Blue removal processing agent for wooden single plate and blue removal method of wooden single plate

A treatment method and treatment agent technology, applied in wood treatment, wood treatment details, wood impregnation, etc., can solve the problems of blue stain with little effect, achieve strong loss resistance, ensure workers' physical safety, and low corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

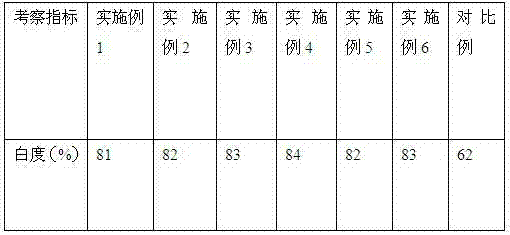

Examples

Embodiment 1

[0026] First configure the wood veneer blue treatment agent, the wood veneer blue treatment agent is composed of the following mass concentrations of substances mixed: sodium chloride 1%, NH 2 SO 3 H 0.04%, HOOCCOOH 0.7%, CH 3 COOH 0.2%, H 3 PO 4 0.5%, ethylenediaminetetraacetic acid 0.2%, sodium dihydrogen phosphate 0.1%, solvent is water. H 3 PO 4 Prepare H with a pH of 4 and a temperature of 45°C with water 3 PO 4 solution, and then pour the wood veneer deblueing treatment agent into CH 3 PO 4 The solution is prepared into a temporary liquid, and the wood veneer deblueing treatment agent and H in the temporary liquid 3 PO 4 The volume ratio of the solution is 1:3. During treatment, first prepare sodium hydroxide water into a sodium hydroxide solution with a pH value of 9, then immerse the wooden veneer for 1 hour for pretreatment, and then immerse the pretreated veneer in the liquid for decolorization , the treatment time is 2 hours. During the decolorization tr...

Embodiment 2

[0028] With embodiment 1, difference is that described drying adopts solar drying; After drying, moisture content is controlled at 5%.

Embodiment 3

[0030] First configure the wood veneer blue treatment agent, the wood veneer blue treatment agent is composed of the following mass concentrations of substances mixed: sodium chloride 2%, NH 2 SO 3 H 0.11%, HOOCCOOH 0.8%, CH 3 COOH 0.3%, H 3 PO 4 0.7%, 0.3% ethylenediaminetetraacetic acid, 0.3% sodium dihydrogen phosphate, and the solvent is water. H 3 PO 4 Prepare H with a pH of 5 and a temperature of 50°C with water 3 PO 4 solution, and then pour the wood veneer deblueing treatment agent into CH 3 PO 4 The solution is prepared into a temporary liquid, and the wood veneer deblueing treatment agent and H in the temporary liquid 3 PO 4The volume ratio of the solution is 1:5. When processing, first prepare sodium hydroxide water into a sodium hydroxide solution with a pH value of 10, then immerse the wooden veneer for 1.5 hours for pretreatment, and then immerse the pretreated veneer in the liquid for decolorization Treatment, the treatment time is 3 hours, during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com