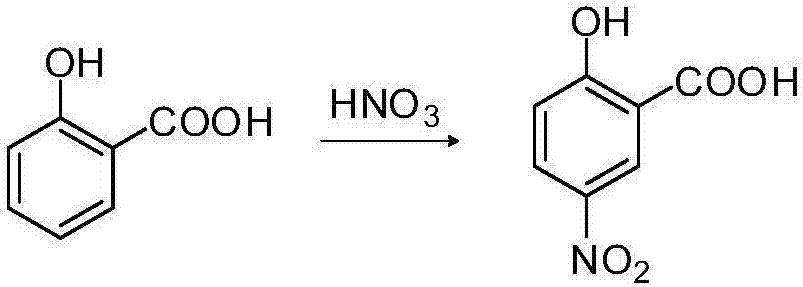

5-nitrosalicylic acid preparation process adopting microchannel continuous flow reactor

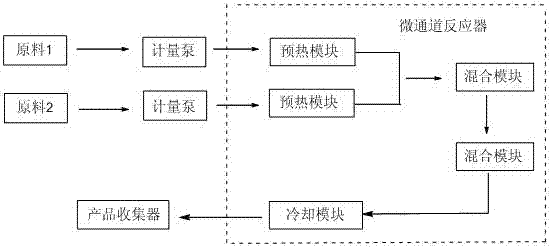

A technology of microchannel reactor and nitrosalicylic acid, which is applied in the direction of sustainable manufacturing/processing, chemical/physical/physicochemical reactors, nitro compound preparation, etc., to achieve pollution reduction, simple preparation process, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

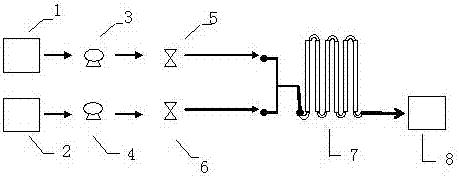

[0021] (1) add the aqueous solution of salicylic acid (the mass percentage composition of salicylic acid is 15%) in the storage tank 1, utilize metering pump 3 to inject in the preheating module of microchannel reactor with the speed of 100mL / min; Add the mixed solution of concentrated nitric acid and glacial acetic acid (mass ratio 1:1) in 2, utilize metering pump 4 to inject in another preheating module of microchannel reactor with the speed of 33mL / min; The module reacts, the reaction temperature is controlled at 60°C, and the reaction retention time is 30s, then enters the cooling module, and finally enters the product collector in a continuous flow state.

[0022] (2) The product precipitated after adding water, was filtered and washed with water, and then recrystallized to obtain a white powdery solid with a yield of 79%.

Embodiment 2

[0024] (1) add the aqueous solution of salicylic acid (the mass percentage composition of salicylic acid is 15%) in the storage tank 1, utilize metering pump 3 to inject in the preheating module of microchannel reactor with the speed of 100mL / min; Add concentrated nitric acid in tank 2, utilize metering pump 4 to inject in another preheating module of microchannel reactor with the speed of 15mL / minute; The retention time is 10s, after which it enters the cooling module, and finally enters the product collector in a continuous flow state.

[0025] (2) The product precipitated after adding water, was filtered and washed with water, and then recrystallized to obtain a white powdery solid with a yield of 78%.

Embodiment 3

[0027] (1) add the aqueous solution of salicylic acid (the mass percentage composition of salicylic acid is 15%) in the storage tank 1, utilize metering pump 3 to inject in the preheating module of microchannel reactor with the speed of 50mL / min; Add the mixed solution (mass ratio 1:1) of concentrated nitric acid and glacial acetic acid in tank 2, utilize metering pump 4 to inject in another preheating module of microchannel reactor with the speed of 11mL / minute; Two preheating modules enter simultaneously The reaction is carried out in the mixing module, the reaction temperature is controlled at 65°C, and the reaction retention time is 100s. Then it enters the cooling module, and finally enters the product collector in a continuous flow state.

[0028] (2) The product precipitated after adding water, was filtered and washed with water, and then recrystallized to obtain a white powdery solid with a yield of 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com