Patents

Literature

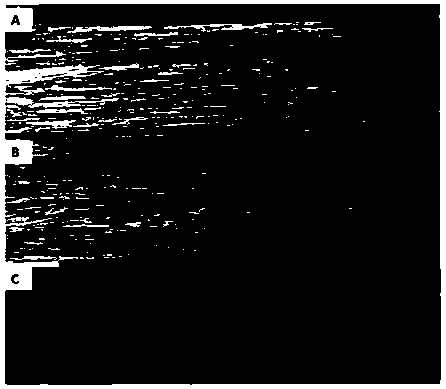

101results about How to "Strong loss resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

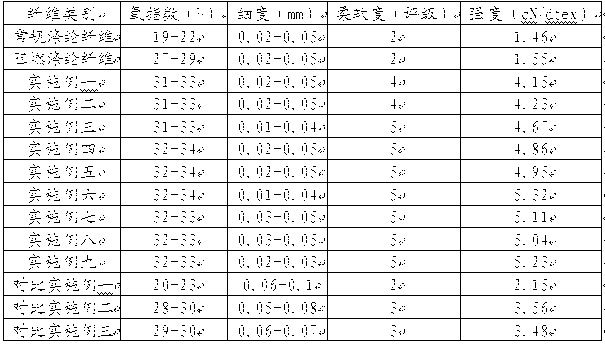

Fire retardant for wood, and preparation method and treatment process thereof

ActiveCN102069519ASimple processRealize industrial productionPressure impregnationWood impregnation detailsEnvironmental resistanceSilicon dioxide

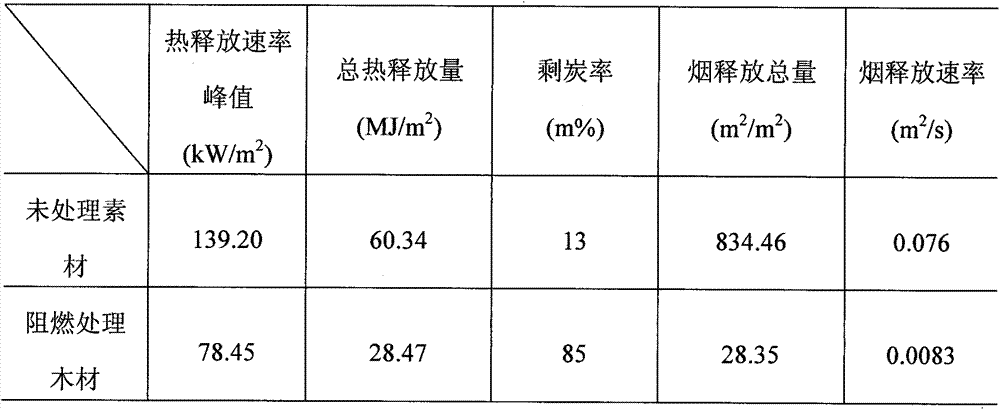

The invention discloses a fire retardant for wood, and a preparation method and a treatment process thereof. The fire retardant for wood is prepared from the following raw materials in percentage by weight: 40 to 60 percent of silica sol, 5 to 20 percent of sodium octaborate tetrahydrate, 1 to 20 percent of ammonium polyphosphate, 1 to 20 percent of carbonate and 0 to 53 percent of water. The preparation method comprises steps of: putting the substances into a stirrer, and uniformly mixing fully to obtain the flame retardant. During use, wood is put into a treatment tank, and is vacuumized, the flame retardant is injected at normal temperature, the treatment tank is vacuumized and the vacuum is eliminated so as to obtain the flame-retardant wood. By utilizing advantages of nontoxicity, environmental friendliness, high flame-retardant efficiency, low price, wide sources and easy preparation of the materials such as the sodium octaborate tetrahydrate and the silica sol, after the materials are compounded, the flame retardant with good anti-loss performance is obtained and can be used for flame-retardant protection of interior and exterior decorative wood and wood structures of buildings.

Owner:ZHEJIANG UNIV

Preparation method for multifunctional resin modifier for wood impregnation and application of multifunctional resin modifier

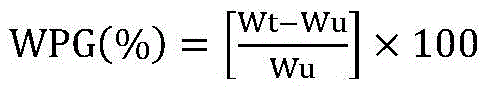

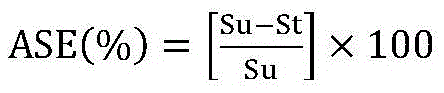

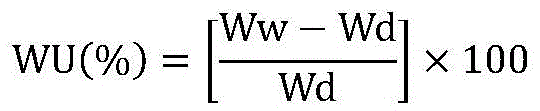

InactiveCN104070572AStrong loss resistancePromote environmental protectionWood treatment detailsPressure impregnationPhenolWeight gain

The invention belongs to a preparation method for a multifunctional resin modifier for wood impregnation and application of the multifunctional resin modifier. The low-alkali multi-element copolycondensation resin modifier which has functions of weight gaining enhancement, flame retardance and corrosion prevention is synthesized by taking phenol, formaldehyde, melamine and urea as main agents and taking boric acid and zinc borate as functional auxiliaries. By the adding of a certain amount of dipropylene glycol, the modifier can be stored stably for a long time, and repeated cyclic use is realized. The size stability, density, surface hardness, bending strength, bending-resistant elastic modulus, processing characteristic, the flame retardancy, the corrosion prevention and the abrasion resistance of plantation woods treated by the modifier are greatly improved; furthermore, the modifier is high in runoff resistance and high in environment al protection, does not have a loss effect on the toughness of the wood and cannot affect the painting decoration performance of the wood, and the application value of the plantation woods is increased.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Multifunctional wood inflaming retarding agent and method for preparing smoke suppressing and inflaming retarding pinus sylvestris solid wood by utilizing of multifunctional wood inflaming retarding agent

InactiveCN103158181AEasy to infuseImprove immersion effectWood treatment detailsPressure impregnationSolubilitySolid wood

The invention discloses a multifunctional wood inflaming retarding agent and a method for preparing smoke suppressing and inflaming retarding pinus sylvestris solid wood by utilizing of the multifunctional wood inflaming retarding agent, and relates to the multifunctional wood inflaming retarding agent capable of antiflaming, suppressing smoke and preventing running off and a technique for processing the pinus sylvestris solid wood by utilizing the antiflaming and smoke suppressing properties of the multifunctional wood inflaming retarding agent. To solve the problems that the pinus sylvestris solid wood is rich in grease and can not be immersed easily, the flame retardation property of an existing wood inflaming retarding agent is single, and antiflaming components are easy to run off, the wood inflaming retarding agent comprises, by weight, 22-56 parts of phosphoric acid amidinourea, 15-25 parts of boric acid, 24-56 parts of water-solubility ammonium polyphosphate, 1-5 parts of ammonium molybdate and 20-45 parts of silica sol. The preparation method of the inflaming retarding and smoke suppressing pinus sylvestris solid wood comprises the following steps. Firstly, the microwave process is carried out on the dried pinus sylvestris solid wood. Secondly, the pinus sylvestris solid wood is placed in inflaming retarding liquid to be pressurized and immersed in a vacuum mode. The dried inflaming retarding and smoke suppressing pinus sylvestris solid wood has a good smoke suppressing property, the smoke suppressing effect and anti-running-off property are obvious.

