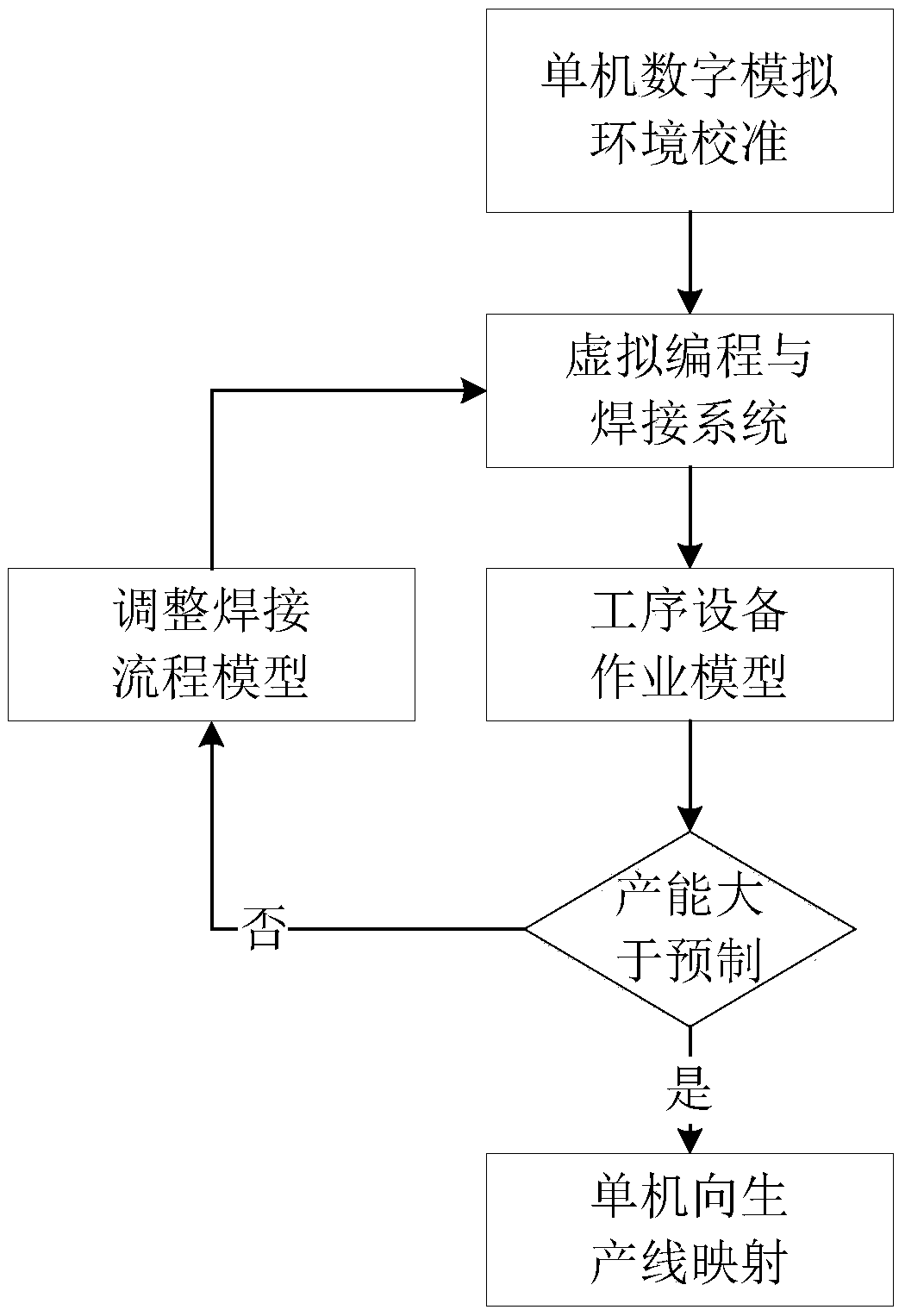

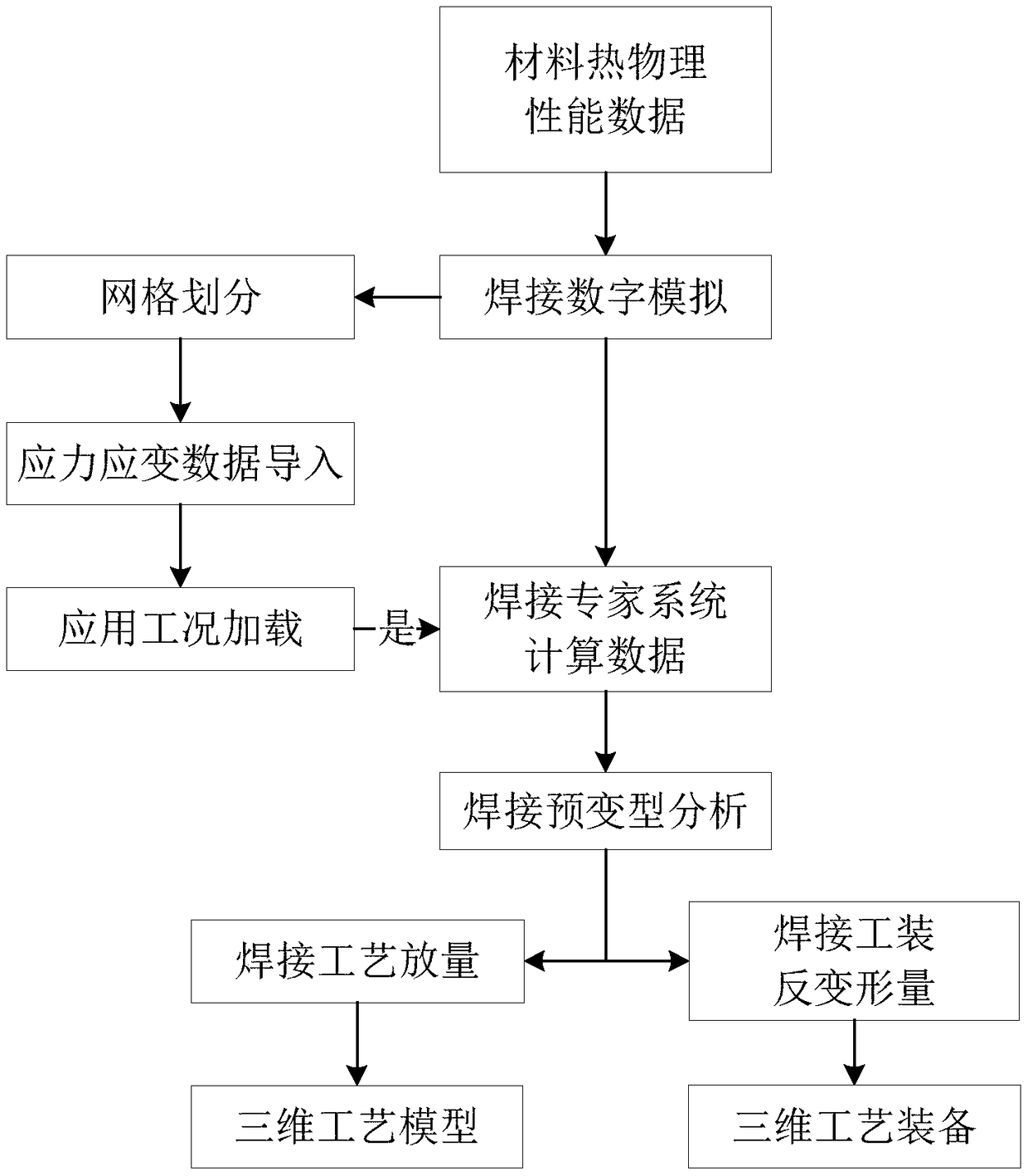

Welding-based virtual production manufacturing method and system

ActiveCN108646689AShorten the production cycleReduce manpowerTotal factory controlProgramme total factory controlProcess equipmentMaterial resources

The invention provides a welding-based virtual production manufacturing method and system. The method includes the steps of according to a base material of each welding joint in a to-be-produced product and thermophysical performance parameters corresponding to a preset welding material, conducting elastoplasticity calculation, deformation analysis and stress analysis on each welding joint, and obtaining welding parameters and a welding sequence of the welding joints; according to the welding parameters of each welding joint, obtaining a three-dimensional process model and three-dimensional process equipment of the to-be-produced product; according to the three-dimensional process model, the three-dimensional process equipment and the welding sequence of the to-be-produced product, generating a welding process model of the to-be-produced product on the basis of three-dimensional offline programming, and adjusting each process in the welding process model; according to the adjusted welding process model, conducting virtual production manufacturing on the to-be-produced product. Manpower and material resources are reduced, and the production cycle of the to-be-produced product is shortened.

Owner:CRRC QINGDAO SIFANG CO LTD

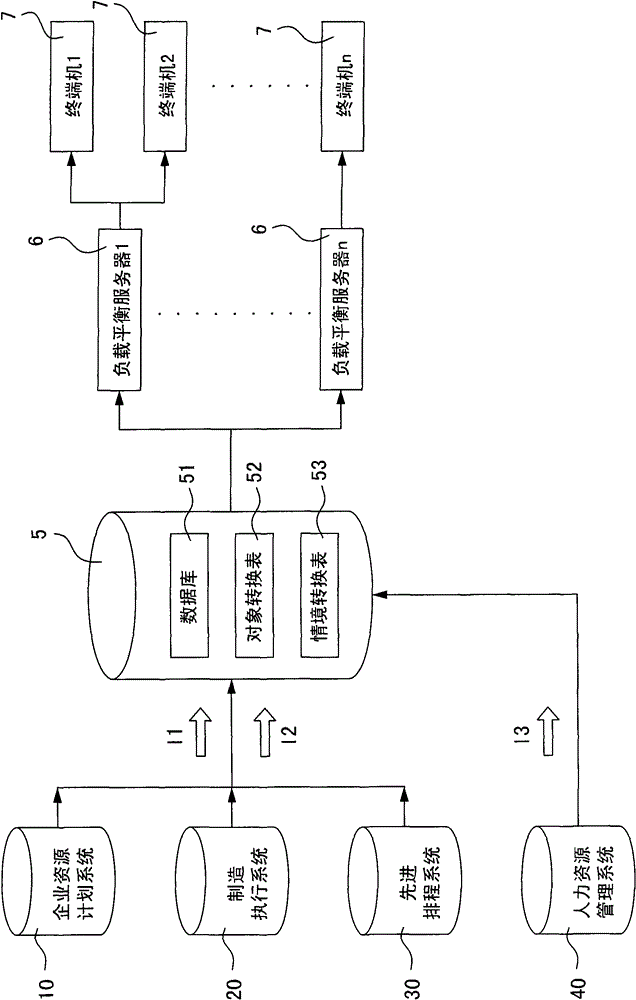

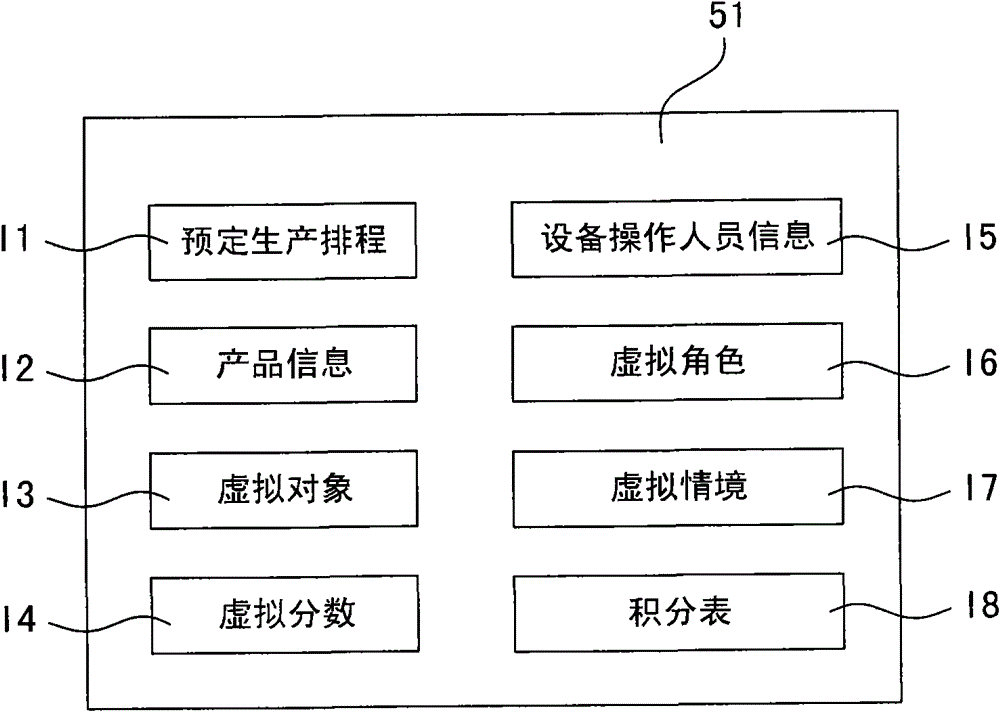

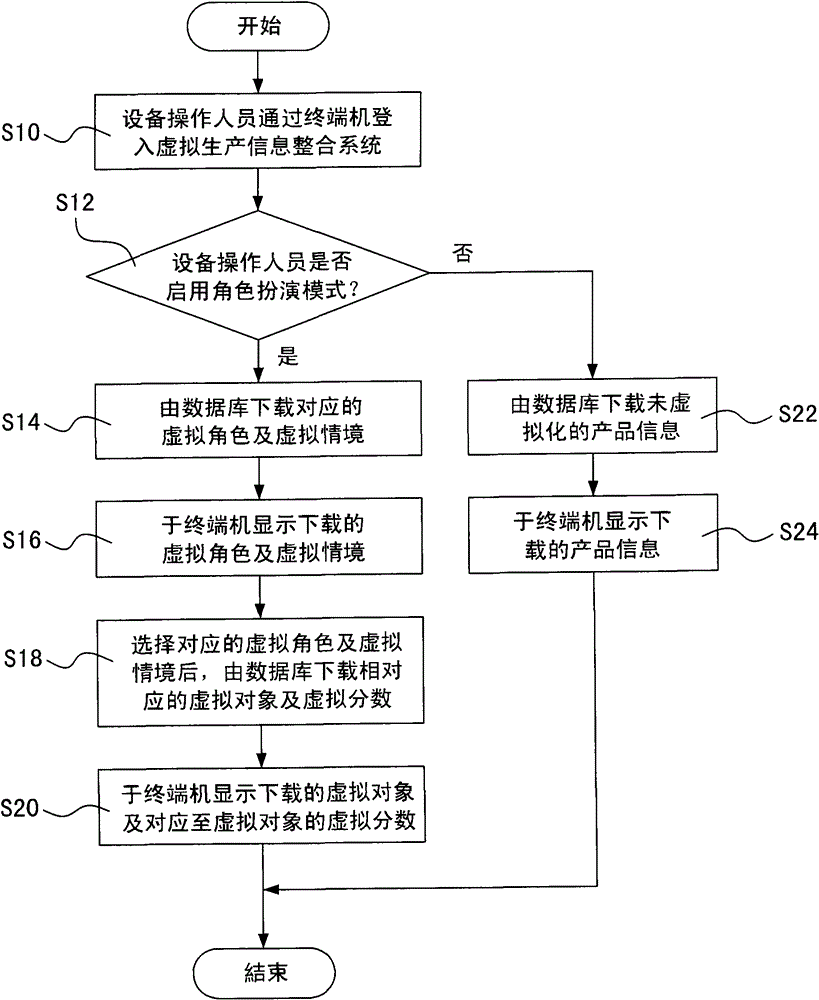

System and method combining virtual situation and used for managing production line

