Patents

Literature

103results about How to "Light and thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

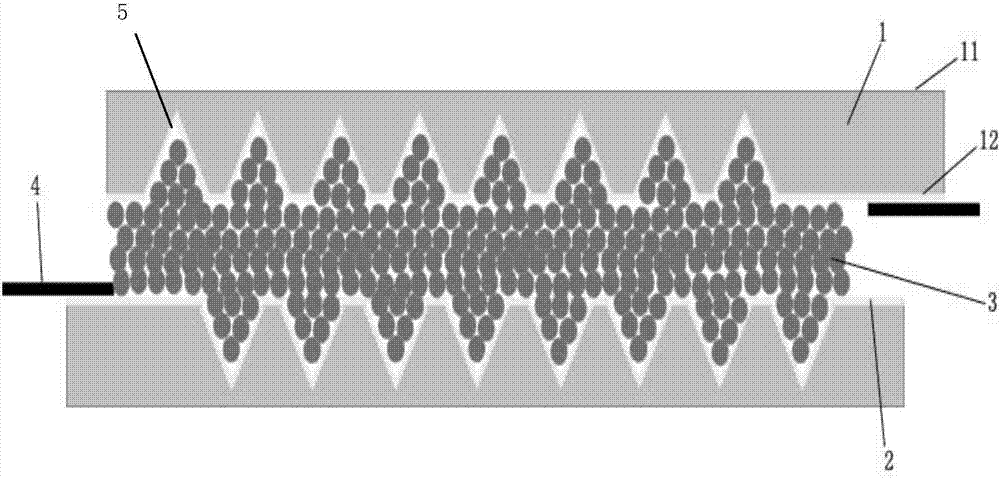

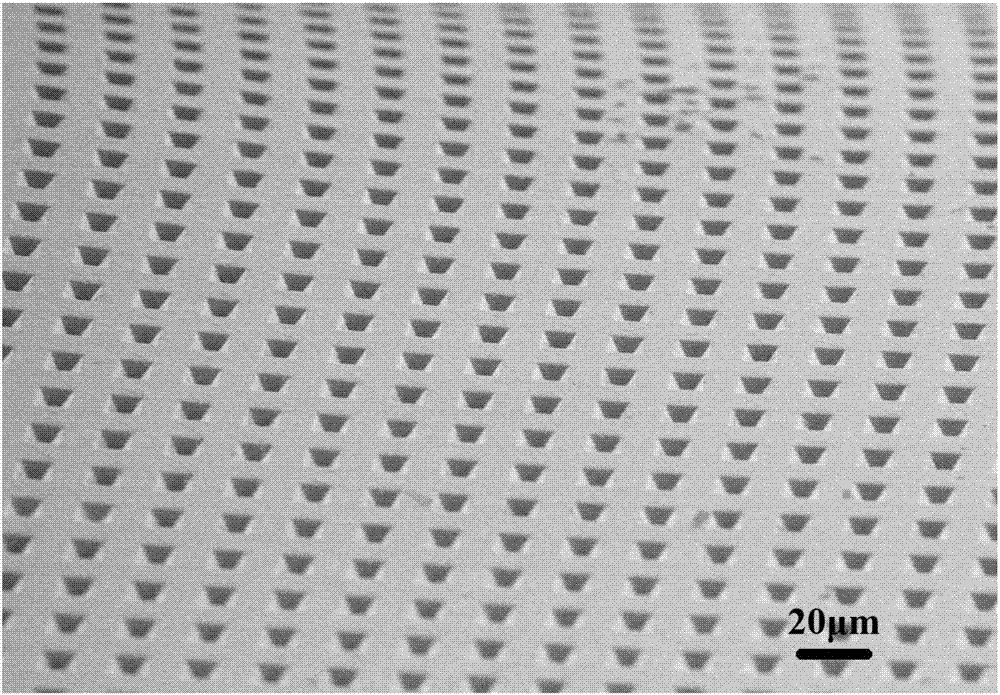

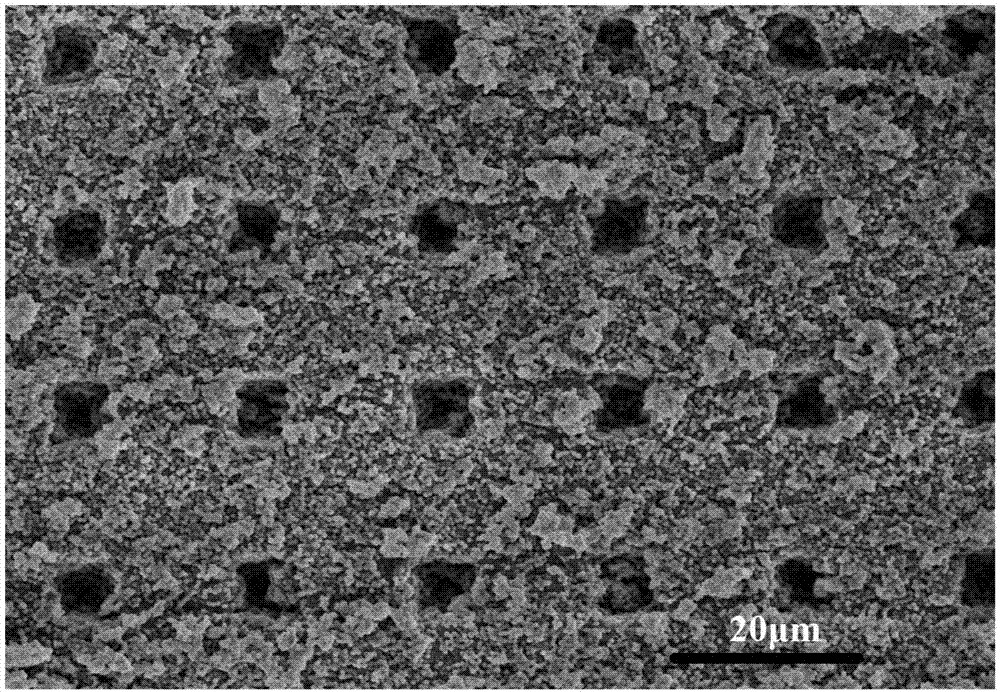

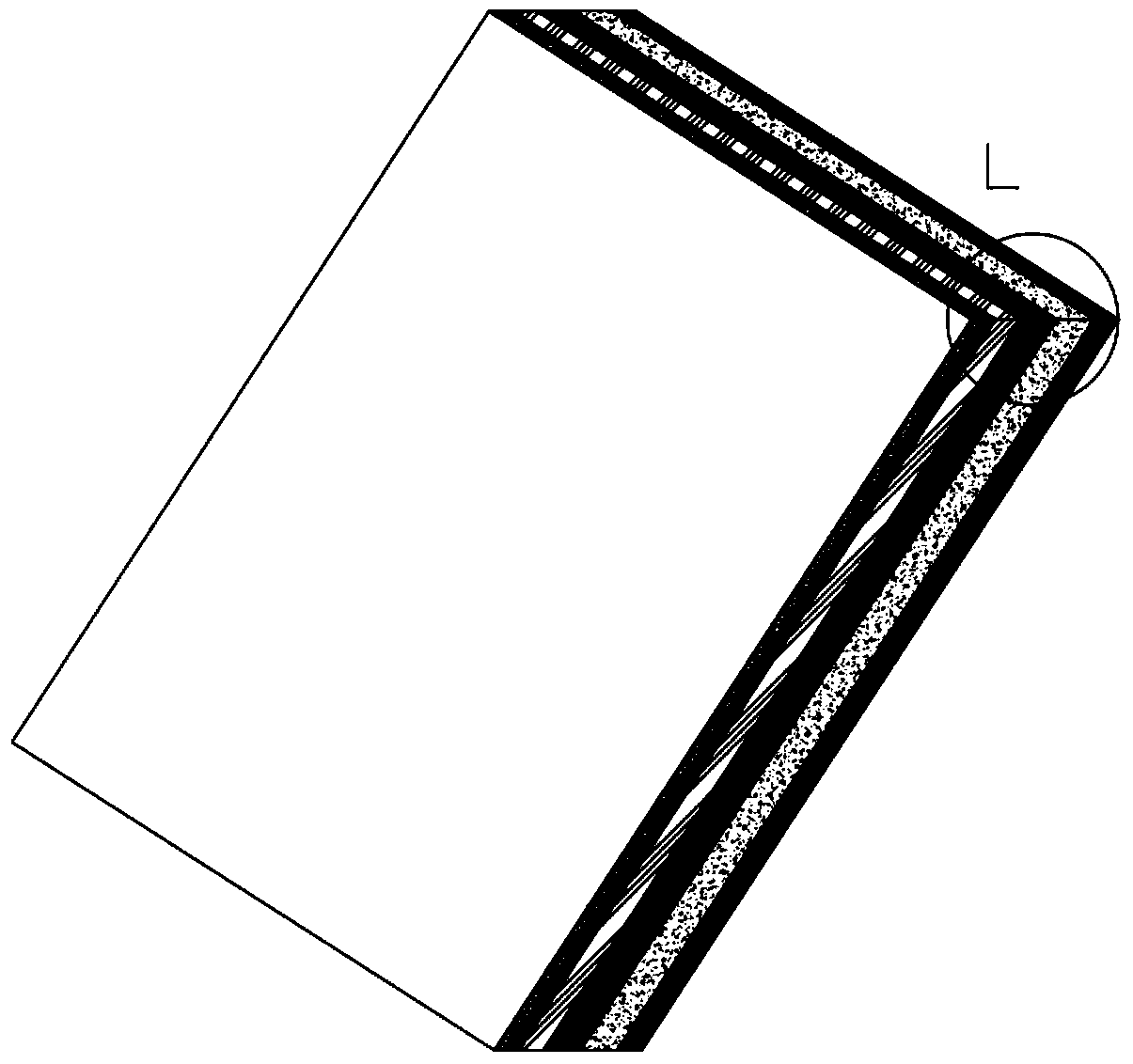

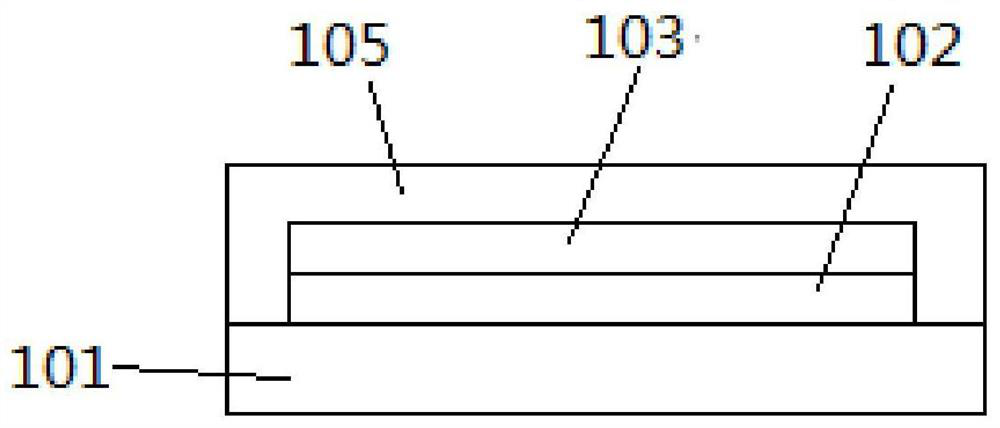

Multiphase dielectric layer capacitive pressure sensor with microstructure and preparation method thereof

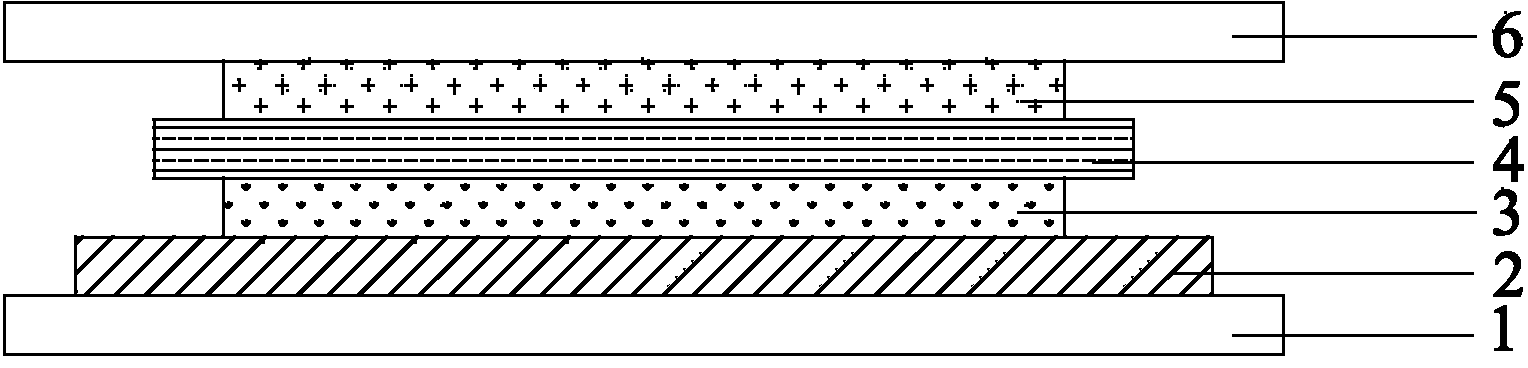

The invention discloses a multiphase dielectric layer capacitive pressure sensor with a microstructure and a preparation method thereof. The pressure sensor comprises the components of two flexible electrodes which are oppositely arranged, wherein at least one in two opposed surfaces of the two flexible electrodes has the microstructure which is formed by a plurality of projections and / or recessed parts; and a multiphase dielectric layer which is arranged between the two flexible electrodes, wherein the multiphase dielectric layer comprises a micro-ball dielectric layer which is formed by a plurality of micro-balls that can freely move and air and / or flexible polymer that are filled in the micro-ball dielectric layer. The multiphase dielectric layer capacitive pressure sensor with the microstructure has advantages of small thickness, high softness, etc. The multiphase dielectric layer capacitive pressure sensor can be machined to various shapes and has advantages of wearability and adhesiveness. The multiphase material is used as the dielectric layer, thereby improving device sensitivity and reducing least measurement pressure.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Manufacturing method of hot bent 3D (Three Dimensional) glass white sheet

InactiveCN106746525AEliminate internal stressFlat surfaceEdge grinding machinesPolishing machinesNumerical controlHeating time

The invention relates to a manufacturing method of a hot bent 3D (Three Dimensional) glass white sheet. The manufacturing method comprises the following steps: (1) cutting a material: cutting a glass white sheet material into a plurality of small glass white sheets with proper sizes; (2) finely engraving: putting the small glass white sheets into a CNC (Computer Numerical Control) fine engraving machine, and punching and grinding edges; (3) cleaning: carrying out cleaning treatment on the glass white sheet by utilizing a glass cleaning machine; (4) carrying out ultrasonic treatment: washing surface residual waste dreg on the surface of the glass white sheet by utilizing an ultrasonic washing machine; (5) hot bending: putting the glass white sheet into a hot bending mold and hotly bending, machining and molding the glass white sheet into a 3D curve surface; (6) tempering: putting the hotly bent glass white sheet into a tempering frame; conveying the tempering frame into a tempering furnace and raising the temperature to 380 DEG C-420 DEG C, wherein the heating time is 4h-8h and the hardness reaches 7H; (7) carrying out plasma spraying: putting the glass white sheet into a fingerprint oil spraying machine and spraying fingerprint oil on a surface through plasmas; baking at a temperature of 140 DEG C-160 DEG C for 25-30 minutes until the fingerprint oil is dried; (8) fitting: fitting release films on upper and lower surfaces of the glass white sheet; and (9) packaging.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

Foam glass insulation and photovoltaic decoration integrated panel and preparation method thereof

ActiveCN103410289ALow thermal conductivityGood thermal performanceRoof covering using slabs/sheetsRoof covering using tiles/slatesThermal insulationGreen building

The invention discloses a foam glass insulation and photovoltaic decoration integrated panel and a preparation method thereof. The integrated panel comprises an insulation layer and a photovoltaic decoration layer, the insulation layer is a foam glass insulation board and is wrapped by a waterproof rolling material in a sealing way, and the photovoltaic decoration layer comprises a flexible film battery component, a film layer and a coating layer in sequence from inside to outside. The integrated panel has fire resistance, flame-retardant performance and good durability, thermal insulation and photovoltaic power generation can be realized, and the integrated panel complies with green building concepts such as energy conservation, emission reduction and zero power consumption.

