Patents

Literature

37results about How to "Avoid pollution effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

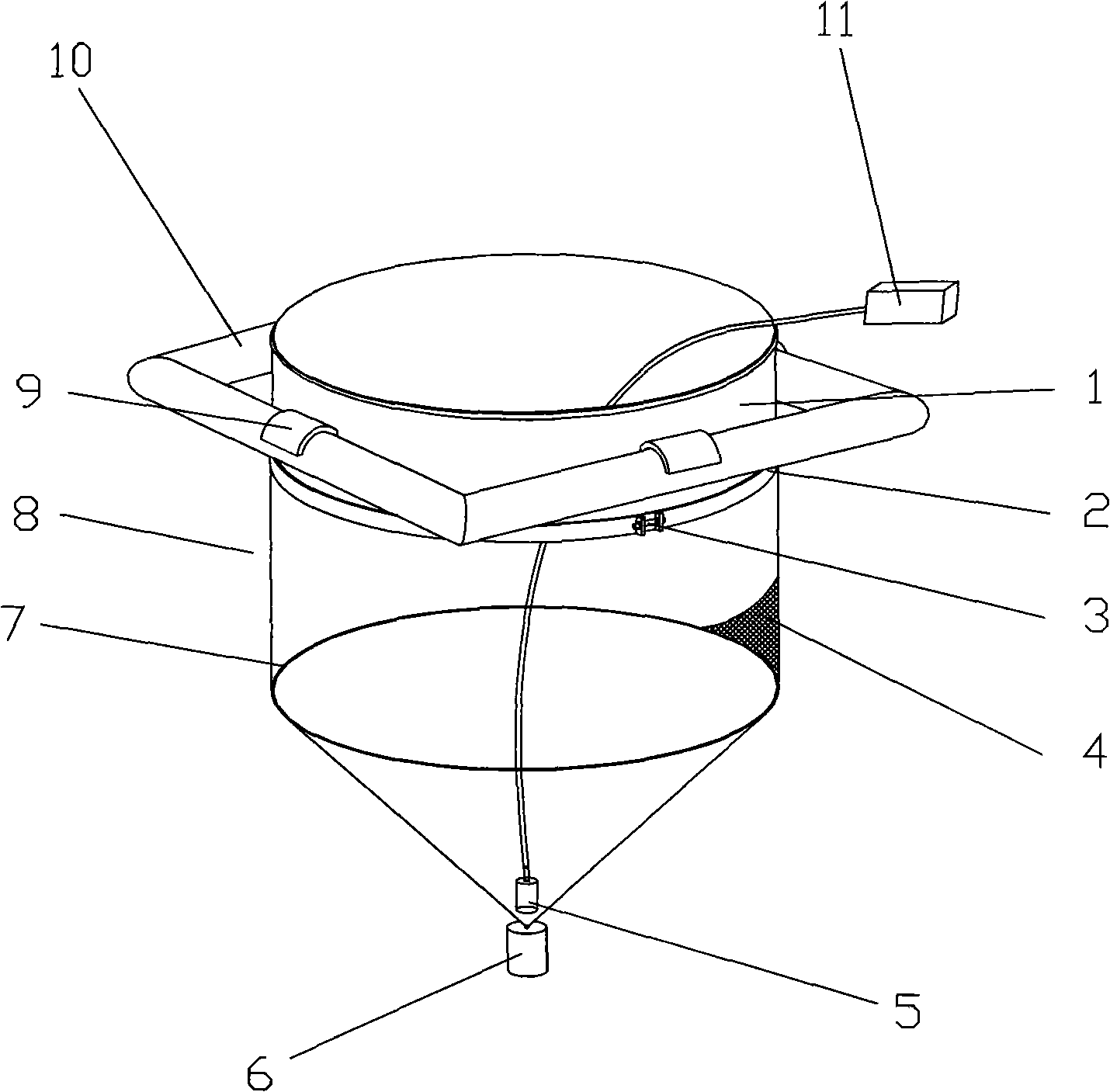

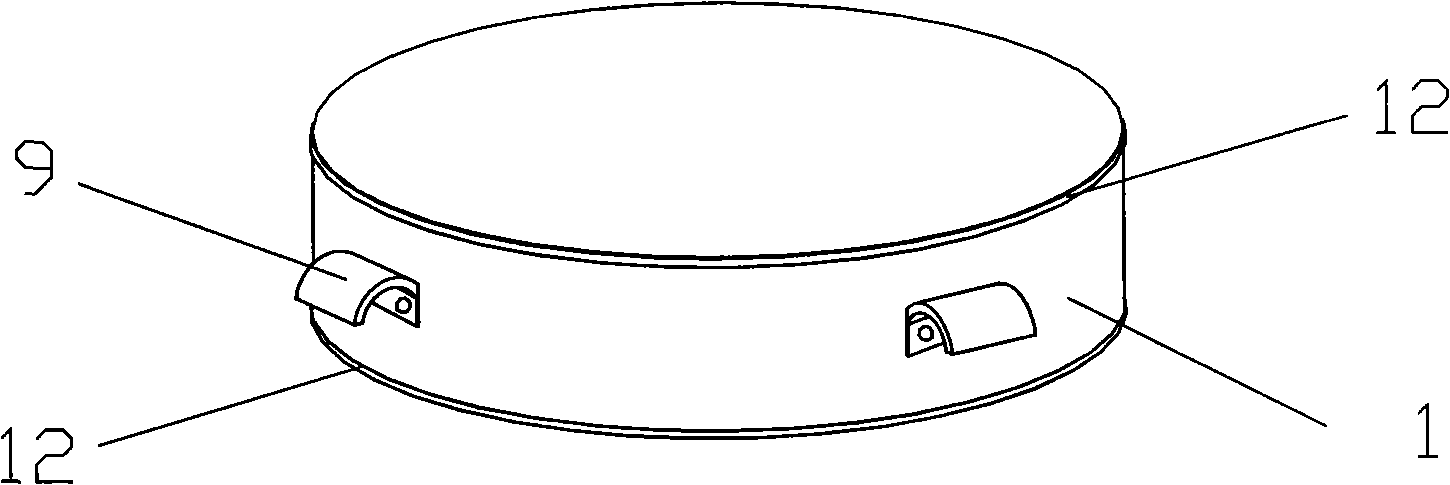

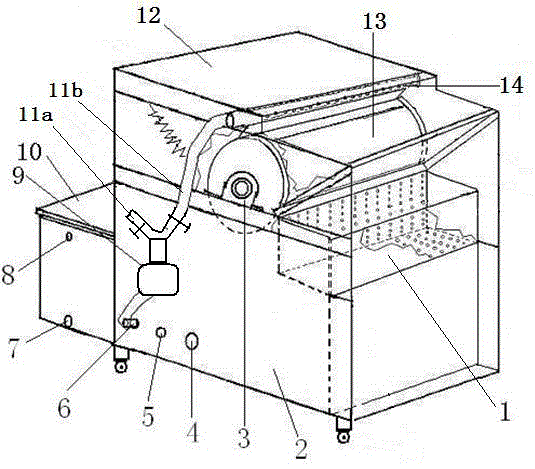

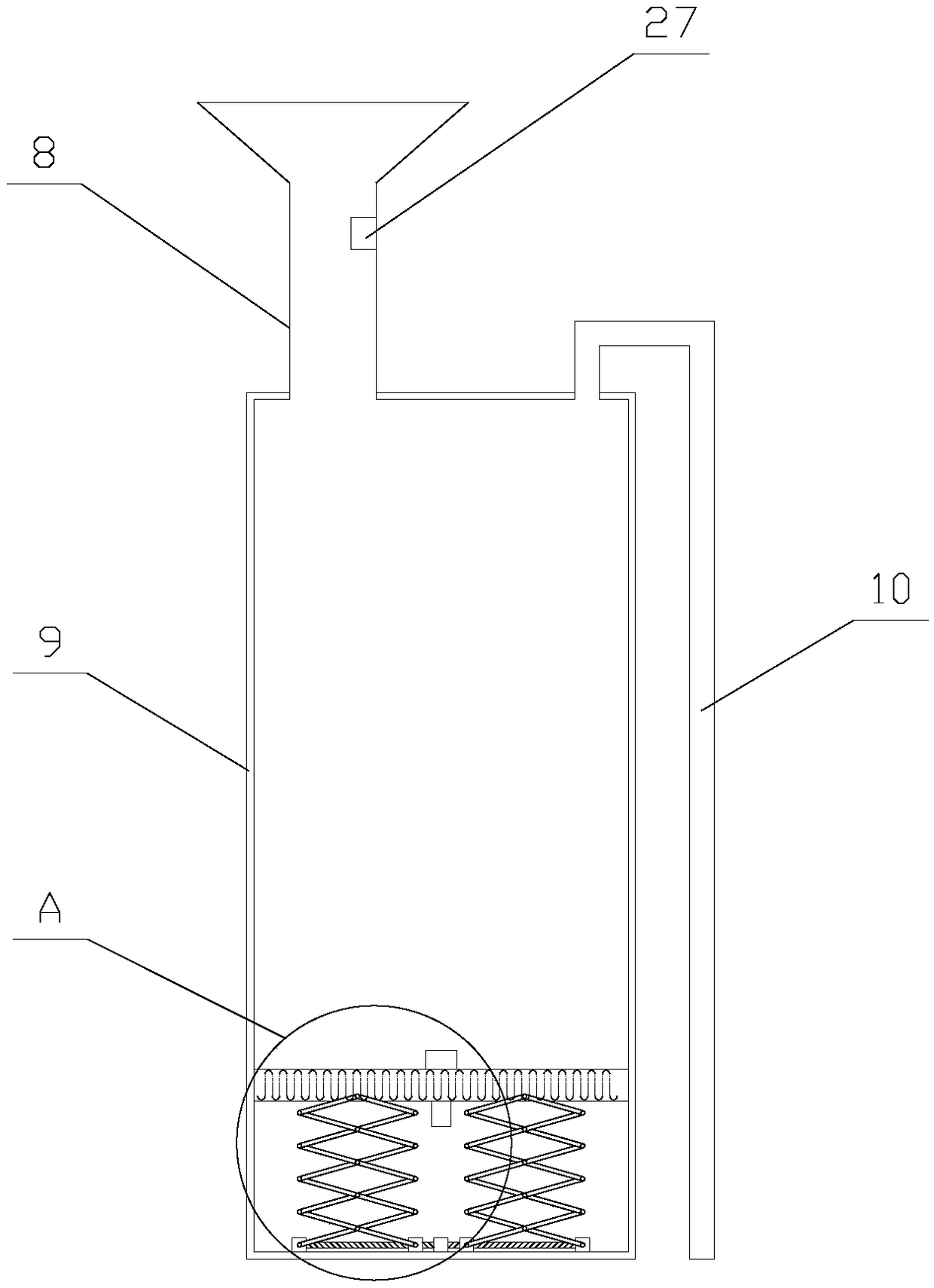

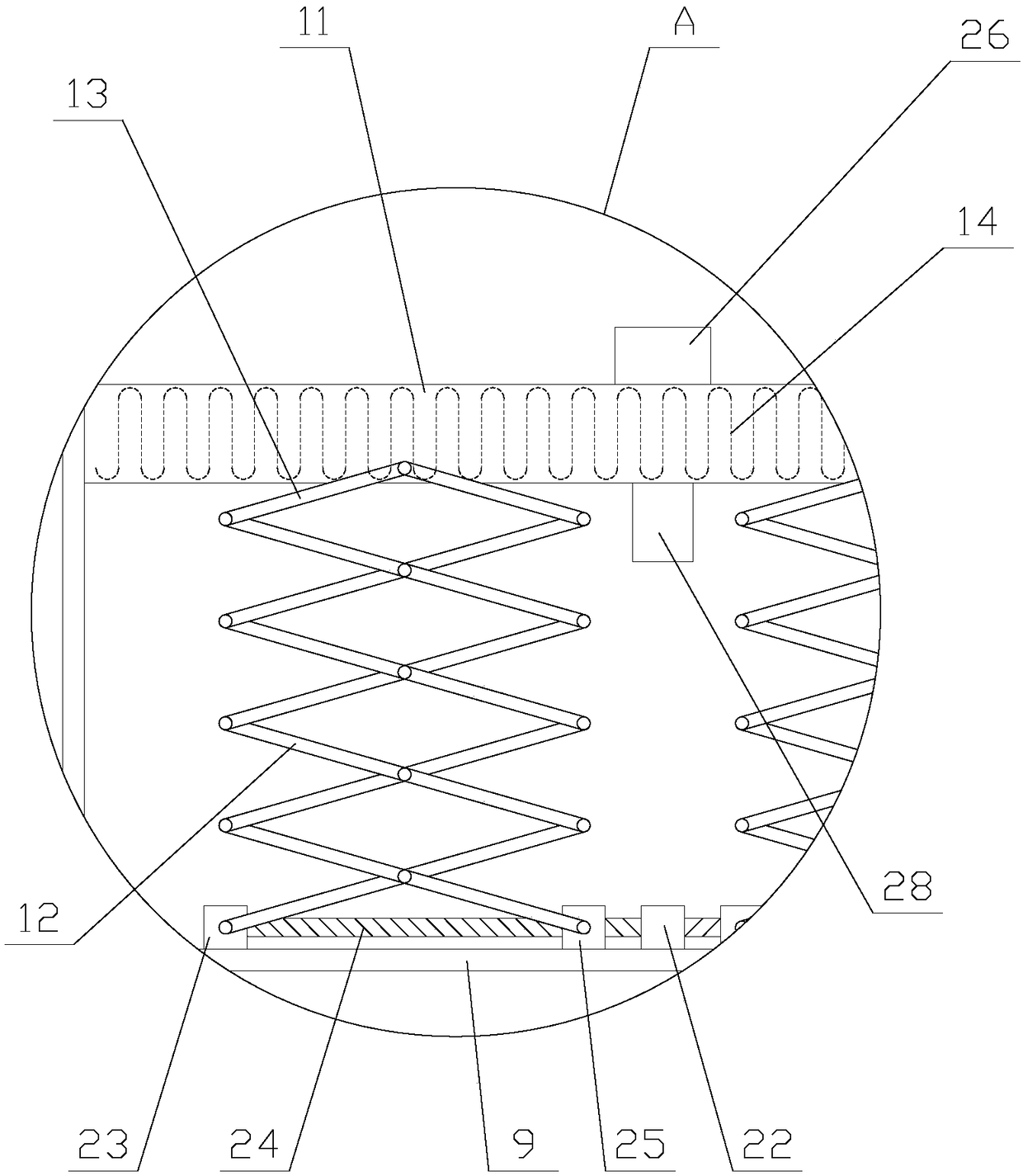

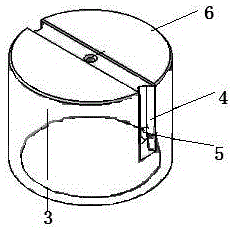

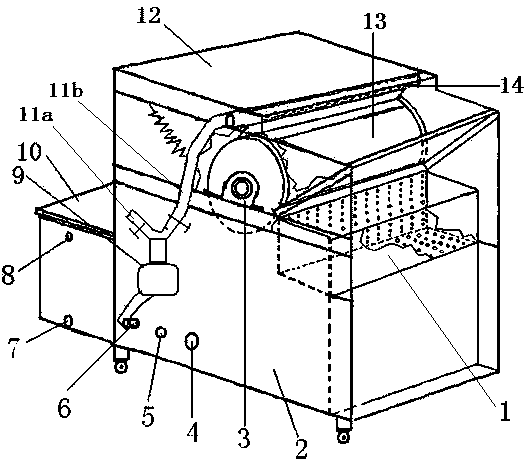

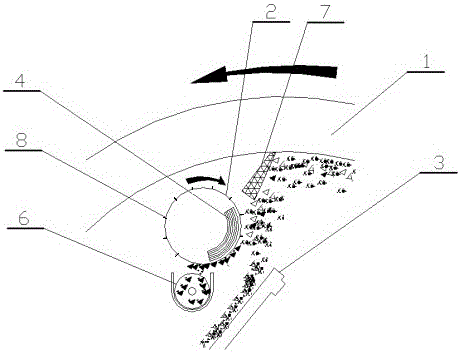

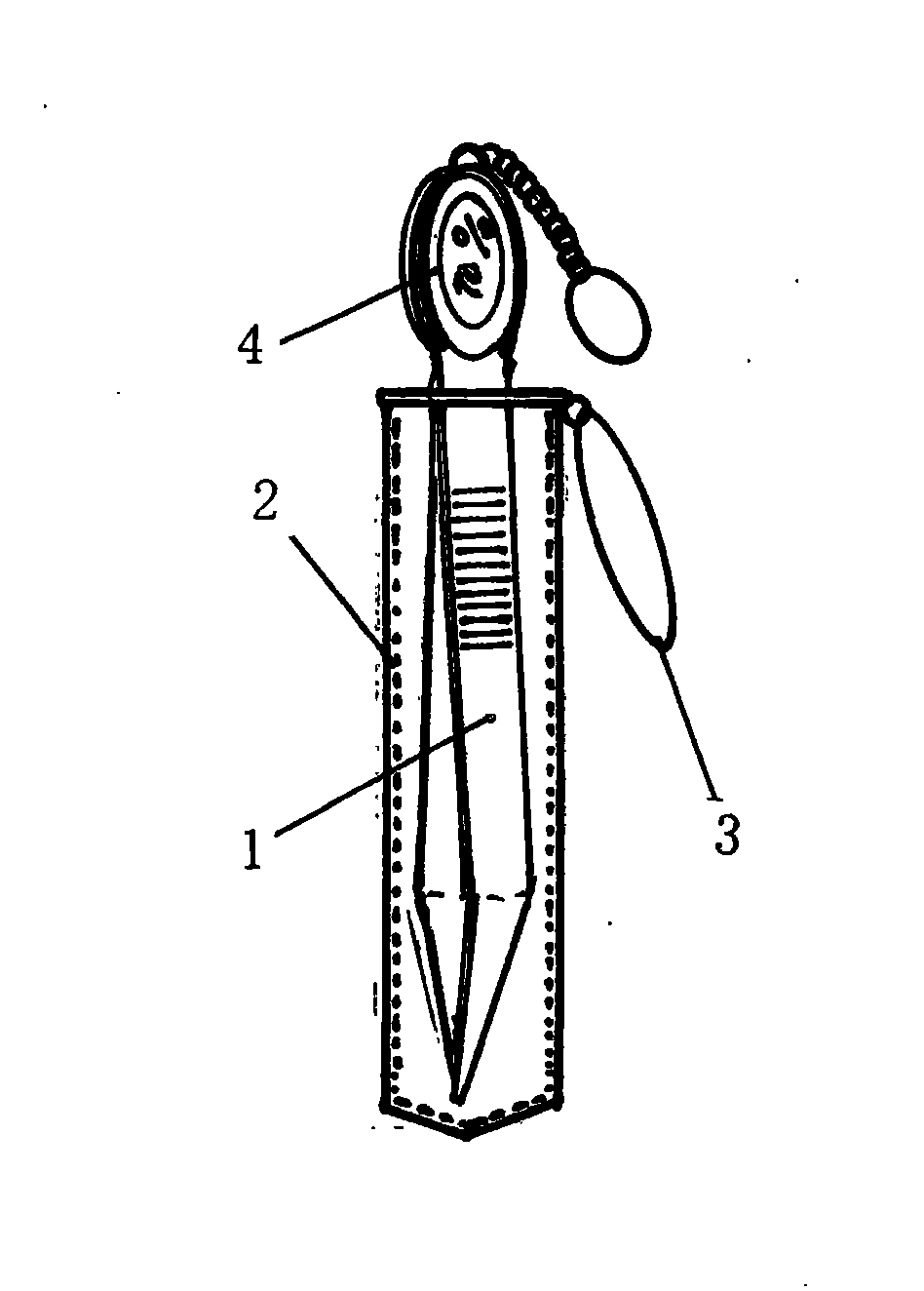

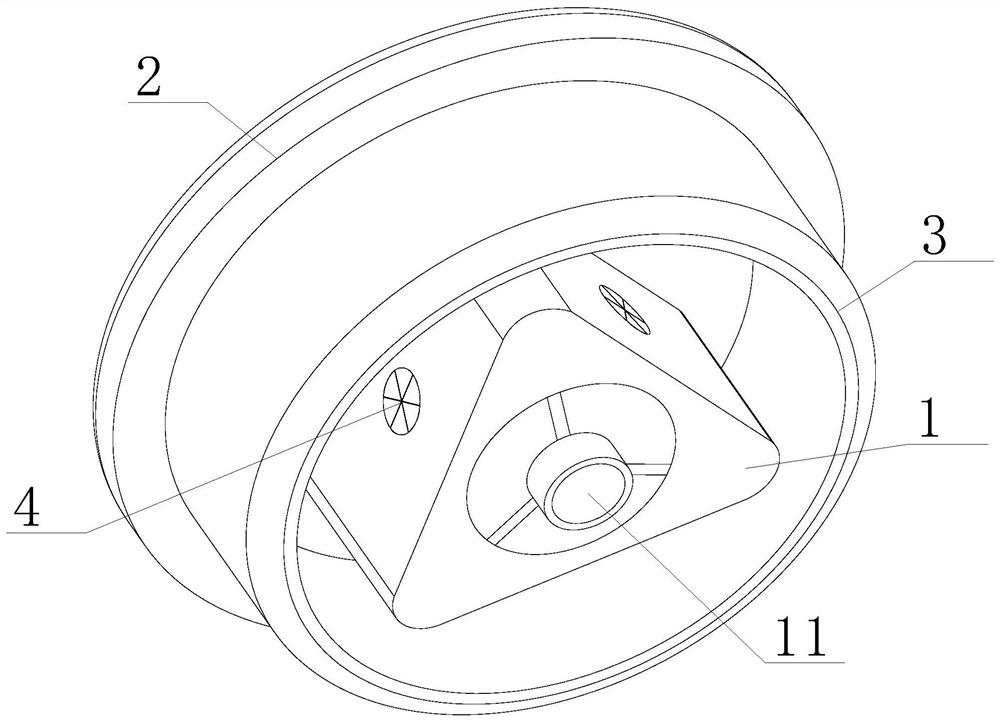

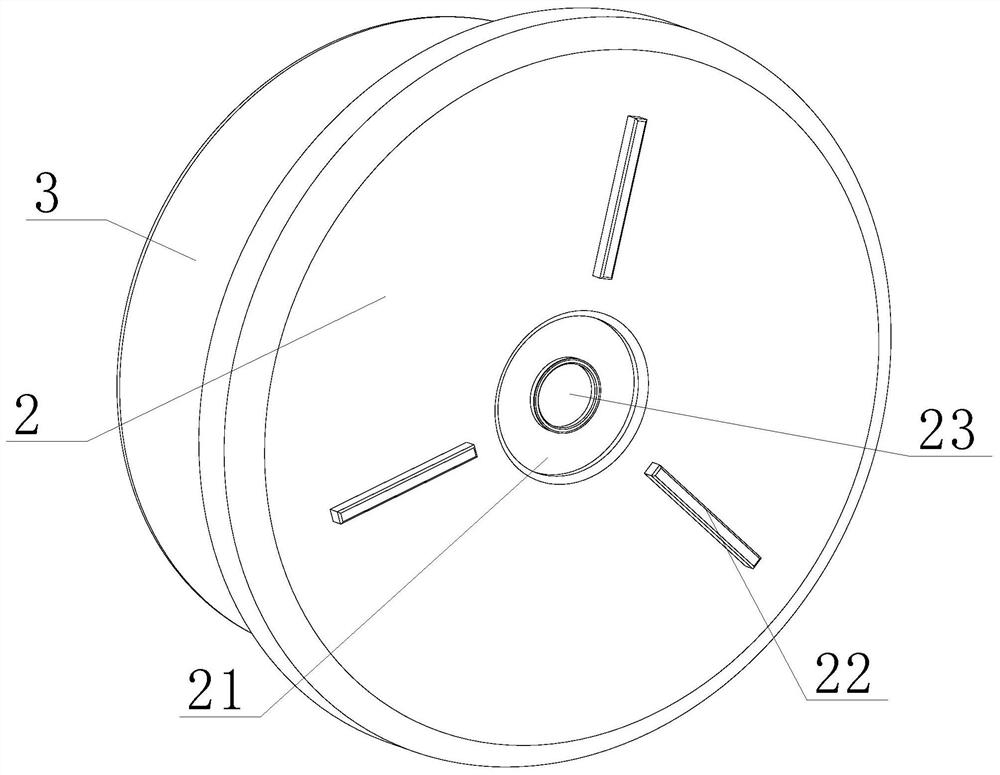

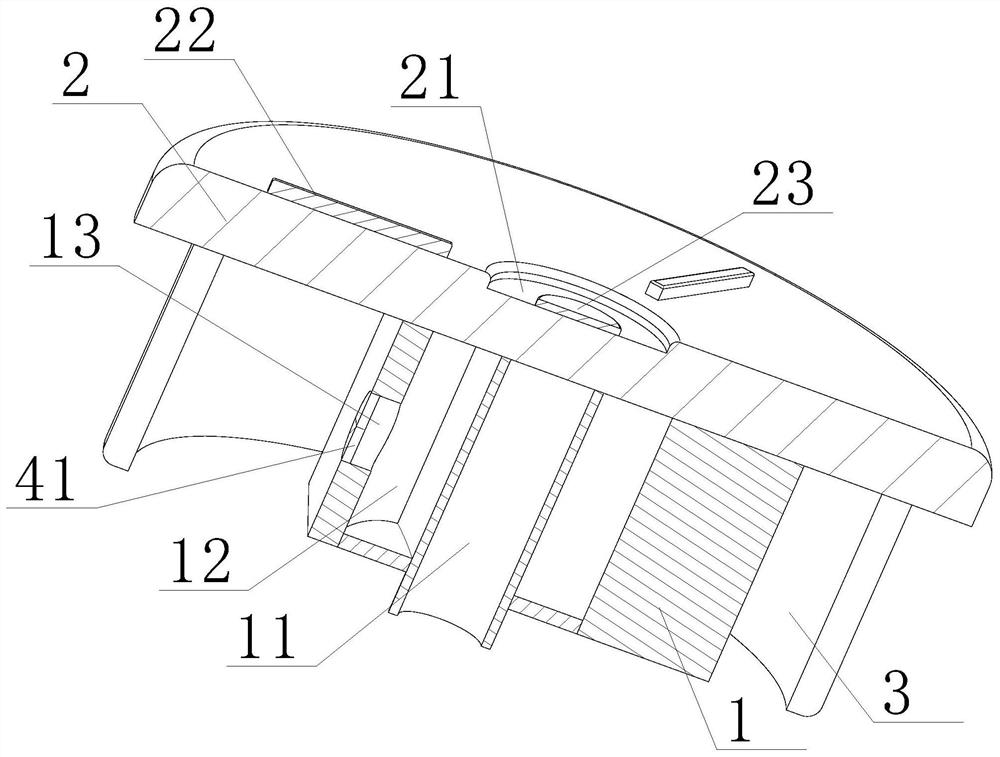

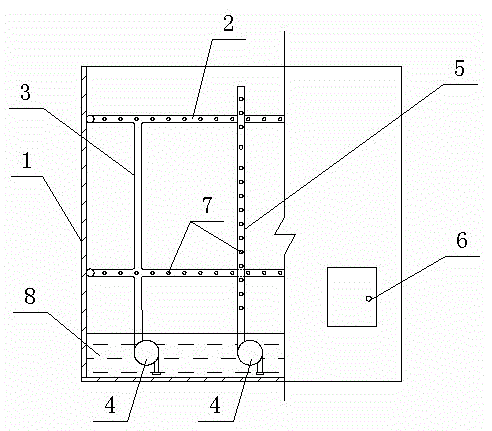

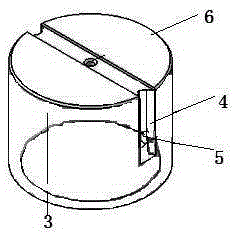

Suspended fish egg incubator

InactiveCN101524055AAvoid pollution effectsSimple structureClimate change adaptationPisciculture and aquariaWater sourceAquatic product

A suspended fish egg incubator is composed of a net incubation bucket and a suspended bracket which is used for hanging the net incubation bucket and suspensible on the water face, and an air cascade head is arranged at the bottom of the net incubation bucket. The invention has the beneficial effects that: the structure is simple and the manufacture cost is low; a micro air pump is used for replacing a water tower to supply water for stirring the fish eggs being incubated, the mounting and using are more convenient and the cost is low, and the water source pollution influence can be avoided; mounting