Patents

Literature

45results about How to "Avoid production safety hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorosurfactant free of perfluorooctanoic acid as well as preparation method and process system of fluorosurfactant

ActiveCN105170018ASolve pollutionPromote decompositionPreparation from carboxylic acid halideTransportation and packagingProcess systemsPeroxide value

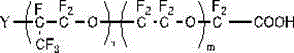

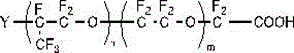

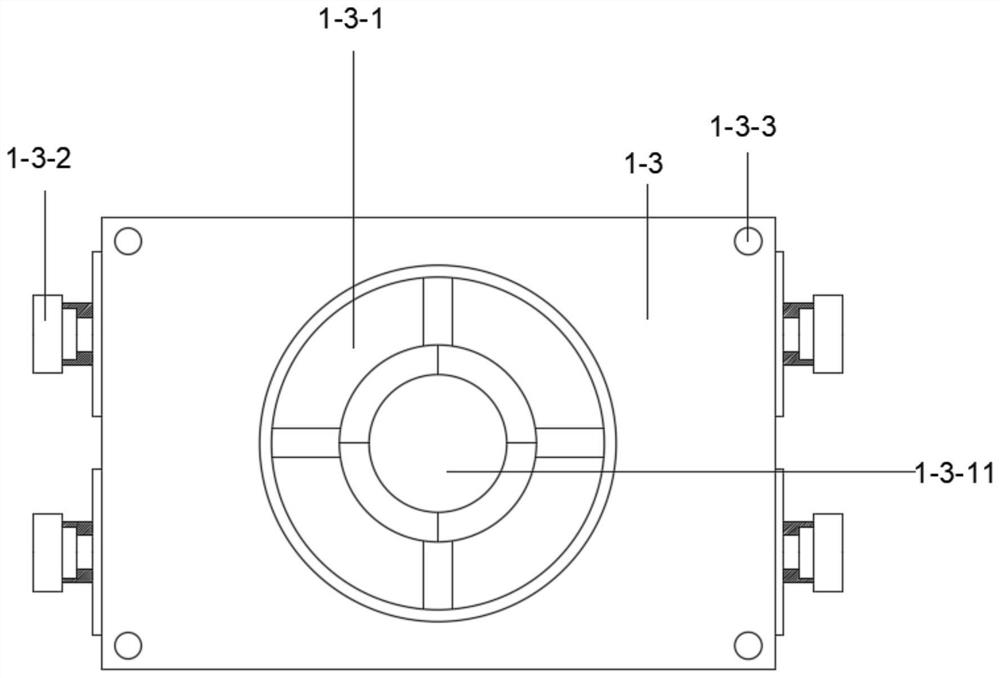

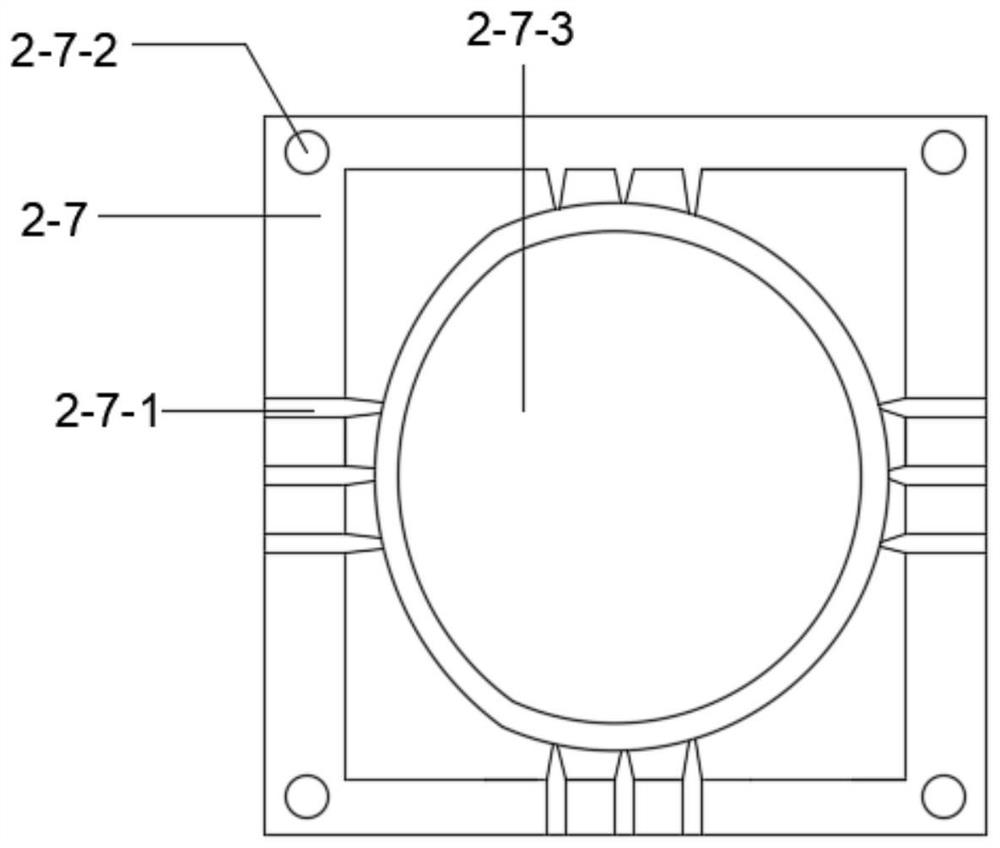

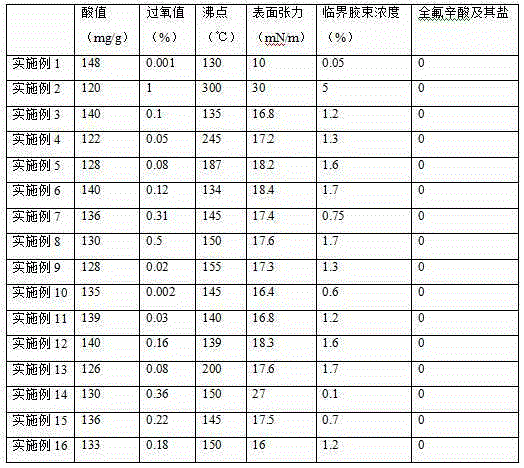

The invention discloses a fluorosurfactant free of perfluorooctanoic acid as well as a preparation method and a process system of the fluorosurfactant. The fluorosurfactant is a repeated structure unit which comprises at least one oxoperfluoropropenyl and one or a combination of more of perfluoromethoxyl, a Y group and oxoperfluorovinyl and is provided with a carboxyl group or carboxylate at one end. The fluorosurfactant is a fluoropolymer with the C-O-C ether bond structure as the main structural body; in view of indexes, the fluorosurfactant does not contain perfluorooctanoic acid with a 8-C straight-chain structure or salt of the perfluorooctanoic acid, is easily decomposed in nature and is proved to be harmless to human bodies, the peroxide value is 0.001%-0.1%, the surface tension is 10-30 mN / m, and the fluorosurfactant has an amphiphilic structure of a surfactant.

