Ammonium nitrate cladding method

A technology of ammonium nitrate coating, applied in the generation of compressed gas, offensive equipment, explosives, etc., to achieve the effects of improved mechanical properties, strong binding force, and reduced surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

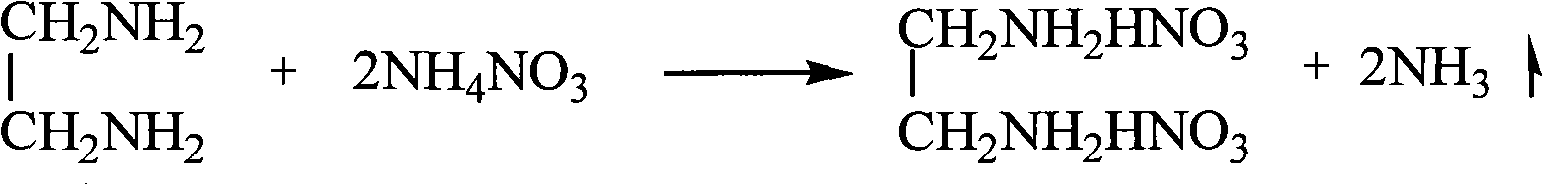

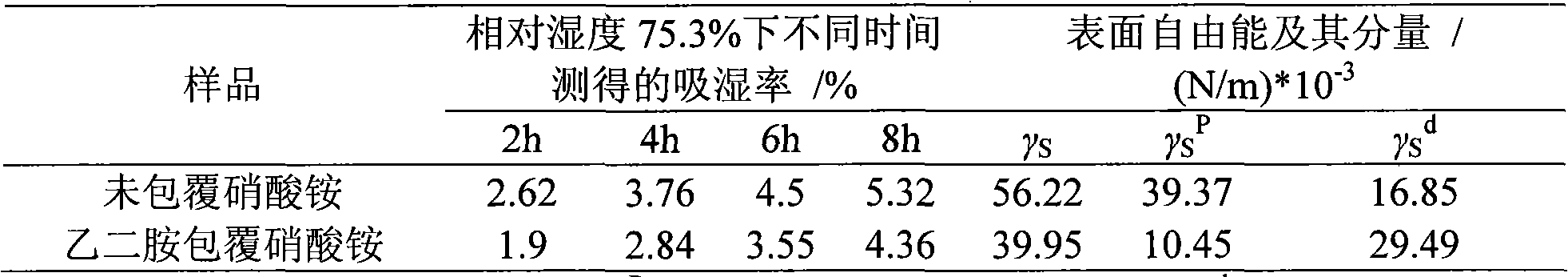

[0035] A kind of coating method of ammonium nitrate, its specific preparation steps are:

[0036] 1) Add ammonium nitrate particles and petroleum ether to the reactor, heat and stir to disperse them in petroleum ether; the heating temperature is 50°C; the mass ratio of ammonium nitrate to petroleum ether is 1:5;

[0037] 2) adding the coating agent ethylenediamine and ethyl acetate to another reactor, so that the ethylenediamine is dissolved in ethyl acetate; the mass ratio of ethylenediamine to ethyl acetate is 1:100;

[0038] 3) Add the solution in the reactor in step 2) dropwise to the reactor in step 1), the mass ratio of ethylenediamine to ammonium nitrate is 0.002: 1, and the dropping time is 2 hours; and stir to make the ethylenediamine Diamine is precipitated in a mixed solvent of ethyl acetate and petroleum ether, and ethylenediamine is uniformly attached to the surface of ammonium nitrate and chemically reacts with the surface of ammonium nitrate; the reaction time b...

Embodiment 2

[0055] A kind of coating method of ammonium nitrate, its concrete preparation steps are the same as embodiment 1, and wherein different is that coating agent is diethylenetriamine, and polar solvent is acetone; Table 4 is the coating nitric acid of diethylenetriamine chemical reaction type The effect of ammonium on the hygroscopicity and surface free energy of ammonium nitrate;

[0056] The reaction formula between diethylenetriamine amine and ammonium nitrate is:

[0057]

[0058] Table 4 The effect of diethylenetriamine chemical reaction coating ammonium nitrate on the hygroscopicity and surface free energy of ammonium nitrate

[0059]

[0060] The application of ammonium nitrate coated with diethylenetriamine in propellant, its specific implementation steps and formula are the same as in Example 1, the difference is that ammonium nitrate coated with ethylenediamine is changed to ammonium nitrate coated with diethylenetriamine , Table 5 is the mechanical properties of...

Embodiment 3

[0064] A kind of coating method of ammonium nitrate, its specific preparation steps are the same as embodiment 1, and wherein different is that coating agent is triethylene tetramine, and polar solvent is methanol; Table 6 is triethylene tetramine chemical reaction type coated nitric acid The effect of ammonium on the hygroscopicity and surface free energy of ammonium nitrate;

[0065] The reaction formula between triethylenetetramine and ammonium nitrate is:

[0066]

[0067] Table 6 Effect of triethylenetetramine chemical reaction coating ammonium nitrate on hygroscopicity and surface free energy of ammonium nitrate

[0068]

[0069] The application of ammonium nitrate coated with triethylenetetramine in propellant, its specific implementation steps and formula are the same as in Example 1, the difference is that ammonium nitrate coated with ethylenediamine is changed to ammonium nitrate coated with triethylenetetramine , Table 7 is the mechanical properties of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com