Patents

Literature

52 results about "Resorcinol diglycidyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

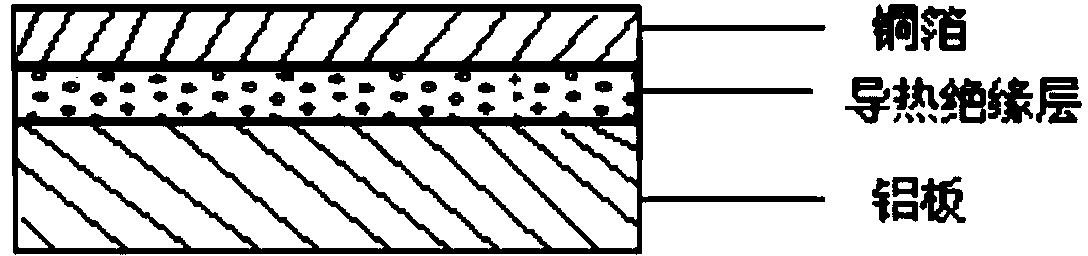

High-thermal conductivity high-performance aluminum-based copper-clad plate and preparation method thereof

InactiveCN104228186AConvenient sourceSimple preparation processLamination ancillary operationsNon-macromolecular adhesive additivesEpoxyBenzene

The invention relates to a high-thermal conductivity high-performance aluminum-based copper-clad plate and a preparation method thereof. The copper-clad plate is composed of copper foil, a high-thermal conductivity electric insulating paste and an aluminum plate. The preparation method comprises the following steps: mixing multifunctional fluorine-containing epoxy resin with 1,4-di(2,4-diamino phenoxy) benzene for reacting, adding resorcinol diglycidyl ether epoxy resin and partial inorganic filler, and uniformly stirring and mixing to obtain a component A; uniformly mixing and stirring methyl tetrahydrophthalic anhydride and inorganic filler to obtain a component B; and uniformly mixing and stirring the component A and the component B to obtain the high-thermal conductivity electric insulating paste, then uniformly applying the high-thermal conductivity electric insulating paste onto the surface of the copper foil and the aluminum plate, and pressing and curing by a high-temperature panel pressing machine, thereby obtaining the high-thermal conductivity high-performance aluminum-based copper-clad plate. The operation process is simple; with the green and clean production process, a solvent is avoided, and the copper-clad plate has an environment-friendly effect; the copper-clad plate is wide in application range and has good market prospects, and the large-scale mass production can be easily carried out.

Owner:DONGHUA UNIV +2

High-strength flame-retardant modified polyurethane composite material

The invention discloses a high-strength flame-retardant modified polyurethane composite material including: hydroxyl-terminated polybutadiene, polytetrahydrofuran ether glycol, polypropylene glycol, toluene diisocynate, 4,4'-diphenylmethane diisocynate, bisphenol A, dibromoneopentyl glycol, dimethythiotoluene diamine, diaminodiphenylmethane, 2-ethyl-4-methylimidazole, dibutyltin dilaurate, diglycidyl resorcinol ether, a filling material, melamine, ammonium polyphosphate, and N,N'-bis(2-thio-5,5-dimethyl-1,3,2-dioxaphosphocyclohexyl)ethylenediamine. The high-strength flame-retardant modified polyurethane composite material has high strength, is excellent flame-retardant performance and can satisfy use demands in various fields.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Multi-layer barrier film structure

InactiveUS20060233988A1Raise the barrierImprove barrier propertiesSynthetic resin layered productsBagsPolyethylene terephthalatePolyolefin

A laminate film having a polyetheramine resin-containing layer on a first polyolefin resin-containing layer or a first polyethylene terephthalate resin-containing layer, wherein the polyetheramine resin contains of at least 30% resorcinol diglycidyl ether comonomer content is disclosed. The laminate film could further have additional layers such as a second polyolefin resin-containing layer, a second polyethylene terephthalate resin-containing layer, a metal layer or combinations thereof.

Owner:TORAY PLASTICS AMERICAS

Porous wet friction material utilizing a compliant epoxide resin binder system

InactiveUS20040229029A1Increase coefficient of frictionFew friction plateLayered productsNon-woven fabricsEpoxyResorcinol diglycidyl ether

A wet friction material is disclosed bonded to a plate for transmission of motion, with the friction material made up of a porous fiber substrate, which is at least partially impregnated with a catalyzed resorcinol diglycidyl ether resin to improve friction properties.

Owner:DRIVETRAIN GRP HLDG +1

Multi-layer barrier film structure

InactiveUS20070031653A1Improve barrier propertiesEnhance printing propertySynthetic resin layered productsRecord information storagePolymer sciencePolyolefin

A laminate film including a polyetheramine resin-containing layer that has at least 30% resorcinol diglycidyl ether comonomer content, and a first polyolefin resin-containing layer which includes an amount of a tie-layer resin additive is disclosed. The laminate film could further have additional layers such as a second polyolefin resin-containing layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Sealant for photovoltaic module and preparation method of sealant

ActiveCN104178040AStable chemical propertiesStable and water resistantOther chemical processesOrganic non-macromolecular adhesivePolymer scienceOctanoic Acids

The invention belongs to the technical field of sealants and relates to a sealant for a photovoltaic module. The sealant is characterized by comprising the following raw materials in parts by weight: 100 parts of E-51 epoxy resin, 15-25 parts of 201 polysulfide rubber, 10-15 parts of m-phenylenediamine, 10-20 parts of dibutyl phthalate, 1-3 parts of diethylenetriamine, 30-50 parts of talc power, 10-15 parts of maleic anhydride, 15-20 parts of 651 low-molecular-weight polyamide, 4-6 parts of stannous octoate and 20-30 parts of epoxypropane phenyl ether or diglycidyl resorcinol ether or ethylene glycol diglycidyl ether. The invention also discloses a preparation method of the sealant. The sealant disclosed by the invention has the beneficial effects of convenience in operation, short curing time, good adhesion, low water vapor and gas permeability, good sealing property / weather resistance and UV resistance and wide application temperature range and the long-term performance is maintained.

Owner:特瓦特能源科技有限公司

High-toughness anti-stripping epoxy resin adhesive

InactiveCN106047243ASmall particle sizeLarge particle sizeNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAcrylonitrile

The invention discloses a high-toughness anti-stripping epoxy resin adhesive. The high-toughness anti-stripping epoxy resin adhesive is prepared from, by weight, 20-50 parts of phenolic modified epoxy resin, 5-15 parts of resorcinol diglycidyl ether type epoxy resin, 20-35 parts of E-12 epoxy resin, 15-30 parts of modified wheat gluten, 1-8 parts of polyimide modified epoxy resin, 1-2 parts of carboxyl-terminated butadiene acrylonitrile rubber, 1-2 parts of polybutadiene-polymethyl methacrylate, 1-10 parts of methylene bicyclohexyl amine, 2-6 parts of epoxidized SBS (styrene butadiene styrene), 1-4 parts of vinyl triamine, 1-2 parts of triethanolamine, 5-15 parts of calcined clay, 1-5 parts of sodium carboxymethylcellulose and 20-50 parts of diglycidyl ether. The high-toughness anti-stripping epoxy resin adhesive is excellent in toughness, favorable in anti-stripping effect, high in thermal stability and long in storage time even at a high temperature and is safe, environment friendly and free of environment pollution.

Owner:HEFEI DONGCAI PRINTING TECH

Porous wet friction material utilizing a compliant epoxide resin binder system

ActiveUS20060115641A1Synthetic resin layered productsNon-woven fabricsEpoxyResorcinol diglycidyl ether

A wet friction material is disclosed bonded to a plate for transmission of motion, with the friction material made up of a porous fiber substrate, which is at least partially impregnated with a catalyzed resorcinol diglycidyl ether resin to improve properties.

Owner:FRICTION PROD COMPANY +1

Sealing adhesive for solar photovoltaic module and preparation method of sealing adhesive

ActiveCN104194712AEasy to buyEasy to prepareNon-macromolecular adhesive additivesPhotovoltaic energy generationFiberMeth-

The invention relates to the technical field of sealing materials, and in particular relates to a sealing adhesive specific for a solar photovoltaic module. The sealing adhesive is characterized by being prepared from the following raw materials in parts by weight: 90 parts of polydimethylsiloxane, 8 parts of white carbon black or titanium dioxide, 18 parts of phthalic acid dibutyl ester or triphenyl phosphate, 12 parts of resorcinol diglycidyl ether or ethanol, 7 parts of acrylamide, 4 parts of phthalic anhydride, 13 parts of aluminum hydroxide or magnesium hydroxide, 30 parts of glass fiber or asbestos fiber with the maximum size of 0.05mm, 4 parts of anti-aging agent D, 2 parts of methylparaben and 5 parts of methyl trimethoxy silane or ethyl trimethoxy silane. The invention further discloses a preparation method of the sealing adhesive. The sealing adhesive has the beneficial effects that the tensile strength is relatively high, the breakage elongation is relatively high, the volume resistivity is relatively high, the dielectric strength is relatively high, the binding force is relatively high, the anti-yellowing resistance and the cracking resistance are relatively good, the expiration date is relatively long, and the like.

Owner:广东汇能硅胶制品有限公司

Affinity chromatography medium with glutathione as ligand

ActiveCN107866205AImprove solubilityHigh densityOther chemical processesSolid sorbent liquid separationMicrosphereBoron nitride

The invention relates to an affinity chromatography medium with glutathione as a ligand. Agarose gel microspheres with boron nitride dispersed on surfaces are taken as a core, the surfaces of the agarose gel microspheres are activated by a first crosslinking agent and a second crosslinking agent, both the first crosslinking agent and the second crosslinking agent are coupled with glutathione as the ligand, the first crosslinking agent adopts epichlorohydrin, and the second crosslinking agent adopts resorcinol diglycidyl ether or neopentyl glycol diglycidyl ether; meanwhile, acetonitrile whichis cheaper and more environmentally friendly is selected as a solvent for coupling with glutathione, so that the dissolution degree of the crosslinking agents is increased, and the agarose gel microspheres are activated sufficiently. The affinity chromatography medium has the advantages that the density of active epoxy groups is high, the amount of coupled glutathione is large, the separation efficiency is higher, a preparation process of the affinity chromatography medium with glutathione as the ligand is simple, the production cost is lower, and large-scale popularization and application arefacilitated.