Owner:成都晨光博达新材料股份有限公司

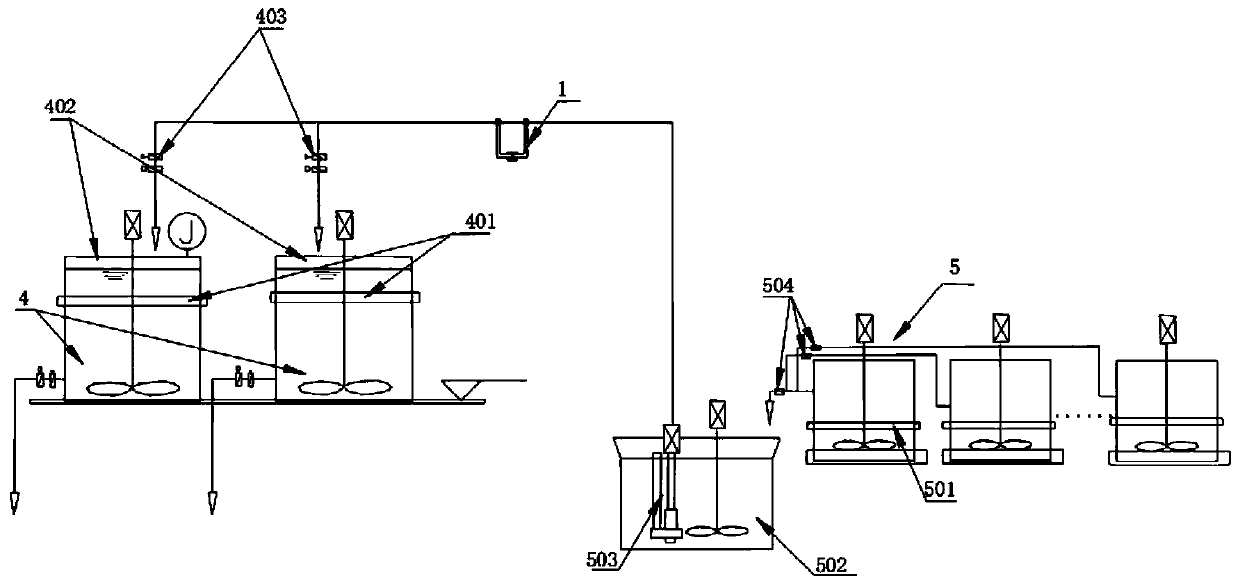

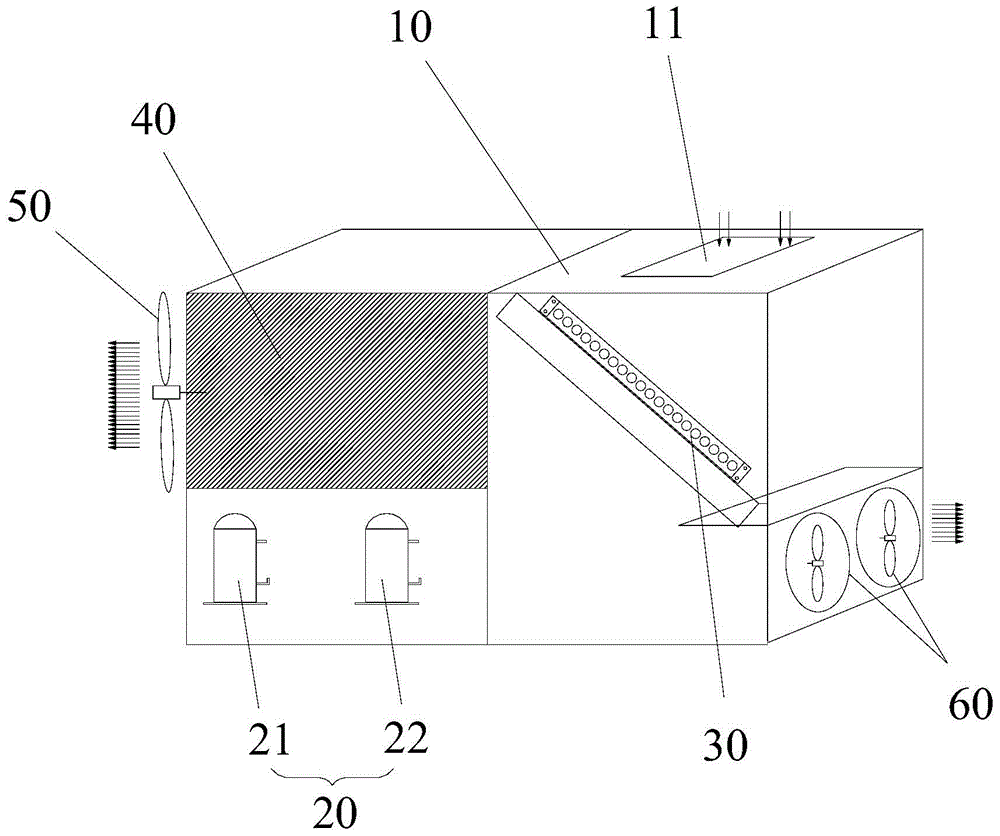

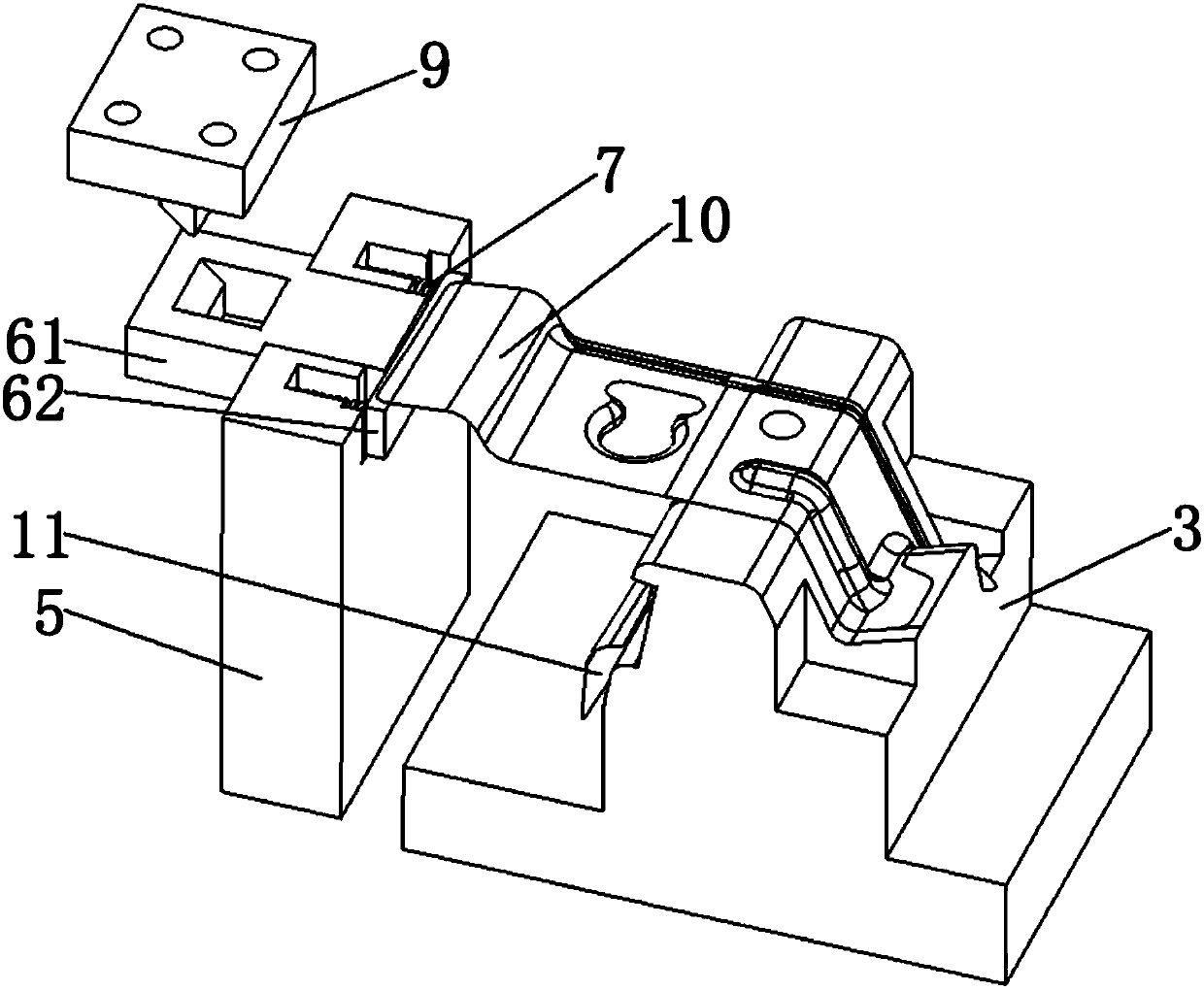

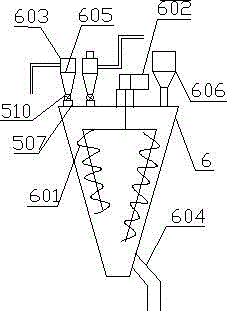

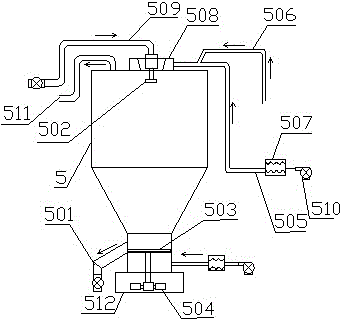

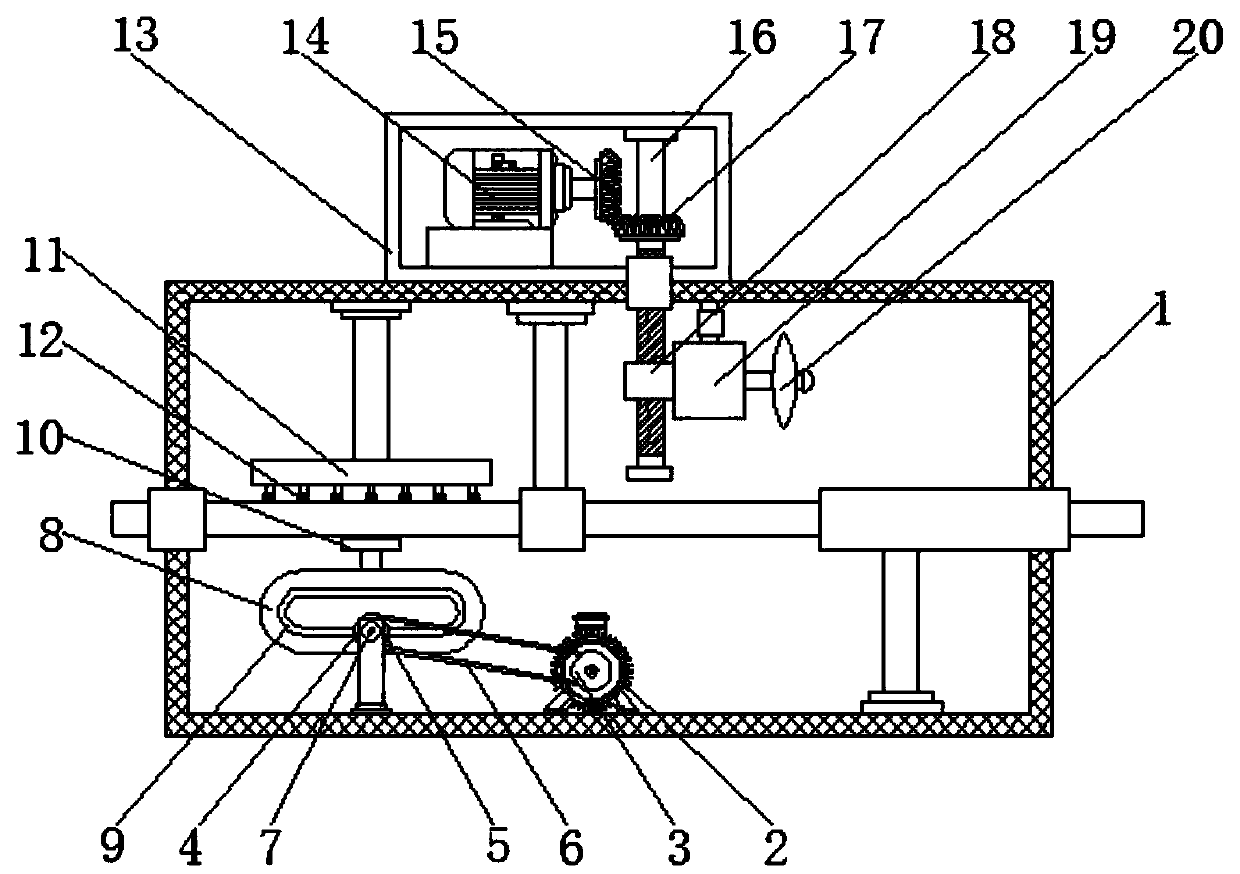

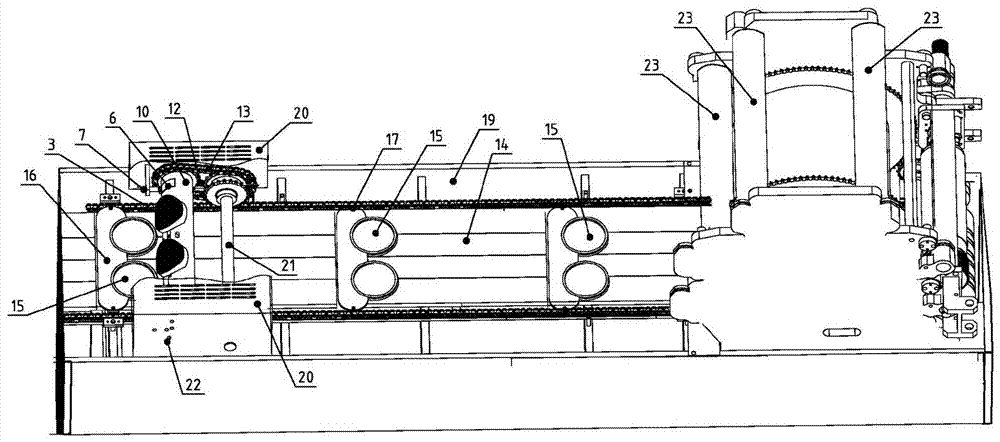

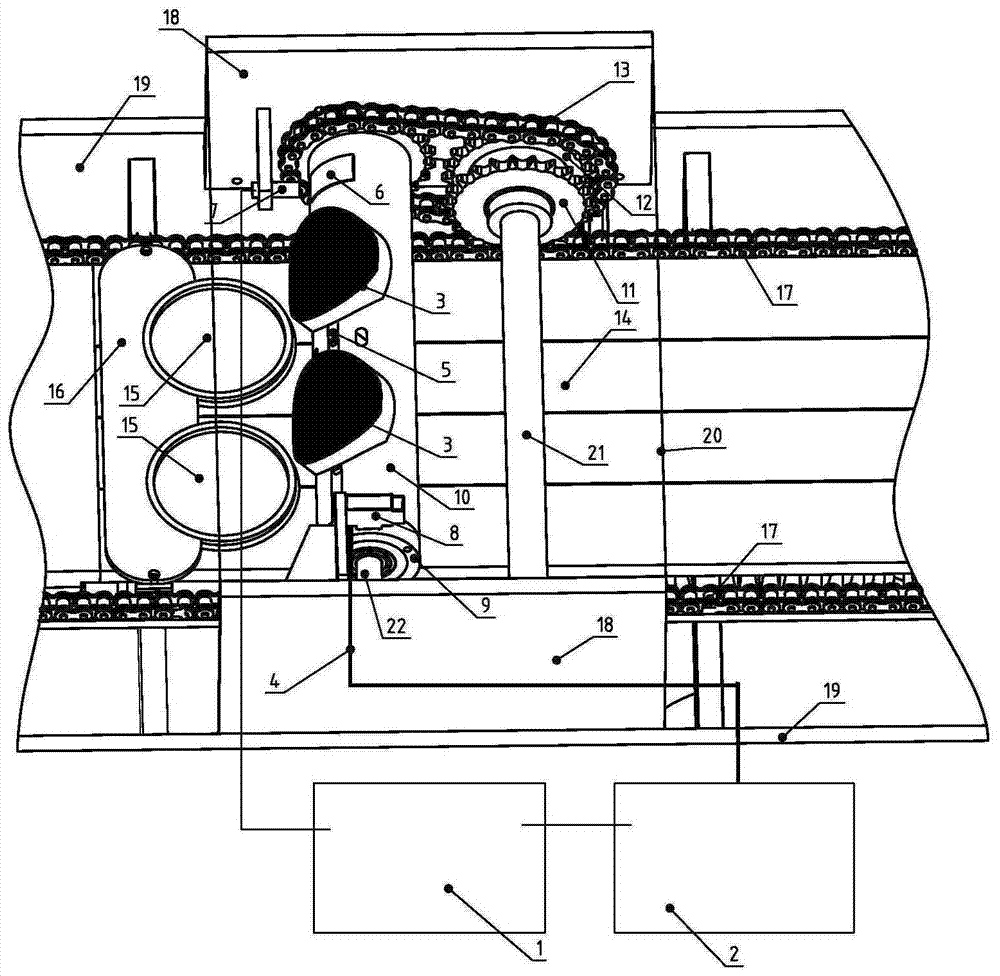

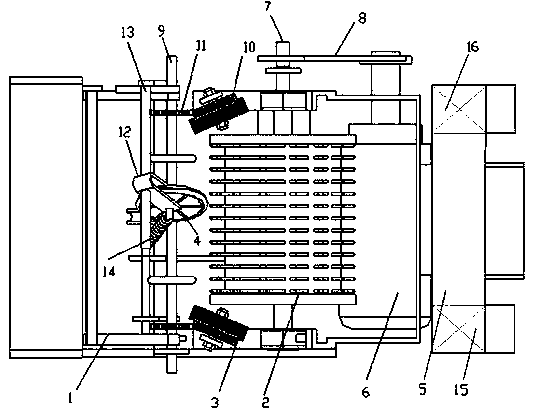

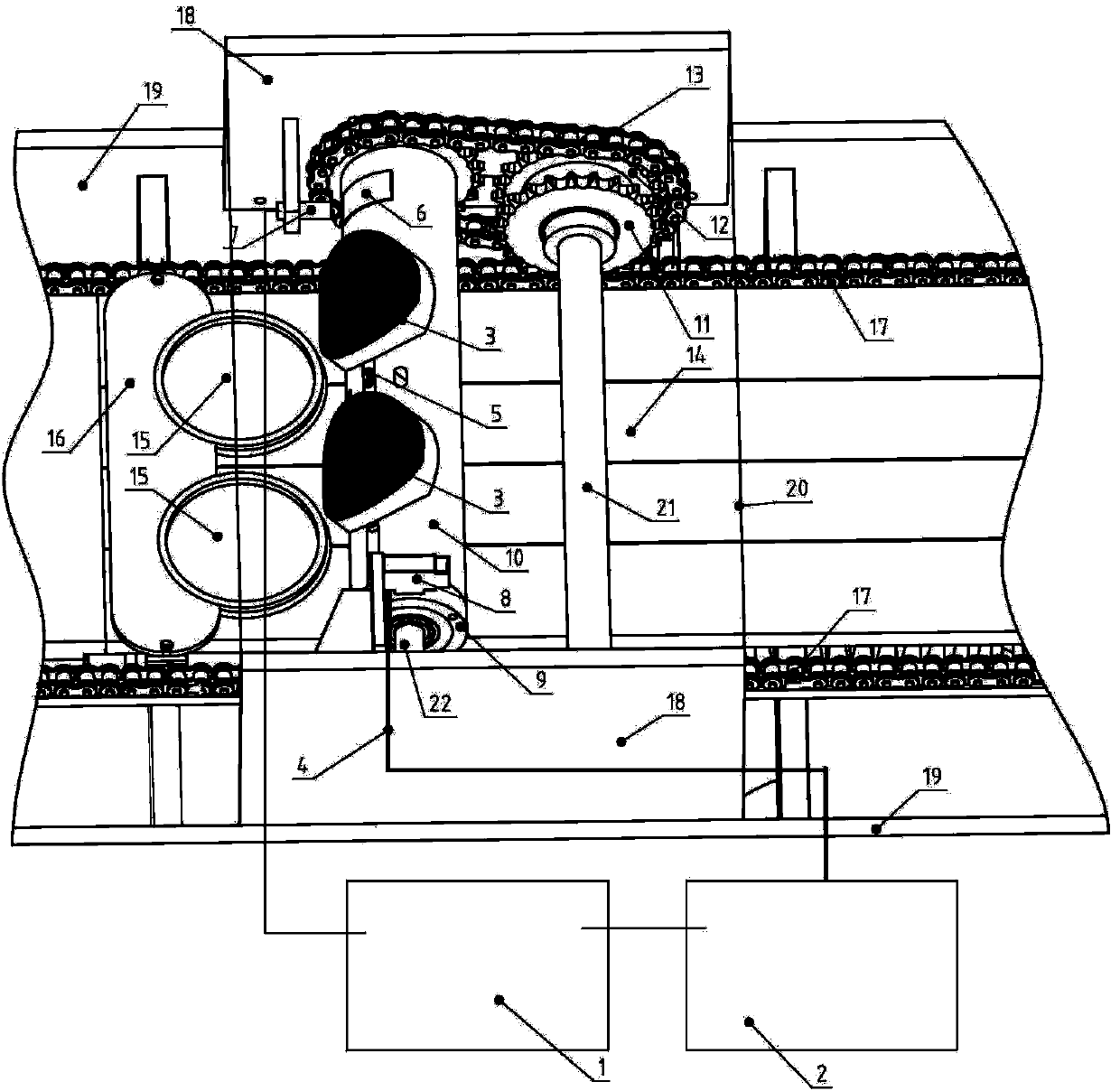

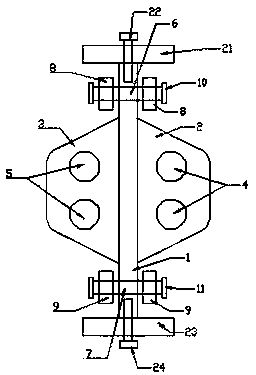

Preparation process and device of vitamin D3 microcapsule powder

ActiveCN104306353AImprove liquidityGreat tasteOrganic active ingredientsPressurized chemical processCalcium biphosphateSolubility

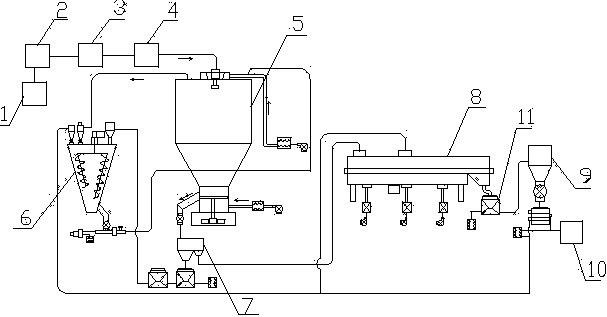

The invention relates to a preparation process and a preparation device of vitamin D3 microcapsule powder. In the preparation process, VD3 oil, sunflower seed oil or corn oil, medicinal starch, maltodextrin, modified starch, white sugar, calcium phosphate and 2,6-di-t-buty-4-methylphenol (BHT) are used as main raw materials. The preparation process and the preparation device are reasonably improved and optimized, the production time is greatly shortened and the whole production process is controlled; through layer-by-layer drying and step-by-step recycling, the prepared vitamin D3 microcapsule powder has smooth and flat surface, and the safety, the fluidity, the mouth feel and the water solubility of the vitamin D3 microcapsule powder are greatly improved; the waste of resources is reduced, the continuous large-scale production is implemented, and the production cost is reduced.

