Patents

Literature

143 results about "Cuprammonium rayon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cuprammonium rayon is a rayon made from cellulose dissolved in cuprammonium solution. It is produced by making cellulose a soluble compound by combining it with copper and ammonia. The solution of this material in caustic soda is passed through the spinneret and the cellulose is regenerated in the hardening baths that remove the copper and ammonia and neutralize the caustic soda. Cuprammonium rayon is usually made in fine filaments that are used in lightweight summer dresses and blouses, sometimes in combination with cotton to make textured fabrics with slubbed, uneven surfaces.

Mulberry silk and cuprammonium rayon yarn interwoven fabric and weaving method thereof

InactiveCN101532199ALow costImprove comfortLiquid/gas/vapor removalDyeing processYarnCuprammonium rayon

The invention provides a fabric, in particular to a mulberry silk and cuprammonium rayon yarn interwoven fabric. The fabric is interwoven by the mulberry silk and the cuprammonium rayon yarn, wherein warp is made of the mulberry silk, while weft is made of the cuprammonium rayon. The invention also provides a method for weaving the fabric, which is a method of interweaving the mulberry silk warp and the cuprammonium rayon yarn weft into the fabric, wherein the cuprammonium rayon yarn as the weft is subjected to predrying treatment before use; process steps of the warp and the weft are as follows: the warp adopts reeled silk to be subjected to rolling, primary twisting, doubling, second twisting, skeining, degumming, dyeing, rolling, warping and weaving; and the weft adopts cone winded yarns to be subjected to roll separating, twisting, skeining, dyeing, rolling, quilling, predrying and weaving. The method provides the product interwoven by the mulberry silk and the cuprammonium rayon yarn, and adds new content for colorful silk variety.