Owner:SUZHOU BOJIN BIOLOGICAL TECH

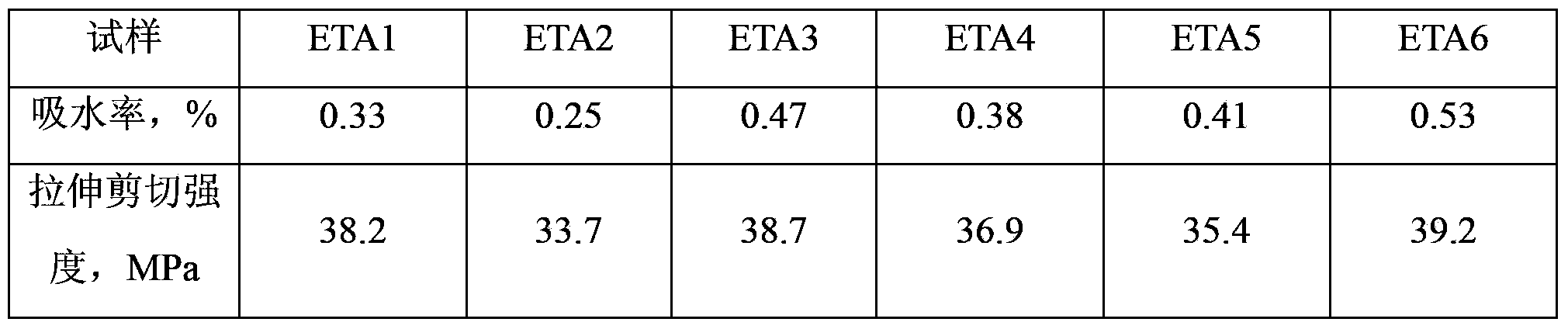

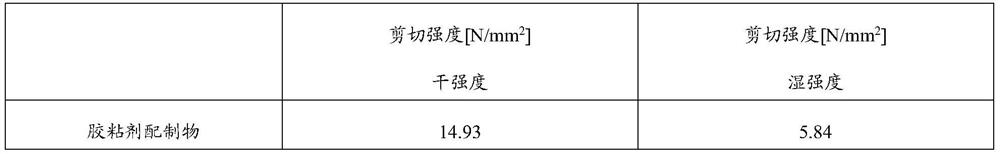

Solvent-free epoxy-tetramaleimide resin adhesive and preparation method thereof

InactiveCN103409092AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesEpoxy resin adhesivesSolvent freeResin-Based Composite

The invention relates to a solvent-free epoxy-tetramaleimide resin adhesive and a preparation method thereof. The adhesive is composed of a component A and a component B with a mass ratio of 1-4:1. The component A is composed of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane epoxy resin, resorcin diglycidyl epoxy resin, an active diluting agent, aromatic diamine, and tetramaleimide resin with a mass ratio of 100:10-80:10-50:5-10:10-30. The component B is composed of resorcin diglycidyl epoxy resin, xylylenediamine, and tetramaleimide resin with a mass ratio of 20:50-100:5-10. The method provided by the invention has the advantages of simple synthesis process and environment friendliness. The adhesive has excellent comprehensive performance, and can be used in bonding of substrates such as glass, ceramic, metal, epoxy resin-based composite material, and the like. The adhesive has high bonding strength and wide market prospect.

Owner:DONGHUA UNIV +1

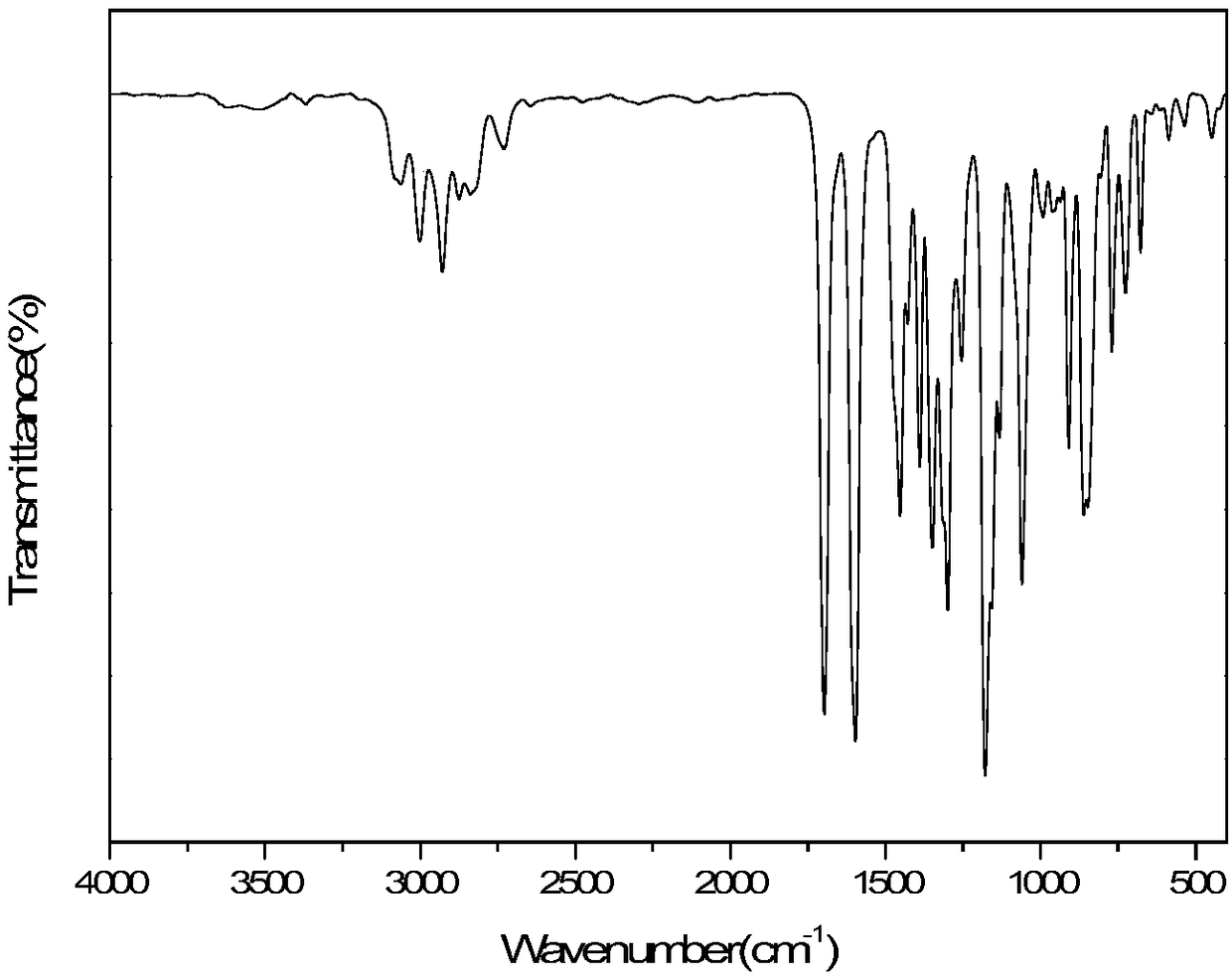

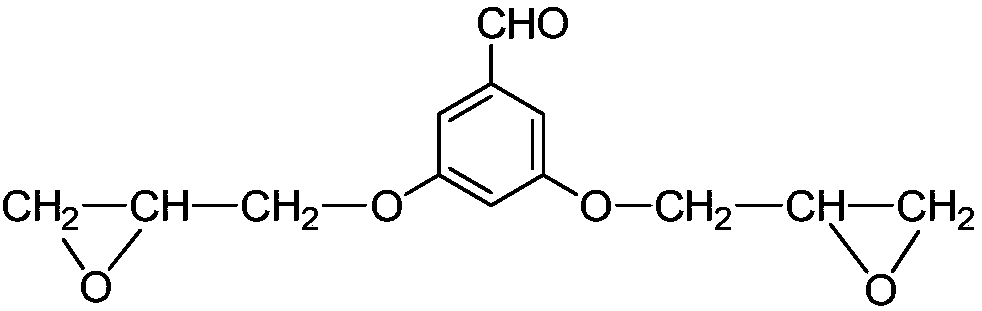

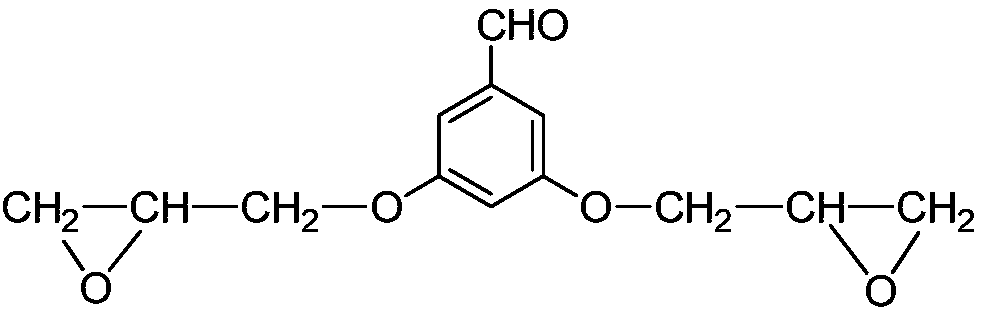

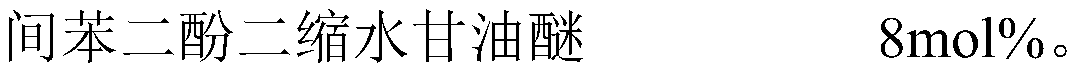

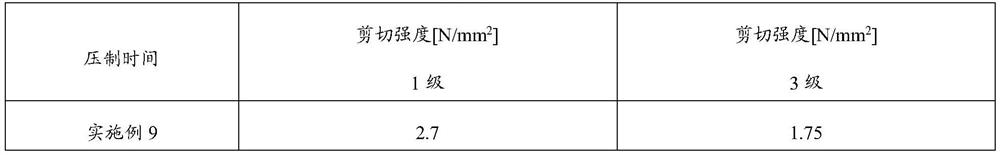

5-aldehyde resorcinol diglycidyl ether and preparation method thereof

ActiveCN109503520ANarrow molecular weight distributionMild reaction conditionsOrganic chemistryChemical recyclingOrganic solventBenzaldehyde

