Patents

Literature

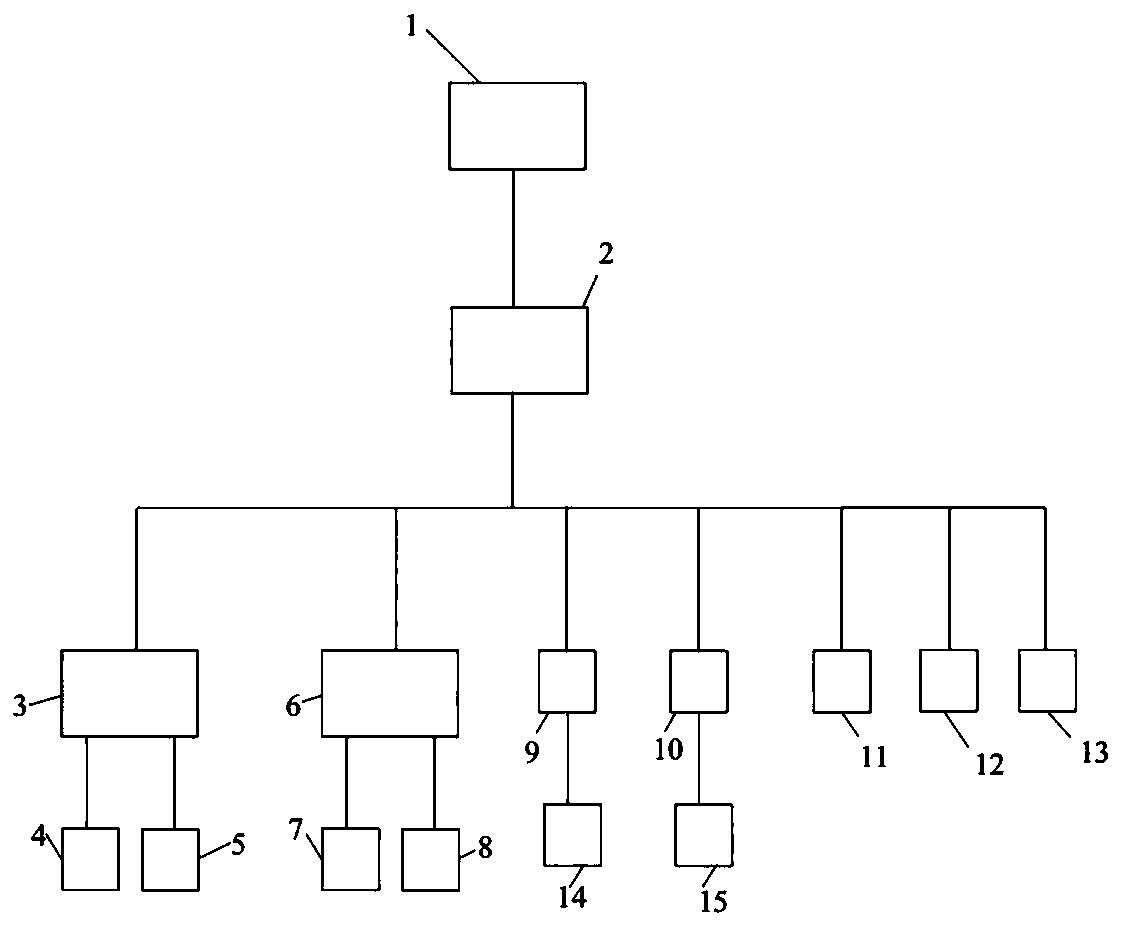

139results about How to "Solve fit problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

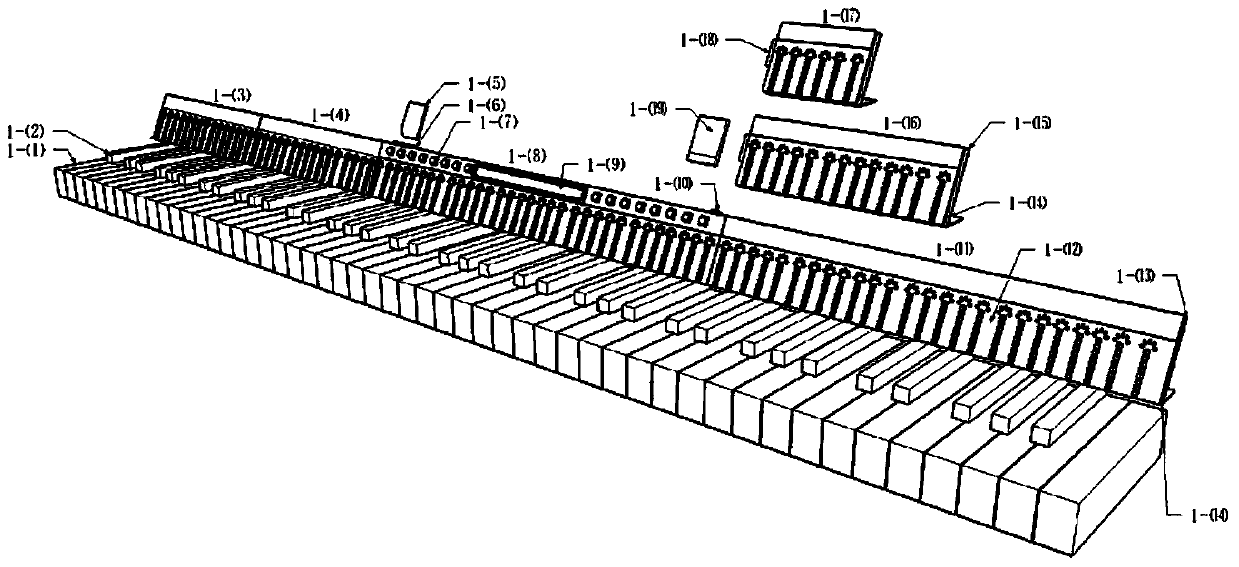

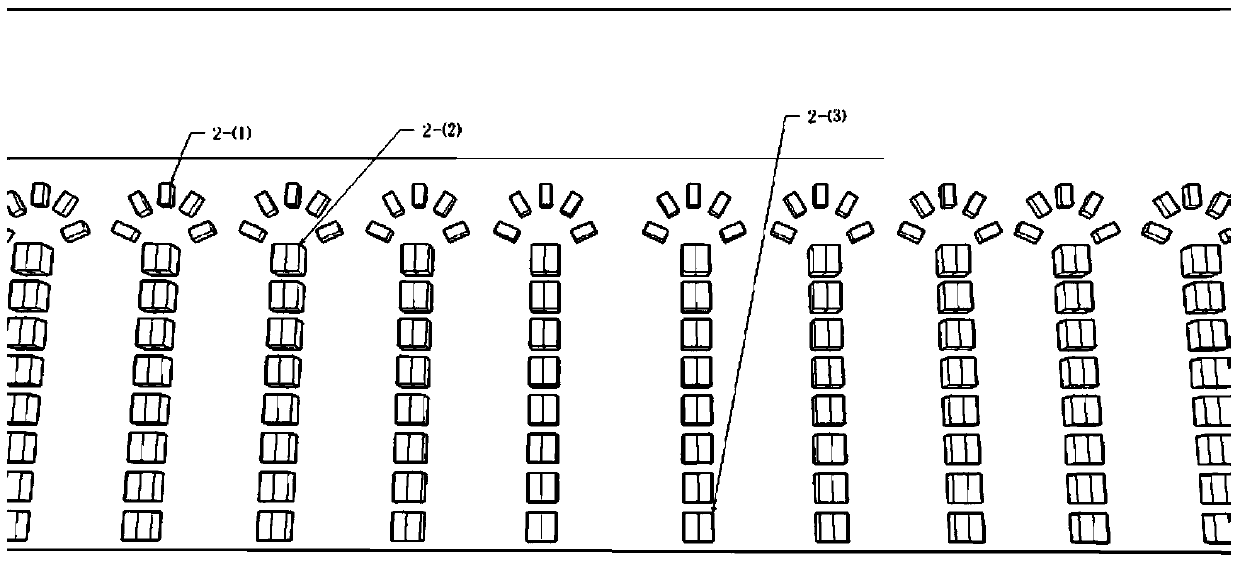

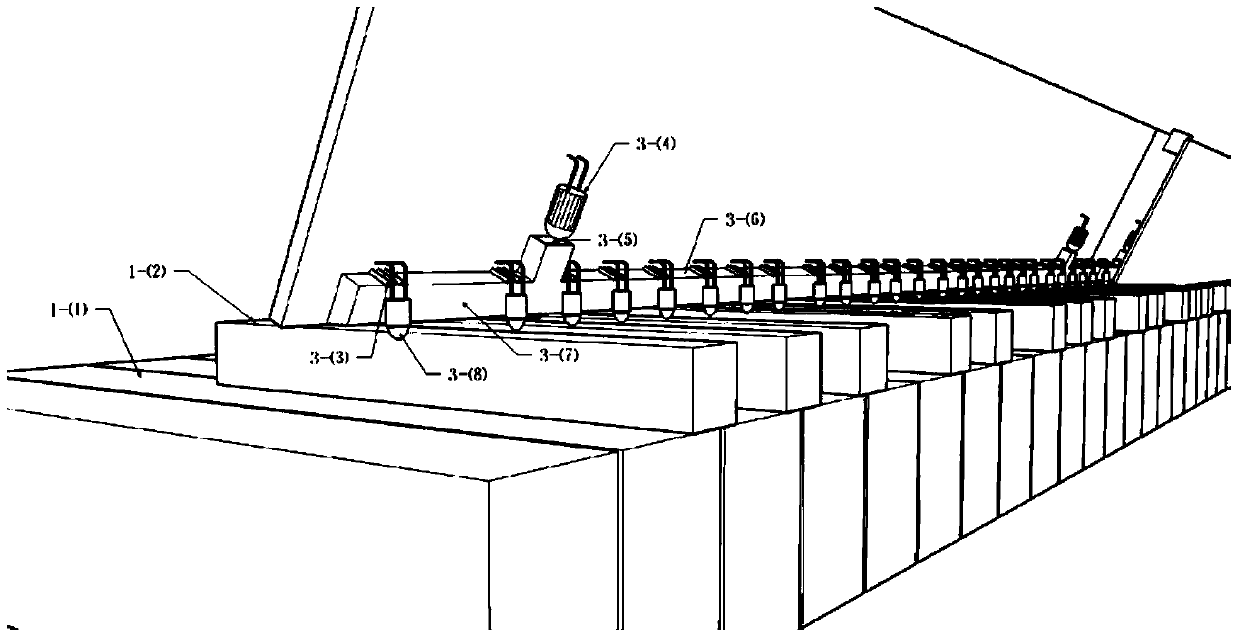

Music score and fingering electronic lamplight analog display method and keyboard instrument auxiliary teaching device

ActiveCN103778821AOvercoming Spectrum DisordersRelieve spectrum barriersStringed musical instrumentsMusicDigital interfaceHarmonic

The invention belongs to the technical field of music teaching equipment, in particular to a music score and fingering electronic lamplight analog display method and a keyboard instrument auxiliary teaching device. The method comprises the following implementation steps: (1) converting a music score or an MIDI (Musical Instrument Digital Interface) file into an electronic music score file which can be decoded by using a display device together with the fingering information of each pitch; (2) saving the converted electronic music core file in mobile storage equipment, and connecting the mobile storage equipment to the display device; (3) erecting the display device above keys corresponding to each key, and displaying pitches, lengths, rhythms, beats, themes, harmonics, combos and fingering in the form of light by using the display device along with the playing of an electronic music score file. By directly placing an electronic music score display screen on the keys in the auxiliary teaching device for implementing the method, the problem of matching of hands and eyes of a learner is solved completely, and the learning interest of the learner is increased greatly.

Owner:罗淑文

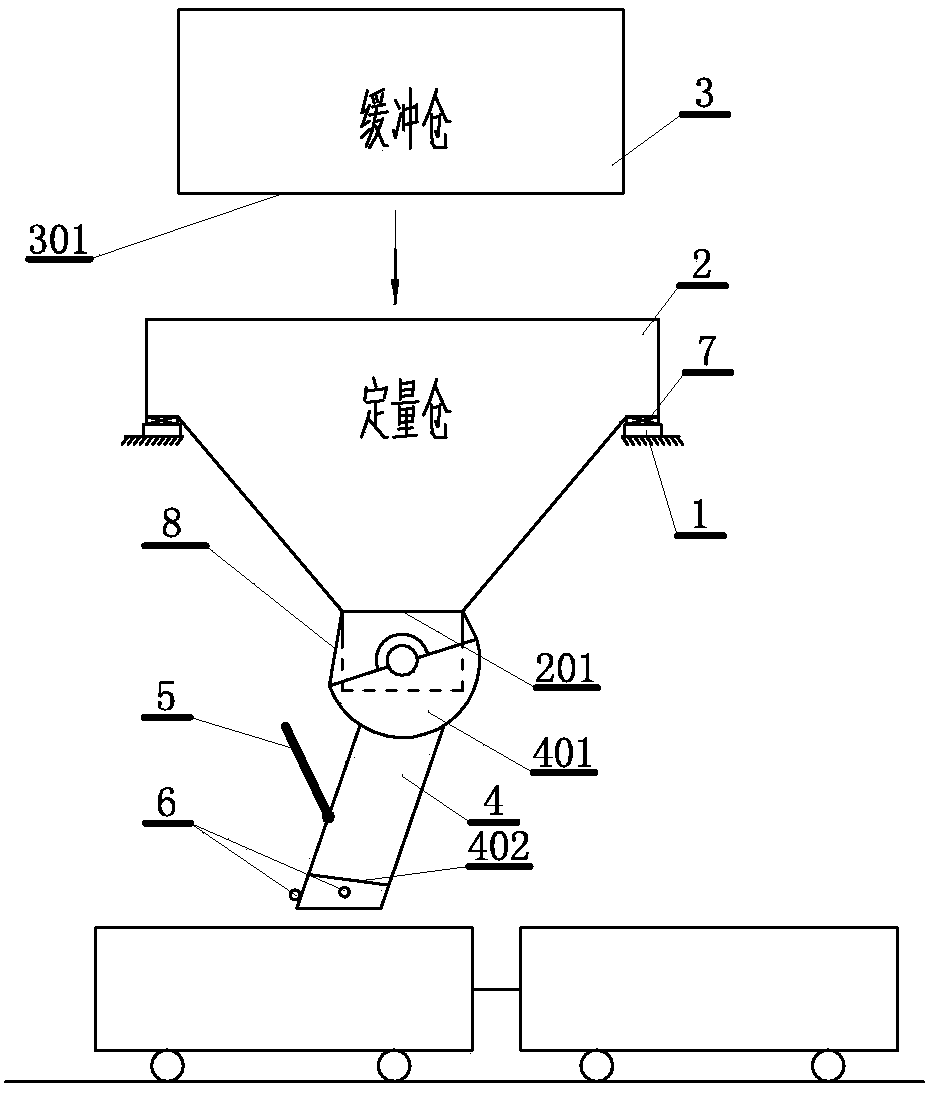

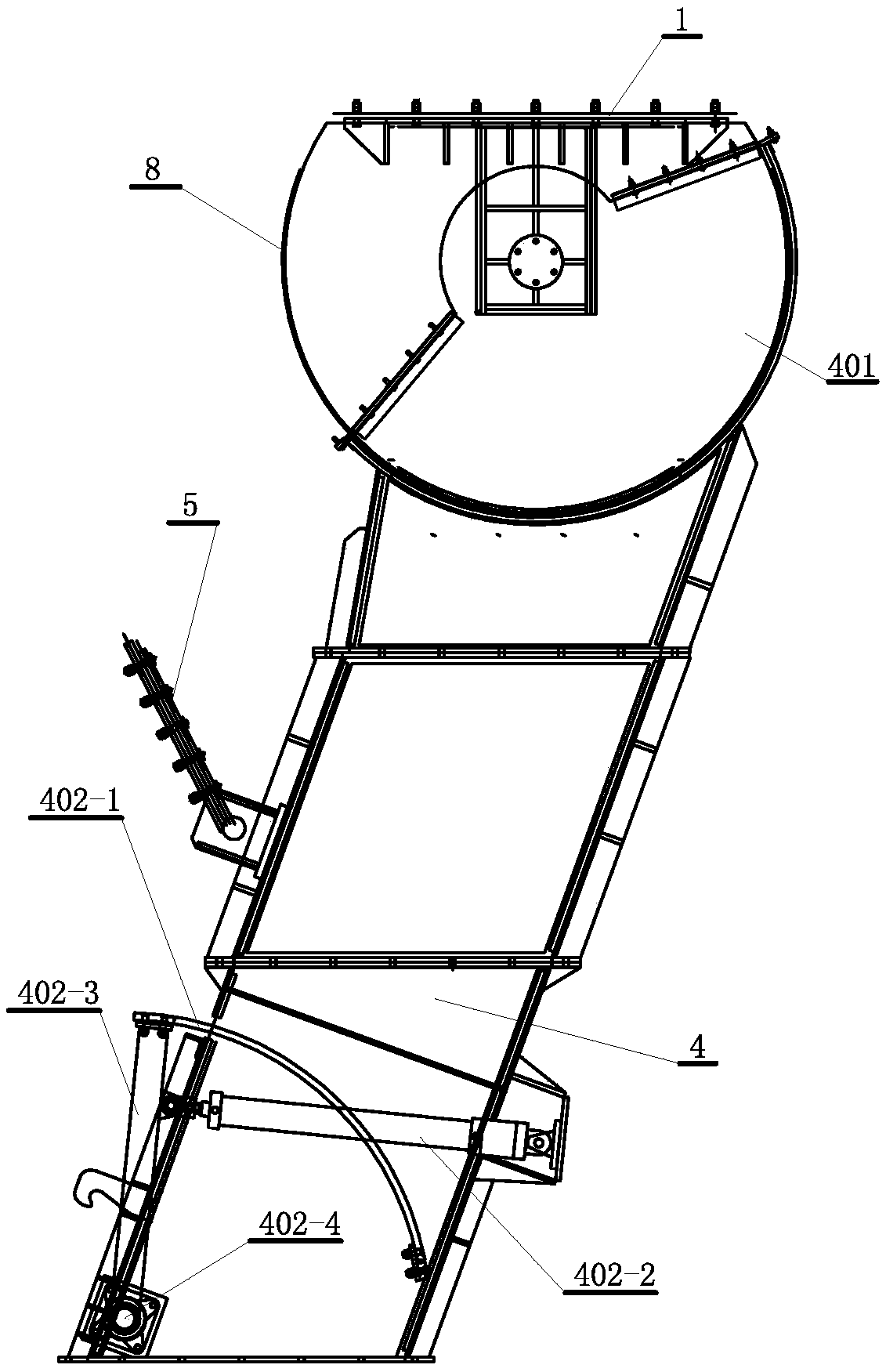

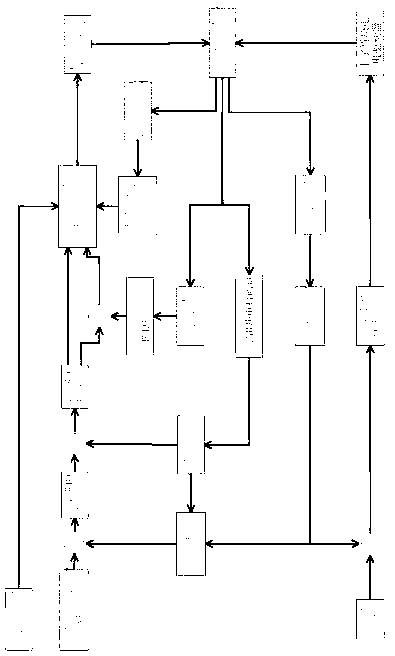

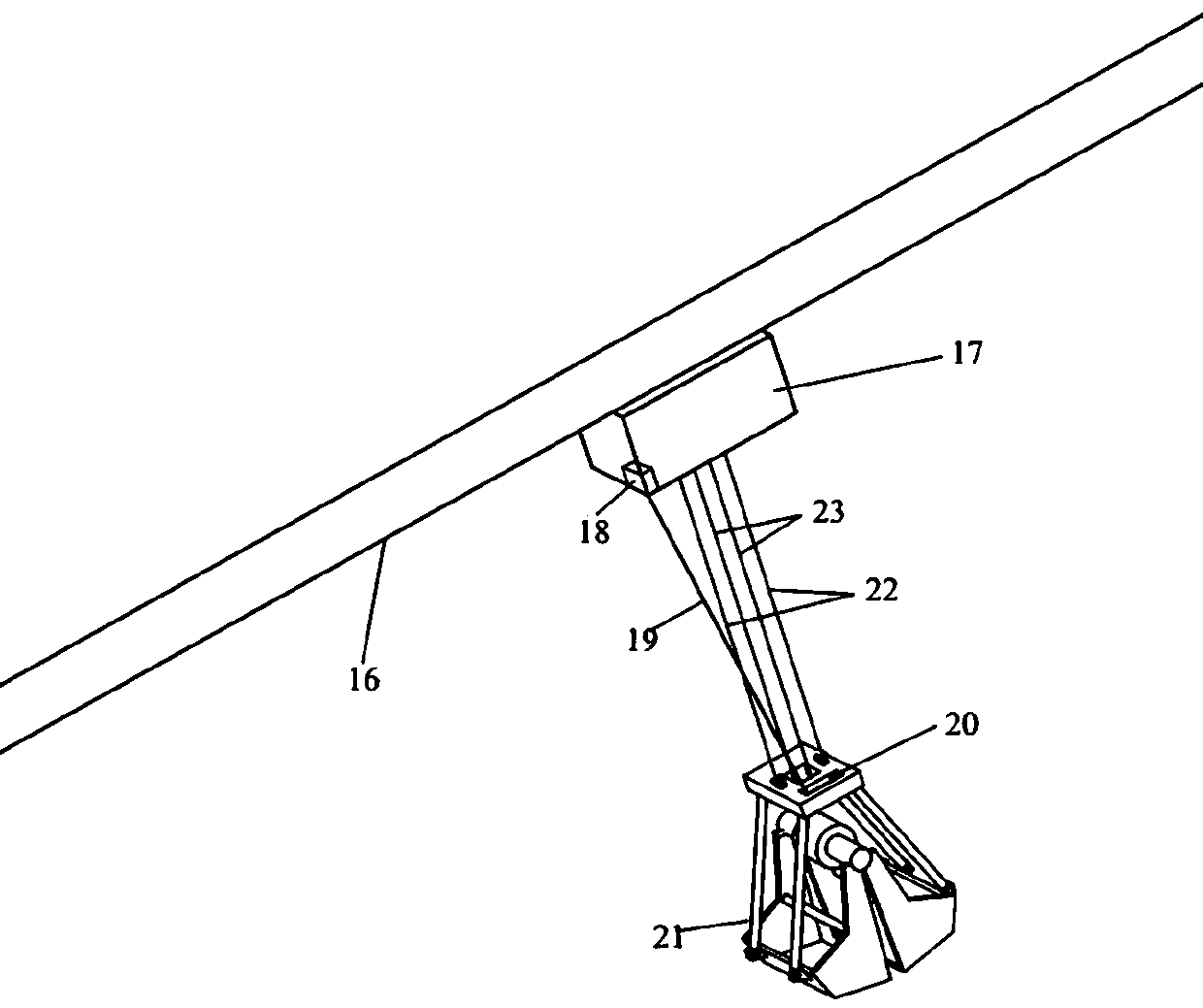

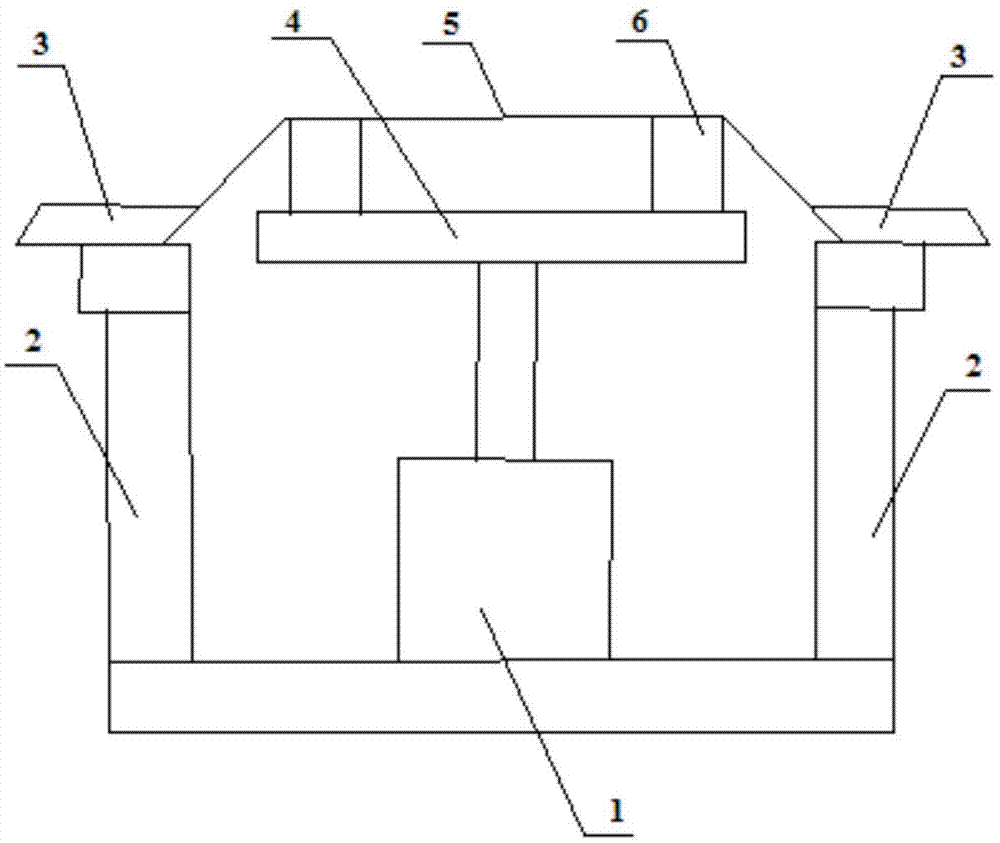

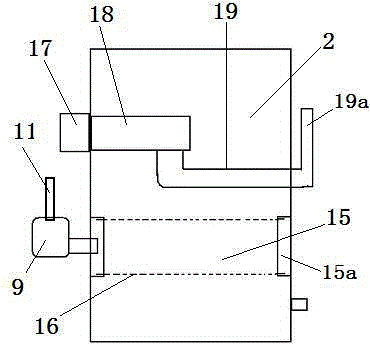

System and method of full-automatic continuous quantitative loading of railway freight train

PendingCN108792662ASolve fit problemsSolve coordination problemsConveyorsControl devices for conveyorsFreight trainsControl system

The invention discloses a system and a method of full-automatic continuous quantitative loading of a railway freight train. The system comprises a quantitative bin which is arranged in a train carriage loading region across a train track through a support, a material buffering bin is arranged on the upper side of the quantitative bin, a feeding gate is arranged at the lower end of the buffering bin in an alignment mode, and a material discharging gate is arranged at the lower end of the quantitative bin; the lower end of the quantitative bin is connected with a loading sliding groove, a vehicle loading control system is used for control the buffer bin and the quantitative bin to carry out continuous and quantitative loading of a freight train by judging the identification and the speed ofa vehicle identification. According to the system and the method, the problem of synchronization in cooperation and coordination of equipment and the train carriage is solved, the equipment feeding issynchronous with the train, manual intervention is not needed in a cooperating problem of the sliding groove and the carriage during material discharging, so that the labor intensity is reduced; andautomatic adjustment of the loading sliding groove can be realized, weighing, loading and leveling are realized, and the transportation efficiency is improved.

