Patents

Literature

225 results about "4-Methylimidazole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

4-Methylimidazole (4-MeI or 4-MEI) is a heterocyclic organic chemical compound with molecular formula H₃C–C₃H₃N₂ or C₄H₆N₂. It is formally derived from imidazole through replacement of the hydrogen in position 4 by a methyl group. It is a slightly yellowish solid.

Method for Preparing Flavorful and Aromatic Compounds

InactiveUS20100037903A1Add flavorIncrease aromaTobacco treatmentSolid sorbent liquid separationMaillard reactionPyrazine

The invention provides a method of preparing a purified, pyrazine-containing aqueous composition by mixing a reducing sugar, a base, and an amino acid in water to produce a mixture; heating the mixture for a time and under conditions conducive to Maillard reactions such that a flavorful and aromatic aqueous solution is formed, the aqueous solution comprising a plurality of pyrazines and a first 4-methylimidazole concentration; distilling the aqueous solution to produce an aqueous distillate comprising a plurality of pyrazines and having a second 4-methylimidazole concentration lower than the first 4-methylimidazole concentration; and collecting the aqueous distillate. The invention also includes flavorful and aromatic aqueous compositions formed by this inventive method, as well as tobacco products (e.g., smokable materials, smoking articles, and smokeless tobacco) incorporating the flavorful and aromatic composition.

Owner:R J REYNOLDS TOBACCO COMPANY

Inhibitors and methods of use thereof

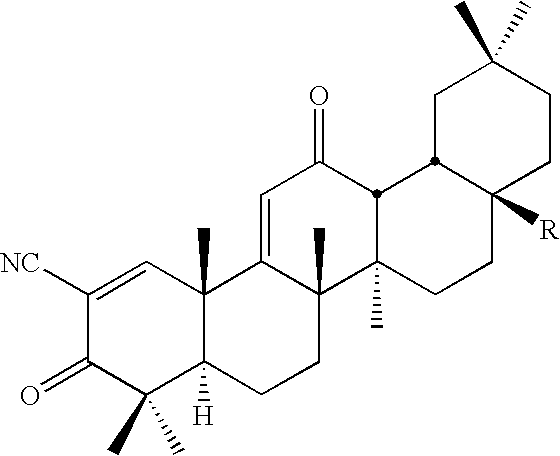

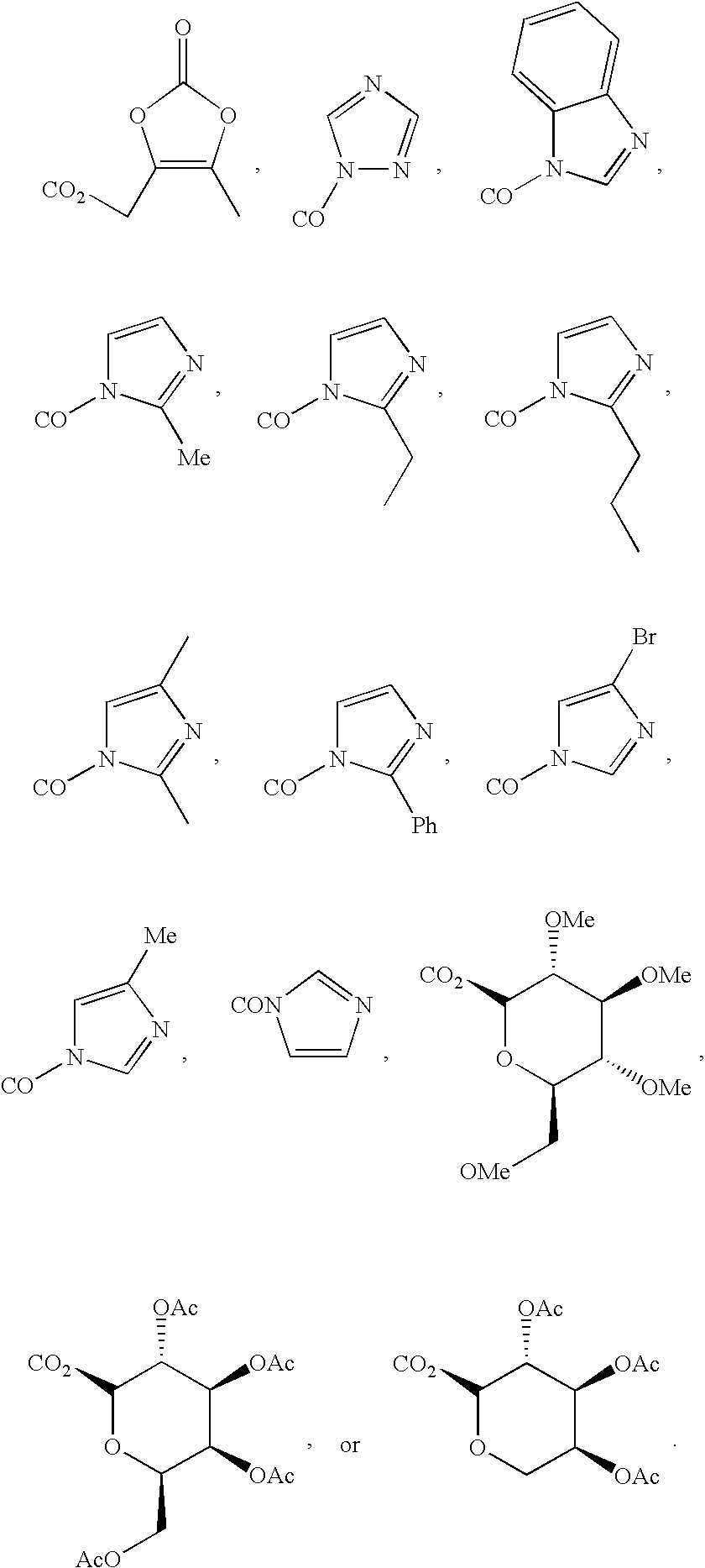

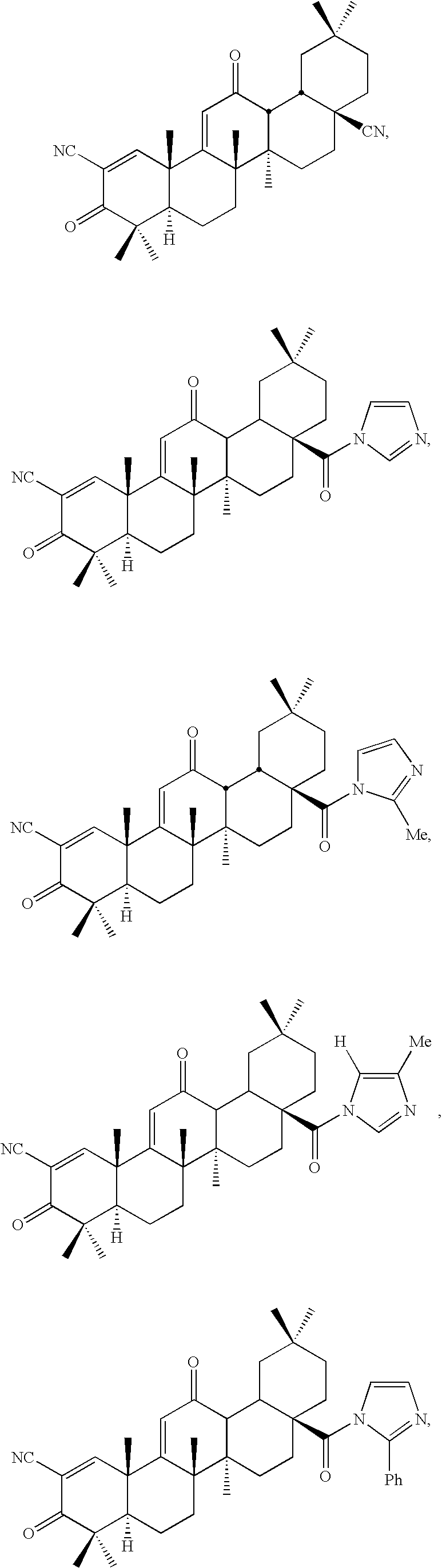

New triterpenoid derivatives with various substituents at the C-17 position of 2-cyano-3,12-dioxooleana-1,9(11)-dien-28-oic acid (CDDO) were synthesized. Among them, 2-cyano-3,12-dioxooleana-1,9(11)-dien-28-onitrile (CNDDO), 1-(2-cyano-3,12-dioxooleana-1,9(11)-dien-28-oyl) imidazole, 1-(2-cyano-3,12-dioxooleana-1,9(11)-dien-28-oyl)-2-methylimidazole, 1-(2-cyano-3,12-dioxooleana-1,9(11)-dien-28-oyl)-4-methylimidazole show extremely high inhibitory activity (IC50=0.01-1 pM level) against production of nitric oxide induced by interferon-γ in mouse macrophages. These compounds can be used in the prevention or treatment of diseases such as cancer, Alzheimer's disease, Parkinson's disease, multiple sclerosis, rheumatoid arthritis, and other inflammatory diseases. All the new triterpenoid derivatives are more potent than previously known CDDO.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