Owner:NORTHEAST FORESTRY UNIVERSITY

Wood and cotton fiber treating agent and preparation method and application thereof

ActiveCN105599085AGood dimensional stabilityGood mechanical strengthWood treatment detailsVegetal fibresMaleic anhydrideFurfuryl alcohol

The invention provides a wood and cotton fiber treating agent which is prepared from, by weight, 60-100 parts of furfuryl alcohol, 4-5 parts of maleic anhydride, 4-8 parts of borax, 0-4 parts of nanosilicon dioxide and 88-128 parts of water. Wood treated through the treating agent has the excellent size stability, hydrophobicity and leach resistance, and meanwhile has the good mechanical strength, and particularly, the bending strength can be improved. When the treating agent is used for treating cotton fiber, the hygroscopicity of the cotton fiber can be lowered, and the leach resistance rate of the cotton fiber can be improved.

Owner:山东堡珍家居板材有限公司

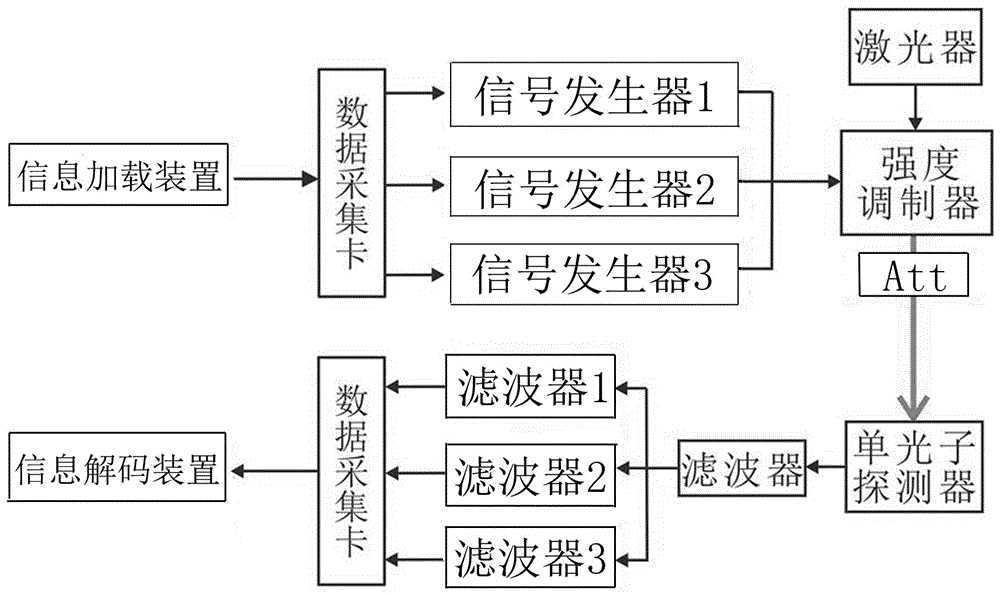

Multi-channel frequency coding information transmission system based on single photon detection