Owner:TIANDI SCI & TECH CO LTD

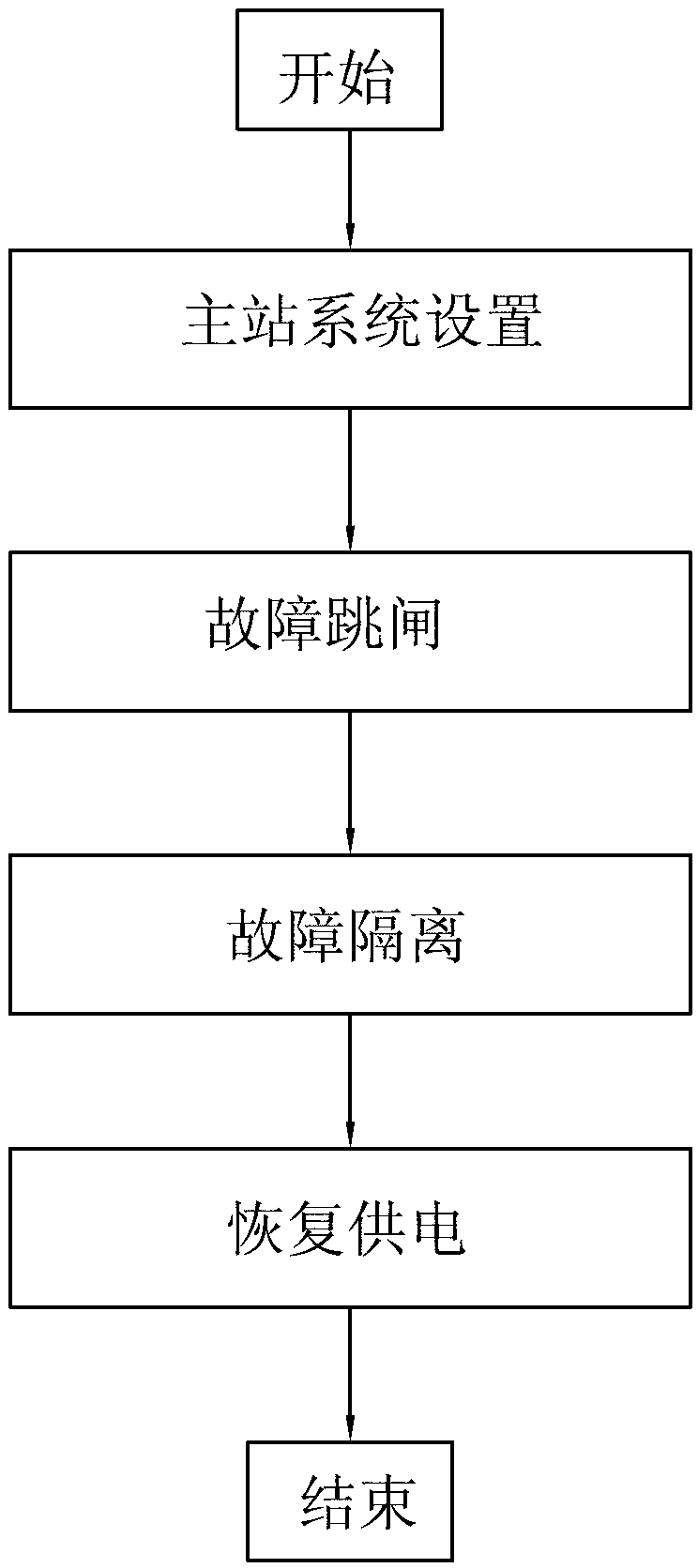

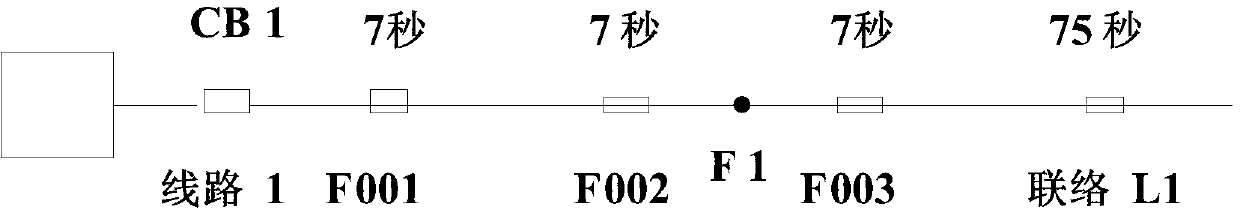

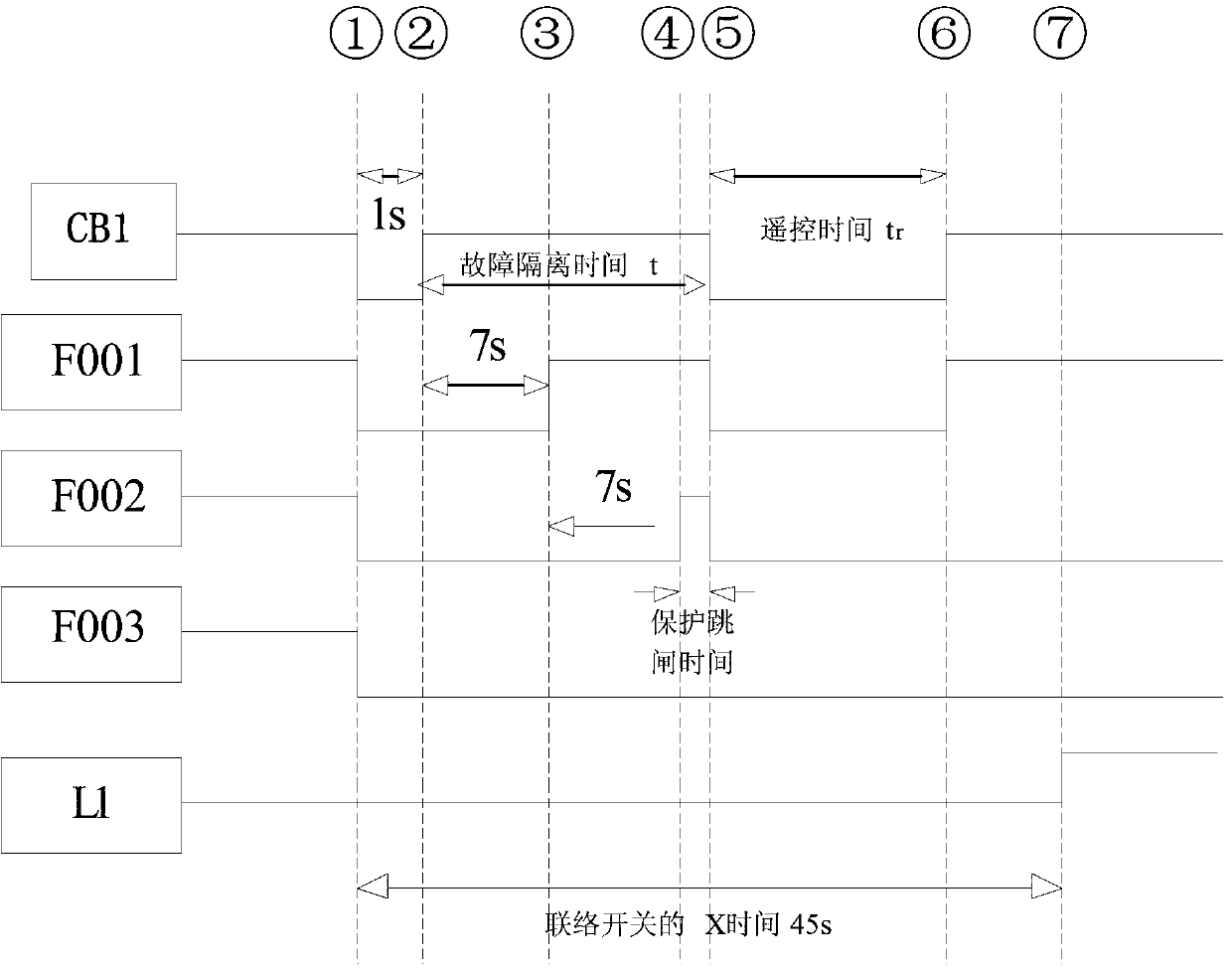

Voltage-time feeder automation control method based on primary station control strategies

InactiveCN103001192ASolve fit problemsImprove securityEmergency protective circuit arrangementsSustainable buildingsResidencePrimary station

The invention discloses a voltage-time feeder automation control method based on primary station control strategies. The method includes the steps of firstly, configuring a distribution automation primary station, namely configuring criterion conditions of 'remote switching on' of the distribution automation primary station; secondly, fault tripping, namely switching off all voltage-time switches on a distribution line and starting count down; thirdly, fault separating, namely simultaneously locking voltage-time section switches on two sides of a fault point to realize fault section separation; and fourthly, recovering power supply, namely sequentially switching on voltage-time section switches, from voltage-time section switches near a converting station to voltage-time section switches distant from the converting station, on the distribution line with the fault point to realize power supply of non-fault areas. By modifying distribution automation primary station control strategies, coordination of single shot reclosing of the voltage-time feeder automation and the converting station is achieved, safety and reliability of distribution lines are improved greatly, production and living power of factories and residence are guaranteed effectively.

Owner:STATE GRID CORP OF CHINA +1

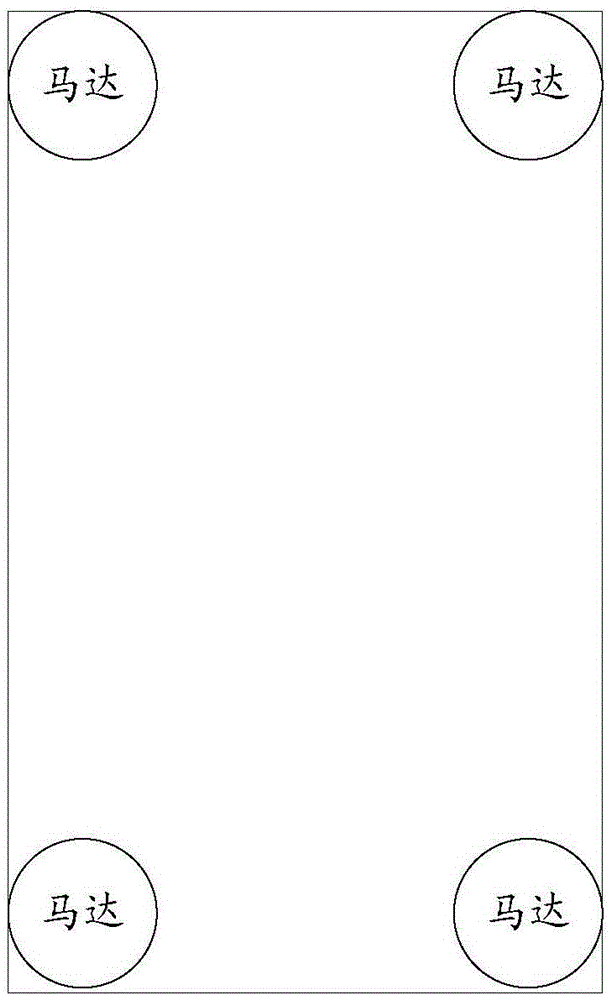

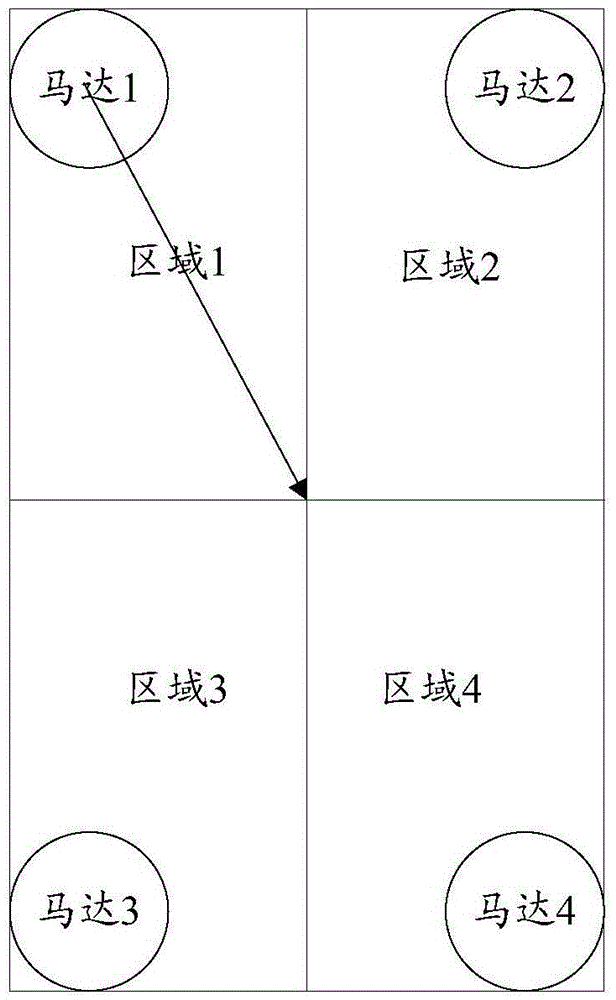

Electronic equipment and control method

InactiveCN105549777ASolve fit problemsImprove user experienceDigital data processing detailsInput/output processes for data processingComputer scienceHeavy weight

The invention discloses electronic equipment. The electronic equipment comprises N motors, a processor and a controller, wherein N is a positive integer greater than or equal to 2; the N motors are uniformly distributed in an electronic equipment space; the processor is used for judging whether a trigger condition is satisfied according to the current state of the electronic equipment; and the controller is used for controlling at least one motor of the N motors to start according to a preset rule when the trigger condition is satisfied so as to ensure that the at least one motor is in a working state in a preset time. Meanwhile, the invention furthermore discloses an electronic equipment control method. By adopting the technical scheme in the invention, the problem of weak vibration sense or no vibration sense caused by the heavy weight of the electronic equipment can be solved, the problem of coordination among the motors can be solved at the same time, and the user experience can be improved.

Owner:LENOVO (BEIJING) CO LTD

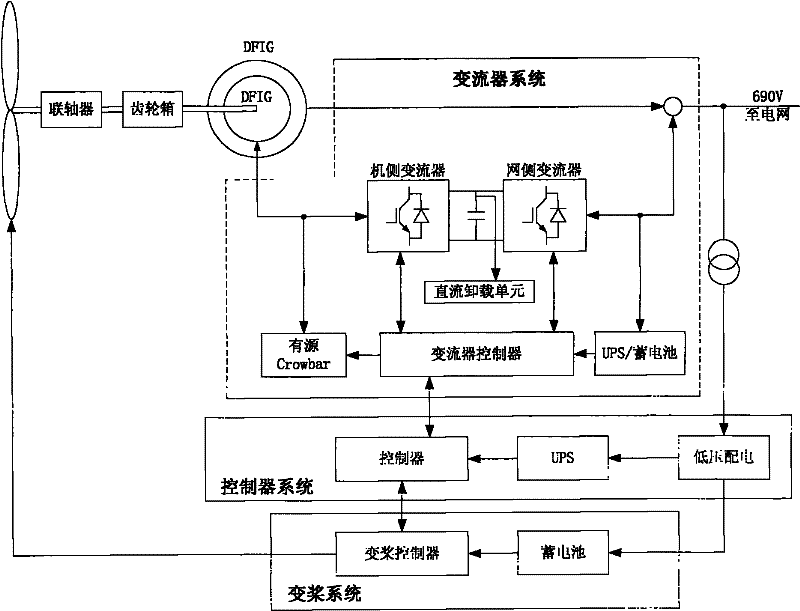

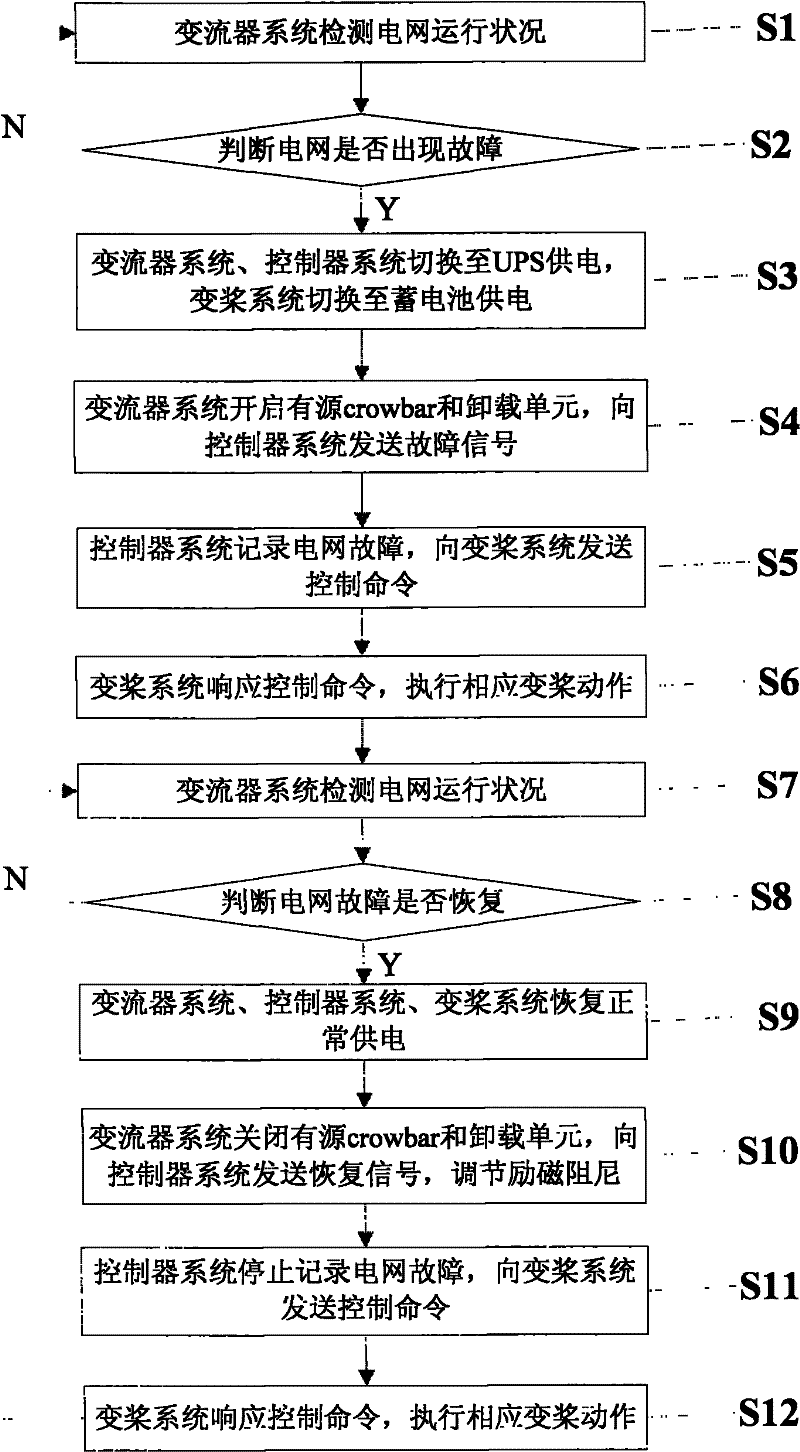

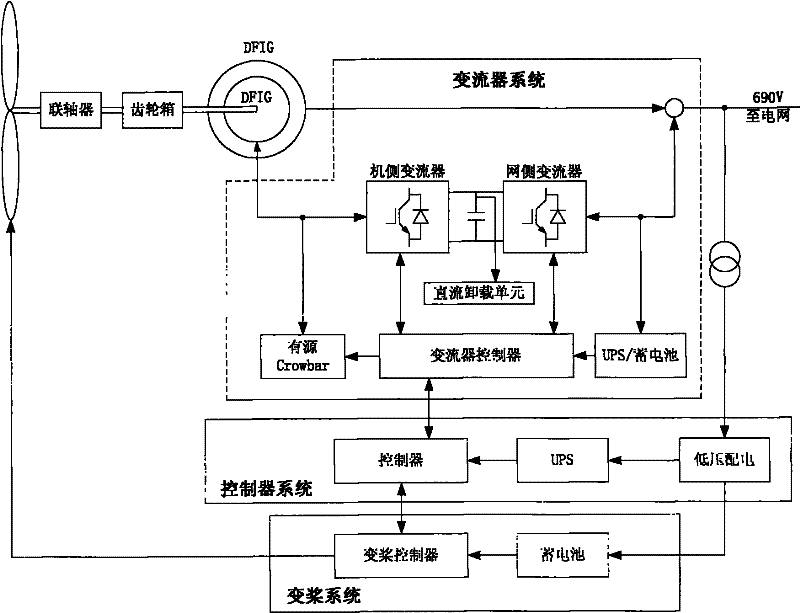

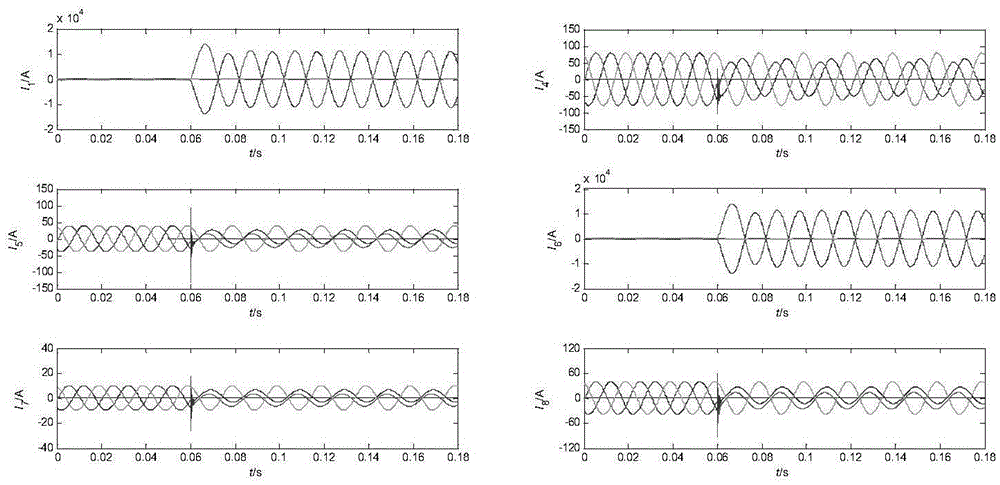

Power grid failure traversing system and method of 2 MW and more than 2 MW double-fed wind generating set complete machine

InactiveCN102457195AReduce speedReduce maintenance costsSingle network parallel feeding arrangementsAc-ac conversionFailure ratePower grid

The invention provides a power grid failure traversing system and method of a 2 MW and more than 2 MW double-fed wind generating set complete machine. The system comprises a convertor system, a controller system, a pitch system and a torque limiter. The method comprises the following steps: detecting the operation condition of a power grid; judging whether a failure appears: if not, returning to the step S1, and if so, dynamically switching to a failure traversing operation mode; detecting the operation condition of the power grid; and judging whether the failure recovers: if not, returning to the step S7, if so, recovering a normal operation state, and then returning to the S1. According to the invention, while the protection actions of each part in a failure period are ensured, the conjugation problem of an integrated system is solved, no-network operation in the failure period is realized, the power grid is supported, and the service life of a machine set is prolonged; and the failure rate of the machine set is reduced, thereby greatly reducing the maintenance cost of the machine set.

