Lithium ion battery cathode material with variable slope concentration gradient doping structure and preparation thereof

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of lithium ion battery positive electrode materials with variable slope concentration gradient doping structure and its synthesis field, can solve the problems of limiting large-scale application process, material capacity and rate decay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a positive electrode material of a lithium ion battery with a variable slope concentration gradient doping structure, which specifically includes the following steps:

[0041] (1) Solution configuration: Prepare a precipitant aqueous solution with a concentration of 0.01mol / L~5mol / L, a complexing agent aqueous solution with a concentration of 0.02mol / L~15mol / L, and a metal salt solution with a concentration of 0.01mol / L~4mol / L , 0.01-2mol / L doping element solutions e and f; wherein at least one of e and f contains one or more doping elements, and the concentrations of the same type of metal ions contained in e and f are different;

[0042] (2) Preparation of precursor: Dilute the complexing agent aqueous solution c prepared in step (1) into an aqueous solution with a concentration of 0.01 mol / L to 5 mol / L, and then add it to a continuously stirring liquid phase reactor as the initial reaction bottom After starting the reacti...

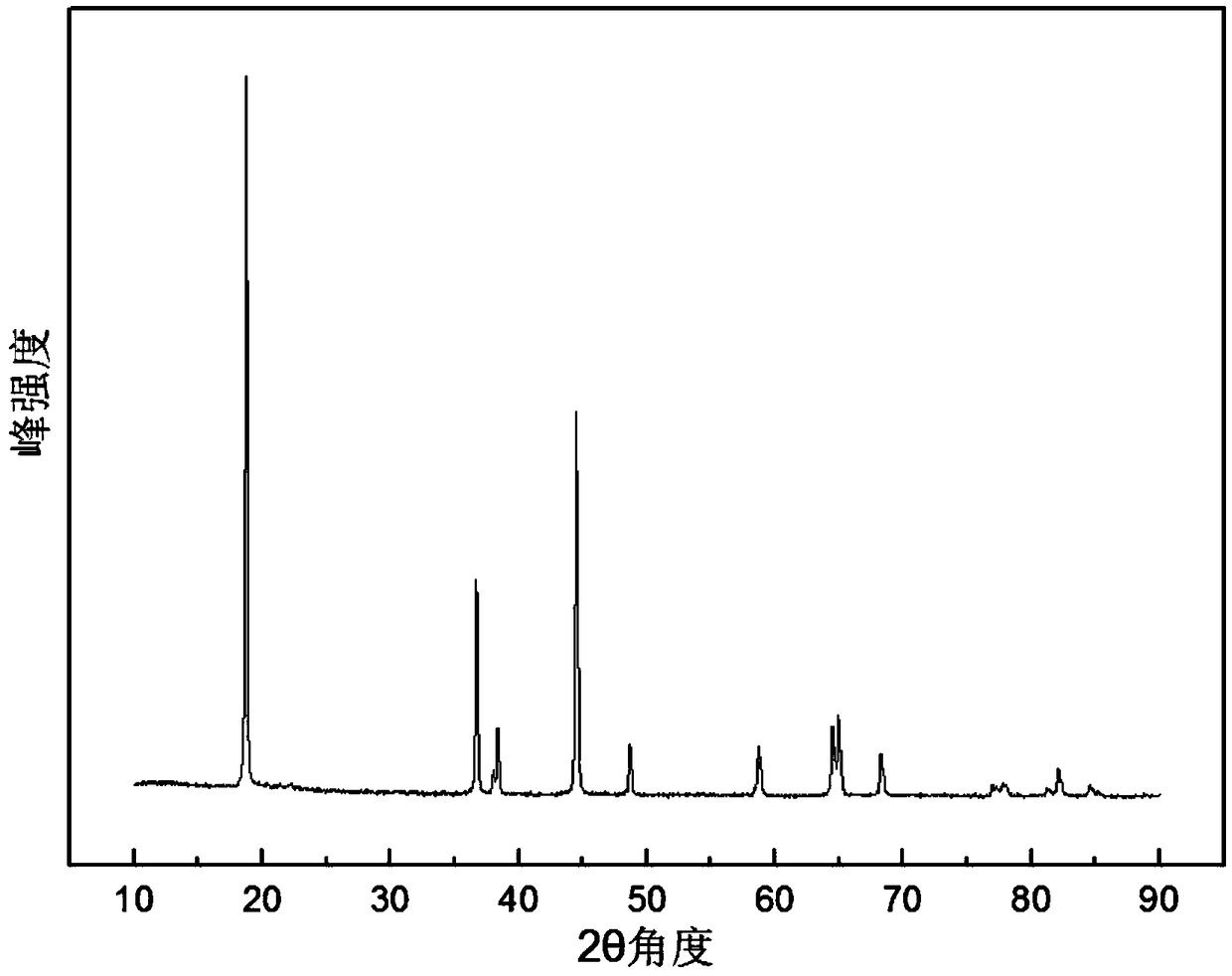

Embodiment 1

[0052] Prepare a mixed metal salt solution d of nickel sulfate, cobalt sulfate and manganese sulfate with a molar ratio of Ni:Co:Mn=8:1:1 and a total concentration of 2.0mol / L, and prepare isopropanol with a concentration of 0.2mol / L Aluminum e solution and concentration are 0.1mol / L aluminum isopropoxide f solution, 4.0mol / L complexing agent ammonia solution c, 2.0mol / L precipitant sodium hydroxide solution b;

[0053] Get the complexing agent ammonia solution of 4.0mol / L and dilute it into the ammonia solution of 0.5mol / L and join in the reactor as the bottom liquid of reaction, in inert N 2 Under the protection of the atmosphere, the reaction bottom liquid was heated to 50°C, and then the aluminum isopropoxide e solution was gradually pumped into the continuously stirring aluminum isopropoxide solution f at a rate of 0.5L / h, and then the solution in f was pumped into 1L The rate of / h is gradually pumped into the coprecipitation reactor, and at the same time, the mixed meta...

Embodiment 2

[0056] The difference between this embodiment and Example 1 is that the precipitation agent is a mixture of sodium hydroxide and lithium hydroxide, and the molar ratio of the two is 1:1; the lithium source is a mixture of lithium hydroxide, lithium nitrate and lithium sulfate, and hydrogen The molar ratio of lithium oxide: lithium nitrate: lithium sulfate is 1:1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com