Patents

Literature

203results about How to "Continuous industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

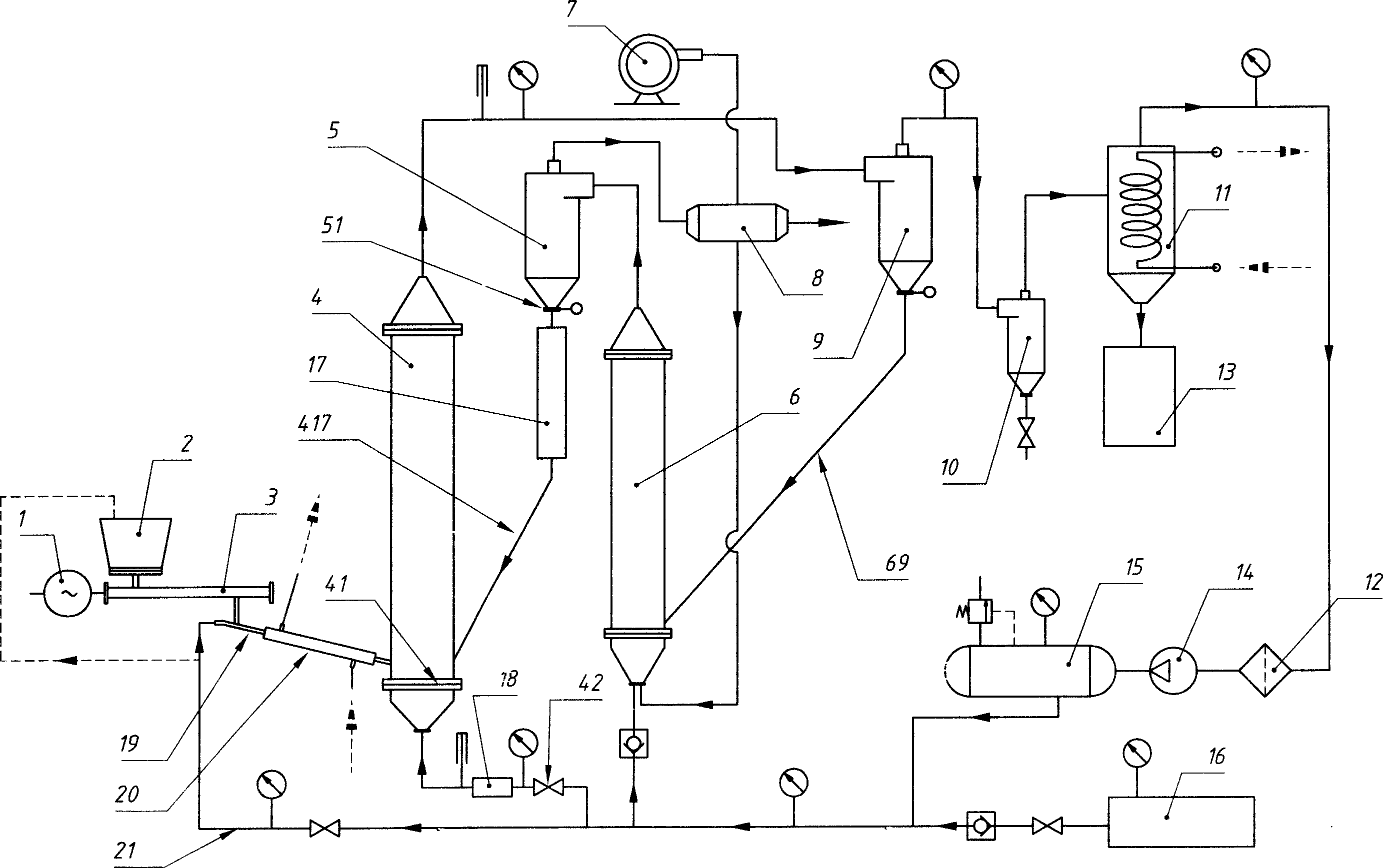

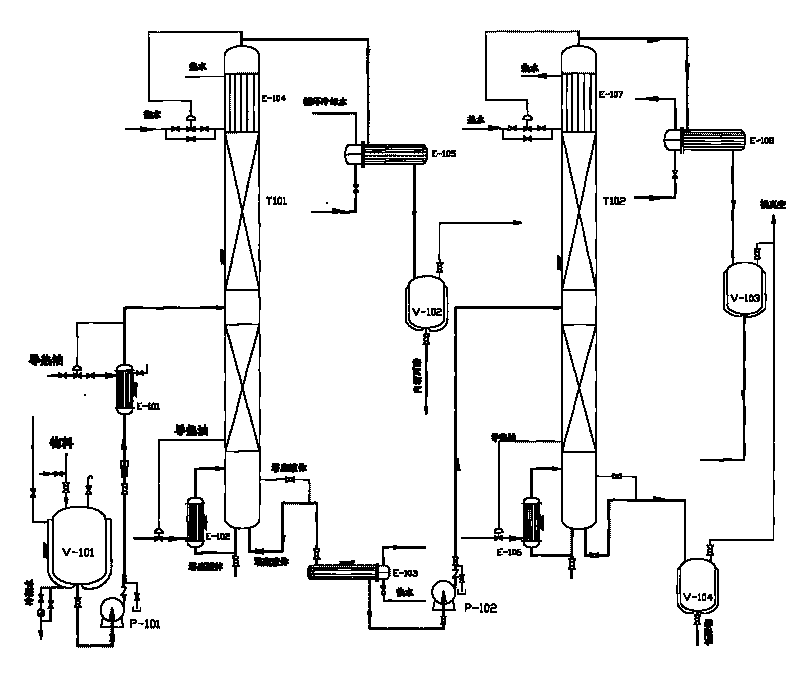

Biomass pyrolysis liquefied technique and double tower apparatus system thereof

InactiveCN1730177AImprove pyrolysis efficiencyWell mixedSolid waste disposalGas phaseProcess engineering

The invention relates to a biomass analgesic liquidation method and its twin-tower set system, the processes of which comprise the following steps: sending biomass to pyrolytic reaction tower and blending it with high-heat fluidized gas to subject biomass to pyrolytic cracking; separating thermal cracking gas with carbon residue and ash content in separator; and condensing thermal cracking gas to biological oil in condenser. In the process, heat-carrying agent is exported from pyrolytic reaction tower along with thermal cracking gas, carbon residue and so on, and carbon residue is used to preheat heat-carrying agent. The invention is special for heat-carrying agent heating tower to burn carbon residue and primary separator to separate heat-carrying agent, carbon residue and other materials. The invention can not only increase circulation rate to ensure uniform and stable temperature field in pyrolytic reaction tower, higher heating rates and shorter detention period of gas phase, but also make use of carbon residue as heat source by using existing apparatus.

Owner:CHONGQING UNIV

Method for making microwave vaccum frozen and dried lemon piece

InactiveCN1849921AExtended production periodSolve the problem of excessive pesticide residuesFood preservationMicrowaveFreeze-drying

The present invention relates to a production method of microwave vacuum freeze-dried lemon slices. Said method includes the following steps: (1), sorting lemon fruit; (2), storing lemon fruit under the condition of constant temperature; (3), utilizing ozone to degrade pesticide residue on the lemon fruit and make sterilization; (4), cutting head and tail of lemon fruit, cleaning the lemon fruit by using ozone water and sterilizing; (5), slicing; (6), freezing sliced lemon; (7), prefreeze-drying; (8), microwave vacuum-drying; and (9), sealing and packaging so as to obtain the invented product.

Owner:SICHUAN HUATONG LEMON

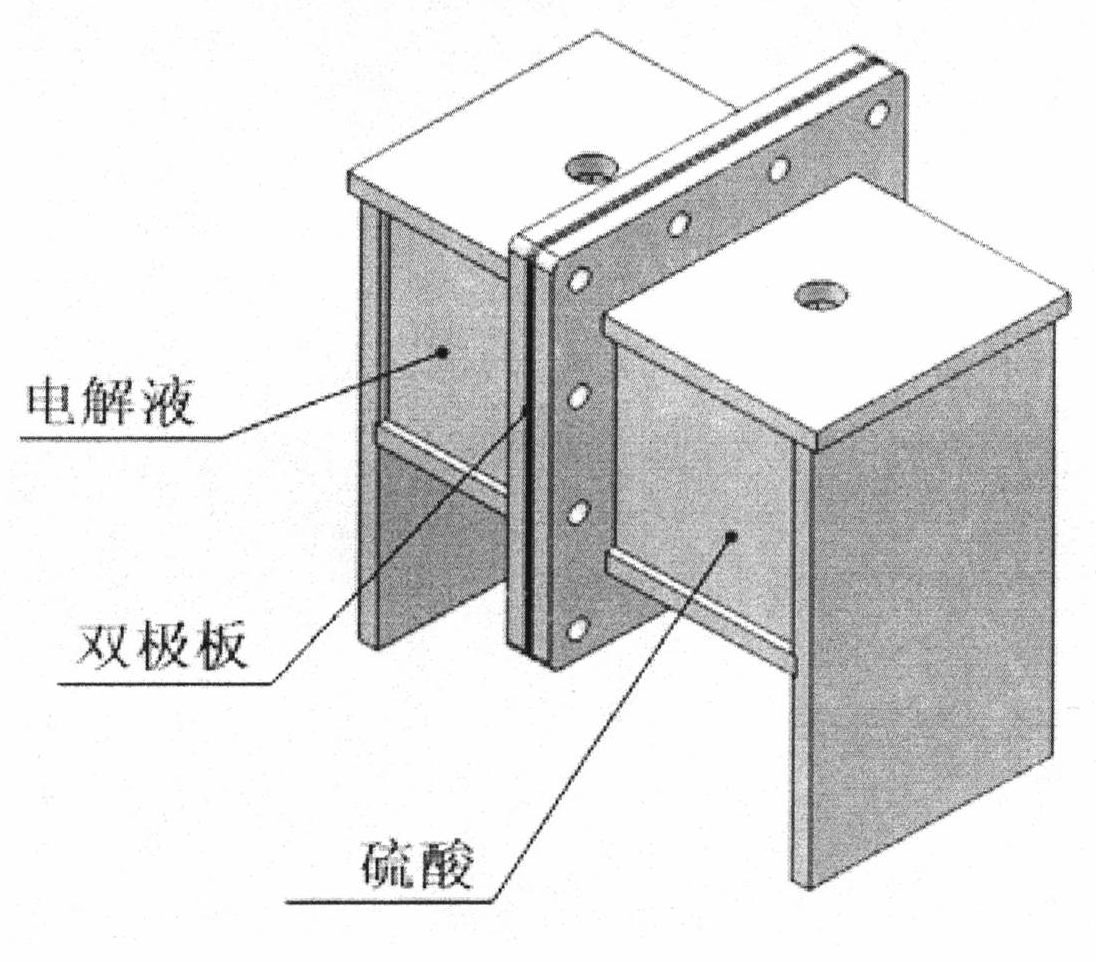

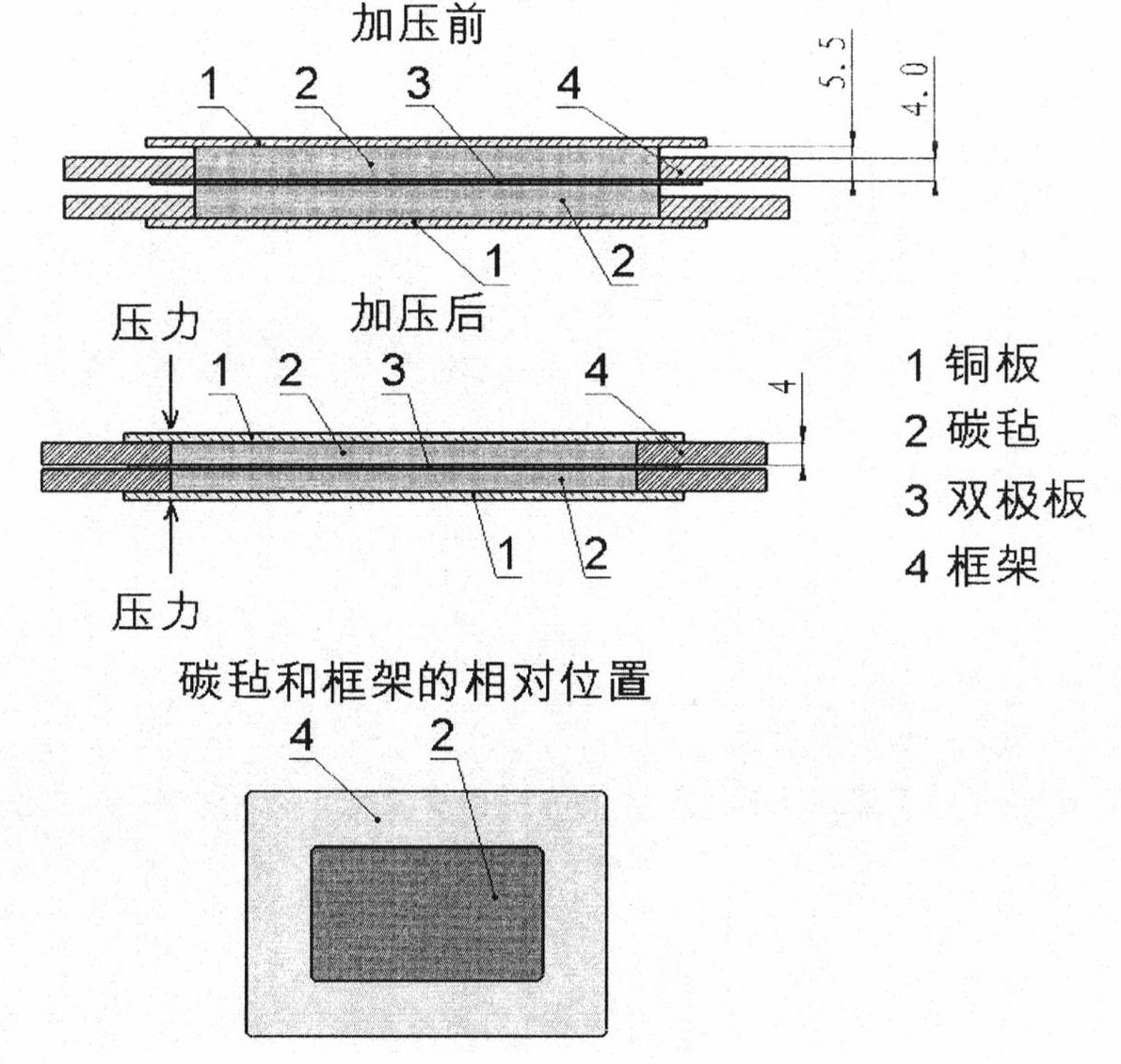

Elastomer plastic, conductive plastic, conductive plastic bipolar plate and preparation methods thereof

InactiveCN102120836AImprove mechanical propertiesExtended service lifeFinal product manufactureCell electrodesElastomerEngineering

The invention relates to an elastomer plastic which is characterized by being blended from single thermoplastic resins with at least two different specifications. The invention also relates to a conductive plastic containing the elastomer plastic and a conductive plastic bipolar plate. The invention also relates to preparation methods of the elastomer plastic, the conductive plastic containing the elastomer plastic, and the conductive plastic bipolar plate.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

Graft polymerization method of vegetable protein and polysaccharide

InactiveCN101785522AQuick responseLittle effect on appearance colorVegetable proteins working-upSolubilityMass ratio

The invention discloses a graft polymerization method of vegetable protein and polysaccharide, which includes that: (1) the graft polymerization of vegetable protein and polysaccharide: the vegetable protein is dissolved and is mixed with polysaccharide to obtain mixture solution, the mass ratio of vegetable protein and polysaccharide is 0.1-10:1; (2) the mixture solution is stirred for 2-3 hours, and then the mixture solution is treated by the pulse electric field with frequency of 500-2000 Hz and voltage of 15-45KV for 480-2000us to obtain copolymer; (3) the copolymer is concentrated and dried through atomizing. The invention has high reaction efficiency, short reaction time, stable performance, no pollution and also greatly improves the solubility and emulsifying of the copolymer; meanwhile, the equipment can be used for continuous industrial production.

