Hot continuous rolling process monitoring and early warning method based on digital twinning

A rolling process, hot continuous rolling technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the unfavorable product quality and production process stability, the inability to realize the actual monitoring of the production process, and the difficulty of real-time quality indicators Measurement and other issues, to achieve the effect of perfecting the production organization model, enriching the production organization model, and reducing the generation of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

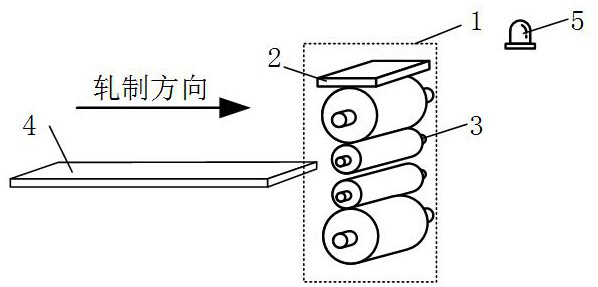

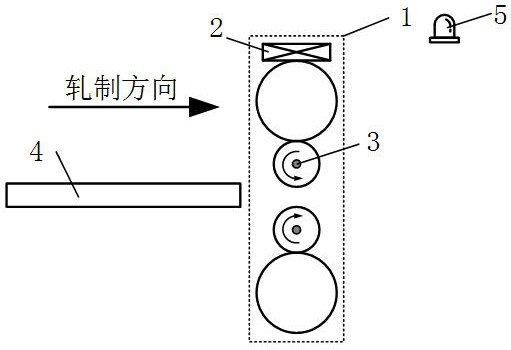

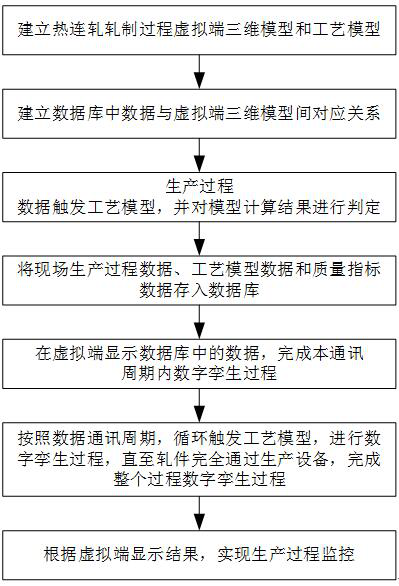

[0028] Because the hot continuous rolling process includes numerous production equipments, the main production process includes the vertical roll rolling process that deforms the width and the flat roll rolling process that makes the thickness change; this embodiment takes the flat roll rolling process as an example The digital twin construction process of the hot continuous rolling process is described. The flat roll rolling process is as follows: figure 1 and figure 2 Shown; Among them, the flat roll is used as a virtual device, and the thickness of the rolled piece after flat roll rolling is used as a quality index. The thickness of the rolled piece 4 changes after p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com