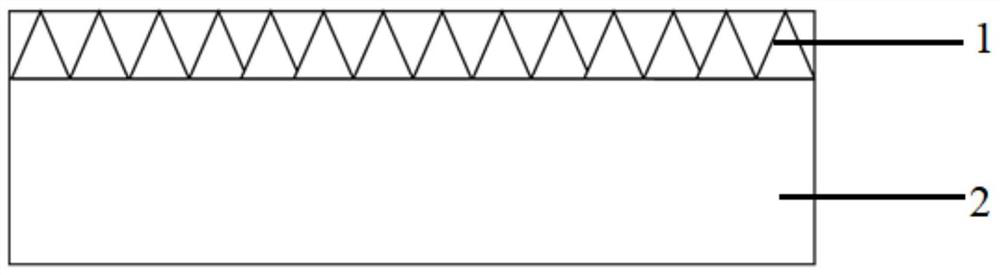

Automobile interior decorative plate with self-repairing function, and preparation method thereof

A self-repairing technology for interior decorative panels, applied to chemical instruments and methods, household appliances, flat products, etc., can solve problems such as scratches and damages, improve hardness and wear resistance, excellent weather resistance, improve hardness and resistance scratchy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

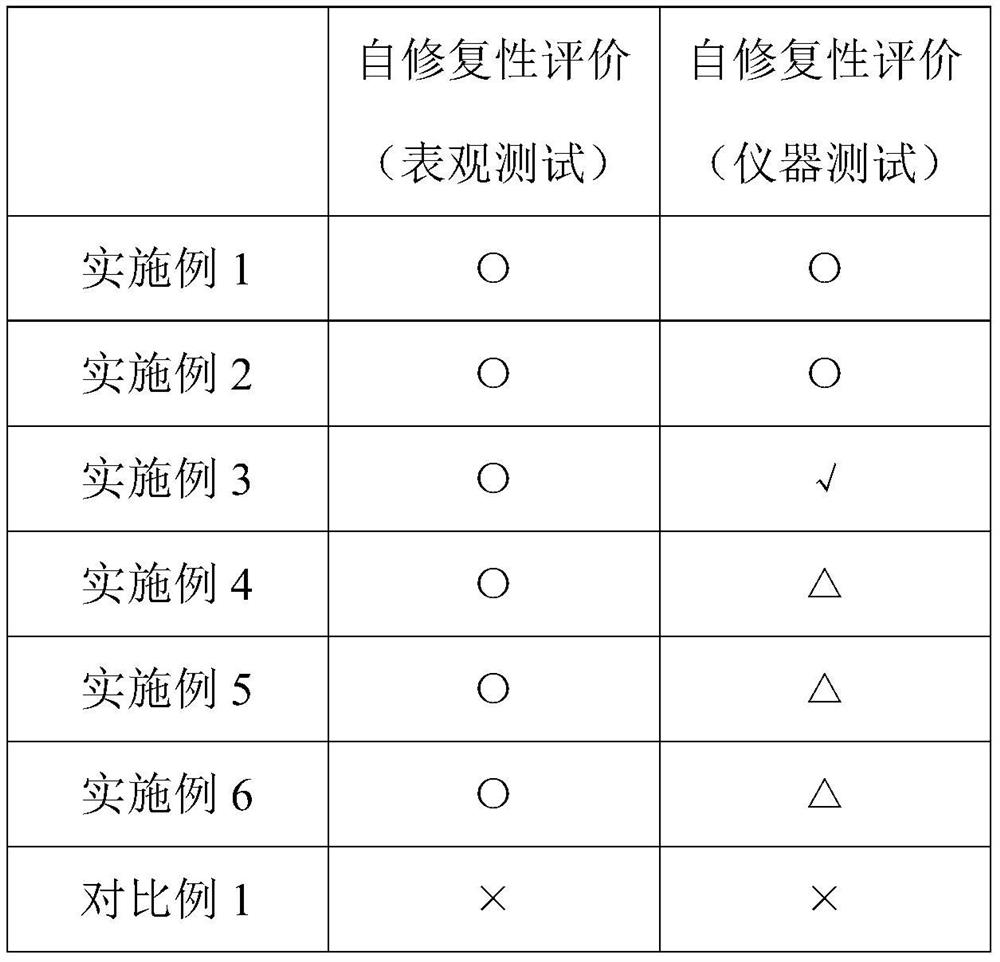

Embodiment 1

[0050] The present embodiment provides a kind of preparation method of the automotive interior trim panel with self-repairing function, it comprises the following steps:

[0051] (1) Preparation of self-healing water-based polyurethane emulsion: Take 70 parts of 1,6-hexanediol polycarbonate and 1 part of internal crosslinking agent trimethylolpropane, vacuum dehydrate at 120°C for 3 hours, wait for cooling After reaching 55°C, add 25 parts of hexamethylene diisocyanate and 0.3 parts of stannous octoate, mix well, then raise the temperature to 90°C and stir for 2 hours, then add 5 parts of alcohol chain extender 1,3-butanediol into the reactor React in medium for 3 hours to obtain prepolymer A; then lower the temperature of the above prepolymer A to 55°C, add 2 parts of disulfide bond-containing chain extender 2,2'-dithiodiethanol, react for 2 hours, and then cool to Add 2 parts of triethylamine at 40°C, neutralize and react for 10 minutes, add deionized water to vigorously sti...

Embodiment 2

[0056] The present embodiment provides a kind of preparation method of the automotive interior trim panel with self-repairing function, it comprises the following steps:

[0057] (1) Preparation of self-healing water-based polyurethane emulsion: Take 70 parts of polypropylene glycol and 1 part of internal crosslinking agent trimethylolpropane, vacuum dehydrate at 120°C for 3 hours, and add 30 parts of 4 after cooling down to 55°C , 4'-dicyclohexylmethane diisocyanate and 0.2 parts of dibutyltin dilaurate, mix evenly, heat up to 90°C and stir for 2 hours, add 5 parts of alcohol chain extender 1,4-butanediol into the reactor React for 3 hours to obtain prepolymer A; then lower the temperature of the above prepolymer A to 55°C, add 2 parts of disulfide bond-containing chain extender 4,4'-diaminodiphenyl disulfide, react for 2 hours, and then Cool to 40°C and add 2 parts of triethylamine, neutralize and react for 10 minutes, add deionized water to vigorously stir and emulsify and ...

Embodiment 3

[0062] The present embodiment provides a kind of preparation method of the automotive interior trim panel with self-repairing function, it comprises the following steps:

[0063] (1) Preparation of self-healing water-based polyurethane emulsion: take 55 parts of polypropylene glycol and 0.2 part of internal crosslinking agent triethanolamine, dehydrate in vacuum for 4 hours at 115°C, add 30 parts of hexamethylene after cooling down to 55°C Diisocyanate and 0.01 part of dioctyltin dilaurate, mix evenly, heat up to 90°C and stir for 2 hours, add 5 parts of alcohol chain extender 1,3-butanediol into the reactor and react for 2.5 hours to obtain a prepolymer A; then lower the temperature of the above prepolymer A to 55°C, add 1 part of chain extender 2,2'-dithiodiethanol containing disulfide bonds, react for 1.5 hours, then cool to 35°C and add 3 parts of triethylamine, Neutralize and react for 10 minutes, add deionized water to vigorously stir and emulsify and disperse, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com