Owner:上海电气风能装备有限公司

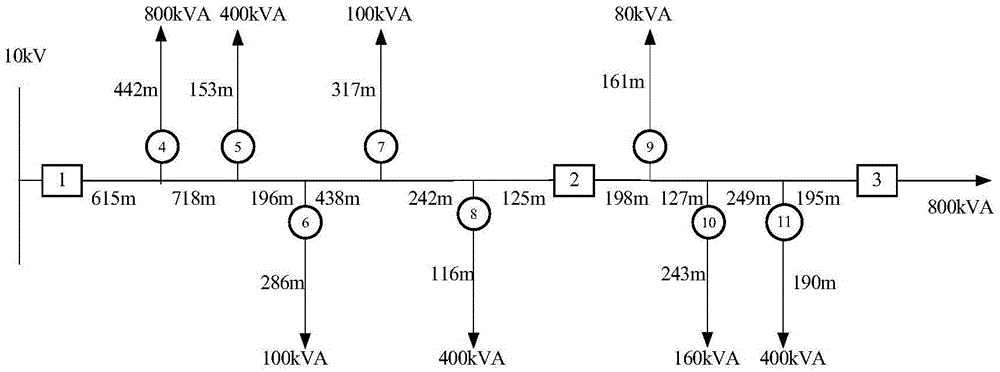

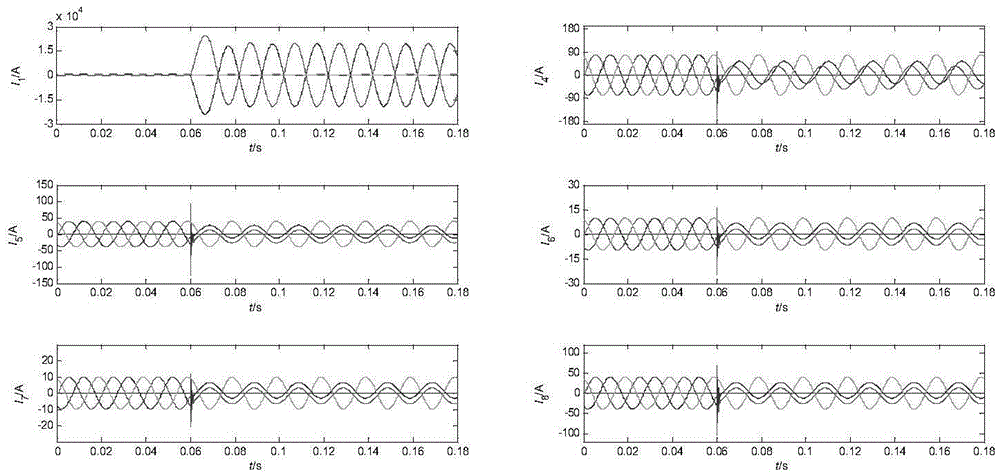

Fault indicator and distributed intelligent terminal matched overhead distribution network fault positioning method

ActiveCN105527540AReduce labor intensityLess investmentFault location by conductor typesInformation technology support systemFault indicatorDistributed intelligence

The invention relates to a fault indicator and distributed intelligent terminal matched overhead distribution network fault positioning method, and belongs to the technical field of relay protection of power systems. On the premise that overcurrent relay protection of a traditional distribution network is not changed, distributed intelligent terminals are installed on circuit breakers at all trunk section points and fault indicators are installed on all branch circuits, the installation positions of the distributed intelligent terminals are taken as nodes, a relation between the fault indicators and the nodes is defined according to the positions of the nodes and the fault indicators, and trunk units and branch units are divided and numbered to form a unit adjacency list. When faults occur, an automatic reclosing lock recloses transient faults, the distributed intelligent terminals isolate permanent faults, and meanwhile, the distributed intelligent terminals and the fault indicators detect current values and compare maximum branch current values in the relevant unit adjacency list to position trunk faults and branch faults.

Owner:DALI POWER SUPPLY BUREAU YUNNAN POWER GRID +1

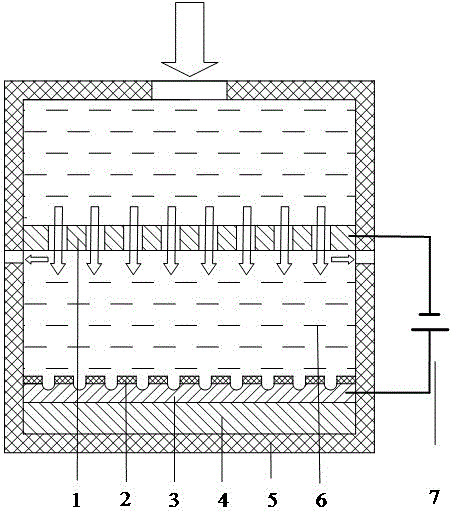

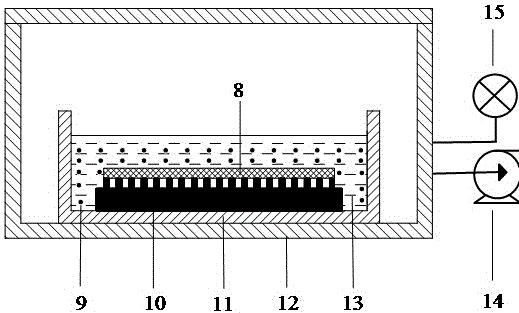

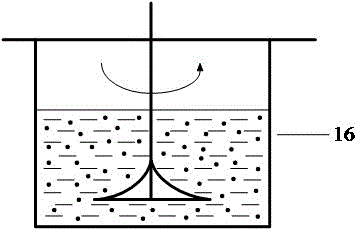

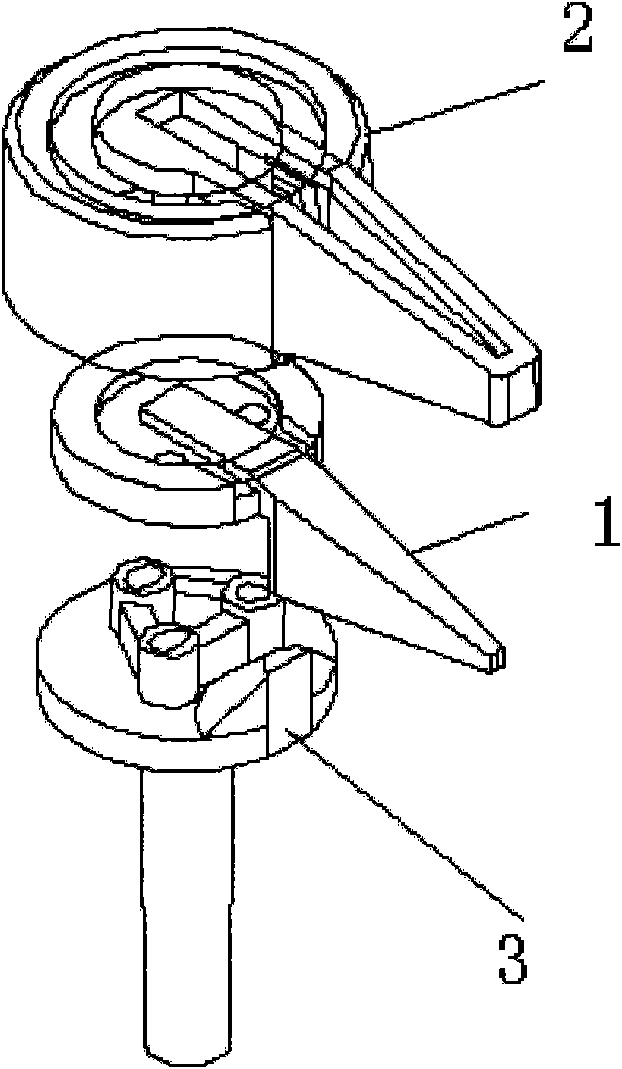

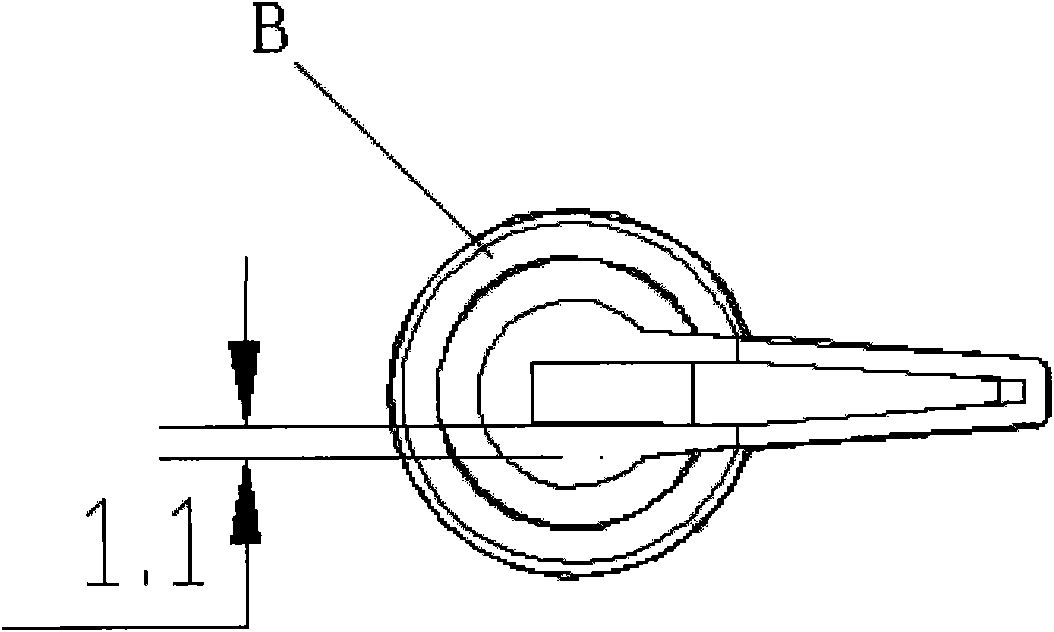

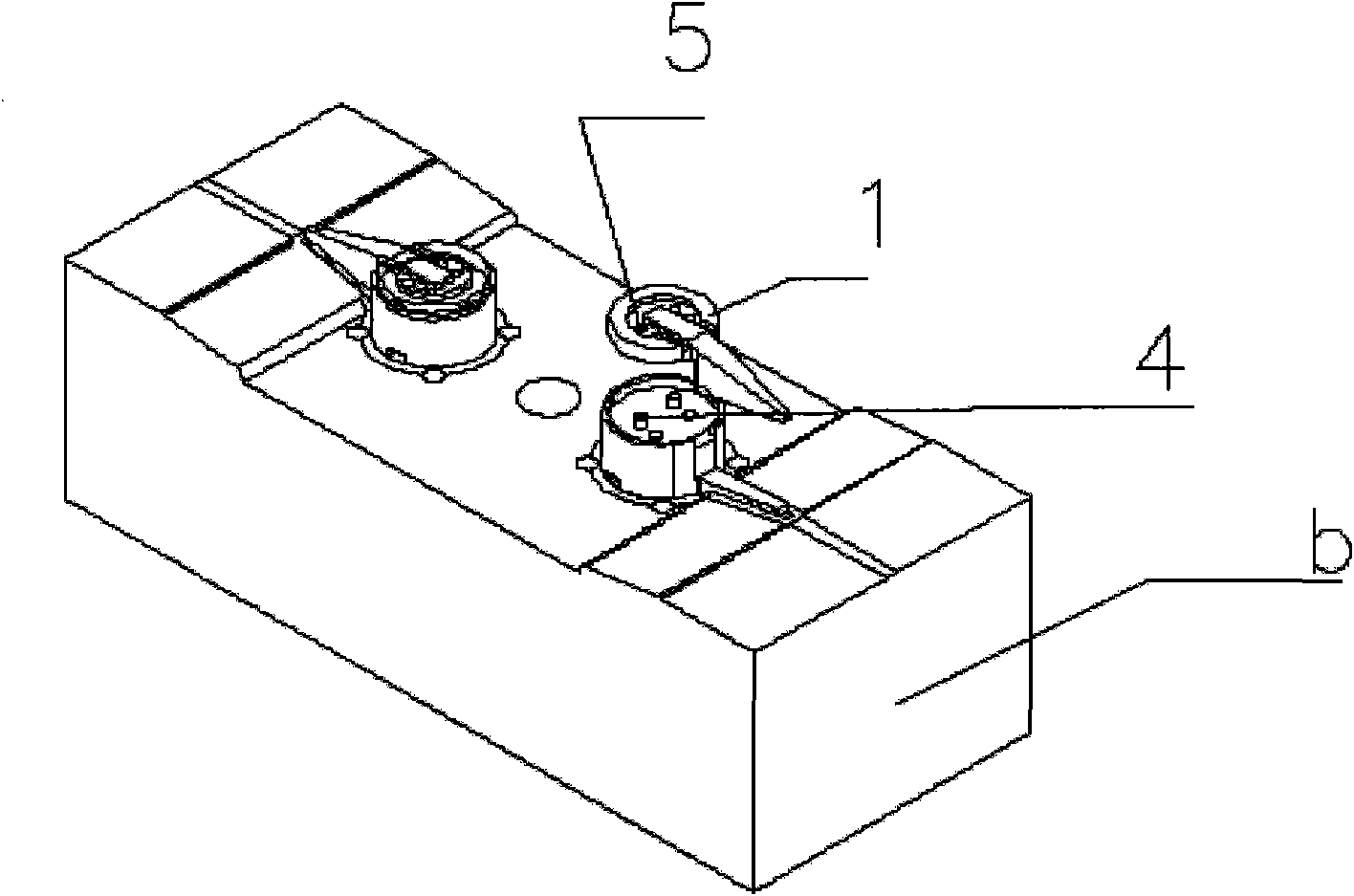

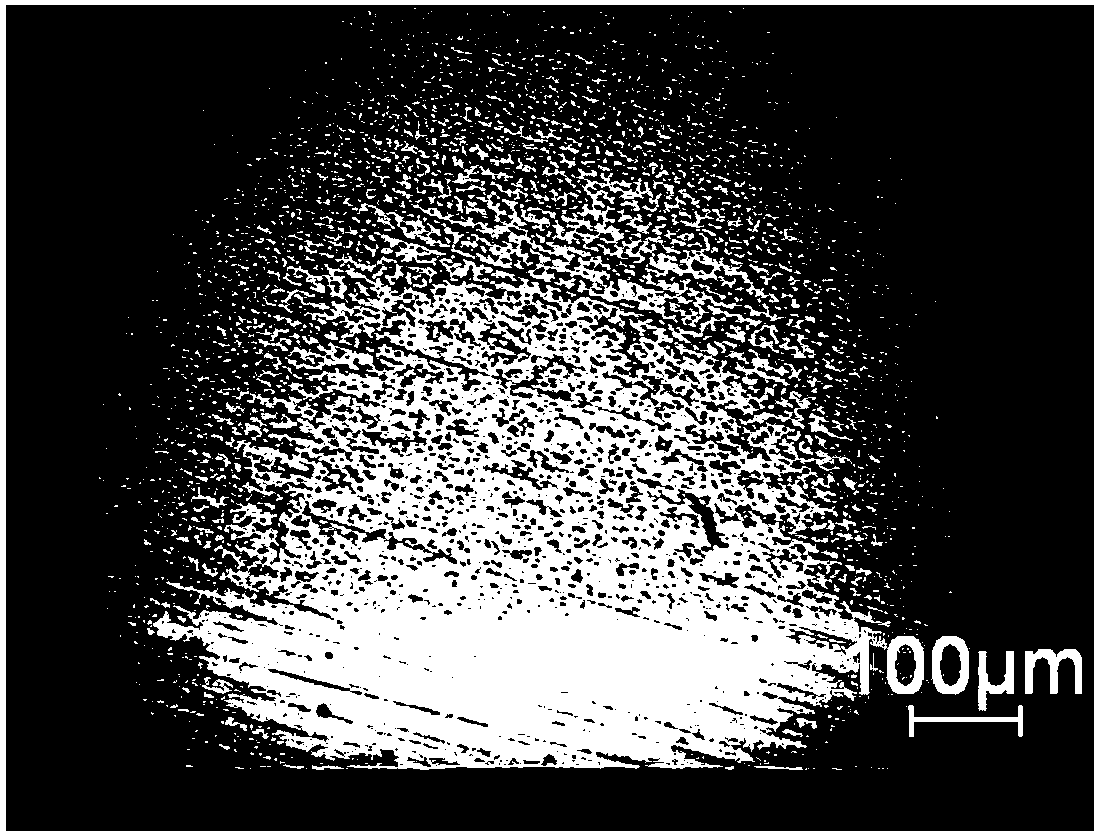

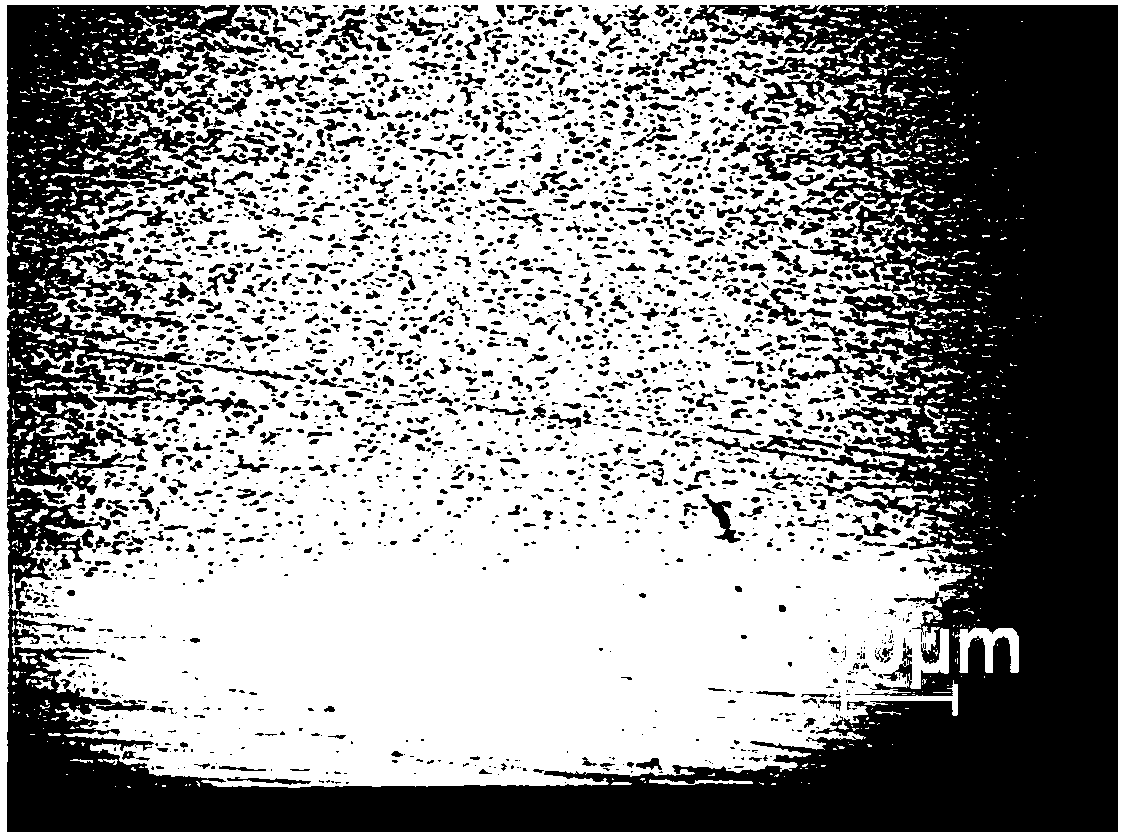

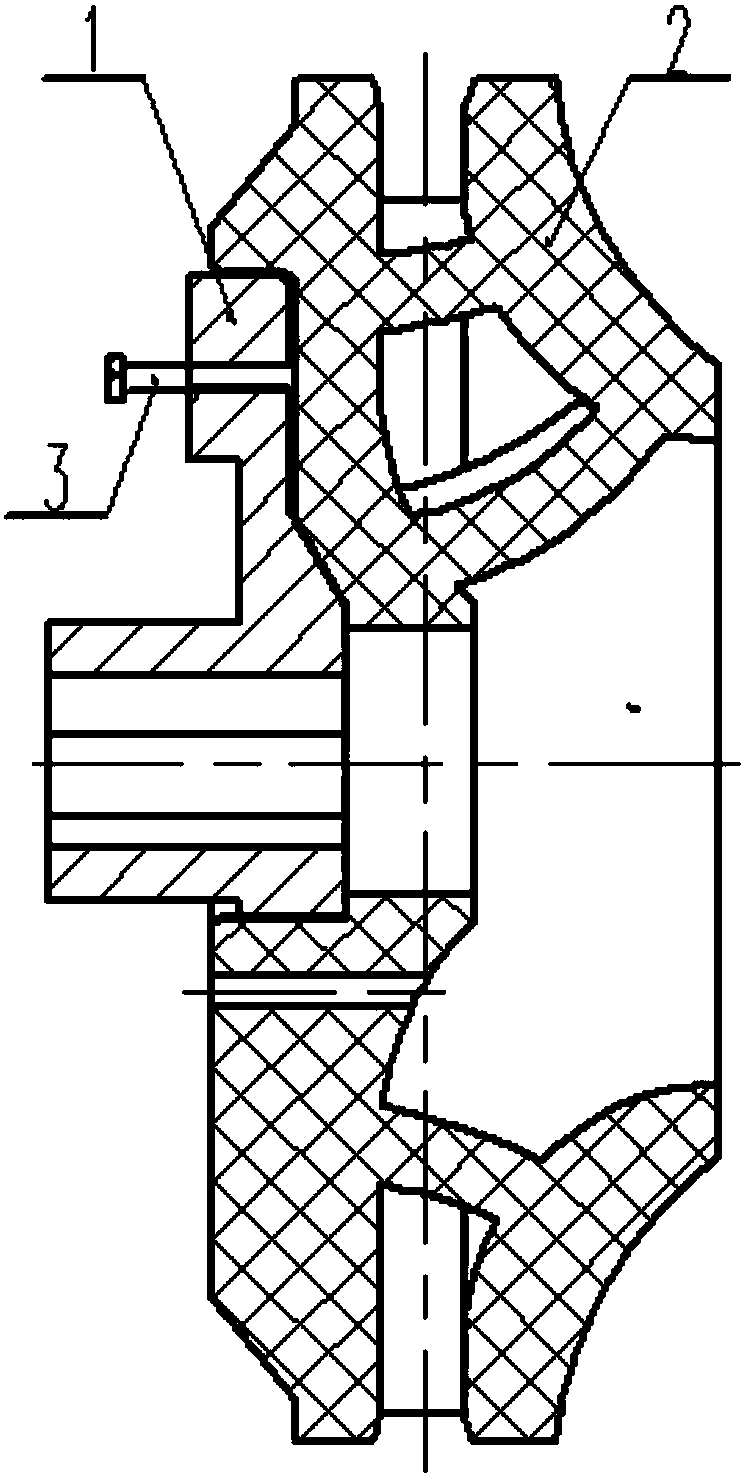

Magnetic polydimethylsiloxane (PDMS) mask-based micro-pit array electrolytic machining system and method

ActiveCN106064261APDMS is stableImprove processing localityElectrochemical machining apparatusMagnetEngineering

The invention relates to a magnetic polydimethylsiloxane (PDMS) mask-based micro-pit array electrolytic machining system and method and belongs to the field of micro-electrolytic machining. The system comprises a cathode tool (1), a PDMS mask, an anode workpiece (3), a clamp (5), an electrolyte (6) and a power supply (7) and is characterized in that the PDMS mask is a magnetic PDMS mask (2), and a permanent magnet (4) for attracting the magnetic PDMS mask (2) to enabling the magnetic PDMS mask (2) to be closely attached to the surface of the anode workpiece (3) is further arranged below the anode workpiece (3). The system and the method are adopted for electrolytic machining, the magnetic PDMS mask can be closely attached to the surface of the anode workpiece under the action of a magnetic field, and the electrolytic machining locality of a micro-pit array is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Control method for moving mechanism of all-wheel-drive combined attracting-type wall-climbing robot

ActiveCN102699921AQuick checkDoes not affect motion controlWelding/cutting auxillary devicesArc welding apparatusHorizontal axisEngineering

The invention belongs to the technical field of specialized robots, and particularly relates to a control method for the moving mechanism of an all-wheel-drive combined attracting-type wall-climbing robot. The control method comprises the following steps: A, acquiring two-dimensional welded joint position information provided by a welded joint tracking sensor, and carrying out filter processing; B, sending a speed command to the motor driver of a crosshead shoe according to the processed information, so as to fulfill the horizontal axis movement and the longitudinal axis movement of the crosshead shoe, and realize the fast accurate movement of a welding gun; C, calculating the distance between a movable platform and a welded joint according to the welded joint position information provided by the welded joint tracking sensor and crosshead shoe motor code disc information; D, calculating the movement parameter of the movable platform according to the information; and E, sending a command to a platform motor driver, so as to fulfill multi-wheel matching movement. The control method has the advantages that the filter processing method can detect error data fast, so as not to impact movement control; the real-time tracking performance on continuous variation of a welded joint is favorable, so as to avoid additional latency; and the responding capability on the wide range step variation of a real welded joint position is better.

Owner:DONGFANG ELECTRIC CORP LTD

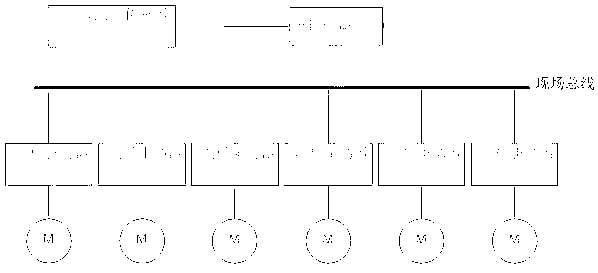

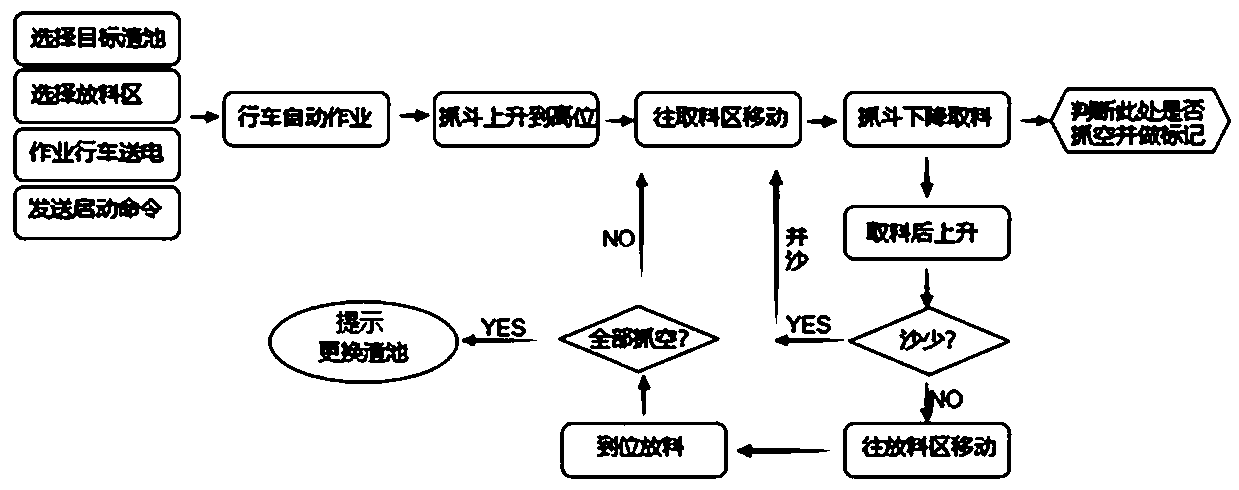

Four-rope grab bucket slag material grabbing system

The invention provides a four-rope grab bucket slag material grabbing system which comprises a computer, a PLC, a lifting frequency converter, an incremental encoder A, an opening-closing frequency converter, an incremental encoder B, a cart and trolley positioning device, a twisted rope detecting device, an overload limiter, a cart walking motor, a trolley walking motor, a runway girder, a travelling crane trolley and a grab bucket, wherein the travelling crane trolley is in sliding fit with the runway girder; the computer, the lifting frequency converter, the opening-closing frequency converter, the cart and trolley positioning device, the twisted rope detecting device, the overload limiter, the cart walking motor and the trolley walking motor are connected with the PLC separately; and the PLC and the computer realize data exchange through the wired or wireless communication manner. Compared with the existing manual operation, the four-rope grab bucket slag material grabbing system can still carry out safe operation on the condition that heavy fog or water vapor affects the sight line to reduce potential safety hazard and prevents a worker from operation under sulfur-containing water vapor to reduce health hazard.