and dismounting and carrying are convenient, and the using is not restrained by places; the invention is applicable to direct fish egg incubation in mountain reservoir, lakes and other natural waters as well as in indoor pools, the water temperature can be adjusted, the incubation period can be shortened, and the incubation rate can be improved; use and management are convenient and the labor intensity is light; the invention provides a simple, convenient, efficient and economic fish egg incubation device for the small-scale proliferation of young fishes and famous-brand high-quality marine young products.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

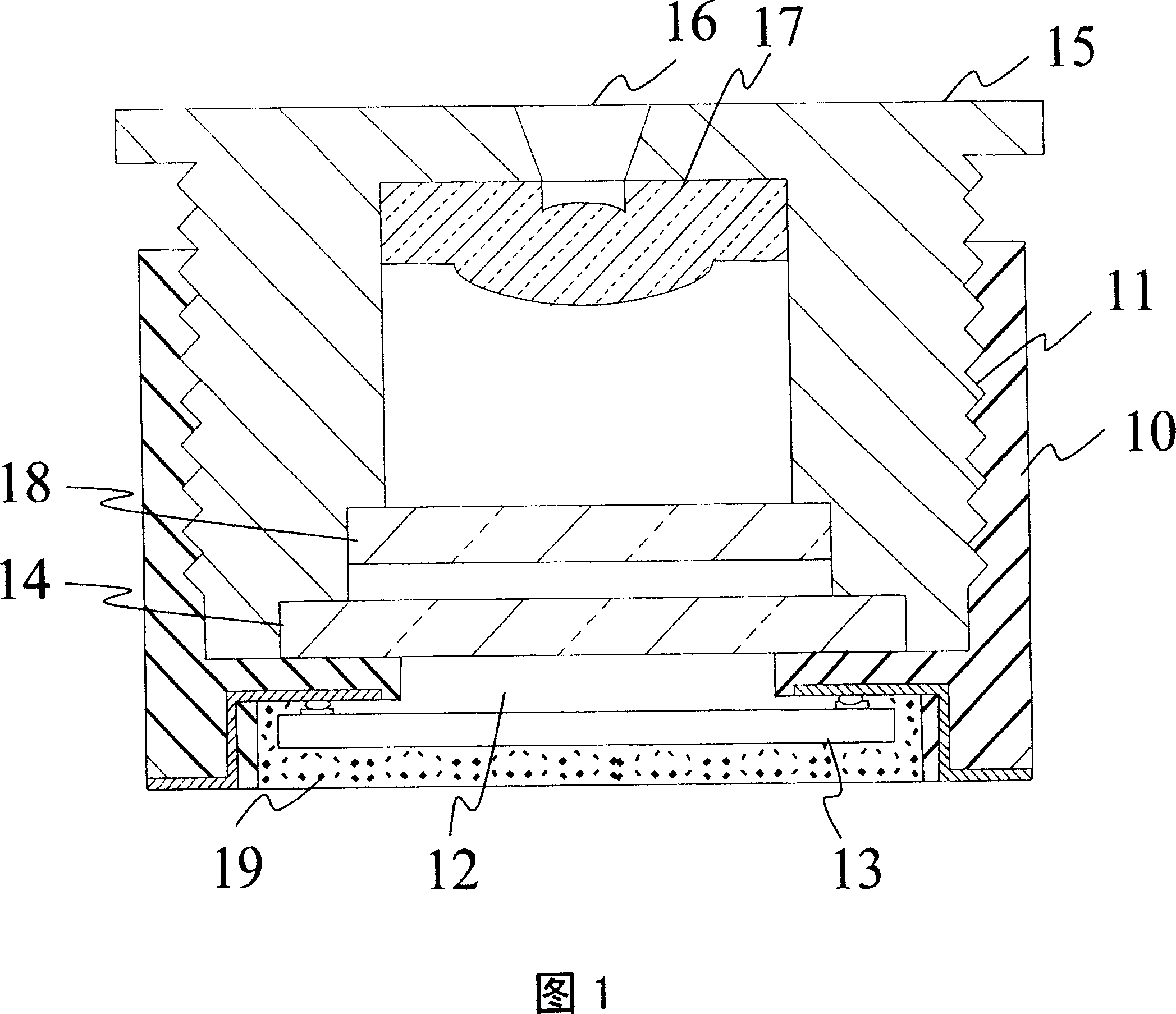

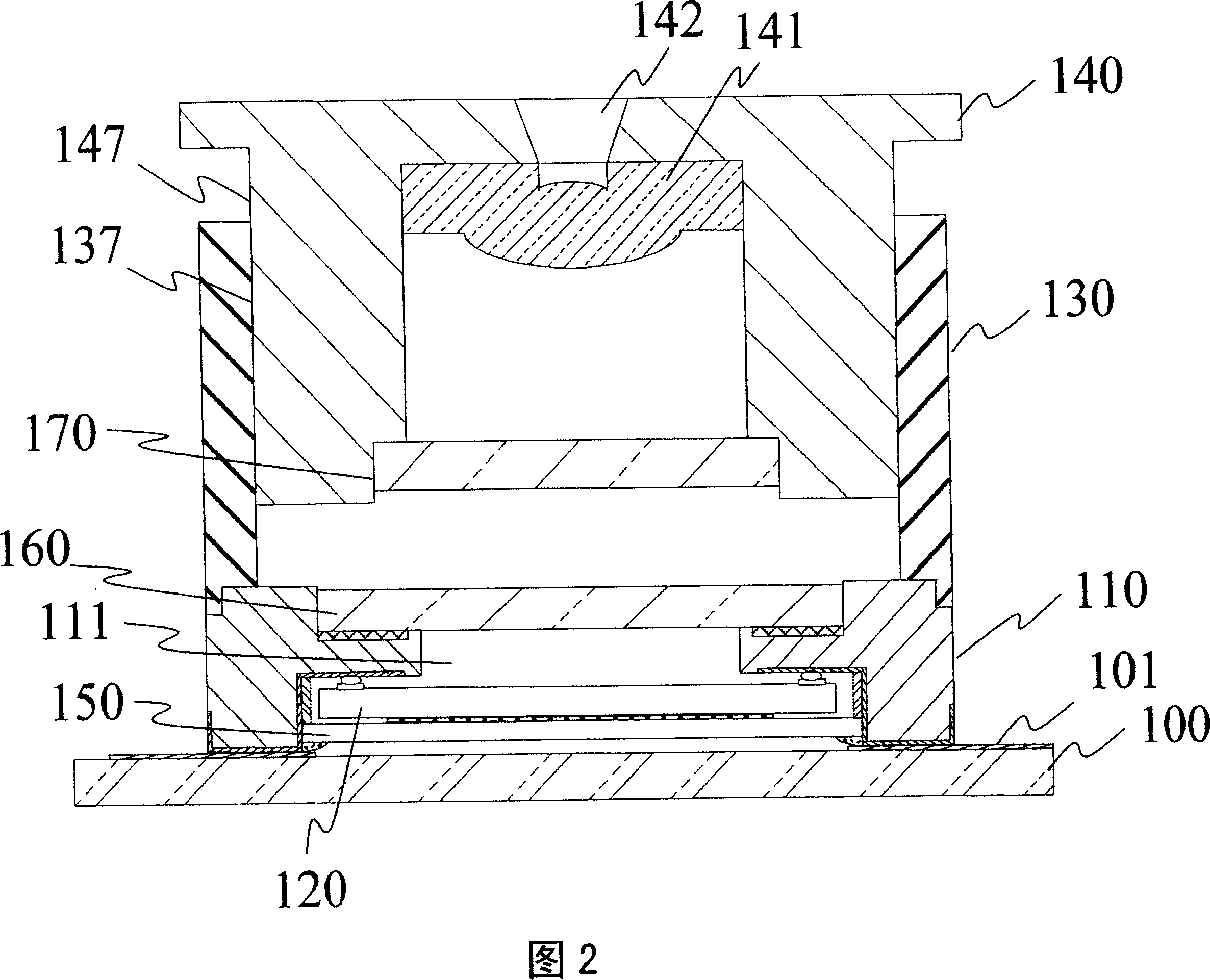

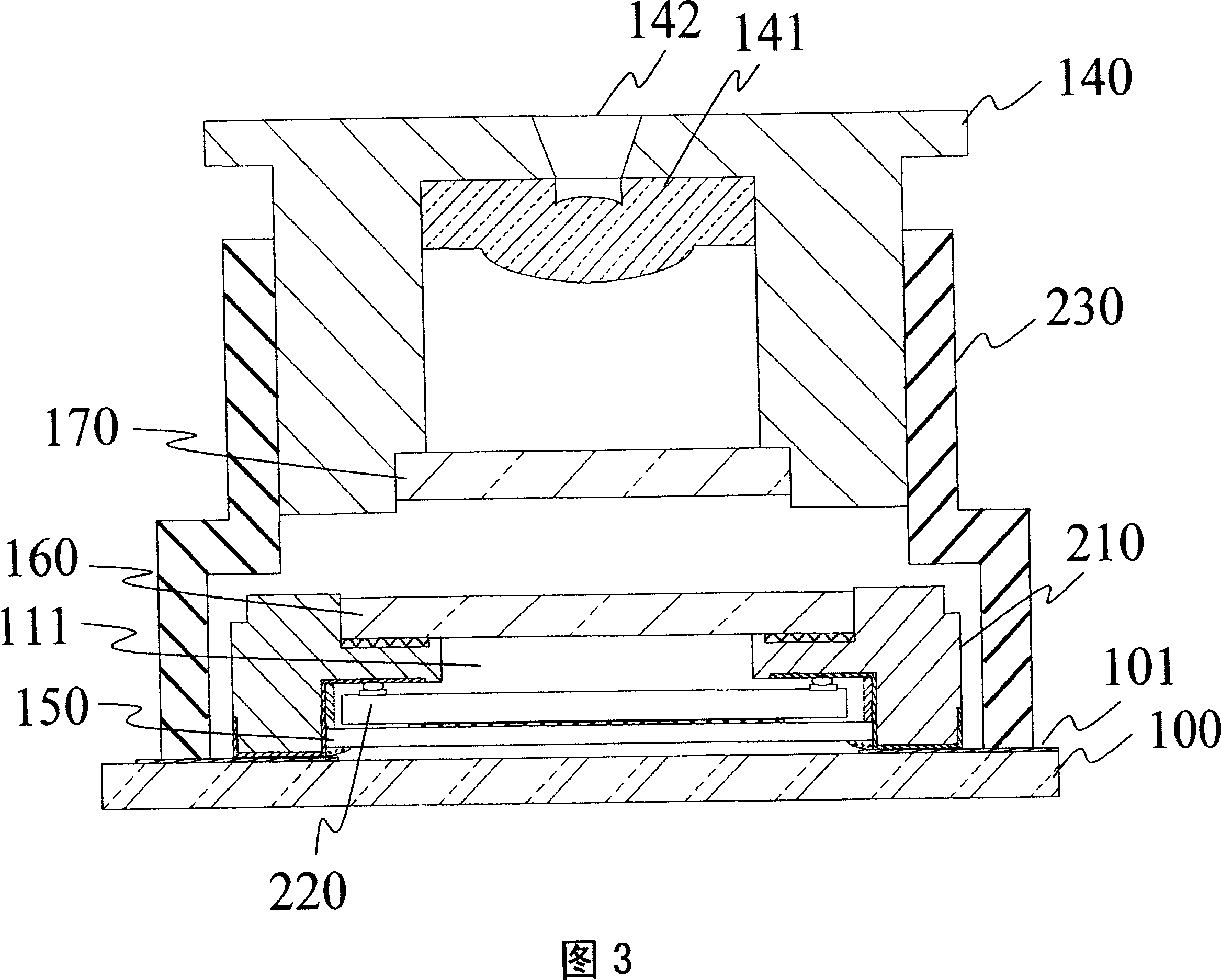

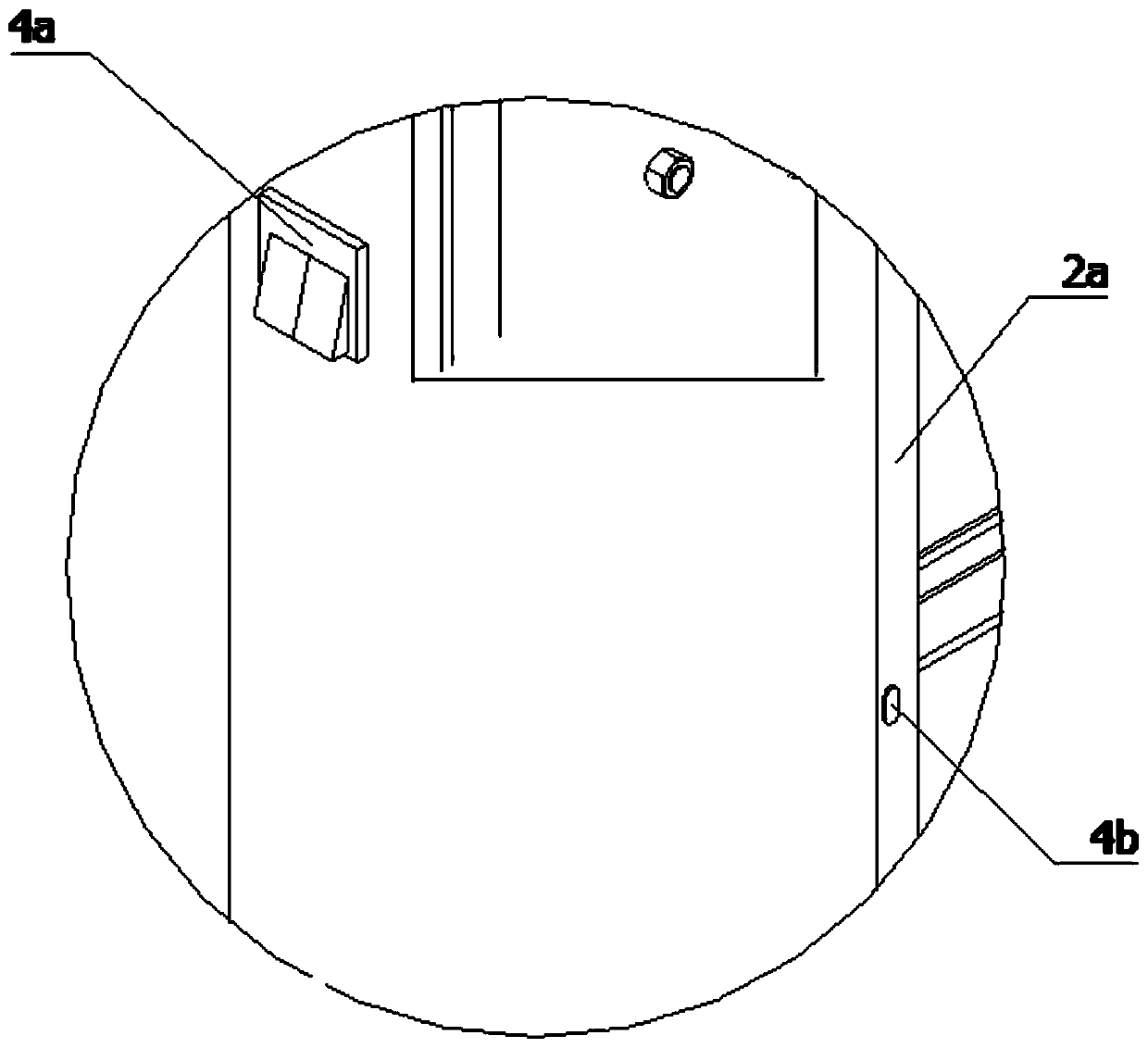

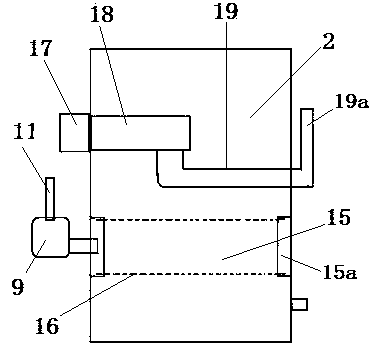

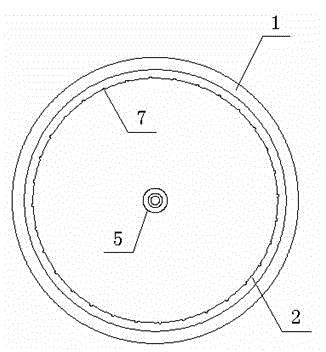

Packaging structure for optical sensing module

InactiveCN1921127AAvoid pollution effectsImprove processing yieldRadiation controlled devicesEngineeringOptical sensing

The invention relates to a package of light-sensitive module, which processes the electric connection of light-sensitive chip and the installment of lens base and cylinder, to avoid the effect of external contaminant; in addition, designs the opposite surface between lens base and cylinder into smooth surface, to avoid accumulating contaminant, improve yield and reduce the cost.

