Patents

Literature

51 results about "Dibromoneopentyl glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength flame-retardant modified polyurethane composite material

The invention discloses a high-strength flame-retardant modified polyurethane composite material including: hydroxyl-terminated polybutadiene, polytetrahydrofuran ether glycol, polypropylene glycol, toluene diisocynate, 4,4'-diphenylmethane diisocynate, bisphenol A, dibromoneopentyl glycol, dimethythiotoluene diamine, diaminodiphenylmethane, 2-ethyl-4-methylimidazole, dibutyltin dilaurate, diglycidyl resorcinol ether, a filling material, melamine, ammonium polyphosphate, and N,N'-bis(2-thio-5,5-dimethyl-1,3,2-dioxaphosphocyclohexyl)ethylenediamine. The high-strength flame-retardant modified polyurethane composite material has high strength, is excellent flame-retardant performance and can satisfy use demands in various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Novel flame-retardant polyurethane adhesive and preparation method thereof

InactiveCN104232006ASimple production processImprove flame retardant performancePolyureas/polyurethane adhesivesCross-linkPolyurethane adhesive

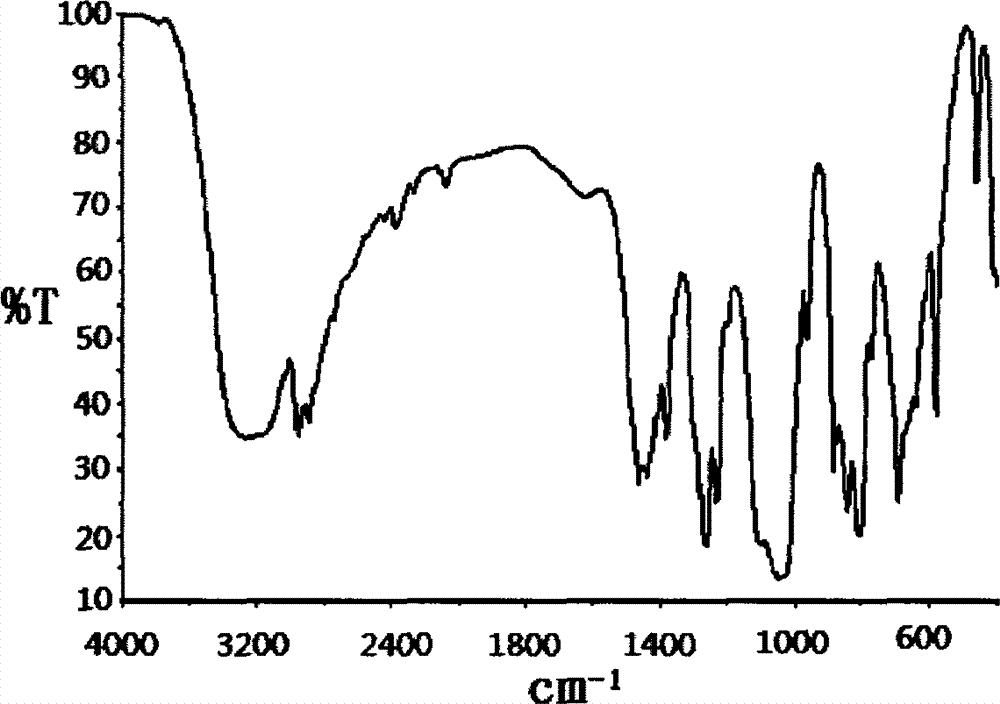

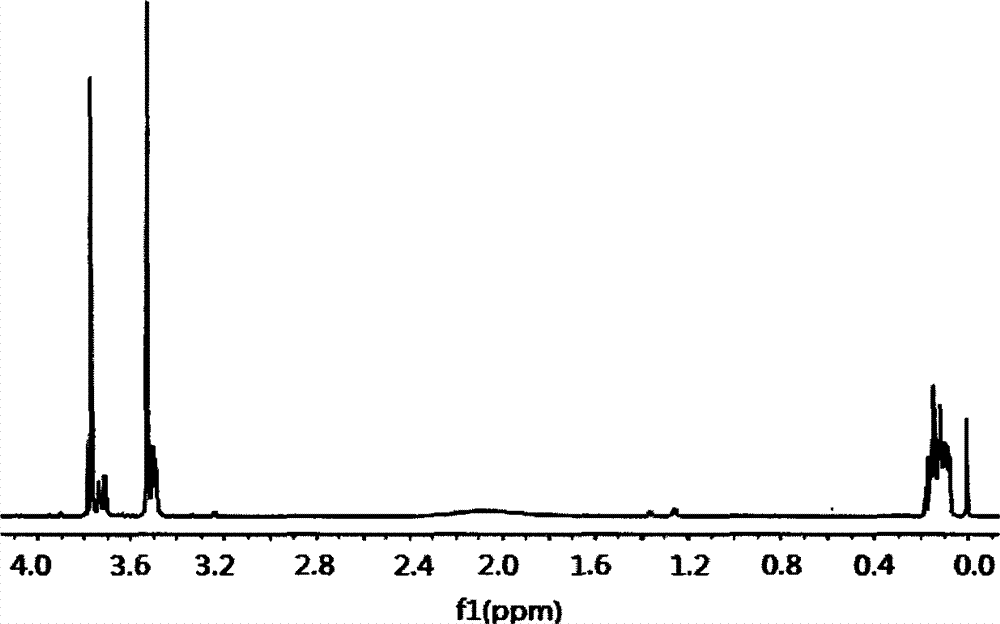

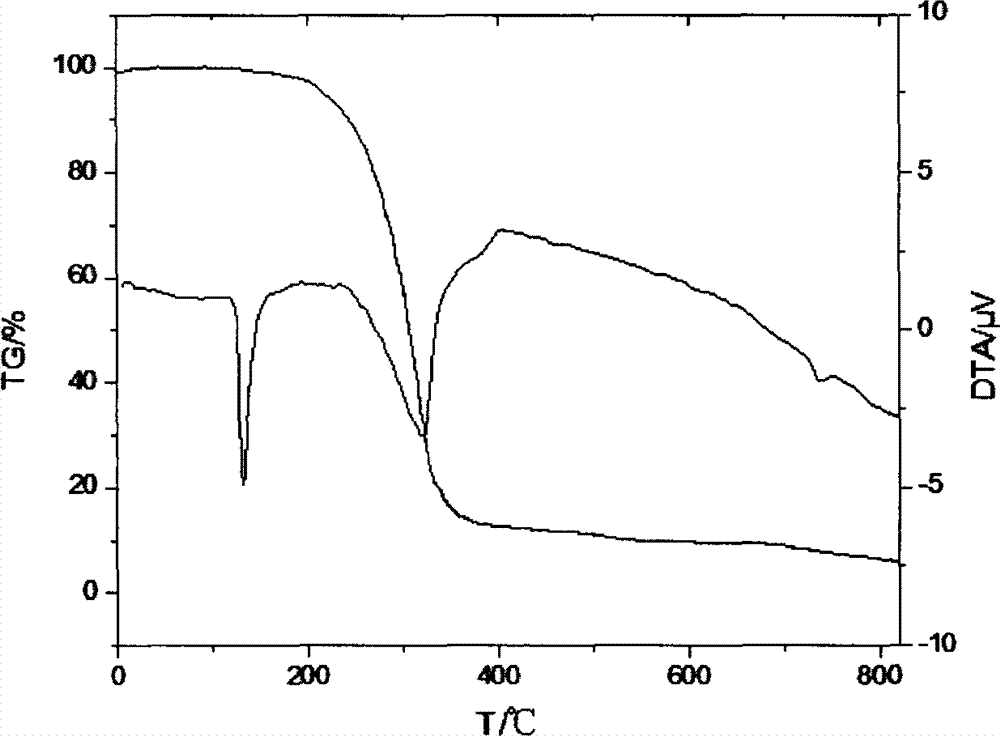

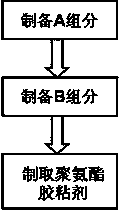

The invention provides a novel flame-retardant polyurethane adhesive and a preparation method thereof. The novel flame-retardant polyurethane adhesive is prepared from polytetrahydrofuran diol 1000, toluene diisocynate, a reaction type flame retardant, a chain extender and a cross-linking agent, wherein the reaction type flame retardant is dibromoneopentyl glycol; the chain extender is 1,4-butanediol; the cross-linking agent is trimethylolpropane. The preparation method comprises the following steps: (a) preparing a component A; (b) preparing a component B; and (c) preparing the polyurethane adhesive. The invention discloses the novel flame-retardant polyurethane adhesive and the preparation method thereof. The polyurethane adhesive is simple and feasible in production process, is not only excellent in flame retardant property, but also relatively long in service life, relatively good in thermal stability and relatively low in glass-transition temperature.

Owner:太仓康盛化工有限公司

High-strength polyurethane composite material

The invention discloses a high-strength polyurethane composite material. The high-strength polyurethane composite material comprises the following raw materials: hydroxyl-terminated polybutadiene, polytetrahydrofuran ether glycol, toluene diisocynate, 4,4'-diphenyl methane diisocyanate, 1,4-butanediol, dibromoneopentyl glycol, dibutyltin dilaurate, dimethythiotoluene diamine and a modified composite filler, wherein the modified composite filler is prepared according to the following process: adding a silane coupling agent TM551 and anilinomethyl triethoxysilane to toluene, stirring the materials uniformly, adding carbon black, medium super abrasion furnace black, multiwalled carbon nanotubes, barium sulfate and nano titania and stirring the materials to react at room temperature after ultrasonic dispersion, thus obtaining the high-strength polyurethane composite material. The high-strength polyurethane composite material provided by the invention has high strength and good heat resistance and can meet the use requirements of various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

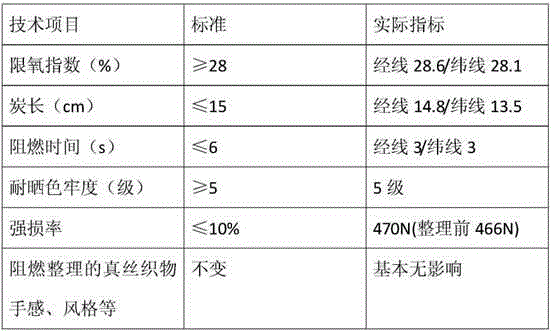

Silkworm silk flame retardant aid and flame retardation arrangement method

ActiveCN102660868AEfficient Flame RetardancyGood flame retardant propertiesAnimal fibresOligomerPhosphate

The invention provides a silkworm silk flame retardant aid which comprises the components of dibromoneopentyl glycol (DBNPG), a dibromoneopentyl glycol phosphate cyanamide salt, a hydroxy-containing non-polar phosphorus oligomer (HFPO), and 1,2-butanetetracarboxylic acid (BTCA), wherein the mass of the components of same mass or largest contents in the flame retardant aid does not exceed 10% of the mass of component of the lowest mass. The invention also provides a silkworm silk flame retardation arrangement method. The method comprises the following steps: 1, preparing or providing the flame retardation aid; 2, diluting by adding purified water having a weight two times the weight of the flame retardation aid, and uniformly stirring; 3, adding silkworm silk to be subjected to flame retardation arrangement to a flame retardation arrangement liquid prepared in last step, wherein the weight ratio of the silkworm silk to the flame retardation arrangement liquid does not exceed 0.9:1, and the error is equal to or less than 10%; and 4, drying the silkworm silk subjected to the flame retardation arrangement in step 3 with a dewaterer, and drying with a flat tender. The flame retardation aid provided in the invention is halogen-free and nontoxic. The silkworm silk flame retardation arrangement method provided in the invention, which effectively uses the flame retardation aid, is economic and reasonable.