The invention discloses 5-aldehyde resorcinol diglycidyl ether and a preparation method thereof, relates to glycidyl ether and a preparation method thereof, and aims at solving the problem of poorer bonding strength of the conventional glycidyl ether epoxy resin at high temperature. The preparation method of the 5-aldehyde resorcinol diglycidyl ether comprises the following steps: firstly, putting3,5-dihydroxy benzaldehyde, epibromohydrin and a catalyst into a reaction still, raising the temperature for reaction, decompressing and evaporating out to obtain a concentrated solution; secondly, after the temperature of the concentrated solution is lowered, adding an organic solvent and metal alkali solid particles and stirring; thirdly, after the reaction ends, repeatedly washing with water,and separating liquid to remove an aqueous phase; finally, performing reduced pressure distillation on an organic phase to remove an organic solvent, and recycling to obtain the 5-aldehyde resorcinoldiglycidyl ether. The 5-aldehyde resorcinol diglycidyl ether is used for preparing a high temperature resisting epoxy resin adhesive. The epoxy resin adhesive prepared from the 5-aldehyde resorcinol diglycidyl ether disclosed by the invention has the characteristic of high temperature resistance. The 5-aldehyde resorcinol diglycidyl ether and the preparation method disclosed by the invention are used for the field of the epoxy resin adhesives.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Sealant for solar photovoltaic module and preparation method thereof

ActiveCN104194712BHigh tensile strengthHigh volume resistivityNon-macromolecular adhesive additivesPhotovoltaic energy generationFiberMeth-

The invention relates to the technical field of polymer sealing materials, in particular to a special sealant for solar photovoltaic modules, which is characterized in that it is composed of the following raw materials in parts by weight: polydimethylsiloxane: 90 parts, white carbon black Or titanium dioxide: 8 parts, dibutyl phthalate or triphenyl phosphate: 18 parts, resorcinol diglycidyl ether or ethanol: 12 parts, acrylamide: 7 parts, phthalic anhydride: 4 parts Parts, aluminum hydroxide or magnesium hydroxide: 13 parts, glass fiber or asbestos fiber with a maximum size of 0.05 mm: 30 parts, antioxidant D: 4 parts, methylparaben: 2 parts, methyltrimethoxysilane Or ethyltrimethoxysilane, etc.: 5 parts. The invention also discloses its preparation method. The invention has the advantages of greater tensile strength, higher elongation at break, greater volume resistivity, higher dielectric strength, stronger adhesion, better resistance to yellowing and cracking, and longer shelf life. Effect.