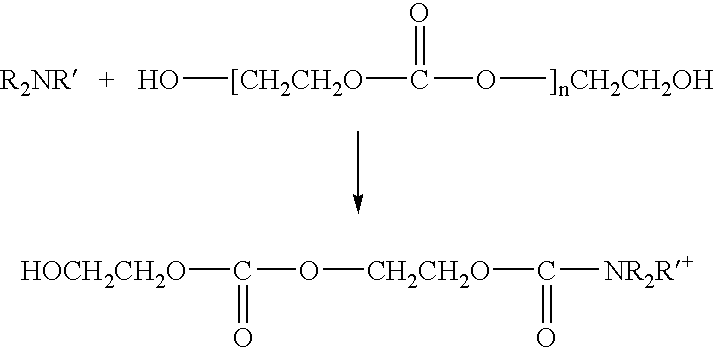

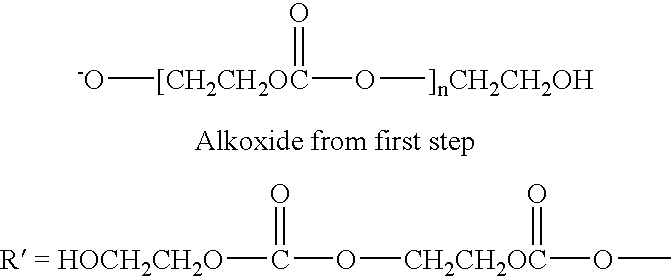

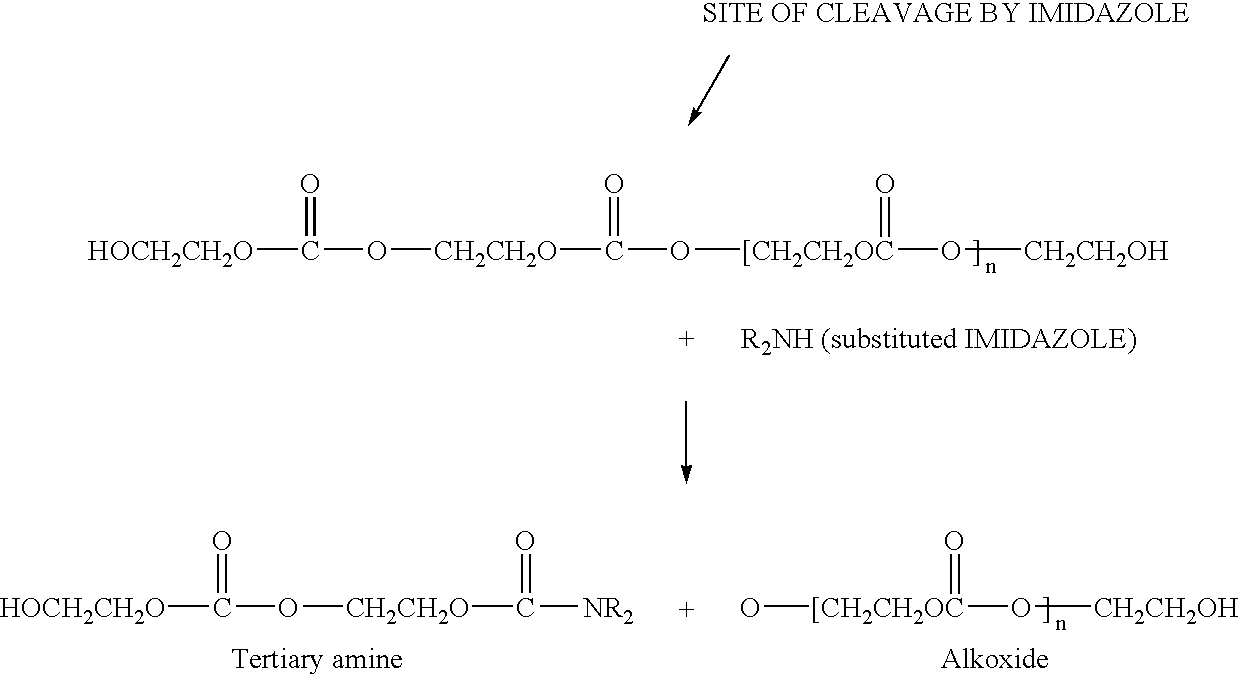

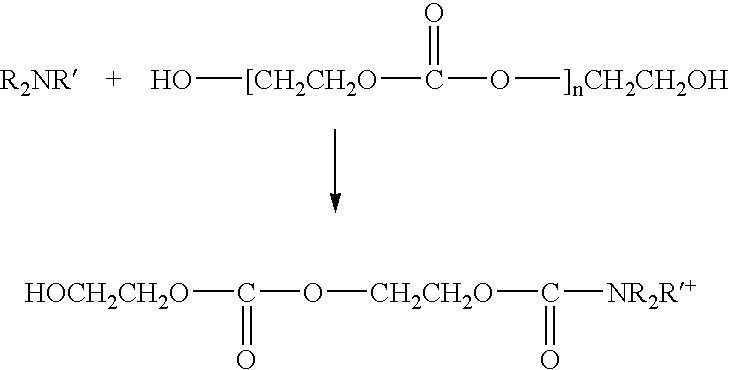

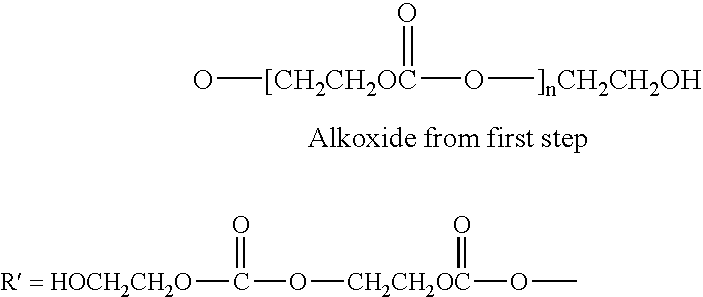

Stabilizing polyalkylene carbonate resins

InactiveUS20040171721A1Simple processNot impair clean burning characteristicDecomposition4-Methylimidazole

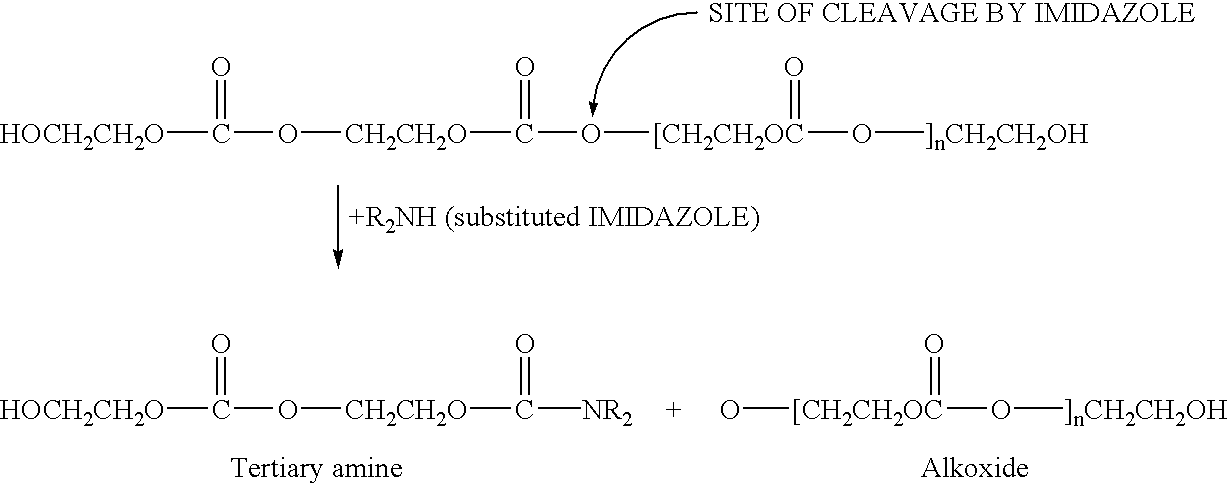

Polyalkylene carbonate resins are stabilized against thermal and hydrolytic decomposition by the addition of a cyclic amine eliminating the need for complex chemical or other purifying techniques. Cyclic amines such as imidazole and substituted imidazoles (specifically 2-ethyl 4-methyl imidazole) were found to be effective at 5-30%, preferably 10-30%. Processes for producing stable flux containing coatings for the aluminum brazing industry are detailed. The modified polyalkylene carbonate resins have better adhesive properties than the unmodified resins while maintaining their low ash, clean burning characteristics.

Owner:ESEMPLARE PASCAL E

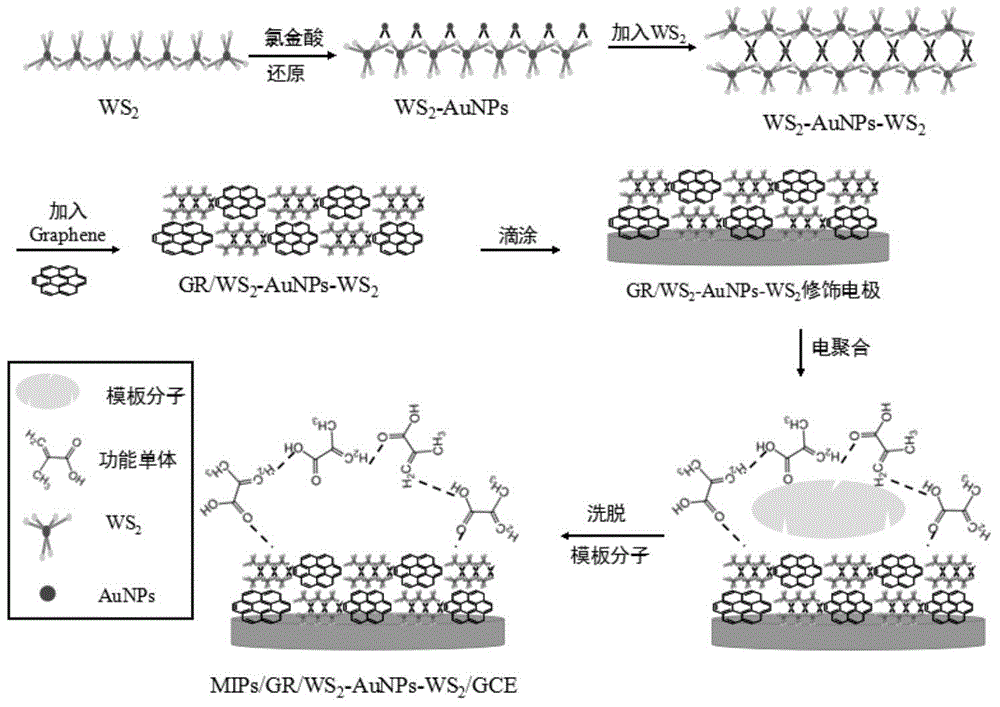

Preparation method and application of GR/WS2-AuNPs-WS2 compound molecular imprinting sensor

ActiveCN104833767AHigh electrochemical catalytic activityLarge specific surface areaChemical analysis using catalysisMaterial electrochemical variablesFunctional monomerPhenylalanine

The invention discloses a preparation method of a GR / WS2-AuNPs-WS2 compound molecular imprinting sensor. The preparation method includes the steps: 1) preparing tungsten sulfide which is nanosheet transition metal; 2) preparing an AuNPs / WS2 compound; 3) preparing a GR / WS2-AuNPs-WS2 compound; 3) preparing a GR / WS2-AuNPs-WS2 compound modified electrode; 4) taking the GR / WS2-AuNPs-WS2 compound as a substrate of the modified electrode, L-phenylalanine as a template molecule, 2-ethyl-4-methylimidazole as a crosslinking agent and methacrylic acid as a functional monomer to prepare an L-phenylalanine molecular imprinting sensor. The invention further provides an application of the molecular imprinting sensor in detection and separation of L-phenylalanine. L-phenylalanine detection sensitivity of the sensor is greatly improved owing to the GR / WS2-AuNPs-WS2 compound, and the prepared L-phenylalanine molecular imprinting sensor is high in L-phenylalanine sensitivity and selectivity by taking advantages of molecular imprinting.

Owner:QINGDAO UNIV

Method of stabilizing a normally solid polyalkylene carbonate resin against thermal and hydrolytic decomposition for at least producing tough coatings with excellent adhesion to both ferrous and non-ferrous metals

A method of stabilizing a normally solid polyalkylene carbonate resin against thermal and hydrolytic decomposition, including the step of adding a cyclic amine selected from the group consisting of imidazole and 2-ethyl 4-methylimidazole at a wt. % of 5 to 45% of the normally solid polycarbonate resin. And, a method of producing tough coatings with excellent adhesion to both ferrous and non-ferrous metals, including the steps of: a) dissolving polyalkylene carbonate resin and a cyclic amine selected from the group of consisting of imidazole and 2-ethyl 4-methylimidazole at a wt. % of 5 to 45% of the normally solid polycarbonate resin in a solvent selected from the group consisting of methyl ethyl ketone and propylene glycol mono methyl ether acetate by mechanical mixing so as to form a solution; b) coating the ferrous or non-ferrous metals with the solution so as to form a coated metal; c) air drying the coated metal to evaporate the solvent so as to form an air-dried coated metal; and, d) curing the air-dried coated metal for a time selected from the group consisting of at least 12 hours at ambient temperature and 15 minutes at 150° C.

Owner:ESEMPLARE PASCAL

Heat-resistant and flame-retardant modified acrylic emulsion paint

InactiveCN105176287AImprove flame retardant performanceImprove the defect of low bond strengthFireproof paintsEpoxy resin coatingsEpoxyNano al2o3

The invention discloses a heat-resistant and flame-retardant modified acrylic emulsion paint. The paint comprises the following raw materials: acrylic emulsion, copolymer emulsion of vinyl acetate and ethylene, brominated epoxy resin, boron phenolic resin, zinc borate, nanometer magnesium hydroxide, hexamethylene tetramine, organic modified montmorillonite, sepiolite, nanometer silicon nitride, nanometer silicon carbide, aluminum tripolyphosphate, nanometer zinc oxide, nanometer aluminum oxide, ethanol, 2-ethyl-4-methylimidazole, polyvinylpyrrolidone, dodecyl mercaptan, 1,2-benzisothiazole-3-ketone, sodium carboxymethylcellulose, a defoaming agent and water. The heat-resistant and flame-retardant modified acrylic emulsion paint has the advantages of good heat resistance and water resistance, excellent weather resistance, good flame retardant effect, strong adhesive force with a substrate, and long service life.