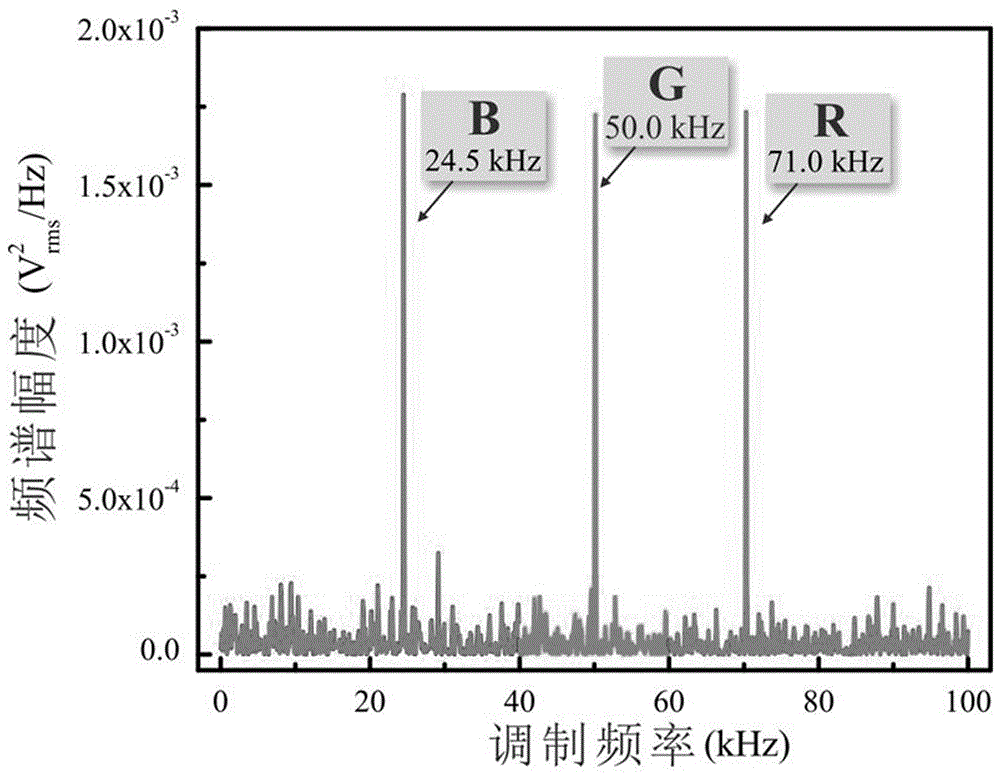

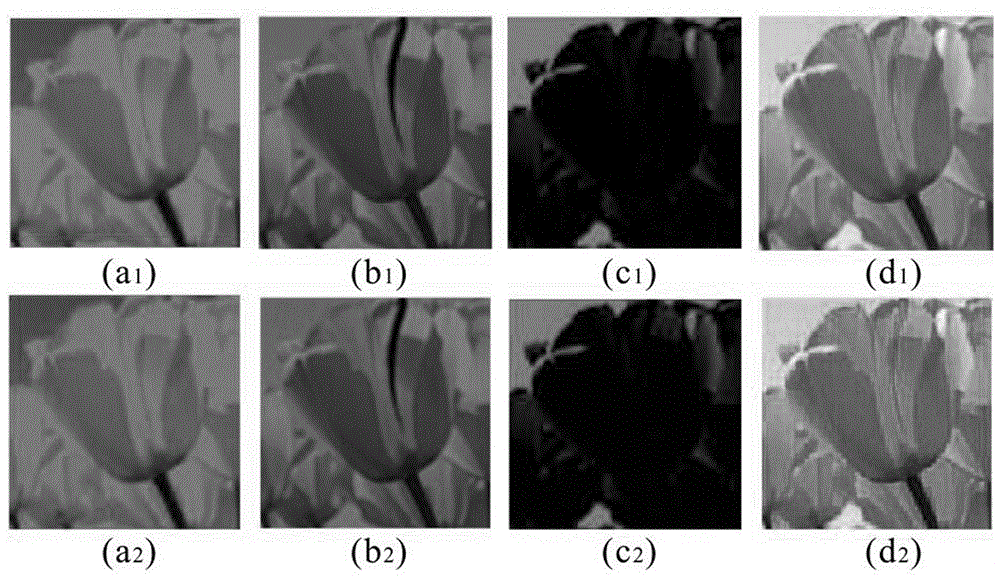

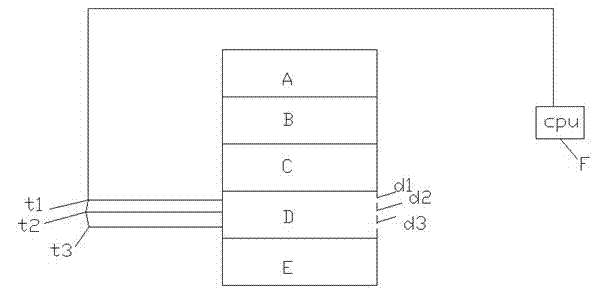

ActiveCN106059676AImprove frequency band utilizationImprove coding efficiencyPhotonic quantum communicationElectromagnetic transmittersFault toleranceTransport system

The invention relates to fault tolerance single photon communication technology, and in particular to a multi-channel frequency coding technology based on single photon detection with laser light as an information carrier. Laser light undergoes frequency modulation at a transmitting end and is loaded with information. After channel transmission, the intensity of the laser light attenuates to a single photon magnitude, and the laser light is measured by a single photon detector at a receiving party, and the detected single photon pulse sequence undergoes Fourier transformation so as to extract frequency information. According to the invention, the system has very strong fault tolerance in terms of channel loss and noise. The system addresses the problem of information loss and errors that are caused by channel loss and noise in long-distance laser communication and quantum communication, and provides technical means for the realization of satellite-ground laser communication and quantum secure direct communication.

Owner:山西重明光子通信技术有限公司

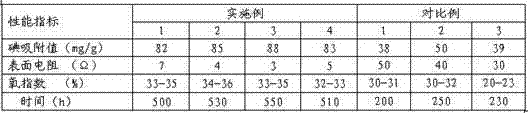

Preparation method of carbon granules used for air circulation of air conditioner

InactiveCN102963892AAids in preparationImprove conductivityCarbon compoundsMicrowaveRoom temperature

The invention relates to the field of macromolecules and particularly relates to a preparation method of carbon granules used for air circulation of an air conditioner. The carbon granules are prepared by the following steps of: pretreating raw materials: feeding plant materials into a microwave vacuum tank, vacuumizing, and then carrying out microwave treatment; then sequentially drying, pre-carbonizing, carbonizing, sintering and cooling, controlling combustion to heat up to 700-750 DEG C or 900-1000 DEG C at the rate of 5-15 DEG C / min, preserving heat for 40-80 minutes, then heating up to 1000-1500 DEG C or 1600-1800 DEG C at the rate of 5-15 DEG C / min, preserving heat for 2-8 hours, then cooling to 300-400 DEG C at the rate of 18-25 DEG C / min, and then cooling to room temperature along with a furnace to obtain primary carbon; activating: mixing the obtained primary carbon with a 8-10% potassium oxalate solution according to the mass ratio of 1:(3-4), immersing for 3-5 hours, then cleaning with deionized water until the pH value is neutral, and then carrying out vacuum pressurized flame retardant treatment, primary bamboo vinegar treatment, secondary bamboo vinegar treatment and microwave treatment; and preparing carbon granules. The carbon granules prepared by the preparation method has good antistatic property and air purification effect, and has the flame retardant function.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

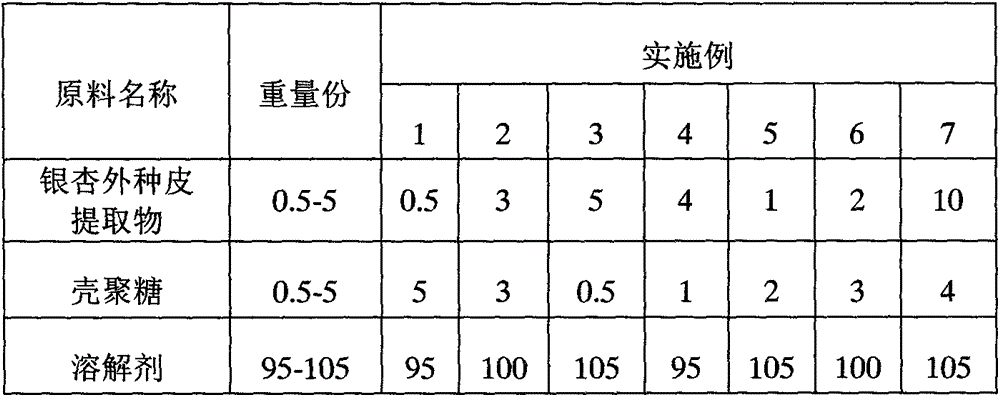

Natural mildew-proof and corrosion-proof agent for bamboos and woods

ActiveCN106553242AStrong loss resistanceGood long-term anti-mildew effectBiocideFungicidesCorrosionChange color

The invention provides a natural mildew-proof and corrosion-proof agent for bamboos and woods. The natural mildew-proof and corrosion-proof agent for the bamboos and the woods is composed of 0.5-10 parts of gingko testa extracts, 95-105 parts of dissolutions and 0.5-5 parts of chitosan. A production method of the gingko testa extracts includes the steps of drying and smashing operation, ultrasonic extraction of ethanol solutions, acidified extraction and purification and rotary evaporation and concentration. The natural mildew-proof and corrosion-proof agent has the beneficial effects of being friendly to environment, safe, harmless, high in leaching resistance and good in long-term mildew-proof effect because the gingko testa extracts are adopted as main functional agents and the chitosan is adopted as an auxiliary agent. In addition, the natural mildew-proof and corrosion-proof agent can be used for changing colors of the bamboos and the woods.

Owner:ZHEJIANG FORESTRY ACAD

Shield tail sealing grease

The invention provides shield tail sealing grease with high water resistance and high water sealing performance. The shield tail sealing grease has high pump pressure conveyance feasibility, does not corrode spacers among cement annular duct pieces, is easily filled among wire brushes, and has long using cycle and high quality. The shield tail sealing grease comprises the following components: base oil, lubricating oil, chlorinated paraffin, polybutene, fibers and calcium carbonate. When coated on metal plates or concrete surfaces or in the dry and wet state or in water, the shield tail sealing grease has the advantages of high adhesivity, high sealing performance, high abrasion resistance, high leachability resistance, good pumping effect, environmental friendliness, no toxicity, no odor, no corrosion to equipment, reduction in abrasion of shield equipment, stable products, ageing resistance and oxidation resistance.

