Patents

Literature

263results about How to "Moisture-absorbing and breathable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

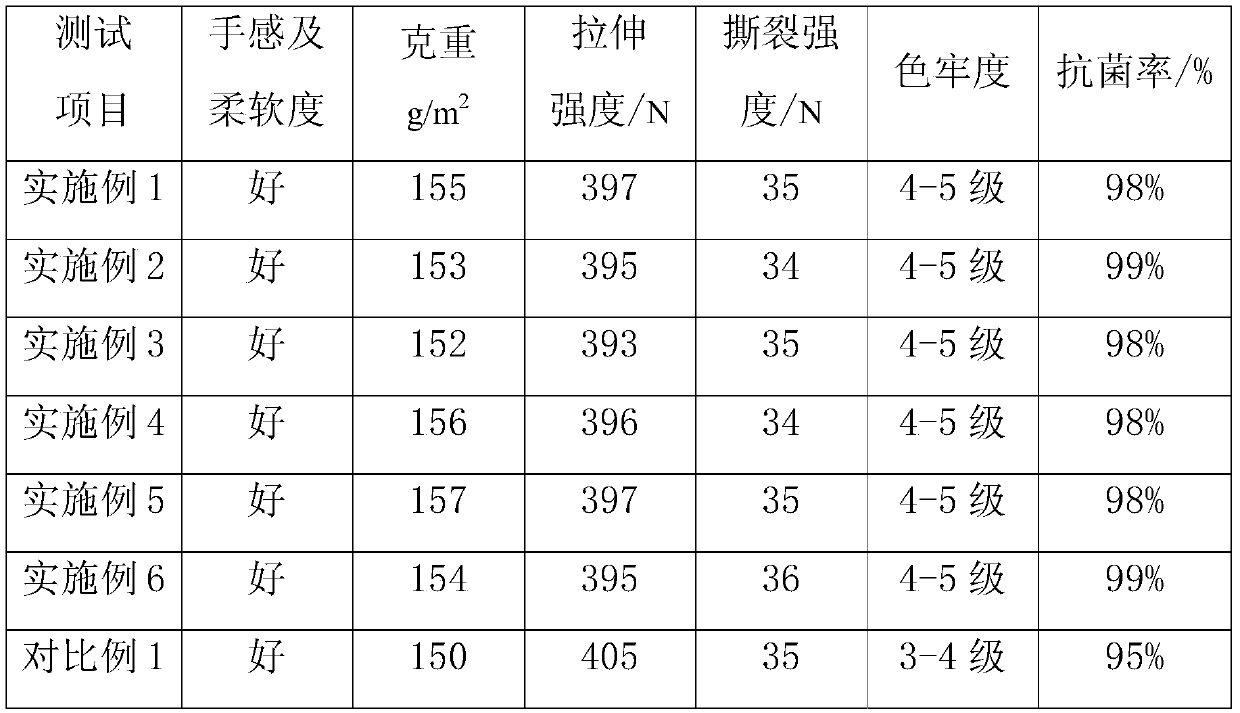

Antimicrobial pearl viscose fiber, preparation method and application thereof

InactiveCN101270508AExpand the range of dosageRaise the ratioMonocomponent cellulose artificial filamentArtifical filament manufactureAntibiosisViscose fiber

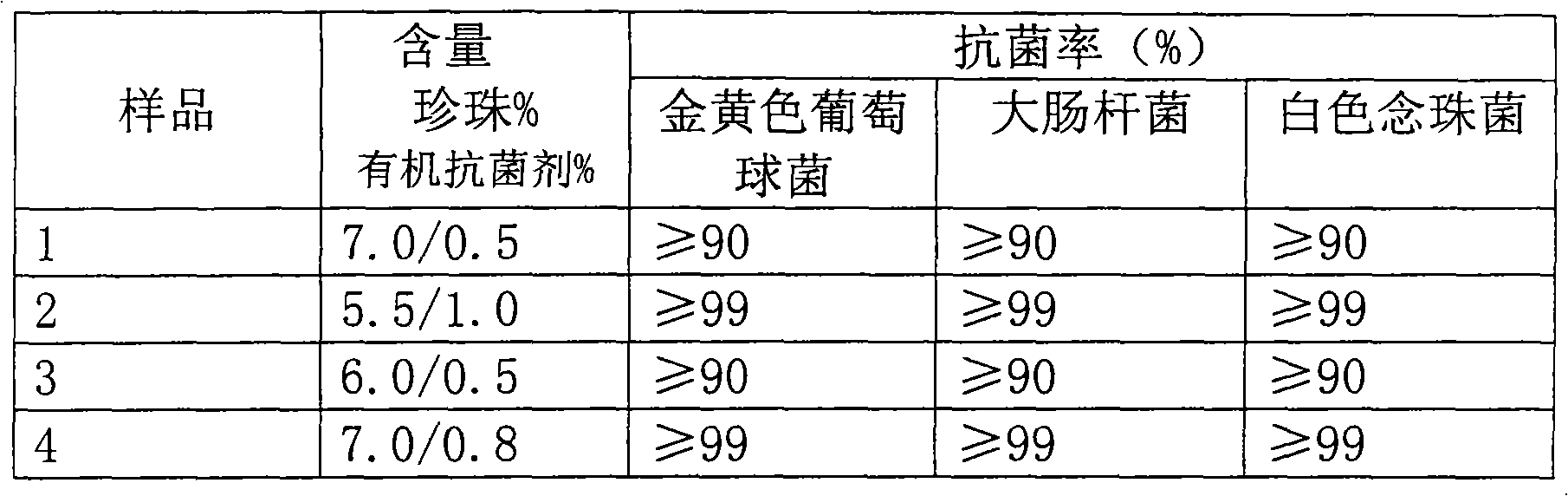

The invention discloses an antibiosis pearl mucilage glue fiber as well as a manufacture method and application thereof. The fiber is manufactured by mixing the mucilage glue, pearl powder accounting for 5.5 to 7.0 percent of the total weight of the fiber as well as organic antimicrobial accounting for 0.5 to 1.0 percent of the total weight of the fiber. The antibiosis pearl mucilage glue fiber of the invention not only has the advantages of pure savageness, being degradable and excellent chromaticity but also has the functions of smart appearance, smooth and cool hand feeling and being softer than pure cotton that are specifically owned by pearl; the fiber also has particularly comfort feeling when contacting with skin and the function of antibiosis and health care.

Owner:FUJIAN ZHONGHE

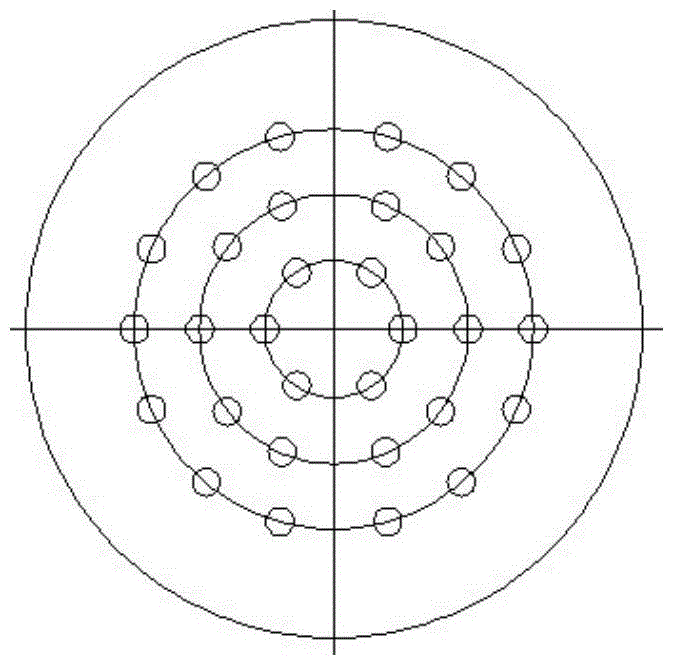

Multi-hole superfine denier polyamide 6 POY/FDY interlacing composite fiber, its preparation method and its device

InactiveCN102517680AImprove the comprehensive performance of fibersSmall shrinkageArtificial thread manufacturing machinesMelt spinning methodsPolyamideMelt extrusion

