Solvent-free epoxy-tetramaleimide resin adhesive and preparation method thereof

A solvent-free and adhesive technology is applied in the field of solvent-free epoxy-tetrama adhesive and its preparation, and can solve the problems of high cost, high price, and unfavorable large-scale popularization and application of polyetherimide resin. , to achieve the effect of good comprehensive performance, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the preparation of A component

[0039] Mix 100 grams of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane (TGBAPOPP) epoxy resin, 50 grams of isophthalic Add phenol diglycidyl ether epoxy resin to the reaction kettle, add 3 grams of 4,4'-bis(4-aminophenoxy)diphenyl sulfide and 3 grams of 2,2-bis[4-(4-aminobenzene oxy)phenyl]propane and 20 grams of 1,4-bis(2,4-dimaleimidophenoxy)benzene, stirred and reacted at 80°C for 0.5 hours, cooled to 50°C, and added 10 grams Hydrogenated bisphenol A epoxy resin and 15 grams of 3,4-epoxy cyclohexanoic acid-3',4'-epoxy cyclohexyl methyl ester were stirred and reacted at 50°C for 0.5 hour to obtain 201 grams of component A, Denote it as A1.

[0040] Mix 100 grams of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane (TGBAPOPP) epoxy resin, 10 grams of isophthalic Add phenol diglycidyl ether epoxy resin to the reaction kettle, add 5 grams of 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropa...

Embodiment 2

[0043] Embodiment 2: the preparation of B component

[0044] Put 50 grams of m-xylylenediamine, 20 grams of resorcinol diglycidyl ether epoxy resin and 10 grams of 1,3-bis(2,4-bismaleimidophenoxy)benzene into the reaction In the still, stir and react at 60° C. for 0.5 hour to obtain 80 g of component B, which is designated as B1.

[0045] Mix 60 grams of m-xylylenediamine, 20 grams of resorcinol diglycidyl ether epoxy resin, 4 grams of 2,2-bis[4-(2,4-dimaleimidophenoxy)benzene Base] propane and 2 grams of 1,3-bis(2,4-dimaleimidophenoxy)benzene were put into the reaction kettle, stirred and reacted at 100°C for 1.5 hours, and 86 grams of component B were obtained. Do B2.

[0046] Put 80 grams of m-xylylenediamine, 20 grams of resorcinol diglycidyl ether epoxy resin and 8 grams of 1,4-bis(2,4-bismaleimidophenoxy)benzene into the reaction In the still, stir and react at 80° C. for 1 hour to obtain 108 grams of component B, which is designated as B3.

[0047] 100 grams of m-xy...

Embodiment 3

[0048] Embodiment 3: the preparation of adhesive

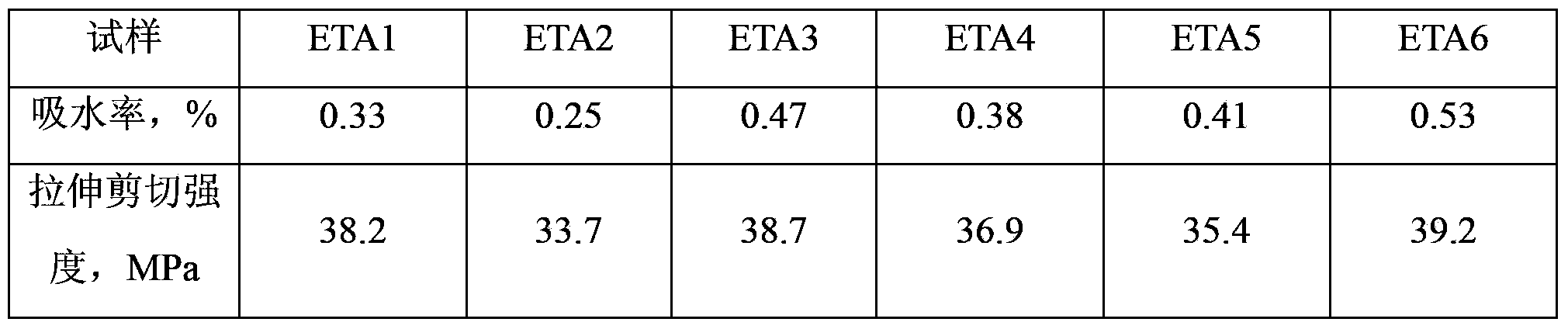

[0049] At room temperature, add 20 grams of A1 and 20 grams of B3 into the reaction kettle and stir and mix evenly to obtain 40 grams of solvent-free epoxy-tetrama adhesive, which is designated as ETA1.

[0050] At room temperature, add 10 grams of A1, 20 grams of A3 and 20 grams of B1 into the reaction kettle and stir and mix evenly to obtain 40 grams of solvent-free epoxy-tetrama adhesive, which is designated as ETA2.

[0051] At room temperature, add 10 grams of A2, 15 grams of A3, 5 grams of A4, 10 grams of B2, and 5 grams of B4 into the reaction kettle and stir and mix evenly to obtain 45 grams of solvent-free epoxy-tetrama adhesive, which is designated as ETA3.

[0052] At room temperature, add 40 grams of A4, 5 grams of B1, and 5 grams of B4 into the reactor and stir and mix evenly to obtain 50 grams of solvent-free epoxy-tetrama adhesive, which is designated as ETA4.

[0053] At room temperature, add 20 grams of A1, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com