Owner:ZHEJIANG GOOD LUCK GROUP

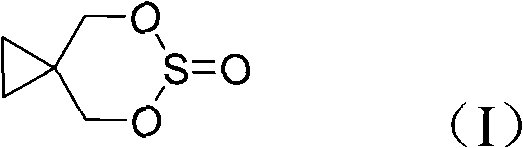

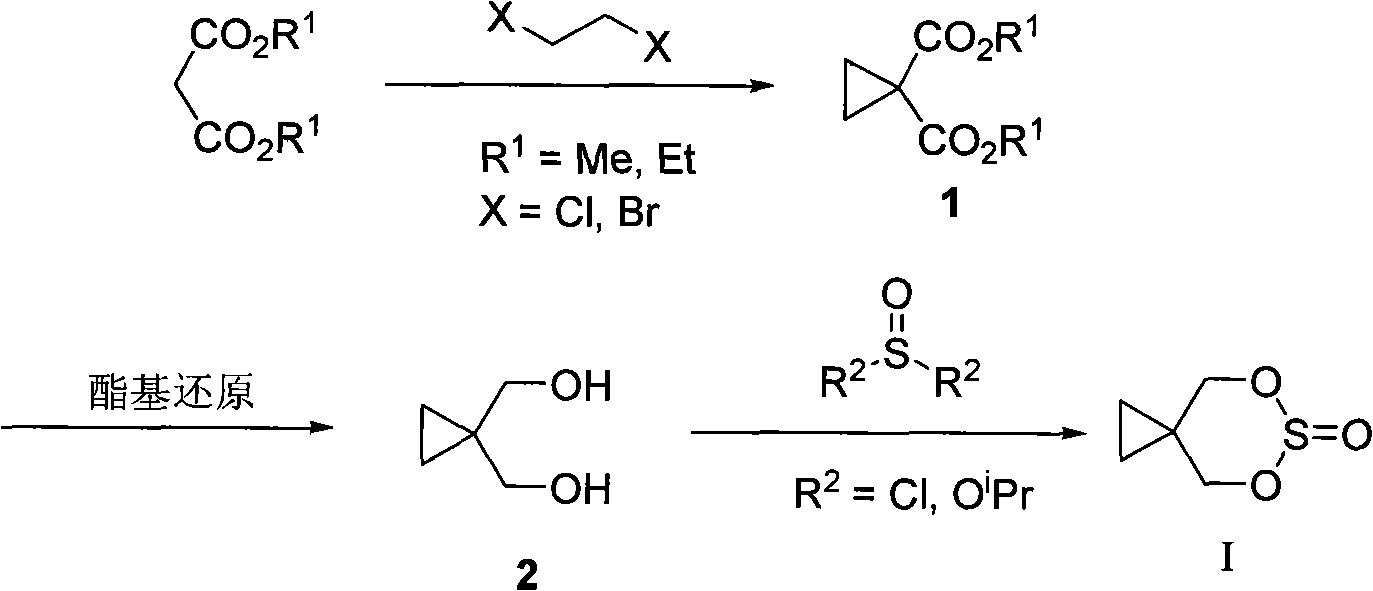

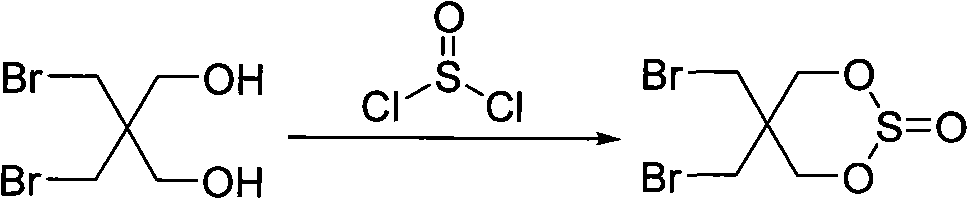

Method for preparing 1,1-cyclopropanedimethyl cyclicsulfite

The invention discloses a method for preparing 1,1-cyclopropanedimethyl cyclicsulfite. In the method, dibromoneopentyl glycol serving as a raw material is reacted with thionyl chloride in a first reaction solvent to form cyclicsulfite serving as a solid intermediate; and the cyclicsulfite is reacted with zinc powder in a second reaction solvent to form a 1,1-cyclopropanedimethyl cyclicsulfite product. The preparation method provided by the invention achieves high reaction yield, simplifies reaction steps, reduces cost and is more favorable for industrial production.

Owner:GROWINGCHEM

Composite flame retardant modified polyurethane composite material

The invention discloses a composite flame retardant modified polyurethane composite material, the raw materials of which include: polyether polyol, 4,4'-diphenylmethane diisocyanate, toluene diisocyanate, epoxy resin, acrylic resin, pentaerythritol tri Allyl Ether, Anilinomethyltriethoxysilane, Trimethylolpropane, Dibromoneopentyl Glycol, Dibutyltin Dioctoate, Dimethylthiotoluenediamine, 4,4'-Methylenebis-Ortho Chloroaniline, attapulgite, montmorillonite, hollow glass microspheres, white carbon black, expanded vermiculite, multi-walled carbon nanotubes, epoxidized natural rubber, composite flame retardant; composite flame retardant consists of expandable graphite, A mixture of zinc stannate and P‑N‑Si flame retardant. The composite flame retardant modified polyurethane composite material proposed by the invention has high strength and excellent flame retardancy, and can meet the use requirements in various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Preparation method of polyurethane composite material with heat-resistant property

InactiveCN108864694AHigh benzene ring contentImprove rigidityDibutyltin dilaurateMechanical property

The invention discloses a preparation method of a polyurethane composite material with heat-resistant property, and relates to the technical field of preparation of polyurethane. The preparation method comprises the following steps of mixing epoxidated hydroxyl terminated polybutadiene, polytetrahydrofuran ether glycol, 4,4'-diphenylmethane diisocyanate, and dibutyltin dilaurate, heating to react,adding 3,5-dimethyl sulphide toluene diamine and dibromo neopentadiol, stirring to react, defoaming, drying and aging, so as to obtain a polyurethane prepolymer; adding the polyurethane prepolymer, phenolic resin, styrene, xanthophyll, white carbon black, nanometer silicon dioxide, kaolin and a plasticizer into a double-screw mixer, mixing, adding aluminum hydroxide, zinc borate, zinc stearate, avulcanizing agent and a vulcanizing accelerator, mixing, and discharging, so as to obtain the mixed material; molding and forming the mixed material, and radiating by 60Co gamma rays, so as to obtainthe polyurethane composite material. The polyurethane composite material has the advantages that the heat stability and the mechanical property are good, and the aging-resistant property is good.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