Owner:湖北亚细亚陶瓷有限公司 +1

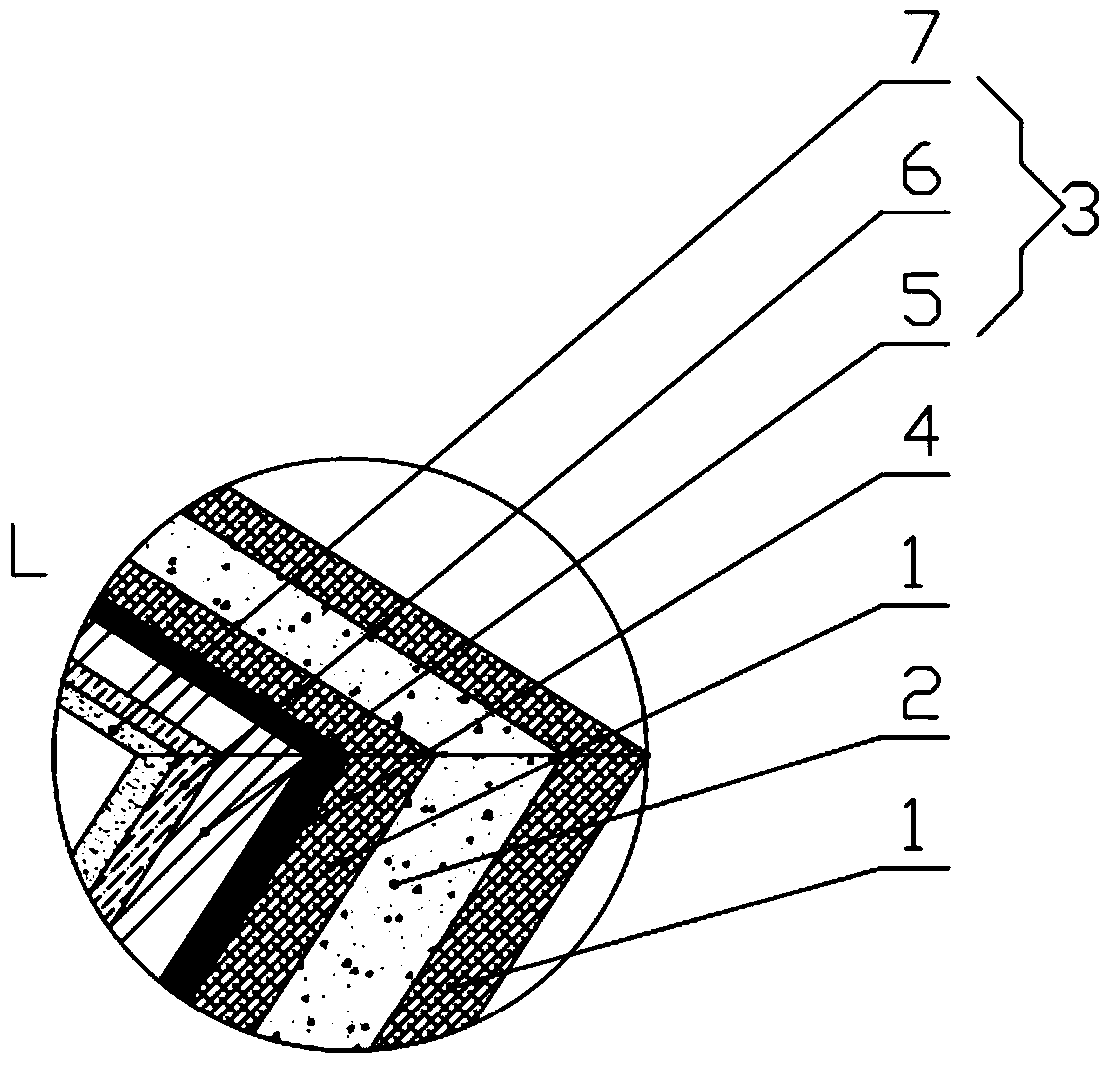

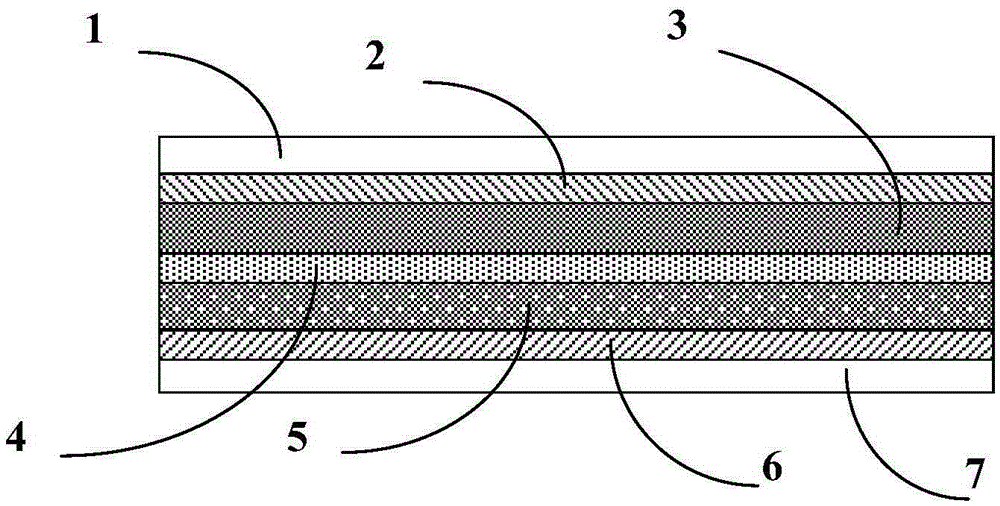

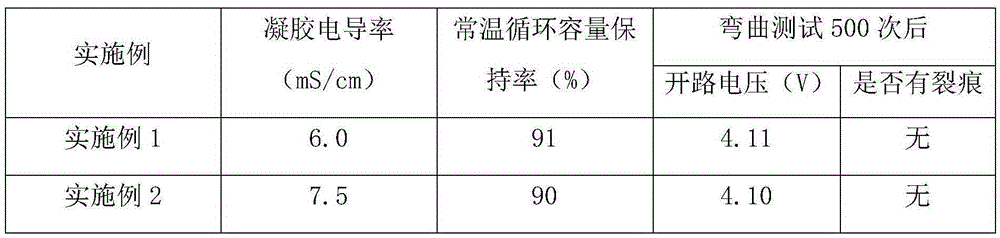

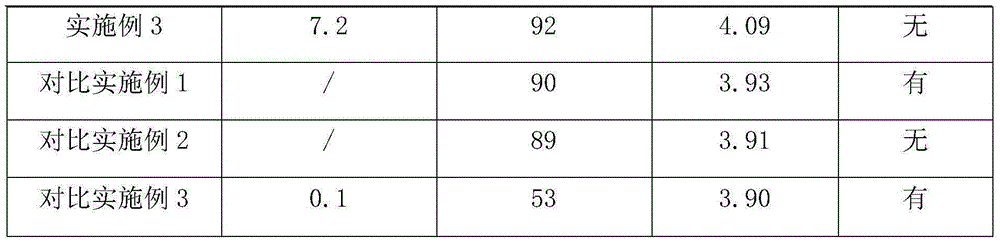

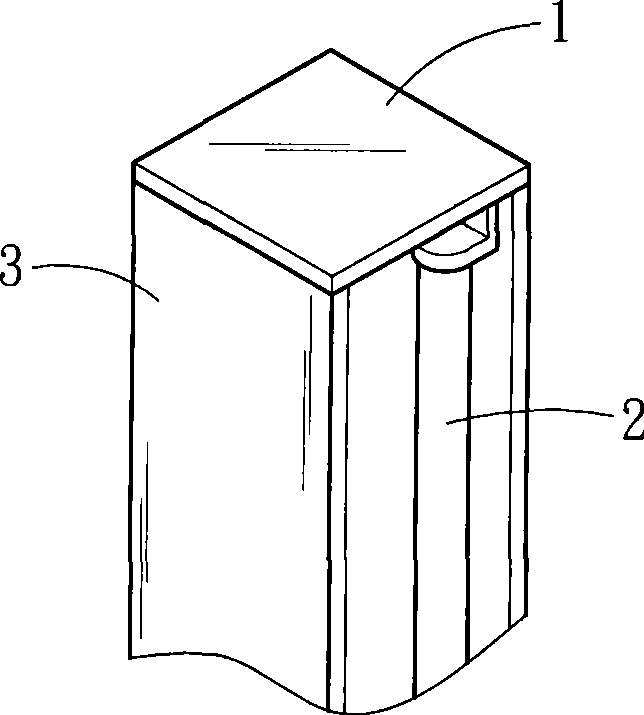

Polymer lithium ion battery and preparation method thereof

InactiveCN106711498AChangeable shapeFlexibleFinal product manufactureElectrode carriers/collectorsOrganic solventPositive current

The invention discloses a polymer lithium ion battery. The polymer lithium ion battery comprises a positive electrode layer, a gel electrolyte layer and a negative electrode layer, wherein the positive electrode layer comprises a base material, a positive current collector and a positive material, the gel electrolyte layer comprises a macromolecular polymer, a lithium salt, an organic solvent and a functional additive, and the negative electrode layer comprises a base material, a negative current collector and a negative material. The invention also provides a preparation method of the polymer lithium ion battery. A preparation process provided by the invention is simple and low-cost; the prepared polymer lithium ion battery has the characteristics of flexibility, light weight, thinness and variable shapes, and is suitable for being used in the field of wearable devices and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

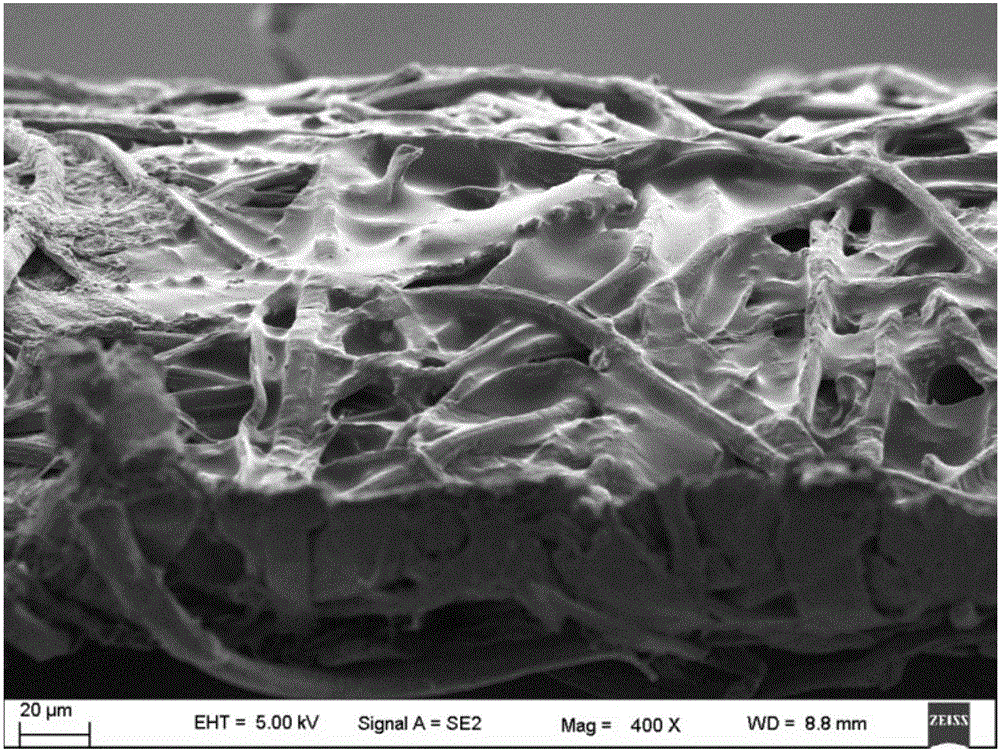

Natural down flocculus made of composite thermal insulation materials and manufacturing process of the natural down flocculus

The invention relates to a natural down flocculus made of composite thermal insulation materials, which is made through taking down mainly comprising duck down and goose down as a main material, as well as a manufacturing process of the natural down flocculus. The natural down flocculus made of the composite thermal insulation materials is made of blend fiber and down mainly comprising duck down and goose down, wherein the blend fiber is formed by blending meldable fibers and polyester staple fibers according to weight ratio of (13-18):(6-15); and the blended ratio of the down and the blend fiber is determined according to the requirement of a down product. In manufacturing, animal down serves as a main material while the meldable fibers and the polyester staple fibers serve as auxiliary materials; and the composite thermal insulation material with the down content of above 65% is produced according to different ratios of all materials. The down flocculus has a good thermal insulation property like a down product or a cashmere product, is green and environment-friendly, and also has spinnability and tailorability. The process is relatively low in cost, concise and mature in process and easy to operate, and has a great market potential.

