Patents

Literature

30results about How to "Extended production period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making microwave vaccum frozen and dried lemon piece

InactiveCN1849921AExtended production periodSolve the problem of excessive pesticide residuesFood preservationMicrowaveFreeze-drying

The present invention relates to a production method of microwave vacuum freeze-dried lemon slices. Said method includes the following steps: (1), sorting lemon fruit; (2), storing lemon fruit under the condition of constant temperature; (3), utilizing ozone to degrade pesticide residue on the lemon fruit and make sterilization; (4), cutting head and tail of lemon fruit, cleaning the lemon fruit by using ozone water and sterilizing; (5), slicing; (6), freezing sliced lemon; (7), prefreeze-drying; (8), microwave vacuum-drying; and (9), sealing and packaging so as to obtain the invented product.

Owner:SICHUAN HUATONG LEMON

Straw mushroom cultivating material, its prepn process and straw mushroom cultivating method

InactiveCN1402963AShorten the growth cycleExtended production periodHorticultureBiotechnologyPlastic film

The present invention relates to the straw mushroom cultivating material, its preparation process and straw mushroom cultivation method. The cultivating material includes waste seed cotton, lime and water. It is prepared through mixing waste seed cotton, lime and water, stacking and densifying and covering with plastic film; and fermentation for 72 hr., loosening; sealing in mushroom bed inside mushroom house; heating to 65-70 deg.c for 6-8 hr, cooling to 50-55 deg.c and maintaining for 6-8 hr for second fermentation to complete the preparation of the cultivating material. The present invention relates to high straw mushroom yield and short production period.

Owner:姜建新

Phyllostachys propinqua sprout planting method

InactiveCN103782775AExtended production periodIncrease productionHorticulturePhyllostachys propinquaPollution

The invention discloses a phyllostachys propinqua sprout planting method. The method mainly comprises the steps of selecting a non-pollution complete land parcel as a base, managing the base, determining plant space between bamboo sprouts, selecting bamboo sprouts resisting to diseases and pests, excavating soil holes in the managed base, applying sufficient base fertilizer on the managed base, planting the bamboo sprouts, irrigating animal manure mixed liquid, watering sufficient water, covering a layer of organics, covering a layer of film, and applying different fertilizers and conducting disease and pest prevention according to different growth periods of phyllostachys propinqua. The planting method enables phyllostachys propinqua sprouts to appear on the market in advance and can improve the quality of bamboo sprouts. By the adoption of the planting technology, the phyllostachys propinqua sprouts can be made to appear on the market in advance, and the quality of the phyllostachys propinqua sprouts is improved.