Owner:TIANCHANG YINHU PAINT

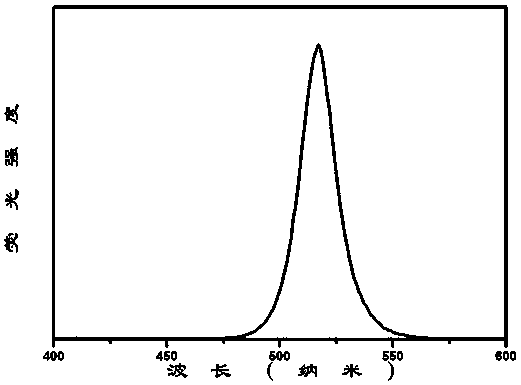

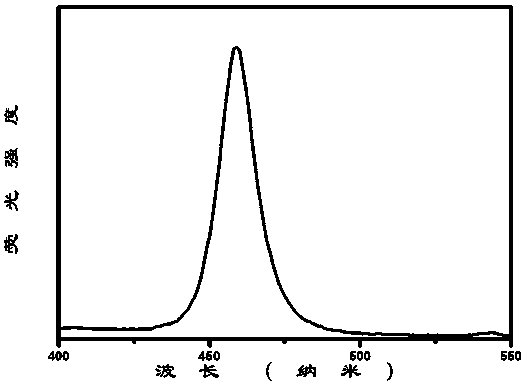

All-inorganic lead halogen perovskite nano composite luminous material and preparation method and application

ActiveCN108034418AImprove stabilityEasy to operateMaterial nanotechnologyNanoopticsFluorescenceOrganic dye

The invention discloses an all-inorganic lead halogen perovskite nano composite luminous material and a preparation method and application. A chemical general formula of the material is Cs4PbX6-CsPbX3-imidazole, X is one or multiple of Cl, Br and I, and imidazole is one or multiple of methyl imidazole, dimethyl imidazole and 4-methylimidazole. The material is composed of CsPbX3 luminous crystal nucleus of 20nm and a Cs4PbX6 frame of 160nm, a capsule-type core-shell structure is formed, and imidazole serves as a chelating agent to chelate with lead ions in Cs4PbX6 through nitrogen-containing groups of imidazole, so that waterproof stability and heatproof stability of the luminous material are improved greatly. The luminous material can be synthesized at room temperature by adopting a one-step precipitation method simple in process. Successful cell fluorescence labeling can be realized under laser irradiation by jointly incubating the luminous material and biological cells. The luminousmaterial is expected to replace conventional rare earth trichromatic phosphor and organic dye, can improve stability of devices and widen color domain of the devices and is of important significance in promoting development of the application field of photoelectric devices and biological fluorescent markers.

Owner:EAST CHINA NORMAL UNIVERSITY +1

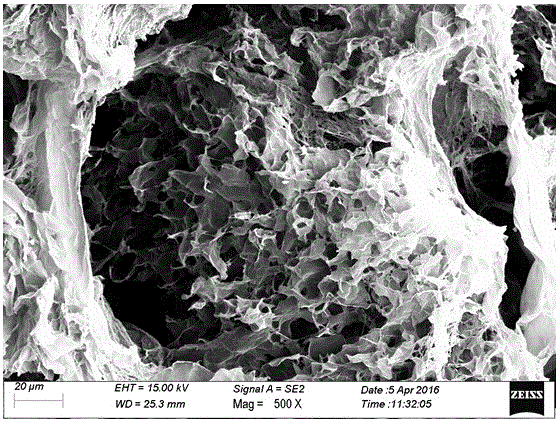

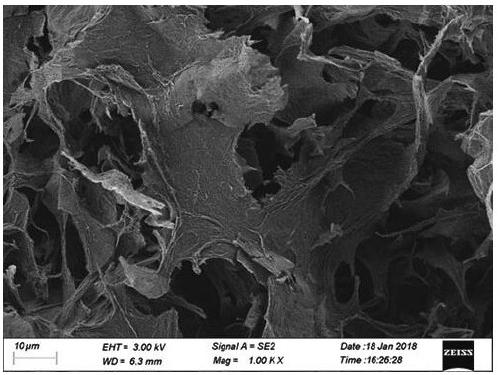

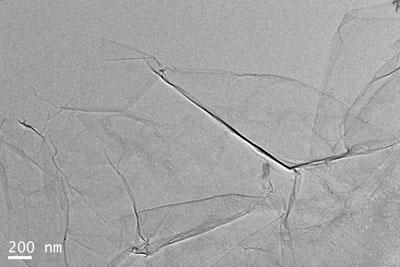

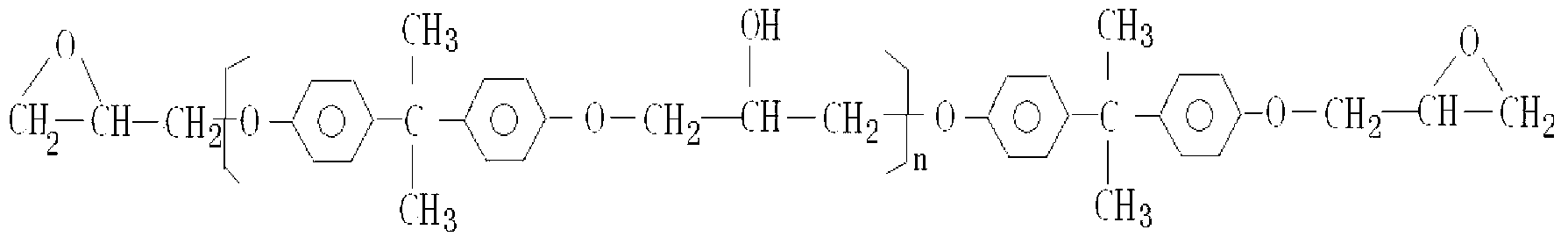

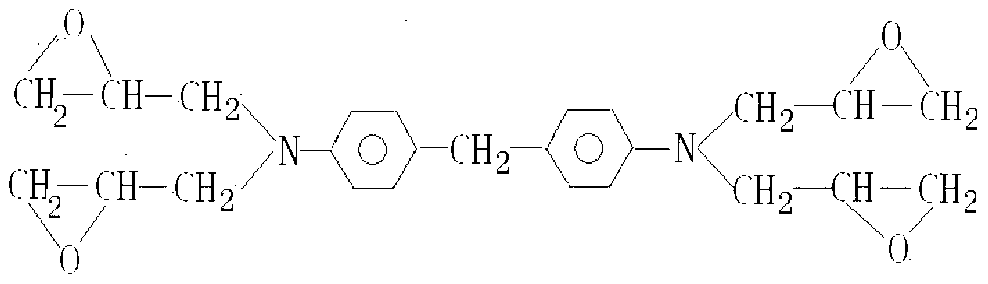

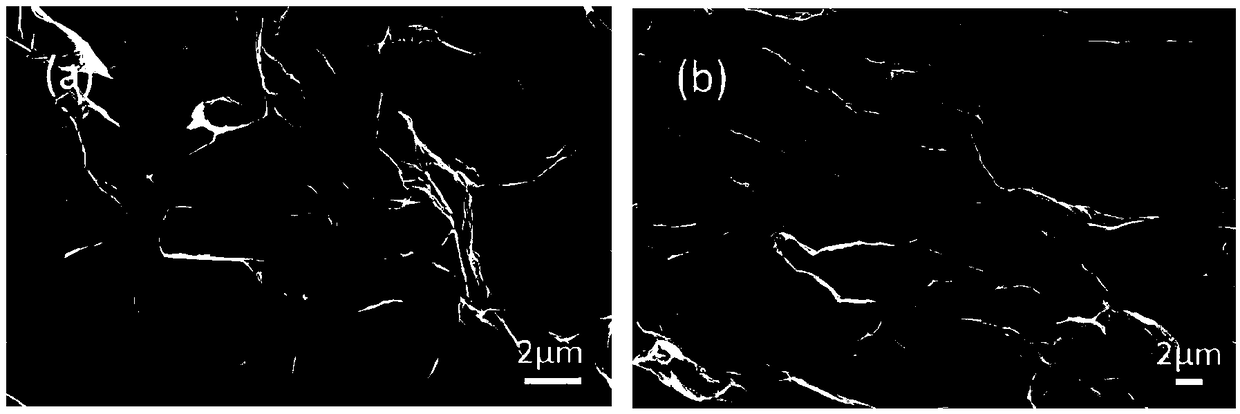

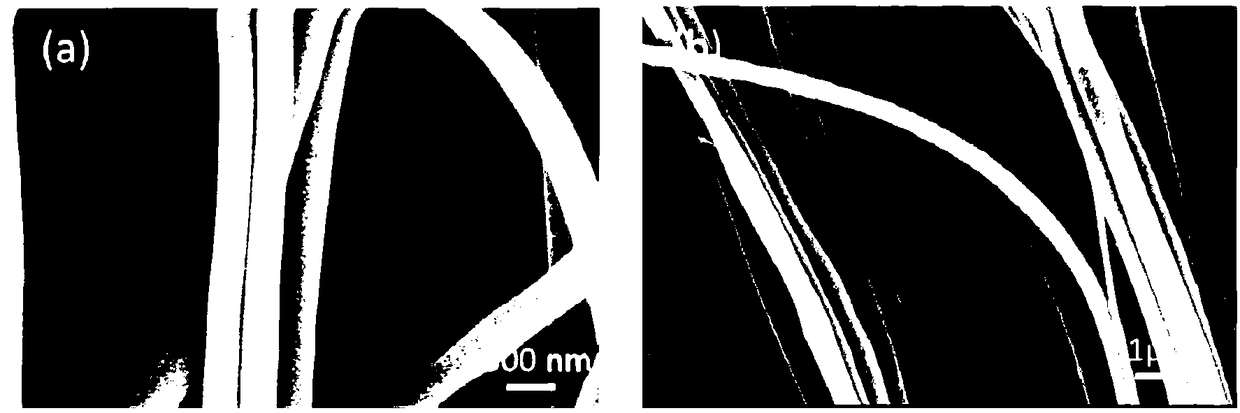

Preparation method of carbon nanotube-graphene oxide mixed reinforced composite material

ActiveCN106189088AEvenly dispersedGood self-sustainabilityHeat-exchange elementsPorous carbonResin matrix

The invention belongs to the field of polymer matrix composite manufacturing, and particularly relates to a preparation method of a carbon nanotube-graphene oxide mixed reinforced composite material. Graphene oxide and carbon naotubes are assembled into a nano-carbon mixed structure reinforcement with the high self-supporting property, and after resin matrix infiltration and polymerization, the carbon nanotube-graphene oxide mixed reinforced composite material is obtained; the porous carbon nanotube-graphene oxide reinforcement with the low density and the high specific surface area is prepared by taking 2-ethyl-4-methylimidazole as a bridge between the nanotubes and graphene oxide, and the reinforcement retains the respective characteristics of graphene oxide and the carbon nanotubes and is composited with multiple resin matrixes by serving as three-dimensional macroscopic continuous reinforcement with the high electricity conductivity and thermal conductivity, and then the multifunctional low-cost carbon nanotube-graphene oxide mixed reinforced composite material is prepared.