Owner:上海丝绸集团股份有限公司

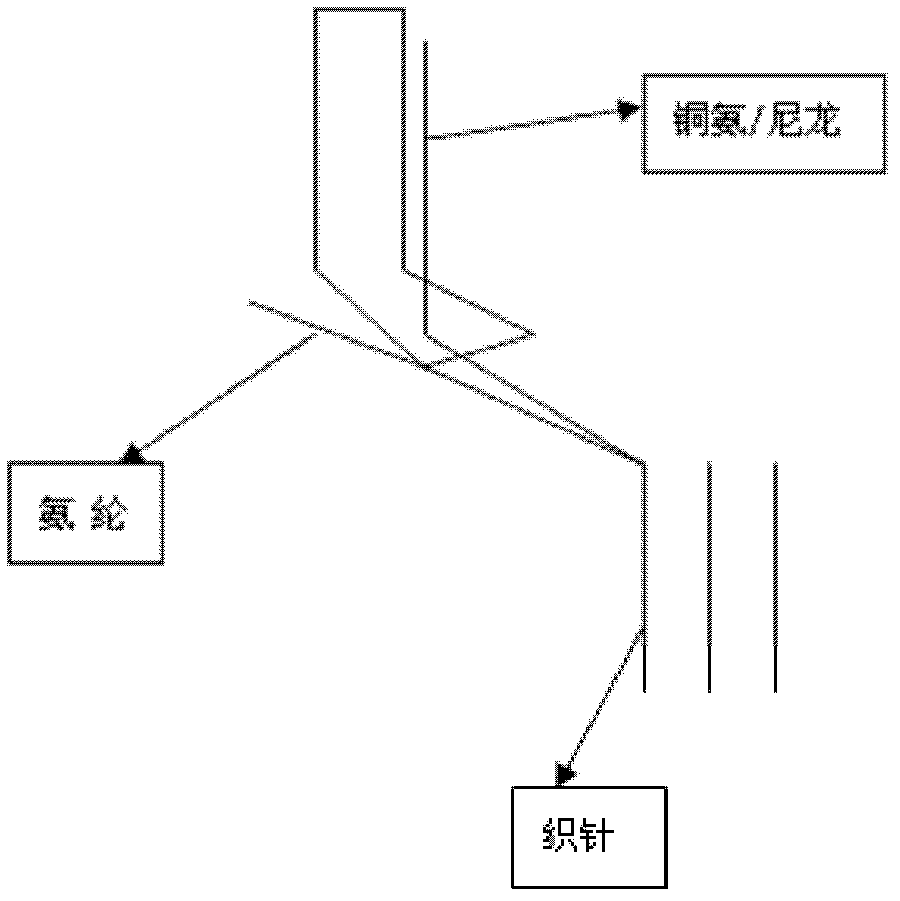

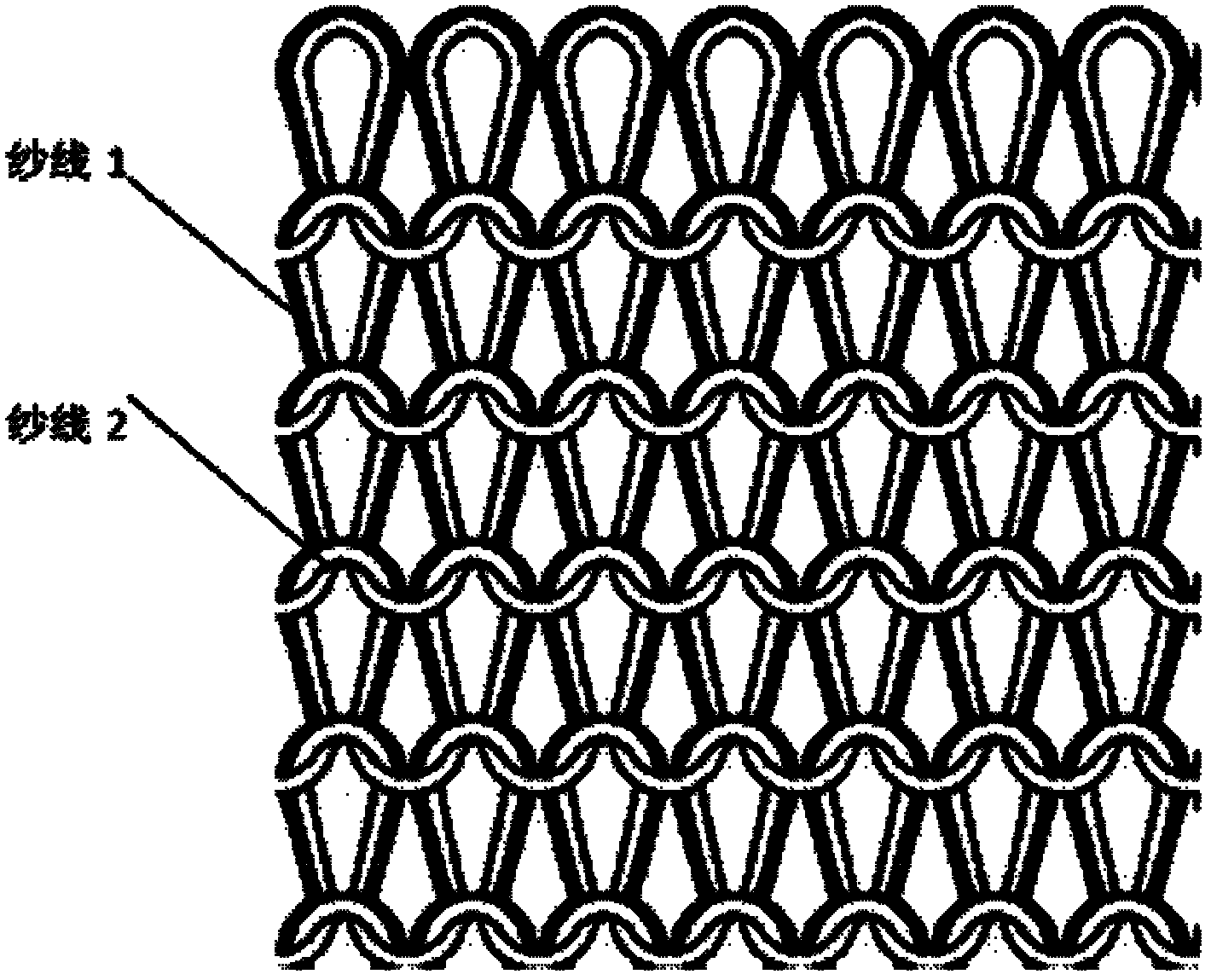

Imitated silk high-elasticity knitted underwear fabric and preparation method thereof

ActiveCN102631030AControl flatnessGuaranteed weightWeft knittingBleaching apparatusYarnBursting strength

The invention relates to imitated silk high-elasticity knitted underwear fabric and a preparation method thereof. The fabric is formed by interweaving fine-denier copper ammonia / nylon bi-component filament and spandex yarn, wherein the fine-denier copper ammonia / nylon bi-component filament is located on the front of the fabric and completely covers the spandex yarn. The preparation method comprises the following steps of: sequential weaving, fabric pre-sizing, pretreatment, copper ammonia dyeing, aftertreatment, nylon dyeing, soaping, soft finish, dehydration and re-sizing. The imitated silk high-elasticity knitted underwear fabric provided by the invention has smooth handfeel, brightness, full appearance, soft handfeel, antibacterial property, comfort and the like; the problems of low bursting strength and insufficient elasticity of the single copper ammonium imitated silk fabric are solved; and the problems of non-uniform blend dyeing of copper ammonium and chemical fiber, color yellowing and rough cloth cover are solved.

Owner:NINGBO DAQIAN TEXTILE

Method of staining copper ammonia fiber and tencel interwoven cloth

ActiveCN101016683AFeel goodIncrease elasticityLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonCellulose

The invention relates to a dying method of copper ammonia fiber and silk interwoven cloth, comprising that (1) washing with water, (2) refining, (3) washing with cellulose, (4) dying. And the fur burning process is purpose to remove silk fiber exposed outside the interwoven cloth and the short flannel, eyebrow and foreign material adhered on the face of cloth. The water washing process is purposed to clean the dirt on the face of interwoven cloth. The refining process is purposed to remove the slurry, grease of wrap and the dirt on the face of cloth. The cellulose washing process is purposed to remove the hair generated by fibrosis, to avoid balling. The inventive product has the appearance of silk brocade cloth and improves bacteria resistance function.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Strength-improvable blended regenerated cotton yarn and preparation method thereof

InactiveCN104911909AHigh strengthGood sun protectionYarnMonocomponent polyolefin artificial filamentYarnStaining

The present invention discloses a strength-improvable blended regenerated cotton yarn which is characterized being prepared from the following raw material by weight: 30-33 parts of waste cotton fabrics, 15-17 parts of cotton yarn leftover material, 2-3 parts of glycerin, 8-10 parts of copper ammonia fibre, 3-4 parts of starch, 3-5 parts of nano-silica, 39-44 parts of polypropylene, 3-5 parts of nano-zinc oxide, 12-14 parts of liquid paraffin, 9-10 parts of nano-titanium dioxide, 1.5-parts of carboxymethyl cellulose, 1-2 parts of glyceryl stearate, and proper amount of water; the starch, the nano-silica and other components are used for prepare processing slurry to process waste cotton fabric renewable fiber, the strength and sunscreen resistance of the fiber are improved, then the waste cotton fabric renewable fiber is mixed with the copper ammonia fiber, and strength and hand feel of the fiber are improved by cotton carding; the strength-improvable blended regenerated cotton yarn is prepared by addition of the nano-titanium dioxide and the nano-zinc oxide-modified polypropylene staple fiber for blending, the strength of the cotton fiber is improved, and the strength-improvable blended regenerated cotton yarn has the characteristics of easy staining and grinding resistance.

