Patents

Literature

435results about "Purification by physical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

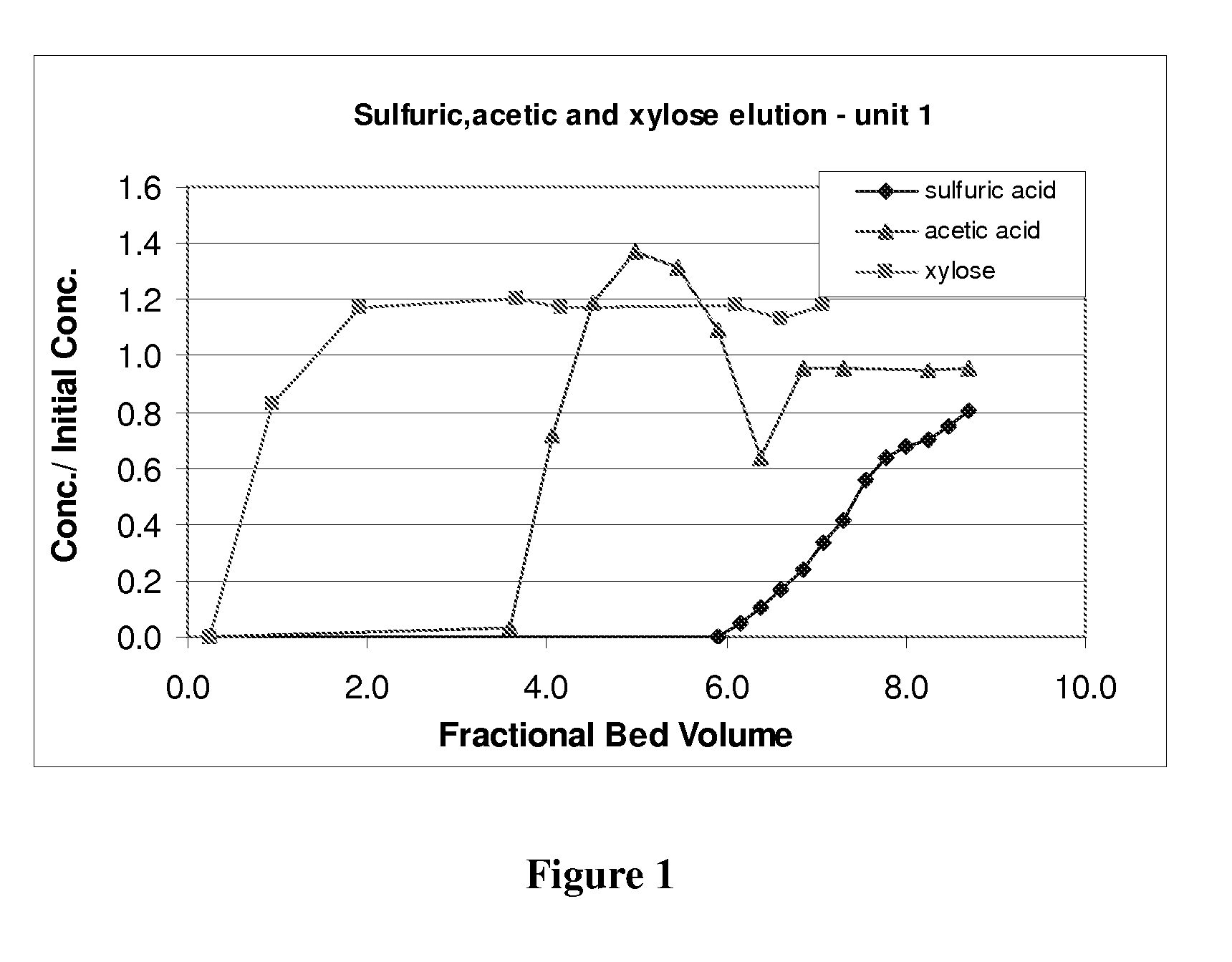

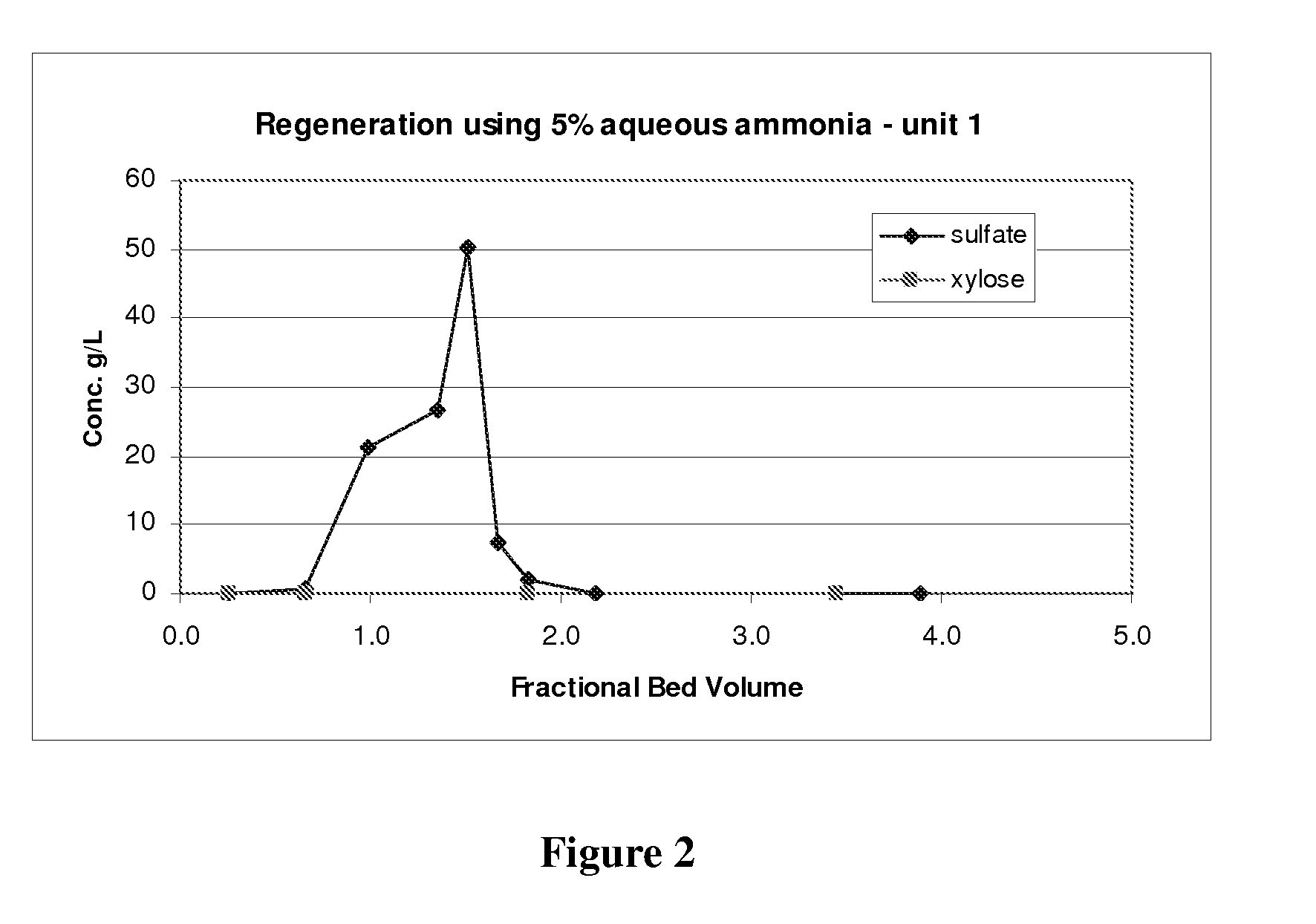

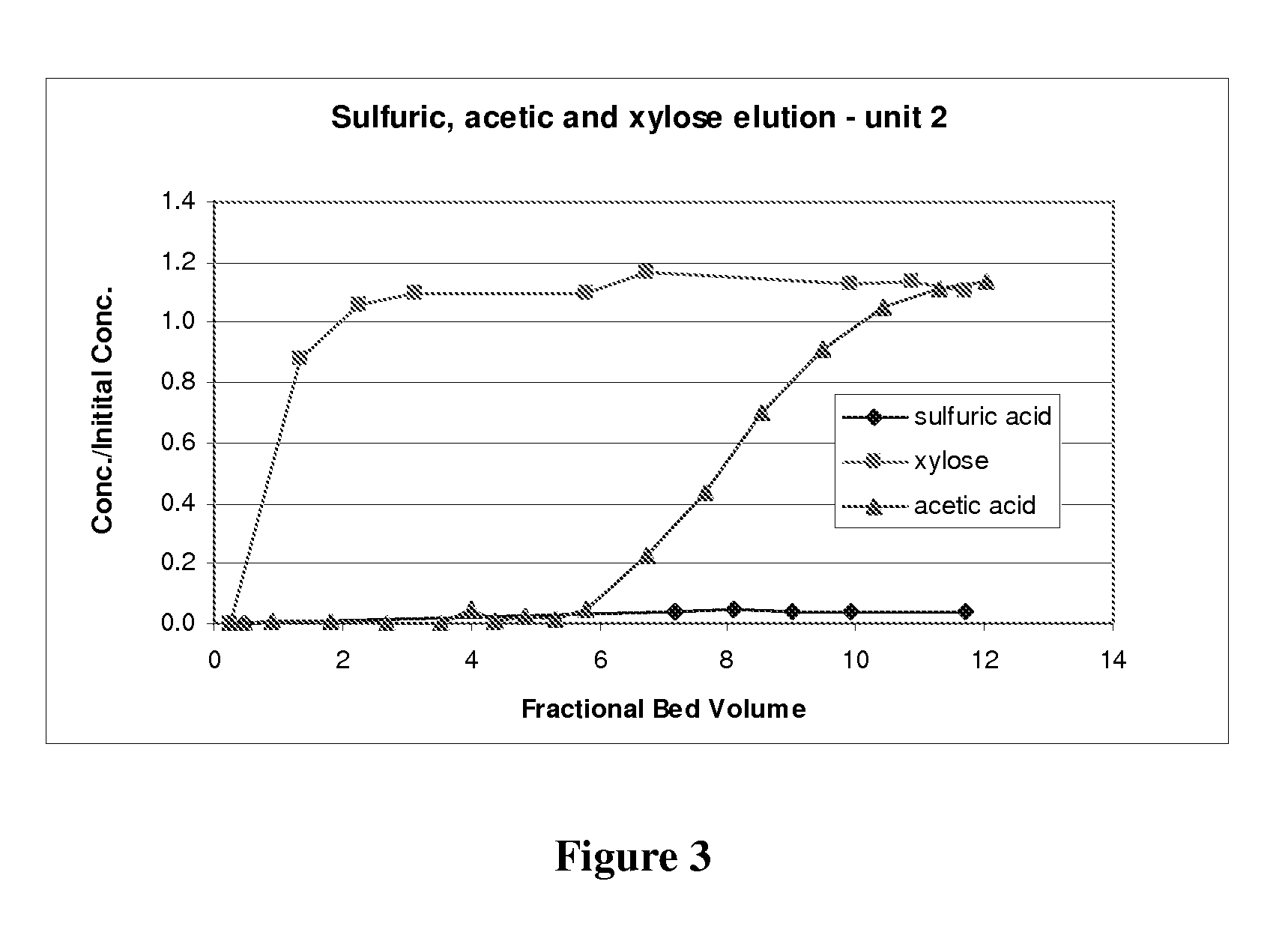

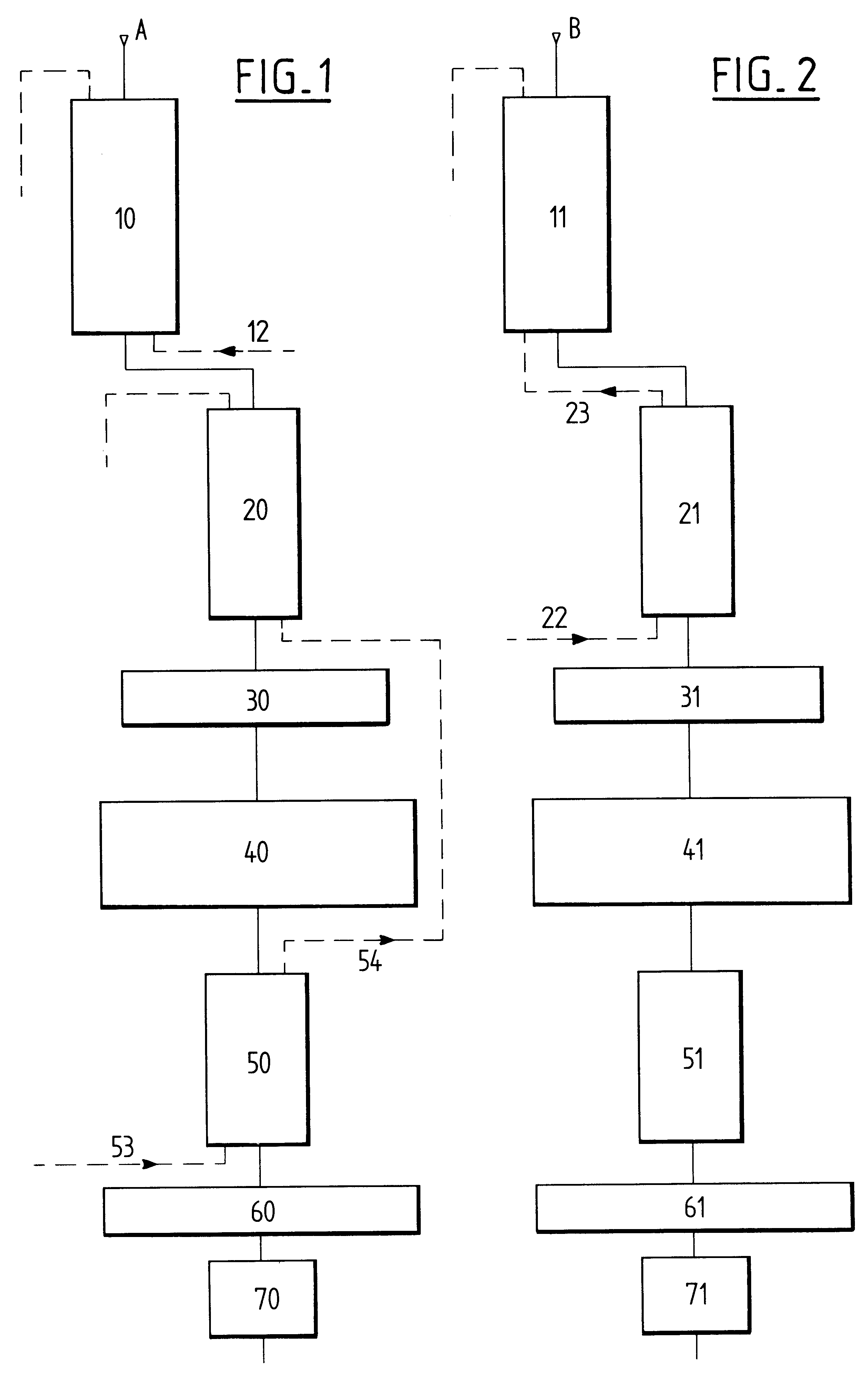

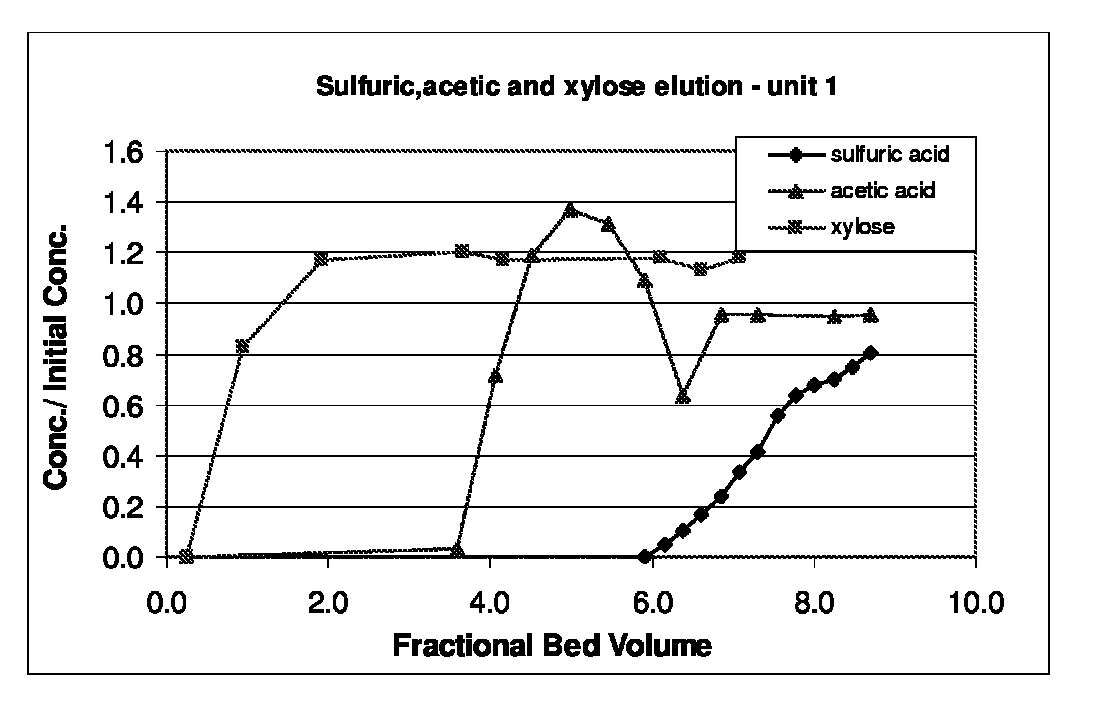

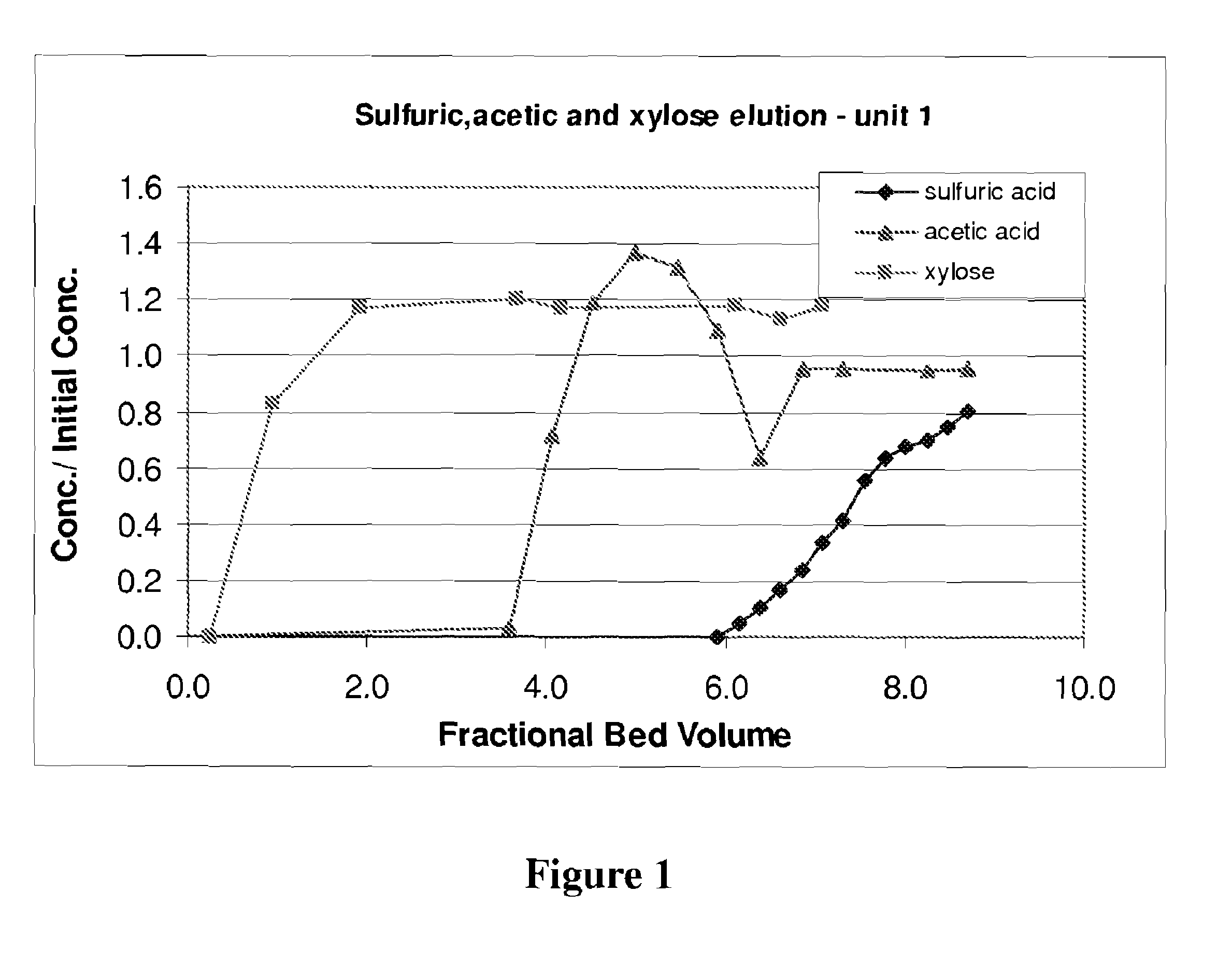

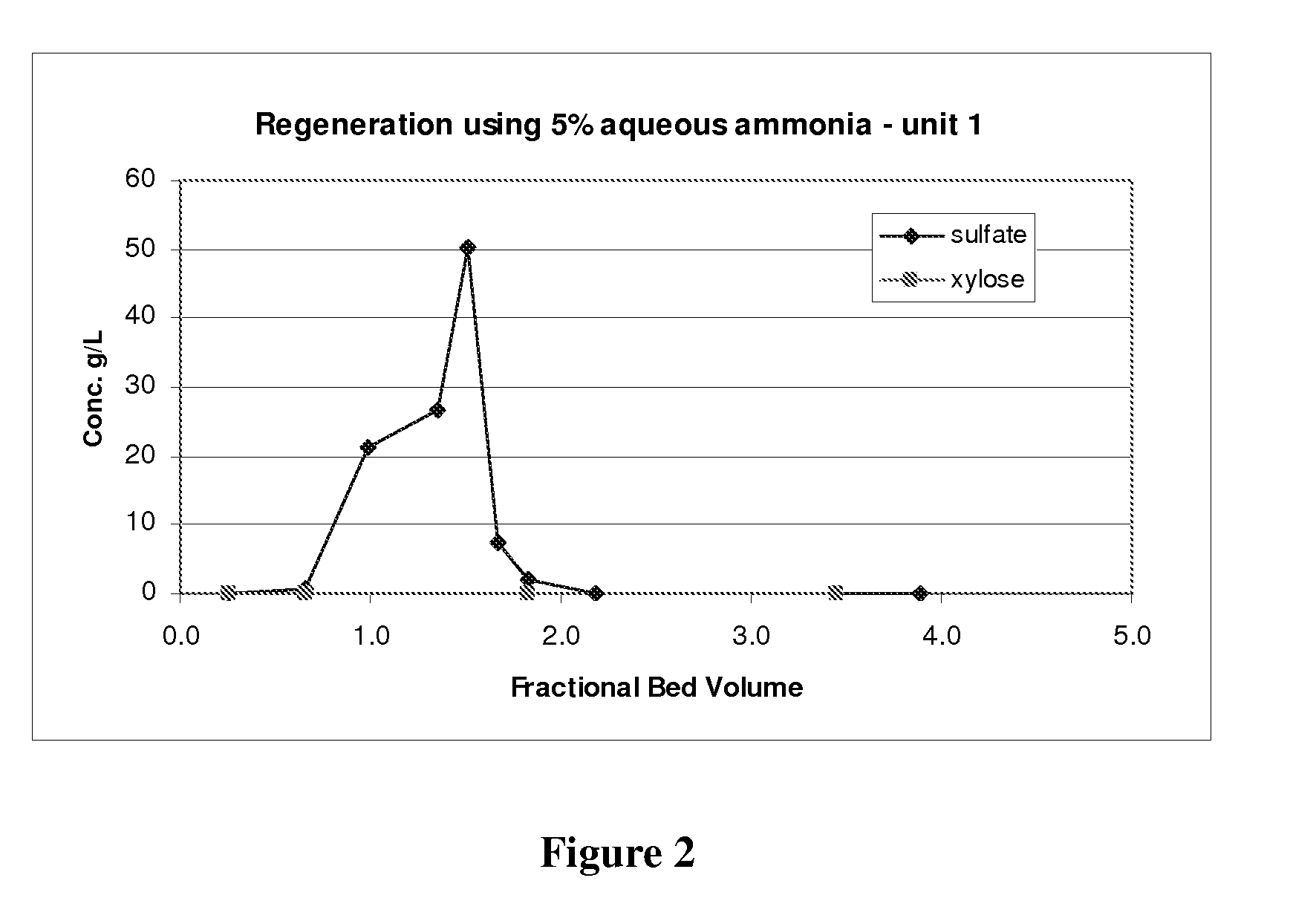

Method of obtaining an organic salt or acid from an aqueous sugar stream

InactiveUS20080041366A1Low costPromote recoverySugar derivativesComponent separationOrganic acidOrganic Ester

