High-temperature-resistant solid propellant for deep oil-gas well and preparation method thereof

A solid propellant and high-temperature-resistant technology, which is applied in the direction of offensive equipment, inorganic oxyhalide salt explosive composition, explosives, etc., can solve problems such as inability to use, and achieve the effects of good temperature resistance and hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned high temperature resistant solid propellant for deep oil and gas wells, the method is carried out according to the following steps:

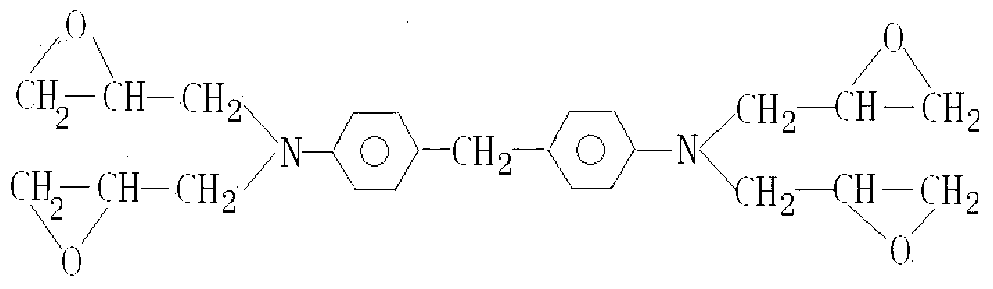

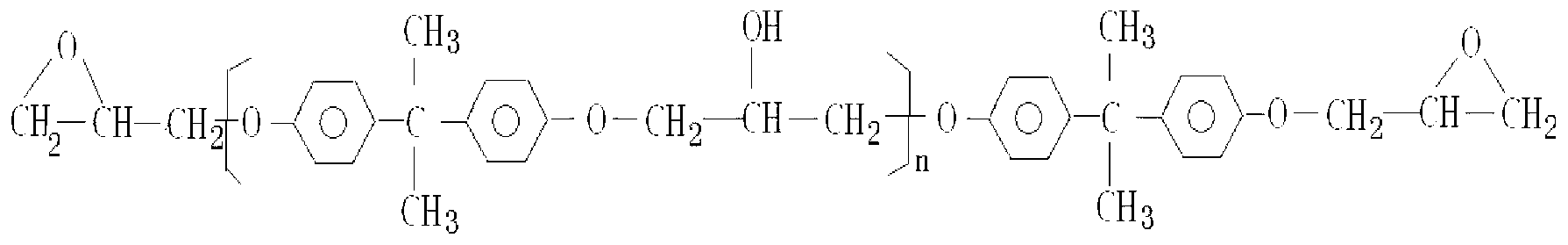

[0038] Step 1, according to the formula proportion, in weight percentage, the high temperature resistant epoxy resin is 10.00%-32.37%, the bisphenol A epoxy resin is 0-11.79%, the epoxy resin reactive diluent is 0-12.77%, and the Add 0.03% foaming agent to the mixing pot and premix for 10 minutes;

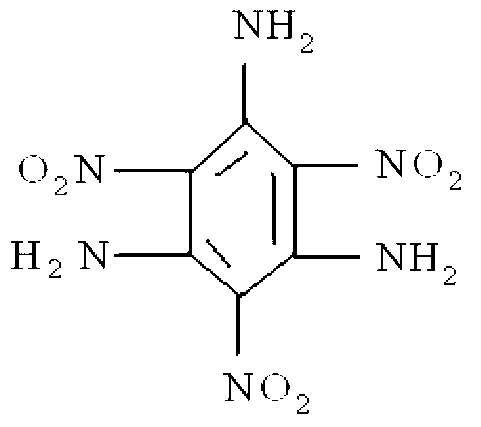

[0039] Step 2, in weight percentage, add potassium perchlorate to the system of step 1 in an amount of 33.00% to 58.00%, and 1,3,5-triamino-2,4,6-trinitrobenzene in an amount of 8.00% to 33.00%, After mixing for 50 minutes, add 2-ethyl-4-methylimidazole to a concentration of 0.98% to 1.60%, and stop mixing after 15 minutes to obtain medicinal slurry;

[0040] In step 3, the slurry obtained in step 2 is poured into a mold, put into a 70° C. oven for curing for 24 hours, and demolded to obtain a fin...

Embodiment 1

[0043]The high temperature resistant solid propellant for oil and gas deep wells of the present embodiment is composed of the following raw materials in percentage by weight: potassium perchlorate is 33.00%, TATB is 33.00%, TGDDM is 14.40%, epoxy resin E-51 is 5.40%, and Tolyl glycidyl ether was 12.77%, silicone resin was 0.03%, and 2-ethyl-4-methylimidazole was 1.40%.

[0044] Performance Testing:

[0045] Detonation heat is determined according to GJB770B-2005 method 701.2 explosion heat and combustion heat constant temperature method.

[0046] The specific volume is determined by the GJB770B-2005 method 702.1 specific volume pressure sensor method.

[0047] The test method of high temperature resistance is: Ф20mm×20mm grain column (1) 3℃ / min rise to 180℃, keep warm for 48h; (2) Temperature control point: The thermocouple is suspended directly above the sample and is not in contact with the sample. The thermal weight loss of the sample is not more than 3%, and the test is ...

Embodiment 2

[0054] The high temperature resistant solid propellant for oil and gas deep wells of the present embodiment is composed of the following raw materials in weight percentage: potassium perchlorate is 41.00%, TATB is 25.00%, TGDDM is 32.37%, silicone resin is 0.03%, 2-ethyl -4-Methylimidazole was 1.60%.

[0055] The performance test method of the high temperature resistant solid propellant for oil and gas deep wells of this embodiment is the same as that of embodiment 1, and the performance test results are shown in Table 2.

[0056] Table 2 embodiment 2 performance test results

[0057]

[0058]

[0059] It can be concluded from Table 2 that the explosion heat (ie energy) of the propellant is moderate, the specific volume is moderate, and the high temperature resistance, water resistance and salt water resistance all meet the performance requirements. It is suitable for the use of heat-resistant fracturing ammunition in deep oil and gas wells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com