Owner:SHUNTIAN SPINNING LIMITED

Water-washable silk composite fiber and preparation method thereof

InactiveCN104213247AUV resistantAntistaticConjugated cellulose/protein artificial filamentsArtifical filament manufacturePolyesterFiber

Disclosed water-washable silk composite fiber is characterized by being prepared from the following raw materials in parts by weight: 18-22 parts of silk, 11-13 parts of wool, 4-7 parts of cuprammonium rayon, 6-8 parts of polyester fiber, 8-10 parts of newdal fiber, 10-12 parts of bast fiber, 0.6-1.1 parts of nanometer TiO2, 6-9 parts of aloe viscose fiber, 0.7-0.9 parts of hydroxypropyl methyl cellulose, 0.8-1.4 parts of polypropylenglycol diglycidyl ether, 100-110 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 1-3 parts of radix aucklandiae, 2-4 parts of cortex moutan, 3-5 parts of an auxiliary agent, and proper amount of water. By adding cuprammonium rayon and nanometer TiO2, the silk composite fiber has performances of resisting ultraviolet, resisting static electricity, resisting water washing and the like; and additionally by adding aloe viscose fiber, the Chinese herbal medicines and other compositions, the prepared silk composite fiber has the characteristics of resisting bacteria, diminishing inflammation, light and soft texture, excellent air permeability, high strength and high elasticity, and thus the silk composite fiber is repeatedly cleanable and keeps comfortableness, and is not flat or sunk after being used for a long time.

Owner:TONGCHENG SHUANGLONG SILK

Preparation method of milk fiber/cuprammonium rayon blended yarn

The invention discloses a preparation method of a milk fiber / cuprammonium rayon blended yarn which is prepared by the following spinning procedures: opening and cleaning, carding, drawing, roving, spinning and winding with the materials by weight percent: 40%-60% of the milk fiber and 60%-40% of the cuprammonium rayon. The preparation method for producing the milk fiber / cuprammonium rayon blended yarn has stable and reliable process and convenient application to production, and the prepared milk fiber / cuprammonium rayon blended yarn has reliable quality, high strength, good post processing property and good yarn unevenness and low yarn knotting rate, thus the method is a mature spinning process which is very applicable to industrial production.

Owner:李睿

Dye process of mixed fabric of cuprammonium fiber and rayon

InactiveCN101046068AAnti-crack performanceFeel goodLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonEngineering

The dyeing process of cuprammonium rayon includes the following steps: water washing, refining and dyeing. In the water washing step, stains on the cuprammonium rayon is eliminated initially; the refining step eliminates sizing material, grease and stains, improves the hand feeling, and raises the dyeing permeability and homogeneity. The dyed cuprammonium rayon fabric is hygroscopic, air permeable and comfortable.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Dyeing method for copper ammonia fiber and cotton, cotton brocade core-spun yarn interwoven cloth

ActiveCN101082183AIncrease elasticityFeel goodLiquid/gas/vapor open-width material treatmentBiochemical fibre treatmentYarnCuprammonium rayon

The present invention relates to the process of dyeing interwoven fabric of cuperammonium fiber and cotton / cotton-Jinlun covering yarn. The dyeing process includes the following steps: water washing, refining, leaching, cellulose water washing, and dyeing. Thus dyed interwoven fabric has the style similar to silk fabric, good hydroscopic and permeating performance, high elasticity, and other advantages, and is fashionable.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Slub dyeing technique for bamboo charcoal modified polyester fibre

InactiveCN101041936ADo not change colorGuaranteed fastnessDyeing processMonocomponent polyesters artificial filamentPolyesterAcetic acid

The invention relates to a dye method of bamboo charcoal modified polyester fiber, which uses Ascracen disperse cation dye produced by German Desda Fabric Dye Company. And the method comprises that coming bamboo charcoal modified polyester fiber to be arranged in high-temperature drying machine to operate for 3-5min at 30-40Deg. C, adding 0.3-0.5g / L glacial acetic acid and 2.5-4g / L glauber salt to operate for 5-10min, adding dye to operate for 5-10min, increasing temperature at 1-2Deg. C / min, stopping increasing temperature when the temperature is 80+-2Deg. C, and holding temperature for 10-15min, increasing temperature to 100-115Deg. C at 0.75-1Deg. C / min, to operate for 40-60min, discharging liquid and washing, then arranging the dyed bamboo charcoal modified polyester fiber into soap detergent, to process for 20-30min at 80-90Deg. C. The invention can be used dye bamboo charcoal modified polyester fiber, with better dye effect, high color stability and no hurt on copper ammonia fiber in the dye process.