A process for obtaining one or more than one salt of an organic acid(s), or organic acid(s), from an aqueous sugar stream comprising one or more than one mineral acid and the organic acid(s) is provided. The process comprises introducing the aqueous sugar stream to a separation system comprising one or more beds of anion exchange resin and obtaining a stream therefrom comprising the sugar. The one or more beds of anion exchange resin are then regenerated in one or more stages to produce at least one product stream comprising the organic acid, a salt of the organic acid, or a combination thereof, and a separate outlet stream comprising the mineral acid, a salt of the mineral acid, or a combination thereof. The product stream is then recovered. The separation may be conducted with two separation units, or using a single anion exchange unit.

Owner:IOGEN ENERGY CORP

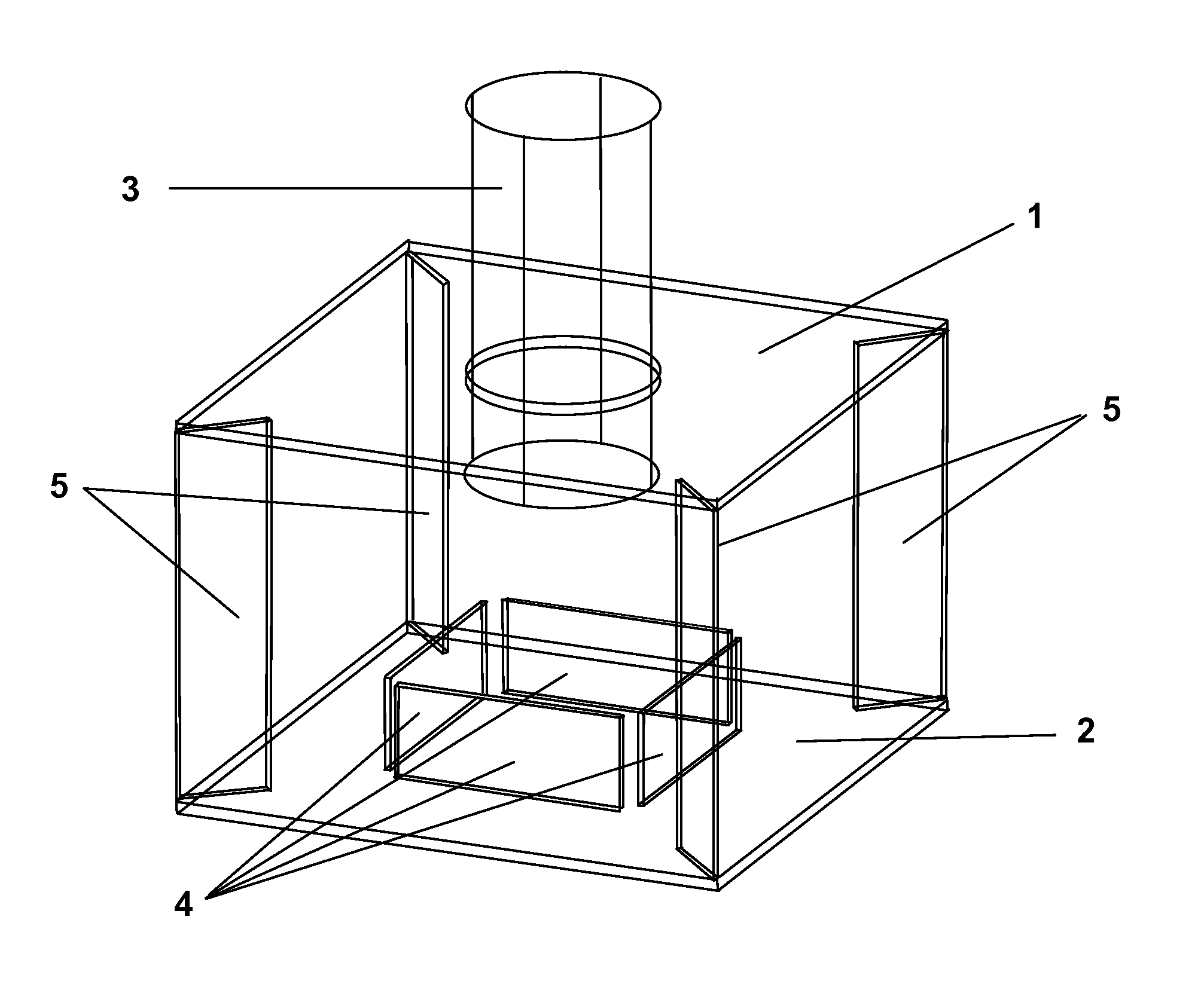

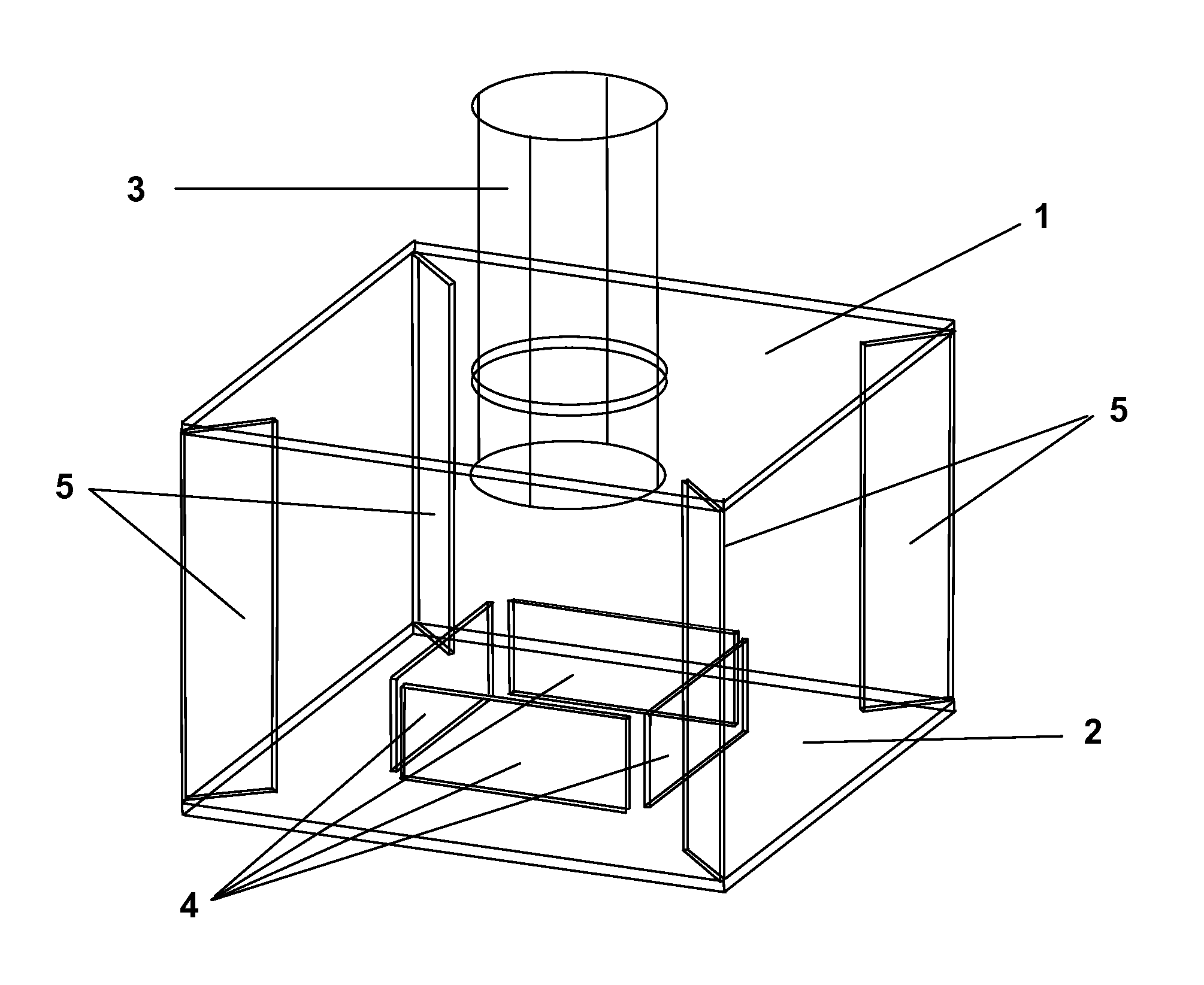

Device for turbulence reduction

ActiveUS9023216B2Reducing momentum and velocityReduce or even eliminate large-scale turbulent eddiesJuice extractionFluid dynamicsMomentumMechanical engineering

Apparatus is disclosed for substantially reducing the momentum, velocity, or both of a first liquid that is flowing into a second liquid. The device allows one to substantially reduce or even eliminate large-scale turbulent eddies that could otherwise be produced by liquid flowing into or within a vessel, for example in a clarifier. Suitably-sized and positioned plates and baffles induce changes of flow direction in a limited volume. By the time the fluid leaves this volume, the fluid velocity is low, and turbulence is nearly or entirely eliminated. Several of the devices may be placed at different inputs within a single clarifier, and thus increase efficiency further.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