Owner:豆源和(山东)食品饮料有限公司

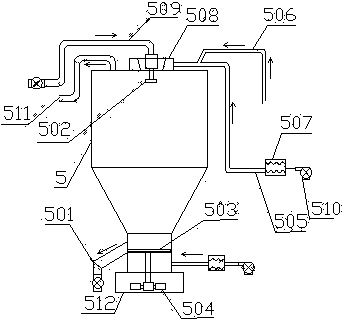

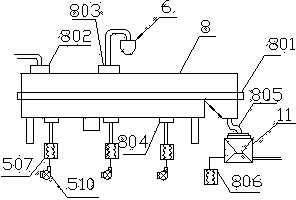

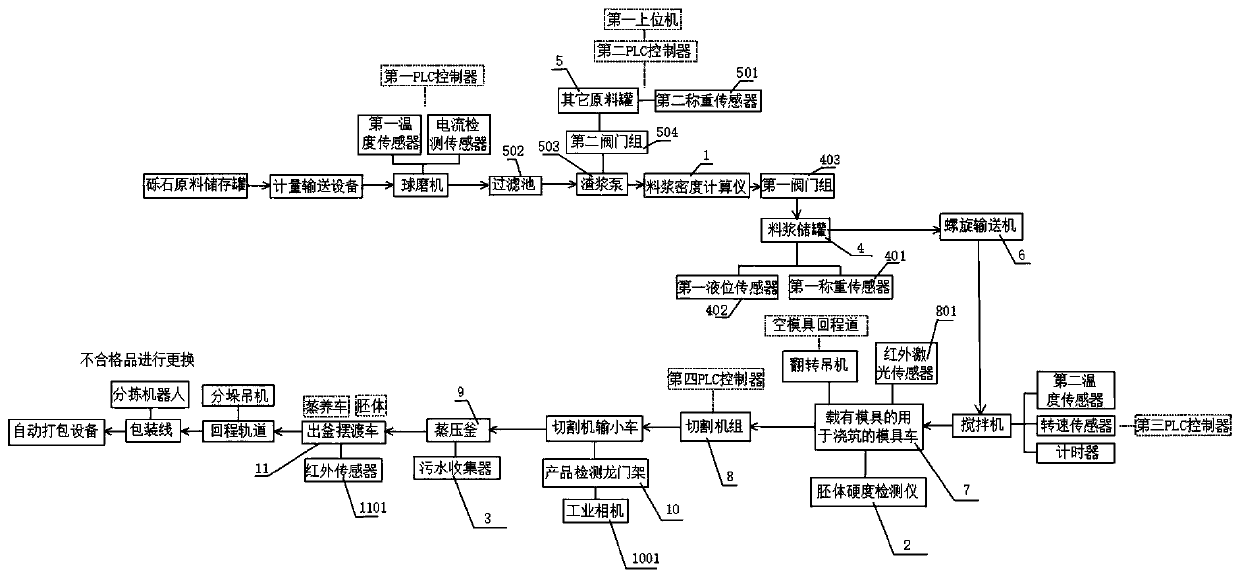

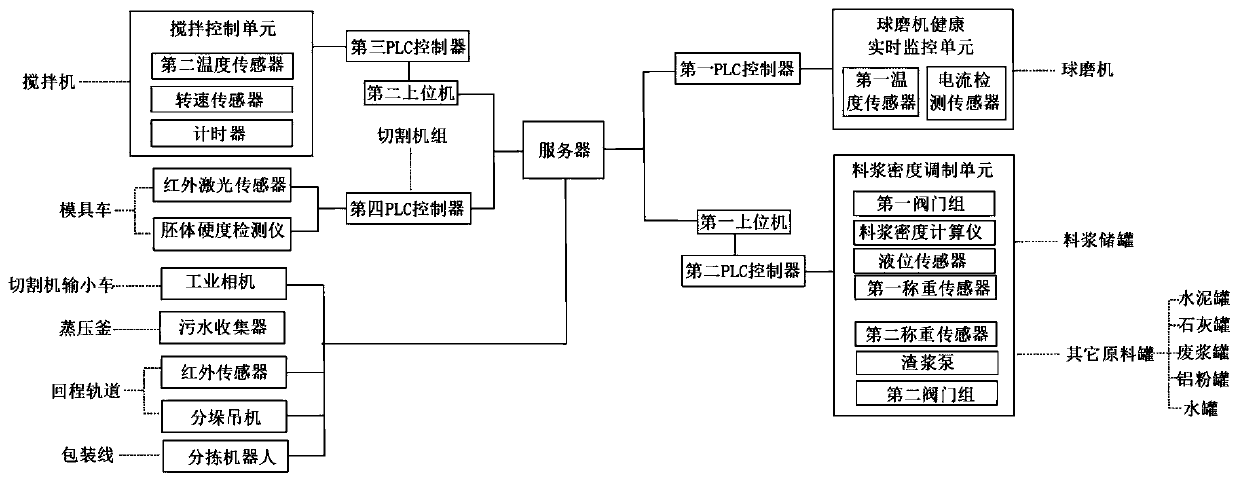

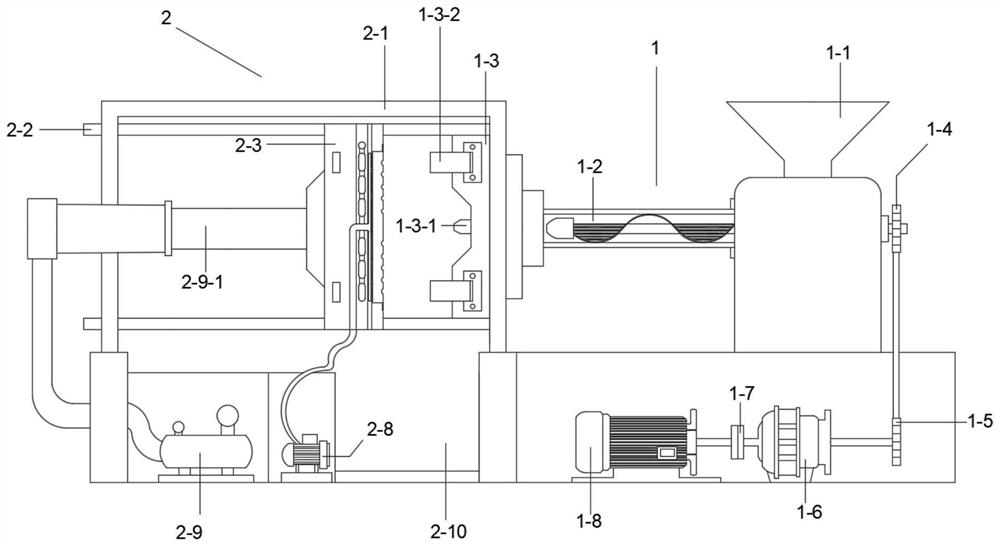

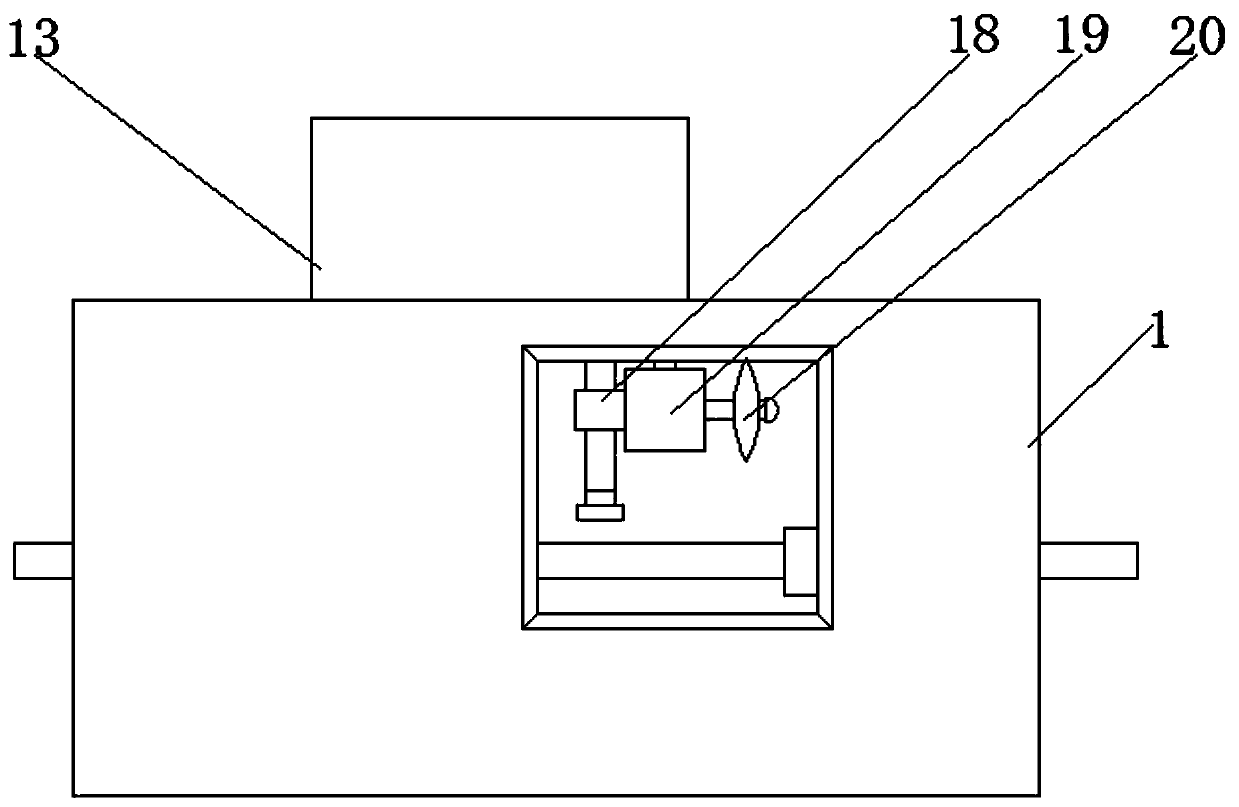

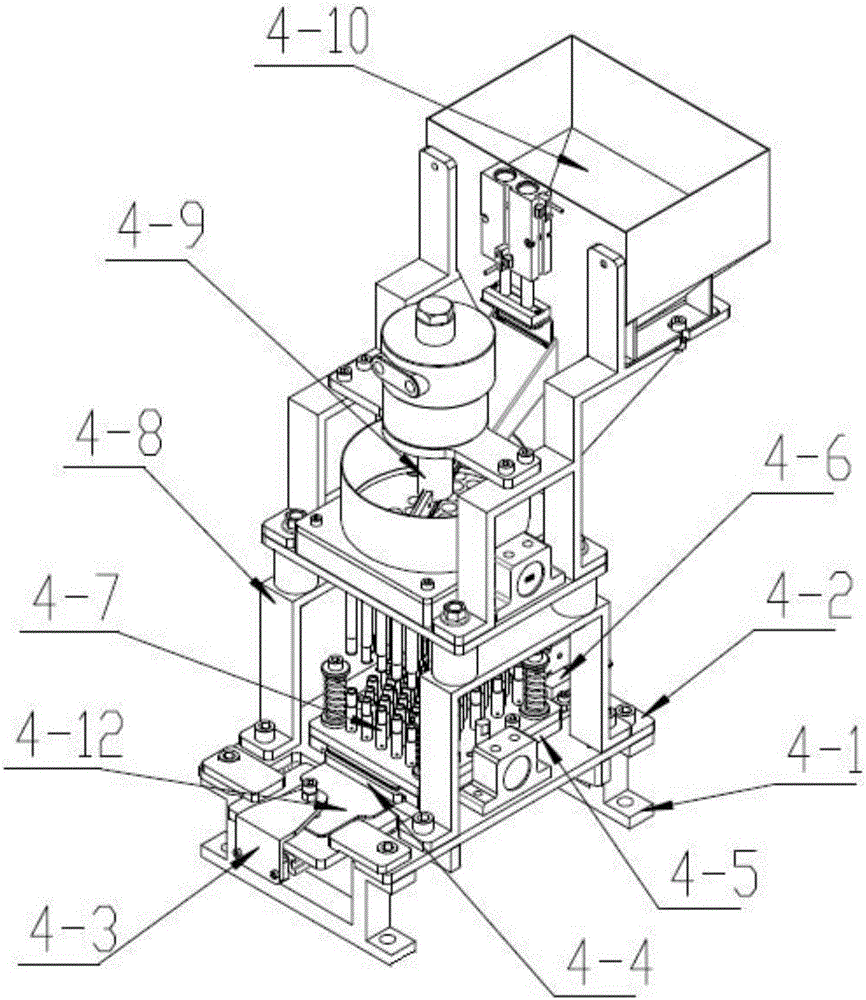

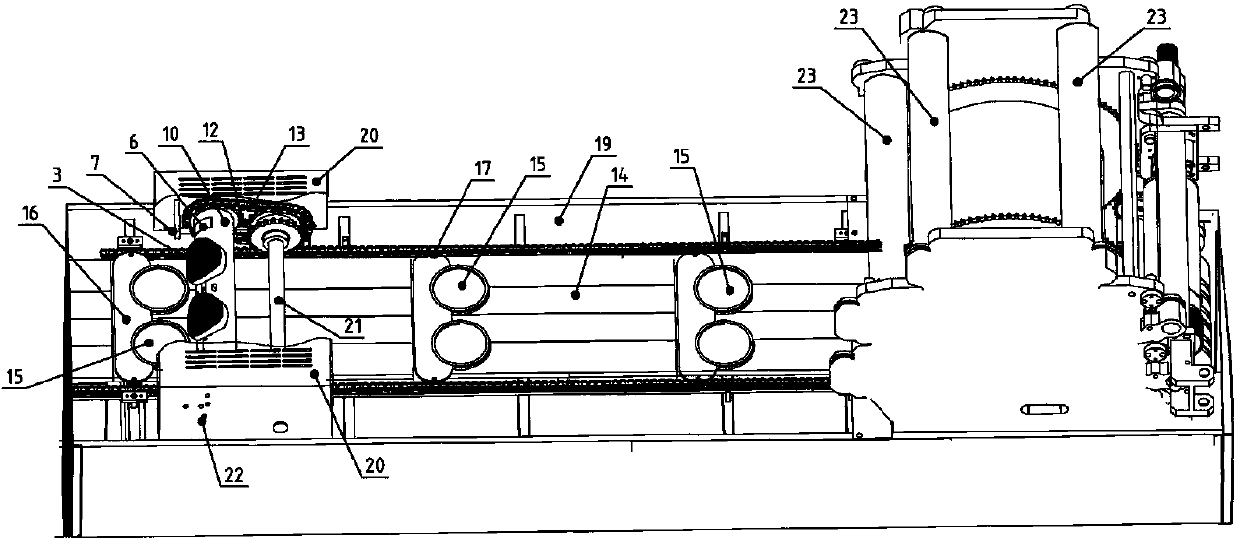

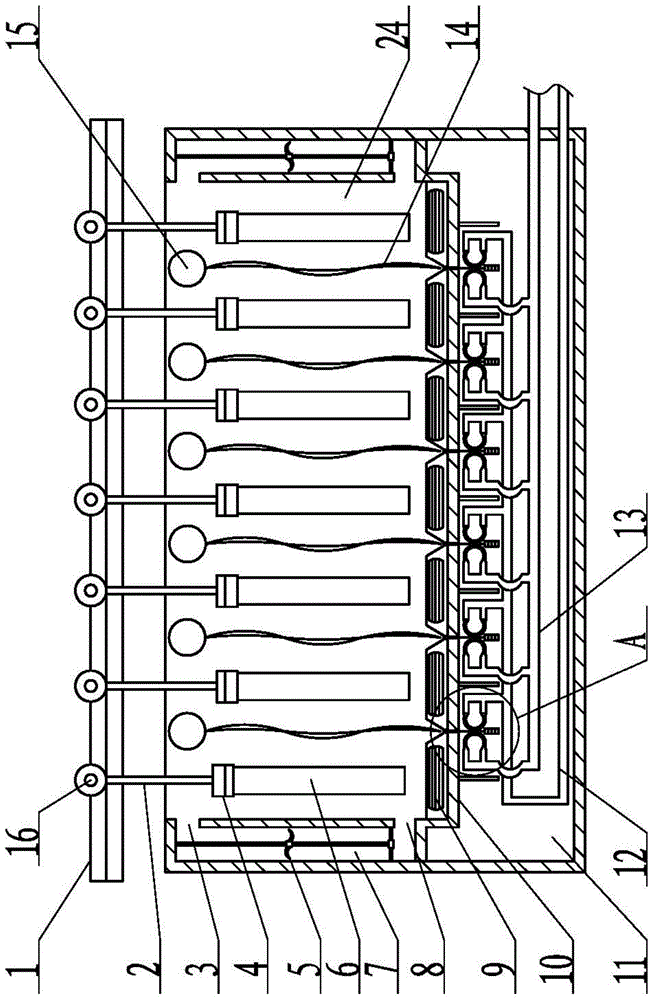

Autoclaved aerated concrete product production line system and control method thereof

PendingCN111231094ARealize automatic controlImprove efficiencyMixing operation control apparatusCeramic shaping plantsControl cellLaser sensor

The invention discloses an autoclaved aerated concrete product production line system and a control method thereof, and relates to the technical field of autoclaved aerated concrete manufacturing. A ball mill health real-time monitoring unit is arranged in a ball mill. A stirring control unit is arranged in a stirrer. The ball mill ball mill health real-time monitoring unit is connected with a system control server through a first PLC, a slurry density modulation unit is connected with the system control server through a second PLC and a first upper computer, the stirring control unit is connected with the system control server through a third PLC and a second upper computer, and an infrared laser sensor and a green body hardness detector are connected with the system control server through a fourth PLC, an industrial camera, a sewage collector, an infrared sensor, a stacker crane and a sorting robot. The system solves the problems of low operation efficiency, low safety and reliability, low productivity and the like caused by manually controlling equipment operation of a production line. The production and allowable cost of an enterprise is reduced through differential control metering and the like.