Owner:HEILAN HOME

Dyeing method for cuprammonium fabric

ActiveCN1888184AGood hygroscopicityImprove breathabilityLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonFiber

The present invention relates to a dyeing method of cuprammonium rayon fabric. Said method successively includes the water washing process, scouring process and dyeing process. The water washing process is used for debatching and primarily cleaning the grease and blob on the fabric surface, and the scouring process is used for removing size mixture and grease contained in the cuprammonium rayon fabric and blob on the fabric surface and can be used for raising permeability of coloring agent and uniformity of color absorption.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Production method of copper ammonia/viscose/linen cotton fiber blended fabric

The invention discloses a production method of a copper ammonia / viscose / linen cotton fiber blended fabric. According to the production method, selected warp and weft materials are as follows in parts by mass: 30-50 parts of copper ammonia fibers, 15-25 parts of linen fibers, 40-90 parts of viscose fibers, 20-40 parts of combed cotton and 8-18 parts of ultrafine fine denier polyester. A step of slashing in the production process comprises the specific steps: (1) mixing size: adding water into a size mixing bucket and raising the temperature of the water to 50 DEG C, adding a pre-dyeing agent, wherein the adding mass of the pre-dyeing agent is 15-18% of that of water, starting a stirrer and adding solid PVA (Polyvinyl Acetate) at the mass ratio of the solid PVA to the water of (1-4) to 80, raising the temperature to 90 DEG C, and stirring and dissolving to prepare slurry; and (2) sizing: sizing by adopting a slashing machine, wherein size in a size tank does not need to be heated. The yarns of the sizing procedure are subjected to sizing by adopting the PVA with the concentration which is not higher than 4%; the sizing rate is low, size skins are not easy to form by a sizing agent and desizing is easy to carry out by post-finishing; and meanwhile, the sizing agent can be stored after being prepared and can be used at any time in future, and does not need to be prepared when being needed, so that the energy and time are saved.

Owner:SUZHOU CHENHENG WEAVING

Dyeing method of interwoven fabric made of cuprammonium fibers and tencels

ActiveCN102312374AFeel goodImprove permeabilityBiochemical fibre treatmentDry-cleaning apparatus for textilesCuprammonium rayonFiber

The invention discloses a dyeing method of an interwoven fabric made of cuprammonium fibers and tencels. The dyeing method comprises the following steps of: (a) an enzyme desizing procedure, (b) a water scrubbing procedure, (c) a refining procedure, and (d) a dyeing procedure. Compared with the prior art, the dyeing method has the following advantages that the water scrubbing procedure aims at cleaning the blots on the fabric surface of the interwoven fabric; and the refining procedure plays roles in not only fading the sizing agent and oil in the interwoven fabric and the blots on the fabricsurface, but also improving the hand feeling of regenerated fibers, enhancing dyeing permeability and color absorption uniformity and reducing color difference and color stain. By using the dyeing method, the plus material of the obtained interwoven fabric made of the cuprammonium fibers and the tencels has an appearance style of a real silk plus material, further can adequately embody the humidity management function of a tencel home textile plus material, and has an excellent skin affinity effect and a functional characteristic of inhibiting the breeding of bacteria. Due to the outstanding characteristics, the plus material of the interwoven fabric becomes one of the high-quality home texture plus materials known internationally at present.

Owner:SUZHOU JINKEDA TEXTILE SCI & TECH

Anti-bacterial health fabric

The invention discloses anti-bacterial health fabric which is formed by interweaving warps and wefts. The anti-bacterial health fabric is characterized in that the warps are made of viscose fiber blended yarns; the wefts are made of polyester fiber blended yarns; bamboo fibers are selected as viscose fibers; the warps can also be made of cellulose acetate fibers or copper ammonia fibers; polyesteramide fibers, polyvinyl alcohol ester fibers or polyvinyl chloride ester fibers are selected as polyester fibers. The anti-bacterial health fabric has the characteristics of being anti-bacterial, bacteriostatic, hygroscopic, breathable, ultraviolet-proof, disinfectant, and anti-static, further has the anti-bacterial, anti-inflammation, deodorant and breathable effects, further has the advantages of being ultraviolet-proof, comfortable and silky in hand feel, hygroscopic, moisture-holding, anti-static and the like, and is simple in production method, and high in production efficiency and product quality.

Owner:茅伟萍

Antibacterial health-caring fabric

InactiveCN105088477AAntibacterialMoisture-absorbing and breathableWoven fabricsPolyesterCuprammonium rayon

The invention discloses an antibacterial health-caring fabric formed by warp yarns and weft yarns interweaved with the warp yarns. The antibacterial health-caring fabric innovates in a way that the warp yarns are viscose fiber blended yarns; the weft yarns are polyester fiber blended yarns; the viscose fibers are bamboo fibers; the warp yarns can be also formed by cellulose acetate fibers or copper ammonia fibers; and the polyester fibers can be polyesteramide fibers, polyvinyl alcohol ester fibers or polyvinyl chloride ester fibers. The antibacterial health-caring fabric is characterized by bacteria prevention, moisture absorption, ventilation, ultraviolet ray releasing, disinfection and static prevention; the antibacterial health-caring fabric also possesses functions of bacterial prevention, inflammation removal and odor elimination as well as ventilation; the antibacterial health-caring fabric is advantaged by ultraviolet ray prevention, comfortable hand feeling, moisture absorption and retention and static prevention; and the production method of the fabric is simple, has high production efficiency and great product quality.

Owner:JIANGSU JUWEI NEW MATERIALS

Pure copper ammonia fiber high-density imitated silk jacquard plus material and preparing method of pure copper ammonia fiber high-density imitated silk jacquard plus material

InactiveCN104047093AWideConsistent qualitySwivel-woven fabricsLappet-woven fabricsFiberCuprammonium rayon

The invention provides a pure copper ammonia fiber high-density imitated silk jacquard plus material and a preparing method of the pure copper ammonia fiber high-density imitated silk jacquard plus material. Warp yarns of the plus materials are copper ammonia 75D / 45F, weft yarns are copper ammonia 75D / 54F, the warp yarn density is 750 to 787 / 10cm, the weft yarn density is 630 to 709 / 10cm, the breadth is 250 to 340cm, the plus material is jacquard fabrics, the pattern width is 60 to 64cm, and the length is 90 to 100cm. The plus material is woven by a single weaving shaft of a rapier loom, the luster, the drapability, the ventilation performance and the hand feeling of the plus material are very similar to those of real silk, the breadth of the plus material is greater, in addition, the quality of the plus material on the whole breadth is identical, and front and back side defect spots do not exist.