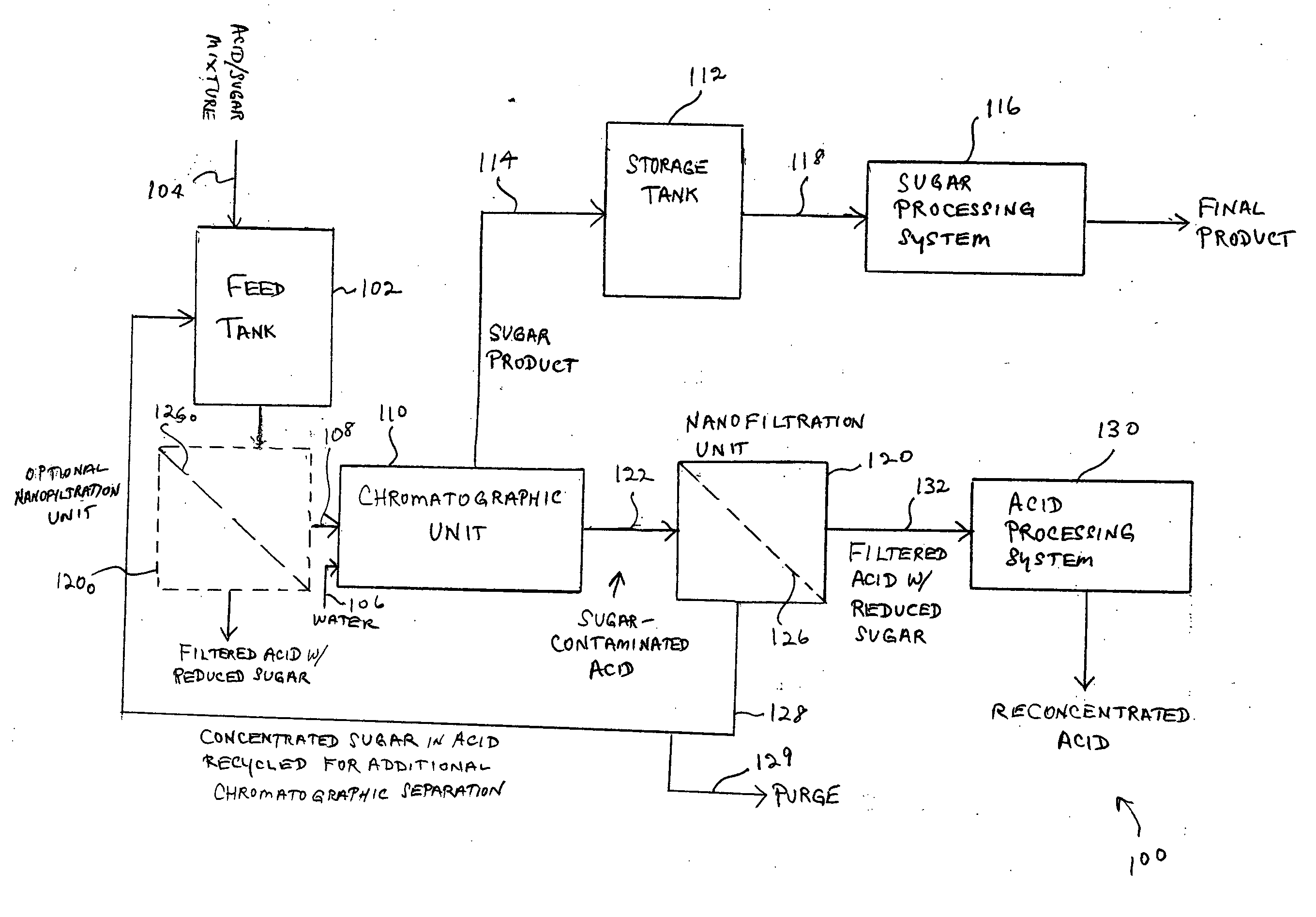

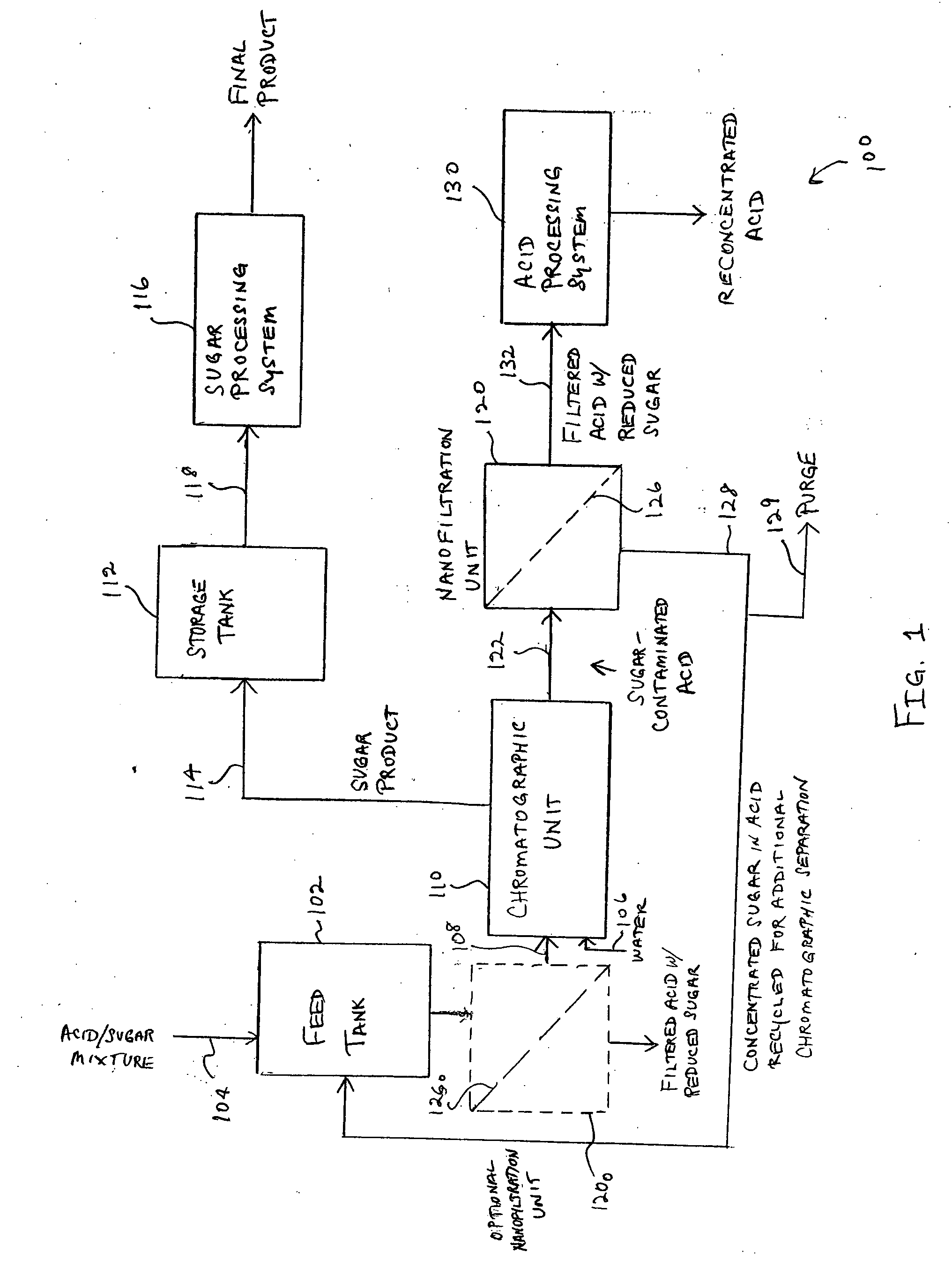

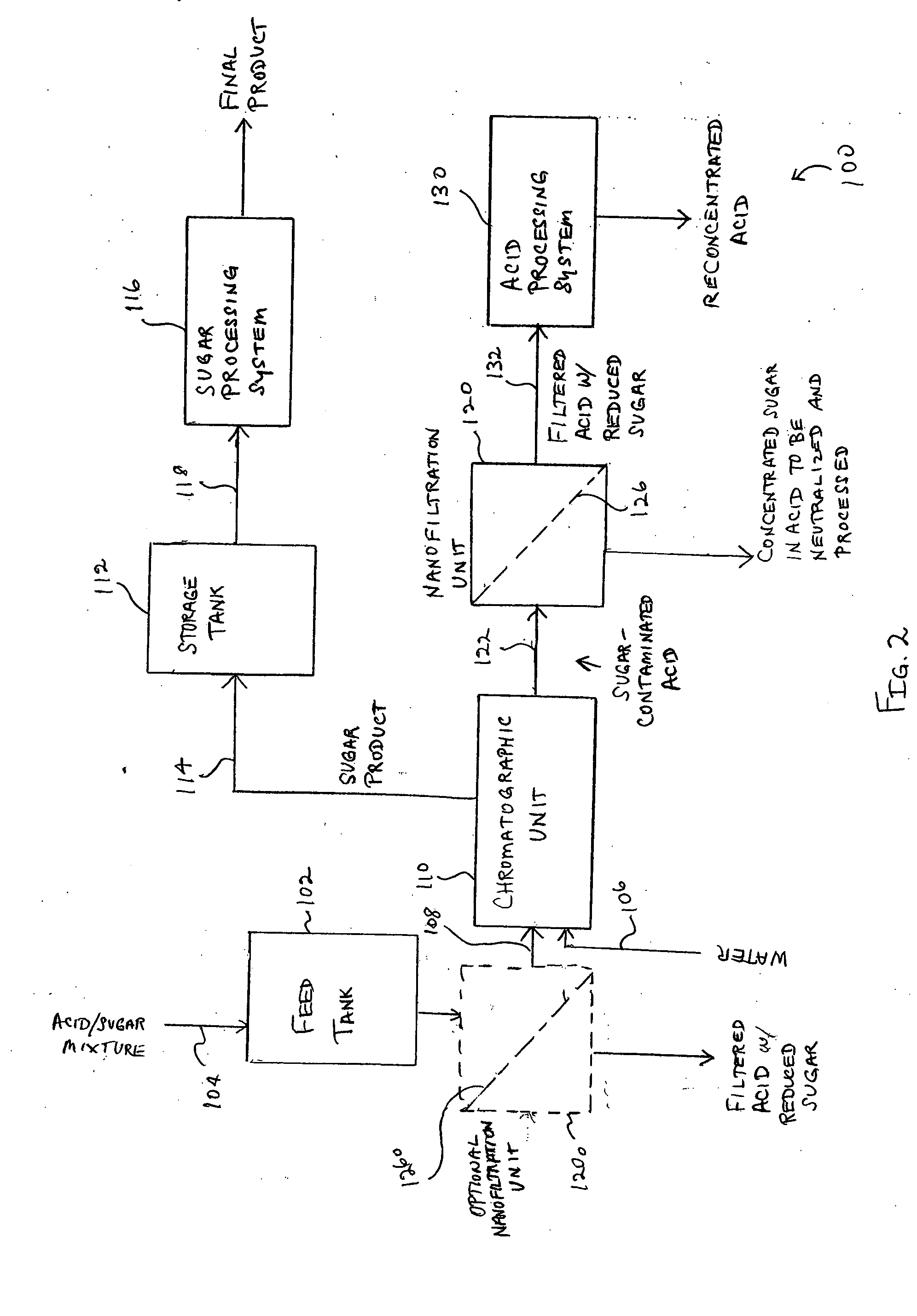

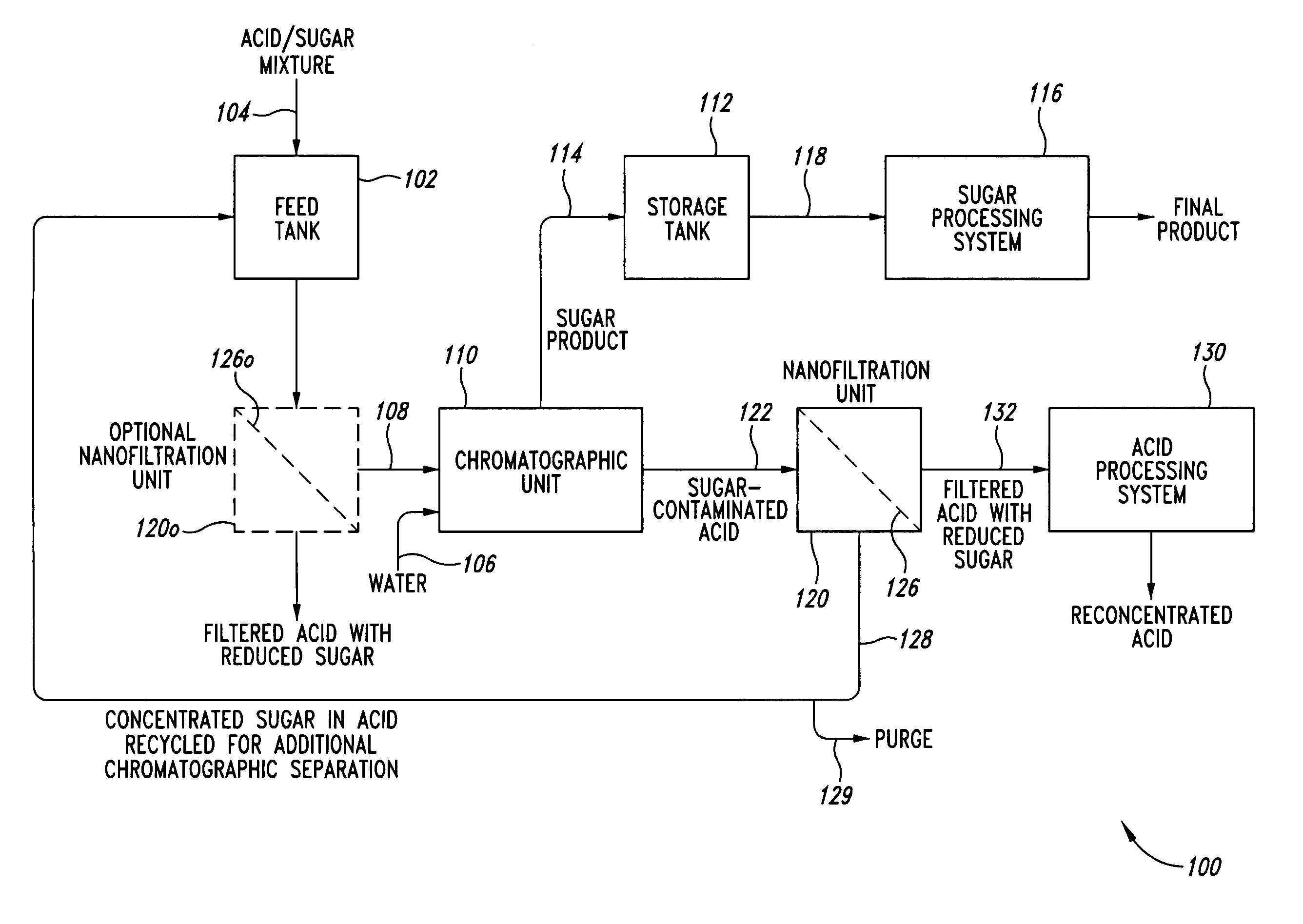

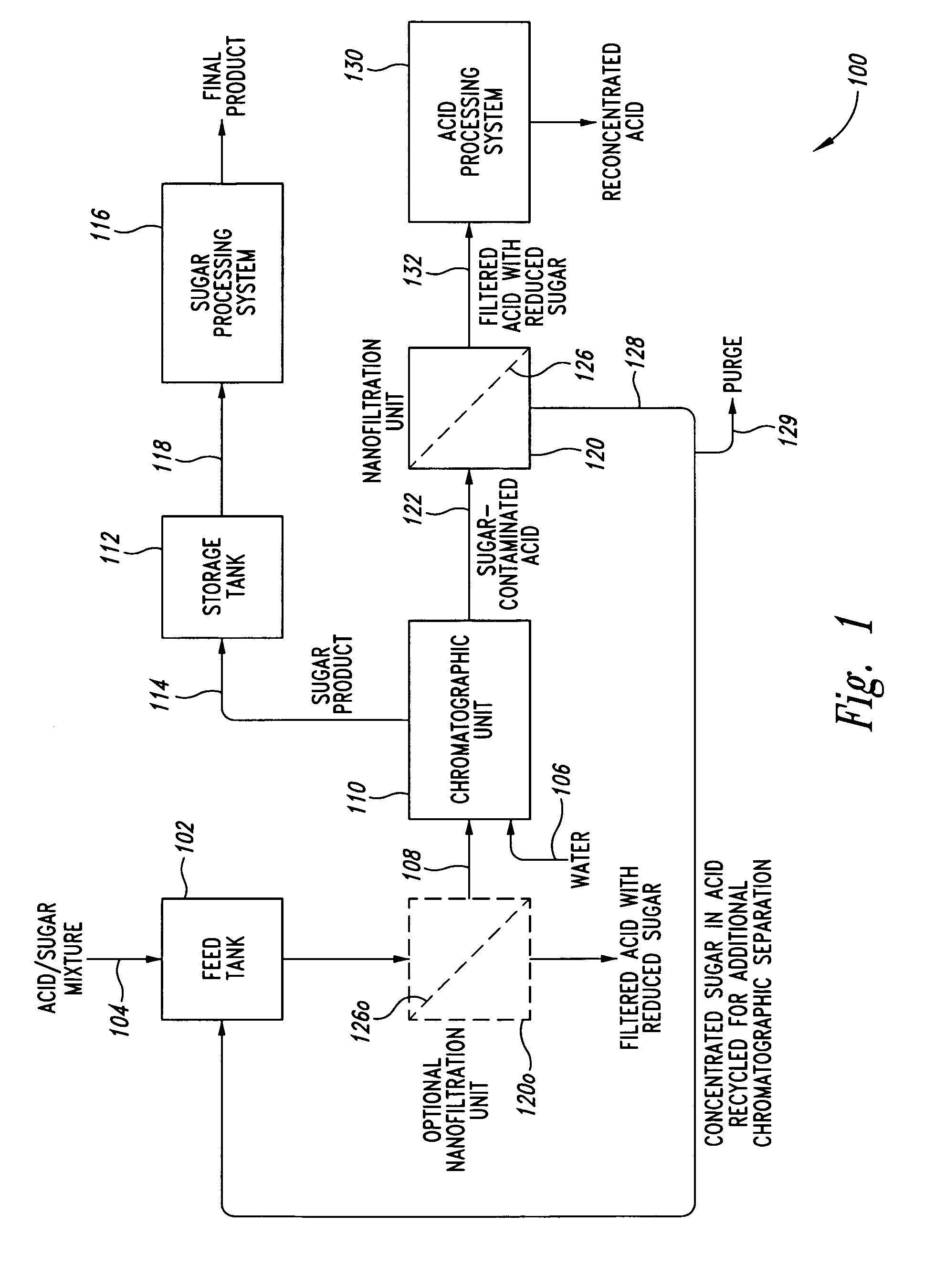

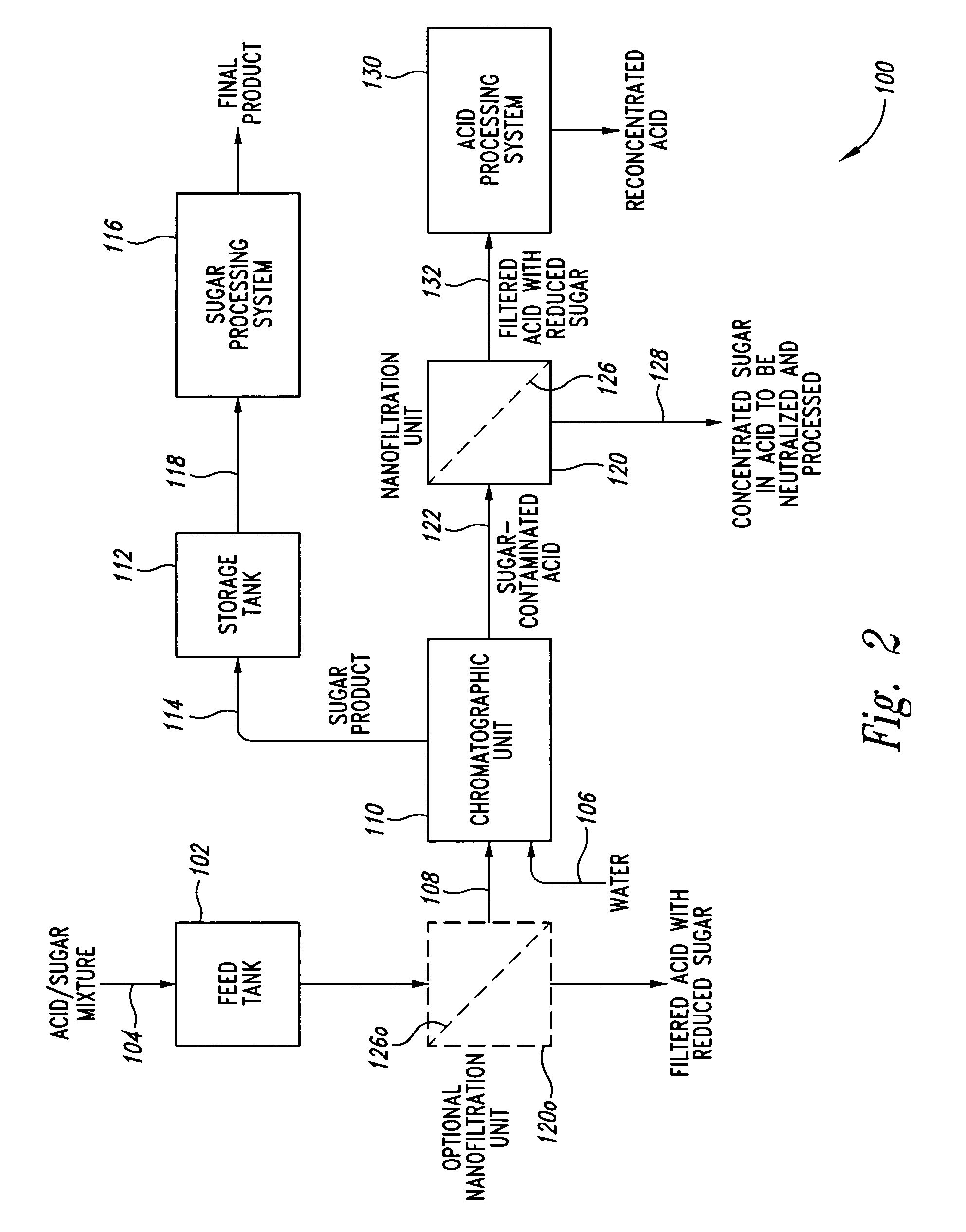

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

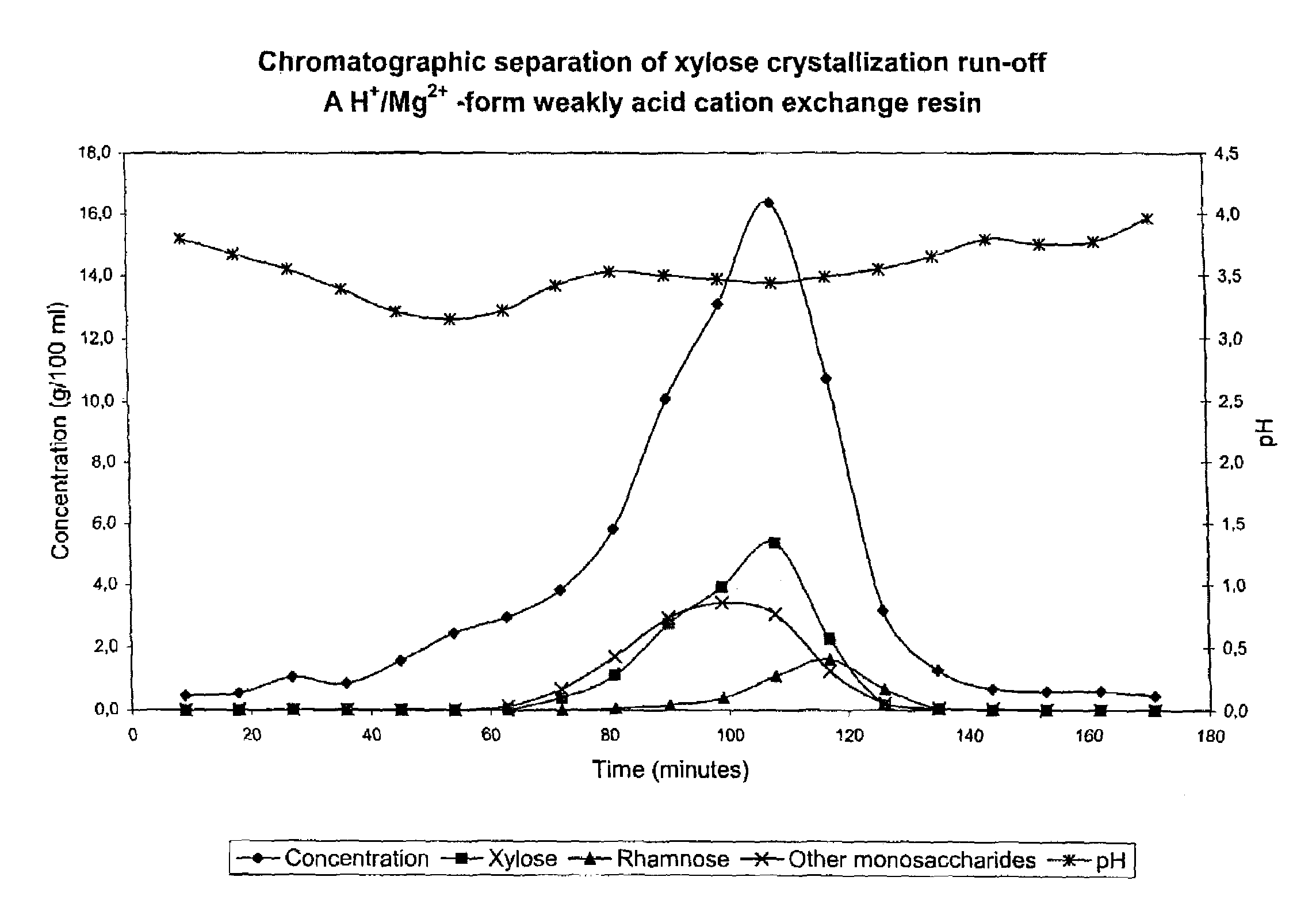

Separation of sugars, sugar alcohols, carbohydrates and mixtures thereof

InactiveUS7361273B2Efficient separationCation exchanger materialsIon-exchanger regenerationChromatographic separationAlcohol sugars

The present invention relates to a method of separating sugars and sugar alcohols from each other. More particularly the present invention relates to the use of a weakly basic anion exchange resin in a chromatographic separation process. The advantage of the present invention compared with the prior art is that it is especially suitable for separating reducing sugars in acidic conditions as well as for example in weakly acidic conditions. The method using chromatographic separation comprises at least one step where a weakly basic anion exchange resin is used in a chromatographic column or in a part of a column.

Owner:DUPONT NUTRITION BIOSCIENCES APS

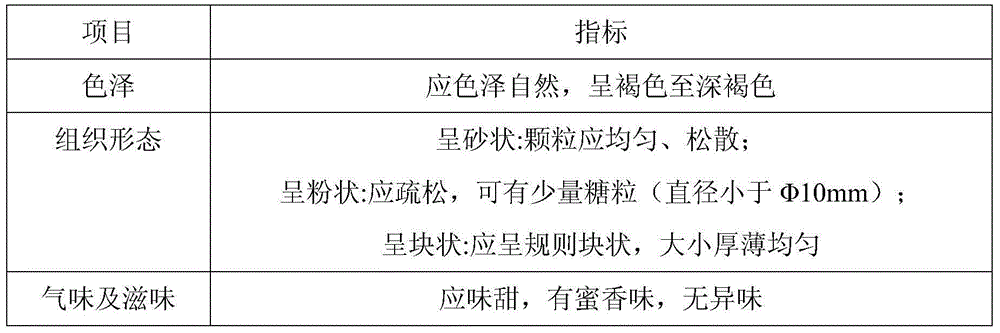

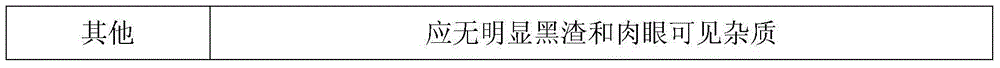

Industrialized production method of primitive brown sugar

ActiveCN103993106ARetract lowPromote recoverySugar crystallisationPurification by physical meansSlagMicrofiltration

The invention discloses an industrialized production method of primitive brown sugar. The method comprises the steps of with cane sugar factory mixed juice as a raw material, adding lime milk to regulate the pH value to 5.8-6.6; sieving and filtering; heating, floating and removing floating slag; removing impurities through microfiltration; evaporating and concentrating to obtain syrup with the concentration of 60-65-degree Bx; boiling sugar at the temperature of 125-130 DEG C at normal pressure to obtain syrup with the concentration of 95-98-degree Bx; sanding and forming to realize industrialized production of the primitive brown sugar. When used for producing brown sugar, the industrialized production method disclosed by the invention is safe and reliable in production process, high in mechanization degree, capable of realizing large-scale production of the primitive brown sugar and stable in product quality.

Owner:GUANGXI UNIV +1

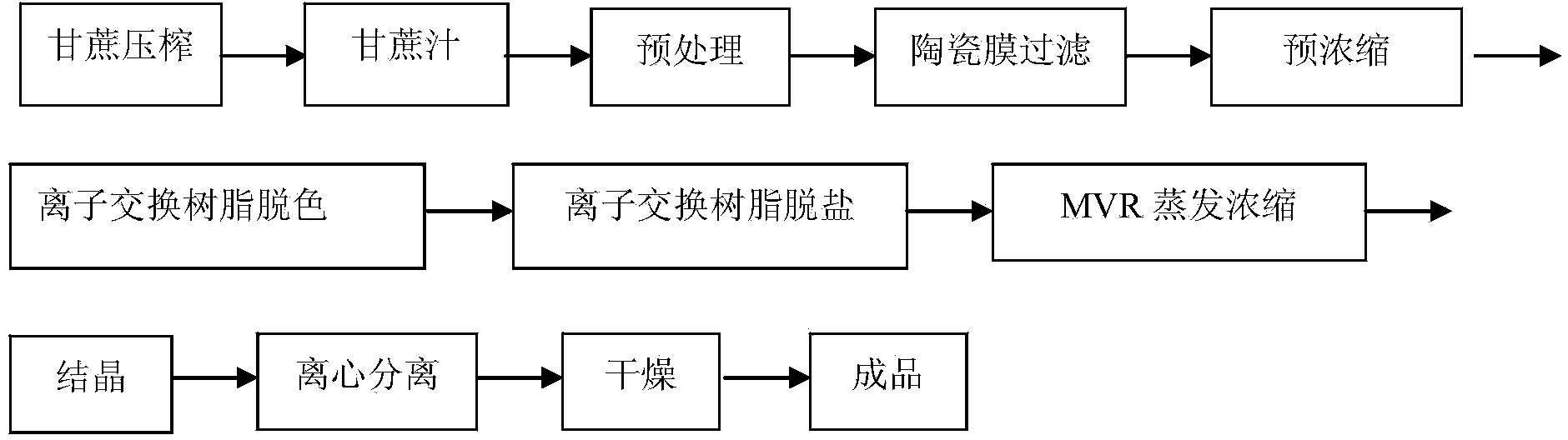

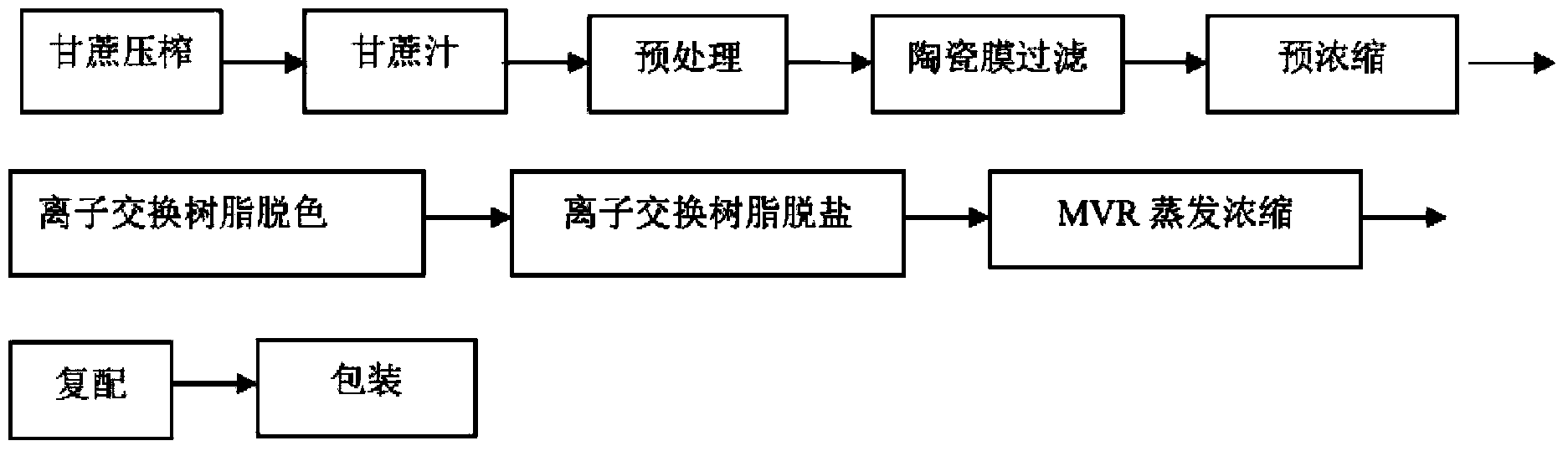

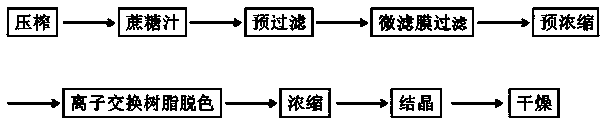

Technology for refining saccharose

ActiveCN103725802ANo color reversionOptimal production process parametersSugar crystallisationPurification using ion-exchange materialsInorganic saltsSucrose

The invention discloses a technology for refining saccharose. The technology comprises specific steps of juicing, pretreating, micro-filtering by a membrane, pre-concentrating, decoloring through ion exchange, desalting, evaporating and concentrating through MVR (mechanical vapor recompression), crystallizing, separating through centrifuging, and drying so as to obtain the saccharose crystal. The technology has the advantages that ceramic microfiltration substitutes for sedimentation by sheet frames and lime, so that the step of ultrafiltration is saved; due to concentration by the membrane, the evaporation capacity of evaporation and concentration equipment is reduced, the energy consumption is lowered, and part of inorganic salt is removed; the technology of decoloring and removing impurities through ion exchange substitutes for the technology of stoving, so that the problem of residual sulphur in the saccharose is solved, and the quality of the product is improved; the manner of ion exchange can effectively remove the salt in cane juice; energy consumption is effectively lowered due to the MVR; by adopting the membrane concentration and separation and ion exchange equipment, the floor space of the equipment is reduced, and investment of capital construction is lowered.

