Patents

Literature

121results about "Inorganic oxygen-halogen salt explosive compositions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nontoxic, noncorrosive phosphorus-based primer compositions and an ordnance element including the same

A primer composition that includes red phosphorus having an acid scavenger and a polymer thereon. The primer composition includes at least one other component that is substantially free of lead. The other component is at least one oxidizer, or at least one oxidizer and at least one of at least one secondary explosive composition and at least one energetic binder. The primer composition optionally includes at least one element having an ionic charge to ionic radius ratio of 4 or of 8, such as magnesium, zirconium, aluminum, silicon, titanium, tungsten, alloys thereof, and combinations thereof. The red phosphorus and the at least one oxidizer are present in the primer composition at approximately stoichiometric amounts. An ordnance element including the primer composition is also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

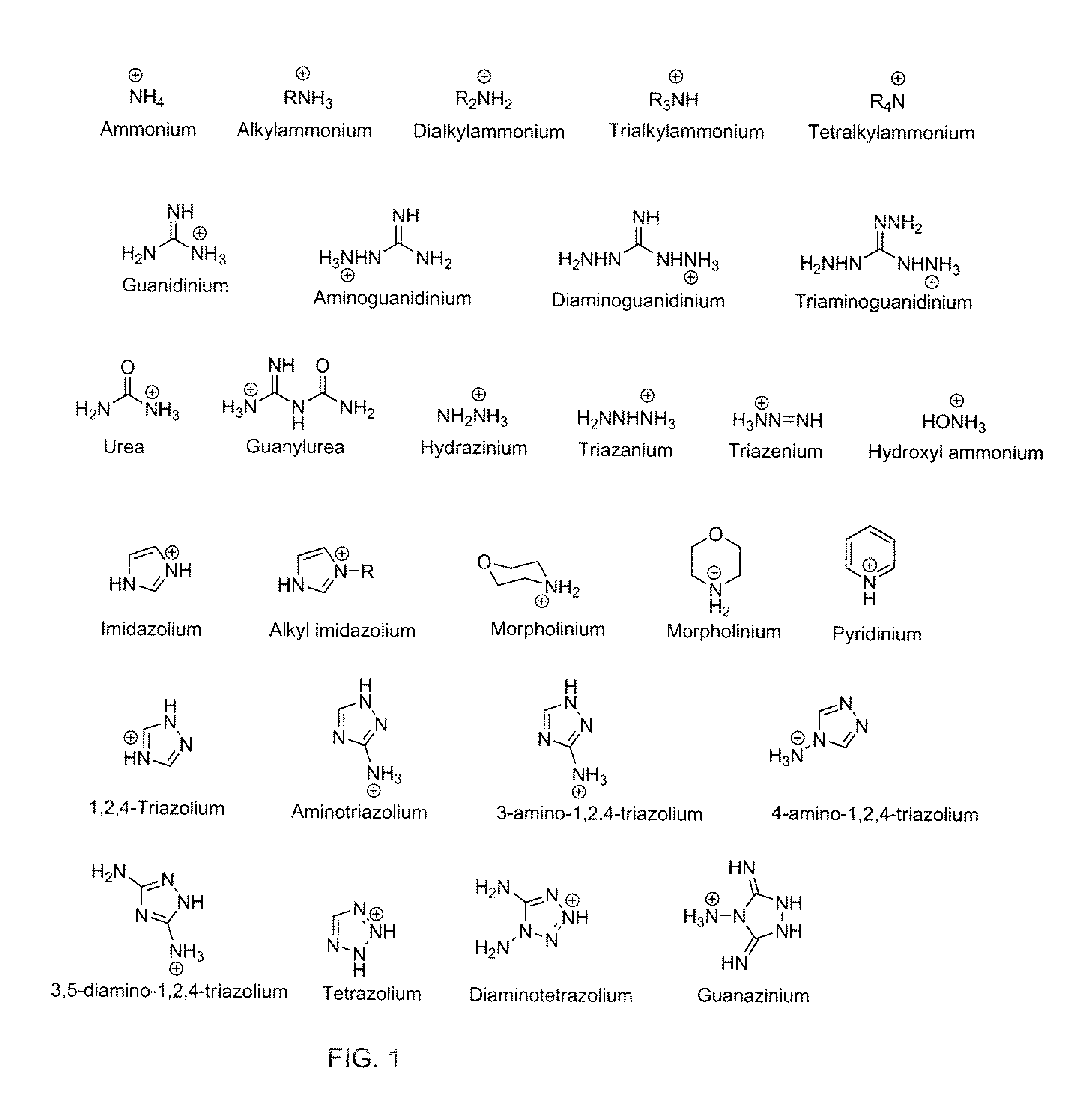

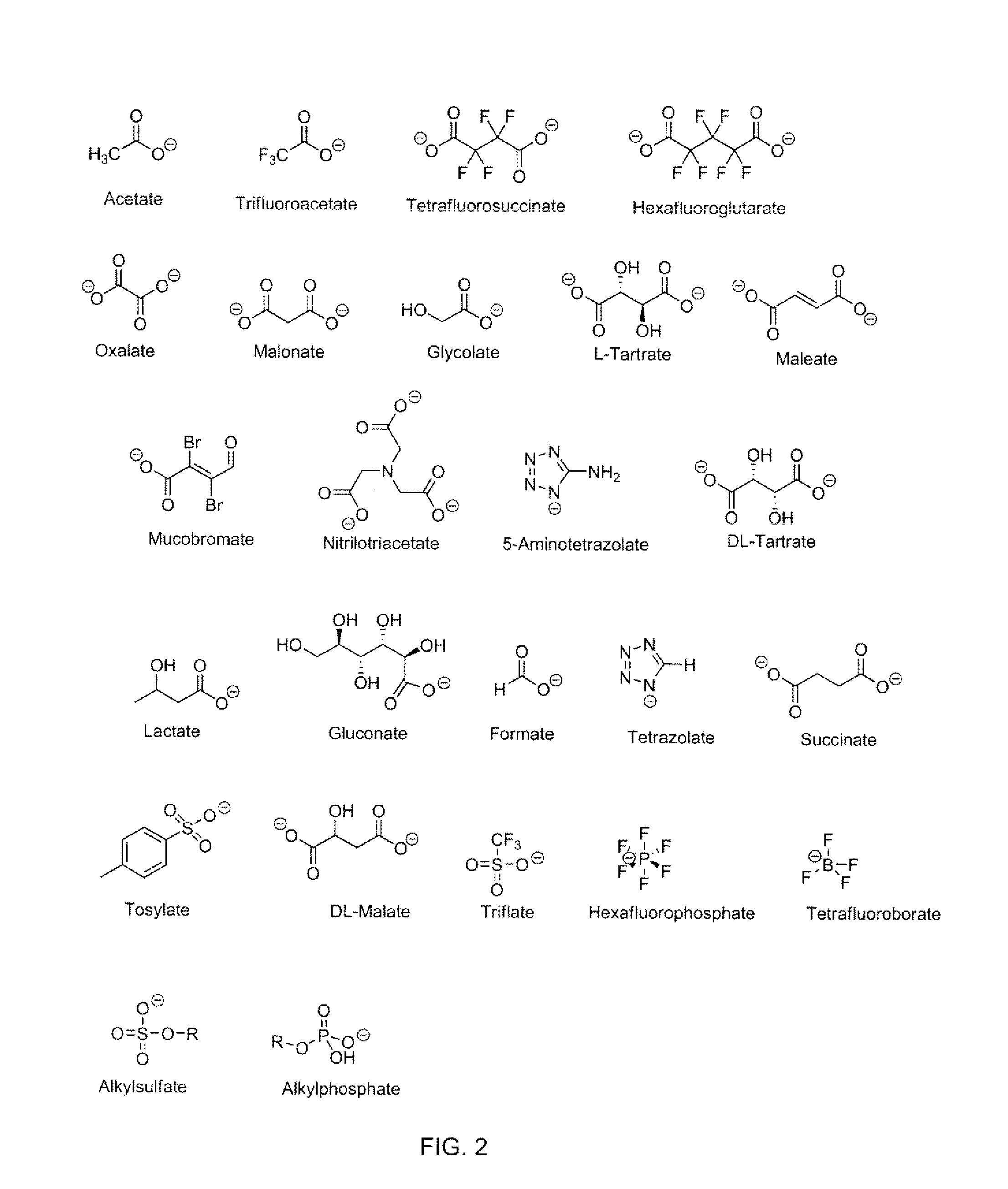

Ionic liquid, a method of synthesizing an ionic liquid, a precursor of an explosive composition including at least one ionic liquid, and a method of desensitizing an explosive composition

InactiveUS20080251169A1Sure easyUrea derivatives preparationOrganic compound preparationIonic liquidEnergetic material

An ionic liquid is disclosed A precursor composition that comprises at least one ionic liquid and at least one energetic material is also disclosed, as is a method of synthesizing an ionic liquid and a method of desensitizing an explosive composition.

Owner:NORTHROP GRUMMAN SYST CORP

Metal complexes for use as gas generants

InactiveUS20100084060A1Improve crush strength and other mechanical propertyEfficient combustionInorganic oxygen-halogen salt explosive compositionsNitrated metallo-organic explosive compositionsMetal nitrateHydrogen

Gas-generating compositions and methods for their use are provided. Metal complexes are used as gas-generating compositions. These complexes are comprised of a metal cation template, a neutral ligand containing hydrogen and nitrogen, and sufficient oxidizing anion to balance the charge of the complex. The complexes are formulated such that when the complex combusts, nitrogen gas and water vapor is produced. Specific examples of such complexes include metal nitrite amine, metal nitrate amine, and metal perchlorate amine complexes, as well as hydrazine complexes. A binder and co-oxidizer can be combined with the metal complexes to improve crush strength of the gas-generating compositions and to permit efficient combustion of the binder. Such gas-generating compositions are adaptable for use in gas-generating devices, such as automobile air bags.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

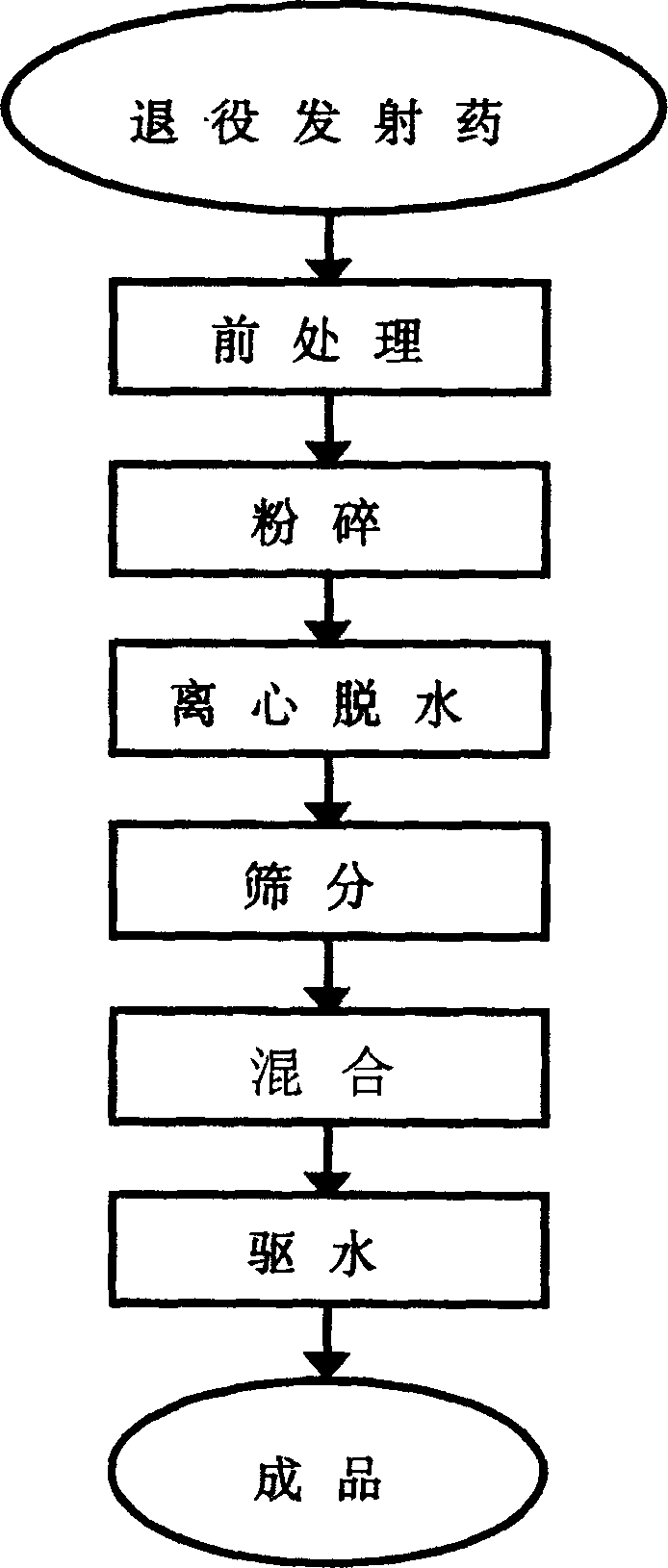

Smokeless gun propellant for fireworks and its prepn

InactiveCN1526687AReduce generationReduce pollutionExplosive working-up apparatusInorganic oxygen-halogen salt explosive compositionsFireworksOxidizing agent

The smokeless gun propellant for fireworks consists of retired gunpowder 70-90 wt%, oxidant 5-10 wt% and inflammable 1-5 wt%. The oxidant is nitrate, chlorate or perchlorate; and the inflammable is carbon powder, aluminum powder, magnesium powder or aluminum-magnesium alloy powder. The preparation process includes crushing, dewatering, mixing, dispelling water and drying. The smokeless gun propellant is used in ground fireworks product to replace black powder as propellant agent, and this can reduce smoke produced during firing fireworks greatly, reduce dust pollution to environment and lower production cost. The present invention paves one way of utilizing retired gun powder resource in large scale.

Owner:中国北方化学工业总公司

Blast black powder for fireworks

InactiveCN101270014ANo pollution in the processGood detonation effectInorganic oxygen-halogen salt explosive compositionsMetallic materialsFireworks

The present invention discloses explosive black powder that is used for fireworks. The black powder contains the following components with the following weight portions: 40 to 75 portions of potassium perchlorate, 0 to 35 portions of potassium nitrate, 1 to 5 portions of potassium dichromate, 5 to 15 portions of sulfur, 5 to 25 portions of charcoal, 0.5 to 2 portions of carbon black, and 5 to 20 portions of potassium terephthalic acid or potassium acid phthalate. The explosive black powder is made of the components according to the ratio. No metal material or toxic substances are used. The explosive black powder has the advantages of low mechanical sensitivity, excellent stability, large explosive scale, excellent explosive sound, black medicine, easily prepared raw materials and relatively low cost. Thus the explosive black powder is the ideal explosive black powder.

Owner:湖南省浏阳金生花炮有限公司

Metal complexes for use as gas generants

InactiveUS20050067074A1Increased crush strengthImprove other mechanical propertyInorganic oxygen-halogen salt explosive compositionsNitrated metallo-organic explosive compositionsMetal nitrateHydrogen

Gas generating compositions and methods for their use are provided. Metal complexes are used as gas generating compositions. These complexes are comprised of a metal cation template, a neutral ligand containing hydrogen and nitrogen, and sufficient oxidizing anion to balance the charge of the complex. The complexes are formulated such that when the complex combusts, nitrogen gas and water vapor is produced. Specific examples of such complexes include metal nitrite ammine, metal nitrate ammine, and metal perchlorate ammine complexes, as well as hydrazine complexes. A binder and co-oxidizer can be combined with the metal complexes to improve crush strength of the gas generating compositions and to permit efficient combustion of the binder. Such gas generating compositions are adaptable for use in gas generating devices, such as automobile air bags.