Owner:LANE BEST TECH

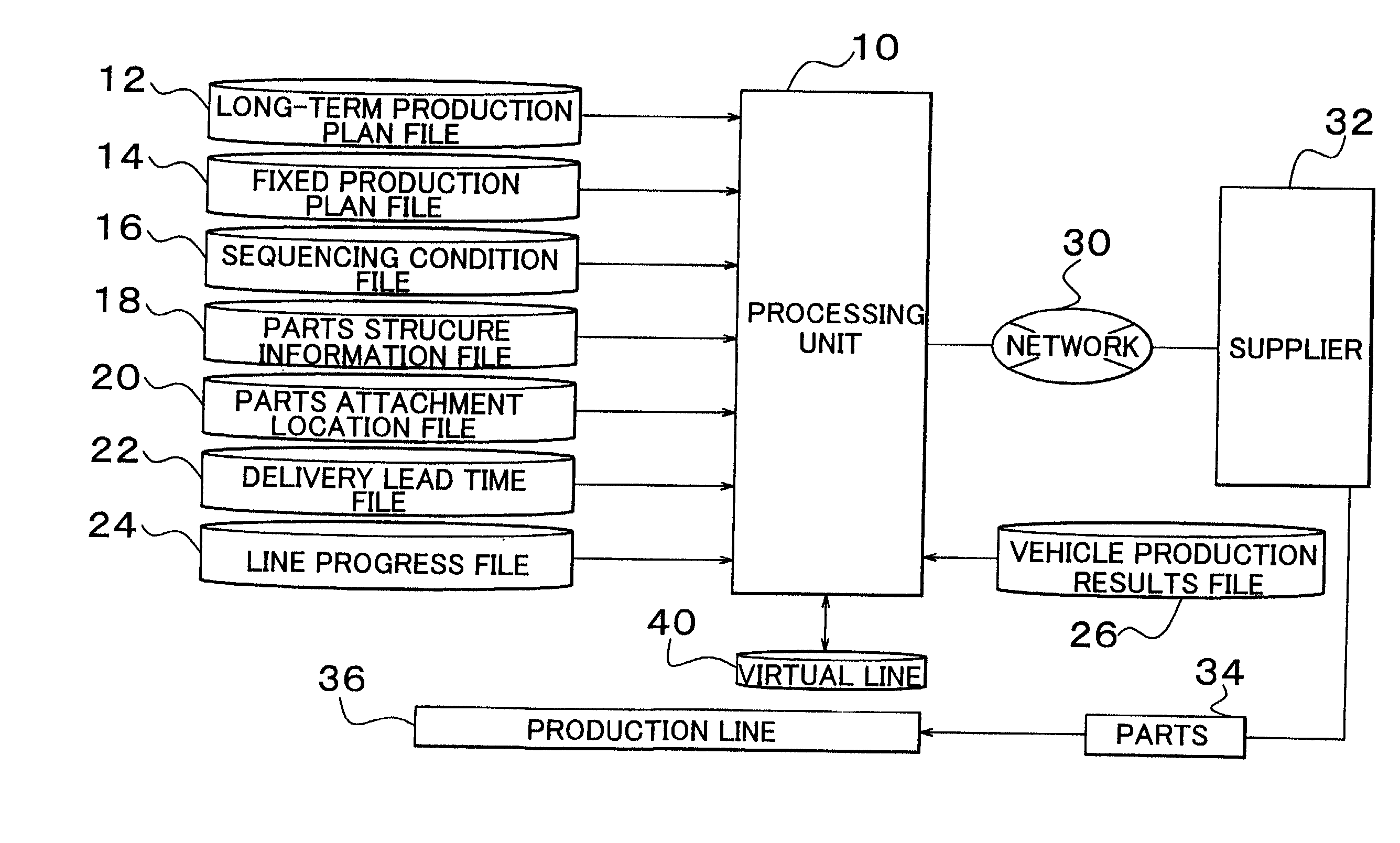

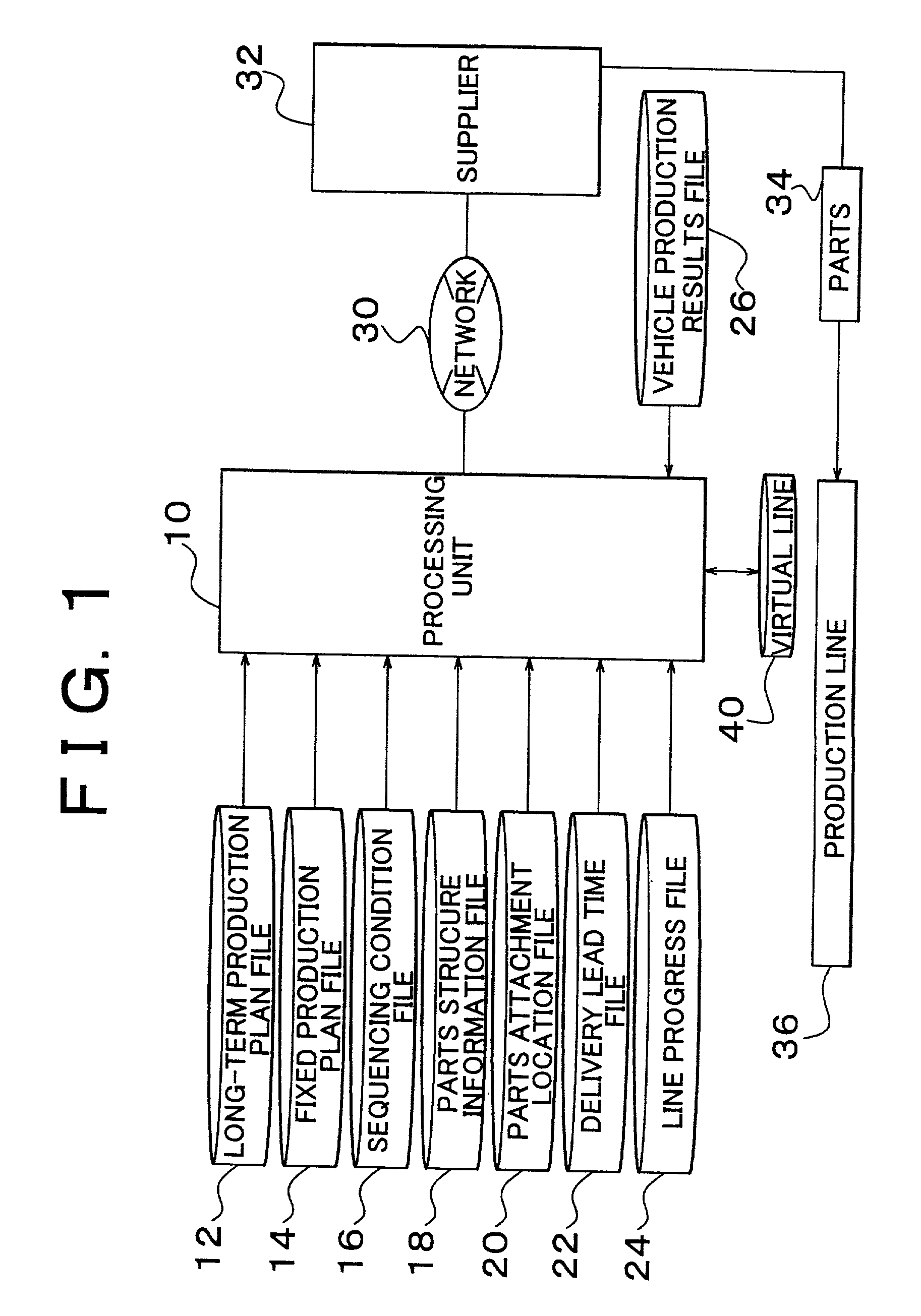

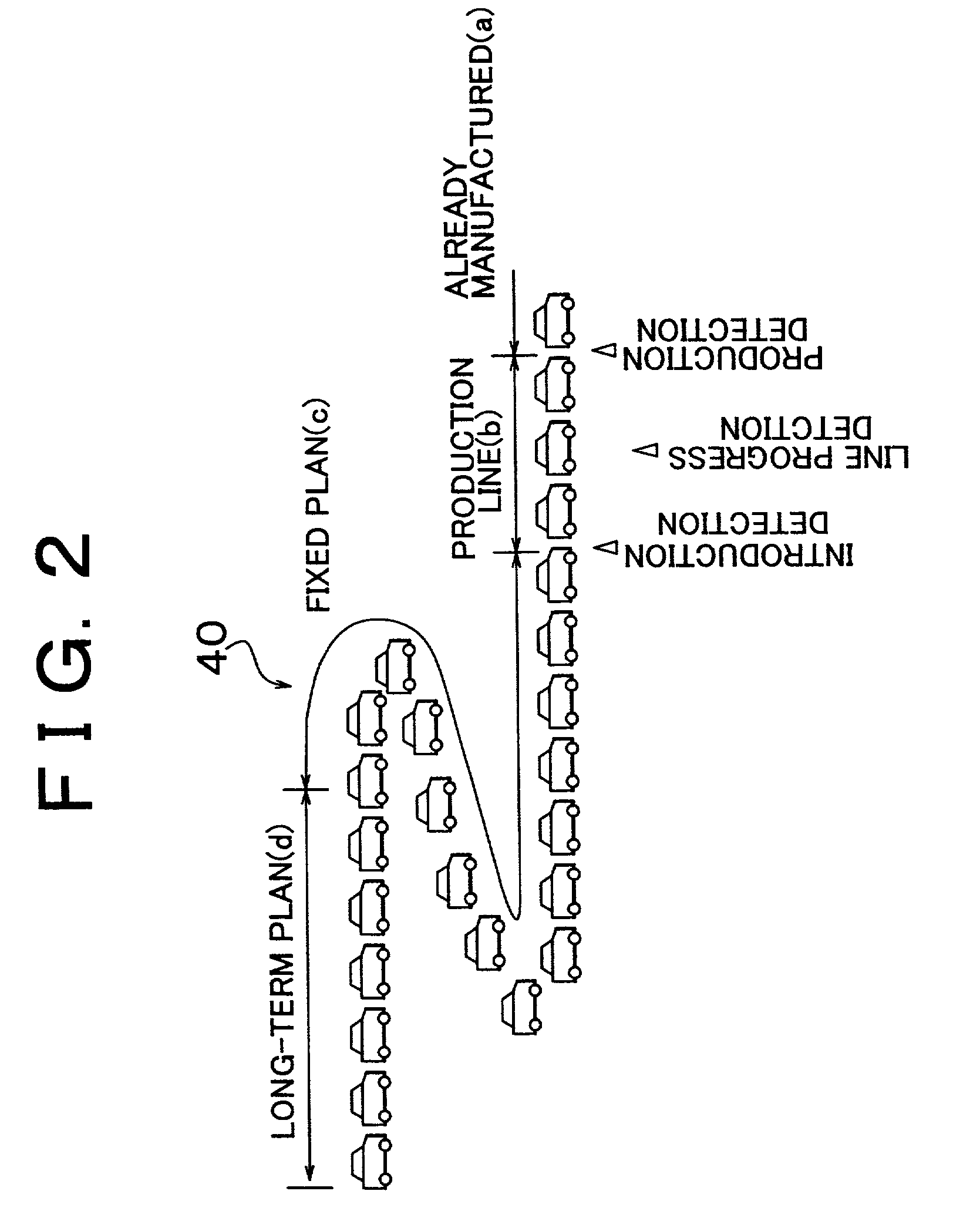

Parts procurement system and method

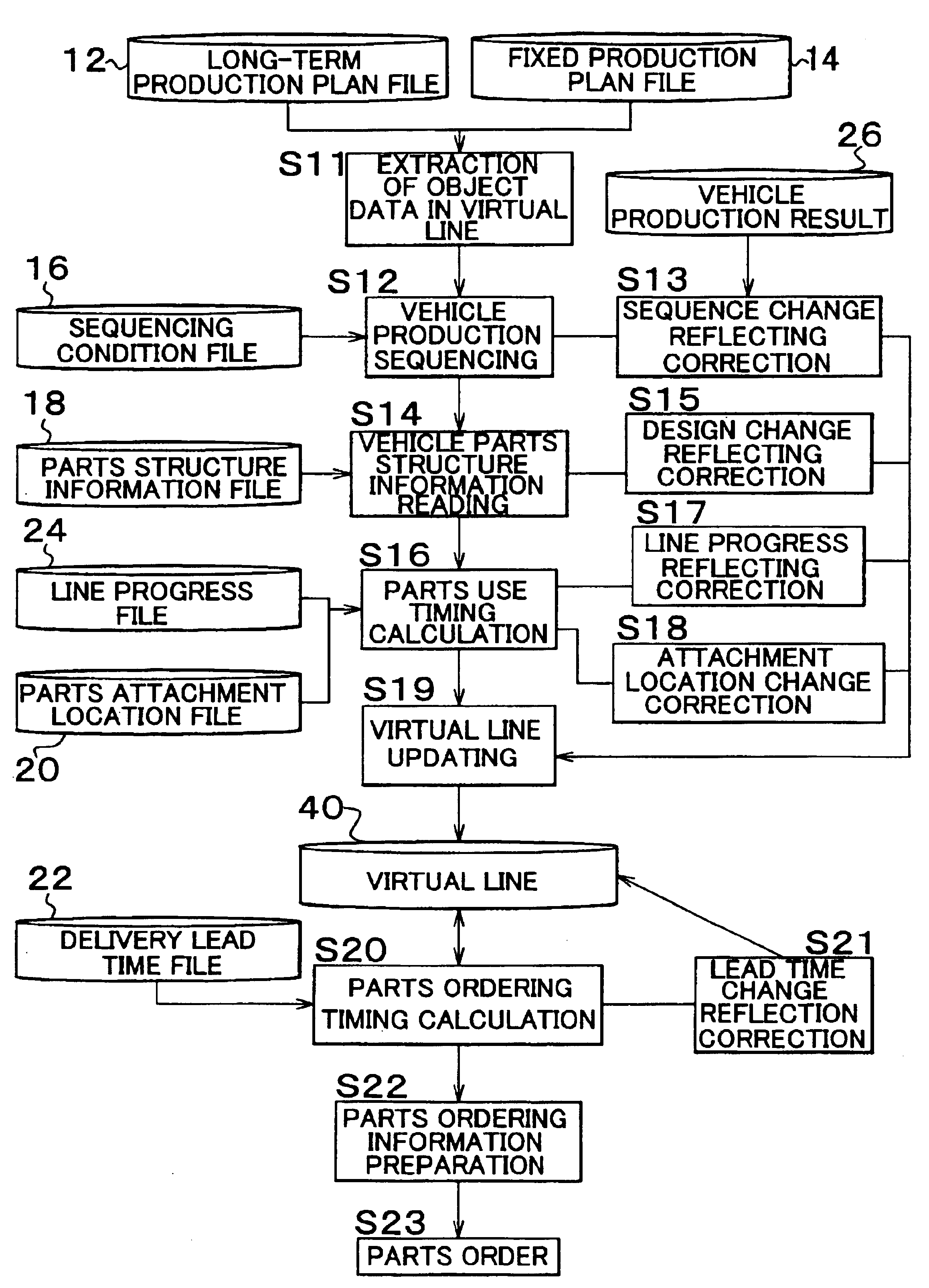

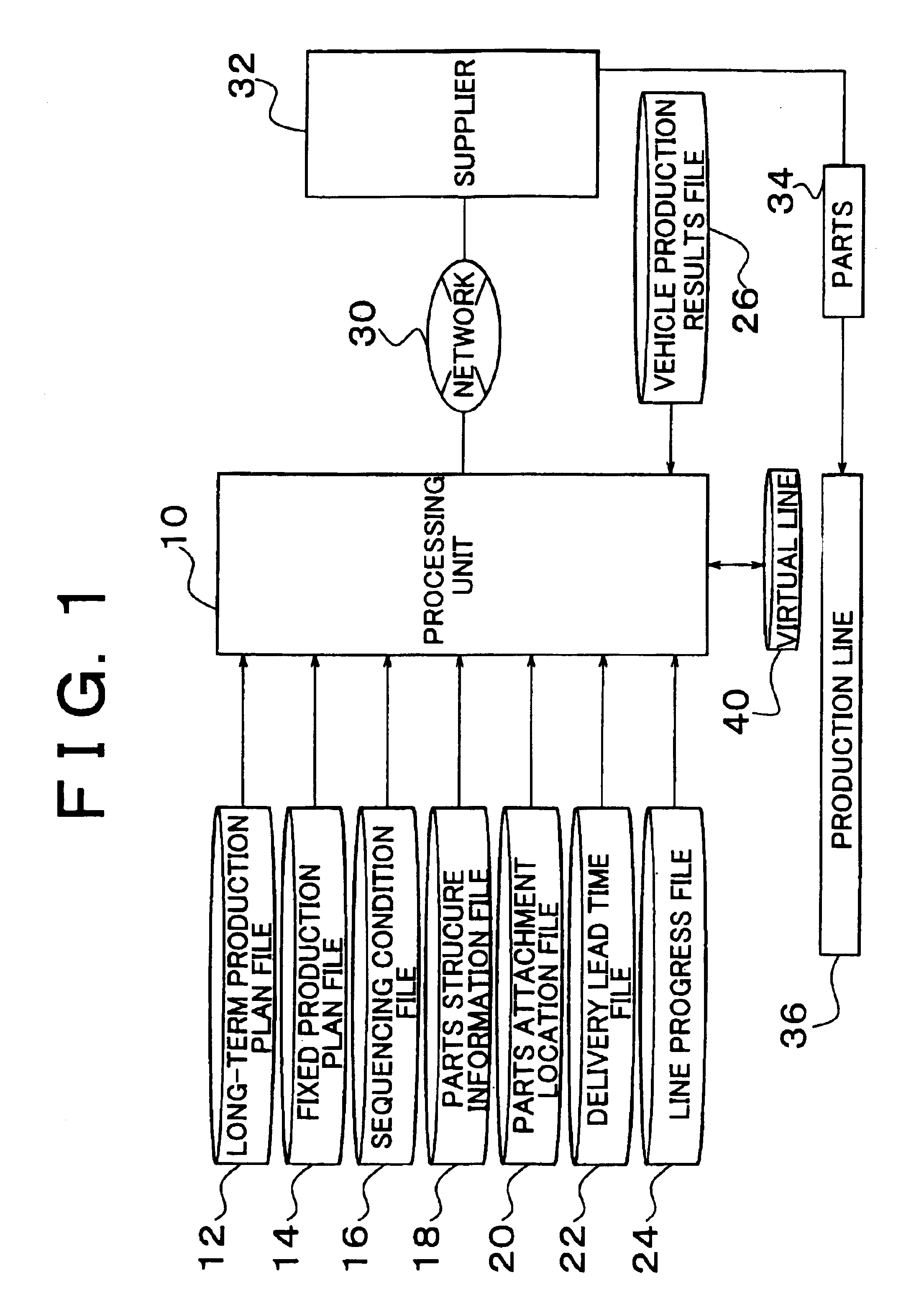

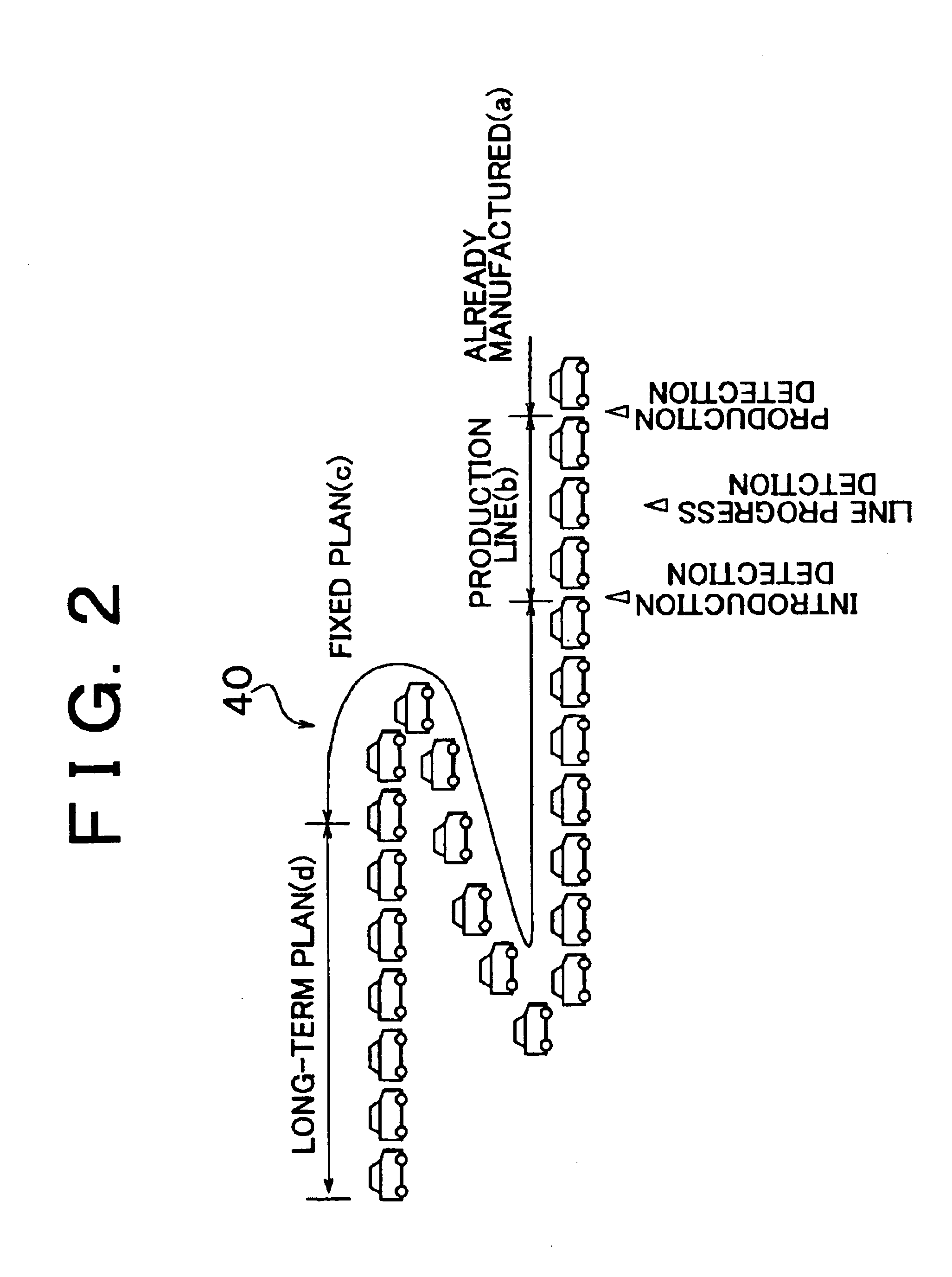

A virtual production line indicating an object (e.g., a vehicle) sequence for an actual production line and objects (e.g., vehicles) planned in the future is updated based on a long-term production plan, a fixed production plan, and actual production results. Then, the ordering timings for the parts necessary for the respective objects in the virtual production line are calculated based on the timing for using the parts and the delivery lead time, and the orders are placed according to those timings.

Owner:TOYOTA JIDOSHA KK

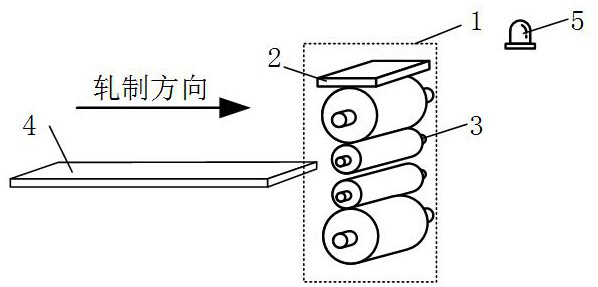

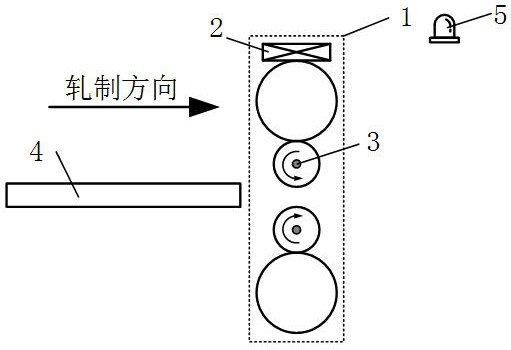

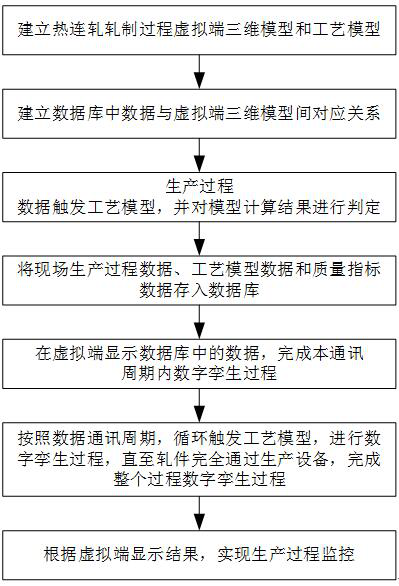

Hot continuous rolling process monitoring and early warning method based on digital twinning

InactiveCN112507573AEnrich and improve the production organization modelReduce generationDesign optimisation/simulationSpecial data processing applicationsProcess engineeringData store