Owner:淮安航空产业研究院有限公司

High-strength flame-retardant modified polyurethane composite material

The invention discloses a high-strength flame-retardant modified polyurethane composite material including: hydroxyl-terminated polybutadiene, polytetrahydrofuran ether glycol, polypropylene glycol, toluene diisocynate, 4,4'-diphenylmethane diisocynate, bisphenol A, dibromoneopentyl glycol, dimethythiotoluene diamine, diaminodiphenylmethane, 2-ethyl-4-methylimidazole, dibutyltin dilaurate, diglycidyl resorcinol ether, a filling material, melamine, ammonium polyphosphate, and N,N'-bis(2-thio-5,5-dimethyl-1,3,2-dioxaphosphocyclohexyl)ethylenediamine. The high-strength flame-retardant modified polyurethane composite material has high strength, is excellent flame-retardant performance and can satisfy use demands in various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Single-component water-based epoxy resin emulsion and preparation method thereof

InactiveCN102675861ASmall particle sizeEvenly distributedPolyurea/polyurethane coatingsWater basedEpoxy

The invention discloses a single-component water-based epoxy resin emulsion, which comprises the following components in percentage by weight: 100 percent of a modified epoxy resin, 5-35 percent of an efficient emulsifier, 0-1 percent of a surfactant, 0-70 percent of a cosolvent and an appropriate amount of water, wherein the modified epoxy resin comprises an epoxy resin, polyglycol ether, isocyanate, a sealing agent and a catalyst; the efficient emulsifier consists of an epoxy resin, polyether, organic silicon and a catalyst; the surfactant is one or a mixture of more than two of sodium dodecylbenzene sulfonate, sodium lauryl sulfate and potassium dodecyl sulfate; the cosolvent is one or a mixture of more than two of propylene glycol methyl ether, glycol ethylene ether, ethylene glycol monomethyl ether and diacetone; the sealing agent is one or a mixture of more than two of caprolactam, phenol and methyl ethyl ketoxime; and the catalyst is one or a mixture of more than two of 2-ethyl-4-methylimidazole, triphenylphosphine, triphenylhydrogen phosphide or benzyl dimethylamine.

Owner:上海富朗化工科技发展有限公司

Water-resistant fireproof coating

The invention discloses a water-resistant fireproof coating. The coating comprises the following raw materials by weight: 20 to 50 parts of self-crosslinking elastic acrylic emulsion, 5 to 10 parts of copolymer emulsion of vinyl acetate and ethylene, 10 to 25 parts of a flame retardant, 10 to 25 parts of a pigment filler, 2 to 10 parts of propylene glycol, 0.2 to 1 part of 2-ethyl-4-methylimidazole, 0.5 to 1 part of polyvinylpyrrolidone, 0.2 to 1 part of sodium carboxymethylcellulose, 0.2 to 1.5 parts of 1,2-benzisothiazol-3-one, 0.3 to 1.2 parts of dodecyl mercaptan, 0.1 to 0.8 part of dodecyl dimethyl benzyl ammonium chloride, 0.5 to 1.5 parts of a defoaming agent, 0.5 to 2 parts of aluminium triphosphate and 25 to 40 parts of water. The water-resistant fireproof coating provided by the invention has the advantages of high strength, excellent fireproof property and water resistantce, strong adhesive force with a substrate, high bonding strength and long service life.

Owner:TIANCHANG YINHU PAINT

Aminomethyl-4-imidazoles

The present invention relates to amino-4-methyl imidazoles and pharmaceutically-acceptable salts thereof.The compound may be used for the treatment of depression, anxiety disorders, bipolar disorder, attention deficit hyperactivity disorder (ADHD), stress-related disorders, psychotic disorders such as schizophrenia, neurological diseases such as Parkinson's disease, neurodegenerative disorders such as Alzheimer's disease, epilepsy, migraine, hypertension, substance abuse and metabolic disorders such as eating disorders, diabetes, diabetic complications, obesity, dyslipidemia, disorders of energy consumption and assimilation, disorders and malfunction of body temperature homeostasis, disorders of sleep and circadian rhythm, and cardiovascular disorders.

Owner:F HOFFMANN LA ROCHE INC

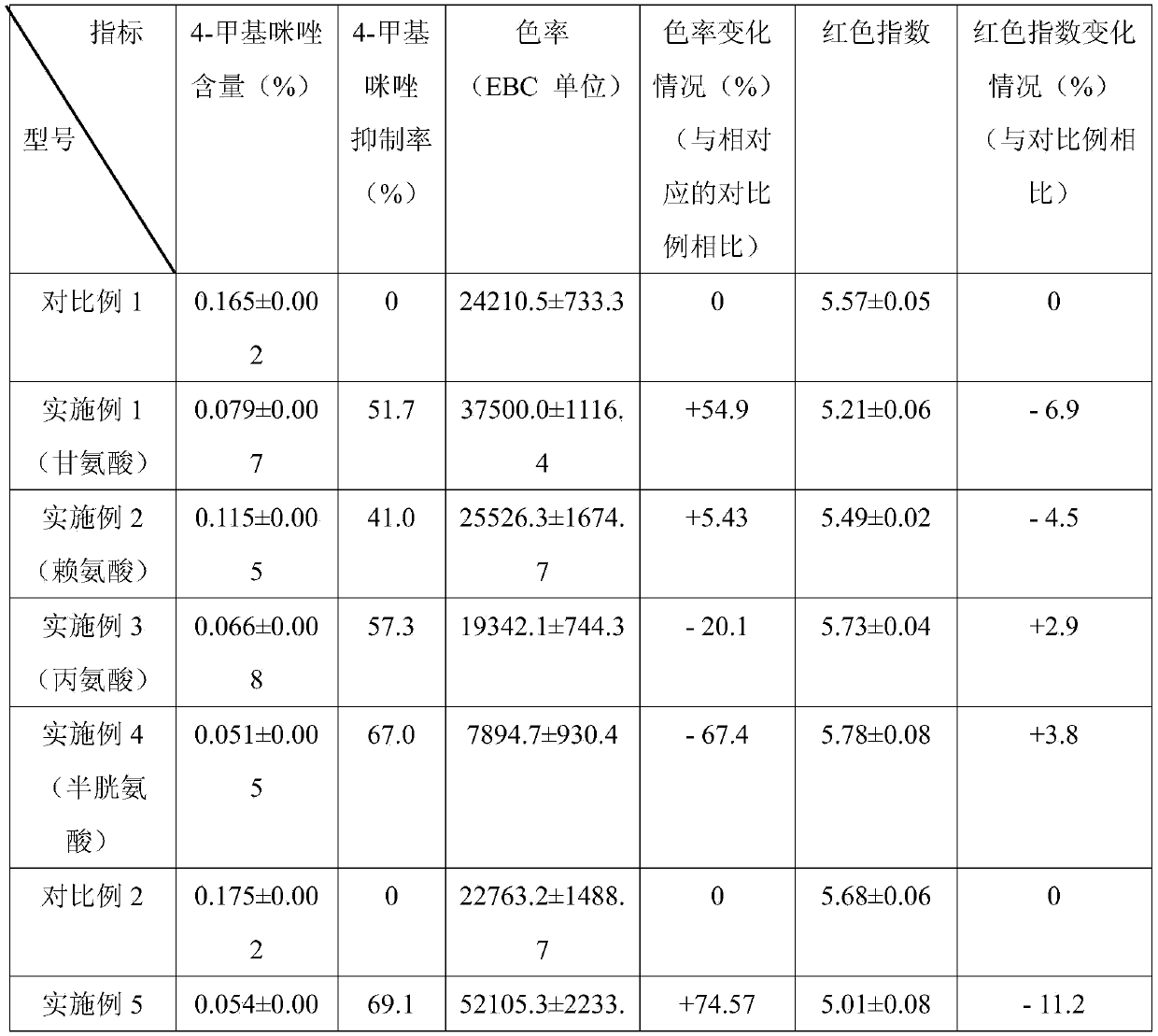

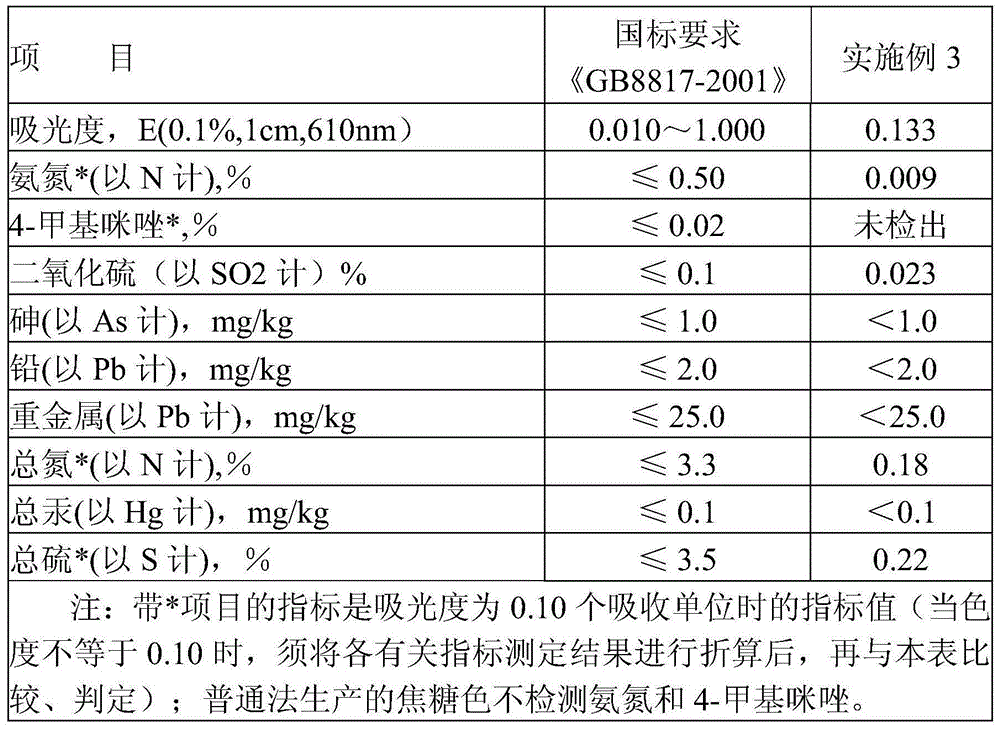

Preparation method of caramel pigment without 4-methylimidazole

ActiveCN104861736AImprove salt toleranceImprove acid resistanceNatural dyesIsoelectric point4-Methylimidazole

The invention discloses a preparation method of a caramel pigment without 4-methylimidazole. The preparation method comprises the following steps of: 1) sugar-melting, to be specific, adding a sugar source to a reaction kettle with a condensing and draining device while mixing, turning on a heating device for heating, melting the sugar source after the temperature of the reaction kettle rises above the melting point of the sugar source; 2) draining, to be specific, turning on condensing water, collecting cooling water, and controlling the volume of the cooling water to 5%-8% of the volume of the sugar source; 3) caramelization reaction, to be specific, after draining is finished, changing a condenser pipe into a cooling water return pipe, and keeping at 150 DEG C to 170 DEG C for 1 h-2 h; 4) diluting (neutralizing), to be specific, before the caramelization reaction is finished, adding an alkaline solution to the reaction system slowly to adjust the pH value of the system to be close to the isoelectric point of the caramel pigment, and mixing slowly and continuously until complete reaction is finished; 5) obtaining the product, to be specific, obtaining liquid caramel pigment without 4-methylimidazole after the reaction. The preparation method of the caramel pigment without 4-methylimidazole is economical, practical, safe and high in quality, industrial production is realized, and quality of the caramel pigment is controlled.