Owner:JIANGSU JIUWU HITECH

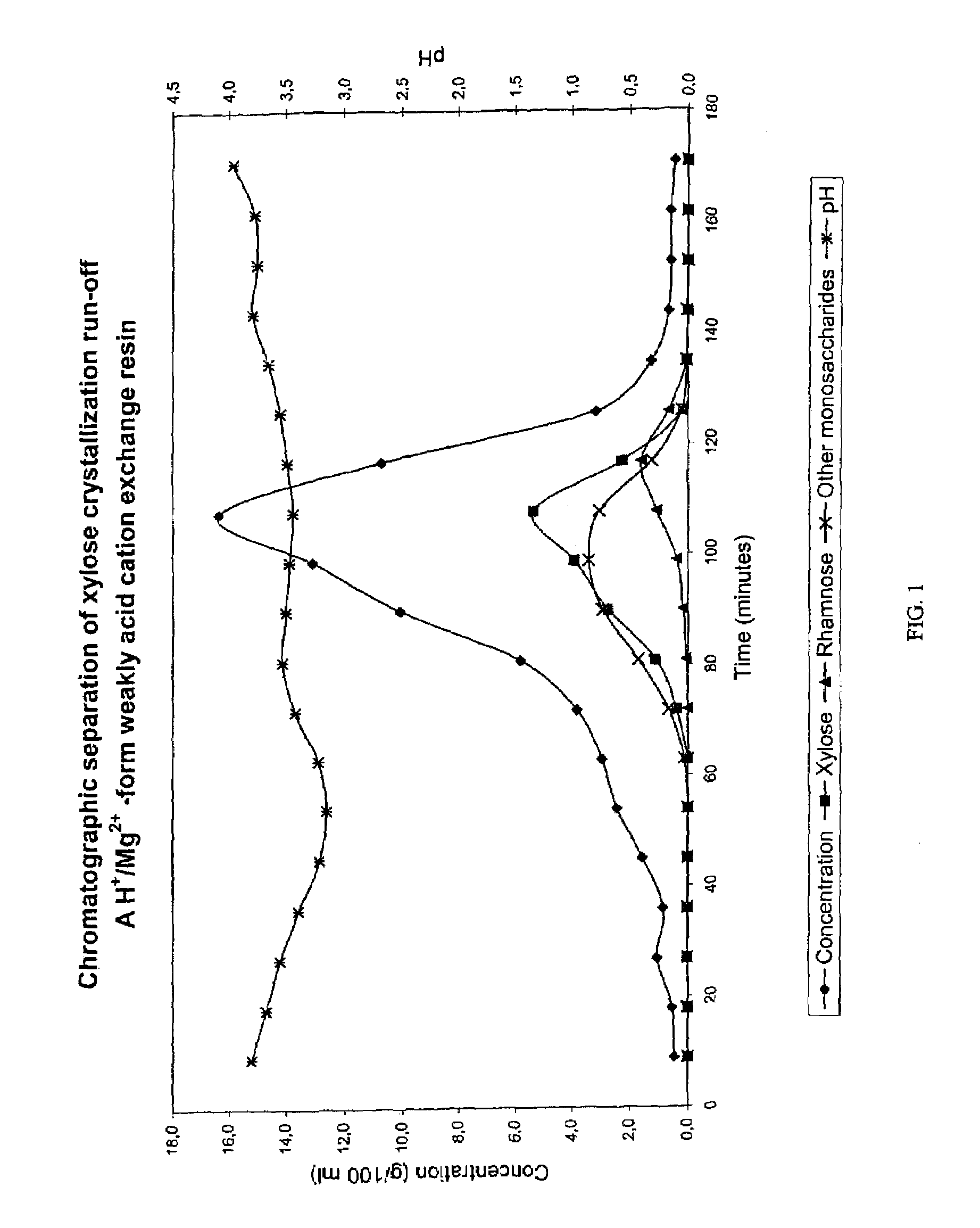

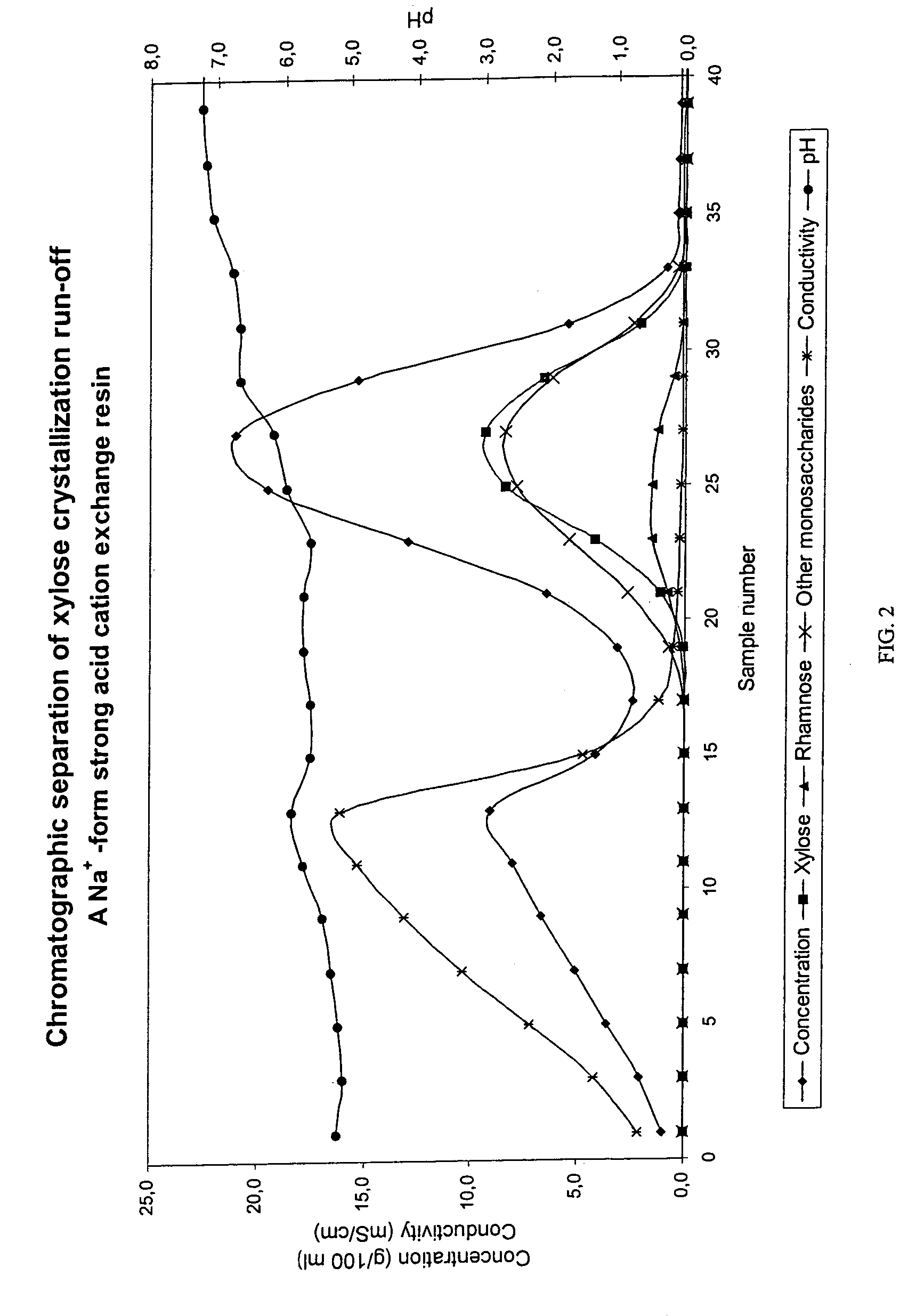

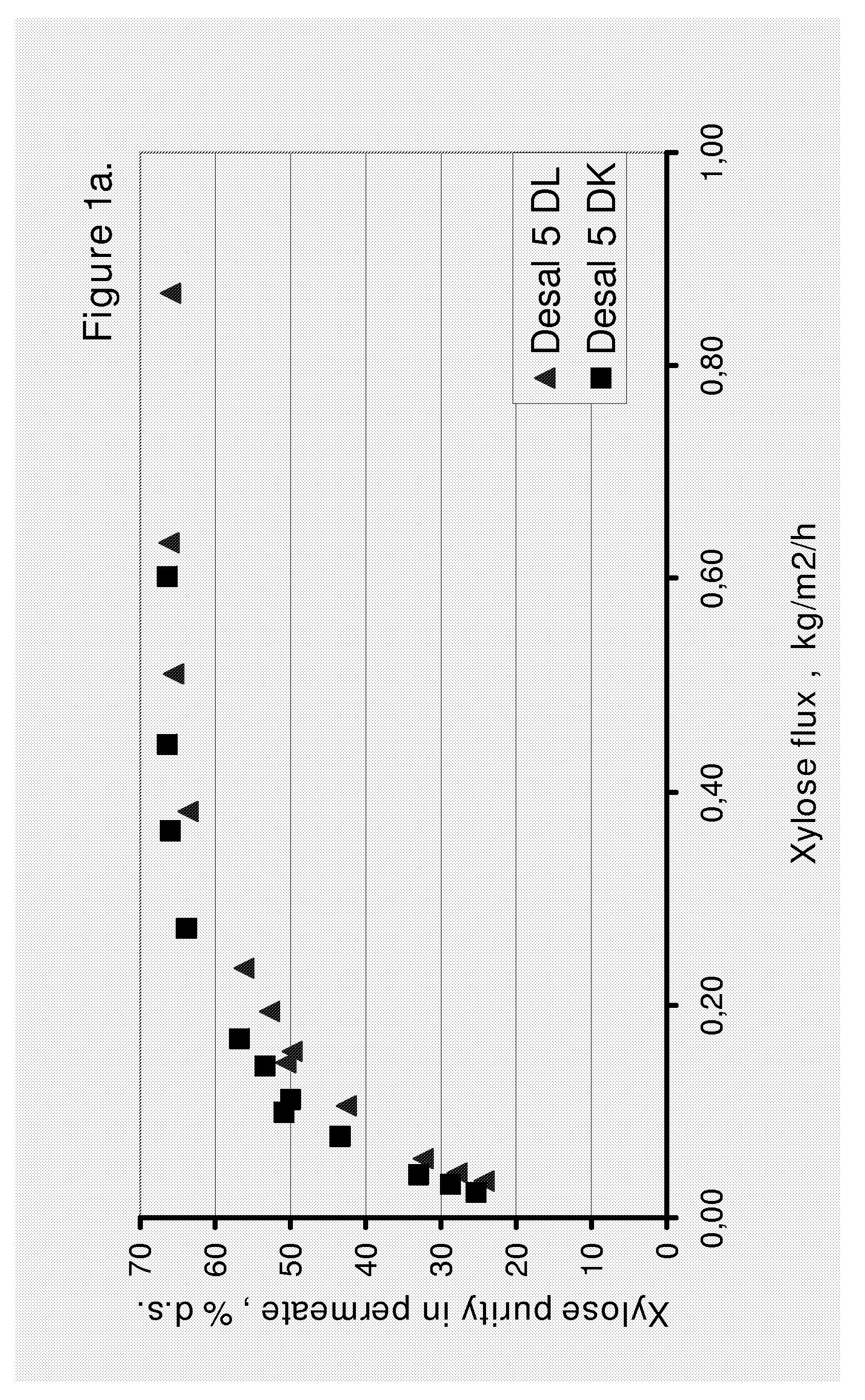

Separation process

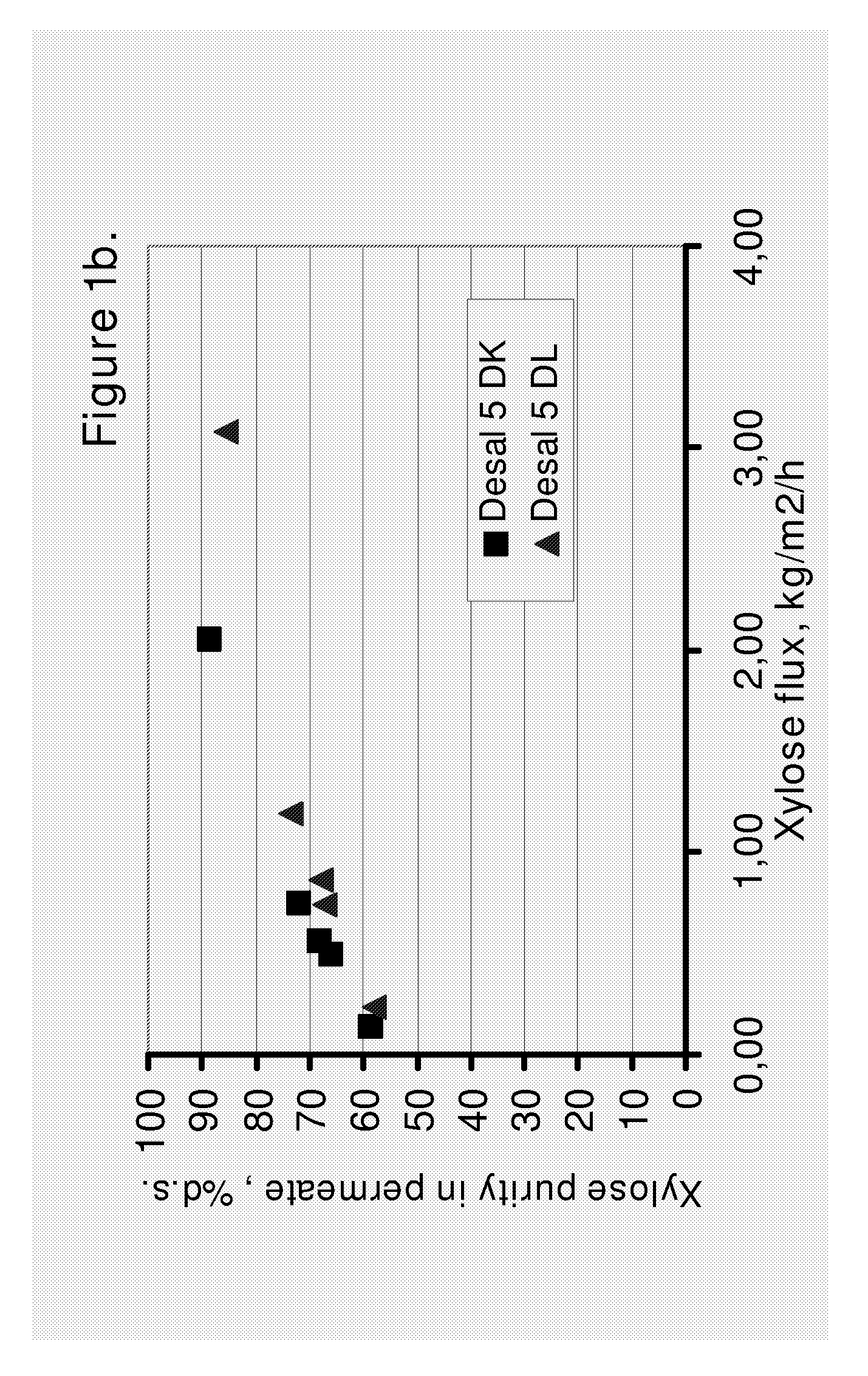

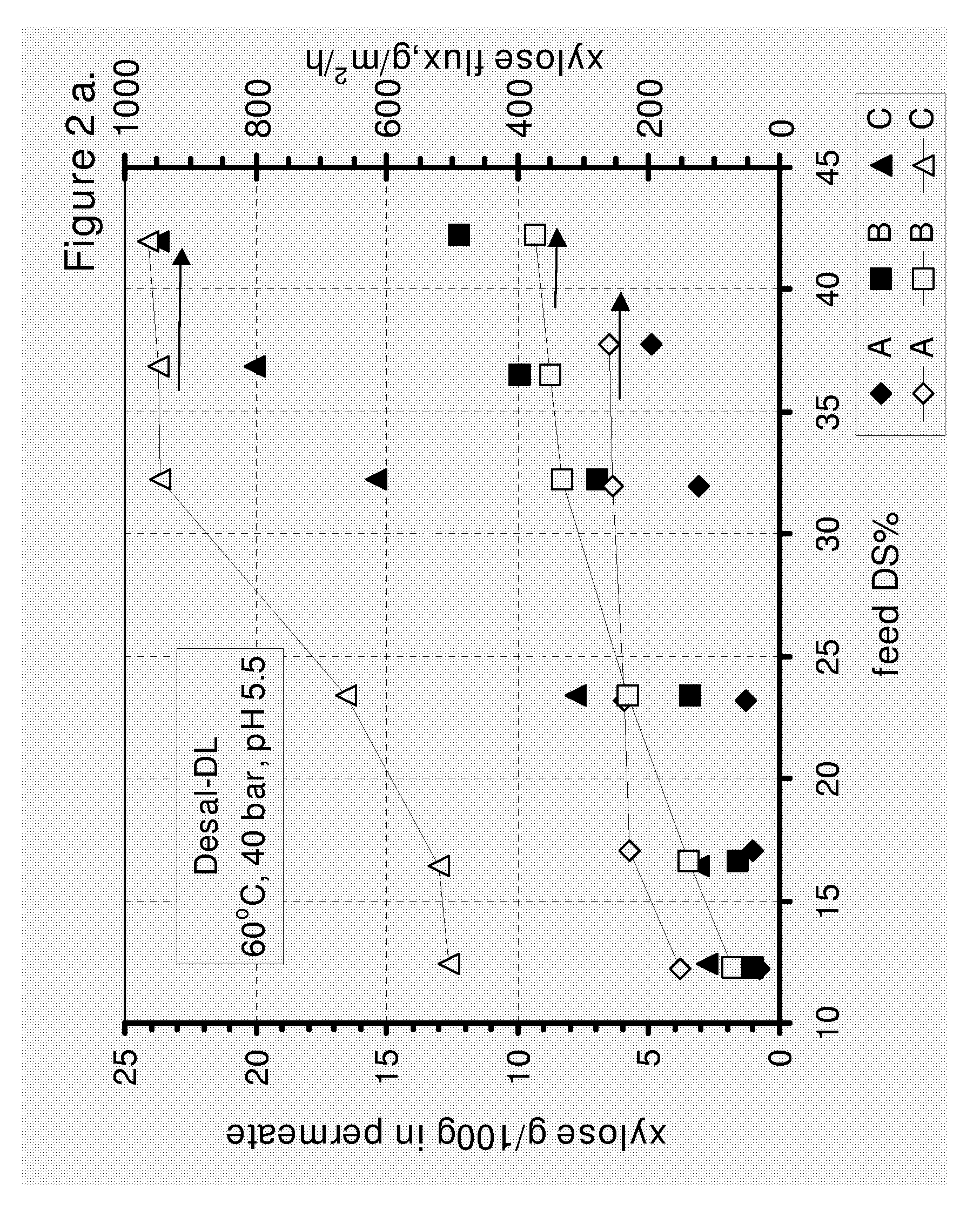

ActiveUS20090173339A1Improve performanceFavorable enrichment factor of xyloseMembranesPurification using adsorption agentsHydrolysateNanofiltration

The invention relates to an improved nanofiltration process of recovering xylose from a solution of a plant-based biomass hydrolysate. The process of the present invention is based on the regulation of the xylose flux in the nanofiltration process.