The invention provides a hot continuous rolling process monitoring and early warning method based on digital twinning, and relates to the technical field of rolling process intelligent manufacturing.The method comprises the following steps: firstly, establishing a three-dimensional solid model and a process model of a hot continuous rolling process at a virtual end; obtaining existing hot continuous rolling production process data, storing the existing hot continuous rolling production process data into a database, and establishing a corresponding relationship between the data in the databaseand the three-dimensional entity model of the virtual end; then calculating by using the process model and utilizing the actual production process data of hot continuous rolling, judging a calculatedvalue, and giving an early warning according to a judgment result; and further storing the hot continuous rolling actual production process data, the process model calculation value data and the judgment result data into a database, establishing an action corresponding relationship between the hot continuous rolling actual production process data and virtual production equipment, and carrying outthree-dimensional presentation on the production process at a virtual end, completing the construction of digital twins in the hot continuous rolling process, and continuously performing the digitaltwins according to a fixed communication period until the production of the rolled piece product is finished.

Owner:NORTHEASTERN UNIV

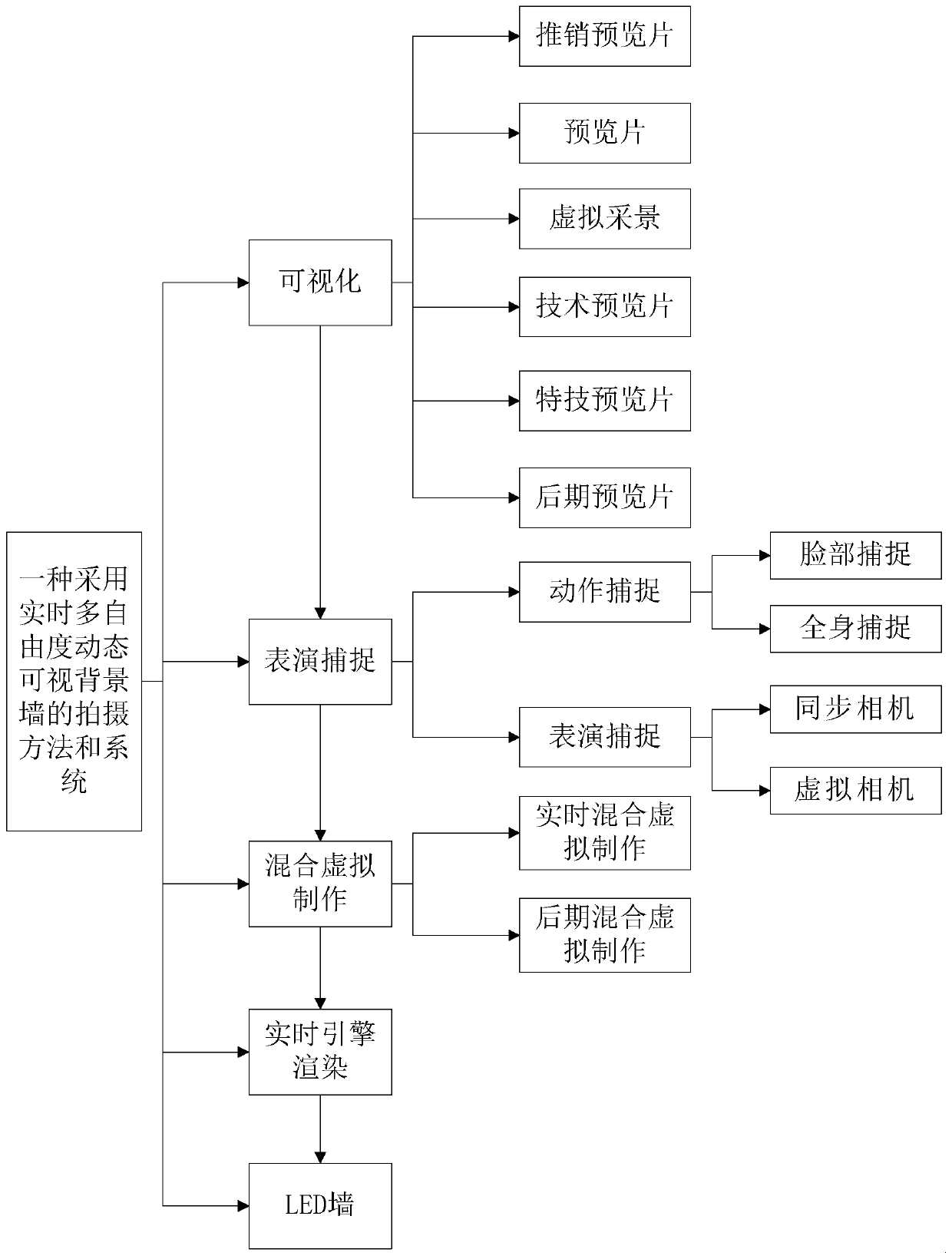

Shooting method and system of real-time multi-degree-of-freedom dynamic visual background wall

