Antibacterial jeans-imitation fabric

A technology for imitating denim and fabrics, applied in the direction of adding pigments, textiles, cellulose/protein conjugated artificial filaments, etc. Functional limitations and other issues, to achieve the effect of reducing shrinkage and deformation after washing, good natural antibacterial effect, and improving antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

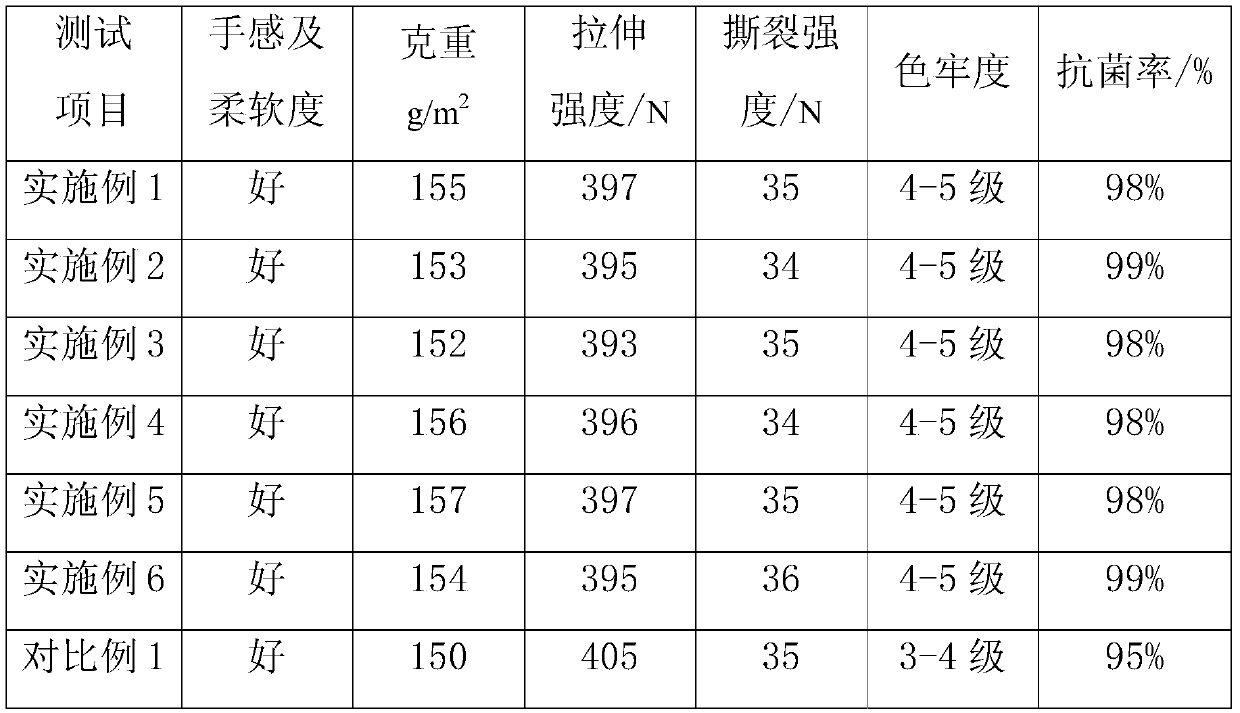

Examples

Embodiment 1

[0046] Embodiment 1: a kind of antibacterial imitation denim fabric, comprises the component of following weight portion:

[0047]200 parts of mixed cellulose fiber, 50 parts of bamboo charcoal fiber, 60 parts of polyester, 5 parts of spandex, 35 parts of conductive fiber, 25 parts of cupro ammonia fiber, and 10 parts of antibacterial agent.

[0048] in:

[0049] Mixed cellulose fibers are blended with cotton and tencel at a mass ratio of 1:1;

[0050] Polyester is composed of polyester low elastic yarn and polyester elastic yarn with a mass ratio of 1:1;

[0051] The conductive fiber is one or both of carbon fiber and metal compound fiber;

[0052] The antibacterial agent is an organosilicon quaternary ammonium salt antibacterial agent.

[0053] A kind of preparation step of antibacterial imitation denim fabric is as follows:

[0054] S1. Fiber dyeing: Dye cotton, tencel, and polyester with color masterbatches respectively. The specific steps are: add 2% color masterbatch...

Embodiment 2

[0061] Embodiment 2: a kind of antibacterial imitation denim fabric, comprises the component of following weight portion:

[0062] 240 parts of mixed cellulose fiber, 55 parts of bamboo charcoal fiber, 65 parts of polyester, 6 parts of spandex, 40 parts of conductive fiber, 27 parts of cupro fiber, and 11 parts of antibacterial agent.

[0063] in:

[0064] Mixed cellulose fibers are blended with cotton and tencel with a mass ratio of 1:1.5;

[0065] Polyester is composed of polyester low elastic yarn and polyester elastic yarn with a mass ratio of 1:1.5;

[0066] The conductive fiber is one or both of carbon fiber and metal compound fiber;

[0067] The antibacterial agent is an organosilicon quaternary ammonium salt antibacterial agent.

[0068] A kind of preparation step of antibacterial imitation denim fabric is as follows:

[0069] S1. Fiber dyeing: Dye cotton, tencel, and polyester with color masterbatches respectively. The specific steps are: add 2.5% color masterbatc...

Embodiment 3

[0076] Embodiment 3: a kind of antibacterial imitation denim fabric, comprises the component of following weight portion:

[0077] 260 parts of mixed cellulose fiber, 60 parts of bamboo charcoal fiber, 70 parts of polyester, 7 parts of spandex, 45 parts of conductive fiber, 29 parts of cupro fiber, and 12 parts of antibacterial agent.

[0078] in:

[0079] Mixed cellulose fibers are blended with cotton and tencel at a mass ratio of 1:1;

[0080] Polyester is composed of polyester low elastic yarn and polyester elastic yarn with a mass ratio of 1:1;

[0081] The conductive fiber is one or both of carbon fiber and metal compound fiber;

[0082] The antibacterial agent is an organosilicon quaternary ammonium salt antibacterial agent.

[0083] A kind of preparation step of antibacterial imitation denim fabric is as follows:

[0084] S1. Fiber dyeing: Dye cotton, tencel, and polyester with color masterbatches respectively. The specific steps are: add 3% color masterbatches to w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com