Owner:HINSHAW JERALD C +3

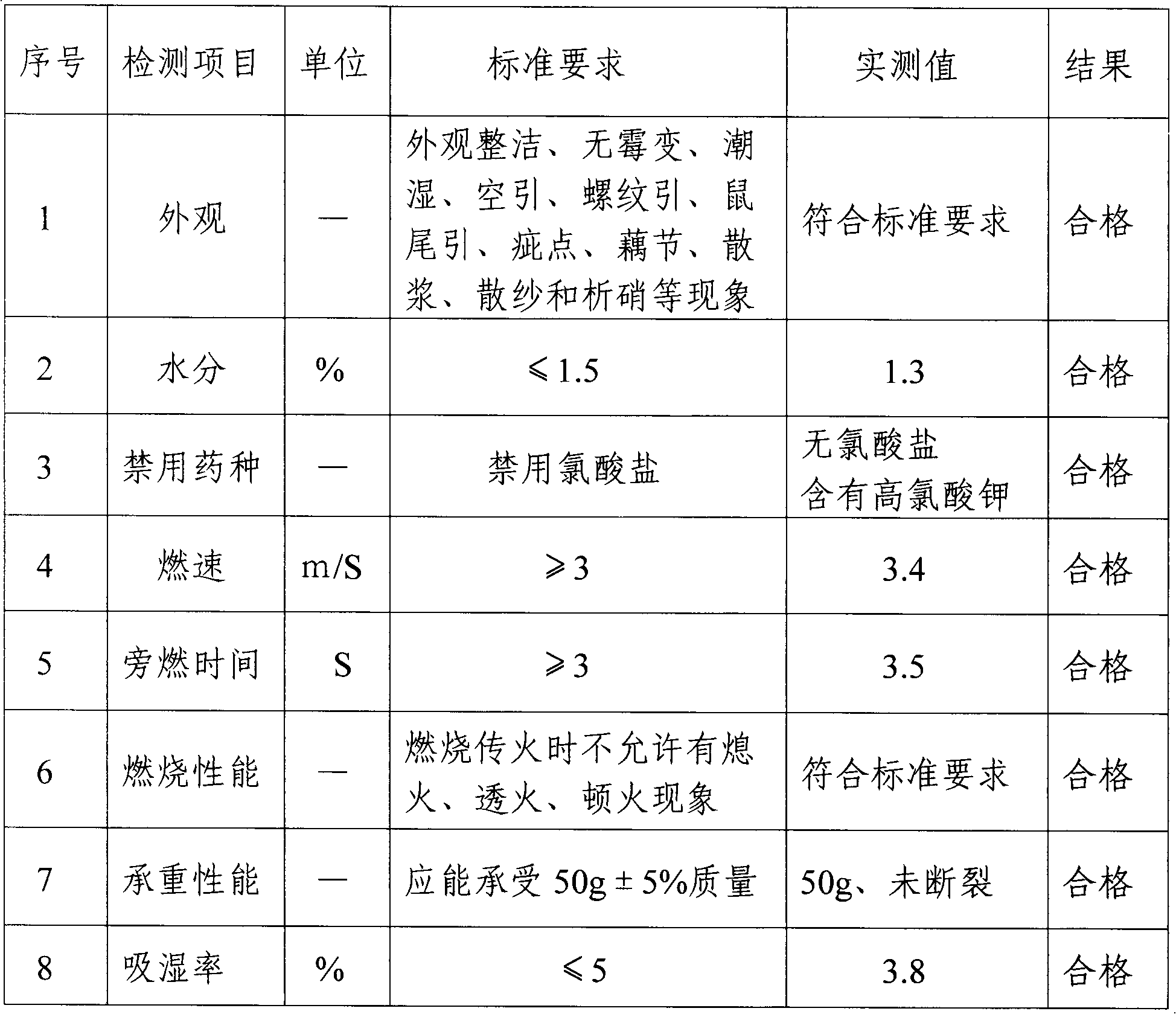

Blasting fuse of high-safety firecracker and preparation method thereof

InactiveCN101270015AStable chemical propertiesLow mechanical sensitivityInorganic oxygen-halogen salt explosive compositionsFuse detonationYarnDecomposition

The present invention relates to a preparation method of a safe firing cable of firecrackers. In the method, yarn is used as a carrier to infuse the following medicines, which are used raw materials, according to the following steps. The medicines comprise potassium perchlorate, potassium terephthalic acid, ammonium dichromate, polyethylene alcohol, moisture resistant agent, charcoal and sulfur. The method has the following steps: the potassium perchlorate, the potassium terephthalic acid, the ammonium dichromate, the charcoal, the sulfur and the polyethylene alcohol are arranged in a container according to the weight ratio; water with a certain proportion is added into the container; the mixture is stirred so that the medicines can be dissolved in the water; then the moisture resistant agent is added; and the mixture is mixed well; the yarn is infused in the container, taken out and then sent to a drying device to be dried; thus the safe firing cable can be prepared. In the method, the yarn is used as the carrier to infuse the medicines of the firing cable; the production is simple; the amount of the medicines is reduced; the method is safe; and the cost is reduced. The application of the potassium perchlorate has the advantages of low oxygen content, low decomposition temperature, excellent stability and low sensitivity. Thus the application of the potassium perchlorate is superior to the application of potassium chlorate. The firing cable solves the problems of storage, transportation and insecurity in use.

Owner:醴陵神马花炮有限公司

Igniting agent composition and ignitor using same

An igniting agent composition substantially free of a lead compound, characterized in that it comprises a metal power and one or more selected from the group consisting of nitrate salt, basic nitrate salt, a metal oxide and a basic carbonate salt; and an igniter using the igniting agent composition. The igniting agent composition shows no delay in ignition time and no reduction in igniting capability, as compared to conventional lead-containing composition.

Owner:NIPPON KAYAKU CO LTD

Smokeless propellant powder with safe, environmental-friendly and porous structure for fireworks

ActiveCN102924193AEnsure safetyBurn quicklyInorganic oxygen-halogen salt explosive compositionsEnvironmental resistanceFoaming agent

Owner:浏阳象形精品烟花出口造有限公司

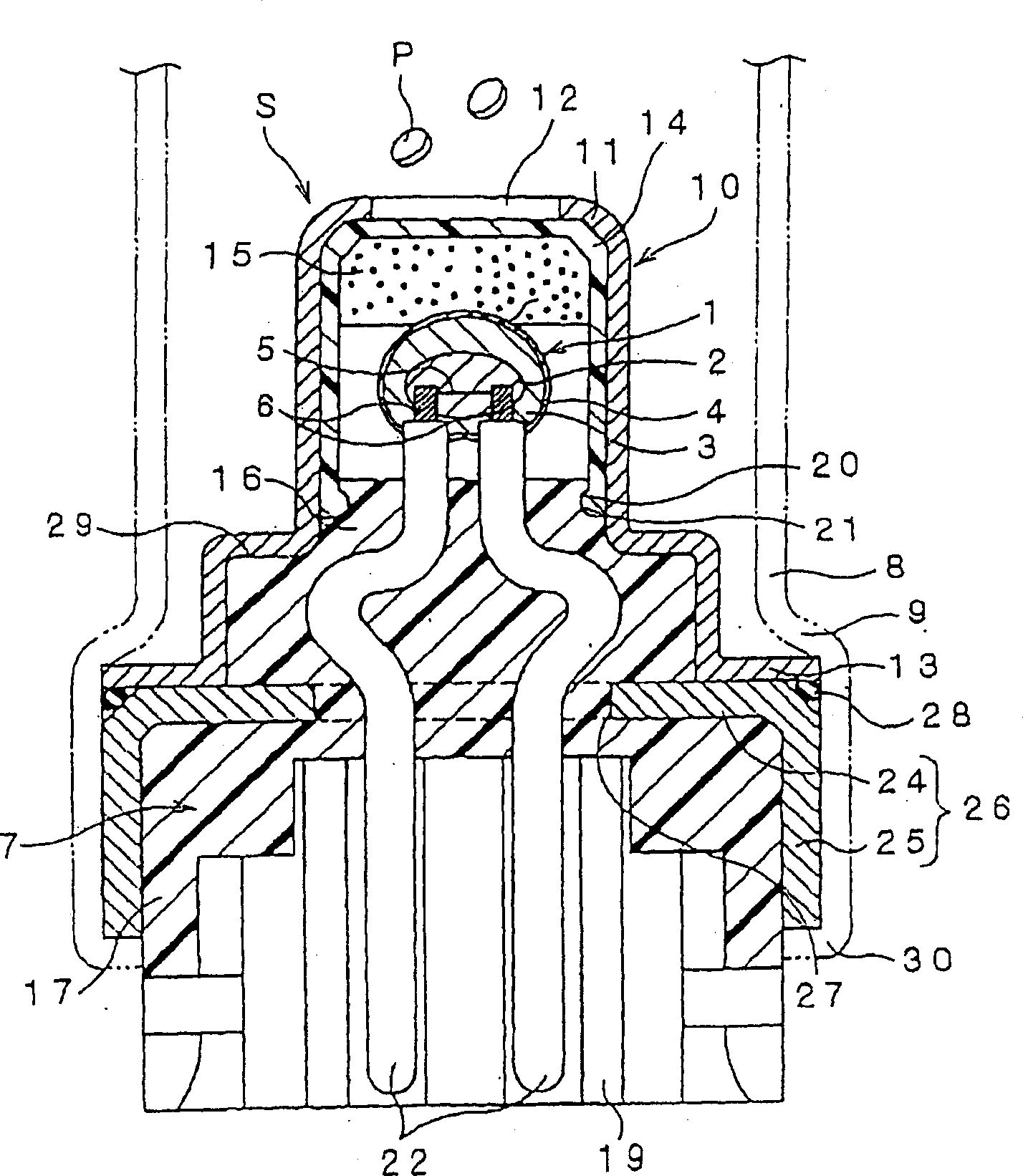

Gas generant

InactiveUS6073962APedestrian/occupant safety arrangementInorganic oxygen-halogen salt explosive compositionsEngineeringSodium azide

The present invention is directed to an airbag system that includes a gas generant, which is improved in the defects of gas generants using sodium azide in a practical use and has stable combustion capability. A molecular compound comprising (a) a gas generant component, (b) an oxidant component and (c) a reaction accelerator component, preferably represented by the composition formula (I).M.mX.nY(I)is disclosed

Owner:DAICEL CHEM IND LTD

Formula of gunpowder for timing firing cable of display shell

InactiveCN102249824ASafe storagePromote safe productionInorganic oxygen-halogen salt explosive compositionsNon-explosive/non-thermic compositionsPotassium nitrateCombustion

The invention relates to a formula of gunpowder for a timing firing cable of a display shell. According to the invention, because in the formula provided by the invention, potassium perchlorate is used as a main component, thereby completely avoiding the use of a high-risk potassium nitrate product and effectively reducing the generation of risk accidents caused by a firing cable; barium nitrate in the components has combustion and speed regulation effects, so that the combustion speed of the firing cable meets the timing ignition requirement of the display shell, thereby effectively achieving the timing effect; and the combustion color of the firing cable is golden or silvery through using larch carbon powder, a yellow light agent or titanium sponge in the components.

Owner:徐敏

Sulfur-free propellant powder

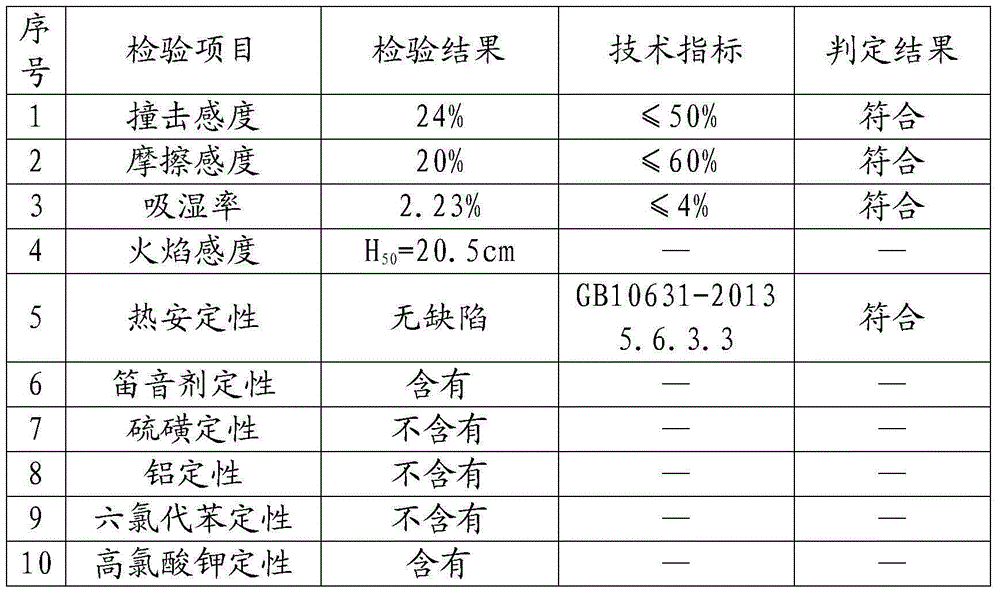

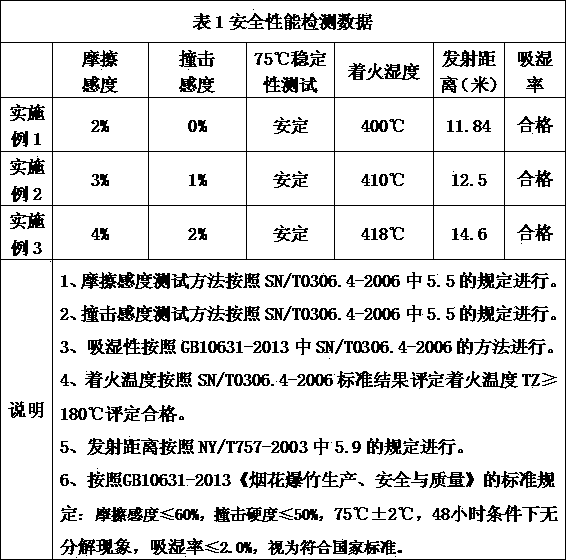

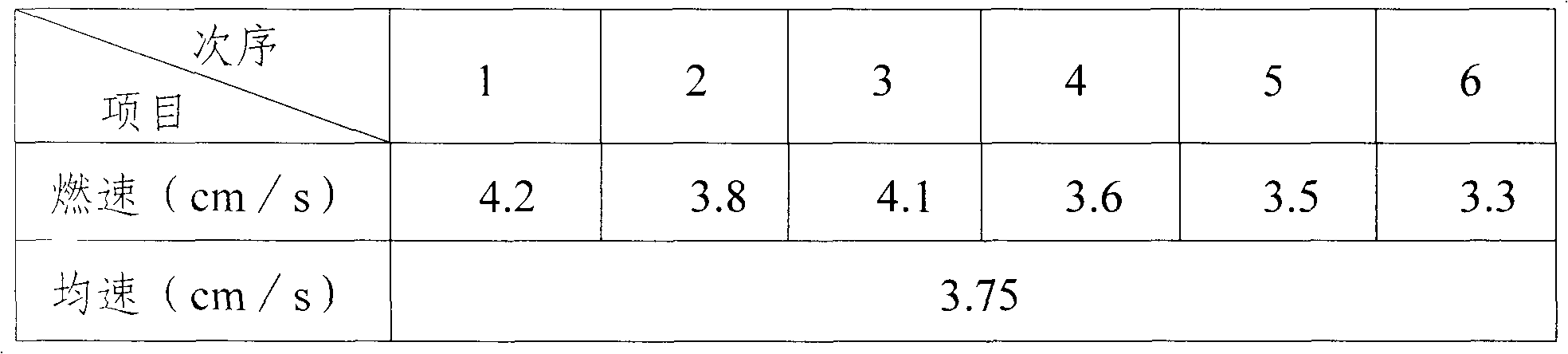

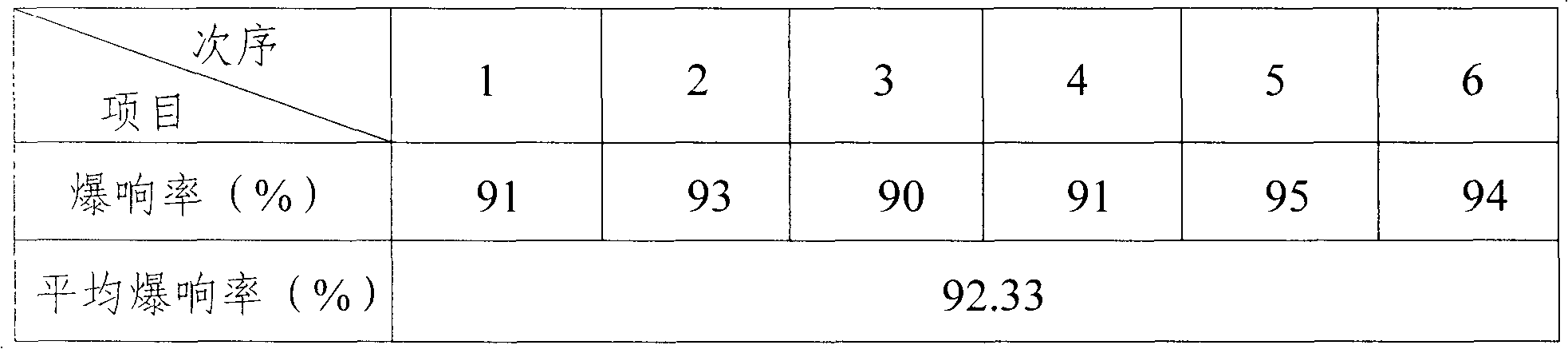

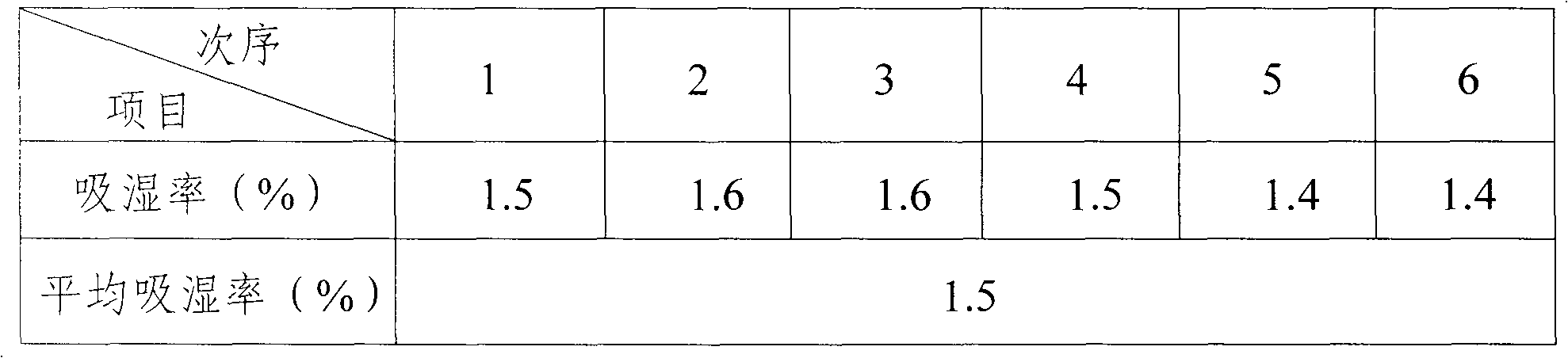

InactiveCN105016933ALow moisture absorptionGood storage stabilityInorganic oxygen-halogen salt explosive compositionsFireworksPerformance index

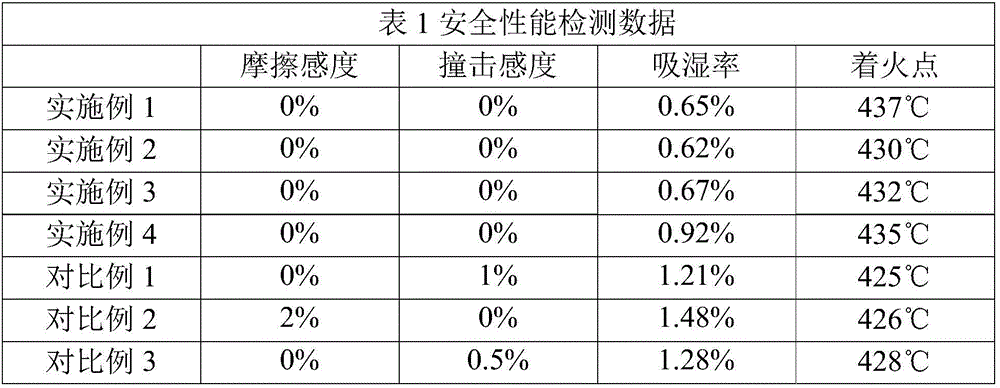

The invention discloses sulfur-free propellant powder composed of the following components in parts by weight: 34-36 parts of potassium perchlorate, 24-26 parts of carbon powder, 7-9 parts of calcium stearate, 4-6 parts of phenolic resin, 14-16 parts of hydroxyethyl cellulose and 16-18 parts of polytetrafluoroethylene. The propellant powder contains no sulfur components so that environment pollution caused by sulfur dioxide and sulfide is eliminated when fireworks are displayed; no restricted articles are contained, so that the environment-friendly property is greatly improved; the emission performance is better than that of the traditional black powder under the same working condition; all safety performance indexes such as shock sensitivity and friction sensitivity are excellent, so that potential safety hazards are fundamentally reduced; and the propellant powder is low in moisture rate, favorable in storage stability and capable of overcoming the defect that the black powder easily absorbs moisture.