Owner:SOUTH CHINA UNIV OF TECH

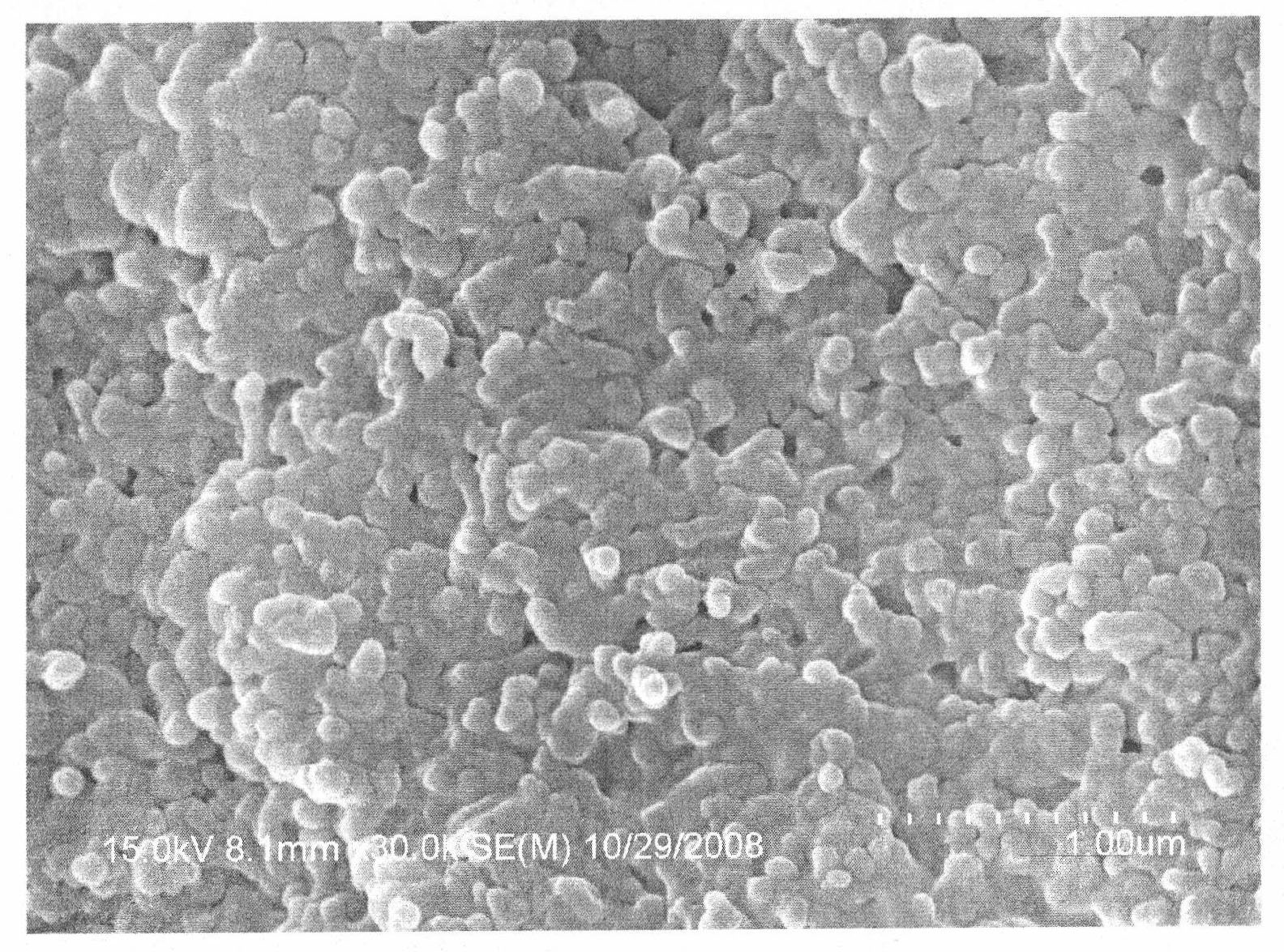

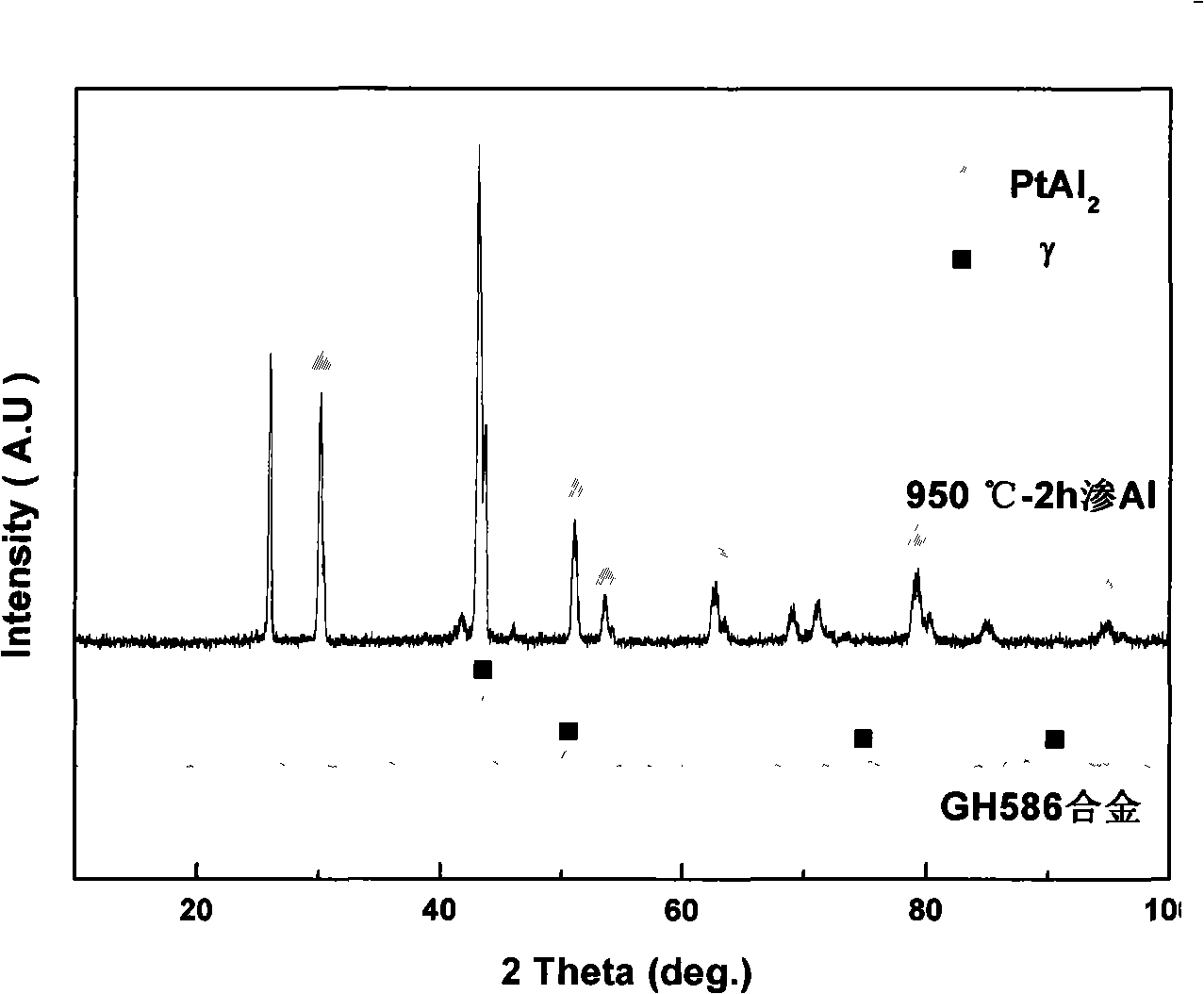

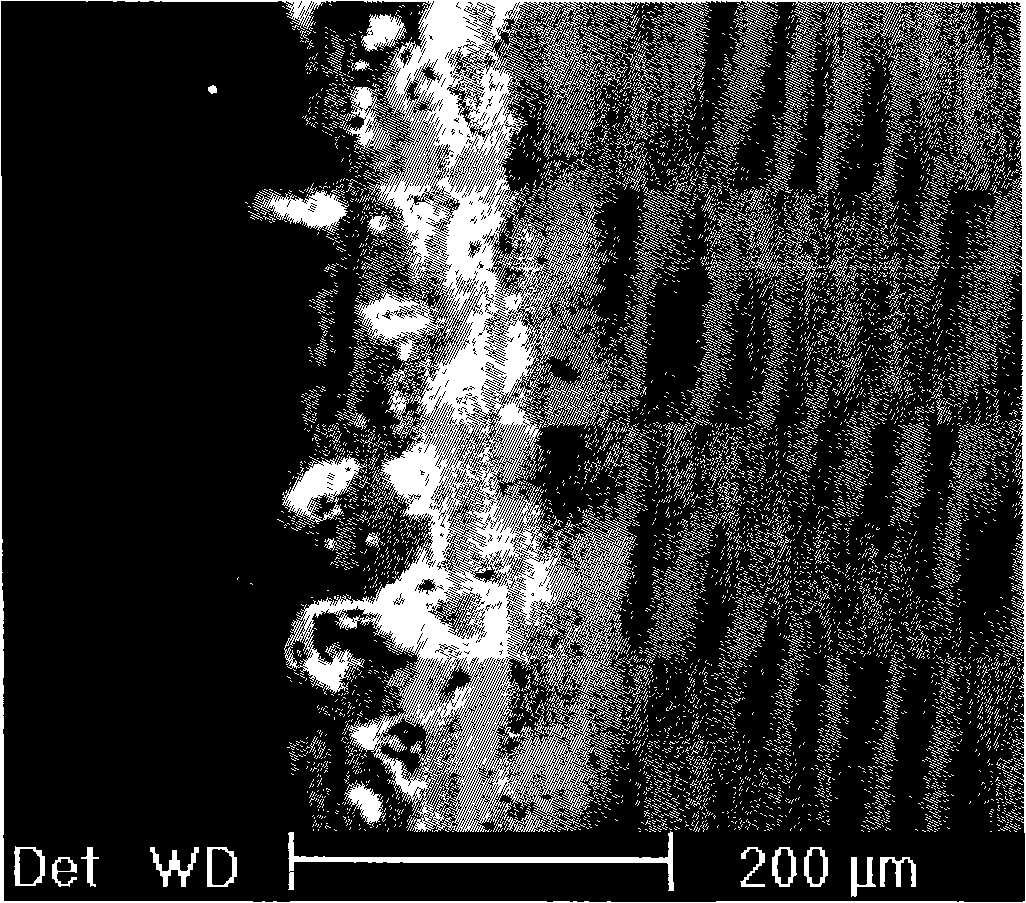

Method for preparing nano platinum oxidation coating for high temperature alloy

InactiveCN101358351AImprove uniformityImprove bindingSolid state diffusion coatingPlatinumCoated surface

The invention discloses a preparation method of nano Pt-Al coating, which comprises the following steps: first, a high-temperature alloy matrix receives surface treatment; second, a layer of about 0.5 micrometer to 10 micrometer thick pure platinum is plated on the cleaned alloy surface; finally, powder embedding aluminizing is conducted under a certain temperature, to obtain the nano Pt-Al coating. The surface of the coating is compact, can be highly adhered to the matrix, can be widely applied to all high-temperature alloys, in particular the nickel-based high-temperature alloy, can effectively improve the service life of the high-temperature alloys, so that the alloys have excellent cold and hot impact resistant capability as well as oxidation resistant capability at high temperature.

Owner:KUNMING INST OF PRECIOUS METALS

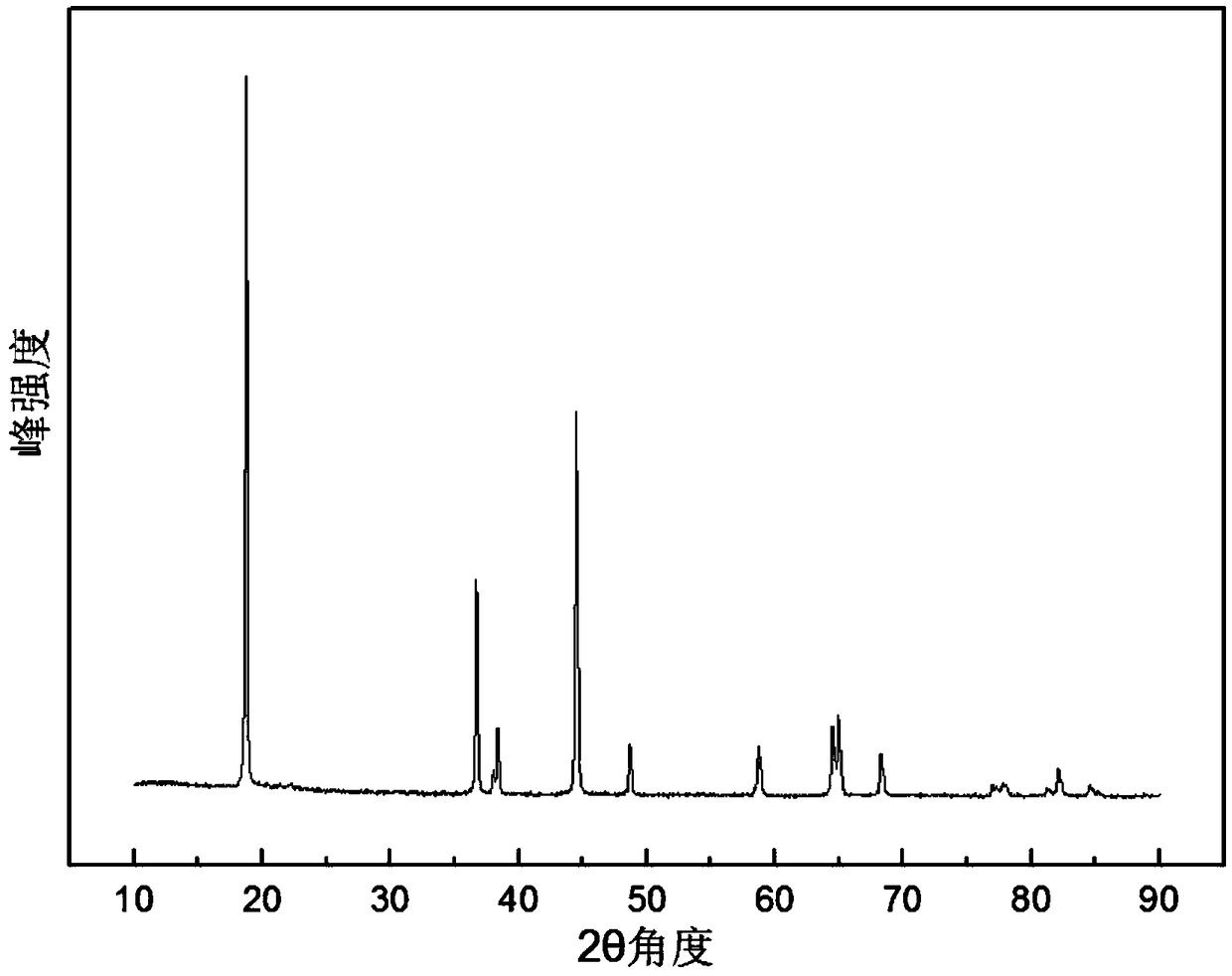

Lithium ion battery cathode material with variable slope concentration gradient doping structure and preparation thereof

InactiveCN108649205AThe rate of change of concentration increasesGood element doping distributionElectrode thermal treatmentSecondary cellsSurface layerSynthesis methods

The invention discloses a lithium ion battery cathode material with a variable slope concentration gradient doping structure and a synthesis method thereof. For solving the problems of capacity fadingand rate performance degradation which are brought by the conventional doping method, an element with a variable slope concentration gradient structure is doped, thereby obtaining the lithium ion battery cathode material with the concentration of a doping element continuously changed from the center of a material particle to the surface of the material particle; and change rate is gradually increased from inside to outside, so that the concentration of the doped element inside the material is slowly changed, the concentration of the doped element on the surface of the material is rapidly changed, and change of the concentration of the doped element is mainly concentrated on a surface layer. The method improves stability of the internal structure and the surface of the material while sideeffect is not introduced, the problems such as phase change of the material, volume change and dissolution of transition metal elements in a charge-discharge cycle process are reduced, cycle life of the material is greatly prolonged, and safety performance of the material is greatly improved.

