Natural mildew-proof and corrosion-proof agent for bamboos and woods

A preservative and wood technology, applied in the direction of impregnating wood, wood impregnation, wood processing appliances, etc., can solve the problems of human harm, mildew-proof and preservative toxicity, etc., and achieve the effect of strong anti-loss and long-term mildew-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The production method of Ginkgo biloba extract: (1) Drying and crushing: Fresh ginkgo fruits are removed from the ginkgo biloba to obtain the testa, dried in a vacuum drying oven at 65°C to a moisture content of 4.65%, and crushed until most of the particles pass 50 mesh Sieve; (2) Extraction: use 70% ethanol solution as the extraction liquid, and carry out extraction according to the material-to-liquid ratio (material weight / solution weight) 1:5, and the extraction time is 5 hours; during the extraction process, ultrasonic treatment 4 30 minutes each time; (3) Purification: filter the extract to obtain the filtrate, add 0.1 mol / L acetic acid to the filtrate, adjust the pH to 3.0, extract 4 times with ethyl acetate, and separate ethyl acetate Ester phase; (4) Concentration: The ethyl acetate phase was subjected to rotary steaming at 75°C to obtain the Ginkgo biloba exocarp extract.

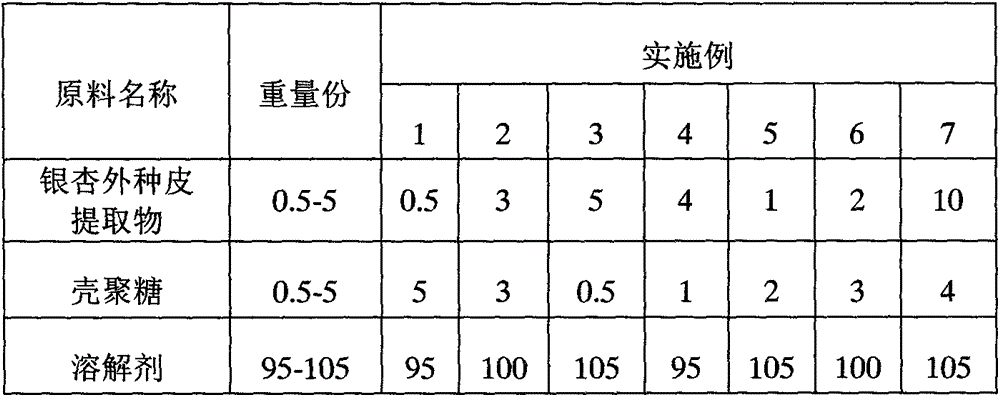

[0019] With reference to the raw materials and parts by weight of Example 1 in the above t...

Embodiment 2

[0021] Production method of Ginkgo biloba extract: (1) Drying and crushing: Fresh ginkgo fruits are removed from the ginkgo fruit to obtain the extrus, dried in a vacuum drying oven at 65°C to a moisture content of 4.28%, and crushed until most of the particles pass 50 mesh Sieve; (2) Extraction: use 50% ethanol solution as the extraction liquid, and carry out extraction according to the material-to-liquid ratio (material weight / solution weight) 1:10, and the extraction time is 3 hours; during the extraction process, ultrasonic treatment 3 20 minutes each time; (3) Purification: filter the extract to obtain the filtrate, add 0.1 mol / L acetic acid to the filtrate, adjust the pH to 3.5, and extract 3 times with ethyl acetate to separate ethyl acetate Ester phase; (4) Concentration: The ethyl acetate phase was subjected to rotary steaming at 70°C to obtain the Ginkgo biloba exocarp extract.

[0022] With reference to the raw materials and parts by weight of Example 2 in the above ta...

Embodiment 3

[0024] The production method of Ginkgo biloba exocarp extract: (1) Same as Example 1; (2) Extraction: 30% ethanol solution is used as the extraction liquid, and the material-to-liquid ratio (material weight / solution weight) is 1:5 for extraction , The extraction time is 2 hours; during the extraction process, ultrasonic treatment is performed twice, each time is 15 minutes; (3) purification: the extraction liquid is filtered to obtain the filtrate, and 0.1 mol / L acetic acid is added to the filtrate to adjust the pH value To 3, extract twice with ethyl acetate, and separate the ethyl acetate phase; (4) Concentration: the ethyl acetate phase is rotary evaporated at 70°C to obtain the Ginkgo biloba exocarp extract.

[0025] With reference to the raw materials and parts by weight of Example 3 in the above table, first add 5 parts of Ginkgo biloba exocarp extract to 105 parts of dissolving agent (ethanol to water ratio 5:5), and slowly add 0.5 part of chitosan after it is completely di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com