Owner:JIANGSU YUEDA HOME TEXTILE

Production process of copper ammonia and spun silk twill fabric

InactiveCN108060492ASmall beating resistanceEasy to tightenArtificial filaments from cellulose solutionsGrip property fibresCuprammonium rayonFiber

The invention discloses a production process of a copper ammonia and spun silk twill fabric. The process includes the following steps of key point designing, spooling, warping, sizing, drafting and weaving. The four-in-one product formed by blending and interweaving copper ammonia fiber, spun silk, jute fibers and tencel fibers has the inherent advantages of a real silk fabric of being comfortable, soft, elegant and cool, is good in drapability, stiff and smooth, free of creases, not prone to ageing after sunburn, free of yellowing after sweat absorption and better in performance compared withthe real silk fabric and is a high-grade summer clothes fabric.

Owner:IANGSU COLLEGE OF ENG & TECH

Special process for dyeing and finishing multi-F viscose rayon

InactiveCN101880975AImprove verticalityImprove breathabilityLiquid/gas/vapor open-width material treatmentDyeing processAcetic acidCuprammonium rayon

The invention relates to a special process for dyeing and finishing multi-F viscose rayon, comprising the following steps of desizing by using sodium carbonate, neutralizing by using glacial acetic acid, rinsing by using tap water and the like. After the multi-F viscose rayon is specially dyed and finished, fabrics woven by the multi-F viscose rayon has a silk-imitating effect superior to that of fabrics woven by cuprammonium rayon raw materials produced in Japan, and the fabrics woven by the fibers have the advantages of favorable smoothness, air permeability and moisture absorption and bright luster after dyed.

Owner:王水泉

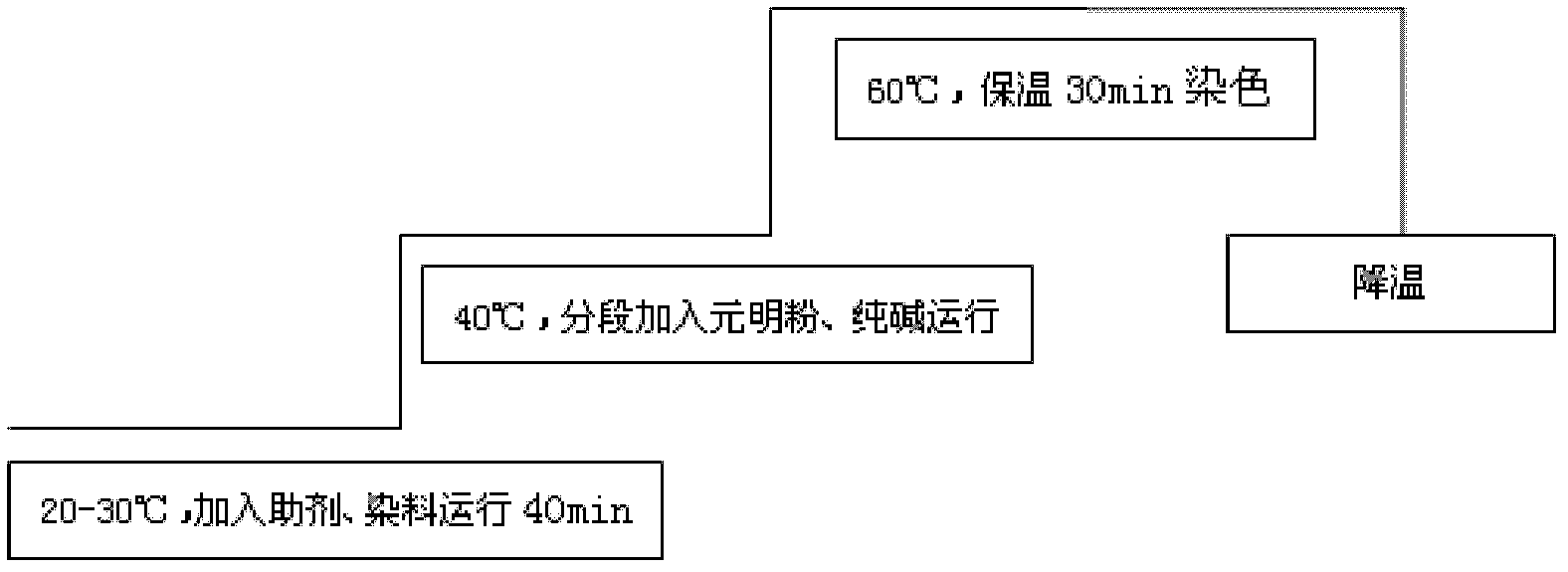

Method of dyeing acrylic fiber/hair/copper ammonia fiber blended knitting fabric by use of one-bath two-stage process

ActiveCN103774461AReasonable dyeing processAchieve simultaneous dyeingDyeing processVegetal fibresCuprammonium rayonAcid dye