Owner:广东汇能硅胶制品有限公司

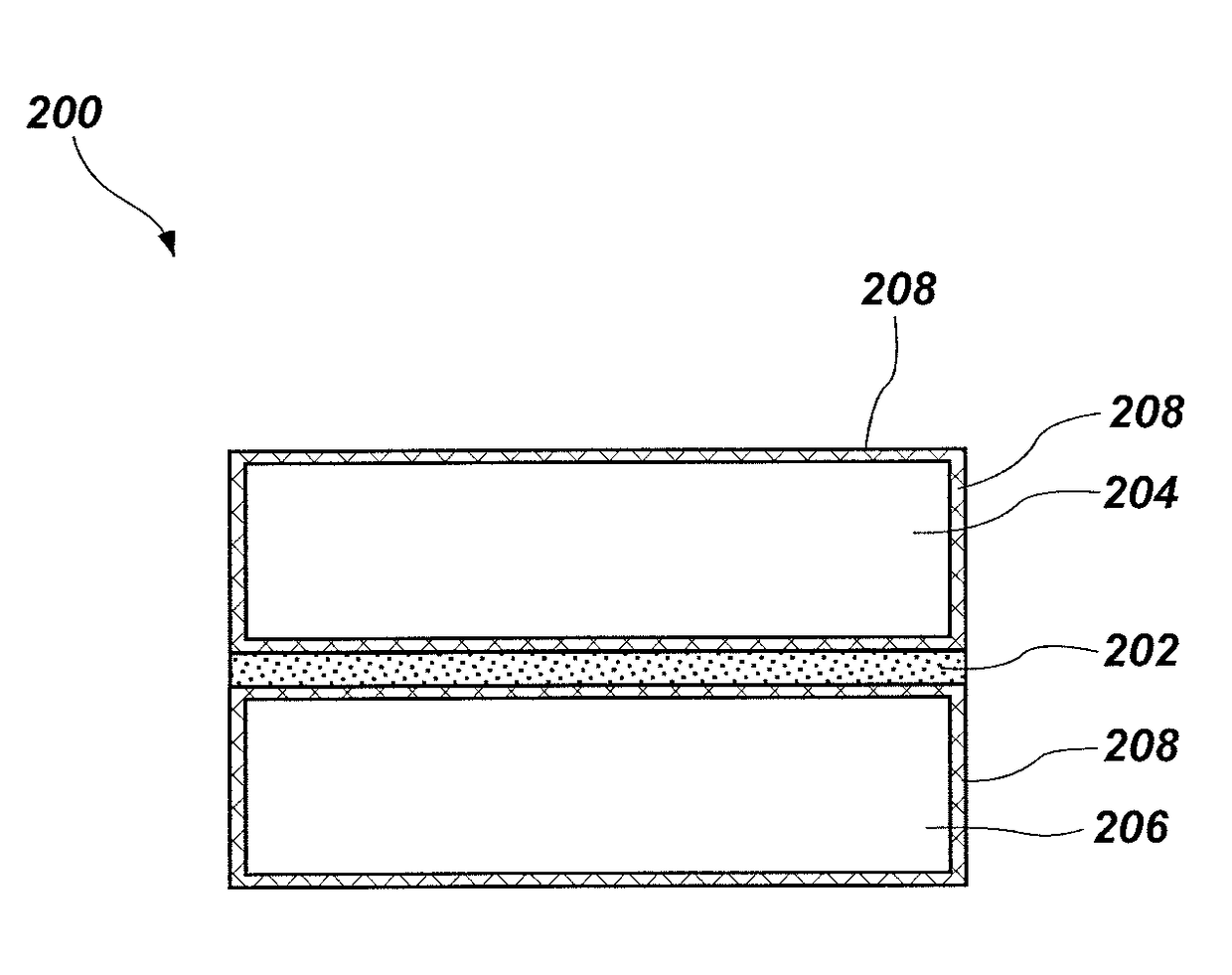

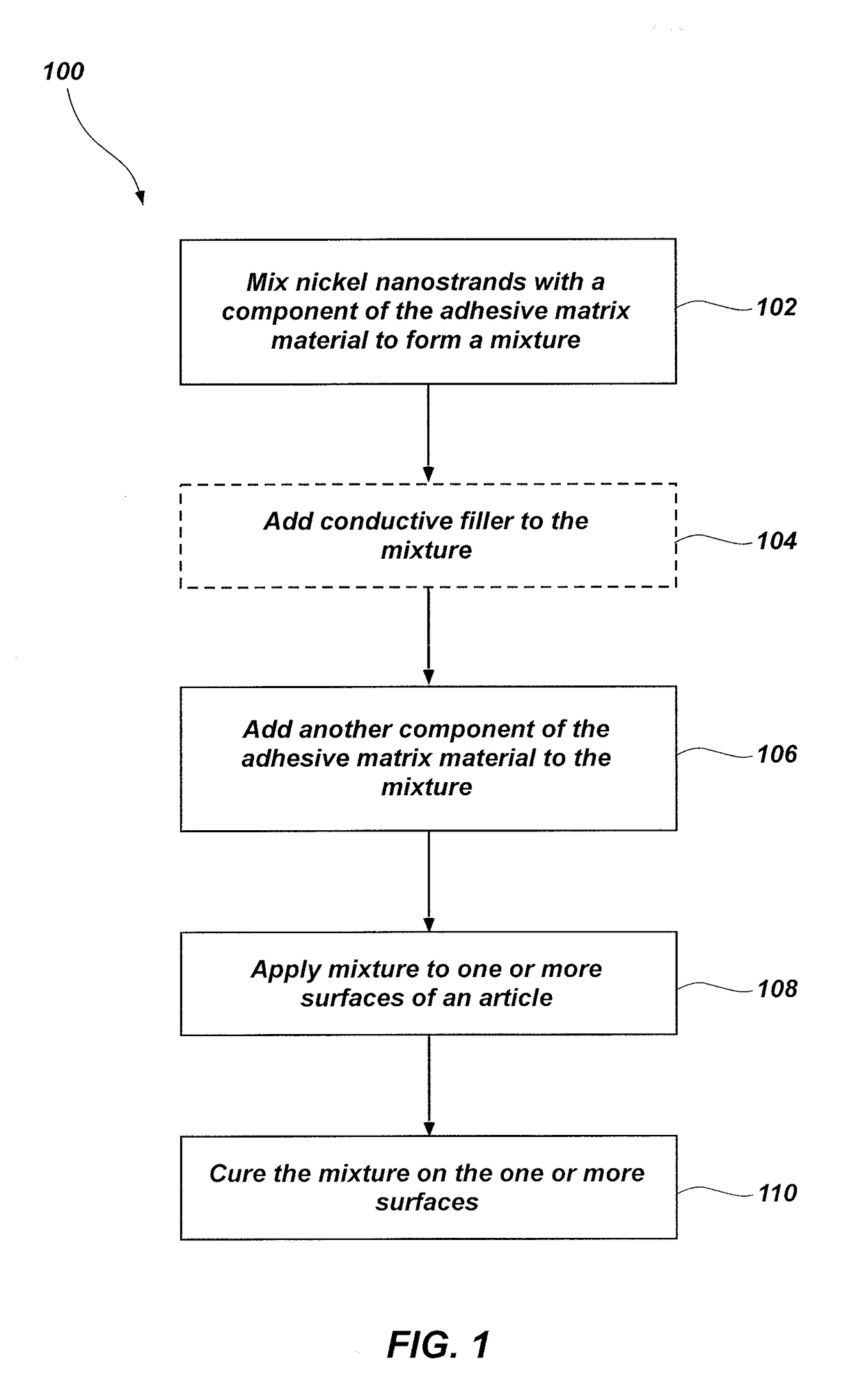

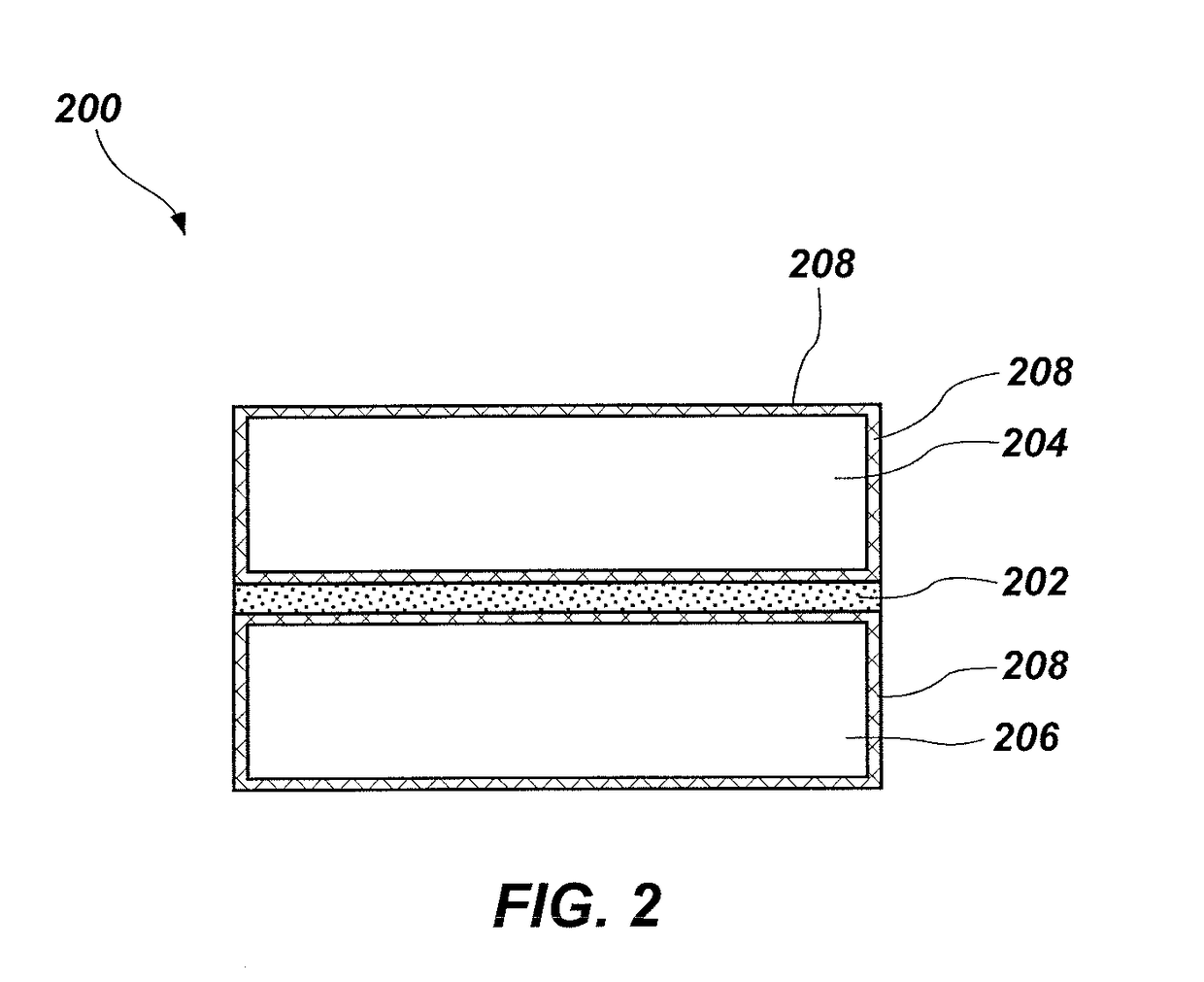

Electrically conductive adhesives, assemblies including the electrically conductive adhesives, and related methods

ActiveUS20170145264A1Adhesive processesSynthetic resin layered productsResorcinol diglycidyl etherAdhesion strength

An assembly comprising a first article, a second article adjacent the first article, and an electrically conductive adhesive in electrical communication with the first article and the second article. The electrically conductive adhesive comprises nickel nanostrands dispersed in a matrix comprising a reaction product of bisphenol-F epoxy resin, resorcinol diglycidyl ether epoxy monomer, and at least one amine-containing curing agent. The electrically conductive adhesive exhibits a tensile adhesion strength greater than about 5,000 psi and a volume resistivity less than about 0.01 Ω·cm. Electrically conductive adhesives including nickel nanostrands, precursor packages of the electrically conductive adhesive, related methods of forming the electrically conductive adhesive and an assembly including the electrically conductive adhesive are also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

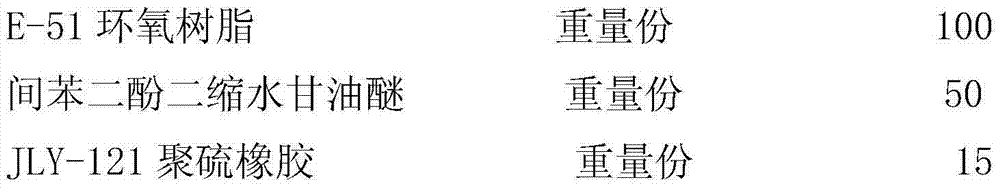

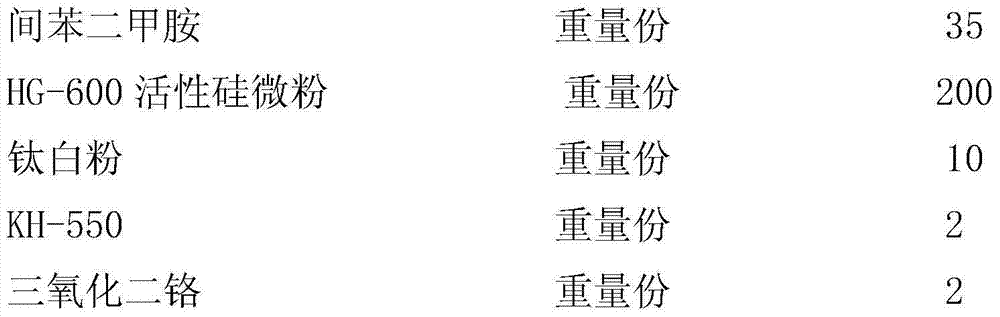

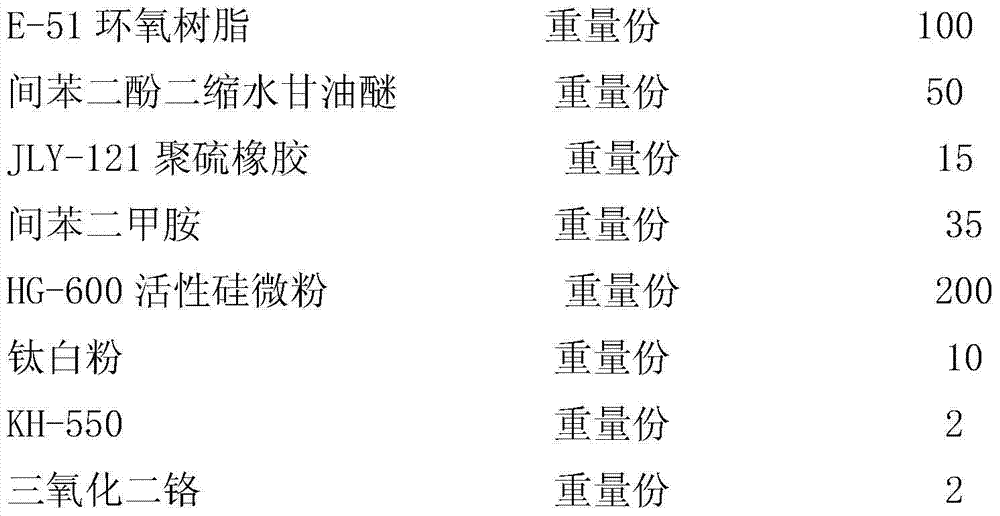

High-strength strong-acid/alkali-resistant epoxy resin sealant

InactiveCN103614106AGood workmanshipStable potting qualityNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberAdhesive

The invention provides a high-strength strong-acid / alkali-resistant epoxy resin sealant, relating to the technical field of adhesives. The sealant is characterized by comprising the following components in parts by weight: 100 parts of E-51 epoxy resin, 50 parts of resorcinol diglycidyl ether, 15 parts of JLY-121 polysulfide rubber, 200 parts of HG-600 activated silica micropowder, 10 parts of titanium white, 2 parts of KH-550 and 2 parts of chromic oxide. The components are cured by heating. The adhesive is simple in formula and convenient to manufacture, and has the advantages of excellent curing property and favorable technical properties.

Owner:ANHUI KANGRUIXIN ELECTRONICS TECH

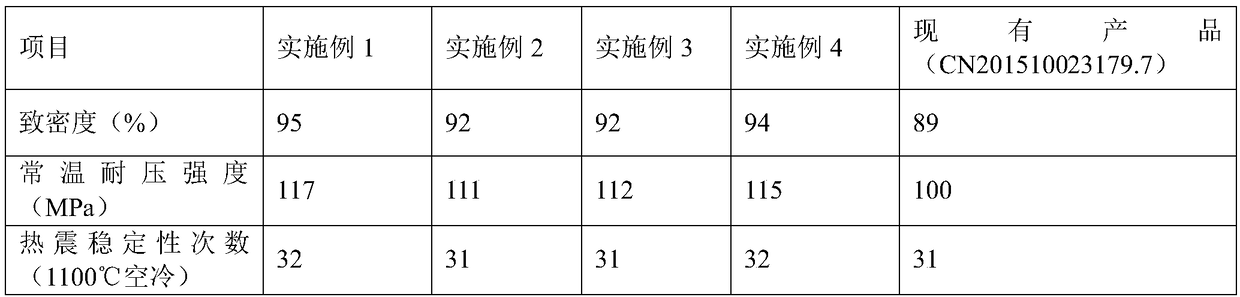

Two-component refractory brick and production method thereof

The invention relates to the field of refractory materials, and discloses a two-component refractory brick and a production method thereof. The brick is produced from a slurry A and a slurry B; the slurry A includes fused chromium oxide, sintered chromium oxide particles, chrome corundum particles, alumina micro-powder, magnesium oxide micro-powder, zirconia micro-powder, yttrium oxide micro-powder, lanthanum and / or lanthanide metal oxide micro-powder, metallic aluminum micro-powder, metallic chromium micro-powder, metallic zirconium micro-powder, metallic yttrium micro-powder, resorcinol diglycidyl ether, sodium dodecyl benzene sulfonate, ethanol and water; and the slurry B includes the fused chromium oxide, sintered chromium oxide particles, chrome corundum particles, alumina micro-powder, magnesium oxide micro-powder, zirconia micro-powder, yttrium oxide micro-powder, lanthanum and / or lanthanide metal oxide micro-powder, metallic aluminum micro-powder, metallic chromium micro-powder, metallic zirconium micro-powder, metallic yttrium micro-powder, a cationic photocuring initiator, tetradecyltrimethylammonium bromide, ethanol and water. The two slurries are adopted to reduce the use amount of a binder and improve the physical properties of the refractory brick.