Owner:DUPONT NUTRITION BIOSCIENCES APS

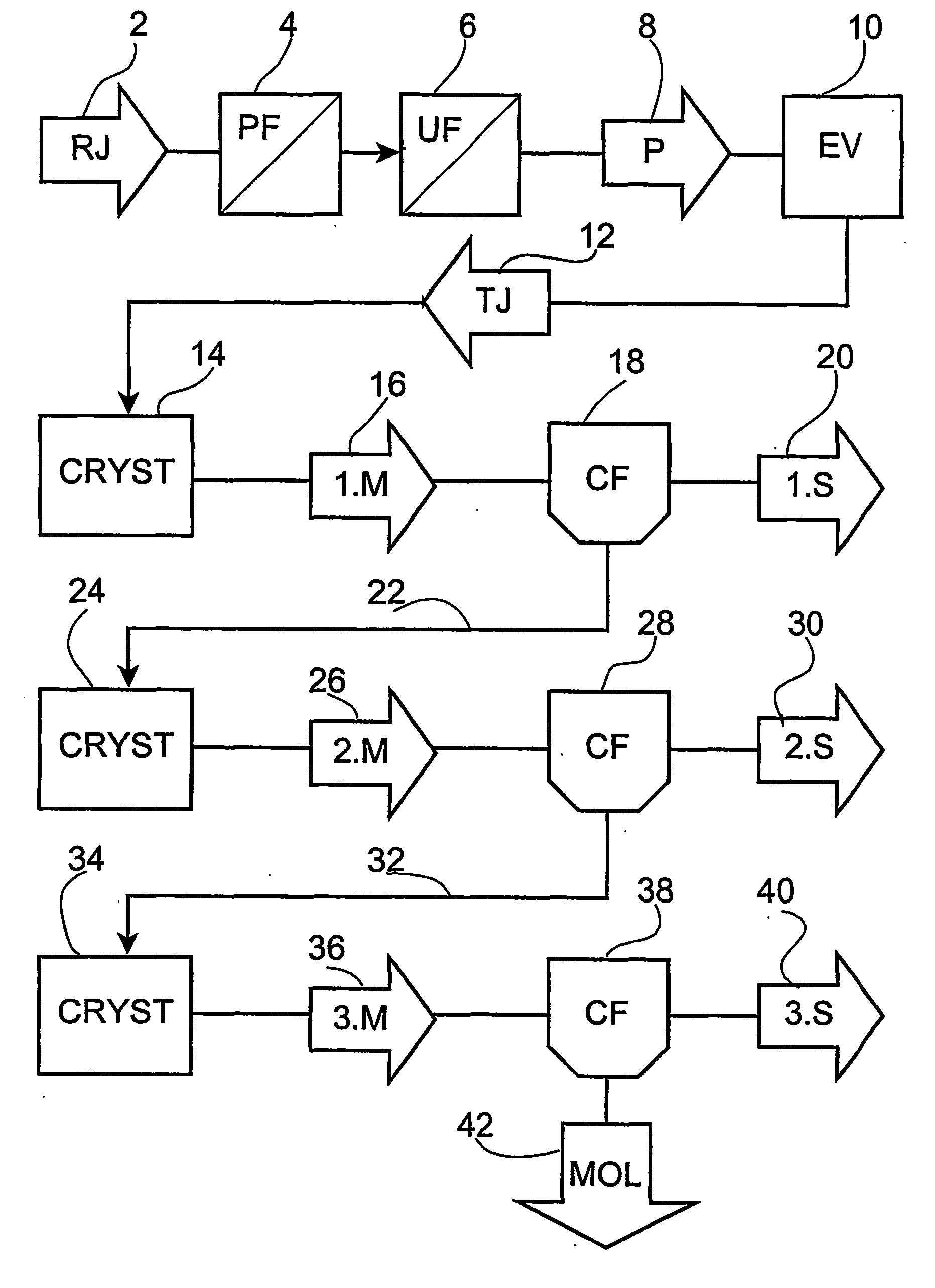

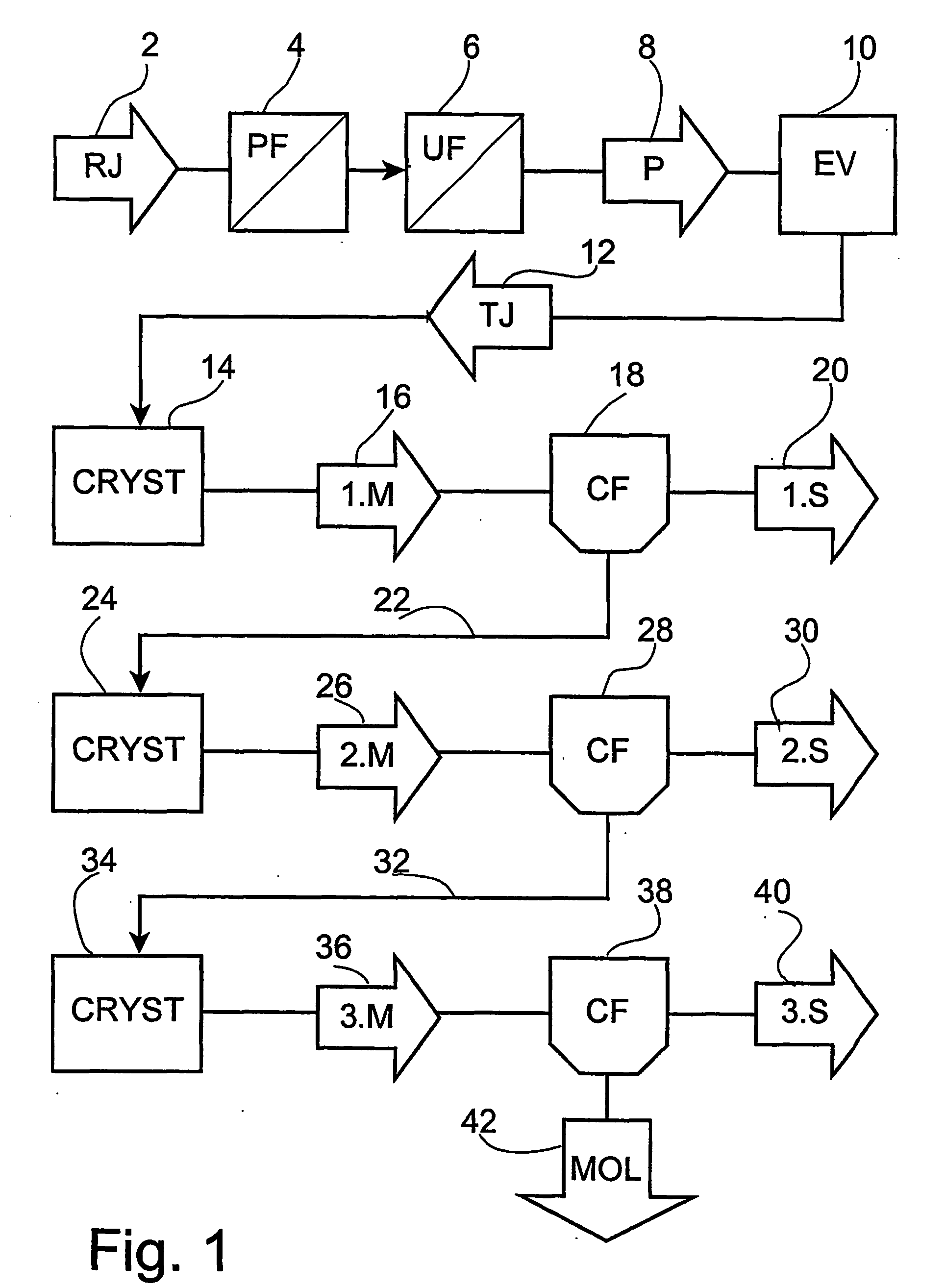

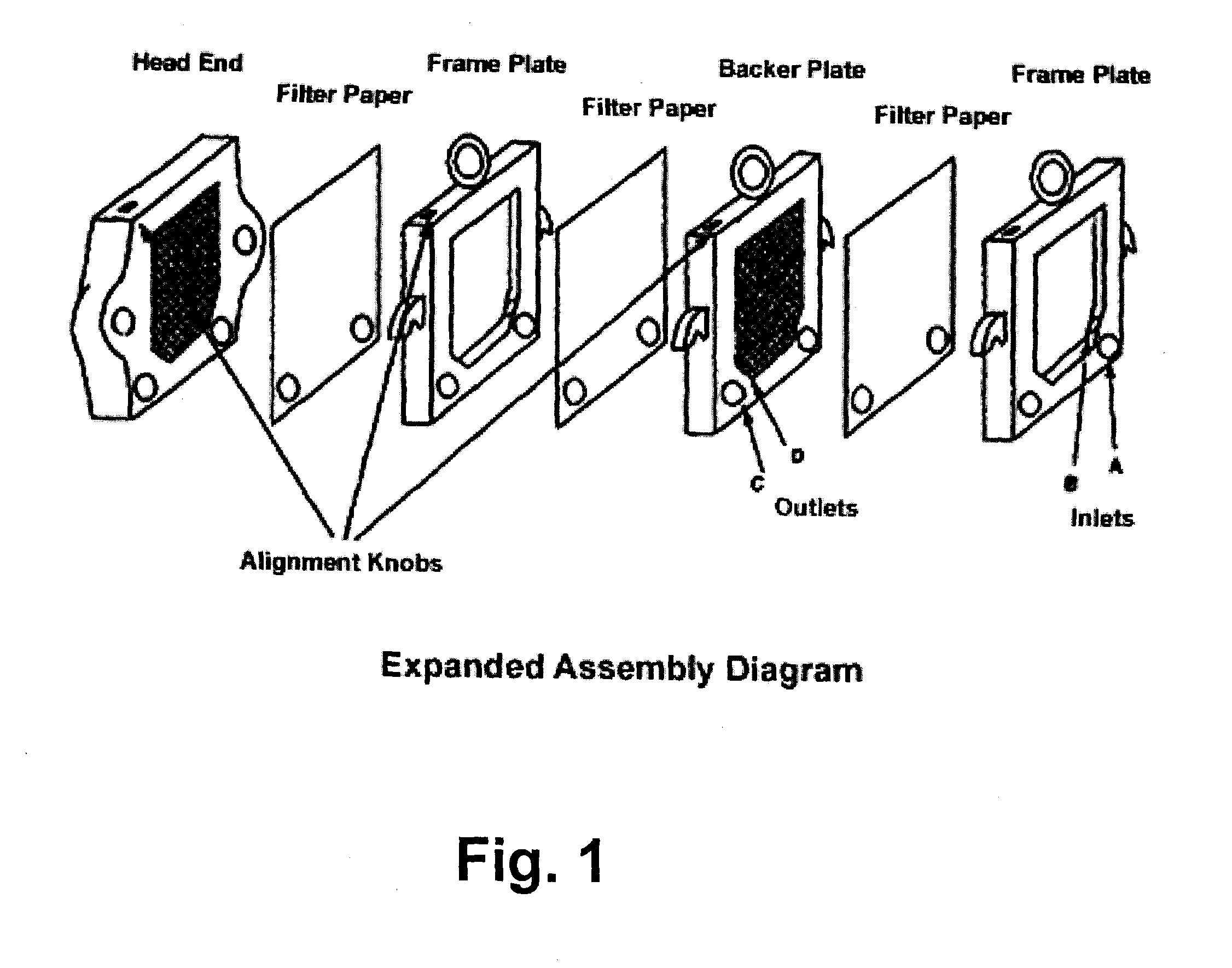

Process for the preparation of white and brown sugar from sugar beets

InactiveUS20040231663A1Avoid the needEasy to mergeSugar productsSugar crystal separationBiotechnologySugar

A process for the preparation of white and brown sugar from raw diffuser beet juice. The juice is purified by membrane filtration at 70-95° C. on a filter having a molecular weight cut-off between 2,000 and 500,000 Dalton and evaporated to a dry matter content of between 60 and 80% by weight under vacuum to a thick juice. A conventional multi-step evaporative crystallisation of the thick juice gives crops of white and brown sugar crystals. The brown sugar obtained have valuable organoleptic properties.

Owner:AS DE DANSKE SUKKERFABRIKKER

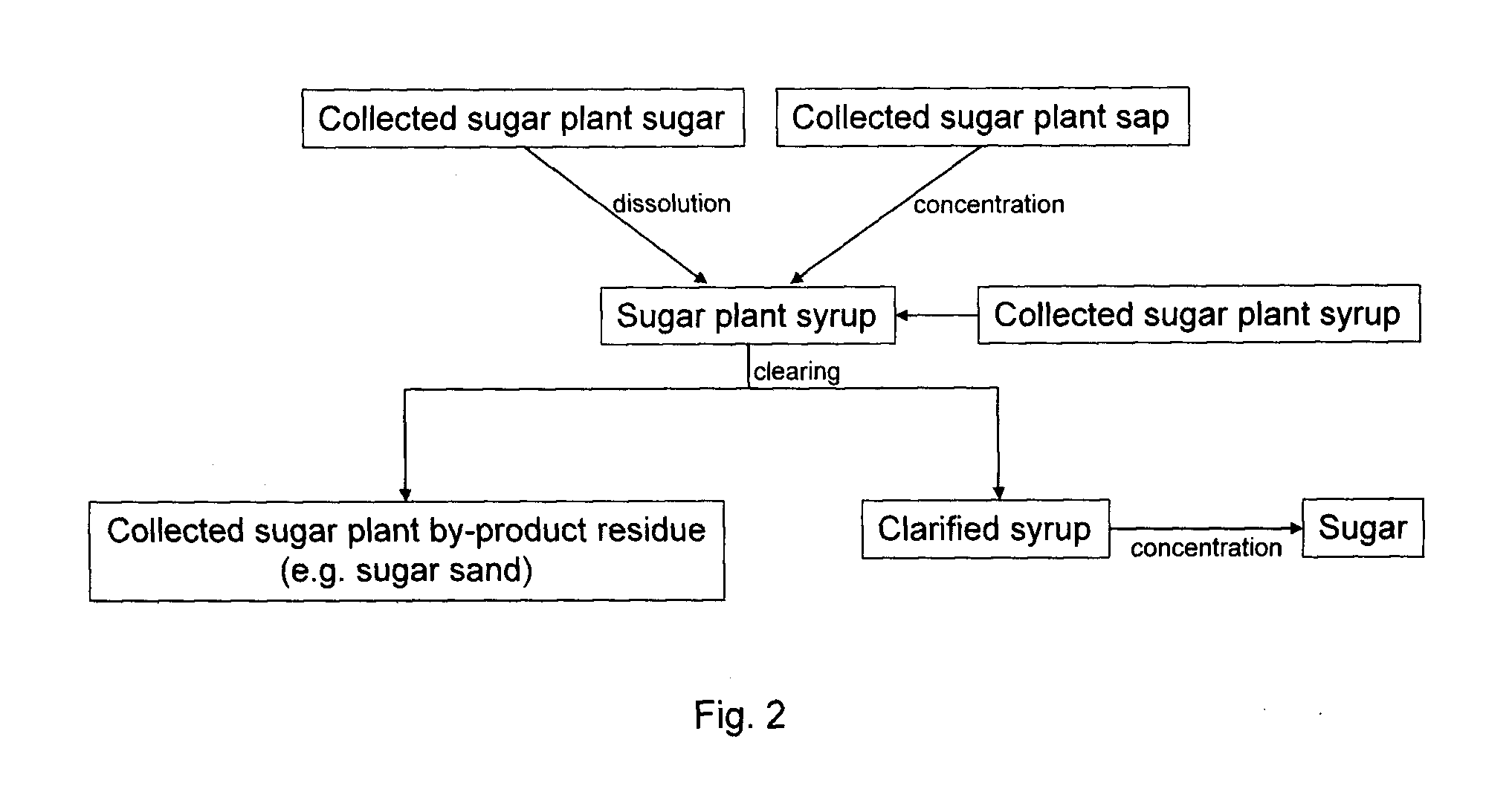

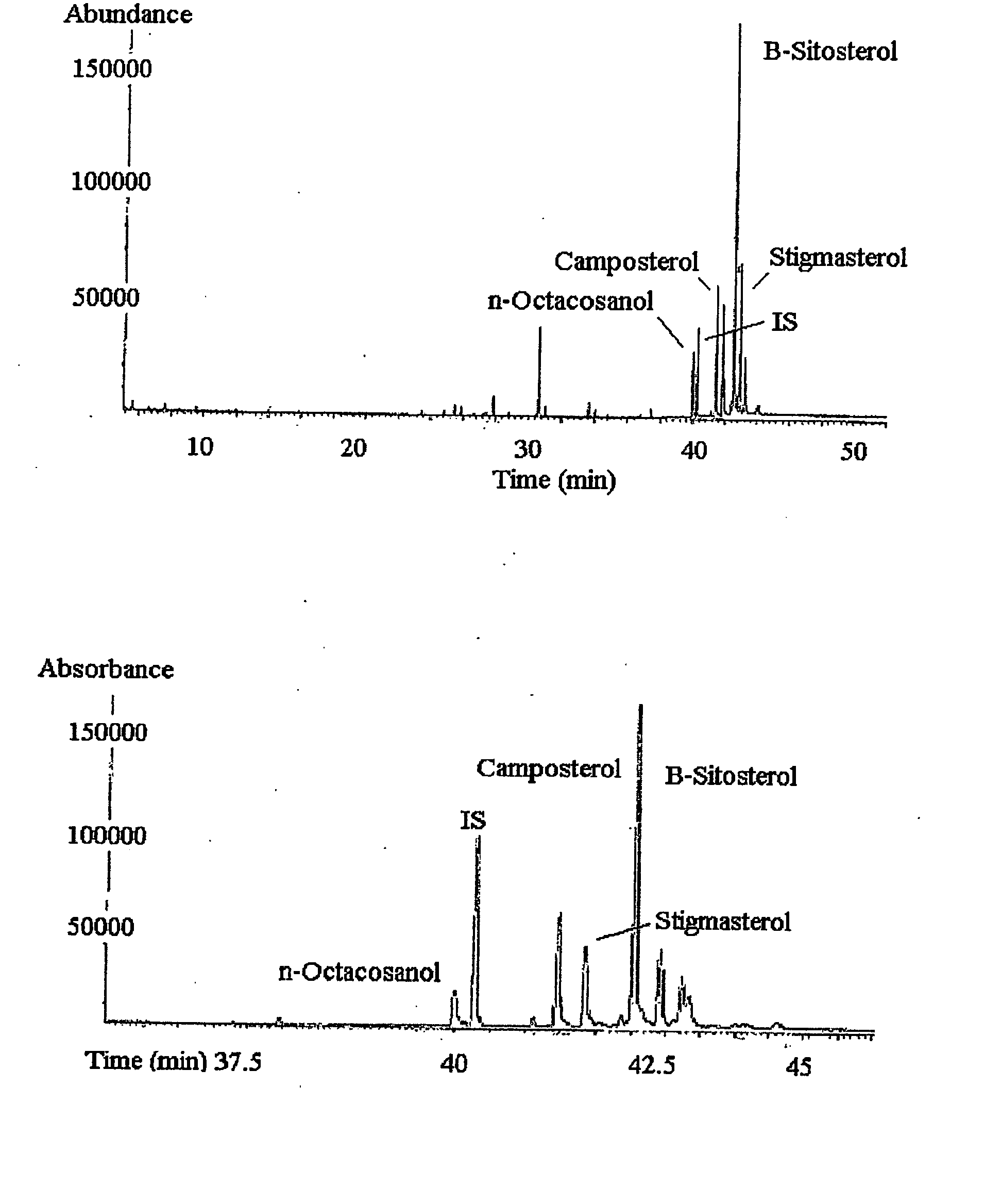

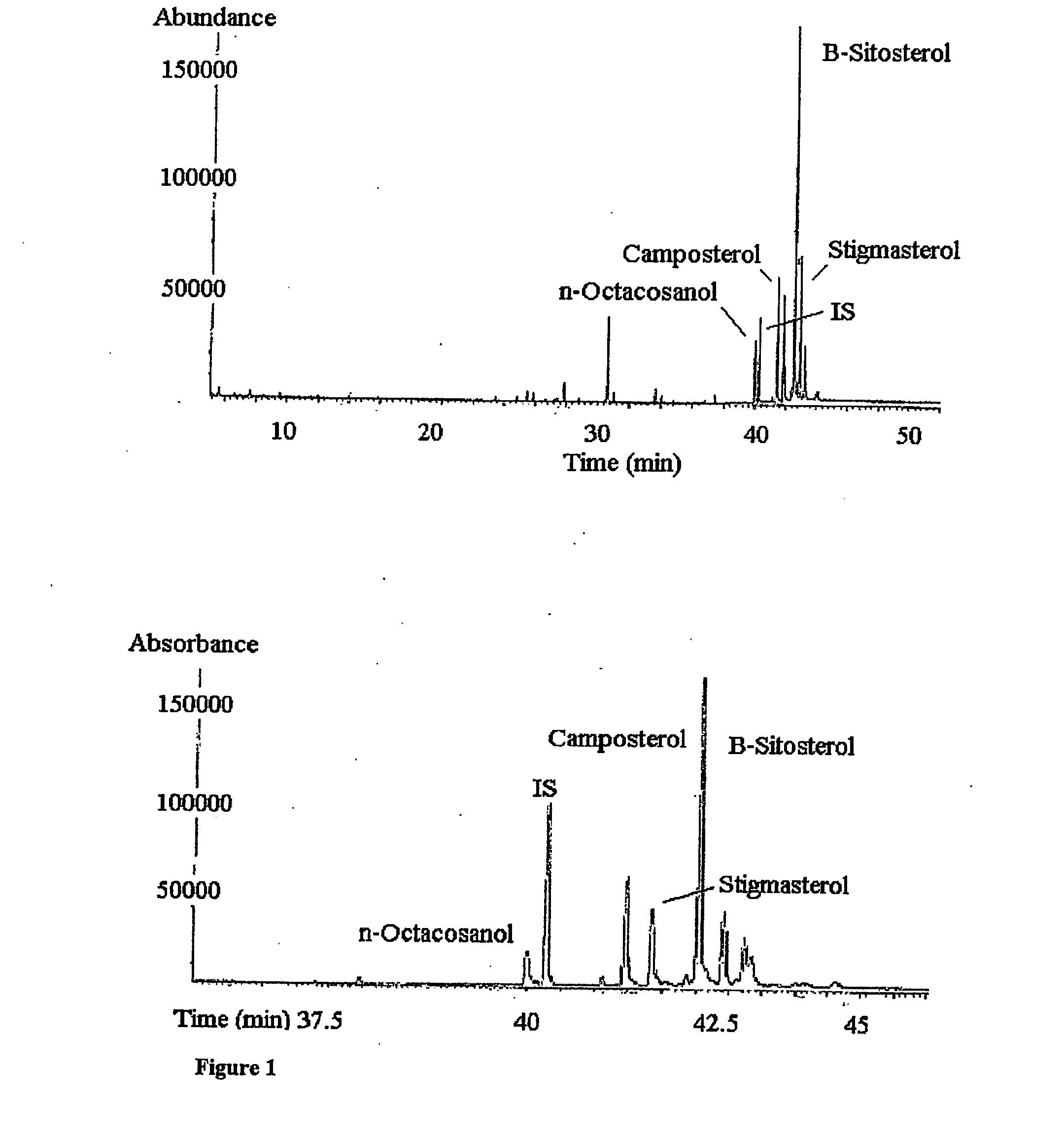

Sugar plant derived by-products and methods of production thereof

InactiveUS20130203688A1Good for healthBiocideEther/acetal active ingredientsFiltrationHealth condition

The present document describes a nutraceutical or cosmeceutical composition for the prophylaxis of an ailment comprising a therapeutically effective amount of a sugar plant syrup filtration residue in association with a pharmaceutically acceptable carrier. The present document also describes a nutraceutical or cosmeceutical composition for improving health condition of skin. The present document describes a method of producing a sugar plant syrup-derived product; wherein the improvement is characterized in the step of: collecting a sugar plant syrup residue during the production of sugar or syrup to produce a syrup-derived by-product.