Owner:JIANGSU JINHENG INFORMATION TECHNOLOGY CO LTD

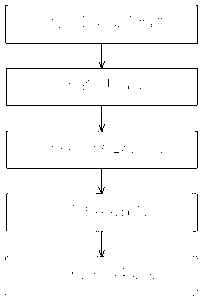

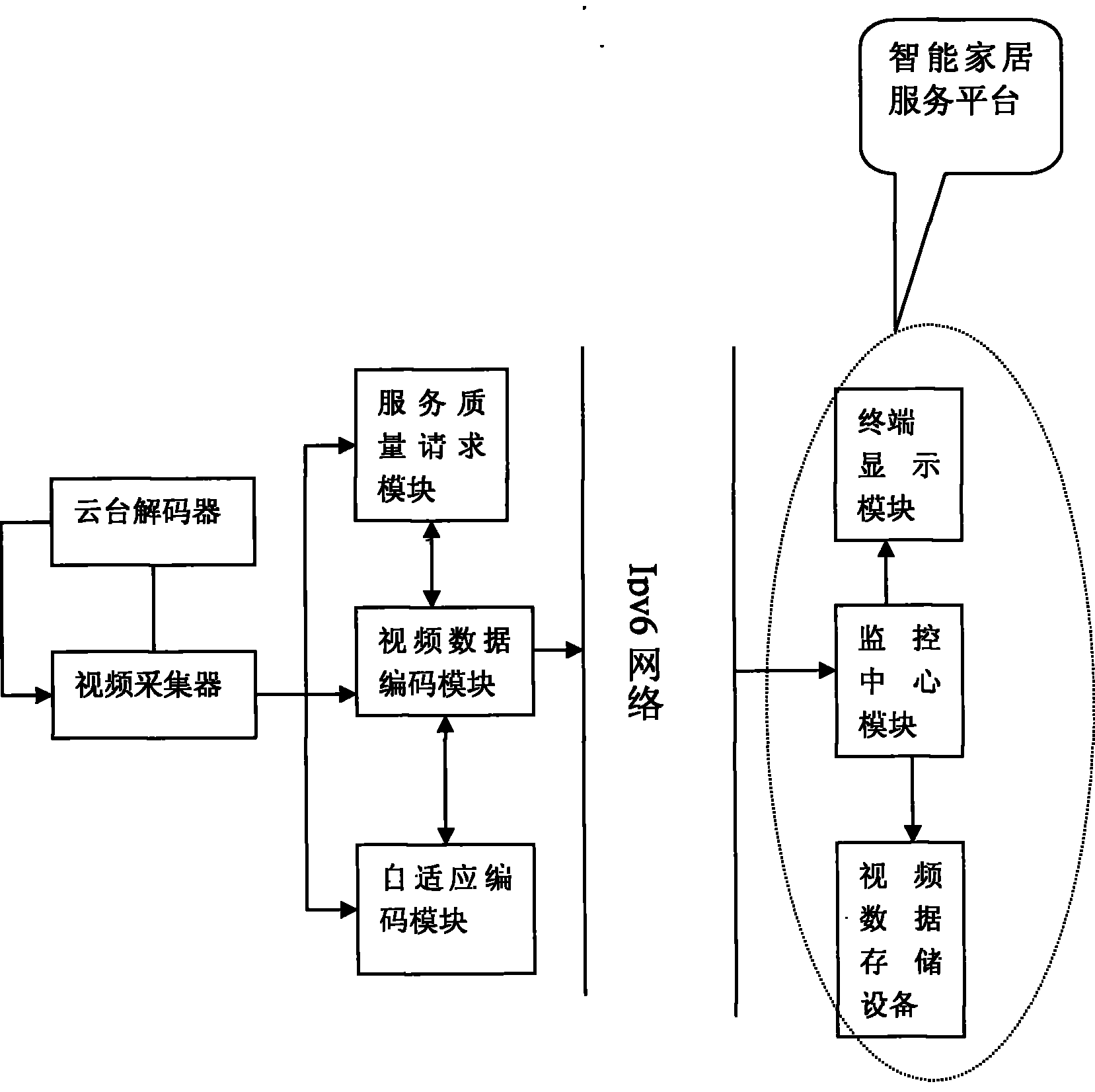

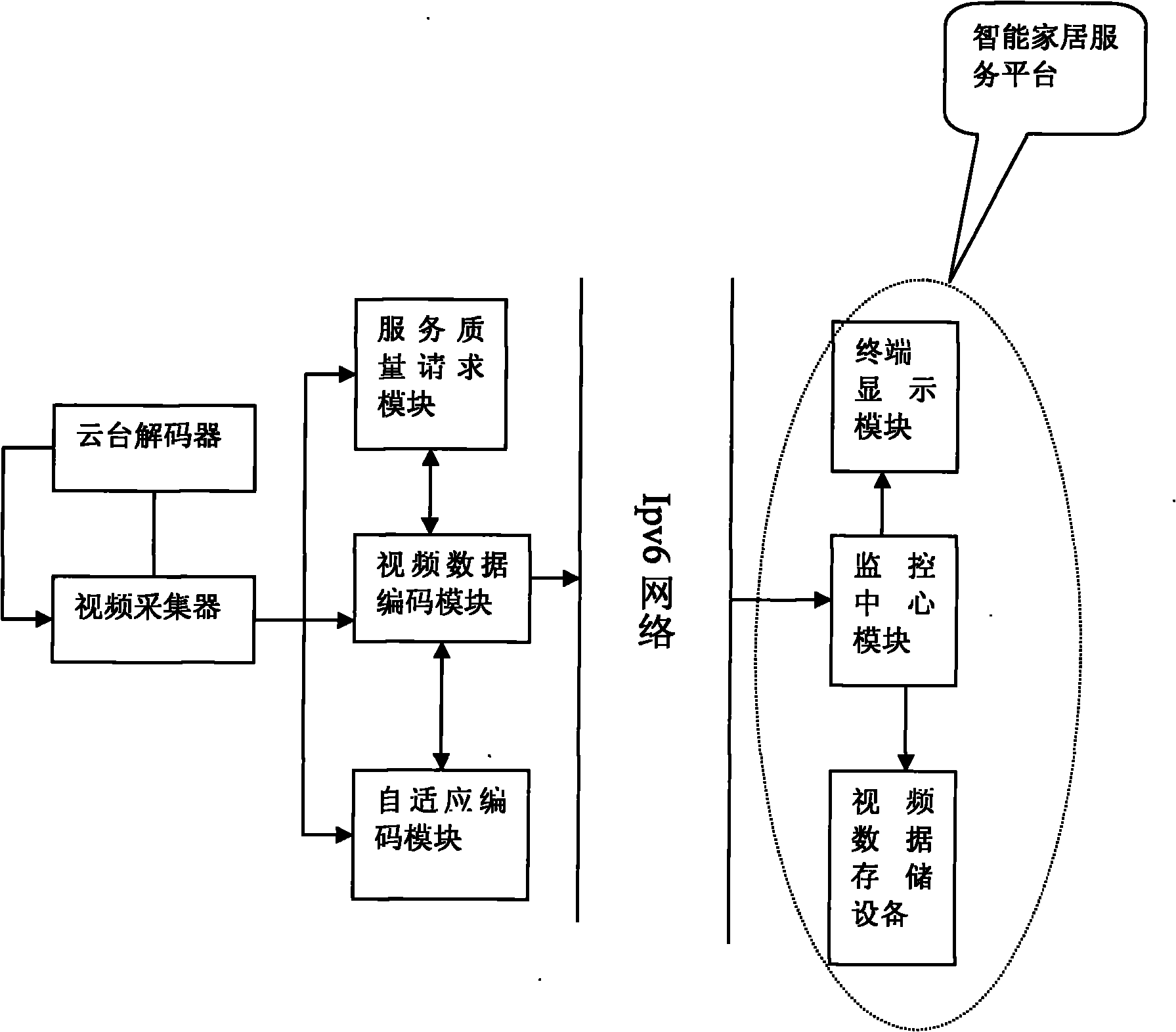

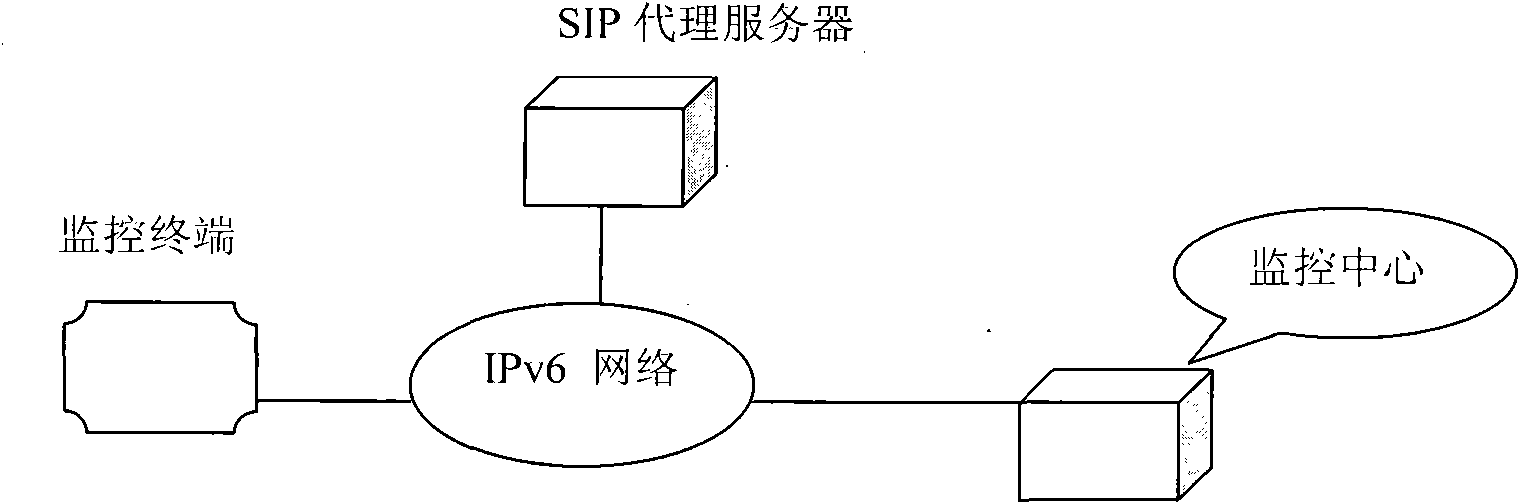

Digital home remote video monitoring system based on next-generation network

InactiveCN101815210AReduce time delayImprove securityClosed circuit television systemsDigital video signal modificationSelf adaptiveSystem requirements

The invention discloses a digital home remote video monitoring system based on a next-generation network, which comprises a video capture device, a video data encoding module, a self-adaptive encoding module, a service quality request module, a home gateway and an intelligent home service platform module. The intelligent home service platform module comprises a terminal display module, a monitoring center module and a video data storage device. Based on the next-generation network (NGN), the invention can realize the remote video monitoring with low cost, and promptly reflect the real-time situation of the monitored object. Moreover, the invention has the advantages of good universality, easy transformation of the achievements, no need for additional equipment and simple system requirements, and avoids the coorperation problem.

Owner:广东中大讯通信息有限公司 +2

Method for assembling automobile gauge point

InactiveCN101934568ASolve fit problemsImprove work efficiencyDomestic articlesEngineeringNeedle guard

The invention relates to a method for assembling an automobile gauge point. The method is realized by the following steps: putting an injected molding component point into a lower cavity plate of a needle guard; positioning a point in the cavity by two positioning holes on the point and two positioning nails on the lower cavity plate; after an upper cavity plate of the needle guard and the lower cavity plate are connected, the point is completely coated by plastics; and combining the point and the needle guard by injection; and staying the molded combined part in the lower cavity after the upper cavity plate and the lower cavity plate are separated, and separating the product and the die by an ejector. The method has the advantages that the problem of match of all components in assembly can be solved so as to improve the yield of products because the point and the needle guard form into a part; and the unqualified rate of the products is reduced to below 5 per mill from the original 10 percent so as to improve the working efficiency of the company.

Owner:上海敏越汽车零部件有限公司

Preparation process of high-weldability flaky silver graphite contactor of parallel structure

The invention discloses a preparation process of a high-weldability flaky silver graphite contactor of a parallel structure. The process sequentially comprises the following steps that 1), the use amount of needed graphite powder and silver powder is calculated according to the material ratio of the silver graphite contactor needing to be prepared, powder mixing is carried out after weighing is carried out, and mixed powder is obtained; 2), the obtained mixed powder is subjected to isostatic compaction, and a silver graphite billet is obtained; 3), the obtained silver graphite billet is subjected to decarburization, and a decarburized silver graphite billet is obtained; 4), the obtained decarburized silver graphite billet is sintered under a protective atmosphere condition, and a sinteredsilver graphite billet is obtained; and 5), the obtained sintered silver graphite billet is subjected to conventional extruding, normal-temperature rolling and conventional stamping, and the silver graphite contactor is obtained. The preparation process is simple and low in production cost, and the machining performance and welding performance of the contactor material can be effectively improved.

Owner:桂林金格电工电子材料科技有限公司

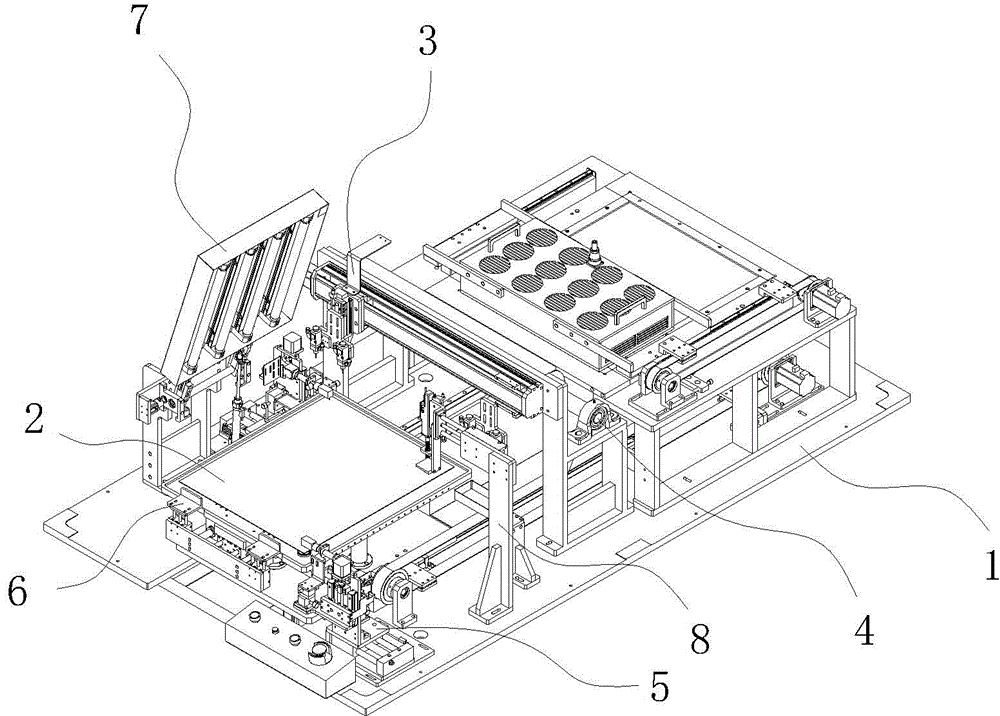

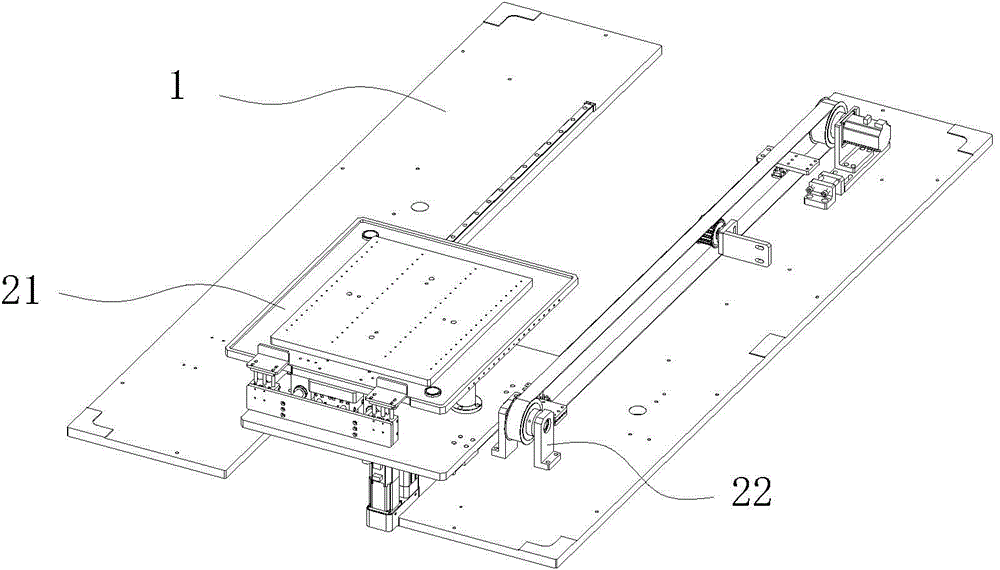

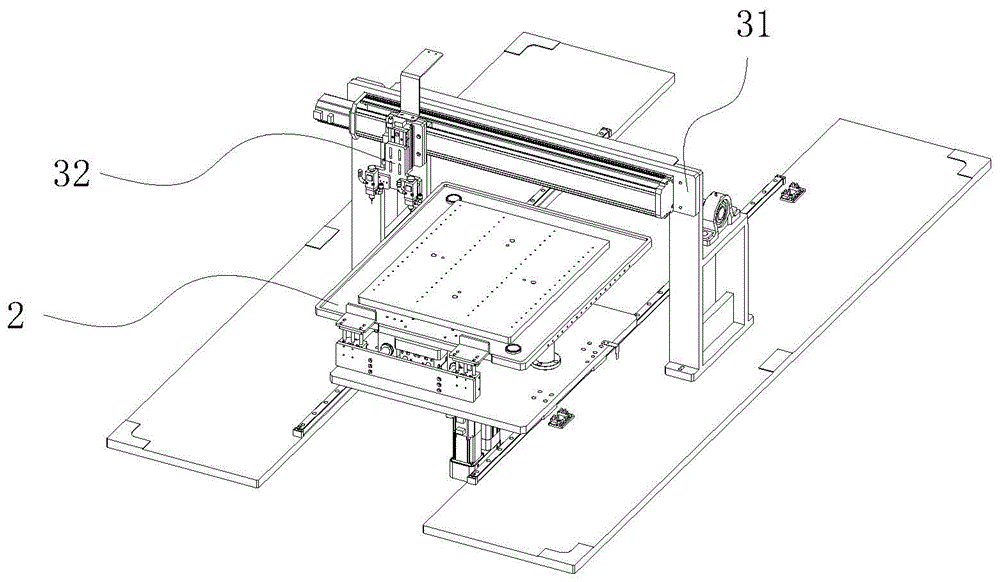

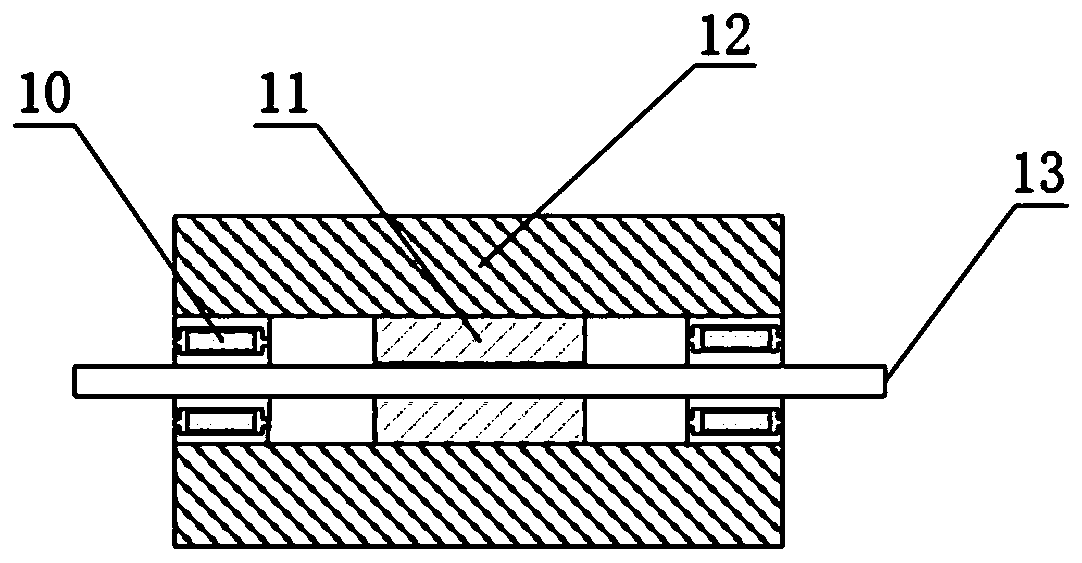

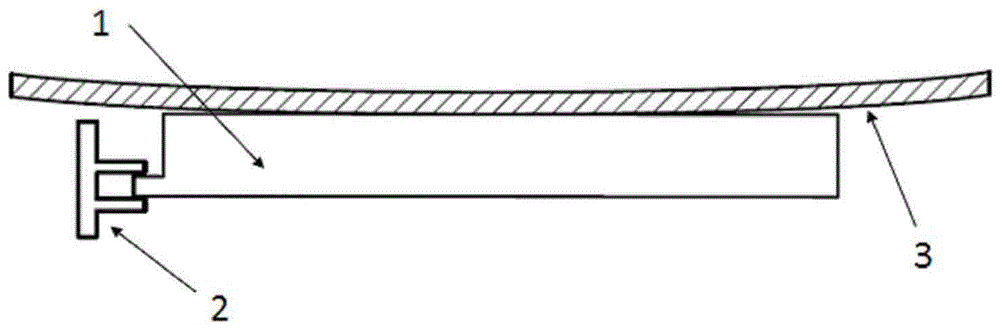

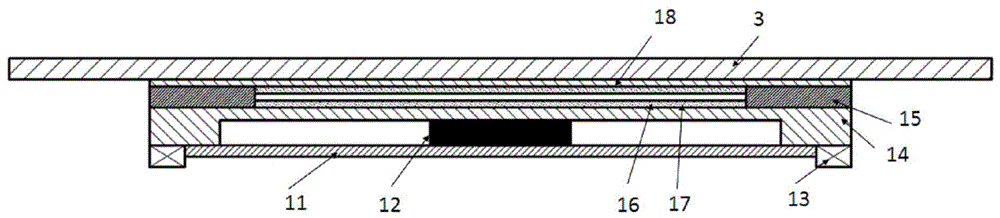

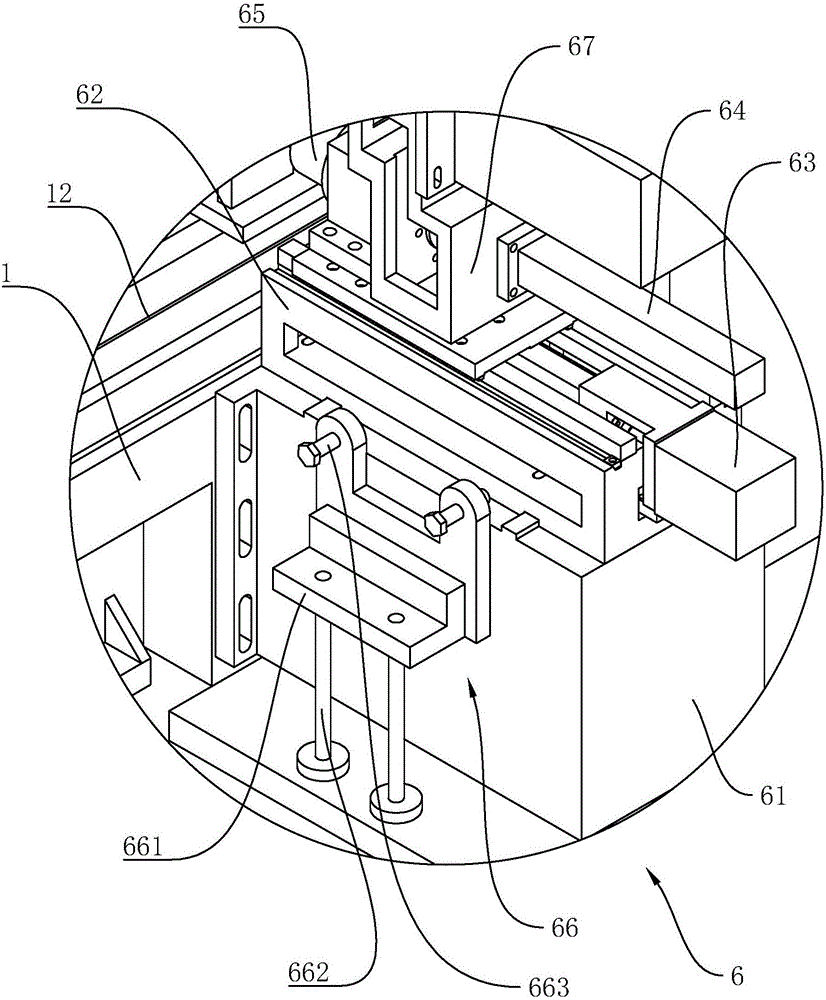

Glass lamination fitting equipment

ActiveCN104589771ASolve fit problemsGuaranteed alignment accuracyLamination ancillary operationsLaminationEngineeringAutomation