Owner:长兴正发热电耐火材料有限公司

Sealing gum for photovoltaic module and preparing method of sealing gum

ActiveCN105086853AEasy to prepareShort preparation timeNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer sciencePhenyl Ethers

The invention belongs to the technical field of sealants and relates to a sealant for a photovoltaic module. The sealant is characterized by comprising the following raw materials in parts by weight: 100 parts of E-51 epoxy resin, 15-25 parts of 201 polysulfide rubber, 10-15 parts of m-phenylenediamine, 10-20 parts of dibutyl phthalate, 1-3 parts of diethylenetriamine, 30-50 parts of talc power, 10-15 parts of maleic anhydride, 15-20 parts of 651 low-molecular-weight polyamide, 4-6 parts of stannous octoate and 20-30 parts of epoxypropane phenyl ether or diglycidyl resorcinol ether or ethylene glycol diglycidyl ether. The invention also discloses a preparation method of the sealant. The sealant disclosed by the invention has the beneficial effects of convenience in operation, short curing time, good adhesion, low water vapor and gas permeability, good sealing property / weather resistance and UV resistance and wide application temperature range and the long-term performance is maintained.

Owner:上海拜高高分子材料有限公司

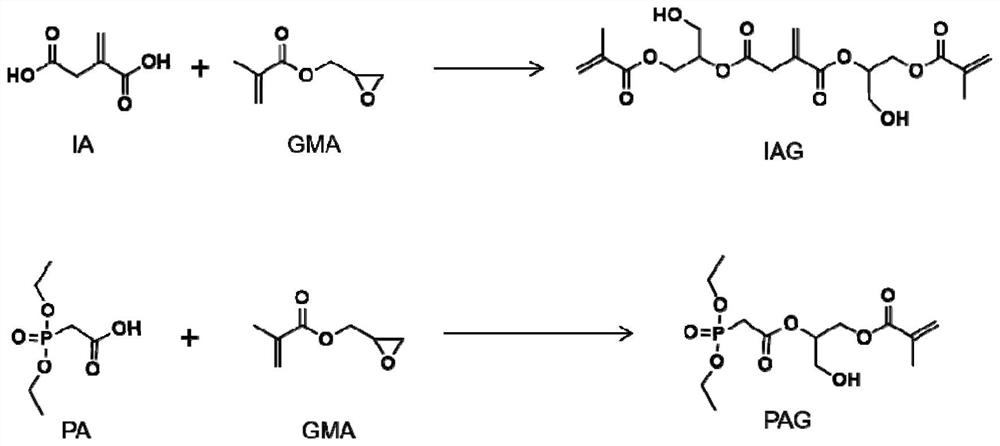

Wear-resistant ultraviolet (UV) photo-curing coating and preparation method thereof

InactiveCN103525290AImprove adhesionImprove wear resistancePolyurea/polyurethane coatingsGlycidyl methacrylateCarbamate

The invention relates to wear-resistant ultraviolet (UV) photo-curing coating. The wear-resistant UV photo-curing coating is prepared from the following raw materials in parts by weight: 2 to 3 parts of dicyclopentadiene, 3 to 4 parts of glycidyl methacrylate, 45 to 50 parts of carbamate acrylate, 10 to 12 parts of trimethylolpropane triacrylate, 2 to 5 parts of tetrabutylammonium bromide, 1 to 2 parts of yttrium oxide, 2 to 3 parts of trichloroethyl phosphate, 1 to 2 parts of resorcinol diglycidyl ether, 3 to 4 parts of isopropylthioxanthone, 8 to 10 parts of benzil dimethyl ketal and 4 to 5 parts of dispersing aid. The carbamate acrylate serves as a main material, and plastifying and reinforcing substances such as the yttrium oxide, benzil dimethyl ketal and the dicyclopentadiene are added, so that the obtained coating has high caking property, wear resistance, acid and alkali resistance and corrosion resistance. The UV coating is applicable to friction occasions, can serve as primer of hardware, zinc alloy, aluminum alloy, stainless steel and vacuum electroplating coating, and has durable performance and high curing speed.

Owner:安徽蓝柯复合材料有限公司

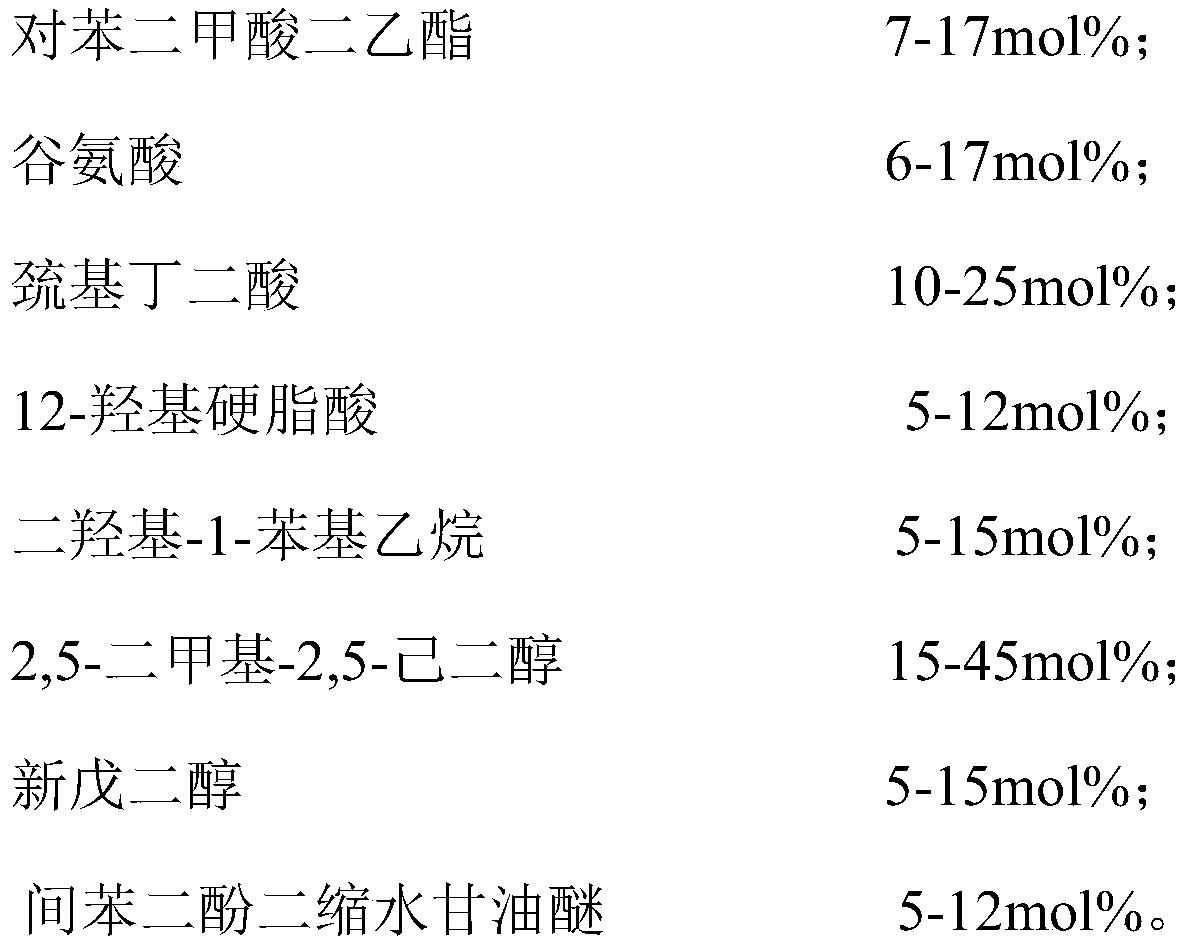

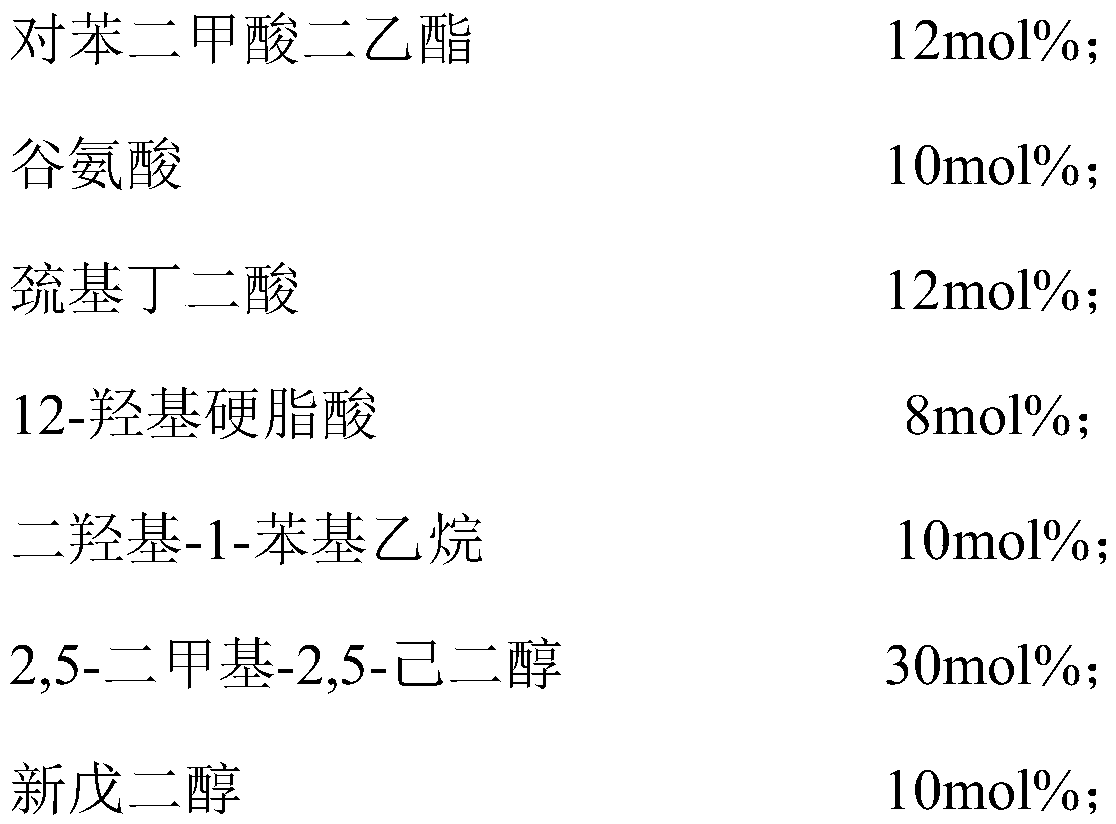

A kind of epoxidized polyester resin and its preparation method and application

ActiveCN108503814BLow acid valueImprove stabilityPowdery paintsPolyester coatingsDiethyl terephthalatePolymer science