Owner:江西省东安新材料有限公司

Environment-friendly sulfur-free propellant formula

InactiveCN103626612AImprove performanceNot susceptible to moistureInorganic oxygen-halogen salt explosive compositionsPerchlorate saltProcess engineering

Owner:湖南明义烟花集团有限公司

Sulfur-free fountain-type firework drug

InactiveCN103224434AImprove harmImprove pollutionInorganic oxygen-halogen salt explosive compositionsDrugSulfur dioxide

The present invention relates to a sulfur-free fountain-type firework drug, which refers to two firework drugs in fountain-type products, wherein the two firework drugs comprise effect bright star and black powder, the effect bright star is divided into color effect bright star and sound effect bright star, the color effect bright star comprises red color effect bright star, yellow color effect bright star, blue color effect bright star, green color effect bright star, white color effect bright star and purple color effect bright star, and the effect bright star and the black powder are prepared from drug components according to a certain weight ratio. The sulfur-free fountain-type firework drug has characteristics of high melting point, low mechanical sensitivity, and good safety, does not adopt sulphur, and is prepared by using the components according to a certain weight ratio to eliminate the sulphur substance so as to overcome defects of low melting point of the sulphur and easy accident occurrence, and substantially improve environment pollution and harm on human health due to sulphur contained in the original fountain-type firework drug and sulfur dioxide gas generated after igniting.

Owner:醴陵神马花炮有限公司

Sulfur-free firework propellant

InactiveCN103739412AReduce pollutionReduce manufacturing costInorganic oxygen-halogen salt explosive compositionsPyrotechnic compositionPharmaceutical drug

The invention relates to a pyrotechnic composition, and especially relates to a sulfur-free firework propellant. The sulfur-free firework propellant is composed of 60-75 parts of potassium perchlorate, 10-20 parts of charcoal, 10-20 parts of potassium biphthalate and 5-10 parts of resin. Compared with the prior art, the sulfur-free firework propellant has the following advantages that 1)while combusting, the combustion products is potassium chloride, carbon dioxide and water, nitrogen, sulfur and harmful forbidden drugs are not contained, atmosphere pollution is greatly reduced, and environmental protection performance is provided; 2)safety performance can satisfy the national standard requirement; 3)moisture resistance is good, the medicament is stable, long-term (in five years) storage performance is normal; and 4) economy is good, and the popularization and application are easy.

Owner:JIANGXI PROVINCE LIDU FIREWORKS

Safety firecracker compound containing perchlorate

InactiveCN1528719AGood chemical stabilityIncrease the explosion temperatureInorganic oxygen-halogen salt explosive compositionsFireworksFirecrackerSulfur

The invention relates to a perchlorate-containing safe firecracker powder, combined of perchlorate, aluminum powder, sulfur and perlite powder, where the perchlorate is potassium perchlorate, barium perchlorate, ammonium perchlorate, or their optional combination. If adopting a perchlorate, first choose potassium perchlorate. Its formula is simple, its components are little, its chemical stability and safety are good, without potassium chlorate. It has advantages of low mechanical sensibility and high safety, good bang rate and sound-level value, etc. It is an ideal safe firecracker powder.

Owner:湖南协力房地产开发(集团)有限公司

Novel moisture absorption flame agent for artificial influencing weather and productive process

InactiveCN1358694AGood hygroscopicityIdeal artificial rainfallFog dispersionInorganic oxygen-halogen salt explosive compositionsAdhesiveAluminium powder

The present invention relates to a moisture-absorbing flame agent for weather modification. It is made up perchlorate, halide, magnesium powder, aluminium powder, carbonate and adhesive according to a certain weight portion ratio. The number of nuclear particles produced by 1g of said flame agent is equal to number of particles produced by one ton-tens tons of salt powder or urea. After having been covered said invented product has no moisture-absorbing denaturalization problem. According to the different requirements for weather modification its formula also can be regulated, so that it is an ideal catalyst for artificial rain, hail suppression and antifogging.

Owner:汪学林 +3

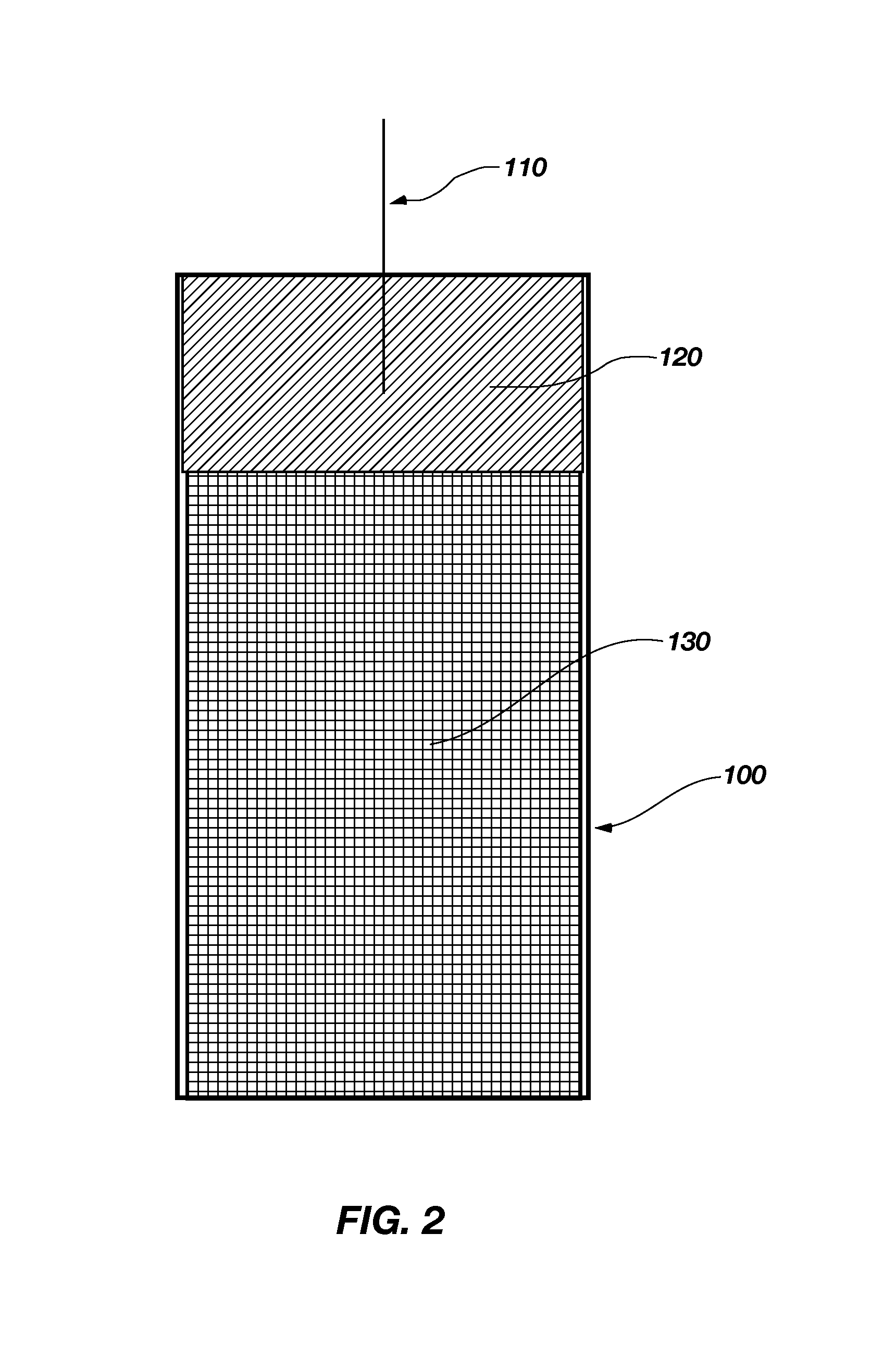

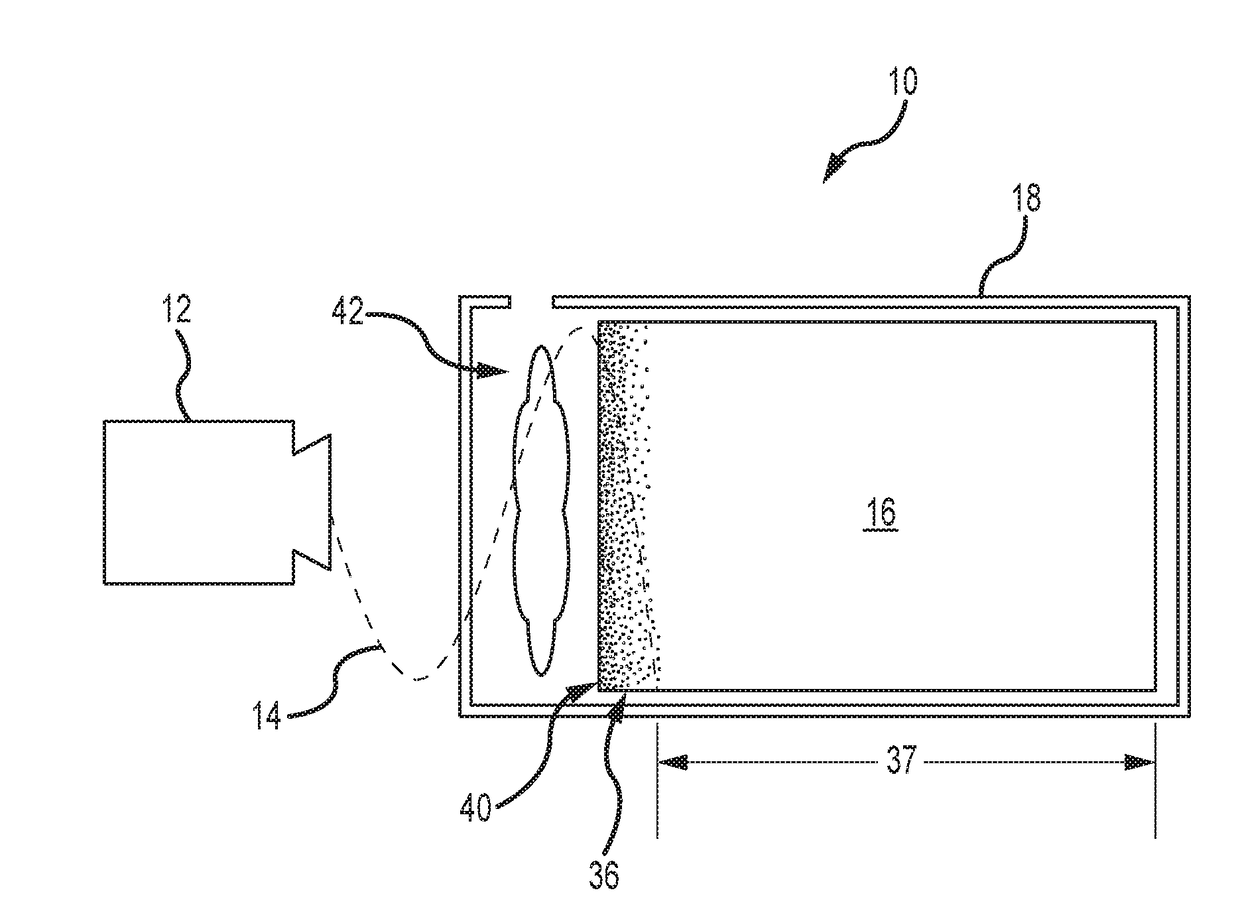

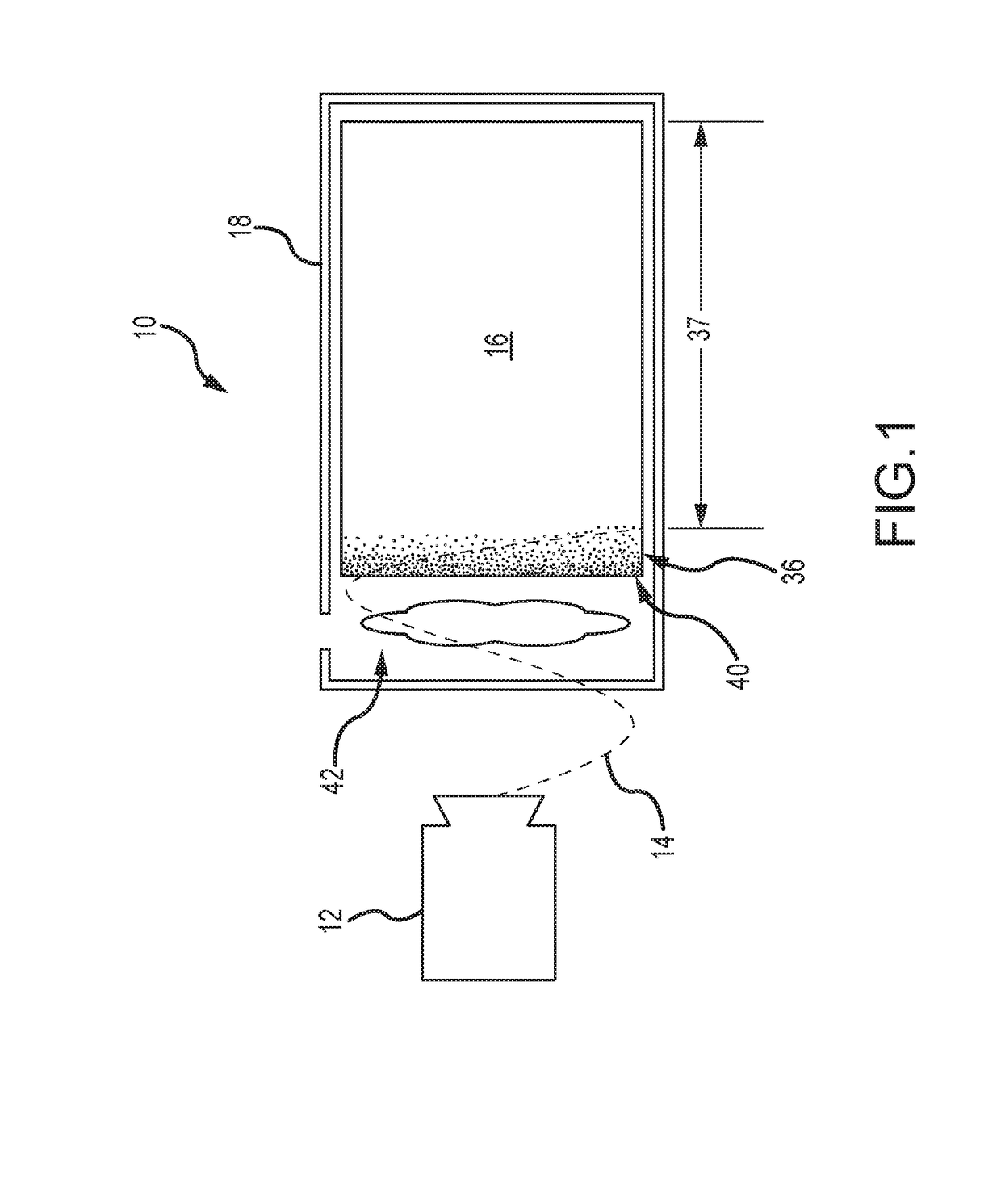

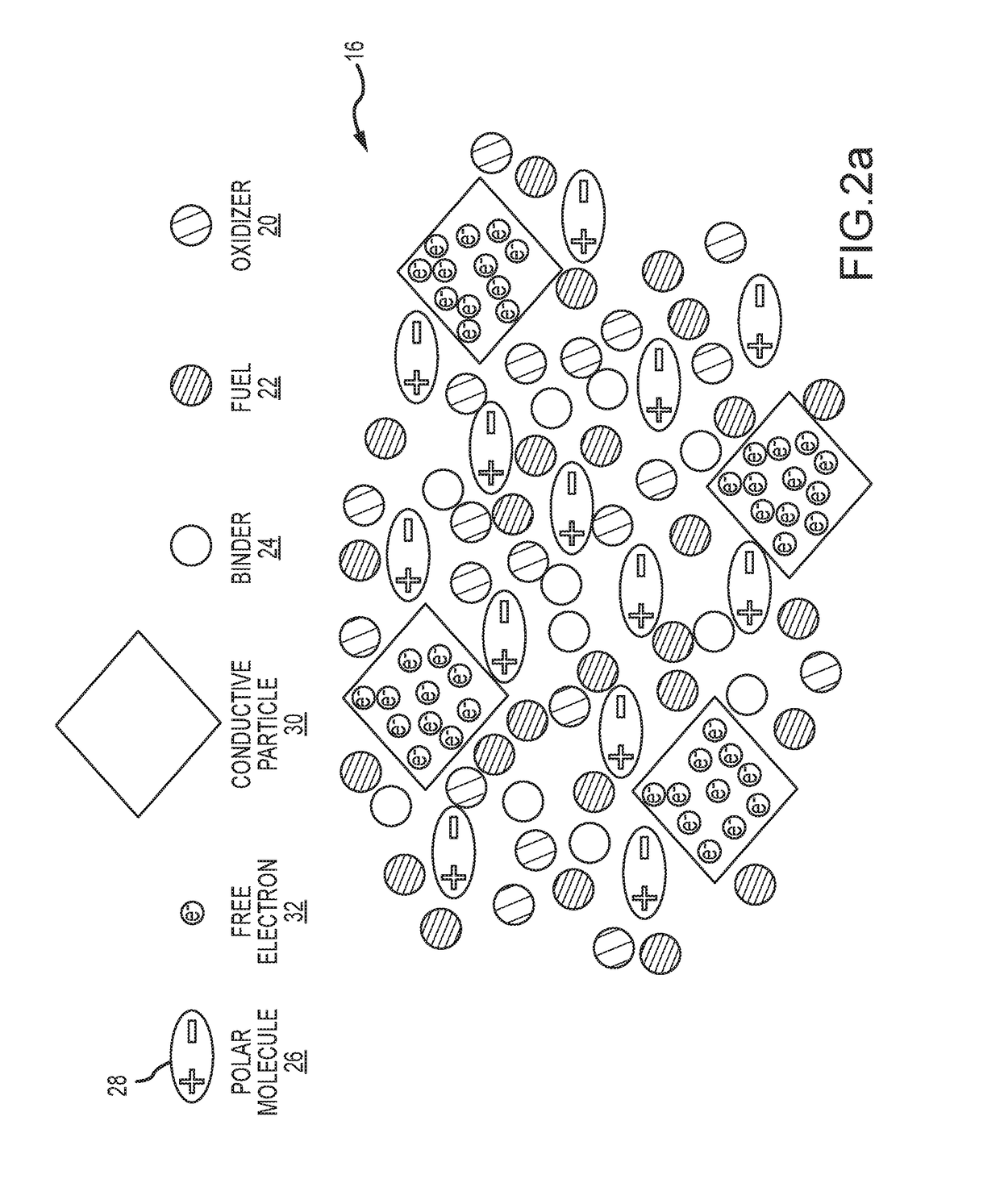

Microwave ignition of electrically operated propellants

ActiveUS20180051657A1Efficient couplingInorganic oxygen-halogen salt explosive compositionsRocket engine plantsUltrasound attenuationPower flow

Microwave energy is used to ignite and control the ignition of electrically operated propellant to produce high-pressure gas. The propellant includes conductive particles that act as a free source of electrons. Incoming microwave energy accumulates electric charge in an attenuation zone, which is discharged in the form of dielectric breakdowns to create local randomly oriented currents. The propellant also includes polar molecules. The polar molecules in the attenuation zone absorb microwave energy causing the molecules to rapidly vibrate thereby increasing the temperature of the propellant. The increase in temperature and the local current densities together establish an ignition condition to ignite and sustain ignition of an ignition surface of the attenuation zone as the zone regresses without igniting the remaining bulk of the propellant.