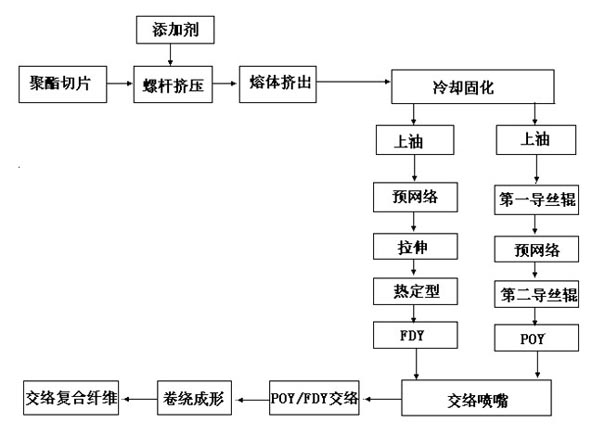

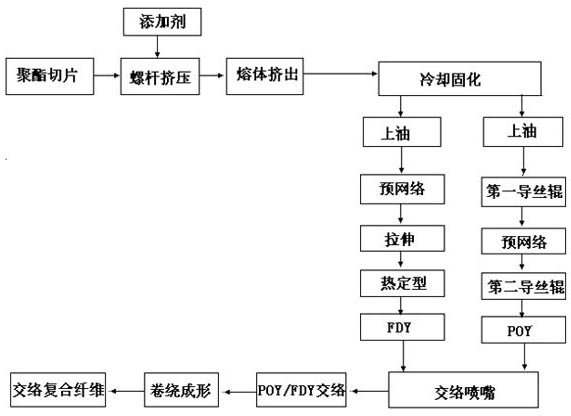

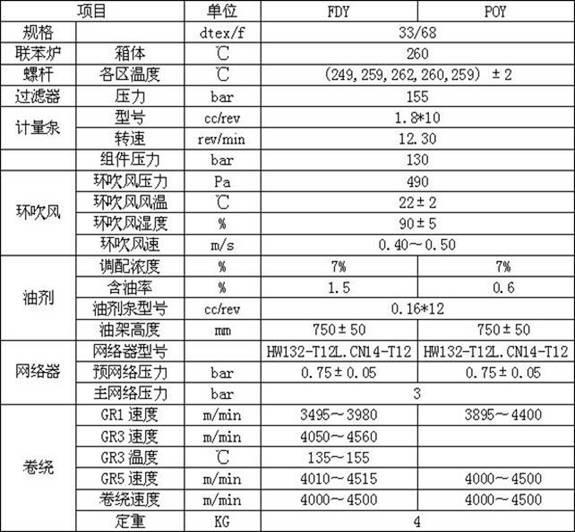

The invention discloses a multi-hole superfine denier polyamide 6 POY / FDY interlacing composite fiber, its preparation method and its device. The invention is characterized in that a current FDY production device is used, a raw material polyamide 6 is sliced and dried, an additive is on-line added, the sliced polyamide 6 is subjected to screw extrusion and melt extrusion, strand which is subjected to annealing and circular-blow wind cooling solidification is divided in to two beams, one beam of the strand is subjected to oiling, pre-networking, stretching and thermosetting to obtain FDY; another beam of the strand is subjected to oiling and then is input to a first godet roller, and then subjected to pre-networking and input to a second godet roller to obtain POY, then simultaneously input in an interlacing nozzle for compositing, a process of winding formation is carried out to prepare the multi-hole superfine denier polyamide 6 POY / FDY interlacing composite fiber. According to the fiber molecular structure performance design and the fiber form control, a process optimization scheme is determined to obtain the composite silk fiber with differential linear density, differential elongation and differential shrinkage, the fiber has the advantages of moisture absorption, breathability, good drapability, high color rendering, good comfortableness and the like.

Owner:吴江赴东扬程化纤有限公司

Method for performing crease-resistant finishing on cotton textile fabrics or garments

ActiveCN102926146AFeel goodSoft touchHeating/cooling textile fabricsLiquid/gas/vapor removalEngineeringHigh pressure

The invention relates to a method for performing crease-resistant finishing on cotton textile fabrics or garments. The method comprises the following steps of: putting the cotton textile fabrics or garments into a rotation cage of a potion spraying machine, and uniformly spraying an anti-crease potion onto the cotton textile fabrics or garments by a high pressure nozzle of the potion spraying machine; performing dehydration treatment after fully and uniformly absorbing the anti-crease potion; pressing the pre-dried cotton textile fabrics or garments; putting the preset cotton textile fabrics or garments into a baking oven for high temperature setting; placing the baked cotton textile fabrics or garments in a ventilated and humid environment for naturally restoring the humidity, and then washing the cotton textile fabrics or garments by a washing machine; dehydrating the cotton textile fabrics or garments washed in the above step, and drying the cotton textile fabrics or garments by a dryer; and entirely pressing and packaging.

Owner:GUANGDONG QUNHAO CLOTHING

Method for producing jute natural antibiotic bath mat

InactiveCN101260588AGood antibacterialGood antibacterial effectBleaching apparatusDyeing processMoisture absorptionEngineering

The invention relates to a manufacturing method for a jute natural antibacterial floor towel, blending jute and cotton, adequately utilizing the characteristics of the jute such as excellent moisture absorption and moisture wicking, high strength and tensile stretch and good antibacterial and bacteriostatic capability. Jute fibre is humidified before spinning, and the humidified percentage reaches 12-15 percent; the mixture ratio of jute and cotton is 20-50 percent / 50-80 percent during spinning, the relative humidity of spinning environment reaches 83-86 percent, and the relative humidity of textile environment reaches above 85 percent; in order to make up strength and fix short fiber, the sizing ratio is adjusted below 1 percent, and softening treatment and flexible treatment are performed. The manufacturing method for the jute natural antibacterial floor towel changes the jute performance that jute can not be woven, and has the advantages of anti-bacteria, anti-corrosion, anti-wrinkle, moisture absorption, ventilation, flatness and flexibility, good slip resistant and so on.

Owner:石磊

Inside-wearable radiation-proof garment fabric

The invention discloses an inside-wearable radiation-proof garment fabric, which is formed by interweaving warp yarns and weft yarns. The warp yarns and the weft yarns are both core spun yarns. Each core spun yarn comprises a core yarn and a blended fiber coating, the corn yarn is one of a copper fiber, a sliver fiber and a stainless steel fiber, and the blended fiber coating comprises natural colored cotton, milk protein fibers and Tencel fibers, and the blended fiber coating is wrapped on the corn yarn. Therefore, the inside-wearable radiation-proof garment fabric is radiation-proof and wearable inside and fully meets people's requirements, and has the advantages of healthiness, comfortableness and breathability.

Owner:苏州市伸越纺织贸易有限公司

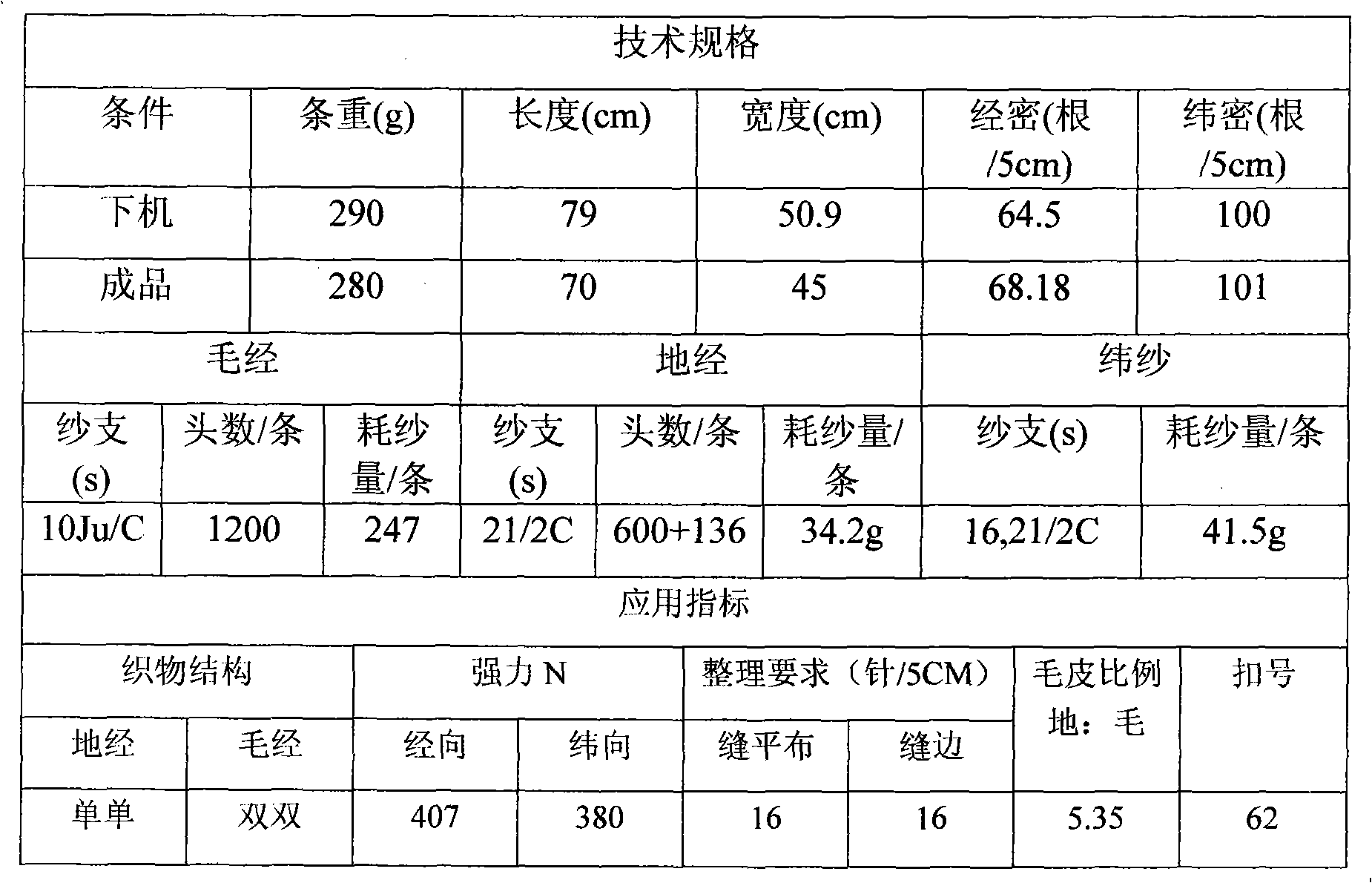

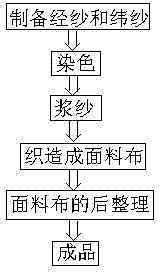

Production process of cotton-hemp blended yarn-dyed woven fabric

InactiveCN103397428ASoft touchMoisture-absorbing and breathableBleaching apparatusDyeing processYarnEngineering

The invention discloses a production process of cotton-hemp blended yarn-dyed woven fabric. The production process mainly includes the steps of a, producing warps and wefts; b, dyeing; c, sizing; d, weaving fabric; e, finishing the fabric. The production process has the advantages that hemp fiber is treated reasonably so that spinnability and spinning quality of the hemp fiber are improved; the warps and wefts are produced by the unique production method according to a unique raw material ratio, so that the blended fabric produced has excellent properties such as softness in touch, breathability, high wearing comfort, mildew resistance and microbial proofing.