Owner:芜湖誉路智能装备有限公司

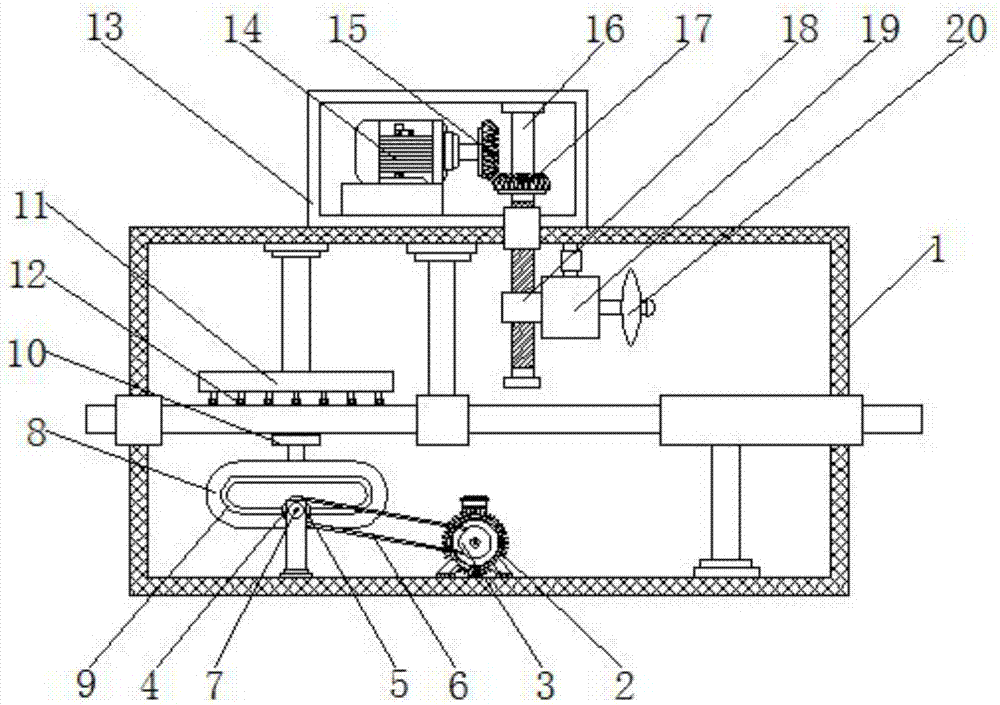

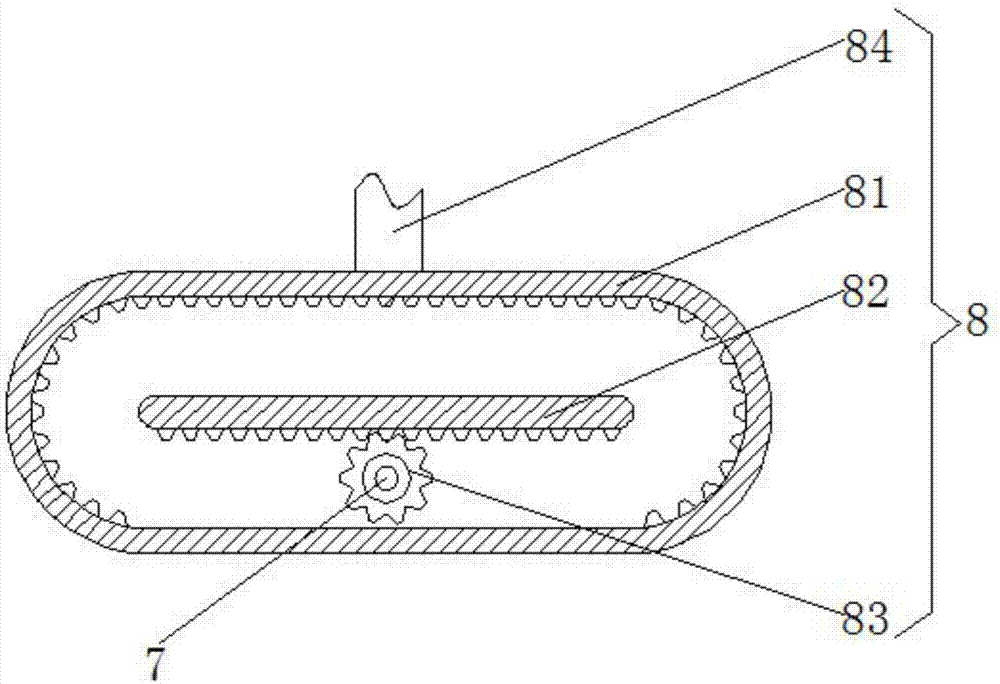

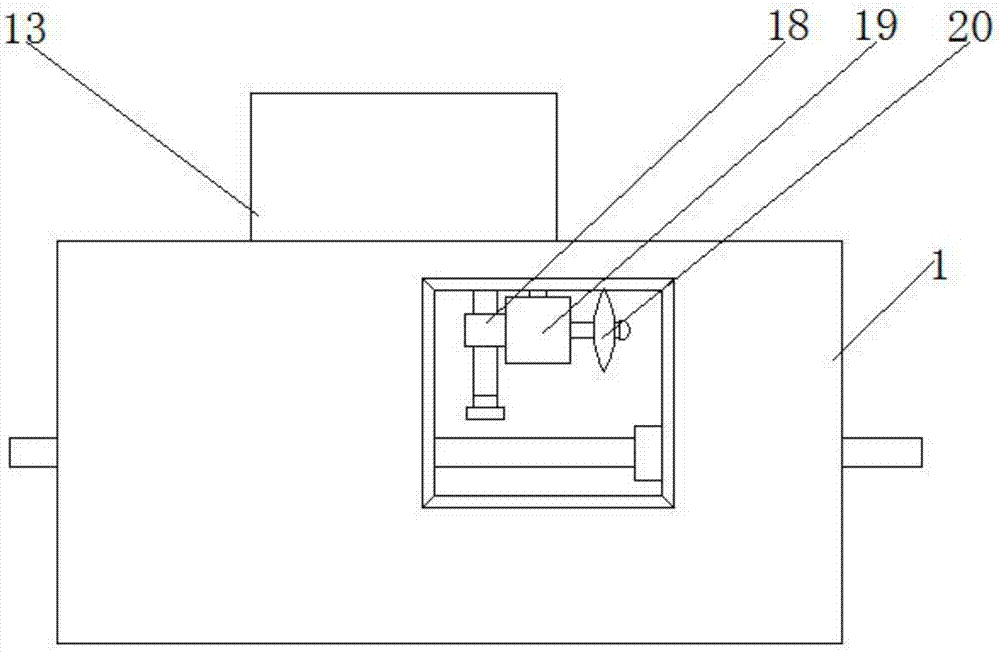

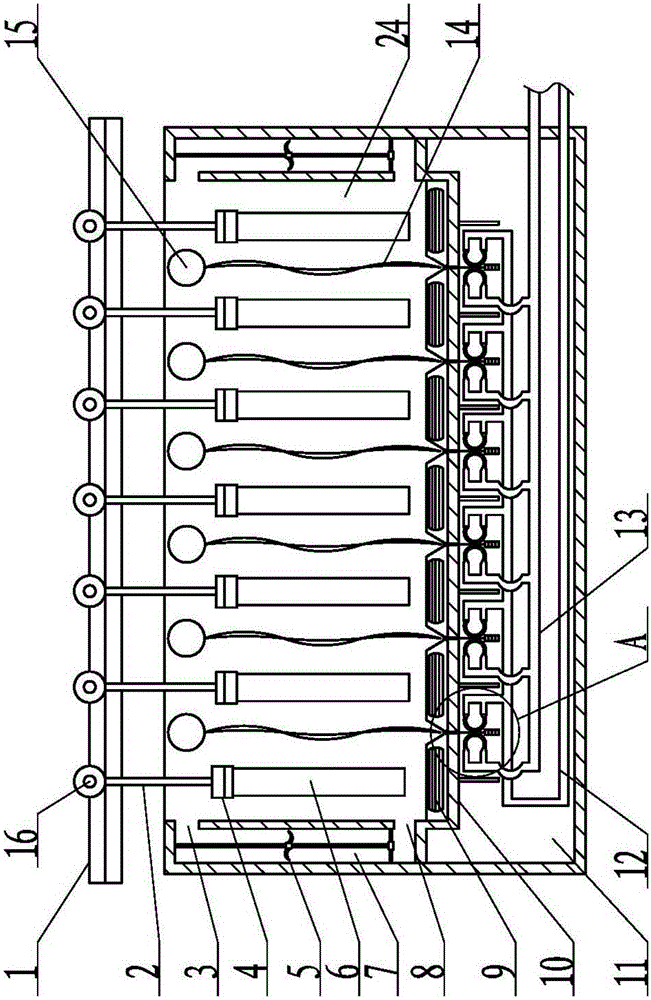

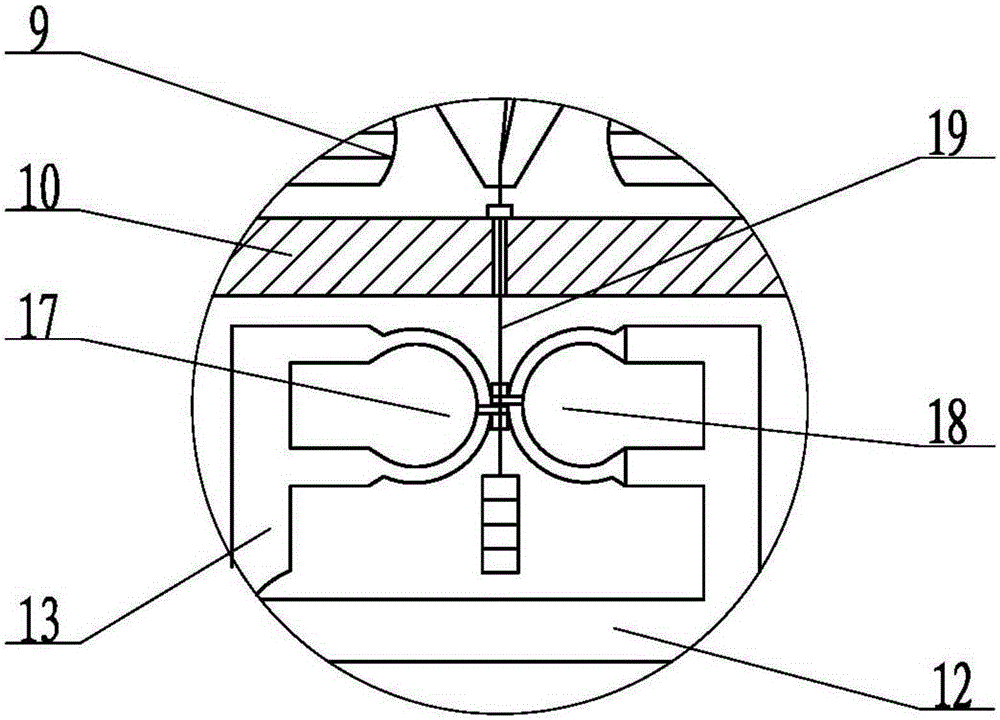

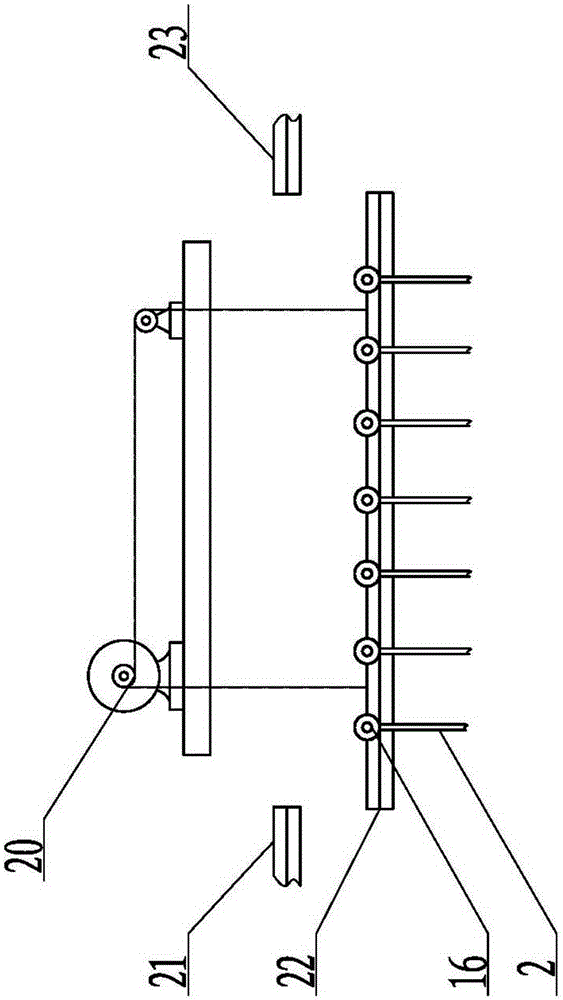

Automatic pipeline cutting machine for electrical equipment

ActiveCN107378096AReach automatic pushImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringElectrical equipment

The invention discloses an automatic pipeline cutting machine for electrical equipment, and relates to the technical field of electrical equipment. The automatic pipeline cutting machine comprises a box body. The bottom of the inner wall of the box body is fixedly connected with a first motor. The surface of an output shaft of the first motor is sleeved with a first belt wheel. The left side of the bottom of the inner wall of the box body is rotationally connected with a rotary rod through a connecting rod. The surface of the rotary rod is sleeved with a second belt wheel. The surface of the second belt wheel is in transmission connection with the surface of the first belt wheel through a belt. A rotating rod is fixedly connected to the surface of the axis of the back face of the second belt wheel. The end, away from the second belt wheel, of the rotary rod is in sliding connection with a transmission device. According to the automatic pipeline cutting machine for the electrical equipment, a pipeline is pushed automatically, workers are prevented from doing manual pushing, production potential safety hazards caused by manual cutting are avoided, the efficiency of cutting the pipeline is greatly improved, and the overall pipeline machining efficiency is improved.

Owner:宜兴市苏哈电力设备有限公司

Tobacco drying machine and tobacco drying room

InactiveCN105495673BPrecise control of temperature and humidityAffect qualityTobacco preparationProcess engineeringEngineering

The invention discloses a tobacco dryer and a tobacco drying room. The tobacco dryer comprises a case shell, a compressor, a mixing condenser, an evaporator and a throttling device. The compressor, the mixing condenser, the evaporator and the throttling device are arranged in the case shell and communicated through a pipe to form a circulation system. The evaporator is arranged towards the outside of the tobacco drying room, and an evaporator heat-exchange fan is arranged on the evaporator. The mixing condenser is arranged towards the inside of the tobacco drying room, and a drying circulation heat-exchange fan is arranged on the mixing condenser. A traditional coal fuel heating type tobacco heating energy consumption mode is changed, the effects of energy conservation and emission reduction and reduction of environmental pollution can be achieved, potential production safety hazards in the traditional coal fuel heating type drying mode are avoided, precise control over the temperature and humidity in the tobacco drying room can be achieved, the influence on tobacco quality due to loss of essence during tobacco drying caused by exhaust and dehumidification is prevented, and accordingly quality of finished tobacco is guaranteed.

Owner:曾文

A kind of perfluorooctanoic acid-free fluorine-containing surfactant and its preparation method and process system

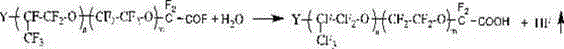

ActiveCN105170018BSolve pollutionPromote decompositionPreparation from carboxylic acid halideTransportation and packagingProcess systemsPerfluorooctanoic acid

The invention discloses a fluorine-containing surfactant without perfluorooctanoic acid and its preparation method and process system. A repeating structural unit with a carboxyl group or a carboxylate at one end formed by one or more combinations of radicals and oxygen perfluorovinyl groups. The fluorine-containing surfactants involved in the present invention have a C-O-C ether bond structure Fluoropolymer is the main structure. It can be seen from the indicators that this fluorosurfactant does not contain perfluorooctanoic acid and its salts with an 8-carbon linear structure. It is easily decomposed in nature and has been proven to be harmless to the human body. , the peroxide value satisfies 0.001-1%, the surface tension satisfies 10-30mN / m, and has the amphiphilic structure of surfactant.

Owner:成都晨光博达新材料股份有限公司

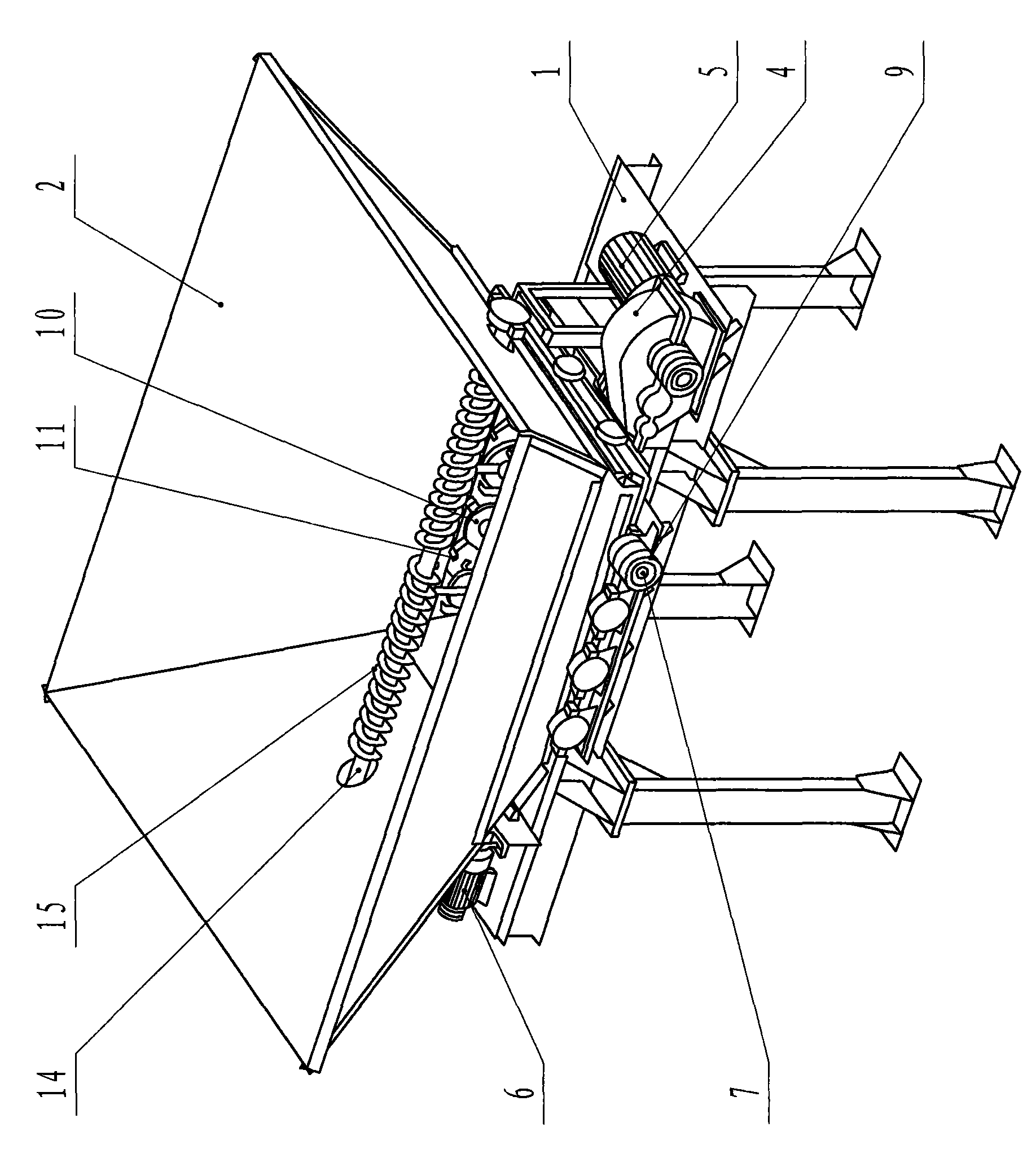

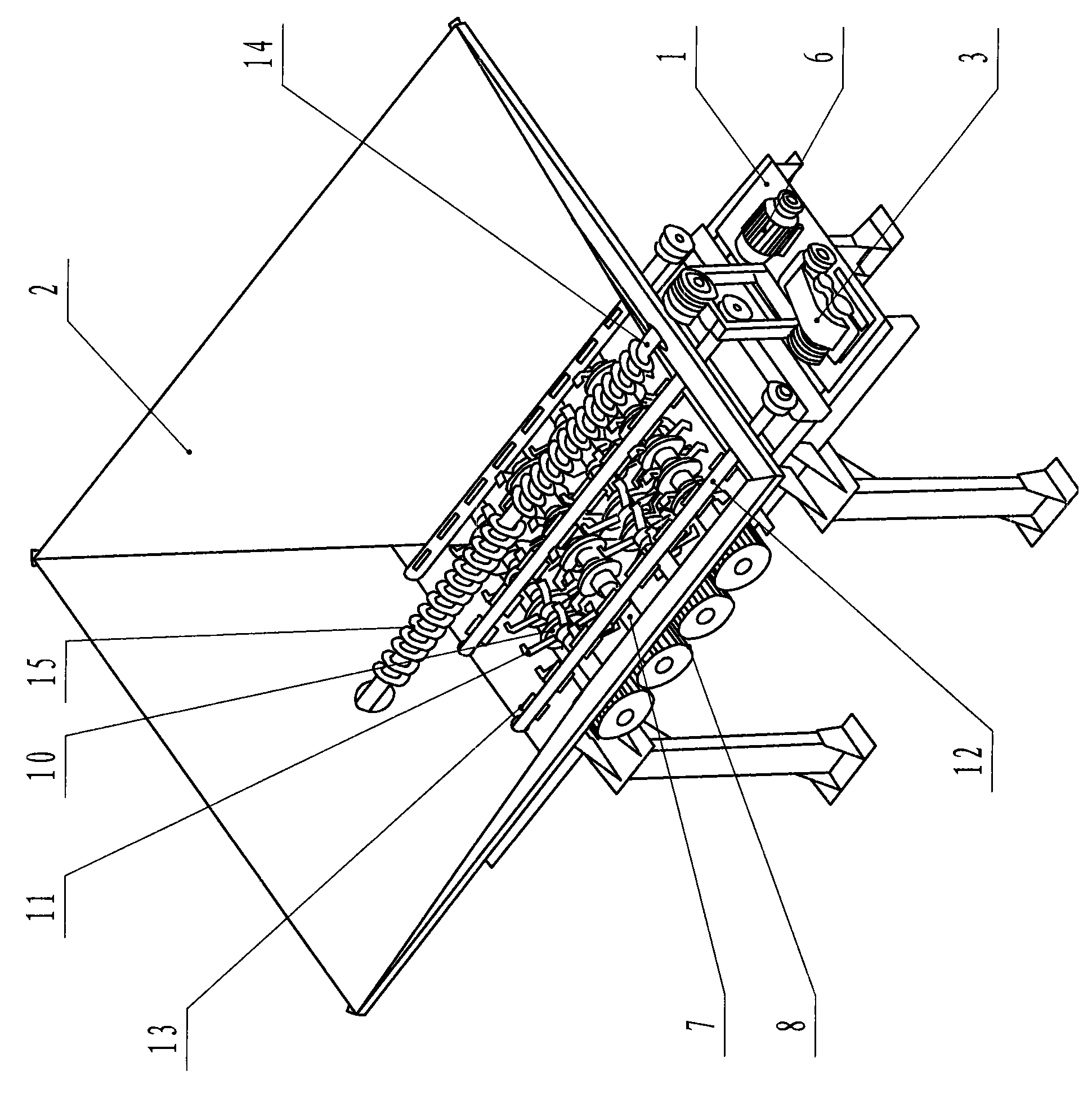

Material boiling device for bamboo bone of folding fan and boiling technique thereof

InactiveCN105150326AAvoid settling and cokingImprove cooking qualityReed/straw treatmentWood impregnation detailsBone fixation devicesBiomedical engineering

The invention discloses a material boiling device for a bamboo bone of a folding fan and a boiling technique thereof, and belongs to the field of mechanical automation equipment. The material boiling device is characterized by comprising a bamboo bone conveying device, a bamboo bone fixing device and a branch knot removing linear cutting tool. Because of the growth characteristic of bamboos, branch knots only grow in the positions of bamboo knots. By the adoption of the device, the middle of the bamboo bone can be clamped, and then the branch knots at the two ends of the bamboo bone are treated through rotation of the bamboo bone by a reversing motor. The technique is simple, and processing reliability and precision are both excellent.