Owner:RAYTHEON CO

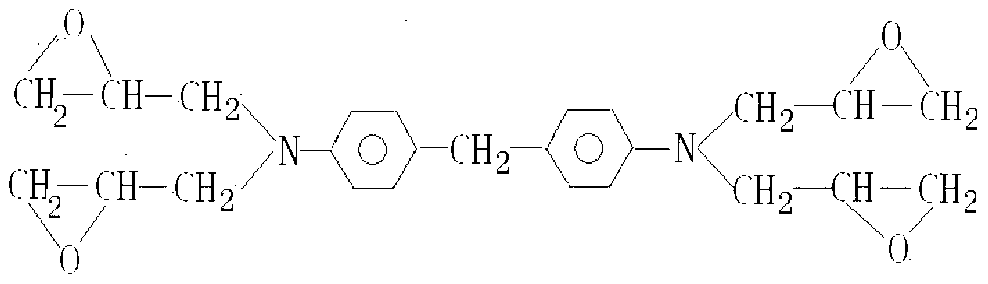

Auto-igniting pyrotechnic booster composition

InactiveUS20050161135A1Eliminate needSimple designInorganic oxygen-halogen salt explosive compositionsPressure gas generationOrganic acidNitrogen

The present invention generally relates to auto-ignition / booster compositions for inflators of occupant restraint systems, for example. An exemplary auto-ignition composition in accordance with the present invention includes a metal chlorate, an auto-ignition fuel selected from the group including sugars and orgainic acids, and a nitrogen-containing secondary fuel.

Owner:AUTOMOTIVE SYST LAB

Propellant for fireworks and crackers

InactiveCN101913971ALow moisture absorptionLow hygroscopicityInorganic oxygen-halogen salt explosive compositionsFirecrackerFireworks

The invention discloses a propellant for fireworks and crackers. The propellant for the fireworks and crackers is prepared from potassium perchlorate, boony carbon, sulphur, an additive, reinforcing agent powder and water according to a certain mass percentage, wherein the additive is magnesium carbonate; and the reinforcing agent powder is sticky rice powder or flour. A preparation process of the propellant for the fireworks and crackers comprises the following steps of: I, mixing the potassium perchlorate, the boony carbon, the sulphur and the additive magnesium carbonate uniformly according to the mass percentage by using a propellant-mixing machine to obtain mixed explosive powder; II, adding the reinforcing agent powder and the water in the mixed explosive powder obtained by the step I, and stirring the mixture and pressing the mixture into an explosive cake; and III, pelleting the explosive cake obtained by the step II, drying the particles in the air, and polishing and screening the particles to prepare the propellant for the fireworks and crackers. The propellant for the fireworks and crackers has the advantages of low hygroscopicity, stable properties, small using amount of the explosive, long quality guarantee period, simple preparation process, low production cost and safe and reliable use and preparation.

Owner:陕西省蒲城县新型花炮技术推广中心

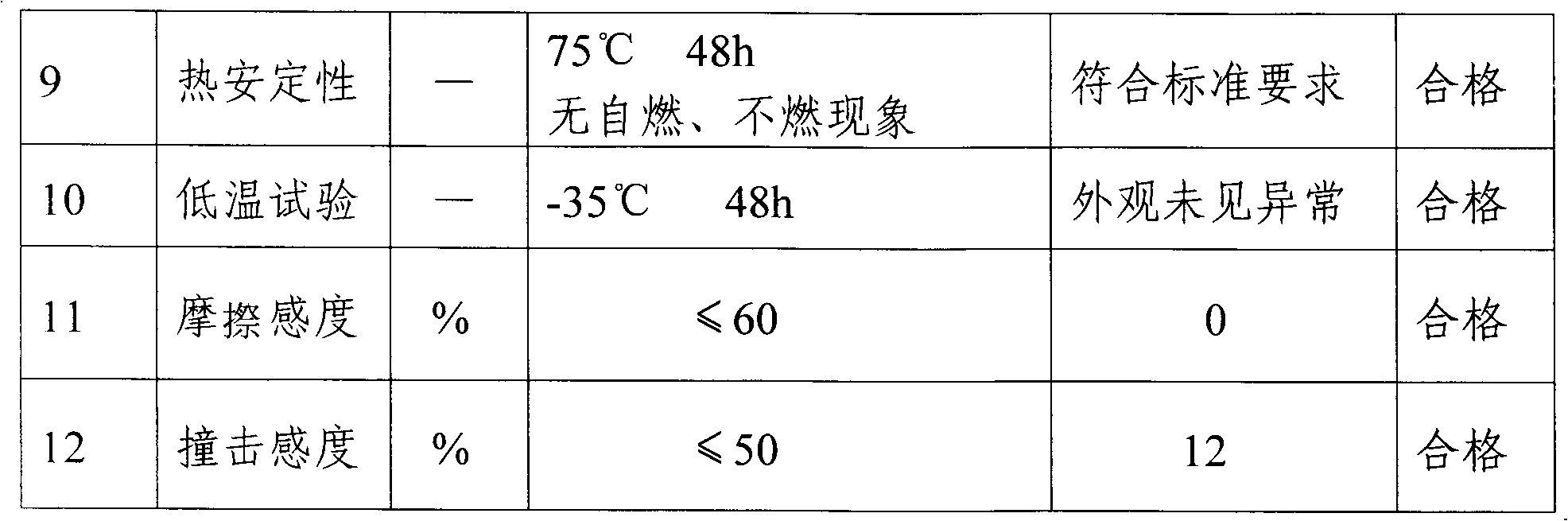

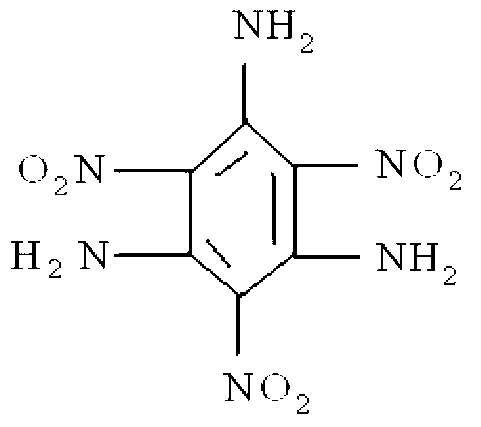

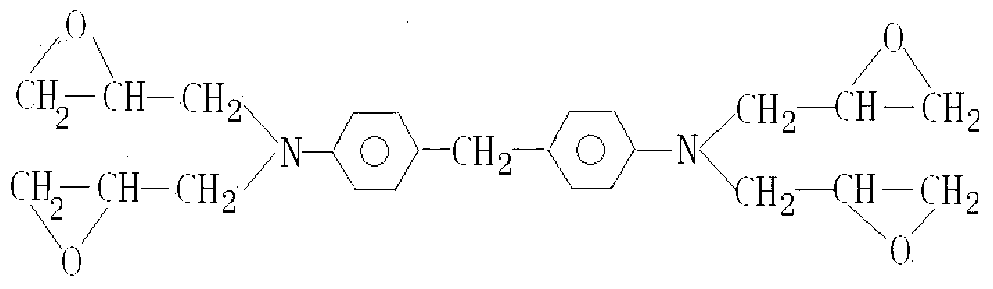

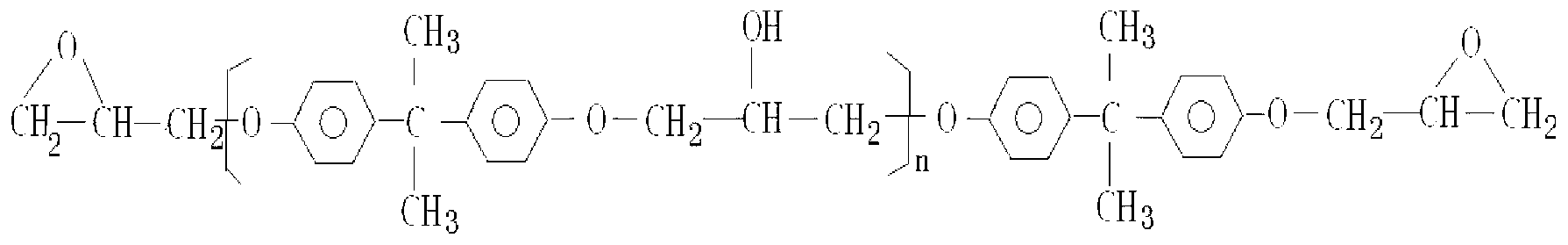

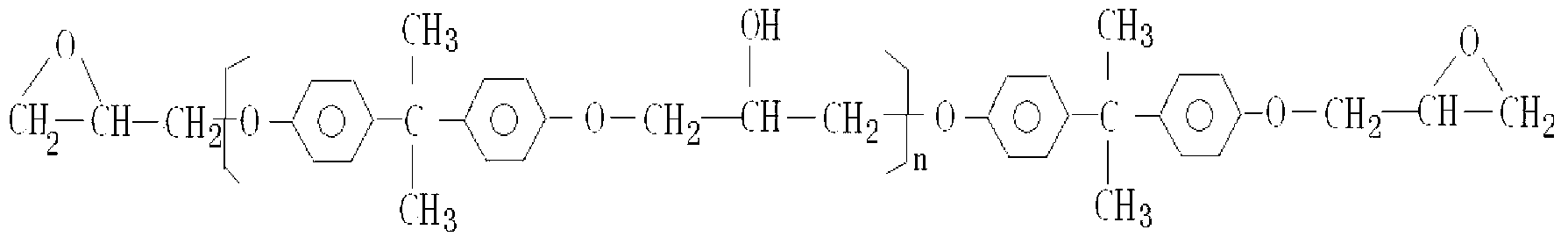

High-temperature-resistant solid propellant for deep oil-gas well and preparation method thereof

InactiveCN103304351AImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsSpontaneous combustion4-Methylimidazole

The invention provides a high-temperature-resistant solid propellant for a deep oil-gas well. The solid propellant is prepared from the following raw materials in percentage by weight: 33.00-58.00% of potassium perchlorate, 8.00-33.00% of TATB, 10.00-32.37% of high-temperature-resistant epoxy resin, 0-11.79% of bisphenol A epoxy resin, 0-12.77% of epoxy-resin reactive diluent, 0.03% of defoamer and 0.98-1.60% of 2-ethyl-4-methylimidazole, wherein the sum of the weight percent of the raw materials is 100%; and the raw materials of the propellant are subjected to premixing, remixing and molding so as to prepare a finished product. When the solid propellant is soaked in clean water and 3.5% brine for 24-48 hours, the loss of weight is lower than 3%, and the volume change is lower than 2%; and the temperature resisting level reaches 180 DEG C in 48 hours, and the spontaneous combustion does not occur, thus the solid propellant can be used in high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