Owner:河北兴瑞羽绒制品有限公司

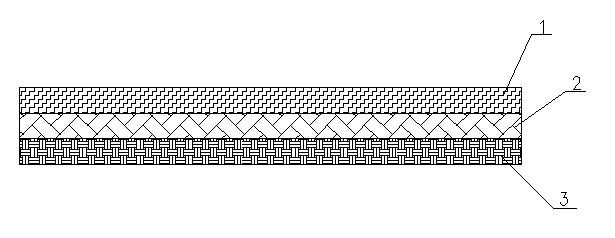

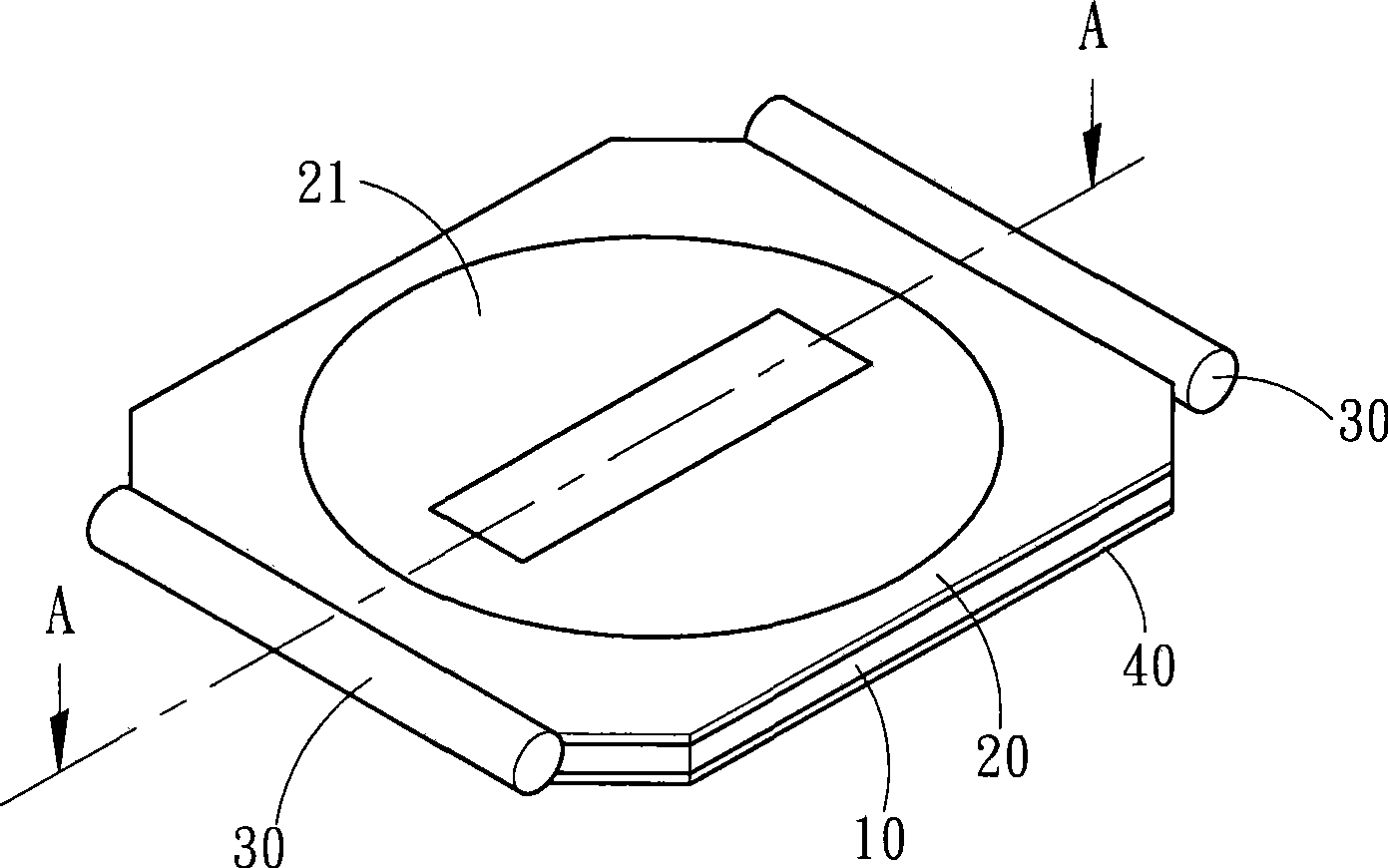

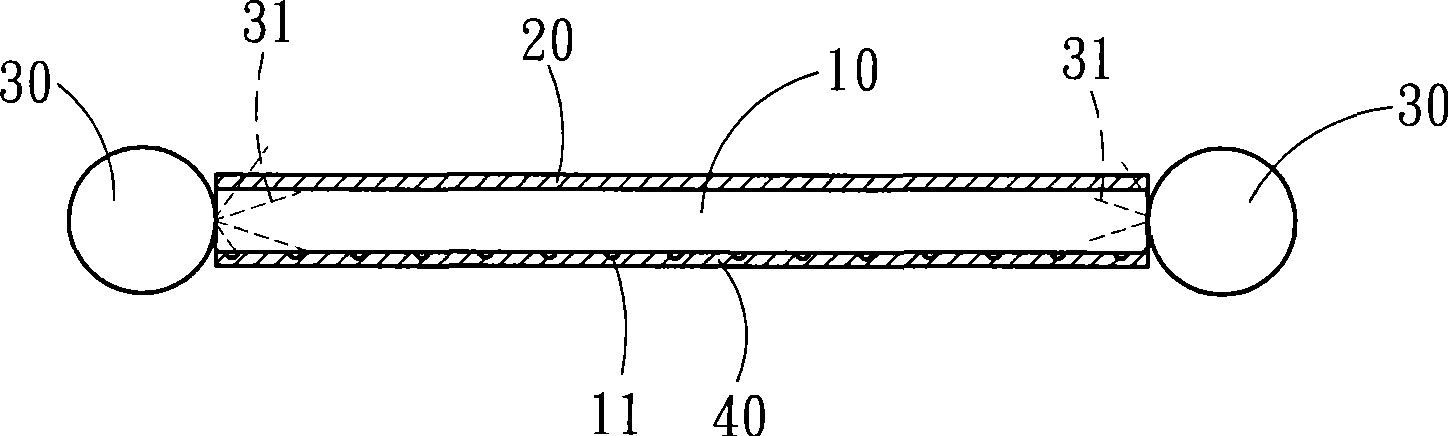

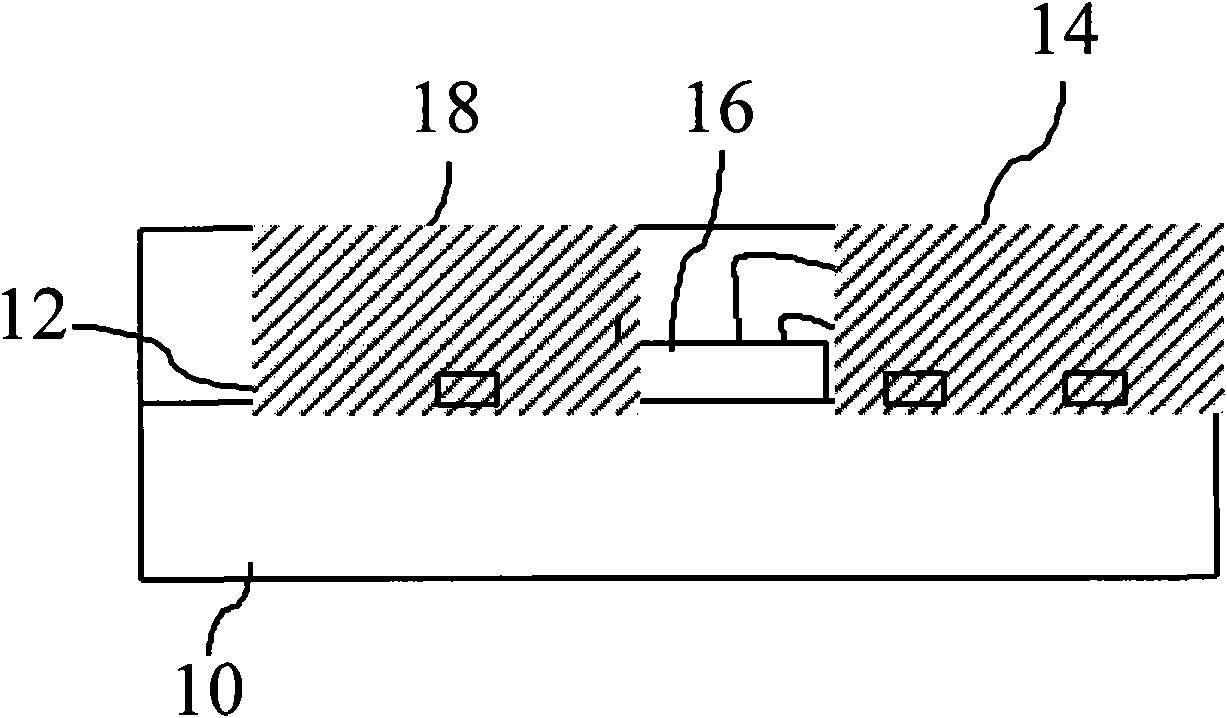

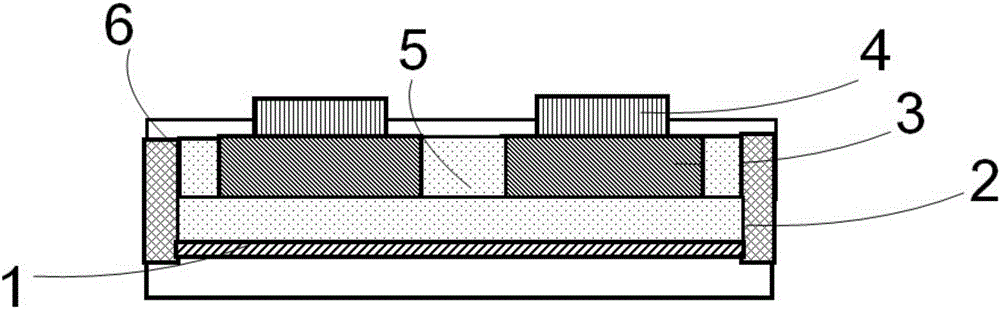

Thinned energy storing device and manufacture process thereof

ActiveCN103824997AHigh electrochemical conversion rateFacilitate integration and applicationPrimary cell manufactureElectrode manufacturing processesFilm materialEnergy conversion efficiency

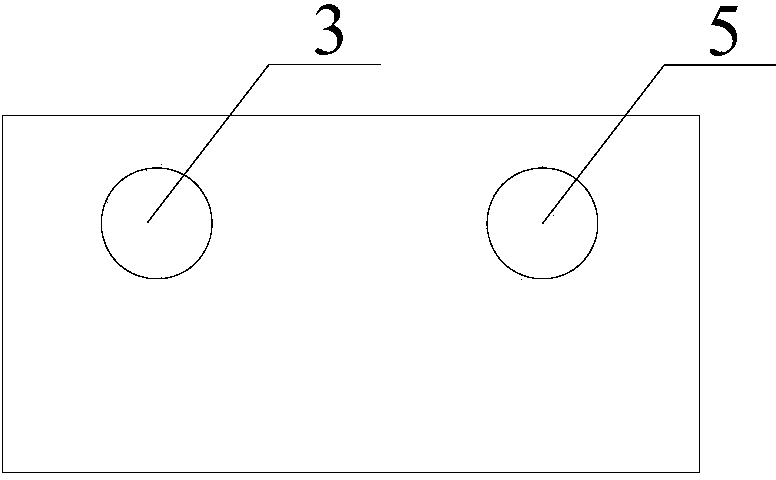

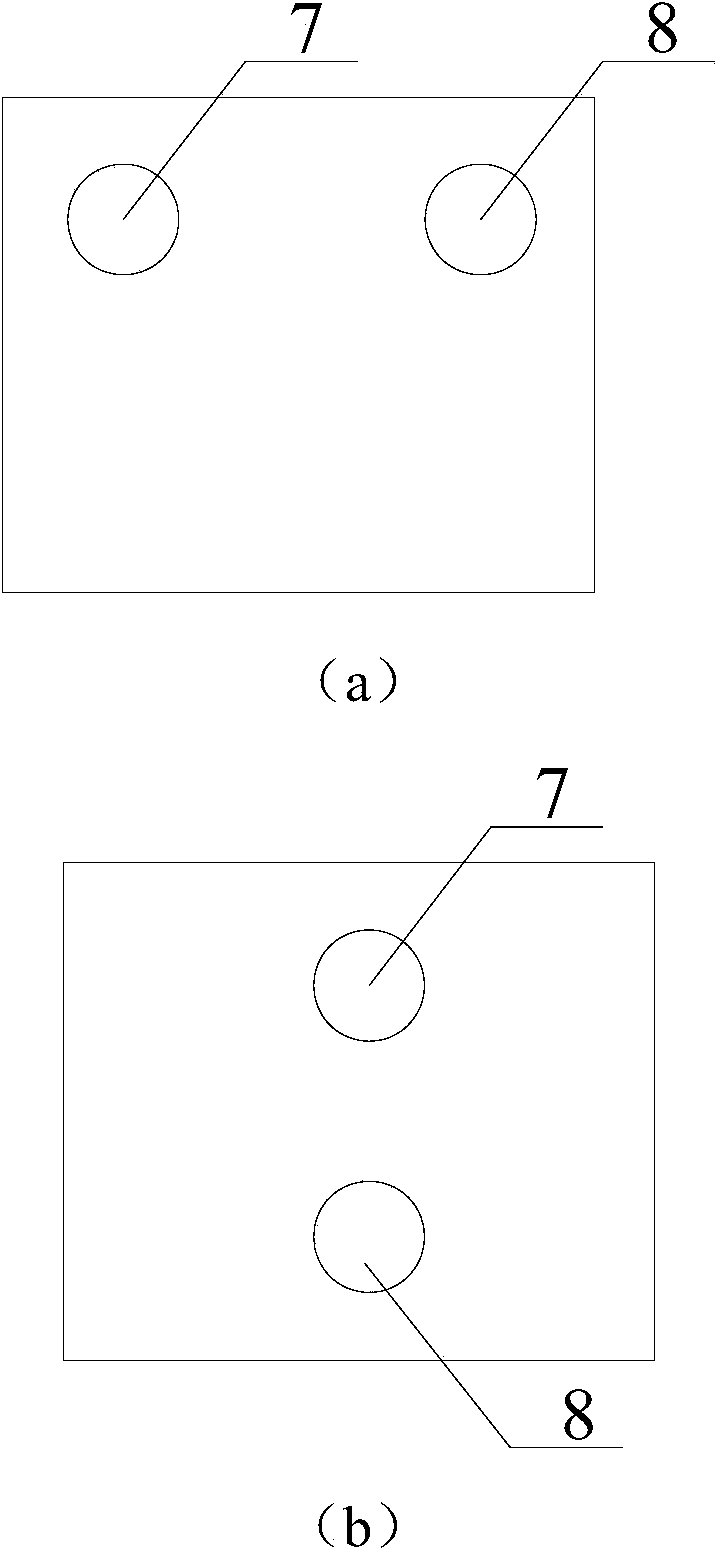

The invention relates to a thinned energy storing device and a manufacture process thereof. The thinned energy storing device sequentially comprises a lower encapsulating layer, a collector layer, a positive layer, an isolation layer, a negative layer and an upper encapsulating layer from bottom to top, wherein the lower encapsulating layer and the upper encapsulating layer are made of barrier thin-film materials; the collector layer is made of a conducting material; the positive layer is prepared from inorganic active slurry with oxidizability; the isolation layer is made of specialty paper or a plastic film with electrical insulation property; the negative layer is made of a metal film material with reduction property. Compared with the prior art, the thinned energy storing device has the advantages that the process is more simplified, the manufactured thinned energy storing device has no internal pressure and high negative material activity, the electric capacity and the unit area capacity of the thinned energy storing device are improved, and besides, the electrodes and the isolation layer are positioned at the same axis, so that the connection with an energy dissipation device is facilitated, and the energy conversion efficiency is improved.

Owner:江苏恩福赛柔性电子有限公司

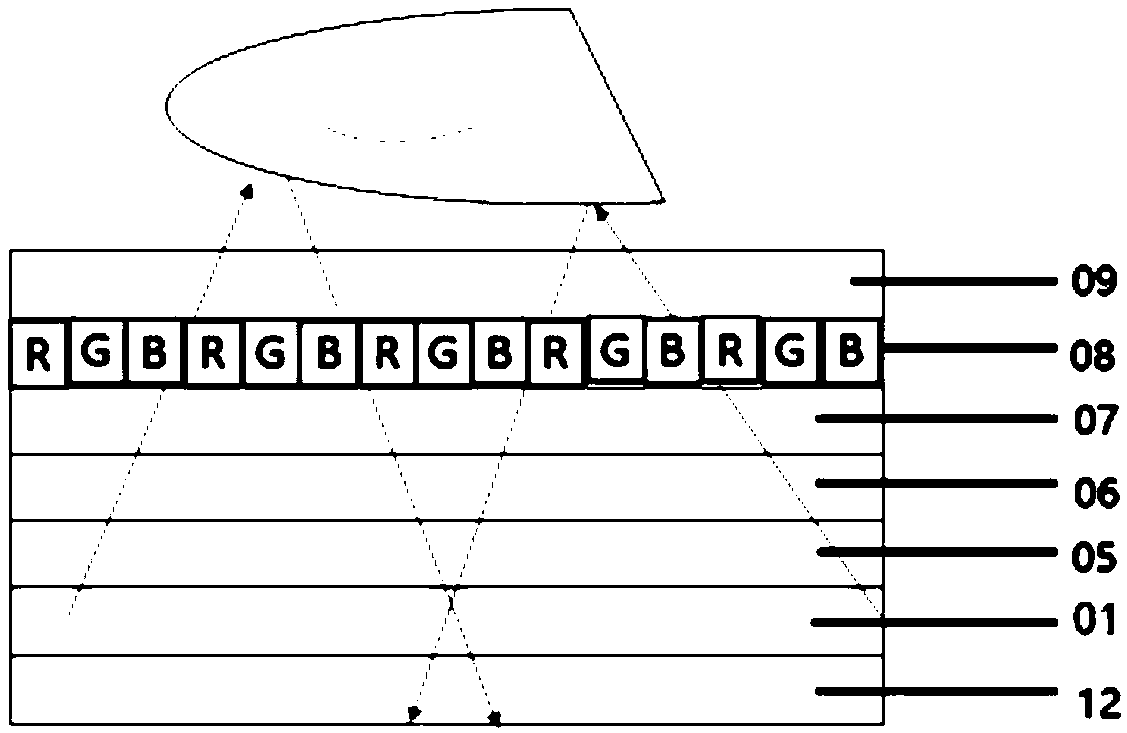

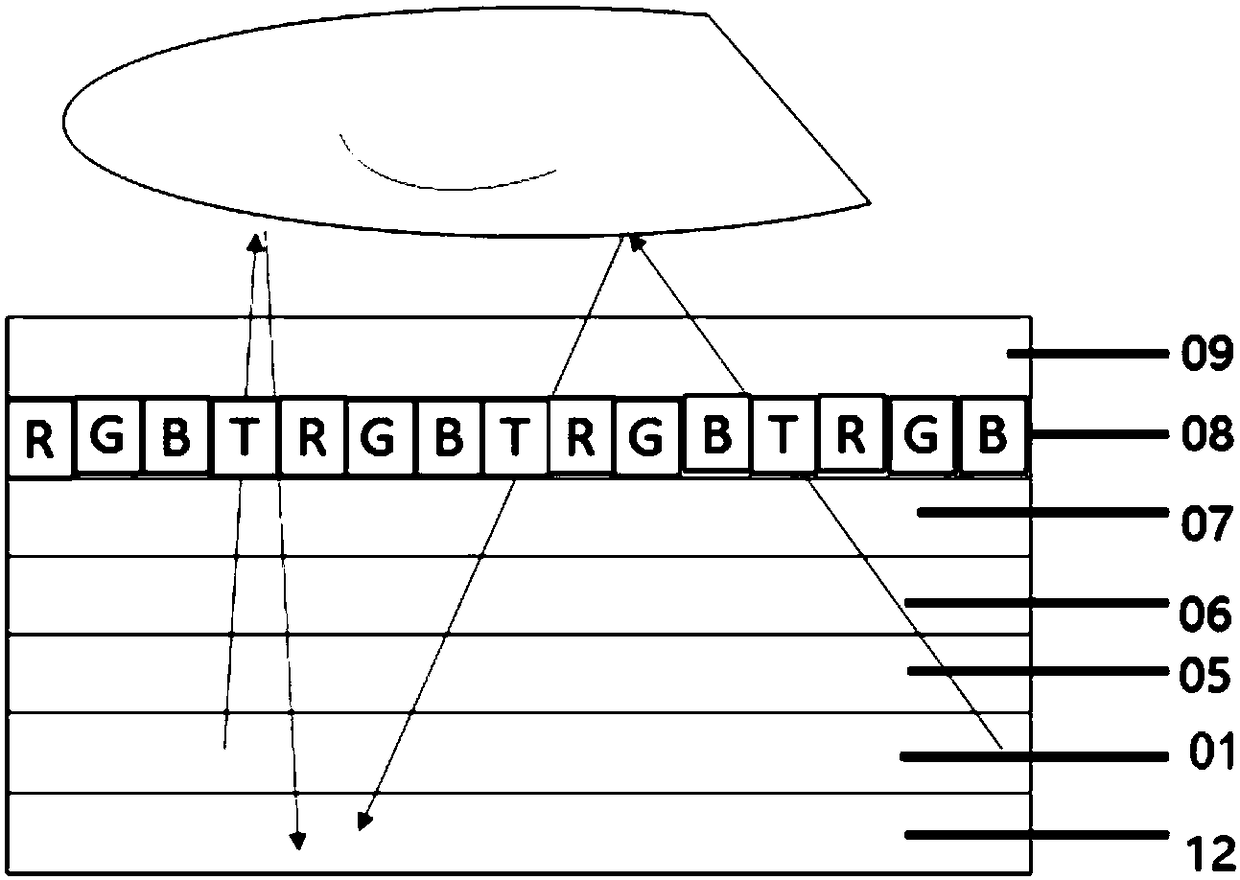

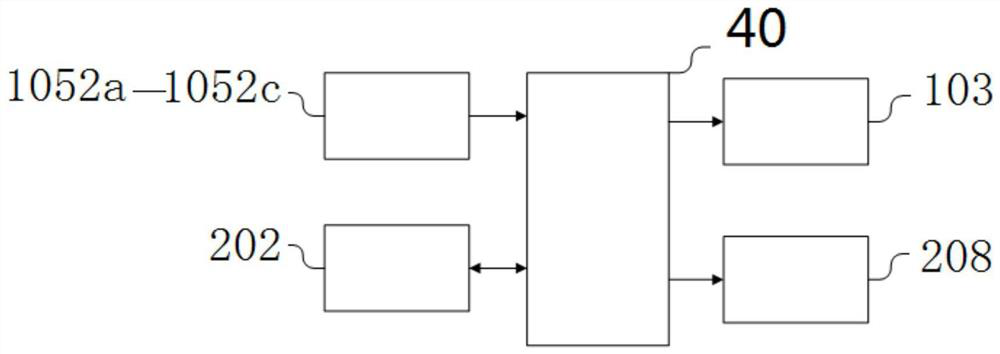

Liquid crystal display screen body with fingerprint recognition

PendingCN108957856AWith fingerprint recognition functionLight and thinSolid-state devicesPrint image acquisitionFingerprintLight characteristic