Owner:TONGLING JIAYAN ECOLOGICAL AGRI DEV

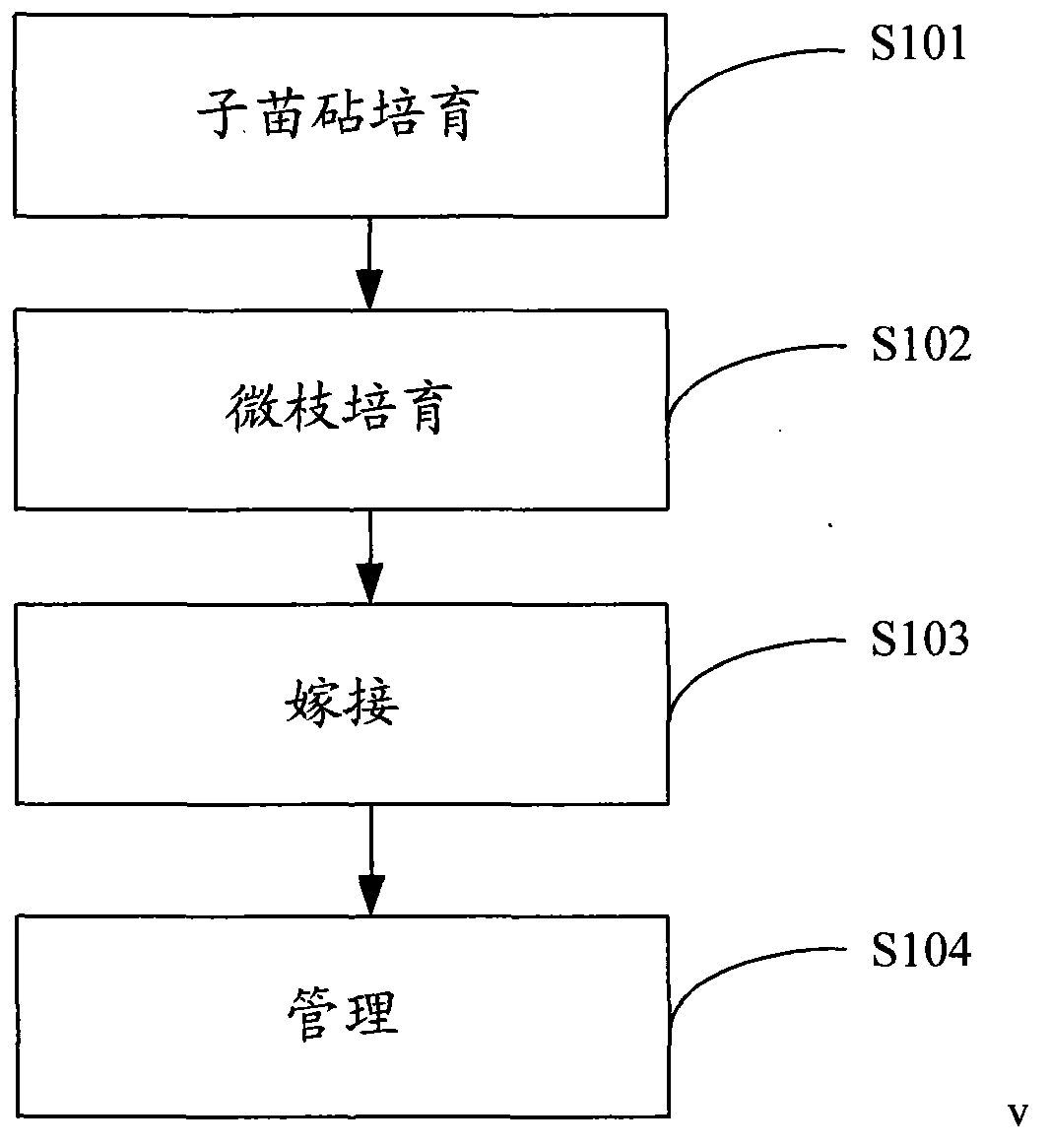

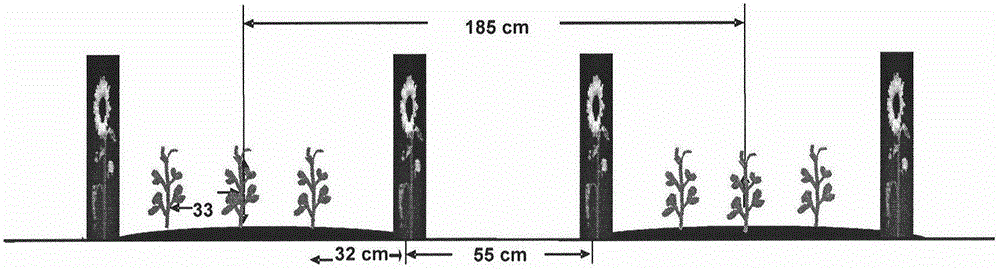

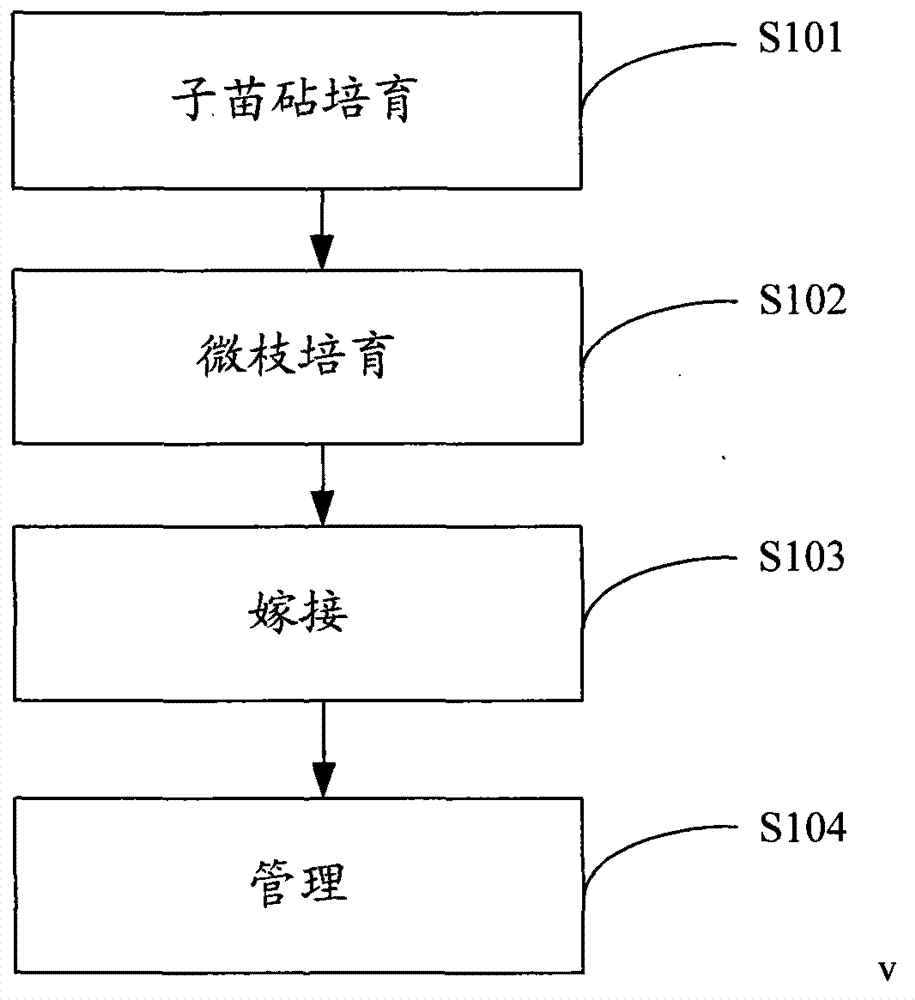

Non-tissue-cultured walnut micro-cutting grafting seedling raising method

InactiveCN102696407AShorten the production cycleExtended production periodSeed and root treatmentHorticultureGreenhouseEthephon

The invention discloses a non-tissue-cultured walnut micro-cutting grafting seedling raising method. A walnut grafted seedling which is cultured by using soil is used as a female parent tree for producing micro-cuttings, the nutrition of the tree is increased by flexibly adopting a rhizosphere fertilization mode and a leaf spray fertilization mode according to the growth vigor of a nursery stock, the germination speed is high, and the production period of the micro-cuttings is short; the female parent tree is planted in a plastic greenhouse and an open field respectively, so that complementation in time can be realized, the production time of the micro-cuttings is prolonged, and the cost is reduced; the walnut grafted seedling which is cultured by using soil is used as the female parent tree for producing the micro-cuttings, the produced micro-cuttings has the base diameter of greater than 0.4 cm, is well matched with seedlings in the roughness, and is robust in the growth, and thus the problems of leaf yellowing, withering, slimness and weakness and the like of the tissue-cultured micro-cuttings which occur frequently are solved; the method is easy to operate without specialized training, and the grafting survival rate of normal personnel reaches 79 percent; the requirements on environment conditions are loose, i.e., the environment conditions can be spring, summer and autumn, the micro-cuttings can be produced in the outdoor fields under natural conditions, and the propagation coefficient is large; and by applying ethephon, the growth speed of the micro-cuttings is flexibly controlled, and adjustment and control are performed to enable that the production of the micro-cuttings is consistent with that of the seedlings.

Owner:付德明

Gen-seng health feed addictive

InactiveCN1593185AWide variety of sourcesPromote growth and weight gainAnimal feeding stuffFood safetyFeed additive

The invention relates to an animal fodder, in particular a gen-seng health feed addictive which is prepared from gen-seng corner material powder and mulberry leaves powder through a finite proportion. The prepared fodder is safe and nuisance free, it produces no drug resistance and tolerance, nor any residual hazards.

Owner:钟惠伦

Planting method for interplanting pea before sowing of sunflower

InactiveCN104871760APromote growthHigh input costCultivating equipmentsPlant cultivationEcological environmentEarth surface

The invention discloses a planting method for interplanting pea before sowing of sunflower. The planting method mainly includes: when fertilizing and mulching a land block where sunflower is prepared to be planted in early spring, planting pea on line space films reserved for sunflower at planting time about 20th March; watering the pea for the first time in early May, and combining watering with fertilizing; planting sunflower in reserved lines at the time from the end of May to the beginning of June; harvesting pea at the beginning of July, wherein yield of pea per mu is about 200kg generally, and yield of sunflower is not reduced basically and can reach about 250kg. High-efficiency three-dimensional planting technology is developed according to the circumstance that a Hetao irrigation area is sufficient for one crop and insufficient for two crops, and has the advantages that light, heat and soil resources are utilized fully, one-season two-harvest is realized, ground surface exposure is reduced, and sand storm is prevented. The planting method has double effects of increasing yield and income and protecting ecological environment of farmland and is high in practicability and wide in application prospect.

Owner:INNER MONGOLIA AUTONOMOUS REGION ACAD OF AGRI & ANIMAL HUSBANDRY SCI

Normal temperature compressed flyash brick and its making method

InactiveCN1426977ASimple processReduce energy consumptionSolid waste managementPolyvinyl alcoholFly ash brick

A normal temp. compressor flyash brick contains a component A consisting of nitrified flyash and a solidifying assistant A, and a component B which is the solidifying assistant B (the aqueous solution of polyvinyl alcohol). The assistant A is the aqueous solution of soluble alkali-metal silicate. It is made up through gradually adding the said assistants A and B to flyash, shaping, solidifying, water-proofing treating, natural drying.

Owner:肖劲东

Method for making microwave vaccum frozen and dried lemon piece

InactiveCN100382721CUniform shapeUniform sizeFood preservationFood preparationMicrowavePesticide residue

The present invention relates to a production method of microwave vacuum freeze-dried lemon slices. Said method includes the following steps: (1), sorting lemon fruit; (2), storing lemon fruit under the condition of constant temperature; (3), utilizing ozone to degrade pesticide residue on the lemon fruit and make sterilization; (4), cutting head and tail of lemon fruit, cleaning the lemon fruit by using ozone water and sterilizing; (5), slicing; (6), freezing sliced lemon; (7), prefreeze-drying; (8), microwave vacuum-drying; and (9), sealing and packaging so as to obtain the invented product.