Owner:HARBIN INST OF TECH

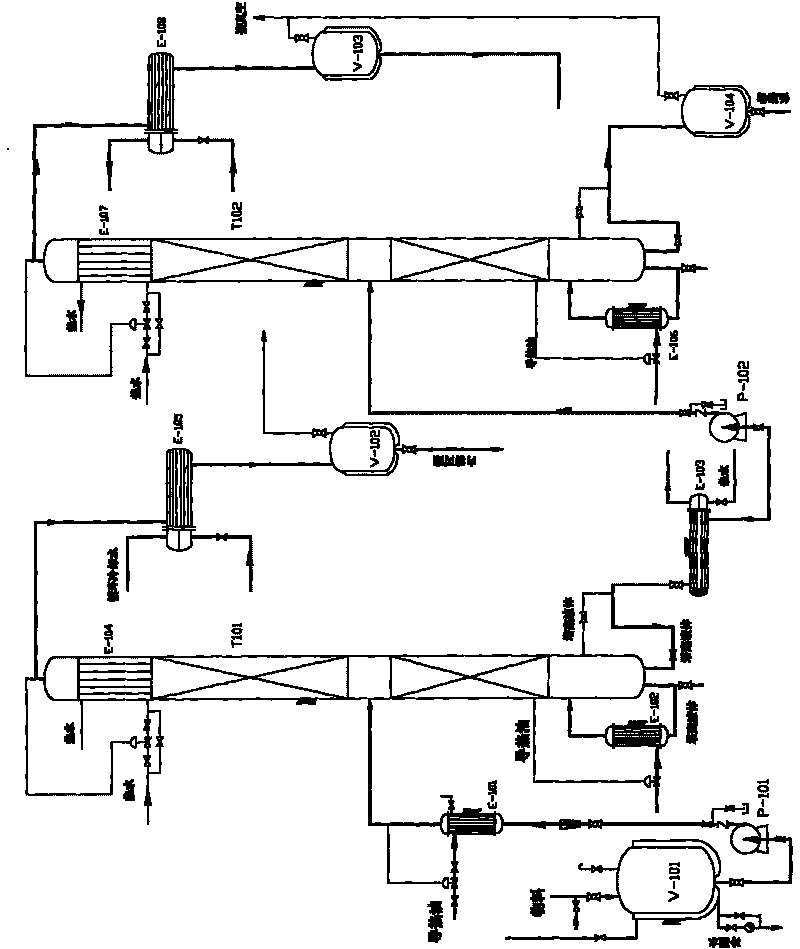

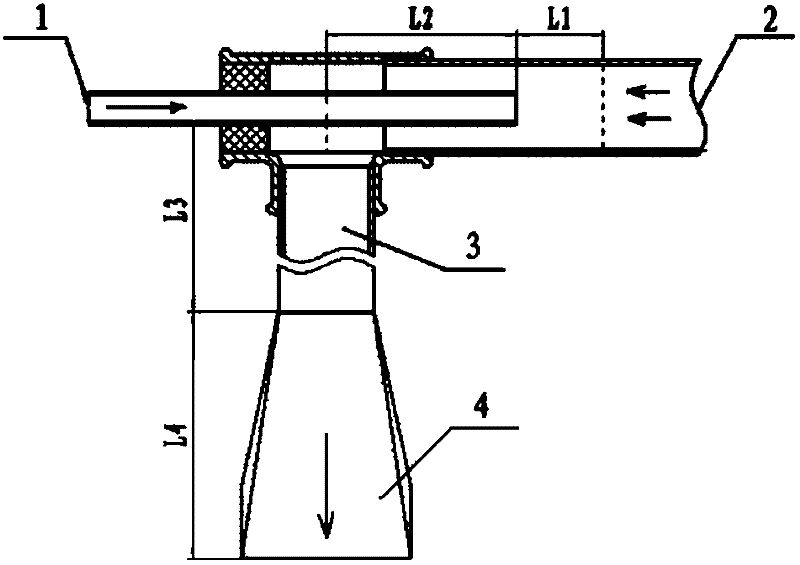

Method for continuously refining L-lactide from crude L-lactide

The invention discloses a method for continuously refining L-lactide from crude L-lactide, which comprises the following steps of: firstly, performing at least once lightness removal to the crude L-lactide by using a lightness-removing column, sending melted crude L-lactide into the middle of the lightness-removing column, refluxing and separating as well as distilling the crude L-lactide in the lightness-removing column, condensing vapor distillate at the upper end of the lightness-removing column for removing water, L-lactate and meso-lactide; secondly, enabling column bottom liquid to enter a reboiler for vaporization and then enter into the column, performing at least once rectification to the left column bottom liquid through a treating column after cooling, wherein the lower end of the lightness-removing column mainly has high-boiling point distillate liquid comprising the L-lactide and lactate oligomer; and when in rectification, refluxing and separating the column bottom liquid of the lightness-removing column to obtain a refined L-lactide; refining column bottom flow to obtain concentrated lactate oligomer. The L-lactide purified by the method can be directly used in the polymerization of poly L-lactate, thereby lowering the purifying cost of the L-lactide, increasing the yield, and being environmental friendly without organic solvents.

Owner:南京冠创生物科技有限公司

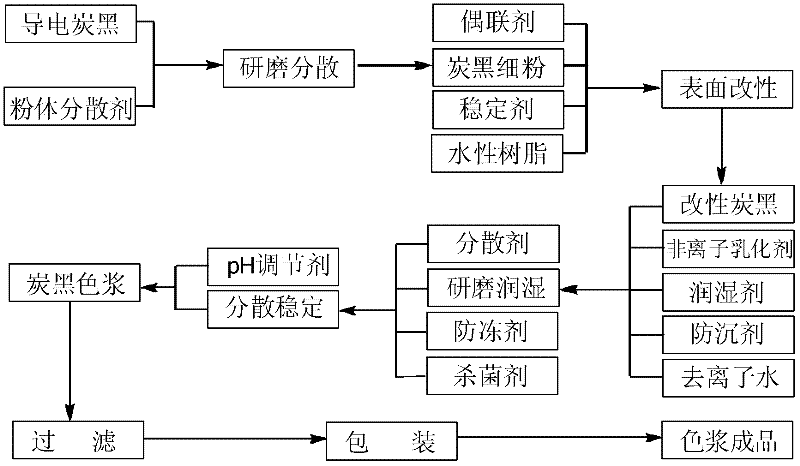

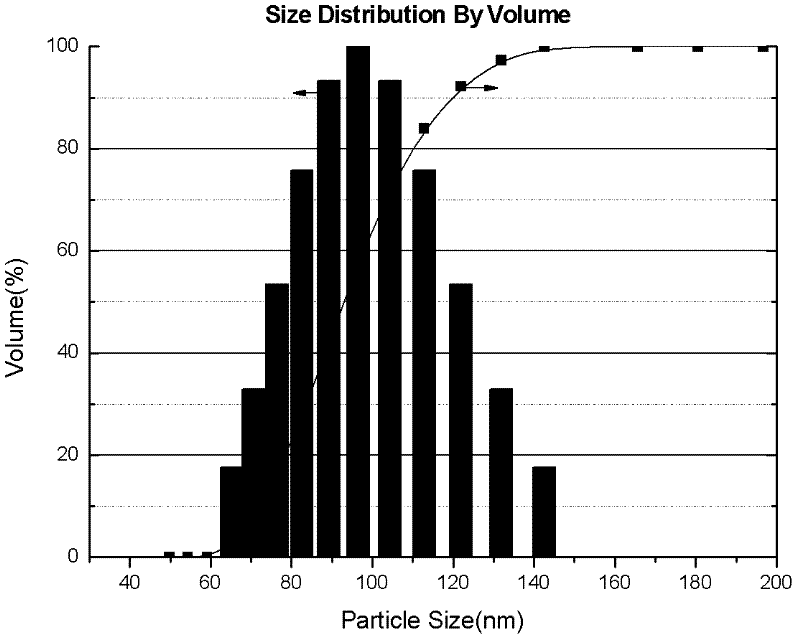

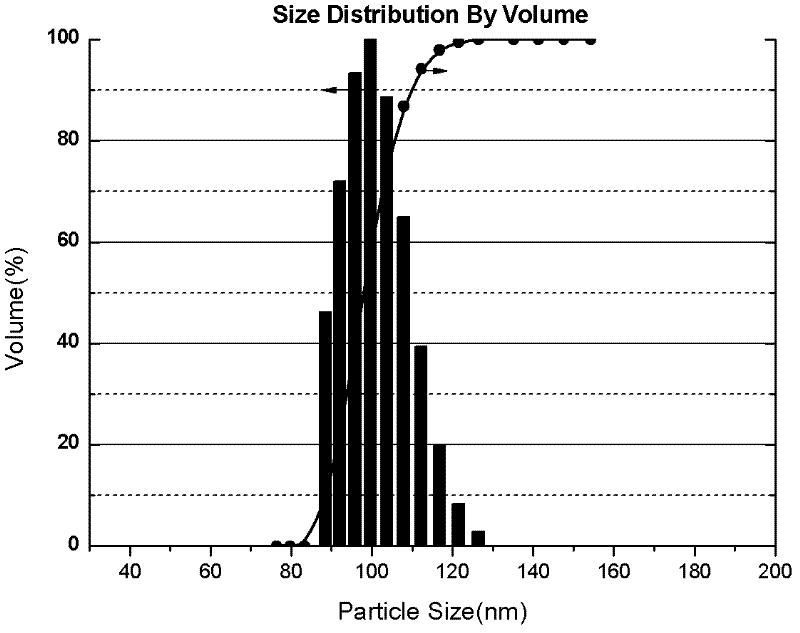

Nano aqueous conductive carbon black color paste and preparation method thereof

ActiveCN102532975ALarge particle sizeGood dispersionAntifouling/underwater paintsPaints with biocidesParticle-size distributionSurface modification

The invention provides a nano aqueous conductive carbon black color paste which comprises the following components by weight percent: 18.0-30.0% of conductive carbon black, 0.35-1.4% of powder dispersing agent, 0.7-2.0% of coupling agent, 0.02-0.24% of stabilizing agent, 0.35-1.4% of water-soluble resin, 2.0-5.5% of dispersing agent, 1.0-3.2% of wetting agent, 0.04-0.26% of anti-sedimentation agent, 0.3-1.3% of nonionic emulsifying agent, 0.002-0.008% of pH regulating agent and 55-75% of deionized water. According to the invention, the conductive carbon black color paste is prepared through a method of combing physics and chemistry by adopting dry grinding and dispersing, dry surface modification and wet grinding technologies, thus the problem that the conductive carbon black is difficult to disperse is solved, the particle size distribution of the color paste is narrow, the color paste has good compatibility with adhesive resin and is high in carbon black content, filmed paint can reduce the resistance of a coating to the greatest extent, and the prepared conductive color paste is good in stability.

Owner:GUANGDONG LEPUTAI NEW MATERIAL TECH

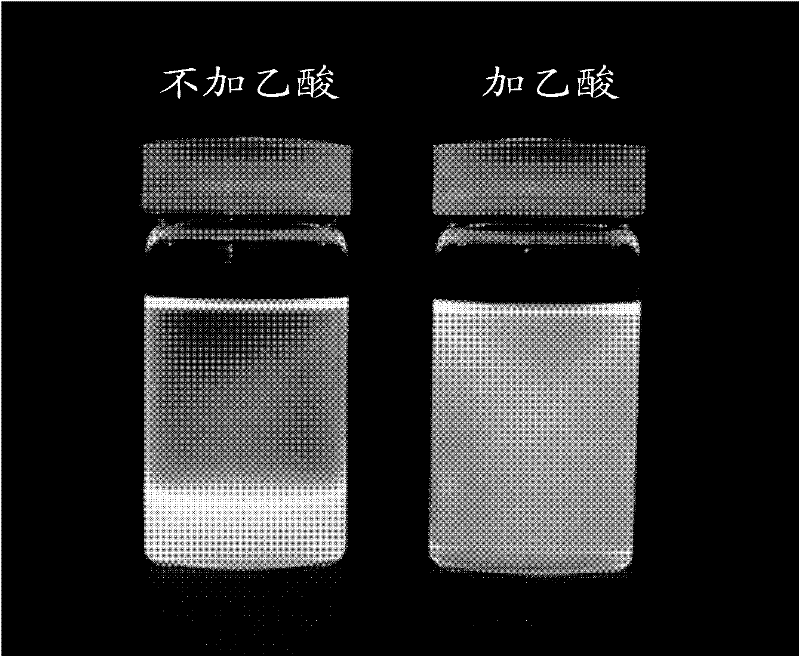

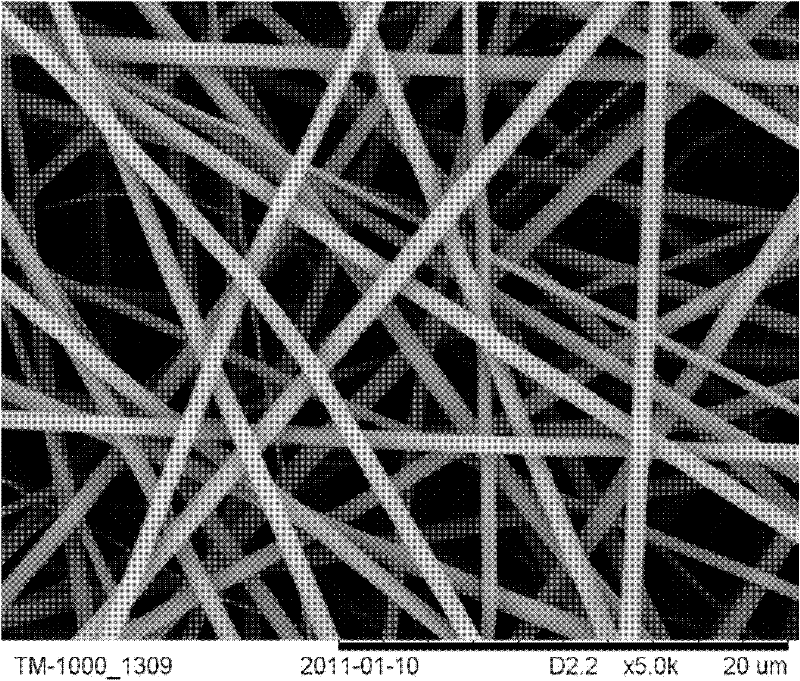

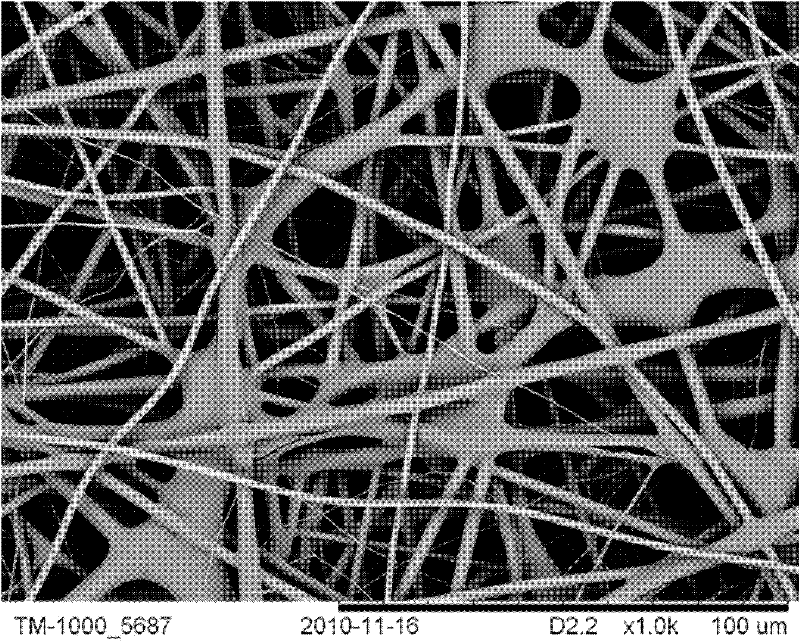

Method for preparing gelatin/polycaprolactone composite nanometer fiber membrane through electrostatic spinning