Owner:重庆臻冠科技有限公司

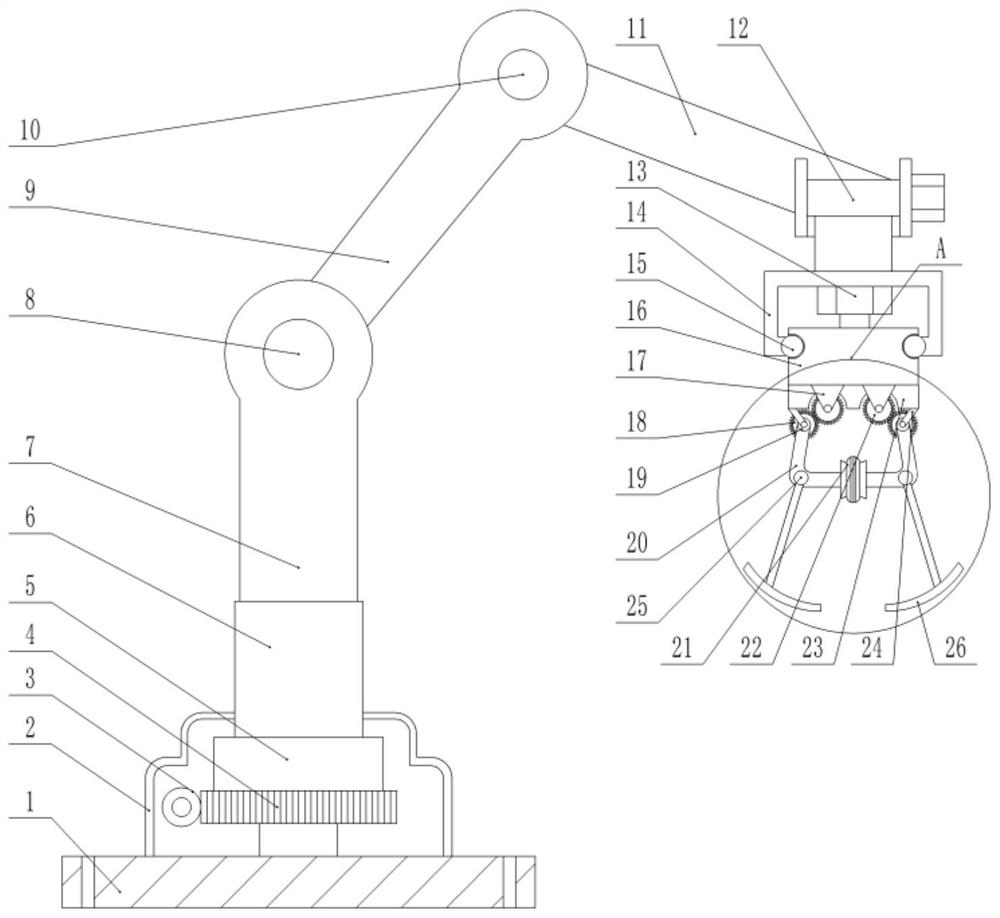

Six-degree-of-freedom manipulator firm in grabbing and capable of preventing sliding

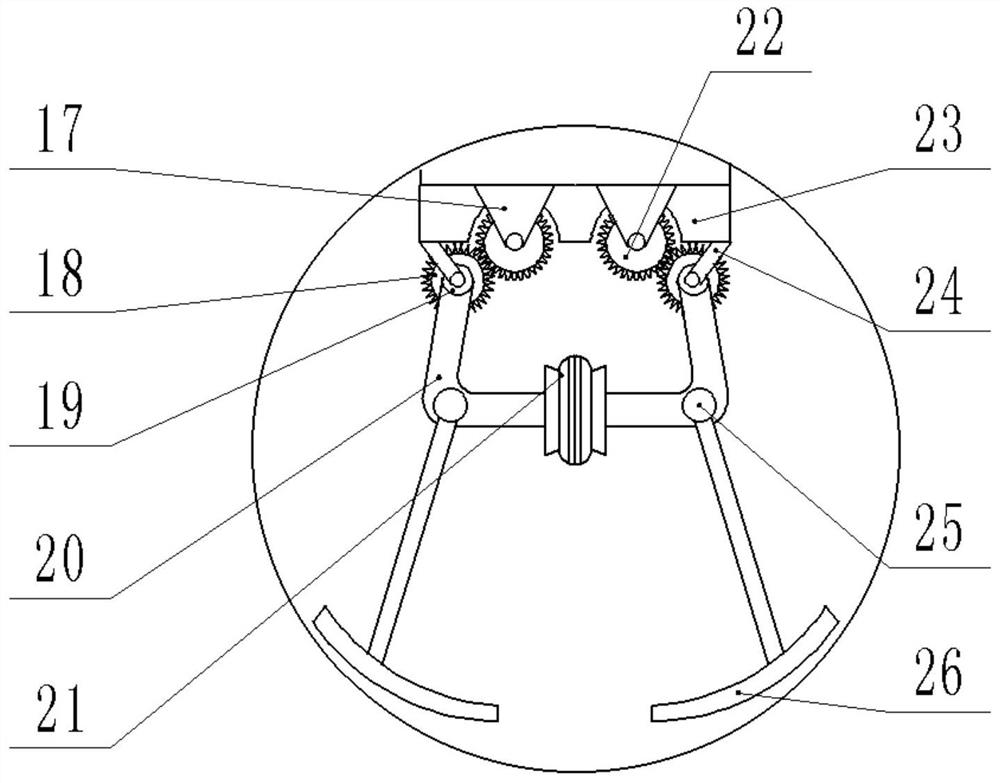

PendingCN111791249AIncrease clamping forceIncrease flexibilityGripping headsArmsRobot handElectric machine

The invention provides a six-degree-of-freedom manipulator firm in grabbing and capable of preventing sliding. The six-degree-of-freedom manipulator comprises a base and is characterized in that a rotating shell is fixedly connected to the base, a rotating assembly is installed in the rotating shell, a motor is fixedly connected to the center in a connecting support, a rotating base is coaxially installed at the rotating end of the motor, a mounting base is fixedly connected to the bottom of the rotating base, left and right corresponding grippers are arranged below the mounting base, the opposite ends of the left and right grippers are fixedly connected with pressing plates, and pressure sensors are mounted on the pressing plates. According to the six-degree-of-freedom manipulator, fastening anti-slip assemblies and the pressure sensors are arranged on the left gripper and the right gripper, so that the clamping force of the six-degree-of-freedom manipulator is effectively enhanced, goods slip caused by insufficient gripping force of the grippers is avoided in the goods clamping process, potential production safety hazards are prevented, and the use requirements are well met; andin addition, the rotating assembly and a lifting electric cylinder are arranged on the base, so that the flexibility of the six-degree-of-freedom manipulator is enhanced.