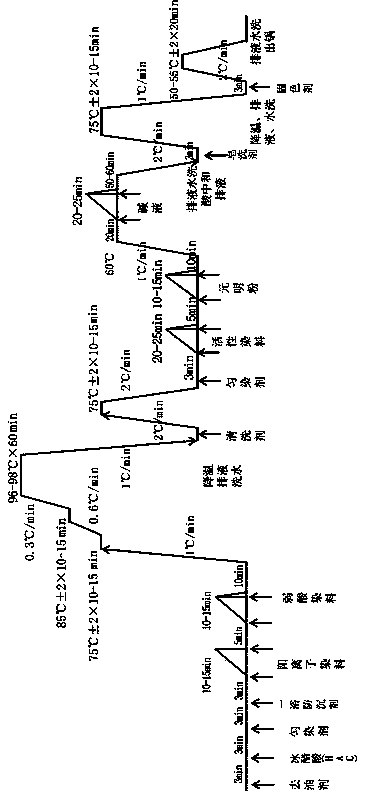

The invention provides a method of dyeing an acrylic fiber / hair / copper ammonia fiber blended knitting fabric by use of a one-bath two-stage process. The dyeing method is characterized by technically comprising the following steps: (1) pre-treating; (2) dyeing acrylic fiber / hair / copper ammonia fiber; (3) neutralizing; (4) soaping; (5) performing color fixation. Various dyes and assistants are placed in a same dye bath, and the temperature and pH value of the dye bath are changed in different dyeing periods of time, so that cationic dyes, weak acid dyes and active dyes meet the optimal dyeing condition to dye various fibers in different properties at the same time, thereby simplifying the production step, improving the production efficiency, improving the utilization ratio and the dyeing quality of the dyes, and meanwhile, further saving a lot of water resources, reducing the discharge of sewage so as to facilitate environmental conservation.

Owner:QINGDAO XUEDA GRP

A kind of bemberg fiber and preparation method thereof

InactiveCN102286798AAppropriate glossEasy to takeArtificial filaments from cellulose solutionsCuprammonium celluloseNatural fiber

The invention provides a new Bemberg fiber and a preparation method thereof: dissolving natural cellulose raw materials such as cotton linters in a concentrated ammonia solution of copper hydroxide or alkaline copper salt, making spinning solution, and spinning in a coagulation bath The cupro ammonia cellulose molecular chemical decomposes to regenerate cellulose, and the resulting hydrated cellulose is post-processed to obtain Benbemberg fiber. Bemberg fiber is a cellulose fiber made of cotton linters, which is organically decomposable and very beneficial to the protection of the natural environment. Moreover, the preparation process of the present invention is simple, low in cost and high in yield.

Owner:LUOLAI LIFESTYLE TECH CO LTD

Anti-ultraviolet umbrella fabric

InactiveCN107791645AImprove waterproof performanceGood adhesionWalking sticksSynthetic resin layered productsFiberAcrylic resin

The invention discloses an anti-ultraviolet umbrella fabric, which comprises a cloth layer, a coating layer, a thin film layer and a pressure adhesive layer. The specific formula of each layer of thefabric is as follows: the cloth layer is prepared from the following components by mass percent: 50 to 75% of polymethyl acrylate fiber, 20 to 40% of cuprammonium fiber and 20 to 35% of polyimide fiber; the coating layer is prepared from the following components by mass percent: 40 to 60% of phytic acid, 15 to 25% of defoamer, 10 to 15% of ammonium phosphate and 10 to 15% of zinc yellow; the thinfilm layer is prepared from the following components by mass percent: 40 to 60% of PVDF, 30 to 40% of acrylic resin, and 20 to 35% of chlorinated PVC resin; the pressure adhesive layer is prepared from the following components by mass percent: 45 to 85% of natural rubber, 8 to 16% of anti-ozone anti-aging agent and 20 to 30% of hard pottery clay. The anti-ultraviolet umbrella fabric provided by the invention has the advantages that the waterproof effect can be well improved by providing a four-layer structure, and the thin film layer arranged on the coating layer can prevent a coating from wearing severely after long-term use.

Owner:CHENGDU JIELEI SHADING ENG CO LTD

Simulated linen fabric

InactiveCN102418192AComfortable to wearGood drapabilityResilient fabricsCuprammonium rayonPulp and paper industry

Owner:CHANGSHU MEILI TOWN BINLI GARMENT & CLOTHING FACTORY

Textile material and preparation method thereof

InactiveCN105220289AImprove antibacterial propertiesImprove tensile propertiesYarnYarnBiocompatibility Testing

The invention provides a textile material and a preparation method thereof. The textile material mainly comprises yarn. The yarn is prepared from, by weight, 5-20 parts of copper ammonia fiber, 25-50 parts of chitosan fiber, 25-45 parts of cotton fiber, 25-40 parts of bamboo charcoal fiber, 10-20 parts of acrylic fiber and 5-15 parts of dacron. The textile material has excellent antibacterial performance and tensile performance; meanwhile, the textile material has the heat preservation function, the moisture absorption function and the breathable function at the same time, has excellent flexibility, has biological activity and biocompatibility and is suitable for large-scale application and popularization.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Copper ammonia antibacterial fabric

The invention discloses a copper ammonia antibacterial fabric, wherein warp yarns comprise two kinds of yarns; the first warp yarns adopt copper ammonia fibers; the second warp yarns are low-twist composite yarns formed by terylene low-elasticity yarns and spandex high-elasticity yarns; weft yarns comprise two kinds of yarns; the first weft yarns are antibacterial yarns; and the second weft yarns are composite yarns comprising copper ammonia fibers and fine staple cotton. The copper ammonia antibacterial fabric maintains the excellent properties of the copper ammonia fibers, thereby having high service performance, good hydroscopic property and excellent drapability and being consistent with the trend of environment-friendly clothings.