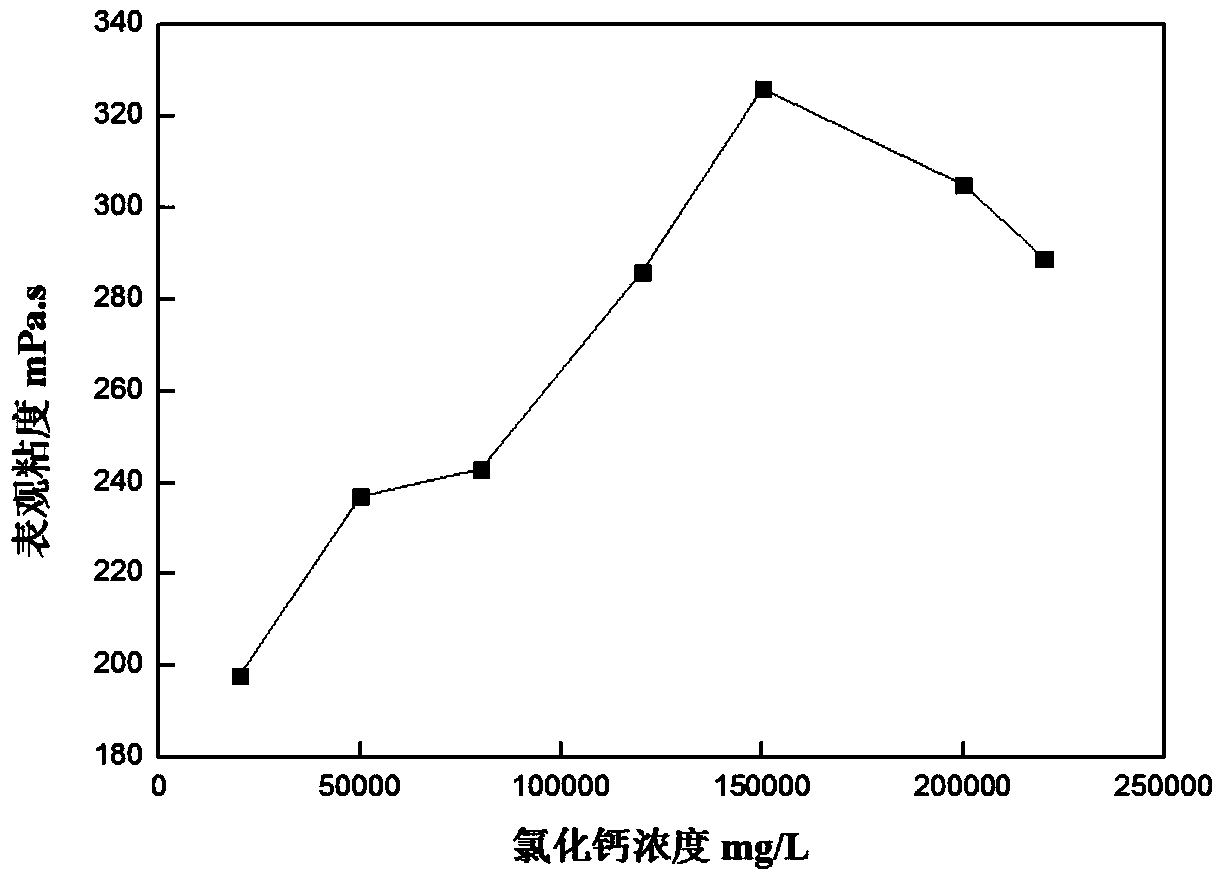

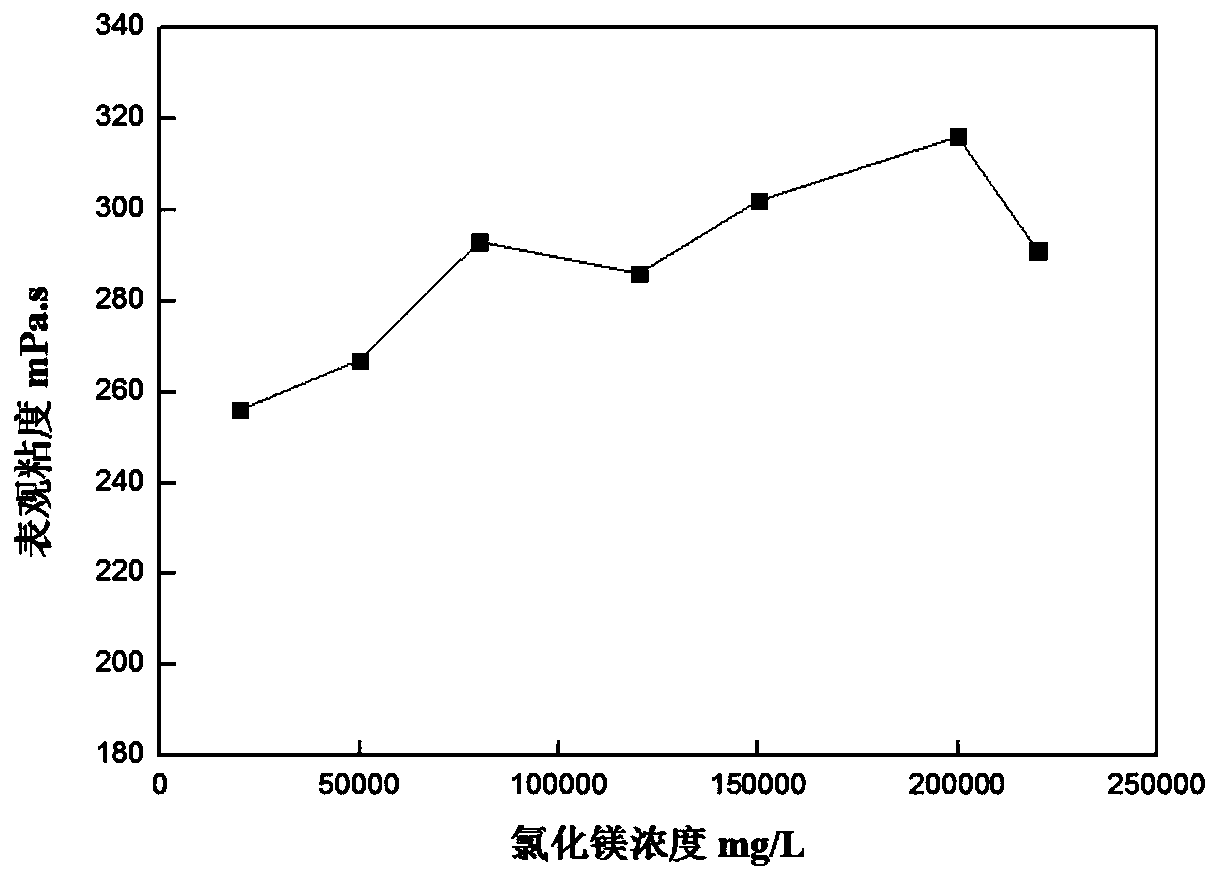

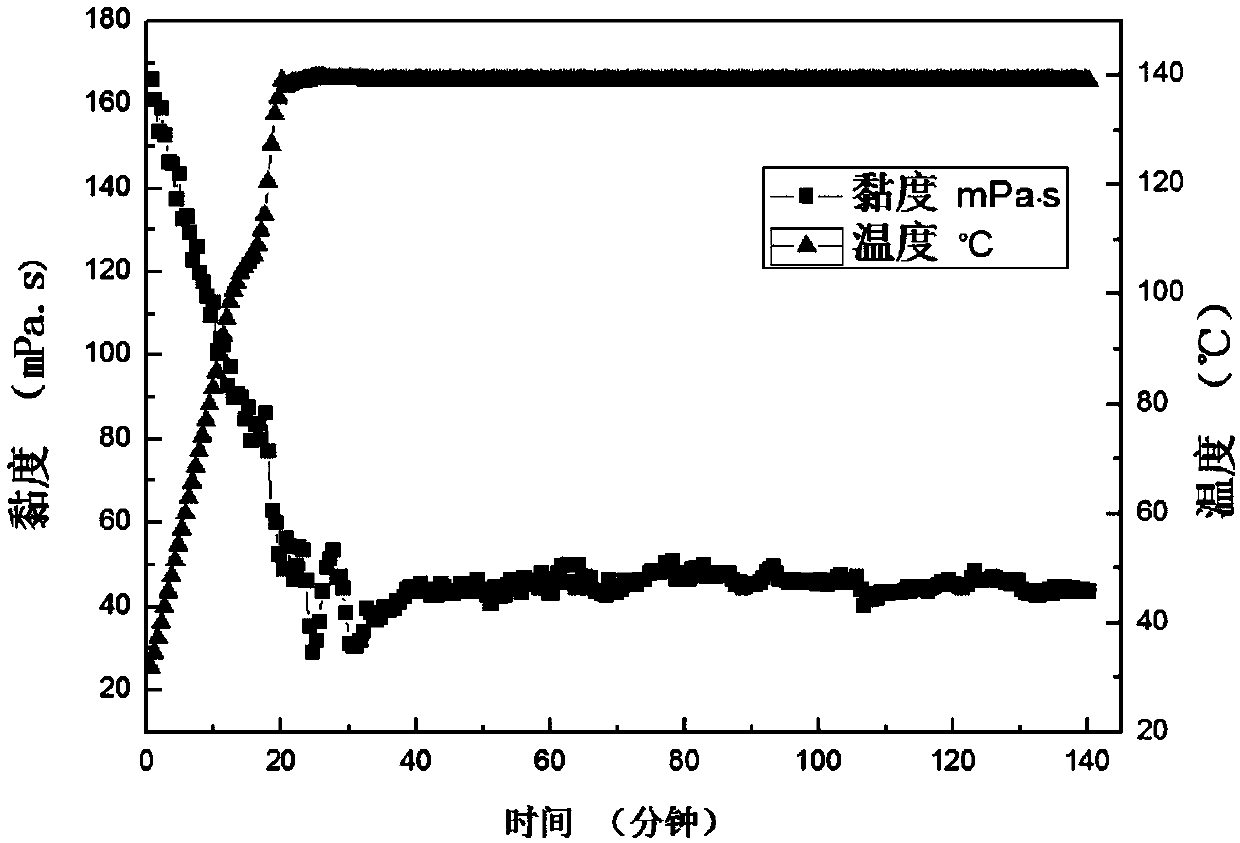

Salt-tolerant Gemini cation VES (Viscoelastic Surfactant) as well as preparation method thereof and salt-tolerant clean fracturing fluid

InactiveCN109536155AImprove surface activityHigh viscoelasticityDrilling compositionFracturing fluidSalinity

The invention discloses a salt-tolerant Gemini cation VES (Viscoelastic Surfactant) as well as a preparation method thereof and salt-tolerant clean fracturing fluid. The salt-tolerant Gemini cation VES is synthesized and obtained by taking fatty acid amide propyl dimethylamine and dibromoneopentyl glycol as raw materials, micelle can be formed by the salt-tolerant Gemini cation VES under the action of hypersalinity sea water or stratum water, so that a solution can have good viscoelasticity, the salinity tolerance of the salt-tolerant Gemini cation VES can be up to 150,000 mg / L or above, the salt-tolerant Gemini cation VES can be used for preparing seawater-based clean fracturing fluid, and meanwhile, gel breaking caused after the salt-tolerant Gemini cation VES encounters the hypersalinity stratum water can be avoided; the salt-tolerant Gemini cation VES can also be used for preparing the seawater-based clean fracturing fluid, and the tolerable maximum salinity can be up to 200,000 mg / L. The preparation method disclosed by the invention is simple, and the yield of products is increased to a large extent and is commonly up to 96 percent; in addition, reaction byproducts are less, and the influence on the properties of the products is small; during preparation of the clean fracturing fluid, the using amount of the salt-tolerant Gemini cation VES is reduced, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

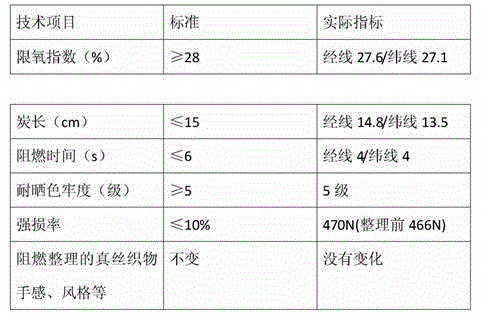

Mulberry silk flame retardant agent

The invention relates to a mulberry silk flame retardant agent. The innovation point is that the flame retardant agent is composed of the following ingredients: dibromoneopentylene glycol DBNPG, dibromoneopentyl glycol phosphate ester cyanamide salt, polyhydroxyl organophosphorus oligomer HFPO and 1,2,3,4-butanetetracarboxylic acid BTCA. The mass ratio of the above ingredients in the flame retardant agent is 2:3:3:1. By the technical scheme, BTCA in the flame retardant agent is connected with a hydroxyl group on silk fiber through simple ester bond, and BTCA can be directly connected with silk and HFPO or a BTCA-HFPO-BTCA bond can be connected between two silk protein molecules. After finishing with BTCA and HFPO, silk shows high-efficiency flame retardancy. In addition, the flame retardant agent provided by the invention is nontoxic and has no adverse effect on the environment. By a mulberry silk flame-proof treatment method, the above flame retardant agent can be effectively utilized, and mulberry silk treated by the use of the flame retardant agent has excellent flame retardancy property and still maintains original silk quality. Besides, flame-proof treatment cost is the most economic and rational.