InactiveCN102242463AVolatile fastEasy to operateConjugated cellulose/protein artificial filamentsFilament/thread formingAcetic acidFiber

The invention relates to a method for preparing a gelatin / polycaprolactone composite nanometer fiber membrane through electrostatic spinning, comprising the steps of: (1) mixing gelatin with polycaprolactone, adding the mixture into trifluoroethanol or hexafluoroisopropanol, stirring, adding acetic acid and stirring till the solution is transparent so as to obtain a gelatin / polycaprolactone spinning solution; and (2) extracting the gelatin / polycaprolactone spinning solution, fixing on an electrostatic spinning device to carry out electrospinning, collecting fiber membranes, and drying in vacuum to obtain the gelatin / polycaprolactone composite nanometer fiber membrane. The method provided by the invention has the advantages of quickness, simpleness, convenience, low cost and good spinnability; the prepared composite nanometer fibers have smaller diameter and very good mechanical property and are suitable for batch preparation and mass production of the gelatin / polycaprolactone composite nanometer fiber membrane.

Owner:DONGHUA UNIV

Preparation method of long-fiber reinforced polypropylene microcellular foam material

The invention discloses a preparation method of a long-fiber reinforced polypropylene microcellular foam material. The method includes the following steps of adding 45-80 parts of raw material into an extruder, wherein the raw material is polypropylene resin; adding 10-45 parts of long fiber and 2-12 parts of supercritical fluid into the middle section of the extruder respectively to be sufficiently mixed to obtain a melt mixture; making the melt mixture pass through a die head of the extruder to be subjected to depressurization foaming to obtain the long-fiber reinforced polypropylene microcellular foam material, wherein the extruder is formed by connecting a twin-screw extruder with a single-screw extruder in series, the temperature of the first region of the single-screw extruder is 120-140 DEG C, the temperature of the die head is 150-175 DEG C, and the pressure of melt in the die head is 6-20 MPa. Compared with a material where fiber is not added or ordinary short-cut fiber is added, the strength and modulus of the long-fiber reinforced polypropylene microcellular foam material can be remarkably improved; the material is formed, extruded and prepared through one step, continuous industrial production can be achieved, and production efficiency is greatly improved. The material is safe, free of toxin, green and environmentally friendly.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Crystallization apparatus and purification method for refining and purifying ethylene carbonate

PendingCN108440489APromotes the formation of a large number of crystalsHigh purityOrganic chemistrySolution crystallizationChemistryHigh energy

The invention discloses a crystallization apparatus for refining and purifying ethylene carbonate and a purification method with its application. Specifically the ethylene carbonate obtained through the rectification and purification processes is transported into a crystallizer to be crystallized by a stepwise cooling method. Through step-by-step heating and melting processes, the ethylene carbonate of over 99.99% purity is obtained. The invention introduces a continuous industrial production, which solves the problems such as high energy consumption, high cost and unmanageable quality controlin preparing high-purity ethylene carbonate in the prior art. By comparison, the obtained product has the advantages of high purity, high yield, stable quality and low cost. In addition, the invention has the advantages of simple processes, convenient operation, easy control, low energy consumption, less equipment investment, low operation cost, stable and reliable operation, high safety, considerable economic benefit and suitability for mass production.

Owner:LIAONING GANGLONG CHEM

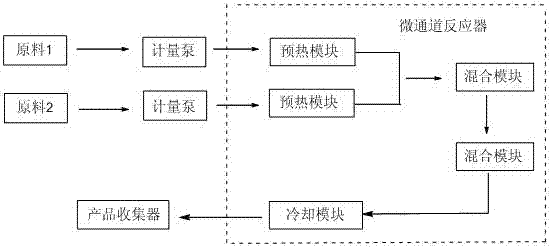

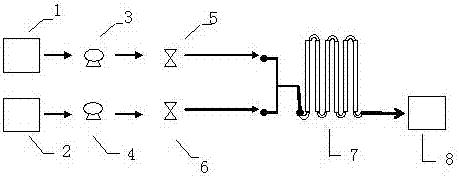

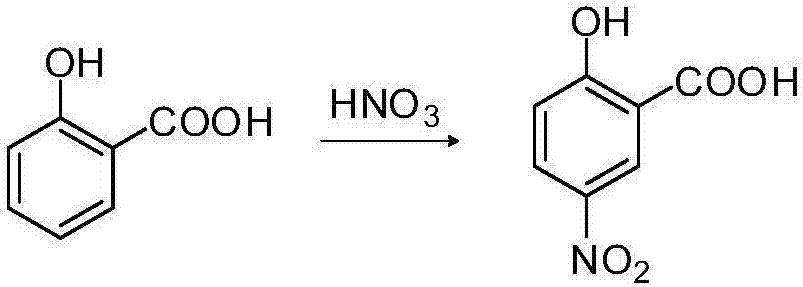

5-nitrosalicylic acid preparation process adopting microchannel continuous flow reactor

InactiveCN107353208AReduce generationSimple preparation processChemical industryChemical/physical/physico-chemical microreactorsIce waterRetention time

The invention relates to a novel 5-nitrosalicylic acid preparation process adopting a microchannel continuous flow reactor and belongs to the technical field of organic synthesis. According to the process, salicylic acid is taken as a raw material, concentrated nitric acid or a mixture of concentrated nitric acid and glacial acetic acid is taken as a nitrification reagent, the raw material and the nitrification reagent are injected into a reaction module of the microchannel reactor by a metering pump respectively, a material discharged from the reactor is directly injected into ice water, solids are separated out, and 5-nitrosalicylic acid is obtained through water washing. Continuous, efficient, safe and energy-saving industrial production is realized with the microchannel continuous flow process, the preparation process is simple, conditions are mild, retention time is short, product quality is stable, consumed acid content is reduced, yield is high and reaches 75% or higher, and industrial popularization and application are greatly facilitated.

Owner:PUYANG VOCATIONAL & TECHN COLLEGE

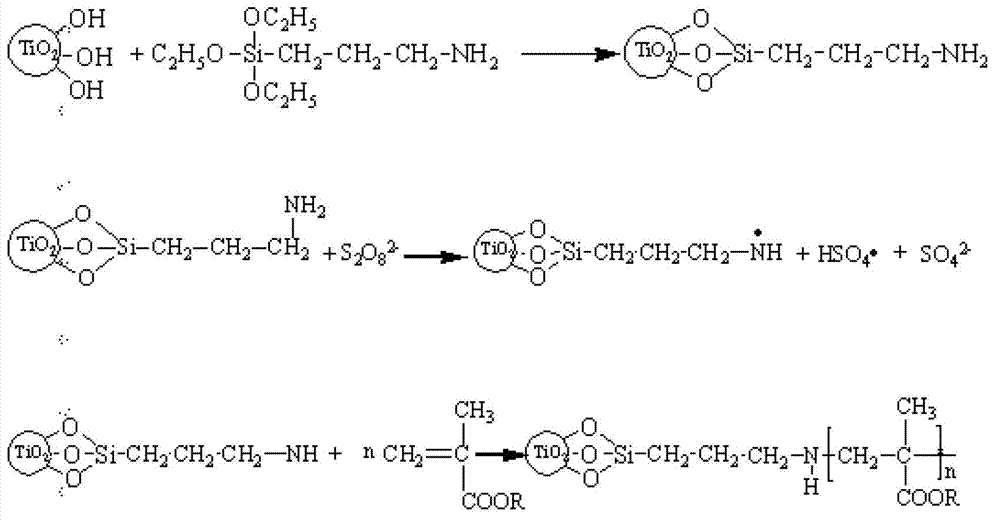

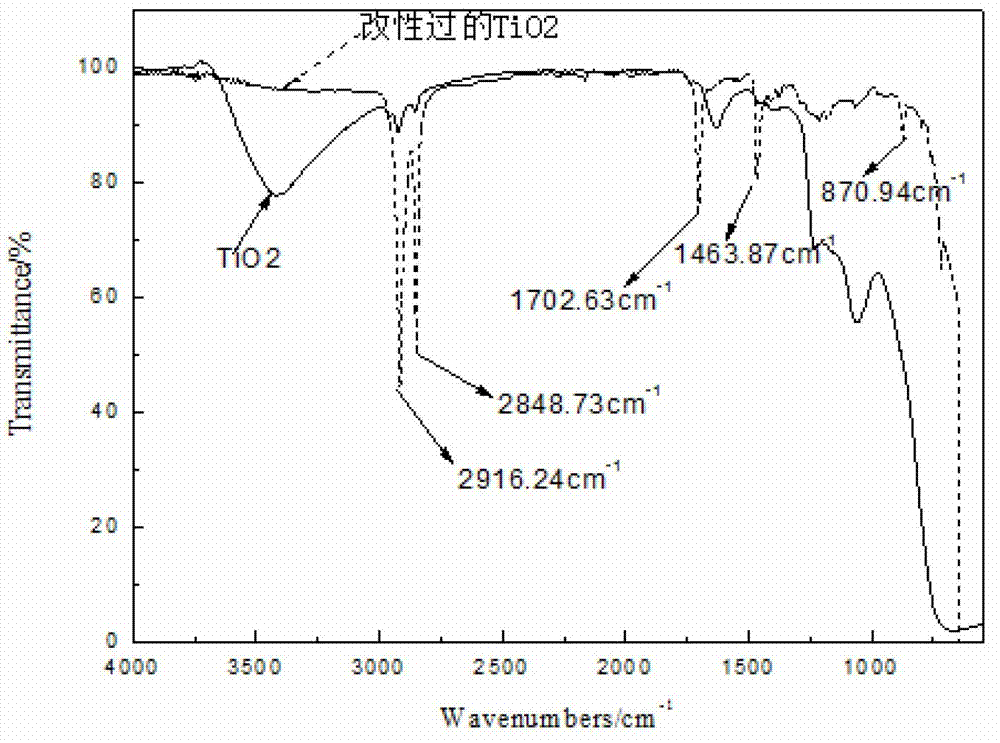

PVDF (polyvinylidene fluoride) film modified with nano-titanium dioxide and preparation method for PVDA film

The invention provides a PVDF (polyvinylidene fluoride) film modified with nano-titanium dioxide and a preparation method for the PVDA film. Fluorinated polyacrylate is grafted on the surface of the nano-titanium dioxide in the film, compatibility of TiO2 in PVDF is greatly improved due to the existence of a graft monomer, and when the PVDF film is used for solar cell back films, bonding force between the PVDF film and other dorsal plate base materials is greatly enhanced. The preparation method includes: firstly grating the fluorinated polyacrylate on the surface of TiO2, weighing graft copolymer and the PVDF according to a part ratio for mixing in a mechanical stirring manner, using an extruder for extrusion and strip formation after uniformly mixed, placing into a drying oven to dry moisture after being cut into granules, squeezing out by a single screw for tape casting, and obtaining the modified PVDF film.

Owner:CHANGZHOU UNIV +1

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795AIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Chemical fibre containing organic metal catalyst, production and use thereof

InactiveCN1746342ADeodorization solutionGood effectMonocomponent cellulose artificial filamentMonocomponent polypropylene artificial filamentOrganometallic catalysisManganese

The invention provides a chemical fiber containing organ-metallic catalyst. The weight ratio of the organ-metallic catalyst and the macromolecular compound which is nitrile, cellulose fiber, is (0.5-8): (92-99.5). The organ-metallic catalyst is the organic compound of the Fe, cobalt or manganese. a) phthalocyanine Fe, cobalt or manganese; b) porphyrin Fe, cobalt or manganese; c)porphin Fe, cobalt or manganese. The organ-metallic catalyst is dissolved in the spinning slurry, so to get the fibre by the wet spinning technology. The fiber is deodorant.

Owner:DONGHUA UNIV

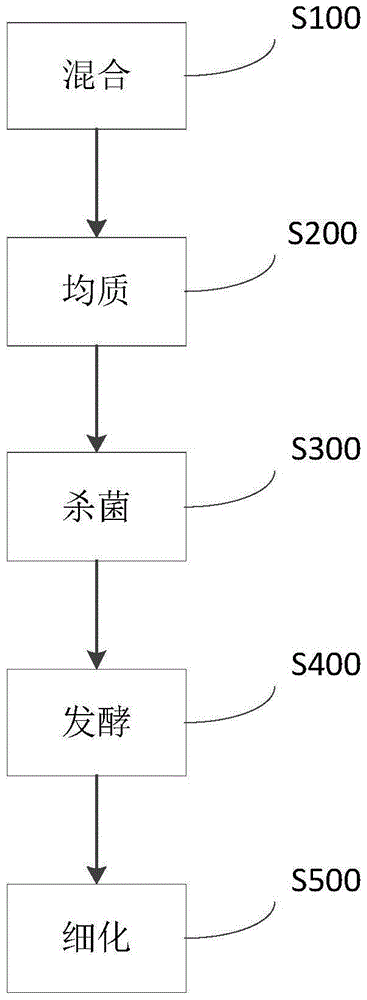

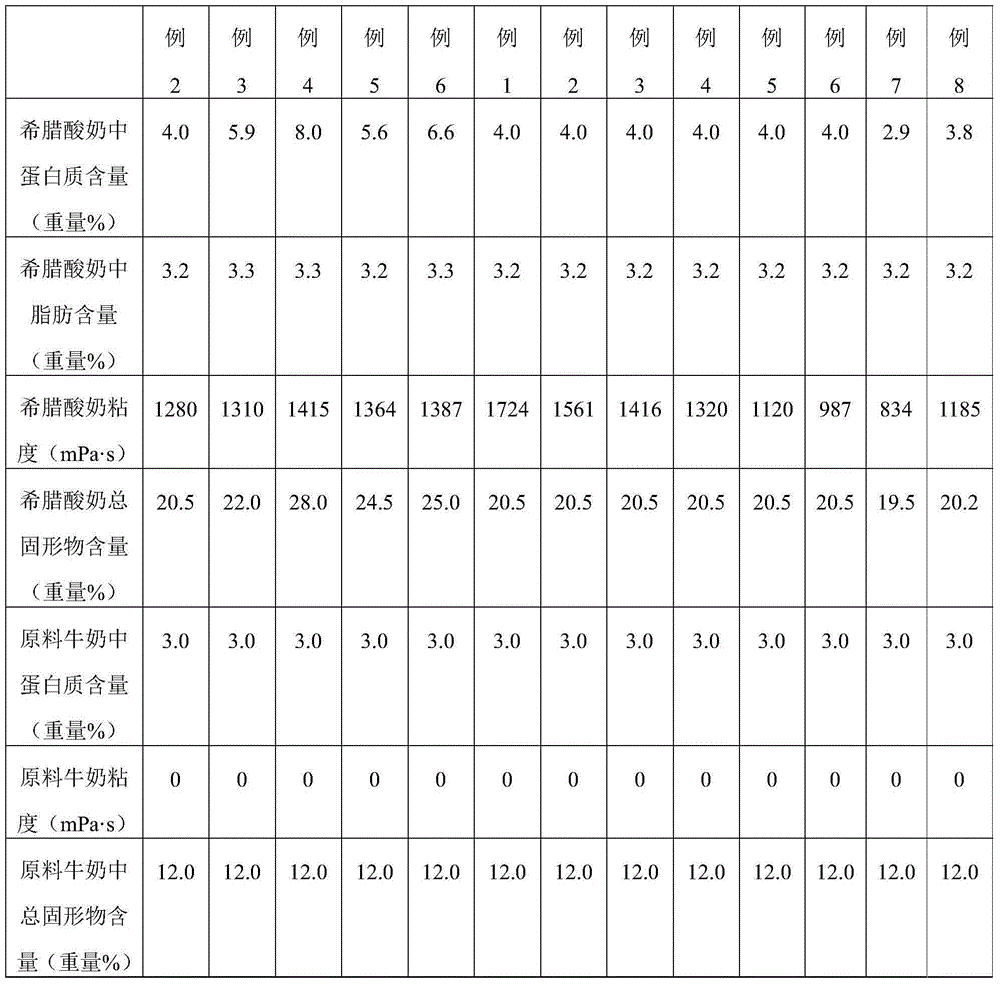

Greece yoghourt and preparation method thereof

The invention provides Greece yoghourt and a preparation method thereof. On the basis of the total weight of the Greece yoghourt, raw materials of the Greece yoghourt comprise 81 to 90 weight percent of milk, 1 to 5 weight percent of milk protein powder, 0.5 to 6 weight percent of whey protein powder, 7 to 10 weight percent of white granulated sugar and 0.05 to 0.1 weight percent of fermentation agents. The Greece yoghourt provided by the invention has at least one of the advantages of very good flavor and mouthfeel, high stability, rich nutrition, rich probiotics and continuous industrial production capability.