Owner:CHANGSHU CITY XINDA WEFT KNITTING FACTORY

Preparation method of home textile fabric

InactiveCN104404679ASimple processSimple and efficient operationWoven fabricsYarnAgricultural engineeringAfter treatment

The invention discloses a preparation method of a home textile fabric. The method comprises the following steps: (1) preparing raw materials; (2) spinning; (3) spooling; (4) performing beam warping; (5) slashing; (6) weaving; (7) performing after-treatment. The preparation method of the home textile fabric disclosed by the invention is simple in process, and is easy and convenient to operate; through reasonable process adjustment and blending of cotton fibers, the defects caused by spinning and weaving through separate use of tencel fibers are overcome effectively; the woven tencel / surface blended home textile fabric has the advantages of tencel fibers and cotton fibers, has the advantages of soft handfeel, skin friendliness, smoothness, hygroscopic property, air permeability, high intensity, durability and the like, and is a high-grade home textile fabric.

Owner:CHANGSHU TIANCHEN KNITTING

Anti-aging UV curing coating

InactiveCN104927628AGuaranteed aging resistanceMoisture-absorbing and breathablePolyurea/polyurethane coatingsEpoxy resin coatingsFiberCrack resistance

The invention relates to the field of coatings, in particular to an anti-aging UV curing coating. The anti-aging UV curing coating comprises the following raw materials in parts by weight: 35-45 parts of polyurethane acrylate, 10-15 parts of grapheme, 3-6 parts of bamboo carbon fiber, 25-30 parts of hydrobisphenol-A epoxy resin, 3-5 parts of a photoinitiator, 3-8 parts of an anti-aging agent, 7-12 parts of a reactive diluent, 0.3-0.6 part of a leveling agent, 0.2-0.5 part of an anti-settling agent and 1-1.5 parts of a foam breaking agent. The anti-aging UV curing coating is excellent in aging resistance, can ensure long-term effectiveness after being used, and has the characteristics of good corrosion resistance, excellent crack resistance and the like.

