System and method of full-automatic continuous quantitative loading of railway freight train

A rail freight, fully automatic technology, applied in the direction of transportation and packaging, loading/unloading, conveyor control devices, etc., to achieve the effect of reducing costs, improving transportation efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

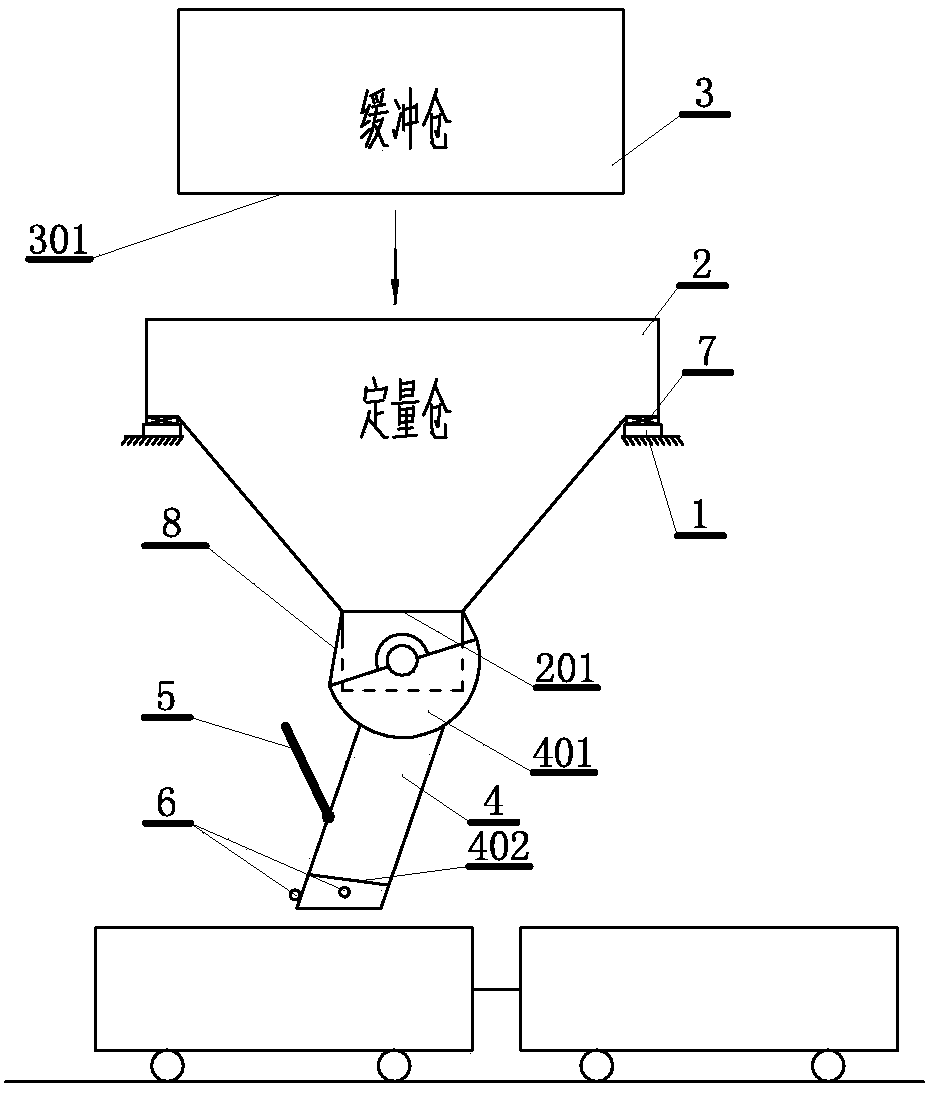

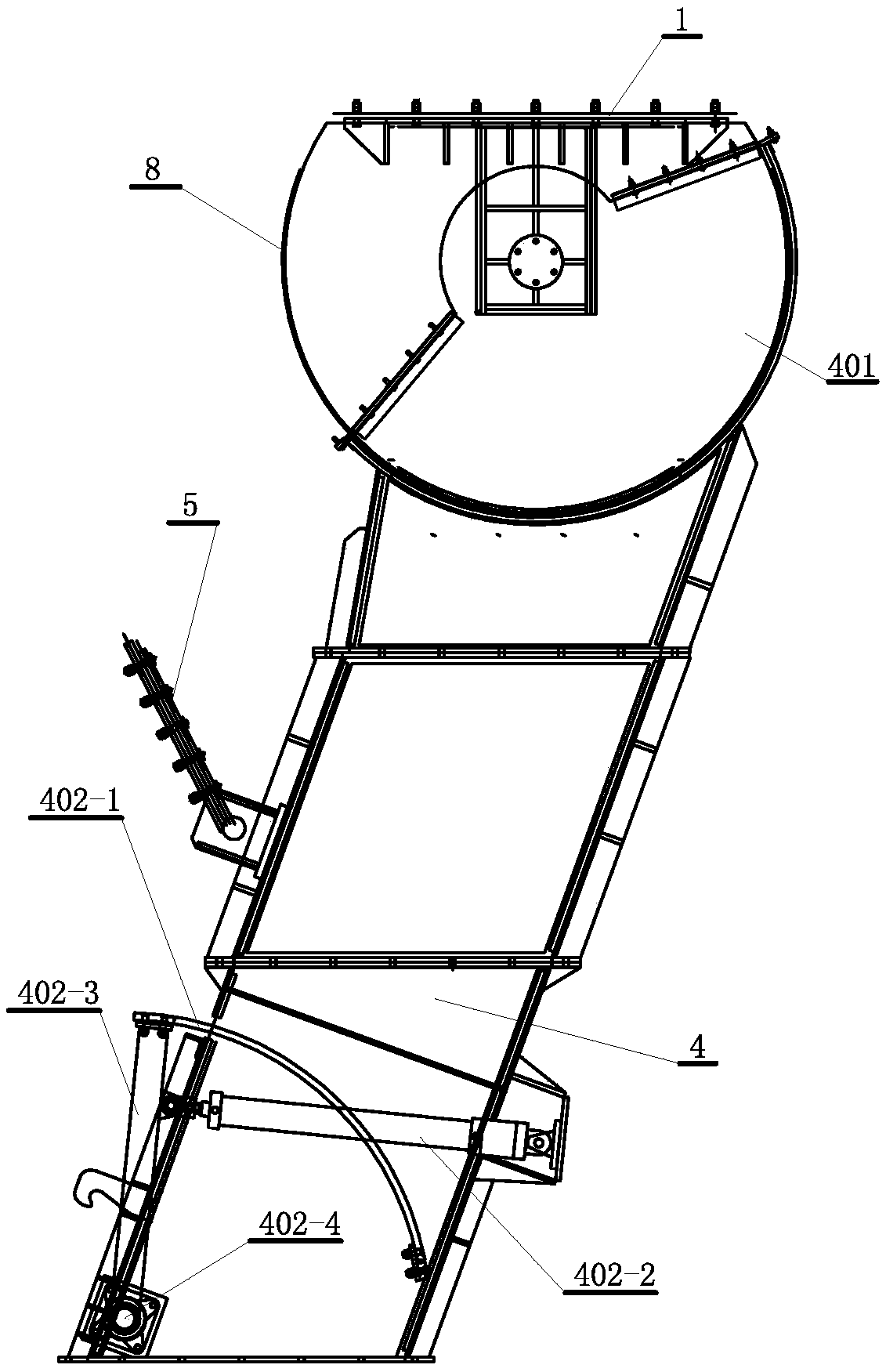

[0026] A fully automatic continuous quantitative loading system for railway freight trains, such as figure 1 and figure 2 As shown, the system includes a quantitative warehouse 2 set across the train track in the loading area of the train carriage through a bracket 1, a material buffer warehouse 3 is arranged on the upper side of the quantitative warehouse, and a feed gate is arranged at the lower end of the buffer warehouse to align with the quantitative warehouse 301, a discharge gate 201 is arranged at the lower end of the quantitative warehouse, and the lower end of the quantitative warehouse is connected with a loading chute 4 through a bracket. A loading control system controls the impact of the buffer warehouse and the quantitative warehouse on the freight by identifying the identification of the vehicle and judging the speed. Continuous quantitative loading of trains; wherein: the loading chute is a chute with a rectangular cross-section, the forward direction of th...

Embodiment 2

[0034] A method for fully automatic continuous quantitative loading of railway freight trains is based on the method of the automatic continuous quantitative loading system of railway freight trains described in embodiment 1, so the content in embodiment 1 should be used as the content of this embodiment. Wherein: the volume of the quantitative bin in the system is to ensure that the weighed material meets the loading capacity of a compartment, and the volume of the loading chute in the system is at least one-fifth of the volume of the quantitative bin , the method includes: obtaining the loading information of the train carriages, the loading information including the number of carriages, the loading weight of each carriage and the size data of the carriages, determining the time for each carriage to complete loading, and determining the freight train according to each A car runs through the car loading area at the speed of the loading time, determines the height of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com