Owner:蒙牛乳制品(天津)有限责任公司

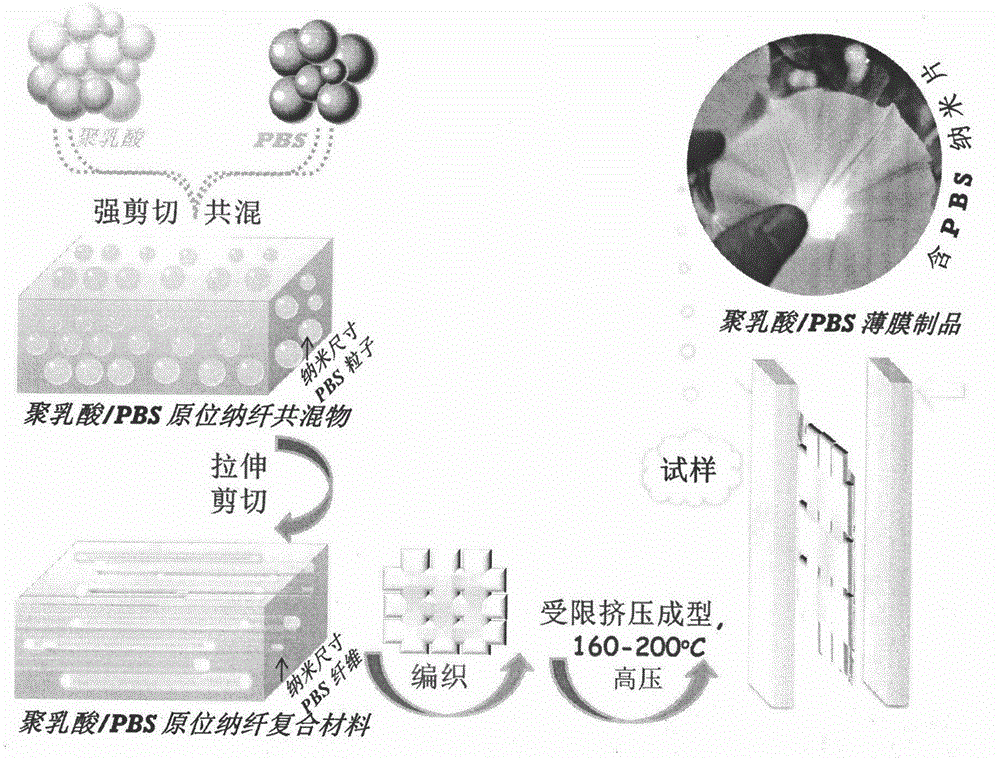

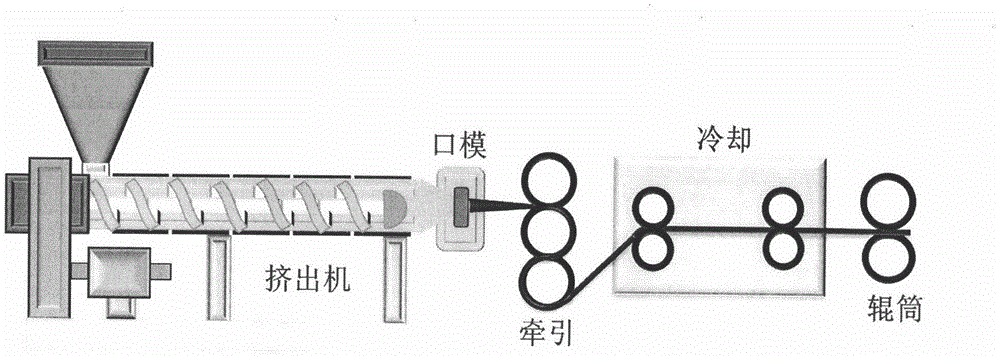

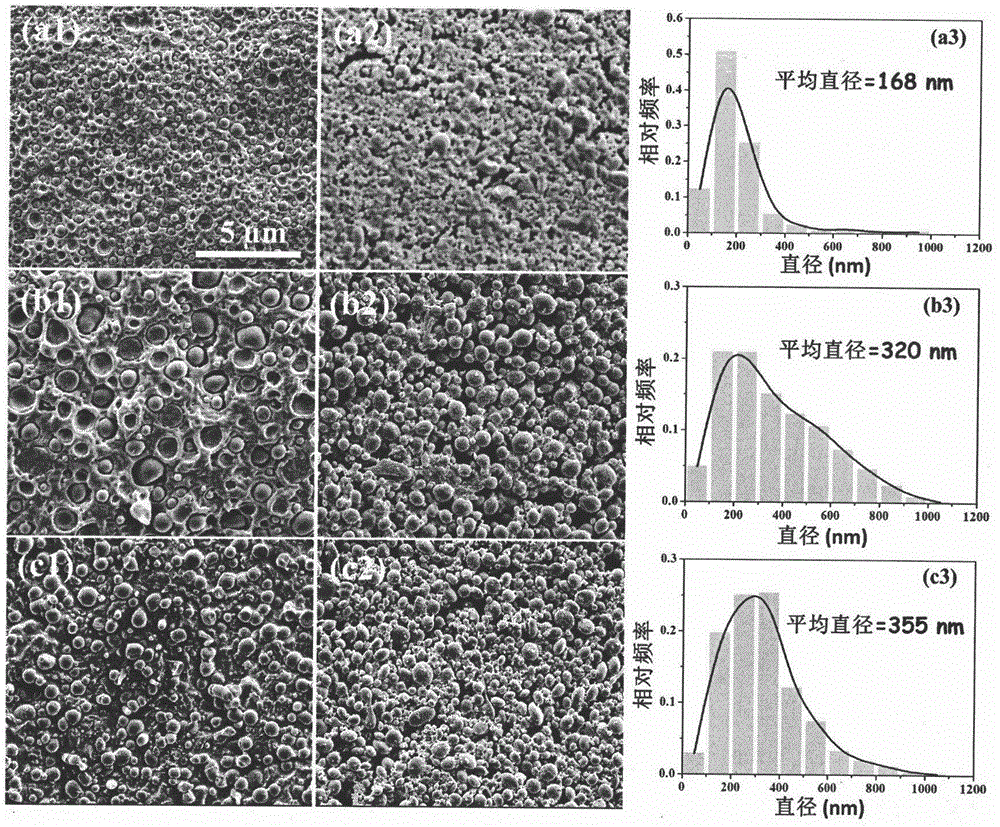

Preparation method of full-degradable high-strength high-barrier polylactic acid film by in-situ introduction of poly butylene succinate nanosheet

InactiveCN105733212AContinuous industrial productionDoes not compromise biodegradable propertiesPoly(butylene succinate)Quenching

The invention discloses a preparation method of a fully degradable high-strength and high-barrier polylactic acid film. The method is to firstly melt and blend polylactic acid and PBS under strong shear, so that the PBS droplets are violently broken into nanoparticles in the matrix. The strong tensile / shear field transforms PBS nanoparticles into nanofibers, and finally uses the "confined sheet" method to transform PBS nanofibers into regular and dense PBS nanosheets in a molding machine or a twin-roller continuous extrusion molding device, A polylactic acid high-strength and high-barrier film containing PBS nanosheets was obtained. The polylactic acid film products containing PBS nanosheets prepared by the present invention retain the good biodegradability of PBS and polylactic acid on the one hand, and on the other hand, a large number of oriented and straightened PBS nanosheets can block the infiltration of gas / water molecules and act as self-reinforcement The structural unit obtains simultaneous improvement of mechanical properties and barrier properties.

Owner:谢兰 +2

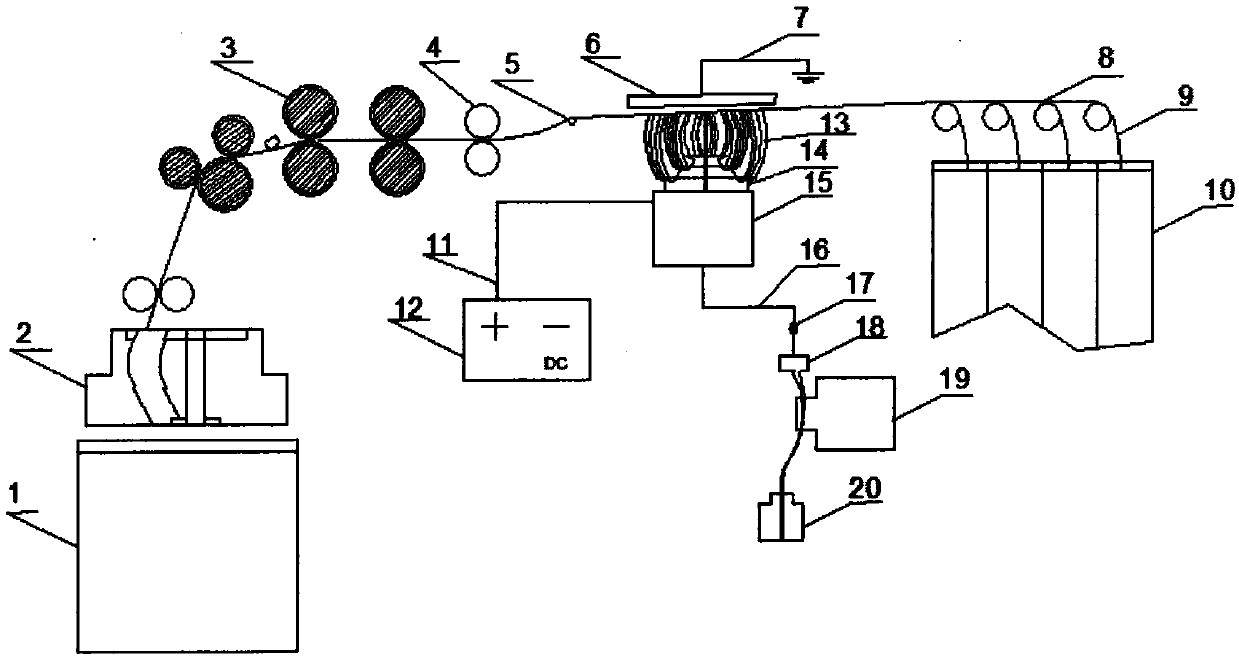

Electrostatic spinning submicron fiber and sliver composite blended yarn preparation device and method

ActiveCN107904732AEquipment modification is simpleWide range of applicationsFilament/thread formingYarnElectrospinningSolvent

The invention discloses an electrostatic spinning submicron fiber and sliver composite blended yarn preparation device and method. The preparation device comprises a drawing frame and an electrostaticspinning device, the electrostatic spinning device comprises needle-free electrostatic spinning spray heads located on the two sides of a sliver respectively and a receiving pole plate, and the needle-free electrostatic spinning spray heads are connected with a high voltage generator; a liquid storage bottle is communicated with the needle-free electrostatic spinning spray heads. The preparationmethod comprises the steps that a control valve and a liquid supply pump are opened, and a spinning solution in the liquid storage bottle flows into the needle-free electrostatic spinning spray heads;the drawing frame is started, the high voltage generator is connected with the needle-free electrostatic spinning spray heads, the high voltage generator is started, multiple jet flows are sprayed out from the needle-free electrostatic spinning spray heads, in the process that the jet flows fly to the receiving pole plate, solvent is volatilized, high polymer is stretched and cured, and submicronfibers are formed and deposited on the sliver. Accordingly, blending of electrostatic spinning submicron fibers and fibers for traditional textile can be achieved, and the functional characteristicsof the submicron fibers are applied to the traditional textile.