Owner:XINYUAN SILKWORM SILK GRP CO LTD

Preparation method of heat-resistant flame-retardant polyurethane

InactiveCN105860502AImprove mechanical propertiesImprove hydrolysis resistanceGlutaric acidTrimethylolpropane

The invention discloses a preparation method of heat-resistant flame-retardant waterborne polyurethane. The method comprises the following steps of stirring gamma-(Trimethoxysilyl)-3-aza-hexylamine, N, N-dimethylcyolohexlemine and tetrahydrofuran, and then adding phenyl dichlorophosphate; after the reaction, obtaining a P-N-Si flame retardant; performing a heat insulation reaction on dibromoneopentyl glycol, m-phthalic acid-5-stannous octoate, and then adding the terephthalic acid, glutaric acid and trimethylolpropane; performing heating and stannous octoate, and adding dimethyl benzene until the materials are fused; performing backflow reaction to obtain polyester polyol; adding the polyester polyol and toluene di-isocyanate into a reaction device; adding 1, 4-butylene glycol after the reaction; after the reaction, adding the P-N-Si flame retardant, expansible graphite, multiwalled carbon nanotube and triethylamine; after the reaction, adding acetone; obtaining a finished product after the treatment. The preparation method of heat-resistant flame-retardant polyurethane provided by the invention has the advantages that the steps are simple; the conditions are mild; the obtained composite material has high intensity, excellent flame-retardant performance and good heat resistance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Preparation method and application of flame-retardant polyether containing N and Br

The invention discloses a preparation method and application of flame-retardant polyether containing nitrogen and bromine. The flame-retardant polyether contains N and Br elements and is reactive flame-retardant polyether. According to the preparation method, the flame-retardant polyether containing N and Br is prepared from the following raw materials in parts by weight: 5-10 parts of ethylenediamine, 20-35 parts of dibromoneopentyl glycol, 0.5-2.0 parts of dimethylamine and 53-74.5 parts of epoxy propane. Polyurethane foaming plastics prepared from the flame-retardant polyether have a favorable flame-retardant effect and have the advantages of stable flame retardance and better foam quality as comparison with polyurethane foaming plastics prepared by additionally adding a flame retardant.

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

Flame retardant plastic woven bag

InactiveCN105400070AImprove flame retardant performanceMeet needsPolymer scienceTetrabromobisphenol A

The invention discloses a flame retardant plastic woven bag. According to the formula and technology, 30-80 parts by weight of a plasticized flame-retardant master batch A, 30-80 parts by weight of a plasticized flame-retardant master batch B, 30-80 parts by weight of a plasticized flame-retardant master batch C, 10-30 parts by weight of nanom calcium carbonate and 100 parts by weight of polypropylene grain are jointly put into a drying mixer to be stirred and mixed into a mixture; the mixture is blown into films through a film blowing machine, and drawing and winding are performed; the wound wires are circularly knitted and formed. Due to the fact that various flame retardants with the good flame retardant efficiency such as antimonous oxide, dibromoneopentyl glycol, decabromodiphenyl ether, magnesium hydrate and aluminum hydroxide are adopted in the flame retardant master batches, the flame retardant performance of the woven bag is improved, and the films are washed through TBBP-A in the production process, so that the flame retardant performance of the woven bag is further improved, and the requirement of the market for the flame retardant woven bag is met.

Owner:潜山县恒源塑业有限责任公司

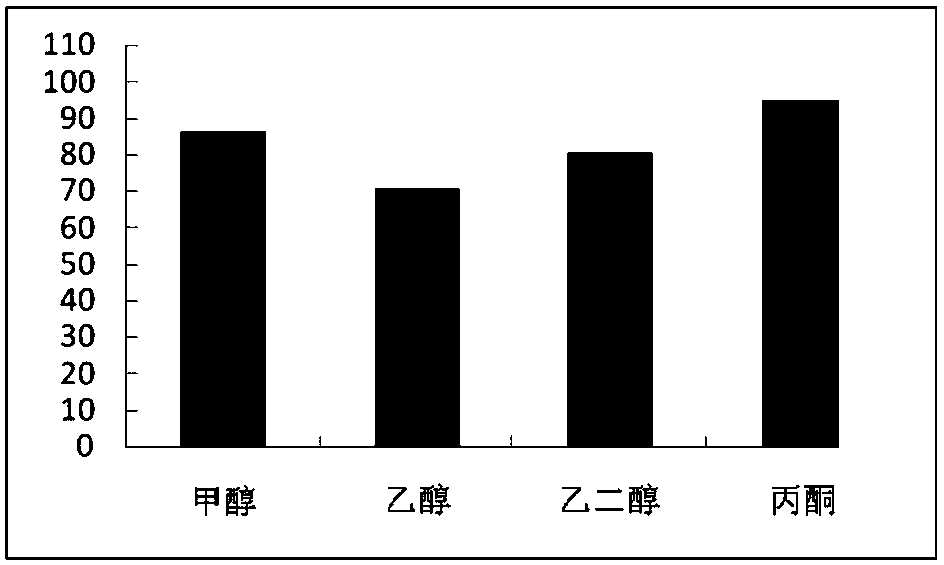

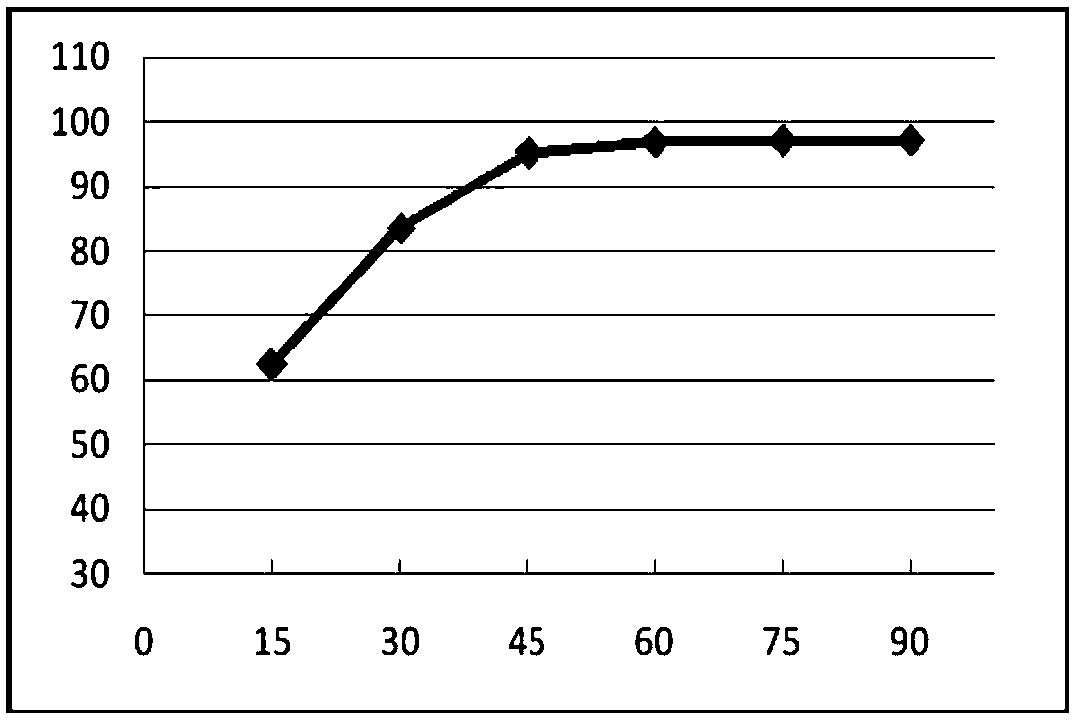

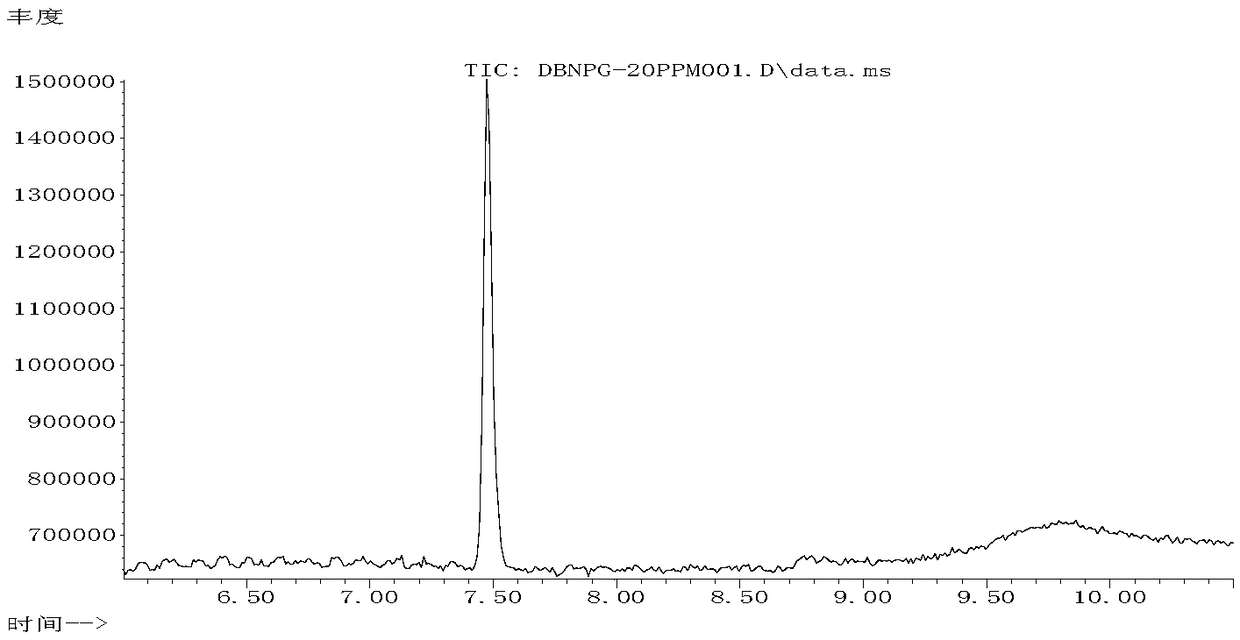

Method for detecting dibromoneopentyl glycol in textiles

ActiveCN108205036AQuickly know the concentrationThe test result is accurateComponent separationRelative standard deviationGas chromatography–mass spectrometry

The invention discloses a method for detecting dibromoneopentyl glycol in textiles. The method comprises pre-treatment on a sample: taking a sample to be tested, adding acetone into the sample, carrying out ultrasonic extraction and collecting the extract to obtain a solution to be tested, and gas chromatography-mass spectrometry detection: carrying out gas chromatography-mass spectrometry detection on the filtrate and carrying out quantification through an external standard method, wherein the gas chromatography conditions comprise a DB-624 capillary column as a chromatographic column, a programmed heating mode, a sample inlet temperature of 230-260 DEG C and a splitless sample introducing mode and the mass spectrometry conditions comprise electron bombardment ionization, an ion source temperature of 200-230 DEG C, a gas chromatography-mass spectrometry interface temperature of 230-280 DEG C and a full scanning mode and a selected ion scanning mode as collection modes. The method hasa fast detection rate, a detection limit of 0.045 mg / L, an adding standard recovery rate of 99.4%-100.7% and relative standard deviation of less than or equal to 3.6%.