Owner:FEDERATION DES PRODUCTEURS ACERICOLES DU QUEBEC

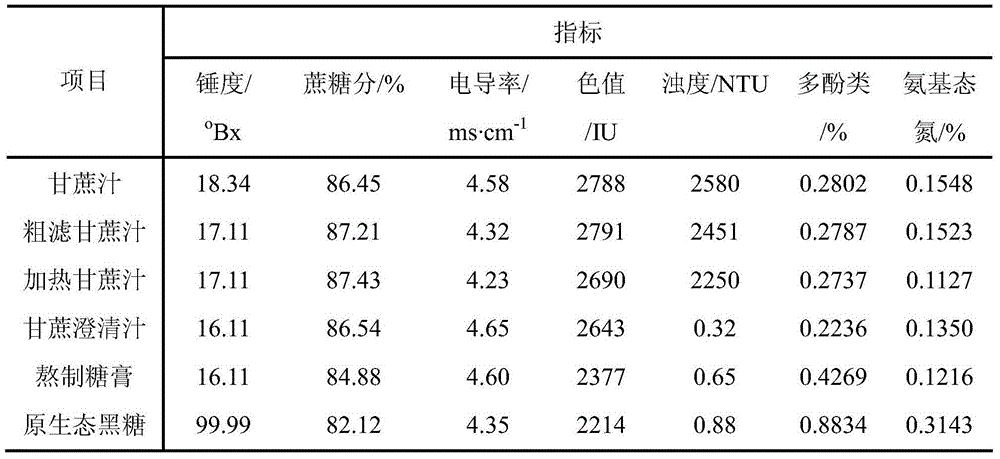

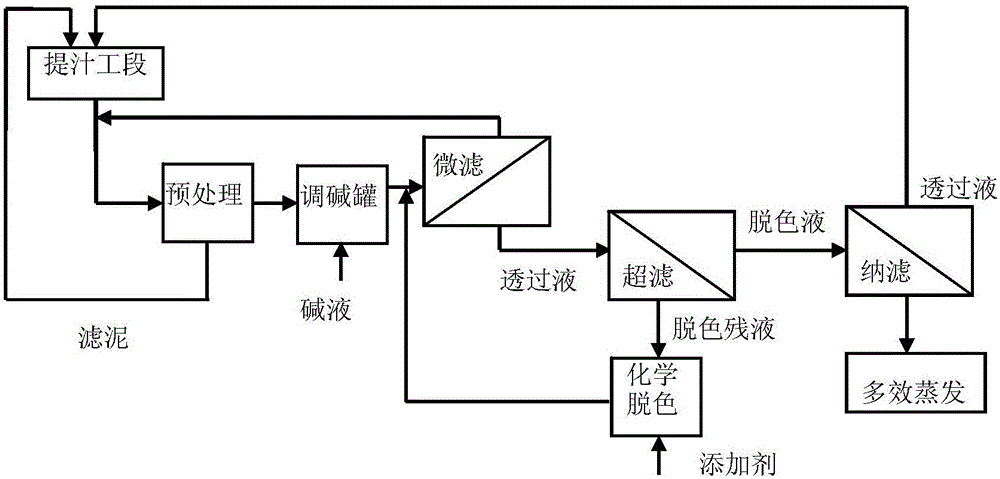

Originally ecological black sugar processing method

ActiveCN104805225ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

Method of processing whey for demineralization purposes

InactiveUS6383540B1Reduce maintenanceLess upkeepIon-exchanger regenerationSolid sorbent liquid separationProtonChloride

A method of treating whey for demineralization purposes, the method comprising a stage of separating out salts by transfer through electrodialysis or nanofiltration membranes, wherein, upstream from this separation stage, the method comprises in succession at least one step of exchanging divalent cations for protons and at least one step of exchanging divalent anions for chloride ions.

Owner:EURODIA IND SA

Method of obtaining an organic salt or acid from an aqueous sugar stream

InactiveUS7718070B2Facilitates recovery and further processingLow costSugar derivativesComponent separationOrganic acidSugar

A process for obtaining one or more than one salt of an organic acid(s), or organic acid(s), from an aqueous sugar stream comprising one or more than one mineral acid and the organic acid(s) is provided. The process comprises introducing the aqueous sugar stream to a separation system comprising one or more beds of anion exchange resin and obtaining a stream therefrom comprising the sugar. The one or more beds of anion exchange resin are then regenerated in one or more stages to produce at least one product stream comprising the organic acid, a salt of the organic acid, or a combination thereof, and a separate outlet stream comprising the mineral acid, a salt of the mineral acid, or a combination thereof. The product stream is then recovered. The separation may be conducted with two separation units, or using a single anion exchange unit.

Owner:IOGEN ENERGY CORP

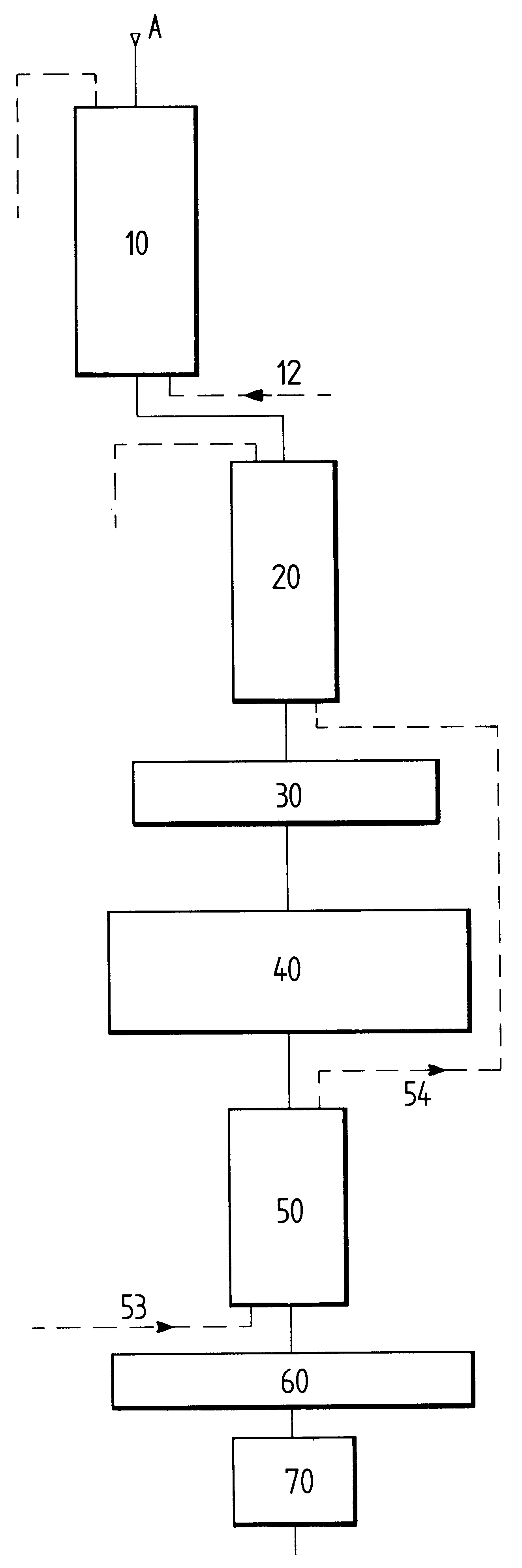

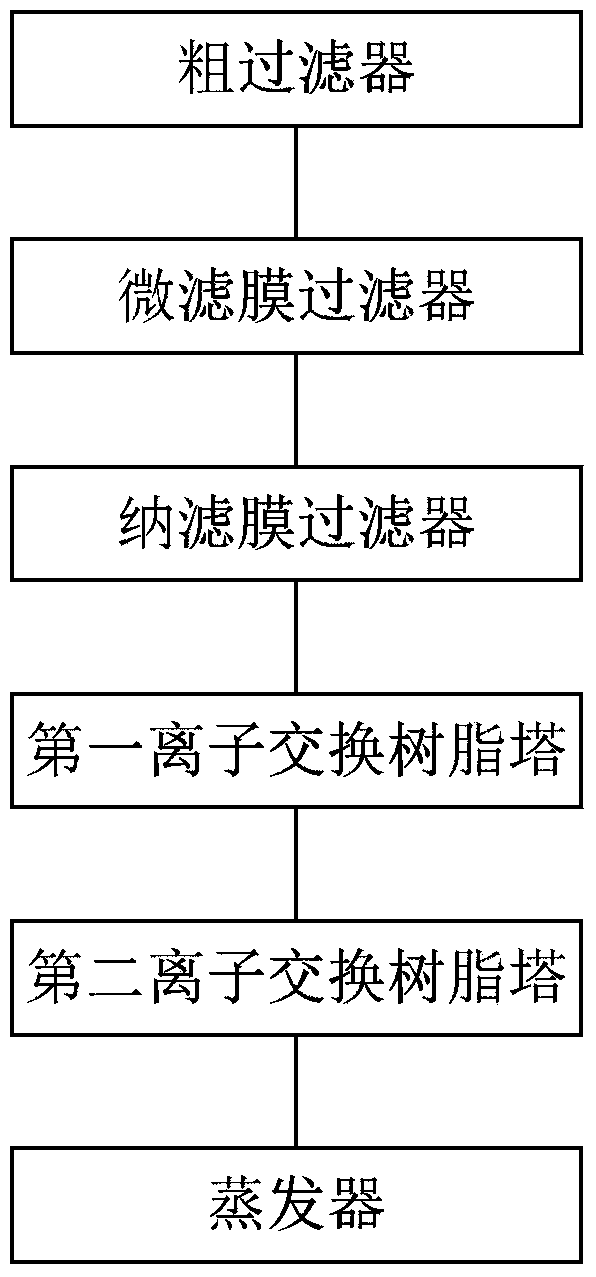

Production technique and device of directly edible edible syrup

ActiveCN103710469ALow chroma valueHigh desalination ratePurification using ion-exchange materialsPurification by physical meansSucroseMicrofiltration membrane

The invention relates to a production technique and device of directly edible syrup. The method comprises the following steps: pressing sugar cane with a juice press to obtain a sugar cane juice; prefiltering the sugar cane juice through a coarse filter, and filtering with a microfiltration membrane to obtain a sucrose juice clear solution; concentrating the sucrose juice clear solution through a nanofiltration membrane to obtain a concentrated solution; sending the concentrated solution into a first ion exchange resin tower to obtain a first permeation solution; sending the first permeation solution into a second ion exchange resin tower to obtain a second permeation solution; and concentrating the second permeation solution in an evaporator to obtain a refined concentrated solution, adding additives and uniformly mixing to obtain the syrup. The product produced by the production technique provided by the invention has the advantages of low chromatic value, high desalting rate and high yield.

Owner:JIANGSU JIUWU HITECH

Process for fractioning vinasse

InactiveUS6022394AIncrease PotassiumPromote crystallizationIon-exchange process apparatusBy-product recoveryOrganic fractionOrganic acid

PCT No. PCT / FI95 / 00329 Sec. 371 Date Mar. 10, 1997 Sec. 102(e) Date Mar. 10, 1997 PCT Filed Jun. 7, 1995 PCT Pub. No. WO96 / 00776 PCT Pub. Date Jan. 11, 1996The invention relates to a process for fractioning vinasse, in which process the pH value of the vinasse is lowered by adding acid, and the formed precipitate is separated in order to obtain an inorganic fraction, whereupon an organic fraction remains. The invention also relates to the products obtained. The inorganic fraction mainly contains potassium salt, and it is useful for example as a fertilizer. The organic fraction mainly contains organic acids, and it is useful for example as an additive in animal feed and in producing silage.

Owner:CULTOR LTD +1

Process for preparing sugar from cane

InactiveCN103981290AWell mixedLow ash contentPurification using alkaline earth metal compoundsPurification by physical meansActive carbonActivated carbon

The invention discloses a process for preparing sugar from cane. The process comprises the following steps: pressing, namely horizontally pressing at first and then longitudinally pressing to obtain cane juice; filtering, namely putting the cane juice into a filter to obtain pure cane juice, and separating out cane residues; clarifying and decolorizing, namely heating the pure cane juice, adding citric acid and calcium hydroxide for mixing, adding lime milk for neutralizing, carrying out secondary heating, and adding polyacrylamide for settling separation to obtain clear juice and mud juice; filtering the mud juice to obtain filtered clear juice, combining the clear juice, and adding active carbon into the clear juice for deodorizing; performing evaporation concentration, sugar boiling and crystallization, honey separation and drying to obtain the finished sugar. The process has good filtering, clarifying and deodorizing effects, and is time-saving, labor-saving and simple to operate.

Owner:彭华成

Separation process

The invention relates to an improved nanofiltration process for separating and recovering components, such as sugars and sugar alcohols from multicomponent mixtures. The process of the invention is characterized by collecting the nanofiltration retentate / permeate in several fractions with different purity, optional recycling of at least one of the collected nanofiltration retentate / permeate fractions to the nanofiltration and recovering the desired component from the nanofiltration permeate / retentate fractions by different methods. In one embodiment of the invention, the process comprises a combination of nanofiltration and chromatography.

Owner:DUPONT NUTRITION BIOSCIENCES APS

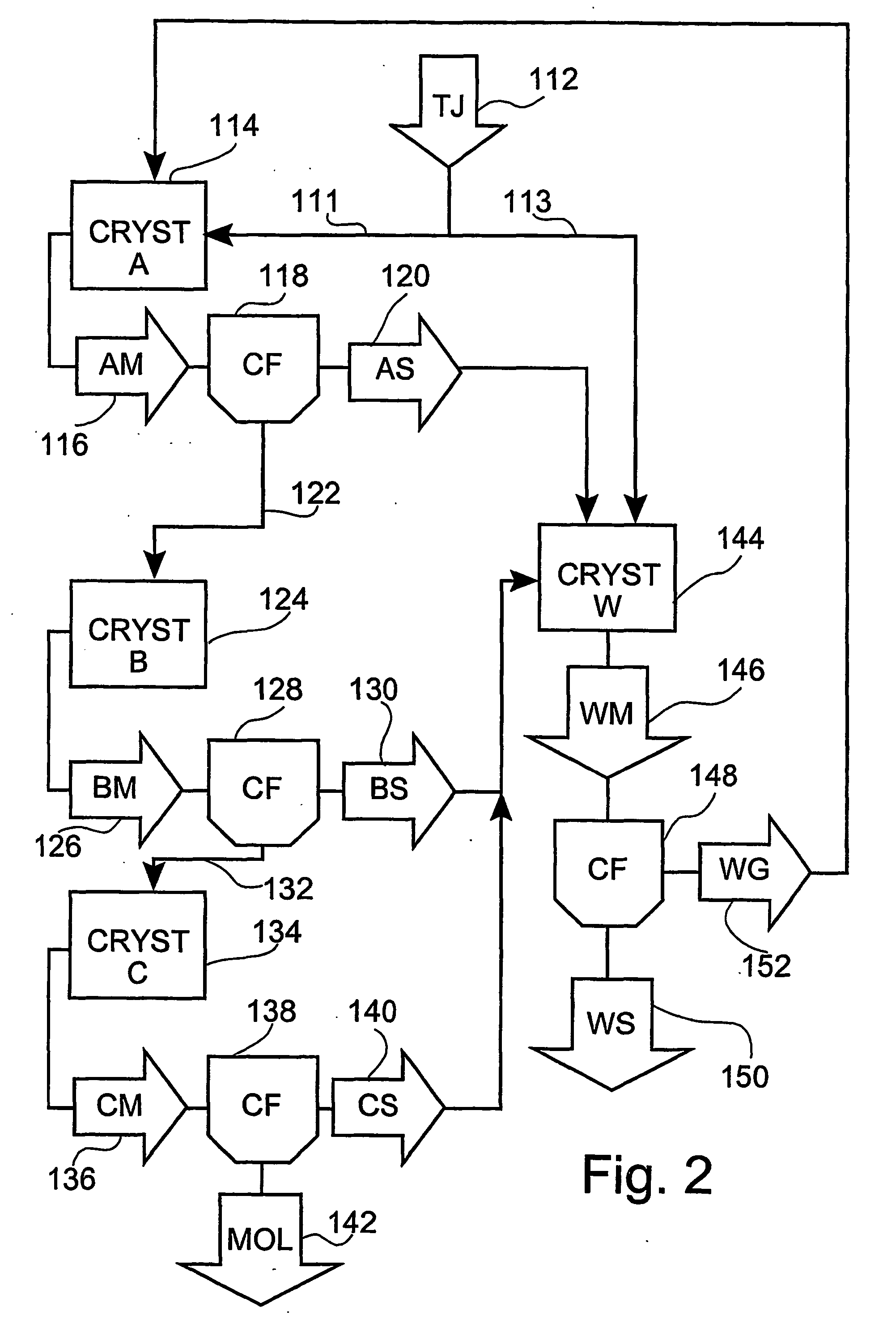

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

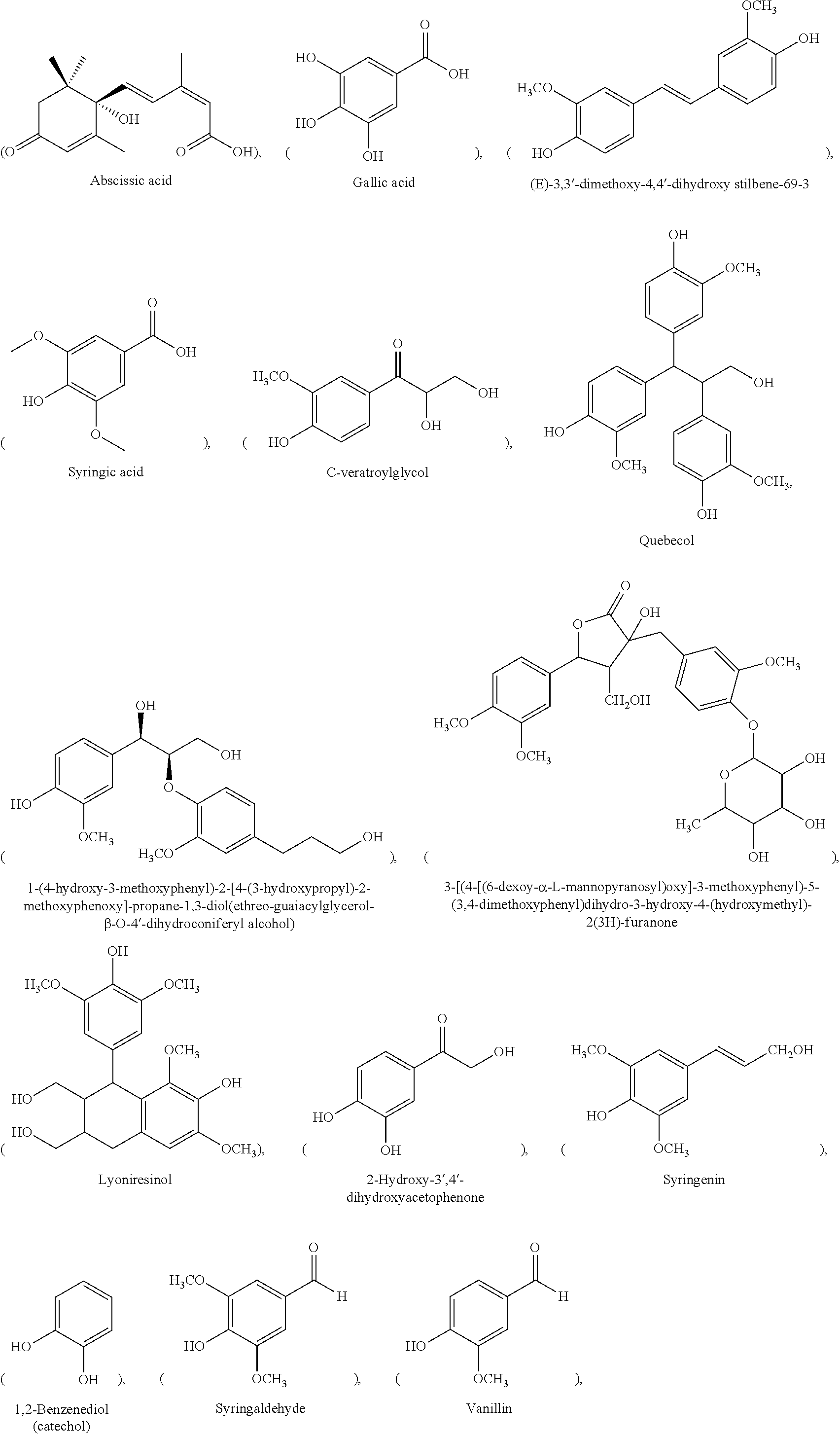

Natural Sweetener

ActiveUS20080045464A1Improve gutLowering GIOrganic active ingredientsSugar food ingredientsPhytochemicalWaste product