Owner:SICHUAN HUATONG LEMON

Non-tissue-cultured walnut micro-cutting grafting seedling raising method

InactiveCN102696407BShorten the production cycleExtended production periodSeed and root treatmentHorticultureEthephonWeakness

Owner:付德明

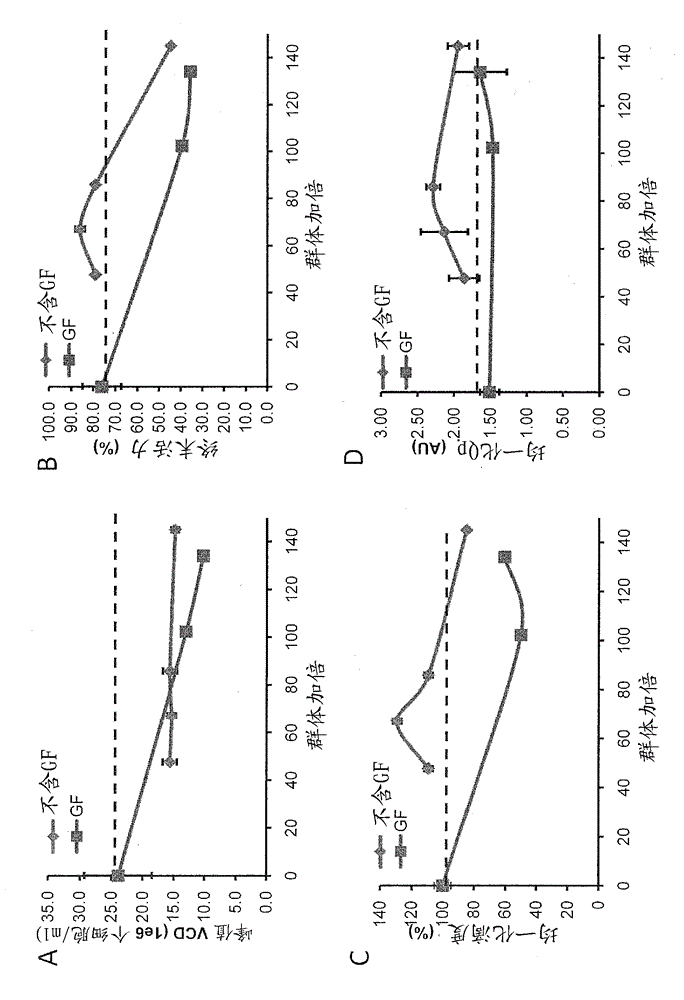

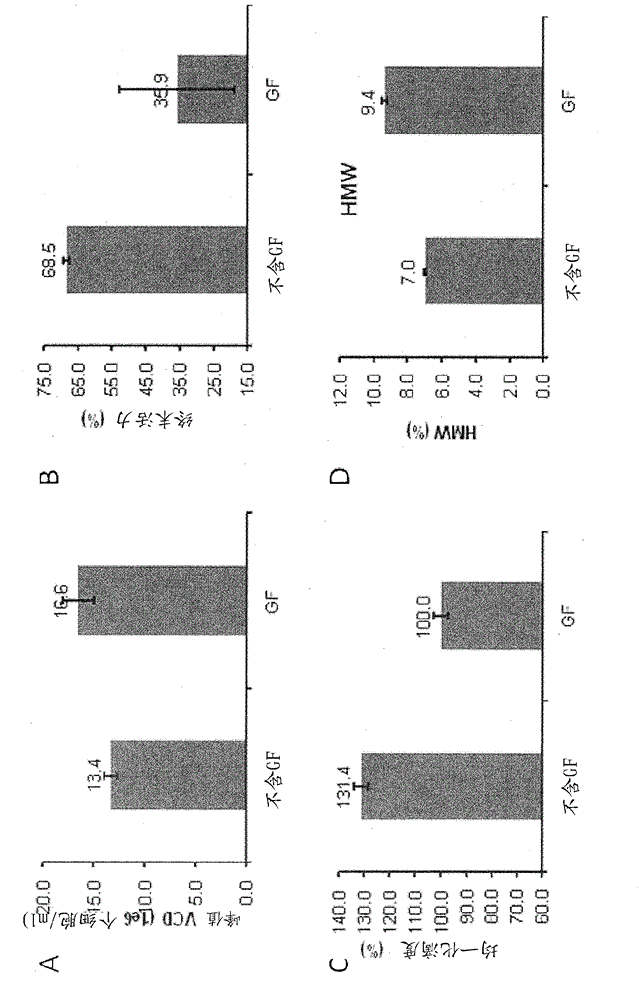

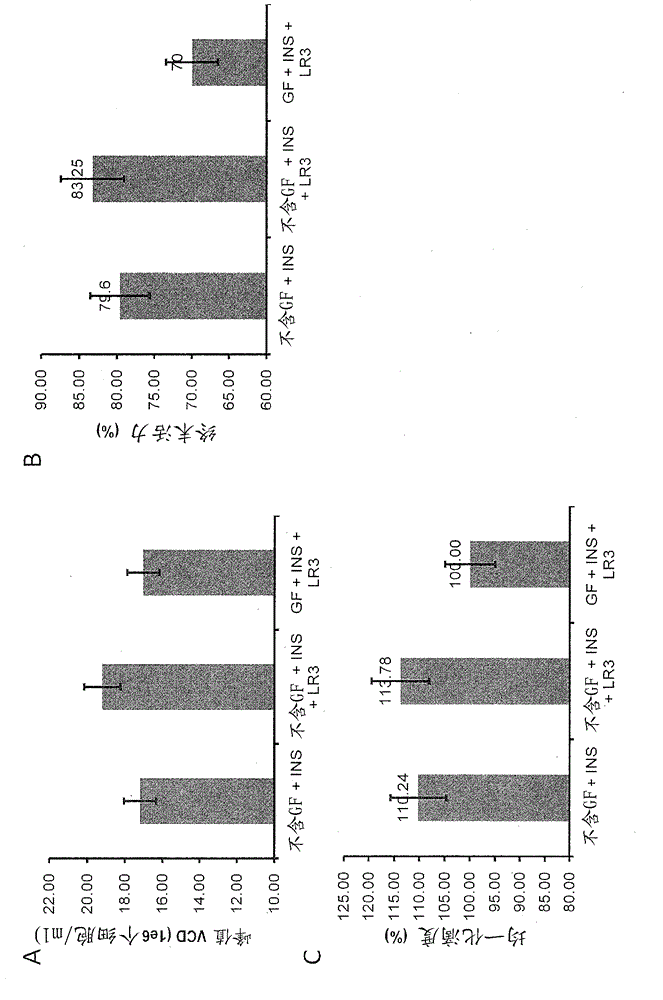

Mammalian cell culture processes for protein production

ActiveCN104822826ARaise specific productivityEnhance cell viabilityAntibody mimetics/scaffoldsGenetically modified cellsBiotechnologyCultured cell

The present invention describes methods and processes for the production of proteins by animal cell or mammalian cell culture. In one aspect, the methods comprise the growth of cells in a growth factor / protein / peptide free medium. In another aspect, the methods comprise the addition of growth factors during the production phase. The methods sustain a high viability of the cultured cells, and can yield an increased end titer of protein product, and a high quality of protein product.