Owner:CHENGDU NASHUO TECH

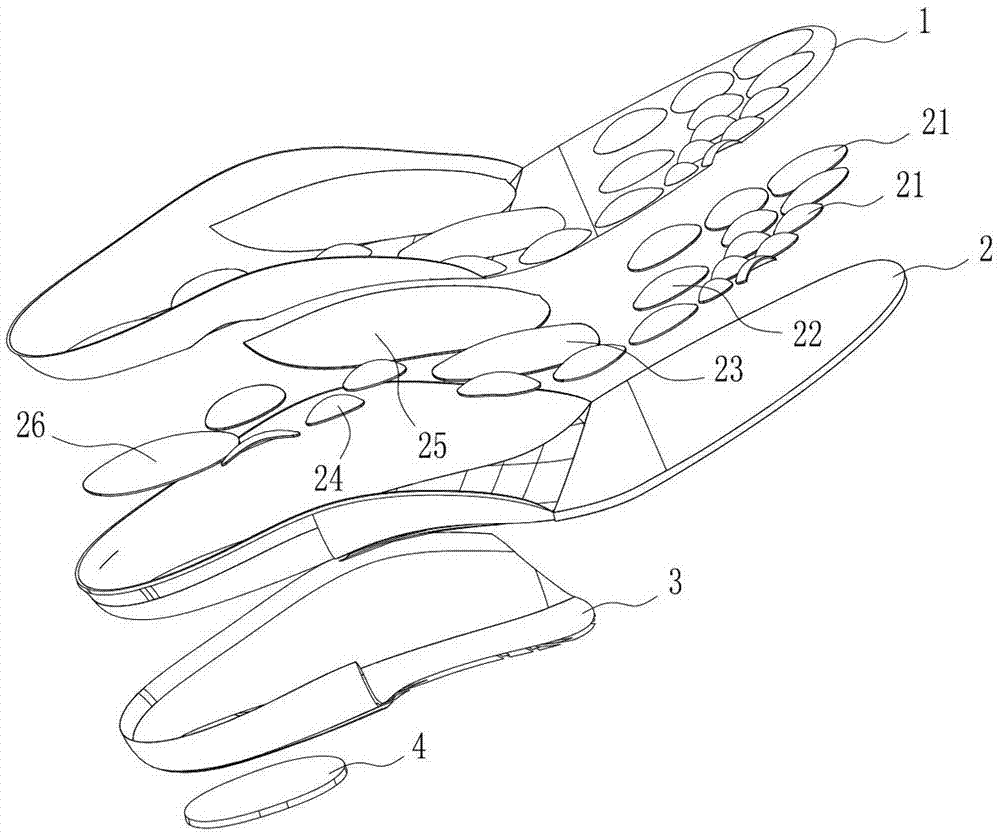

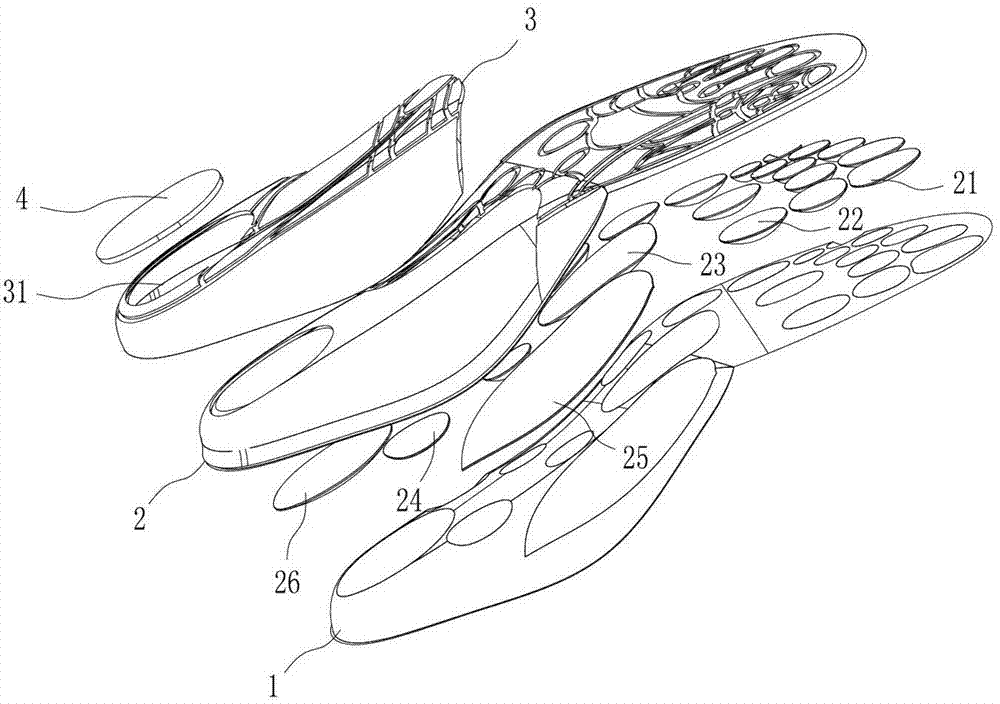

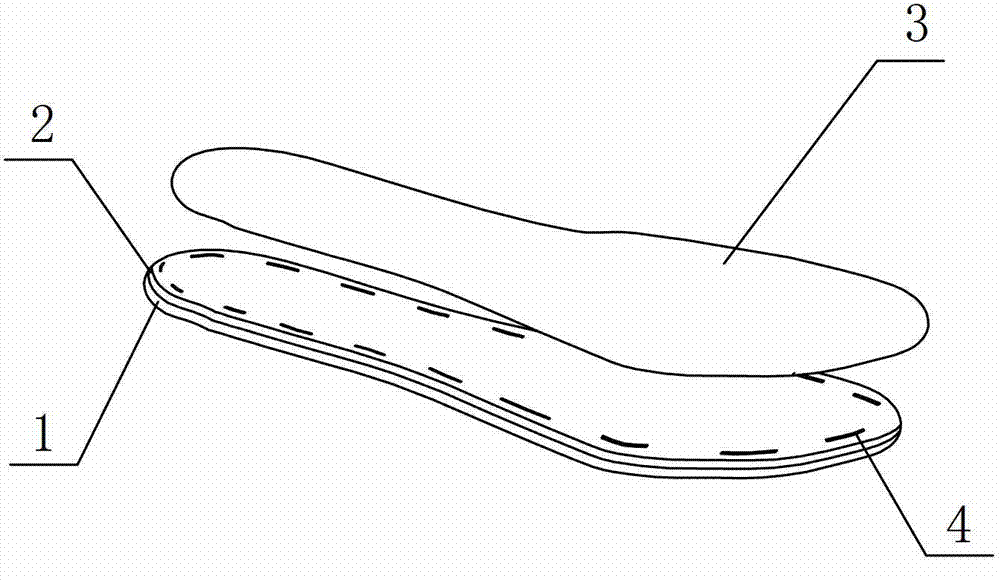

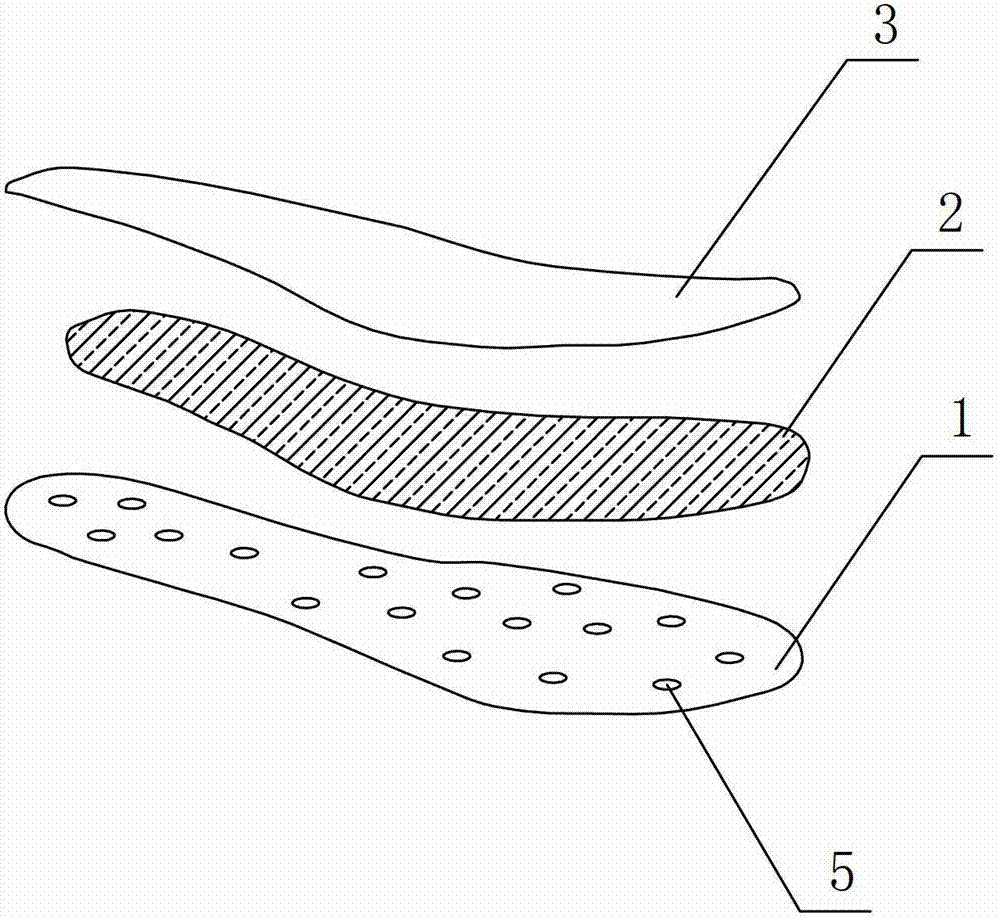

Foot physical therapy insole

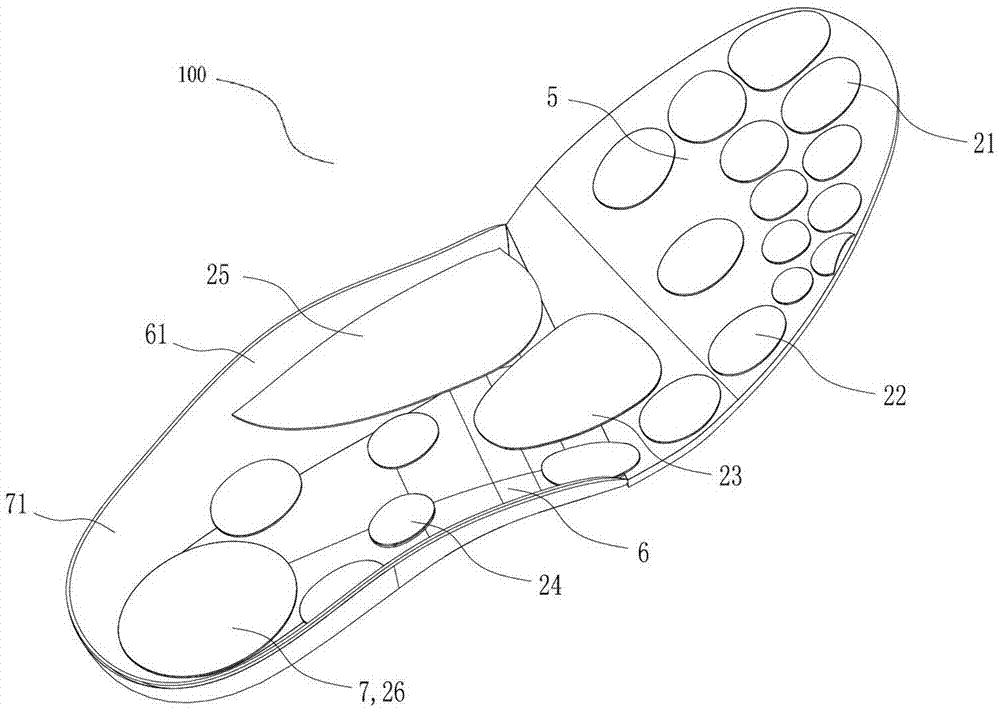

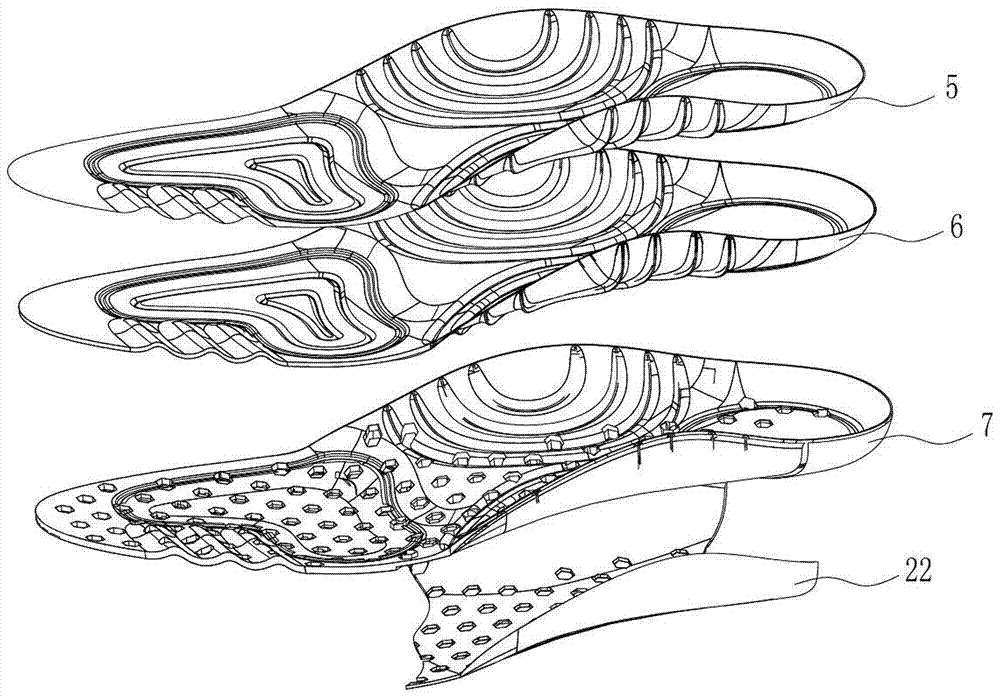

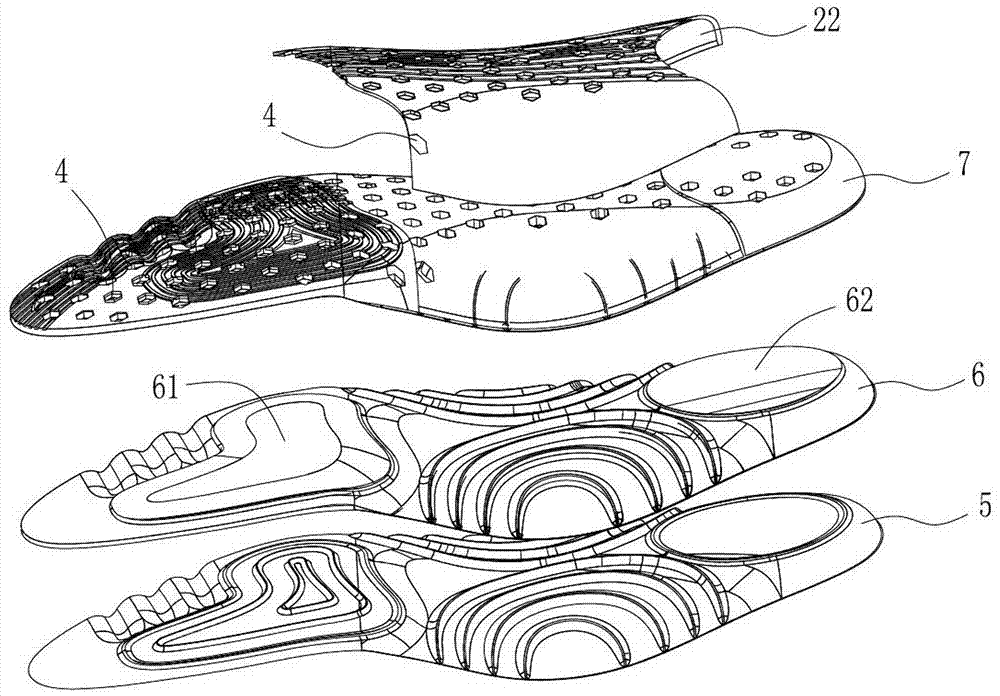

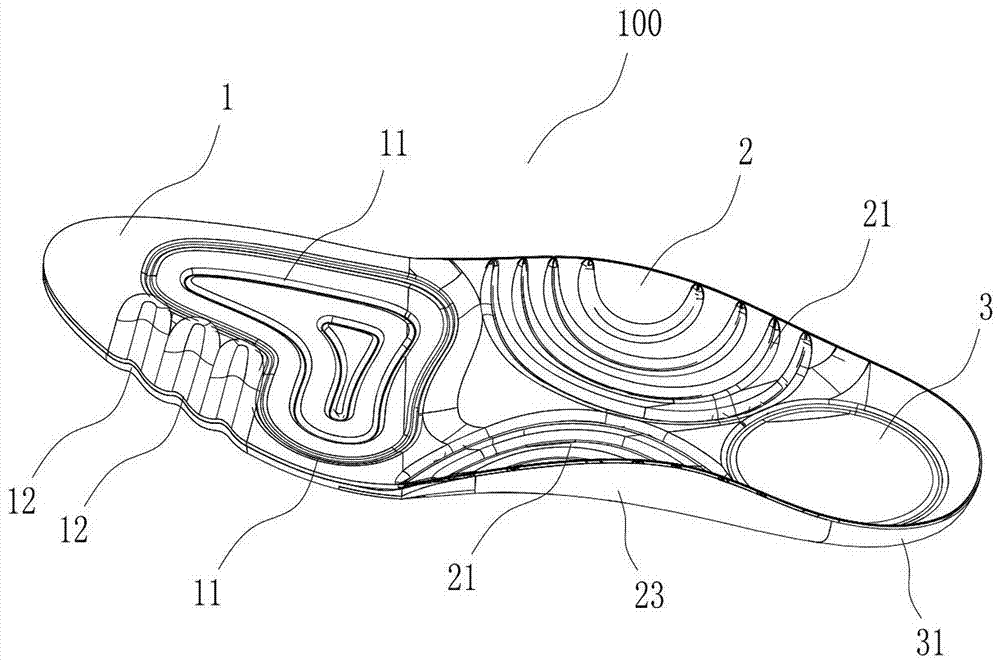

ActiveCN107157014APromote blood circulationIncrease elasticityBio-packagingInsolesHeart massageMassage

