Flame-retardant oriented strand board and preparation process thereof

A particleboard and flame retardant technology, applied in the field of flame-retardant oriented strand board and its preparation, can solve the problems of flame-retardant oriented Strong loss performance and improved flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of phosphoric acid-activated chitosan / MPB composite flame retardant of the present embodiment, its preparation method comprises the following steps: (1) prepare phosphorylated chitosan: in 200g mass fraction, add 20g chitosan in the phosphoric acid aqueous solution of 85% Sugar, stir quickly and evenly, then heat up to 120°C, and react at 120°C for 2h to generate phosphorylated chitosan.

[0037] (2) Preparation of melamine borate phosphate:

[0038] (a) Add 20g of phosphoric acid and 6g of ammonium dihydrogen phosphate to 200g of water, react at 50°C for 20 minutes, add 20g of melamine, react for 2.5 hours, cool, vacuum filter, wash and dry to obtain a white solid, which is phosphoric acid Melamine (MP).

[0039] (b) Add 30g MP into 20mL 20% boric acid aqueous solution, react at 80°C for 2.5h, cool, vacuum filter and dry to obtain melamine phosphate borate (MPB).

[0040] (3) Slowly add 20 g of chitosan phosphate and 20 g of MPB into 300 g of water, and stir r...

Embodiment 2

[0042] This embodiment is a flame-retardant adhesive, and its preparation method comprises: adding 10 g of the phosphoric acid-activated chitosan / MPB compound flame retardant prepared in Example 1 into 50 g of urea-formaldehyde resin, stirring, and mixing evenly to obtain the present invention. The flame retardant adhesive A of the embodiment.

[0043] And, 10g of MPB was added to 50g of urea-formaldehyde resin, stirred, and mixed evenly to obtain the flame-retardant adhesive B of this embodiment.

