Continuous production technology of fluorine-containing surfactant without perfluorocaprylic acid

A surfactant, perfluorooctanoic acid technology, applied in organic chemistry, carboxylate preparation, carboxylate preparation, etc., can solve the problem that chemical characteristics cannot be characterized by any molecular chain or group in its structural formula, vary widely, and are Amplification and other problems, to achieve the effect of good surface activity characteristics, low yield, and avoid hidden dangers of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

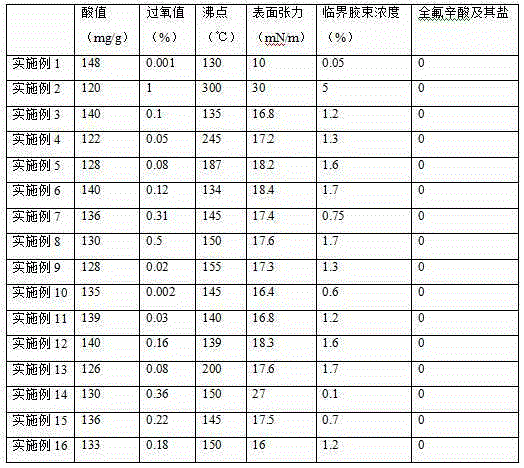

Examples

Embodiment 1

[0056] This embodiment proposes a continuous production process for a fluorosurfactant that does not contain perfluorooctanoic acid, comprising the following steps:

[0057] A: Perfluoroalkene, oxygen and a third monomer (such as chloroacetylene) continuously enter the photooxidation reaction loop at a temperature of 0°C and a pressure of 0.1Mpa, and produce terminal products containing acyl fluoride after photooxidation;

[0058] B: Send the product containing acyl fluoride end group to the hydrolysis unit, after hydrolysis and separation, obtain a fluorine-containing low polymer with a carboxylic acid group at one end;

[0059] C: Feed the fluorine-containing low polymer with a carboxylic acid group at one end obtained in step B into the salt-forming configuration unit, and after the salt-forming configuration, the finished fluorine-containing surfactant is obtained, and the finished fluorine-containing surfactant is sent to finished product storage tanks for storage,

[00...

Embodiment 2

[0068] The continuous production process of the fluorosurfactant not containing perfluorooctanoic acid involved in this embodiment comprises the following steps:

[0069] A: Perfluoroolefins, oxygen and a third monomer (such as vinylidene fluoride) continuously enter the photooxidation reaction loop at a temperature of 20°C and a pressure of 0.5Mpa, and produce terminal products containing acyl fluoride after photooxidation;

[0070] B: Send the product containing acyl fluoride end group to the hydrolysis unit, after hydrolysis and separation, obtain a fluorine-containing low polymer with a carboxylic acid group at one end;

[0071] C: Feed the fluorine-containing low polymer with a carboxylic acid group at one end obtained in step B into the salt-forming configuration unit, and after the salt-forming configuration, the finished fluorine-containing surfactant is obtained, and the finished fluorine-containing surfactant is sent to finished product storage tanks for storage,

...

Embodiment 3

[0080] The difference between this example and Example 1 is that in step A involved in this example, the mass ratio of perfluoroolefin to the third monomer is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com