Owner:SIGURD MICROELECTRONICS CORP

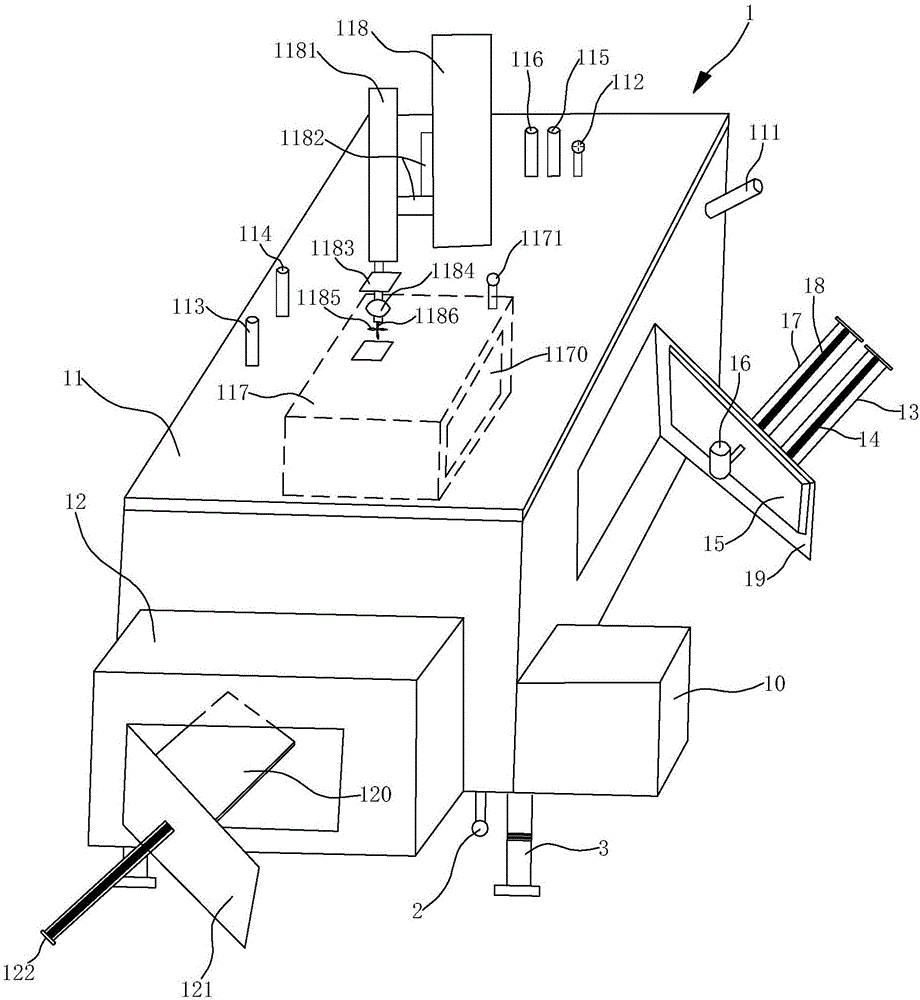

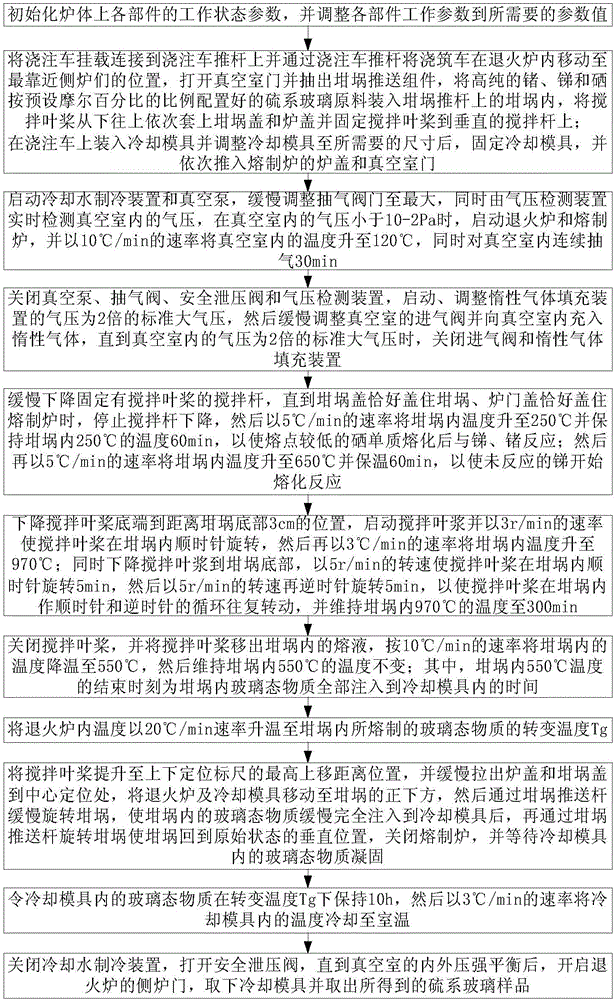

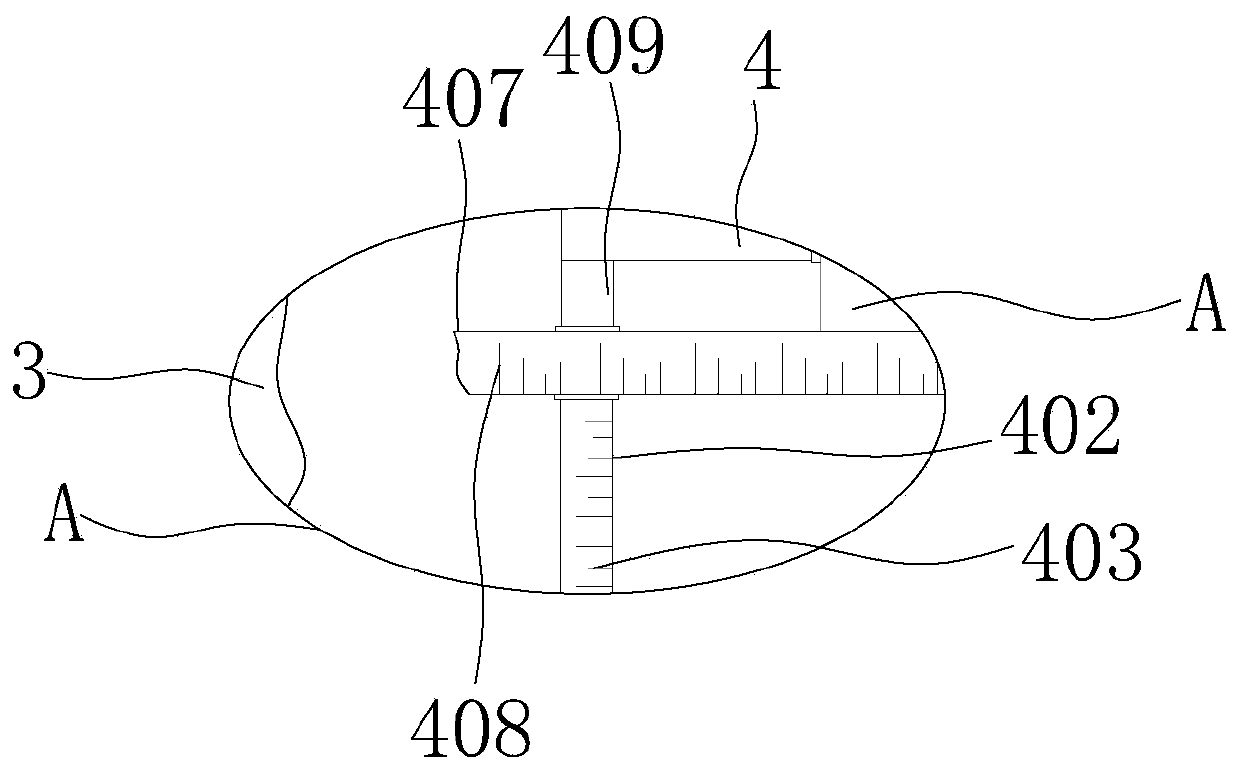

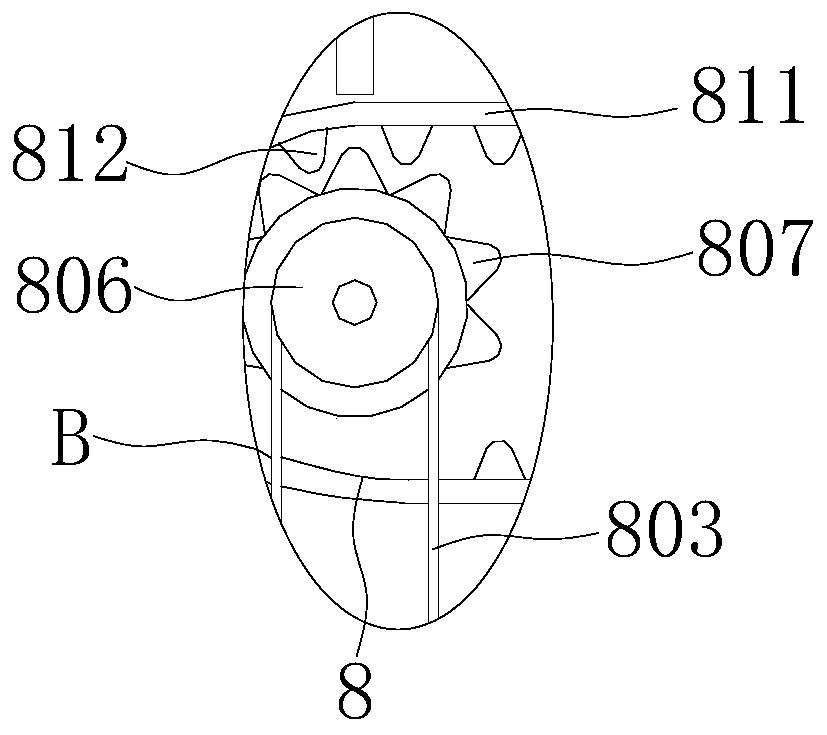

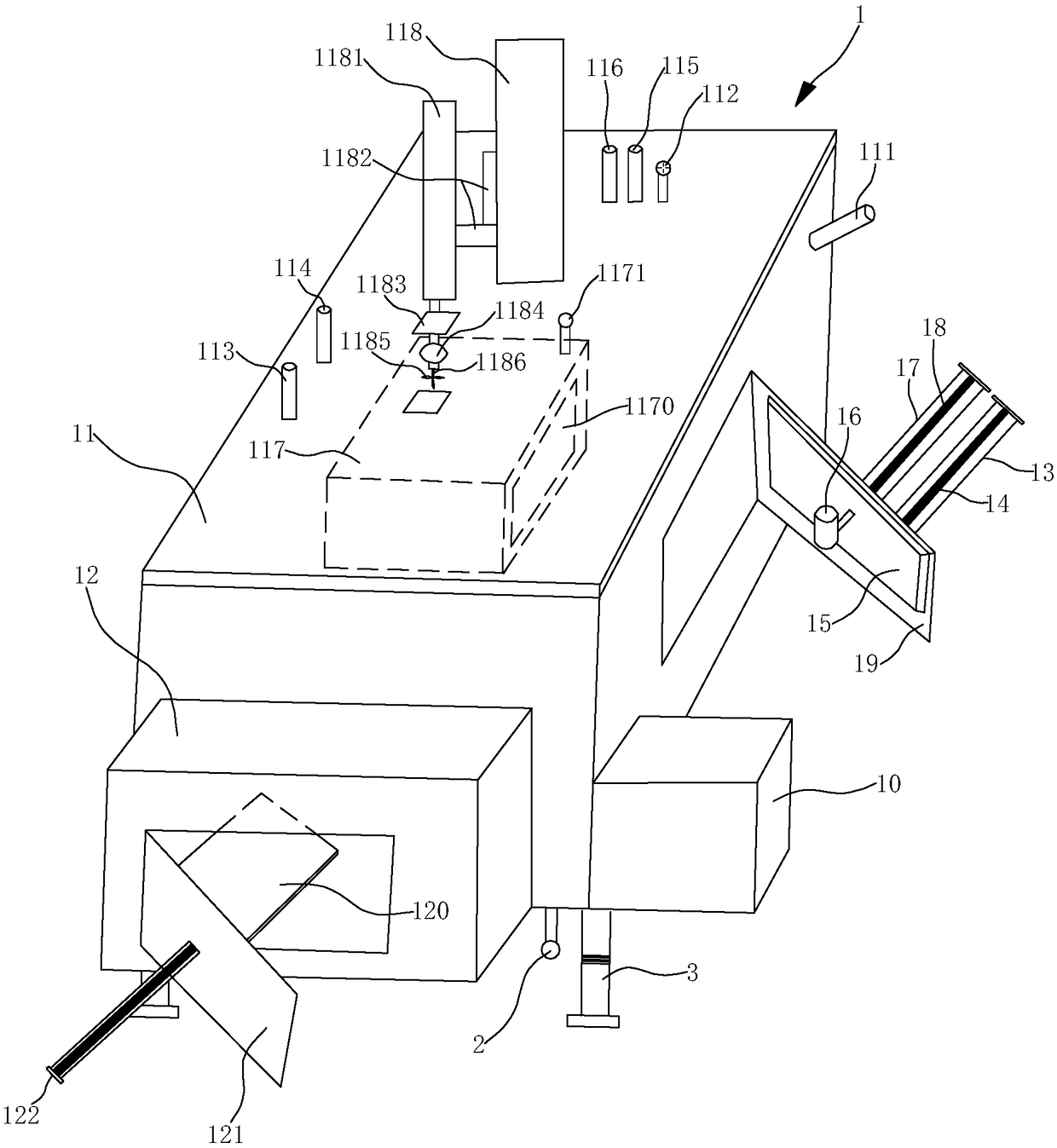

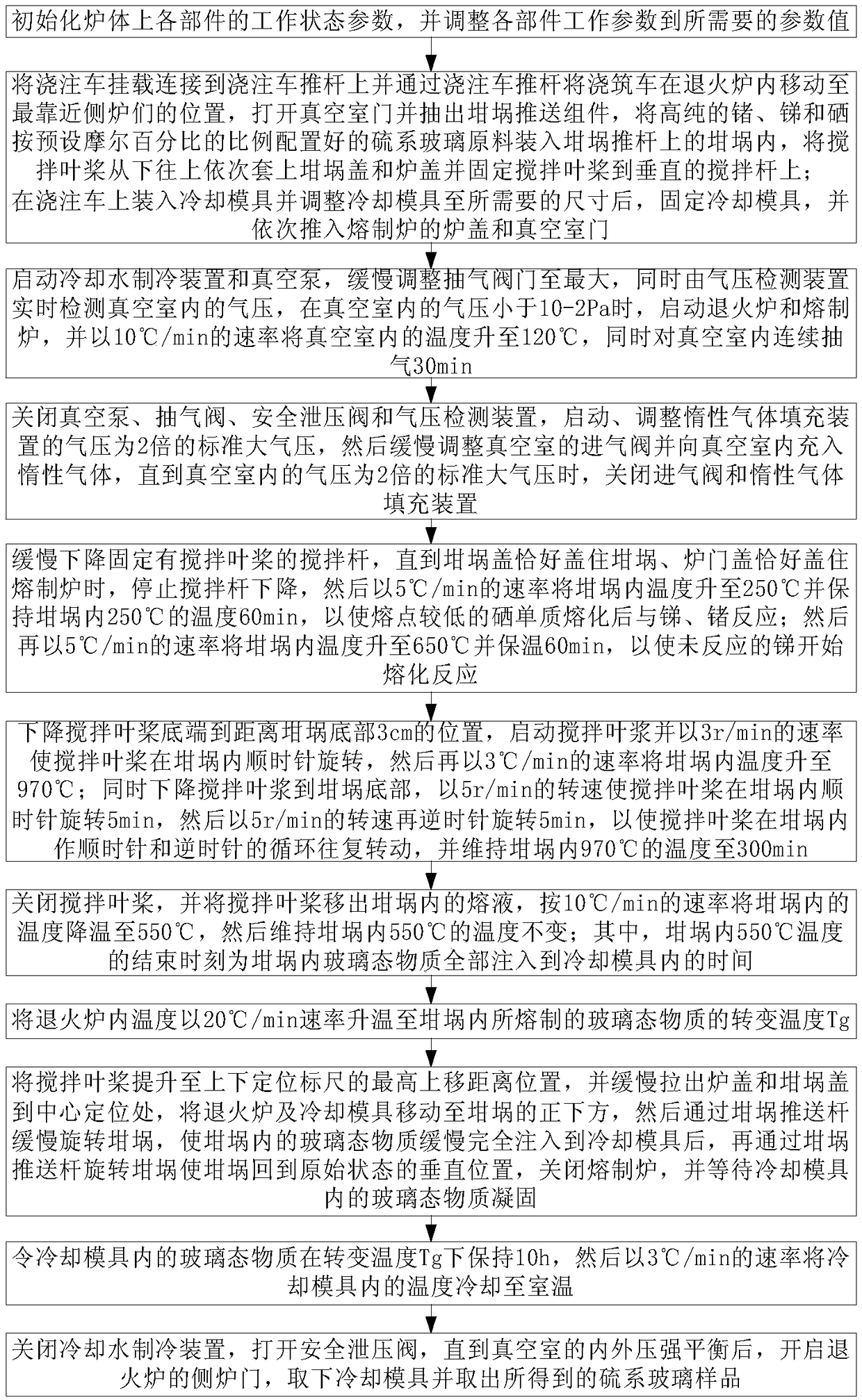

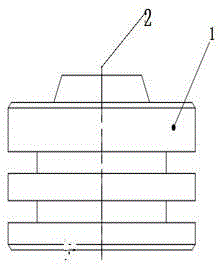

Production method of large-size chalcogenide glass

ActiveCN106517739AAvoid secondary pollutionEasy to operateGlass furnace apparatusGlass shaping apparatusState parameterCrucible

The invention relates to a production method of large-size chalcogenide glass. A chalcogenide glass production device used in the invention comprises a furnace body and a center console positioned outside the furnace body and used for controlling all parts to work, and the furnace body comprises a vacuum chamber and an annealing furnace with a side furnace door. After the working state parameters of all the parts of the chalcogenide glass production device are normal, a crucible on a crucible pushing rod is filled with a chalcogenide glass raw material which is prepared from germanium, antimony and selenium according to a preset molar percentage ratio, the temperature in the vacuum chamber, the temperature in the crucible and the rotating speed are adjusted in vacuum environment to fully and uniformly stir chalcogenide glass in a glassy state, and the size of a cooling die is adjusted to obtain the large-size chalcogenide glass product with high purity.

Owner:NINGBO UNIV

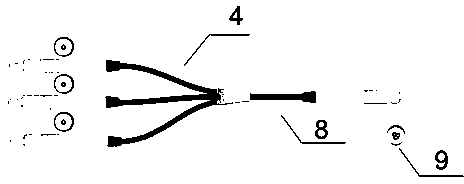

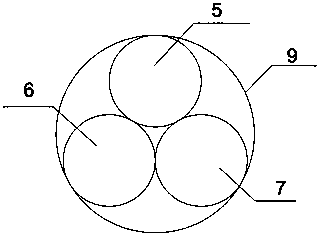

Laser beam light combining and dodging device used for full color laser computer moving head light

InactiveCN103398347AEliminate speckleAvoid pollution effectsMechanical apparatusElectric lightingFiberMicrometer

The invention discloses a laser beam light combining and dodging device used for a full color laser computer moving head light. The laser beam light combining and dodging device comprises a full color laser light source, beam combining optical fibers, a light mixing optical fiber and a dispersion head. The full color laser light source is composed of a plurality of laser devices with different colors, the beam combining optical fibers are composed of a plurality of coupling optical fibers, lasers output by each laser device enter a corresponding coupling optical fiber in a coupling mode, and the other ends of all the coupling fibers are distributed in the space in an evenly arrayed mode and packaged together to be the output end of the beam combining optical fibers. The light mixing optical fiber is a single coupling optical fiber, the excircle of a fiber core of the light mixing optical fiber is equivalent to the excircle of a fiber core of the beam combining optical fibers in size, and moreover the light mixing optical fiber and the output end of the beam combining optical fibers are connected and packaged together. The dispersion head is a dense combination of short optical fibers with fiber cores of 10-100 micrometers. The laser beam light combining and dodging device has the advantages that a plurality of small-power laser modules can be used for light combining and dodging through optical fiber coupling, and the requirements of the computer moving head light for laser total power are met.