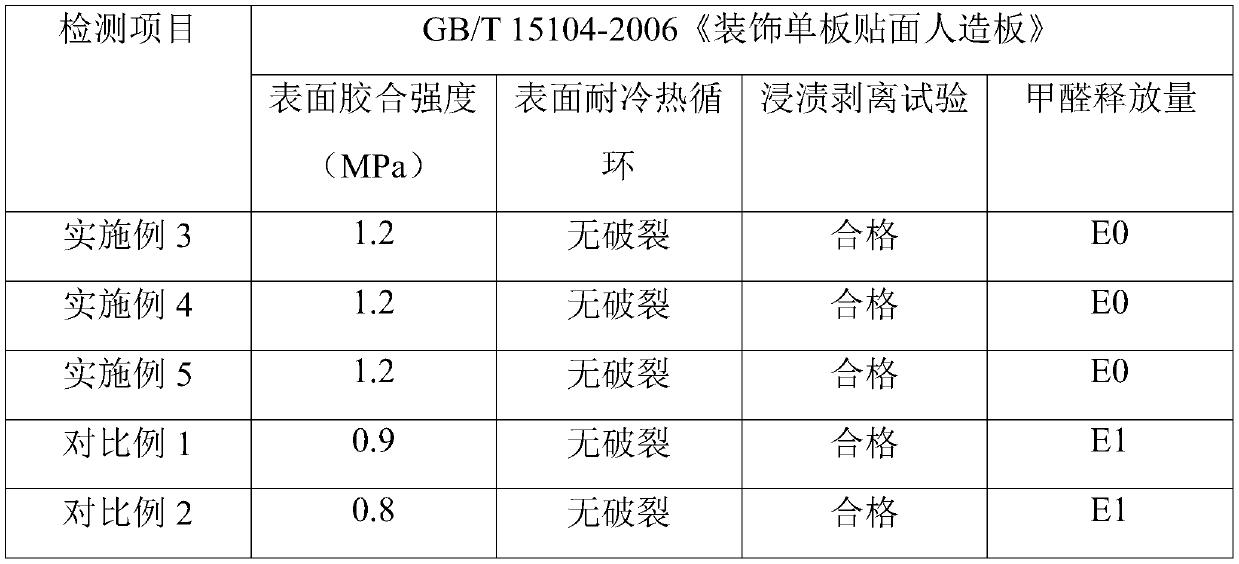

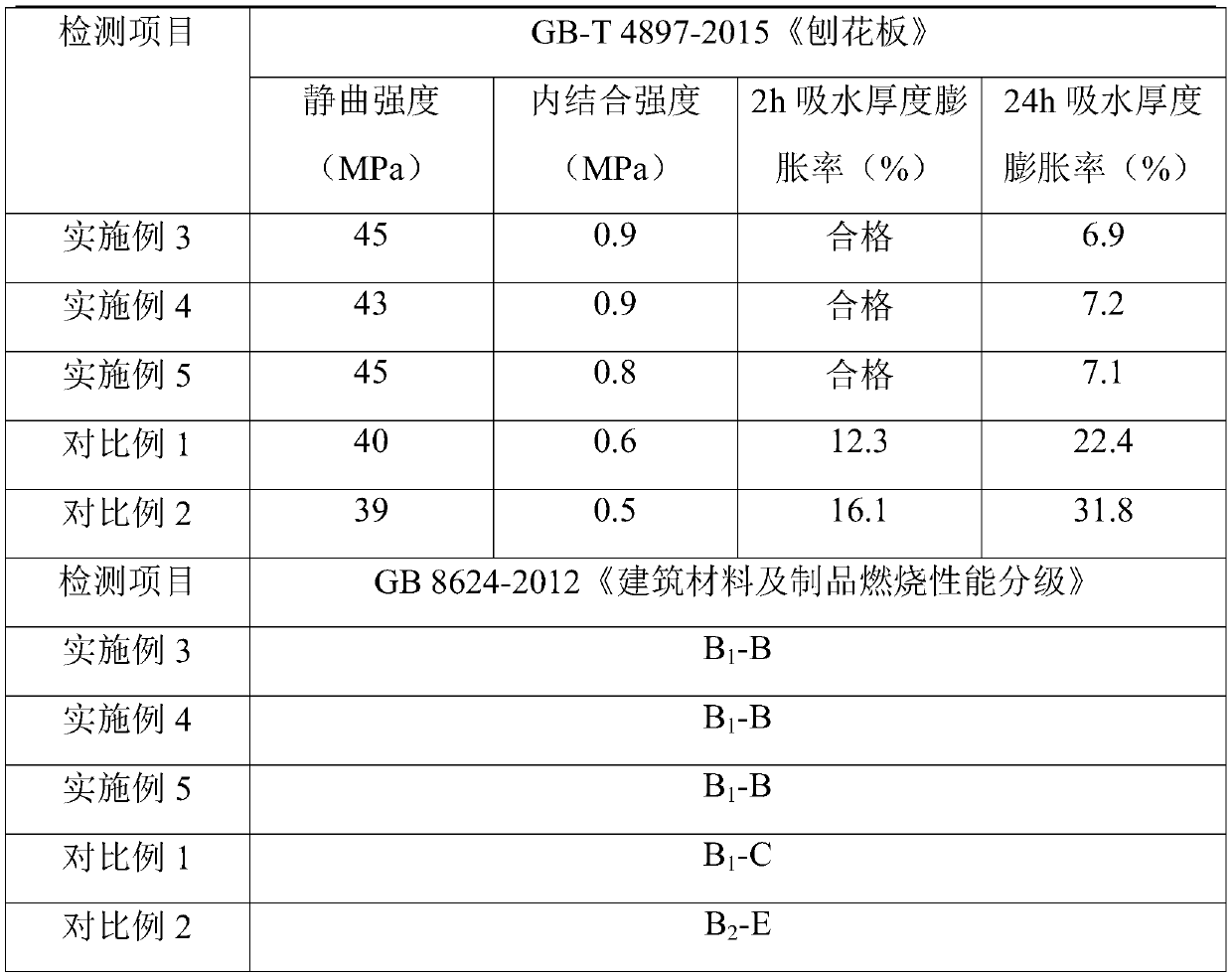

Embodiment 3

[0045]In this embodiment, a flame-retardant oriented strand board includes a core layer and surface layers arranged on both sides of the core layer. The preparation process of the flame-retardant oriented strand board includes the following steps:

[0046] (1) Put 100 parts of coarse shavings (the length of coarse shavings is between 60-120mm, width 5-20mm, thickness 0.2-0.8mm), 20g of flame-retardant adhesive B into a mixer and stir well, continue to add The paraffin emulsion accounting for 0.35% of the mass of the coarse shavings and the ammonium chloride accounting for 1% of the mass of the flame-retardant adhesive B are stirred evenly to obtain the core layer slurry;

[0047] (2) Put 74 parts of fine shavings (the length of the fine shavings is less than 60mm, the width is 5-20mm, and the thickness is 0.2-0.8mm), 10g of sawdust, and 16g of flame-retardant adhesive A. 0.6% of the mass of coarse shavings of paraffin emulsion and 1% of ammonium chloride by mass of the flame-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com