Owner:广电计量检测(成都)有限公司 +1

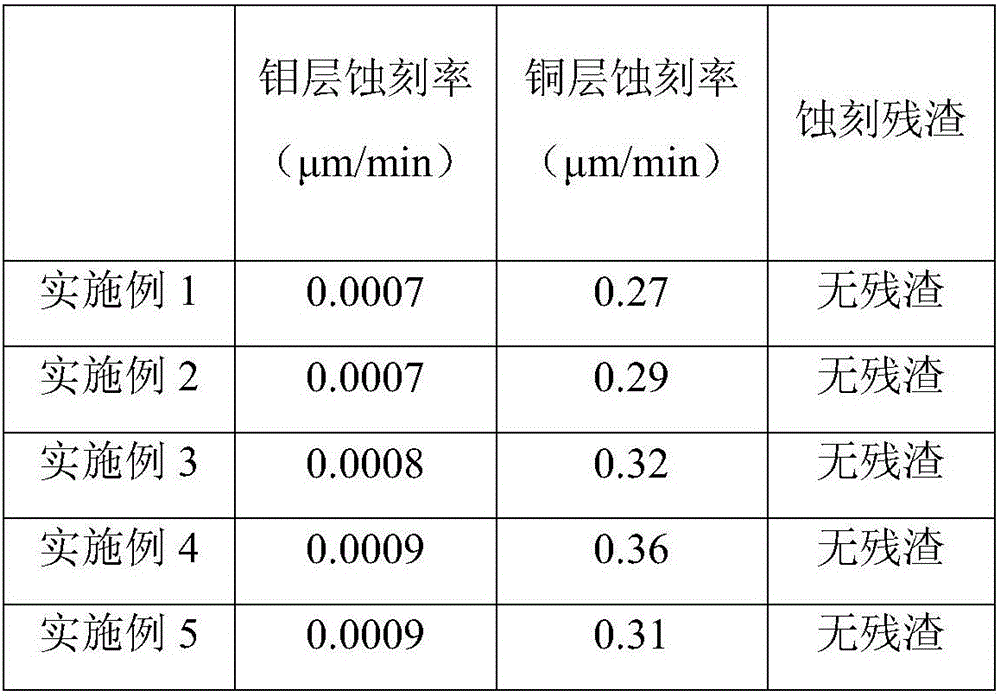

High-elasticity anti-shock polyimide foamed material and preparation method thereof

The invention discloses a high-elasticity anti-shock polyimide foamed material and a preparation method thereof. The material is prepared from, by weight, 60-80 parts of benzophenone tetracarboxylic dianhydride, 60-70 parts of methyl alcohol, 40-50 parts of malondialdehyde, 12-14 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 6-8 parts of triethylamine, 7-9 parts of n-pentane, 3-4 parts of dibasic lead stearate, 8-10 parts of 4,5-cyclohexene oxide-1,2-diformic diglycidyl ester, 5-7 parts of didodecyl carbon alcohol ester, 6-9 parts of phenyl triethoxy silane, 4-6 parts of epoxidized soybean oil, 4-5 parts of dibromoneopentyl glycol, 20-25 parts of ceramsite sand, 10-12 parts of tomentum powder, 5-7 parts of hollow silicon dioxide nanospheres, 4-5 parts of pyrolysis waste rubber powder, 4-6 parts of expanded graphite, 3-5 parts of hydrotalcite, 5-8 parts of jute fibers and 2-4 parts of molybdenum disulfide. The added 4,5-cyclohexene oxide-1,2-diformic diglycidyl ester has high rebound resilience, torsion stress and toughness, and foam has good shock resistance and buffer performance after the 4,5-cyclohexene oxide-1,2-diformic diglycidyl ester is combined with the added hollow silicon dioxide nanospheres, tomentum powder and the like; the added expanded graphite and hydrotalcite are compounded in use, so that the flame retardant property of the material is enhanced.

Owner:瑞安市智造科技有限公司

Radiation-resistant paint for walls and preparation method thereof

InactiveCN104893480AImprove stabilityGood chemical resistanceFireproof paintsAntifouling/underwater paintsPolymer scienceMeth-

The invention relates to a radiation-resistant paint for walls and a preparation method thereof. The paint contains the following components in parts by mass: 22-34 parts of nano modified pure acrylic emulsion, 10-20 parts of hydroxy ethyl polymethacrylate, 15-25 parts of zinc methacrylate soap, 2-7 parts of tri(2,3-dibromopropyl) phosphate, 1-7 parts of trimethylolpropane, 2-9 parts of melamine formaldehyde resin, 1-6 parts of rosin modified phenolic resin, 1-5 parts of polyphosphonate, 4-16 parts of argil, 0.4-2.2 parts of clay, 8-22 parts of zirconium oxide whisker, 3-10 parts of glass microsphere, 7-15 parts of dicumyl peroxide, 5-15 parts of boric acid, 7-16 parts of dibromoneopentyl glycol, 1-6 parts of propanediol aether acetate and 2-10 parts of distilled water. The paint provided by the invention can effectively barrier electromagnetic waves, static electricity rays, infrared heating effects and other radiations.

Owner:SUZHOU DEXIANG DECORATION ENG

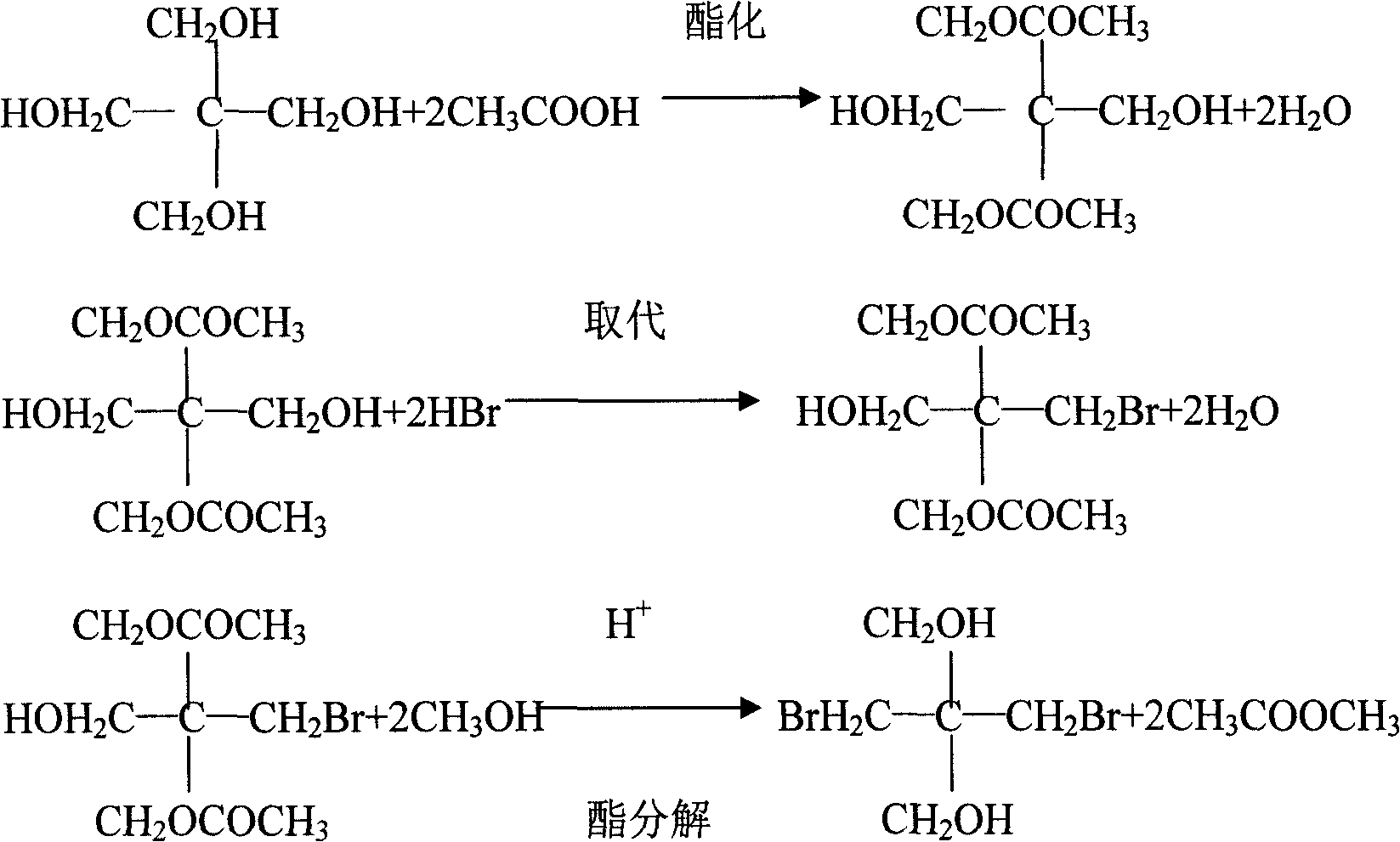

Preparation method of 5-oxaspiro[2,4]heptane-6-one and intermediate thereof

The invention relates to a preparation method of 5-oxaspiro[2,4]heptane-6-one (I). The preparation method comprises the following steps: taking dibromoneopentyl glycol (V) as the primary raw material, carrying out a cyclization reaction in the presence of zinc powder so as to obtain cyclopropyl dimethanol (IV), subjecting the cyclopropyl dimethanol (IV) to react with thionyl chloride so as to obtain cyclopropyl dimethanol cyclicsulfite (III); carrying out a ring-opening reaction on the cyclopropyl dimethanol cyclicsulfite (III) in the presence of cyanide so as to obtain a nitrilo-alcohol compound (II); hydrolyzing the compound (II) under an alkaline condition, and then carrying out a ring-closing reaction under an acidic reaction so as to obtain the 5-oxaspiro[2,4]heptanes-6-one (I), whose structural formula is represented in the description. The preparation method has the advantages of smart design, cheap and available primary raw materials, simple and applicable technology process, benefit for industrial production, and suitability for large-scale promotion and application.