Owner:SHANGHAI INST OF LASER TECH

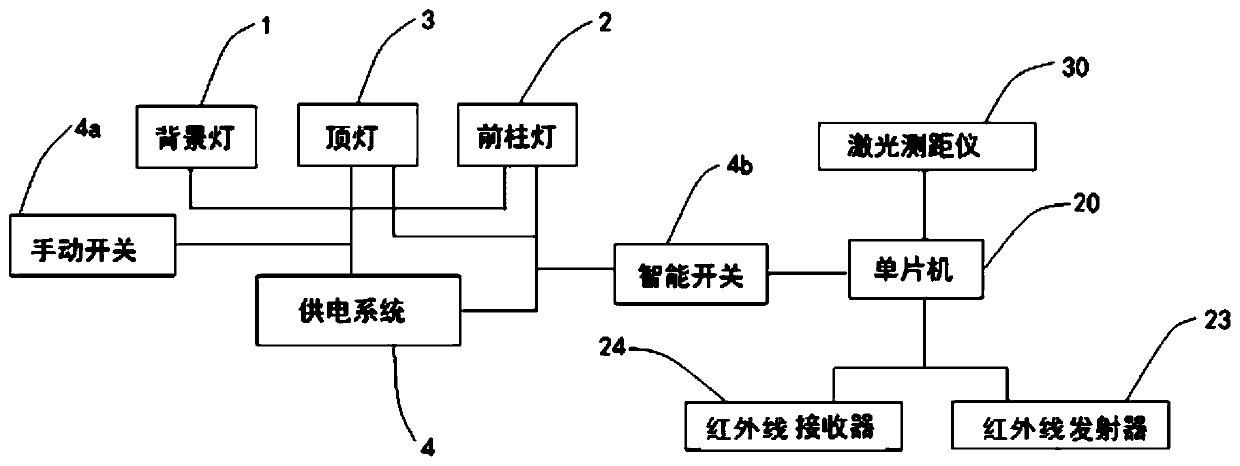

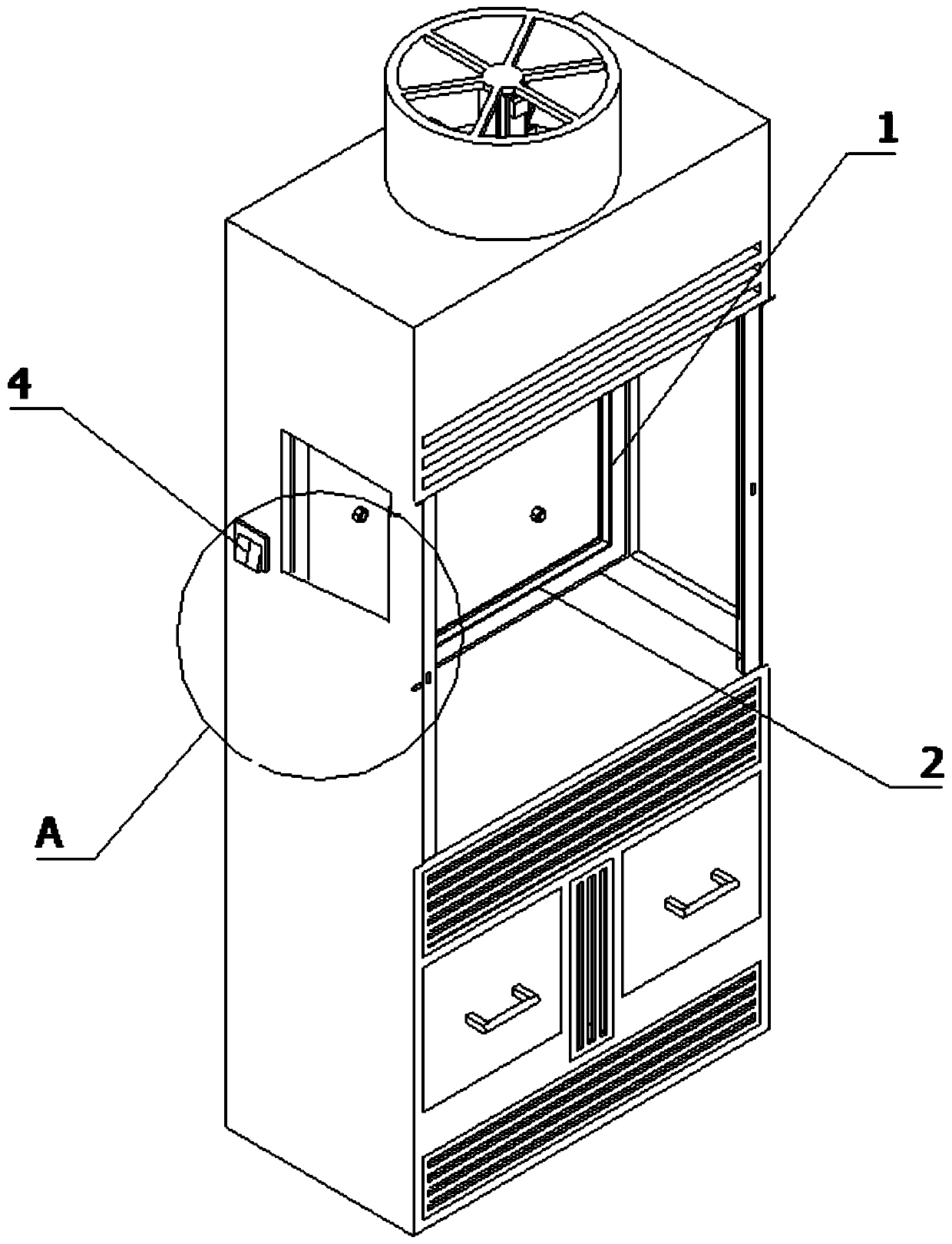

Laboratory ventilation cabinet LED illumination lamp set

ActiveCN110542034ASave powerEnergy savingNon-electric lightingElectrical apparatusInfrared emitterLight pollution

The invention relates to the technical field of ventilation cabinet illumination lamps, in particular to a laboratory ventilation cabinet LED illumination lamp set. The illumination lamp set comprisesa background lamp, a front pillar lamp, a top lamp and a power supply system, wherein an intelligent switch is arranged between the front pillar lamp and the power supply system, an intelligent switch is arranged between the top lamp and the power supply system, infrared transmitters are arranged at two sides of the lower end of a ventilation cabinet body, infrared receivers are arranged at two sides of the lower end of a sliding door, and the intelligent switches, the infrared transmitters and the infrared receivers are electrically connected with a single-chip microcomputer respectively. According to the illumination lamp set, when the infrared receivers receive signals sent by the infrared transmitters, the single-chip microcomputer receives the signals sent by the infrared receivers and controls the corresponding induction switches to turn off the front pillar lamp and the top lamp; in an experiment state, the illumination lamp set cannot perform perpendicular incidence towards the outer side of the cabinet body, so that both eyes of an experimenter are effectively protected, and the situation that light pollution influences observation of an experiment process by the experimenter is avoided; and in a non-experimenter state, only the background lamp in the illumination lamp set works, so that energy is saved.

Owner:北京戴纳实验科技有限公司

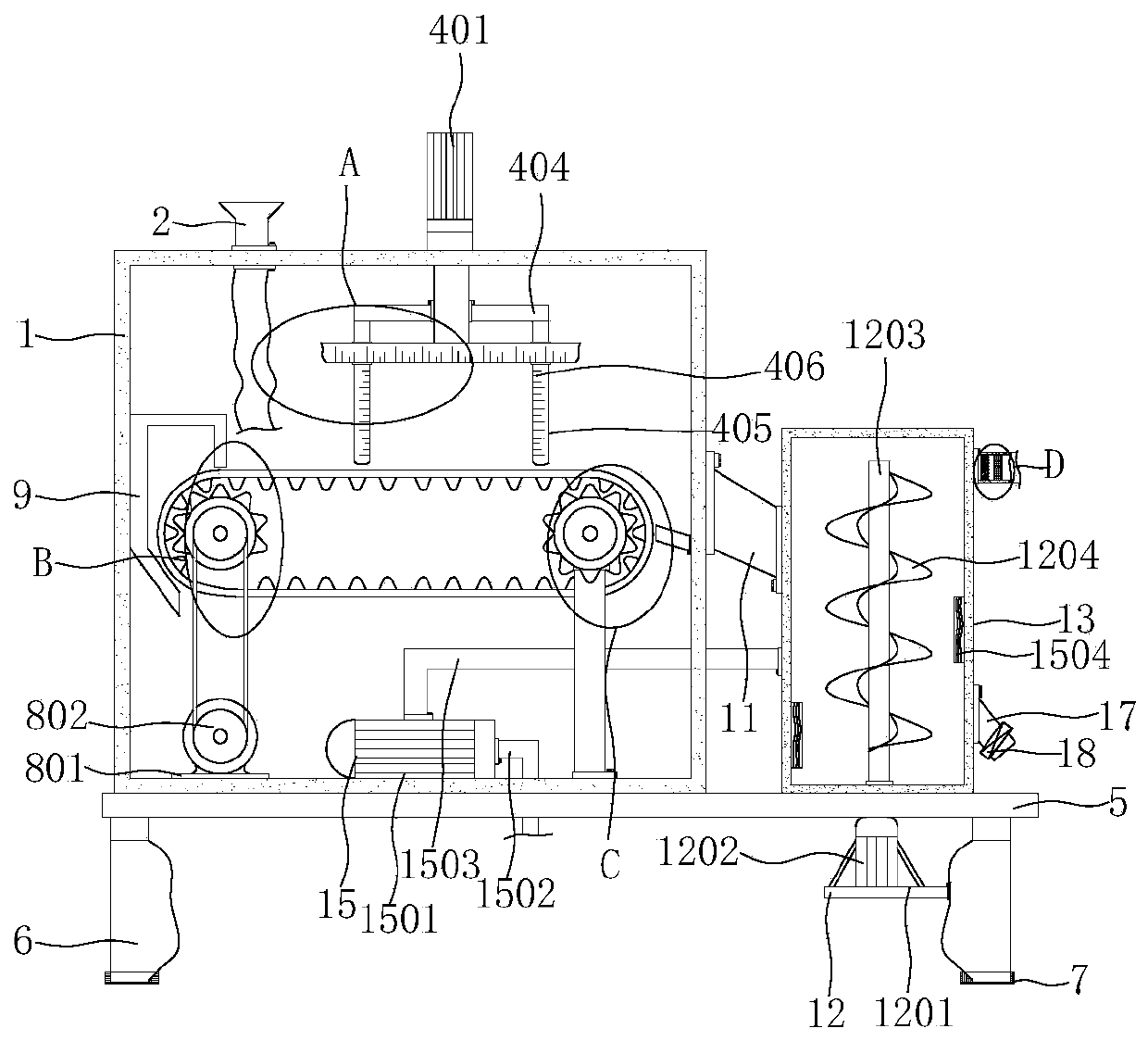

Silk floss processing line equipment

InactiveCN105648541AEasy to processAvoid pollution effectsSilk reelingWater storageCombustion chamber

The invention discloses silk floss processing line equipment. The equipment comprises a silk floss machine, a degumming device and a drying device, a heating component in a water storage bin of the silk floss machine is an oil burner, a combustion chamber of the oil burner is formed in the water storage bin, a filter box is manufactured in the water storage bin, and a water outlet of the filter box is connected with a hot water circulating pump; an outlet of the hot water circulating pump is connected with two pipes, the first branch pipe is communicated to a spray pipe located above a silkworm cocoon squeezing roll barrel of the silk floss machine, and the second branch pipe is communicated to a water inlet of the drying device; the drying device is constituted by a drying chamber located on the lower portion of the drying device, a draught fan chamber located on the upper portion of the drying device and a hot water circulation drying pipe located in the drying chamber; the degumming device comprises an air pressure pot and a support of the air pressure pot, a pot bottom mesh partition plate is installed at the bottom of an inner chamber of the air pressure pot, and a cover top mesh partition plate is installed at the top in an air pressure cover of the air pressure pot. By means of the silk floss processing line equipment, it is helpful for silkworm raisers of a silkworm breeding and mulberry growing base to meet the requirement of conducting on-site processing on cocoon shells, the situations that the cocoon shells go bad due to centralized processing and accumulation of the cocoon shells and good products cannot be obtained from good raw materials are avoided, and the influence of environmental pollution caused by centralized processing is also avoided.

Owner:党金峰

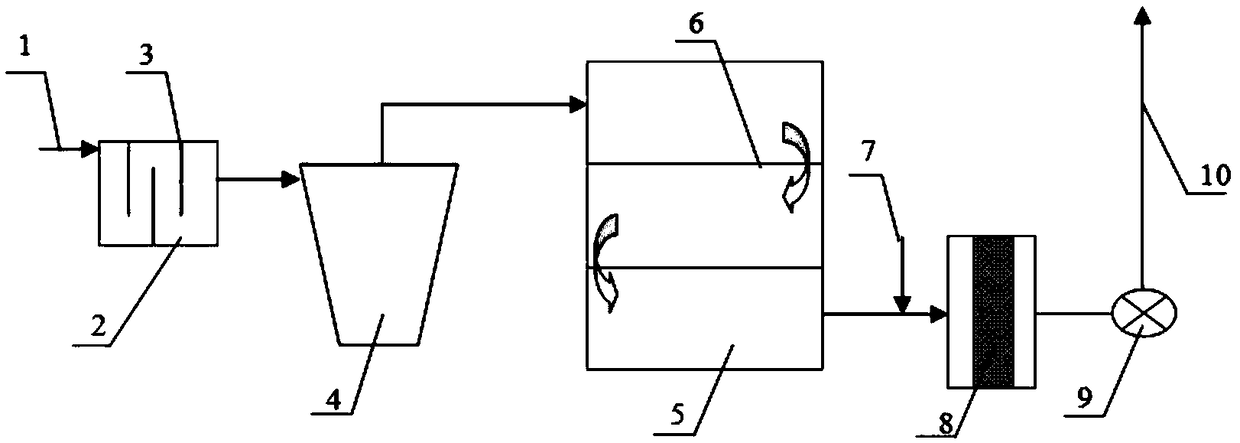

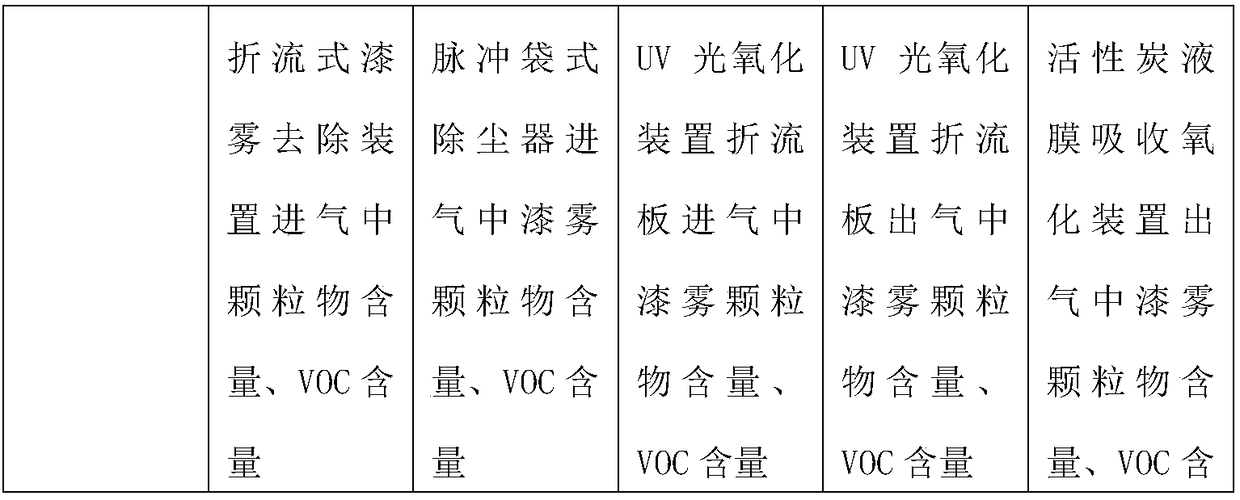

Paint spraying waste gas treatment device

PendingCN109200728AImprove removal efficiencyReduce loadCombination devicesGas treatmentWaste managementActive carbon

The invention discloses a paint spraying waste gas treatment device, which comprises a baffling paint mist removal device, a paint mist removal device baffling plate, a pulse bag type dust remover, aUV light oxidization device, a UV light oxidization device baffling plate, a spraying humidification pipe, an active carbon liquid film absorption oxidization device, a draft fan and an exhaust tube in sequential connection, wherein the active carbon is filled in a sealing cavity to form the active carbon liquid film absorption oxidization device. The paint spraying waste gas treatment device hasthe advantages that the structure is simple; the design and the idea are ingenious; the use is safe and convenient; the application environment is friendly; the paint spraying waste gas purification can be efficiently realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

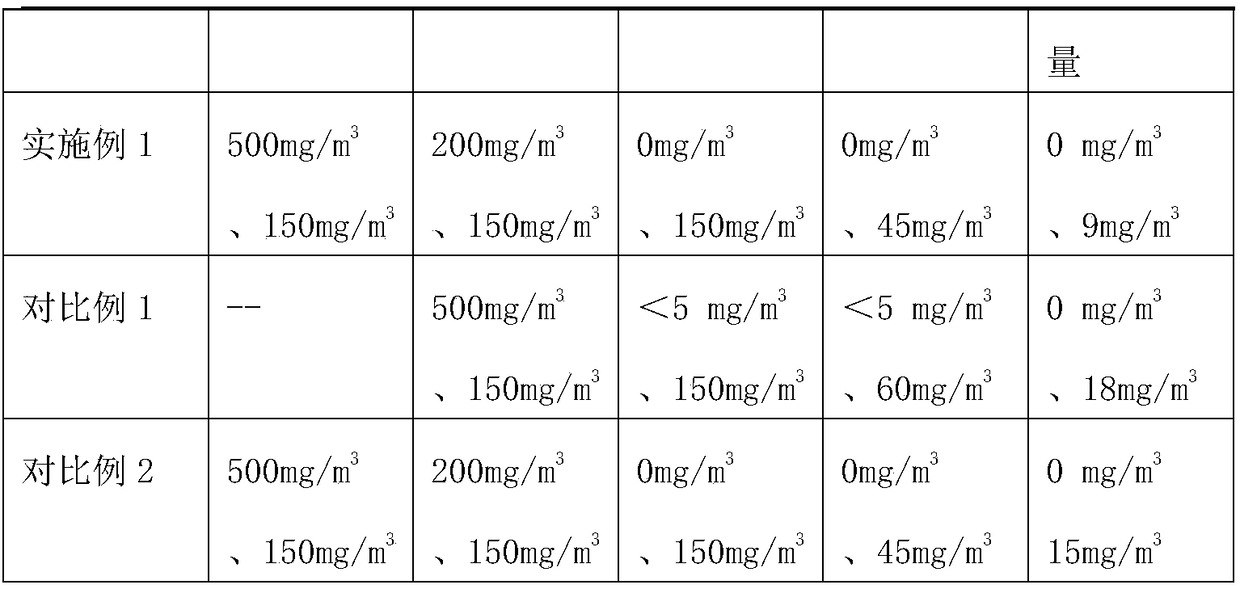

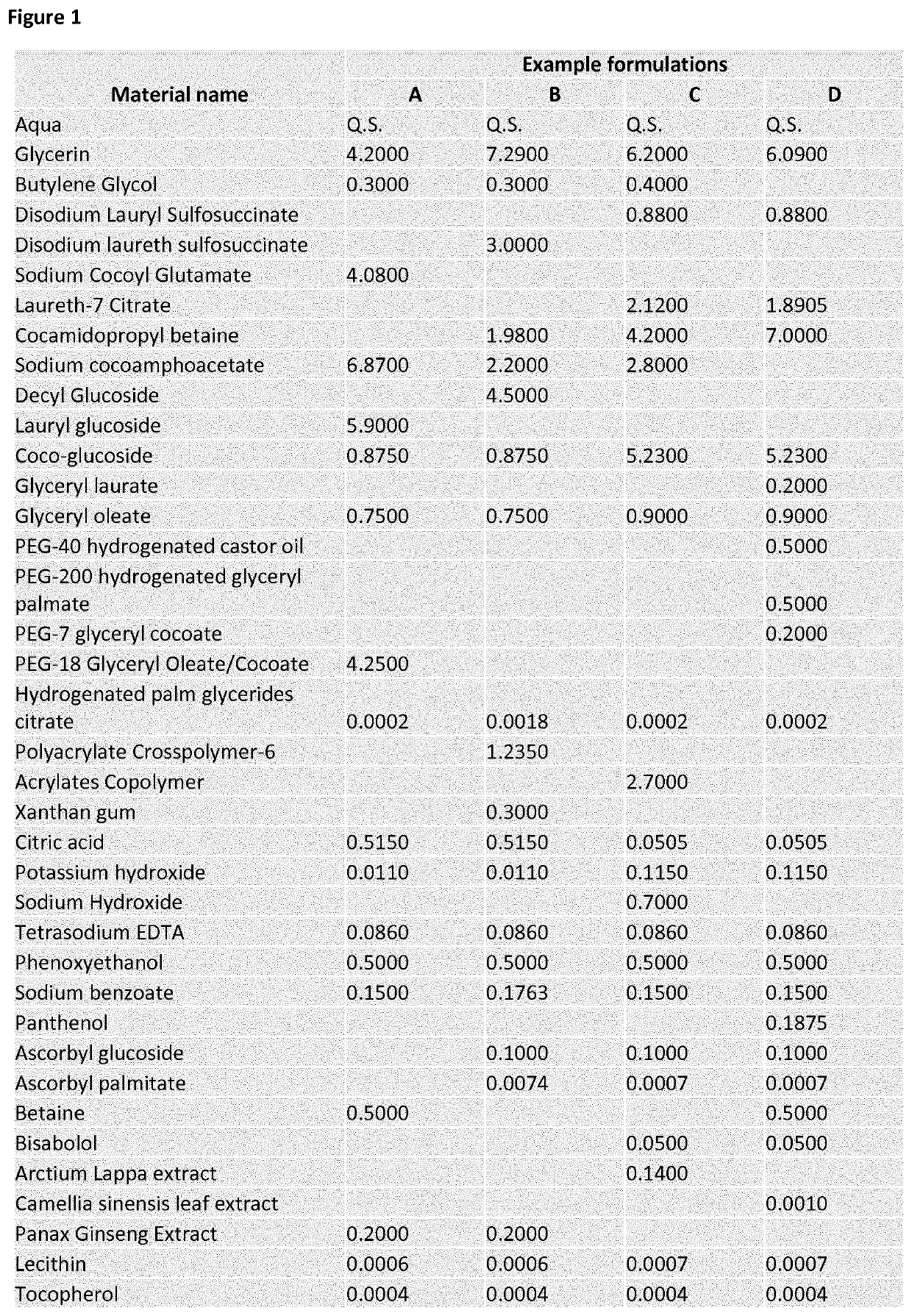

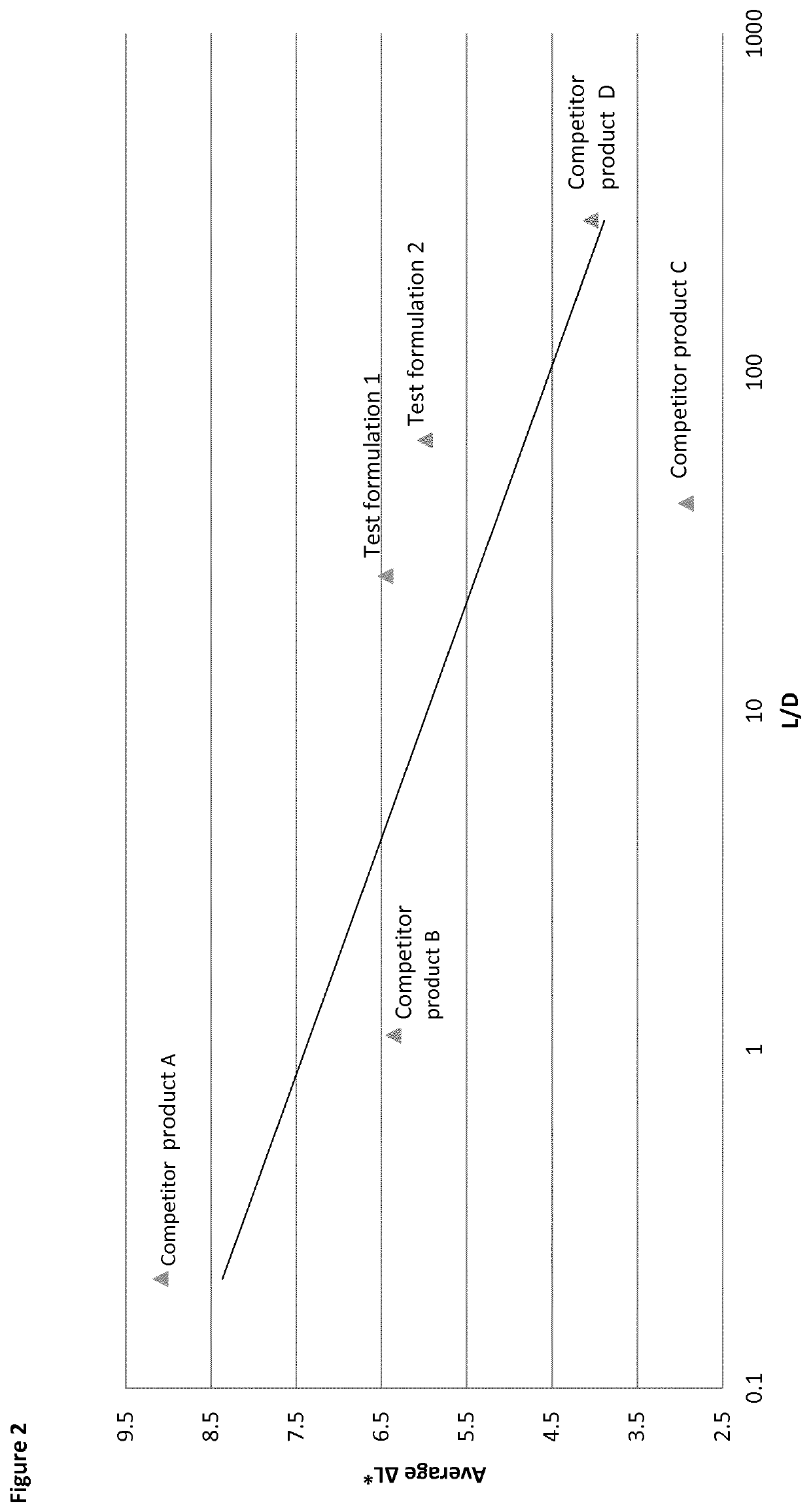

Cosmetic cleansing compositions

ActiveUS20210196604A1Strong washing powerImprove toleranceCosmetic preparationsHair cosmeticsActive agentSurface-active agents

According to the present invention there is provided a cosmetic composition comprising a cosmetically acceptable carrier and a surfactant system consisting of: (i) an anionic surfactant; (ii) an amphoteric surfactant; and (iii) a non-ionic surfactant, wherein the anionic surfactant is present in an amount of from about 0.5% to about 25% by weight of the surfactant system, wherein the amphoteric surfactant is present in an amount of from about 0.5% to about 50% by weight of the surfactant system, wherein the non-ionic surfactant is present in an amount of from about 0.5% to about 45% (e.g. 43%) by weight of the surfactant system, and wherein the total amount of the surfactant system present in the cosmetic composition is from about 1.5% to about 25% by weight of the composition.