Owner:POLY GAIN PTE LTD

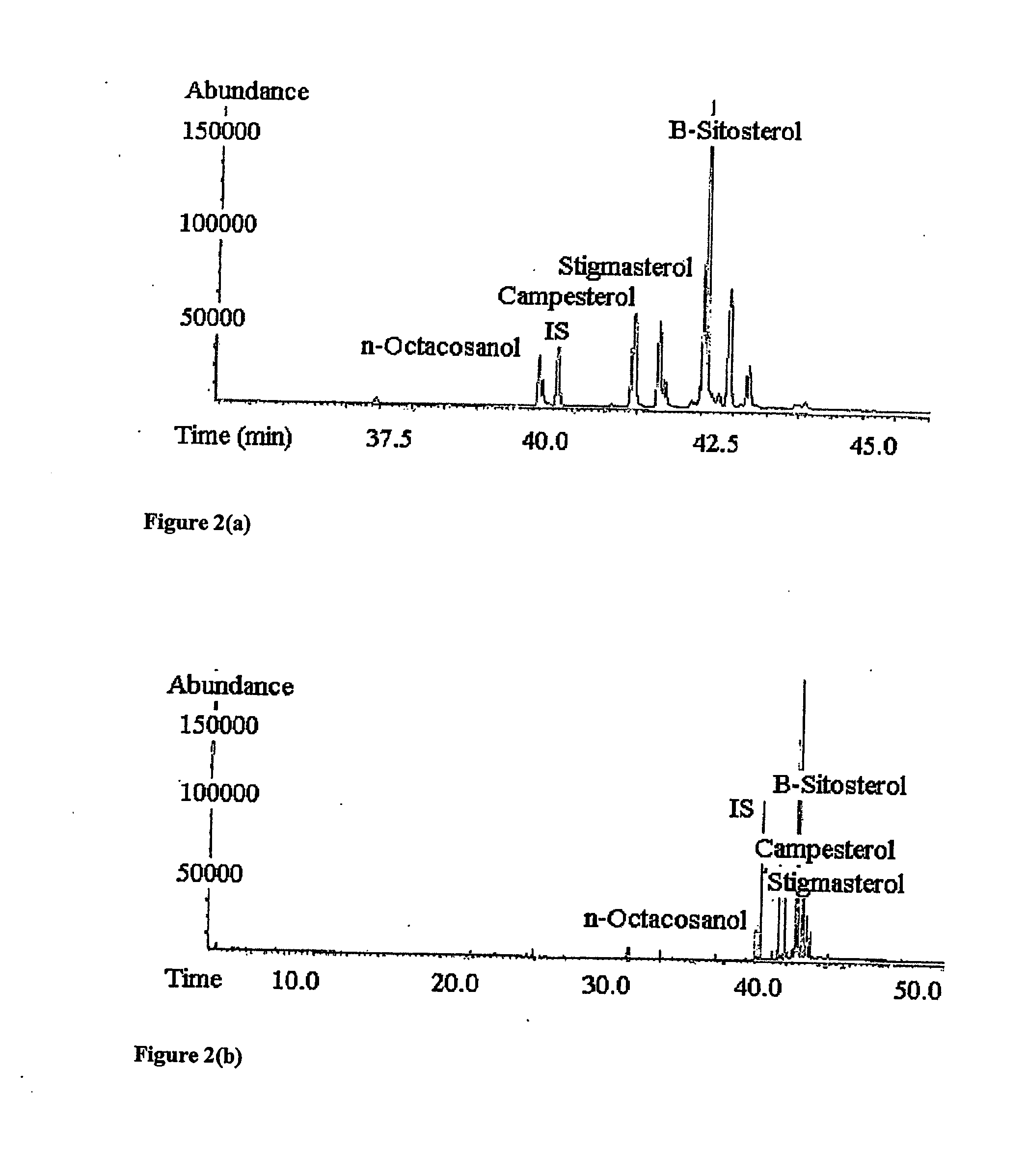

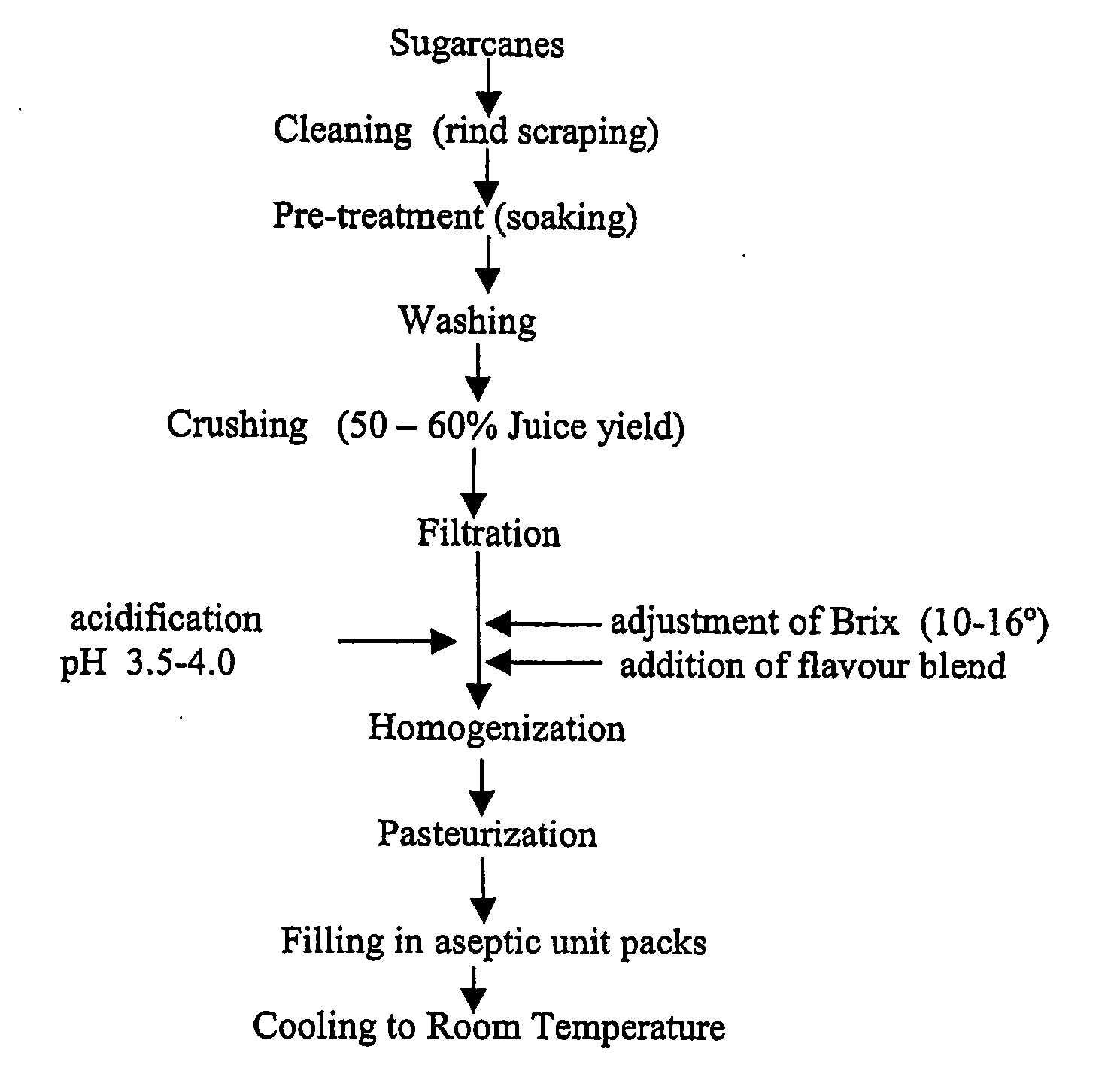

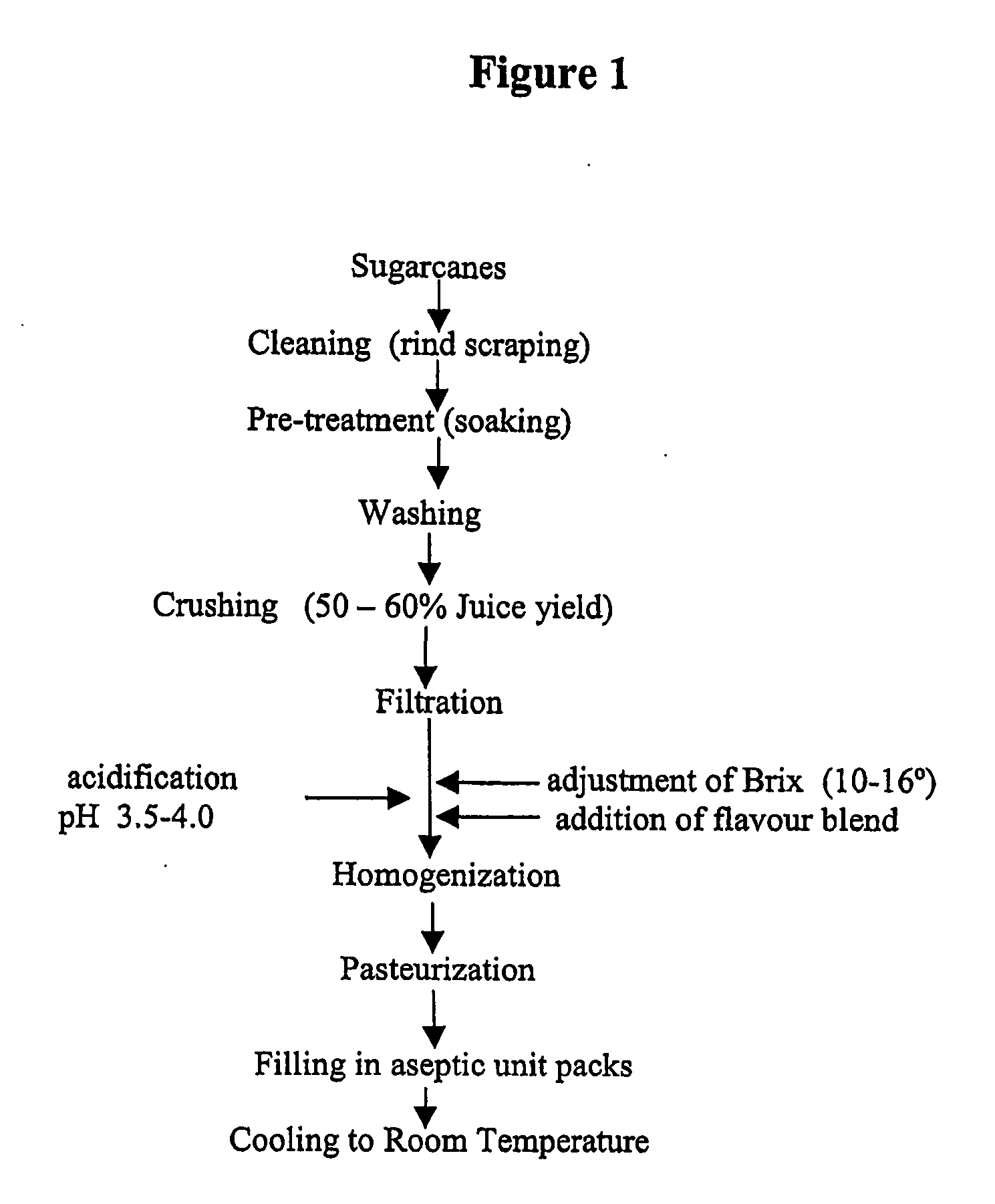

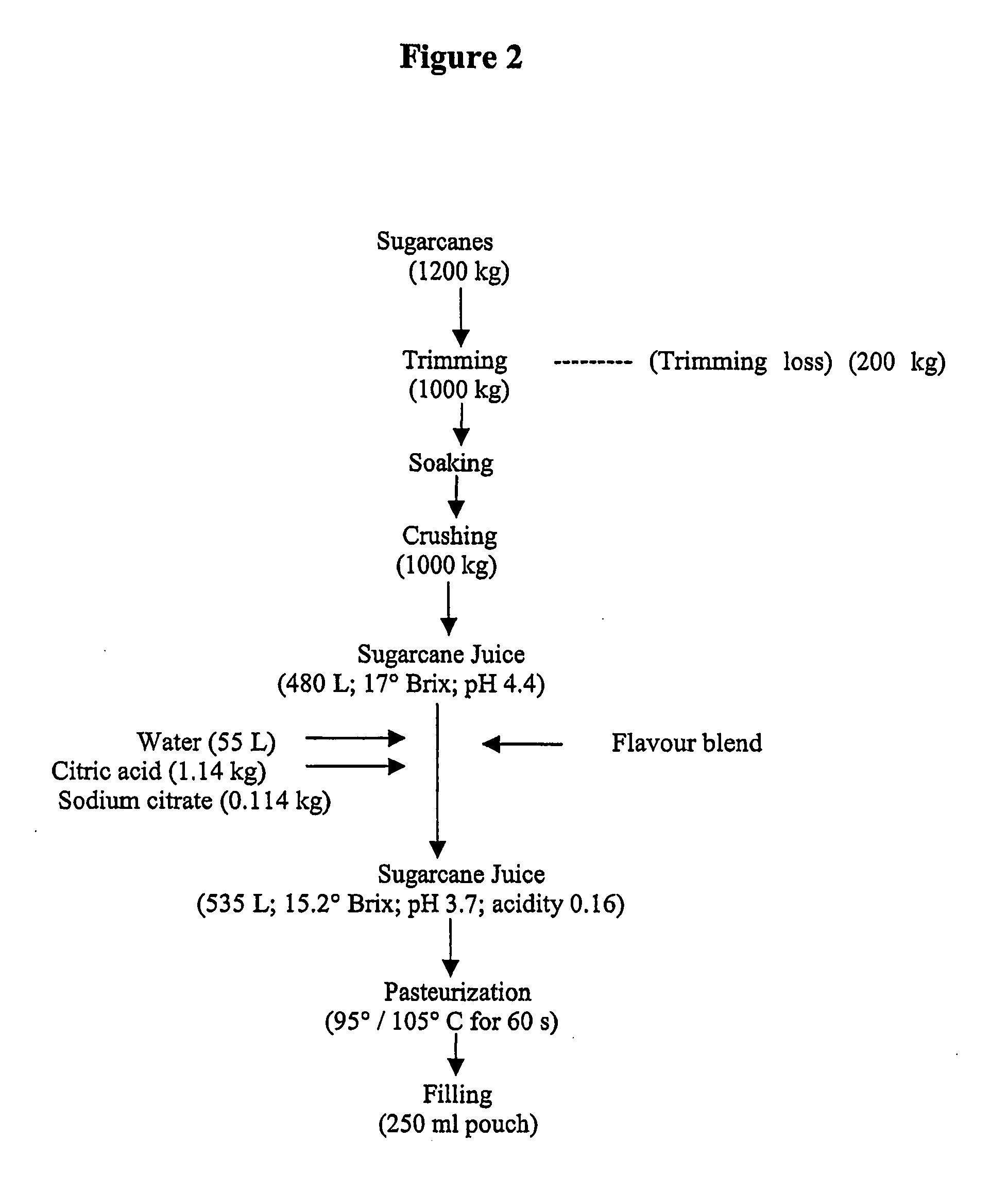

Flavored sugarcane juice in aseptic unit packs

InactiveUS20060083835A1Increase aromaFood preservationPurification by physical meansSoluble solidsChemistry

The present invention provides a method wherein flavored sugarcane juice containing 18-20% soluble solids and can be preserved after suitable dilution in aseptic unit packs.

Owner:COUNCIL OF SCI & IND RES

Sugar manufacture clarification process

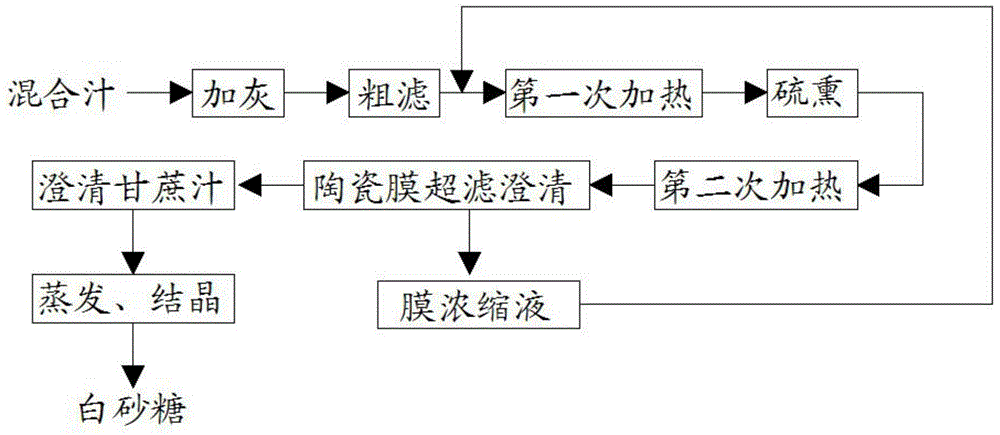

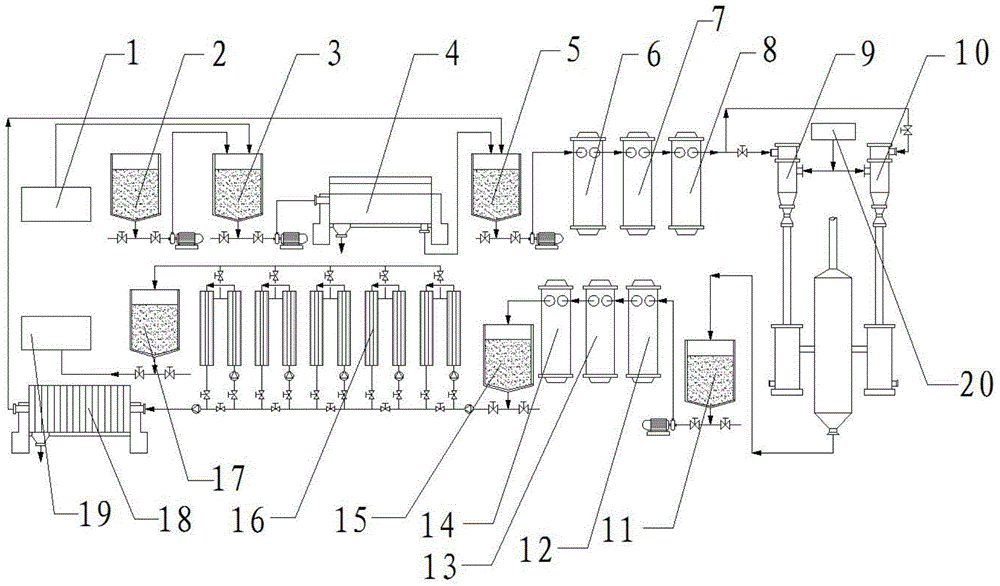

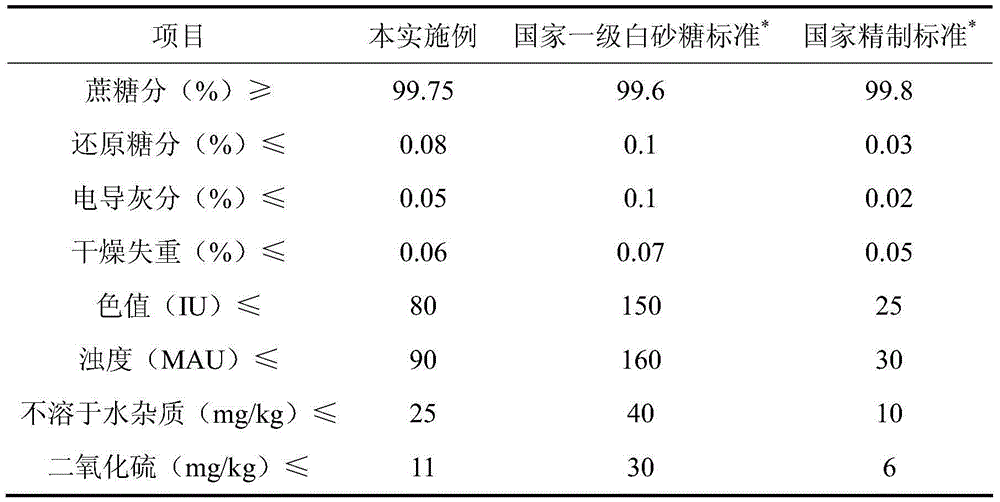

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

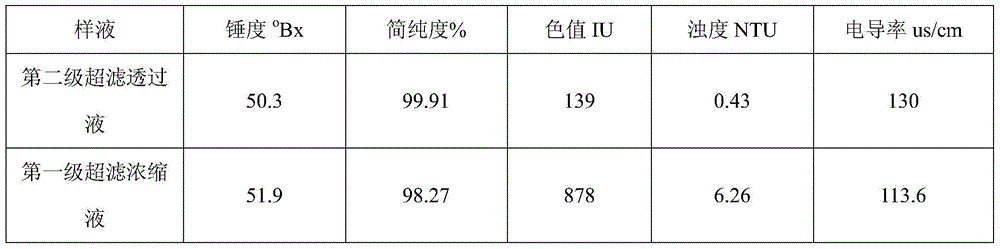

Sugar making process for refining cane mixed juice by use of multi-stage membrane filtration technology

ActiveCN105063247AReduce chromaReduce turbidityPurification by physical meansSucroseSeparation technology

The present invention relates to a sugar making process for refining cane mixed juice by use of a membrane separation technology. The process comprises: heating cane mixed juice; adding an alkaline substance into the heated cane mixed juice to regulate the pH value;separating suspended impurities such as bagasse and the like from the cane mixed juice; collecting a separated liquid phase; removing suspended impurities with small particle sizes, macromolecules, colloids and the like through filtration of a microfiltration membrane; putting the collected filtrate into an ultrafiltration membrane with the molecular weight cutoff greater than that of sucrose; removing pigments and non-sugar substances with molecular weight greater than that of sucrose; using a nanofiltration membrane with the molecular weight cutoff less than that of sucrose molecules to concentrate a decolorized clear liquid; and removing inorganic salts with molecular weight less than that of the sucrose, monosaccharide and the like by virtue of the nanofiltration membrane. Compared with the traditional process, the process provided by the present invention is capable of greatly reducing the chroma and turbidity of the sugar juice, greatly reducing the content of nonsugar macromolecular substance in the sugar juice, and increasing the purity and yield of sucrose, and is free of clarifying agents such as lime and the like in the main process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