Owner:DONGHUA UNIV

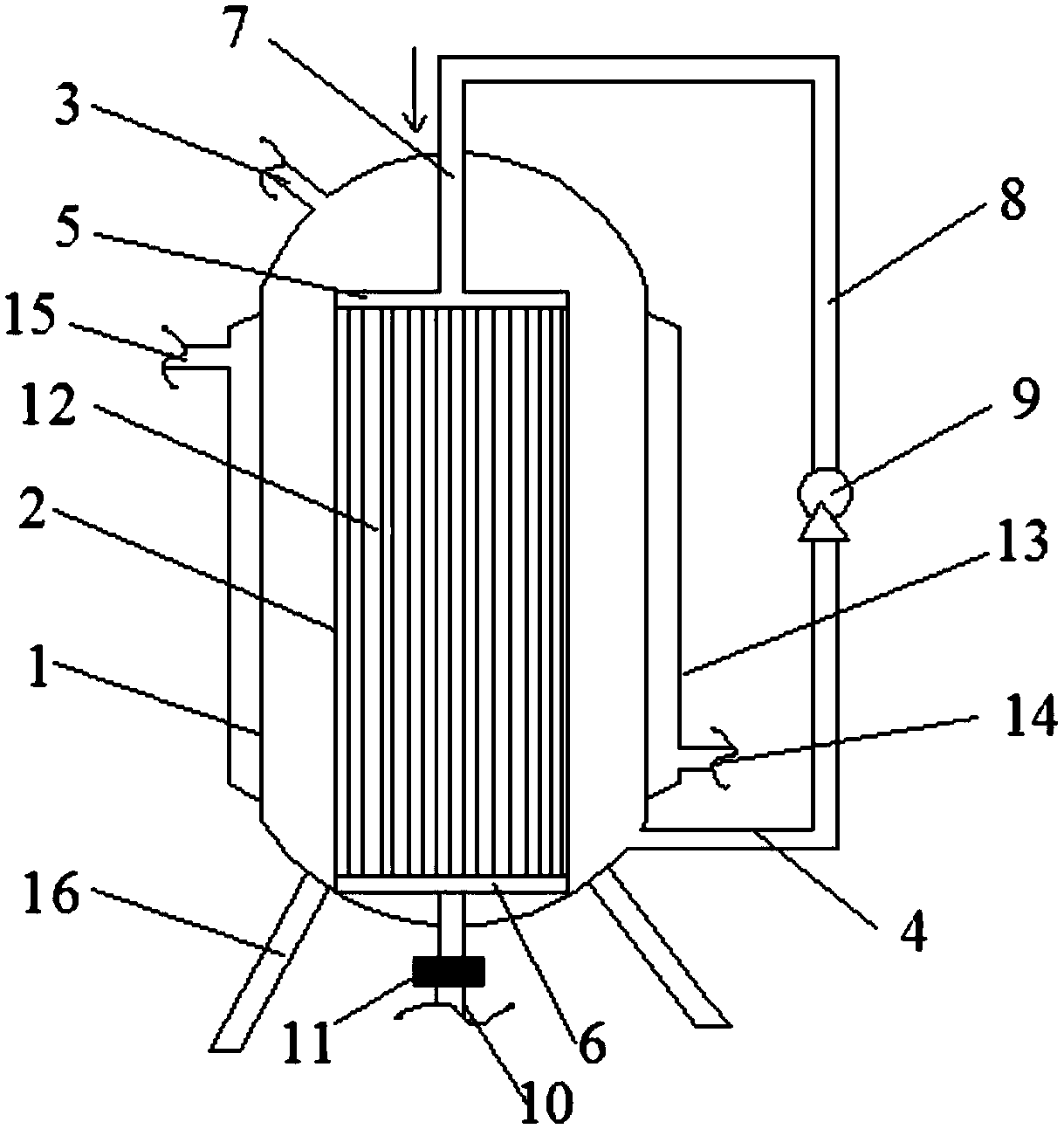

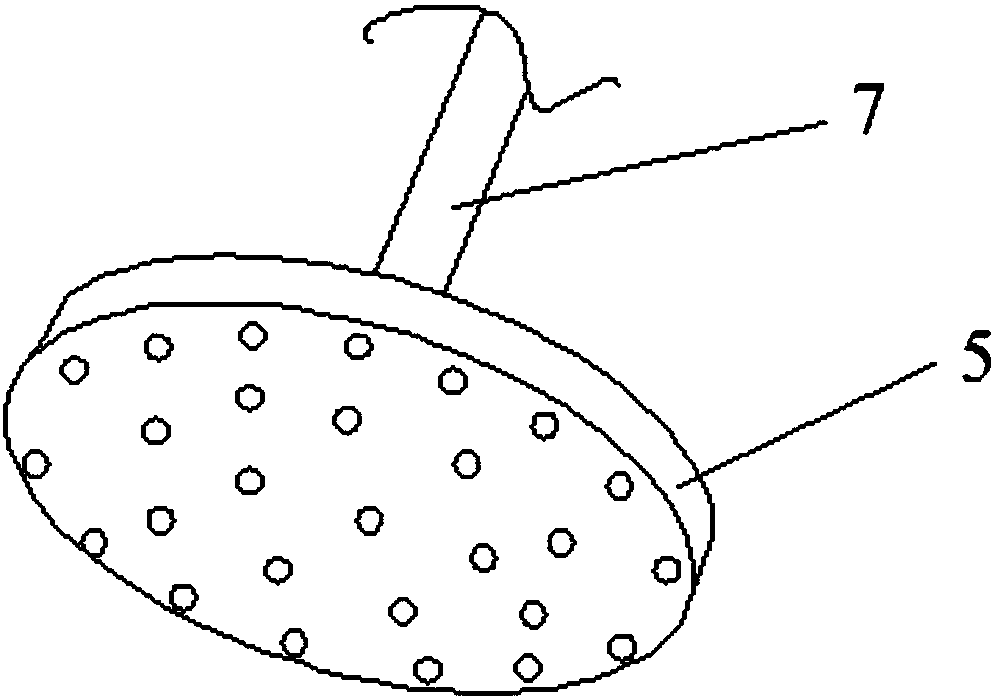

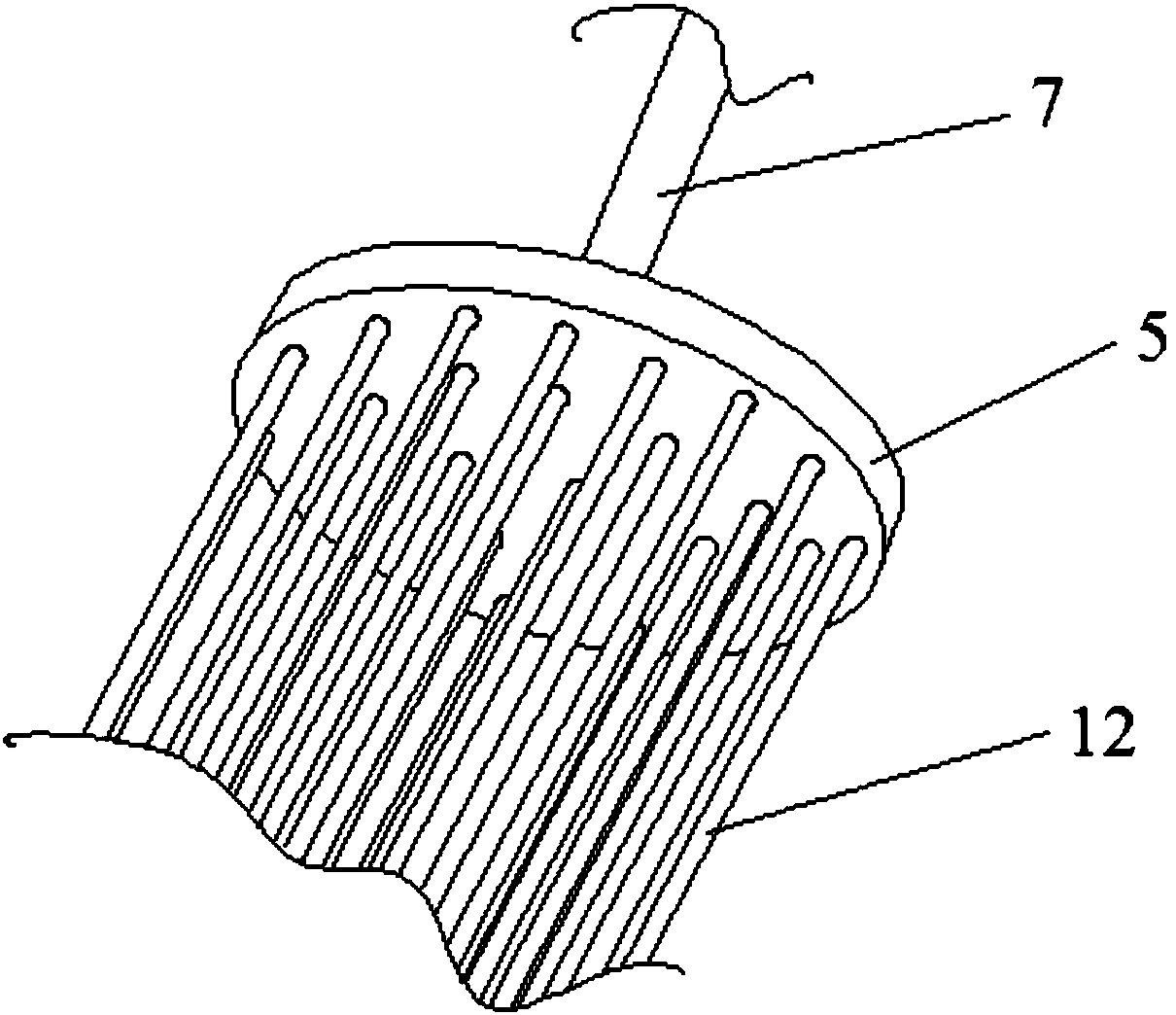

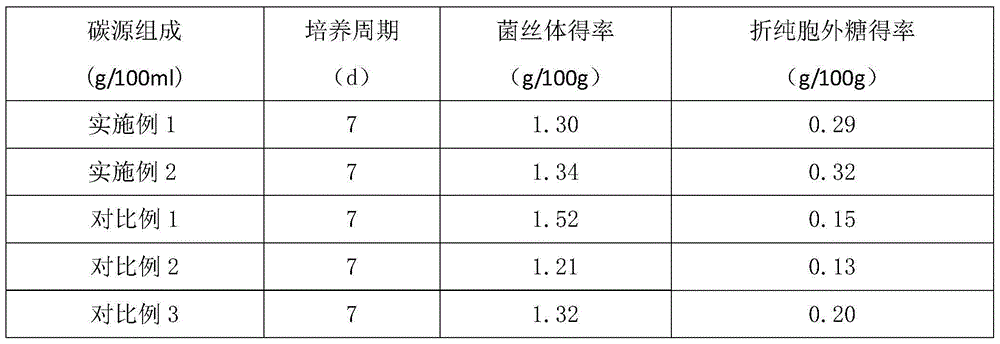

Method for producing inonotus obliquus exopolysaccharides through submerged fermentation

ActiveCN104099385AImprove qualityContinuous industrial productionMicroorganism based processesFermentationModel selectionInonotus obliquus

The invention belongs to the technical field of microorganisms, and relates to a method for producing inonotus obliquus exopolysaccharides through submerged fermentation, particularly to a method for industrial-scale production of the inonotus obliquus exopolysaccharides. The method comprises the steps as follows: activated inonotus obliquus strains are inoculated into a seed tank for propagation, then propagated liquid seeds are inoculated into a specially-made polysaccharide-producing liquid culture medium for fermentation, and a fermentation liquid is separated to extract the exopolysaccharides. According to the method, research is conducted to overcome defects in the prior art, on the premises that a fermentation culture medium (especially a carbon source) is continuously optimized through small and medium tests and the biomass and the exopolysaccharides are increased, the problems of fermentation process parameter control, extracting equipment model selection, optimization and the like in the process of enlargement from the small tests to industrial production are solved, the strains are successfully inoculated into fermentation tanks of 10-20 t finally for industrial production, the high-quality inonotus obliquus polysaccharides are produced smoothly, and the continuous, automatic and industrial production is actually realized.

Owner:JIANGSU SHENHUA PHARMA

Bean curd and bean curd production method

ActiveCN102524418AFully automatedImprove automationCheese manufactureFood scienceEmbryoCotyledon plant

The invention discloses bean curd and a bean curd production method. The bean curd production method comprises the following steps: preparing soybean milk; and mixing the soybean milk with a coagulant, coagulating to obtain bean curd. The preparation of the soybean milk comprises 1) adopting soybean cotyledon particles to serve as a raw material after breaking, embryo removal and soybean skin removal; 2) grinding after soaking the soybean cotyledon particles in water for 30-60 minutes, removing bean dregs after grinding so as to obtain raw soybean milk, and enabling the weight ratio between the cotyledon particles and water for soaking the cotyledon particles to be 1:6-11 during soaking; and 3) boiling the raw soybean milk, maintaining the temperature at over 85 DEG C for 30-45 minutes toobtain the soybean milk. The bean curd production method is scientific and simple, overcomes various shortcomings in the prior art, enables coagulating process of the soybean milk to be effectively adjusted, is favorable for achieving industrialized production of bean curd, and has the advantages of saving energy, simplifying equipment and reducing sewage discharge. Besides, the quality of the produced bean curd is equal to or close to that of northern bean curd.

Owner:FOODSTUFF INST BEIJING

Material of polyolefin elastomer dedicated to skins of instruments decorated inside auto car

This invention discloses an automobile inner decoration material of polyolefin elastomer. The material comprises: ternary ethylene-propylene rubber 30-60 wt.%, polyethylene 10-35 wt.%, polypropylene 6-35 wt.%, silane coupling agent 3-7 wt.%, organic Sn 0.5-3.5 wt.%, perfluorodibenylethane 5-8 wt.%, Ti2O3 1.5-3 wt.%, antioxidant-1010 0.3-0.5 wt.%, and zinc stearate 0.3-0.8 wt.%. The material can be produced by traditional ABS / PVC resin production process and apparatus. The material has such advantages as good physical properties, light weight, high elasticity, and good permanent deformation performance, high scrape resistance, and high heat and cold resistance, and can be used for automobile inner decoration.

Owner:双嘉新材料科技(浙江)有限公司

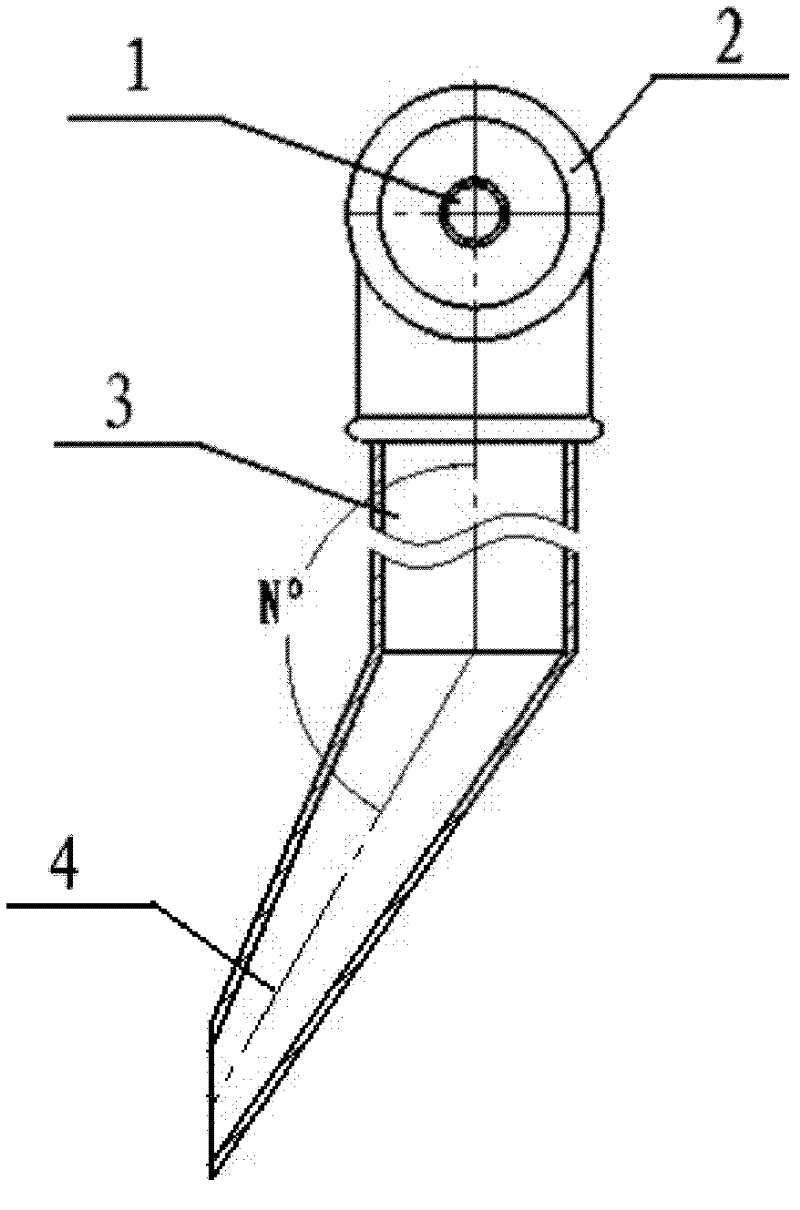

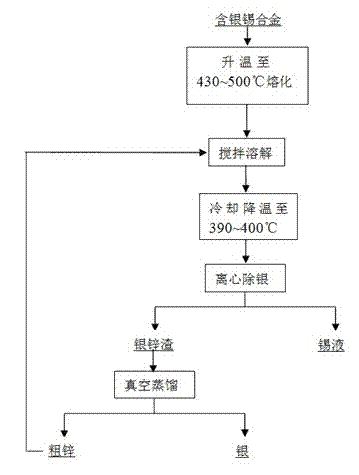

Method for extracting silver from silver-containing crude tin alloy

The invention provides a method for extracting silver from silver-containing crude tin alloy. The method comprises the following steps of: heating the silver-containing crude tin alloy to reach the temperature of 430 to 500 DEG C for melting; feeding a zinc ingot into the molten silver-containing crude tin alloy, and agitating to dissolve; cooling the dissolved mixture to reach the temperature of 390 to 400 DEG C; and centrifugally separating at a rotating speed of 200-700rpm until the surface of the liquid at the upper layer has no floating slags, so as to obtain the tin liquid at the upper layer and the sliver-zinc slags at the lower layer; naturally cooling and condensing the tin layer to obtain the tin alloy without silver; and distilling the silver-zinc slags under the vacuum to obtain the silver and the crude zinc, wherein the silver in the tin alloy subjected to silver extracting is less than 10g / t. According to the method, the whole process is safe and controllable; the method is convenient to operate, and has no exhaustion of three wastes; and the method has high universality to the raw materials; the tin alloys with different silver contents can be effectively processed; the continuous industrial production can be achieved; and high recovery rate of the tin and the silver can be ensured; the silver in the silver-containing tin alloy can be efficiently extracted; with adoption of the method, the quality of the tin can be improved, and large amounts of silver can be recovered for the enterprises.