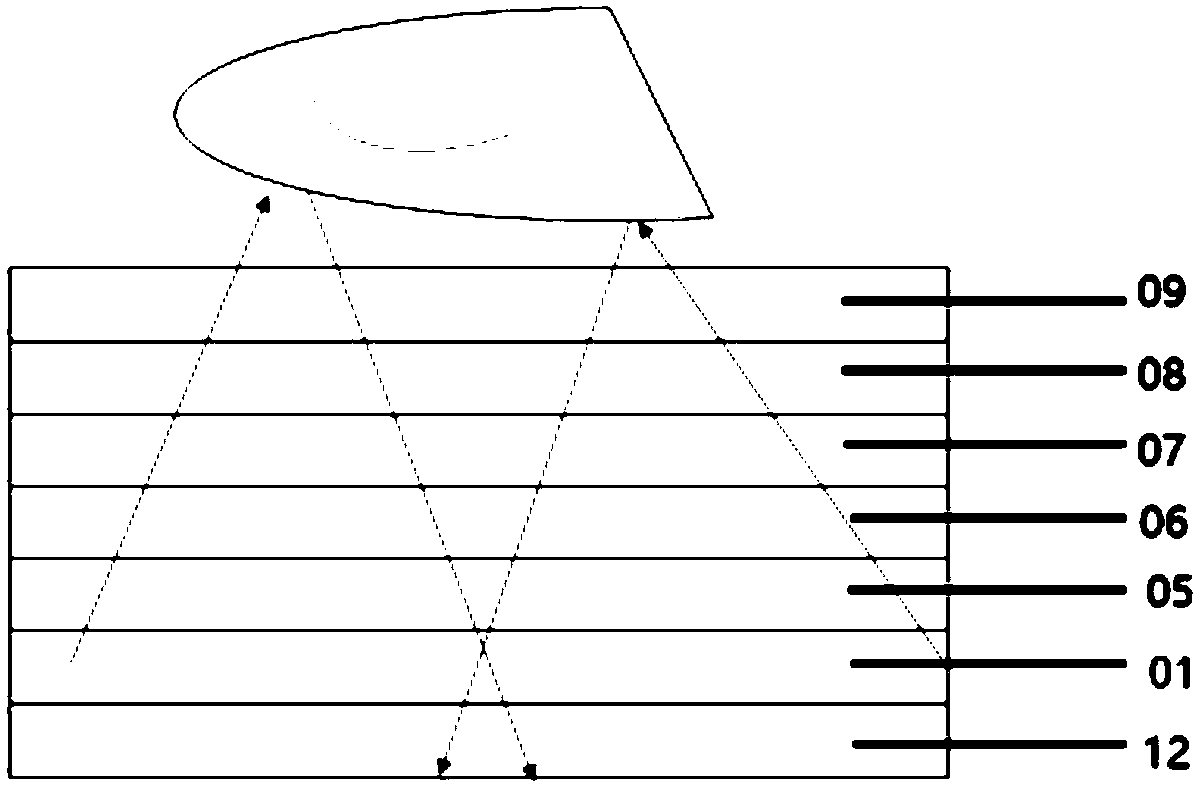

The invention provides a liquid crystal display device with a fingerprint recognition function. The liquid crystal display device comprises a liquid crystal display screen body and a backlight assembly, wherein the backlight assembly comprises a fingerprint recognition backlight module, and the liquid crystal display screen body is arranged on the side of a light-emitting direction of the fingerprint recognition backlight module. Because of the thin and light characteristics of the liquid crystal display screen body, the liquid crystal display screen body can easily integrate an under-screen optical fingerprint scheme. By means of a self-illumination characteristic of an OLED, and cooperating with a liquid crystal display screen, an OLED screen body replaces or partially replaces a previous LED and light guide backlight module, thereby overcoming the shortcoming that optical fingerprint recognition cannot be performed caused by a light guide plate problem, and an optical fingerprint recognition process is completed through the detailed design of an OLED illumination screen body.

Owner:GUAN YEOLIGHT TECH CO LTD

Novel loratadine oral quickly soluble film and preparation method thereof

InactiveCN106619577AImprove complianceQuick releaseOrganic active ingredientsPharmaceutical non-active ingredientsLoratadineEthanol

The invention relates to a novel loratadine oral quickly soluble film and a preparation method thereof. The oral quickly soluble film comprises the following components: loratadine, a surfactant, a film-forming material, a flavoring agent, a corrigent and a small amount of ethanol. The invention further provides a preparation method of the novel loratadine oral quickly soluble film. The oral quickly soluble film is small in size and convenient to carry; the dosage is convenient to control, a preparation process is simple and controllable, special production equipment is not required, the novel loratadine oral quickly soluble film is suitable for industrial massproduction, can be quickly dissolved in the oral cavity of a patient who does not need to drink water or chew, and tastes good; compliance of medication for children is greatly improved; the dissolution condition of the novel loratadine oral quickly soluble film in a citric acid-disodium hydrogen phosphate buffer solution with pH of 4.0 is remarkably better than the dissolution condition of commercially available tablets; and the novel loratadine oral quickly soluble film has significance on gerontal patients and other patients with achlorhydria.