Owner:东莞市明洁隧道建设材料有限公司

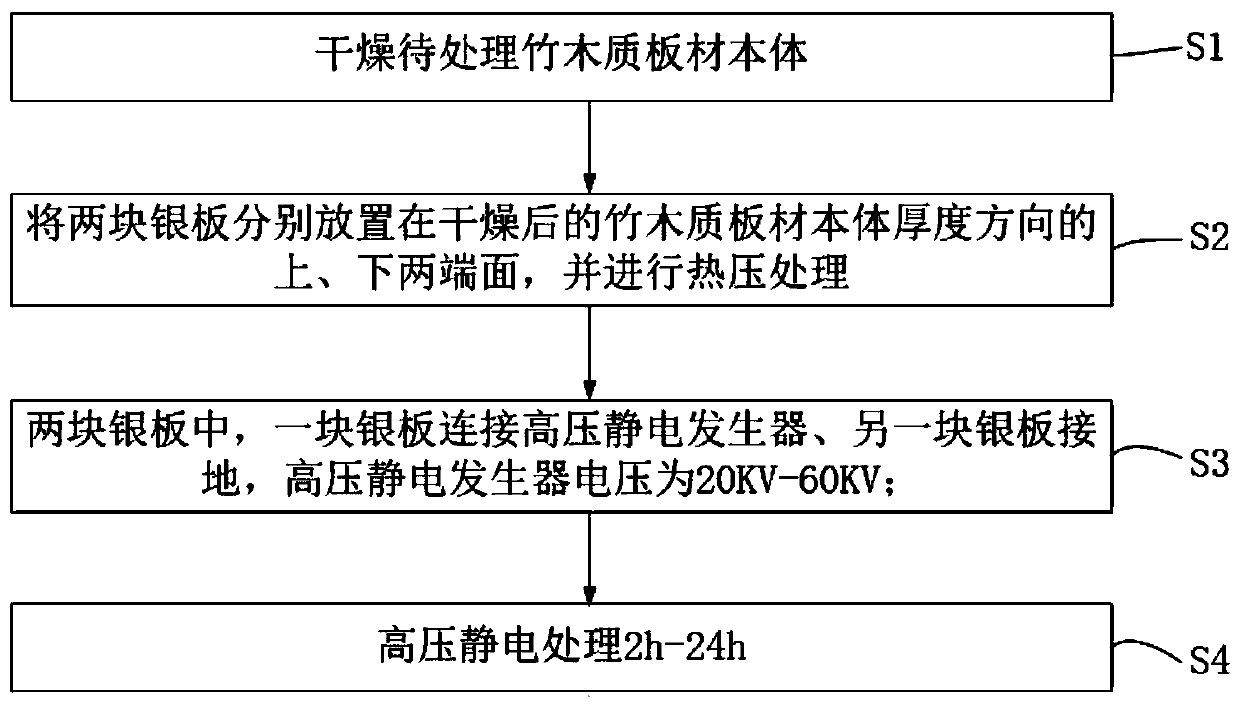

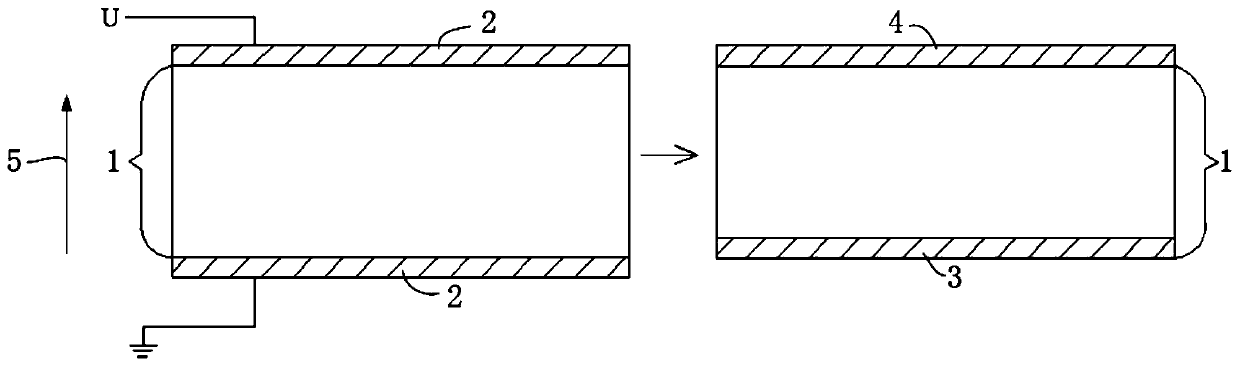

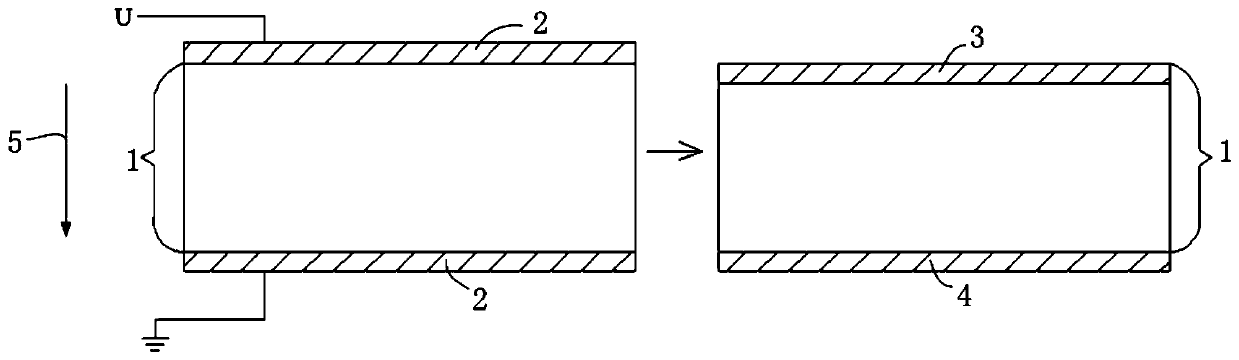

Bamboo material modifying method and bamboo plate

ActiveCN110202649AHigh modification treatment depthModification treatment is easy to operateLamination ancillary operationsElectric wood treatmentSilver plateHigh pressure

The invention discloses a bamboo material modifying method and a bamboo plate and belongs to the field of wood materials. According to the bamboo material modifying method, under the action of a 20-60KV high-voltage electrostatic field, high-voltage electrostatic treatment is carried out on a bamboo plate body with silver plates fitting on the upper and lower end faces. The bamboo plate after modified treatment sequentially comprises a nano-silver element permeation layer, a bamboo plate body, and a nano-silver element deposition layer / nano-silver element permeation layer in the thickness direction of the plate. The bamboo material after high-voltage electrostatic modified treatment has larger anti-corrosive and mildewproof treatment depth; the permeation depth of the nano-silver elementin the plate is 0.05-1mm; and the modified bamboo material is higher in anti-corrosive and mildewproof effect.