Owner:BRISTOL MYERS SQUIBB CO

Method for producing arachidonic acid with fresh water green algae cultivation by photoautotroph mode

InactiveCN101096640ASolving Harvest ProblemsSave waterUnicellular algaeFermentationFresh waterCulture mediums

The invention relates to a technology for culturing and producing microalgae in particular to a method for producing arachidonic acid (tetracosenoic acid)by culturing fresh water algae with photoautotroph method. The technical project comprises the following steps: (1)domesticating and screening green algae seed; (2)culturing the domesticated green algae seed in the culture medium with photo biological reactor; (3)accumulating the quick growth of the algae cell and polyunsaturated fatty acid; proceeding with a large scale culture of the green algae; (4)collecting when the biomass in the culture liquid and the arachidonic acid in the algae reach the requirements; (5)getting arachidonic acid by collecting the algae cell; (6)circulating the collected breeding waste water. The invention is used to produce arachidonic acid.

Owner:天津禄升海洋生物科技有限公司

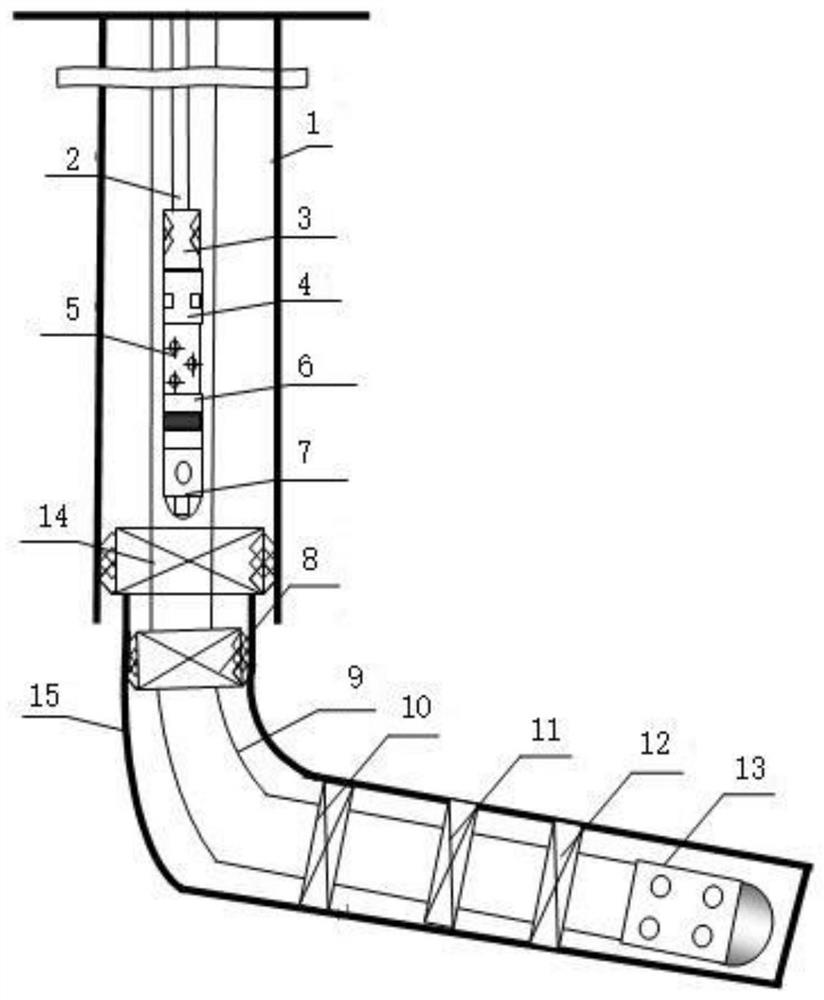

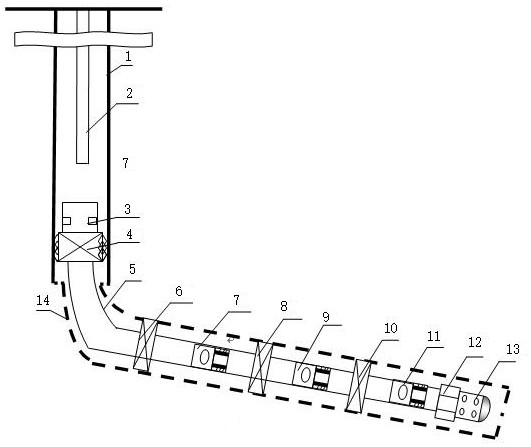

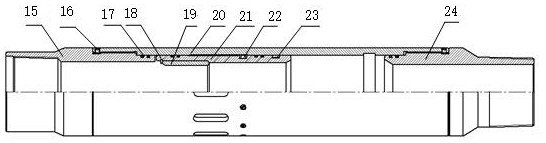

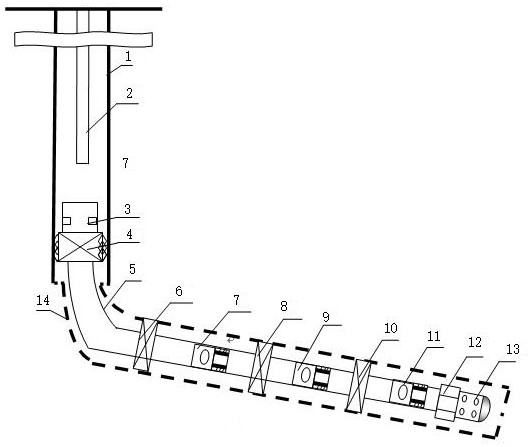

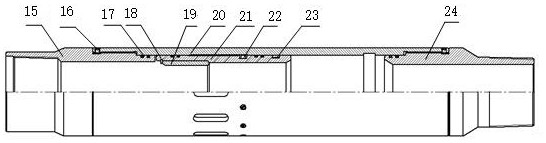

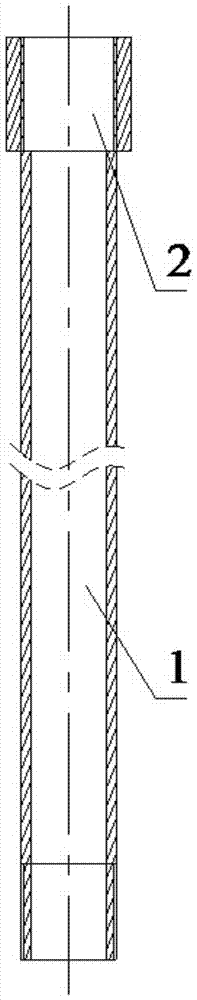

Small-diameter pipe staged fracturing production string and method for sidetracking wells and slim-hole wells

The invention provides a small-diameter pipe staged fracturing production string and method for sidetracking wells and slim-hole wells. The small-diameter pipe staged fracturing production string comprises a fracturing string, a large casing pipe, a suspension packer, a small casing pipe, and a packing string composed of a small-diameter pipe, a packing string upper packer, a plurality of packingstring lower packers and a guide screen pipe; the suspension packer is arranged on the lower portion in the large casing, the upper end of the small casing pipe is connected to the suspension packer,and the inner diameter of the large casing pipe is larger than that of the small casing pipe; and the small casing pipe comprises a vertical corner section and an inclined section, the packing stringupper packer is arranged on the upper portion in the small casing pipe, the small-diameter pipe extends downwards in the direction of a center shaft of the large casing pipe, and the small-diameter pipe penetrates through the vertical corner section of the small casing pipe and extends towards the inclined section. According to the small-diameter pipe staged fracturing production string and methodfor the sidetracking wells and the slim-hole wells, after fracturing is completed, a packer string serves as the production string, stable production of the gas wells can be guaranteed, the full-life-cycle drainage gas recovery effect of the gas wells is improved, the service life of the gas wells is prolonged, and the development cost and the production cost of the gas wells are greatly reduced.