Owner:KUNMING UNIV OF SCI & TECH

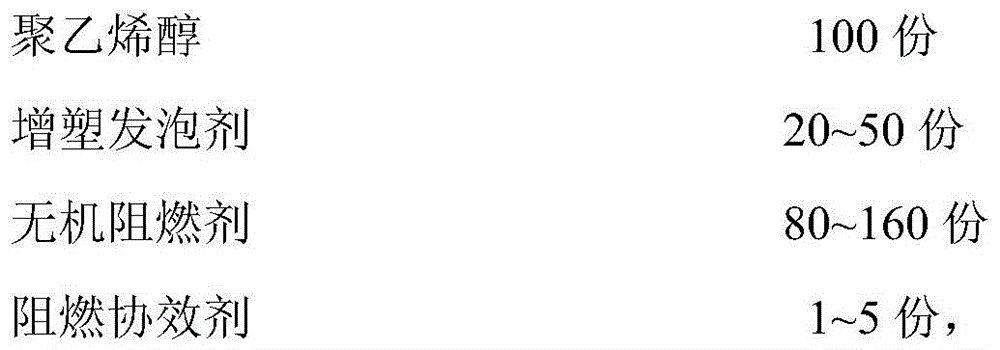

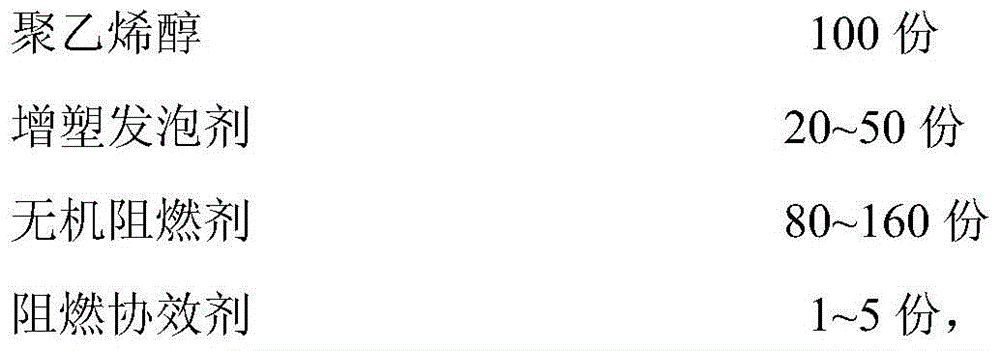

High-fill high-heat-resistance polyvinyl alcohol-based microcellular foam type flame retardant paper and thermoplastic processing method thereof

The invention discloses high-fill high-heat-resistance polyvinyl alcohol-based microcellular foam type flame retardant paper.The microcellular foam type flame retardant paper is prepared through the steps that polyvinyl alcohol and a plasticizing foaming agent are mixed and swelled and then mixed with an inorganic flame retardant and a flame retardant synergist to obtain composite powder; the composite powder is added into a screw extruder for microcellular foam extrusion, cooling traction, flattening and winding are conducted.The vertical burning class is V-0, the limit oxygen index is 35%-41%, the tensile strength is 1.0-4.5 MPa, the apparent density is 0.05-0.50 g / cm<3>, the average cell diameter is 70-200 micrometers, and the thickness is 0.1-2.0 mm.The flame retardant paper is excellent in thermal resistance, can meet the requirement of rapid laser printing, is excellent in comprehensive performance and low in cost and can be prepared by directly adopting a thermoplastic processing method, the technology is simple and easy to operate, and continuous industrialized production can be achieved.

Owner:SICHUAN UNIV

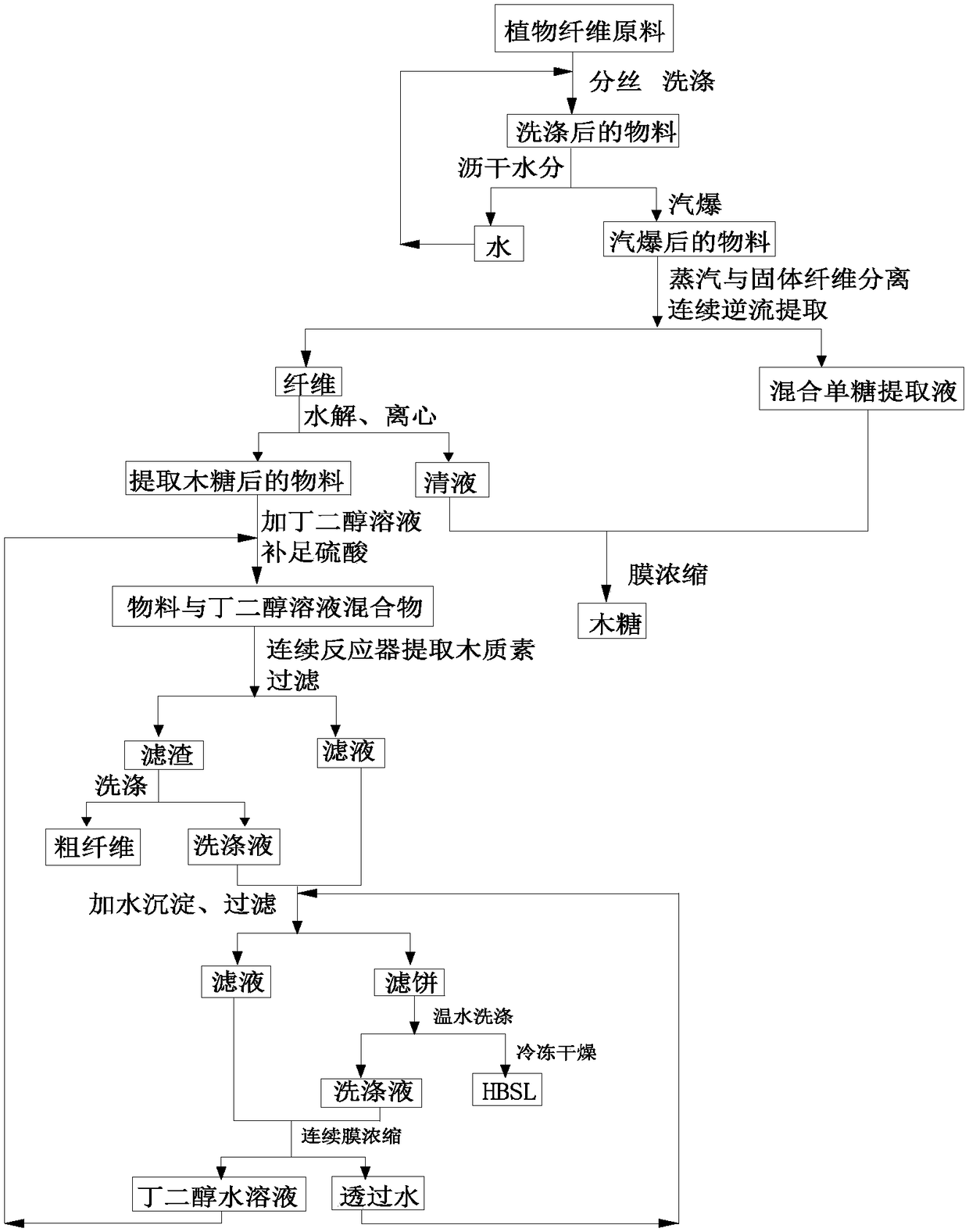

Method of using plant fibrous materials to produce xylose, high boiling solvent lignin and fiber

InactiveCN108179646ATake advantage ofEfficient use ofPulp liquor regenerationPulp bleachingState of artPlant fibre

The invention discloses a method of using plant fibrous materials to produce xylose, high boiling solvent lignin and fiber. The problem in the prior art that a traditional paper industry only uses thefiber, causes the waste of other elements and environmental pollutionis solved. By adopting a gas explosion method, the xylose is extracted from the plant fibrous materials, after that, the high boiling solvent lignin is extracted from the rest of materials, and the materials which the xylose and high boiling solvent lignin are previously extracted from are used for papermaking and dissolving thefiber. The method of using plant fibrous materials to produce the xylose, the high boiling solvent lignin and the fiber has a simple process and convenient operation, can fully and respectively extract the fiber, the xylose, and hemicellulose so that the elements are effectively utilized, completely utilizes the materials, and reduces the environmental pollution.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

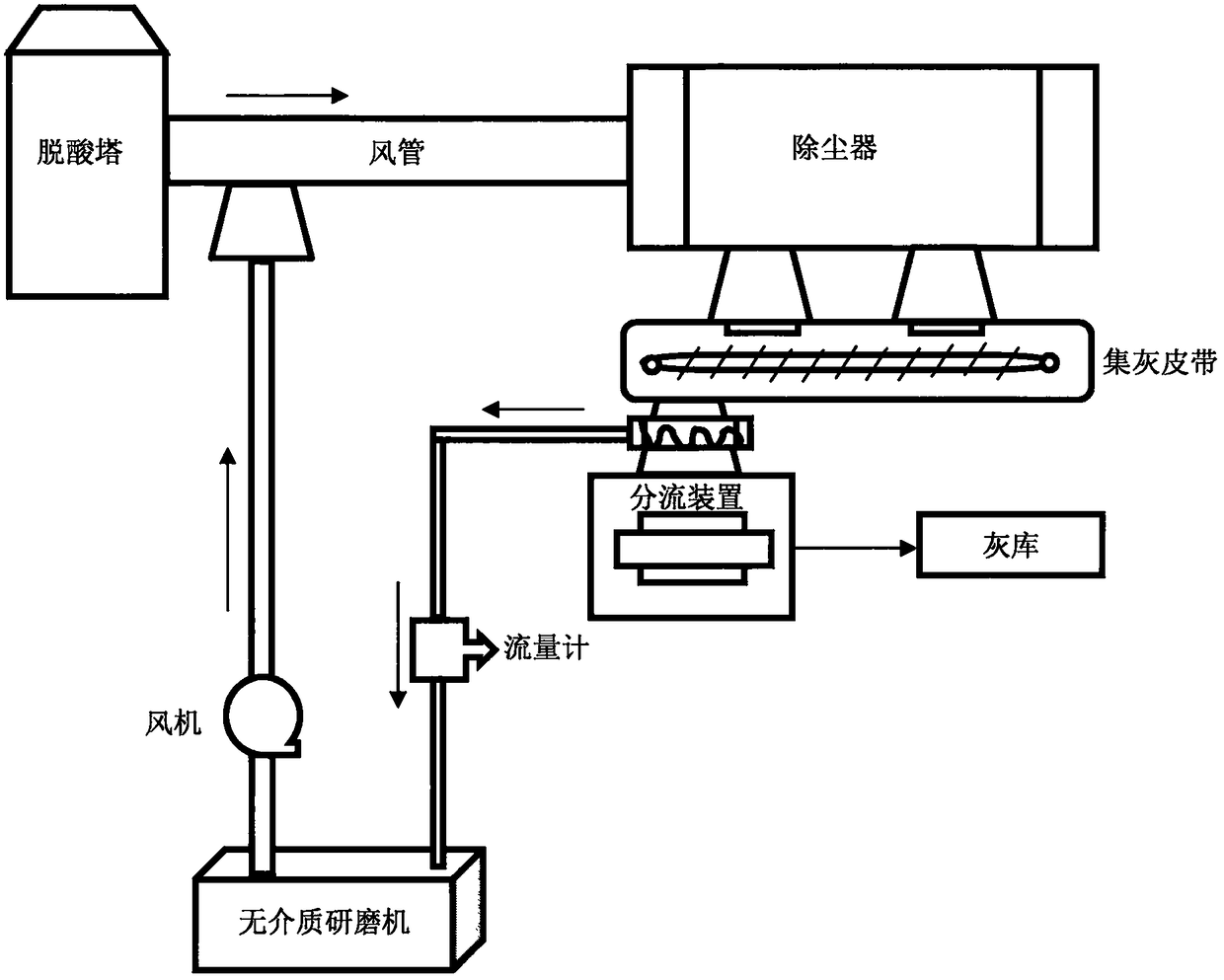

Household waste incineration fly ash cyclic utilization method

ActiveCN108273825AFlexible control of the amount of fly ashContinuous industrial productionSolid waste disposalTransportation and packagingPrillPhosphate

The invention relates to a household waste incineration fly ash cyclic utilization method. A flow distributing device is installed at the lower end of a dust remover of a waste incineration smoke treatment system and controls the amount of fly ash circularly entering a non-medium grinding machine, and therefore the phenomenon that since the fly ash agglomerates at a grinding medium or adheres to the inner wall of the grinding machine, the grinding effect is influenced is avoided. After the fly ash is smashed in a grinding bin, a high-pressure centrifugal fan brings the grinded powder materialsinto a powder selecting machine, fine powder meeting the fineness requirement enters a circulatory system along with airflow, and coarse particle materials incapable of meeting the fineness requirement return to the grinding bin to continue to be grinded. It is guaranteed that the particle sizes of the grinded fine powder are uniform and kept within a certain range, unreacted calcium hydroxide isfully exposed, the specific surface area of the fly ash is increased, the utilization rate of the calcium hydroxide in the fly ash can be improved to be 80% or over, and continuous industrial production can be achieved. Meanwhile, phosphate is fed into the non-medium grinding machine so as to pre-stabilize heavy metal and reduce the application amount of follow-up deacidification agents, and thephosphate also has the grinding assistance function. A strong oxidant is added and achieves the desulfurization and denitration function and the function of promoting dioxin to decompose.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

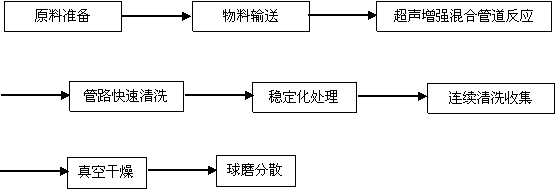

Process method of continuously producing ultra-fine nickel powder

The invention provides a process method of continuously producing ultra-fine nickel powder. The process method comprises the working procedures of preparation of raw materials, material conveying, ultrasound enhancement tubular reaction, rapid cleaning of pipelines, ultrasonic agitation stabilizing treatment, continuous cleaning and collection of the powder, vacuum drying, ball-milling dispersion and the like. By means of the technologies, in a preparation course, the process method has the advantages that continuous industrial production can be achieved, equipment investment is small, product quality is stable, and the shapes and the particle sizes of products are controllable.