InactiveCN110942018AIterative modification is easyIterative modification is very easy to implementCharacter and pattern recognitionAnimationAnimationEngineering

The invention discloses a shooting method and system of a real-time multi-degree-of-freedom dynamic visual background wall. The invention belongs to the technical field of movie image production. Theinvention discloses a shooting method and system of a real-time multi-degree-of-freedom dynamic visual background wall. Motion capture and hybrid virtual production can be used for interaction betweenvirtual characters and the real world. Motion data are only captured from actors; a scene can be read from the scene library as required; reconstituting animation, when the camera is used for tracking data; real-time green matting and accurate picture synthesis are provided for shooting; in addition, the manufacturing process is simple, a photographer can set a picture of a real object through the LED wall. Therefore, the actor does not need to face the imaginary picture of the green screen, because the LED wall vividly displays the scene picture, important artistic clues are provided for images and light rays on all the LED walls, the authenticity of the picture is enhanced, and color pollution caused by green overflow does not need to be avoided as in the past.

Owner:北京华严互娱科技有限公司

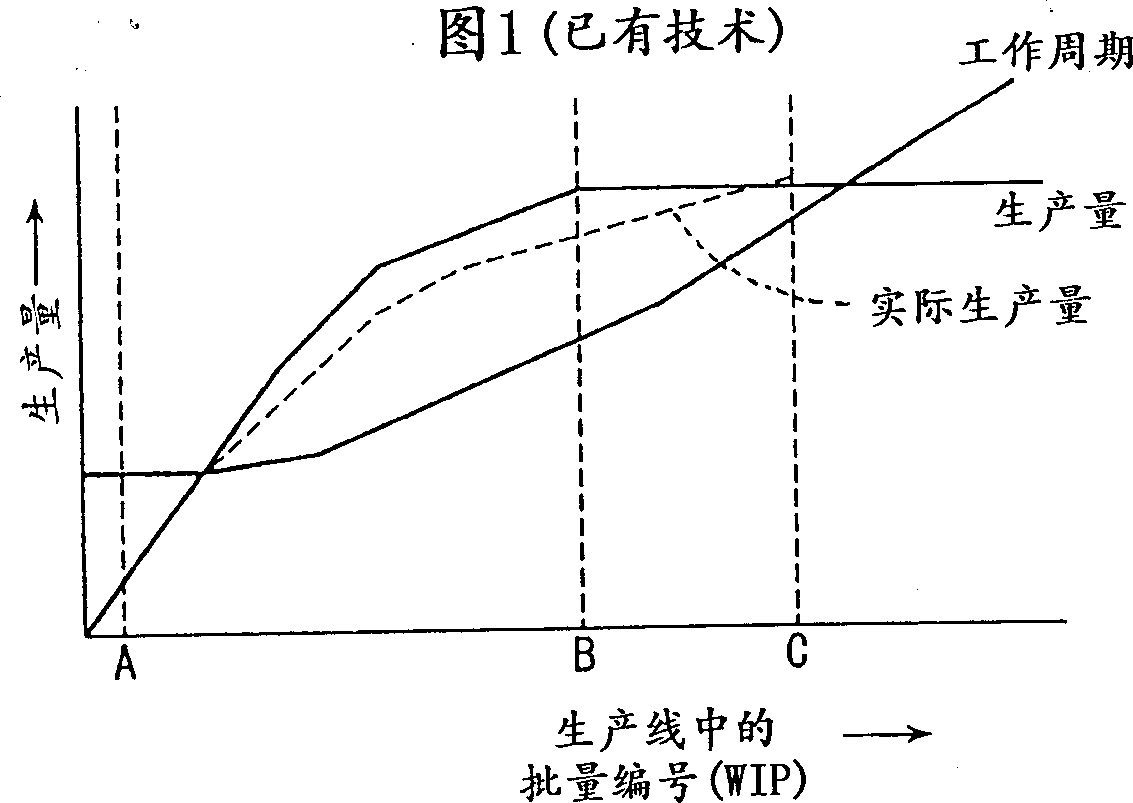

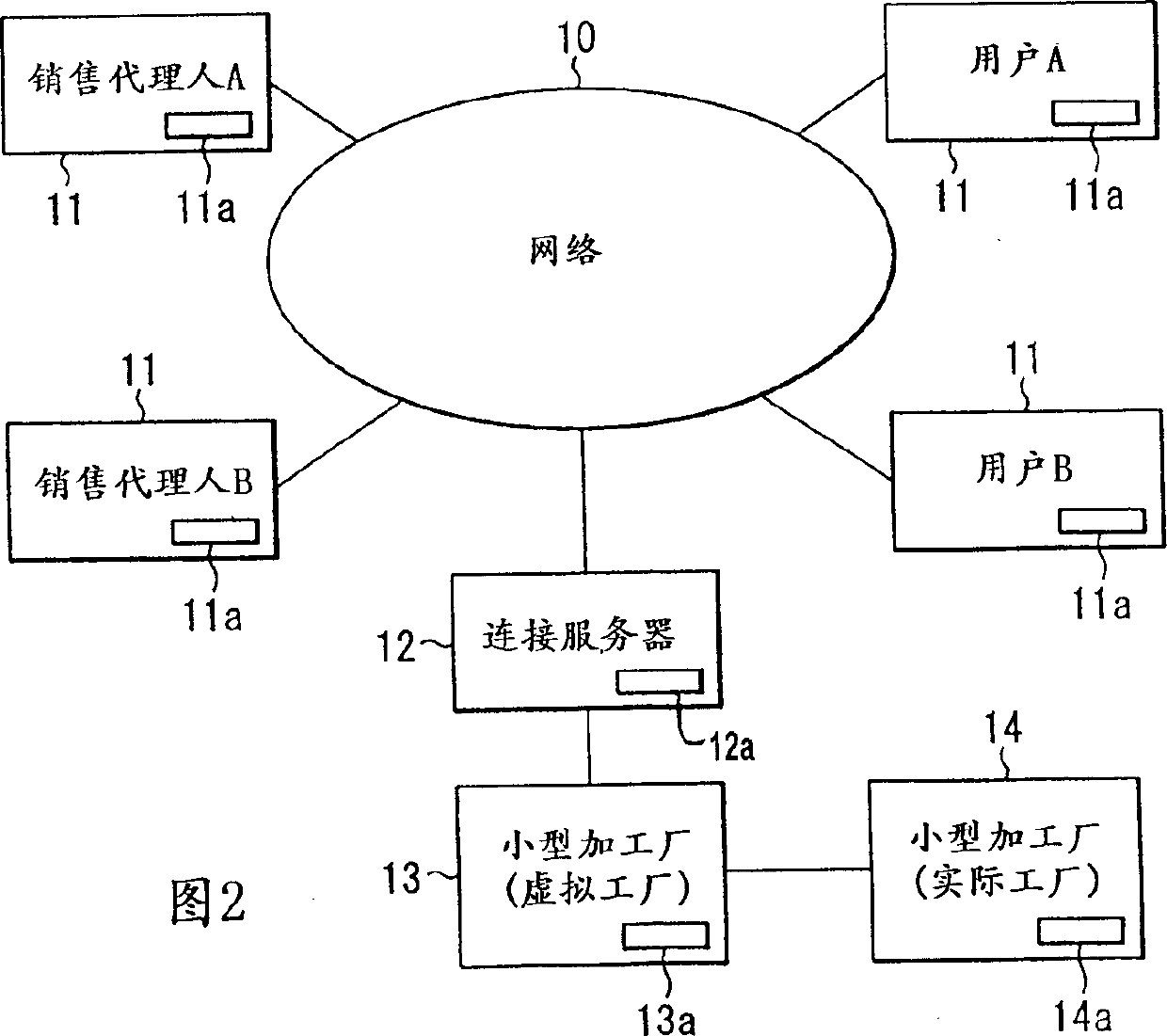

Semiconductor article production and producing apparatus, and electronic transaction system and method

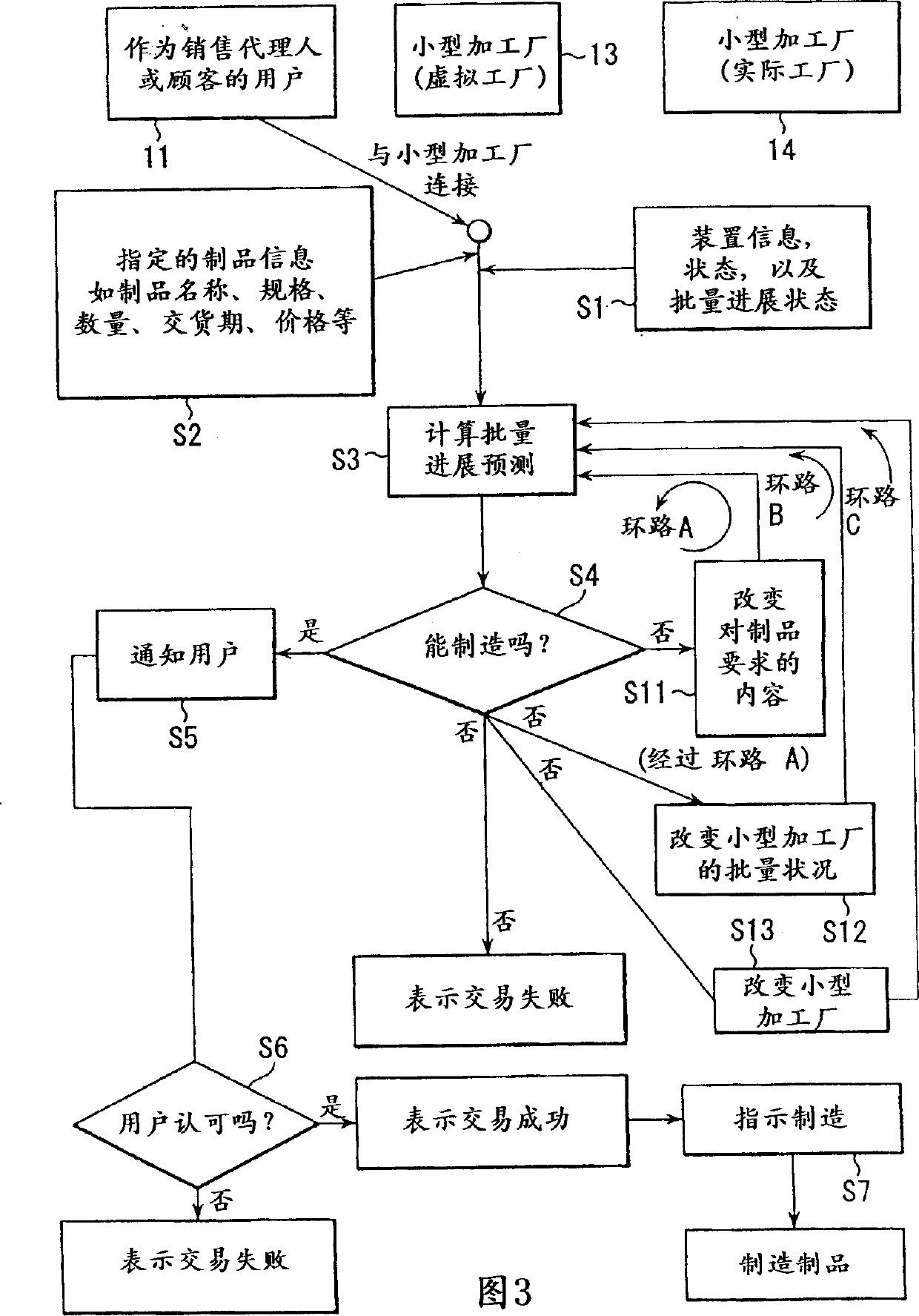

InactiveCN1347054AImprove productivityShorten the construction periodSimulator controlBuying/selling/leasing transactionsProduction lineComputer terminal

An electronic commerce for semiconductor products comprises a network, a client terminal, a connection server, a virtual production line, and a real production line. The real production line actually manufactures semiconductor products. The virtual production line provides a computer with substantially the same functions as the real production line and computes an optimal lot progress. The connection server connects the virtual production line to the client terminal via the network. When a condition is entered from the client terminal, the connection server transfers this condition to the virtual production line. Simulation is performed realtime for determining whether a product flows in the virtual production line under the transferred condition. The connection server transfers a simulation result to the client terminal. Based on the simulation result, a electronic commerce is conducted.

