Black sugar and processing method thereof

A processing method and technology of brown sugar, which is applied in the direction of using physical methods to purify, sugar products, sugar crystallization, etc., can solve the problems of affecting product taste and nutritional value, inability to accurately control heating temperature, lack of brown sugar caramel aroma, etc., and achieve operation and maintenance costs Low, shorten the evaporation time, increase the effect of water evaporation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

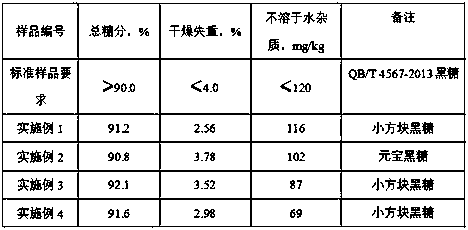

Examples

Embodiment 1

[0029] The processing method of the black sugar of the present embodiment, comprises the following steps:

[0030] Step (1), clear juice preparation

[0031] Squeeze 1 ton of sugarcane juice with a five-roller press, filter the sugarcane juice through a 100-mesh filter under normal pressure, pump the filtrate into a defoaming pot and heat it to boiling, and skim off the black foam that keeps rising to get clear juice;

[0032] Step (2), cooking

[0033] Filter the clear juice through a vacuum suction filter equipped with a 300-mesh filter cloth, pump the filtrate into the evaporating pot, heat and evaporate at 135°C until the concentration of the syrup is 70°Bx, and then transfer it to the sugar boiling pot and cook at 115°C until the concentration is 90°Bx, to obtain about 100L of thick syrup, add 5L of hot water at a temperature of 85°C, stir well and mix well, and then boil for the second time until the concentration reaches 95°Bx;

[0034] Step (3), sanding

[0035] Put...

Embodiment 2

[0039] The processing method of the black sugar of the present embodiment, comprises the following steps:

[0040] Step (1), clear juice preparation

[0041] Squeeze 1 ton of sugarcane juice with a five-roller press, filter the sugarcane juice through a 100-mesh filter under normal pressure, pump the filtrate into a defoaming pot and heat it to boiling, and skim off the black foam that keeps rising to get clear juice;

[0042] Step (2), cooking

[0043] Filter the clear juice through a vacuum suction filter equipped with a 400-mesh filter cloth, pump the filtrate into the evaporating pot, heat and evaporate at 130°C until the syrup concentration is 75°Bx, and then transfer it to the sugar boiling pot and boil at 120°C until the concentration is 92°Bx, to obtain about 90L of thick syrup, add 9L of hot water at a temperature of 80°C, stir well and mix well, and then boil for the second time until the concentration reaches 93°Bx;

[0044] Step (3), sanding

[0045] Put the thi...

Embodiment 3

[0049] The processing method of the black sugar of the present embodiment, comprises the following steps:

[0050] Step (1), clear syrup preparation

[0051] Put 100kg of brown sugar powder into the dissolving tank, add 200kg of hot water with a temperature of about 80°C, turn on the stirring motor and stir until the brown sugar is completely dissolved to obtain clear syrup;

[0052] Step (2), cooking

[0053]Filter the clear syrup in step (1) through a 400-mesh filter cloth vacuum suction filter, pump the filtrate into the evaporating pot and heat and evaporate at 127°C to obtain a syrup with a concentration of 72°Bx, and then transfer it to the sugar boiling pot at 115°C Boil to a concentration of 91°Bx to obtain about 70L of thick syrup, add 6 L of hot water at a temperature of 80°C, stir well and then boil again until the concentration reaches 94°Bx;

[0054] Step (3), sanding

[0055] Put the thick syrup prepared in step (2) into the casserole and start sanding immedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com