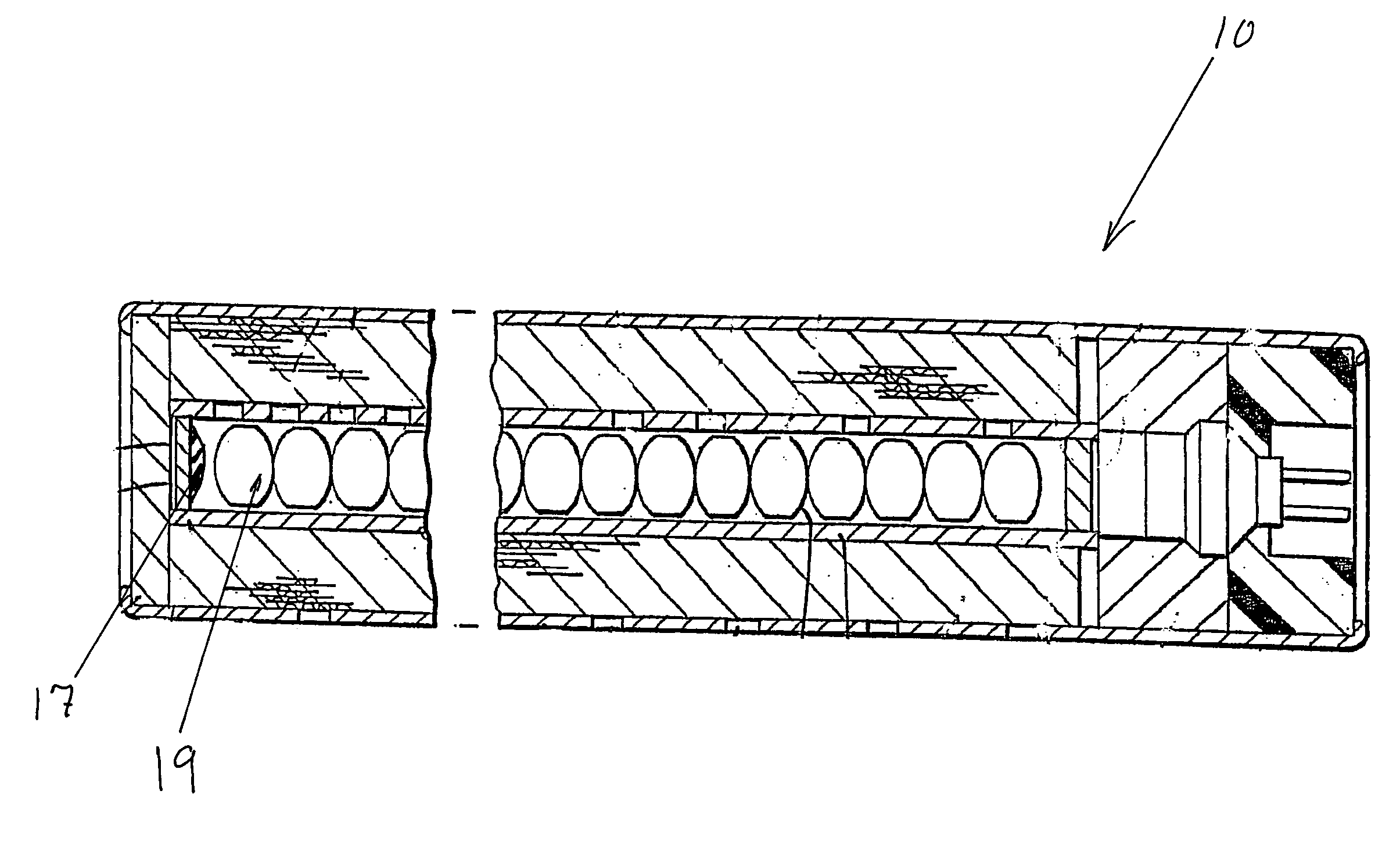

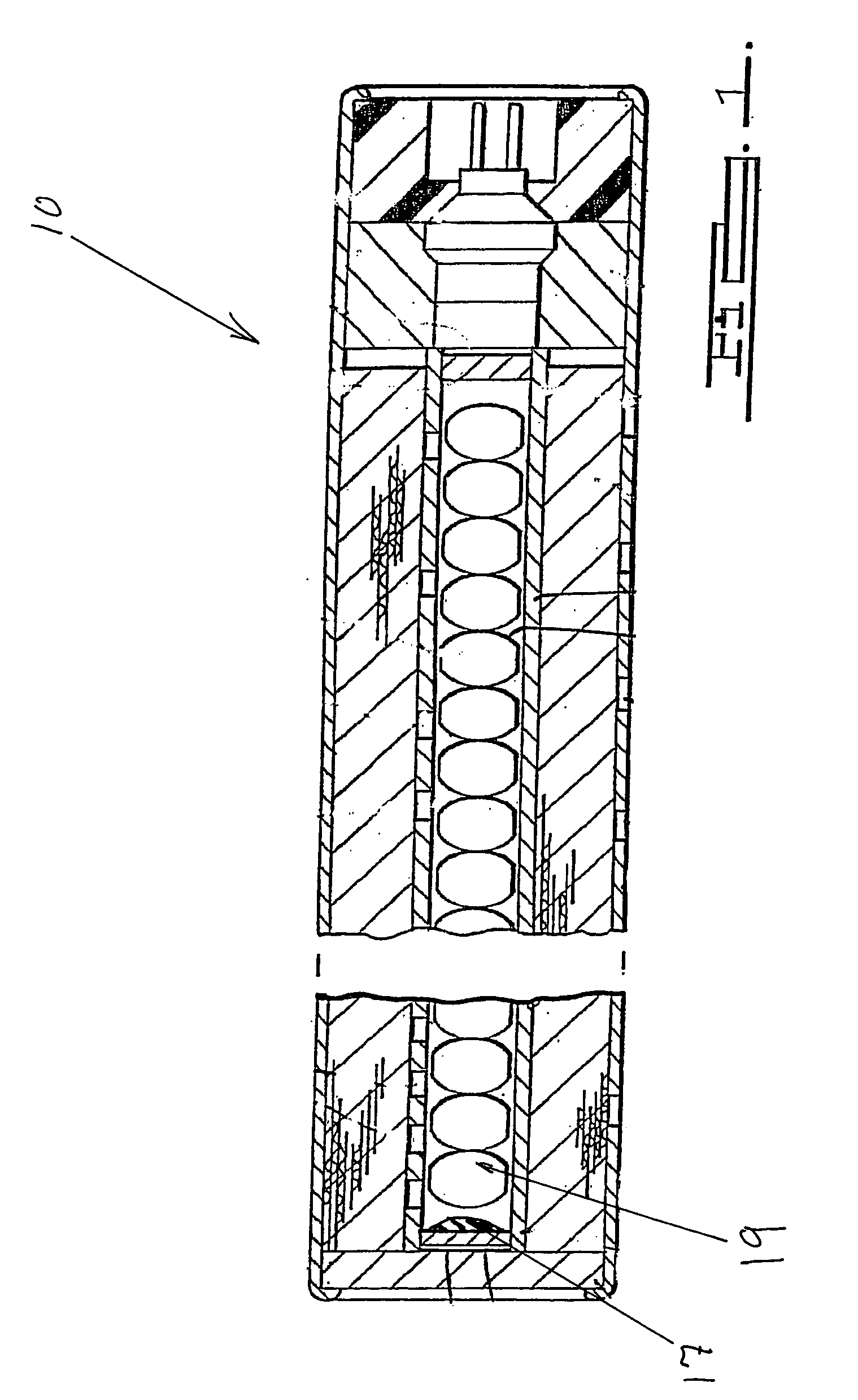

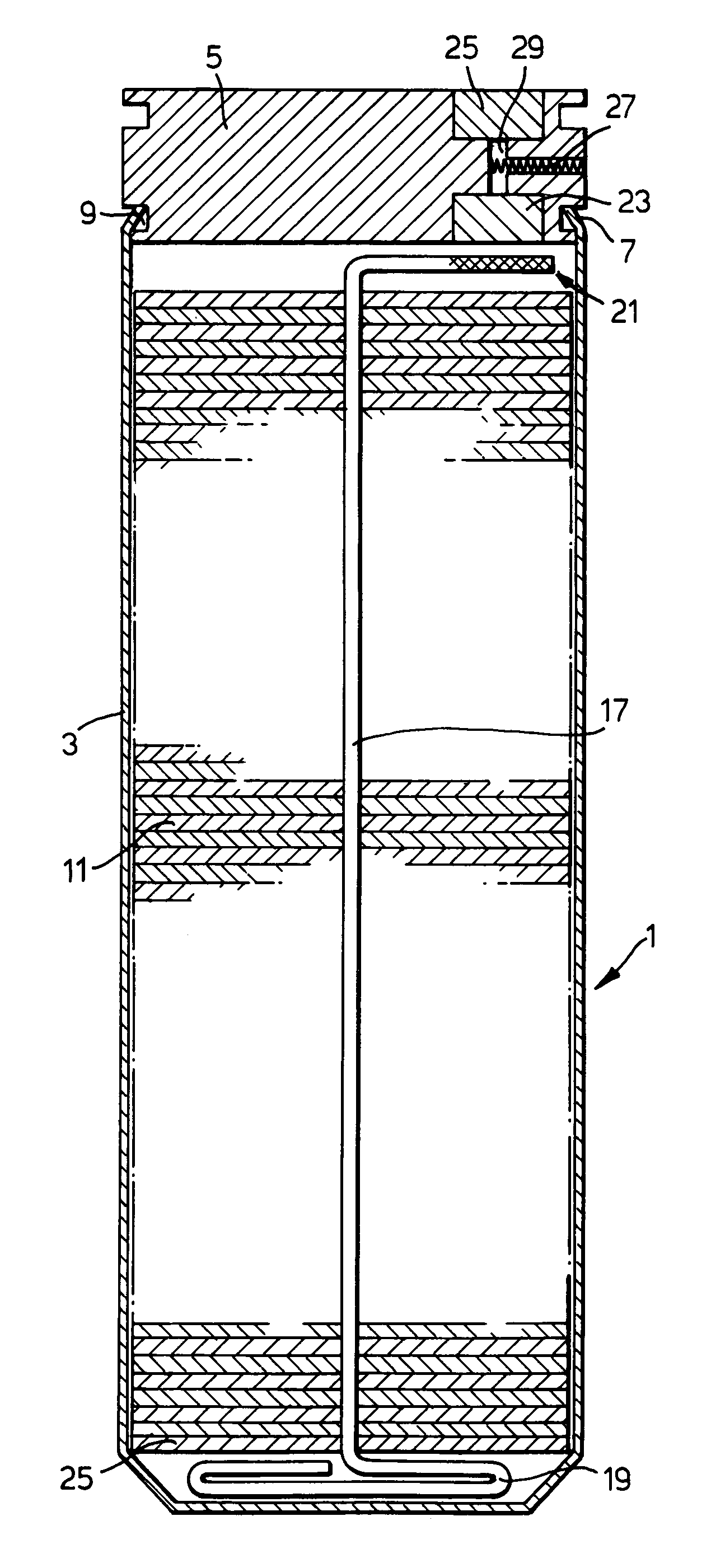

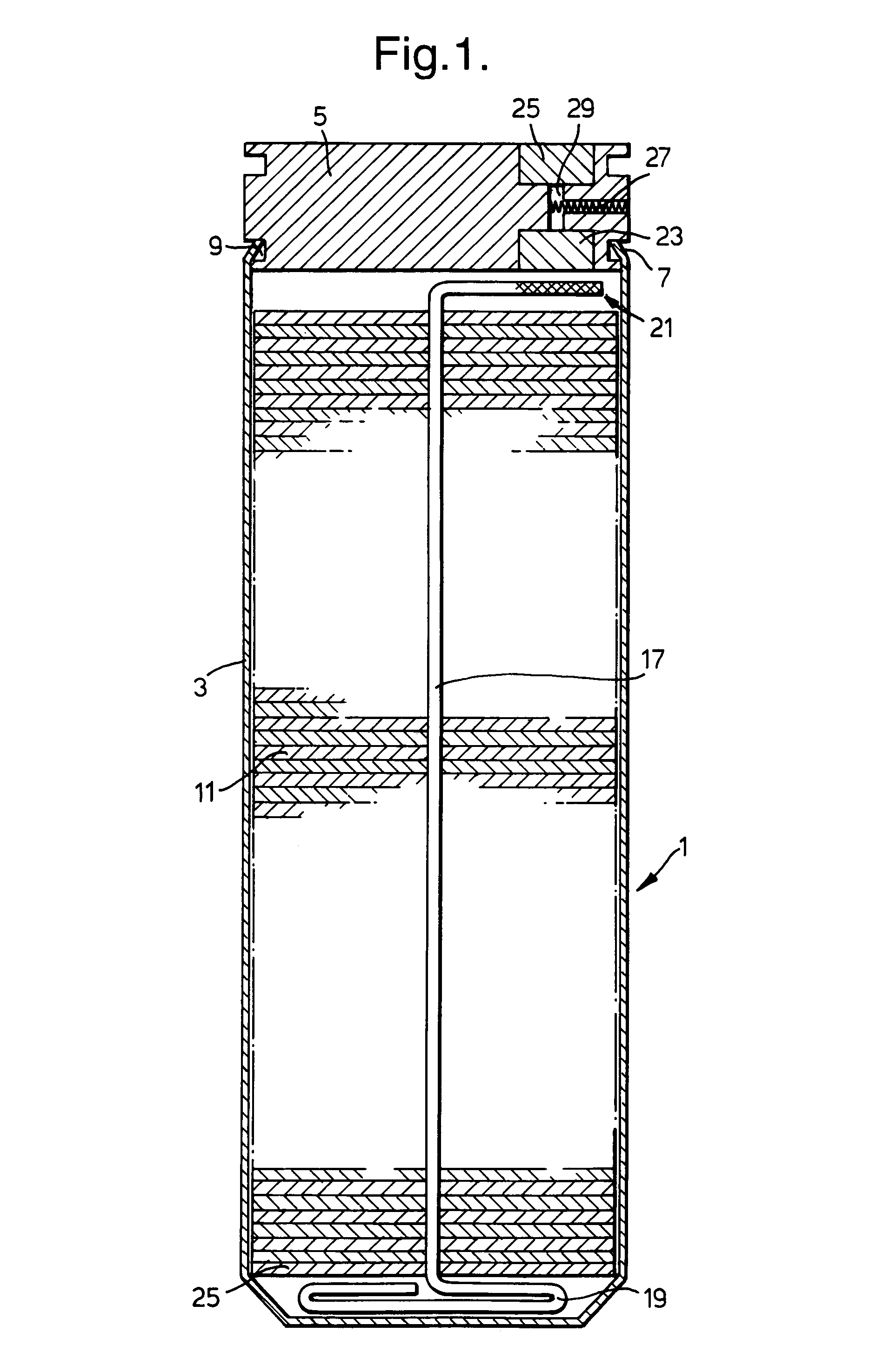

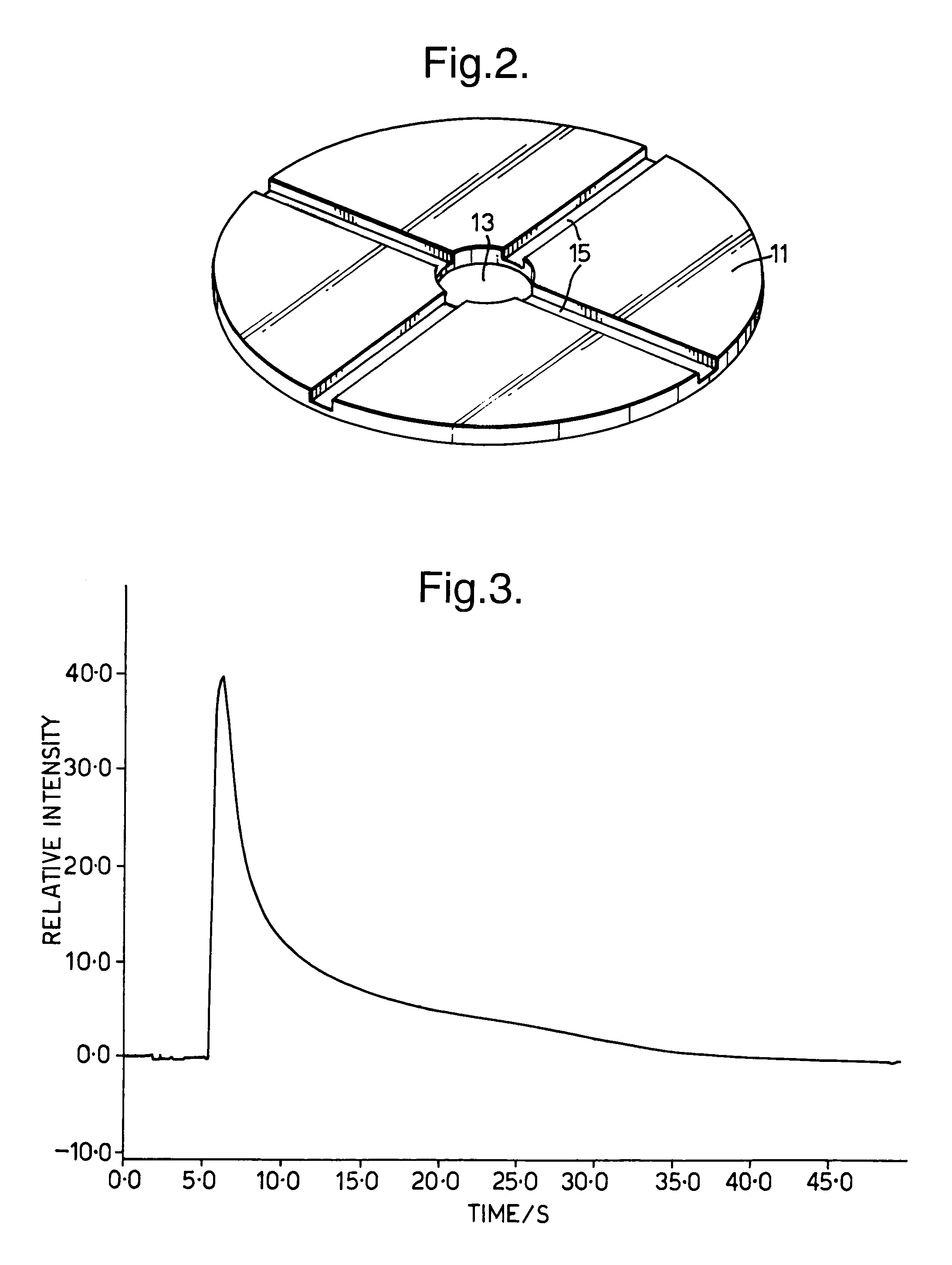

Expendable infra-red radiating means

InactiveUS7441503B1Optimization rangeEfficiently incidentAmmunition projectilesFirework flares/torchesCombustionUltraviolet