Owner:THE BOOTS CO PLC

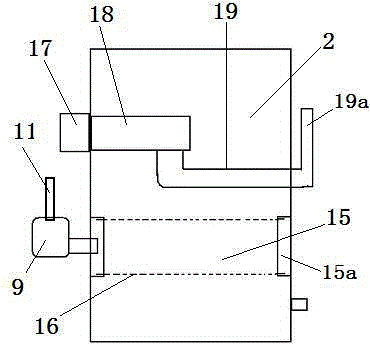

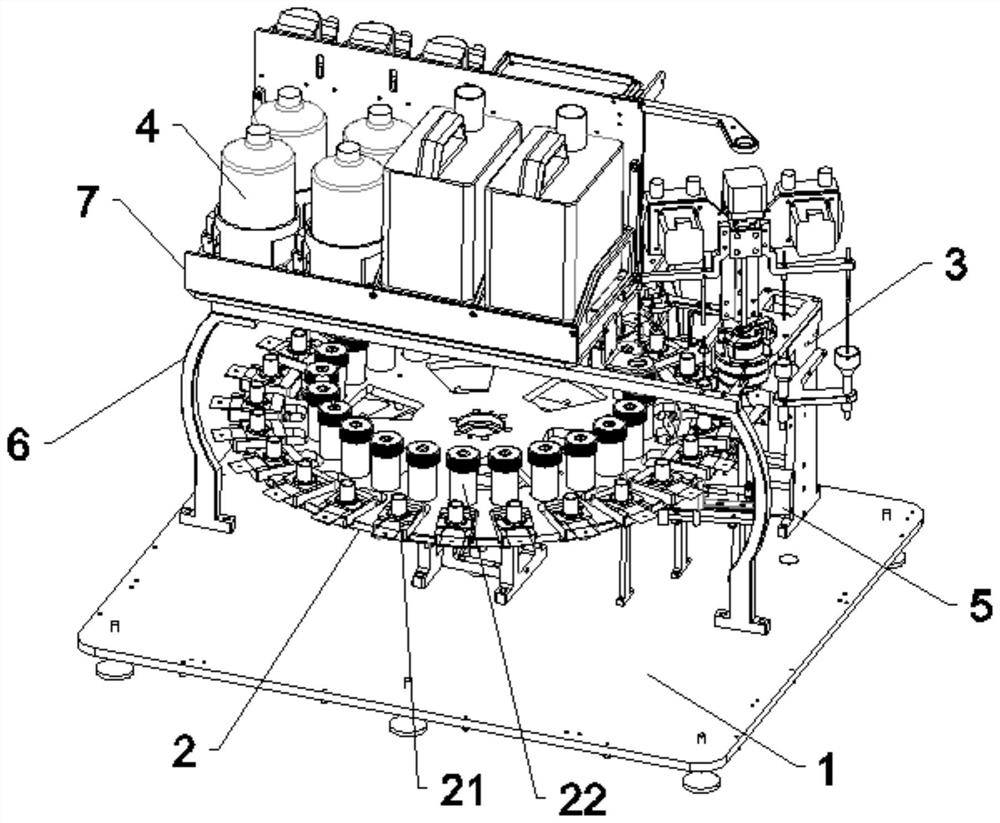

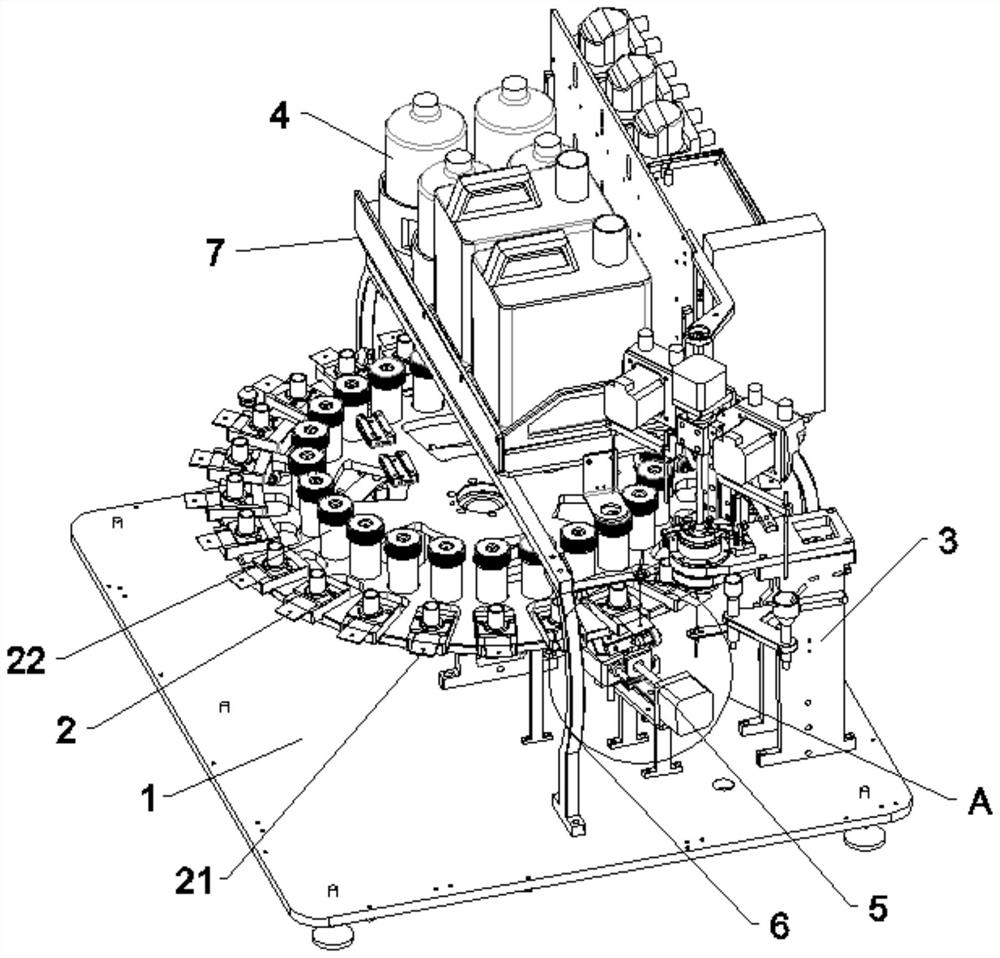

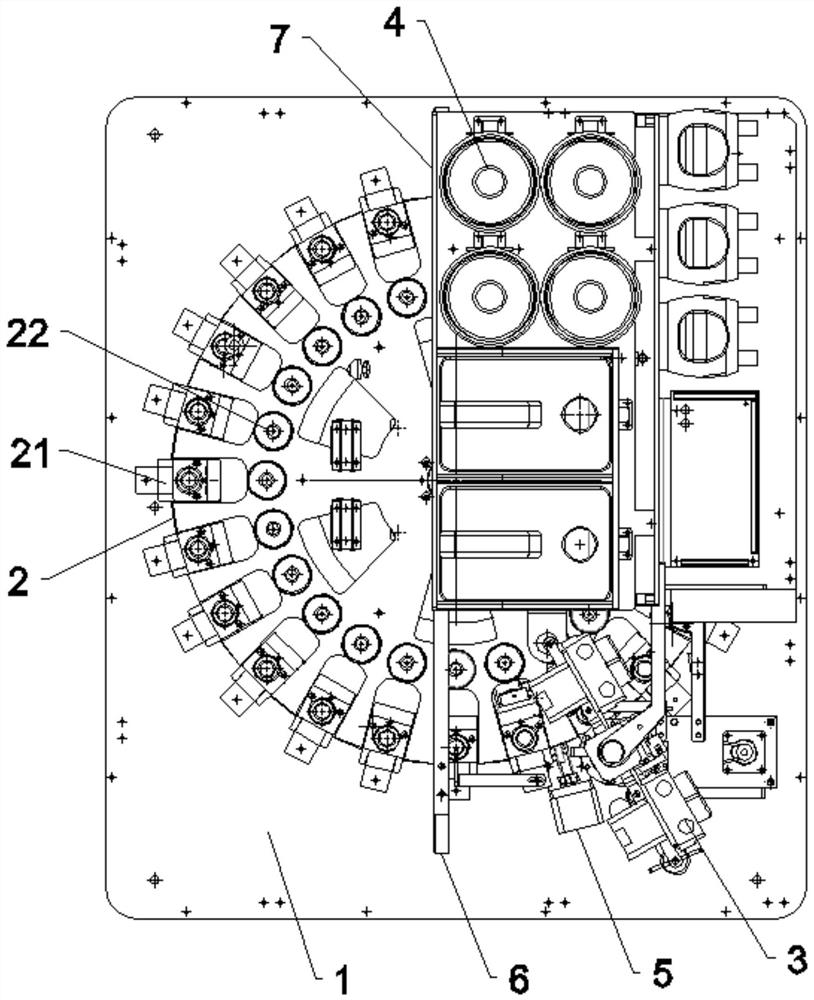

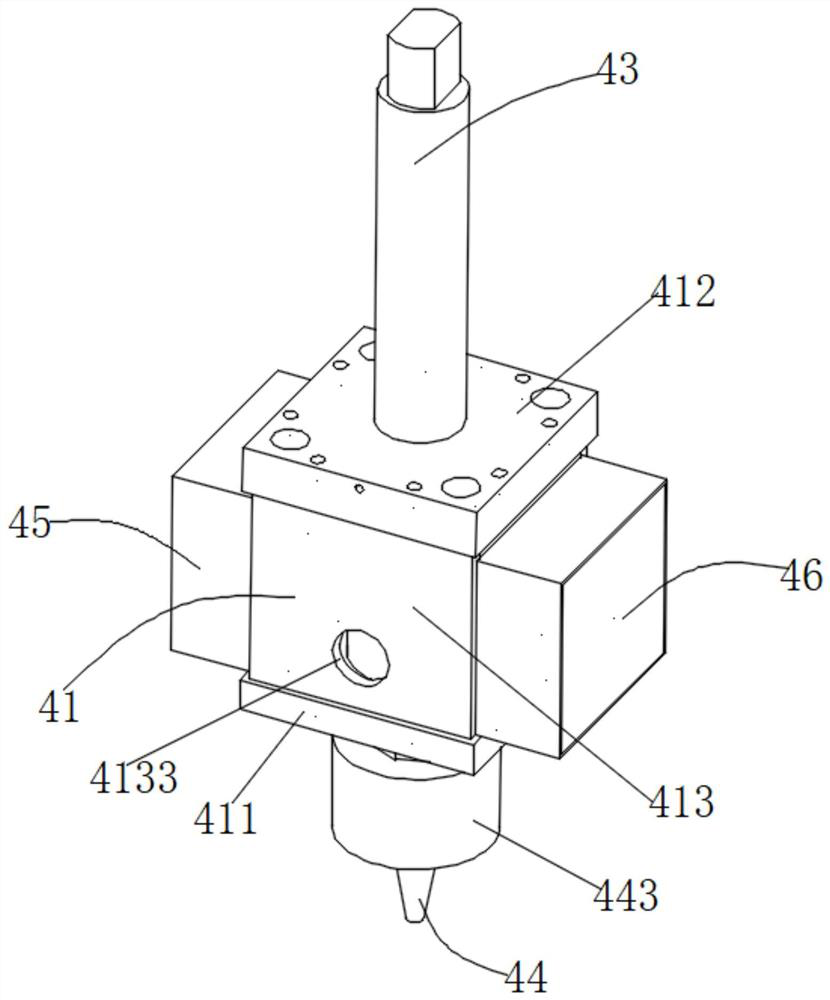

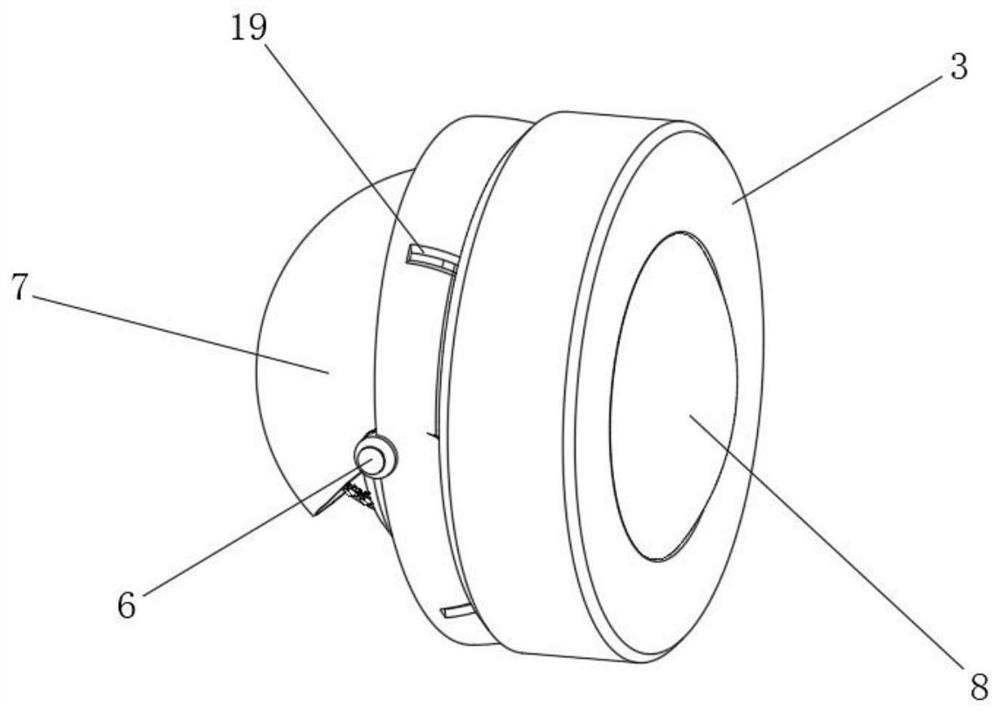

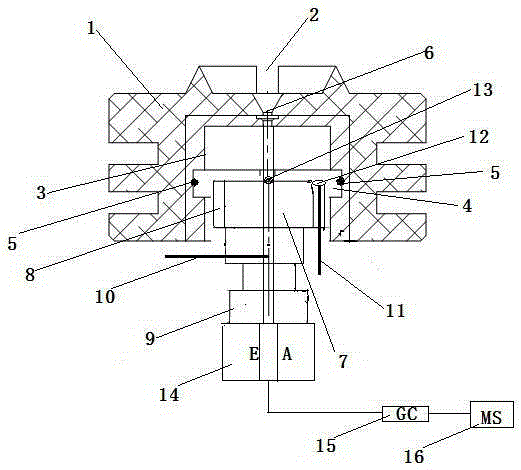

Semi-automatic liquid-based cell slide processor

PendingCN113624576AAvoid pollution effectsImprove production efficiencyPreparing sample for investigationTest tubeEngineering

The invention relates to a semi-automatic liquid-based cell slide processor which comprises a rotating mechanism and a slide making and dyeing mechanism, the slide making and dyeing mechanism is located on the outer side of the rotating mechanism, the slide making and dyeing mechanism comprises a sample transfer module and a dyeing module, the sample transfer module comprises a rotating unit and a lifting unit, and the lifting unit is installed on the rotating unit. A plurality of groups of slide making units are arranged on the upper side of the rotating mechanism, each slide making unit comprises a sample test tube and a cell sedimentation assembly, the sample transfer module is suitable for transferring liquid-based cells in the sample test tube into the cell sedimentation assembly, and the staining module is suitable for adding a liquid-based cell staining agent into the cell sedimentation assembly. According to the liquid-based cell slide processor, after the sample test tube, the sedimentation bin and the slide are manually placed, automatic staining and slide making can be achieved, manual guarding is not needed in the whole process, subjectivity of manual sampling and sample adding can be avoided, the high efficiency and accuracy of slide making can be improved, and large-scale high-efficiency staining and slide making are facilitated.

Owner:深路医学科技(武汉)有限公司

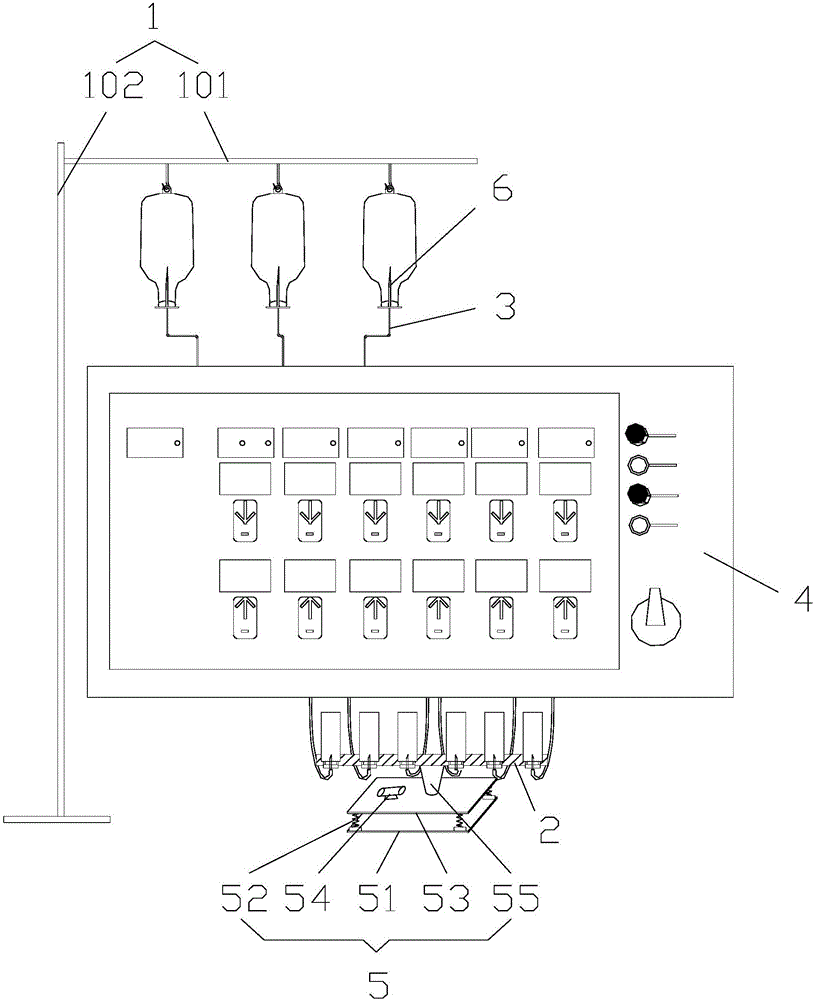

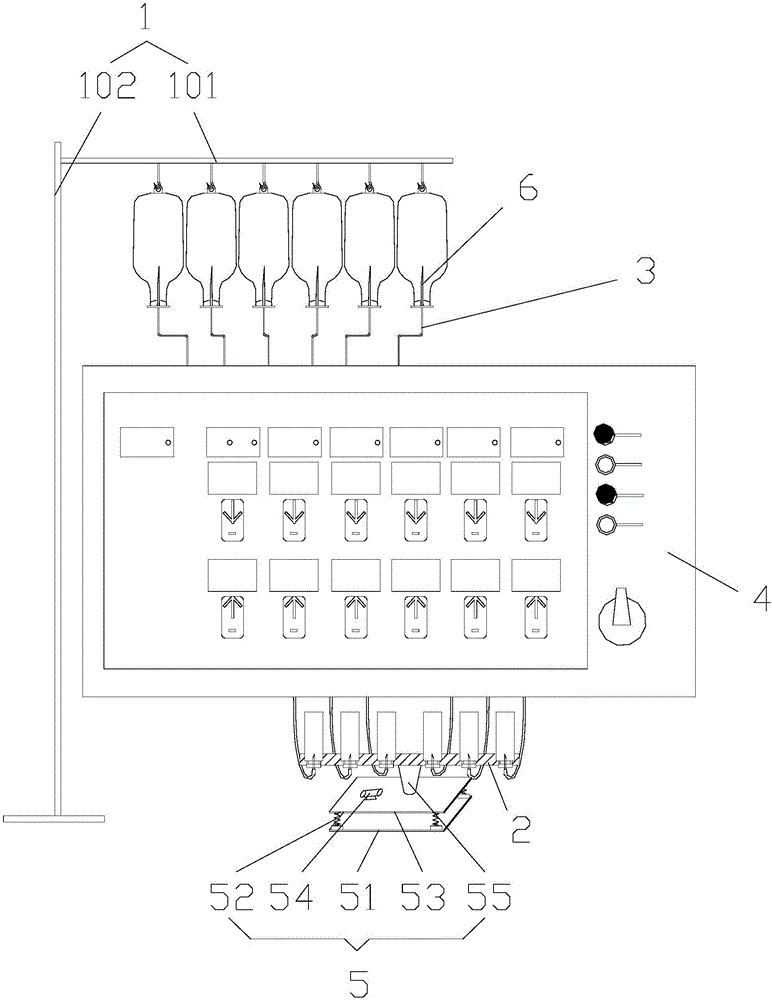

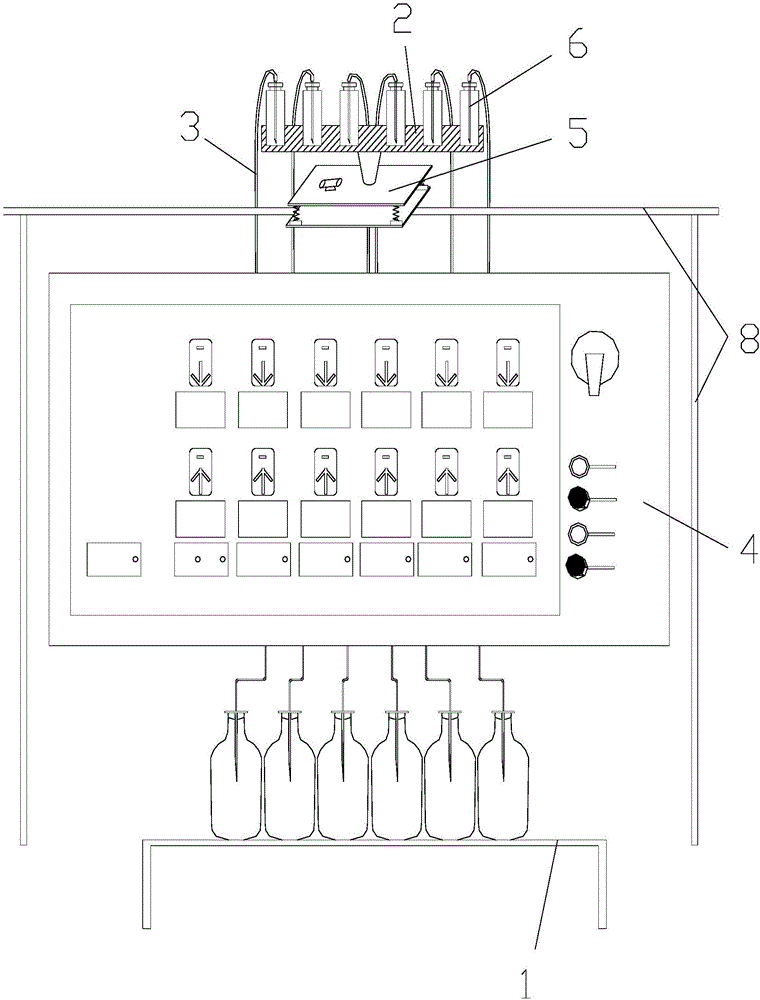

Full-automatic drug mixing machine

InactiveCN106667770AAvoid wastingWell mixedPharmaceutical containersMedical packagingPeristaltic pumpMedicine