The invention discloses glass lamination fitting equipment which comprises a base, and a feeding platform, a dispensing mechanism, an image sampling mechanism, a fitting mechanism, a correcting mechanism and a curing mechanism which are arranged on the base, wherein first glass is mounted on the feeding platform, the dispensing mechanism is used for dispensing glue on the glass, second glass is placed on the glue level of the first glass, the fitting mechanism is used for flattening the glass, the correcting mechanism is used for mutually aligning the glass, and the curing mechanism is used for curing glue. According to the glass lamination fitting equipment, multiple pieces of glass are fitted together, and the alignment accuracy is ensured by virtue of the image sampling mechanism and the correcting mechanism, the automation degree is high, the operation is simple, the problem of fitting multiple pieces of glass is solved, and the post processing is facilitated.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

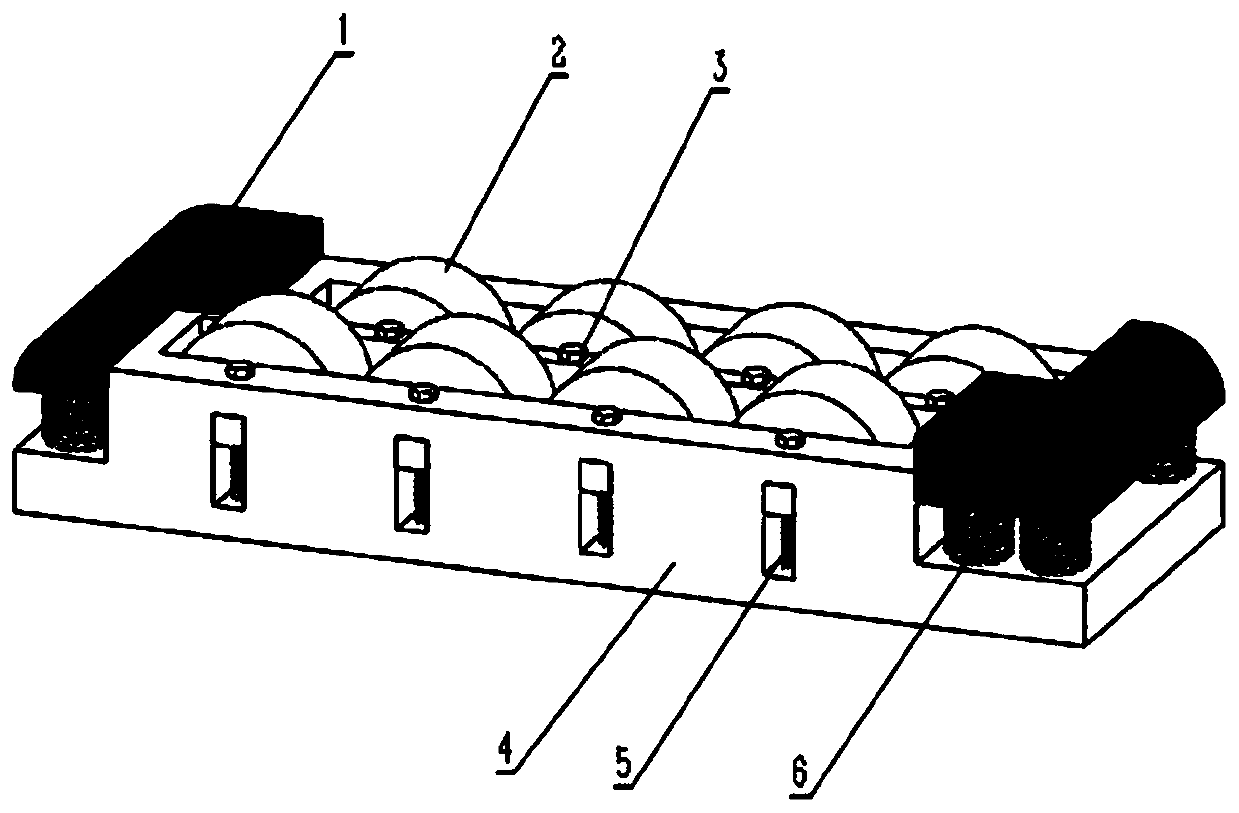

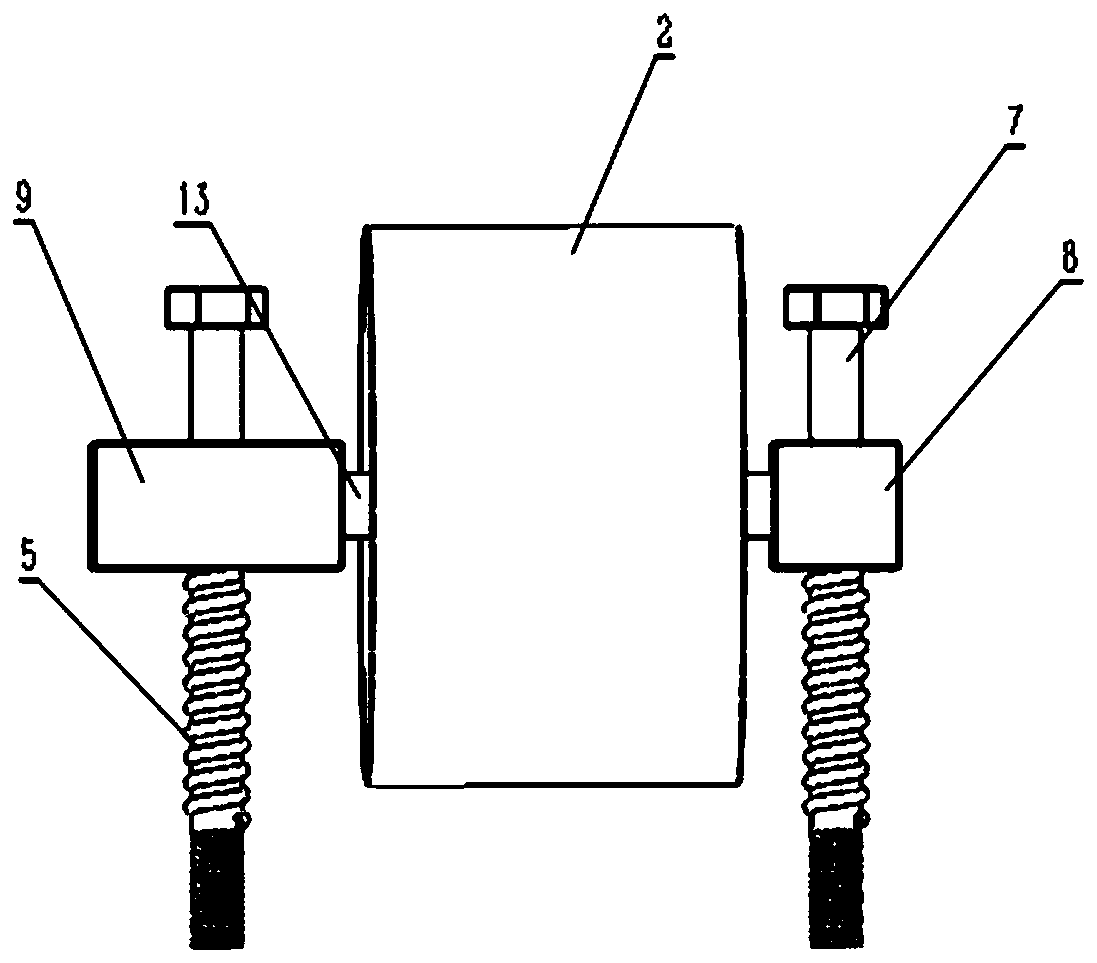

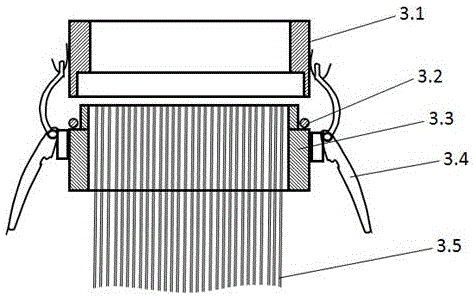

Double-row multi-roller type modular current-receiving device for electric locomotive

PendingCN110370936AReduce wearReduced service lifeRotary current collectorPower current collectorsModularitySlide plate

Disclosed is a double-row multi-roller type modular current-receiving device for an electric locomotive. According to the double-row multi-roller type modular current-receiving device for the electriclocomotive, two rows of metal rollers are annularly arranged on an insulating base; each rolling wheel is arranged in the manner that two insulating stand columns are fixed to the insulating base, compression springs sleeve the two insulating stand columns correspondingly, insulating blocks sleeve the insulating stand columns and are located above the compression springs, metal shells of the rollers are installed on metal shafts through two insulating bearings, the metal shafts are fixed to the two insulating blocks, the outer surface of an annular current receiving electric brush makes contact with the roller metal shells to receive current, the inner surface of the annular current receiving electric brush is fixed to the metal shafts, all the metal shafts are connected through cables and are then used for supplying power to vehicle-mounted power consuming equipment, and two pure carbon sliding plates are fixed to the insulating base through more than four springs. The friction forceand the friction noise of the current-receiving device and a rigid contact rail can be effectively reduced, and the double-row multi-roller type modular current-receiving device can adapt to the changes of locomotive traction power requirements and has good buffering performance, heat dissipation performance and rail attaching performance.

Owner:SOUTHWEST JIAOTONG UNIV

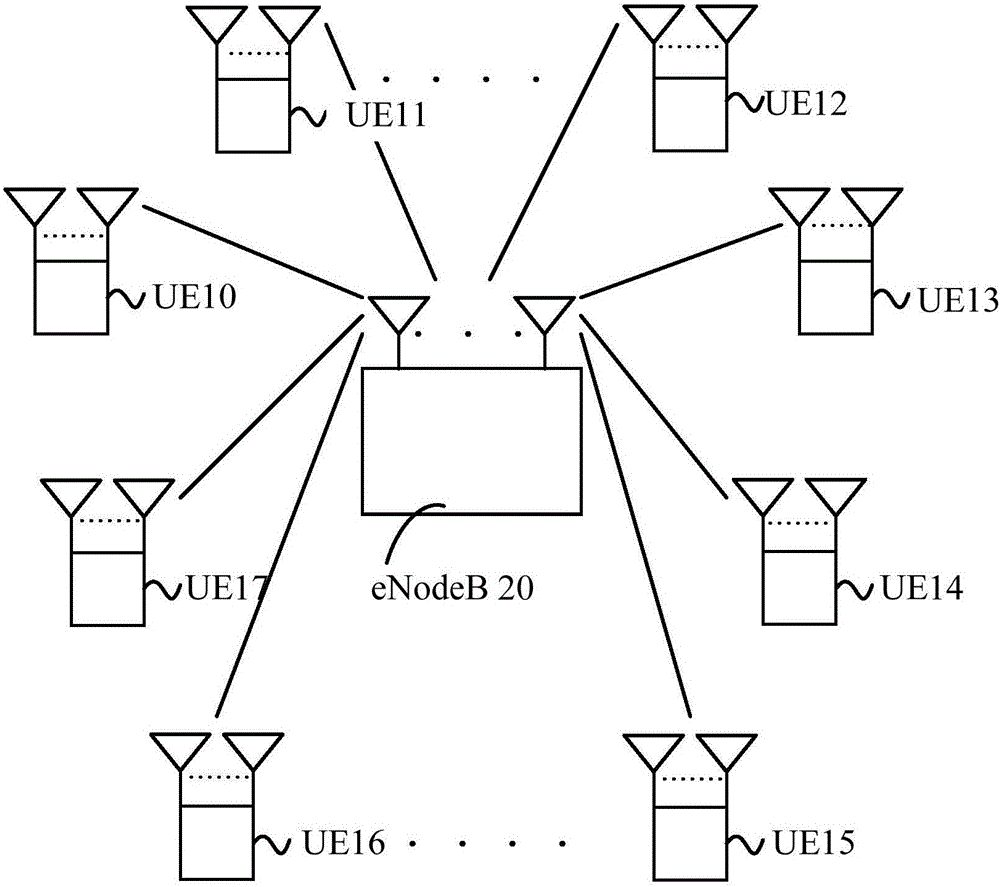

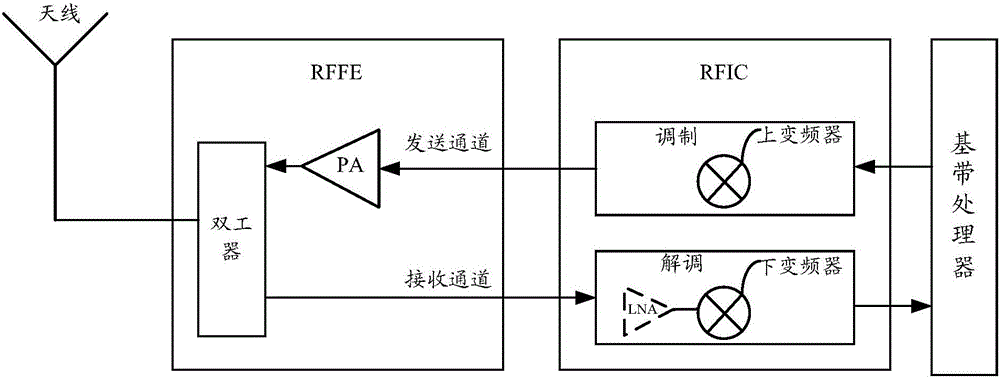

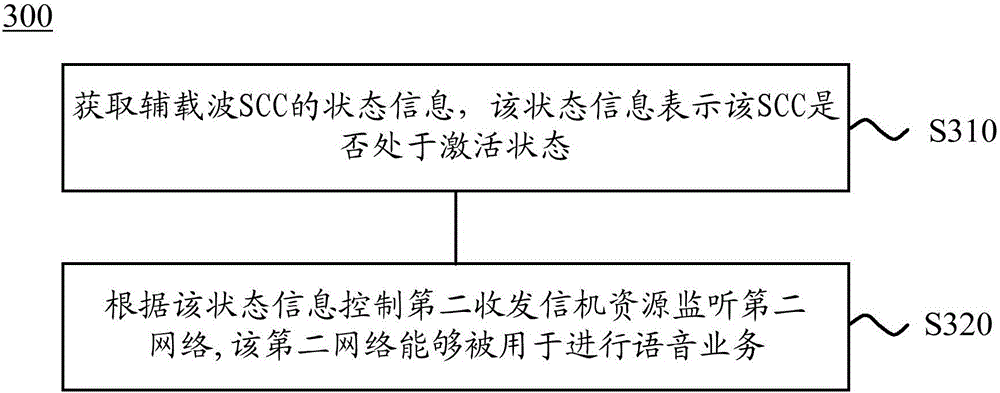

Method used for voice service used of user equipment, use equipment and device

ActiveCN105813125ALow costReduce power consumptionPower managementHigh level techniquesTransceiverComputer network

The invention discloses a method used for voice service used of user equipment, the use equipment and a device. The UE comprises a first transceiver resource corresponding to primary component carriers PCC of a first network and aggregated with support carriers (CA), and a second transceiver resource corresponding to secondary component carriers SCC of the first network. The first network can be used for the data business of the UE. The method comprises the steps of: obtaining the state information of the SCC, wherein the state information indicates whether the SCC is in an activated state; and according to the state information, controlling the second transceiver resource to monitor a second network, wherein the second network can be used for performing the voice business. By adopting the method used for voice service used of user equipment, the use equipment and the device, the power consumption is lowered.

Owner:CHINA TELECOM CORP LTD

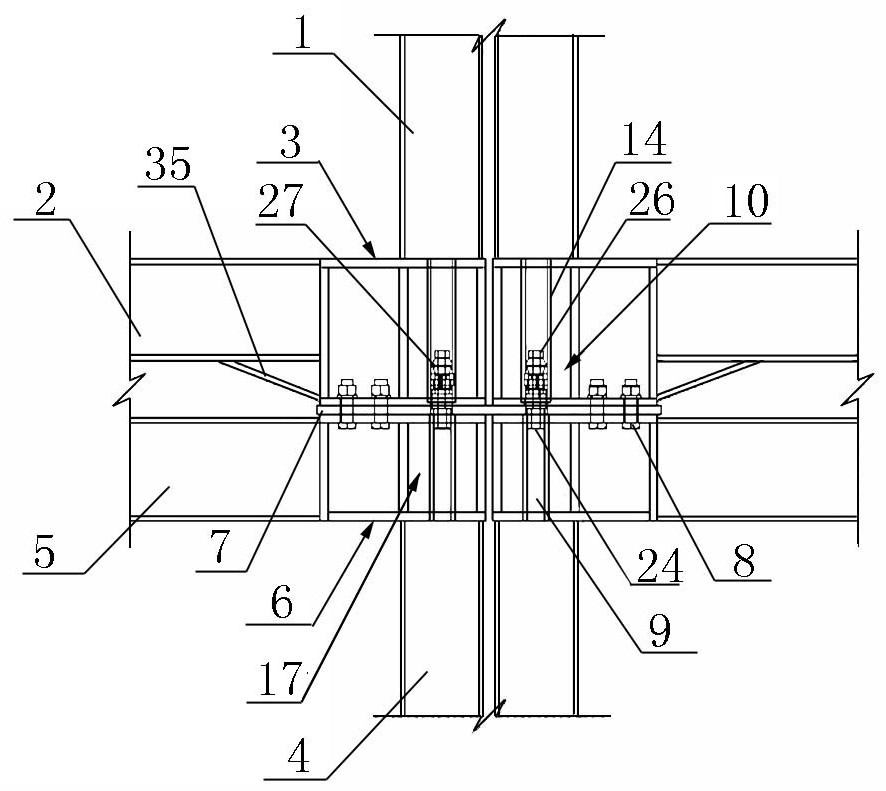

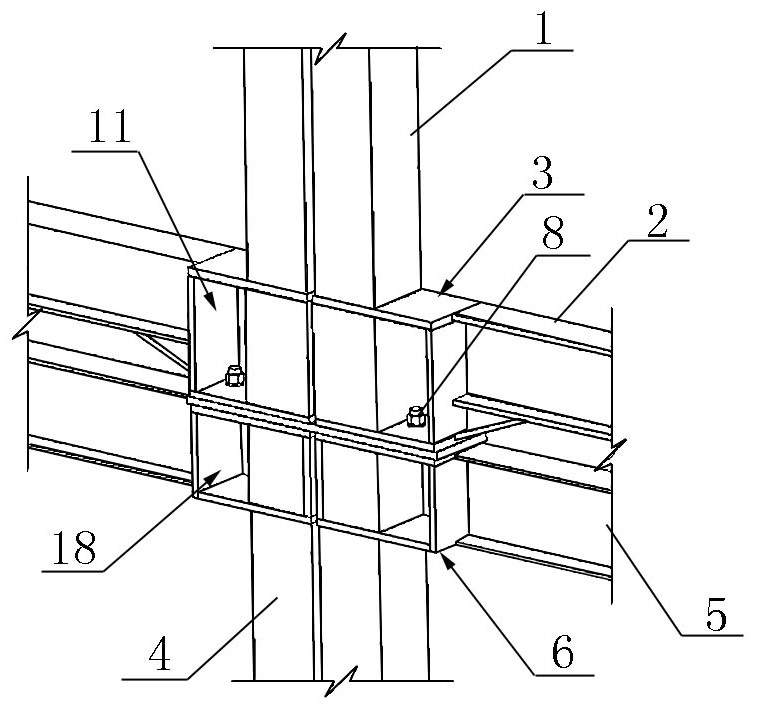

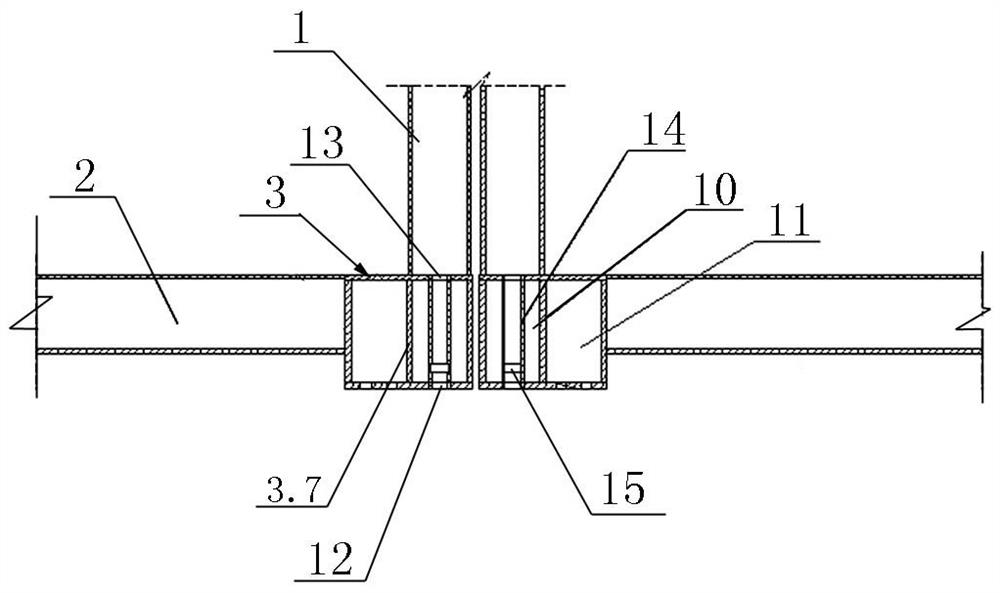

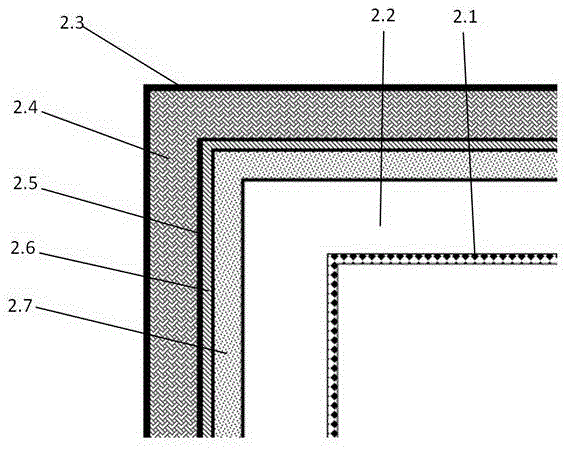

Module node structure connected by adopting clamping device and construction method thereof

ActiveCN112095782AImprove reliabilityIncrease shear resistanceBuilding constructionsIndustrial engineeringScrew thread

Owner:中建集成建筑有限公司

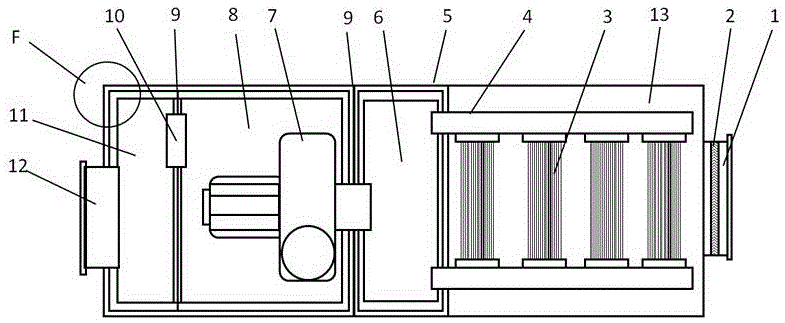

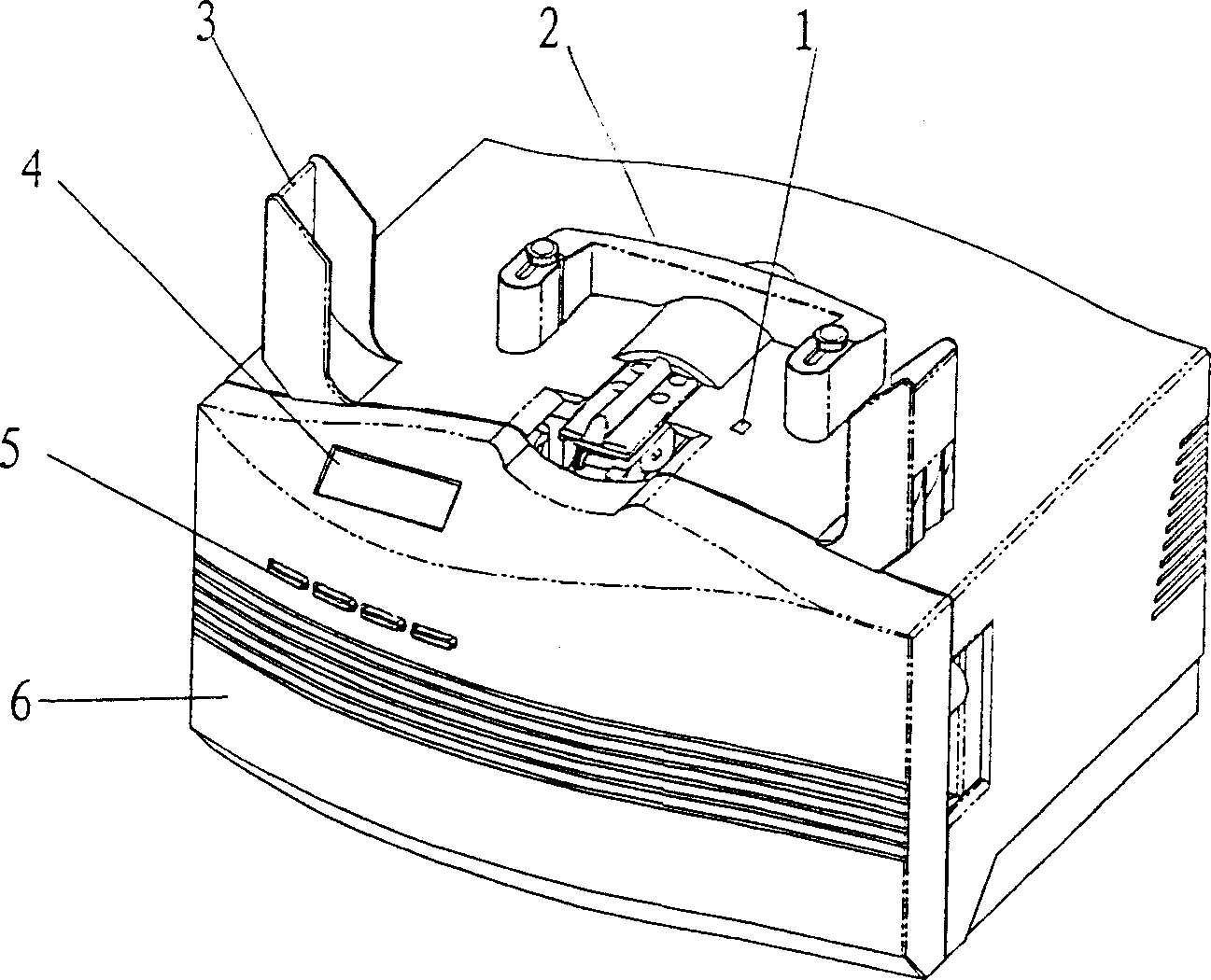

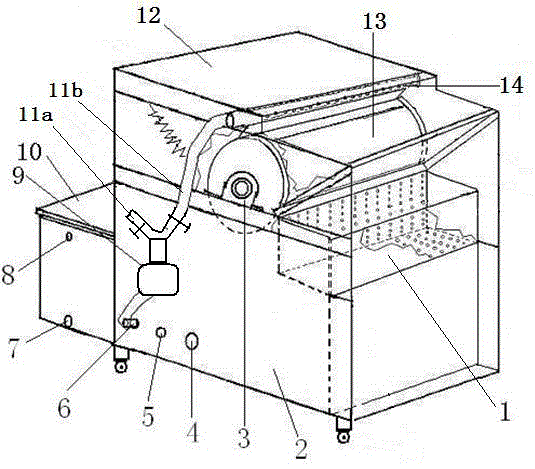

High-wind-quantity purification fresh air machine using hollow fibrous membrane as main filtering material

PendingCN106731266AStructural solutionSolve fit problemsDispersed particle filtrationTransportation and packagingUltrasound attenuationFiber

The invention relates to a high-wind-quantity purification fresh air machine using a hollow fibrous membrane as a main filtering material. The fresh air machine consists of parts such as a machine cabinet, an air inlet assembly, a front filtering material assembly, a membrane assembly array cabin, a membrane assembly, a confluence branch pipe box, a confluence sound insulation and attenuation cabin, a fan motor unit, a fan motor sound insulation and attenuation cabin, a roundabout air outlet hole passage, an air outlet sound attenuation cabin and an air outlet. The multistage sound insulation and attenuation cabin chamber is used, so that the noise problem of the high-wind-quantity purification fresh air machine is solved. Over ten thousands of cubic meter of clean fresh air can be provided. As the hollow fibrous membrane, particularly a polytetrafluoroethylene hollow fibrous membrane is used as the main filtering material, great dust containing capacity is realized and the maintenance and operation cost can be greatly reduced.

