Technology for refining saccharose

A sucrose and process technology, applied in the production of sugar, sugar crystallization, juice extraction from sugar cane, etc., can solve the problems of wasting energy, uneconomical and reasonable, increasing production costs, etc., and achieves reduction of labor input, significant economic benefits, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

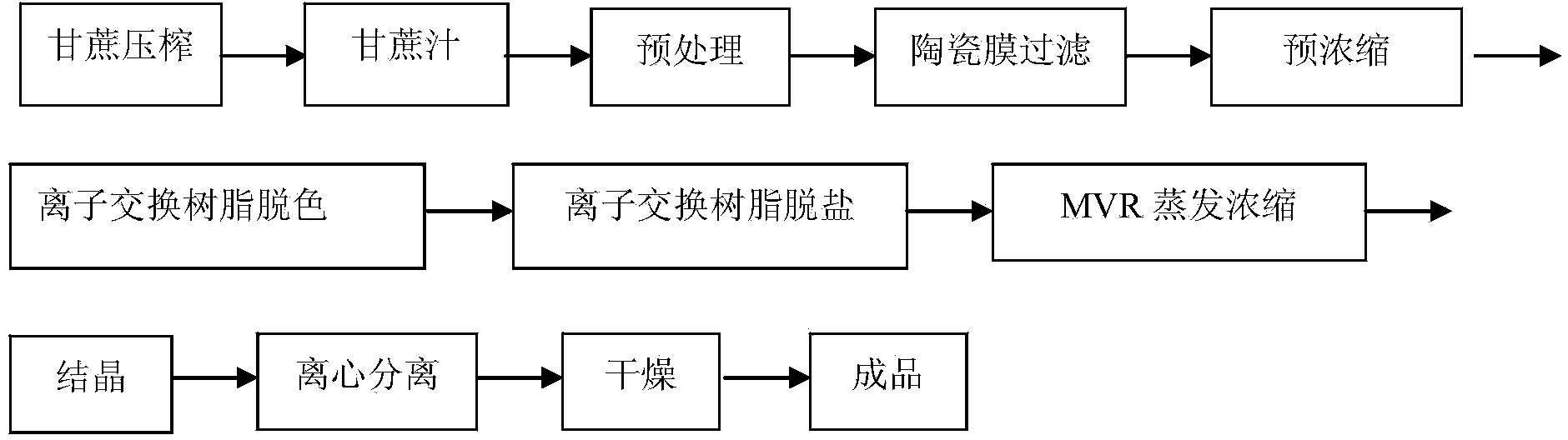

[0046] Such as figure 1 Shown, the novel technique of sucrose refining of the present invention comprises the following steps:

[0047] A. Juicing: squeeze the sugarcane through a juice extractor to obtain sugarcane juice;

[0048] B, pretreatment: the sugarcane juice obtained in the step A is pretreated by a sieve to remove larger bagasse, and the aperture of the sieve is 100 orders;

[0049] C, microfiltration membrane filtration: the sugarcane juice collected in step B is microfiltered through a 50nm ceramic membrane, the temperature of the filtration is 20° C., and the filtration pressure is 0.5Mpa to obtain a sucrose juice clear liquid with a sucrose concentration of 12%;

[0050] D, pre-concentration: the sucrose juice obtained in step C is sent to the second-effect evaporator for evaporation and pre-concentration, and the sucrose concentration is concentrated to 40%;

[0051] E. Ion exchange decolorization: the concentrated sucrose juice obtained in step D is decolori...

Embodiment 2

[0063] Such as figure 1 As shown, the new process for refining sucrose of the present invention comprises the following steps: sugarcane juice is obtained after the sugarcane is squeezed, and the sugarcane juice is pretreated through a 200-mesh screen to remove larger bagasse to obtain sugarcane juice; the sugarcane juice is passed through a 200nm Ceramic membrane microfiltration, the filtration temperature is 80°C, and the filtration pressure is 0.1Mpa to obtain the sucrose juice serum with a concentration of 12.5%; the sugarcane juice serum enters the nanofiltration membrane device for concentration, and the nanofiltration membrane is made of ceramic material. The molecular weight is 100Da, the control pressure is 4.0MPa, the sugar juice concentration is 30%, and the salt removal rate is 53%. The concentrated sucrose juice enters the macroporous strong basic anion exchange resin for decolorization. The diameter-to-height ratio is 1 / 10, the flow rate is 2BV / h, and the tempera...

Embodiment 3

[0067] Such as figure 1 As shown, the new process for refining sucrose in the present invention comprises the following steps: pressing sugarcane through a juicer to obtain sugarcane juice; then pre-treating the sugarcane juice through a filter bag filter to remove larger bagasse, and then passing it through a 500nm Ceramic membrane microfiltration, the filtration temperature is 50°C, and the filtration pressure is 0.3Mpa to obtain sucrose juice clear liquid with a concentration of 11.5%; then the obtained sucrose juice is sent to an organic nanofiltration membrane concentration device, and the sucrose juice is obtained at a pressure of 4.0 Mpa, the nanofiltration membrane with a molecular weight of 100Da is pre-concentrated, so that the concentration of the sugar juice is concentrated to 30%, and 57% of the salt is removed. Then the obtained concentrated sucrose juice is decolorized with a macroporous strong basic anion exchange resin, the diameter-to-height ratio is 1 / 8, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com