Bio-based multifunctional flame-retardant epoxy acrylate as well as preparation method and application thereof

A technology based on epoxy acrylate and epoxy acrylate, which is applied in the field of bio-based multifunctional flame-retardant epoxy acrylate and its preparation, can solve the problems of ecological damage and restricted use, and achieve improved functionality and enhanced flame resistance , Improve the effect of crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

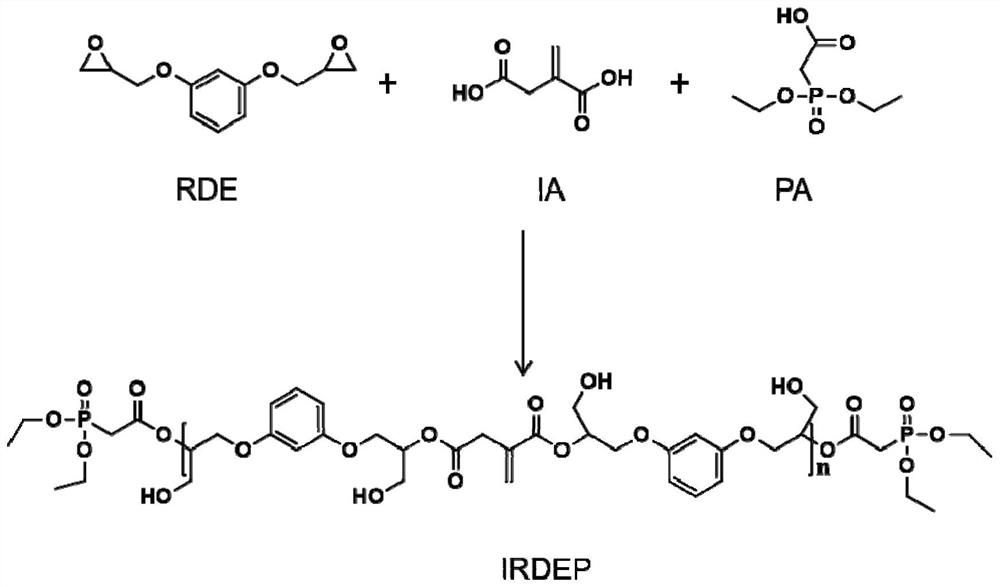

Method used

Image

Examples

Embodiment 1

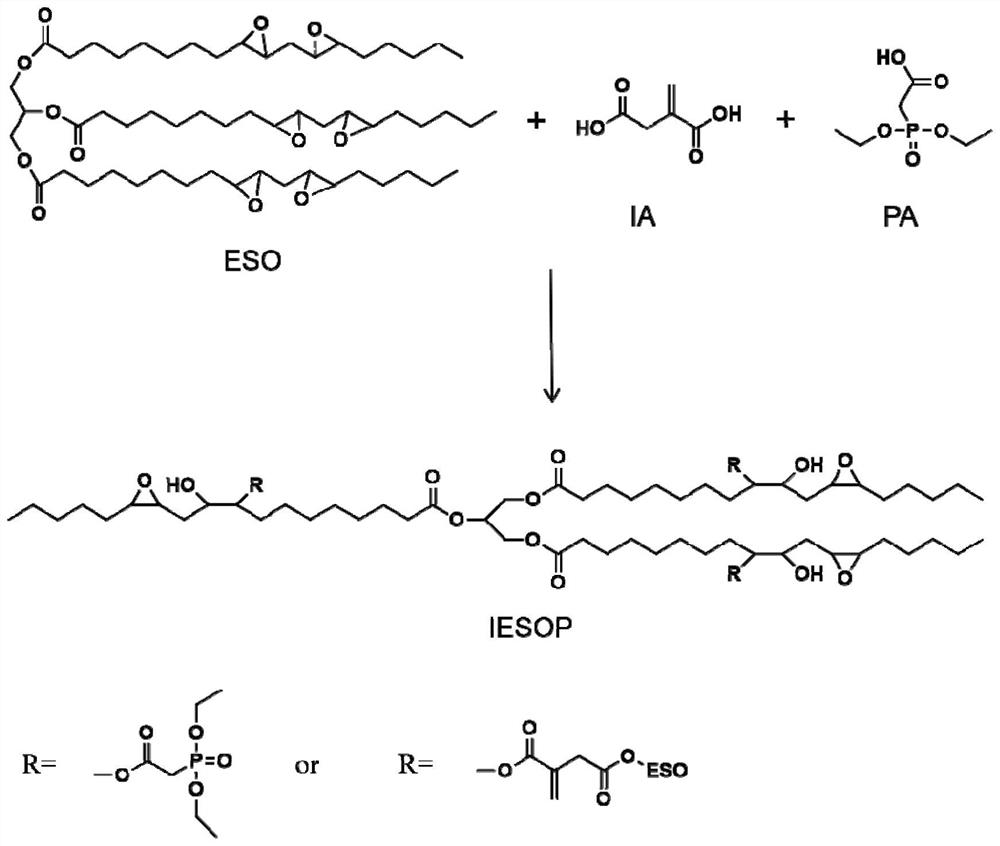

[0043] A preparation method of bio-based multifunctional flame-retardant epoxy acrylate, comprising the steps of:

[0044] (1) In a three-necked flask with a thermometer, add epoxidized soybean oil (24.00g), itaconic acid (3.23g, purity 99%), diethylphosphonoacetic acid (5.08g, purity 95%), triphenyl Phosphine (0.32g) and hydroquinone (0.03g) were stirred with a stirrer at 80°C for 0.5h, and then the temperature was raised to 120°C to continue the reaction for 2h to obtain a phosphorus-containing soybean oil-based epoxy acrylate. The molar ratio between the epoxidized soybean oil, itaconic acid and diethyl phosphonoacetic acid is 1:1:1, and the amount of triphenylphosphine is the total weight of epoxidized soybean oil, itaconic acid and diethyl phosphoacetic acid 1%, the consumption of hydroquinone is 1% of the total weight of itaconic acid.

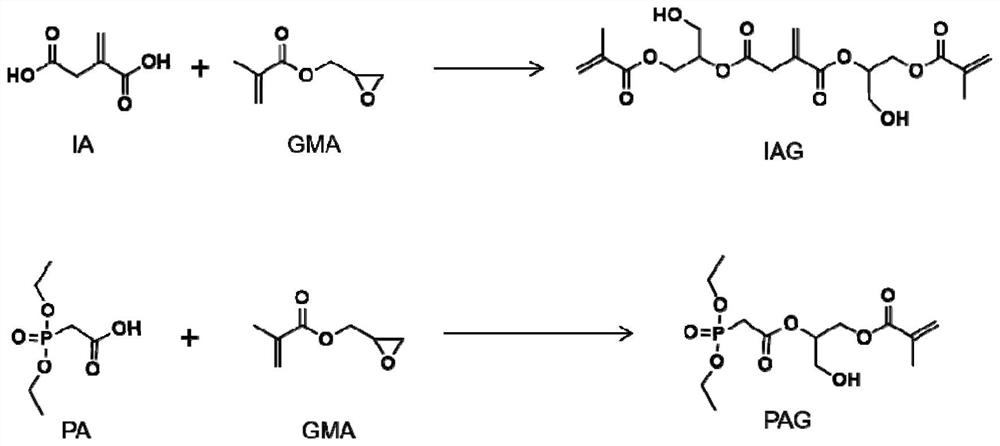

