High-efficiency and energy-saving manganese washing process without arranging tailing pond or polluting environment

A high-efficiency, energy-saving and tailings storage technology, which is applied in solid separation, wet separation, grain processing, etc., can solve the problems that manganese washing wastewater cannot be recycled, large mining and backfill transportation, and large production water consumption, etc., to overcome Hidden dangers in production safety, less production water consumption, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

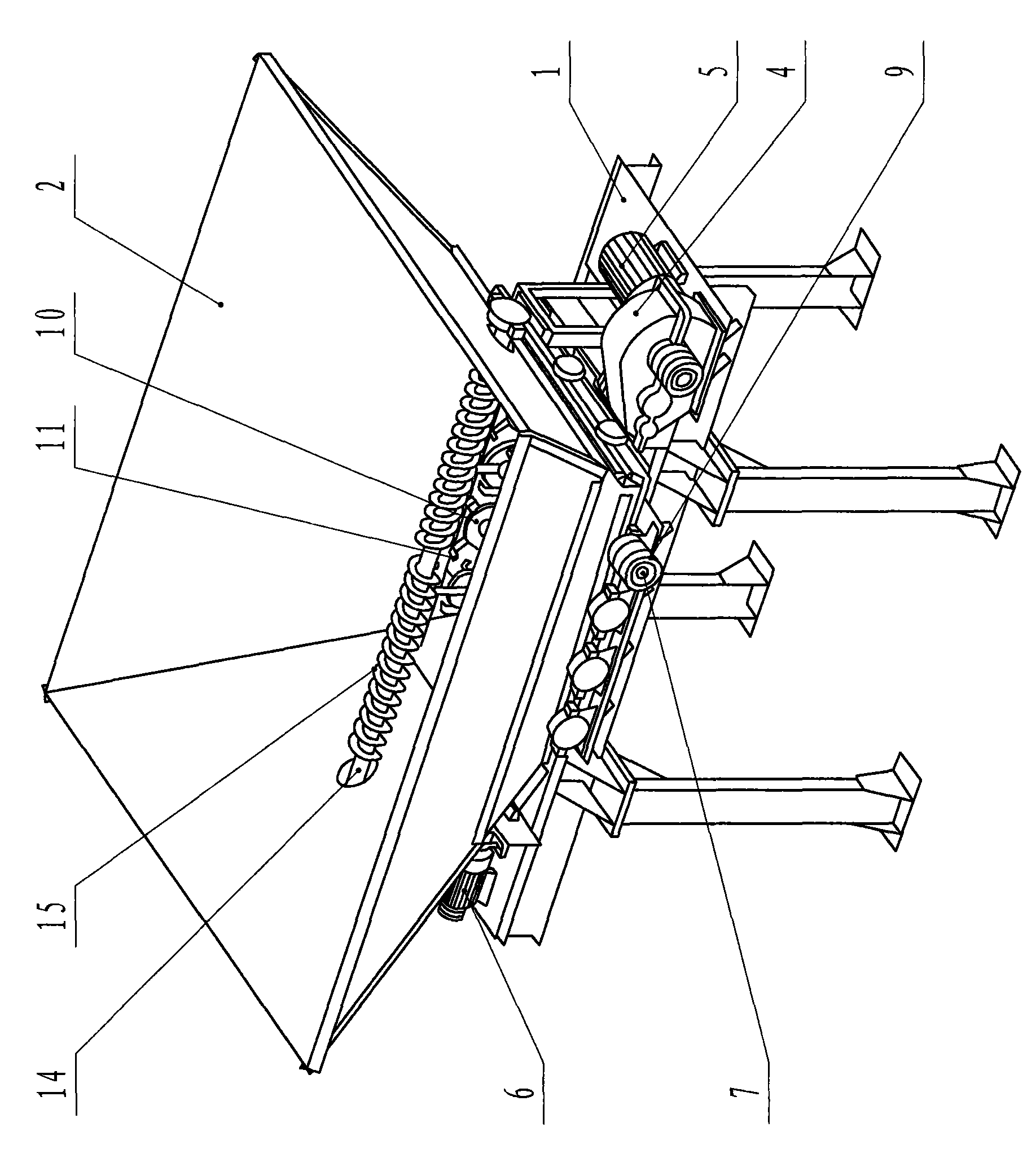

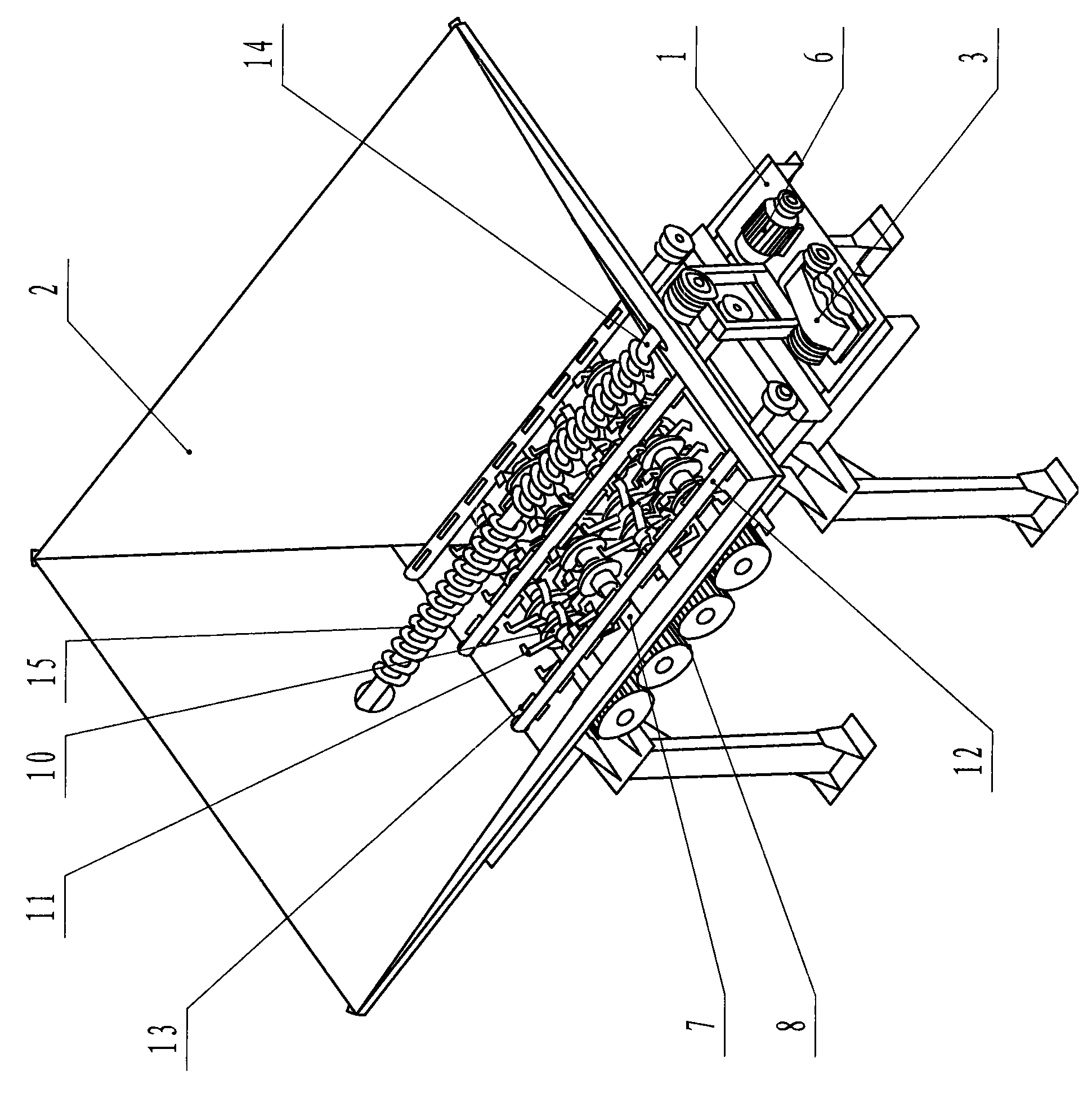

[0025] Further illustrate the present invention below in conjunction with accompanying drawing.

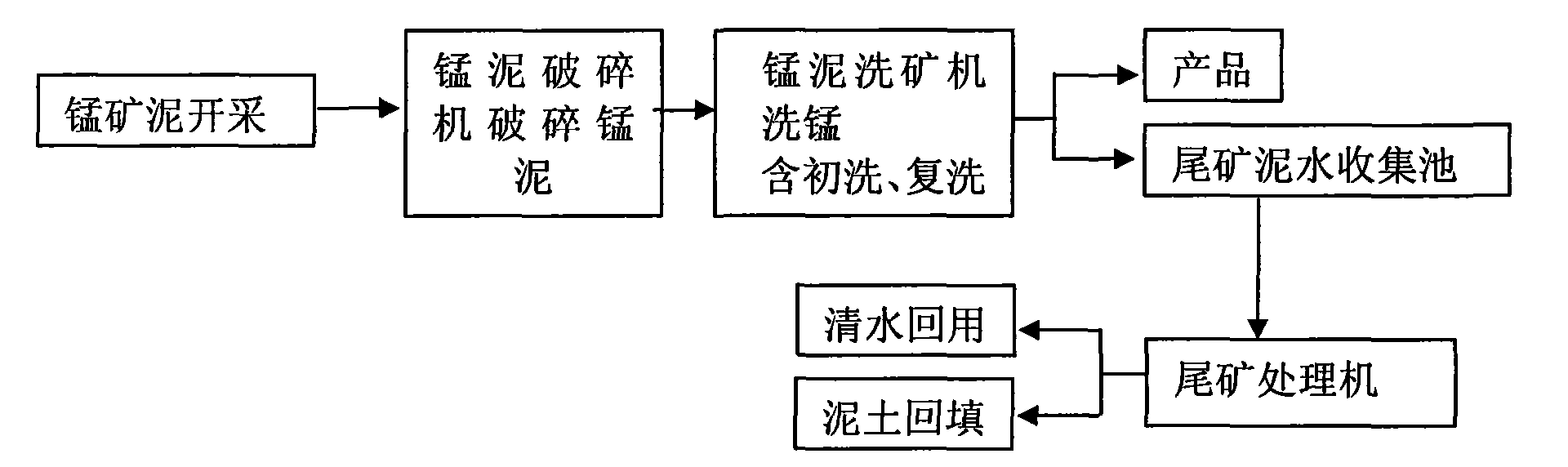

[0026] figure 1 Shown, the manganese washing technique of the present invention contains following steps:

[0027] (1) Install manganese mud crusher, manganese mud washing machine, tailings mud water collection pool and tailings processing machine next to the manganese ore mining site;

[0028] (2) Send the manganese mud mined from the manganese ore into the manganese mud crusher, and crush the large manganese mud into small pieces of manganese mud less than 120mm by the manganese mud crusher;

[0029] (3) The above-mentioned crushed manganese mud is initially washed and rewashed by the manganese mud washing machine to obtain manganese ore products, and the manganese mud washing water is collected into the tailings mud water collection pool at the same time;

[0030] (4) Use the tailings processing machine to separate the mud and water from the tailings mud water collection tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com