The invention discloses a foot physical therapy insole, and relates to the technical field of insoles. The insole comprises an insole body, and the insole body sequentially comprises a bamboo charcoal fiber layer, a first polyurethane foam layer and a second polyurethane foam layer from top to bottom. From the front end to the rear end of the insole body, the first polyurethane foam layer is sequentially provided with toe massage protruding points, forefoot massage protruding points, sole heart massage protrusions, foot arch massage protruding points, foot arch massage protrusions and heel massage protrusions; the part, corresponding to the front end of the insole body, of the second polyurethane foam layer is lacked, a containing cavity is formed in the lower side of the second polyurethane foam layer, and one heel shock-absorption mat is embedded into the containing cavity. The foot physical therapy insole is high in shock-absorption and foot-protection effect, good in air permeability and capable of remitting the flat foot and conducting massage and health care physiotherapy treatment.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

Shoe pads having protection effect during strenuous exercise

PendingCN107440231AReduce the risk of accidental injuryImprove breathabilityInsolesReticular formationEngineering

The invention discloses shoe pads having a protection effect during strenuous exercise. Each shoe pad comprises a shoe pad body, wherein the shoe pad body sequentially comprises a shoe pad half sole, a shoe pad middle-rise part and a shoe pad heel from the front end to the rear end, 2-5 rings of annular grooves are arranged at the upper side of the shoe pad half sole, and 2-5 horizontal wavy grooves are formed at the positions, corresponding to the toes of the human body, of the shoe pad half sole; 3-5 C-shaped grooves are formed in each of two sides of the shoe pad middle-rise part; a plant fiber arch supporting cushion plate is arranged at the lower side of the shoe pad middle-rise part; 80-150 small holes are distributed at the lower side of the shoe pad body, so that an elastic net-shaped structure is formed; the shoe pad body comprises a bamboo carbon fiber layer, a first PU polyurethane foam layer and a second PU polyurethane foam layer in the sequence from top to bottom, and a half sole cushioning pad and a heel cushioning pad are arranged at the lower side of the first PU polyurethane foam layer. The shoe pads having a protection effect during strenuous exercise provided by the invention have good damping and foot protecting effects and good slip resistance, can prevent the ankles from being injured, and are good in breathability.

Owner:DONGGUAN SHUNFENG SPORTS EQUIP CO LTD

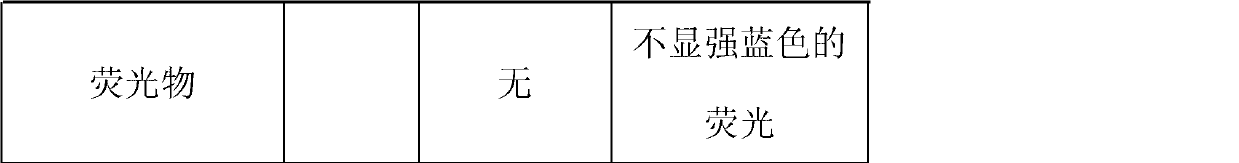

Multifunctional fabric

InactiveCN103445360AGood fluorescenceGlossyProtective garmentSpecial outerwear garmentsYarnPolyester

The invention discloses a multifunctional fabric which is formed by blended knitting of the following components in percentage by weight: 13-17 percent of fully-drawn nylon yarn fiber attached with organic fluorescent substances, 19-23 percent of polyester drawn textured yarn fiber attached with organic fluorescent substances, 23-36 percent of spun silk fiber and 32-37 percent of tencel fiber. Since being formed by blended knitting of the four material fiber including the fully-drawn nylon yarn fiber attached with organic fluorescent substances, the polyester drawn textured yarn fiber attached with organic fluorescent substances, the spun silk fiber and the tencel fiber, the fabric is good in fluorescent effect, thin and soft, light in weight, and comfortable and smooth and has good moisture absorption performance and air permeability.

Owner:WUJIANG HAIFENG WEAVING

Traditional Chinese medicine health-care insoles

InactiveCN102948964ASimple recipeEasy to manufactureInsolesAntisepticsTherapeutic effectChinese drug

The invention discloses a pair of traditional Chinese medicine health-care insoles, which comprises a bottom layers made from PU (Poly Urethane) plastic, a traditional Chinese medicine layers containing the traditional Chinese materials and a top layers made from the bamboo charcoal fibers, wherein the bottom layers is are fixed with the traditional Chinese medicine layers through a threads, the traditional Chinese medicine layers is are movably glued with the top layers, and the each bottom layer is further opened formed with a plurality of breathable through holes. According to the invention, the traditional Chinese medicine layers is are arranged between the bottom layers and the top layers of the insoles, and the traditional Chinese medicine layers is are simple in formula, convenient to prepare, and has have the effects of sweat absorption, sterilization and deodorization; and the traditional Chinese medicine layers is are fixedly sewn with the bottom layers and movably connected with the top layers, and the top layers is are taken out for washing when the insoles is are needed to wash. Therefore, the efficacy of the traditional Chinese medicine components is more lasting, the prevention and treatment effects are better, and the insoles is are more solid and durable.

Owner:王馨洁

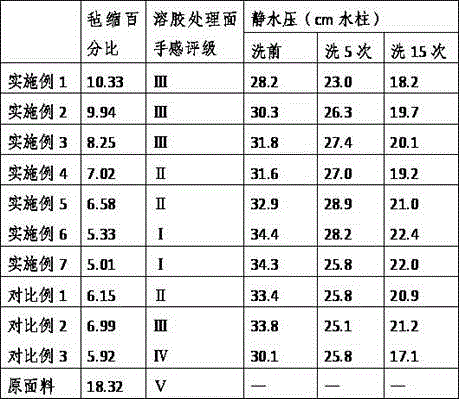

Production method of dirt repelling and felting resisting wool fabric

ActiveCN105568665AFeel goodIncreased cross-linking sitesUltrasonic/sonic fibre treatmentGrip property fibresCross-linkFiber

The invention discloses a production method of a dirt repelling and felting resisting wool fabric. The method comprises the following steps: preprocessing a wool fabric, preparing a chitosan silica sol finishing liquid, finishing the obtained wool, and drying the finished wool. Hydrogen peroxide pretreatment and chitosan solution are adopted to protect the wool fabric, so damages to the surfaces of fibers obtained after plasma treatment in low temperature atmosphere are small; the chitosan silica sol finishing liquid is finished to the surface of one side of the wool fabric, and components in the finishing liquid undergo a condensation reaction, and are cross-linked on the surface of the wool fabric to form a film with certain rigidity, so the wool fabric has single side dirt repelling and felting resisting performances; the film formed on the surface of the wool fabric also has flexibility adapting to the fabric, the bonding area between the film and the fabric is large, the bonding strength is good, and the service life of the film bonded wool fabric is long; and chitosan has bacterium prevention and moisture absorption characteristics, so the finished wool fabric has the advantages of good handle, bacterium prevention, moisture absorption and breathability.

Owner:常熟市易美纺织品有限公司

Method for preparing bamboo charcoal non-glue cotton with health-care function

InactiveCN104178922AMoisture-absorbing and breathableAntibacterial and antibacterialNon-woven fabricsEnvironmental resistanceCarding

The invention relates to a method for preparing bamboo charcoal non-glue cotton with the health-care function. The method is characterized by including the steps that raw materials such as dacron or polypropylene fibers or acrylic fibers, aramid fibers, PPS and PTFE bamboo charcoal fibers with certain proportions are mixed according to different proportions, and the raw materials are sequentially treated through the procedures of treatment of a cotton feeder, pre-carding, treatment of an opener, treatment of a carding machine, treatment of a lapping machine, treatment of an oven, pressing of a hot iron roller, cooling and reeling. According to the method, the advantages of bamboo charcoal are mainly fused in the non-glue cotton, the bamboo charcoal non-glue fibers have the advantages of being smooth, soft, warm, breathable, warm in winter and cool in summer, environmentally friendly, good in filterability, capable of absorbing moisture and resisting bacteria and ultraviolet light and the like. The compounded bamboo charcoal non-glue cotton has strong tension and has the advantages of the bamboo charcoal fibers, the bamboo charcoal fibers contain mineral substances beneficial to the human body, the good health-care effect is achieved, and the bamboo charcoal non-glue cotton is an ideal article for use for home life and outdoor travel.

Owner:DANYANG YUSHENG TEXTILE NEW MATERIAL

Antibacterial jeans-imitation fabric

InactiveCN109943953AImprove antistatic performanceReduce static electricityConjugated cellulose/protein artificial filamentsWoven fabricsOrganosiliconBamboo charcoal

The invention discloses an antibacterial jeans-imitation fabric. The fabric comprises, by weight, 200-320 parts of a mixed cellulose fiber, 50-80 parts of a bamboo carbon fiber, 60-90 parts of terylene, 5-10 parts of spandex, 35-60 parts of a conductive fiber, 25-35 parts of a copper ammonia fiber and 10-15 parts of an organosilicon quaternary ammonium salt antibacterial agent. The mixed cellulosefiber is formed by blending cotton and tencel with the mass ratio of 1:(1-2), a gray fabric is formed through the processes such as mixing of spinning color master batch and a fiber stock solution, high-temperature fusion extrusion spinning and fabric weaving, the color fastness of the fabric is improved, and through an antibacterial finishing process, the antibacterial performance of the fabricis further improved. The antibacterial jeans-imitation fabric has the advantages of being comfortable, soft, capable of achieving moisture absorption and air permeation, efficient and resistant to bacteria.

