CPCI module cooling method

A heat dissipation method and heat technology, applied in the computer field, can solve problems such as unsatisfactory heat conduction effect, and achieve the effects of easy promotion, small footprint, and reduced contact thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

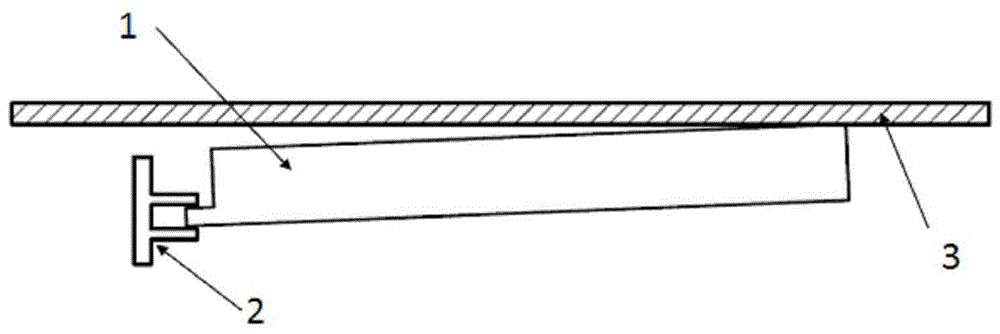

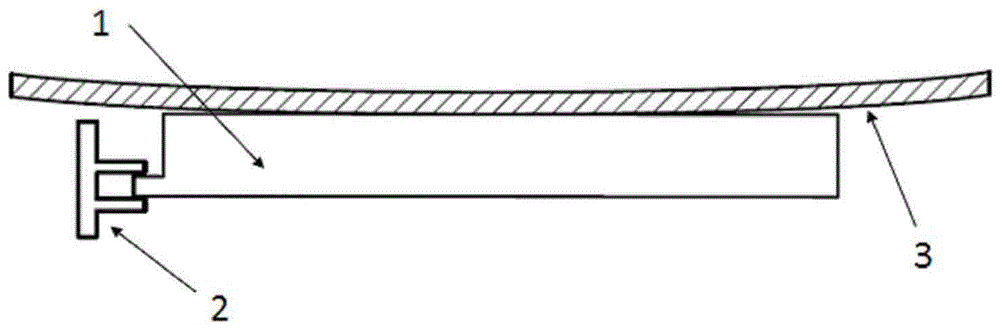

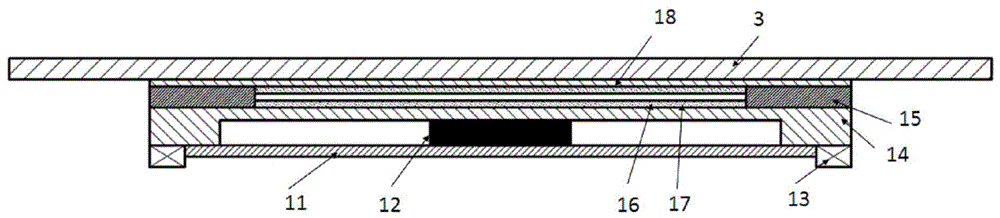

[0022] In order to overcome the problem of excessive conduction thermal resistance caused by small contact area or loose fit when the upper reinforced CPCI module is bonded to the chassis. as attached image 3 , Figure 4 As shown, the present invention provides a kind of CPCI module cooling method, and this method is realized based on CPCI module 1, and described CPCI module 1 comprises mainboard 11, the heating element 12 that is installed on mainboard 11 and, is installed on mainboard 11 upper side and is used for The specific implementation process of the cold plate that transmits the heat of the heating element 12 is: the cold plate is designed as an elastic and stretchable structure to make it compressible, so that when the CPCI module 1 is in contact with the chassis 3, it can be closely attached to the cold plate. On chassis 3.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com