Owner:SHAANXI UNIV OF SCI & TECH

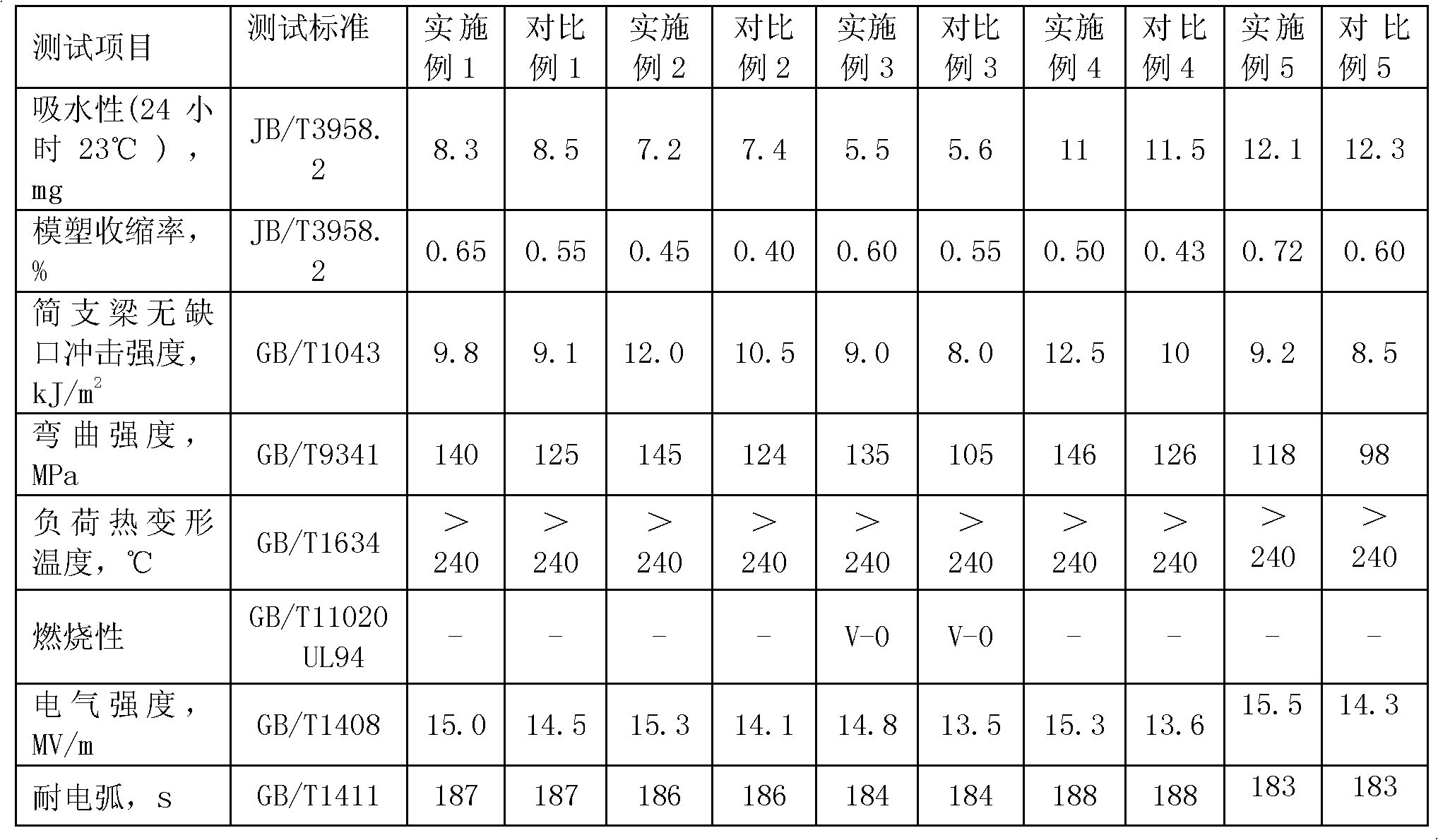

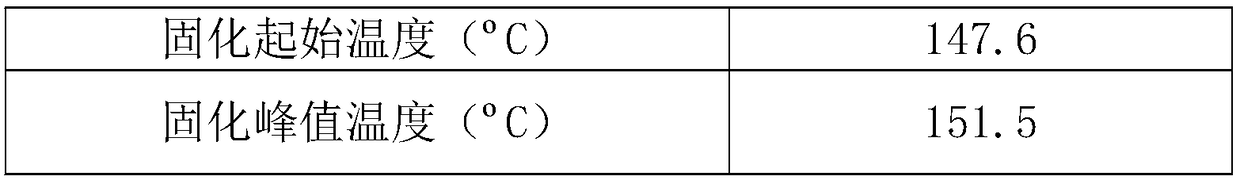

Injection moldable electric epoxy molding plastic and preparation method thereof

The invention discloses an injection moldable electric epoxy molding plastic and a preparation method thereof. The molding plastic comprises the following components in percentage by weight: 10 to 25 percent of epoxy resin, 5 to 20 percent of curing agent, 0.2 to 1.5 percent of curing accelerator, 30 to 65 percent of filler, 1 to 3 percent of releasing agent and 15 to 35 percent of reinforcing fibers, wherein the epoxy resin consists of 75 to 100 weight percent of primary resin with a softening point of 65 to 100 DEG C and 0 to 25 weight percent of secondary resin with a softening point of 60to 100 DEG C; the curing agent is linear phenolic resin with a softening point of 80 to 110 DEG C; and the curing accelerator is a 2-ethyl-4-methylimidazole derivative. The molding plastic disclosed by the invention is prepared by using specific raw materials and mixing ratio and can be molded by injection in a common thermosetting plastic injection machine; and the preparation method of the molding plastic is simple and easy to control.

Owner:桂林金格电工电子材料科技有限公司

Preparation method of caramel pigment with reduced 4-methylimidazole content

The invention discloses a preparation method of caramel pigment with a reduced 4-methylimidazole content. The method includes the steps of: firstly preparing raw material sugar into a sugar solution, then adding ammonia water serving as the catalyst and adding amino acid, stirring the substances evenly, then rapidly raising the temperature to 140+ / -2DEG C and carrying out heat preservation reaction for 55-65min; cooling the reaction product to lower than or equal to 50DEG C rapidly, and concentrating the cooled reaction product to obtain a concentrated caramel pigment solution; and further drying the concentrated caramel pigment solution to a water content of less than or equal to 5% so as to obtain solid caramel pigment. According to the invention, the level of 4-methylimidazole in caramel pigment is significantly lowered by means of adding amino acid in the production link, thereby realizing production of high quality and safe edible caramel pigment with low 4-methylimidazole content without changing the existing production process and facilities.

Owner:ZHEJIANG UNIV

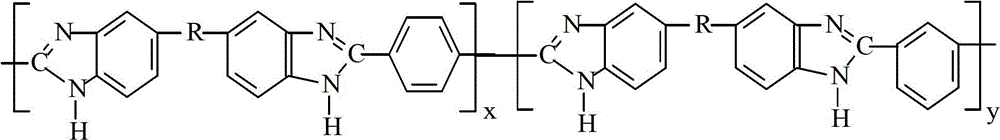

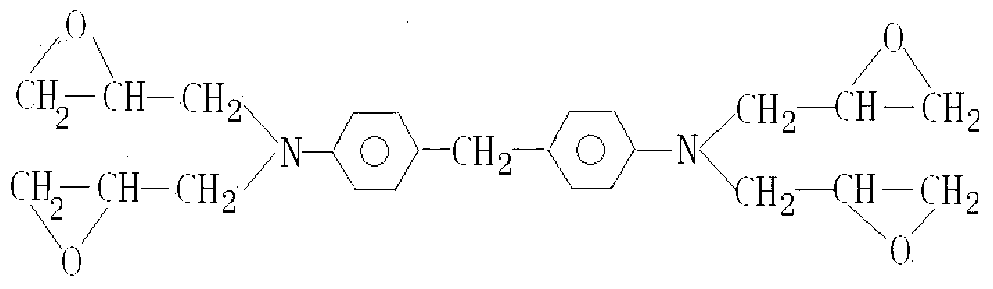

Polyimide-epoxy type electrical insulating paint and preparation method thereof

The invention relates to a polyimide-epoxy type electrical insulating paint and a preparation method thereof. The polyimide-epoxy type electrical insulating paint comprises the components: a maleimide polyimide resin solution, N, N, N', N', O-5-penta-glycidyl-4,4'-diamido-4''-hydroxyl triphenylmethane, N, N, N', N'-4-tetra-glycidyl-4,4'-diamido-diphenyl methane and 2-ethyl-4- methylimidazole which have the weight ratio of 100: (80-100): (80-100):(10-30). The preparation method comprises the steps of: evenly stirring and mixing all the components at the room temperature to obtain the paint. The polyimide-epoxy type electrical insulating paint is moderate in viscosity, good in using technological efficiency, excellent in adhesive property for metal base materials (such as iron, copper, aluminium alloy, glass and ceramics), simple in preparation technology and convenient in operation and reaction raw material source; and the preparation process can be completed in general equipment and is beneficial to realization of industrial production.

Owner:DONGHUA UNIV +1

High-temperature resisting corrosion-resistant modified epoxy resin pad for laboratory table board

The invention discloses a high-temperature resisting corrosion-resistant modified epoxy resin pad for a laboratory table board. The pad is made of a modified epoxy resin material which comprises the following raw materials: epoxy resin, styrene-butadiene rubber, polytetrafluoroethylene, carboxyl-terminated butadiene-acrylonitrile rubber, zinc oxide, stearic acid, sulfur, benzoyl peroxide, aluminum oxide, a modified coupling agent, triethylene tetramine, 2-ethyl-4-methyl imidazole, oxidized graphene, di(2,4-di-tert-butyl phenyl) pentaerythrite diphosphate, 2,2'-ethylidene di(4,6-di-tert-butyl phenyl)fluoro-phosphite ester, and an accelerator. The pad provided by the invention is high in strength, excellent in high-temperature resisting performance, high in corrosion resistance, can meet the requirement of the laboratory table board, and is long in service life.

Owner:ANHUI YUAN LAB EQUIP

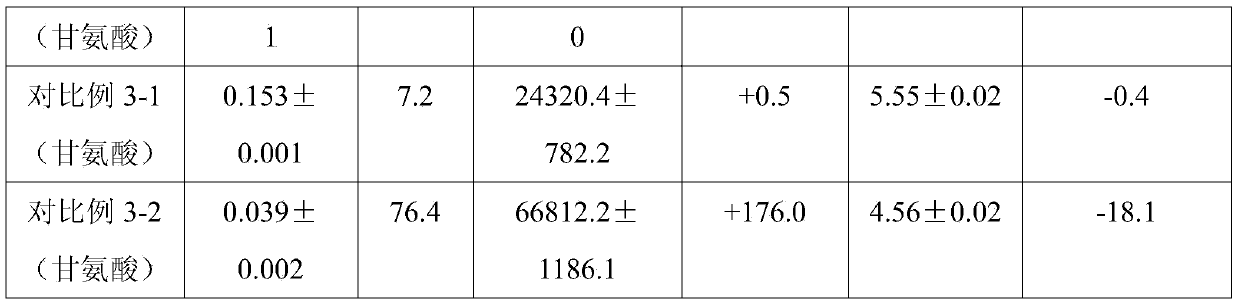

Benzimidazole-type humidity-sensitive high-molecular coating material and preparation method and application thereof

The invention relates to a benzimidazole-type humidity-sensitive high-molecular coating material and a preparation method and application thereof. The humidity-sensitive high-molecular coating material comprises poly(benzimidazole-imide), N,N,N',N'O,O'-hexa-glycidyl group-2,2-bis(3-amino group-4-hydroxyphenyl)-hexafluoropropane, 2-ethyl-4-methylimidazole and an organic solvent. The preparation method comprises the following steps of: putting 2-(4-aminophenyl)-5-aminobenzimidazole and a strongly polar non-protonic organic solvent into a reaction vessel, and stirring and dissolving under room temperature; then adding 3,5-bis(4-aminophenoxy)benzoic acid and other aromatic diamines, stirring, dissolving and adding aromatic dianhydride, stirring, and reacting; adding methylbenzene, heating, refluxing, separating water, reacting, and cooling to room temperature to obtain A component; adding B component, and uniformly stirring and mixing to obtain the benzimidazole-type humidity-sensitive high-molecular coating material. The invention has the advantages of excellent comprehensive performance, simple manufacturing method, capability of completing preparation process in general-purpose equipment, and suitability for industrialized production.