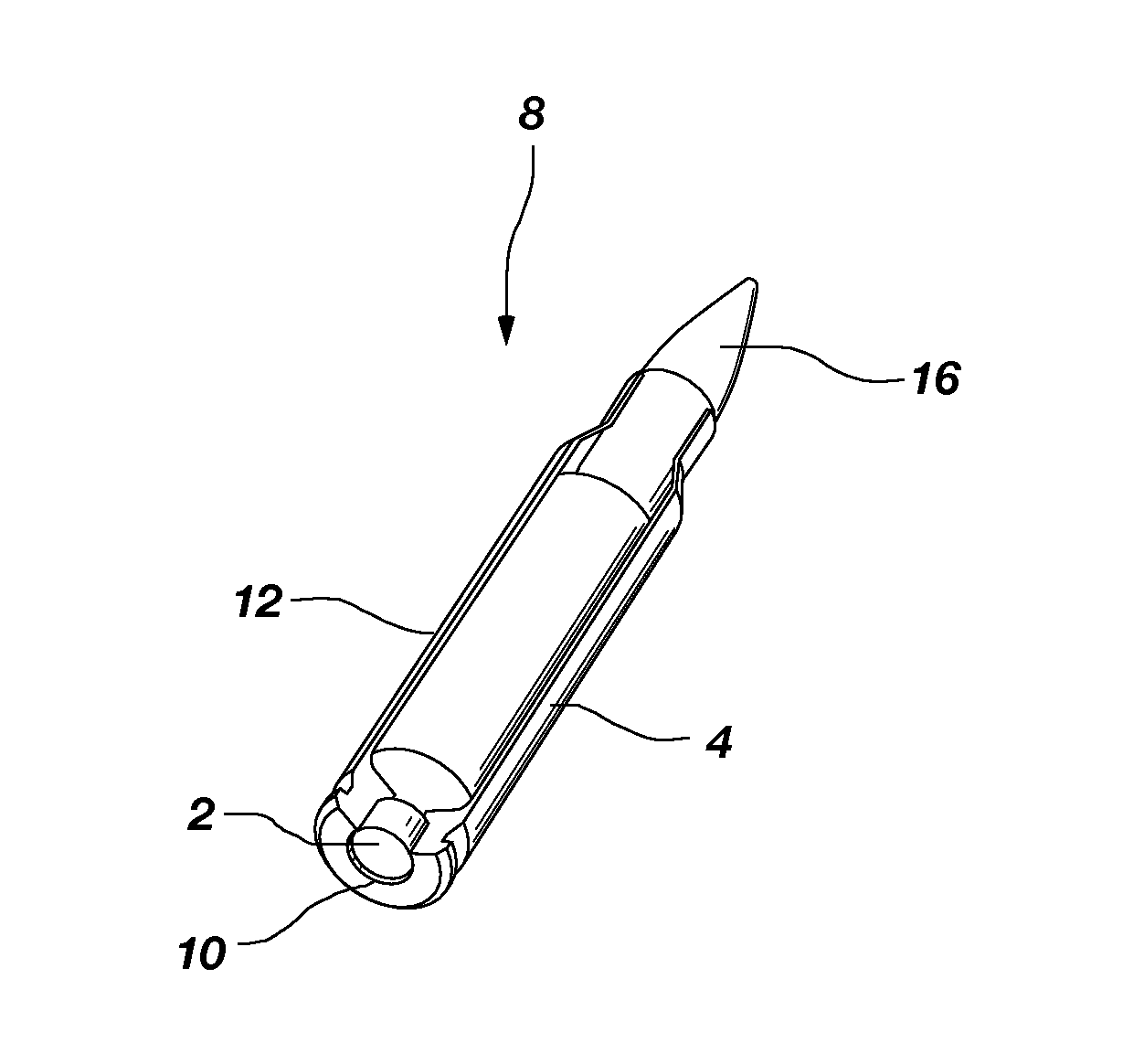

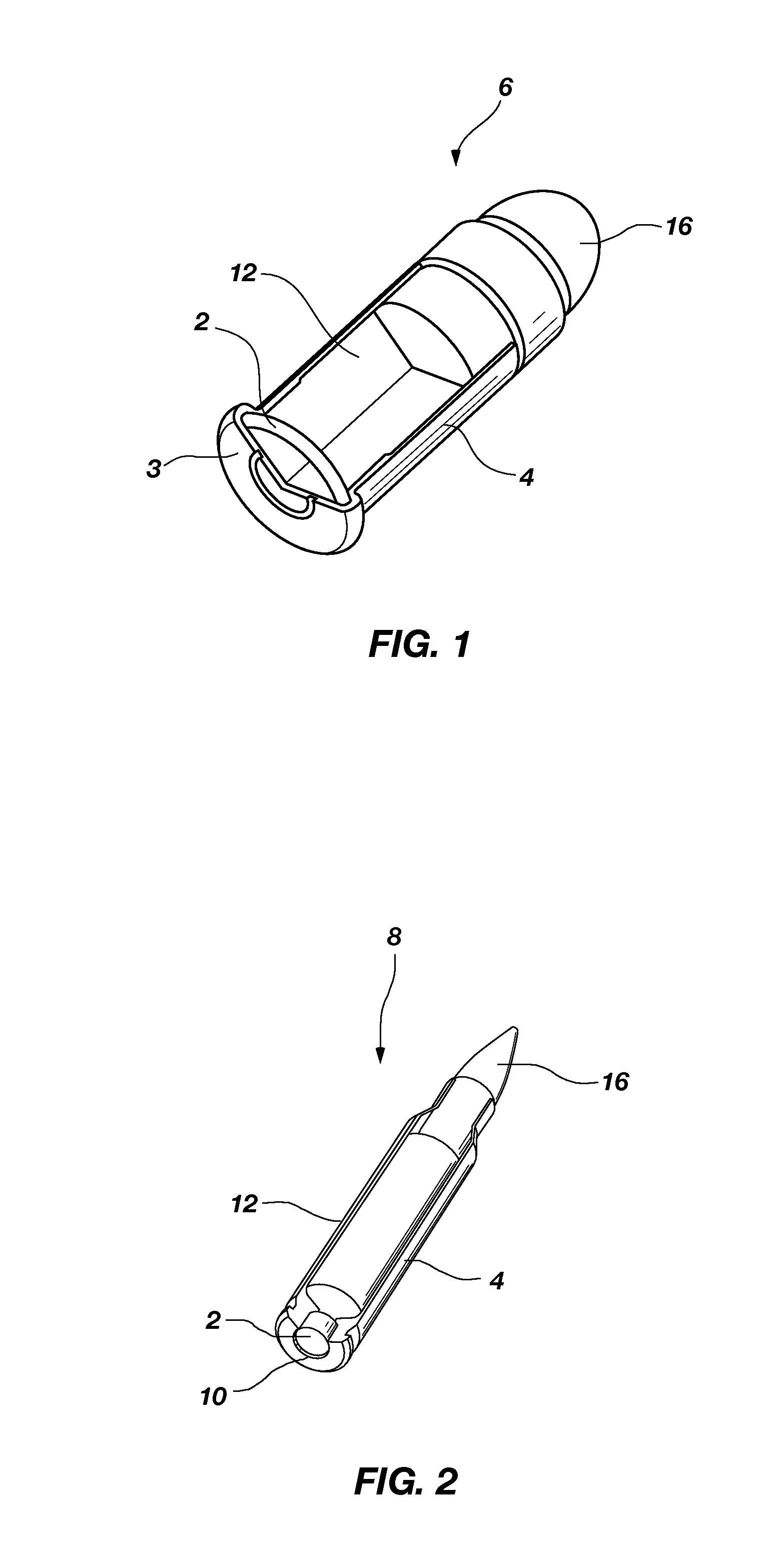

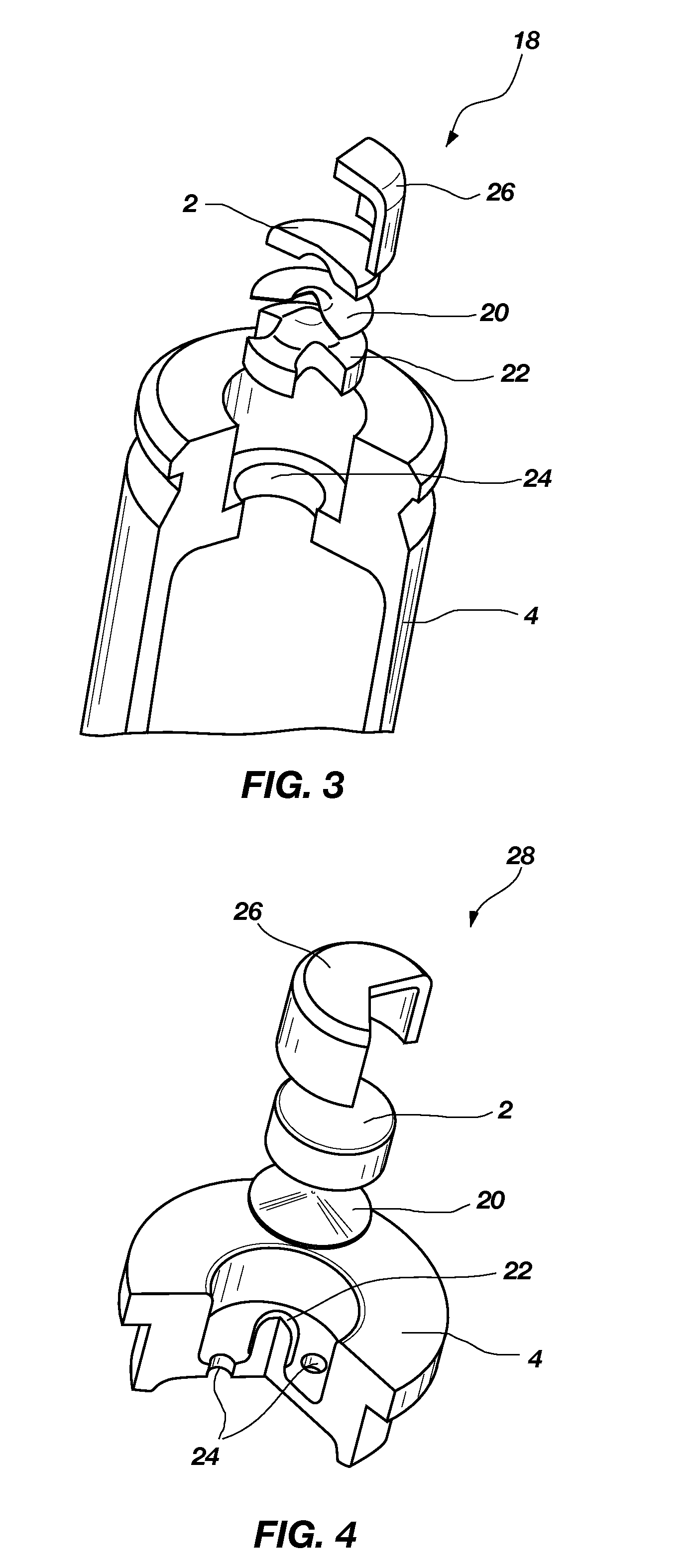

An expendable infra-red radiating means having a rupturable container 1 housing a plurality of decoy plates (11) and an ignition means (17) for igniting the decoy plates (11). Each of the decoy plates (11) comprises a composition of a metal and an oxidant capable of an exothermic combustion reaction upon ignition which produces negligible quantities of radiation in the visible or ultra-violet regions and which results, after the combustion reaction is completed, in the decoy plates (11) containing hot metal emitting infra-red radiation.

Owner:THE SEC OF STATE FOR DEFENCE IN HER BRITANNIC MAJESTYS GOVERNMENT OF THE UK OF GREAT BRITAIN & NORTHERN IRELAND

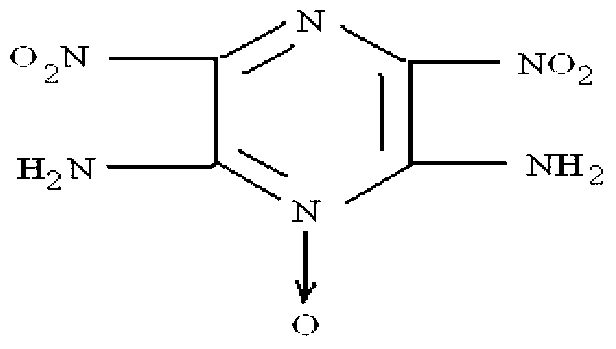

High-temperature-resistant solid propellant for deep oil-gas well and preparation method thereof

InactiveCN103304350AImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsSpontaneous combustion4-Methylimidazole

The invention provides a high-temperature-resistant solid propellant for a deep oil-gas well. The solid propellant is prepared from the following raw materials in percentage by weight: 41.00-56.00% of potassium perchlorate, 10.00-25.00% of LLM-105, 10.00-32.37% of high-temperature-resistant epoxy resin, 0-11.79% of bisphenol A epoxy resin, 0-12.77% of epoxy-resin reactive diluent, 0.03% of defoamer and 0.98-1.60% of 2-ethyl-4-methylimidazole, wherein the sum of the weight percent of the raw materials is 100%; and the raw materials of the propellant are subjected to premixing, remixing and molding so as to prepare a finished product. When the solid propellant is soaked in clean water and 3.5% brine for 24-48 hours, the loss of weight is lower than 3%, and the volume change is lower than 2%; and the temperature resisting level reaches 180 DEG C in 48 hours, and the spontaneous combustion does not occur, thus the solid propellant can be used in high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