Owner:PETROCHINA CO LTD

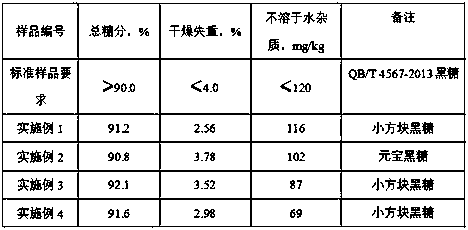

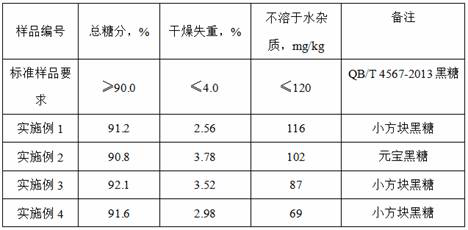

Black sugar and processing method thereof

ActiveCN108251567ASolve the problem that the temperature cannot be accurately controlledImprove liquiditySugar productsSugar crystallisationSugarRaw material

The invention discloses black sugar and a processing method thereof, and belongs to the field of sugar processing. The method comprises the following steps: juicing sugarcane, coarsely filtering sugarcane juice, then boiling the sugarcane juice, removing floating black foam, and filtering by using a vacuum suction filter to obtain clear juice; or by adopting brown sugar as a raw material, dissolving by adding water, then vacuum suction filtering to obtain clear sugar pulp, evaporating and concentrating the clear juice (clear sugar pulp), decocting twice, sanding, forming, cooling, and demolding to obtain the black sugar with the color being sepia to dark brown. The method adopts mature equipment, achieve easy operation, low investment expense and stable product quality, and has the characteristics of pure color, thick sugar fragrance, moderate empyreumatique, softness and deliciousness.

Owner:云南滇王驿农业科技开发有限公司 +1

Production method of preset small-diameter pipe for sidetracking well and slim hole well

ActiveCN112502682AReservoir damage is smallExtended well lifeFluid removalSealing/packingPipeOpen hole

The invention provides a method for producing a preset small-diameter pipe for a sidetracking well and a slim hole well, which comprises the following specific steps: 1, lowering a fracturing pipe column produced by fracturing the sidetracking well and the slim hole well by using an open hole packer and the preset small-diameter pipe to a preset position of a target reservoir, and ensuring that acasing packer is suspended at a position 10-15m above a sidetracking well windowing position; aligning the sand blaster to a reservoir to be transformed, and the reservoir packers clamp the reservoirtransformation section and avoid the casing joint hoop; 2, locating a pumping large-diameter steel ball at a reducing release tie-back cylinder, and when the pumping large-diameter steel ball is pressed to 25 Mpa, a casing packer and a reservoir packer are subjected to setting; and when the pressure is increased to 35Mpa, releasing the releasing tie-back cylinder for three times, and pulling out the part above the releasing tie-back cylinder. The fracturing fluid is injected from the oil jacket annulus, the construction displacement can reach 6 m < 3 > / min or above, the transformation scale can be enlarged, and the crack extension distance can be prolonged; The liquid carrying capacity of the gas well is improved, and the production cost of the gas well can be greatly reduced while the production period of the gas well is prolonged.

Owner:PETROCHINA CO LTD

Straw mushroon cultivating material, its prepn process and straw mushroom cultivating method

InactiveCN1169417CShorten the growth cycleExtended production periodHorticultureBiotechnologyPlastic film

The present invention relates to the straw mushroom cultivating material, its preparation process and straw mushroom cultivation method. The cultivating material includes waste seed cotton, lime and water. It is prepared through mixing waste seed cotton, lime and water, stacking and densifying and covering with plastic film; and fermentation for 72 hr., loosening; sealing in mushroom bed inside mushroom house; heating to 65-70 deg.c for 6-8 hr, cooling to 50-55 deg.c and maintaining for 6-8 hr for second fermentation to complete the preparation of the cultivating material. The present invention relates to high straw mushroom yield and short production period.

Owner:姜建新

Super insulation lighting film or board for greenhouse and production process of lighting film or board

PendingCN109673333AGood light transmissionSlow storageClimate change adaptationGreenhouse cultivationElastomerPolyolefin

The invention belongs to the technical field of greenhouse insulation lighting and relates to a super insulation lighting film or board for a greenhouse and a production process of the lighting film or board. The film or board comprises a body, wherein the interior of the body is closed to form a plurality of independent cavities; and each cavity is filled with nitrogen or inert gases to form an airbag. The production process mainly comprises the following steps: extruder heating, raw material stirring and feeding, raw material extrusion, setting, pulling, annealing, secondary pulling, metering, cutting and rolling. In the raw material stirring and feeding step, the raw materials comprise PE, PP, POE (Polyolefin Elastomer), mPE, EVA (Ethylene-Vinyl Acetate) and an anti-aging agent; and inthe raw material extrusion step, nitrogen or inert gas filling and solder seal is performed while extruding the raw materials. The greenhouse film is free in water drop, slow in nighttime heat dissipation and excellent in insulation effect.