Owner:SHANGHAI PUYI CHEM CO LTD

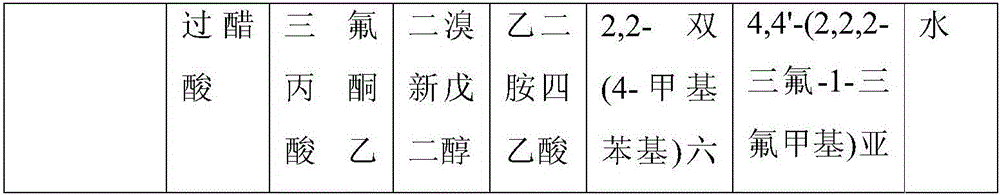

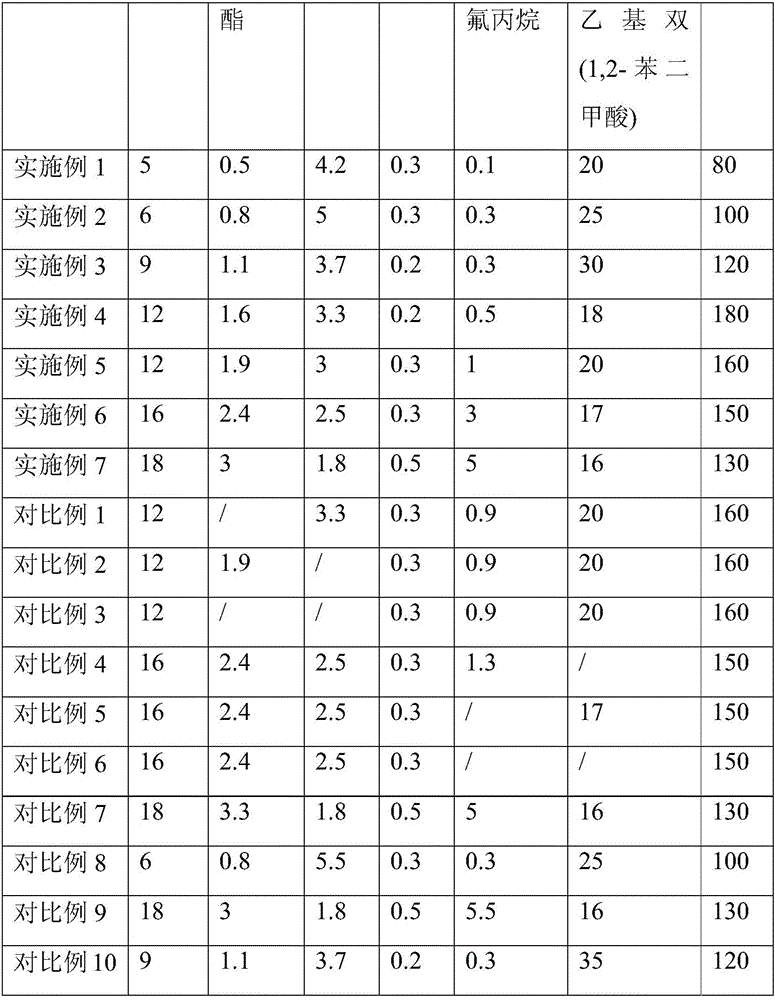

Selective etching solution for copper or copper alloy

The invention provides a selective etching solution for copper or copper alloy. The etching solution comprises peracetic acid, ethyl trifluoropyruvate, dibromoneopentyl glycol, ethylenediamine tetraacetic acid, 2,2-bis(4-methylphenyl)hexafluoropropane, 4,4'-(2,2,2-trifluoro-1-(trifluoromethyl)ethylidene)bisphthalic acid and water. The etching solution has obviously high etching efficiency and etching selectivity, hardly etches a molybdenum layer, and has a high etching rate for a copper layer. Besides, the etching solution provided by the invention can not produce etching residue in the etching process, thereby having important application value.

Owner:江苏和达电子科技有限公司

Radiation protective paint

InactiveCN106433366AAvoid interferenceAvoid harmAntifouling/underwater paintsPaints with biocides(Hydroxyethyl)methacrylateThermal effect

The invention relates to radiation protective paint which comprises 80-150 parts of flaky graphite powder, 50-80 parts of acetylene carbon powder, 50-100 parts of hydroxy iron powder, 200-300 parts of heavy calcium carbonate, 200-300 parts of dibromoneopentyl glycol, 60-90 parts of magnesium oxide, 60-100 parts of nano-modified pure acrylic emulsion, 0.5-0.8 part of dispersing agents, 20-30 parts of ethylene glycol, 0.5-1.5 parts of antibacterial preservatives, 30-50 parts of poly-hydroxyethyl methacrylate and 0.6-0.8 part of sodium borate. The radiation protective paint is brushed on an inner wall, a ceiling and the ground, radiation waves from all directions of indoor and outdoor places are absorbed, clutter radiation is prevented, and radiation of electromagnetic waves, electrostatic rays, infrared thermal effects and the like can be effectively blocked.

Owner:WEIHAI XINSHENG POWER MACHINERY MFG

Preparation method and application of flame-retardant polyether

The invention discloses a preparation method and application of flame-retardant polyether. The flame-retardant polyether contains N, P and Br elements and is reactive flame-retardant polyether. According to the preparation method, the flame-retardant polyether is prepared from the following raw materials in parts by weight: 5-10 parts of ethylenediamine, 20-30 parts of tri(3-hydroxypropyl)phosphine, 23-28 parts of dibromoneopentyl glycol, 0.5-2.0 parts of dimethylamine and 30-51.5 parts of epoxy propane. Polyurethane foaming plastics prepared from the flame-retardant polyether have a favorable flame-retardant effect and have the advantages of stable flame retardance and better foam quality as comparison with polyurethane foaming plastics prepared by additionally adding a flame retardant.

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

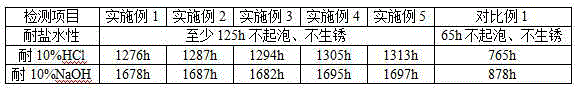

Polyurethane thermal insulation material and preparation method thereof

The invention provides a polyurethane thermal insulation material and a preparation method thereof. The material is composed of a component A and a component B, wherein according to parts by weight, the component A is prepared from 7 to 20 parts of dibromoneopentyl glycol type epoxy resin, 30 to 50 parts of polyester polyol, 20 to 40 parts of polyether polyol, 5 to 10 parts of modified expanded perlite, 20 to 40 parts of catalyst, 15 to 30 parts of flame retardant, 1 to 3 parts of stabilizer and 15 to 30 parts of foaming agent, and the component B is polyphenyl polymethylene polyisocyanate; the foaming agent is prepared from 1 to 5 parts of pentafluoropropane, 6 to 12 parts of pentafluorobutane and 2 to 6 parts of pentane; the modified expanded perlite is mainly prepared from expanded perlite, acrylic resin emulsion, a silane coupling agent and a silicone hydrophobic agent. The composite material is improved in flame retardancy while maintaining excellent compressibility and thermal insulation property.

Owner:合肥泓定科技有限公司

Pressure-resistant PVC water supply pipe material and preparation method thereof

The invention discloses a pressure-resistant PVC water supply pipe material and a preparation method thereof. The wear-resistant PVC water supply pipe material is prepared from the following raw materials in parts by weight: 45-65 parts of SG-3 type PVC resin, 20-30 parts of medium density polyethylene, 12-24 parts of polylactic acid, 10-15 parts of 1,2-polybutadiene, 3-5 parts of ethoxy ethylene bis stearamide, 2-4 parts of tribehenin, 1.5-2.5 parts of montanic acid zinc, 1-2 parts of tribasic lead sulfate, 1-2 parts of dibutyltin bis(isocaprylic acid sulfydryl ethyl ester), 0.5-1 part of 3-methyl 3-aminocrotonate, 1.5-2.5 parts of calcium acetylacetonate, 4-6 parts of white oil, 15-25 parts of nano-hydroxyapatite, 10-15 parts of aluminium borate whisker, 5-10 parts of dibromoneopentyl glycol, 14-26 parts of magnesium hydrate, 15-20 parts of filling master batch, 8-16 parts of acetyl tributyl citrate, 2-3 parts of 4,4'-dihydroxybiphenyl and 1-2 parts of 2,6-butylated hydroxytoluene. The PVC pipe material is good in pressure-resistant property and high in mechanical strength, has excellent water pressure resistant strength, external pressure resistant strength and impact resistant strength, has low possibility of water leakage, water seepage and fracture, is long in service life, is suitable for water supplying piping engineering under various conditions, and is wide in application prospect.

Owner:安徽瑞远管道有限公司

Preparation method of modified polyurethane acrylate light-cured resin

ActiveCN114213622AIncrease crosslink densityImprove adhesionPolyurea/polyurethane coatingsPolymer scienceFunctional monomer

The invention discloses a preparation method of modified polyurethane acrylate light-cured resin, which comprises the following steps: esterifying dibromo neopentyl glycol and acrylic acid, washing with water to obtain dibromo neopentyl glycol diacrylate A, carrying out substitution reaction on the dibromo neopentyl glycol diacrylate A and sodium methacrylate, and washing with water to obtain a functional monomer B; meanwhile, polyisocyanate and hydroxyl-terminated acrylate react to prepare bifunctional polyurethane acrylate C, and finally, the functional monomer B, the polyurethane acrylate C and organic amine are mixed to prepare the modified polyurethane acrylate light-cured resin with the molecular weight of 2000-5000. The modified polyurethane acrylate light-cured resin provided by the invention is high in crosslinking density after film formation, and has the advantages of excellent flexibility and hardness, good adhesion to a base material and the like. And tertiary amine is introduced into a main chain, so that the problem of oxygen polymerization inhibition can be effectively overcome, the curing speed is greatly increased, and good technical progress is achieved.