Owner:NANJING FORESTRY UNIV

Wood modification working liquid used for wet plate processing and use method thereof

InactiveCN104924388AImprove performanceEasy to modifyWood treatment detailsThermal wood treatmentOrganic baseInorganic compound

The invention discloses a wood modification working liquid used for wet plate processing and a use method thereof. The wood modification working liquid used for wet plate processing is prepared from, by weight, inorganic base resin, namely an alkaline silica solution with 2-30% of silicon dioxide by weight, organic base resin, namely water soluble urine aldehyde resin impregnation liquid with 2-30% by solid content, waterproof agents with 0.2-20% by solid content, 0.05-3% of silane coupling agents, 0.2-1% of emulsifying agents, 1-10% of fire-retardant preservative and the balance water through mixing. The wood modified working liquid adopts matching of the inorganic component and the organic component, so that wood has the functions of preventing corrosion and insects, retarding inflaming, being waterproof and the like. All the components are not polymerized by themselves and can meet production requirements; the combination capacity of the components with the wood is high; the leach resistance is high; the obtained modified wood is good in stability, high in waterproof performance and good in corrosion prevention and fire resistance.

Owner:YANGPUJIU JUTAI WOOD TECH CO LTD

Wood fire retardant

InactiveCN104858975AExcellent flame retardant and smoke suppression performanceGood anti-loss performanceWood treatment detailsWood impregnation detailsAmmonium molybdateDiammonium phosphate

The invention discloses a wood fire retardant which comprises the following components by mass: 20%-30% of amidinourea phosphate, 15%-20% of diammonium phosphate, 8%-15% of boric acid, 2%-5% of ammonium molybdate, 5%-10% of sodium octoborate, and 20%-50% of silica sol, and the silica content in the silicon sol is 20wt%-30wt%. The beneficial effect is that the wood fire retardant has the advantages of flame retardance of the amidinourea phosphate, diammonium phosphate, boric acid and silicon compound, smoke inhibition property of the ammonium molybdate, anti erosion performance of the silica sol, and corrosion resistance of the sodium octoborate,. The flame retardant smoke inhibition performances are excellent, the anti erosion performance is significant, and the anti-corrosion effect is good.

Owner:王玉燕

Titanium dioxide-containing wood preservative

InactiveCN104855427AExcellent flame retardantGood smoke suppressionBiocideFungicidesPhosphatePolyethylene glycol

The invention discloses a titanium dioxide-containing wood preservative which comprises the following components by mass: 15%-25% of silicon sol, 1%-3% of isooctanol phosphate, 2%-5% of nano titanium dioxide, 5%-8% of potassium iodide, 1%-2% of fatty alcohol polyoxyethylene ether, 10%-15% of diammonium hydrogen phosphate, 4%-8% of zinc borate, 1%-4% of ammonium heptamolybdate, 4%-7% of disodium octaborate tetrahydrate, 0.5%-2% of sodium polyacrylate, 1%-2% of polyethylene glycol (PEG) and 20%-50% of water. The beneficial effect is that the titanium dioxide-containing wood preservative has good permeability, strong erosion resistance, low cost and other advantages, has good sterilization and anti-corrosion effect on treated wood, gives wood the effects of flame retardance, smoke suppression, enhancement, wear resistance, low tendency to crack, and the like, and the wood durability and dimensional stability and other functions are improved.

Owner:王玉燕

Environmental protection wood flame retardation antiseptic

InactiveCN104858969AImprove flame retardant and smoke suppression performanceBroad-spectrum bactericidal and insecticidal effectWood treatment detailsWood impregnation detailsCarbamatePhosphate

The invention discloses an environmental protection wood flame retardation antiseptic. The flame retardation antiseptic comprises the following ingredients, by weight, 15%-20% of guanylurea phosphate, 4%-6% of zinc borate, 8%-12% of diammonium phosphate, 6%-10% of nanometer titanium dioxide, 1%-4% of ammonium molybdate, 6%-9% of cupric dimethyldithio carbamate, 4%-8% of disodium octoborate tetrahydrate, 1%-3% of dioctyl dimethyl ammonium chloride, 1%-3% of tetradecyl benzyl dimethyl ammonium chloride, 1%-3% of 8-hydroxyquinoline, 0.5%-2% of fatty alcohol polyoxyethylene ether and 20%-50% of water. The beneficial effects are that the flame retardation antiseptic has advantages of high efficiency, no poison and meeting environmental protection requirements, and has advantages of excellent flame retardation smoke inhibition performances, broad-spectrum sterilization and insecticidal effects, excellent anticorrosion and mildew-resistant effects and the like for processing wood. The permeability is good, the leaching resistance is strong and the cost is low.

Owner:王玉燕

Method for preparing methyl cyclohexanecarboxylate from methyl benzoate through hydrogenation reaction

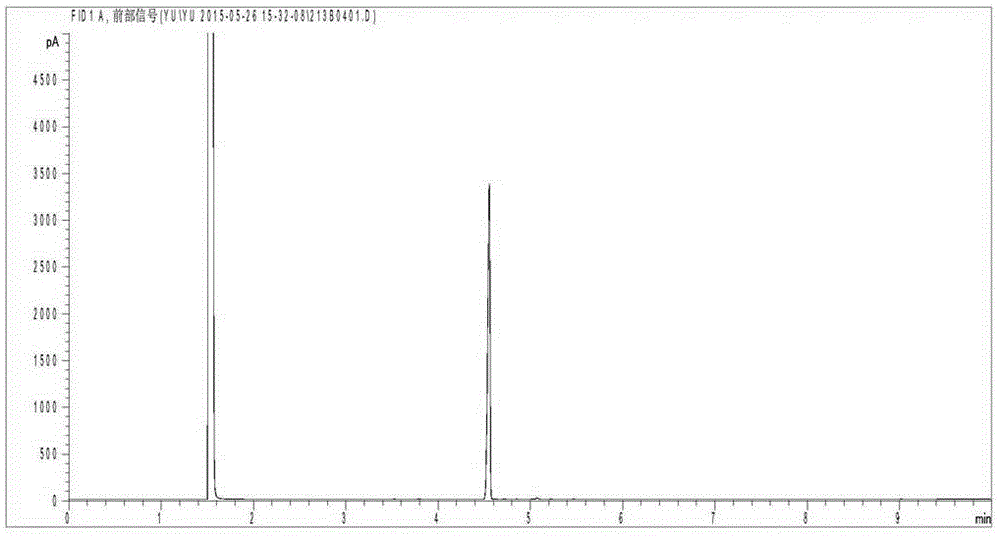

InactiveCN106554281AStrong loss resistanceLow priceOrganic compound preparationCarboxylic acid esters preparationOrganic synthesisMethyl benzoate

The invention discloses a method for preparing methyl cyclohexanecarboxylate from methyl benzoate through hydrogenation reaction. The methyl cyclohexanecarboxylate is an important organic synthesis intermediate and medical intermediate. A loading ruthenium-based catalyst is used, a methyl benzoate methanol solution is used as a reaction material, the reaction temperature ranges from 50 DEG C to 150 DEG C, the reaction pressure ranges from 0.5 MPa to 5 MPa, the reaction time is between 0.5 h and 5 h, the methyl benzoate conversion rate can reach 95%, the methyl cyclohexanecarboxylate selectivity can reach 96%, the production separation purity is larger than 99%, and the catalyst can be circularly and repeatedly used.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Copper dimethyldithiocarbamate wood preservative

InactiveCN105034109ADoes not reduce strength indexImprove anti-corrosion performanceBiocideDisinfectantsActive agentPreservative

The invention relates to a copper dimethyldithiocarbamate wood preservative. The copper dimethyldithiocarbamate wood preservative is a solvent prepared from effective components and water. The effective components comprise, by weight, 16%-30% of bivalent copper ions, 0-32% of dimethyl carbamodithioic acid, 40%-60% of acetone and 4%-15% of surface active agent, and the bivalent copper ions and dimethyl carbamodithioic acid react to obtain copper dimethyldithiocarbamate. The copper dimethyldithiocarbamate wood preservative is formed by the bivalent copper ions and dimethyl carbamodithioic acid (SDDC), acetone is adopted as a solvent, and the preservative for forming preservative-treated wood at a time is formed. The preservative has the good corrosion preventing and termite preventing performance, has no toxic effect on people or environment, and is good in loss resisting performance. Due to the fact that the surface active agent is added, the corrosion preventing capacity of a preparation can be effectively improved, and the stability and penetrating performance of the preparation are guaranteed.