Owner:SUZHOU CHUANGYU WEAVING

Wool/cattle fluff fiber/mulberry silk/copper ammonia fiber blended fabric and preparation method thereof

InactiveCN104514071AFeel smooth and plumpUniform finenessBleaching apparatusDyeing processCuprammonium rayonPolymer science

The invention relates to a wool / cattle fluff fiber / mulberry silk / copper ammonia fiber blended fabric. The fabric comprises the following material components in percentage by weight: 30% of wool fibers, 24% of cattle fluff fibers, 26% of mulberry silk and 20% of copper ammonia fibers. The preparation method includes the steps of: top dyeing and re-combing, spinning, weaving and dyeing and finishing; the top dying and re-combing process includes, dying separately, dehydrating and backwashing, and mixing the wool fibers, the mulberry silk and the copper ammonia fibers by B412, gilling for three times during the mixing process, adding the mulberry silk for three times, gilling by B303 and B304, and combing by B311, adding the cattle fluff fibers during the gilling process of B305, then gilling by B305 for a second time, and at last combing by B306. The prepared product is gentle in gloss, soft, fine and smooth and good in drapability, has the texture and style of silk fabric, and is low in cost.

Owner:江苏华西村纺织服装有限公司

Dyeing and finishing technology for cuprammonium-linen interwoven fabric and cuprammonium-linen interwoven fabric

ActiveCN102418249AImprove comfortLow costSucessive textile treatmentsBiochemical fibre treatmentCuprammonium rayonFiber

The invention relates to a dyeing and finishing technology for a cuprammonium-linen interwoven fabric, which uses a gray cuprammonium-linen interwoven fabric as a raw material. The flow of dyeing and finishing technology is shown as the following: preshrinking-> scouring-> water washing-> enzyme water washing-> dyeing-> water washing-> drying through a setting machine-> adding softener-> setting through the setting machine-> sand washing-> steam setting. By interweaving linen fibers and cuprammonium fibers to obtain the cuprammonium-linen interwoven fabric and by dyeing and finishing the interwoven fabric, the cuprammonium-linen interwoven fabric has the advantages of the two kinds of fibers, the defects that a common linen fabric feels coarse, is apt to be wrinkled and the like are overcome and the fabric is highly comfortable. Beside, compared with a cuprammonium fabric, the cost of the cuprammonium-linen interwoven fabric provided by the invention is lower.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Manufacturing method for boiling and sizing copper ammonia fiber/bamboo fiber anti-bacterial blended fabric

InactiveCN104674432AGood antibacterial and bactericidal effectImprove stabilityHeating/cooling textile fabricsWoven fabricsPolyesterCuprammonium rayon

The invention discloses a manufacturing method for boiling and sizing copper ammonia fiber / bamboo fiber anti-bacterial blended fabric. Selected warp and weft materials are as follows in parts by mass: 35-40 parts of copper ammonia fiber, 40-90 parts of viscose fiber, 20-25 parts of cocoon fiber, 8-15 parts of bamboo fiber, 30-45 parts of cotton fiber and 8-18 parts of super fine denier polyester, wherein warp threads adopt a ratio of 92 / 2, and weft threads adopt a ratio of 48 / 1. A scutching procedure comprises a rough cleaning step and a fine cleaning step, wherein in the rough cleaning step, a bath ratio is 1:(30-50), neutral detergent is added, the dosage of the neutral detergent is 4-5g / L, the water temperature is 55-65 DEG C, and the washing time is 0.5-0.8 hour; in the fine cleaning step, the bath ratio is 1:(11-15), finishing agent solution of which the mass concentration is 26%-32% is added, the adding quantity of the finishing agent solution is 6-9g / L per litre water, the treatment time is 0.5-0.8 hour, and the fine cleaning temperature is 66-72 DEG C. According to the manufacturing method disclosed by the invention, the anti-bacterial performance of the copper ammonia fiber cannot be damaged, the comfort is better, meanwhile, the problems that a fiber molecule is loose in structure, large in moisture absorption and easy to deform and stretch can be effectively solved, and the problems of warp exposing, weft exposing and weak spots on fiber fabric can be prevented from happening.

Owner:SUZHOU CHENHENG WEAVING

Blended yarn of acrylic fiber, kapok fiber and cuprammonuium

InactiveCN102851815AIn line with the trend of environmentally friendly clothingBrightly dyedYarnCuprammonium rayonYarn

The invention provides a blended yarn of acrylic fiber, kapok fiber and cuprammonuium, which comprises the components in parts by weight: 45-55 parts of acrylic fiber, 25-35 parts of kapok fiber and 15-25 parts of cuprammonuium. The blended yarn of the acrylic fiber, the kapok fiber and the cuprammonuium is complementary in characteristics and exerts the advantages of the acrylic fiber, the kapok fiber and the cuprammonuium.

Owner:JIANGSU TONGHAI THREAD

Composite silk fabric containing mulberry silk, bamboo charcoal cotton and copper ammonia fibers

The invention provides composite silk fabric containing mulberry silk, bamboo charcoal cotton and copper ammonia fibers. According to the composite silk fabric, warps are made of the mulberry silk, and wefts are made of blended yarn of the bamboo charcoal cotton and the copper ammonia fibers, wherein the blended yarn contains 65-75% of the bamboo charcoal cotton and 25-35% of the copper ammonia fibers. The composite silk fabric has the advantages that the composite silk fabric integrates good properties of the mulberry silk, the bamboo charcoal cotton and the copper ammonia fibers, has the complementary effect, and can better meet requirements of people due to the fact that the price is lower compared with pure real silk fabric.