Owner:CHINA PHARM UNIV

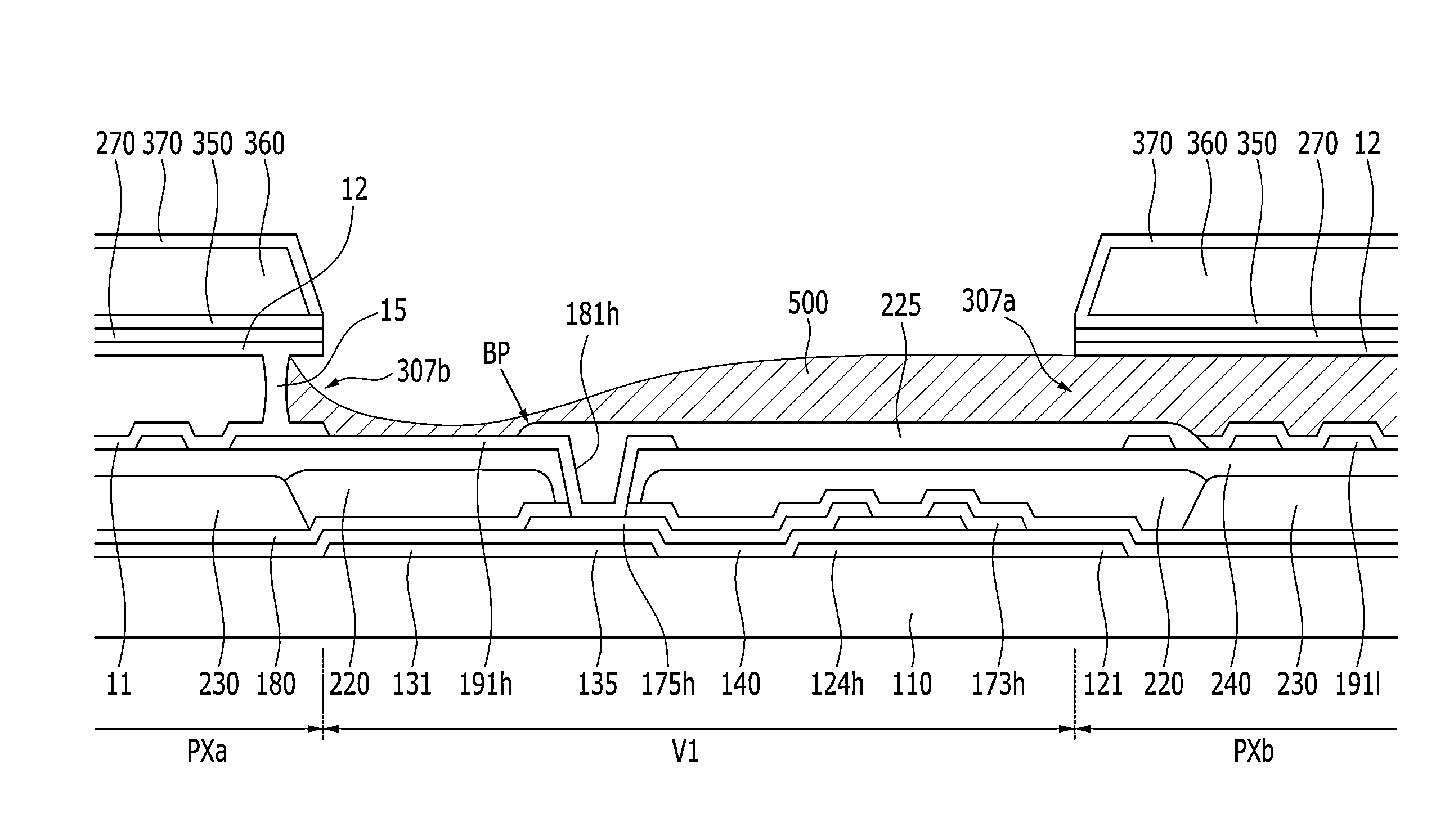

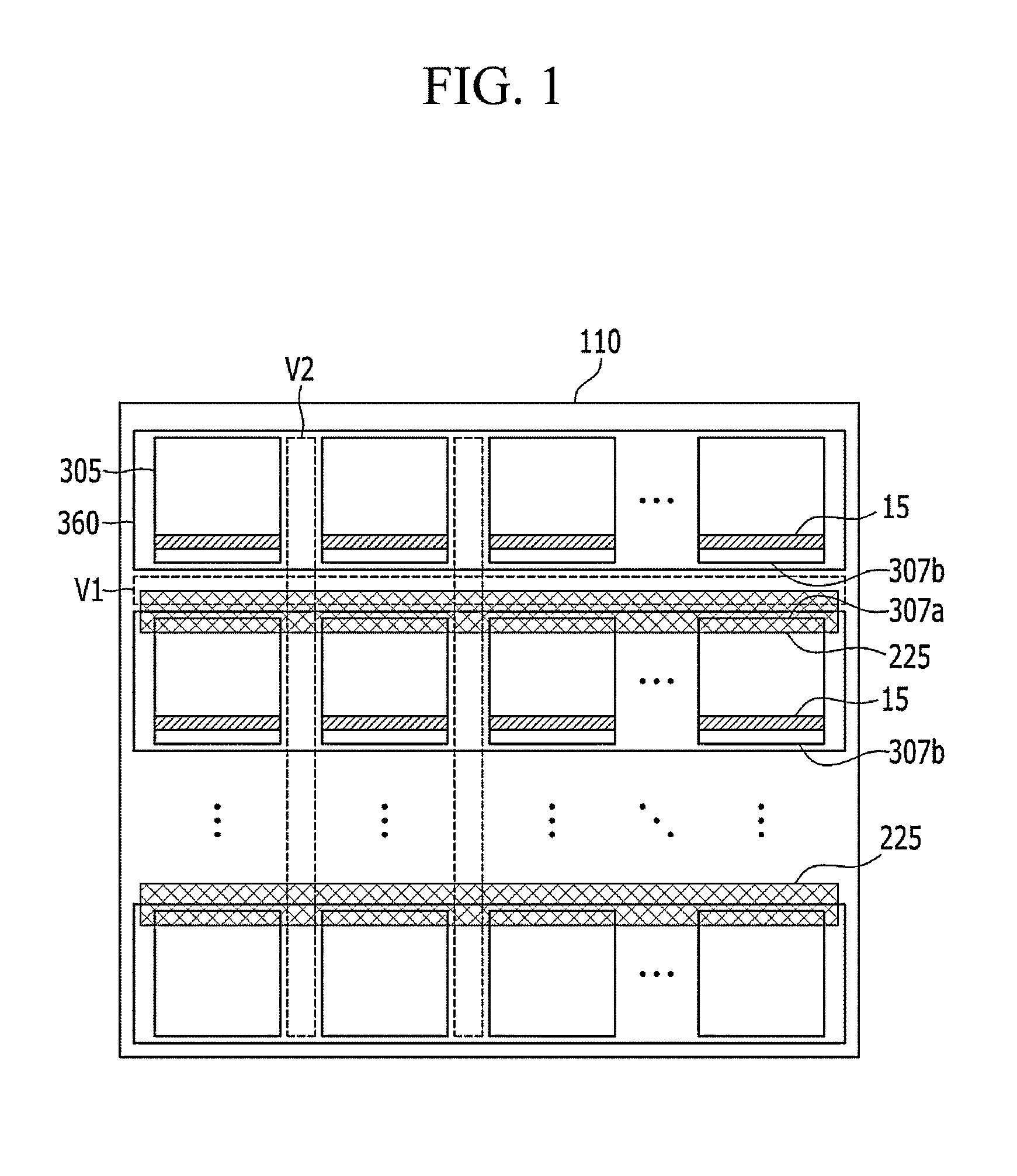

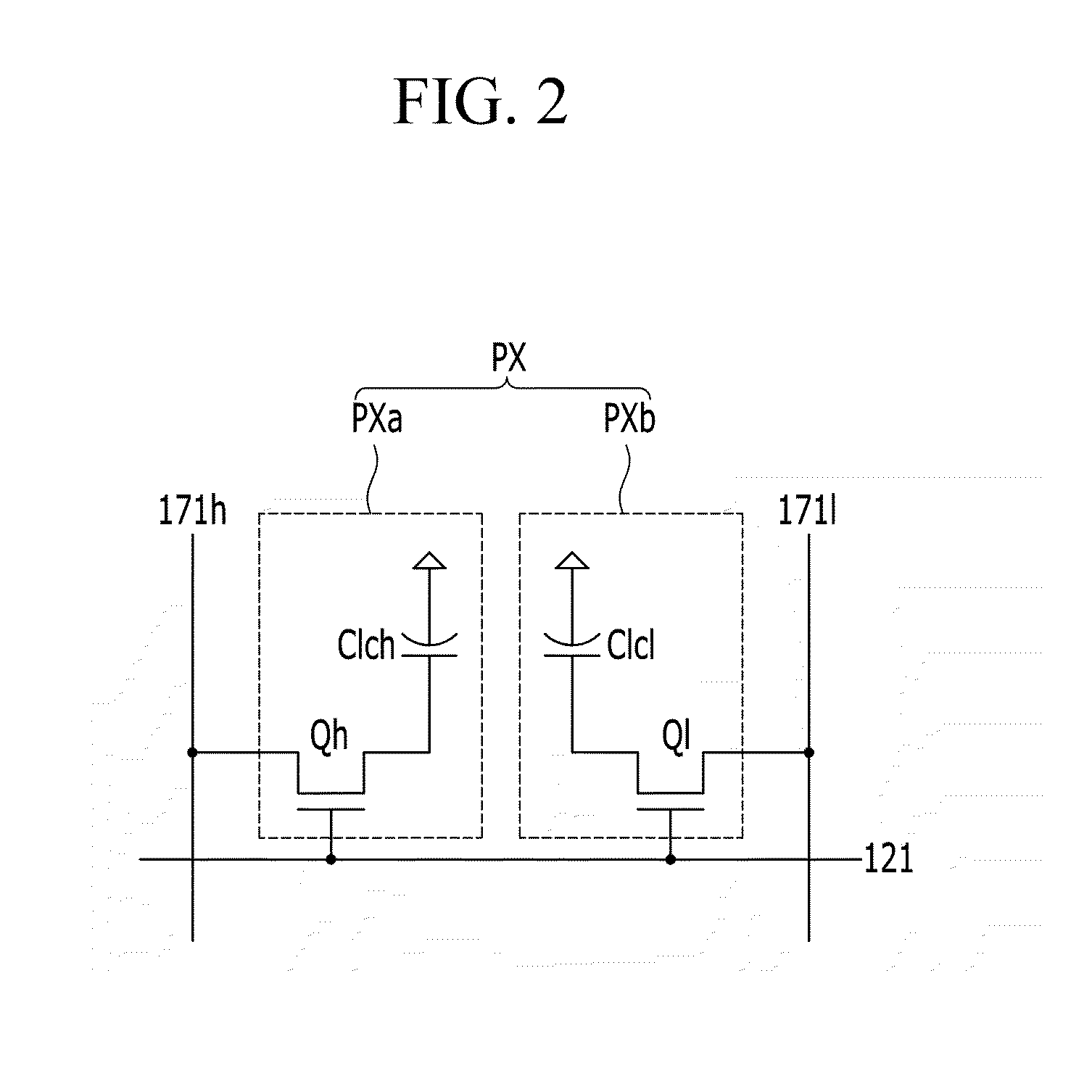

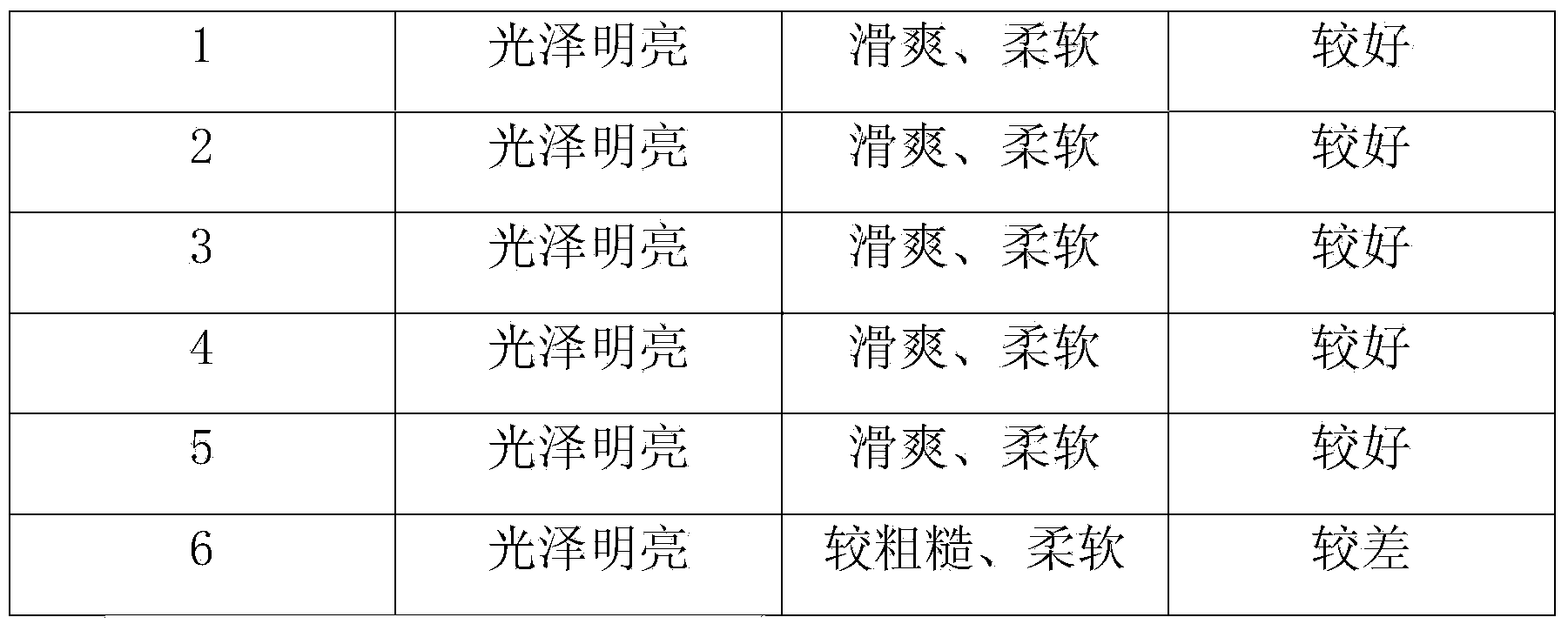

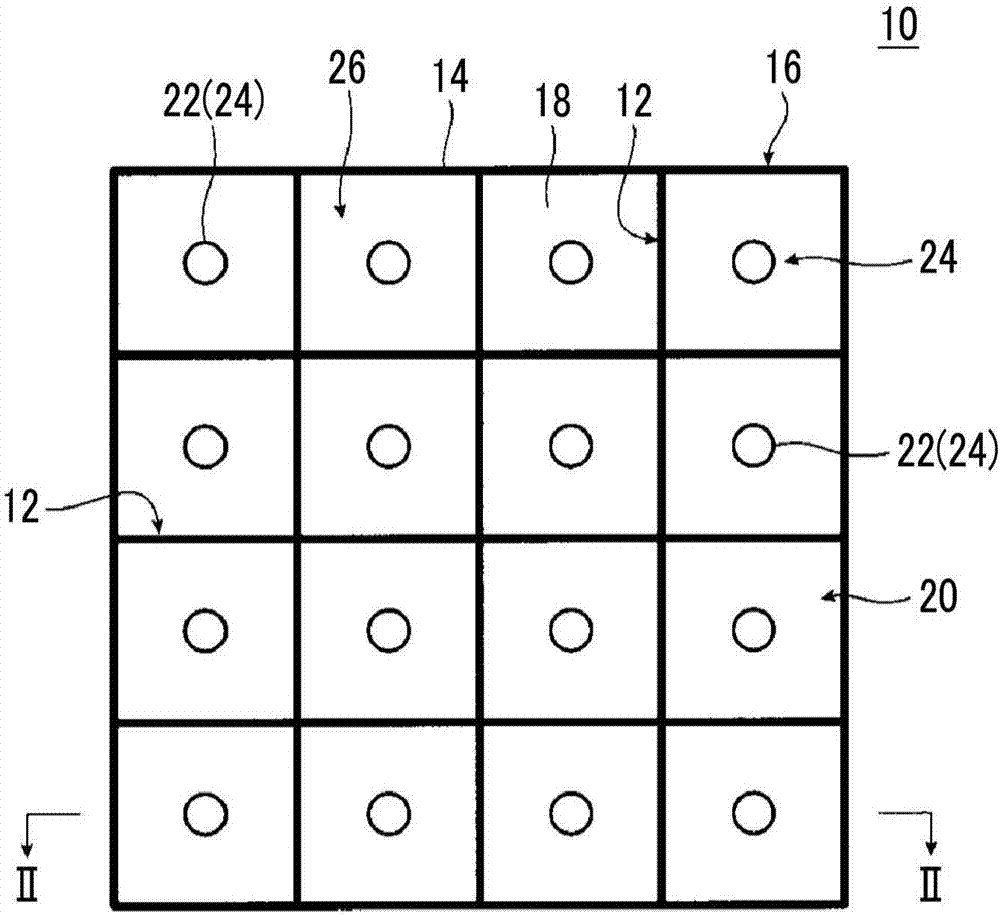

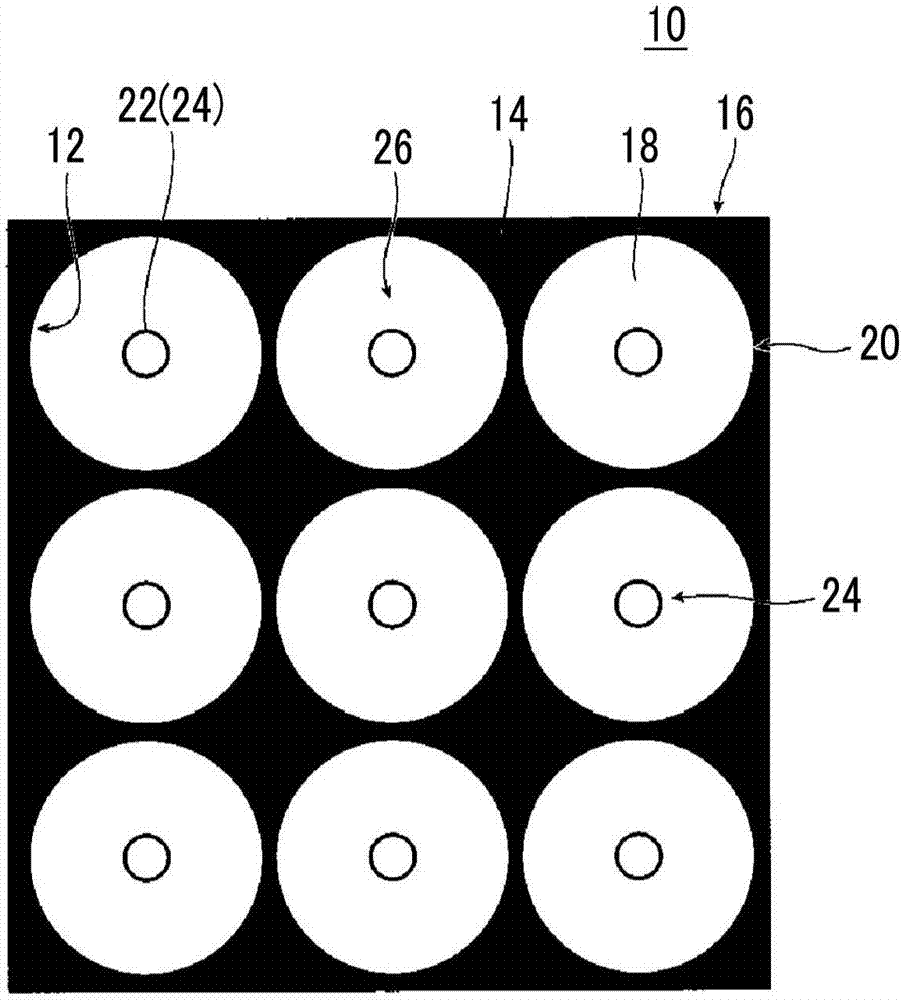

Display device

InactiveUS20150234215A1Reduce weightReduce thicknessNon-linear opticsLiquid-crystal displayDisplay device

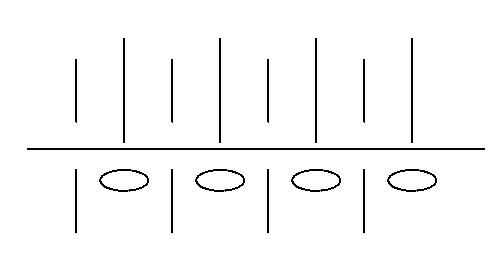

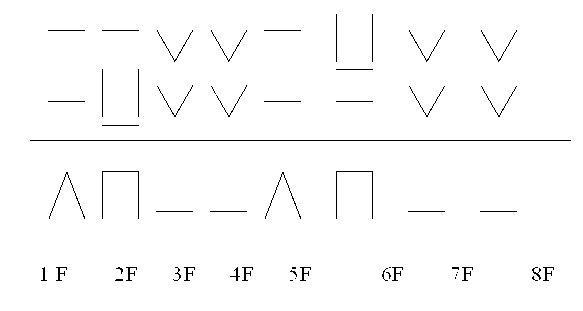

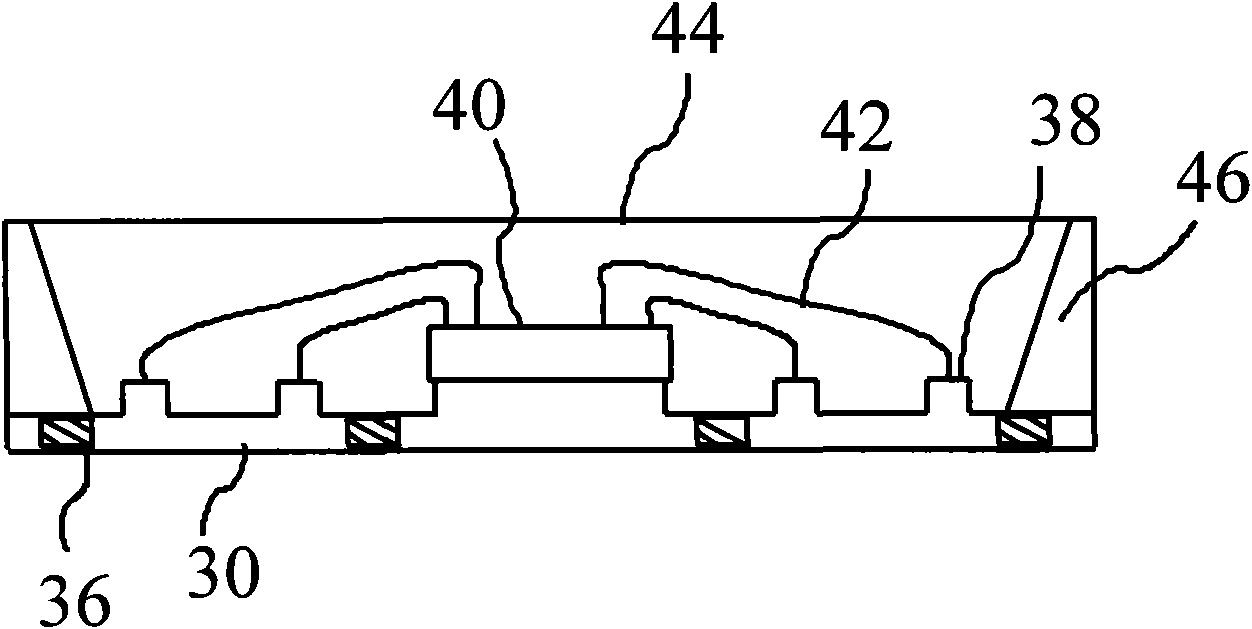

Provided is a display device capable of preventing a liquid crystal from being left outside a microcavity. The display device includes: a substrate; a pixel electrode formed on the substrate; a roof layer formed on the pixel electrode so as to be spaced apart from the pixel electrode with a plurality of microcavities therebetween; a light blocking member positioned between two microcavities of the plurality of microcavities, overlapping with a first edge of one microcavity of the two microcavities, and not overlapping with a second edge of the other microcavity; an injection hole exposing a part of the microcavity; a liquid crystal layer filling the microcavity; and an encapsulation layer formed on the roof layer so as to cover the injection hole to seal the microcavity.

Owner:SAMSUNG DISPLAY CO LTD

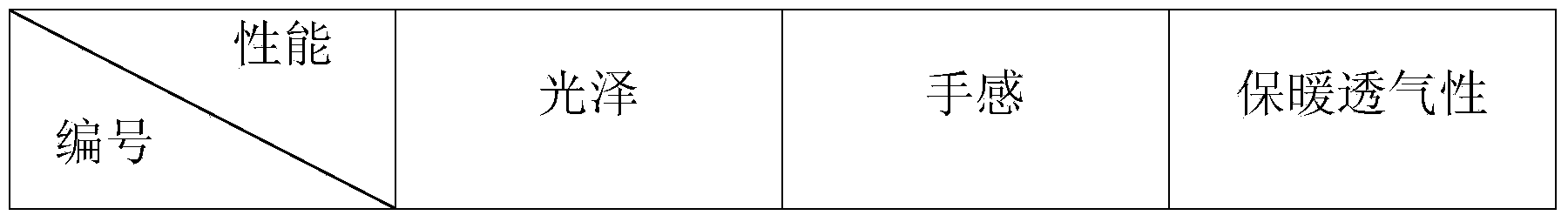

Compound thermal insulation material eiderdown flocculus and making process thereof

InactiveCN102720002ACost-effectiveAffordable priceNon-woven fabricsAdhesivesThermal insulationChemistry

The invention relates to a compound thermal insulation material eiderdown flocculus taking eiderdown, mainly duck down and goose down as the main materials and the making process thereof. The compound thermal insulation material eiderdown flocculus is made by the eiderdown, mainly the duck down and the goose down as well as synthetic fabric, wherein the synthetic fabric is made by meldable fiber and tencel fiber in the weight ratio of 13 to 18:6-15; the mixing ratio of the eiderdown and the synthetic fabric is set by the contents required by the finished eiderdown product; and during making, the animal eiderdown is the main material and the meldable fiber and tencel fiber are the auxiliary materials, and the materials are made into the compound thermal insulation material with 65% content of eiderdown according to different ratios. The compound thermal insulation material eiderdown flocculus not only has the thermal insulation characteristic of the eiderdown and cashmere products, but also is environment-friendly, has spinnability and cuttability, rather lower cost, simple and mature process, easiness for operation and big market potential.

Owner:河北兴瑞羽绒制品有限公司

Large particle dry mixing stone imitation outer-wall brick manufactured by granite stone plate processing tailing and manufacturing method thereof

InactiveCN101011843ASolve environmental problemsHigh strengthCeramic shaping apparatusClay processing apparatusSpray GranulationBrick

The stone imitation outer wall using big particle blended granite slab tailing processing comprises the optimal combination of tailing, clay, talcum powder, china clay, adding dry mixing pigment and artificial big particle for dry mixing, forming, furnishing, and high temperature burning after adequate broken mixing and color tuning spray granulation. It is environment friendly, economical, strong strength, resistant to contamination and acid, with simple process, convenient operation and mimic granolithic stone.