Owner:FUJIAN ZHANGPING KIMURA FORESTRY PROD

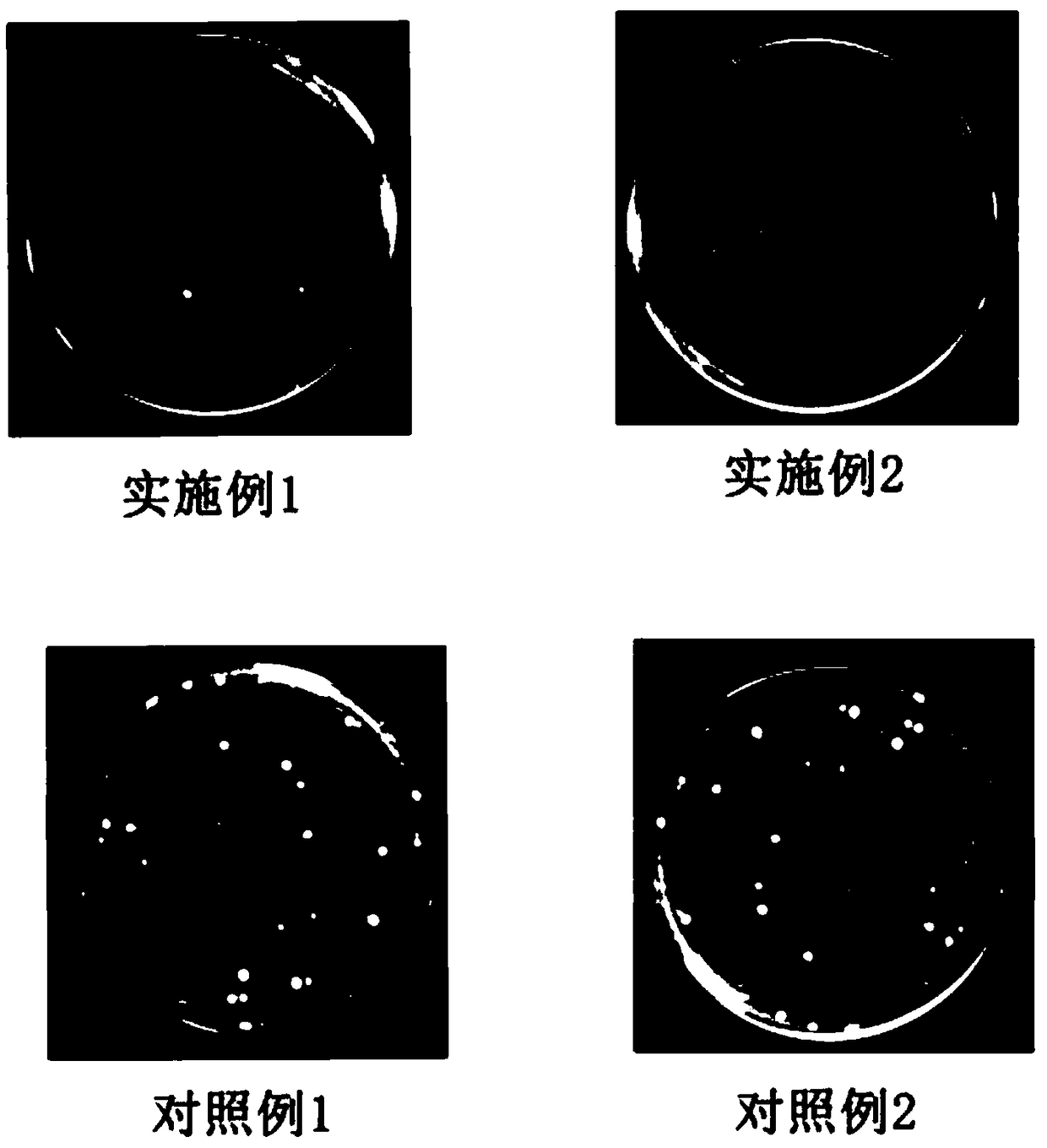

Wood surface chemical color changing method

ActiveCN109333716ARich in colorRich color varietyWood treatment detailsThermal wood treatmentCopper chlorideColor changes

The invention discloses a wood surface chemical color changing method. According to the wood surface chemical color changing method, the surface of wood is coated with copper chloride solution first,after drying, the surface of the wood is coated with a color changing agent, drying is conducted again, color changing of the wood is completed, and a finished product is obtained. The wood surface chemical color changing method has superior permeability, bonding strength of the color changing solution and the wood is higher, loss resistance is better, thus the color presented by the product madethrough the wood surface chemical color changing method is richer, lines are clearer, the layered feeling is higher, the color changing method is simple to operate, and the processing process is moreenvironmentally friendly.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Environment-friendly wood optimization solution

InactiveCN106142259AIncrease profitExtended service lifeWood treatment detailsWood impregnation detailsEmulsionLower grade

The invention relates to an environment-friendly wood optimization liquid, which comprises the following components in parts by weight: 10%-50% of alkaline silica sol, 10%-30% of sodium octaborate, and 2%-vinyl acetate-ethylene monomer emulsion copolymer 10%, magnesium chloride 1%‑2%, catalyst 1.5%‑2%, and water 30%‑60%. This wood optimization solution is compounded with organic and inorganic materials, combining the characteristics of inorganic and organic materials, so that the modified wood has significant advantages such as flame retardancy, loss resistance, and dimensional stability, and realizes the high-grade of low-grade wood. Improve the utilization rate and service life of wood. The formulation of the optimized solution is non-toxic, halogen-free, and has good environmental protection performance. It belongs to an environment-friendly optimized solution for wood modification treatment, and does not pollute the environment during production and use.