Owner:GUANGDONG FENGHE PURIFICATION ENG CO LTD

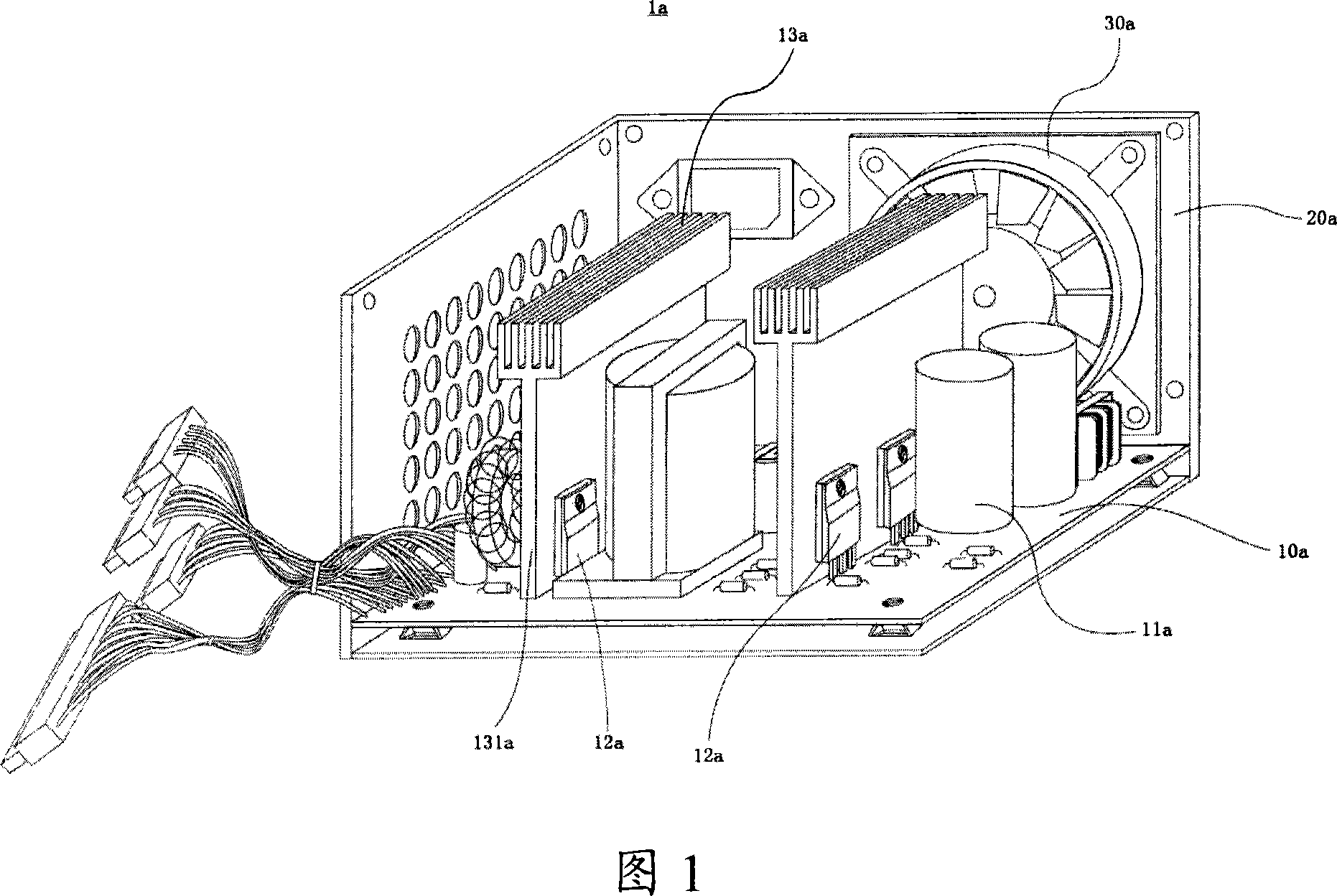

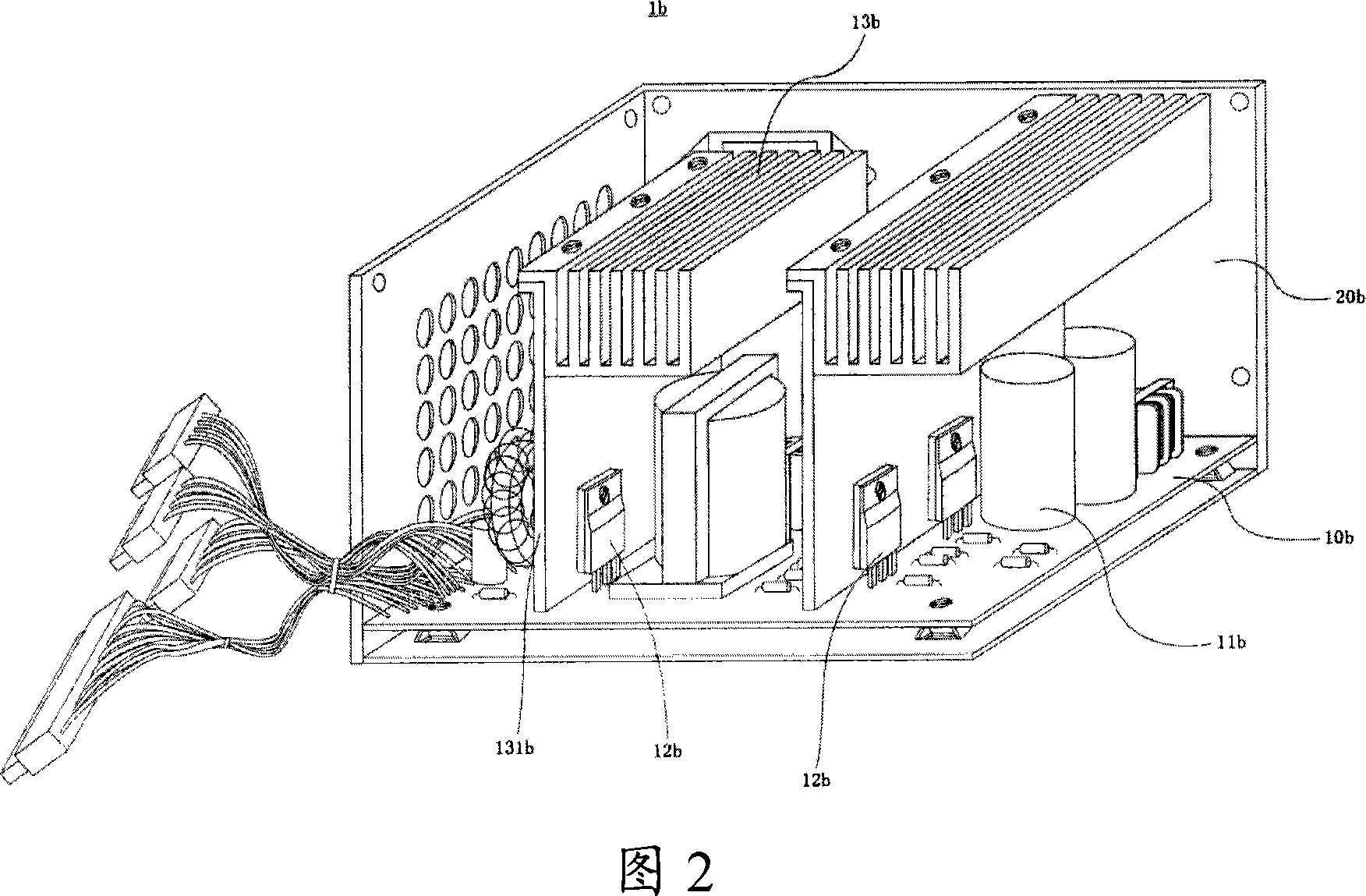

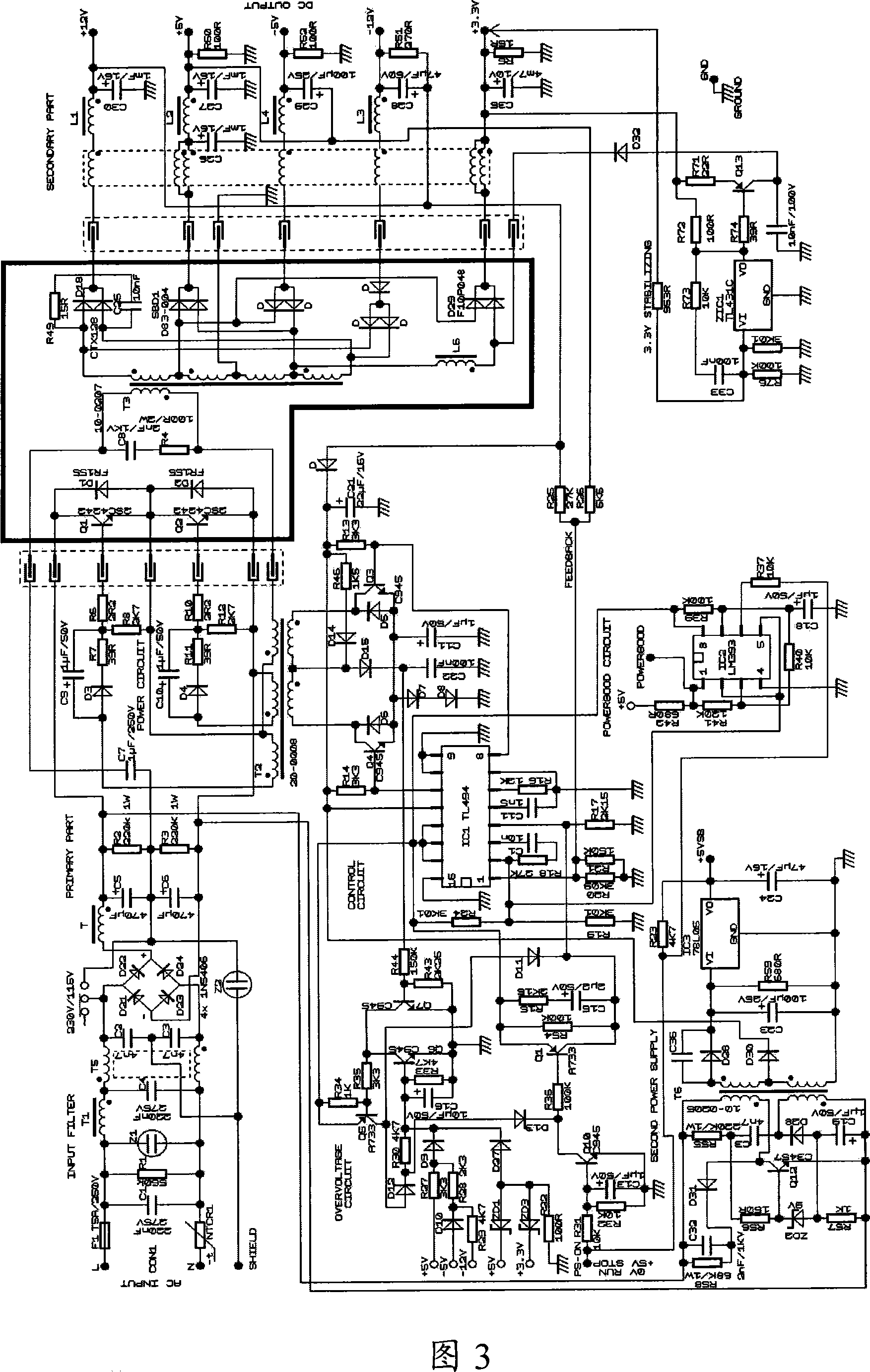

Computer electric source

InactiveCN101067756ASolve fit problemsIncrease production capacityVolume/mass flow measurementPower supply for data processingEngineeringElectronic component

The invention discloses a computer power supply, comprising: a case whose outer wall is equipped with heat radiating fins; sub circuit board equipped with power electronic components and related electronic components of power supply circuit and arranged on the top inner wall of the case and the bodies of the power electronic components are fixed on the top inner wall of the case; a main circuit board, equipped with the other electronic components and arranged inside the case and connected with the sub circuit board. And the advantages of the invention: no fan noises, good heat radiating performance and high power, lower internal temperature and not high cost.

Owner:张文

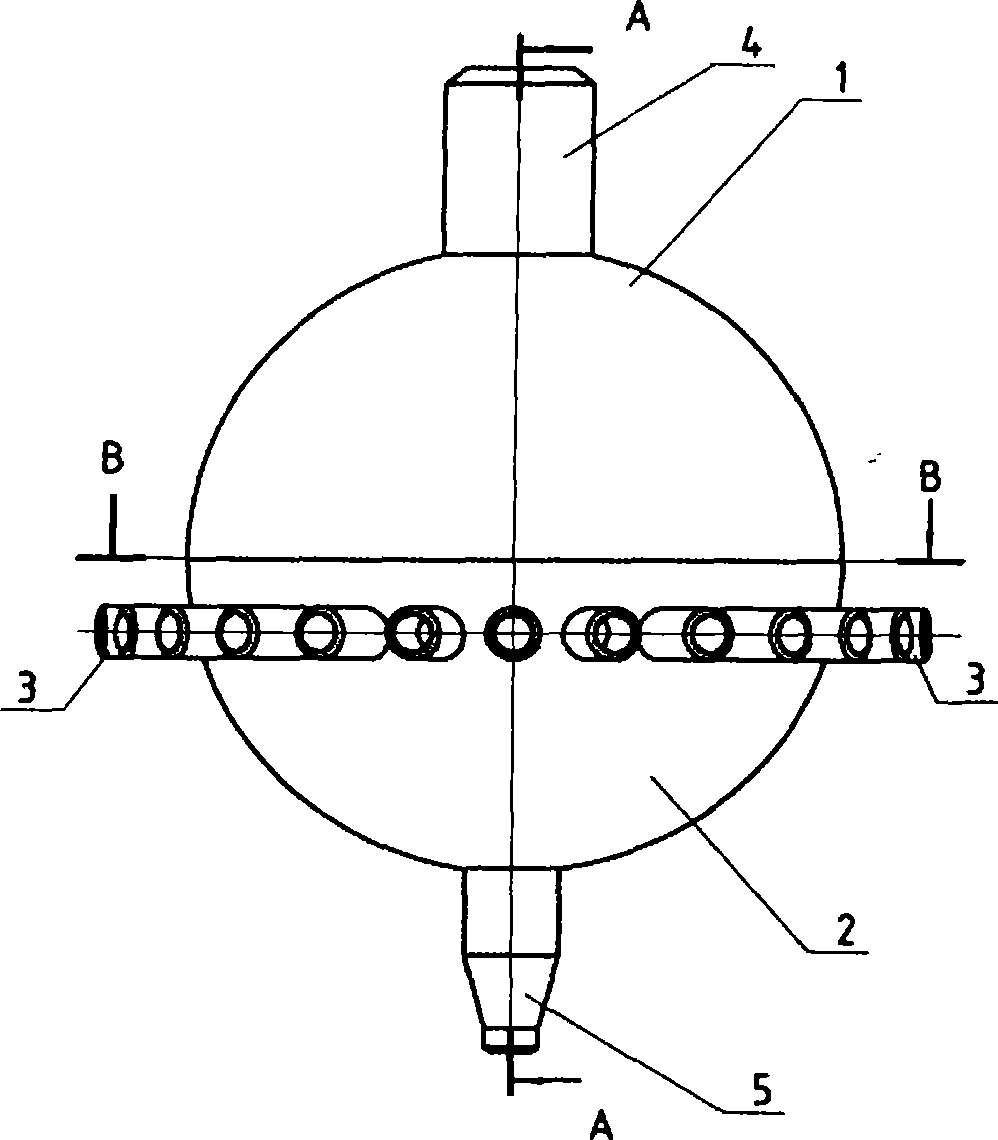

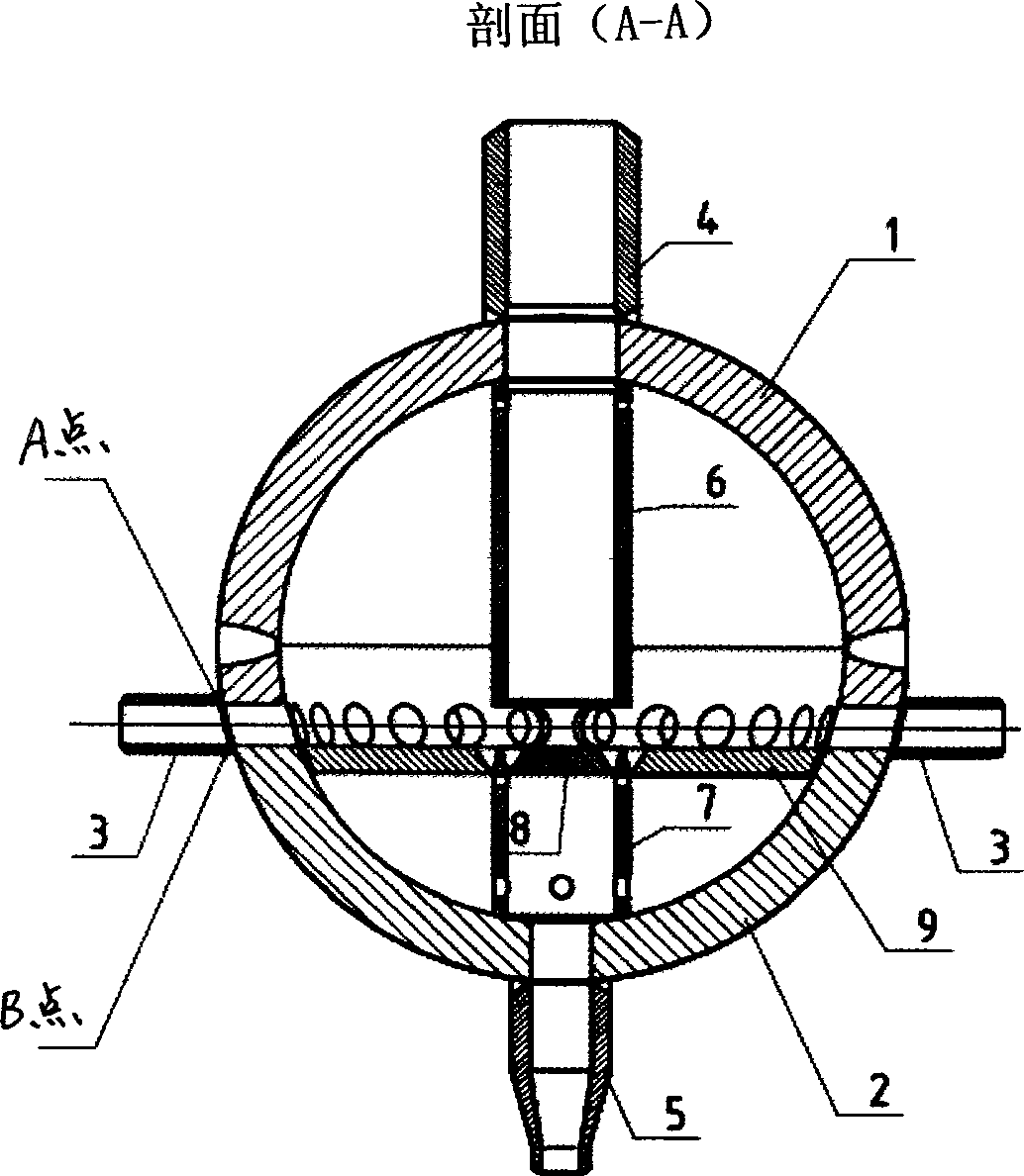

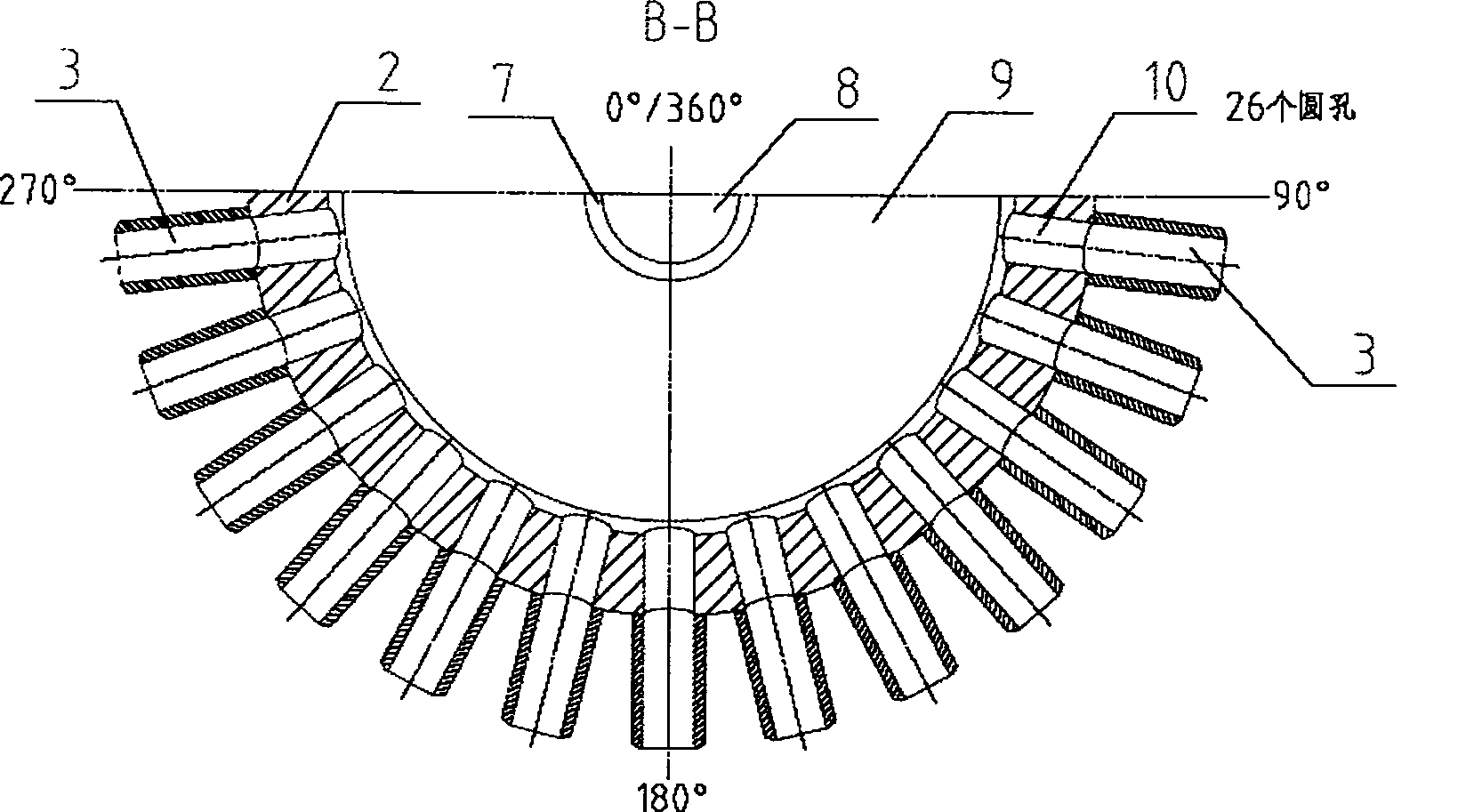

Technique for producing spherical distributor

The invention relates to a technique for producing a spherical distributor, the technique is characterized in that a pipe joint and an inner long pipe are respectively arranged inside and outside the top part of an end enclosure in the upper half part; planes are grinded at each A-B position needed to be drilled for drilling and locating; the fall size of A point and B point is obtained by measuring and is used as the fall size for processing the incline at the position of the orifice of an inclined jointing pipe; then the inclined jointing pipe is processed; a tapered pipe is arranged at the bottom part of an end enclosure in the lower half part; then an inner short pipe is arranged in the bottom part of the end enclosure in the lower half part to lead the tapered pipe, the inner short pipe, the pipe joint and the inner long pipe to be arranged on the same line; moreover, an inner piece is welded in the end enclosure of the lower half part; the tapered pipe is respectively welded with each hole in a circle in the end enclosure of the lower half part; finally the end enclosure of the upper half part and the end enclosure of the lower half part are jointed; an automatic-welding circular seam is employed between the end enclosure of the upper half part and the end enclosure of the lower half part. The technique for producing the spherical distributor has the advantages of solving the problem of localization and saving the producing cost.