Owner:SHENZHEN NONFEMET TECH

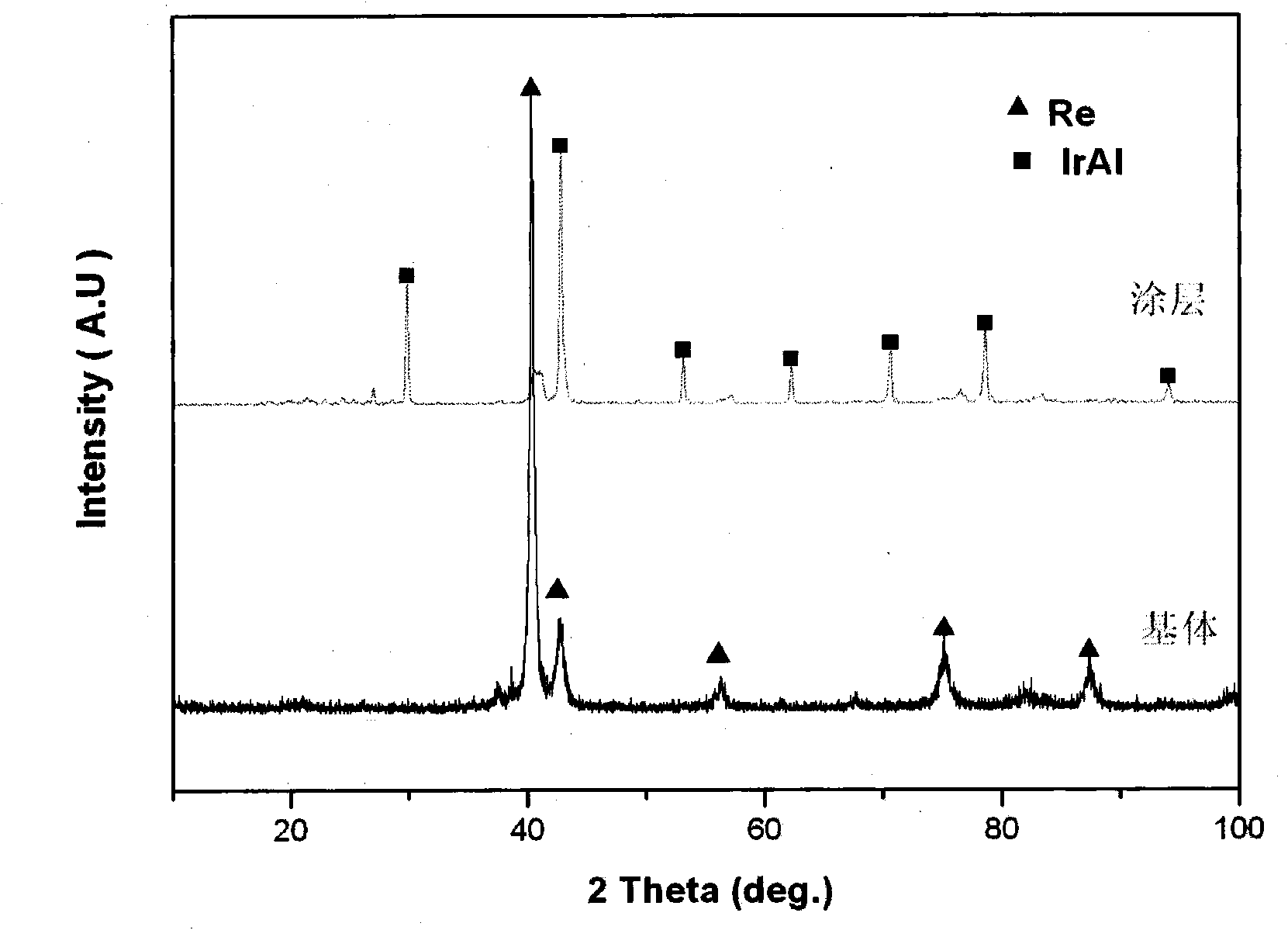

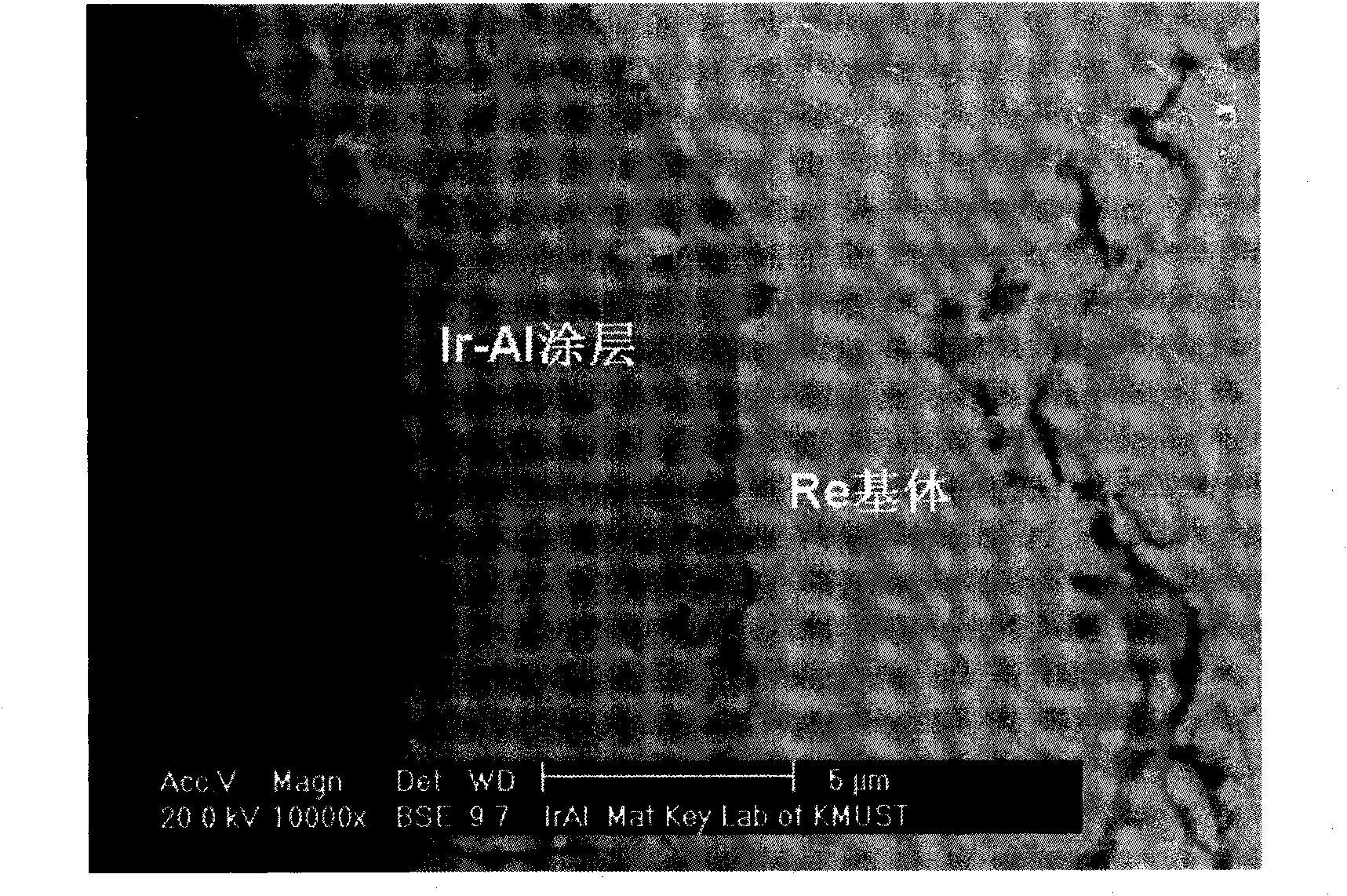

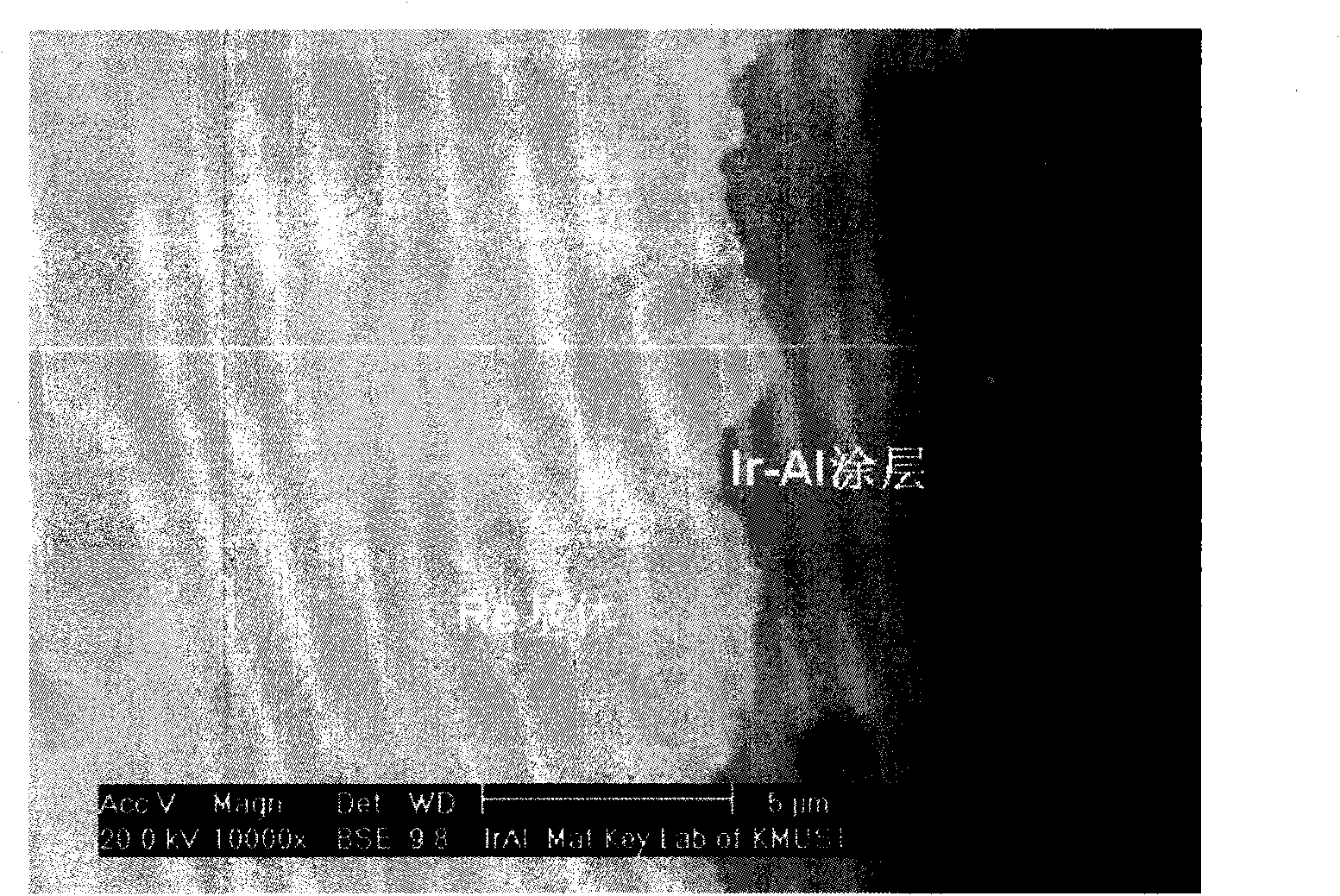

Preparation method of iridium-aluminum high temperature oxidation resistance coating

InactiveCN101643902AImprove bindingThickness is easy to controlSuperimposed coating processIridiumChemical treatment

The invention discloses a preparation method of iridium-aluminum coating, comprising the following steps: firstly performing surface cleaning and chemical treatment to the high temperature alloys or refractory metal substrates; then adopting electroplating process or chemical vapor deposition method to process the surface of the treated alloy to obtain a layer of pure iridium with a thickness of 0.5-10 microns; and finally performing pack cementation aluminizing at a certain temperature to obtain the iridium-aluminum coating. The bonding intensity between the iridium-aluminum coating and the substrate is high and the coating can be widely used in all kinds of high temperature alloys or refractory metals so as to increase the service life of the alloys or metals effectively and ensure the high temperature alloys or refractory metals to have excellent cold resistance, thermal shock resistance and high temperature oxidation resistance.

Owner:KUNMING INST OF PRECIOUS METALS

Active casein phosphopeptide and its preparing process

InactiveCN1378863AImprove immunitySpecial affinityPeptide/protein ingredientsMetabolism disorderDistilled waterPhosphopeptide

An active casein phosphopeptide is prepared from industrial casein (or milk powder) 80-150 g, calcium oxide 2.8-4.8 y, trypsase 2-6 g and distilled water 1000 g through mixing industrial casein with distilled water, stirring while heating to 35-45 deg.C, regulating pH value to 4-5, adding calcium oxide, gradually heating to 60-78 deg.C, holding the temp. for 20-30 min, cooling to 36-39 deg.C, adding trypsase, filtering, deodouring, derusting, spray-drying to obtain the powder and sieving to remove large granules. Its advantages are easy absorption by human body and low cost.

Owner:徐佳立

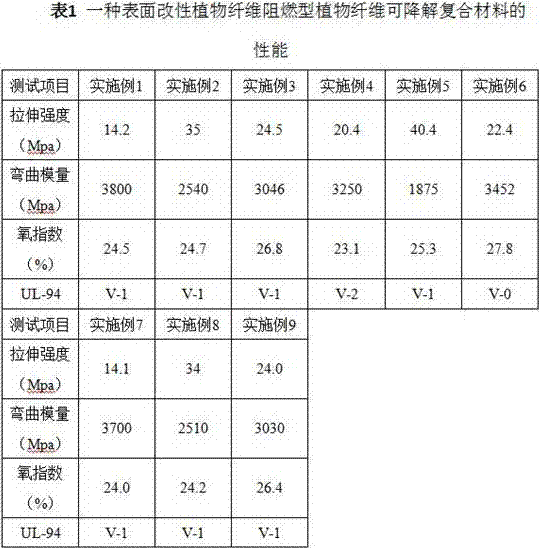

Preparation method of degradable wood-plastic composite material

ActiveCN107254147AGood dispersionImprove the interface binding forceVegetal fibresFiberMechanical property

The invention discloses a preparation method of a degradable wood-plastic composite material, and belongs to the technical field of preparation of composite materials. The preparation method comprises the following steps: preparation of a surface modifying agent, surface modification of plant fibers, preparation of a flame retardant and preparation of the composite material. The composite material has excellent flame-retardant property and mechanical property, influence on the degrading property of the composite material is small, the cost is low, and batched, continuous and large-scale industrial production is facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

White carbon black with dyeing groups on surface and preparation method of white carbon black

InactiveCN106566290AAffinity plusImprove performanceAnthracene dyesPigment treatment with macromolecular organic compoundsPolymer sciencePolyolefin

The invention relates to white carbon black with dyeing groups on the surface and a preparation method of the white carbon black. In a formula I, R represents reactive groups of a silane coupling agent, and Dye represents the dyeing groups. The dye modified white carbon black prepared with the method has wide raw material sources and is lower in cost, part of monomers is the industrialized raw material, and a reaction method is mature. Compared with non-modified white carbon black, the dye modified white carbon black prepared with the method has high hydrophobic and lipophilic properties, and can improve combining property with reinforced rubber and improve reinforcement effect; meanwhile, the white carbon black has different colors and can endow the reinforced rubber with different colors, and besides, transference resistance of the dye is better; an obtained copolymer has broad application prospect in the aspect of improvement of flame retardancy and bonding flame retardancy of polyolefin.

Owner:QINGDAO UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com