Owner:南安协进建材有限公司

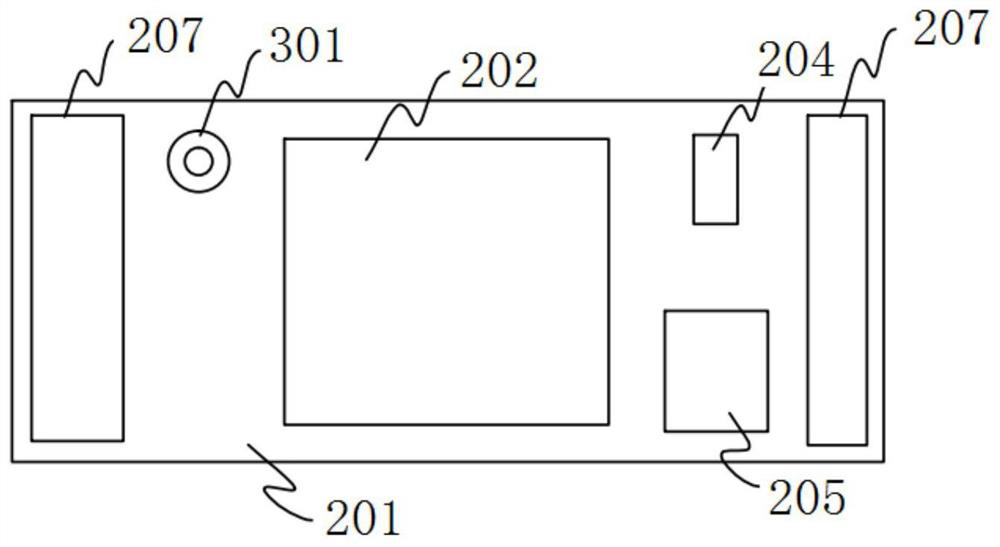

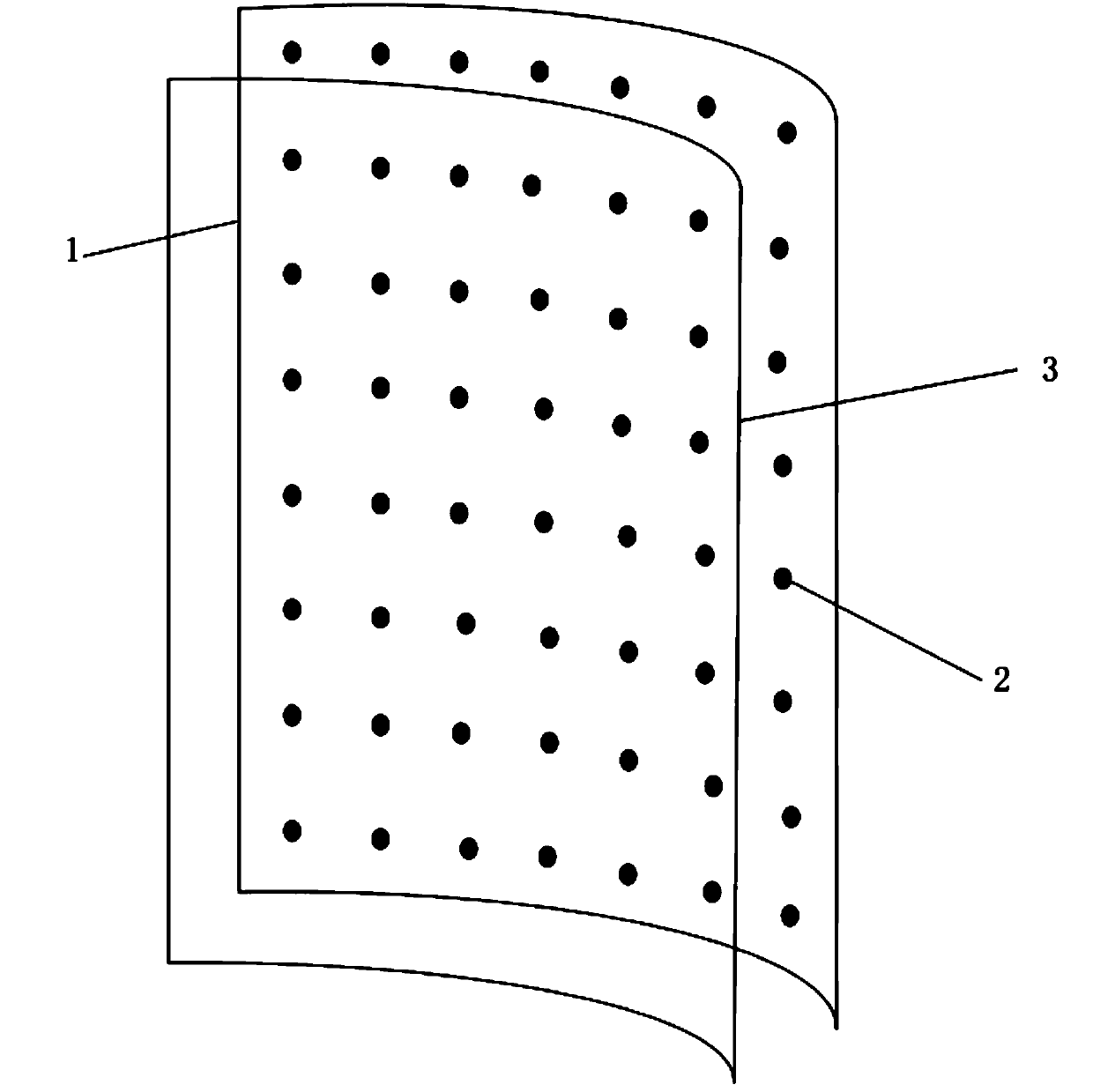

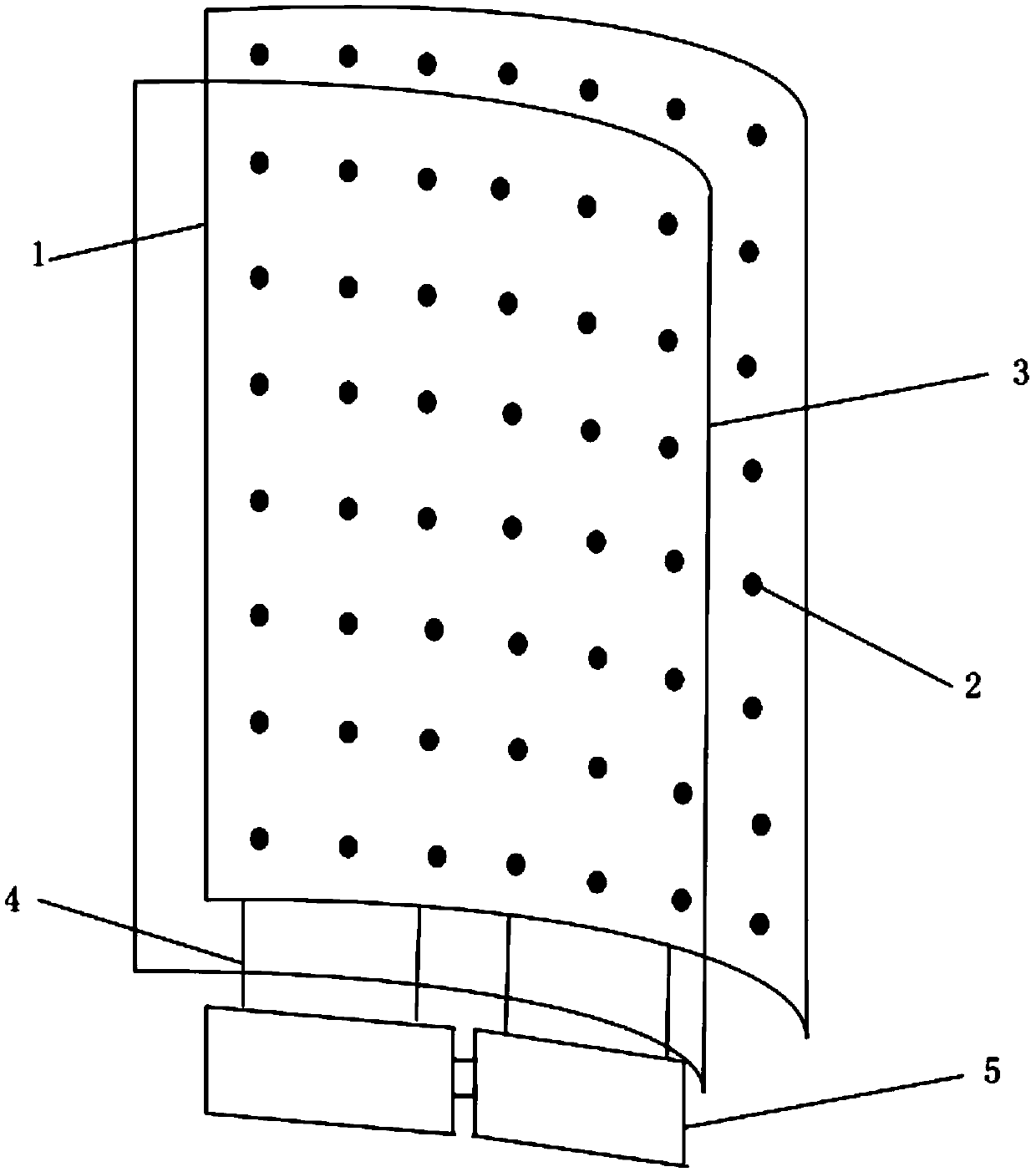

Optical medical device

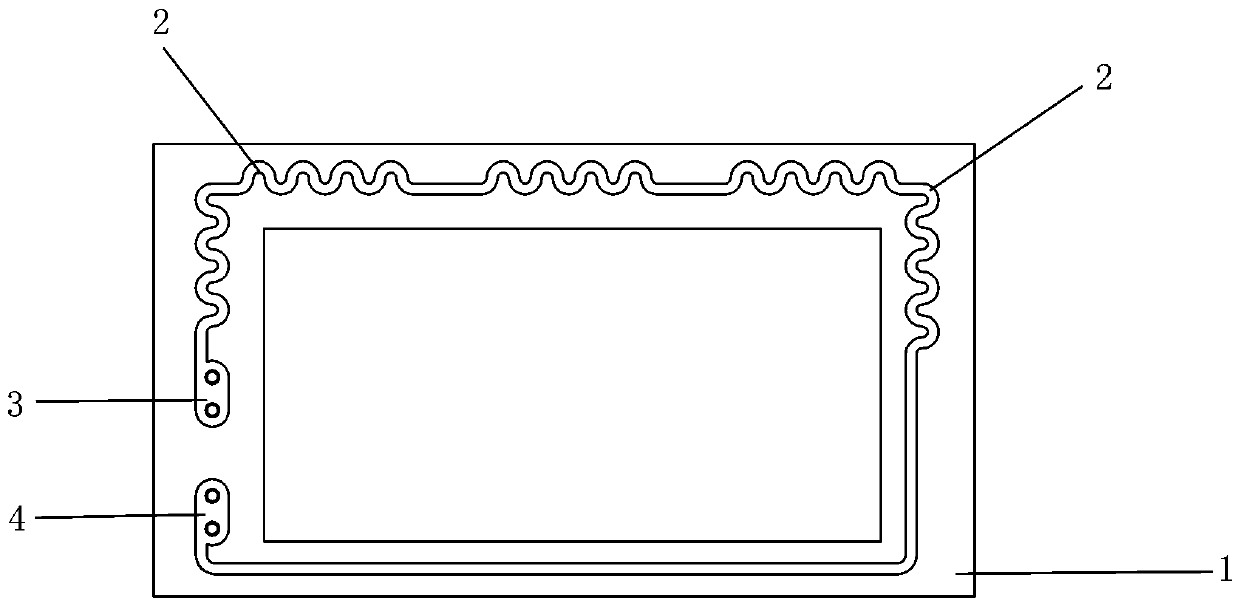

PendingCN111840809AGood uniformity of light emissionLong treatment cycleLight therapyPhysicsEngineering

The invention discloses an optical medical device which comprises a light source part and a power supply part, the light source part is electrically connected with the power supply part; the light source part comprises base cloth, a connecting layer, a light source layer and a covering layer, the connecting layer is laminated on the base cloth, the light source layer is laminated on the connectinglayer, the covering layer is of a light-transmitting structure, is laminated on the light source layer and covers the light source layer and the connecting layer, and the power supply part is used for lightening the light source layer. The light source layer has the characteristics of good light-emitting uniformity, lightness, thinness, bendability, flexibility, stretchability and the like and can be completely attached to a to-be-phototreated part of a patient so that the problems that an existing optical medical device is inconvenient to wear and damages normal tissues can be well solved, the design is more user-friendly, and the comfort and safety of user experience are guaranteed.

Owner:GUAN YEOLIGHT TECH CO LTD

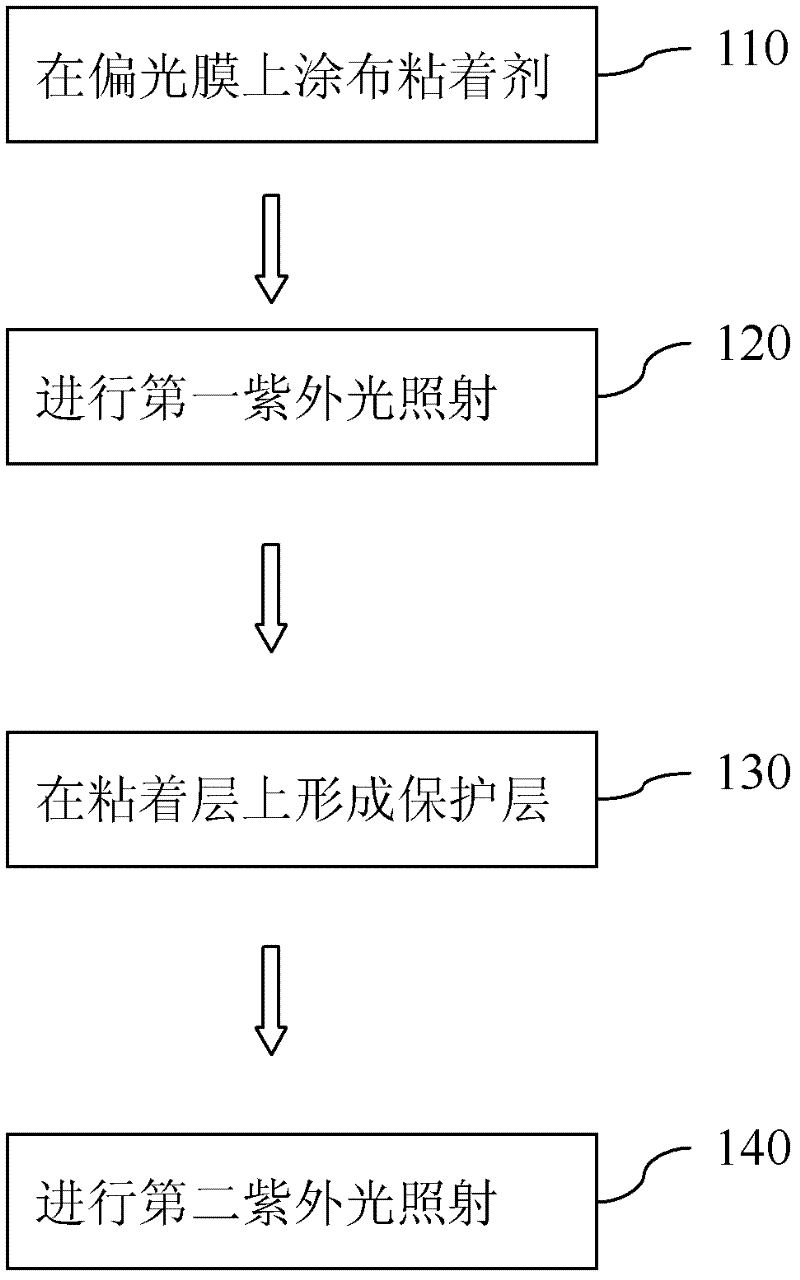

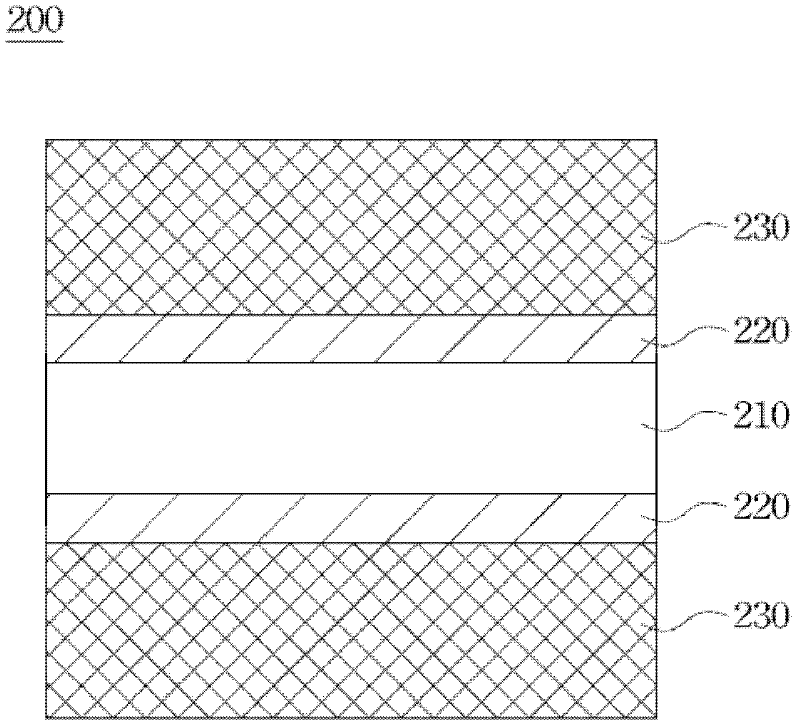

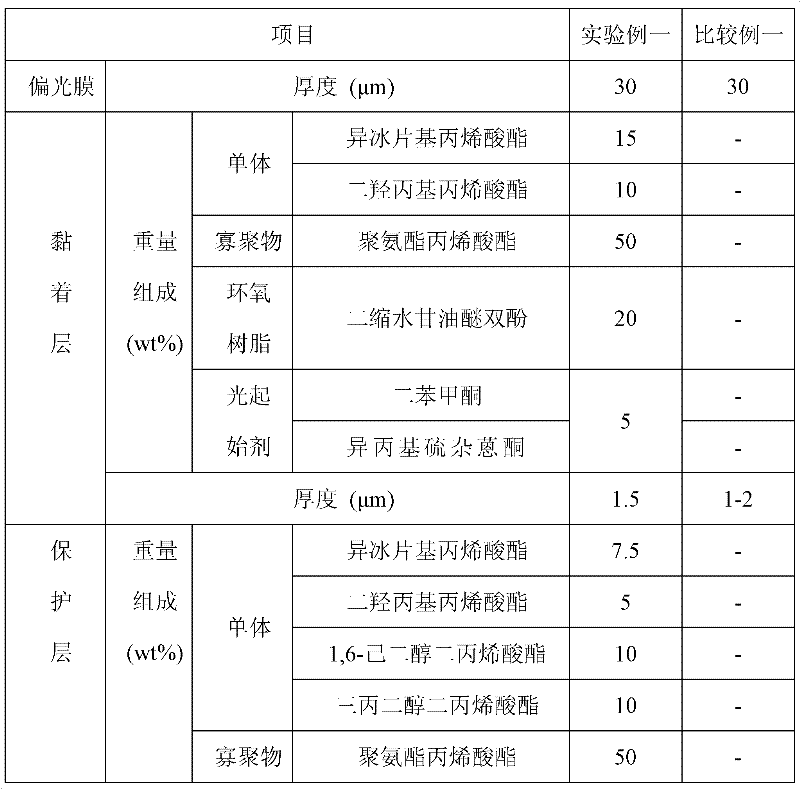

Polarizer and manufacturing method thereof

ActiveCN102269838AGood weather resistanceLight and thinFilm/foil adhesivesPolarising elementsOligomerAdhesive

The invention relates to a polaroid and a manufacturing method thereof. The manufacturing method comprises the following steps of: firstly, coating an adhesive on at least one surface of a polarizing film to form an adhesive layer, wherein the adhesive comprises an acrylic monomer with 1-2 acrylic groups, an acrylic oligomer and a photoinitiator; then carrying out primary ultraviolet irradiation to irradiate ultraviolet light on the adhesive layer to partially solidify the adhesive layer; then forming a protection layer on the adhesive layer, wherein the protection layer includes ultraviolet-curable materials; and finally, carrying out secondary ultraviolet irradiation to irradiate ultraviolet light on the protection layer and the adhesive layer so that the protection layer and the adhesive layer are completely solidified to obtain the polaroid. In the manufacturing method of the polaroid provided by the invention, a heating step is not used so that the equipment cost and the product manufacturing cost are reduced favorably.