Owner:SHANGHAI BOILER WORKS

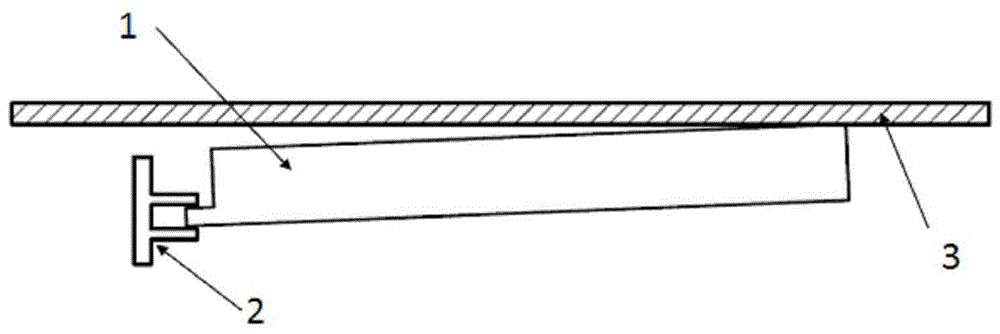

Screen stretching device for screen printer

The invention discloses a screen stretching device for a screen printer, which comprises a working platform and a stretching screen fixed on the working platform, wherein a silk screen, both ends of which are fixed to a frame through splints, abuts against the stretching screen; and an elevating mechanism is installed below the working platform. The screen stretching device is reasonable in design and solves the problem of the matching between the silk screen and the stretching screen, so that the tensile force acted by the stretching screen on the edge of the metal screen is uniform, thereby satisfying the higher accuracy requirement and higher automation requirement for the screen stretching operation.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

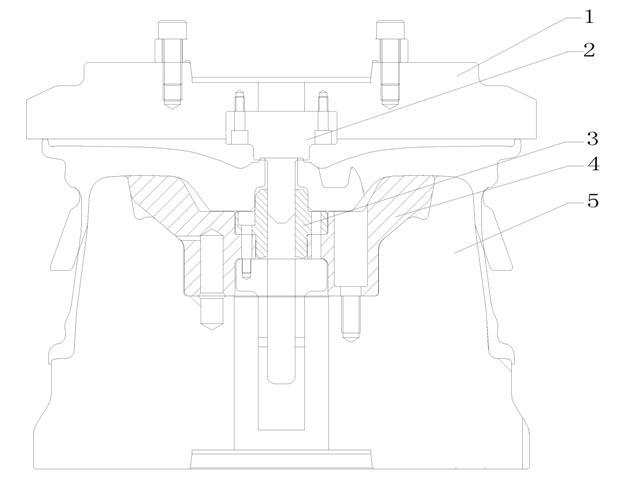

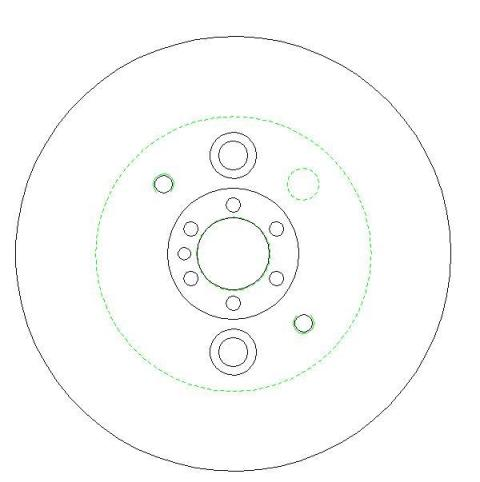

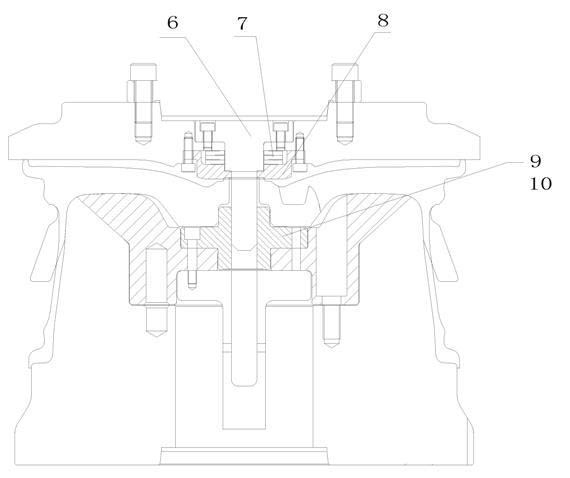

Aluminium wheel spinning mould ejector

InactiveCN101972821ADifficulty in improving positionSolve fit problemsEjection devicesEngineeringConical surface

The invention discloses an aluminium wheel spinning mould ejector. The opening position and the angle of the conical surface of a low die ejector 4 are changed, the middle position of a spoke in the prior art is changed to the circular arc on the joint of the spoke and a rim, and the angle is changed to 45 degrees from 50 degrees. An anti-rotation groove is milled on the faying surface of a spoke back cavity, the connection position of the low die ejector and a guiding copper bush is changed, and an upper die ejector is decomposed into a new upper die ejector 8 and a guidepost 6. The upper die ejector 8 is connected with an upper die bolt, and the guidepost 6 is connected with the upper die bolt to perform the action of guiding. A disc spring 7 is arranged between the new upper die ejector 8 and an upper die 1.

Owner:CITIC DICASTAL

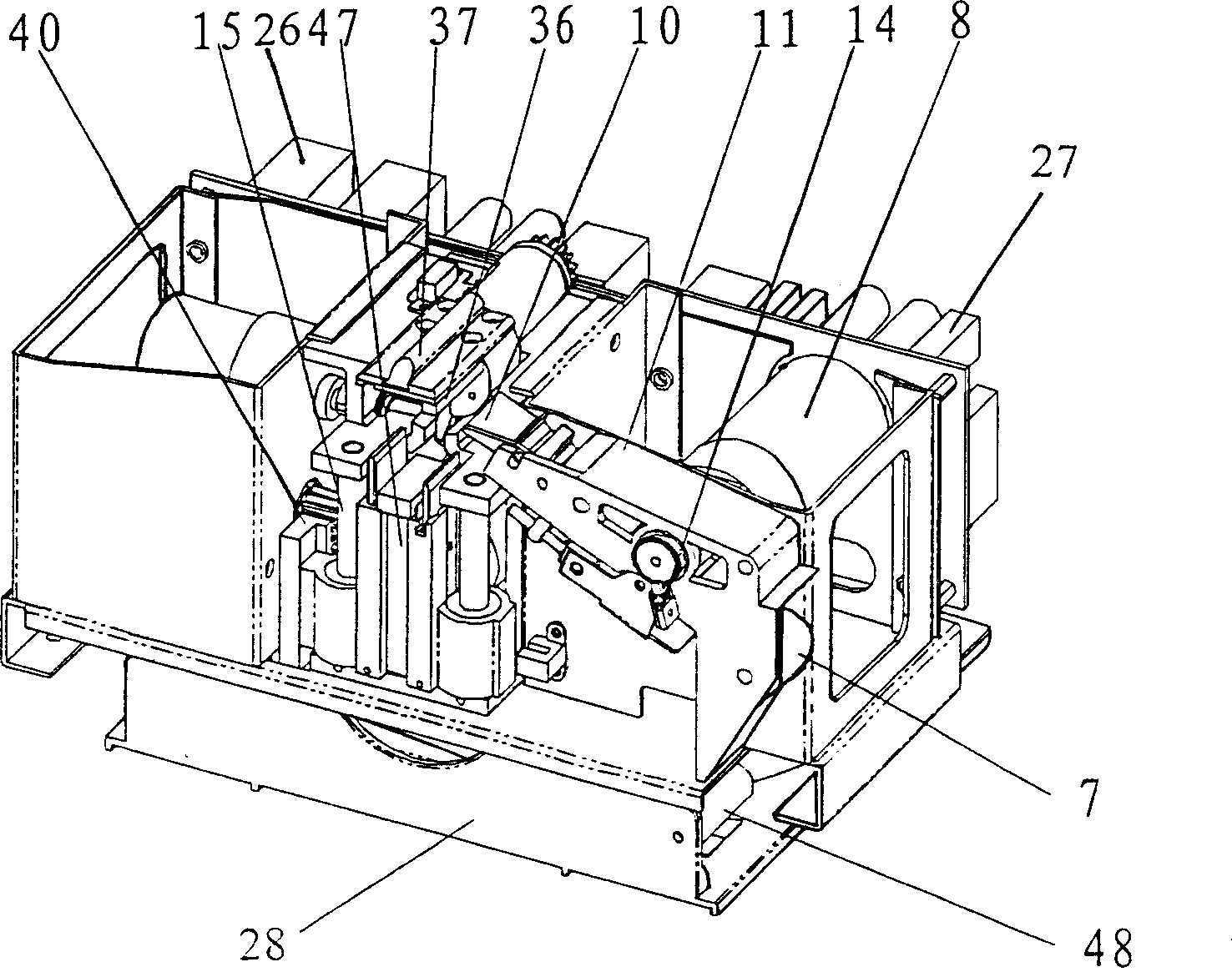

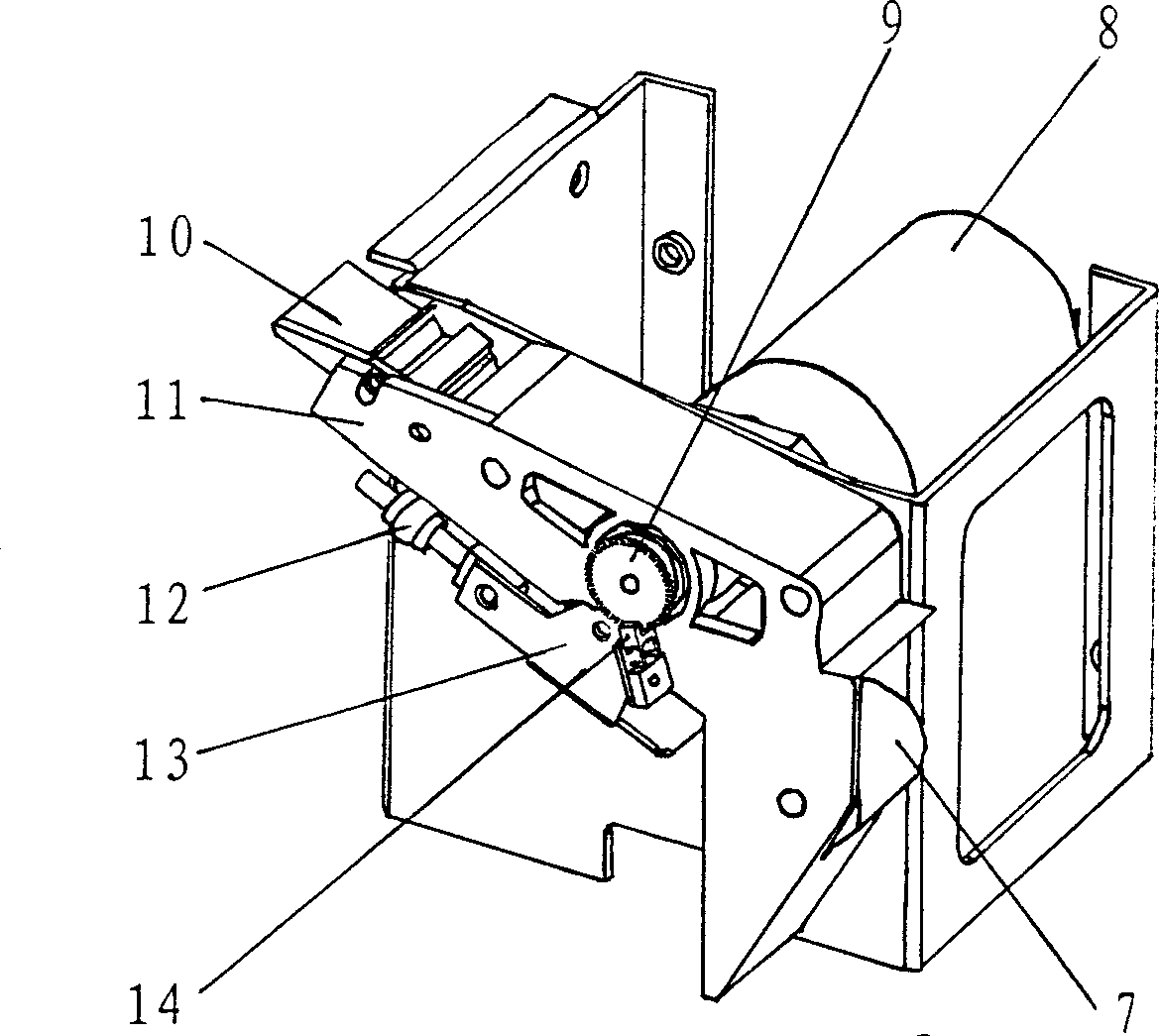

Intelligent full automatic paper money binding machine

InactiveCN1903663ASolve fit problemsGuaranteed uptimePaper article packagingBinding material applicationGear wheelCam

The present invention relates to an intelligent full-automatic bills-binding machine. It is characterized by that its strip winding mechanism is a composite strip winding robot, including: one side of rotating shaft is connected with a robot gear, on its another side a robot is cover-mounted, end portion is connected with a robot finger; one end of torsion spring is connected with robot and robot finger, upper portion of robot is connected with pressure plate, its lower portion is correspondently fit with location cam. The strip-feeding mechanism is positioned at another side of machine frame, the strip outlet of its strip-leading box is correspondent with robot finger of strip-winding mechanism.

Owner:秦卫东

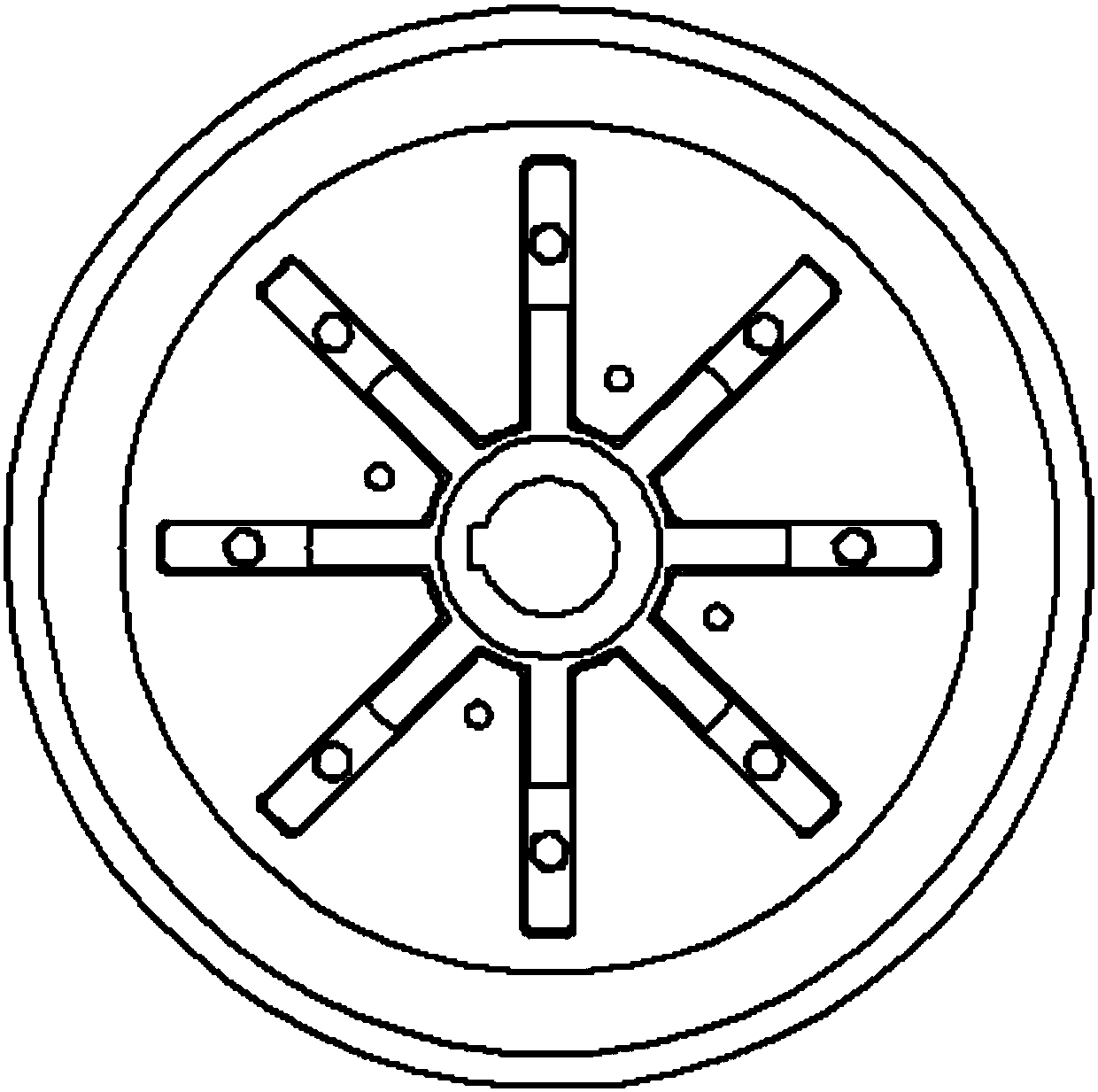

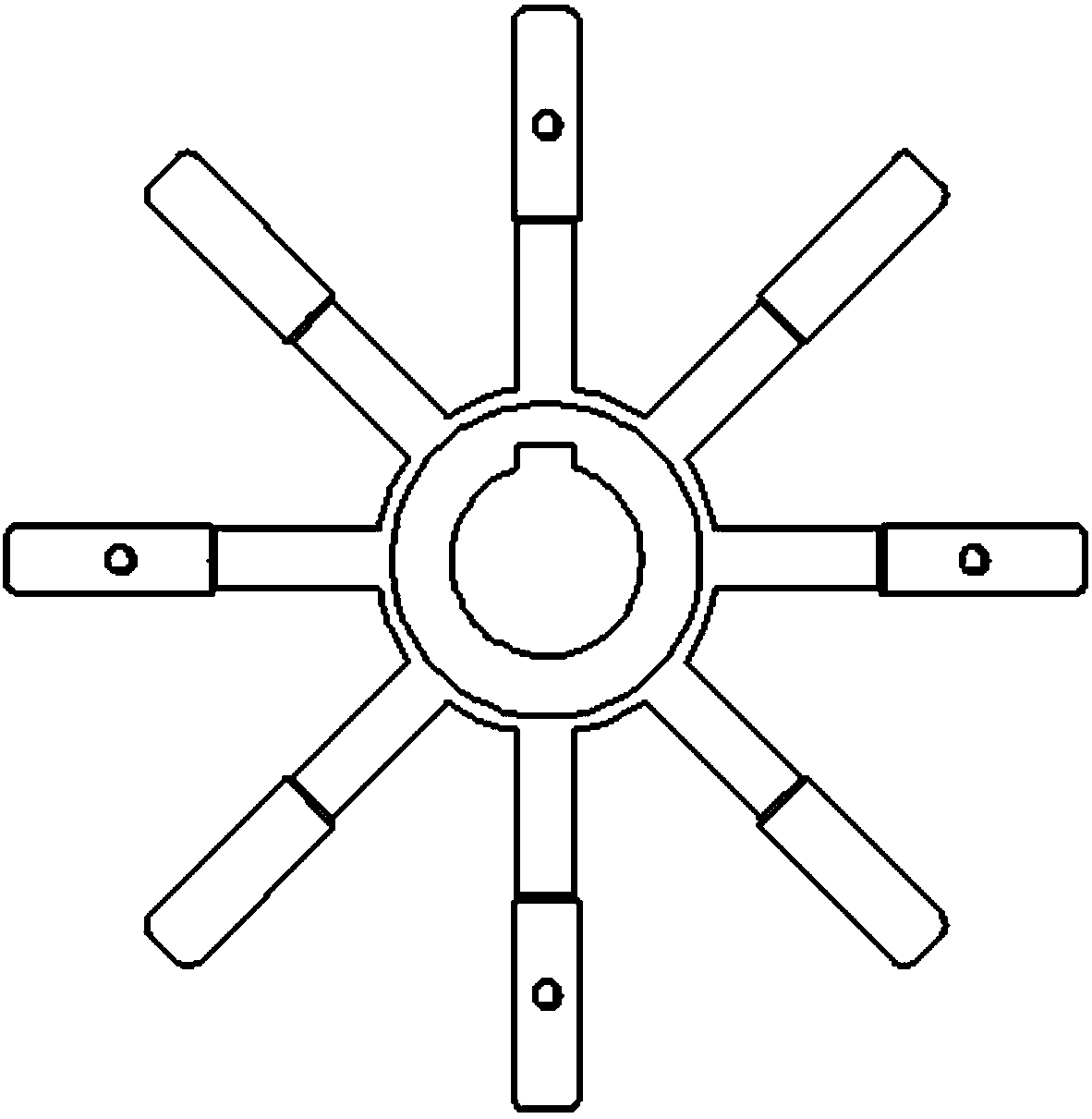

Abrasion-resisting and corrosion-resisting composite impeller

The invention relates to an abrasion-resisting and corrosion-resisting composite impeller, and belongs to the field of fluid machinery. The composite impeller comprises a metal wheel hub and a ceramicblade; the center of the metal wheel hub is provided with a connecting ring, and the outer wall of the connecting ring is provided with connecting rods in a radially outward extending mode; the ceramic blade is of an impeller blade structure machined through ceramic materials, and a hub positioning groove which is matched with the front end of the metal hub in appearance is reserved in the centerof the rear end of the ceramic blade; and the metal hub is inserted into the hub positioning groove in the rear end of the ceramic blade, and the metal hub and the hub positioning groove of the ceramic blade are glued and fixed through resin glue. According to the abrasion-resisting and corrosion-resisting composite impeller, the structure is simple, mounting is convenient, the problem of fast corrosion of the impeller under high abrasion and high corrosion working conditions is solved, and the cooperating problem of the ceramic impeller and a shaft is also solved.

Owner:XIANGYANG WU ER WU PUMP IND

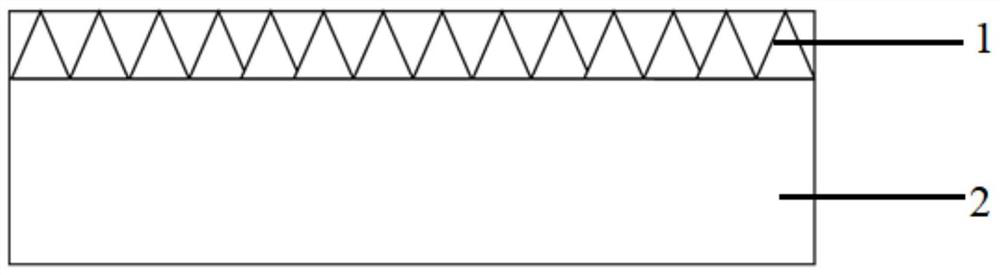

Automobile interior decorative plate with self-repairing function, and preparation method thereof

InactiveCN111645393AImprove scratch resistanceFunction increaseSynthetic resin layered productsSuperstructure subunitsWeather resistanceEmulsion

The invention relates to an automobile interior decorative plate with a self-repairing function, and a preparation method thereof. The automobile interior decorative plate comprises a plastic base layer and a surface layer which are integrally formed, and the surface layer is a self-repairing waterborne polyurethane layer covering the base layer. A waterborne polyurethane emulsion with a self-repairing function is synthesized through a prepolymer method, auxiliaries are added into the waterborne polyurethane emulsion to prepare surface layer slurry, and then the automobile interior decorativeplate with the self-repairing function is prepared through a double-material injection molding process. The automobile interior decorative plate provided by the invention has certain scratch resistance, self-repairing of a damaged coating can be realized at normal temperature, and repeated repairing of the same part can be realized, so that the problem of scratch damage of the automobile interiordecorative plate in the use process is effectively solved; different glossiness values can be provided, and the weather resistance is excellent; and due to the fact that a spraying-free technology isadopted, VOC and air quality in the automobile are effectively improved, and the application value is high.

Owner:CHINA FIRST AUTOMOBILE

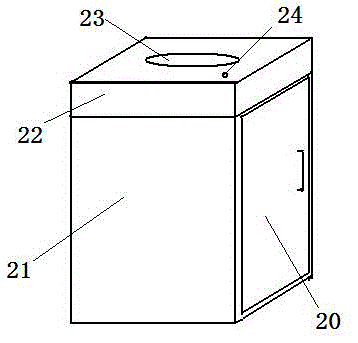

Silk floss processing line equipment

InactiveCN105648541AEasy to processAvoid pollution effectsSilk reelingWater storageCombustion chamber

The invention discloses silk floss processing line equipment. The equipment comprises a silk floss machine, a degumming device and a drying device, a heating component in a water storage bin of the silk floss machine is an oil burner, a combustion chamber of the oil burner is formed in the water storage bin, a filter box is manufactured in the water storage bin, and a water outlet of the filter box is connected with a hot water circulating pump; an outlet of the hot water circulating pump is connected with two pipes, the first branch pipe is communicated to a spray pipe located above a silkworm cocoon squeezing roll barrel of the silk floss machine, and the second branch pipe is communicated to a water inlet of the drying device; the drying device is constituted by a drying chamber located on the lower portion of the drying device, a draught fan chamber located on the upper portion of the drying device and a hot water circulation drying pipe located in the drying chamber; the degumming device comprises an air pressure pot and a support of the air pressure pot, a pot bottom mesh partition plate is installed at the bottom of an inner chamber of the air pressure pot, and a cover top mesh partition plate is installed at the top in an air pressure cover of the air pressure pot. By means of the silk floss processing line equipment, it is helpful for silkworm raisers of a silkworm breeding and mulberry growing base to meet the requirement of conducting on-site processing on cocoon shells, the situations that the cocoon shells go bad due to centralized processing and accumulation of the cocoon shells and good products cannot be obtained from good raw materials are avoided, and the influence of environmental pollution caused by centralized processing is also avoided.