Owner:KK TOSHIBA

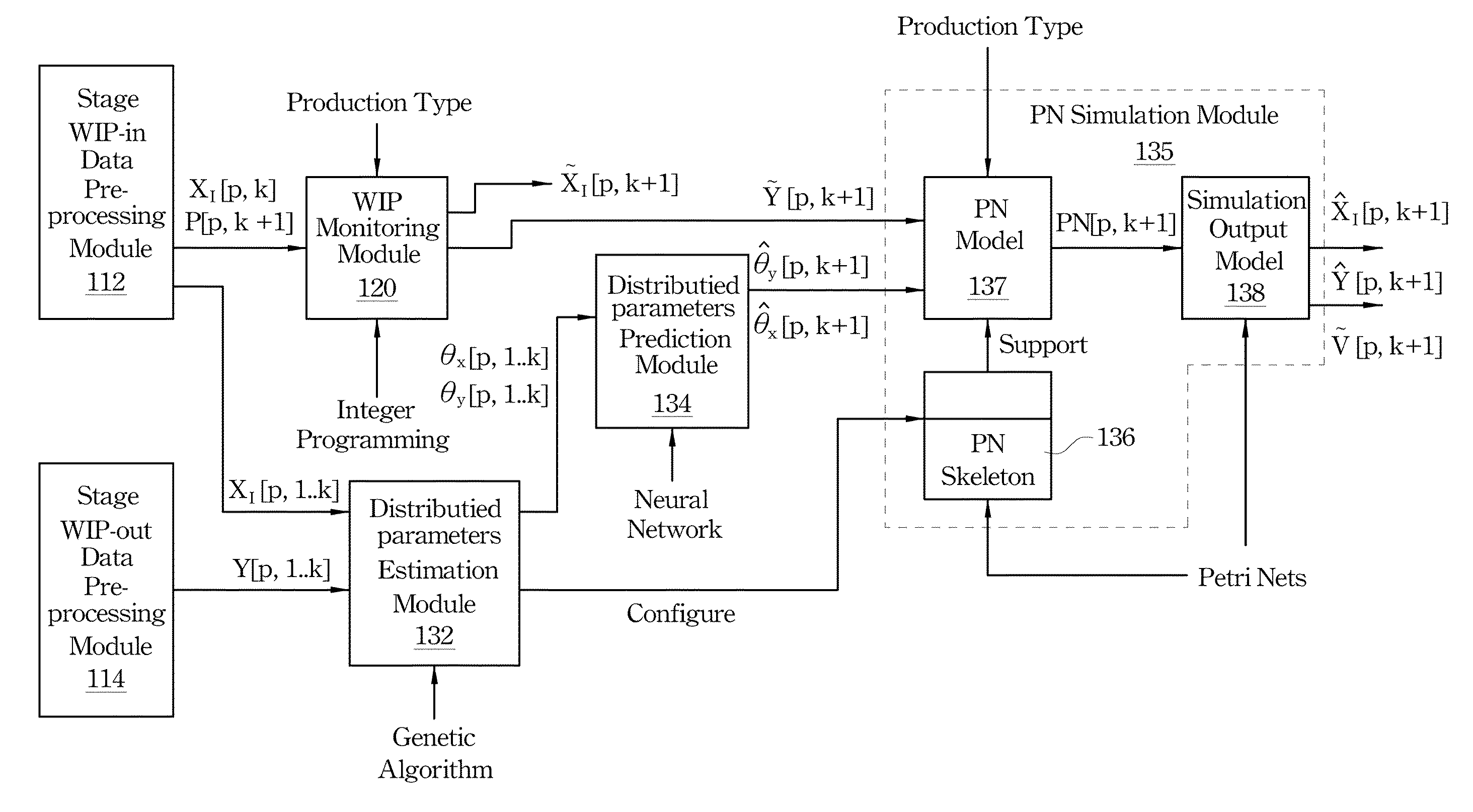

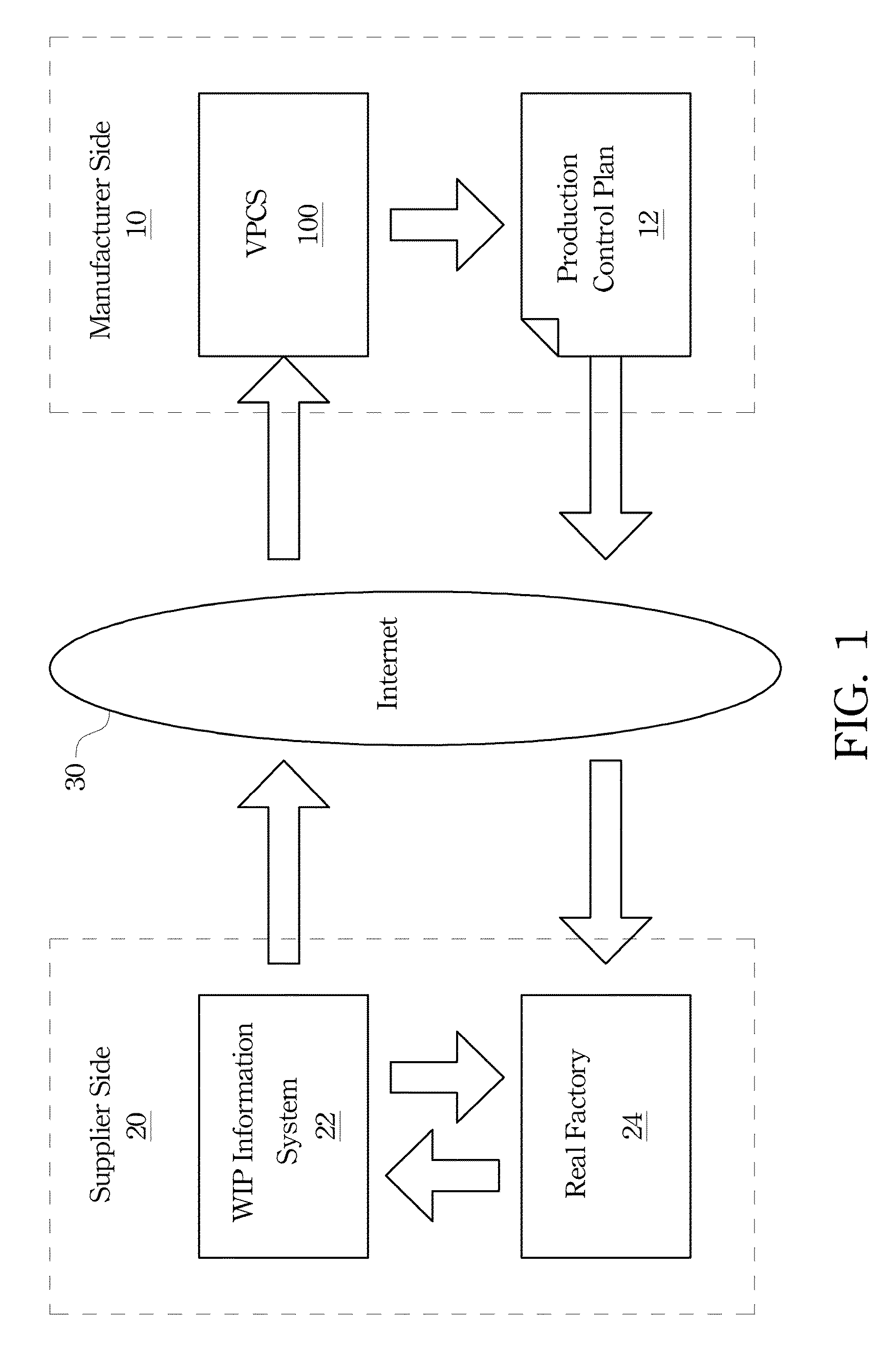

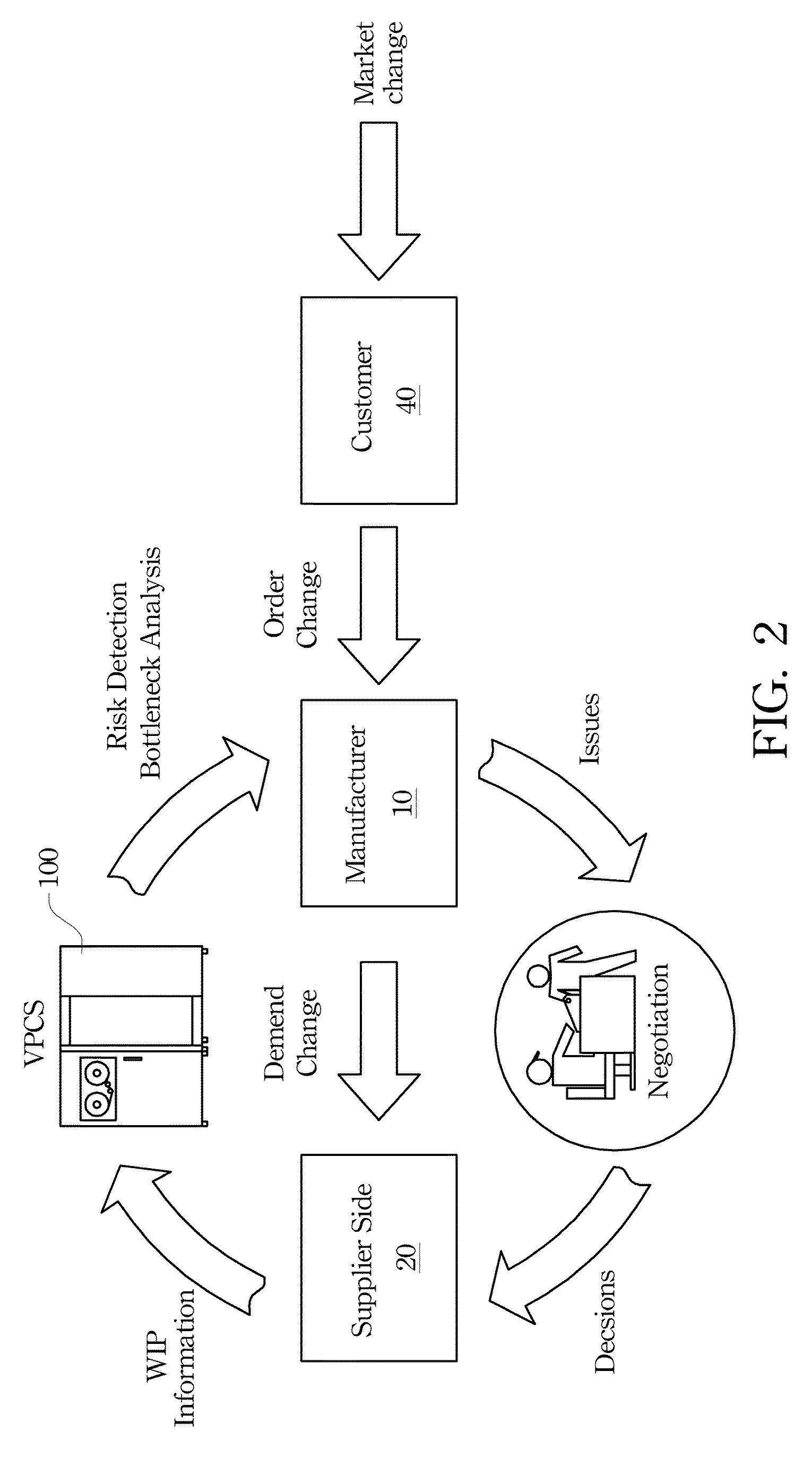

Virtual production control system and method and computer program product thereof

ActiveUS8515793B2Efficient solutionReduce riskGenetic modelsDigital computer detailsTransportation schedulingPetri net

A virtual production control system (VPCS), and a virtual production control method and a computer program product thereof are provided. At first, the VPCS processes historical work-in-process (WIP) information and a current shipping plan sent from a supplier side, thereby obtaining a plurality of sets of WIP input / output historical data and a goods output schedule. Then, the VPCS performs an integer programming (IP) method to find the latest output schedule in accordance to the current shipping plan; uses a genetic algorithm (GA) to fit the historical distributed-parameters; adopts a neural network (NN) method to predict the future distributed-parameters of production; and finally utilizes a Petri Nets to simulate and obtain a latest feasible input schedule and a latest feasible output schedule.