Owner:GUOREN ROBOT TIANJIN CO LTD

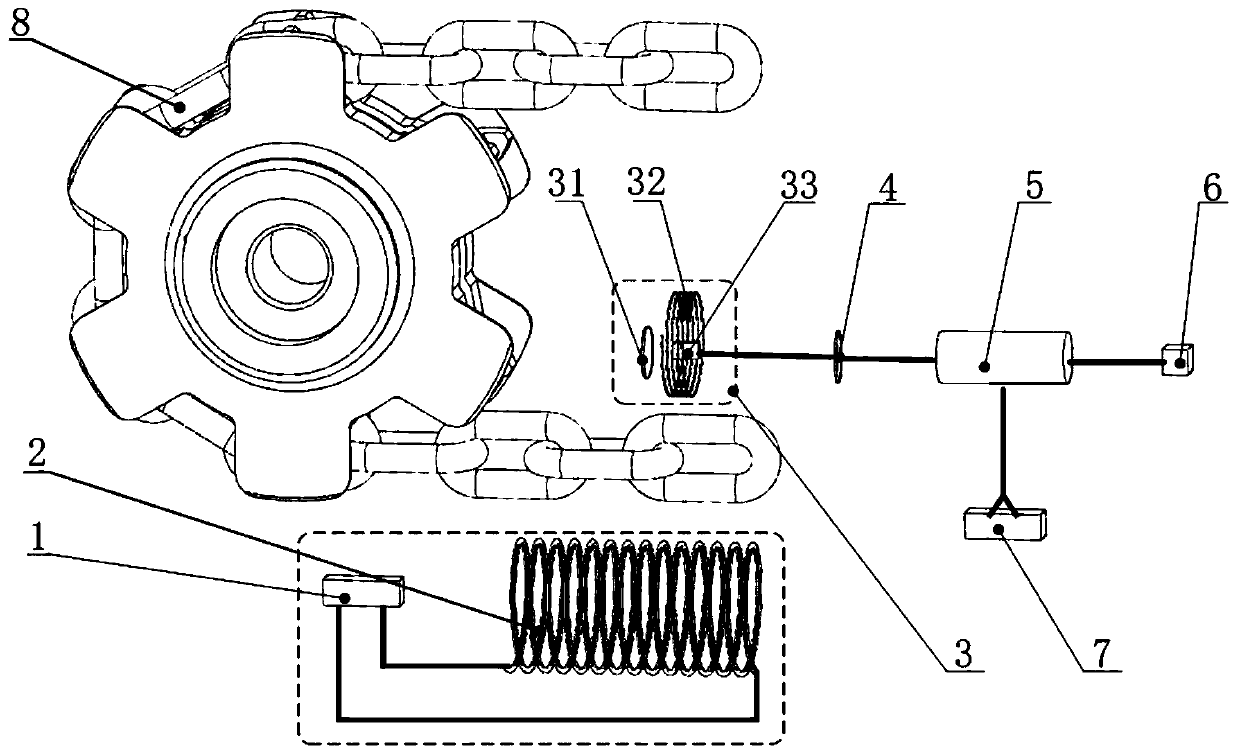

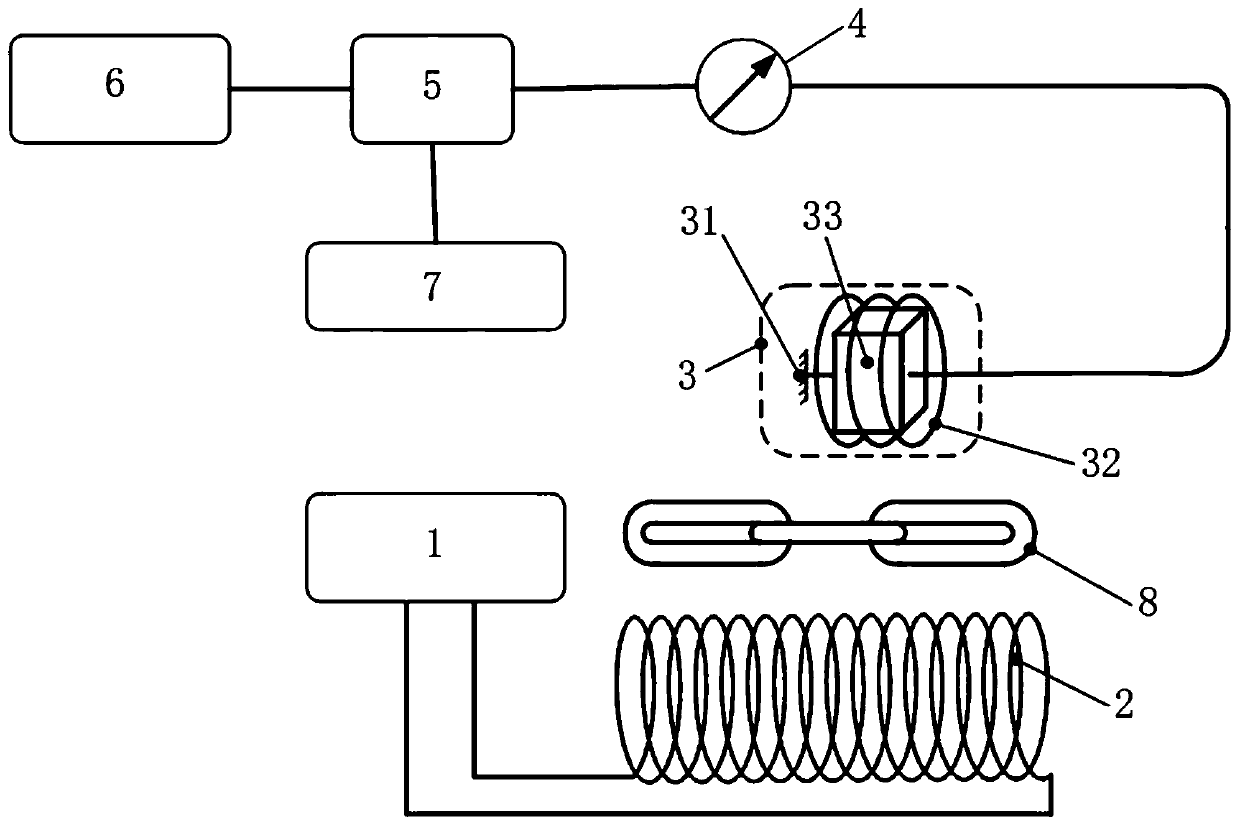

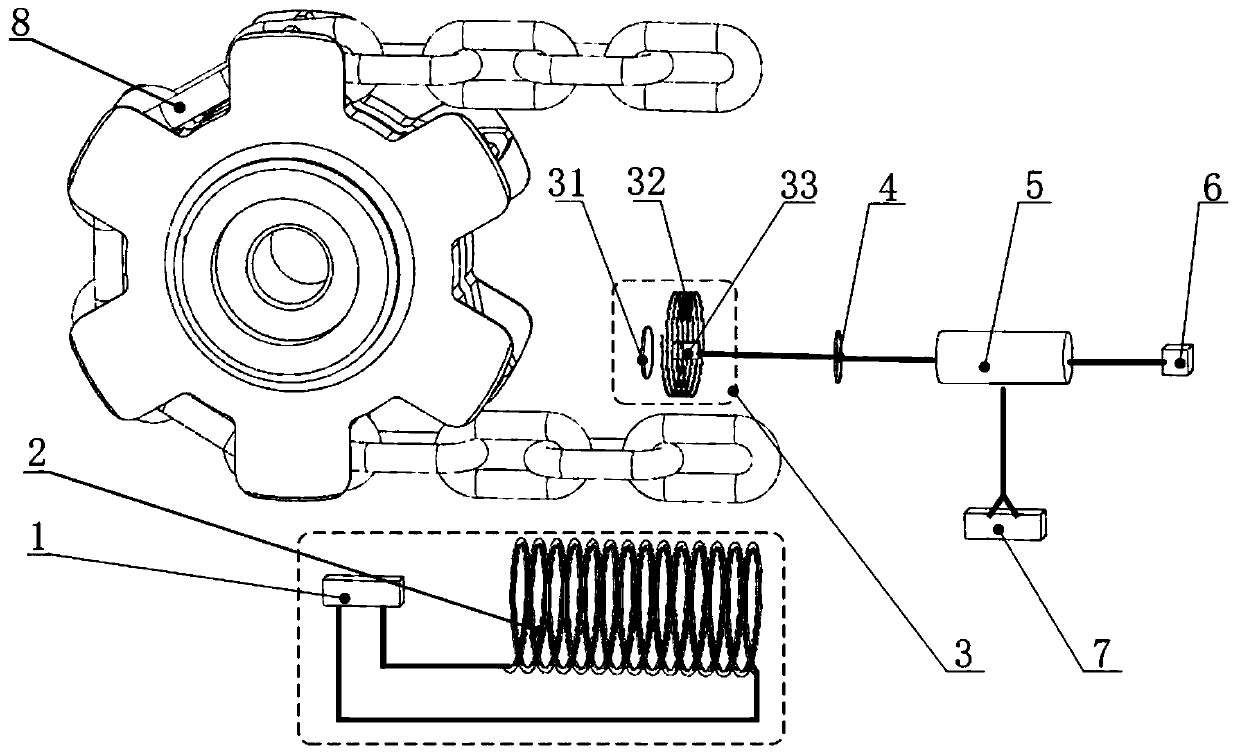

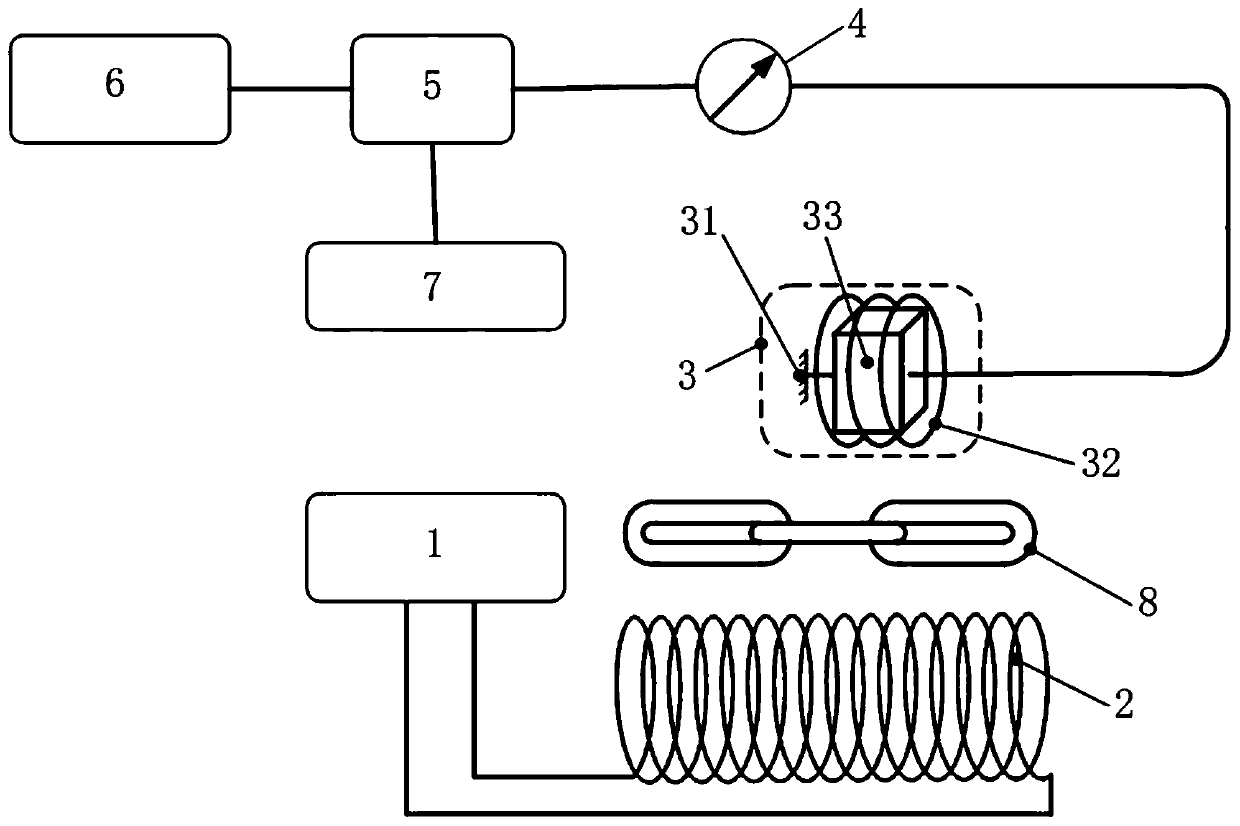

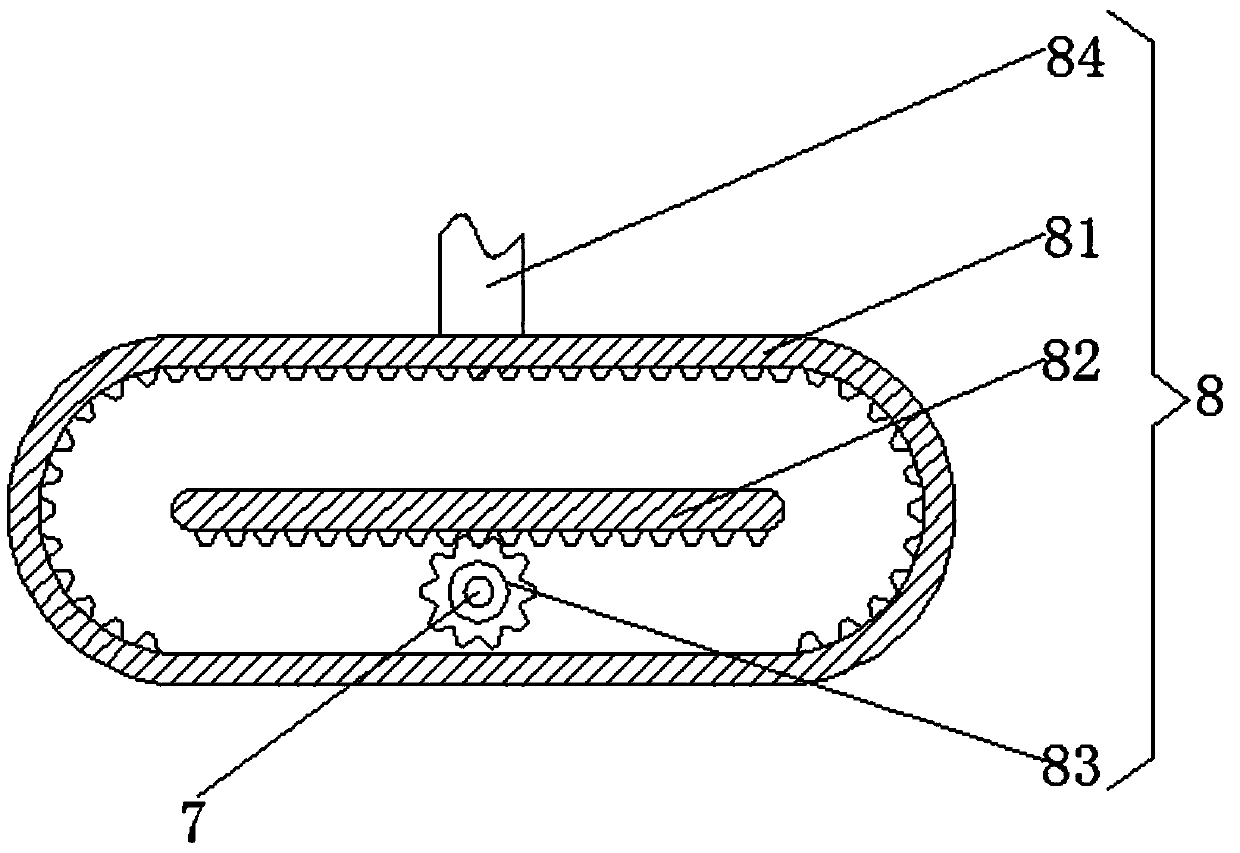

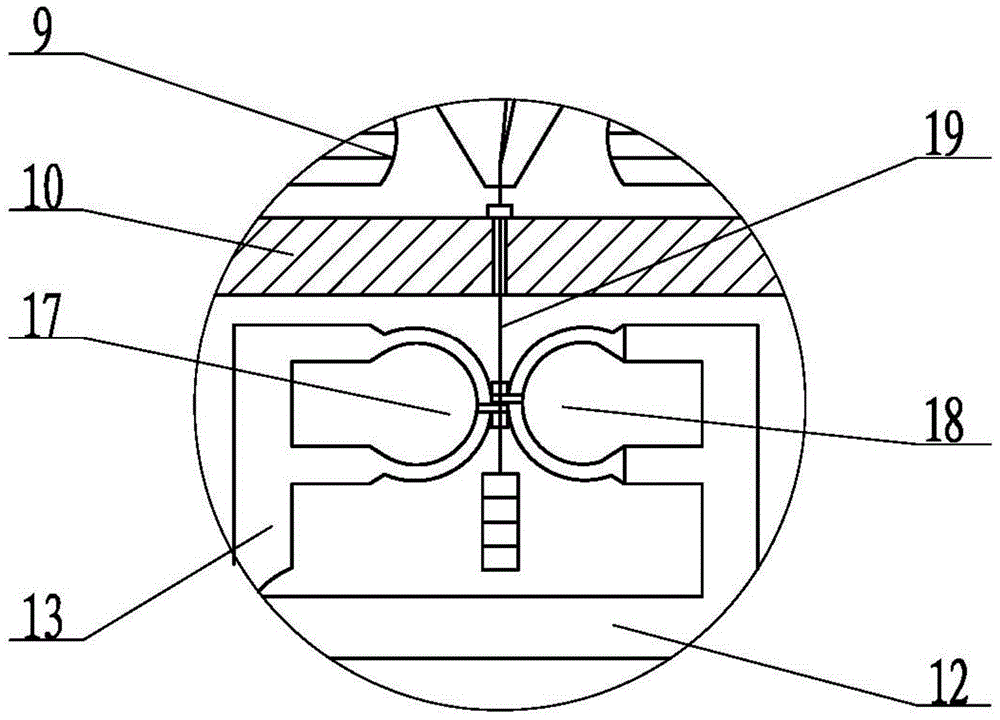

Fully-mechanized mining face scraper conveyor chain state detection device and method

ActiveCN110498188AValid detection status informationSafe and stable operationConveyorsControl devices for conveyorsPolarizerCoal

The invention discloses a fully-mechanized mining face scraper conveyor chain state detection device and method, and relates to the technical field of chain detection. The detection device comprises amagnetic field generation device and a magnetic field detection device. The magnetic field generation device comprises an adjustable direct-current source and a multi-turn coil. The magnetic field detection device comprises a detection probe, a polarizer, an optical fiber circulator, a broadband light source and a photoelectric detector. The detection probe comprises a reflection mirror, a magnetic induction coil and a magneto-optic crystal. The detection probe gets close to a chain through an adjustment support to achieve online detection. According to the fully-mechanized mining face scraper conveyor chain state detection device and method, the scraper conveyor chain is magnetized firstly, mutual inductance is generated between a leakage magnetic field generated by chain defects and themagnetic induction coil of the detection probe, a magnetic signal generated by mutual inductance in the magnetic induction coil is converted into an optical signal in the magneto-optic crystal, the optical signal is then converted into an electrical signal, a state signal of the chain is obtained through signal processing, real-time online detection of the chain can be achieved, it is ensured that a scraper conveyor safely and stably operates, and coal mine production potential safety hazards are avoided.

Owner:CHINA UNIV OF MINING & TECH

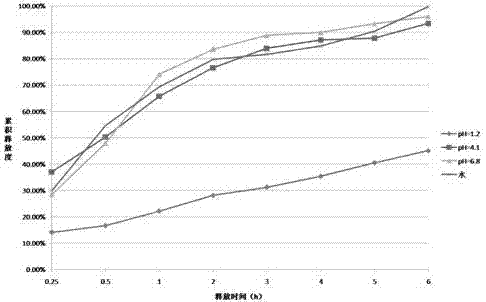

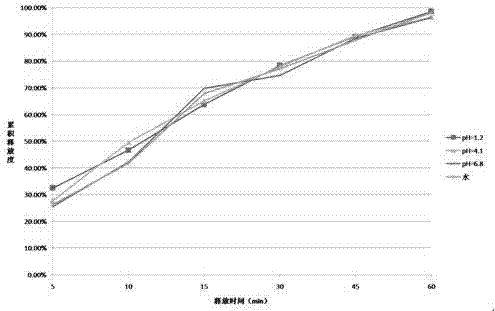

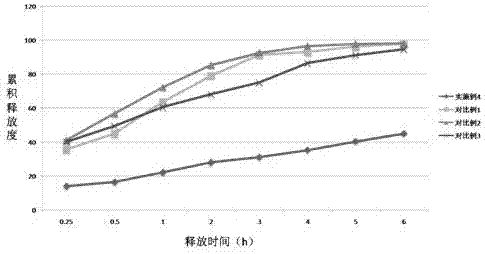

Tilmicosin sustained release enteric-coated powder, preparation method and application thereof

ActiveCN106924189AEasy to passGuaranteed releaseAntibacterial agentsPowder deliveryGLYCERYL PALMITATECellulose acetate

The invention discloses a tilmicosin sustained release enteric-coated powder, a preparation method and application thereof. The tilmicosin sustained release enteric-coated powder comprises the following components by mass percentage: 5-40% of tilmicosin; 10-50% of a hydrophobic carrier; and 20-60% of an enteric material. Specifically, the hydrophobic carrier is one or more of cholesterol, palmitin or castor oil wax; the enteric material includes one or more of cellulose acetate phthalate, hydroxypropyl methyl cellulose phthalate or polyacrylic resin II. According to the tilmicosin sustained release enteric-coated powder provided by the invention, on the one hand, drugs are included in the hydrophobic carrier, and the palatability of enteric-coated powder is improved; and on the other hand, the acid resistance of the drugs is improved, so that drugs can be disintegrated and released after reaching the intestinal environment, the plasma concentration in livestock is relatively stable, the cardiotoxicity of tilmicosin is greatly reduced, at the same time, the effective plasma concentration maintenance time is significantly prolonged, the times of administration is reduced, and man power is saved.

Owner:SOUTH CHINA AGRI UNIV

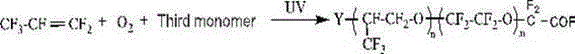

Production technology for preparing fluorine-containing surfactant free from perfluoro caprylic acid

InactiveCN105148794ASolve pollutionPromote decompositionTransportation and packagingMixingPerfluorooctanoic acidOxygen

The invention discloses a production technology for preparing a fluorine-containing surfactant free from perfluoro caprylic acid. The production technology includes the steps of photooxidation, hydrolysis, peroxide removing treatment and neutralization, perfluoroolefine, oxygen and a third monomer serve as reaction raw materials and are prepared into a fluorine-containing surfactant finished product with a C-O-C ether bond structure as the structural body, the finished product index meets the requirement that the surfactant is free from perfluoro caprylic acid and salts thereof, the surfactant is easy to decompose in the nature, the finished product index meets the data range that the peroxide value is 0.001-1%, and the surface tension is 10-30 mN / m; the fluorine-containing surfactant is of an amphiphilic structure of surfactants and suitable for industrial mass production.

Owner:成都晨光博达新材料股份有限公司

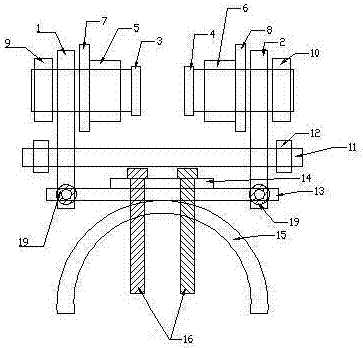

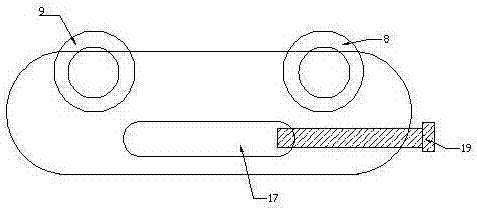

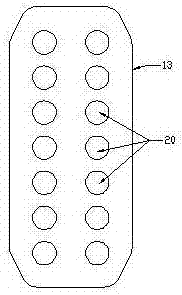

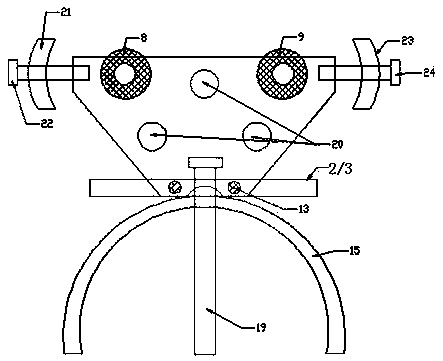

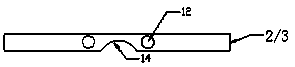

Overhead rail pulley assembly for assembling streamline

The invention belongs to the technical field of application of goods hoisting assembly accessories, and particularly discloses an overhead rail pulley assembly for assembling streamline. The overhead rail pulley assembly comprises a left supporting plate, a right supporting plate, a group of first roller assemblies, a group of second roller assemblies, horizontal supportive connecting plates, and adjusting and supporting assemblies, wherein the group of first roller assemblies and the group of second roller assemblies are respectively arranged on the left supporting plate and the right supporting plate, the horizontal supportive connecting plates are respectively connected with the left supporting plate and the right supporting plate, the adjusting and supporting assemblies are matched with the horizontal supportive connecting plates for use, porous grooves are respectively formed in the left supporting plate and the right supporting plate correspondingly, the horizontal supportive connecting plates are connected with the left supporting plate and the right supporting plate through the porous grooves. The overhead rail pulley assembly has the beneficial effects of being reasonable in an overall stainless steel structure design, strong in toughness and excellent in corrosion resistance and wear resistance, the group of first roller assembly and the group of second roller assembly can ensure the running stability and high efficiency of the overall structure, and the adjusting and supporting assembly can ensure the conveying stability of hoisted goods or products and completely eradicate the hidden production safety.

Owner:东台中海高温合金科技有限公司

Method for solving oxidation material rushing-out in preparation for oxalic acid by virtue of starch

InactiveCN102924261AAvoid punchingAvoid production safety hazardsOrganic compound preparationCarboxylic compound preparationOxalateCacodylic acid

The invention discloses a method for solving oxidation material rushing-out in preparation for oxalic acid by virtue of starch, comprising the following steps of: (1) hydrolyzing the starch in an acidic condition to prepare a monosaccharide liquid; (2) adding an oxalic acid crude product centrifugal mother liquid in a reaction container with an added amount which is 1 / 3-1 / 2 of the whole reaction volume, replenishing concentrated sulphuric acid in a volume which is 5-20% of the total volume of the monosaccharide liquid and a catalyst simultaneously, and then adding an initiator; and adjusting the temperature of the reaction system to be above 50 DEG C, and adding nitric acid in a volume by volume concentration of 50-90%; and (3) immediately adding the monosaccharide liquid obtained in the step (1) after the nitric acid and the initiator start to react, and enabling the nitric acid and saccharides to start to react, so as to generate the oxalic acid. The method disclosed by the invention has the beneficial effects that the material rushing-out phenomenon generated by the directly serious initiation of monosaccharides and the nitric acid during an initiation process in the starting phase of the traditional preparation for oxalic acid by virtue of a starch-nitric acid oxidation process is avoided, and the production potential safety hazards brought by the material rushing-out phenomenon aforementioned are thoroughly solved; and moreover, the method is extremely low in investment cost without influence on the cost of the oxalic acid, high in safety, convenient to operate and extremely easy to popularize.

Owner:HUBEI YITAI PHARMA

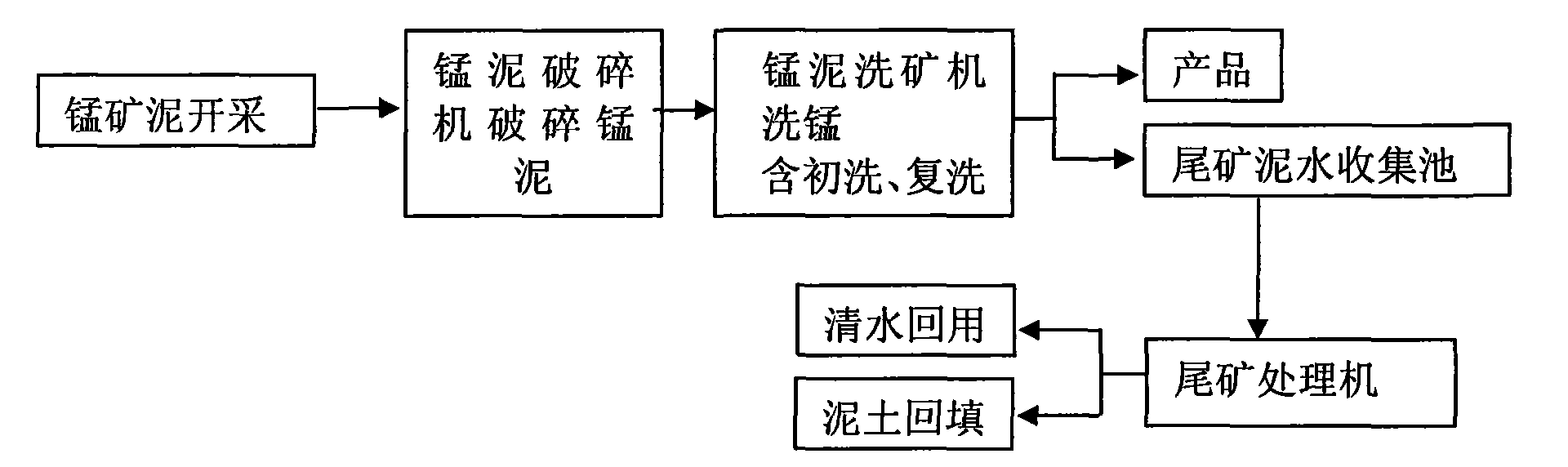

High-efficiency and energy-saving manganese washing process without arranging tailing pond or polluting environment

InactiveCN101628257AAvoid pollution effectsWon't breakGrain treatmentsWet separationManganeseWater resources

The invention discloses a high-efficiency and energy-saving manganese washing process without arranging a tailing pond and polluting the environment. The mined manganese slime is broken by a manganese slime breaking machine and then is washed by a manganese slime manganese-washing machine to obtain manganese ore, the water for washing the manganese slime enters a tailing slime water collecting tank and separated through a tailing treatment machine, the clean water is reused and the slime is back filled. The invention has the advantages that: firstly, the manganese washing is locally carried out after mining the manganese ore, therefore, the link of manganese ore slime transport is reduced and the production and transportation cost is reduced; secondly, water resources are saved and the pollution to the environment is also avoided due to the recycling of the manganese washing water; thirdly, no tailing pond is required, not only the land occupation is little, but also the original potential safety hazard of production of the tailing pond is overcome and the construction investment is reduced; and fourthly, the manganese slime breaking machine is additionally arranged, therefore, the problem that the large manganese slime cannot enter the machine before or the damage to the manganese washing machine is great is solved, and the ore washing efficiency is greatly improved by 35 percent than the original process efficiency.

Owner:陈星亮

Steel material texture detection method and device utilizing same

ActiveCN103357704AAvoid production safety hazardsReduce workloadMetal working apparatusNumerical controlProduction line

The invention discloses a steel material texture detection method and a device utilizing same, and is used for detecting a steel material texture of a workpiece during processing in a numerical control angle steel typing punching shearing production line / a numerical control plate material punching typing machine. The detection method includes the following steps: (1) arranging a pressure detection device on the numerical control angle steel typing punching shearing production line / the numerical control plate material punching typing machine, and employing the pressure detection device to acquire a pressure numerical value when the workpiece to be detected is punched; (2) building a standard punching pressure database of angle steel / plate materials with various textures in a microcomputer, comparing and judging the database with the acquired pressure numerical value, and displaying the judged result through a human-computer interaction interface of the microcomputer; and (3) when the judged result displayed in the human-machine interaction interface is inconsistent with the texture of the workpiece in a processing batch, starting an alarm device for alarm by the microcomputer, and reminding an operator to take out the problem workpiece. The detection method can detecting the texture of each angle steel or each plate material used in a production process, and is accurate and quick.