Owner:党金峰

CPCI module cooling method

ActiveCN106020400ASolve fit problemsReduce thermal contact resistanceDigital data processing detailsState of artHeat resistance

The invention discloses a CPCI module cooling method. The method is implemented on the basis of a CPCI module. The CPCI module comprises a master board, a heating element installed on the master board, and a cold plate installed on the master board and used for transmitting heat of the heating element. The method comprises the specific implementing steps that the cold plate is designed to be of an elastic stretchable structure so that the compressibility is achieved, so that when the CPCI module makes contact with a case, the CPCI module can be tightly attached to the case. Compared with the prior art, the CPCI module cooling method solves the problem of fitting of the cold plate and the case, and contact thermal resistance of the cold plate and the case is reduced; by means of the principle of phase change and heat conduction, the thermal resistance of the cold plate is decreased, so that the heat resistance of a heat path from the heating element of the module to the case is greatly lowered.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

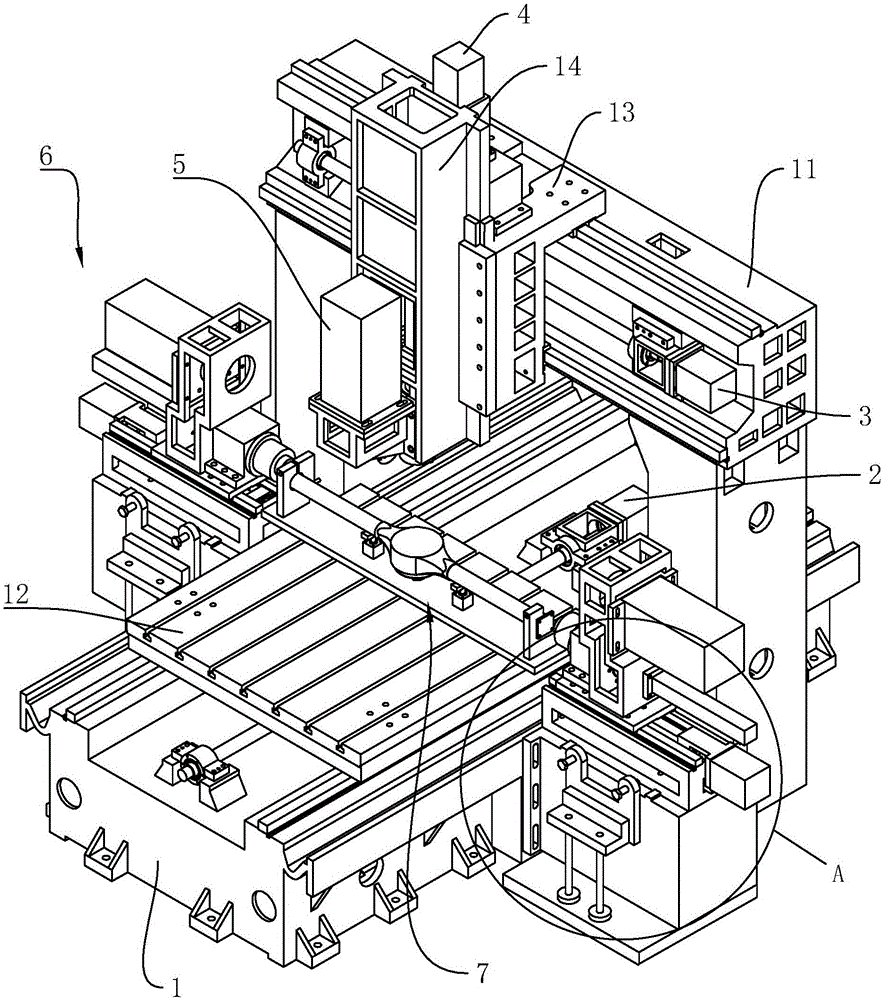

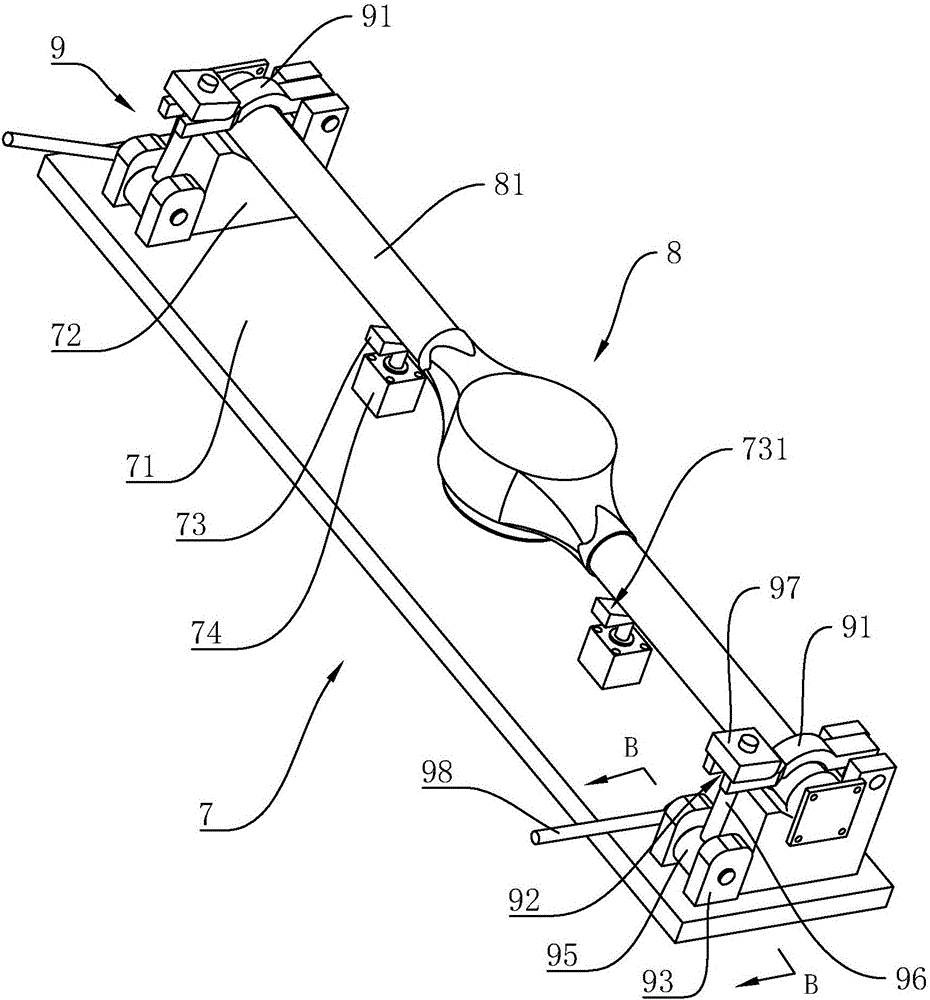

Rear axle processing machine tool

ActiveCN106181438ASimple structureEasy to adjustFeeding apparatusLarge fixed membersEngineeringPower apparatus

The invention discloses a rear axle processing machine tool, which comprises a machine tool body. A portal frame is arranged on the machine tool body; a workbench driven by a first power device and sliding along an X axle is also arranged on the machine tool body; a saddle driven by a second power device is slidably arranged along a Y axle and located on the portal frame above the workbench; a slide seat driven by a third power device is slidably arranged on the saddle along a Z axle; a first spindle driven by a fourth power device is arranged on the slide seat; and end face processing mechanisms arranged in a mirroring way are arranged on two sides of the machine tool body, and are located on one side, provided with the first spindle, on the portal frame. The simultaneous processing of two upper ends and three middle holes on a rear axle can be completed through the one machine tool, so that compared with a traditional rear axle processing machine tool, the problem of requiring the matching of multiple machine tools and multiple clamping is solved, a lot of rear axle transfer time is saved, and the working efficiency is greatly improved; and meanwhile, the rear axle only needs to be clamped and positioned at a time, so that the location degree of the rear axle during processing is ensured, and further the processing accuracy is effectively improved.

Owner:潍坊圣世源电子设备有限公司

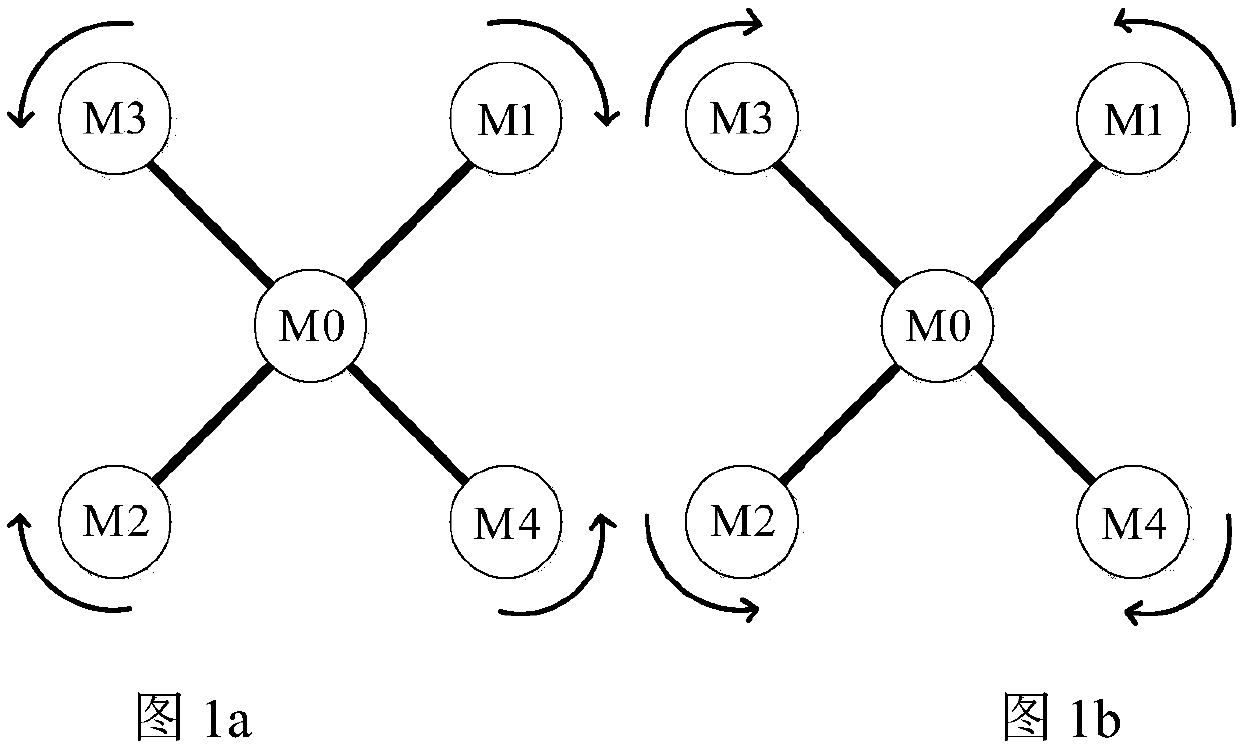

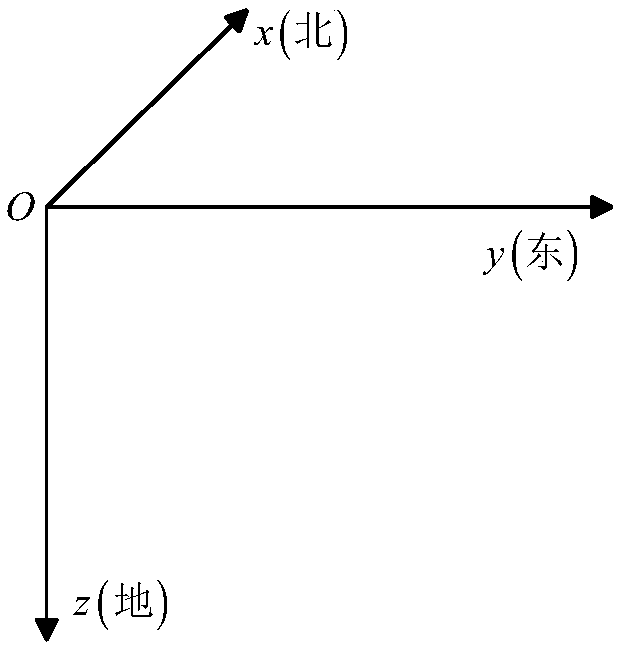

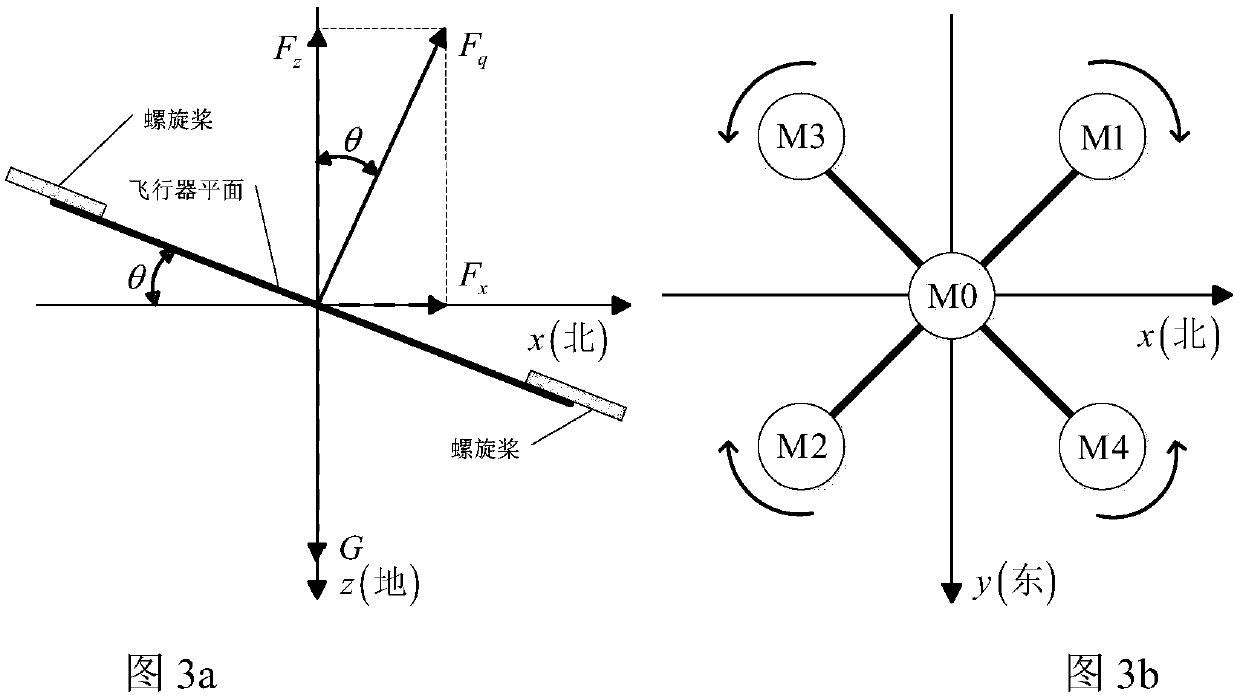

Control system and method for oil-drive variable-pitch multi-rotor aircraft

InactiveCN107329484ADurationHeavy loadAttitude controlPosition/course control in three dimensionsCarrying capacityTime delays

The invention discloses a control system and method for an oil-drive variable-pitch multi-rotor aircraft. The aircraft employs an oil-drive motor to drive a plurality of propellers, and the propellers have the same rotating speed. The aerodynamic force and aerodynamic moment of the aircraft are changed through the changing of the pitch of each propeller, thereby achieving the posture and position control. Compared with a conventional multi-rotor aircraft, the aircraft is long in endurance, is large in carrying capacity, is low in fault rate, is good in maneuvering performances, and is smaller in mass. The control method solves a problem of cooperation of pitch control and the control of the rotating speed of an engine, greatly improves the sensitivity of oil-drive multi-rotor power output, solves a problem, caused by the time delay of the engine, of the control of the whole aircraft, and enables the maneuverability and control accuracy of the oil-drive variable-pitch multi-rotor aircraft to be guaranteed.

Owner:XIAN TANVEN INTELLIGENT TECH CO LTD

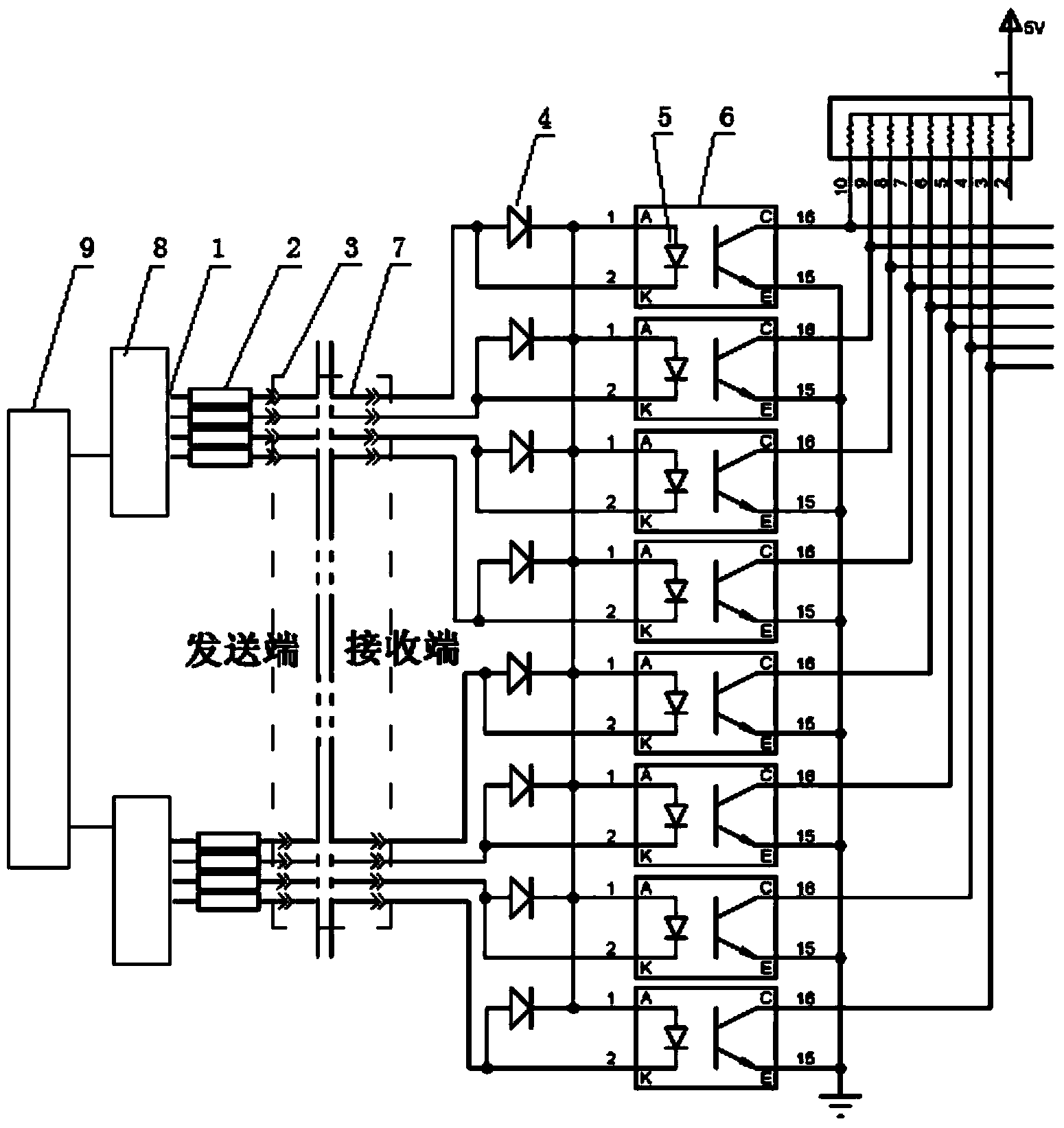

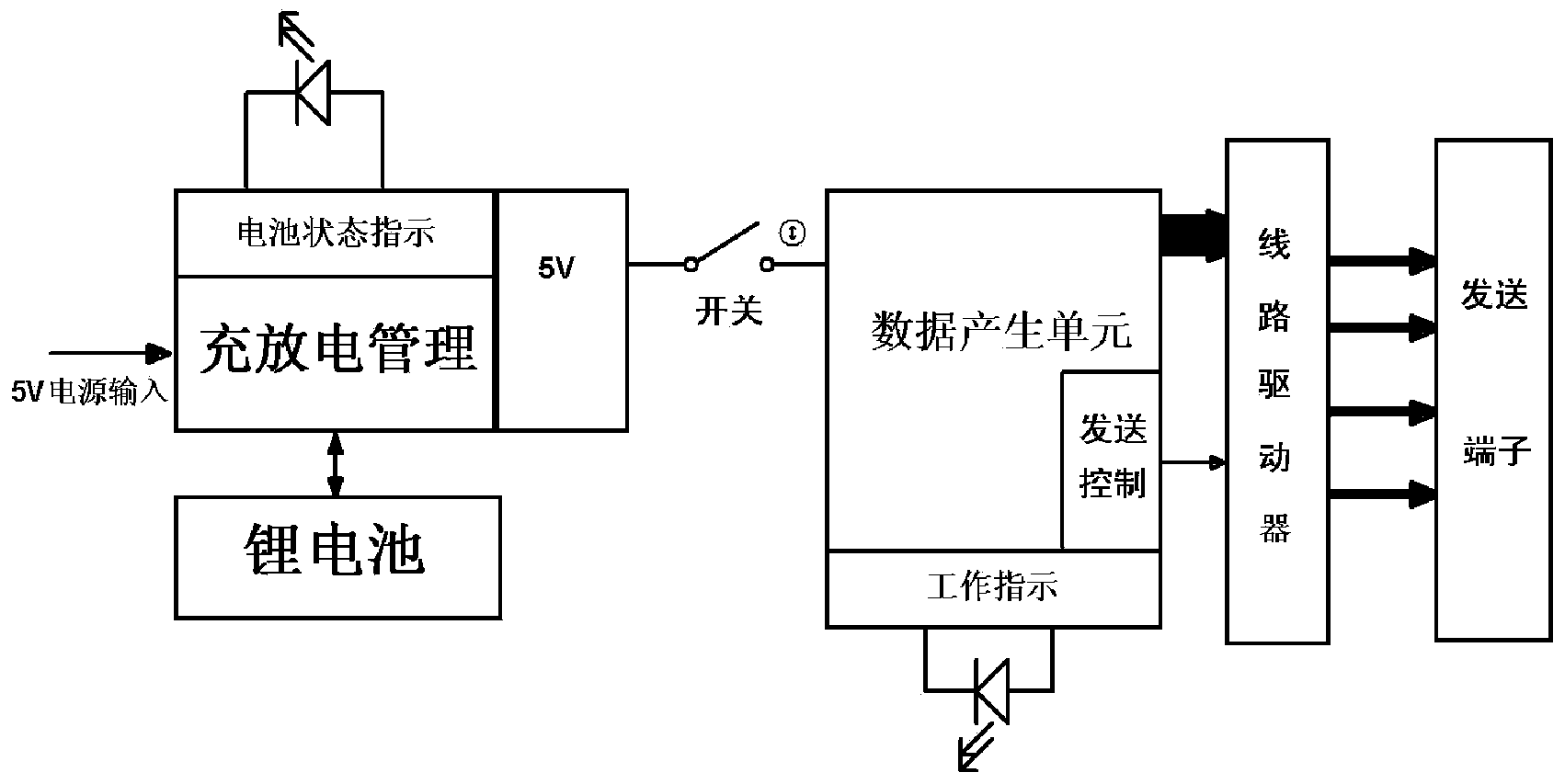

Cable checking circuit structure and common-line-free cable checking method

ActiveCN103760457ASolve fit problemsReduce usage timeElectrical testingElectrical resistance and conductanceCurrent limiting

The invention discloses a cable checking circuit structure and a common-line-free cable checking method. Only tested cables without any common reference end are needed for a circuit crossing a checking signal sending end and a checking signal receiving end, each tested cable checking circuit comprises a current-limiting resistor, a tested cable, an isolation diode and a signal coupler of the checking signal receiving end, and the tested cable, the isolation diode and the checking signal receiving end are sequentially connected from a checking signal sending end equipment port. Cathodes of the isolation diodes are connected with anodes of input ends of the signal couplers, cathodes of input ends of the signal couplers are connected with anodes of the isolation diodes, and the cathode ends of the isolation diodes of the tested cable checking circuits or anode ends of input ends of the signal couplers of the tested cable checking circuits are connected through wires. Unique signals attached to the cables are sent to the corresponding cables respectively and sequentially by the sending end, and serial numbers of the cables are displayed after the signals are received by the receiving end. By means of the method, long-distance cable checking can be quickly and accurately carried out by one person without common lines.

Owner:中铁建电气化局集团南方工程有限公司

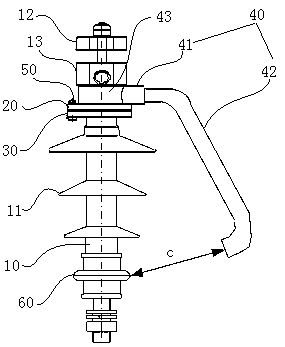

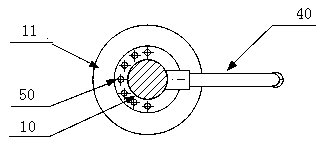

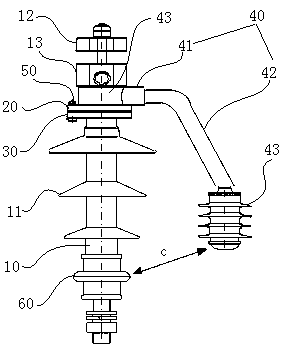

Lightning prevention support column insulator

PendingCN109390111AWith positioning functionRealize position adjustmentSupporting insulatorsElectrical conductorElectric power system

The invention relates to a power distribution device of a power system, in particular to a lightning protection support column insulator. The insulator is provided with a core rod, and two ends of thecore rod are respectively provided with an electrode and a wiring device. The insulator comprises a positioning device cooperating with the core rod, and the positioning device can rotate relative tothe core rod. The positioning device is connected with an arc starting rod. The insulator can adjust the angle between an arc starting body and an installation conductor, can guarantee that the safety distance between a spherical head of the arc starting rod and other metals or conductors is greater than a discharge interval distance of an insulating arc starting body.

Owner:GUANGDONG POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com