Owner:NAT CHENG KUNG UNIV

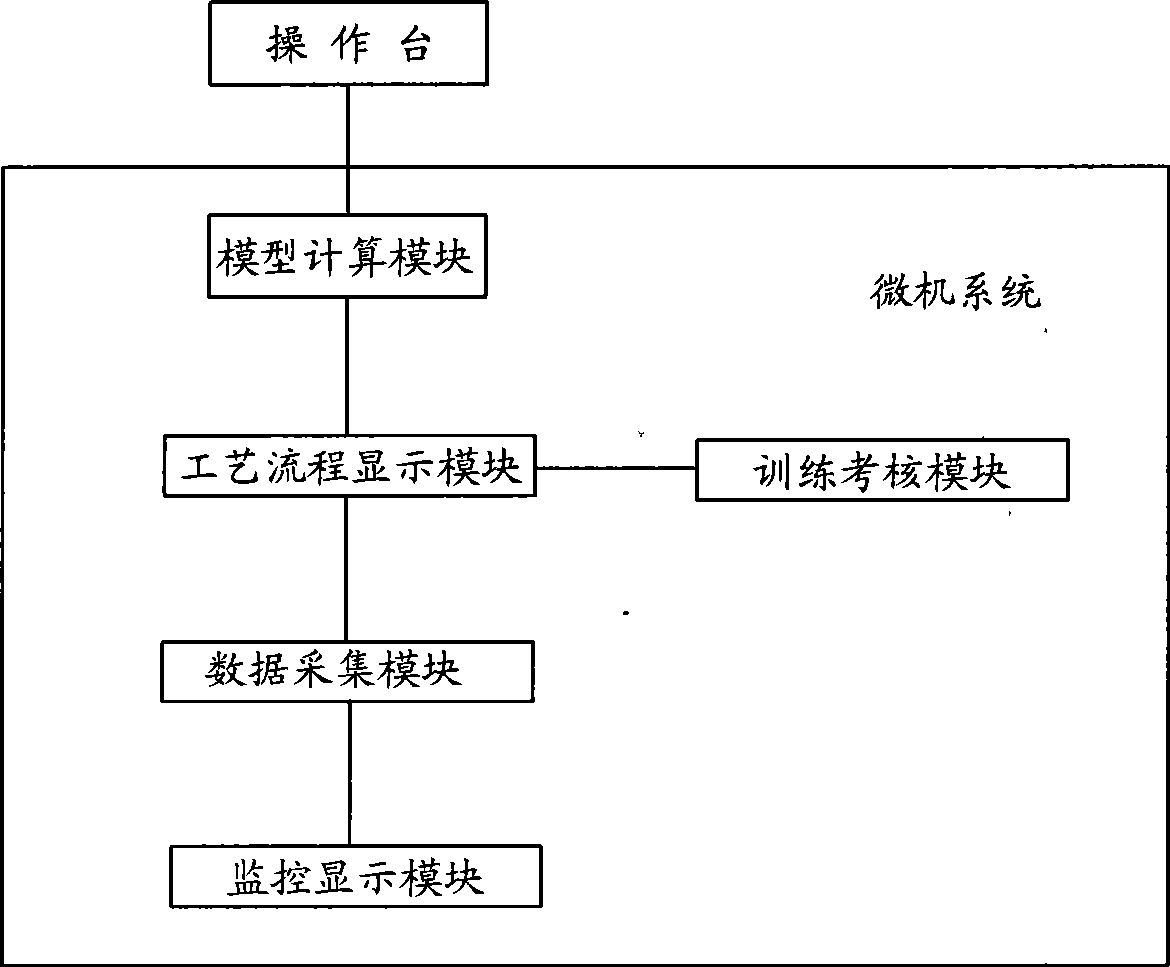

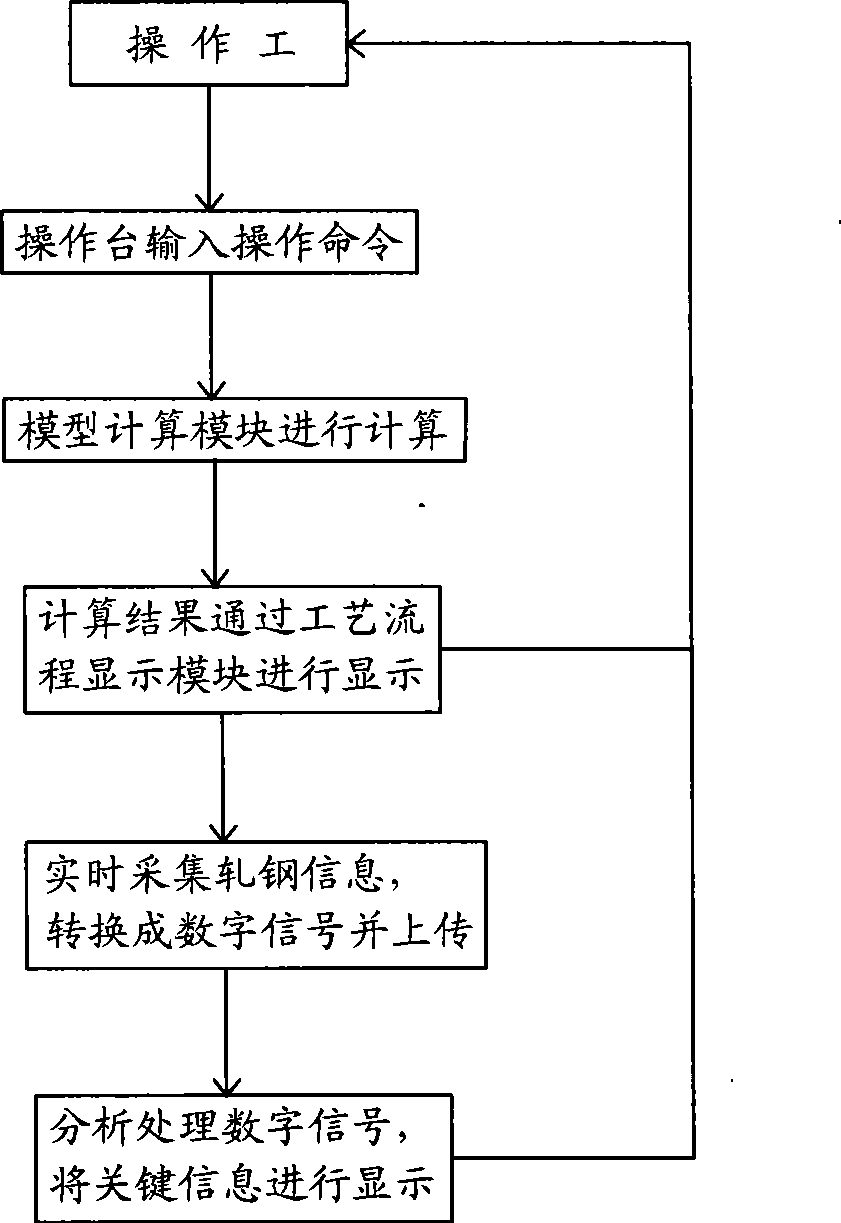

Analog simulation system for steel rolling skill training and assessment

InactiveCN101546487AStimulate creative thinkingSolve knowledge difficultiesElectrical appliancesTeaching apparatusControl signalFiltration

The invention discloses an analog simulation system for steel rolling skill training and assessment, comprising an operating platform connected with a micro-computer system which is provided with a steel rolling analog simulation device. The steel rolling analog simulation device comprises a model computer module, a technical process display module, a data acquisition module and a monitoring display module. The model computer module receives control signals input by the operating platform, carries out calculation and generates process data corresponding to virtual production. The data acquisition module carries out real-time acquisition of the site data generated in the steel rolling process, converts the site data into digital signals after amplification, isolation and filtration and transmits the digital signals to an upper layer through a computer network. The monitoring display module receives the digital signals transmitted by the data acquisition module, adopts a PIC automation program to simulate the monitoring system of a real company, operates and monitors the full simulation of an interface and transmits the obtained key information to a virtual display module for display.

Owner:王继

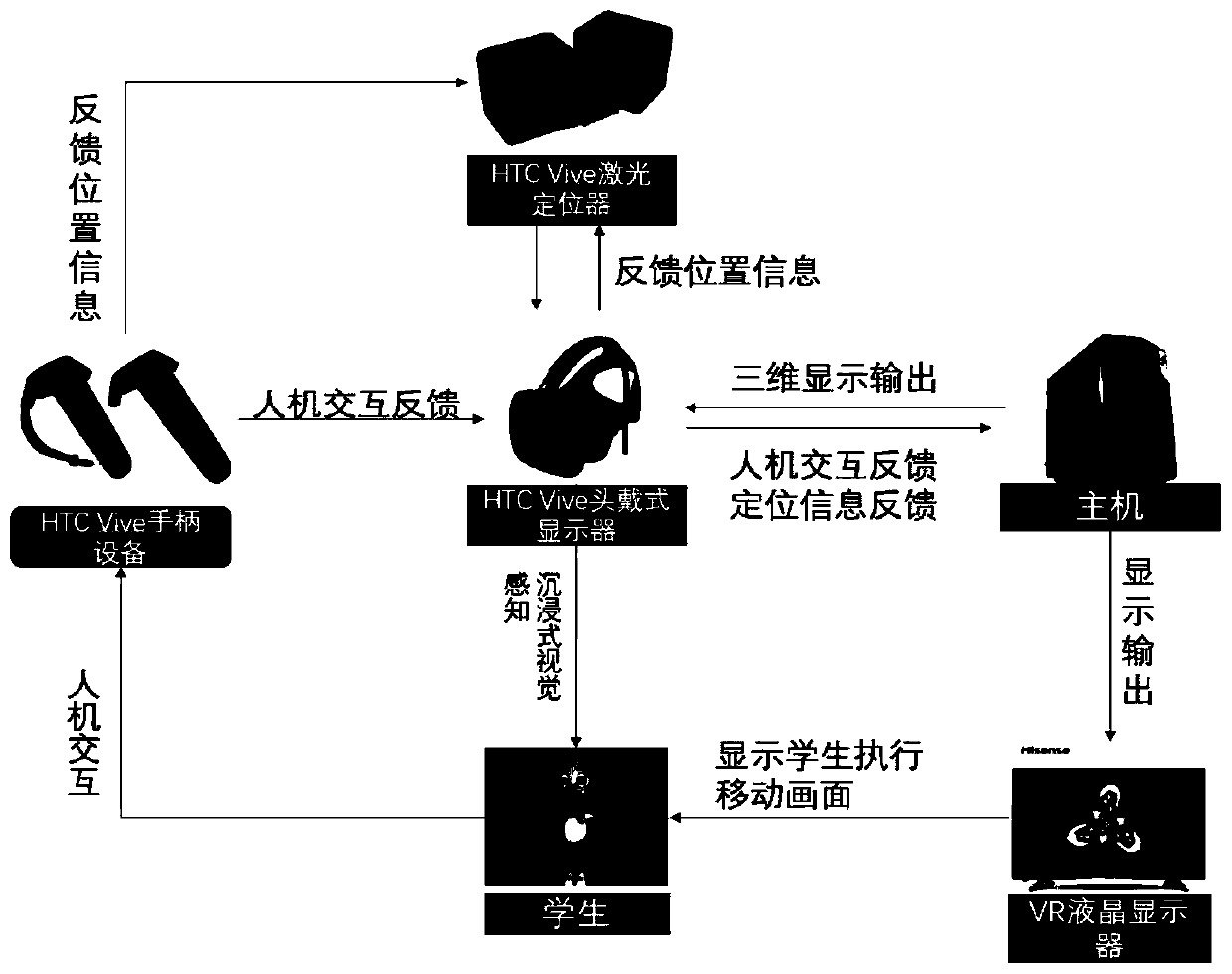

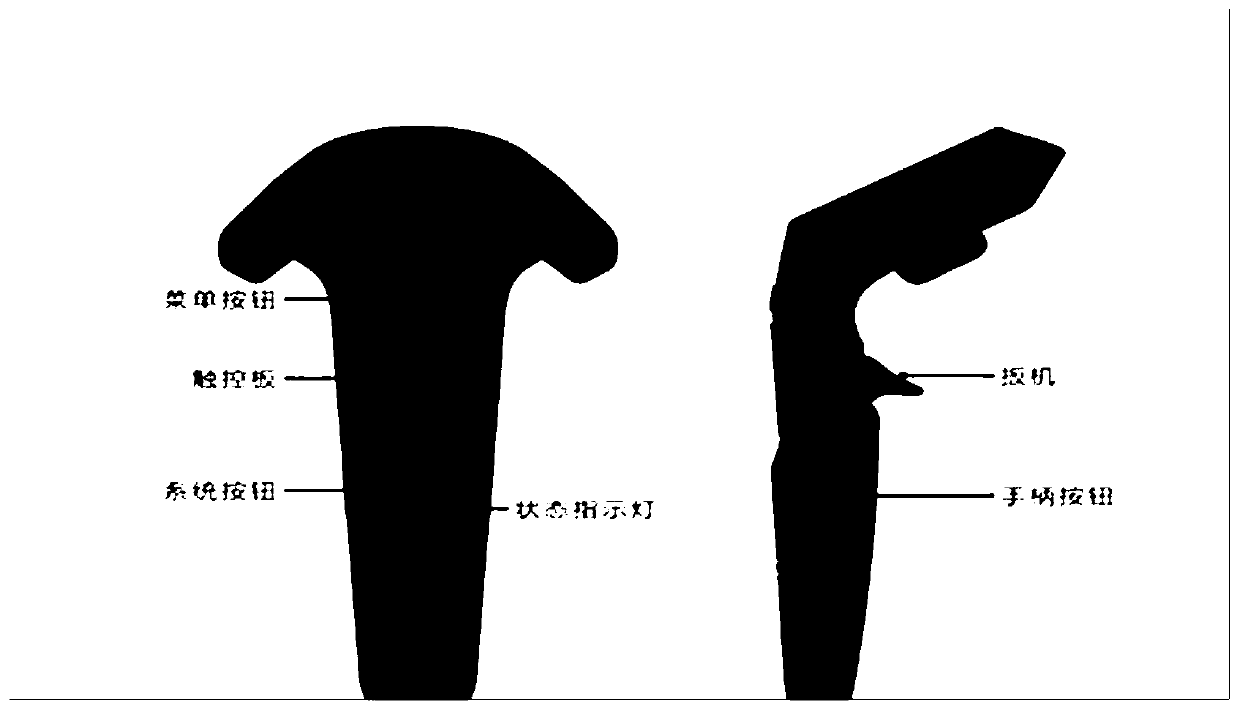

Craft beer saccharification operation system and method based on VR (virtual reality)

InactiveCN109897747AImprove the level of theoretical knowledgeImprove teaching efficiencyInput/output for user-computer interactionWort preparationVirtual userLiquid-crystal display

The invention discloses a craft beer saccharification operation system and method based on VR (virtual reality). The system comprises a graphic workstation, a VR liquid crystal display, a VR head-mounted display, handle equipment and a laser locator, wherein the VR liquid crystal display is used for displaying a 3D panoramic scene of a craft beer virtual production workshop, and synchronously displaying a moving picture and an action execution picture of a virtual user model; the VR head-mounted display is used for immersing the user into the 3D panoramic scene of the craft beer virtual production workshop; the handle equipment is used for allowing the user to control motion and action execution of the user in the virtual scene; the laser locator is used for positioning the user and capturing motion of the user. Operation rules of the actual production flow of the craft beer saccharification process can be showed clearly, and are close to the feeling of real experience of actual operation. Students can complete the study content by similar games, and the teaching effect is improved; the students can be helped to understand the characteristics of the craft beer saccharification process in a short time.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

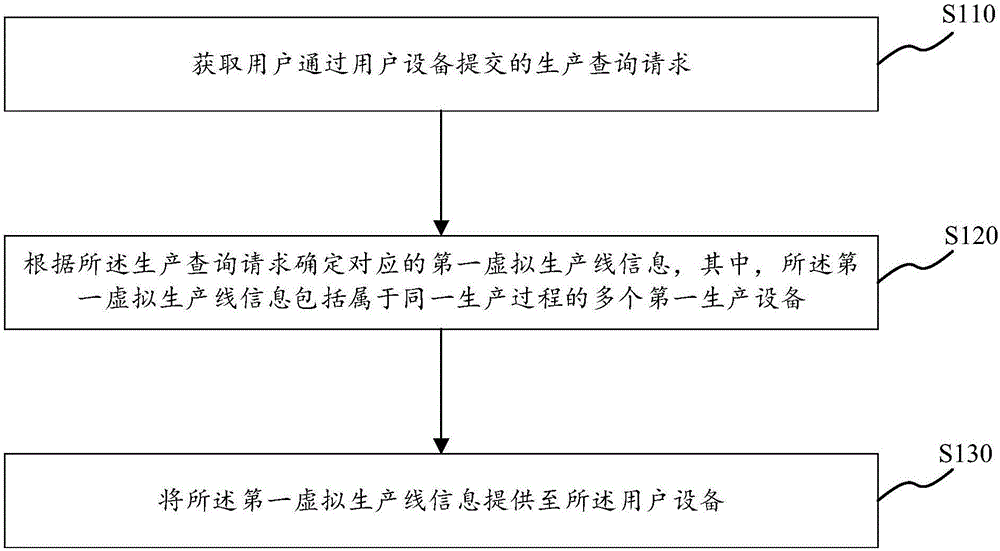

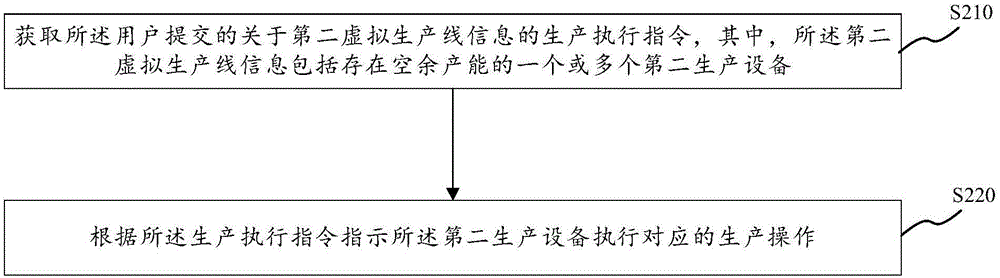

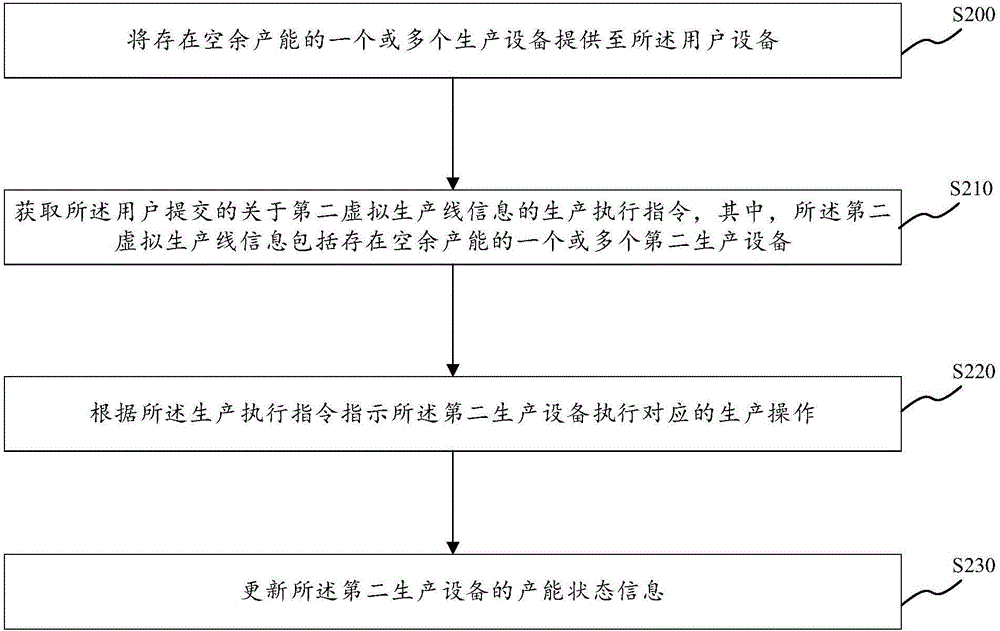

Method and device for providing and controlling production process information

ActiveCN106292617AFlexible configurationTotal factory controlProgramme total factory controlUser deviceProcess engineering