Owner:黄山市向荣新材料有限公司

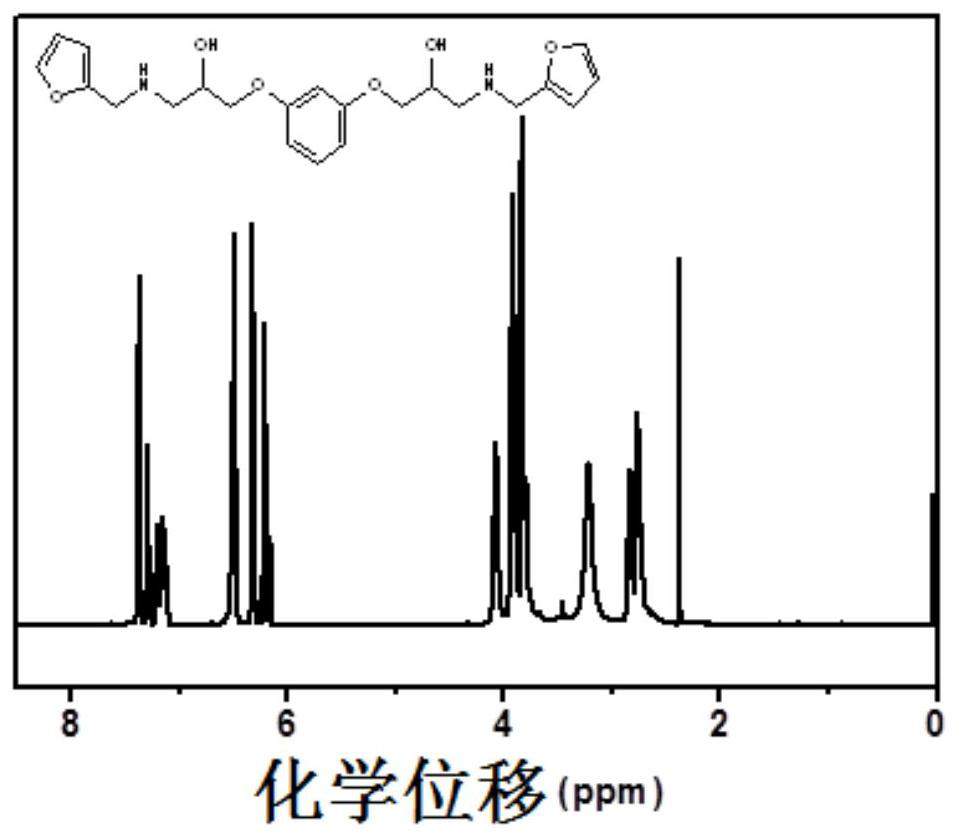

Self-repairing polyurethane based on two-way repairing structure, preparation method and application thereof

The invention relates to the field of self-repairing photo-curing materials, and discloses self-repairing polyurethane based on a two-way repairing structure, a preparation method and application thereof. The polyurethane contains structural units provided by R1, R2, R3, R4, R5, R6 and R7; wherein R1 is polyethylene glycol, R2 is isophorone diisocyanate, R3 is terephthalaldehyde, R4 is oxalyl dihydrazide, R5 is resorcinol diglycidyl ether, R6 is furfuryl amine, and R7 is N, N'-(4, 4'-methylene diphenyl)bismaleimide. The polyurethane provided by the invention has excellent self-repairing capability and high self-repairing efficiency, the service life of the material can be prolonged, and the hidden danger of microcracks caused by mechanical damage is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

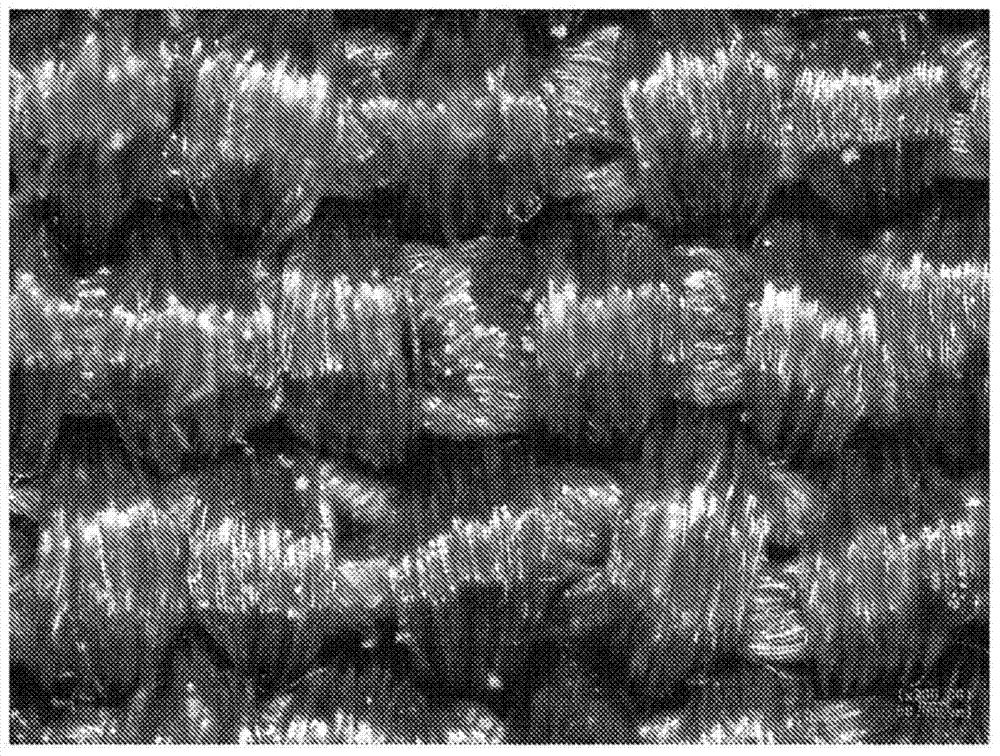

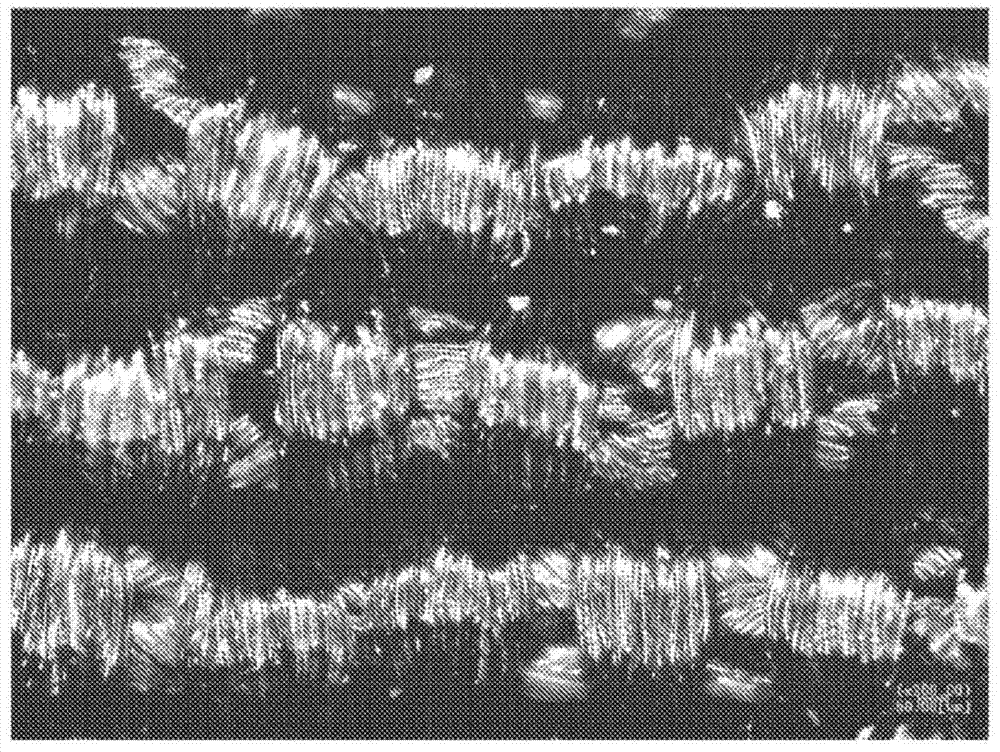

Modified fiber and method for manufacturing same

InactiveCN104718323AExcellent abrasion resistanceSmall size changeAbrasion resistant fibresVegetal fibresEpoxyCuprammonium rayon

The modified fiber according to the present invention pertains to a modified fiber having high abrasion resistance in wet conditions and having high washing resistance. A modified fiber in which an epoxy compound has been bonded to a refined cellulose fiber, a natural cellulose fiber, a cuprammonium rayon, rayon, or silk fiber, the modified fiber being characterized in that the epoxy compound is resorcinol diglycidyl ether and / or hydroquinone diglycidyl ether.