The invention discloses a full-automatic drug mixing machine. The full-automatic drug mixing machine comprises a transfusion bag fixed support, a layer board for placing penicillin bottles, several delivery conduits which are used for connecting transfusion bags and the penicillin bottles, a peristaltic pump connected with the delivery conduits, and a vibrator which vibrates the layer board, wherein the two ends of each of the delivery conduits are provided with puncture needles. According to the full-automatic drug mixing machine, automatic drug mixing is achieved, the drug mixing efficiency is high, a large amount of labor and time is saved, and the waste of consumable items like injectors is avoided; meanwhile, in the drug mixing process, the puncture needles do not need to be repeatedly inserted and pulled out, thus the contamination influence of particles, microorganisms and the like in air on drug liquid can be effectively avoided, and the problem of secondary contamination of drugs is solved.

Owner:北京圣鸿医疗科技有限公司

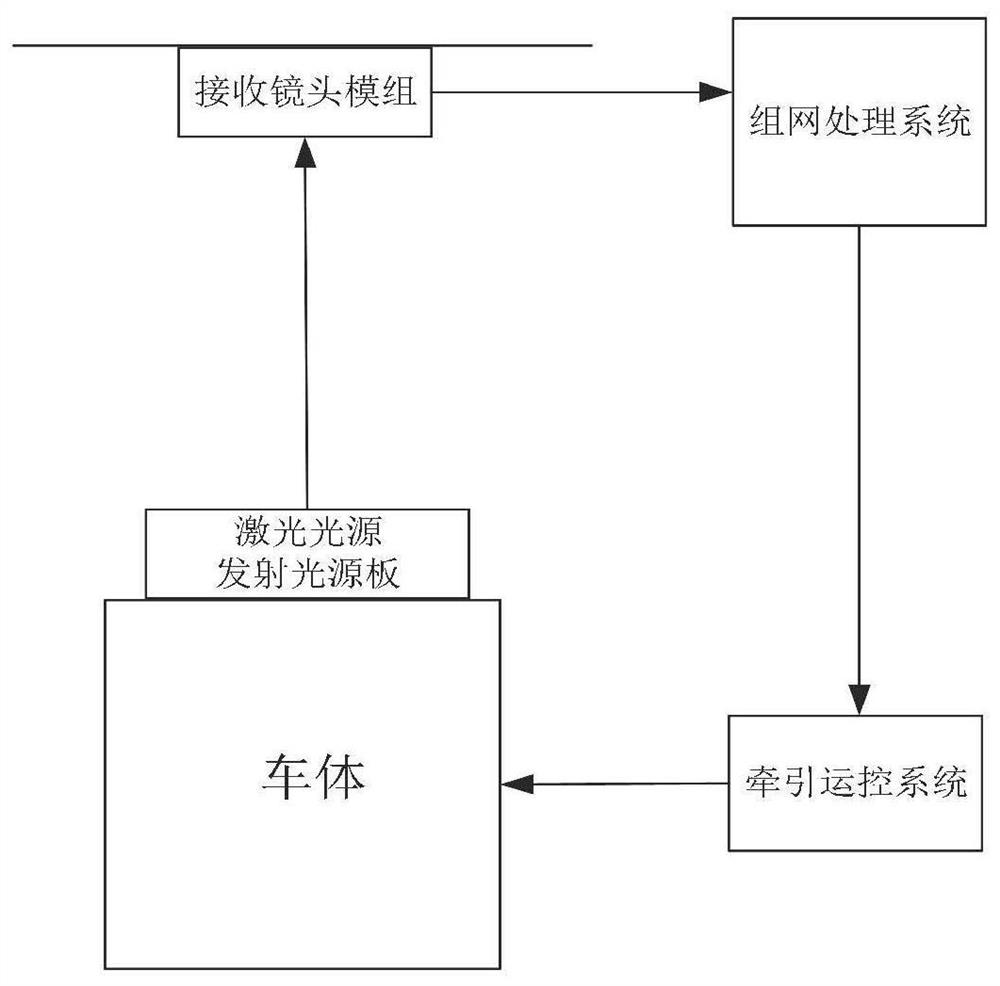

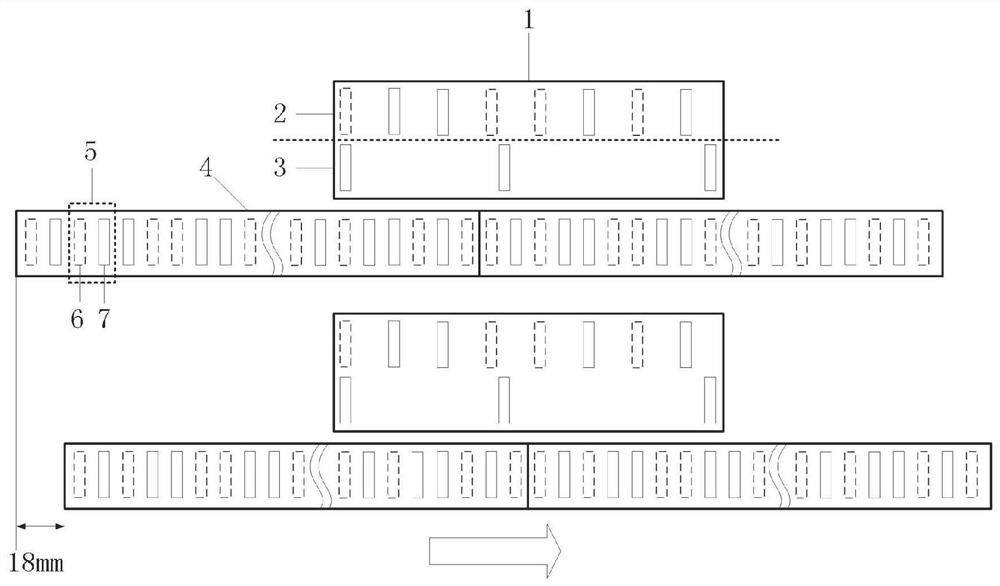

Ultra-high-speed maglev train positioning and speed measuring system based on Manchester encoding

ActiveCN113291353AGuaranteed separatenessDoes not take up weightIndividual digits conversionRailway signalling and safetyContinuous lightUltra high speed

An ultra-high-speed maglev train positioning and speed measuring system based on Manchester encoding comprises a train body, a laser light source, a beam splitter, an emitting light source plate, a receiving lens module, a networking processing system and a traction operation control system. The laser light source, the beam splitter and the emitting light source plate are mounted at the top of the head body of the ultra-high-speed maglev train, and the receiving lens modules are mounted on the inner pipe wall of a pipeline at equal intervals; an optical transmitting lens is mounted on the transmitting light source plate, and an optical receiving lens is mounted on the receiving lens module; continuous optical signals output by the laser light source form linear light at the end of the emitting light source plate through the beam splitter, the receiving lens module receives coded laser signals and transmits the coded laser signals to the networking processing system far away from the pipeline along with movement of the ultra-high-speed maglev train body, and the networking processing system processes the coded laser signals. And the networking processing system converts the received coding laser signal into an electric signal and outputs and transmits the information to the traction operation control system, and the coding laser signal is Manchester coding.

Owner:HIWING TECH ACAD OF CASIC

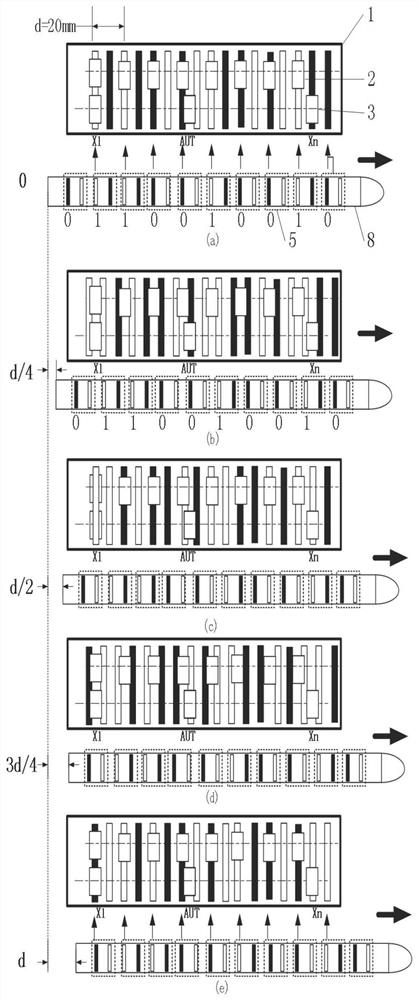

Method for utilizing boiler waste gas in fermentation alcohol production

InactiveCN104998529AEmission reductionAchieve recyclingUsing liquid separation agentMultistage water/sewage treatmentWater savingAlcohol production

The invention provides a method for utilizing boiler waste gas in fermentation alcohol production. The method comprises the following steps that alcohol waste water is treated, the boiler waste gas with sulphur is enriched, and SBR water is acidized; the SBR water is blended, and the blended water is used for an alcohol fermentation process. A circular economy standardization system of waste gas and waste water treatment resource comprehensive utilization is built, natural resources and secondary energy are utilized reasonably through comprehensive utilization of resources, energy saving, consumption reducing and water saving, most rationalization of utilization of natural resources and energy is achieved, and emissions of waste and pollutant are reduced.

Owner:太仓意发石化矿材检测有限公司

Color bean curd machine convenient for cleaning

InactiveCN108617797AQuality assuranceQuantitative control of the amount addedCheese manufactureCleaning using liquidsSprayerEngineering

The invention relates to a color bean curd machine convenient for cleaning. The color bean curd machine comprises a mixing box, a controller, a soybean milk pipe, a first motor, a sealing plate, a cleaning mechanism, a discharging pipe, a plurality of support legs and a plurality of feeding mechanisms. The feeding mechanism comprises a feeding pipe, a material box and a material conveying pipe. The material box is internally provided with a feeding component. The feeding component comprises a driving component, a feeding plate and two telescopic components. The telescopic component comprises atelescopic frame and two first connecting rods. The cleaning mechanism comprises a shielding can and two water tanks. The shielding can is internally provided with a lifting component, a lifting plate and two cleaning components. The cleaning component comprises a sprayer and a water pipe. The color bean curd machine convenient for cleaning is capable of, through the feeding mechanisms, adding vegetable juice solution with a moderate pH value to the mixing box, and guaranteeing the quality of produced bean curd, in addition, enabling a stirring plate to be lifted to the exterior of the mixingbox through the cleaning mechanism, spraying water solution to clean through the sprayers, and removing residual solution on the stirring plate. The follow-up production work is convenient, and the practicability of the device is improved.

Owner:永春辛德环保科技有限公司

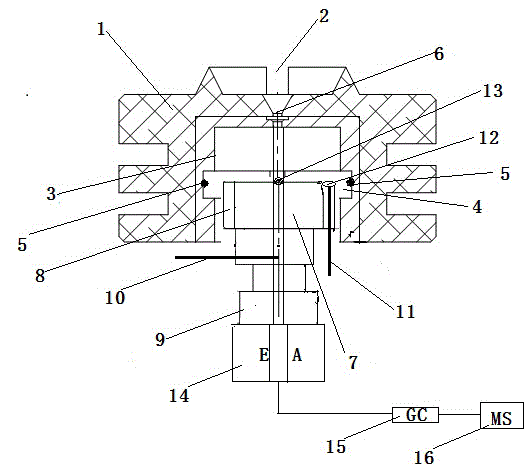

Needle-type sample injection cap

The invention discloses a needle-type sample injection cap used on a liquid injection mouth, which is characterized in that an outer pressing cap injection mouth is arranged on an outer pressing cap; an inner pressing cap injection mouth is arranged at the upper part of an inner pressing cap; a pressing cap blowing air drain is arranged inside the inner pressing cap, and two inner pressing cap blowing holes are formed inside the inner pressing cap; the outer pressing cap and the inner pressing cap are tightly matched, and the bottom edges are welded after assembly; a cap core hole is formed in the top end of a cap core; the upper thread of the cap core and the thread inside the inner pressing cap are tightly matched, and a seal gasket arranged therebetween is used for hermetically connecting the cap core and the inner pressing cap; the lower thread of the cap core is in fixed threaded connection with the connector of an elemental analyzer; a gas loading pipe (mouth), a cap core blowing pipe and a blowing gas port are arranged on the cap core; the outer pressing cap injection mouth, the inner pressing cap injection mouth and the cap core hole are concentric. The needle-type sample injection cap provided by the invention is skillful in structure manufacture, is convenient to replace, can effectively improve the value testing accuracy of key system parts, solves the problem of influence of air on analysis result during the liquid sample injection, and has excellent application and popularization value.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

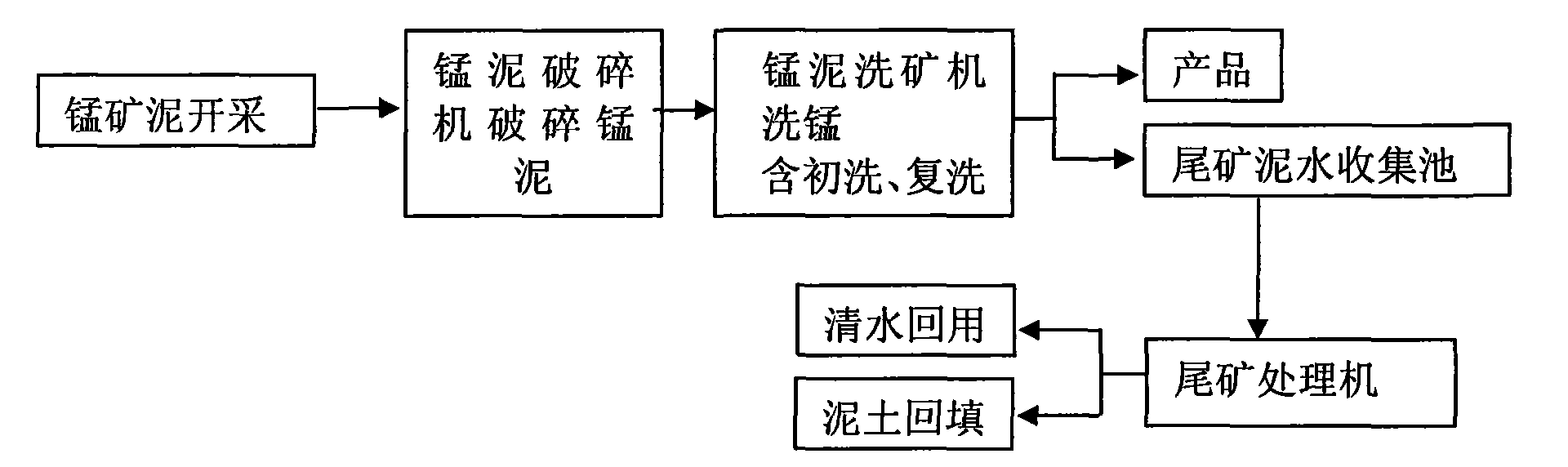

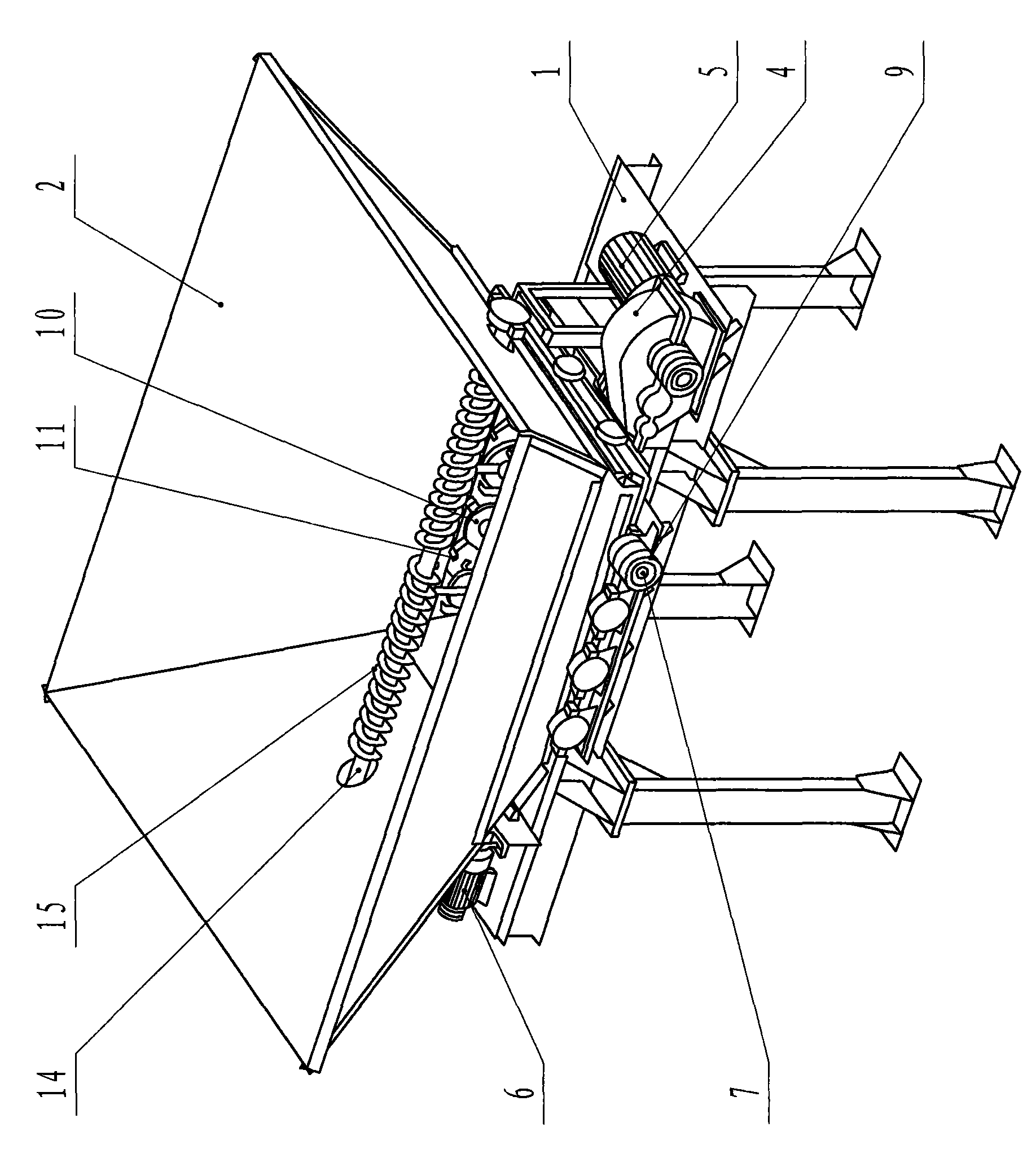

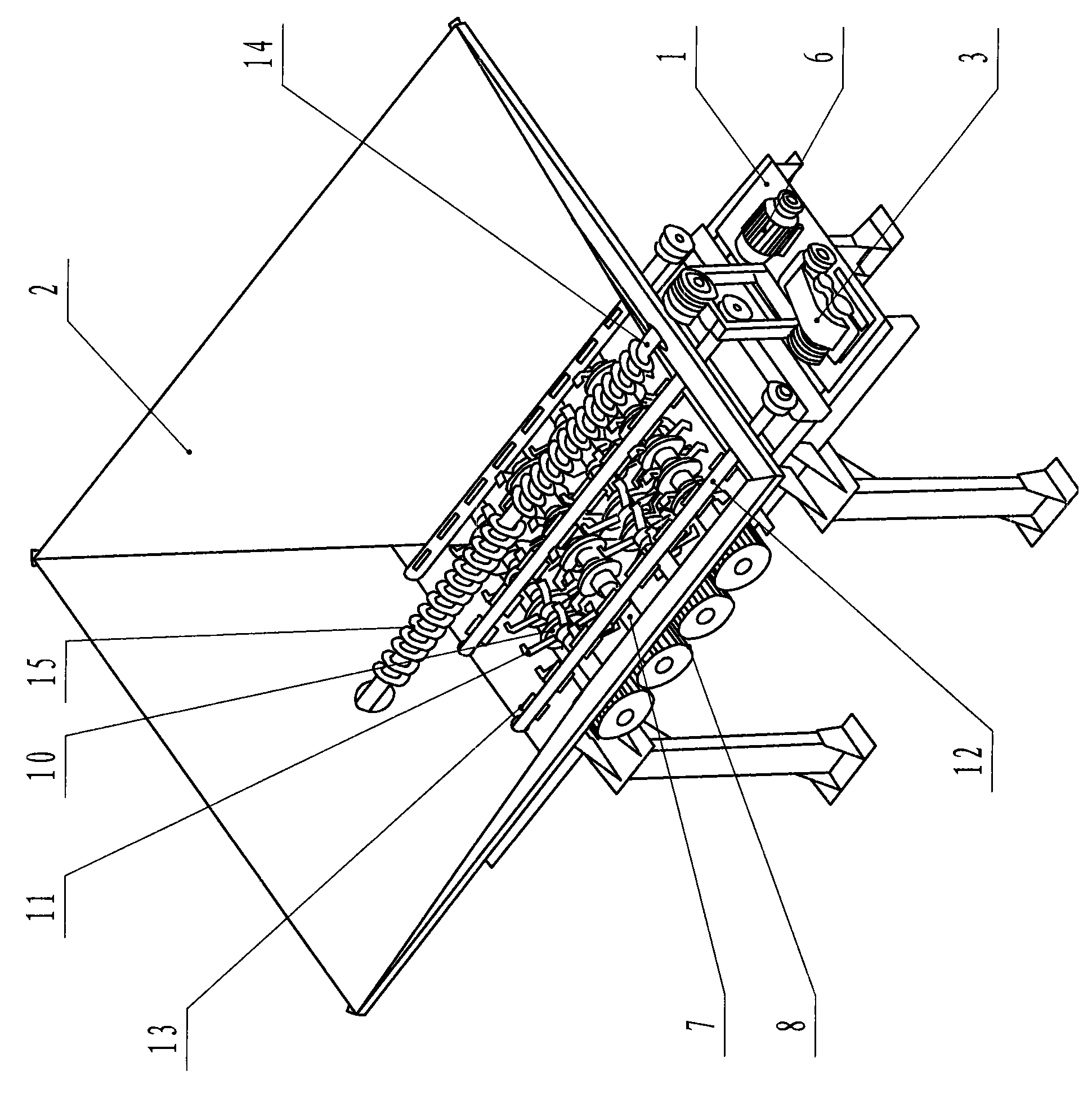

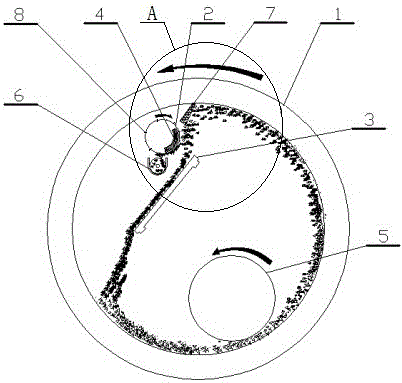

High-efficiency and energy-saving manganese washing process without arranging tailing pond or polluting environment