Owner:JINAN EVERSHINING CNC MACHINE

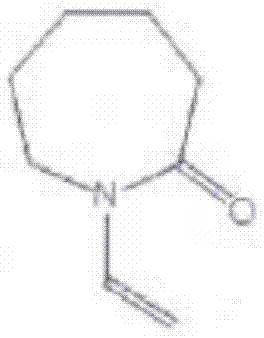

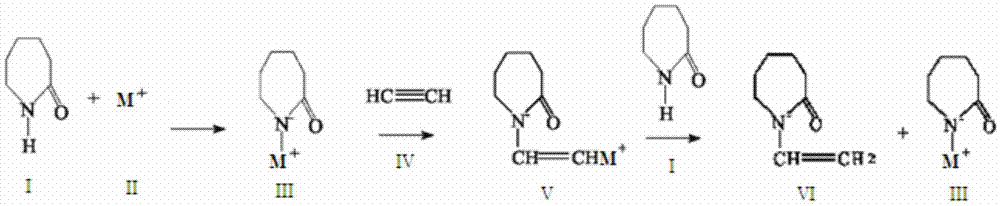

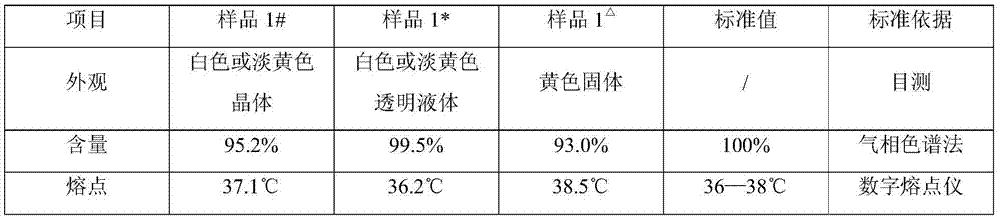

Vinyl caprolactam preparation method

ActiveCN106946778ASolve the problem of decomposition and deactivationEasy to removeOrganic chemistry methodsBulk chemical productionChemical industryDecomposition

The invention discloses a vinyl caprolactam preparation method, and belongs to the technical field of chemical industry production. According to the present invention, based on the nucleophilic addition reaction principle, vinyl caprolactam is subjected to low temperature synthesis through a one-pot method by using an alkali metal salt or alkali metal hydroxide as a catalyst and using acetylene and caprolactam as raw materials, and then the vinyl caprolactam having different purities is obtained through polar solvent recrystallization and vacuum distillation; and the preparation method has characteristics of simple process, simple operation, mild and controlled reaction condition, reaction conversion rate improving, product yield improving and production cost reducing, effectively solves the problem of catalyst decomposition deactivation caused by the presence of the water in the system, avoids the occurrence of the side reaction, and avoids the pollution of the organic solvent on the environment, and the obtained two products such as the crystal and the liquid have different appearance forms and different purities so as to conveniently package and use.

Owner:重庆晶粒化工有限公司

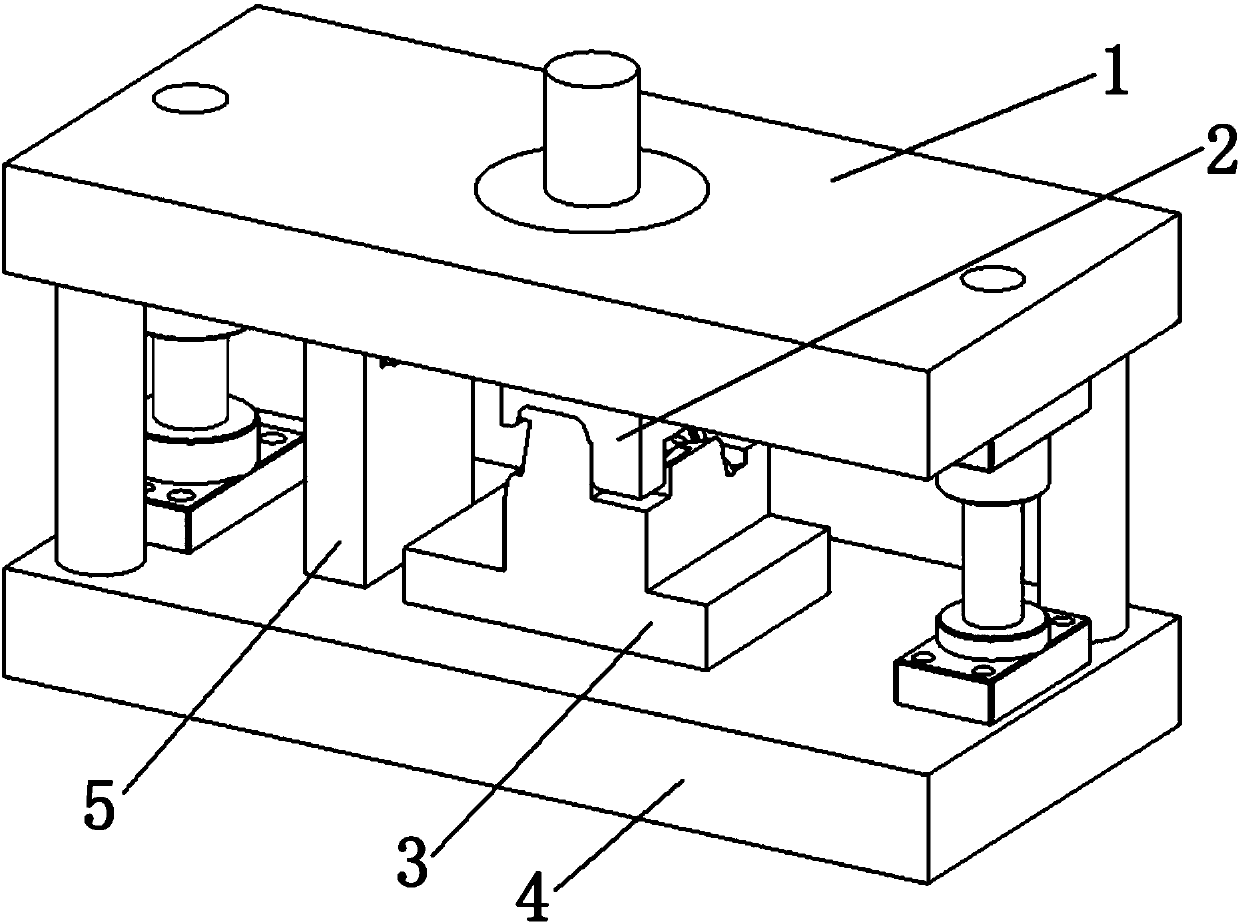

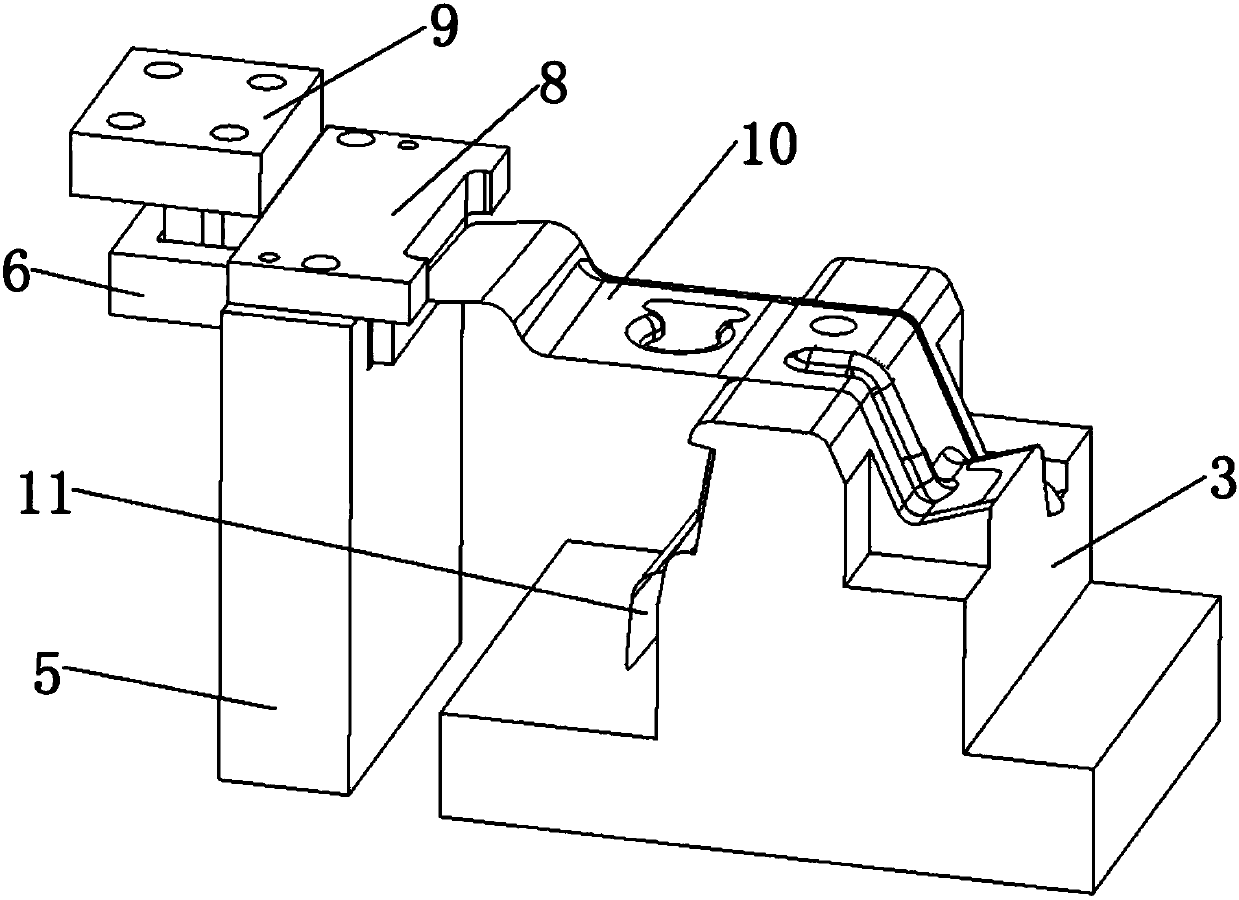

A kind of stamping forming steel plate mold

InactiveCN106180422BAvoid production safety hazardsIncrease productivityShaping toolsGravity centerMaterials science

The invention provides a punch forming steel plate mold. The punch forming steel plate mold comprises an upper mold plate, a female mold, a male mold, a lower mold plate, a base, a material supporting plate, a spring and a driving block; the lower end of the base is fixed to the lower mold plate; the material supporting plate is movably arranged at the upper end of the base, the spring is arranged between the material supporting plate and the base, the upper end of the driving block is fixed to the upper mold plate, and the lower end of the driving block is movably matched with the material supporting plate in an inserted manner; by means of the technical scheme, through application of positioning a material supporting portion in a mold structure, two functions of product material supporting and positioning are effectively achieved at the same time, and the problems that before part forming, the gravity center of a product inclines, product containing is unstable, and positioning is unstable, and consequently, product precision consistency is poor are solved; the problem of production potential safety hazards existing in manual material supporting is solved, and meanwhile the production efficiency is improved; in addition, the structure is simple, and implementation is facilitated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A kind of preparation technology and device of vitamin D3 microcapsule powder

ActiveCN104306353BImprove liquidityGreat tasteOrganic active ingredientsPressurized chemical processSolubilityCalcium biphosphate

The invention relates to a preparation process and a preparation device of vitamin D3 microcapsule powder. In the preparation process, VD3 oil, sunflower seed oil or corn oil, medicinal starch, maltodextrin, modified starch, white sugar, calcium phosphate and 2,6-di-t-buty-4-methylphenol (BHT) are used as main raw materials. The preparation process and the preparation device are reasonably improved and optimized, the production time is greatly shortened and the whole production process is controlled; through layer-by-layer drying and step-by-step recycling, the prepared vitamin D3 microcapsule powder has smooth and flat surface, and the safety, the fluidity, the mouth feel and the water solubility of the vitamin D3 microcapsule powder are greatly improved; the waste of resources is reduced, the continuous large-scale production is implemented, and the production cost is reduced.

Owner:豆源和(山东)食品饮料有限公司

Detection method of chain status of scraper conveyor in fully mechanized mining face

ActiveCN110498188BValid detection status informationSafe and stable operationConveyorsControl devices for conveyorsMagnetoEngineering

Owner:CHINA UNIV OF MINING & TECH

A kind of mould casting equipment and method that can realize three-dimensional pattern

The invention provides a mold pouring equipment and method capable of realizing three-dimensional patterns, including a feeding system and a molding system; the feeding system includes a locking mechanism, and the molding system includes a theme frame, and the locking mechanism is fixed on the The inside of the main body frame; the locking mechanism includes a pressurized extrusion port, a core, a locking clip, an electric cylinder, a locking pin, a contact sensor and a guide pin, and the pressurized extrusion port is fixedly connected to the front of the locking mechanism, The core is fixed with the pressurized extrusion port, and the locking clip and the locking mechanism are fixed by the two ends of the electric cylinder; the present invention provides a mold that can realize 3D patterns of products, and the device is aimed at IML&IMR and Ordinary printing has low qualified rate, high production cost, and hidden dangers in production safety. The invention can realize injection molding on the same machine without post-printing process, effectively control the product appearance and realize a beautiful product appearance.

Owner:天津岐塑科技有限公司

Continuous production technology of fluorine-containing surfactant without perfluorocaprylic acid

InactiveCN105344288AContinuous industrial productionWide molecular weight distributionPreparation from carboxylic acid saltsOrganic compound preparationEtherPerfluorooctanoic acid

The invention discloses a continuous production technology of a fluorine-containing surfactant without perfluorocaprylic acid. The continuous production technology comprises the following steps: using perfluoroolefine, oxygen and a third monomer as reaction raw materials, and adopting a photooxidation reaction loop, a hydrolysis unit and a salt-forming configuration unit respectively to prepare a fluorine-containing surfactant finished product using a C-O-C ether bond structure as a structure body. The finished product indexes not only meet that perfluorocaprylic acid and salt thereof are not contained, the fluorine-containing surfactant is easily degraded in the nature, but also meet data ranges that the peroxide value is 0.001-1% and the surface tension is 10-30 m / Nm. An amphipathic structure having the surfactant has advantages of high product yield, small product quality fluctuation and the like.

Owner:成都晨光博达新材料股份有限公司

An automatic pipe cutting machine for electrical equipment

ActiveCN107378096BReach automatic pushImprove cutting efficiencyTube shearing machinesShearing machine accessoriesElectrical devicesEngineering

Owner:宜兴市苏哈电力设备有限公司

Corona device for flat stamping machine

The invention relates to a corona device for pre-printing treatment of a plane stamping machine, in particular to a corona device for a plane stamping machine. The present invention is a device that integrates signal acquisition, feedback and corona treatment, and aims to provide a pre-press surface technology that has poor controllability in the corona range and potential safety hazards in the existing pre-press surface technology that uses flame treatment. The corona device of the flat stamping machine with more uniform treatment, better effect and better adhesion of printing ink.