Owner:江苏华杰丝绸进出口有限公司

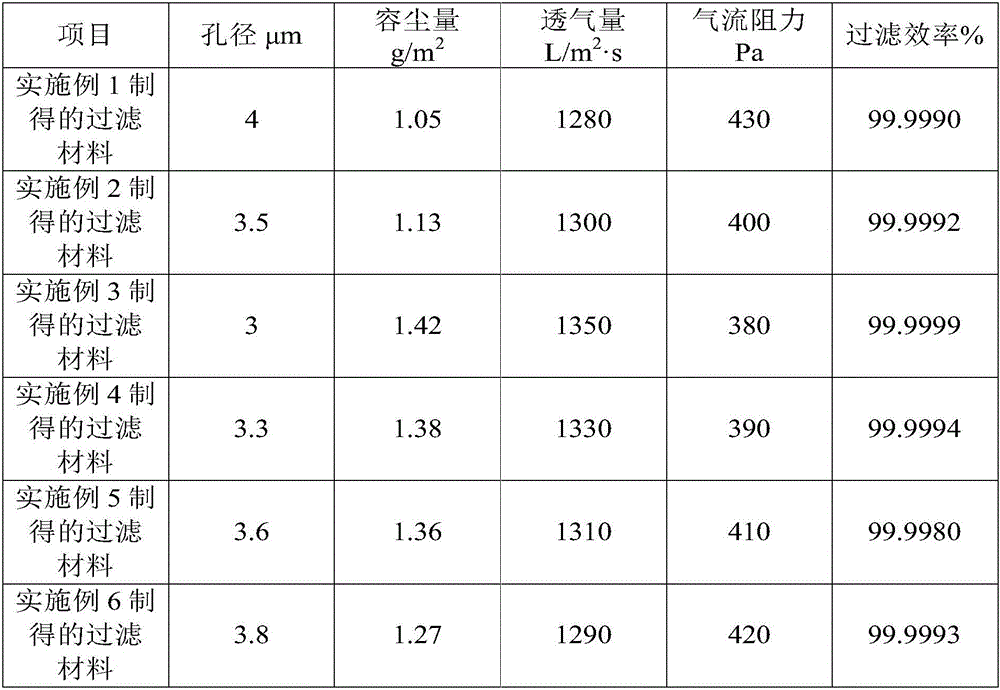

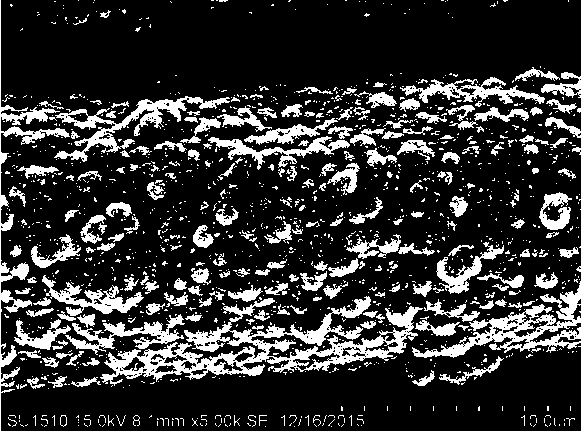

Efficient filter material and preparation method thereof

InactiveCN106512558AImprove filtration efficiencyImprove breathabilityMembrane filtersFiltration separationPolymer scienceFiltration

The invention discloses an efficient filter material and a preparation method thereof. The efficient filter material is formed by compositing a base cloth layer I, an electrostatic spinning layer, a synthetic fiber layer and a base cloth layer II. The base cloth layer I is prepared from any of polyethylene fibers, polypropylene fibers and polyallyl chloride fibers. The electrostatic spinning layer is prepared from any of polytetrafluoroethylene fibers, polyacetate fibers and polyimide fibers. The synthetic fiber layer is prepared from any one or more of polyester fibers, polyamide fibers, polyvinyl alcohol fibers, polyacrylonitrile fibers and copper ammonia fibers. The base cloth layer II is prepared from any of polyethylene fibers, polypropylene fibers, polyallyl chloride fibers and triacetate fibers. The preparation method comprises the steps of compositing of all the layers of materials, electret treatment and thermosetting treatment. The filter material prepared through the method is good in filter efficiency and air permeability, low in filtration resistance and long in service life; the preparation method is easy to operate; and the efficient filter material can be produced massively.

Owner:DSP TECH DEV WENZHOU CO LTD

Preparing method for copper ammonia fiber conductive textile

The invention relates to a preparing method for a copper ammonia fiber conductive textile. According to the preparing method, copper ammonia fibers serve as a base material, and polypyrrole layers and copper layers are deposited on the surfaces of the copper ammonia fibers in sequence. The specific technology comprises the steps of cleaning the copper ammonia fibers, carrying out polypyrrole in-situ chemical polymerization, carrying out self-assembly modification through a silane coupling agent, adsorbing cupric ions, reducing potassium borohydride, carrying out electroless copper plating and the like. According to the preparing method, the copper ammonia fibers serve as the base material of the conductive textile, and thus degradation of the materials and recovery and recycle of copper are facilitated. The copper ammonia fibers and conductive substances (polypyrrole and copper) are combined, the ammonia fibers are changed into a conductor from an insulator, and thus the application of the ammonia fibers is developed. The silane coupling agent can serve as a molecule bridge of the polypyrrole layers and the metal layers, and the reliability of products is improved. Conductive macromolecule chemical polymerization and chemical plating are combined, and thus the problems that a conductive textile prepared from macromolecule polymerization or chemical plating alone is poor in conductivity, low in shielding effect and the like are solved. The cost is low, the process is simple, and the degree of dependency on instruments and equipment is low.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com