Owner:NIHON SANMO DYEING

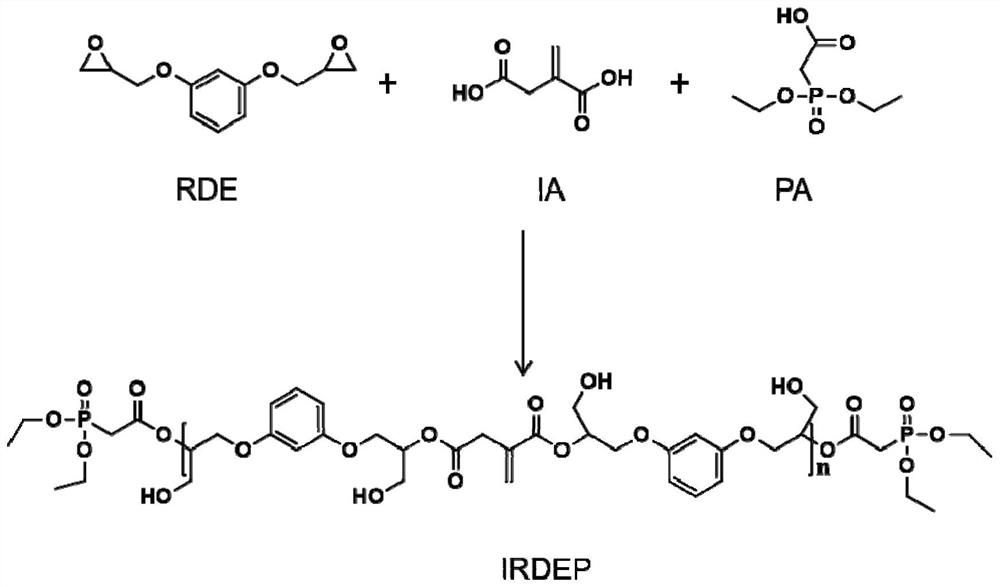

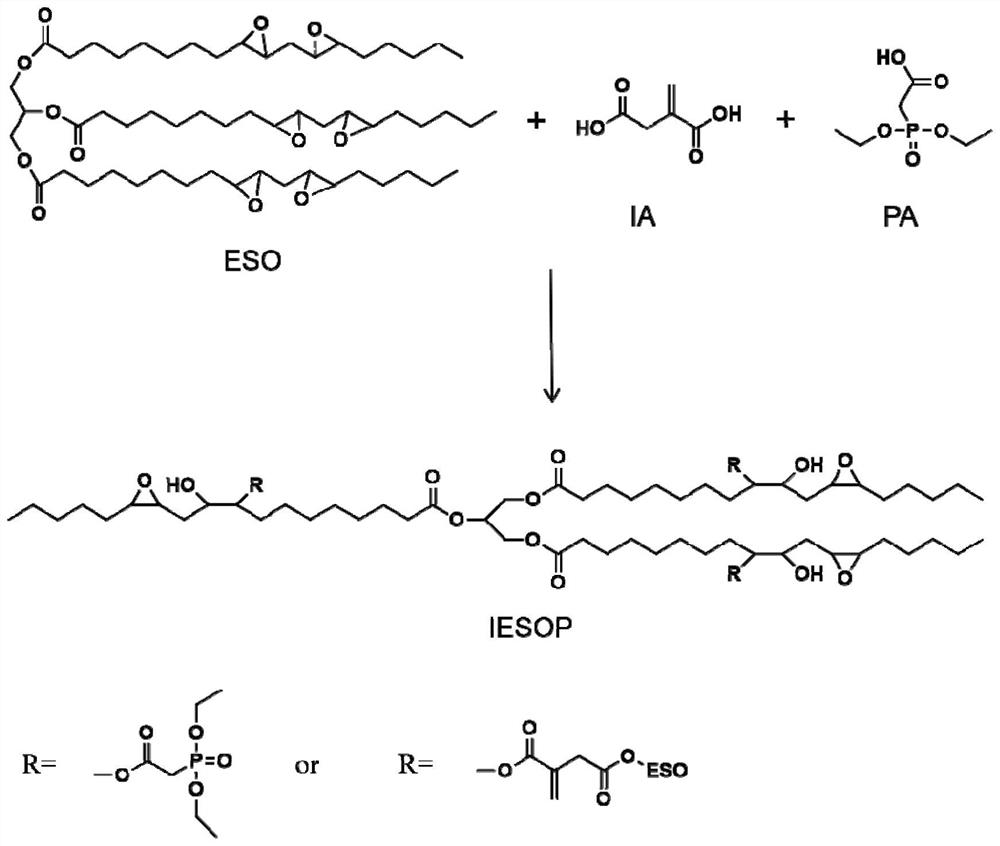

Bio-based multifunctional flame-retardant epoxy acrylate as well as preparation method and application thereof

The invention discloses bio-based multifunctional flame-retardant epoxy acrylate and a preparation method and application thereof. The bio-based multifunctional flame-retardant epoxy acrylate prepolymer is prepared in two modes, diethyl phosphoacetic acid is introduced into bio-based epoxy resin through a ring-opening esterification reaction, the flame-retardant effect can be effectively achieved, and thus the flame resistance of a cured film is enhanced; the resorcinol diglycidyl ether and the epoxidized vegetable oil are used as main raw materials to prepare the multifunctional bio-based epoxy acrylate, so that biomass can be effectively introduced into a photocureable coating, and the use of petroleum-based raw materials is reduced; itaconic acid is selected to replace (methyl) acrylic acid derived from petroleum products, so that the application of biomass in the photocureable coating is increased; and the ring-opening reaction of itaconic acid and epoxidized vegetable oil has a chain extension effect on the polymer, is also beneficial to improving the functionality of epoxidized vegetable oil-based acrylate, and improves the flexibility, tensile strength and other related properties of a photocureable film.

Owner:SOUTH CHINA AGRI UNIV

Process for preparing bonding resin

PendingCN112334560AWood working apparatusLignocellulosic adhesivesPolymer sciencePolyethylene glycol

The present invention relates to a process for preparing a bonding resin, wherein lignin is provided in the form of an aqueous solution and is mixed with one or more of glycerol diglycidyl ether, polyglycerol diglycidyl ether, polyglycerol polyglycidyl ether, glycerol triglycidyl ether, sorbitol polyglycidyl ether, alkoxylated glycerol polyglycidyl ether, trimethylolpropane triglycidyl ether, trimethylolpropane diglycidyl ether, polyoxypropylene glycol diglycidylether, polyoxypropylene glycol triglycidyl ether, diglycidylether of cyclohexane dimethanol, resorcinol diglycidyl ether, isosorbidediglycidyl ether, pentaerythritol tetraglycidyl ether, ethylene glycol diglycidyl ether, polyethylene glycol diglycidyl ether having 2-9 ethylene glycol units, propylene glycol diglycidyl ether having1-5 propylene glycol units, and / or diglycidyl ether of terminal diol having a linear carbon chain of 3-6 carbon atoms; and optionally one or more additives. The bonding resin is useful, for example in the manufacture of laminates, mineral wool insulation and wood products such as plywood, oriented strandboard (OSB), laminated veneer lumber (LVL), medium density fiberboards (MDF), high density fiberboards (HDF), parquet flooring, curved plywood, veneered particleboards, veneered MDF or particle boards.

Owner:STORA ENSO OYJ

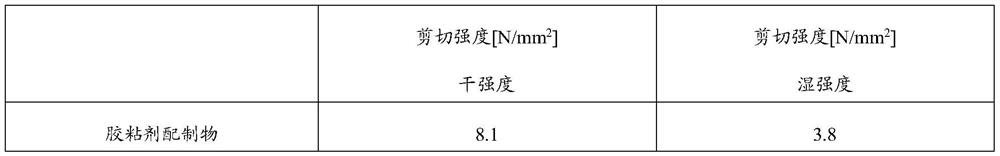

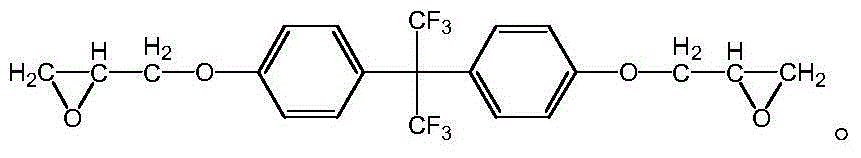

High-thermal conductivity electrical insulation cement and preparation method thereof

InactiveCN104629266AImprove solubilityImprove heat resistanceResorcinol diglycidyl etherStructural formula

The invention relates to electronic and electrical materials and particularly relates to high-thermal conductivity electrical insulation cement and a preparation method thereof. The high-thermal conductivity electrical insulation cement is characterized by comprising fluorine-containing epoxy resin, resorcinol diglycidyl ether epoxy resin, carboxylic group-containing polyimide resin, 1,4-bis(2,4-diaminophenoxy)benzene, methyl tetrahydrophthalic anhydride and inorganic filler at a mass ratio of 100:(100-300):(50-150):(15-30):(100-200):(200-600), wherein the functional fluorine-containing epoxy resin is fluorine-containing bisphenol A epoxy resin, and the structural formula is shown in the specification. The electrical insulation cement has good thermal conduction and high heat resistance, is simple in preparation method and low in cost, has an excellent electrical insulation property, facilitates large-scale batch production, is widely applicable and has a good market prospect.

Owner:SUZHOU HUANYAN ELECTRIC

Active carbon prepared from wastes and method thereof

The invention discloses active carbon prepared from wastes. The active carbon is prepared from the following raw materials in parts by weight: 10 to 15 parts of waste ceramic sheets, 10 to 15 parts of waste tire rubber, 6 to 10 parts of coal slag, 10 to 16 parts of 1,4-cyclohexanedimethanol, 3 to 6 parts of 2-naphthol-6,8-dipotassium disulfonate, 7 to 10 parts of ethopabate, 6 to 12 parts of isoamyl salicylate, 3 to 7 parts of dimethicone, 10 to 15 parts of mercaptosuccinic acid and 8 to 12 parts of resorcinol diglycidyl ether. The waste ceramic sheets, the waste tire rubber and the coal slag are used as raw materials to be prepared into active carbon with high mechanical strength, good adsorption performance and long service life by virtue of steps such as immersing, carbonization and the like, so that the cost is saved, and the resource utilization rate is increased.