InactiveCN101628257AAvoid pollution effectsWon't breakGrain treatmentsWet separationManganeseWater resources

The invention discloses a high-efficiency and energy-saving manganese washing process without arranging a tailing pond and polluting the environment. The mined manganese slime is broken by a manganese slime breaking machine and then is washed by a manganese slime manganese-washing machine to obtain manganese ore, the water for washing the manganese slime enters a tailing slime water collecting tank and separated through a tailing treatment machine, the clean water is reused and the slime is back filled. The invention has the advantages that: firstly, the manganese washing is locally carried out after mining the manganese ore, therefore, the link of manganese ore slime transport is reduced and the production and transportation cost is reduced; secondly, water resources are saved and the pollution to the environment is also avoided due to the recycling of the manganese washing water; thirdly, no tailing pond is required, not only the land occupation is little, but also the original potential safety hazard of production of the tailing pond is overcome and the construction investment is reduced; and fourthly, the manganese slime breaking machine is additionally arranged, therefore, the problem that the large manganese slime cannot enter the machine before or the damage to the manganese washing machine is great is solved, and the ore washing efficiency is greatly improved by 35 percent than the original process efficiency.

Owner:陈星亮

Silk cotton processing line equipment

InactiveCN105648541BEasy to processAvoid pollution effectsSilk reelingWater storageCombustion chamber

The invention discloses silk floss processing line equipment. The equipment comprises a silk floss machine, a degumming device and a drying device, a heating component in a water storage bin of the silk floss machine is an oil burner, a combustion chamber of the oil burner is formed in the water storage bin, a filter box is manufactured in the water storage bin, and a water outlet of the filter box is connected with a hot water circulating pump; an outlet of the hot water circulating pump is connected with two pipes, the first branch pipe is communicated to a spray pipe located above a silkworm cocoon squeezing roll barrel of the silk floss machine, and the second branch pipe is communicated to a water inlet of the drying device; the drying device is constituted by a drying chamber located on the lower portion of the drying device, a draught fan chamber located on the upper portion of the drying device and a hot water circulation drying pipe located in the drying chamber; the degumming device comprises an air pressure pot and a support of the air pressure pot, a pot bottom mesh partition plate is installed at the bottom of an inner chamber of the air pressure pot, and a cover top mesh partition plate is installed at the top in an air pressure cover of the air pressure pot. By means of the silk floss processing line equipment, it is helpful for silkworm raisers of a silkworm breeding and mulberry growing base to meet the requirement of conducting on-site processing on cocoon shells, the situations that the cocoon shells go bad due to centralized processing and accumulation of the cocoon shells and good products cannot be obtained from good raw materials are avoided, and the influence of environmental pollution caused by centralized processing is also avoided.

Owner:党金峰

Steel slag horizontal roller mill iron removing device and iron removing method thereof

InactiveCN106622499AEfficient removalAvoid abrasionsMagnetic separationGrain treatmentsIron removalSlag

The invention provides a steel slag horizontal roller mill iron removing device. The steel slag horizontal roller mill iron removing device comprises a cylinder body, as well as a compression roller, a material guiding plate and a material scraping plate which are arranged inside the cylinder body, wherein a wedged space is formed between the compression roller and the side wall of the cylinder body; the material guiding plate is arranged by forming a certain inclined angle with the axial direction of the cylinder body; the material scraping plate is fixedly arranged in the cylinder body and makes contact with the inner side wall of the cylinder body; the material scraping plate is positioned above the material guiding plate; a non-magnetic roller is arranged between the material scraping plate and the material guiding plate; a permanent magnet is fixedly arranged inside the non-magnetic roller; an iron recovering mechanism is arranged below the non-magnetic roller. The steel slag horizontal roller mill iron removing device is simple in structure, small in size and convenient to mount; grinding and iron removal can be performed at the same time, a magnetic metal body in the grinding process of a horizontal roller mill can be effectively removed, the abrasion of the cylinder body and the compression roller due to enrichment of the magnetic metal body is avoided, and further the service life of the steel slag horizontal roller mill iron removing device is prolonged; compared with an external circulation iron removing mode, the steel slag horizontal roller mill iron removing device provided by the invention has the advantages that the wear of equipment is greatly reduced, and the maintenance quantity of the equipment is reduced, so that the maintenance cost is reduced.

Owner:WISDRI ENG & RES INC LTD

Cosmetic cleansing compositions

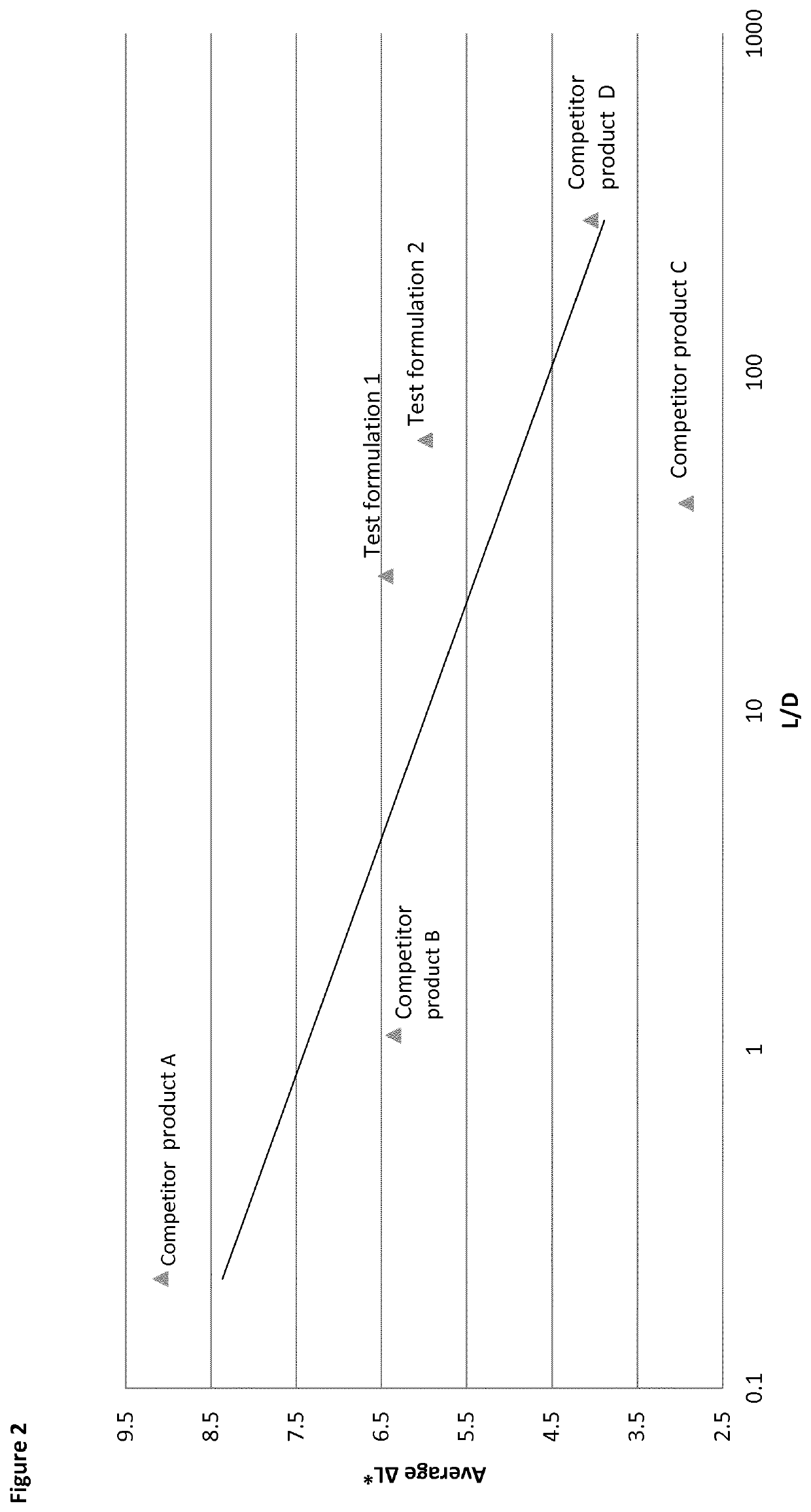

ActiveUS11484486B2Strong washing powerImprove toleranceCosmetic preparationsHair cosmeticsActive agentSurface-active agents

According to the present invention there is provided a cosmetic composition comprising a cosmetically acceptable carrier and a surfactant system consisting of: (i) an anionic surfactant; (ii) an amphoteric surfactant; and (iii) a non-ionic surfactant, wherein the anionic surfactant is present in an amount of from about 0.5% to about 25% by weight of the surfactant system, wherein the amphoteric surfactant is present in an amount of from about 0.5% to about 50% by weight of the surfactant system, wherein the non-ionic surfactant is present in an amount of from about 0.5% to about 45% (e.g. 43%) by weight of the surfactant system, and wherein the total amount of the surfactant system present in the cosmetic composition is from about 1.5% to about 25% by weight of the composition.

Owner:THE BOOTS CO PLC

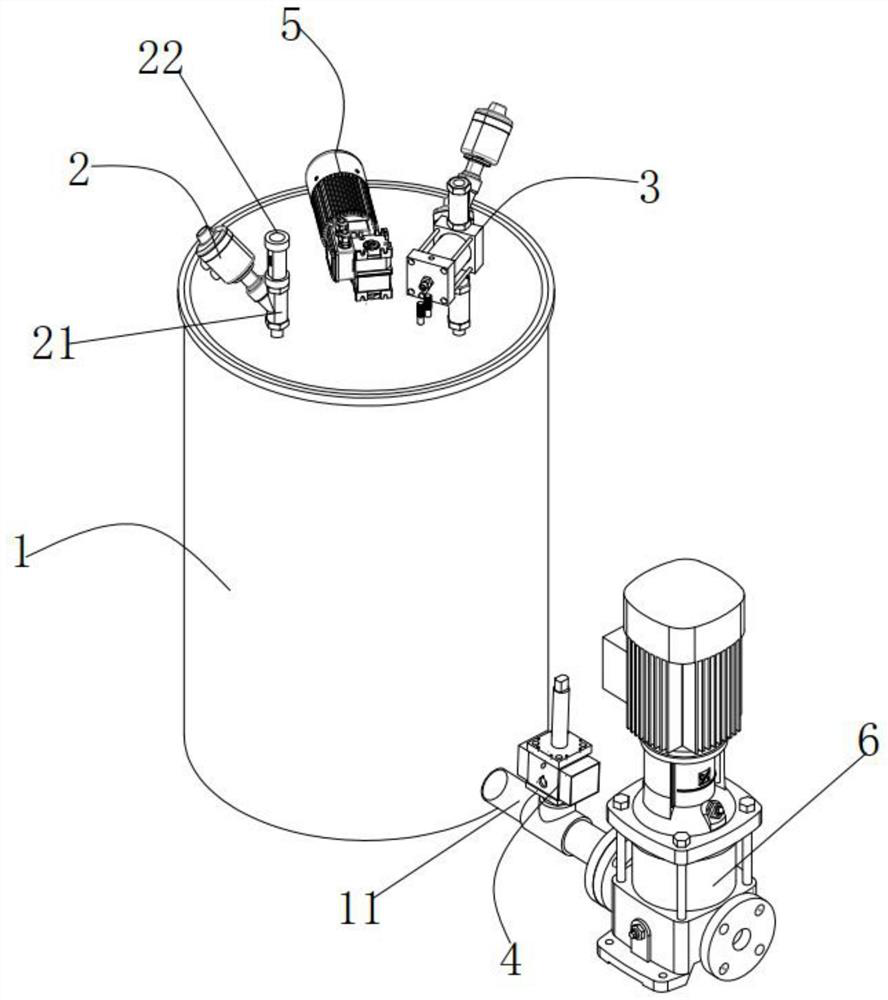

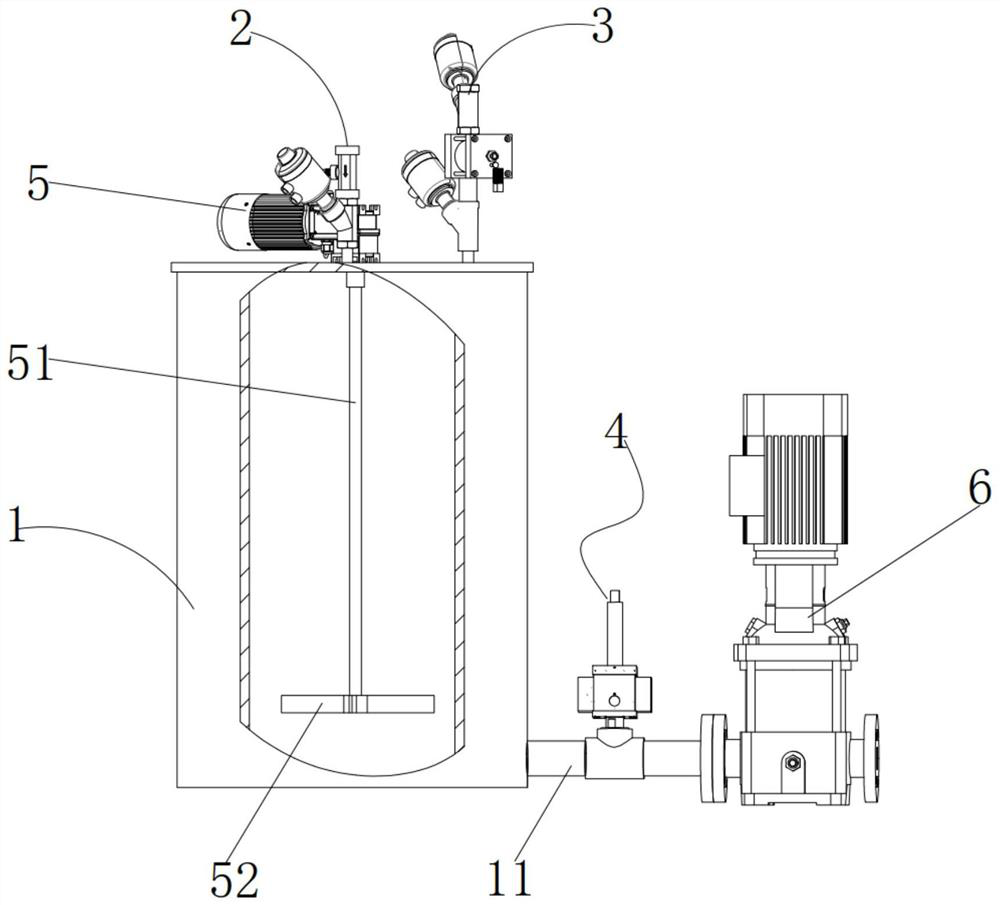

Solution concentration correction device

PendingCN113559740AGuaranteed ratio accuracyImprove correction efficiencyRotary stirring mixersTransmissivity measurementsEngineeringMechanical engineering

The invention provides a solution concentration correction device. The solution concentration correction device comprises a solution tank, a quantitative water supply device, a quantitative stock solution supply device, a solution concentration online detection device and a controller; the quantitative water supply device and the quantitative stock solution supply device are both mounted at the top of the solution tank; a liquid outlet pipe communicated with the solution tank is arranged on the solution tank, and the solution concentration online detection device is mounted on the liquid outlet pipe; the solution concentration online detection device comprises a shading shell, a transparent sampling tube, a piston assembly, a sampling head, a strong light emitting device and a light intensity receiving device; the strong light emitting device and the light intensity receiving device are oppositely arranged on two sides of the transparent sampling tube; the controller is connected with the light intensity receiving device to obtain the concentration of a detected solution; and the controller is connected with the quantitative water supply device and the quantitative stock solution supply device so as to control the water adding amount or the liquid adding amount. On-line detection and on-line correction of the concentration of the solution are achieved through cooperation of all the devices, the solution matching precision is guaranteed, and the solution correction efficiency is improved.

Owner:KOLBENSCHMIDT PIERBURG SHANGHAI NONFERROUS COMPONENTS

Tweezers for test

InactiveCN102729168AAvoid pollution effectsReduce clutterMetal-working hand toolsDisplay deviceEngineering

The invention provides tweezers for a test. A body of the tweezers is provided with an outer protecting bush and the protecting bush is provided with a hanging ring; and a humidity display is arranged at the tail part of the tweezers main body. With the adoption of the outer protecting bush, pollution influences caused by dust, impurities, water and the like can be avoided when the tweezers body is not used; after the tweezers are suspended by the hanging ring, a disorder placing phenomenon of a laboratory can be reduced; and the assembled humidity display can master a moisture condition of a sample in good time and the sampling of various tests is accurate and effective.

Owner:XIANGFAN UNIVERSITY

Detection device for automatic packaging machine

InactiveCN110935642AImprove convenienceReduce work intensityDispersed particle filtrationSortingStructural engineeringAluminium preparations

The invention discloses a detection device for an automatic packaging machine, which relates to the technical field of aluminum products. The detection device for an automatic packaging machine comprises a box body; a placing plate is arranged below the box body; the bottom of the box body is fixedly connected with the top of the placing plate; supporting legs are welded to the bottom of the placing plate; four groups of supporting legs are arranged; a feeding pipe is mounted on a flange at the top of the box body; the feeding pipe is communicated with the interior of the box body; a hose is installed on a flange at the top of the inner side of the box body; the hose is communicated with the interior of the feeding pipe; a conveying mechanism is arranged in the box body; a detection mechanism is arranged above the placing plate; a first baffle is welded to the inner wall of one side of the box body; and a second baffle is welded to the inner wall of the other side of the box body. Thedevice is convenient to operate, the working efficiency is effectively improved, the working performance is conveniently improved, the problems of material mixing and the like caused by manual detection errors are prevented, and the quality of detected and sorted materials is indirectly improved.