Owner:DONGHUA UNIV +1

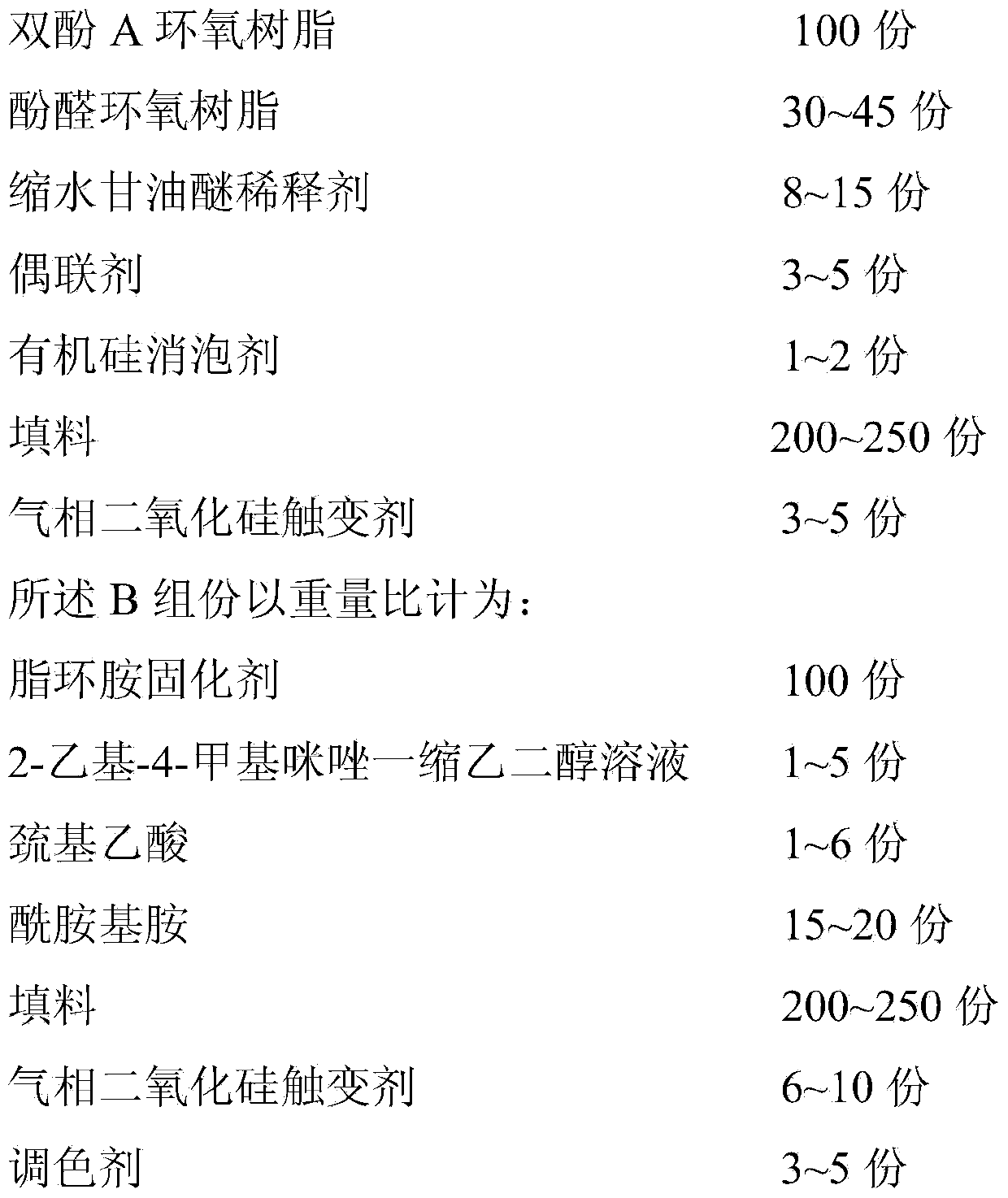

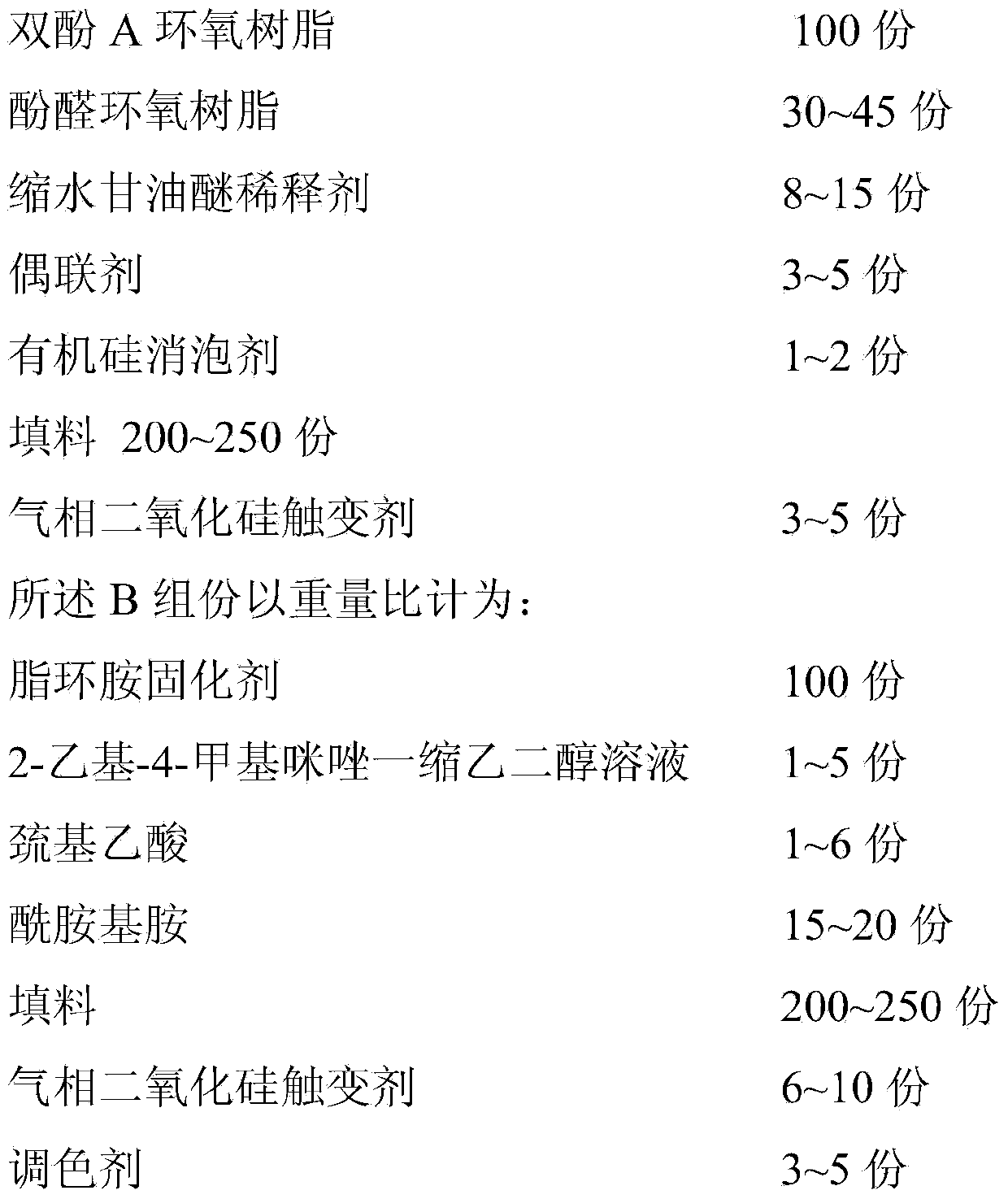

Structural adhesive for building of bridge with precast segmental matching method

InactiveCN103468189ALess heat releaseMeet the matching construction process requirementsNon-macromolecular adhesive additivesEpoxynovolac adhesivesAdhesiveMercaptoacetic acid

The invention relates to a structural adhesive for building of a bridge with a precast segmental matching method. Novolac epoxy resin and bisphenol A epoxy resin are matched via a certain proportion to form an epoxy resin system, an alicyclic amine hardener, amido amine, a 2-ethyl-4-methyl imidazole recoiled glycol solution and mercaptoacetic acid are adopted as accelerants to prepare a curing system, and the structural adhesive which is prepared from the epoxy resin system and the curing system according to the weight ratio of 3:1 has the characteristics that the low heat release and high early strength are realized, and the operable time is not less than 40 min, and meanwhile, in the use process of the structural adhesive, the colour and lustre are stable, and the technological requirements for matching construction of the bridge are met.

Owner:WUHAN JIANQIAO NEW MATERIAL TECH CO LTD

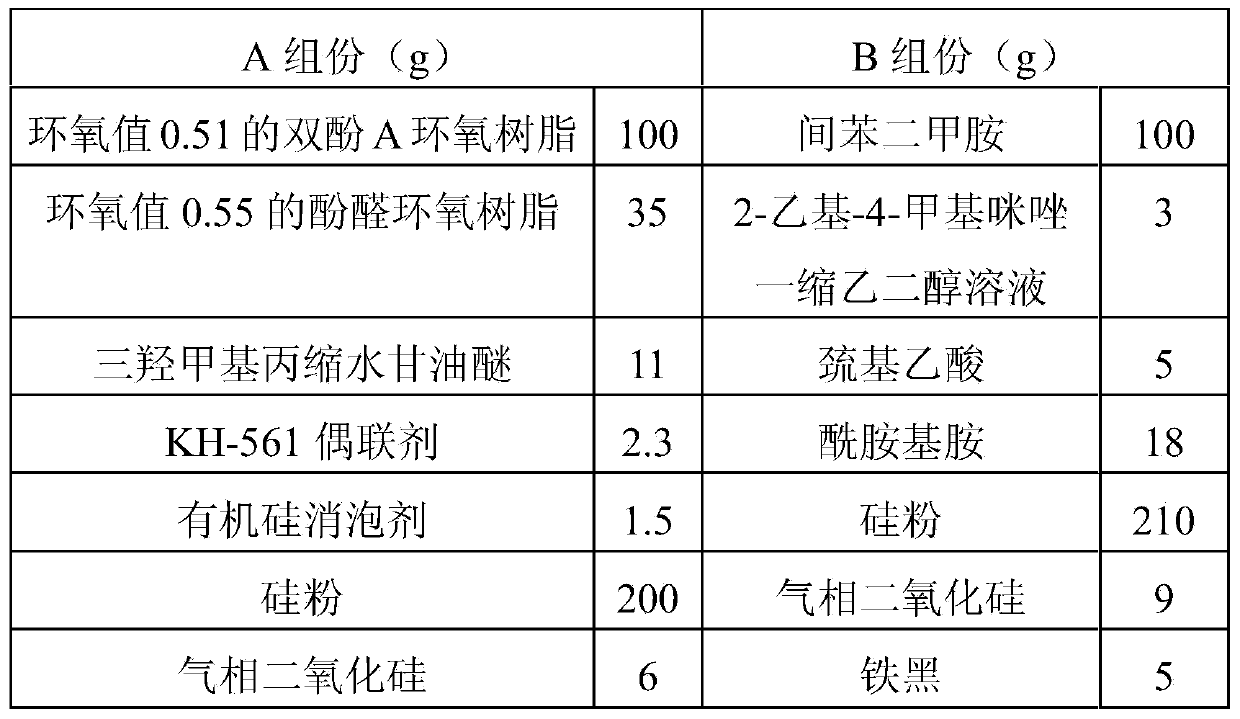

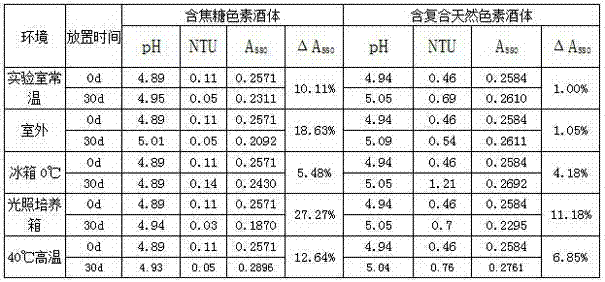

Compound natural pigment solution substituting for caramel pigment in compound wine