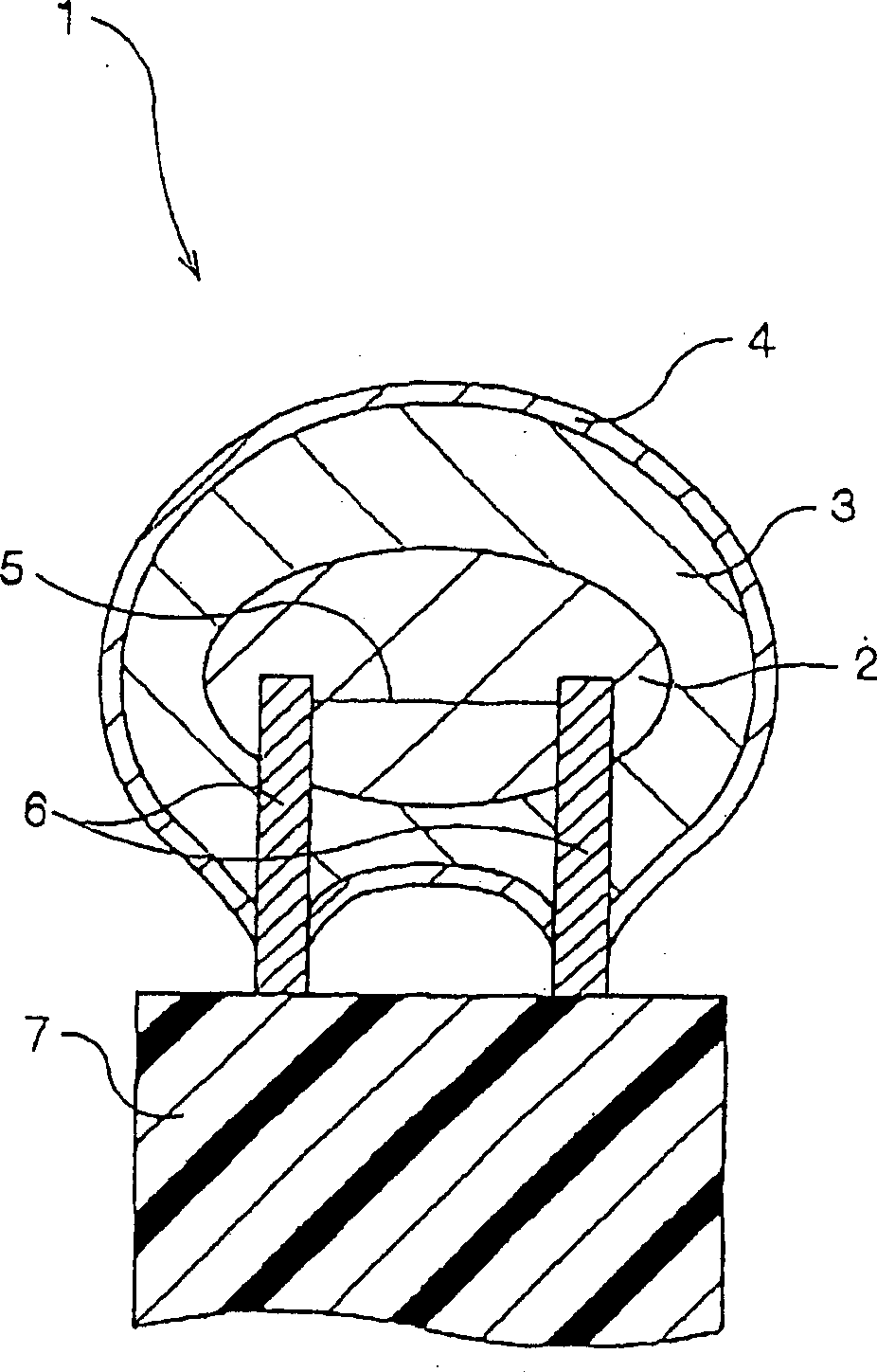

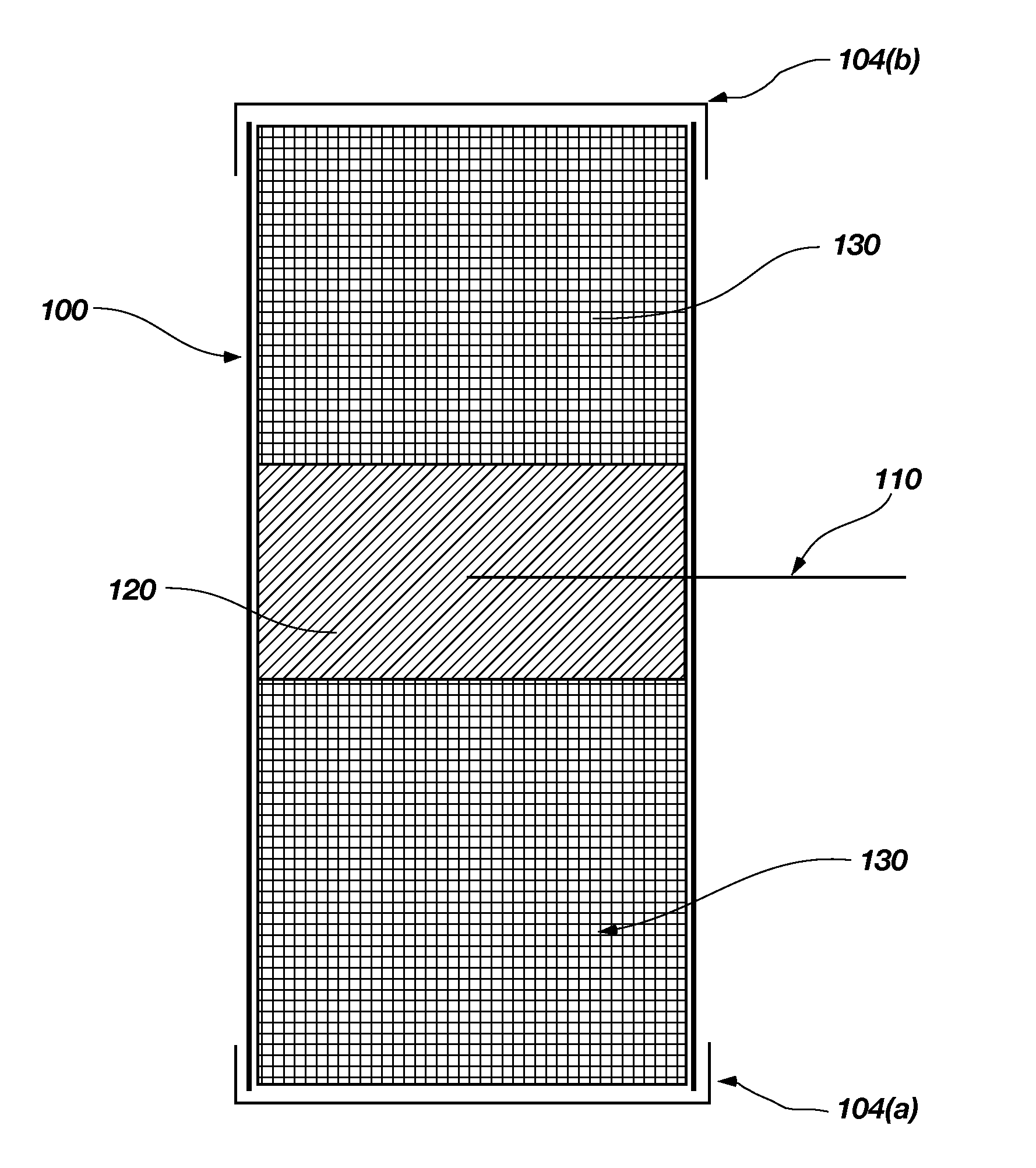

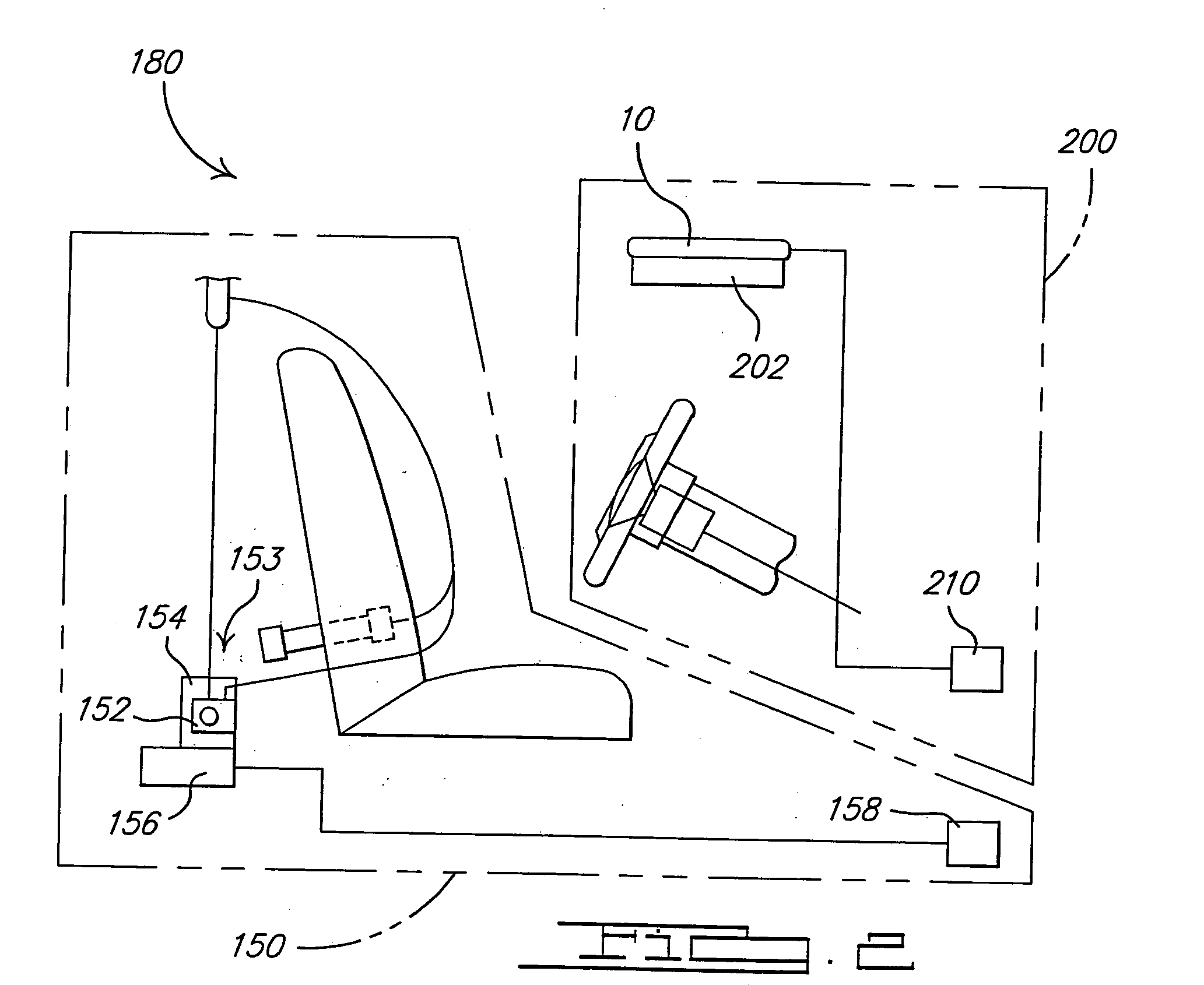

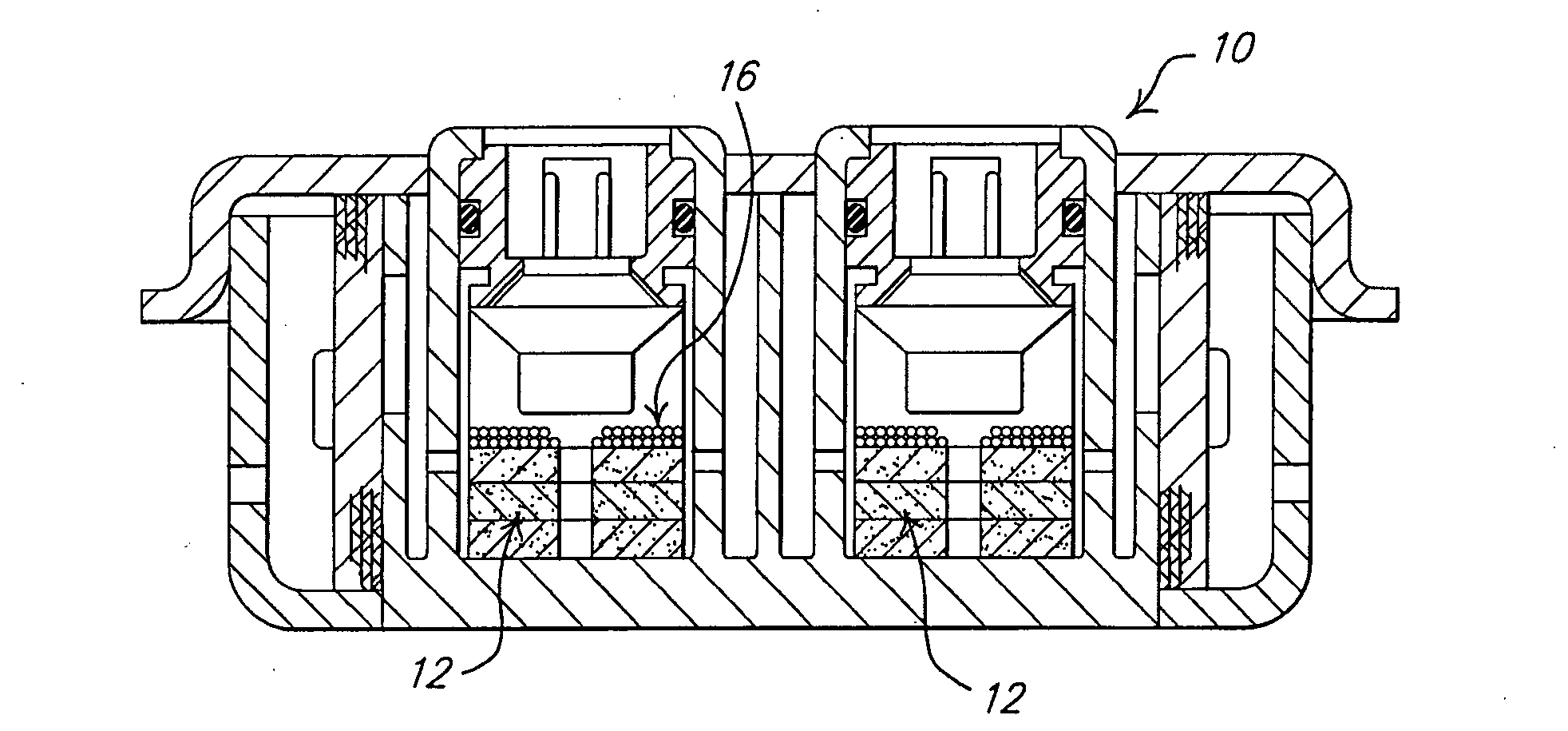

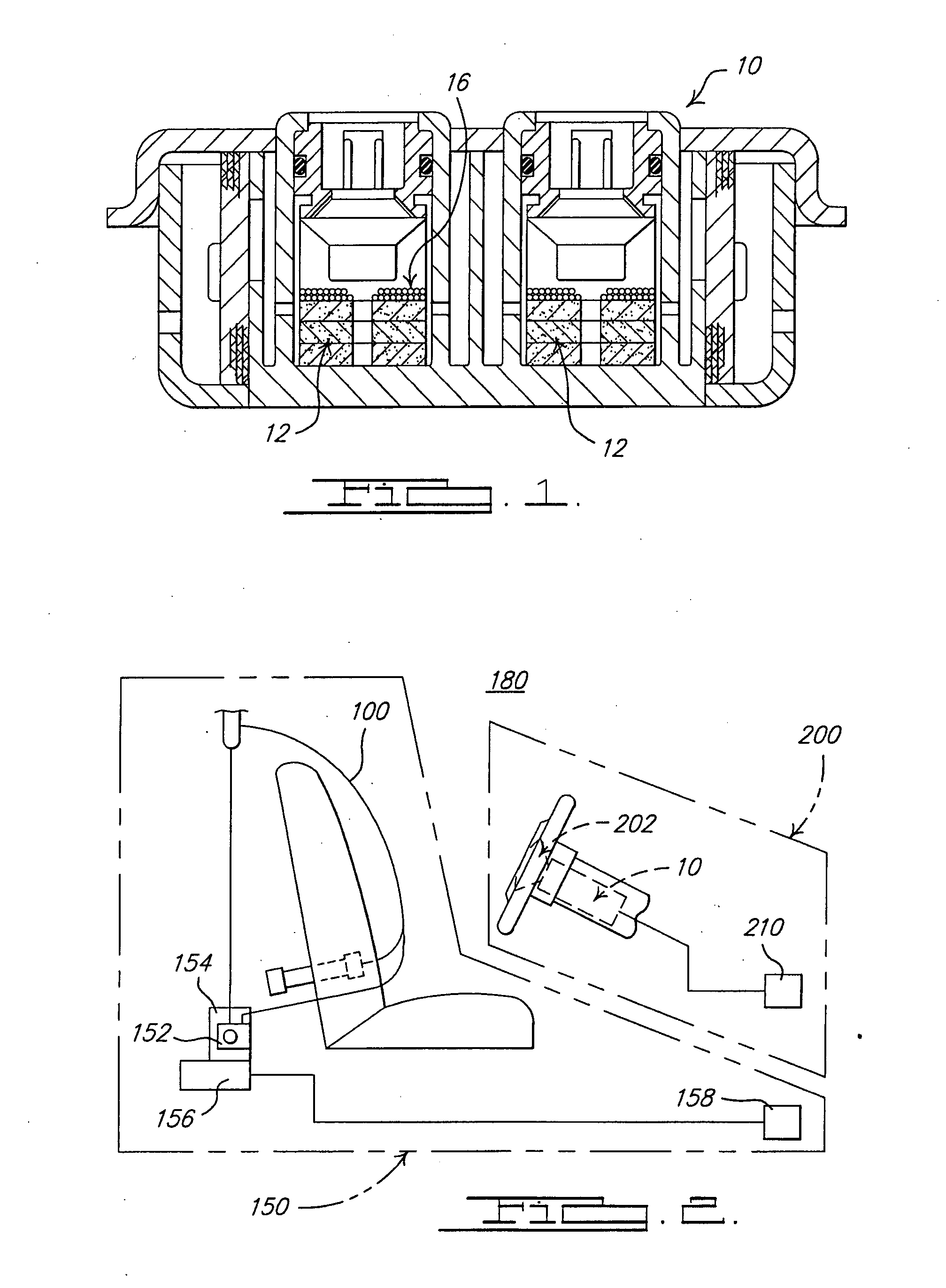

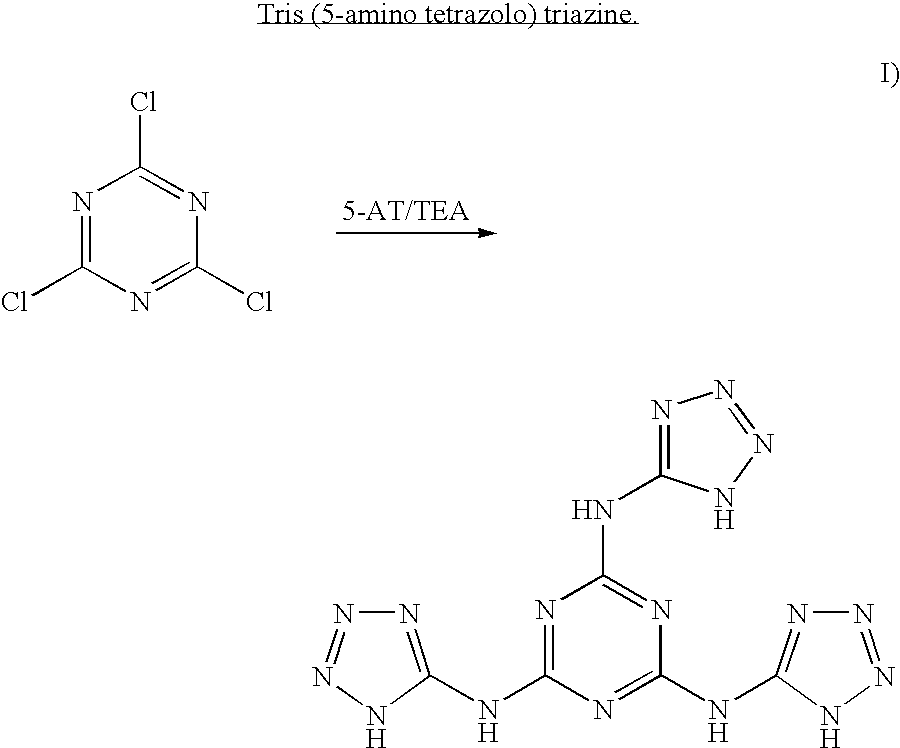

Gas generant compositions

A novel compound, tris (5-amino tetrazolo) triazine is used for example, as a gas generating fuel. A method of making the compound is also provided. A gas generating composition, containing the novel compound as a fuel, and an oxidizer is also provided. The novel compound may be contained within a gas generant composition 12, within a gas generator 10. The gas generator 10 may be contained within a gas generating system 200 such as an airbag inflator 10 or seat belt assembly 150, or more broadly within a vehicle occupant protection system 180.

Owner:JOYSON SAFETY SYST ACQUISITION LLC

Novel potassium perchlorate paper firing line for firecrackers

InactiveCN101973828ALight weightLow hygroscopicityInorganic oxygen-halogen salt explosive compositionsFusesFirecrackerPulp and paper industry

The invention discloses a novel potassium perchlorate paper firing line for firecrackers. Firing powders of the paper firing line are made of potassium perchlorate, hemp stem carbon and magnesium oxide by mass percent. The production process comprises the following steps of: uniformly mixing the hemp stem carbon with the magnesium oxide by adopting a mixing machine by mass percent, and then uniformly mixing with the potassium perchlorate to obtain the firing powders; twisting the firing powders in the step one with firing line paper into a semi-finished paper firing line by adopting a firing line twisting machine, wherein the usage of the firing powders is 0.8 catty to 1.2 catties firing powders / 1 kilometer firing lines; and starching the semi-finished paper firing line of the step 2, and air drying, cutting and pouring disks after starching to prepare the finished paper firing line. The invention has the advantages of stable performance, safe and reliable production and transport, simple production process, high burning rate, low rate of moisture absorption, low friction sensitivity and low impact sensitivity, and the performance and the selected materials are all in line with standards in China.

Owner:陕西省蒲城县新型花炮技术推广中心

Method for sensitizing microporous smokeless firework explosive

InactiveCN101844955AFiring speed is fastImprove ignition performanceNitrocellulose explosive compositionsInorganic oxygen-halogen salt explosive compositionsNon solventCellulose

The invention discloses a method for sensitizing microporous smokeless firework explosive, which comprises the following steps of: dissolving scrapped military smokeless explosive containing nitrated cellulose into a solvent to form macromolecular sol, emulsifying and foaming the sol to form paint emulsion, dispersing the paint emulsion into a non-solvent medium under stirring action to form balls, then driving the solvent to obtain explosive particles suspended in the solution and provided with micropores, separating the explosive particles suspended in the solution and provided with micropores, sensitizing the explosive particles separated from the solution of the suspended explosive particles and provided with micropores, and drying the explosive particles to obtain an explosive particle finished product, wherein the sensitizing mode is to add a sensitizing agent into the explosive particles separated from the solution of the suspended explosive particles in a form of aqueous solution or solid. The sensitizing process improves the fire transfer speed of the explosive particles and improves the ignition performance thereof, and the fire transfer speed of the explosive particles is improved by 10 to 200 percent under a normal pressure condition.