Owner:兰州全达塑胶制品有限公司

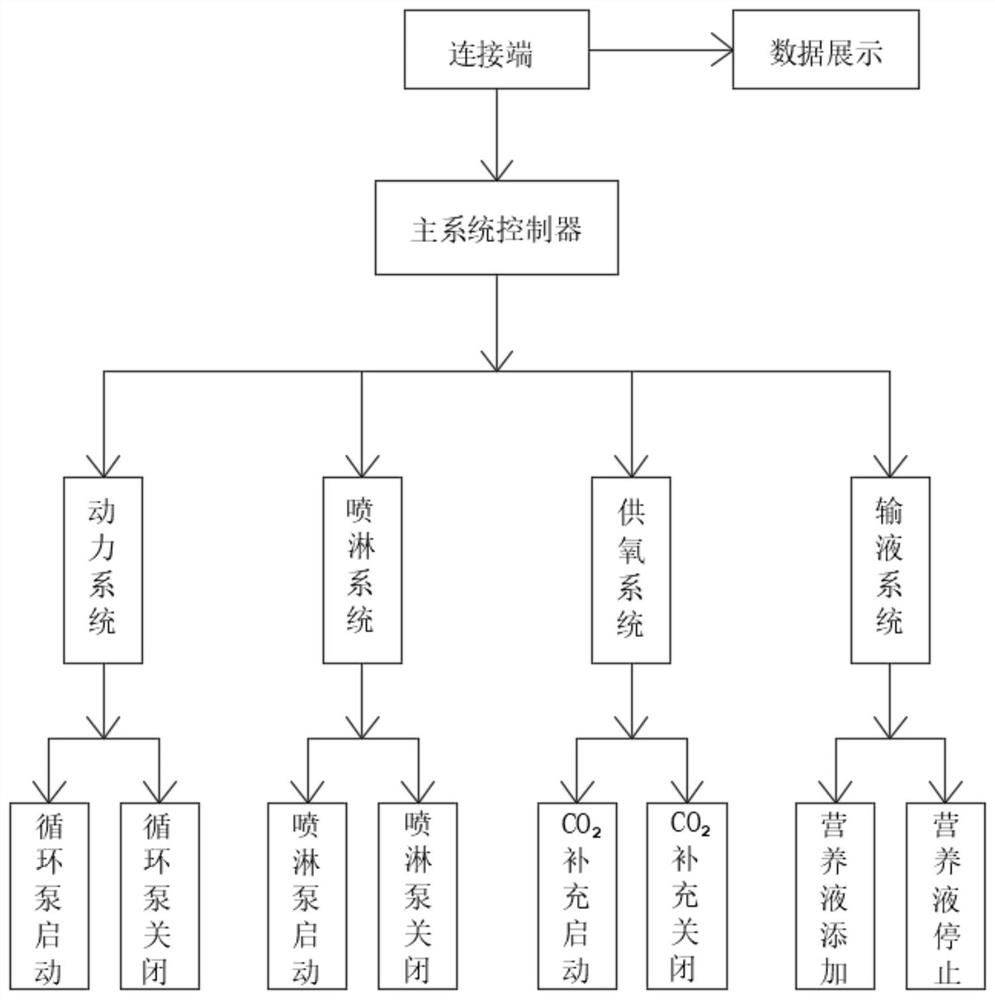

Anti-pollution circulating runway type culture system based on algae culture

PendingCN113403188AUniform water temperatureIncrease culture densityBioreactor/fermenter combinationsBiological substance pretreatmentsMetabolitePh control

The invention relates to the technical field of algae culture and photosynthetic bacteria culture, and discloses an anti-pollution circulating runway type culture system based on algae and photosynthetic bacteria culture. The system comprises a feeding tank, a remote main system controller, a power system, a spraying system, an oxygen supply system, a temperature control system, a PH control system, a spectrum control system, a daytime and night mode and a liquid conveying system, wherein the main control system is connected with the power system, the spraying system, the oxygen supply system, the temperature control system, the PH control system, the spectrum control system, the daytime and night mode, the spraying system, the oxygen supply system and the liquid conveying system. According to the anti-pollution circulating runway type culture system based on algae and photosynthetic bacteria culture, algae plants and photosynthetic bacteria are cultured in the mode, the culture density is high, the harvesting efficiency is remarkably improved, the culture conditions are easy to control, high-density culture is easy to realize, metabolite accumulation is facilitated, the system is not limited by regional environments, the production period is long, and production can be carried out all the year round.

Owner:刘正君

A kind of brown sugar and processing method thereof

ActiveCN108251567BSolve the problem of short production periodExtended production periodSugar productsSugar crystallisationBiotechnologyEngineering

The invention discloses a brown sugar and a processing method thereof, which belong to the field of sugar processing. The method comprises the following steps: pressing the sugarcane to extract the juice, heating the sugarcane juice to boiling after coarse filtration, skimming the floating black foam, and vacuuming the sugar cane to boil. Filter to obtain clear juice; or use brown sugar as raw material, add water to dissolve, then vacuum filter to obtain clear syrup, clear juice (clear syrup) is evaporated and concentrated, boiled twice, sanded, formed, cooled, and demoulded to obtain a brown color Brown sugar to dark brown-black. The method has mature equipment, easy operation, low investment cost, stable product quality, and has the characteristics of pure color, strong sugar aroma, moderate burnt aroma, soft and delicious.

Owner:云南滇王驿农业科技开发有限公司 +1

Normal temperature compressed flyash brick and its making method

InactiveCN1191208CSimple processReduce energy consumptionSolid waste managementPolyvinyl alcoholFly ash brick

Owner:肖劲东

Huaifu hemerocallis miner health-care feed additive

InactiveCN103168922AWide variety of sourcesFacilitate production and weight gainAnimal feeding stuffDiseaseGaining weight

The invention relates to an animal feed, and particularly relates to a huaifu hemerocallis miner health-care feed additive. The huaifu hemerocallis straw and seedcake contain bioflavonoids and vitamin E by detection of scientific research departments, are safe and pollution-free, can produce livestock and poultry feed which accords with the food safety requirements, are significant in antibiosis, antiviral and disease-preventing effects, promote beasts and birds to grow and gain weight rapidly, improve the quality, improve the milk yield and egg yield, prolong the production period, do not generate drug resistance and tolerance, and do not have residue to cause damage. The huaifu hemerocallis miner health-care feed additive is simple in preparation process, wide in material source, low in cost, suitable for raising livestock and poultry animals at different production stages, and is preferred health-care feed of various feed manufacturers.

Owner:叶荣

Low temperature coagulant agent for chlorine-oxygen-magnesium cement and manufacturing technique

Owner:龚兵

A kind of planting method of sunflower covering and re-sowing peas before sowing

InactiveCN104871760BPromote growthHigh input costFabaceae cultivationCultivating equipmentsEcological environmentEarth surface

Owner:INNER MONGOLIA AUTONOMOUS REGION ACAD OF AGRI & ANIMAL HUSBANDRY SCI

Method for extracting betalain from phytolaccic berry

InactiveCN102433013BShorten storage periodReduce processing energy consumptionNatural dyesUltrafiltrationFiltration