ActiveCN103937290ASimilar styleUnique fragranceAlcoholic beverage preparationNatural dyesCarcinogenFood flavor

The invention relates to a compound natural pigment solution substituting for caramel pigment in compound wine. The compound natural pigment solution is prepared from the following raw materials in mass fraction: 80%-90% of chestnut shell extract, 5%-10% of malt extract and 5%-10% of carthamin extract; after all the extracts are mixed, 0.5-1.0 time of water is further added for preparing concentrated liquid; the prepared compound natural pigment solution needs to simultaneously achieve the quality standard requirements of color index of 9000-11000, red index of 5.5-7.0 and absorbance of 0.04-0.07 at 580nm under the concentration of 0.1%. Compared with the wine prepared by the caramel pigment, the wine prepared by the compound natural pigment provided by the invention has similar color, similar style, unique flavor, soft taste, good stability and no carcinogen 4-methylimidazole, and can completely substitute for the caramel pigment in the existing compound wine.

Owner:JING BRAND

Ammonium sulfite method-based caramel colour production process

The invention relates to an ammonium sulfite method-based caramel colour production process, which includes the following steps: after materials are proportioned, the PH is regulated to 1.0 to 10.0; an ordinary method is adopted for a first-time reaction; the first-time reaction is not stopped until no DE value is detected; an ammonium sulfite catalyst is added after the materials are rapidly cooled to below 90 DEG C, and the materials and the ammonium sulfite catalyst are agitated sufficiently to be mixed uniformly; an ammonium sulfite method is adopted for a second-time reaction; the second-time reaction is stopped when the colour index meets the requirement, and cooling, filtration, preparation and filling are then carried out. The invention adopts the combination of an ordinary method-based caramel colour production process and the ammonium sulfite method-based caramel colour production process; the ordinary method-based caramel colour production process is first carried out to deplete the reducing sugar in reactants, blocking the reducing sugar as one of the necessary conditions for producing 4-methylimidazole; the ammonium sulfite catalyst is then added to carry out the ammonium sulfite method-based caramel colour production process to prepare caramel colour, and thereby the 4-methylimidazole content of a caramel colour product can be stably controlled at a level lower than 0.01mg / kg.

Owner:QIANHE CONDIMENT & FOOD CO LTD

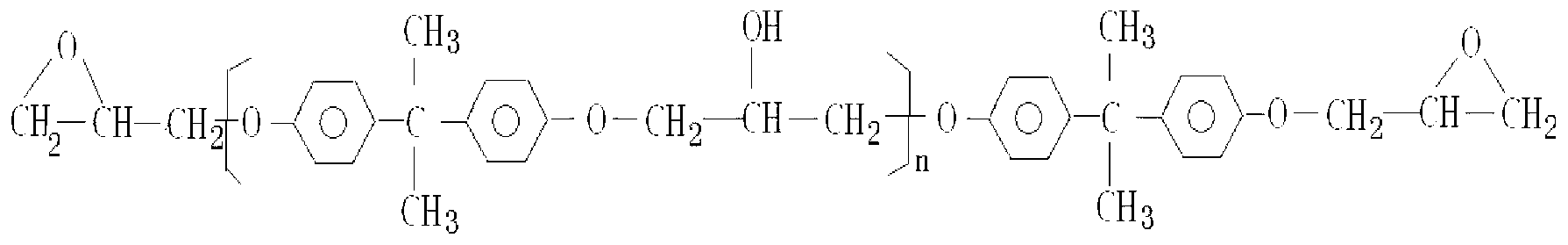

Insulating polymeric-material composition

InactiveUS20090281273A1High mechanical strengthImprove performancePlastic/resin/waxes insulatorsPrinted circuits4-MethylimidazoleHeating temperature

There is provided an insulating polymeric-material composition that is superior in insulating performance and mechanical strength and exerts no adverse influence on the global environment even after discarded. This insulating polymeric-material composition is obtained by mixing lignin as a curing agent with an epoxidized linseed oil and then conducting a heating treatment to cure it. As the lignin, for example, one obtained by blasting a lignin raw material and then conducting an alcohol extraction is used. The epoxidized linseed oil and the lignin are mixed together in such a proportion that epoxy equivalent of the epoxidized linseed oil:hydroxyl equivalent of the lignin=1:1. In the composition, as a curing acceleration agent, for example, 2-ethyl-4-methylimidazole is added by 0.2-2.0 parts by weight relative to 100 parts by weight of the epoxidized linseed oil. Upon this, it is cured under a condition, for example, of a heating temperature of 150-170° C. and a heating time of 10-20 hours. In some cases, the heating temperature is set to be formed of two different temperature regions.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

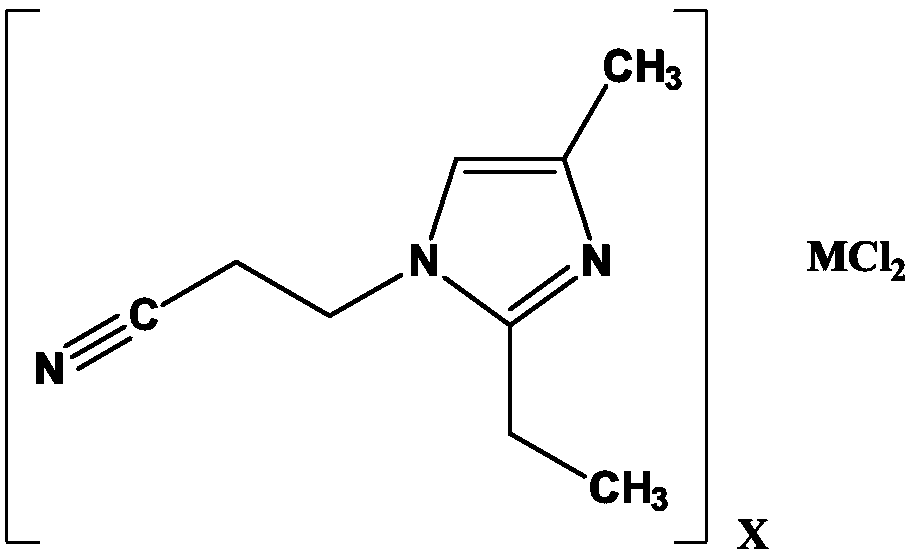

Modified imidazole epoxy resin latent curing agent as well as preparation method and application

The invention relates to a curing agent and particularly relates to a modified imidazole epoxy resin latent curing agent as well as preparation method and application. The curing agent is an imidazolemetal salt complex which is prepared by a reaction between 1-cyanoethyl-2-ethyl-4-methylimidazole and a transition metal chloride, wherein in the reaction, an alcohol compound is adopted as a solvent, and the reaction takes for 4-10 h at 60 DEG C; the solvent is removed by vacuum suction filtration and reduced-pressure distillation to obtain the product. The prepared curing agent and the epoxy resin have the characteristics of high compatibility, long room-temperature storage life and high reaction activity at high temperature; the epoxy curing product has good heat resistance and mechanicalproperty. The curing agent can serve as an epoxy resin latent curing agent and has a good application prospect in the fields of composite material production, adhesives, etc.

Owner:浙江百合航太复合材料有限公司

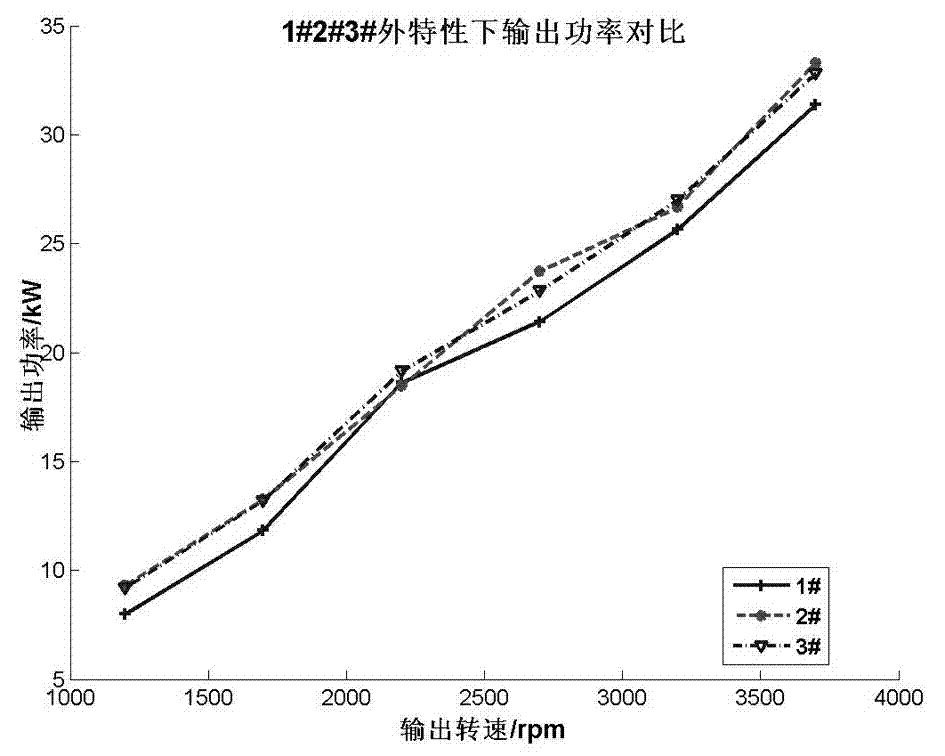

Additive for improving dynamic property of methanol gasoline

ActiveCN103695051AImprove combustion efficiencyImprove skillsLiquid carbonaceous fuelsFuel additivesBenzeneGasoline

The invention discloses an additive for improving dynamic property of methanol gasoline. The additive is prepared from the following raw materials by weight percent: 18.0-31.0% of 2,2-diisopropyl-1,3-dioxolane, 15.0-29.5% of aminoacetaldehyde diethyl acetal, 15.0-24.5% of 1,3-cyclooctadiene, 13.0-24.0% of 1-cyanoethyl-2-ethyl-4-methylimidazole, 10.0-20.5% of 5-methyl-2-heptylene-4-ketone and 9.0-19.5% of 1,4-bi(phenyl acetic diacyl) benzene in a manner of evenly stirring and mixing at normal temperature. According to the additive disclosed by the invention, the improvement effect on heat value power of the methanol gasoline is significant, and the dynamic properties such as acceleration are obviously superior to those of the same mark of methanol gasoline by adding 0.3-1.0% of methanol gasoline into the common methanol gasoline.