Owner:江苏三木化工股份有限公司 +1

Antistatic finishing agent for fabric finishing

InactiveCN107675487AImprove antistatic performanceNot corrosiveFlame-proof filament manufactureVegetal fibresPentaerythritolMethyl salicylate

The invention relates to the technical field of fabrics, in particular to an antistatic finishing agent for fabric finishing. The antistatic finishing agent for fabric finishing is prepared from, by weight parts, 6 parts of ammonium sulfamate, 2.6 parts of methyl salicylate, 6 parts of sodium benzoate, 4.2 parts of alginic acid, 1.5 parts of pentaerythritol, 4.6 parts of methylcellulose, 2.2 partsof soybean peptide, 6.5 parts of ammonium phosphate, 2.1 parts of sodium dodecyl sulfate, 2.1 parts of dibromoneopentyl glycol, 220 parts of water and 5.6 parts of additives. The antistatic agent cangreatly improve the antistatic performance of a fabric, has no corrosiveness to the fabric and does not hurt human skin.

Owner:安徽东锦高科新材料有限公司

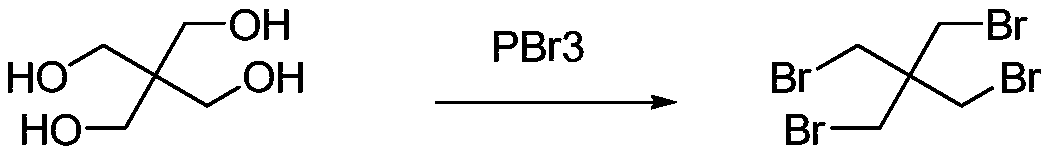

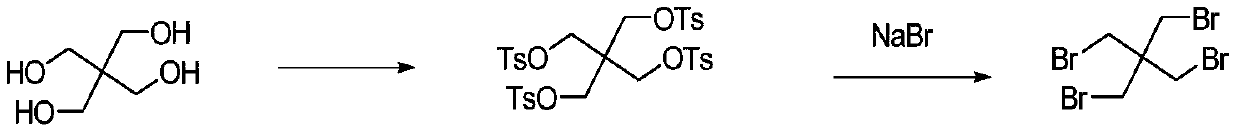

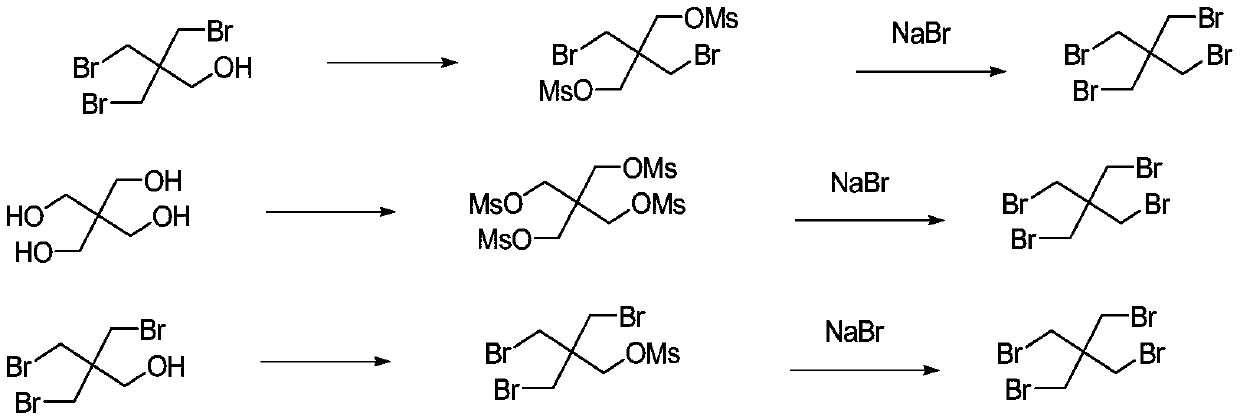

Synthetic method of tetrabromo neopentane

PendingCN111393254AAvoid controlReduce usageSulfonic acid esters preparationHalogenated hydrocarbon preparationPtru catalystPolyethylene glycol

The invention discloses a synthetic method of tetrabromo neopentane. The method is characterized by: adopting pentaerythritol or dibromo neopentyl glycol or tribromo neopentyl alcohol as the raw material to react with methylsulfonyl chloride or p-toluenesulfonyl chloride to perform hydroxyl activation, and then taking diethylene glycol or polyethylene glycol as the solvent and using polyethylene glycol as the catalyst, carrying out substitution reaction with sodium bromide to obtain tetrabromo neopentane; or taking dibromo neopentyl glycol or tribromo neopentyl alcohol as the raw material, firstly reacting with p-toluenesulfonyl chloride to carry out hydroxyl activation, and then taking diethylene glycol as the solvent to carry out substitution reaction with sodium bromide to obtain tetrabromo neopentane. The whole process avoids the generation of water vapor, controls the temperature easily, and is environment-friendly, high in yield and good in product purity.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

Preparation method of flame retardant polyether for polyurethane foam and application of prepared flame retardant polyether

The invention discloses a preparation method of flame retardant polyether for polyurethane foam and application of the prepared flame retardant polyether. The flame retardant polyether contains P and Br elements and is a reaction type flame retardant polyether. The flame retardant polyether is prepared from the following raw materials in parts by weight: 20-30 parts of tri(3-hydroxypropyl)phosphine, 23-28 parts of dibromoneopentyl glycol, 0.5-2.0 parts of dimethylamine and 40-56.5 parts of epoxy propane. The polyurethane foam plastic prepared by adopting the flame retardant polyether has good flame retardant effect and is stable in flame retardant property and good in foam quality compared with the polyurethane foam plastic prepared from extra adding flame retardant.

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

Elastic epoxy resin and application thereof

A preparation method of disclosed elastic epoxy resin comprises the following steps: mixing adipic acid, hexachlorobridge methylene phthalic anhydride, propylene glycol and dibromo neopentyl glycol for reaction to obtain a hydroxyl-terminated flame-retardant elastic polyester prepolymer; and reacting the hydroxyl-terminated flame-retardant elastic polyester prepolymer with bisphenol A epoxy resin under the action of a catalyst to obtain the elastic epoxy resin. The resin provided by the invention has many active groups, so that the adhesive force of the prepared coating film on amorphous alloy, silicon steel and mould pressing composite materials (slot wedges) can reach more than 10 MPa, and the adhesive force on the surface of a fluorosilicone pouring sealant can also reach 5 MPa. The water-based flame-retardant surface insulating paint provided by the invention has an oxygen index greater than or equal to 40, and has good wear resistance.

Owner:株洲市九华新材料涂装实业有限公司

Preparation method for organic amphoteric copolymer interpenetrating network gel

The invention relates to a preparation method for an organic amphoteric copolymer interpenetrating network gel. According to the method, methacryloyloxyethyl trimethyl ammonium chloride, ethoxyethyl methacrylate and sorbic acid are used as comonomers, poly(ethylene glycol) dimethacrylate as a cross-linking agent and potassium persulfate-sodium hydrogen sulfite as an initiator to carry out copolymerization reaction in deionized water, so that an organic amphoteric copolymer first network gel is obtained; the first network gel is swelled in an aqueous solution prepared from 2-methyl-4-pentenoic acid, cyclohexanehexol, vinyl pyrrolidone, dibromoneopentyl glycol dimethacrylate and deionized water, the monomers and cross-linking agent in the aqueous solution undergo the action of potassium sulfate and pyridoxine hydrochloride to carry out copolymerization and esterification reaction, and finally, the organic amphoteric copolymer interpenetrating network gel is obtained.

Owner:SICHUAN NORMAL UNIVERSITY

Flame-retarding shell material for fire alarm device and preparation method of shell material

The invention provides a flame-retarding shell material for a fire alarm device and a preparation method of the shell material and relates to the technical field of fire alarm device production. The fire alarm device is prepared from the following raw materials in parts by weight: 50 to 60 parts of ABS (Acrylonitrile Butadiene Styrene) resin, 15 to 25 parts of polycarbonate, 1 to 2 parts of nano diatomite, 10 to 15 parts of dibromoneopentyl glycol phosphate, 5 to 10 parts of decabromodiphenyl ethane, 5 to 10 parts of aluminum isobutylhypophosphite, 6 to 8 parts of brominated epoxy resin, 2 to4 parts of antimony trioxide, 5 to 7 parts of silicon carbide, 3 to 5 parts of molybdenum disulfide, 2 to 4 parts of zirconium oxide, 0.8 to 1.2 parts of a modifying agent, 1 to 2 parts of a couplingagent and 2 to 3 parts of a dispersing agent. By adopting the flame-retarding shell material, disadvantages in the prior art are overcome; the flame-retarding performance of the shell material for thefire alarm device can be effectively improved, and a condition that a shell cannot work continually after being combusted is prevented; the shell material is high in safety and good in utilization effect; the wear-resisting performance of the shell material also can be effectively improved and the whole performance of the shell material is excellent; the shell material is long in service life andis suitable for popularization.