Owner:BENQ MATERIALS +1

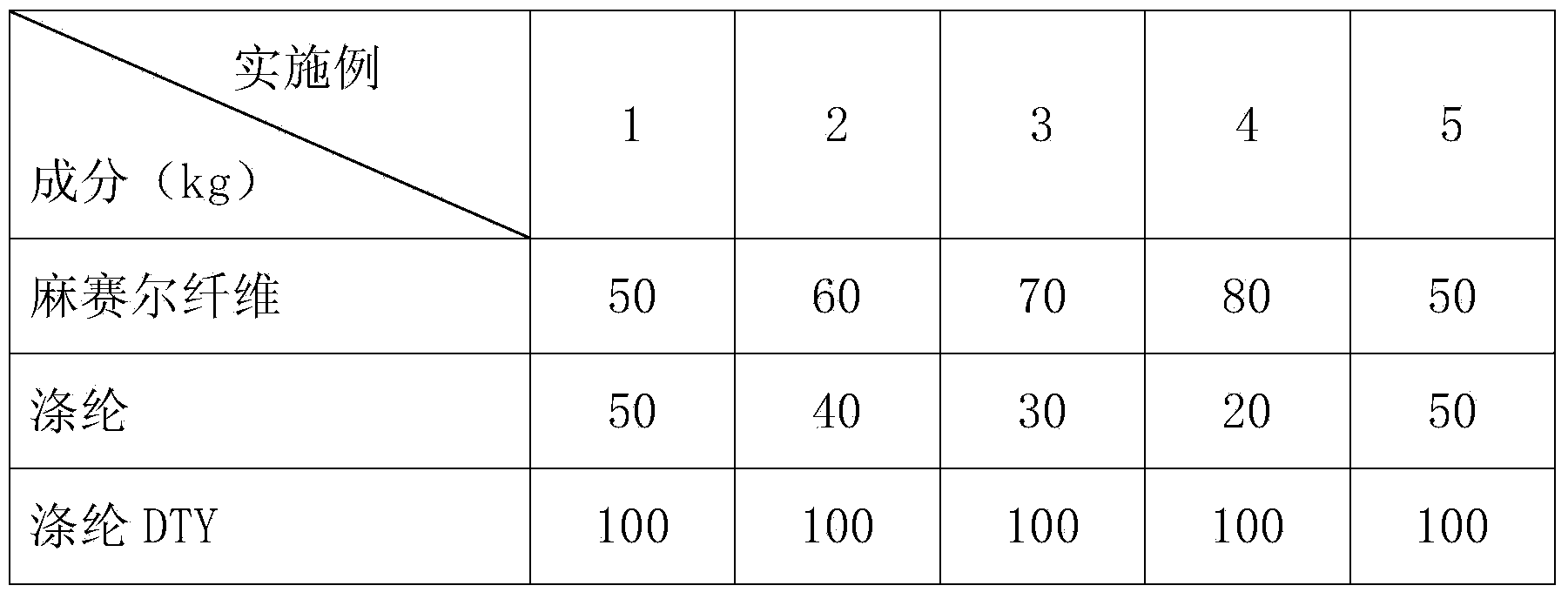

Jutecell fiber Raschel blanket and technology for manufacturing Jutecell fiber Raschel blanket

ActiveCN104109940ALight and thinAntibacterial and antifungalWarp knittingLiquid/gas/vapor removalFiberPulp and paper industry

The invention belongs to the field of production of functional Raschel blankets and relates to a Jutecell fiber Raschel blanket and the technology for manufacturing the Jutecell fiber Raschel blanket. The Jutecell fiber Raschel blanket comprises face yarn and ground yarn, wherein the face yarn is composed of, by weight, 50%-80% of Jutecell fibers and 20%-50% of Dacron fibers, and the ground yarn is composed of, by weight, 100% of DTY. The Jutecell fiber Raschel blanket is formed by weaving blended yarn of 50% of Jutecell fibers and 50% of Dacron fibers and long Dacron filaments on a warp knitting machine. The Jutecell fiber Raschel blanket obtained through weaving is smooth in hand feeling, bright in color and full and smooth in cloth tissue, has the good moisture absorbing and discharging function and the good anti-bacteria and anti-mold function, and is capable of absorbing moisture, breathable, fluffy, soft, extremely comfortable and skin-friendly.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Sound insulation structure and method for manufacturing sound insulation structure

ActiveCN107408378ALight and thinImprove sturdinessSound proofingSound producing devicesNatural resonanceEngineering

A sound insulation structure having one or more sound insulation cells, wherein: each of the one or more sound insulation cells is provided with a frame having through holes, a film affixed to the frame, and an opening part formed from one or more holes penetrating the film; both end parts of the through holes in the frame are not closed; and the sound insulation structure has, on the low-frequency side of a first natural resonance frequency for the film of the one or more sound insulation cells, a masking peak frequency that is determined due to the opening parts of the one or more sound insulation cells and for which transmission loss is maximum, and selectively insulates sound of a fixed frequency band centered on the peak masking frequency. Thus, it is possible to provide a sound insulating structure that is lightweight and thin, is not dependent on the position and shape of holes, has high robustness as an acoustic insulator, has stability, has air permeability, does not retain heat, and has excellent manufacturing suitability, and a manufacturing method for the sound insulating structure.

Owner:FUJIFILM CORP

Production process of high count, high density, waterproof and moisture permeable cotton-polyester fabric

InactiveCN109295592AYarn is drySoft touchSucessive textile treatmentsWoven fabricsCombingWoven fabric

The invention discloses a production process of a high count, high density, waterproof and moisture permeable cotton-polyester fabric. The process includes the following steps of material selection, warping, sizing, drafting and drawing-in, weaving, dyeing and finishing pretreatment, dyeing, windproof finishing, foam shaping, application of a composite waterproof and moisture permeable film, rolling, packing and warehousing. According to the production process of the high count, high density, waterproof and moisture permeable cotton-polyester fabric, combing long stapled cotton yarn of 40-80 Sis used as warp yarn, the yarn evenness is good, the hand feeling is soft, and the strength is good. The diameter of the yarn is small, and thus the woven fabric li light and thin. The used superfine, bright, polyporous polyester filament yarn has more pores compared general polyester filament yarn, and the moisture absorption property and the air permeability can be improved. On the premise of not reducing the air permeability of the down-feather-proof fabric, the cost of the down-feather-proof fabric is reduced, then the fabric is compounded with the waterproof and moisture permeable film,so that the fabric has not only the down-feather-proof effect but also the waterproof and moisture permeable function, and the fabric does not cause a muggy phenomenon in the use process.

Owner:沈玉芳

LED display screen formed by transparent film and manufacturing method thereof

InactiveCN109585629ALight and thinWith retractableIdentification meansSemiconductor devicesLED displayFlexible circuits

The invention discloses an LED display screen formed by a transparent film and a manufacturing method thereof. The display screen comprises a flexible transparent film, a conductive film circuit, LEDchips, a flexible circuit board and a driving strip. The flexible transparent film is an insulating non-conductive film, the conductive film circuit is plated on the flexible transparent film by coating, and the LED chips are attached to the flexible transparent film according to a predetermined arrangement and are connected to the conductive film circuit. The LED flexible display screen of the invention adopts the flexible transparent film and is light and thin, retractable and freely designed, and the human needs can be satisfied to a certain extent. According to the LED flexible display screen of the invention, laser is used to etch a circuit, the line width is controlled well to ensure the uniform impedance, so the brightness of each LED chip is the same, the brightness of display information content is uniform, and a multi-layer effect can be achieved by the cross wiring of the circuit.

Owner:DALIAN JISITE TECH

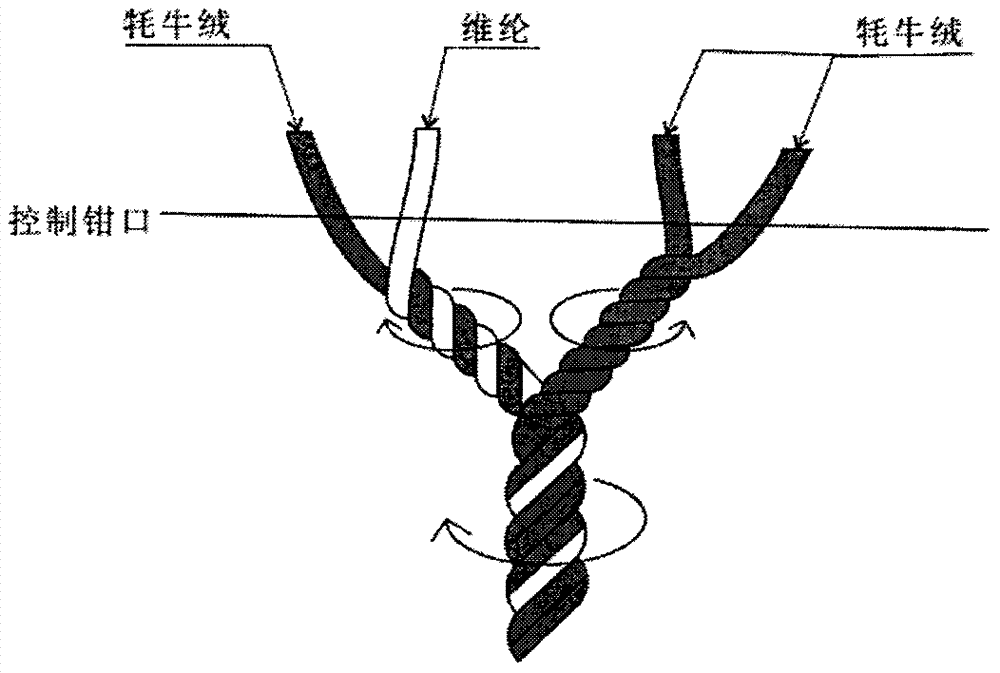

Production method of yakwool hollow yarn

The invention discloses a production method of yakwool hollow yarn. The production method comprises the following steps: taking vinylon as core yarn and yakwool as covering yarn, respectively spinning vinylon roving and yakwool roving by use of semi-worsted spinning, feeding four roving into a ring spinning frame in parallel at the same time by following compact siro spinning, wherein the yakwool roving is three, and the vinylon yarn is one; feeding the vinylon roving from the left second hole of a four-hole horn mouth so that the vinylon roving is centered; therefore, the effect of covering the yakwool on the vinylon can be well realized. By use of the yarn method disclosed by the invention, the process of spinning the core yarn as the spun yarn is omitted, the process flow is shortened, and the effect of being similar to core spun yarn is achieved. And meanwhile, the yakwool only needs to be processed as roving, the procedure that the yakwool is hard to be processed as the spun yarn due to short and thick characteristics is avoided. Finally, a hollow yarn structure is formed by the yarns in the fabric after the dissolution by use of the fabric dissolution method, the air is trapped, the warm keeping coefficient is increased, and the formed fabric has the features of being light and thin, soft, and moisture-absorbing and quick in drying.

Owner:TIANJIN POLYTECHNIC UNIV

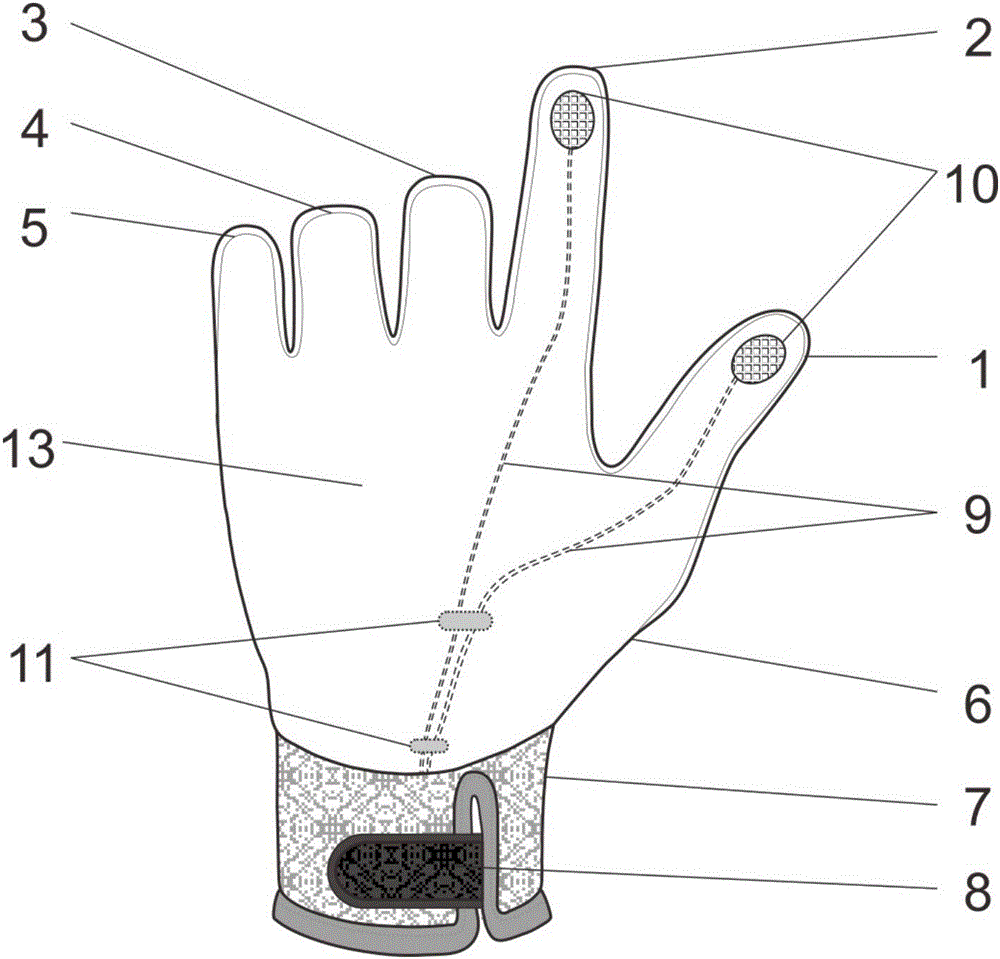

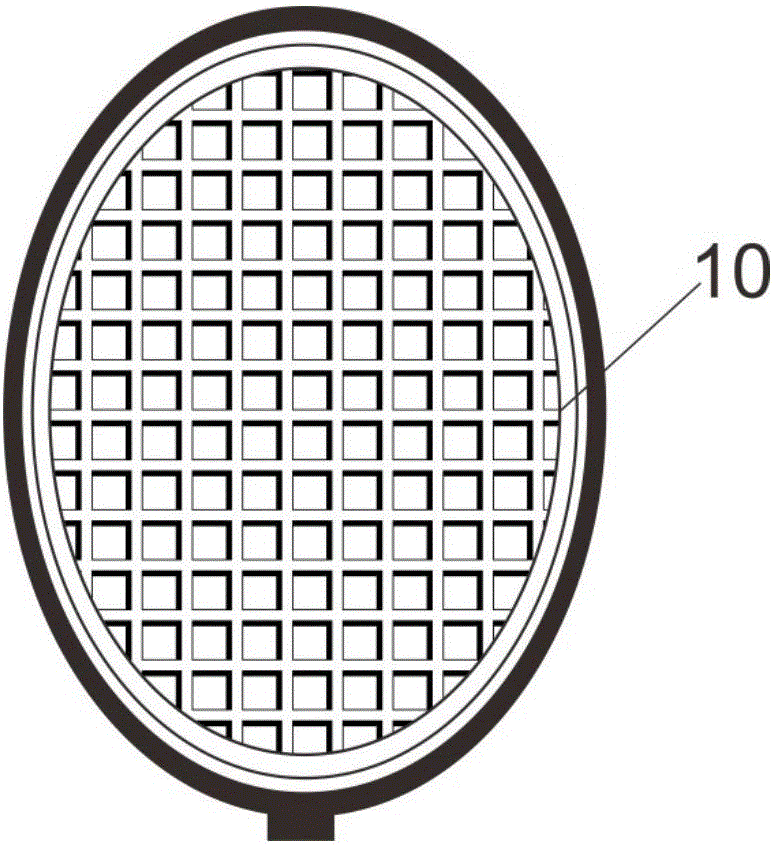

Glove-type ultrasonic probe

InactiveCN105902283AExpand the scope of applicationVarious inspection methodsOrgan movement/changes detectionInfrasonic diagnosticsUltrasound testData transmission

The invention discloses a glove-type ultrasonic probe. The glove-type ultrasonic probe consists of a glove body, ultrasonic transducer assemblies and data transmission lines; the glove body comprises fingers, a palm and a wrist; the fingers comprise a thumb, an index finger, a middle finger, a ring finger and a little finger; an ultrasonic transducer assembly is arranged at the fingertip position of each of the thumb and the index finger; the middle finger, the ring finger and the little finger are all half-fingers. According to the glove-type ultrasonic probe, the ultrasonic transducer assemblies have the advantages of flexibility, lightness and thinness; good coupling between the probe and an examined part can be realized by only relying on slight fingertip force; the glove-type ultrasonic probe can be used for ultrasonic examination of any complex curve surface and space limited part; the application range of the ultrasonic probe is greatly widened. The glove-type ultrasonic probe is convenient to wear and easy to operate; clinical palpation and ultrasonic detection can be performed simultaneously by a doctor; operating steps are simplified, and meanwhile, the misdiagnosis rate and the missed diagnosis rate are greatly reduced.