Owner:QILU UNIV OF TECH

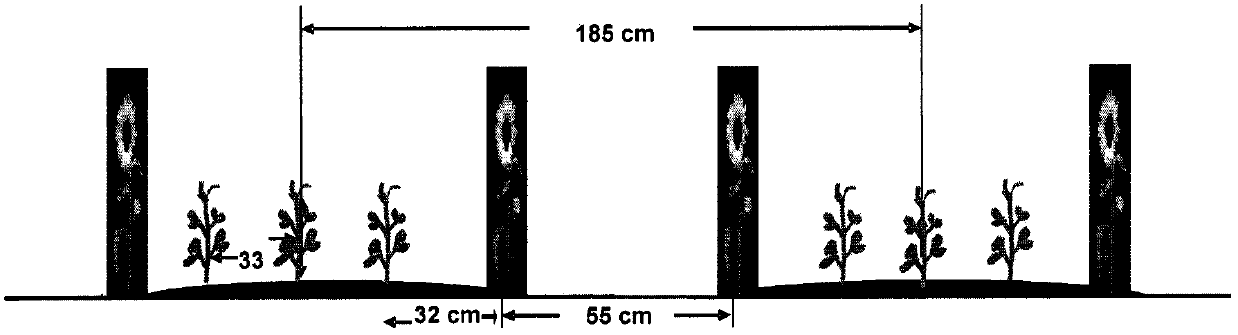

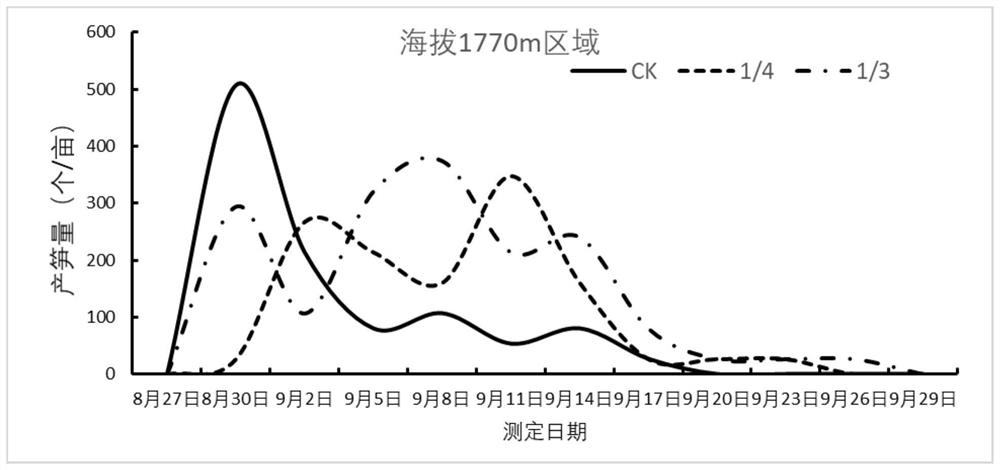

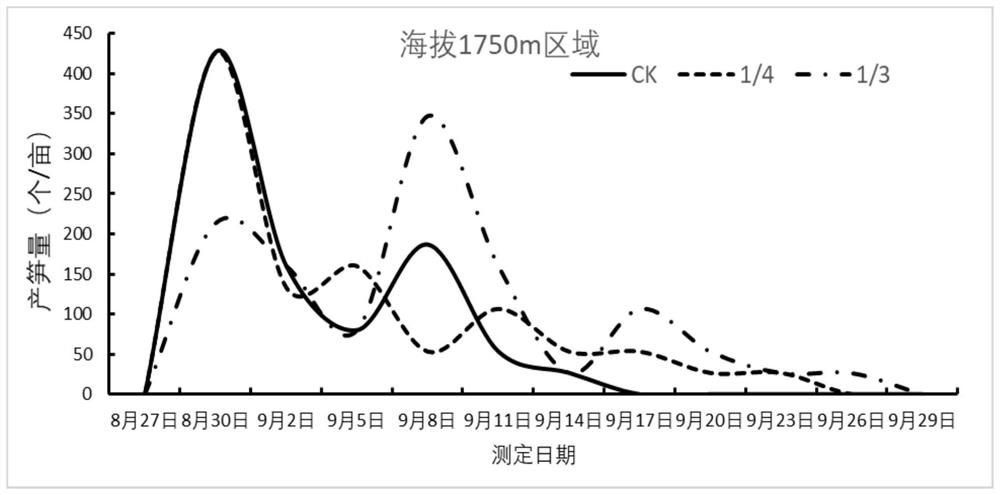

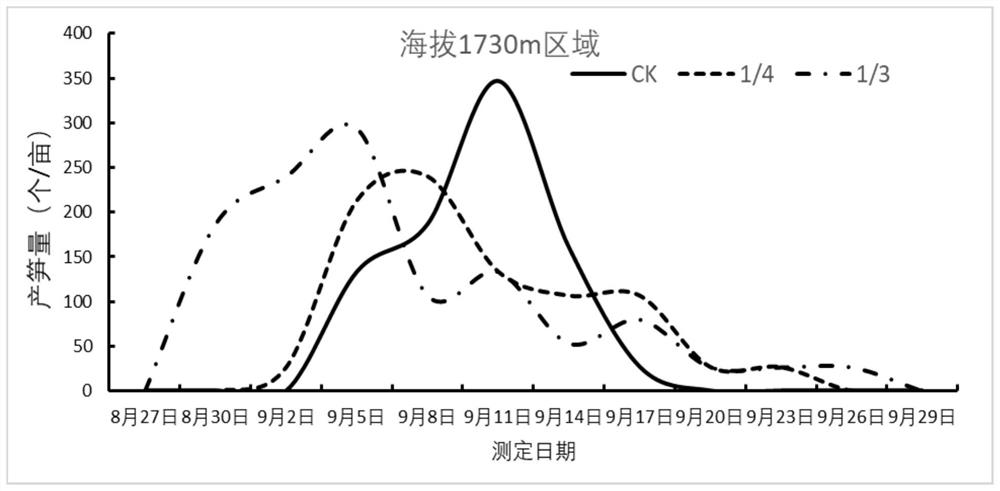

Method for prolonging bamboo shoot production period of Chimonobambusa utilis forest

PendingCN112913593AEasy to carryExtend the number of shootsPlant cultivationCultivating equipmentsAgricultural engineeringEnvironmental geology

The invention belongs to the technical field of bamboo shoot cultivation, and particularly relates to a method for prolonging the bamboo shoot production period of a Chimonobambusa utilis forest. The method comprises the following steps of: selecting the Chimonobambusa utilis forest of mixed growth bamboo category Chimonobambusa; in February and March of each year, selecting a new bamboo which does not sprout or unfold leaves, and carrying out shearing on a position which is far away from the bamboo crown part for 1 / 4-1 / 3 by high-branch scissors; and guaranteeing that a shearing hole is of a horseshoe shape and the shearing hole is not broken. Through the above method disclosed by the invention, the tip of the Chimonobambusa utilis in a mixed growth bamboo category is sheared at an appointed position at specific time, a tool can be conveniently carried, and the method is simple in operation and is convenient in implementation. The bamboo shoot generation period of the Chimonobambusa utilis forest processed by the method disclosed by the invention is prolonged, the amount of bamboo shoot generation peak periods is increased, peak shifting bamboo shoot generation of the Chimonobambusa utilis forest is realized, so that the fresh bamboo shoot supply time of a bamboo shoot processing industry chain is prolonged, meanwhile, market selling time of the fresh bamboo shoots is prolonged, and the economic benefits of Chimonobambusa utilis farmers can be greatly improved.

Owner:NANJING FORESTRY UNIV

Aseptic prouduction process for medicinal plant fresh product

InactiveCN1473457ANo pollution in the processNo pestsCultivating equipmentsHorticulture methodsEnvironment effectSeedling

The bacteria-free production process of fresh medicinal plant product includes the following steps: sterilizing the container and seedling inside a sealed container with culture medium; planting the bacteria-free seedling inside the sealed container; culturing the seeding in culture room for transitional adapting growth; moving the controller to production field; managing the growing plant in field; and collecting grown plant via opening sealed container, taking out plant and washing. The said process is not affected by environment, and has short production period, pure product and low management cost.

Owner:HANGZHOU FANBANG PLANT CELL ENG

Storage and preservation method for sweet persimmons

InactiveCN102986833ASimple processHigh utilization rate of raw materialsFruits/vegetable preservation by freezing/coolingChemistryPreservation methods

The invention discloses a storage and preservation method for sweet persimmons. The storage and preservation method comprises the following steps: (1), harvesting medium-ripe sweet persimmons, and using moisture-holding papers to package and pack the sweet persimmons; (2), putting the packaged sweet persimmons to a refrigerated storage within three hours to five hours; (3), keeping the humidity of the refrigerated storage higher than 85%, keeping the temperature in the packing box at 5 DEG C, wherein the temperature difference does not exceed 0.2 DEG C; (4), controlling the temperature of the refrigerated storage at about 3 DEG C, so that the sweet persimmons are in a dormant state, and the retention period is prolonged. The storage and preservation method is adopted, so that the production period using sweet persimmons as materials is prolonged to 10 months, and the sale period of the fresh fruit is also prolonged to 10 months; the flow is simple and easy to apply, and the utilization rate of the fresh fruit material is high; and the pulp is light yellow or yellow, and has a bright natural color and a strong fragrant and sweet taste.