Owner:南通苏美纺织科技有限公司

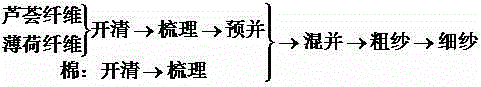

Aloe fiber, mint fiber and cotton blended yarns and production process thereof

InactiveCN104420041AImprove performanceImproved performance of individual spinningYarnBreathingSpecific gravity

The invention discloses aloe fiber, mint fiber and cotton blended yarns and a production process thereof. The yarns consist of the following components in percentage by weight: 10 to 50 percent of aloe fibers, 10 to 50 percent of mint fibers and 40 to 70 percent of cotton fibers, wherein the aloe fibers have high moisture absorption performance and moisture release performance, good hand feeling and high fluffiness; the mint fibers have the characteristics of fragrance, odor removal, antisepsis and anti-inflammation, and high moisture absorption performance and breathability; meanwhile, the cotton fibers also have high moisture absorption performance and breathability; the three types of fibers are blended to take advantages of all fibers; the obtained yarns have the efficacies of moisture absorption, breathing, skin friendliness, skin care and long-time bacteria inhibition.

Owner:NANTONG GRACE SWEATER

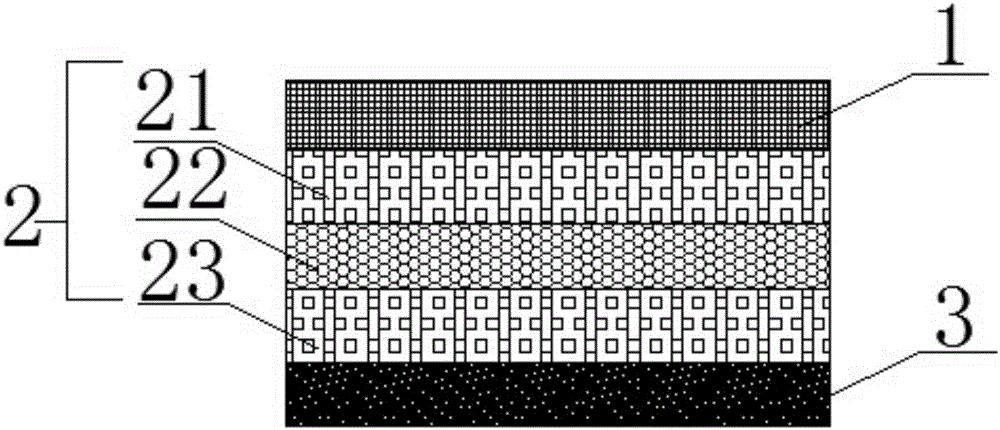

High-strength ultraviolet-proof antibacterial type textile fabric

InactiveCN106739215AImprove fitImprove breathabilitySynthetic resin layered productsCellulosic plastic layered productsSurface layerCarbon fibers

The invention discloses a high-strength ultraviolet-proof antibacterial type textile fabric and a preparation process thereof, and relates to the field of textile fabrics. The high-strength ultraviolet-proof antibacterial type textile fabric comprises a surface layer, a middle layer and an inner layer, wherein the surface layer is made of ultraviolet-proof fabrics; the middle layer comprises a first fabric layer, a second fabric layer and a third fabric layer; each of the first fabric layer and the second fabric layer is formed by 40 to 60 weight percent of bamboo carbon fiber, 10 to 30 weight percent of Shengma fiber and 10 to 30 weight percent of gossamer through blended spinning and weaving; the second fabric layer is formed by weaving 100 weight percent of bamboo carbon fiber; the inner layer is formed by 30 to 40 weight percent of bamboo charcoal fiber, 20 to 30 weight percent of heating fiber and 40 to 50 weight percent of cotton through blended spinning and weaving. The high-strength ultraviolet-proof antibacterial type textile fabric provided by the invention has the efficacies that the strength is high; the wear resistant performance is good; the ultraviolet-proof effect is achieved; bacteria resistance and bacteriostasis are realized; the hand feeling is comfortable; ventilation and heat insulation are realized, and the like. The preparation process is simple and reasonable; the production efficiency is high.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

Collateral-activating and pressure-regulating fabric and processing technology thereof

InactiveCN107805867AImprove microcirculationMoisture-absorbing and breathableProtective fabricsYarnApocynum venetumBlood pressure

The invention discloses a collateral-activating and pressure-regulating fabric which is formed by knitting warp and weft threads. The warp threads formed by blending apocynum venetum fiber, magnetic bamboo charcoal fiber and cotton fiber, the weft threads are formed by blending and knitting magnetic bamboo charcoal fiber and apocynum venetum fiber, the blending ratio of the apocynum venetum fiberto the magnetic bamboo charcoal fiber to the cotton fiber in the warp threads is 2 to 2 to 1, and the blending ratio of the magnetic bamboo charcoal fiber to the apocynum venetum fiber in the weft threads is 1 to 1. The collateral-activating and pressure-regulating fabric has the moisture-absorbing, breathable, soft, smooth, warm and abrasion-resistant advantages and the like and has the health-are effects of inhibiting and killing bacteria, deodorizing, resisting ultraviolet rays and electromagnetic radiation, regulating blood pressure, lowering blood fat, relieving allergy, relaxing tendons,activating collaterals, promoting body microcirculation and the like.

Owner:NANTONG HAONAN TEXTILE CO LTD

Soft and comfortable blended shell fabric

The invention discloses a soft and comfortable blended shell fabric. The soft and comfortable blended shell fabric is formed by blending and weaving high moisture-absorption cotton-like polyester filament yarn fibers, apocynum venetum fibers, kapok fibers and imported long linter fibers. The soft and comfortable blended shell fabric comprises, by weight, 17% to 21% of the high moisture-absorption cotton-like polyester filament yarn fibers, 25% to 29% of the apocynum venetum fibers, 30% to 34% of the kapok fibers and 16% to 28% of the imported long linter fibers. The soft and comfortable blended shell fabric is formed by blending and weaving the high moisture-absorption cotton-like polyester filament yarn fibers, the apocynum venetum fibers, the kapok fibers and the imported long linter fibers, and the woven shell fabric is soft in touch and comfortable to wear, and has the advantages of being capable of absorbing moisture, breathable, cool, thermal, good in drapability and resistant to wear.

Owner:刘喜

Production method of functional composite soft silk yarn

The invention discloses a production method of functional composite soft silk yarn, comprising the following steps of: preparing main yarn, preparing frame yarn, compositely combing yarn, and the like. The functional composite soft silk yarn is prepared from various components, has the functions of softness, comfort, silky smoothness, easy cleaning, rapid drying, moisture absorption, ventilation, and the like, bestows various health and beautifying functions, is popular among wide consumers, can be used for producing clothes and high-grade products of household living types and home textile types and has wide market prospects.

Owner:JIANGSU DASHENG GROUP +1

Polyester fully-drawn slub yarn and preparation method thereof

InactiveCN102828278AGood orientationEnsure productivityNew-spun product collectionFilament forming substance formingPolyesterBreaking strength

The invention discloses a polyester fully-drawn slub yarn and a preparation method thereof. On the basis of not changing the conventional FDY (fully-drawn yarn) production device, the polyester fully-drawn slub yarn is produced by using a one-step method implemented through adding a polymethyl methacrylate additive (mass percentage: 0.5-3.0%) into a polyester chip and then carrying out drawing on an obtained mixture at a drawing speed of 4600-5000m / min. The radial fineness ratio of the obtained slub yarn is 1.20-1.60 / l, the length of a thick section of the slub yarn is 15-40mm, and the slub density is 5-15 / m; and the breaking strength is 2.70-3.40 cN / dtex, and the breaking elongation is 40-80%. The polyester fully-drawn slub yarn prepared by using the technical scheme of the invention has the characteristics of high output, low cost, good quality, stable performance, high added values of products, and obvious price-performance advantages, and achieves the purposes of energy conservation, emission reduction, environmental protection, clean production and benefit incensement.

Owner:SUZHOU UNIV

Weaving method of jutecell/modal siro spinning functional fabric

InactiveCN102634919AEnhanced softness and comfort performanceSolve poor cohesionWeft knittingYarnWoven fabricYarn

The invention relates to a weaving method of a jutecell / modal siro spinning functional fabric, which is characterized by being formed by weaving fabric weaves with single-surface plains; and yarns are formed by stranding two 32S 60% jutecells and 40% modal siro spinning yarns with the twist of 900-1100 twists / m and twist coefficient of 380-430. The finally made fabric is smooth in hand feel, is bright in appearance color, is bright and clean in cloth surface, is excellent in flexibility and elasticity, and has a remarkable vision effect. The jutecell / modal siro spinning functional fabric has the characteristics of excellent moisture absorbing and exhausting properties, good air permeability, bacterium resistance, mildew proofing, and no fluffing and pilling.

Owner:JIANGYIN XIANGFEI APPAREL

Antibacterial health-caring fabric

InactiveCN105088477AAntibacterialMoisture-absorbing and breathableWoven fabricsPolyesterCuprammonium rayon

The invention discloses an antibacterial health-caring fabric formed by warp yarns and weft yarns interweaved with the warp yarns. The antibacterial health-caring fabric innovates in a way that the warp yarns are viscose fiber blended yarns; the weft yarns are polyester fiber blended yarns; the viscose fibers are bamboo fibers; the warp yarns can be also formed by cellulose acetate fibers or copper ammonia fibers; and the polyester fibers can be polyesteramide fibers, polyvinyl alcohol ester fibers or polyvinyl chloride ester fibers. The antibacterial health-caring fabric is characterized by bacteria prevention, moisture absorption, ventilation, ultraviolet ray releasing, disinfection and static prevention; the antibacterial health-caring fabric also possesses functions of bacterial prevention, inflammation removal and odor elimination as well as ventilation; the antibacterial health-caring fabric is advantaged by ultraviolet ray prevention, comfortable hand feeling, moisture absorption and retention and static prevention; and the production method of the fabric is simple, has high production efficiency and great product quality.