Owner:NANJING BOJUN NEW MATERIAL CO LTD +1

Anticorrosive antibacterial wood production method

InactiveCN104858956AImprove permeabilityImprove wettabilityBiocideWood treatment detailsEnvironmental resistanceHigh resistance

The invention discloses an anticorrosive antibacterial wood production method including the steps of pretreatment of wood, preparation of a wood treatment agent, preparation of a wood treatment liquid, dipping treatment, curing treatment, drying treatment and lighting treatment, and the wood treatment agent includes following components by mass: 20-30 parts of n-butyl titanate, 50-80 parts of polyethylene glycol, 0.1-1 part of glacial acetic acid, 320-400 parts of water, 20-30 parts of silica sol, 10-15 parts of trimethyl borate, 8-12 parts of dodecyl dimethyl benzyl ammonium chloride, 2-8 parts of carbendazim, 1-3 parts of isooctanol phosphate, and 1-2 parts of lauryl sodium sulfate. The beneficial effect is that the anticorrosive antibacterial wood production method has the advantages of simple process, high efficiency, low energy consumption, environmental friendliness and the like, the treated wood has good size stability, good resistance to corrosion, anti-bacterial function, high resistance to erosion, high strength, heat resistance, good resistance to wear and the like.

Owner:王玉燕

Catalytic wet-type oxidation catalyst as well as preparation method and application thereof

ActiveCN109465008AStrong loss resistanceImprove efficiencyWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsActive componentMass ratio

The invention provides a catalytic wet-type oxidation catalyst, and relates to the field of catalysts. The oxidation catalyst comprises an active component and a carrier, wherein the active componentcomprises Au and a modified metal; the modified metal is one or more of Ru, Rh, Pd, Pt, Fe, Co, Ni and Cu; the mass ratio of Au in the active component to the carrier is (0.01-5.0):(85-100); and the mass ratio of the modified metal in the active component to the carrier is (0.05-10.0):(85-100). The catalytic wet-type oxidation catalyst provided by the invention is used for performing catalytic wetoxidation bio-safety treatment on wastewater, the catalyst has good anti-leakage performance and can simultaneously remove ammonia nitrogen and organic pollutants in the wastewater, and the conversion rate of ammonia nitrogen in the wastewater is greater than 84.3%, and the removal rate of COD is greater than 85.9%.

Owner:厦门顺米可微电子科技有限公司

Wood preservative treatment method

InactiveCN104441133ASolve problems that destroy the internal structure of woodReduce pollutionPressure impregnationMedicineCell membrane

The invention belongs to the field of wood preservative treatment, and particularly relates to a wood preservative treatment method. The wood preservative treatment method comprises the following steps of injecting purified water into wood cells by utilizing a pressure treatment tank, then permeating a preservative into the wood cells via the permeation effect of cell membranes, so that the wood has a long-time preservative effect. According to the invention, the wood cells are subjected to pressurization and water injection, and the preservative is injected via the permeation effect of the cell membranes, so that on one hand, the problem that the internal structure of the wood is damaged due to direct pressurization and injection of the preservative to the wood cells is solved, and on the other hand, the preservative is injected into the cells, so that the preservative time is prolonged, and good permeation property and high loss resistance are achieved. By adopting the method, even if the chemical preservative is used, the pollution to the environment by the preservative is greatly reduced.

Owner:ANHUI MENGFUJIA ARTS & CRAFTS

Processing technology of carbonizing of recombined bamboos or recombined woods

ActiveCN109304782AImprove waterproof performanceImprove antibacterial propertiesWood treatment detailsReed/straw treatmentEngineeringPollution

The invention discloses a processing technology of carbonizing of recombined bamboos or recombined woods. The processing technology sequentially comprises the following steps of performing carbonizingtreatment, performing drying, performing gum dipping, performing displaying, performing assembling, performing hot pressing and performing aging, specifically comprises the following steps of duringcarbonizing treatment, placing bamboo bundles in a treatment tank containing 0.2-1 part of a carbonizing agent and 0.05-0.2 part of a catalyst for impregnating and carbonizing, wherein the impregnating temperature is 25-80 DEG C, and the impregnating time is 2-6 hours. The processing technology disclosed by the invention has good mold resistance and good size stability, and has the characteristicsof being simple in technology, low in cost, free from discharging, free from pollution, high in maneuverability, stable in medicament performance, capable of being recycled, and good in absorbability; and valuable timbers can be replaced, and valuable timber resources are saved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

A dipping solution used for functional modification of rubberwood timber

ActiveCN104647501AEasy to modifyImprove performanceWood treatment detailsWood impregnation detailsFiberCell wall

A dipping solution used for functional modification of rubberwood timber is disclosed. The dipping solution is prepared by mixing following components by weight: 2-30% of alkaline silica sol calculated based on silicon dioxide, 2-30% of water-soluble urea-formaldehyde resin, 0.2-20% of a waterproof agent, 0.05-3% of a silane coupling agent and 1-5% of borax, with the balance being water. The dipping solution adopts combination of inorganic components and organic components. Wood cell walls are covered with an inorganic-organic glue layer formed by the dipping solution so as to form a separating layer on the surface of wood fiber, so that the timer has functions of corrosion resistance, insect prevention, flame retardance, waterproofness, and the like. Components of the dipping solution are free of self-polymerization at room temperature, thus meeting production requirements. The dipping solution is high in binding capability with rubberwood and high in loss resistance. Obtained modified timer is good in stability, high in waterproofness, good in corrosion resistance and good in flame retardance. Economic value of the rubberwood is increased.

Owner:西双版纳新宏兴木业有限责任公司

Sterilization and smoke suppression halogen-free wood fire retardant

InactiveCN106363742AImprove photocatalytic activityGood killing effectWood treatment detailsWood impregnation detailsDecabromodiphenyl etherMoisture absorption

The invention discloses a sterilization and smoke suppression halogen-free wood fire retardant. The sterilization and smoke suppression halogen-free wood fire retardant is composed of, by mass, 40-80 parts of guanyl urea phosphate, 30-50 parts of urea, 10-20 parts of zinc borate, 5-10 parts of ammonium molybdate, 3-10 parts of pentaerythritol, 1-20 parts of ammonium dihydrogen phosphate, 12-25 parts of silica sol, 3-15 parts of decabromodiphenyl ether, 5-10 parts of fatty alcohol-polyoxyethylene ether, 1-20 parts of hexadecyltrimethoxysilane, and 1-20 parts of nanometer titania modified by one of Pt, Ag and Fe<3+>. The sterilization and smoke suppression halogen-free wood fire retardant is good in flame retardant property, high in anti-moisture absorption property and leaching resistance, good in stability, completely non-poisonous and low in cost and has the smoke suppression and sterilization effects.

Owner:GUANGXI UNIV

Wood fiber used for towels

ActiveCN102995474APlay the effect of cooking wood pulpUnique non-thermal effectInorganic compound additionRaw material divisionWood fibrePulp and paper industry

The invention relates to a wood fiber and in particular relates to a wood fiber used for towels. The wood fiber is prepared by the following steps in sequence: material selecting, grinding, wood pulp cooking, fiber extracting, bleaching, dipping fire-retardant treatment, bio-enzyme treatment and curing, wherein in the step of wood pulp cooking, microwaves are adopted to cook wood pulp; in the step of dipping fire-retardant treatment, vacuum-pressure is adopted for fire-retardant treatment; and in the step of bio-enzyme treatment, water is added after the wood-wool-shaped fiber subjected to dipping fire-retardant treatment is wet by adopting a nonionic wetting agent and the wood-wool shaped fiber is subjected to repeated pressure addition and reduction operations in a pressure tank and then cellulose and lipase are added to carry out degradation treatment for 5-8 minutes under the conditions that the pH value is 3-4 and the temperature is 60-70 DEG C, wherein the bath ratio of water solution to the wood fiber is (3-5):1; the dosage of cellulose is 3-5g / L; and the dosage of lipase is 0.5-1.2g / L. A method is short in treatment time and the prepared wood fiber has a fire retardant effect and fluffy and soft handfeel and is especially suitable for preparing towels.

