Preparation method of degradable wood-plastic composite material

A technology of wood-plastic composite materials and composite materials, which is applied in the field of composite material preparation, can solve problems such as lack of reports, and achieve the effects of low cost, improved dispersion, and low degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

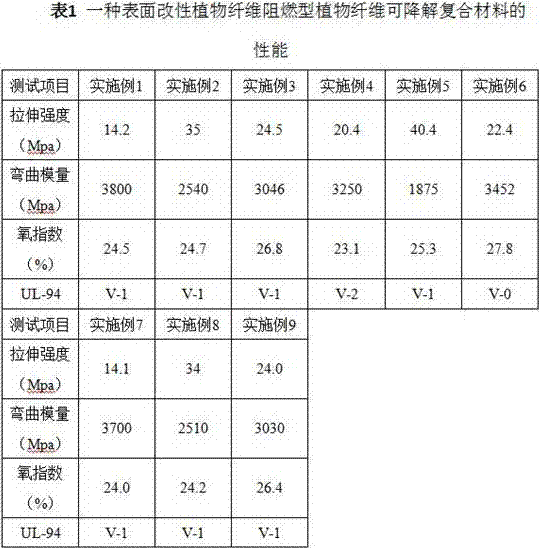

Examples

preparation example Construction

[0032] A preparation method of degradable wood-plastic composite material, comprising the following steps:

[0033] Preparation of surface modifier: Weigh the biomass and dissolve it in an organic solvent to form a biomass solution, drop an esterification reagent into the biomass solution for esterification reaction, and after the esterification reaction, precipitate and separate with absolute ethanol in turn, Obtain the surface modifier after washing with water ethanol and centrifuging;

[0034] The preparation steps of the surface modifier are specifically:

[0035] Step 1): Weigh the biomass, and then dissolve it in an organic solvent to obtain a biomass solution;

[0036] Wherein, biomass is one of starch, lignin or cellulose and derivatives thereof.

[0037] Step 2): The biomass solution is placed in a three-necked flask equipped with a stirrer, a reflux condenser and a constant pressure dropper respectively, and the three-necked flask is placed in a constant temperatur...

Embodiment 1

[0051] In this embodiment, the preparation method of the degradable wood-plastic composite material specifically includes the following steps:

[0052] (1) Preparation of surface modifier:

[0053] Step 1): Weigh 5.0g of starch and dissolve it in 100mL of dimethyl sulfoxide to obtain a solution;

[0054] Step 2): The above solution was placed in a three-neck flask equipped with a stirrer, a reflux condenser and a constant pressure dropper respectively, and placed in a constant temperature oil bath at 105°C.

[0055] Step 3): Add octanoyl chloride dropwise to it with a constant pressure dropping funnel, and the dropwise addition is completed within 15 minutes.

[0056] Wherein, the addition amount of octanoyl chloride is, the molar ratio of octanoyl chloride:starch=1:1, and the time of the whole esterification reaction is 3h.

[0057] Step 4): After the reaction is completed, add 500 mL of absolute ethanol to it for precipitation and separation, and wash with absolute ethanol...

Embodiment 2

[0071] In this embodiment, the preparation method of the degradable wood-plastic composite material specifically includes the following steps:

[0072] (1) Preparation of surface modifier:

[0073] Step 1): Weigh 5.0g lignin and dissolve it in 100mL dimethyl sulfoxide;

[0074] Step 2): Put the lignin dissolved in dimethyl sulfoxide in a three-necked flask equipped with a stirrer, a reflux condenser and a constant pressure dropper respectively, and place it in a constant temperature oil bath at 105°C.

[0075] Step 3): Add palmitoyl chloride dropwise to it with a constant pressure dropping funnel, and the dropwise addition is completed within 15 minutes.

[0076] Wherein, the mass ratio of palmitoyl chloride: lignin is 1:1, and the whole esterification reaction time is 3h.

[0077] Step 4): After the reaction is completed, add 500mL of absolute ethanol to it for precipitation and separation, wash with absolute ethanol several times, and then centrifuge with a centrifuge at 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com