The invention aims at providing a method and device for providing and controlling production process information, wherein the provided method comprises the steps of a, obtaining production query request submitted through user equipment by a user; b, determining a corresponding first virtual production line information according to the production query request, wherein the first virtual production line information comprises a plurality of first production devices which belong to the same production process; c, providing the first virtual production line information to the user equipment. The control method comprises the steps of providing one or more production devices with spare capacity to the user equipment; obtaining a production execution instruction which is about a second virtual production line information and submitted by the user, wherein the second virtual production line information comprises one or more second production devices which are selected from one or more production devices; indicating that the second production devices performs corresponding production operations according to the production execution instruction. According to the method and device for providing and controlling production process information, the control efficiencies of production lines and the allocative efficiencies of the production lines are effectively improved.

Owner:北京华晋恒昇科技有限公司

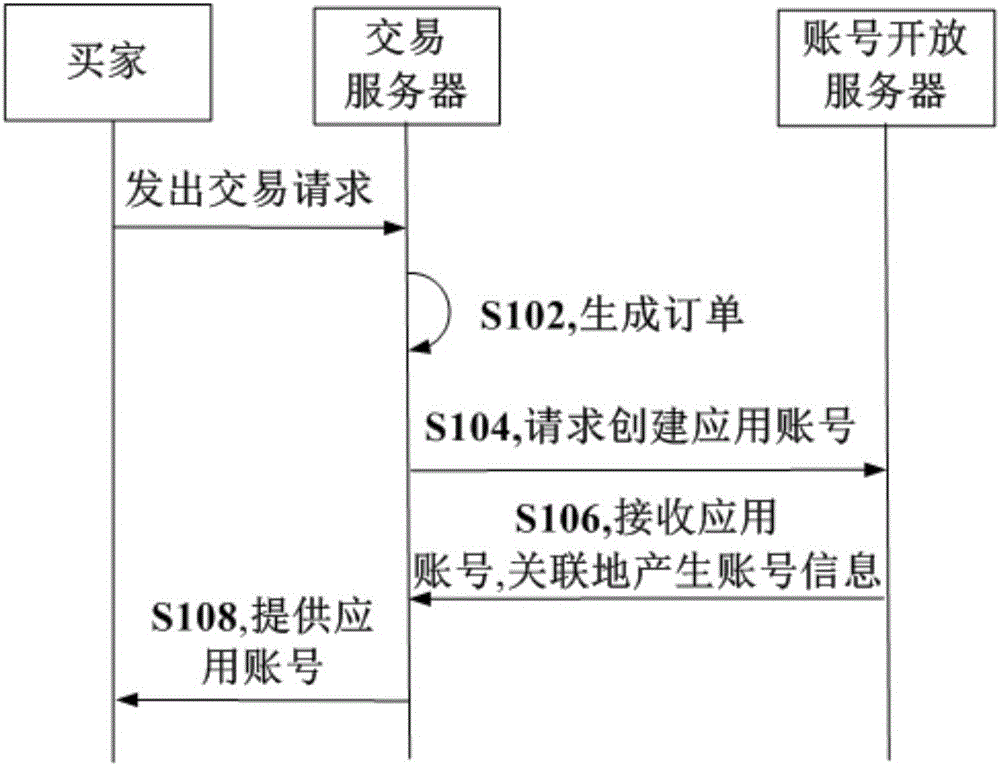

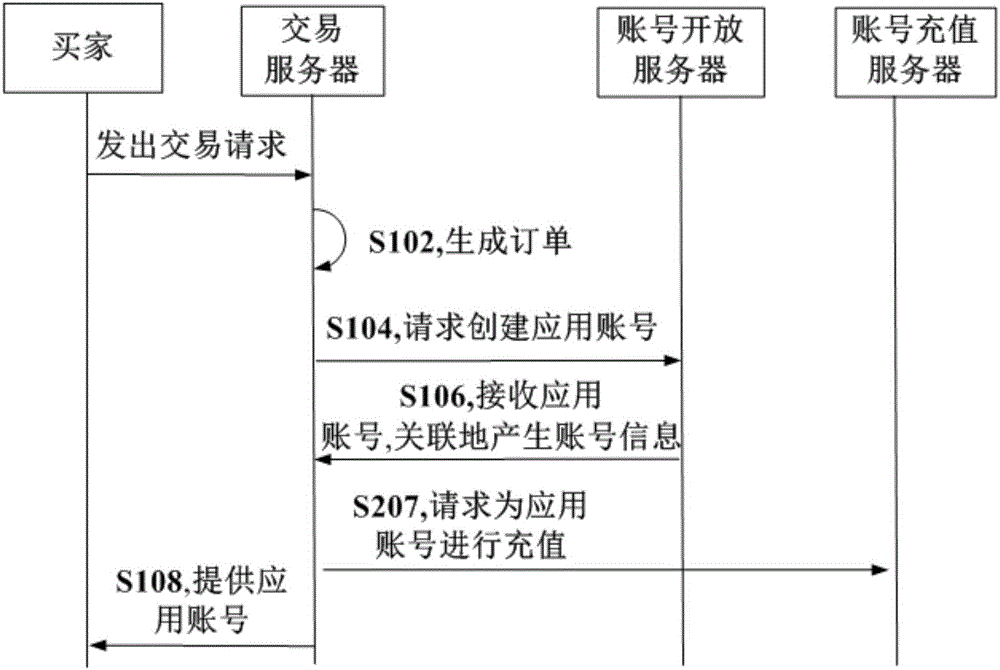

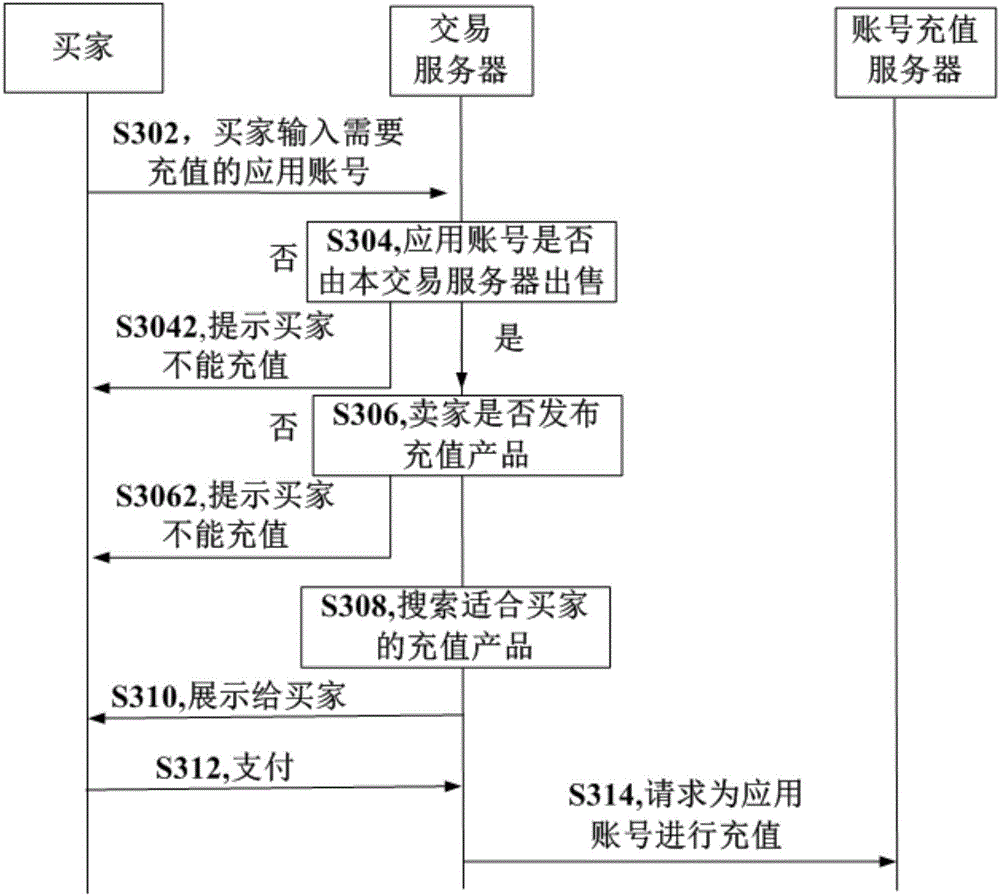

Account product transaction processing method and system and transaction server

ActiveCN105528725AAccurate search serviceEasy to findBuying/selling/leasing transactionsThird partyVirtual production

The invention provides an account product transaction processing method and system and a transaction server, and relates to the field of virtual production transaction of the network. The method comprises that the transaction server generates an order in response to a transaction request emitted by a buyer aimed at account product information issued by a seller, and order information recorded by the order comprises the order number and the number of third-party application to which the account product information belongs; according to the order information, the transaction server asks an account opening server of the third party application to create an application account of the third party application for the order; the transaction server receives the application account, of the third party application, returned by the account opening server, and generates account information, which comprises the application account and the number of the third party application, in an associated manner; and the transaction server provides the application account of the third party application for the buyer. Thus, the account can be created automatically, labor cost is reduced, and the account creating efficiency is improved.

Owner:一点灵犀信息技术(广州)有限公司

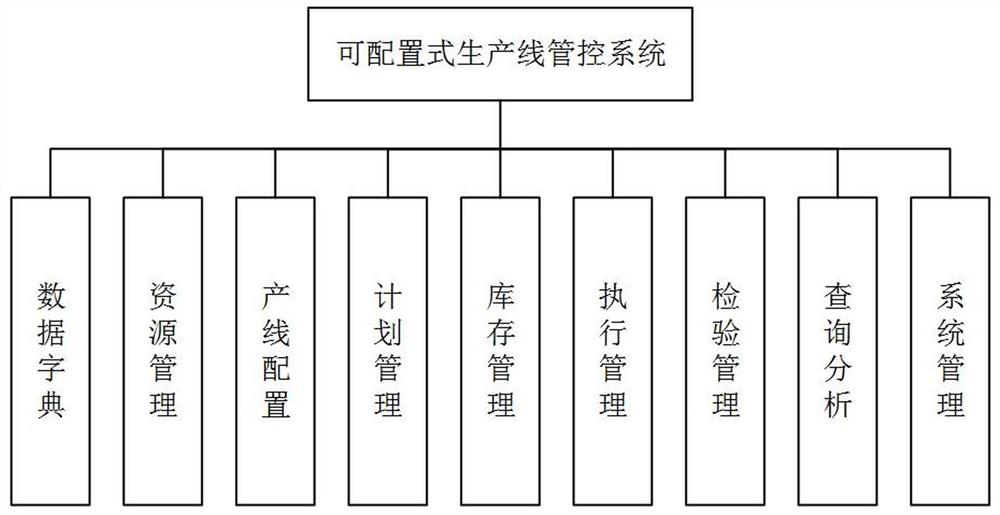

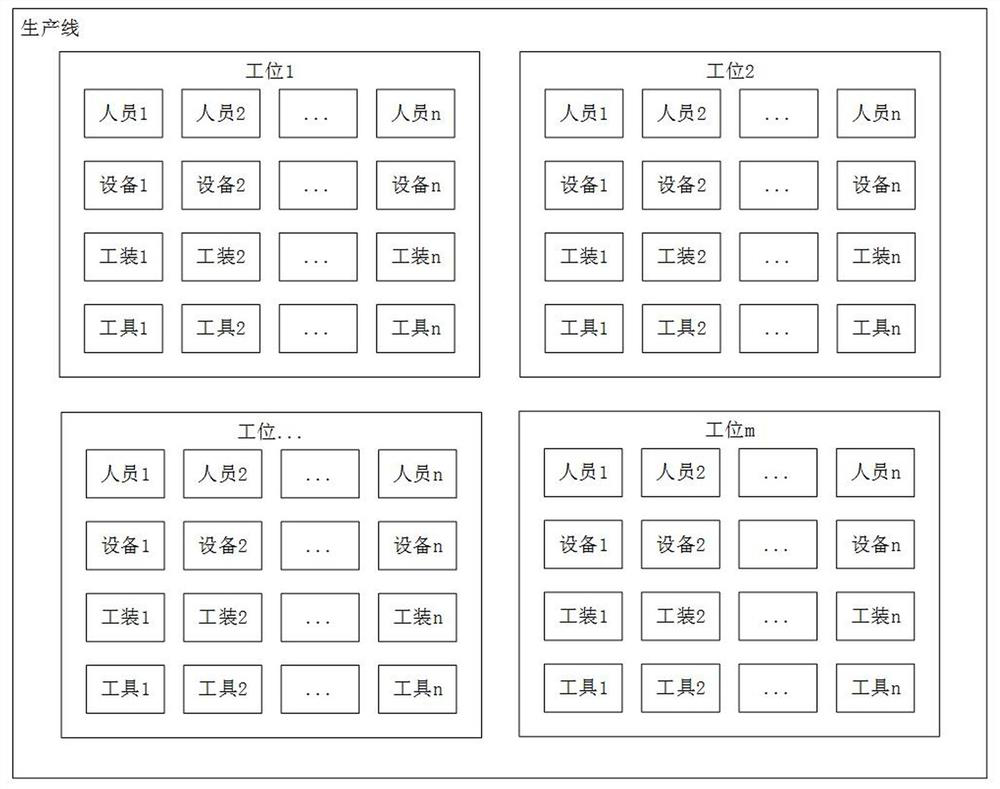

Configurable production line management and control system

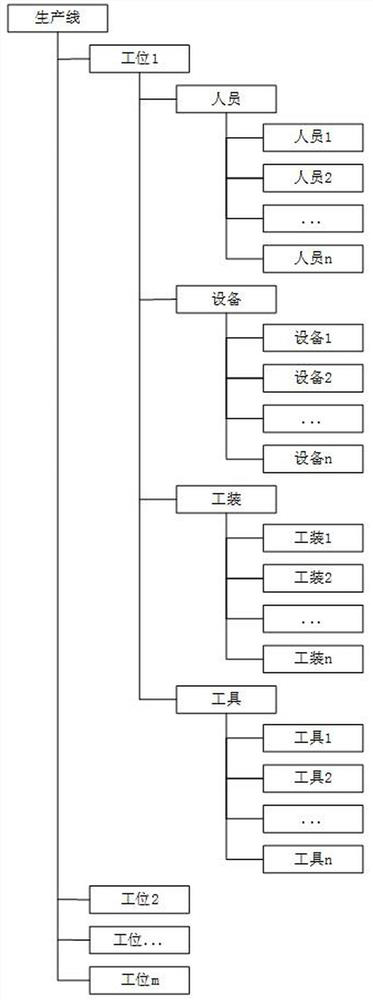

PendingCN113902268AImprove flexibilityImprove adaptabilityTechnology managementOffice automationQuery analysisSystems management