Owner:HAIMEN JINQILIN REDWOOD INVESTMENT DEV

Wooden modifying composition, production and use thereof

InactiveCN100540244CGood weather resistanceExtended service lifeBiocideOther chemical processesIsooctyl acrylateHydration reaction

The invention discloses a new wood modification composition and its preparation method and application. The composition is mainly made of the following raw materials: 37% formaldehyde, borax, ammonia water, urea, melamine, boric acid, dicyandiamide phosphate, High carbon alkyl quaternary ammonium salt, sodium lauryl sulfate, sodium alkylphenol ether sulfosuccinate, decylphenol polyoxyethylene ether, N-methylol acrylamide, butyl acrylate, styrene, Isooctyl acrylate, acrylic acid, tertiary dodecyl mercaptan, ammonium persulfate, sodium bicarbonate, sodium metasulfite, chlorinated paraffin with a chlorine content of 50-60%, silica microemulsion with a solid content of 45% and / or 40 % solid content of hydrated aluminum oxide microemulsion. The artificial forest and low-grade wood modified by the composition of the present invention not only have significantly improved physical and mechanical properties, but also have excellent fire-retardant, moth-proof, mildew-proof and anti-corrosion properties, and also overcome the existing wood preservatives. Generally contain defects such as heavy metal ions and other toxic components.

Owner:陈万利 +3

Antibacterial flame retardant wood production method

InactiveCN104858955AImprove anti-corrosion performanceGood antibacterialWood treatment detailsPressure impregnationPhosphateImidacloprid

The invention discloses an antibacterial flame retardant wood production method including the steps of pretreatment of wood, preparation of a wood treatment agent, preparation of a wood treatment liquid, dipping treatment, curing treatment, drying treatment and lighting treatment, and the wood treatment agent includes ethyl titanate, isopropyl alcohol, acetyl acetone, water, silica sol, sodium octoborate, imidacloprid, magnesium chloride, zinc borate, diammonium phosphate, ammonium molybdate, isooctanol phosphate and sodium dodecyl sulfate. The beneficial effect is that the antibacterial flame retardant wood production method has the advantages of simple process, high dipping efficiency, low energy consumption, environmental protection, and the like, the treated wood has excellent flame retardant, smoke suppression, anti-corrosion, antibacterial, and other functions, and the antibacterial flame retardant wood is stable in dimension, not easy to crack, good in strength, strong in erosion resistance, and durable.

Owner:王玉燕

Flame-retardant oriented strand board and preparation process thereof

InactiveCN110405899ALow hygroscopicityGood hygroscopicityNon-macromolecular adhesive additivesWood working apparatusSurface layerMelamine phosphate

The invention discloses a flame-retardant oriented strand board and a preparation process thereof. The strand board comprises a core layer and surface layers located on the two sides of the core layer, wherein flame retardants in the surface layers are compounds of phosphorylated chitosan and melamine phosphate borate; and a flame retardant in the core layer is melamine phosphate borate. The melamine phosphate borate is low in hygroscopicity and high in loss resistance, and can be used for performing a charring layer at the high temperature, and therefore high flame retardancy and the long flame retardancy life are achieved; the flame retardants in the surface layers further comprise the phosphorylated chitosan, hydroxyl and amino on the surface of the phosphorylated chitosan can react with formaldehyde, the release amount of free formaldehyde of the oriented strand board is reduced, the purpose of removing the formaldehyde is achieved, and the strand board is more environment-friendly; and moreover, the hygroscopicity of the melamine phosphate borate can be further reduced, and the flame retardancy of the oriented strand board is further improved.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Bio-enzyme wood and bamboo protective agent as well as production method and using method thereof

The invention relates to a bio-enzyme wood and bamboo protective agent which is prepared from the following raw materials in parts by weight: 0.05-0.5 part of laccase with the activity of 0.5U / mg, 0.05-0.5 part of enzyme activator, 200-2000 parts of bactericide substrate and 8000-9800 parts of buffer solution with the concentration of 0.1mol / L and pH value of 4-6. A production method of the protective agent comprises the steps of mixing the rest three raw materials according to the proportion except the laccase, evenly stirring at the temperature of 25-30 DEG C, and feeding the laccase into the mixed solution before use; evenly stirring at the rotating speed of 200-1000r / min under the condition of 25-30 DEG C. When the bio-enzyme wood and bamboo protective agent is used, the wood, the bamboo and products of the wood and the bamboo can be treated in a way of spraying, coating, soaking, pressurizing or vacuum impregnation, and then reaction is carried out for 6-18 hours in the environment of 25-40 DEG C, so that the mould-proof and corrosion-resistant treatment for the wood and the bamboo can be completed. The bio-enzyme wood and bamboo protective agent is simple in production technology, low in cost, convenient to use, non-toxic, free from environment pollution, good in mould-proof and corrosion-resistant effects, high in flow-away resistance and degradability resistance, and lasting in effect.

Owner:ZHEJIANG FORESTRY UNIVERSITY

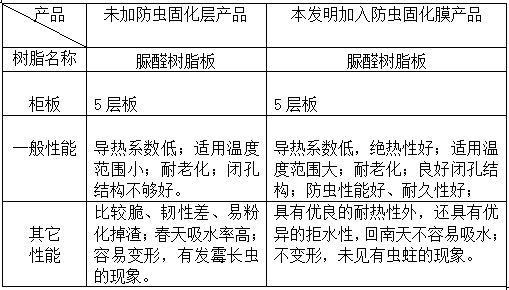

Insect-proof multi-layer eucalyptus wood board and production method thereof

InactiveCN110871477AImprove textureGood dimensional stabilityOther plywood/veneer working apparatusLamination ancillary operationsAdhesive glueSingle plate

The invention provides an insect-proof multi-layer eucalyptus wood board and a production method thereof. The production method of the multi-layer board comprises the steps of single plate thin platesorting, thin plate glue applying, cold pressing, hot pressing, standing curing, dust scraping, sanding, repair, trimming and plate pasting, and is characterized in that a layer of insect-proof curedfilm is sprayed at the peripheral surface, the upper surface and the lower surface of a slab before first hot pressing and final hot pressing to prevents glue from being dried too quickly during the hot pressing process and maintain stress inside the multi-layer board, the urea-formaldehyde glue can be fully reacted completely, the formed multi-layer board is not prone to mildewing, in the use process of a user, volatile formaldehyde is also reduced, and after hot pressing, the board is subjected to standing curing, sanding and plate pasting, so that the insect-proof multi-layer eucalyptus wood board product can be obtained by edge sawing and packaging.

Owner:广西横县正林木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com