Owner:JIANGSU JUWEI NEW MATERIALS

Alginate fiber absorbable medical auxiliary material and manufacture technology thereof

InactiveCN102851878ASkin-friendly and antibacterialMoisture-absorbing and breathableAbsorbent padsNon-woven fabricsFiberBiomedical engineering

The invention relates to an alginate fiber absorbable medical auxiliary material and a manufacture technology of the alginate fiber absorbable medical auxiliary material, belonging to the field of medical accessory. The alginate fiber absorbable medical auxiliary material is characterized by being formed by blending and needling alginate fiber and polylactic acid fiber; the fabric includes the following raw materials by weight: 70-100% of alginate fiber, and 0-30% of polylactic acid fiber. The alginate fiber absorbable medical auxiliary material and the manufacture technology provided by the invention are good in relation to skin, and are bacteriostatic, have functions of humidity absorbing and ventilating, and are safe and environment-friendly.

Owner:山东奈琦尔海洋科技有限公司

Processing process of yakwool silk double-faced woolen goods

ActiveCN105839252AWindproofMoisture-proofShrinkingHeating/cooling textile fabricsSpinningEngineering

The invention discloses a processing process of yakwool silk double-faced woolen goods. The processing process includes the steps of spinning, weaving, body inspection, sewing, preliminary washing, dehydration, milling, inspection, intensive washing, dehydration, baking and brushing, decatizing, fuzzing, shearing and lustring, inspection and sizing, so that processing of the yakwool silk double-faced woolen goods is completed. The environment suitable for combined processing of yakwool fibers and silk fibers is constructed by adjusting the processing temperature, time, consumption of auxiliaries, mechanical pressure and the like; the formed double-faced woolen goods have tenacity, warm keeping performance, waterproof performance, windproof performance and dampproof performance of yakwool, also have the advantages of being light, smooth, capable of absorbing damp and breathable of silk and are free of shrink after being washe.

Owner:西藏圣信工贸有限公司 +1

Jutecell fiber Raschel blanket and technology for manufacturing Jutecell fiber Raschel blanket

ActiveCN104109940ALight and thinAntibacterial and antifungalWarp knittingLiquid/gas/vapor removalFiberPulp and paper industry

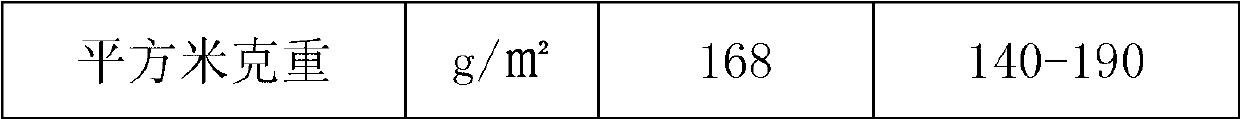

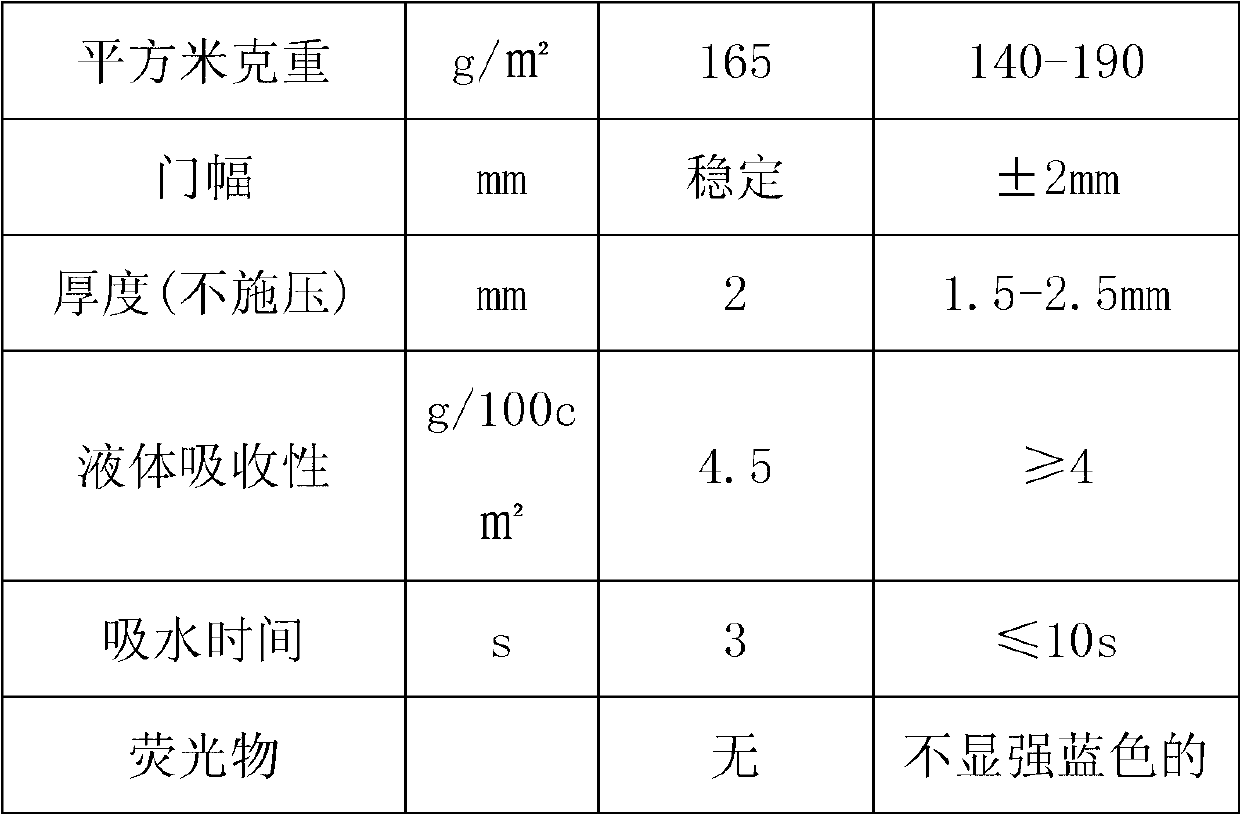

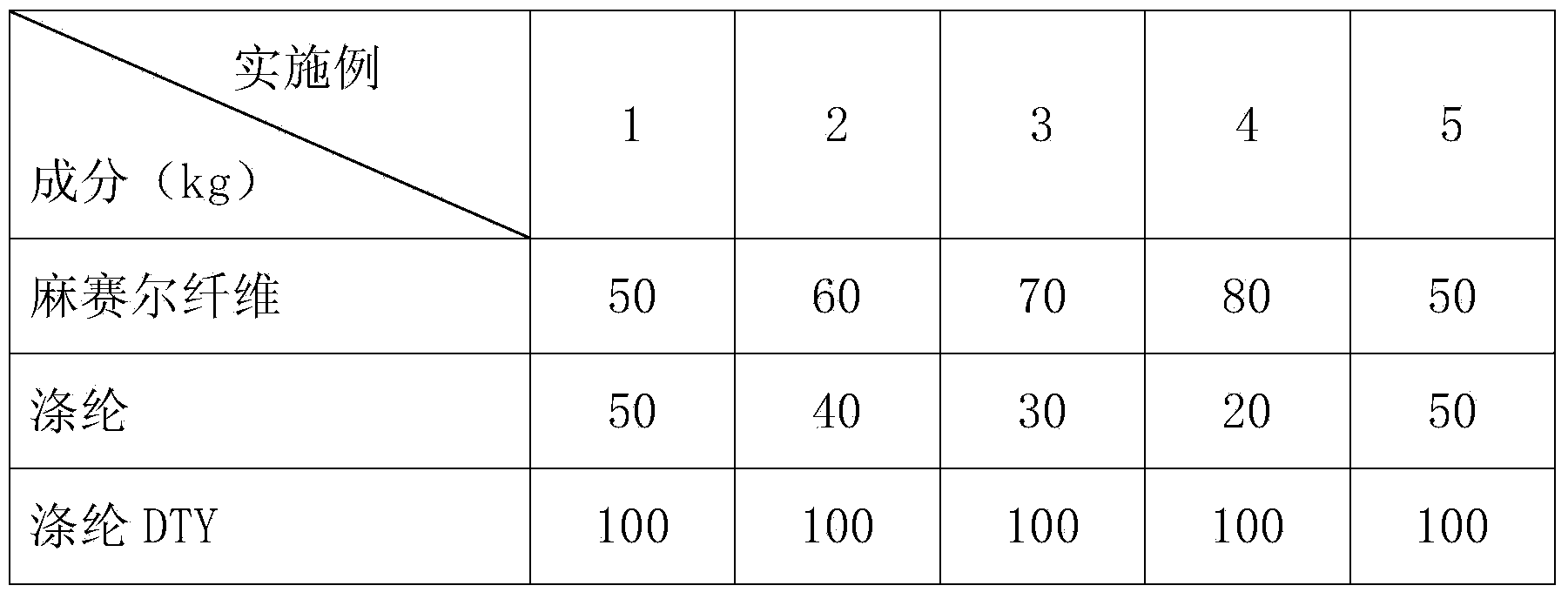

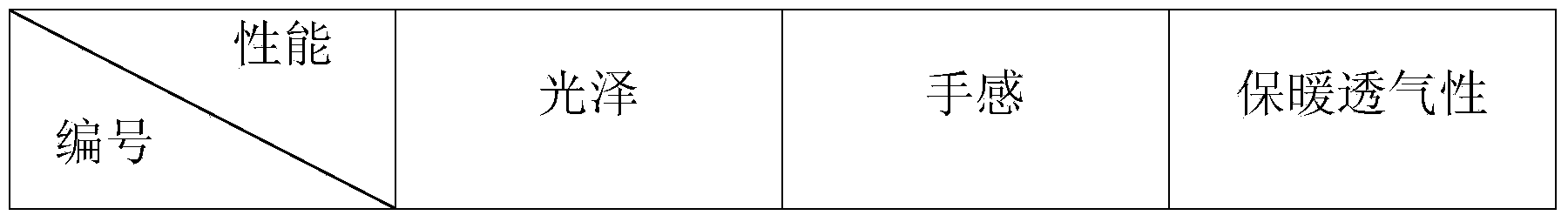

The invention belongs to the field of production of functional Raschel blankets and relates to a Jutecell fiber Raschel blanket and the technology for manufacturing the Jutecell fiber Raschel blanket. The Jutecell fiber Raschel blanket comprises face yarn and ground yarn, wherein the face yarn is composed of, by weight, 50%-80% of Jutecell fibers and 20%-50% of Dacron fibers, and the ground yarn is composed of, by weight, 100% of DTY. The Jutecell fiber Raschel blanket is formed by weaving blended yarn of 50% of Jutecell fibers and 50% of Dacron fibers and long Dacron filaments on a warp knitting machine. The Jutecell fiber Raschel blanket obtained through weaving is smooth in hand feeling, bright in color and full and smooth in cloth tissue, has the good moisture absorbing and discharging function and the good anti-bacteria and anti-mold function, and is capable of absorbing moisture, breathable, fluffy, soft, extremely comfortable and skin-friendly.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Comfortable blend fiber