Owner:GUANGDONG LONGXING PACKAGING IND

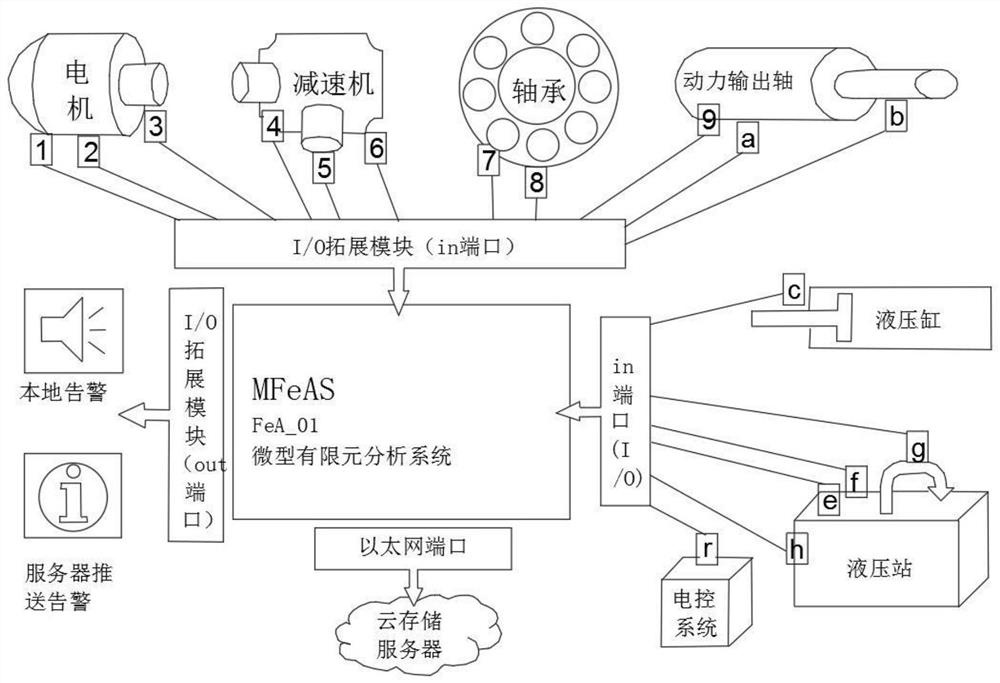

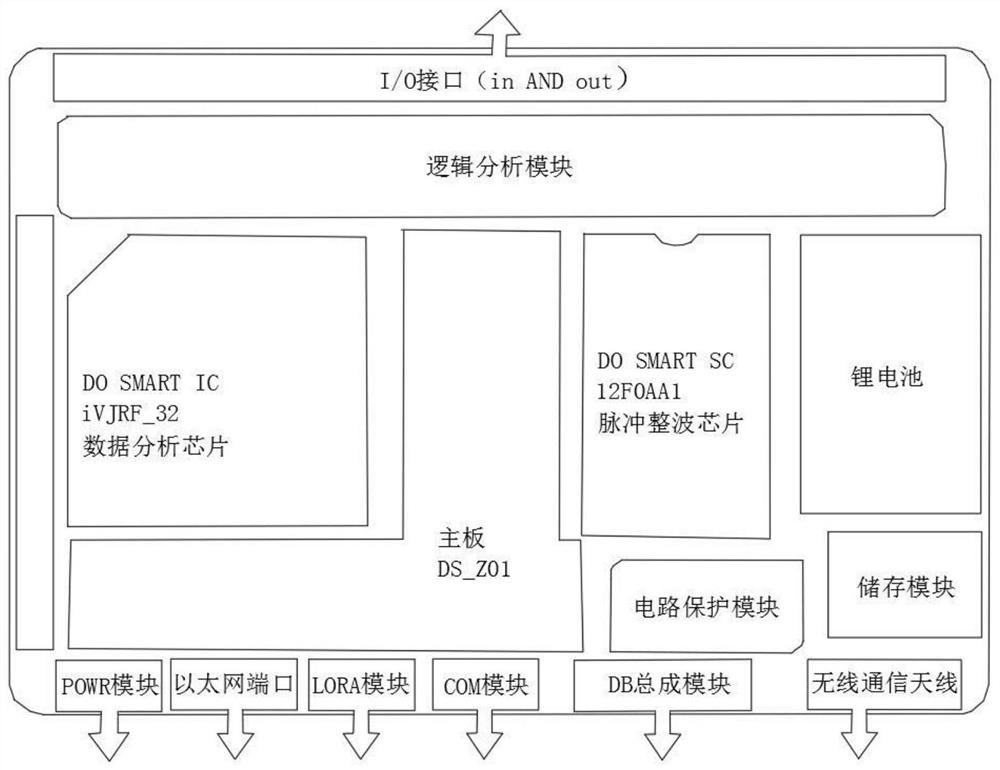

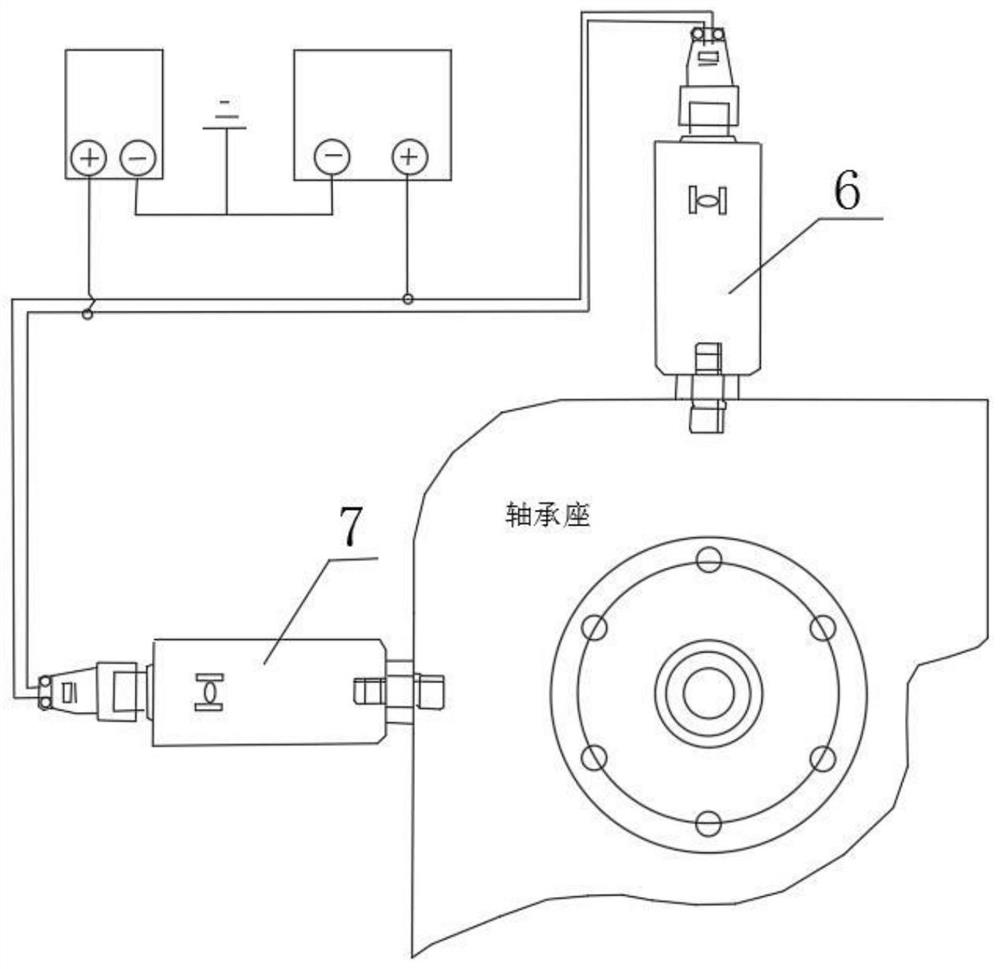

Finite element analysis system for state monitoring and early warning of autoclaved aerated concrete equipment

PendingCN112765847AGuaranteed uptimeEasy to manageMeasurement devicesDesign optimisation/simulationCurrent transducerElement analysis

The invention discloses a finite element analysis system for autoclaved aerated concrete equipment state monitoring and early warning, and relates to the field of autoclaved aerated concrete equipment state monitoring and early warning systems. The device comprises a micro finite element analysis system integration box and a sensor, a mainboard, a data analysis chip, a pulse shaping chip, a lithium battery, a circuit protection module, a storage module, a logic analysis module and an I / O interface are arranged in the micro finite element analysis system integration box; the sensor is connected with the logic analysis module through an I / O interface; the sensors comprise a first temperature sensor, a current sensor, a torsion sensor, a torque sensor, a first motion sensor, a second temperature sensor, a first vibration sensor and a third temperature sensor. According to the invention, real-time monitoring of the healthy operation state of the aerated concrete production line is realized, pre-judgment intervention is realized, stable and efficient operation of the whole production line is ensured, and factory management is effectively improved.

Owner:芜湖誉路智能装备有限公司

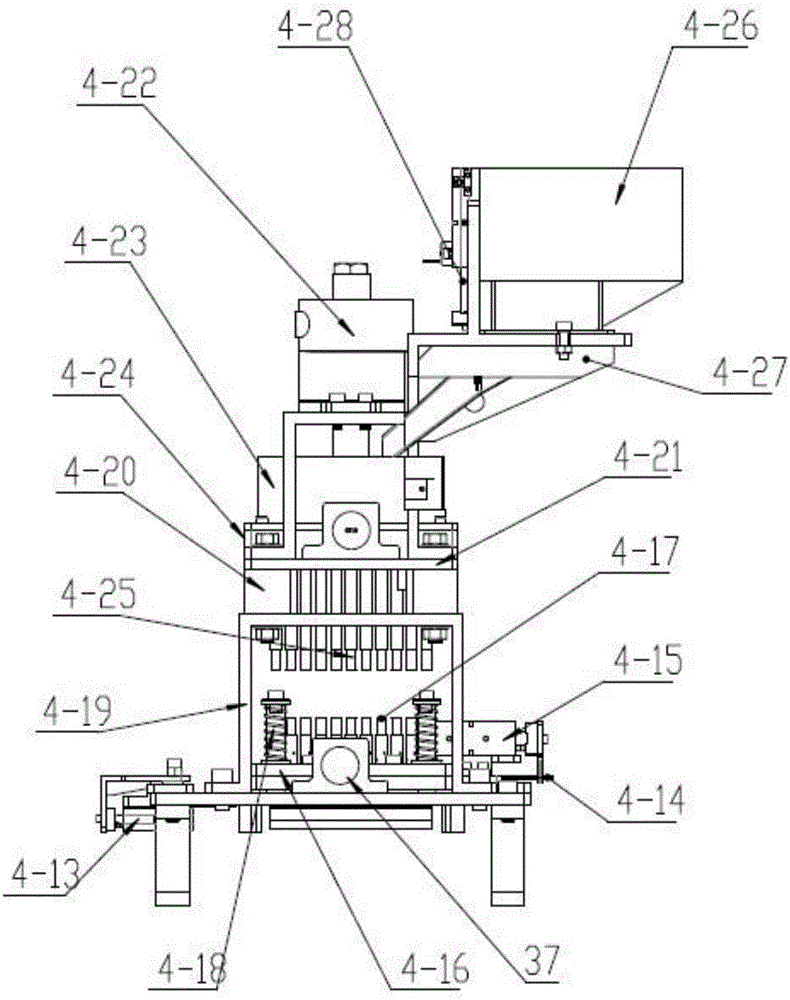

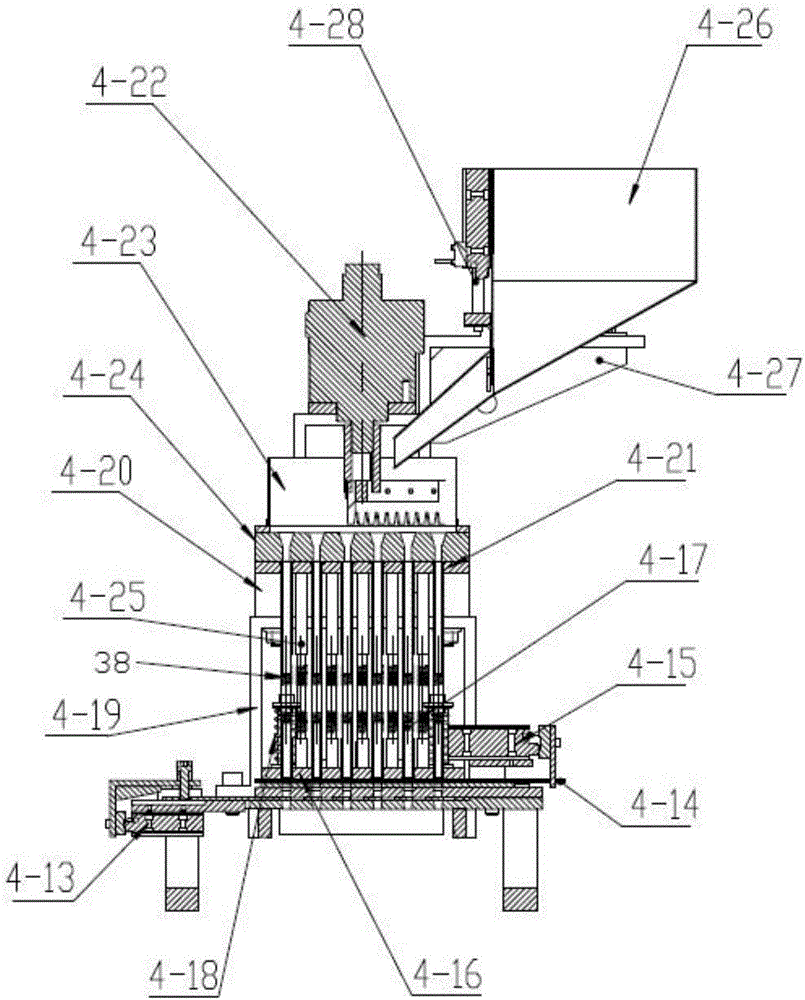

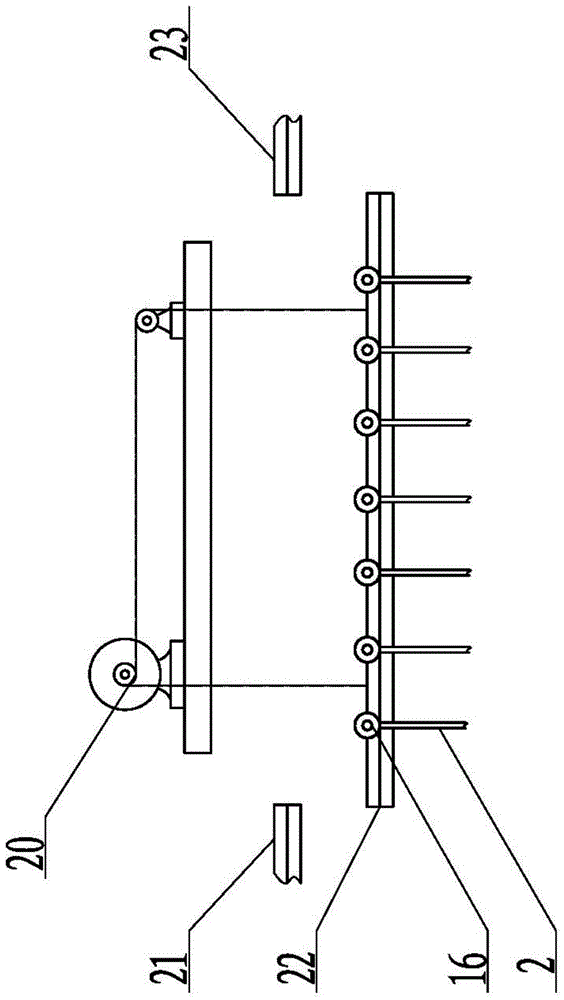

An automatic mold ejection device for an extension body and an automatic mold splitting machine for preloading an extension body

ActiveCN105547057BRealize man-machine interface controlReduce manufacturing costAmmunitionIntrinsic safetyMolding machine

An automatic delay element discharging device comprises a bottom support, a hopper and a discharging assembly. The discharging assembly comprises a round hopper used for receiving delay elements discharged from the hopper, a leaking plate with holes A is arranged at the bottom of the round hopper, and each hole A is connected with a discharging passing pipe. A bottom plate of the bottom support is provided with holes B which correspond to holes in a circulation mold and are used for passing of the delay elements, each hole B is connected with a lower connecting pipe, each lower connecting pipe corresponds to one discharging passing pipe, and an elastic hose is connected between each lower connecting pipe and the corresponding discharging passing pipe. A vibrating device is arranged beside the round hopper and / or the lower connecting pipes. A delay element pre-filling automatic mold splitting machine comprises a mold feeding mechanism, the automatic delay element discharging device, a pressing-correcting device, a circulating assembly and a mold ejecting mechanism. According to the delay element pre-filling automatic mold splitting machine, series of continuous actions such as mold feeding, automatic discharging, automatic pressing-correcting and automatic circulating and demolding can be achieved for the delay elements, so that labor intensity and production cost are lowered, intrinsic safety and labor productivity in the production process are improved.

Owner:HUNAN NANLING IND EXPLOSIVE MATERIAL CO LTD

Wind gathering type weeding machine

InactiveCN111183971AGood effectAvoid causing production safety hazardsWeed killersElectric machineryAgricultural engineering

The invention discloses a wind gathering type weeding machine. The wind gathering type weeding machine comprises a trimming roller, grass trimming wheels, a guide roller and a motor which are arrangedon a frame, wherein the trimming roller is fixedly arranged at the central part of the frame through a rotating shaft; a plurality of rows of convex blades are arranged on the rotary surface of the trimming roller; the blades are uniformly arranged at intervals along the axial direction of the trimming roller; two ends of the rotating shaft are arranged on the frame through bearing pieces; the motor is also arranged on the frame; the motor and the rotating shaft are in transmission through a belt; a draught fan mounting frame is also arranged at the rear side of the frame; a first draught fanand a second draught fan are symmetrically arranged on the draught fan mounting frame; the air outlet of the first draught fan and the air outlet of the second draught fan face the motor; a transmission shaft is arranged at the front side of the trimming roller; the transmission shaft and the trimming roller are axially arranged in parallel; the grass trimming wheels are also arranged on the frame; the grass trimming wheels are fixedly arranged at two sides of the trimming roller through bearing pieces respectively; and the grass trimming wheels respectively located at two sides of the trimming roller are symmetrically arranged.

Owner:陈西

Corona device of plane lid printing machine

ActiveCN104210227AWidely used valueUniform prepress treatmentPrinting press partsPrinting inkEngineering

The invention relates to a corona device for pretreatment of a plane lid printing machine, in particular to a corona device of the plane lid printing machine. The corona device integrates signal acquisition, feedback and corona treatment and is used for solving the problem that an existing before-printing surface technology adopting flame treatment is poor in corona range controllability and has potential production safety hazard, and the corona device of the plane lid printing machine is even in before-printing treatment and good in effect and printing ink adhesion force.

Owner:GUANGDONG LONGXING PACKAGING IND

A folding fan bamboo bone cooker and its cooking process

InactiveCN105150326BAvoid settling and cokingImprove cooking qualityReed/straw treatmentWood impregnation detailsElectric machineryEngineering

Owner:重庆臻冠科技有限公司

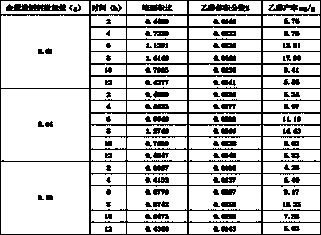

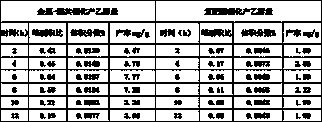

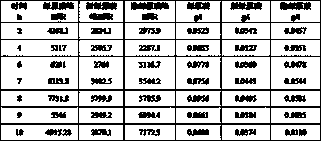

Method for metal-enzyme co-catalyzed ethanol production from honeysuckle leaves and simultaneous extraction of chlorogenic acid

ActiveCN106397202BImprove permeabilityHigh extraction rateBiofuelsMicroorganism based processesChlorogenic acidFermentation

The invention relates to a method for carrying out metal-enzyme co-catalysis on lonicera japonica leaves to produce ethyl alcohol and simultaneously extracting chlorogenic acid, and belongs to the technical field of production of biomass ethyl alcohol and chlorogenic acid series products. According to the method, solid wastes of the lonicera japonica leaves are used as raw materials; prepared manganese zinc ferrite is an enzyme activator; the products are obtained by a process of preparing a metal activator, culturing yeast liquid, pre-treating the raw materials, carrying out co-catalytic simultaneous glycolysis and carrying out analysis detection of the chlorogenic acid and the ethyl alcohol. The method has the characteristics that the raw materials are cheap, easy to obtain and wide in source; diversified products with complete biological activities can be obtained, and biomass resources are sufficiently utilized; energy consumption in the production process is low, corrosion to production equipment is low, and the method is beneficial to environmental protection. The method can be widely applied to simultaneous production of the ethyl alcohol by three processes of catalysis, saccharification and fermentation of biomass and extraction of natural products, such as the chlorogenic acid, neochlorogenic acid, cryptochlorogenic acid and the like, from the solid wastes of the lonicera japonica leaves, and effectively implements resource re-utilization of the lonicera japonica leaves.

Owner:CHONGQING TECH & BUSINESS UNIV

An improved stainless steel suspension rail block

ActiveCN107089594BEliminate collision hazardsReasonable designTravelling gearRunwaysMaterials scienceCorrosion

The invention belongs to the technical field of cargo lifting assembly accessories, and particularly discloses an improved stainless steel hanger rail tackle. The improved stainless steel hanger rail tackle is composed of a supporting plate body, a first lug plate, a second lug plate, a set of first positioning holes, a set of second positioning hole, an adjusting supporting assembly, a first sliding assembly and a second sliding assembly. The stainless steel hanger rail tackle has the beneficial effects that the overall stainless steel structural design is reasonable, the tenacity is high, and the corrosion resistance and abrasive resistance are excellent; by means of the first sliding assembly and the second sliding assembly, the overall structure running stability and efficiency are guaranteed; by means of the adjusting supporting assembly, the conveying stability of hoisted cargoes or products is guaranteed, and the existing production potential safety hazards are avoided; and through the structures of a first arc-shaped limiting plate and a second arc-shaped limiting plate on the two sides, it is guaranteed that collision hidden danger of external components on the hanger rail tackle is avoided in the conveying operation, and the service life of the overall structure is prolonged.

Owner:江苏天硕合金材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com