Owner:SUZHOU DINGYU ENERGY EFFICIENT EQUIP

High-strength fireproof crucible and production method thereof

The invention relates-the field of refractory materials, and discloses a high-strength fireproof crucible and a production method thereof. The crucible is produced from a mud material and additives; the mud material comprises 55-65 parts of magnesium ores, 5-15 parts of zirconia, 5-15 parts of fused magnesia, 5-15 parts of waste graphite micro-powder, 1-5 parts of metallic magnesium micro-powder,1-5 parts of chromium oxide micro-powder, 0.3-0.5 part of resorcinol diglycidyl ether, 0.1-0.3 part of sodium dodecyl benzene sulfonate, 20-30 parts of ethanol and 10-20 parts of water; and the additives include 0.05-0.1 part of a cationic photocuring initiator, 0.05-0.2 part of tetradecyltrimethylammonium bromide, 3-7 parts of ethanol and 3-7 parts of water. The reduction of the use amount of theadditives effectively increases the strength of the crucible. A crucible blank is pre-cured through a photocuring technology before being sintered in order to effectively prevent the cracking of thecrucible.

Owner:长兴正发热电耐火材料有限公司

High-performance epoxy asphalt and preparation technology thereof

The invention discloses high-performance epoxy asphalt. The epoxy asphalt is prepared from asphalt, epoxy resin, 4,4-diaminodiphenylmethane, fumaric acid, benzyl dimethylamine, glacial acetic acid, ammonium humate, styrene-acrylonitrile copolymer, EO-PO segmented copolymer, polyurethane, TNPP, polyoxyethylene stearate, polyisoprene rubber powder, rosin, sulphobetaine, resorcinol diglycidyl ether, sodium gluconate and octamethylcyclotetrasiloxane. The invention further discloses a preparation technology of the high-performance epoxy asphalt. The asphalt prepared through the method is low in viscosity, not likely to be layered and good in storage stability, the tensile strength of the epoxy asphalt is 7.16-10.62 MPa, the breaking elongation rate is 510-658%, the epoxy asphalt shows good strength and toughness, early strength can be improved to a certain degree, construction is convenient, and large-scale application and popularization are promoted.

Owner:SUZHOU AIBOMAIER NEW MATERIAL CO LTD

Composite scaffold for loading bone marrow mesenchymal stem cells and preparation method thereof

ActiveCN109289091AChange molecular structureSimple structureCarbon compoundsPharmaceutical delivery mechanismChlorodimethylsilaneEthyl group

The invention discloses a composite scaffold for loading bone marrow mesenchymal stem cells and a preparation method thereof. Hydroxyapatite and modified graphene are added into methacrylated gelatin,and for improving synergy, a blender and a modifying auxiliary agent are added; a mixture of 1-(3-pyridyl)-3-(dimethylamino)-2-propylene-1-one and diglycidyl resorcinol ether is selected as the blender, and a mixture of 4-(acetylamino)-2,2,6,6-tetramethyl-1-piperidinyloxy, trimethylsilylketene ethyl trimethylsilyl acetal, N,N'-di(chlorodimethylsilane)-1,1-dimethylsilane diamine and 1,5-pentanediol diacrylate is selected as the modifying auxiliary agent. The finally prepared composite scaffold can make the stem cells survive longer, also has large elastic modulus. In addition, due to the addition of modified graphene and hydroxyapatite, the composite scaffold has good biocompatibility and is not easily rejected by a human body.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

Long-lasting wear-resisting aging-resisting UV (Ultraviolet) curing coating and preparation method thereof

InactiveCN103834294AImprove aging resistanceImprove general performanceFireproof paintsPolyurea/polyurethane coatingsOxidation resistantAntimony trioxide

The invention discloses a long-lasting wear-resisting aging-resisting UV (Ultraviolet) curing coating which is characterized by being prepared from the following raw materials in parts by weight: 50-55 parts of urethane acrylate, 9-12 parts of cyclopentane, 7-9 parts of methoxy-polyethylene glycol monoacrylic ester, 3-4 parts of epoxidized soybean oil, 4-5 parts of photoinitiator 2959, 7-9 parts of resorcinol diglycidyl ether, 5-8 parts of ethylene glycol diethyl ether, 5-7 parts of ethyl acetate, 1-2 parts of titanate coupling agent TMC-TTS, 1-2 parts of grape essential oil, 5-7 parts of montmorillonoid, 2-3 parts of chromic oxide, 2-3 parts of antimonous oxide and 4-5 parts of additive. Due to addition of the natural anti-oxidation component grape essential oil, the aging-resistance of the coating is improved, and the coating is safe and non-toxic; due to addition of the antimonous oxide, a good flame retarding effect is achieved; due to addition of the additive, a good leveling property is achieved, a uniform coated layer can be formed, and the coating is fast in curing speed, high in hardness, wear-resisting, good in toughness, high in adhesion property, long-lasting in property and high in universality.

Owner:WUHU EDISON AUTOMATION EQUIP

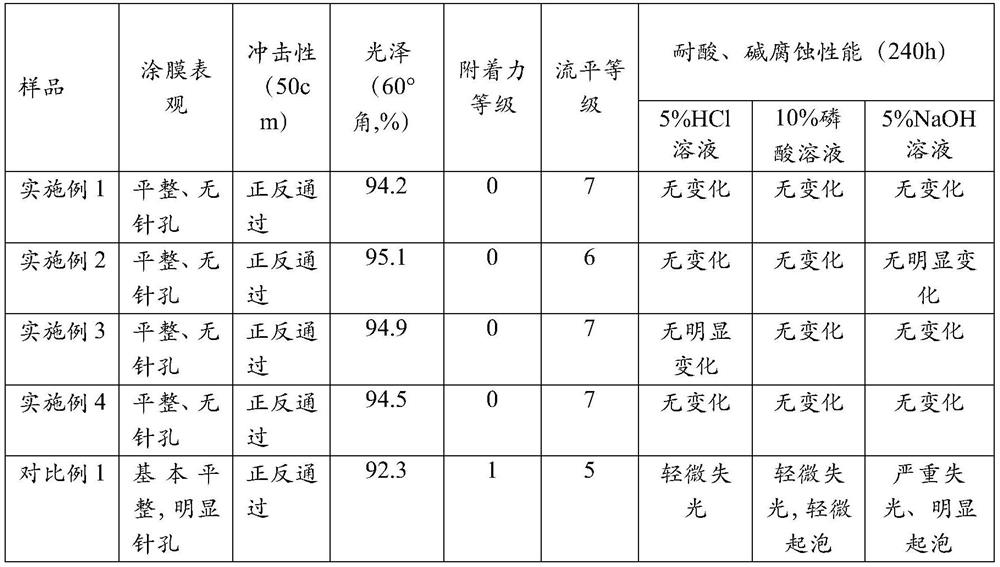

Anti-thick coating pinhole, excellent acid and alkali resistance powder coating and preparation method thereof

ActiveCN112011260BGood acid and alkali resistanceOvercome the shortcomings of poor acid and alkali resistanceAnti-corrosive paintsPolyether coatingsPolymer scienceLow temperature curing

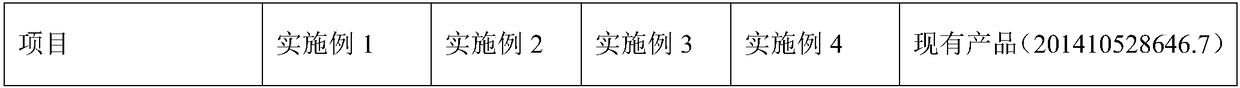

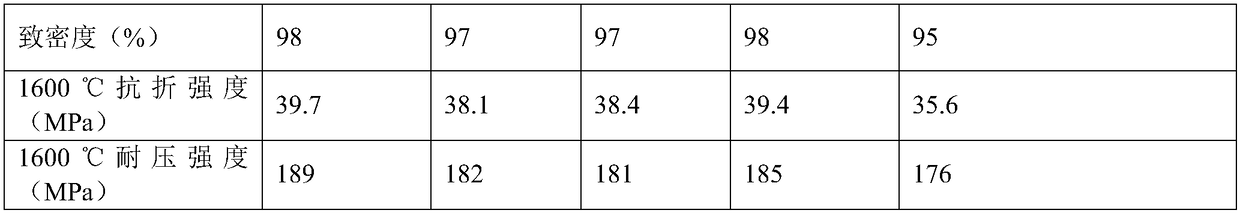

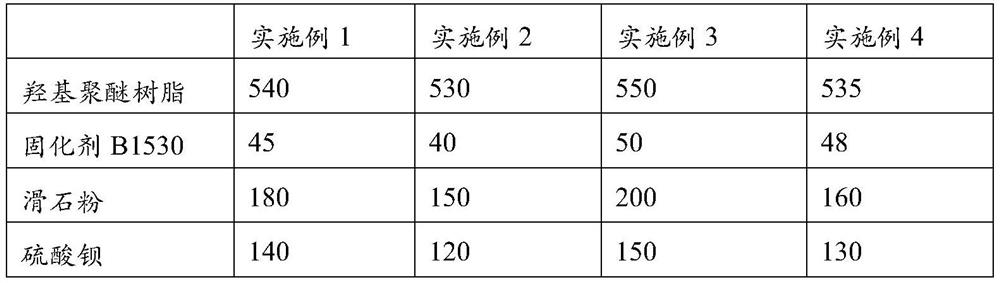

The invention belongs to the technical field of powder coatings, and in particular relates to a powder coating with excellent pinhole resistance and acid and alkali resistance and a preparation method thereof. The parts by weight of the main raw materials of the powder coating of the present invention are: 530-550 parts of hydroxyl polyether resin, 40-50 parts of B1530 curing agent, 150-200 parts of talcum powder, 120-150 parts of barium sulfate, 8-12 parts of brightening agent Parts, 7-10 parts of leveling agent; Hydroxy polyether resin is prepared by polycondensation of materials with the following molar fractions: the molar fractions of each component are: 1,4-cyclohexanedimethanol 4-8 , 1,6-hexanediol 3-6, resorcinol diglycidyl ether 5-10, propylene oxide 30-45, triglycidyl isocyanurate 4-8, octyl glycidyl ether 6-13 . The present invention uses high-functionality hydroxyl polyether resin as the raw material, the hydroxyl value is 15-20mgKOH / g, the amount of B1530 curing agent required for curing is small, the cost of powder coating is low, and it can be cured at 175°C / 15min at low temperature, and The prepared coating film has good resistance to pinholes in thick coating, and the high-functionality polyether has excellent acid and alkali resistance, and can be used for coating metal facilities in industrial cleaning places.

Owner:安徽鑫友高分子新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com