InactiveCN105029792AMoisture-absorbing and breathableWith health careYarnUndergarmentsCarbon fibersPolyvinyl alcohol

The invention discloses a comfortable blend fiber comprising a first blend fiber and a second blend fiber blend-weaved with the first blend fiber. Vinylon fibers, casein fibers and far infrared Nanina fibers are blend-weaved to form the first blend fiber; polyacrylonitrile fibers, bamboo carbon fibers and Lyocell fibers are blend-weaved to form the second blend fiber. The comfortable blend fiber is weaved by various fibers in a blending way and is characterized by great strength, long service life, cooling and comfortable sense, humidity absorbing and ventilation and health-caring performance.

Owner:TAICANG YUEXIANG CHEM FIBER

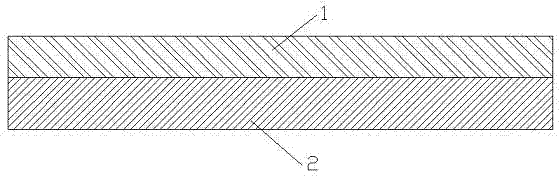

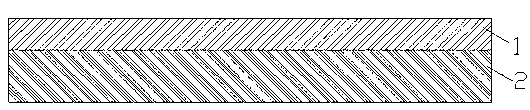

Double-layer composite hygroscopic and breathable fabric

InactiveCN103753877AMoisture-absorbing and breathableSoft textureLayered productsPerspirationWool fiber

The invention discloses a double-layer composite hygroscopic and breathable fabric. The double-layer composite hygroscopic and breathable fabric comprises a breathable fabric layer on the external layer and a hygroscopic fabric layer on the lower layer, the breathable fabric layer is obtained through blended braiding of 35-46wt% of pineapple leaf fibers and 54-65wt% of mercerized wool fibers, and the hygroscopic fabric layer is obtained through the blended braiding of 41-47wt% of ricinus silk fibers and 53-59wt% of hemp fibers. The double-layer composite hygroscopic and breathable fabric adopts a double-layer structure design, the lower hygroscopic fabric layer has the characteristics of close fitting comfortableness, hygroscopic property and perspiration, and the surface breathable fabric layer has the characteristics of humidity elimination, breathability and soft texture.

Owner:SUZHOU TANXI TEXTILE TECH CO LTD

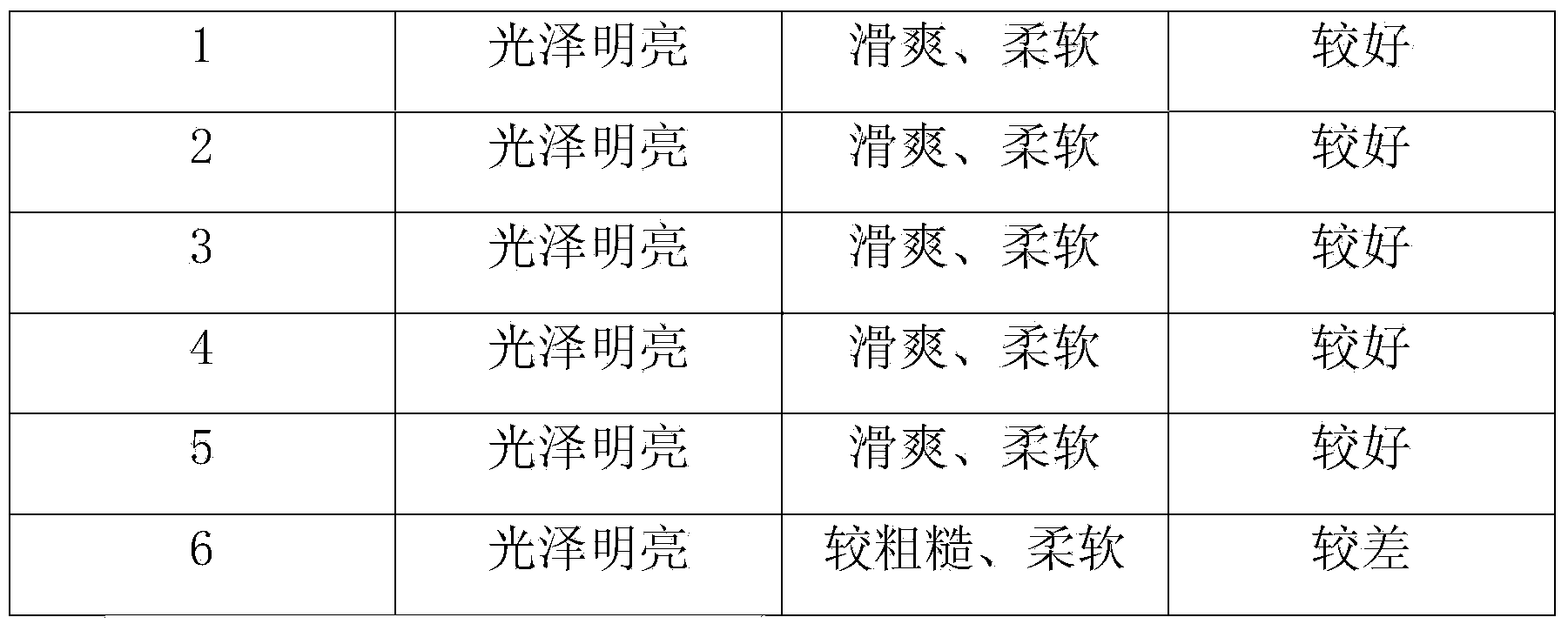

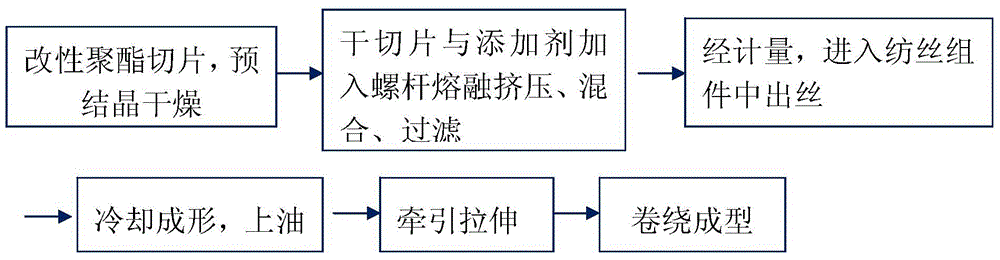

Production process of high-elasticity-feature terylene pre-oriented fibers

InactiveCN104480555AImprove water absorptionImprove sexual functionSpinnerette packsNew-spun product collectionFiberPolyester

The invention provides a production process of high-elasticity-feature terylene pre-oriented fibers. The production process is characterized by comprising the steps of 1) slicing a raw material, namely, modified polyester, conveying the material to a wet material bin to enable pre-crystallizing, and then ventilating and drying to obtain dry slices; 2) feeding the dry slices and an additive into a screw extrusion machine together under a melting condition, filtering and then transferring into a spinning box to obtain a melt; 3) metering the melt through a metering pump, and feeding into a spinning assembly to yield silks; 4) performing slow cooling and side blowing for the silks obtained in step 3) to cool and shape, and then applying oil; 5) pulling, stretching, and thermally shaping; 6) coiling through a coiling head to obtain the high-elasticity-feature terylene pre-oriented fibers. The high-elasticity-feature terylene pre-oriented fibers prepared by the production process have the advantages that the specification is up to 180dtex / 36f, the breaking strength is not less than 1.80cN / dtex, the elongation at break is 200+ / 30; the softness, sense of touch and rebound elasticity are superior to those of the general fibers, and moreover, the water absorbing performance, the oil absorbing performance and the cleaning function are high.

Owner:ZHONGRUN SCI & TECH

Nano anti-bacterial fabric

InactiveCN103264536AFeel comfortableHas antibacterial propertiesLayered productsNano zinc oxideAnti bacterial

The invention discloses a piece of nano anti-bacterial fabric, comprising a thin air permeable layer at the surface layer, and an anti-bacterial fabric layer at the inner layer, wherein the thin air permeable layer is formed by blending and knitting mercerized cotton fibers with bamboo fibers; the anti-bacterial fabric layer is formed by knitting warps and wefts with one another; and the warps are knitted by nano-zinc-oxide-coated spun silk fibers, while the wefts are knitted by copper-oxide-coated Tencel fibers. The thin air permeable layer at the surface layer is formed by blending and knitting moisture-absorbing air permeable fabric, and has the characteristics of light weight, moisture absorption, air permeability, comfortable feeling and the like; the anti-bacterial fabric layer at the inner layer is made of fabric which is formed by knitting common fabric fibers and an anti-bacterial material, so that the fabric has an anti-bacterial effect and also is capable of absorbing moisture and being air-permeable; as a result, the moisture given off by a human body is discharged, and the close-fitting fabric keeps dry and clean; and simultaneously, the peculiar smell given off by the human body also can be eliminated.

Owner:张容宣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com