Owner:CRPC INNOVATION ENERGY

Preparation method of field-induced nonlinear conducting composite material, composite material prepared and application thereof

ActiveCN109370155ASimple processSimple and fast operationPlastic/resin/waxes insulatorsEpoxyOvervoltage

The invention discloses a preparation method of a field-induced nonlinear conducting composite material, a prepared composite material and an application thereof and relates to the field of nonlinearconducting composite materials. The preparation method comprises the following steps: taking KH560, ethanol and deionized water to obtain a solution A; adding GO into the solution A to react for 3-5 hours at 75-85 DEG C to obtain a suspension B; adding alkali into the suspension B till the pH is 10, adding hydrazine hydrate to be dispersed, heating the mixture to 85-95 DEG C to react for 5-7 hoursto obtain a suspension C, washing, suction filtering and drying the filter cake to obtain RKGO powder; mixing the RKGO powder, epoxy resin E-51 and acetone to obtain a suspension D, carrying out a reaction at 75-85 DEG C till the acetone is volatilized fully and cooled to 45-50 DEG C, adding a 2-ethyl-4-methylimidazole liquid to react, and extracting bubbles to be cured to obtain a composite material, wherein the RKGO filling mass fraction in the composite material is 0.75-1.50%. The preparation method is simple, low in cost, short in reaction time and easy to prepare massively. The preparedcomposite material is light in weight, good in uniformity and high in conducting nonlinear coefficient, and can be used in the fields of overvoltage protection, lightning stroke and surge protection,static prevention and self-adaptive electromagnetic pulse protection.

Owner:ARMY ENG UNIV OF PLA

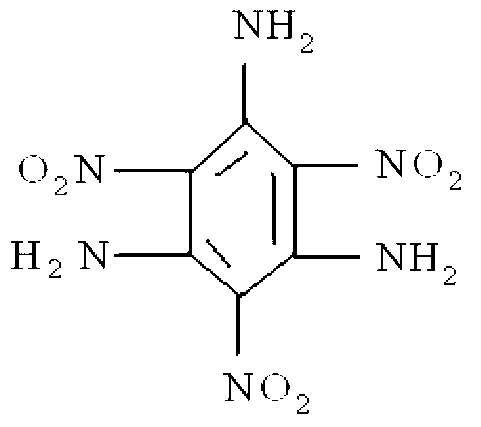

High-temperature-resistant solid propellant for deep oil-gas well and preparation method thereof

InactiveCN103304351AImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsSpontaneous combustion4-Methylimidazole

The invention provides a high-temperature-resistant solid propellant for a deep oil-gas well. The solid propellant is prepared from the following raw materials in percentage by weight: 33.00-58.00% of potassium perchlorate, 8.00-33.00% of TATB, 10.00-32.37% of high-temperature-resistant epoxy resin, 0-11.79% of bisphenol A epoxy resin, 0-12.77% of epoxy-resin reactive diluent, 0.03% of defoamer and 0.98-1.60% of 2-ethyl-4-methylimidazole, wherein the sum of the weight percent of the raw materials is 100%; and the raw materials of the propellant are subjected to premixing, remixing and molding so as to prepare a finished product. When the solid propellant is soaked in clean water and 3.5% brine for 24-48 hours, the loss of weight is lower than 3%, and the volume change is lower than 2%; and the temperature resisting level reaches 180 DEG C in 48 hours, and the spontaneous combustion does not occur, thus the solid propellant can be used in high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

Preparation method of cimetidine

The invention discloses a preparation method of cimetidine. The method comprises the following steps: (1) carrying out condensation reaction on 2-(methylimidazole-4-yl) methyl thioethylamine and N-cyanamide dialkyl carbonate in hot alcohol dehydratum, distilling out alcohol at ordinary pressure, cooling to a room temperature, crystallizing and filtering to obtain N-cyanogroup-N'-[2-(5-methylimidazole-4-yl) sulphur methyl ethyl]-O-R isourea; (2) carrying out amination reaction on the N-cyanogroup-N'-[2-(5-methylimidazole-4-yl) sulphur methyl ethyl]-O-R isourea and methylamine in a reaction medium, after reaction is ended, distilling methylamine at ordinary pressure, cooling to room temperature and crystallizing to obtain a cimetidine crude product; and (3) decoloring the cimetidine crude product in absolute ethyl alcohol, cooling, crystallizing, drying in vacuum, and crushing to obtain a cimetidine refined product. According to the preparation method, the environment pollution caused by by-product methyl mercaptan / sodium methyl mercaptide in an existing cimetidine production process can be solved; the production process is simplified; the cost is reduced; and the product quality is improved.

Owner:YANCHENG KAILI PHARMA

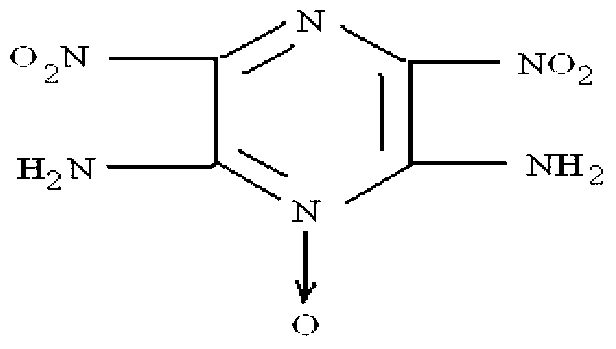

High-temperature-resistant solid propellant for deep oil-gas well and preparation method thereof

InactiveCN103304350AImprove hydrolysis resistanceImprove temperature resistanceInorganic oxygen-halogen salt explosive compositionsSpontaneous combustion4-Methylimidazole

The invention provides a high-temperature-resistant solid propellant for a deep oil-gas well. The solid propellant is prepared from the following raw materials in percentage by weight: 41.00-56.00% of potassium perchlorate, 10.00-25.00% of LLM-105, 10.00-32.37% of high-temperature-resistant epoxy resin, 0-11.79% of bisphenol A epoxy resin, 0-12.77% of epoxy-resin reactive diluent, 0.03% of defoamer and 0.98-1.60% of 2-ethyl-4-methylimidazole, wherein the sum of the weight percent of the raw materials is 100%; and the raw materials of the propellant are subjected to premixing, remixing and molding so as to prepare a finished product. When the solid propellant is soaked in clean water and 3.5% brine for 24-48 hours, the loss of weight is lower than 3%, and the volume change is lower than 2%; and the temperature resisting level reaches 180 DEG C in 48 hours, and the spontaneous combustion does not occur, thus the solid propellant can be used in high-temperature watery environment.

Owner:XIAN MODERN CHEM RES INST

Preparation method of poly(N-isopropyl acrylamide)/graphene composite materials with photo-thermal responsiveness

InactiveCN109023706ARaw materials are easy to getThe experimental ratio is easy to adjustElectro-spinningMonocomponent synthetic polymer artificial filamentElectricityElectrospinning

The invention discloses a preparation method of poly(N-isopropyl acrylamide) / graphene composite materials with photo-thermal responsiveness. The method comprises steps of firstly, adding the poly(N-isopropyl acrylamide) into graphene dispersion liquid; then, adding eight glycidol-based polyhedron polysilsesquioxane and 2-ethyl-4-methylimidazole; carrying out uniform stirring and dispersion, acquiring electricity texture liquid; through an electrostatic spinning method, obtaining a spinning thin film containing poly(N-isopropyl acrylamide) / graphene; and after crosslinking, obtaining composite materials with the photo-thermal responsiveness. According to the invention, based on the electrostatic spinning method, materials are prepared; the material ratio is easy to modulate and control; thematerials are easy to prepare; the obtained materials have advantages of high response speed and obvious response feature change and favorable application prospects.

Owner:HEFEI UNIV OF TECH

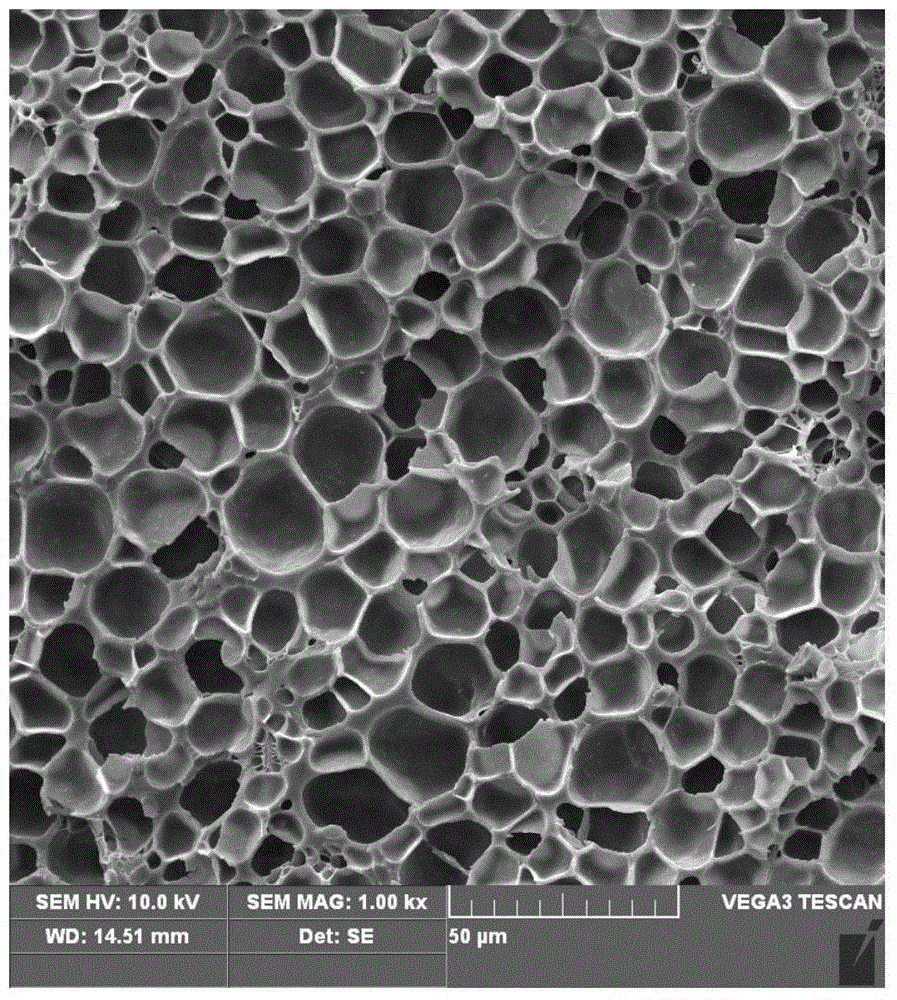

Preparation method of epoxy resin microporous materials

The invention discloses a preparation method of epoxy resin microporous materials in order to solve the technical problems that epoxy resin foam materials prepared through an existing method are large in cell size and small in number of cells. According to the technical scheme, bisphenol-A epoxy resin and 2-ethyl-4 methylimidazole serve as raw materials, and the uniform-structure epoxy resin microporous materials are prepared through pressing forming of pre-curing sheets, gas saturation, high-temperature foaming and post-curing treatment. According to the preparation method, environment-friendly supercritical CO2 serves as foaming agents, because supercritical CO2 fluid has good dissolving capacity and diffusion performance, the average cell size of the prepared epoxy resin microporous materials is reduced to 5.84-20.2 microns from the 100 microns in the technical background, and the minimum cell size reaches 5.84 microns. The cell density is increased to 1.09*108-1.47*109 / cm<3> from the 106 / cm<3> in the technical background, and the maximum cell density reaches 1.47*109 / cm<3>.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com