Owner:湖州荣立包装材料有限公司

Preparation method of large size chalcogenide glass

ActiveCN106517739BAvoid secondary pollutionEasy to operateGlass furnace apparatusGlass shaping apparatusCrucibleState parameter

Owner:NINGBO UNIV

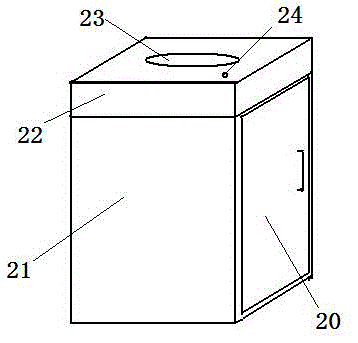

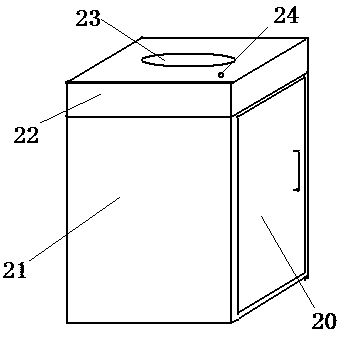

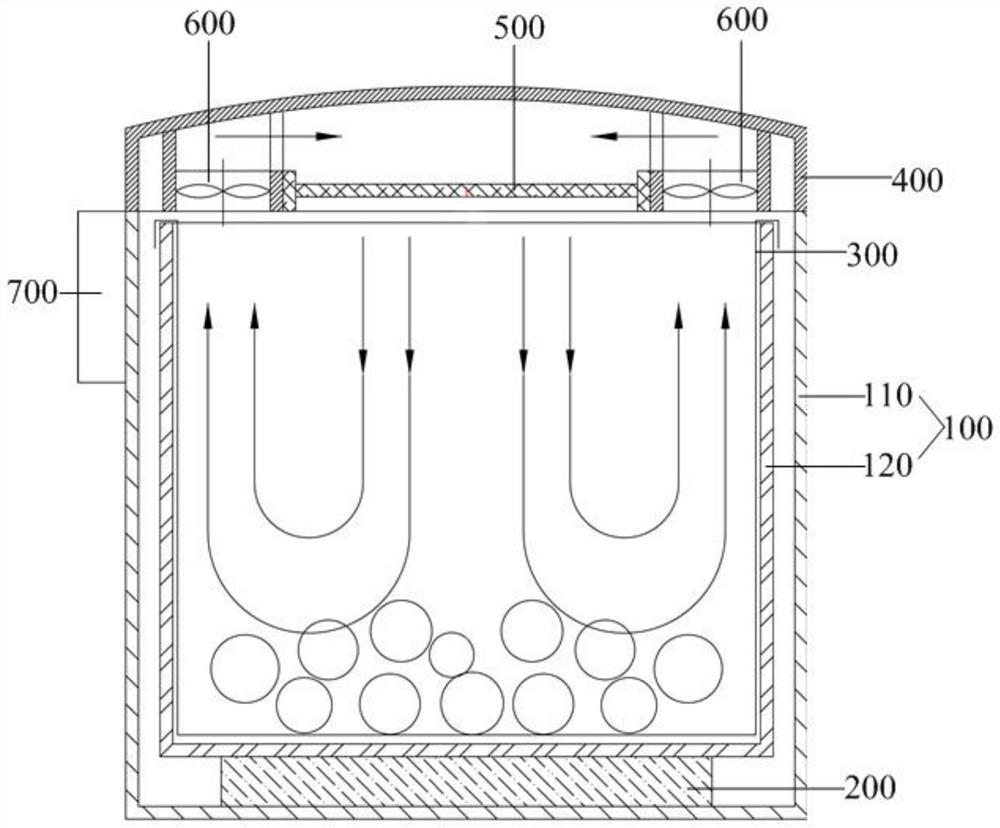

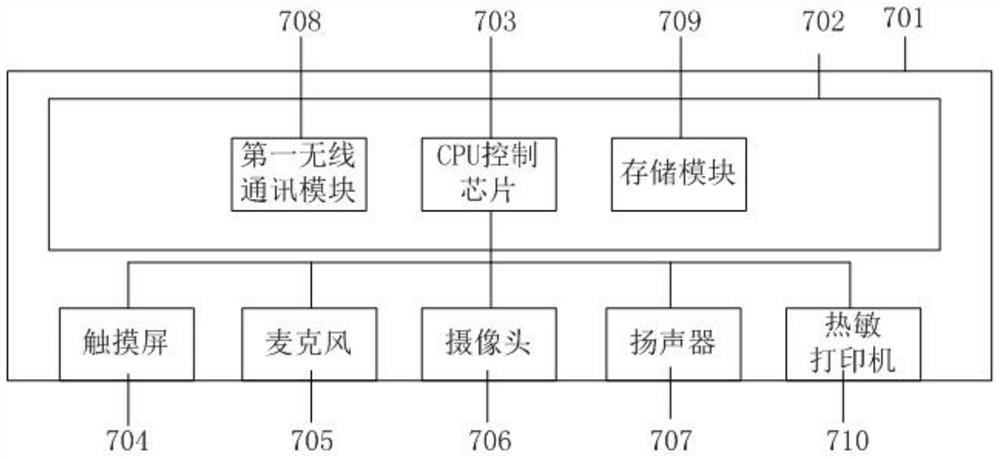

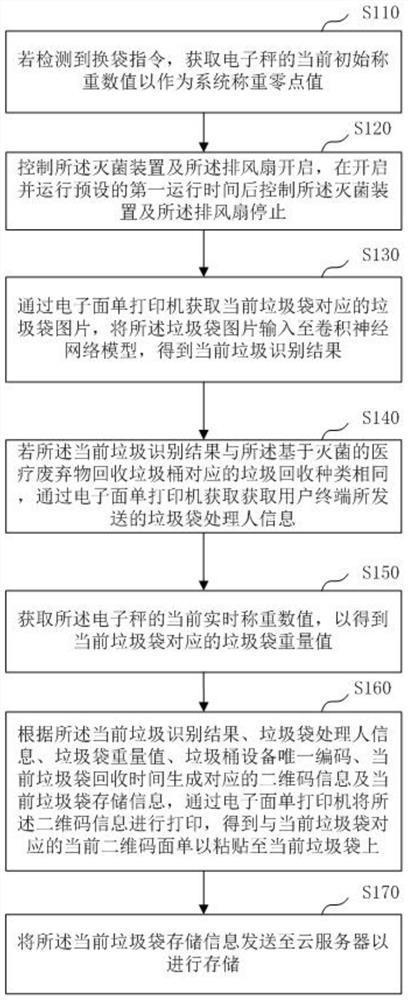

Sterilization-based medical waste recycling bin and its data storage method

ActiveCN111661518BAvoid pollution effectsNo manual weighingRefuse receptaclesRefuse cleaningComputer printingMedical waste

Owner:广东慧福数字智能科技有限公司

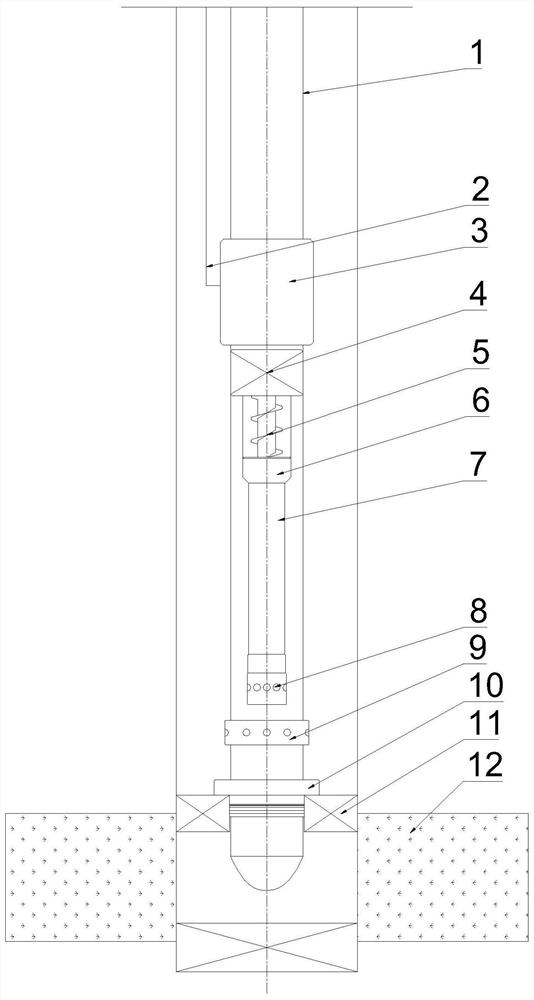

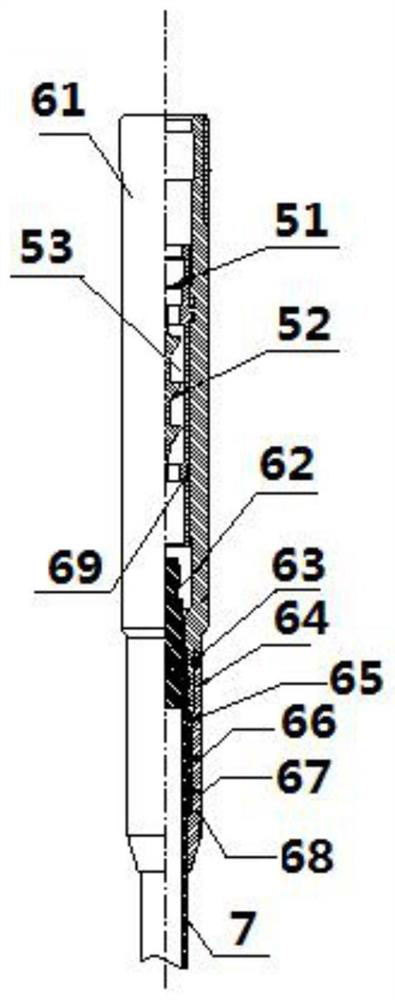

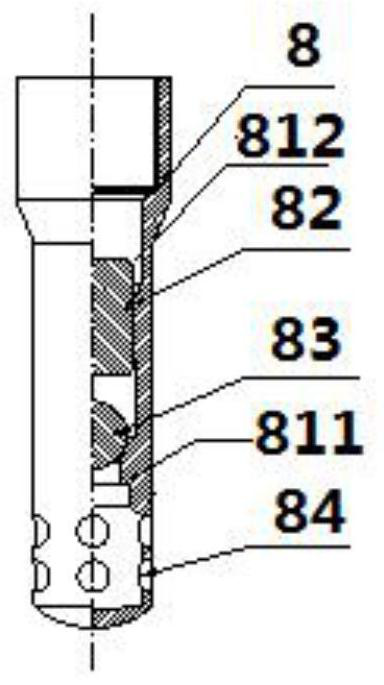

A liquid drainage gas collection string and its production method

ActiveCN107620583BDoes not affect the normal well control functionImprove liquid carrying capacityFluid removalSealing/packingLine tubingOil field

The invention discloses a liquid-unloading gas recovery pipe string. The liquid-unloading gas recovery pipe string is composed of a pipe body with a liquid-controlled pipeline, and the pipe body is sequentially provided with a subsurface safety valve, a sliding sleeve, a positioning seal and a first packer; a second packer, a hanger, a speed pipe string and a blanking plug are arranged between thesubsurface safety valve and the sliding sleeve; an upper body of the hanger is connected into the pipe body sequentially through the second packer and the safety valve, and a lower body of the hangeris connected with the blanking plug through the speed pipe string; and an eddy current tool is movably connected to the interior of the hanger. According to the liquid-unloading gas recovery pipe string, the flow velocity of fluid in a wellbore of a gas well is increased, so that the liquid carrying ability of the gas well is improved, and requirements of liquid-unloading gas recovery in an offshore oilfield gas well are met.

Owner:CHINA NAT OFFSHORE OIL CORP +1

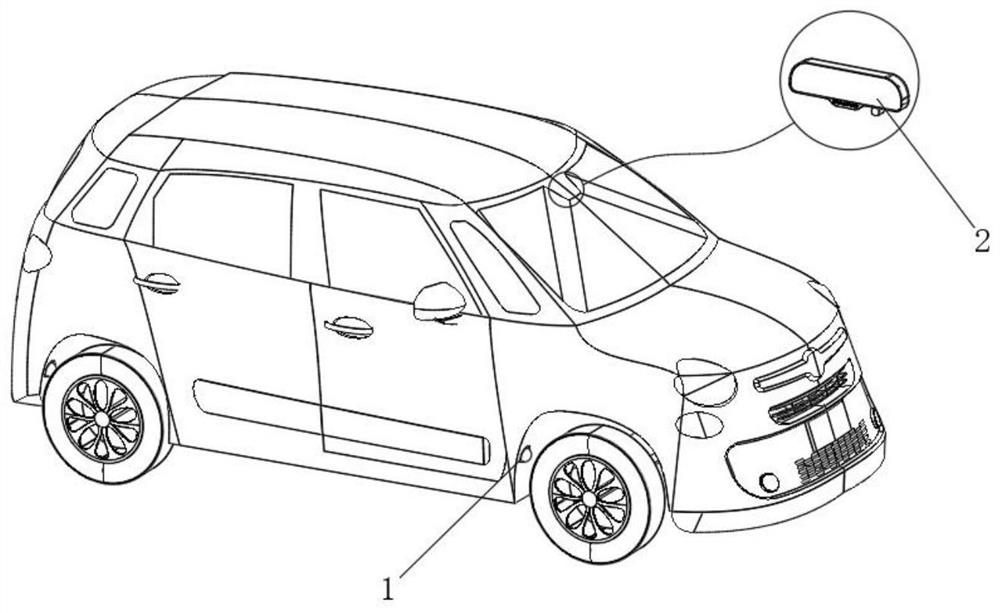

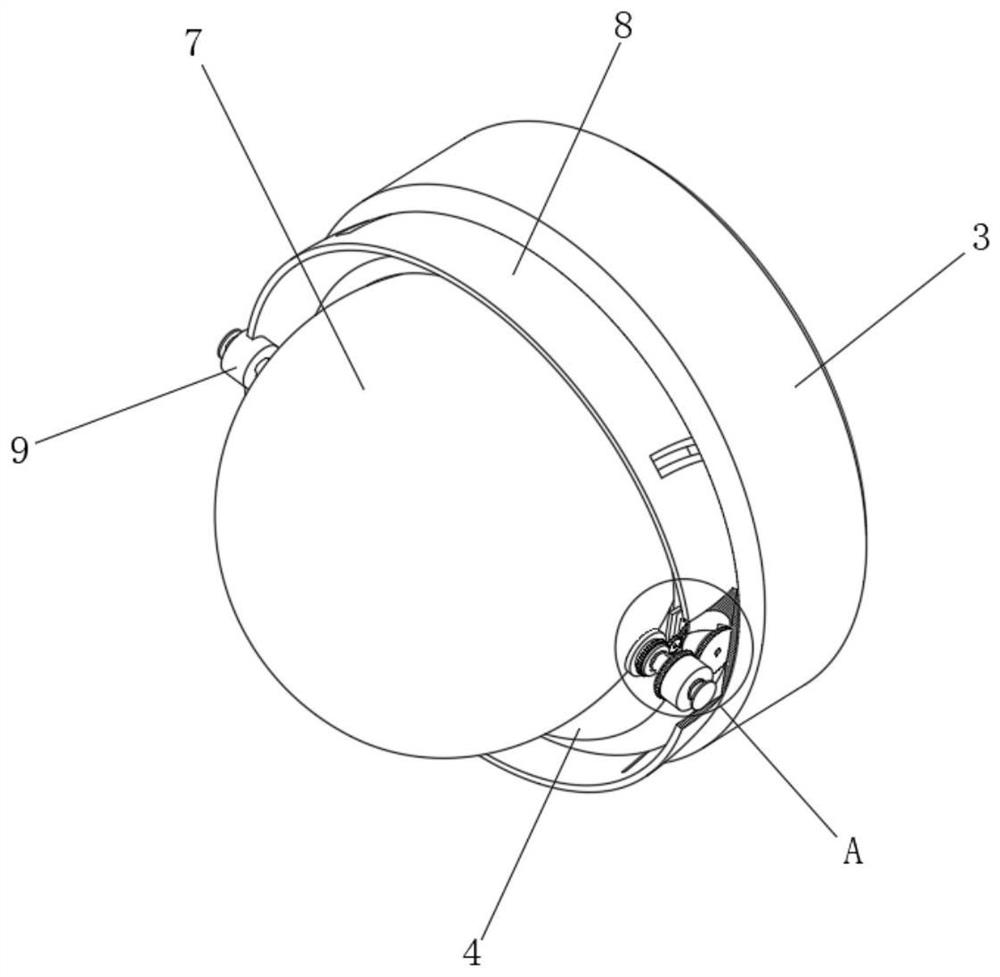

Vehicle-mounted video monitor for tire pressure monitoring

InactiveCN113459950ADriving safetyImprove driving safetyClosed circuit television systemsSuperstructure subunitsIn vehicleNew energy

The invention relates to the field of new energy vehicles, and discloses a vehicle-mounted video monitor for tire pressure monitoring, which is characterized in that the current road surface humidity is obtained through setting of a humidity detector and the like, the self-cleaning intermittent time of a camera assembly is correspondingly adjusted, and the distance between the camera assembly and a tire table surface is judged in real time through an ultrasonic scanner; whether the surface of the tire swells is indirectly detected, warning information is sent out if necessary, meanwhile, whether the section contour of the tire is abnormal or not can be judged through camera integration, driving safety is improved, the surface of a hemispherical mud cover is subjected to self-cleaning treatment through the arrangement of the hemispherical mud cover and the like. The visibility and definition of the hemispherical mud cover are guaranteed, the normal operation effect of the camera integration is prevented from being indirectly influenced, through the arrangement of the hemispherical protective cover and the like, the situation that the surface of the camera integration is polluted by sludge and the like when the hemispherical mud cover is self-cleaned can be effectively avoided, and the practicability of the whole monitoring device is improved.

Owner:深圳市其利天下技术开发有限公司

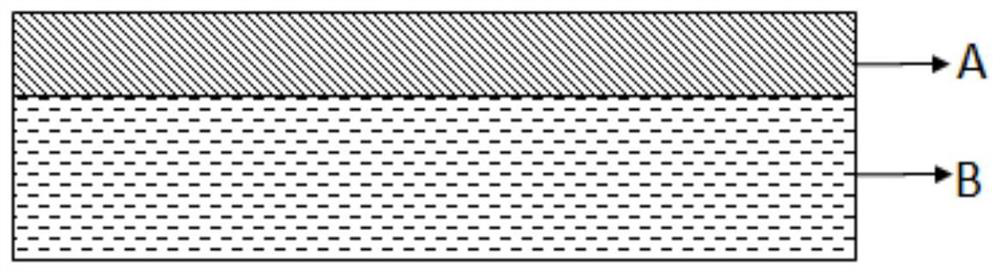

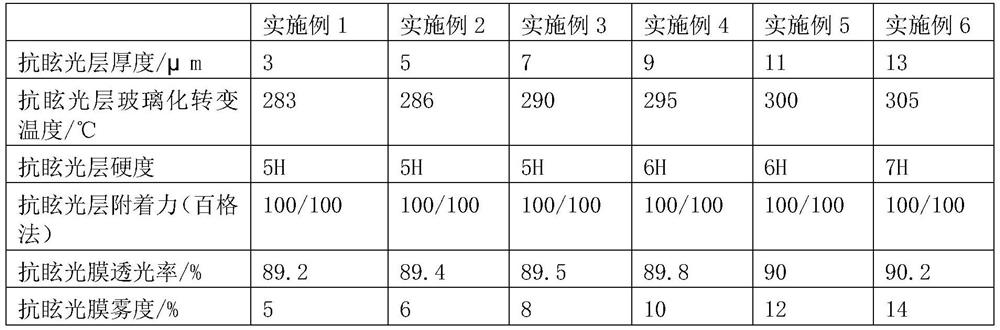

Anti-glare film and preparation method thereof

The invention provides an anti-glare film and a preparation method thereof, the film has high adhesive force and surface hardness, and is flexible, bending-resistant and easy to process. The invention protects a composite film with an anti-glare function, the composite film comprises an anti-glare layer and a plastic substrate layer with a glass transition temperature (Tg) higher than 240 DEG C, and the anti-glare film has the advantages of high particle adhesion, high surface hardness, flexibility and easy processing. The film is particularly suitable for the field of vehicle-mounted curved display screens and foldable and rollable mobile phones.

Owner:NINGBO CHANGYANG TECH

Rubber plug for transfusion

ActiveCN112618359AEasy extractionAvoid interferencePharmaceutical containersMedical packagingPhysicsInfusion solution

The invention relates to a rubber plug for transfusion. The rubber plug for transfusion comprises a regular polygon plug body, a through hole for inserting a liquid injection needle tube is formed in the center of the plug body, a plurality of liquid cavities for independently extracting a solution are annularly distributed around the through hole at equal intervals, and each liquid cavity is respectively communicated with a hole formed in each surface of the regular polygon plug body. The regular polygon plug body is plugged into a bottle opening of a medicine bottle, each regular polygon face of the plug body is provided with the hole, each liquid cavity formed in the plug body is communicated with the medicine bottle, and therefore medicine liquid in the medicine bottle can be extracted from the liquid cavity conveniently, meanwhile, a one-way valve is arranged in each hole, and the one-way valves are closed under the action of no external force of needle tube suction force, each liquid cavity and the medicine bottle are independent of each other, an independent sealed space is formed, the situation that liquid left after last extraction enters the medicine bottle again, and consequently next extraction is disturbed is avoided, and the mutual pollution influence during repeated extraction is avoided through relatively isolated and independent extraction.

Owner:ANHUI HUANENG MEDICAL RUBBER PROD

Anti-pollution complex comprising calendula extracts and an aqueous extract of lilum candidum bulb and uses thereof

ActiveUS10695285B2Avoid harmful effectsAvoid pollution effectsCosmetic preparationsToilet preparationsBiotechnologyLilium carniolicum

The invention relates to an anti-pollution complex comprising an aqueous extract of Calendula, an oily extract of Calendula and an aqueous extract of Lilium candidum, to a cosmetic topical composition comprising such an anti-pollution complex and to a cosmetic process to protect the skin from the harmful effects of pollution, in particular from the harmful effects of exhaust gases and heavy metals.

Owner:MP2 COSMETIC SOLUTIONS

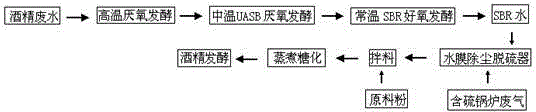

Concrete pipe vertical production process pipe mold release agent spraying machine

InactiveCN102528913BRealize all-round sprayingIncrease productivityCeramic shaping apparatusSpray coatingEngineering

The invention discloses a pipe die releasing agent spraying coater for a concrete pipe vertical production process. The releasing agent spraying coater comprises a cylindrical shell. A spraying mechanism A is arranged at a position close to an inner wall in the shell, and a spraying mechanism B is arranged at a position far away from the inner wall in the shell. A water supply device is arranged on each of the spraying mechanism A and the spraying mechanism B, and the two water supply devices are positioned at the bottom in the shell. With the adoption of the spraying coater, the 360-degree spraying coating of a pipe die is realized, the production efficiency of the concrete pipe is improved, and the influence on the environmental pollution caused by the outflow of a releasing agent in the production process can be avoided. The pipe die releasing agent spraying coater cannot affect other structures and production of concrete pipes, and moreover, the releasing agent spraying coater can be conveniently used for related product equipment which has geometrical characteristics similar to those of the pipe die for the concrete pipe vertical production process and is required to be spraying-coated with a releasing agent and the like.

Owner:SICHUAN GUOTONG CONCRETE PROD +1

Needle Caps for Liquid Injection Ports

The invention discloses a needle-type sample injection cap used on a liquid injection mouth, which is characterized in that an outer pressing cap injection mouth is arranged on an outer pressing cap; an inner pressing cap injection mouth is arranged at the upper part of an inner pressing cap; a pressing cap blowing air drain is arranged inside the inner pressing cap, and two inner pressing cap blowing holes are formed inside the inner pressing cap; the outer pressing cap and the inner pressing cap are tightly matched, and the bottom edges are welded after assembly; a cap core hole is formed in the top end of a cap core; the upper thread of the cap core and the thread inside the inner pressing cap are tightly matched, and a seal gasket arranged therebetween is used for hermetically connecting the cap core and the inner pressing cap; the lower thread of the cap core is in fixed threaded connection with the connector of an elemental analyzer; a gas loading pipe (mouth), a cap core blowing pipe and a blowing gas port are arranged on the cap core; the outer pressing cap injection mouth, the inner pressing cap injection mouth and the cap core hole are concentric. The needle-type sample injection cap provided by the invention is skillful in structure manufacture, is convenient to replace, can effectively improve the value testing accuracy of key system parts, solves the problem of influence of air on analysis result during the liquid sample injection, and has excellent application and popularization value.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com