Owner:NANJING UNIV OF SCI & TECH

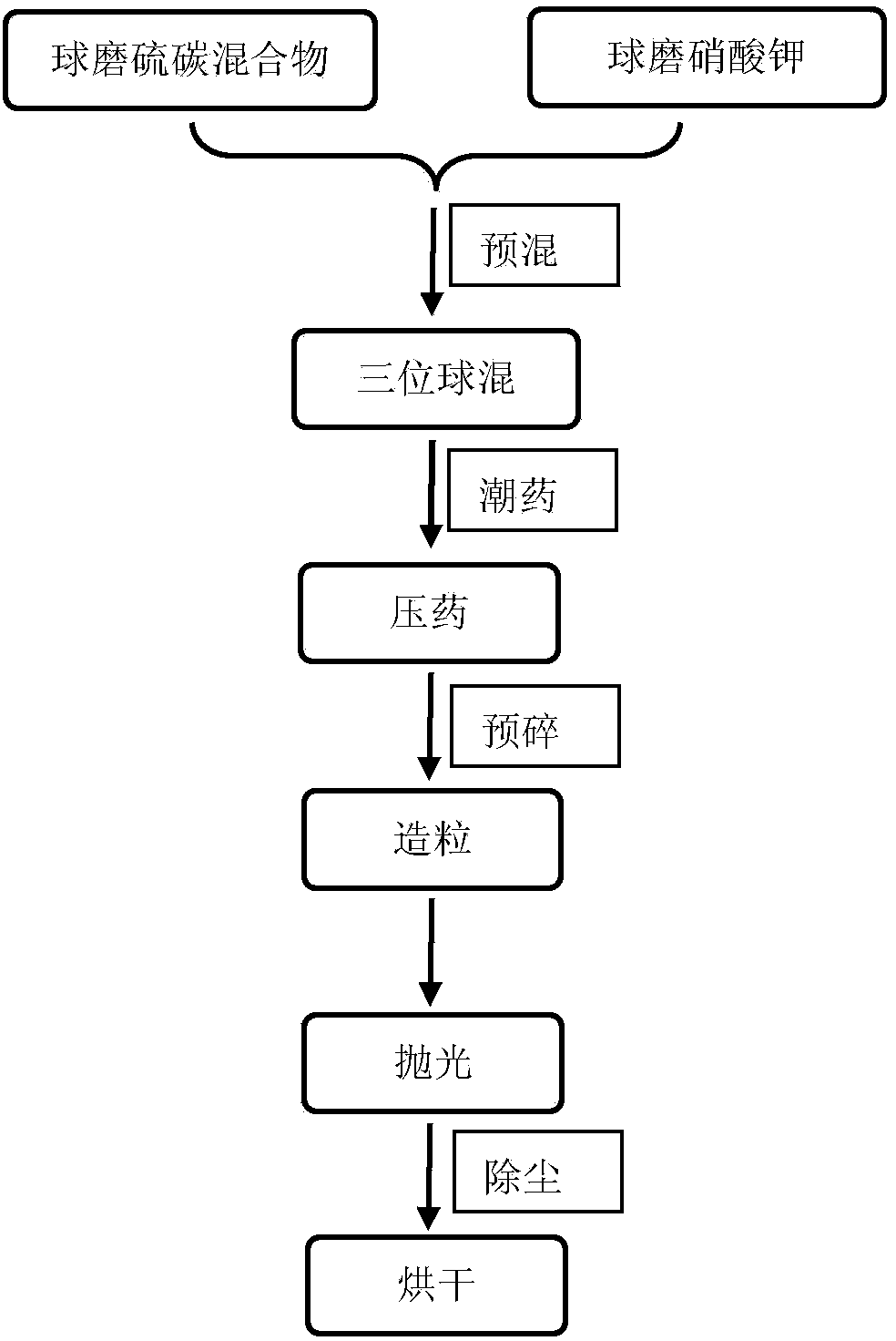

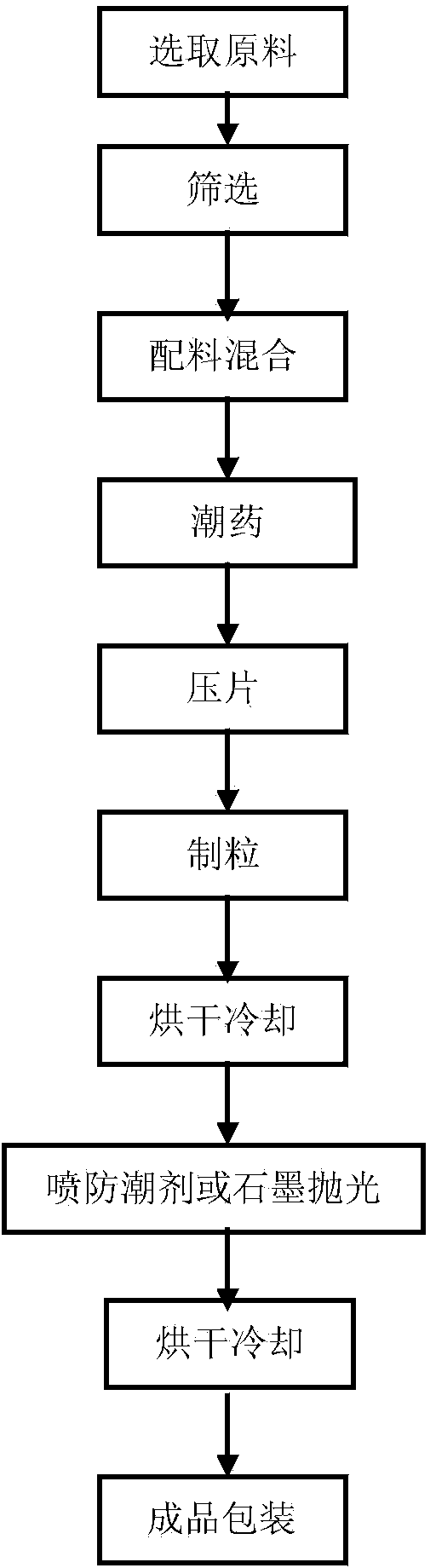

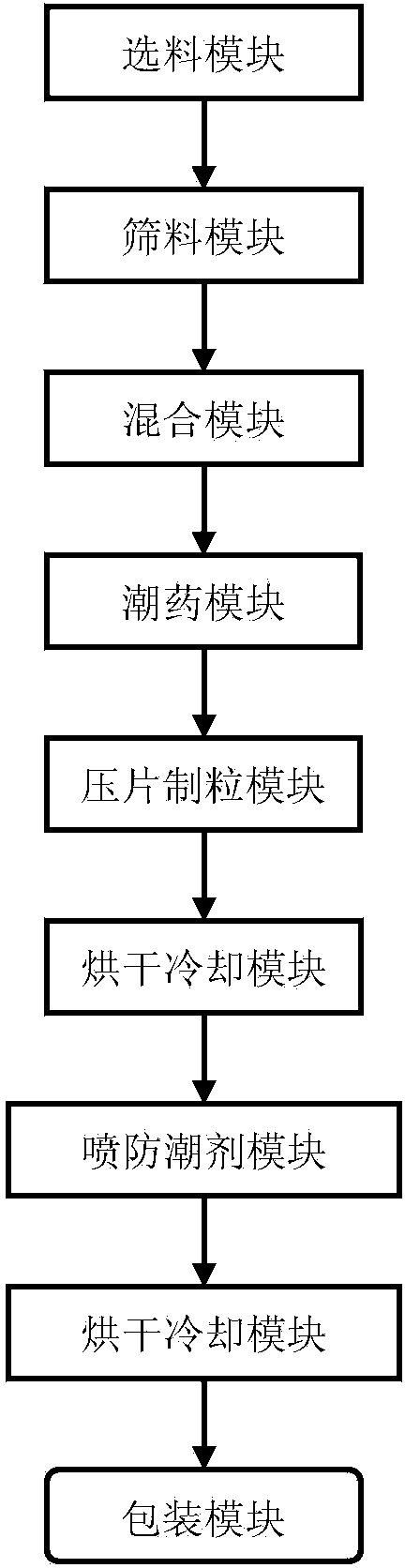

Process and system for manufacturing military nitre or black gunpowder

InactiveCN104030864ASimple contentEasy to operateExplosive working-up apparatusInorganic oxygen-halogen salt explosive compositionsHigh densityPyrotechnic composition

The invention discloses a process for manufacturing military nitre or black gunpowder. The process for manufacturing the military nitre or black gunpowder comprises the following steps: 1) selecting raw materials; 2) respectively screening the raw materials by virtue of a sieve more than 100 meshes; 3) batching and mixing, namely batching the screened single raw material, placing the batched raw materials into an automatic pyrotechnic composition mixing machine, and mixing for 3-5 minutes until the raw materials are uniformly mixed; 4) moistening medicine and carrying out continuous tabletting, pelletizing and sorting; 5) drying and cooling, namely drying gunpowder particles obtained in step 4) by virtue of an infrared ray optical wave pipe or a hot air channel and then cooling the gunpowder particles; 6) spraying a moisture-proof agent or polishing, namely placing the gunpowder particles in step 5) into a moisture-proof agent spraying tank, spraying a proper amount of a moisture-proof agent, spraying while the moisture-proof agent spraying tank is rotated, uniformly covering or polishing, so that a moisture-proof effect is realized; 7) drying, cooling and packaging the medicine particles sprayed with the moisture-proof agent in step 6). The invention also discloses a system for manufacturing the military nitre or black gunpowder. The process and system for manufacturing the military nitre or black gunpowder have the advantages of easy operation, implementation of pipeline process control, low labour cost, high production efficiency, low labour intensity, high safety coefficient, high density of the produced gunpowder particles and good follow-up using effect.

Owner:浏阳市工业园浏河机械厂

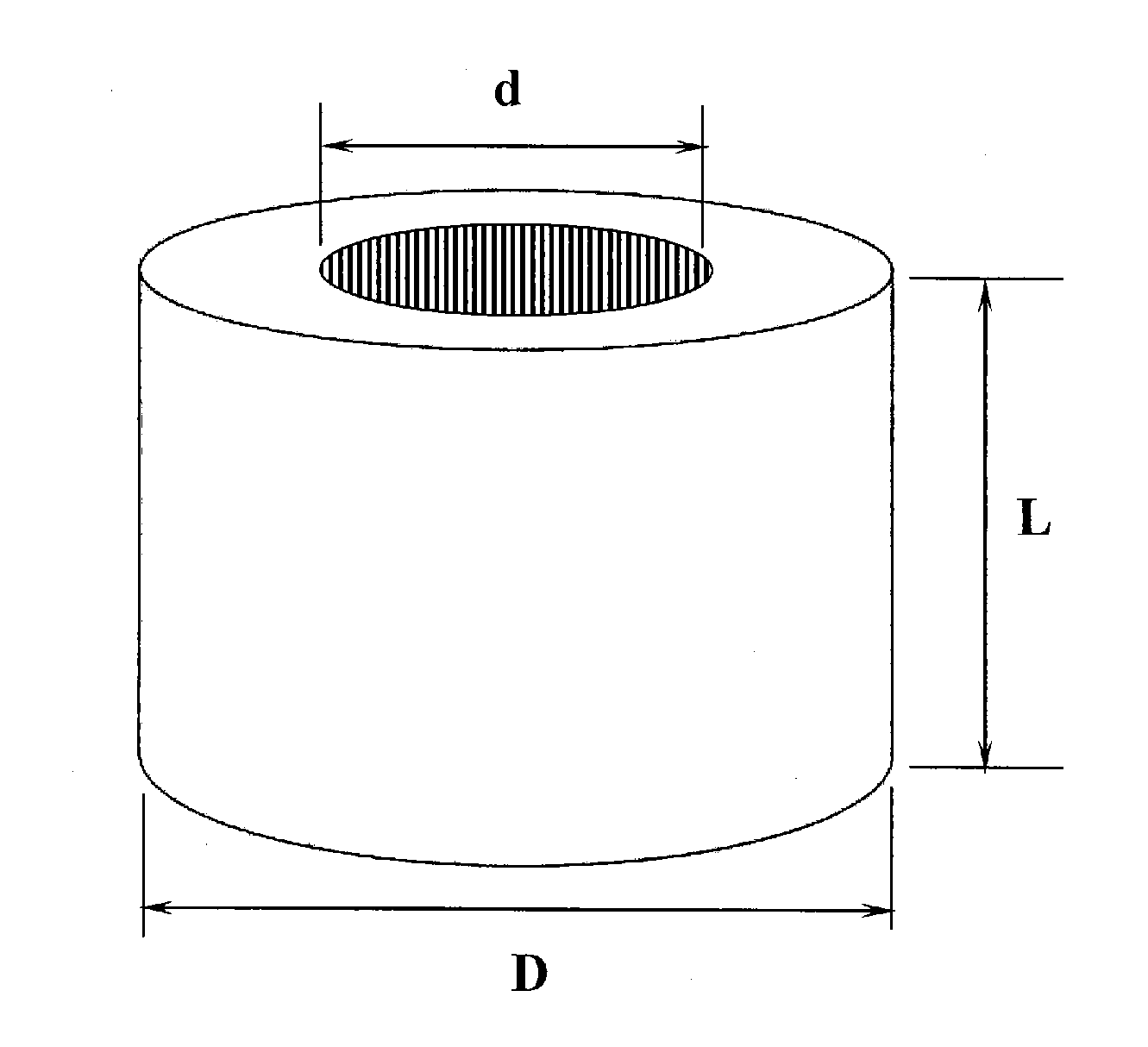

Black Powder Substitutes for Small Caliber Firearms

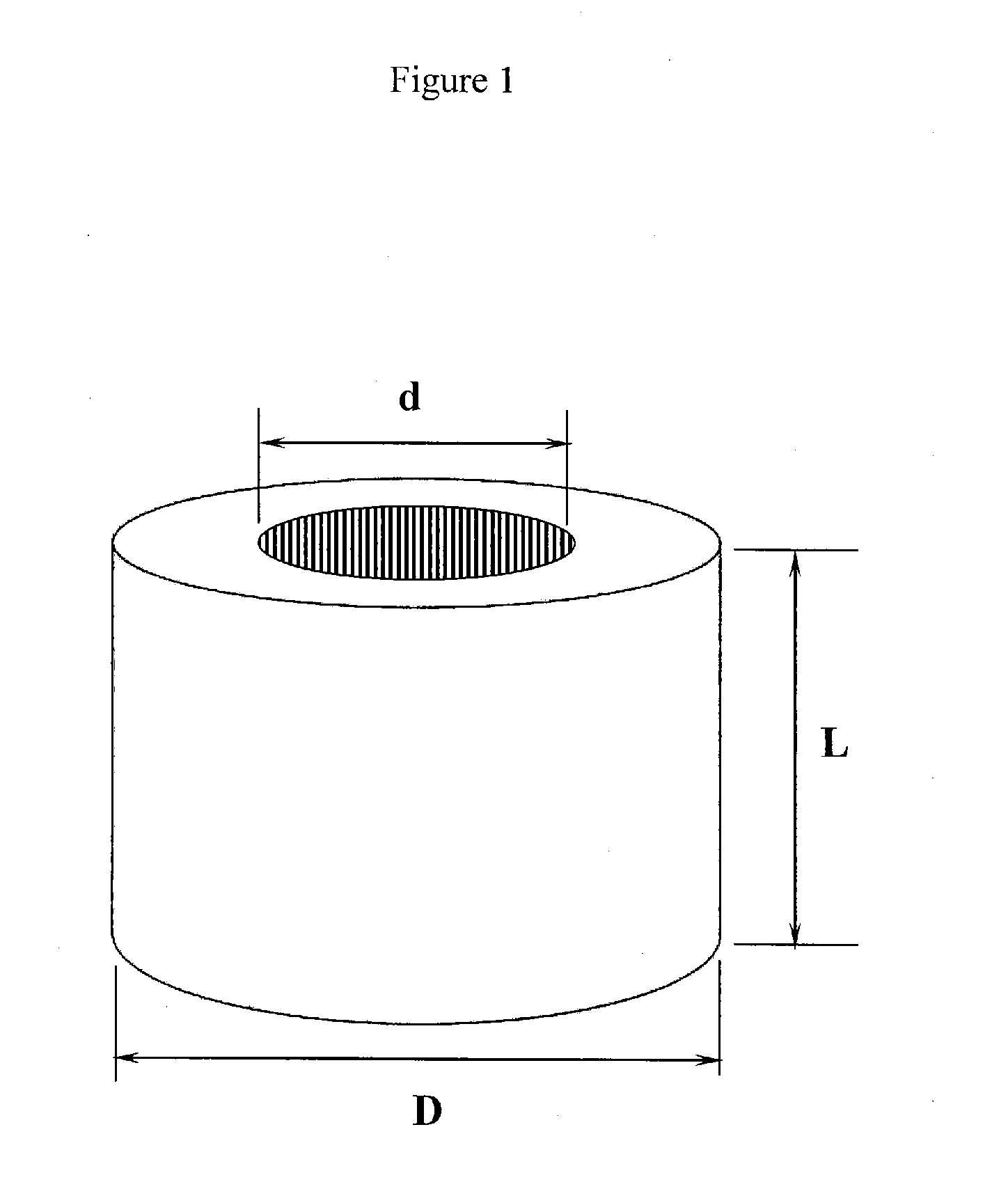

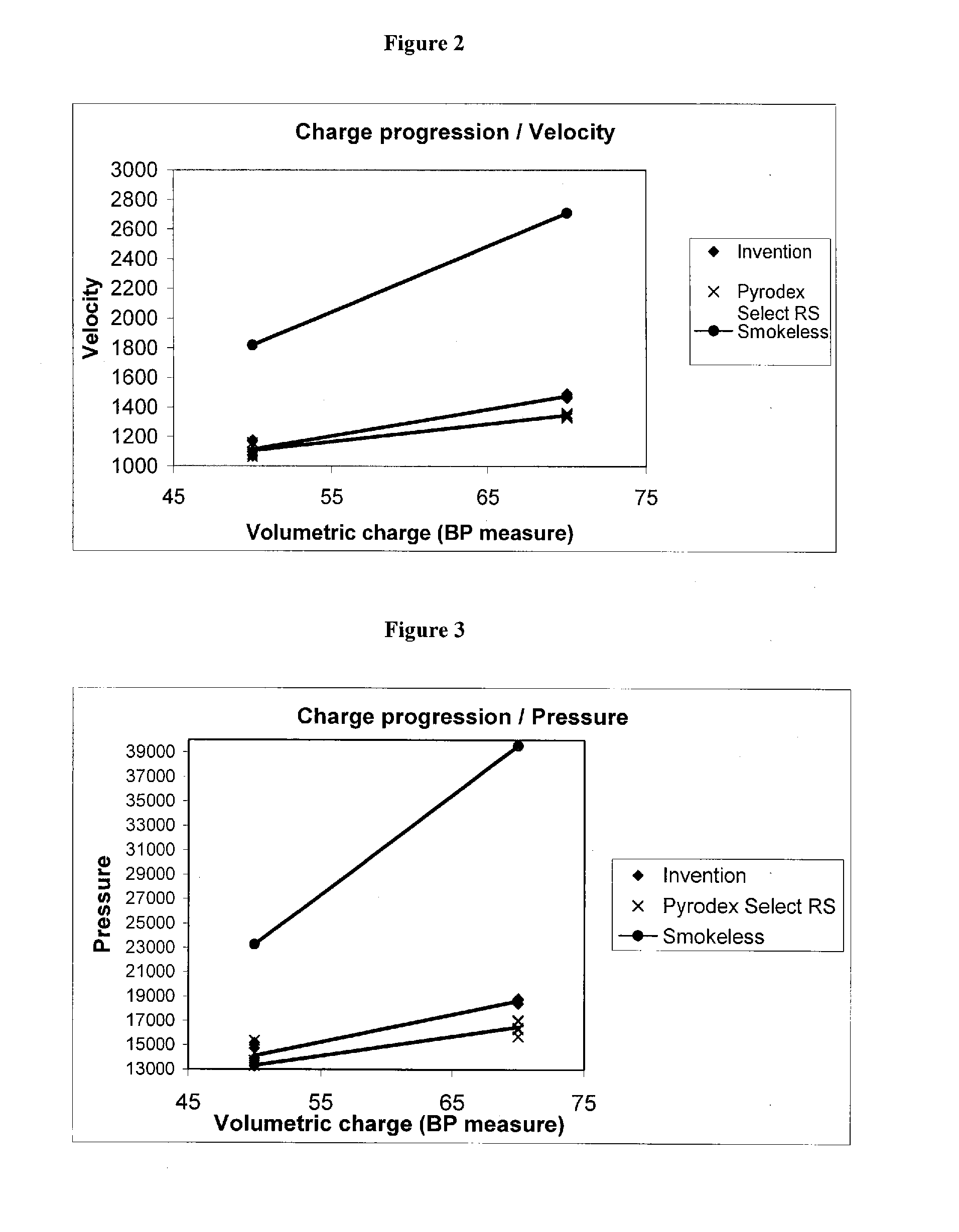

Propellant compositions are provided herein for use in small arms cartridges. Such propellant compositions include a cellulose-based organic fuel, a non-azide, nitrogen-containing primary organic oxidizer and a secondary nitrate, perchlorate, chlorate of peroxide oxidizer. Preferably, such compositions are in the form of extruded shaped hollow cylindrical grains having dimensions that makes it loadable in a muzzleloader firearm or small calibre firearm cartridge case. Ignition grains are also provided for use alone or in a mixture with the propellant compositions. When used in a small calibre firearm or muzzleloader, the temperature of combustion is at a level that ensures substantially complete combustion of the fuel during firing so that the products of combustion are mostly gaseous.

Owner:RACETTE MATHIEU +2

Sulfur-free propellant and preparation method thereof

ActiveCN106316725AReduce pollutionLow costInorganic oxygen-halogen salt explosive compositionsFriction sensitivitySulfur

The invention provides sulfur-free propellant. The sulfur-free propellant is prepared from 35wt%-52 wt% of potassium perchlorate, 5 wt%-15 wt% of a filling agent, 8 wt%-20 wt% of a bonding agent, 5 wt%-18 wt% of calcium stearate and 10 wt%-30 wt% of potassium acid phthalate by taking the total weight of the sulfur-free propellant as a standard. The sulfur-free propellant is low in friction sensitivity, impact sensitivity and moisture absorption capacity and high in thrust, and meanwhile pollution to the environment is reduced.

Owner:陈绍清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com