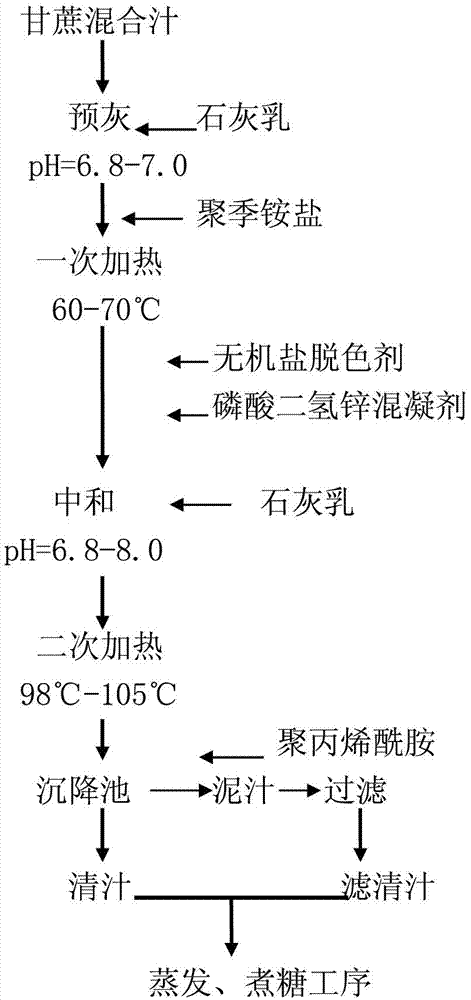

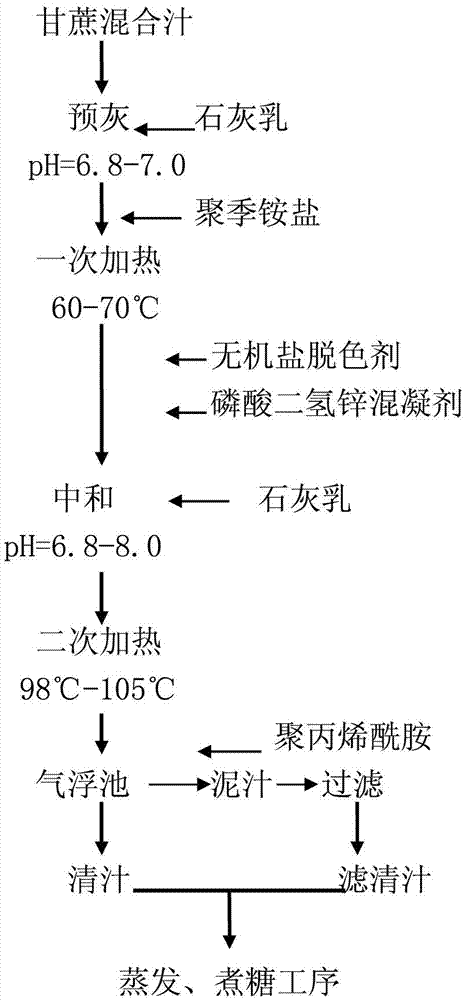

New sugaring and clarifying process of low-sulfur low-phosphorus sugarcane

ActiveCN103114156ASave resourcesShort processSugar productsPurification using alkaline earth metal compoundsPhosphatePhosphoric acid

The invention provides a new sugaring and clarifying process of low-sulfur low-phosphorus sugarcane. The process comprises the following steps of: respectively adding an inorganic salt decoloring agent, polyquaternium and a zinc dihydrogen phosphate coagulant into the mixed sugarcane juice, feeding the mixed juice into a sedimentation tank or a floatation tank to separate out clear juice and mud juice after performing primary heating, the neutralization by adding lime milk and secondary heating; and obtaining a finished product of sugar after the clear juice is evaporated, concentrated, sugar boiled, crystallized and purged. Compared with the existing phosphate-sulfite clarification method, the new sugaring and clarifying process of low-sulfur low-phosphorus sugarcane disclosed by the invention has the advantages of short process flow, low tone and good quality of the clear juice and good thermal stability, and is capable of saving the resources of lime, sulphur and phosphoric acid, shortening the process flow, improving the product quality and realizing the cleaned production by removing the sulphitation process and device.

Owner:广西糖业集团防城精制糖有限公司

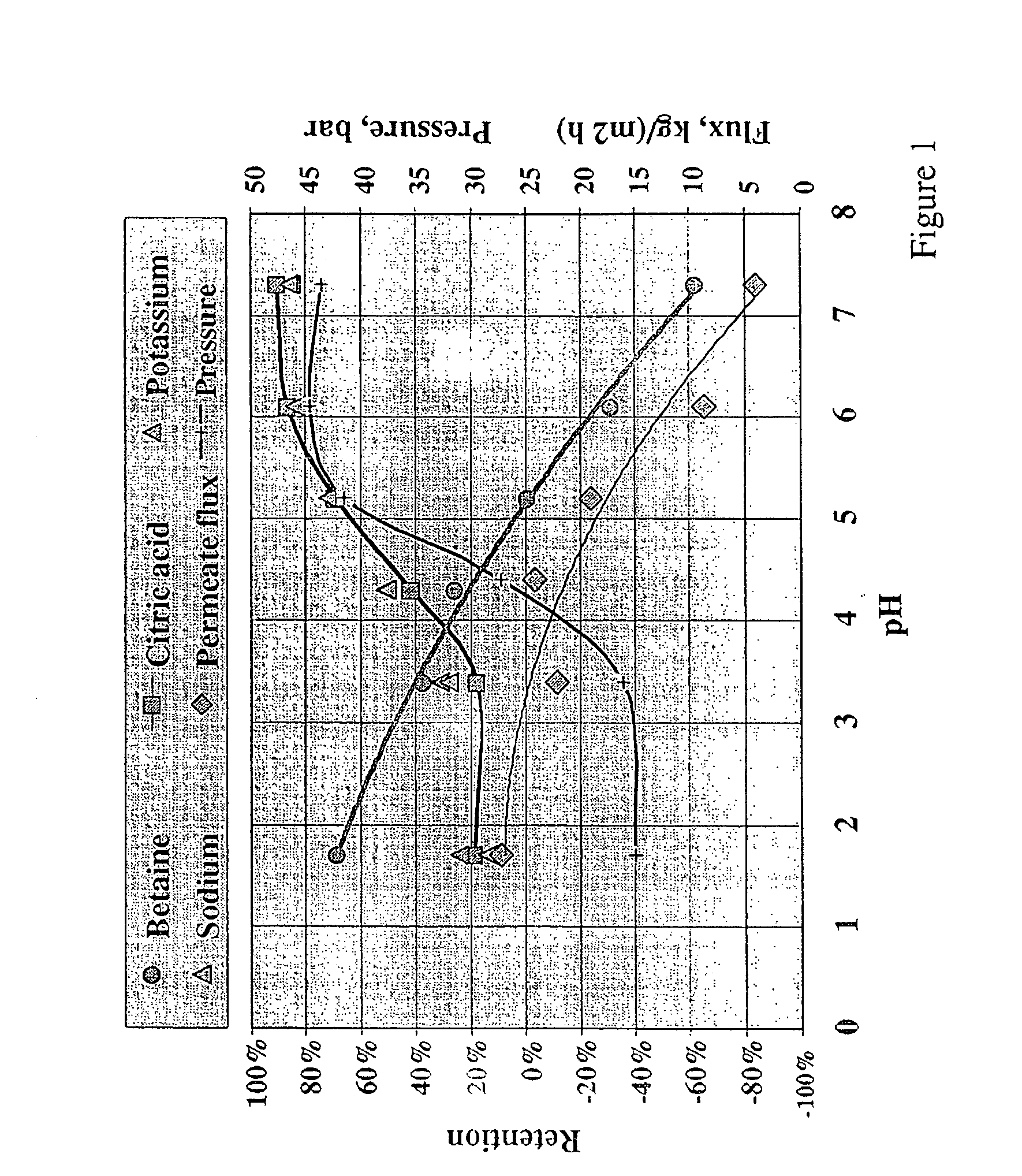

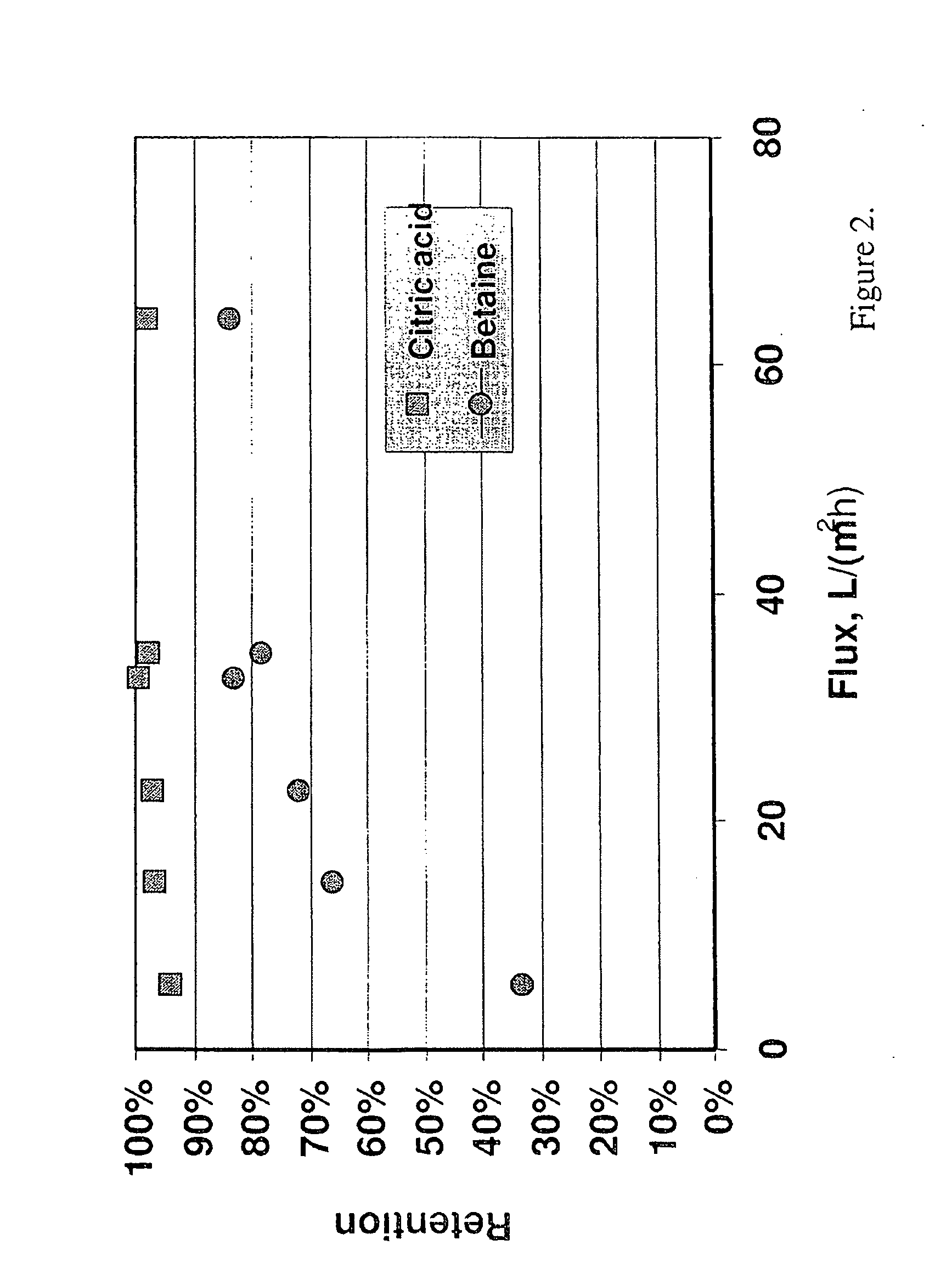

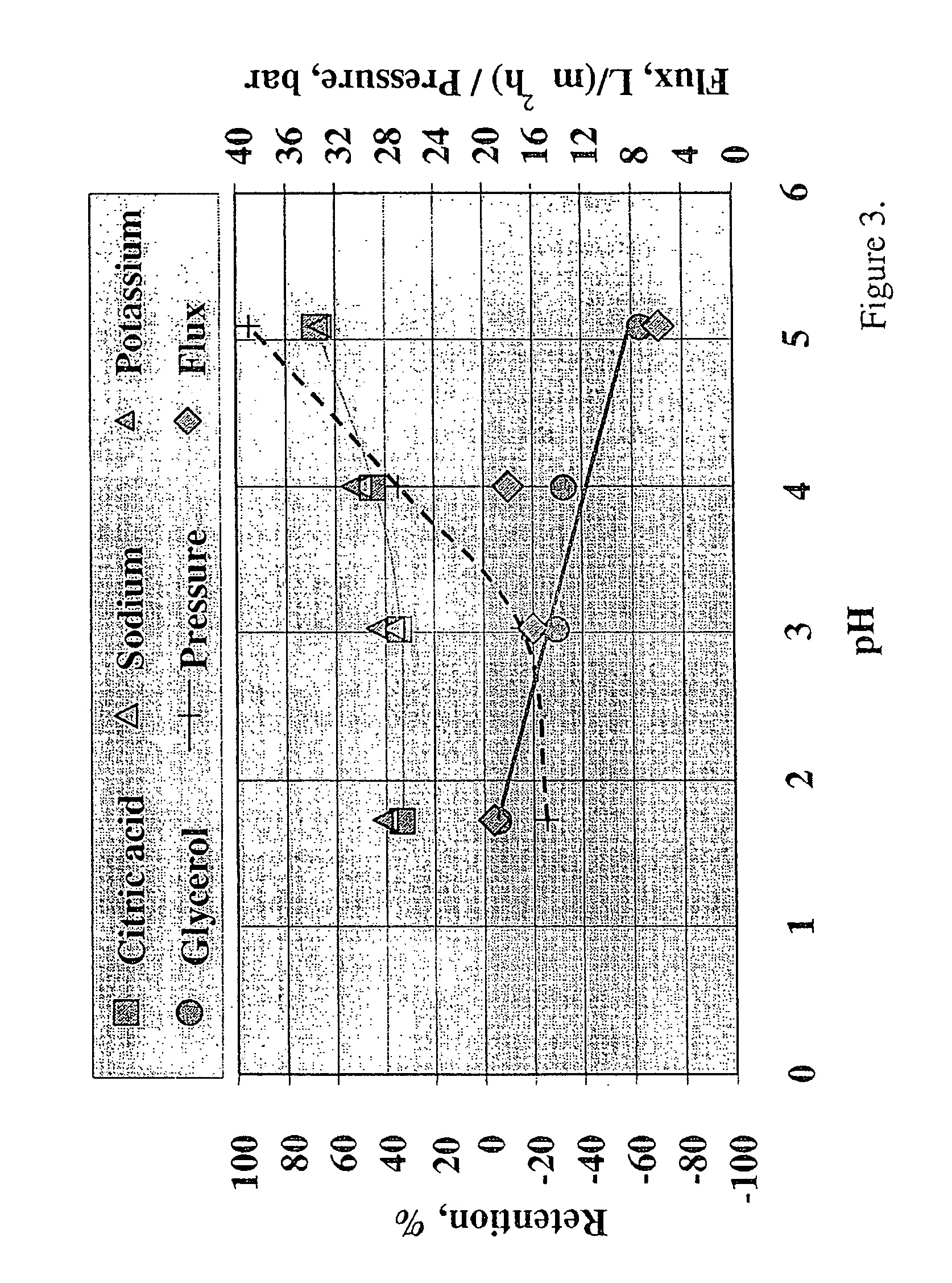

Separation Process

ActiveUS20090014386A1Product yield is lowReduce disadvantagesLiquid separation auxillary apparatusMembranesNanofiltrationOrganic compound

The invention relates to a nanofiltration process for enriching and concentrating a neutral organic compound into the permeated liquid with negative retention.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Method for making sugar from sugar-cane by membrane separation

InactiveCN1451765AReduce chromaHigh clarityPurification by physical meansSeparation technologyWastewater

A process for preparing sugar from cane by membrane separation technique is characterized by that after the cane juice is obtained, the microfilter (or ultrafilter) membrane system is used to remove impurities, gum and pigment from the cane juice. Its advantages are high purity, high output rate of sugar, and less environmental pollution.

Owner:凯能高科技工程(上海)有限公司

Membrane technology-based refined sugar clear-syrup impurity removal and decoloring technology

InactiveCN104404174AReduce turbidityHigh purityPurification by physical meansFiltrationMembrane technology

The invention discloses a membrane technology-based refined sugar clear-syrup impurity removal and decoloring technology. The technology comprises the following steps of carrying out press filtration on syrup to obtain clear syrup, before evaporation, feeding the clear syrup to a microfiltration device, carrying out microfiltration on the clear syrup by a microfiltration device to obtain a microfiltred concentrate liquid and a microfiltred penetrating liquid, removing the microfiltred concentrate liquid, collecting the microfiltred penetrating liquid, feeding the microfiltred penetrating liquid into a ultrafiltration device, carrying out further condensation treatment on the primary ultrafiltration concentrate liquid, carrying out sterilization to obtain a sugar liquid, and feeding the last ultrafiltration concentrate liquid into follow-up processes of sugar refining. The technology does not produce a waste liquid, is free of a chemical reagent, has no damage to the human body, improves syrup purity, reduces syrup turbidity and is conducive to crystallization.

Owner:GUANGXI UNIV

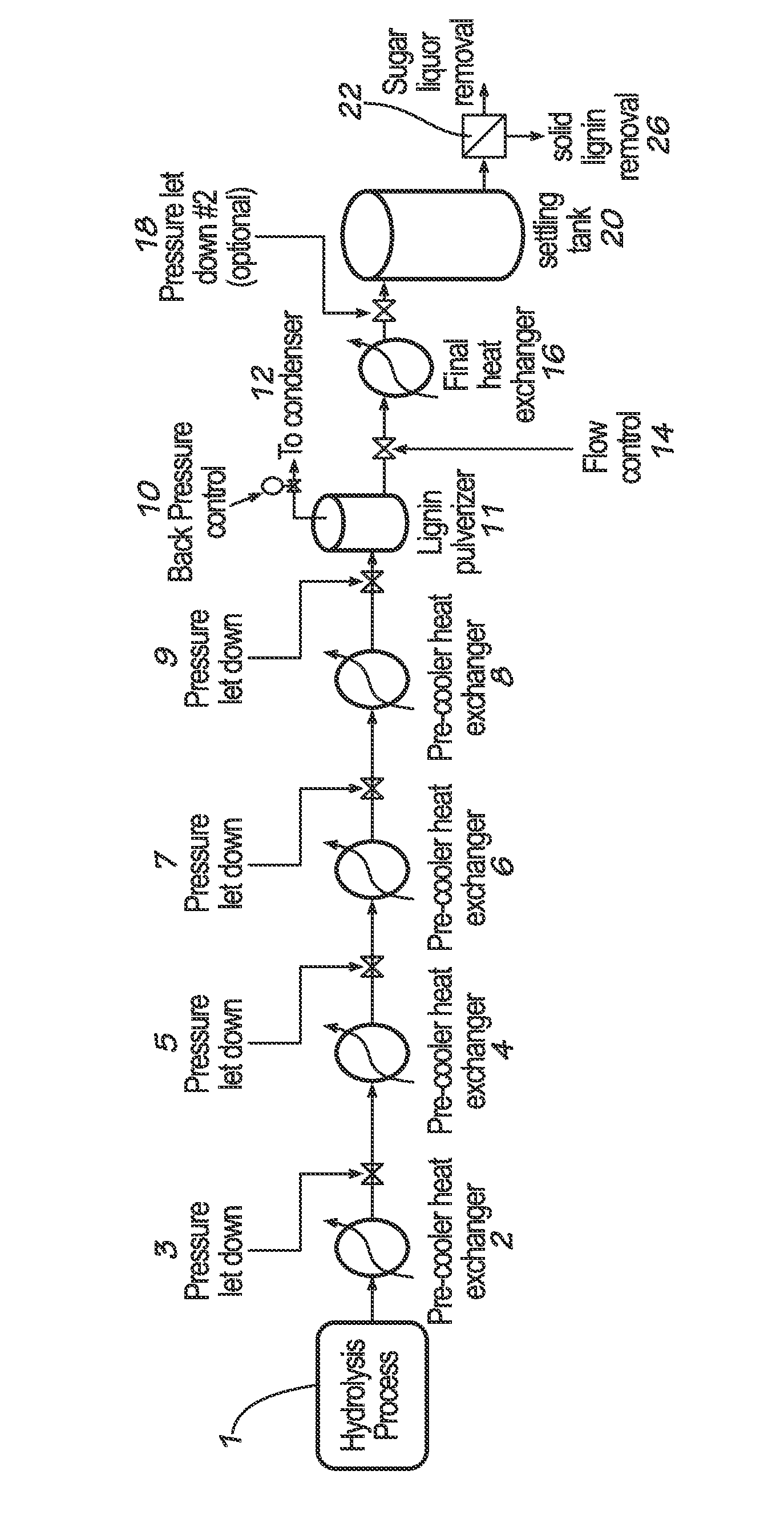

Lignin production from lignocellulosic biomass

ActiveUS8317928B1Easy to handlePrevent scalingLignin derivativesBio-feedstockCelluloseLignocellulosic biomass

Methods are disclosed for providing lignin product of a small particle size for improving burning efficiency and for avoiding typical equipment fouling problems while maximizing energy recovery.

Owner:RENMATIX INC

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

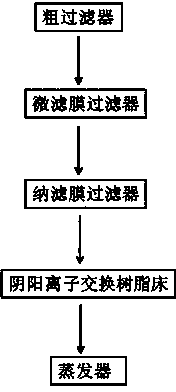

Production process and device of golden sugar

InactiveCN104004860AHigh desalination rateHigh yieldSugar crystallisationPurification using ion-exchange materialsSucroseIon-exchange resin

The invention provides a production process and a production device of golden sugar. The production process comprises the following steps: pressing sugarcane or beets to obtain cane sugar juice; pre-filtering the cane sugar juice through a coarse filter and feeding the pre-filtered crane sugar juice into a microfiltration membrane for filtering to obtain clear cane sugar juice; pre-concentrating the clear cane sugar juice to obtain a pre-concentrated solution; feeding the pre-concentrated solution into ion exchange resin for desalting to obtain a permeation solution; feeding the permeation solution into an evaporator for concentrating to obtain cane sugar concentrated liquid; heating the cane sugar concentrated liquid to be oversaturated, adding crystal seeds, naturally cooling and crystallizing, and centrifuging the obtained crystals to obtain golden sugar crystals; drying the golden sugar crystals to obtain a finished product of the golden sugar. The production device comprises the coarse filter, a microfiltration membrane filter, a nanofiltration membrane filter, an anion exchange resin bed, a cation exchange resin bed and the evaporator which are connected in sequence. The production method provided by the invention is capable of continuously producing high-quality golden sugar, the chromatic value of the obtained product is 800-3,000, the desalting rate is high, and the yield is high.

Owner:JIANGSU JIUWU HITECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com