The invention relates to the technical field of mechanical manufacturing production line management and control, in particular to a configurable production line management and control system which comprises a data dictionary module, a resource management module, a production line configuration module, a plan management module, an inventory management module, an execution management module, an inspection management module, a query analysis module and a system management module. The production line configuration module is used for realizing definition and configuration of a system virtual production line; the inventory management module is used for realizing material on-demand accurate distribution, resource on-time matching and production line internal raw material and work-in-process inventory ledger management; and the execution management module is used for realizing visual guidance and execution data recording of an execution process of an issued production line plan of a set of production line materials and resources. Through the management and control system, the problem that a customized system frequently modifies bottom layer source code files and interfaces can be effectively solved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

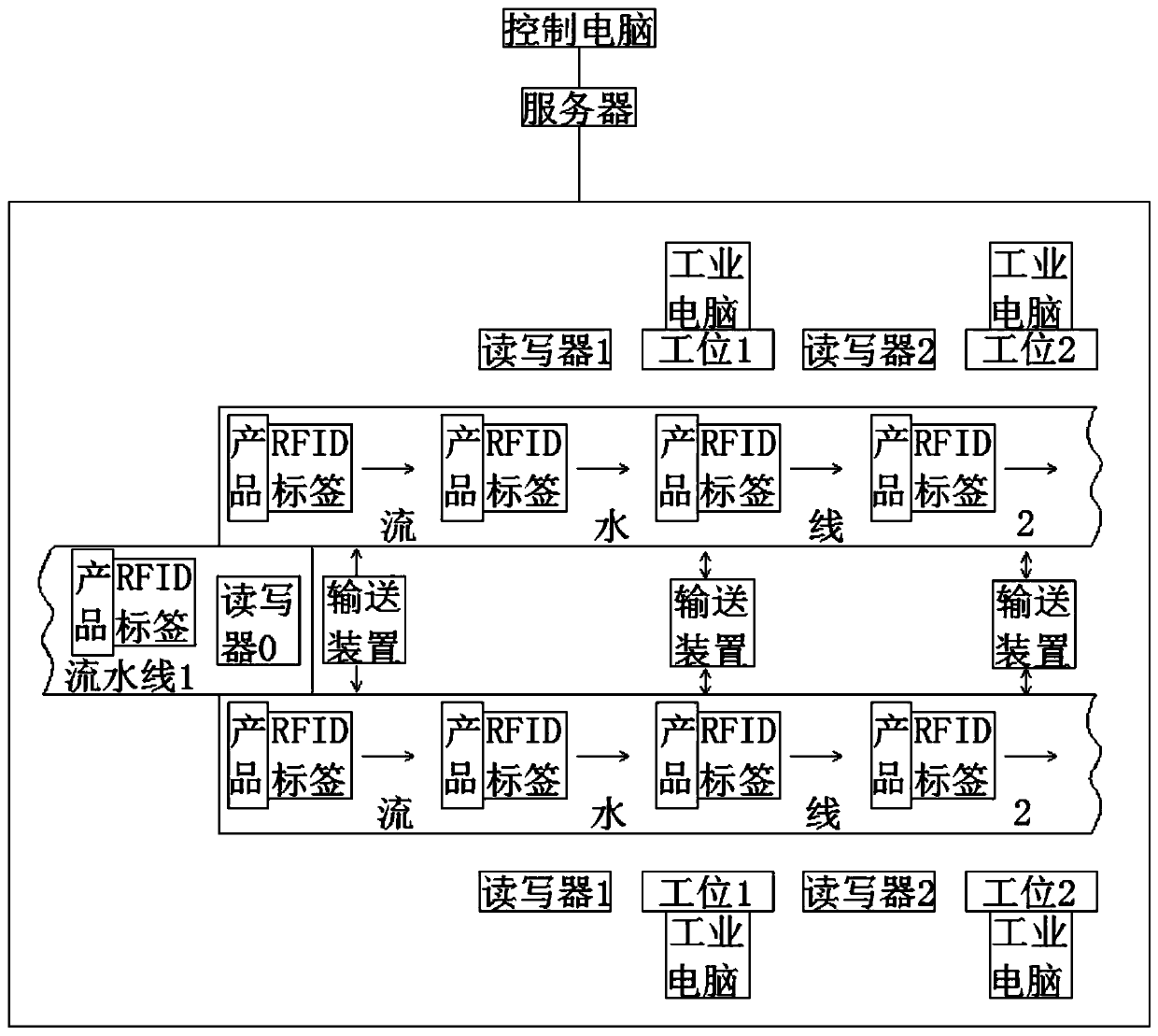

A remote production control method based on an RFID tag

InactiveCN109726781ASolve the problem of not writing informationAddresses ability to update memoryData processing applicationsCo-operative working arrangementsProduction lineRadio frequency signal

The invention relates to the technical field of remote production control methods, and discloses a remote production control method based on an RFID tag, which comprises the following steps that a virtual production line program is generated in a server according to the assembly requirement of a raw product, and the allowable longest dwell time Tmax and the maximum accumulation number Nmax of theraw product at each station are set; the in-situ product code is stored in a chip of the RFID tag, the in-situ product code comprises a mark code at the head end, an assembly line code at the middle end and a station code at the tail end, the station code is matched with a station needing to pass through, and the in-situ product code of the RFID tag is bound with a virtual production line program.The RFID tag is bound with the in-situ product, the reader-writer and the conveying device are matched, the target in-situ product can be conveniently and automatically recognized through radio frequency signals, relevant data of the RFID tag are conveniently obtained, manual intervention is not needed in the recognition work, wireless remote reading and writing and penetrability reading and writing can be achieved, and the production efficiency of a production line is improved.

Owner:ZHEJIANG SHUREN UNIV

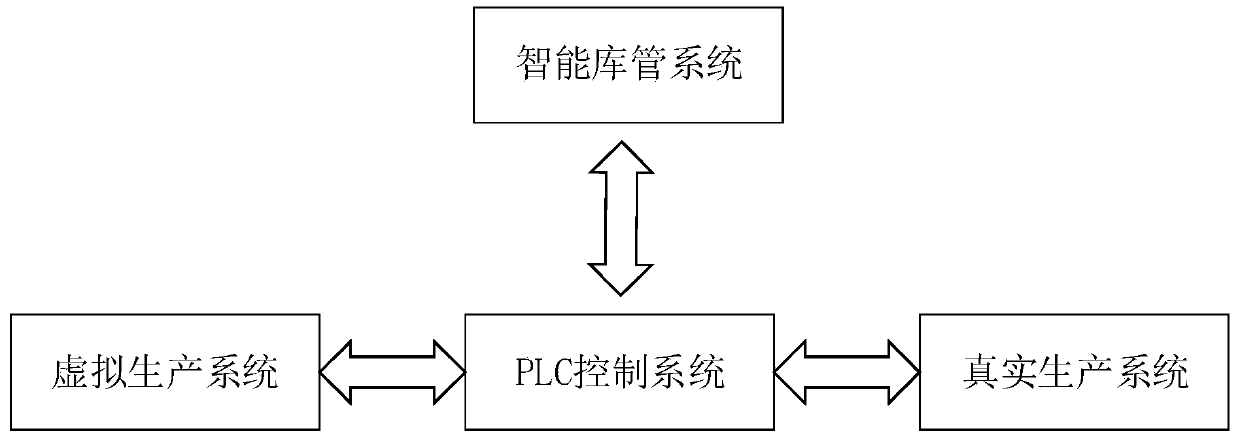

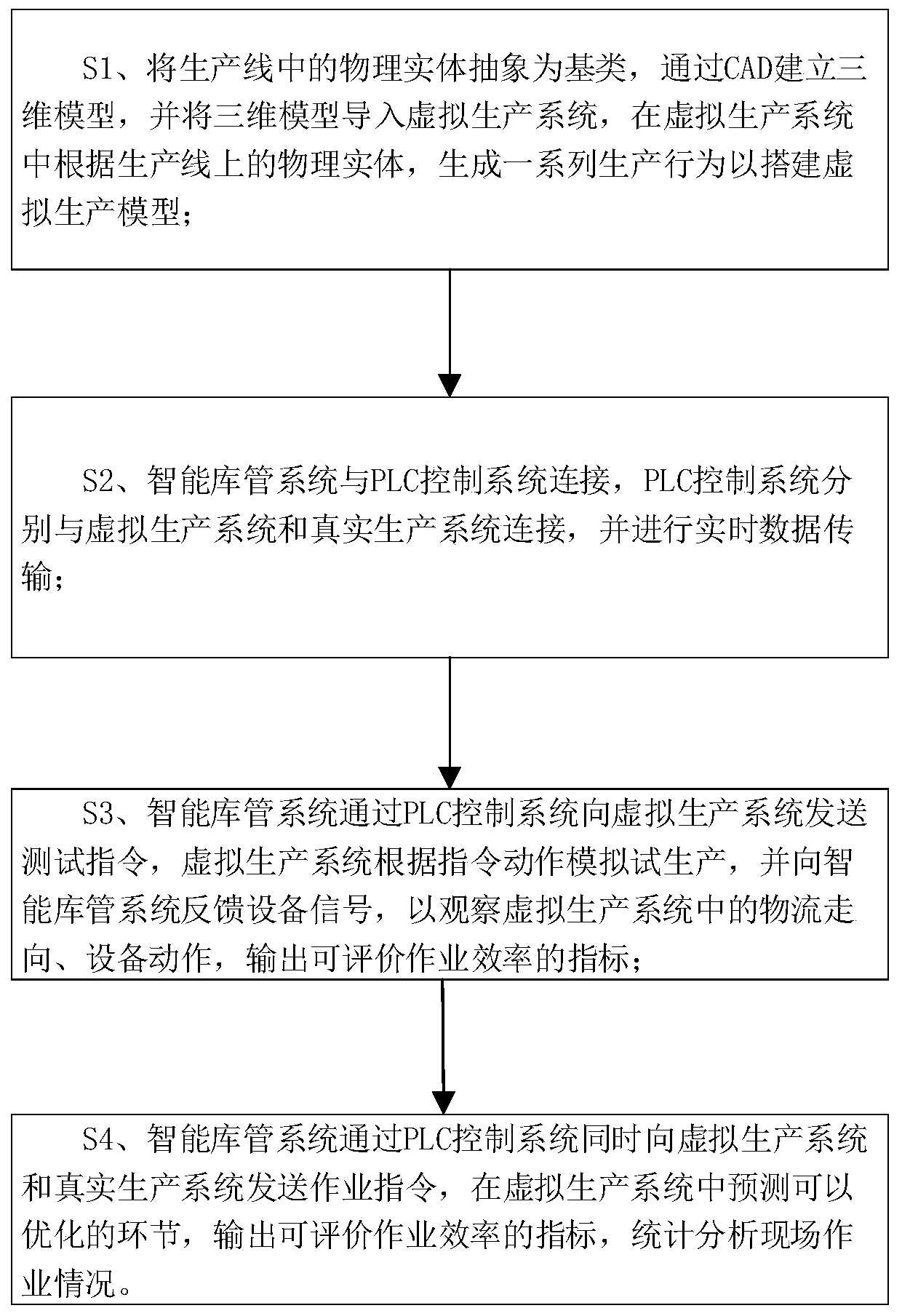

Unmanned warehouse logistics optimization system and method based on virtual production

ActiveCN110244676AWork efficiency can be evaluatedOptimize the logistics linkLogisticsTotal factory controlLogistics managementControl system

The invention provides an unmanned warehouse logistics optimization system based on virtual production. An intelligent warehouse keeper system, a PLC control system and a virtual production system are connected in sequence; the intelligent warehouse keeper system, the PLC control system and a real production system are connected in sequence; the intelligent warehouse keeper system is used for independently driving a virtual production model to act for production trial operation, so as to observe the logistics trend and the equipment action in the virtual production system and output an index capable of evaluating the operation efficiency; the intelligent warehouse keeper system is further used for driving the virtual production model and a real production site to act at the same time, predicting a link capable of being optimized in the virtual production system, outputting the index capable of evaluating the operation efficiency, and counting and analyzing the field operation condition. Through real-time interaction between the intelligent warehouse keeper system, the PLC system and the virtual production model, trial production can be carried out under a new condition, a high-load condition or other conditions, so as to evaluate the production process; virtual production and actual production can be controlled to be conducted synchronously; and the logistics link capable of being optimized can be mined, so that the logistics is more smooth.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Parts procurement system and method

InactiveUS7251539B2Keep for a long timeAccurately reflectOffice automationResourcesProduction lineLead time

A virtual production line indicating an object (e.g., a vehicle) sequence for an actual production line and objects (e.g., vehicles) planned in the future is updated based on a long-term production plan, a fixed production plan, and actual production results. Then, the ordering timings for the parts necessary for the respective objects in the virtual production line are calculated based on the timing for using the parts and the delivery lead time, and the orders are placed according to those timings.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com