Owner:ANHUI SHENGLONG ELECTRIC

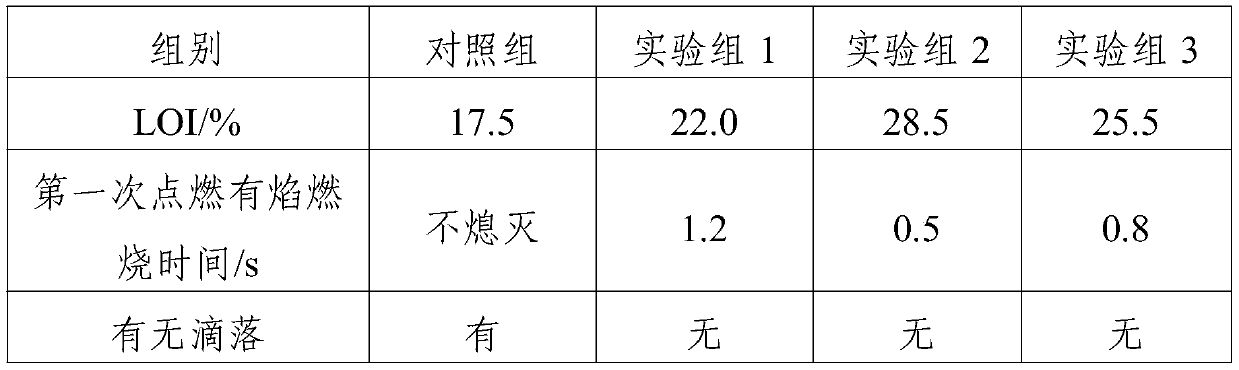

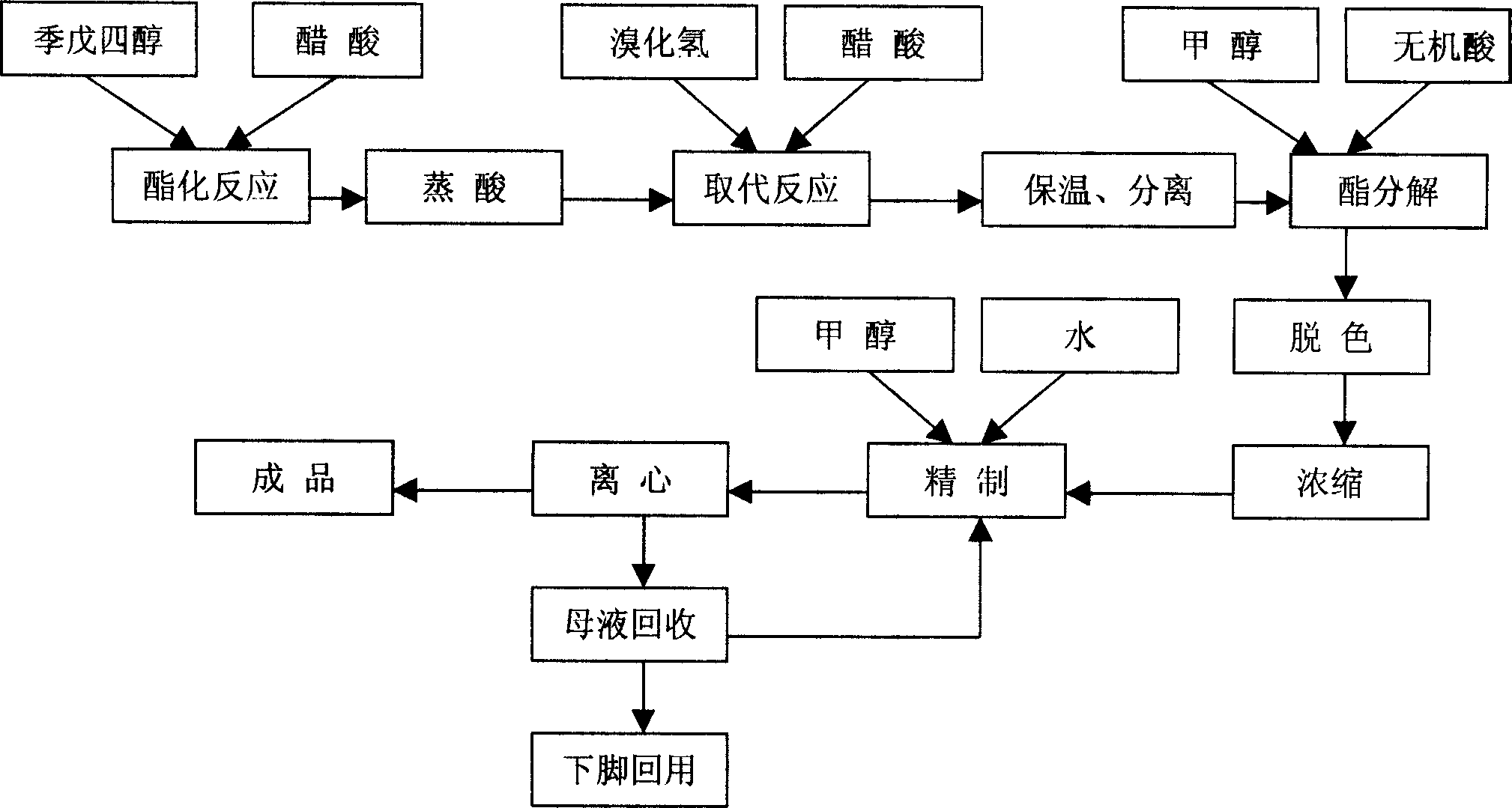

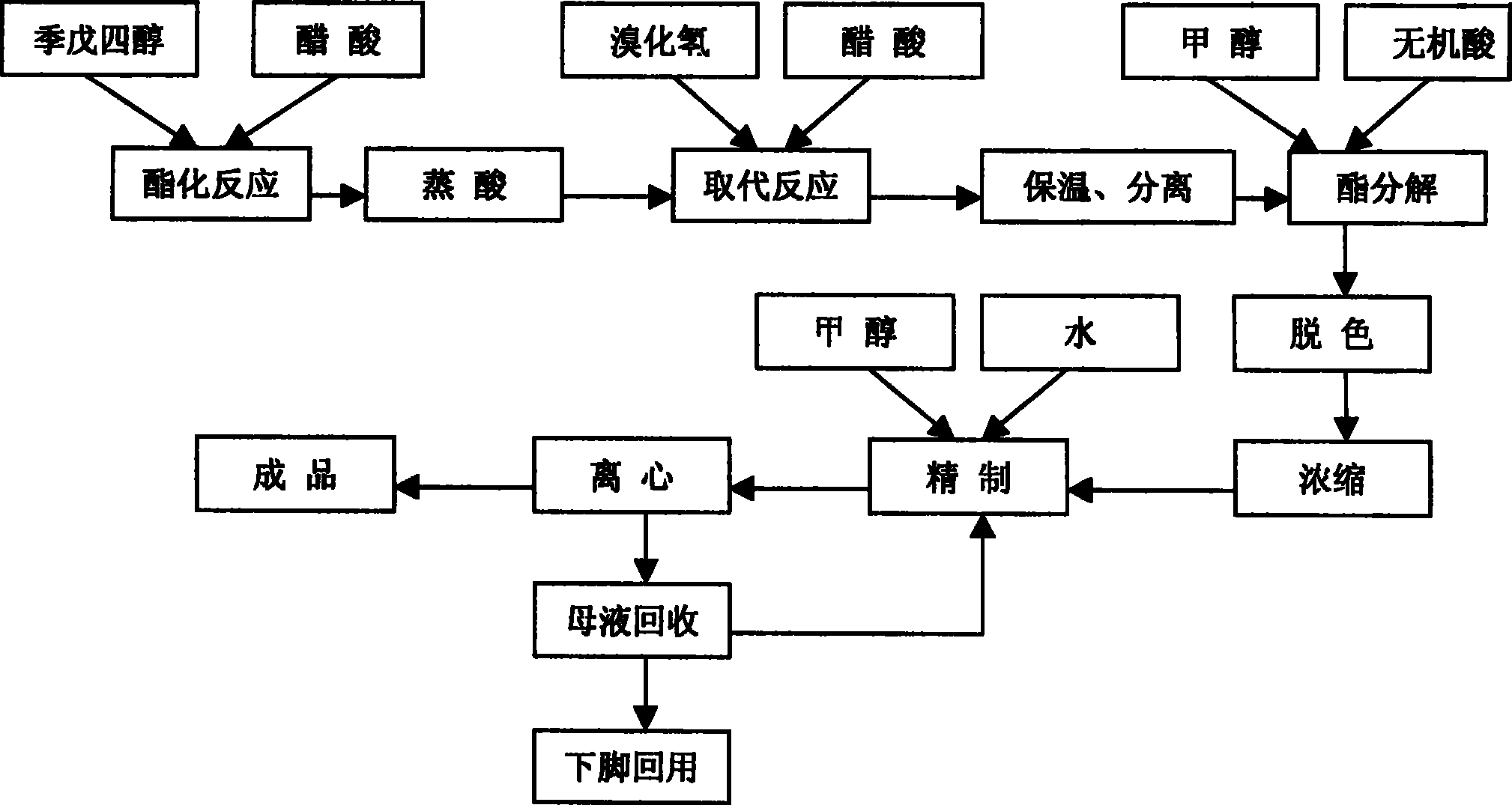

Synthetic method and refining for dibromoneopentyl glycol

InactiveCN101016226BLow reaction temperatureHigh yieldPreparation by halogen introductionAcetic acidPentaerythritol

The invention discloses a synthesizing method of dibromide-neopentyl glycol, which comprises the following steps: esterifying pentaerythritol and acetic acid with density over 98%; dissolving and separating ester the acetic acid; aerating hydrogen bromide to substitute; insulating to separate diester of dibromide-neopentyl glycol; proceeding constant pressure decomposition through carbinol and inorganic acid under 0.4-0.6Mpa.

Owner:宜兴市中正化工有限公司

Preparation method of dimethyl dibromo neopentyl dioxy cyclosilane compound as fire retardant

InactiveCN104710460APhysicochemically stableGood compatibilityGroup 4/14 element organic compoundsEpoxyOrganic solvent

The invention relates to a preparation method of a dimethyl dibromo neopentyl dioxy cyclosilane compound as a fire retardant. The structural formula of the compound is shown in the description. The preparation method comprises the following steps: in a reactor provided with an efficient fractionating device, mixing dibromoneopentyl glycol and equimolar dimethyl dimethoxy silicane with an organic solvent; heating to 80 DEG C until boiling; starting a fractionation reaction; controlling the temperature of the top of a fractionating column to be no higher than 65 DEG C, and continuously separating generated methanol; when the temperature of the reacting system is gradually increased with the progress of the reaction, performing a heat preservation reaction at the temperature of 80-160 DEG C for 5-12 hours; when the fractionated methanol reaches a theoretical amount, stopping the reaction; distilling off the organic solvent, and performing purification so as to obtain a white solid dimethyl dibromo neopentyl dioxy cyclosilane. The fire retardant provided by the invention is high in flame retardant efficacy because of synergistic flame retardant of silicon-bromine bielement, and suitable for being used as the fire retardant of polyolefine, polyurethane, an epoxy resin, an unsaturated resin and the like. The production technology is simple, the investment in equipment is small, the raw materials are easy to obtain, and the cost is low.

Owner:苏州阳桥新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 5-oxaspiro[2,4]heptane-6-one and intermediate thereof Preparation method of 5-oxaspiro[2,4]heptane-6-one and intermediate thereof](https://images-eureka.patsnap.com/patent_img/189847d3-8ced-441f-bffc-67f92f1e23fc/BDA00002747286700011.PNG)

![Preparation method of 5-oxaspiro[2,4]heptane-6-one and intermediate thereof Preparation method of 5-oxaspiro[2,4]heptane-6-one and intermediate thereof](https://images-eureka.patsnap.com/patent_img/189847d3-8ced-441f-bffc-67f92f1e23fc/BDA00002747286700012.PNG)

![Preparation method of 5-oxaspiro[2,4]heptane-6-one and intermediate thereof Preparation method of 5-oxaspiro[2,4]heptane-6-one and intermediate thereof](https://images-eureka.patsnap.com/patent_img/189847d3-8ced-441f-bffc-67f92f1e23fc/BDA00002747286700021.PNG)