[0045] (2) In a three-necked flask with a thermometer, add diethylphosphonoacetic acid (20.00g, purity 95%), glycidyl methacrylate (14...

Embodiment 2

[0049] A preparation method of bio-based multifunctional flame-retardant epoxy acrylate, which is the same as Example 1 except for the following steps:

[0050] (4) In a three-necked flask with a thermometer, add itaconic acid (13.00g, purity 99%), glycidyl methacrylate (28.99g, purity 97%), triphenylphosphine (0.42g) and p-phenylene Diphenol (0.42g) was stirred at 80°C for 0.5h with a stirrer, and then the temperature was raised to 90°C to continue the reaction for 2h to obtain an itaconic acid acrylate. The molar ratio between the itaconic acid and the glycidyl methacrylate is 1:2, the amount of triphenylphosphine is 1% of the total weight of itaconic acid and glycidyl methacrylate, hydroquinone The dosage is 1% of the total weight of glycidyl methacrylate and itaconic acid.

[0051] (5) Mix the phosphorus-containing soybean oil-based epoxy acrylate (6.40g) prepared in (1) with the diethylphosphoacetic acid acrylate (1.60g) prepared in (2) to obtain a phosphorus-containing ...

Embodiment 3

[0053] A preparation method of bio-based multifunctional flame retardant epoxy acrylate is the same as Example 2 except the following steps: the mass ratio between the phosphorus-containing soybean oil-based epoxy acrylate mixture and itaconic acid acrylate is 6:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com