Owner:HUBEI LUOTIAN COUNTY NATURE BIOTECH

A production method of preset small-diameter pipes for sidetracking and slimhole wells

ActiveCN112502682BLong extension distanceExpand the scale of renovationFluid removalSealing/packingSand blastingWell drilling

The invention provides a production method of preset small-diameter pipes for sidetracked wells and slimhole wells. The specific steps are as follows: step 1, fracturing sidetracked wells and slimhole wells with an open-hole packer and the production of preset small-diameter pipes. The split pipe string is lowered to the predetermined position of the target reservoir to ensure that the casing packer is suspended at a position 10-15m above the window of the sidetracking well. The sand blaster is aimed at the reservoir that needs to be reformed, and multiple reservoir packers are stuck. The location of the reservoir stimulation section, while avoiding the casing collar; step 2, the pumped large-diameter steel ball is seated at the variable-diameter return sleeve, and when the pressure reaches 25Mpa, the casing packer and the reservoir are isolated Set the device; when the pressure reaches 35Mpa, drop the return barrel for 3 hands, and lift out the upper part of the return barrel. The invention injects fracturing fluid from the annular space of the oil casing, and the construction displacement can reach 6m 3 / min or more, the reconstruction scale can be expanded and the fracture extension distance can be extended; the liquid carrying capacity of the gas well can be improved, the production period of the gas well can be extended, and the production cost of the gas well can be greatly reduced.

Owner:PETROCHINA CO LTD

Ginseng health feed additive

InactiveCN1235493CWide variety of sourcesPromote growth and weight gainAnimal feeding stuffFood safetyFodder

The invention relates to an animal fodder, in particular a gen-seng health feed addictive which is prepared from gen-seng corner material powder and mulberry leaves powder through a finite proportion. The prepared fodder is safe and nuisance free, it produces no drug resistance and tolerance, nor any residual hazards.

Owner:钟惠伦

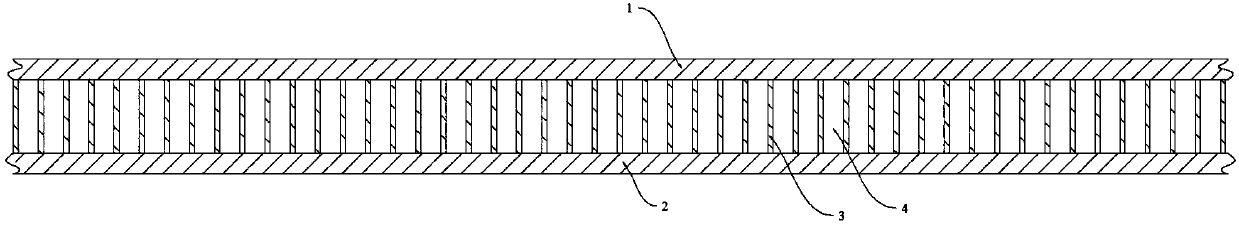

A small diameter drainage gas production pipe string

ActiveCN104632091BLow costImprove liquid carrying capacityDrilling rodsDrilling casingsCarrying capacityCoiled tubing

The invention relates to a minor-diameter water draining and gas producing pipeline column. The pipeline column is composed of a seamless tube (1) and a connector (2). Materials used for the seamless tube (1) are divided into two kinds, one is 45 # carbon steel, and the other is 5083 aluminium alloy. When the well depth is equal or lesser than 3000 meters, the 45 # carbon steel seamless tube (1) and the connector (2) are adopted on the whole well section, and the mode of connecting a single rod is adopted; when the well depth is greater than 3000 meters, the compound mode is adopted by the pipeline column, the 45 # carbon steel seamless tube (1) and the connector (2) are adopted on the upper portion of a shaft; the 5083 aluminium alloy seamless tube (1) and the connector (2) are adopted on the lower portion of the shaft, the mode of connecting the single rod is adopted, an insulated joint is adopted on the transition part between the two kinds of oil pipes, and the galvanic corrosion is prevented from happening; the water draining and gas producing function of the pipeline column is equivalent to a coiled tubing, but the cost of the pipeline column is 40-50 percent of the coiled tubing. By narrowing the gas producing channel of a gas well, the liquid carrying capacity of the gas well is improved, so that water is timely discharged from the shaft, the gas well productivity is recovered, and the production period is prolonged.

Owner:PETROCHINA CO LTD

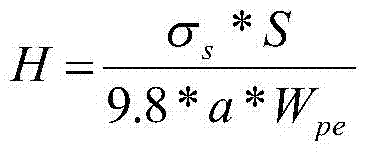

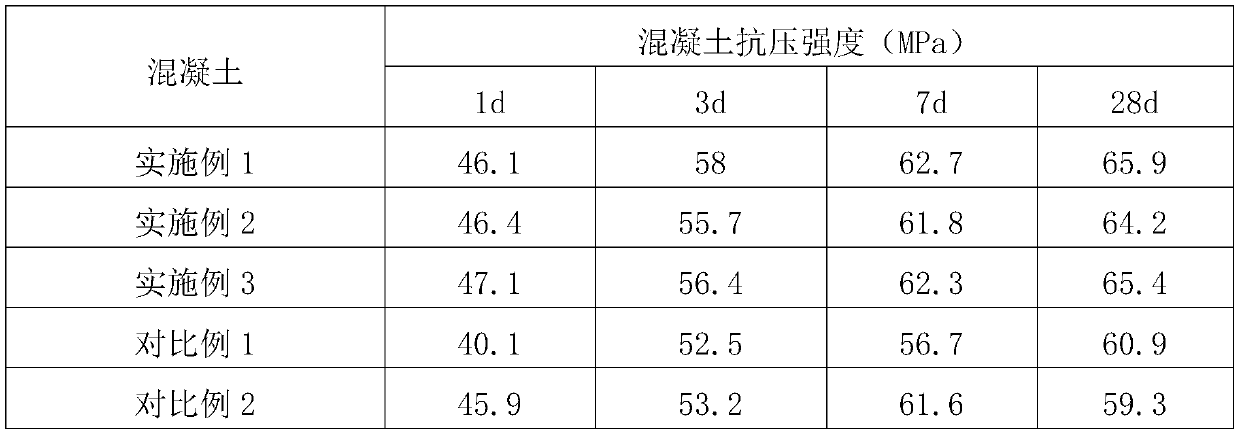

Early strength water reducing agent and preparation method thereof

The invention relates to an early strength type water reducer and a preparation method thereof. The preparation method comprises steps as follows: acrylic acid, sodium methallyl sulfonate, 2-acrylamide-2-methylpropane sulfonic acid, acrylamide and water are mixed to obtain a solution A; a reducer, a chain transfer agent and water are mixed to obtain a solution B; polyether and water are mixed andheated, an initiator is added, the mixture is stirred, the solution A and the solution B are added, the mixture is heated for polymerization, a regulator is added to adjust the pH value to 6-7, and apolycarboxylate water reducer is obtained; a high polymer dispersant, calcium silicate, calcium nitrate, aluminum nitrate and water are mixed, the mixture is heated and stirred, a sodium silicate water solution is added, and a nano crystal nucleus early strength agent is obtained; the polycarboxylate water reducer and water are mixed, stirred and heated, the nano crystal nucleus early strength agent is added, the mixture is heated and stirred, and the early strength type water reducer is obtained. The early strength type water reducer is used for concrete and can make concrete have short setting time, high early strength and excellent work performance and adaptability.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com