Silk cotton processing line equipment

An assembly line and silk floss technology, applied in the fields of silk reeling, silk fiber production, textiles and papermaking, etc., to achieve the effect of small equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

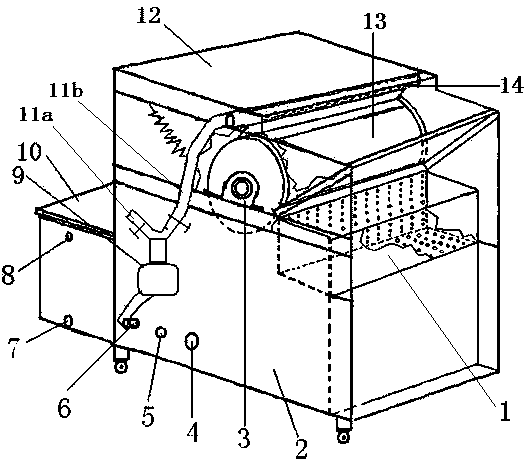

[0023] Below in conjunction with accompanying drawing, scheme is further described as an embodiment.

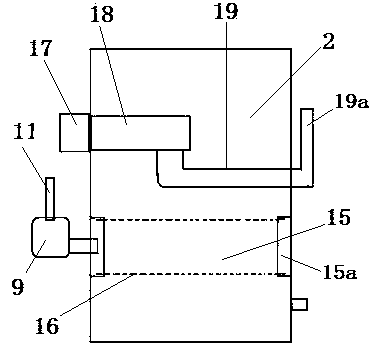

[0024] refer to figure 1 , 2 , the silk floss machine of this example adopts the water silk floss machine of patent No. ZL201420462232.4, mainly the heating element in the water storage bin 2 of processing hot water and the pumping environment of the hot water pump have been improved. Concretely be that the diameter has been expanded near the original electric heating pipe mouth, as combustion chamber mouth 4, a burner 17 is installed, and this example adopts gasoline or diesel oil burner. Correspondingly, an elongated combustion chamber 18 is installed in the water storage bin 2, and the combustion chamber 18 is horizontally fixed on the bottom of the water storage bin 2, and a thermal hysteresis pipe 19 is connected from the side of the combustion chamber 18 in a bent form. It is beneficial to make full use of the heat energy from the combustion chamber 18.

[0025] Fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com