Owner:JILIN UNIV

Multi-layer protein fiber composite fabric for male clothes

InactiveCN104287258AMoisture-absorbing and breathableLight and thinGarment special featuresCellulosic plastic layered productsSurface layerMoisture absorption

The invention discloses a multi-layer protein fiber composite fabric for male clothes. The fabric comprises a first protein fiber fabric layer as a surface layer, a second protein fiber fabric layer and a third protein fiber fabric layer, wherein the first to third protein fiber fabric layers all adopt net-shaped structures formed by interweaving warps and wefts; the warps of the first protein fiber fabric layer are made from soybean protein fibers, and the wefts of the first protein fiber fabric layer are made from milk protein fibers; the warps of the second protein fiber fabric layer are made from silkworm pupa protein fibers, and the wefts of the second protein fiber fabric layer are made from casein fibers; the warps of the third protein fiber fabric layer are made from wool keratin fibers, and the wefts of the third protein fiber fabric layer are made from pearl protein fibers. The fabric is formed by compounding three layers of structures, and has the characteristics of moisture absorption, breathability, light weight, thinness, softness, comfortableness, elasticity and good close-fitting effect.

Owner:苏州艾宸服饰有限公司

Natural thermal effect composite fabric knitting fabric and knitting method thereof

InactiveCN102995261ALight and thinHas natural moisture absorption and heat generationWeft knittingYarnYarnEngineering

The invention provides a knitting method of a natural thermal effect composite fabric knitting fabric. The knitting method is characterized in that wool fiber blended yarns, kam ammonia wrapped yarns and modal are selected to perform interweaving, composite ribs combining plain stitch and rib stitch are adopted, the plain stitch adopts the modal to perform knitting, the rib stitch adopts biological fine-drawn wool / mucilage glue / kapok blended yarns to perform knitting, and the three-layer composite tissue is knitted. The inner surface of the fabric is a comfortable warm-keeping surface, the outer surface of the fabric is a moisture-absorption heat-dissipation warm-keeping surface, and the middle surface of the fabric is a high-elastic comfortable layer formed by wrapped yarns. By means of the knitting method, the elasticity of the fabric is improved, and multifunctional effects of moisture absorption, heat dissipation and the like of the wool, kapok and multi-fiber blended interwoven fabric can be fully achieved. The natural thermal effect composite knitting fabric is knitted by means of selection of raw materials and reasonable organization structures and has the advantages of being light, thin, fashionable, good in breathability and capable of absorbing moisture and dissipating heat naturally.

Owner:QINGDAO XUEDA GRP

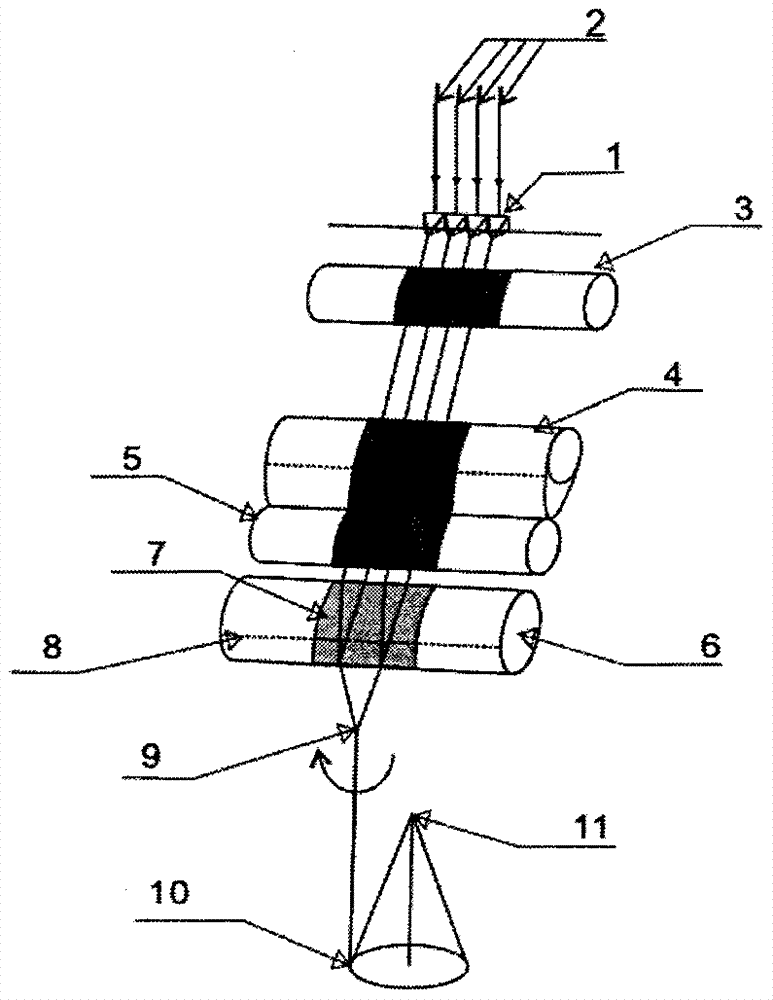

Method for forming traffic sign

InactiveCN101469836AExpand field of viewLight evenlyMechanical apparatusRoad vehicles traffic controlLight guideEffect light

The invention relates to a method for forming traffic light, comprising providing a light-guiding body, printing diffusion dots on the light-guiding body, preparing an optical film, bonding the optical film on the light-guiding body, using at least a light source which emits the light into the light-guiding body, so as to produce a surface light source with high uniformity, and forming traffic indication signs on the surface of the optical film, therefore the traffic light with uniform lighting and thin thickness, and the light source can use LED with advantages of power saving.

Owner:PONTEX POLYBLEND

Heat-radiation packaging structure and packaging method

InactiveCN101685808AImprove heat transfer efficiencyShort cooling pathSemiconductor/solid-state device detailsSolid-state devicesColloidEngineering

The invention discloses a heat-radiation packaging structure and a packaging method which utilize a metal basal plate. The metal basal plate is provided with a plurality of conductive joints, a plurality of insulators, at least one chip, at least one light reflecting mirror and a packaging colloid, wherein the insulators are positioned in the metal basal plate and are arranged between the conductive joints; the chip is installed at the surface of the metal basal plate and is electrically connected with the conductive joints by a plurality of leading wires, and heat energy generated by the chipis dispersed by the metal basal plate; the light reflecting mirror is arranged at the periphery of the metal basal plate and increases the reflection efficiency of a light source; and the packaging colloid covers and protects the metal basal plate. The invention can maintain a favorable heat-radiation effect, simplify the packaging structure and the manufacturing procedure, and lower the production cost.

Owner:何昆耀

Double-layered composite skincare fiber shell fabric

The invention discloses a double-layered composite skincare fiber shell fabric. The double-layered composite skincare fiber shell fabric comprises two fiber shell fabric layers which are of netty structures interwoven by warps and wefts, wherein the warps of the first composite fiber shell fabric layer are bamboo fibers and the wefts are Tancel fibers; the warps of the second composite fiber shell fabric layer are milk fibers and the wefts are pearl fibers. The shell fabric disclosed by the invention is compounded by a two-layer structure and has the characteristics of smoothness, ventilation, lightness and thinness, flexibility, comfort, and elasticity, and is fitted and skincare.

Owner:南安市荣兴专利技术转移中心有限公司

High temperature-resistant flame retardation blend fiber

InactiveCN105040217AHigh temperature and flame retardantHigh strengthYarnProtective garmentCarbon fibersPolymer science

The invention discloses a high temperature-resistant flame retardation blend fiber a first high temperature-resistant flame retardation fiber and a second high temperature-resistant flame retardation fiber blend-weaved with the first high temperature-resistant flame retardation fiber. Carbon fibers, calcium alginate fibers and flam retardation polypropylene fibers are blend-weaved to form the first high temperature-resistant flame retardation fiber; melamine fibers, aramid fibers and basalt fibers are blend-weaved to form the second high temperature-resistant flame retardation fiber. The high temperature-resistant flame retardation blend fiber is weaved by various fibers in a blending way and is characterized by high temperature retardation property, strong strength, light weight, great safety and great durableness.

Owner:TAICANG LIANGXIN CHEM FIBER CO LTD

Polyester thin film heating sheet and preparation method therefor

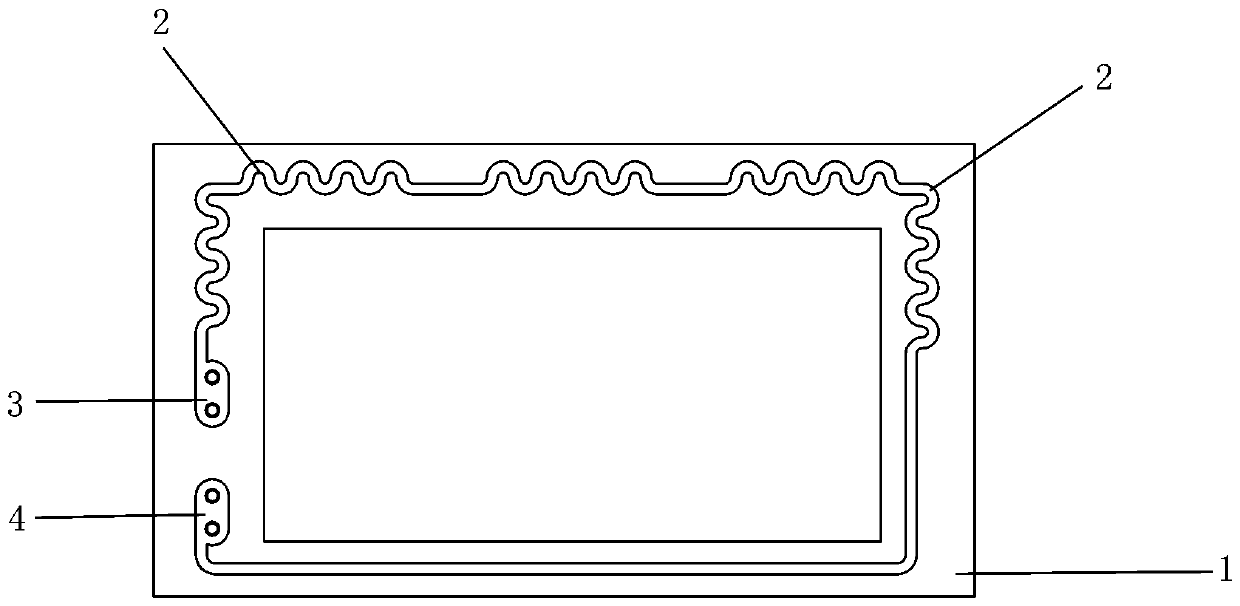

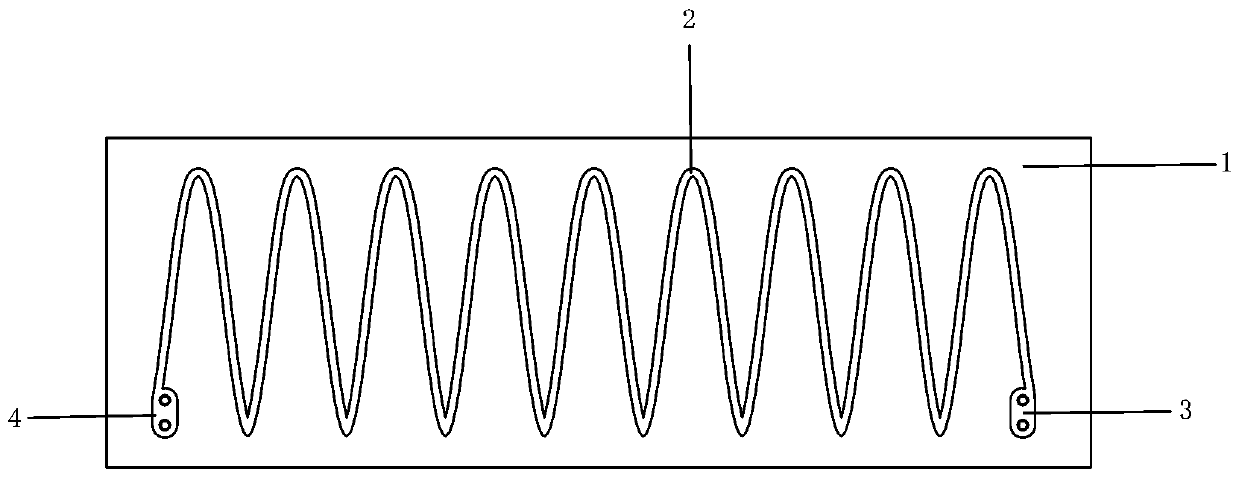

ActiveCN107148097ASimple structureImprove thermal efficiencyHeating element materialsPolyesterLength wave

The invention relates to the technical field of a heating thin film, particularly to a polyester thin film heating sheet. The polyester thin film heating sheet comprises a polyester thin film and a conductive heating layer; the conductive heating layer is electroplated on the polyester thin film; the conductive heating layer is a U-shaped circuit; and a positive electrode connecting point and a negative electrode connecting point are arranged at the two ends of the conductive heating layer respectively. The polyester thin film heating sheet is simple in structure, high in heat efficiency, high in flexibility, and can be applicable to a heating device with any concave and convex surfaces; in addition, the conductive heating layer of the heating sheet can be adjusted according to needs of different heating areas, and 2-13[mu]m far infrared wavelength is generated in operation, so that the heating sheet is beneficial for human health; and in addition, the polyester thin film heating sheet is light in weight, convenient to use and safe.

Owner:张威 +1

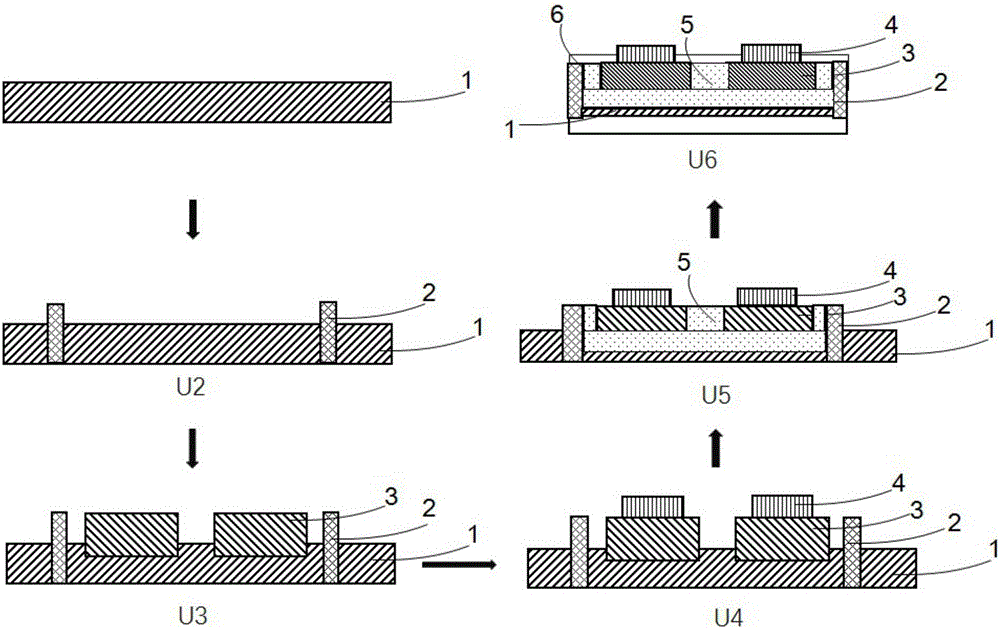

Surface-mounted super capacitor and preparation method thereof

ActiveCN106601498ALow costReduce pollutionHybrid cases/housings/encapsulationsHybrid/EDL manufactureScreen printingSurface mounting

The invention discloses a surface-mounted super capacitor and a preparation method thereof. The method comprises: S1, an active substance slurry is prepared; S2, high-temperature-resistant resin being resistant to the high temperature of over 260 DEG C is printed on a paper substrate in a silk-screen printing manner, the igh-temperature-resistant resin is infiltrated into the paper substrate to form a frame cofferdam, and then heating is carried out to solidify the high-temperature-resistant resin; S3, the active substance slurry obtained by the S1 is printed in the cofferdam obtained at the S2, drying is carried out after printing, and one pair of spaced electrodes is formed in the cofferdam; S4, current collectors being resistant to the high temperature of over 260 DEG C are prepared on one pair of electrodes obtained at the S3; S5, the cofferdam is filled with an electrolyte and thus the electrolyte at least fills the relative gap between the one pair of electrodes distributed in the cofferdam; and S6, device packaging is carried out to obtain a surface-mounted super capacitor. A super capacitor having a surface-mounted structure can be prepared; and the super capacitor has advantages of having low cost, being friendly to the environment, and being resistant to a reflow soldering impact.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Multilayer composite silk fiber fabric

The invention discloses a multilayer composite silk fiber fabric which comprises three fiber fabric layers, wherein the three fiber fabric layers are of meshed structures interwoven by warp yarns and weft yarns; the warp yarns of the first composite fiber fabric layer are made of bamboo fibers, and the weft yarns of the first composite fiber fabric layer are made of silk; the warp yarns of the second composite fiber fabric layer are made of tencel, and the weft yarns of the second composite fiber fabric layer are made of bamboo charcoal fibers; and the warp yarns of the third composite fiber fabric layer are made of milk fibers, and the weft yarns of the third composite fiber fabric layer are made of soybean fibers. The multilayer composite silk fiber fabric disclosed by the invention is compounded by three structure layers and has the characteristics of smoothness, breathability, lightness, softness, comfort, elasticity, fitness and skin beautification.

Owner:南安市荣兴专利技术转移中心有限公司

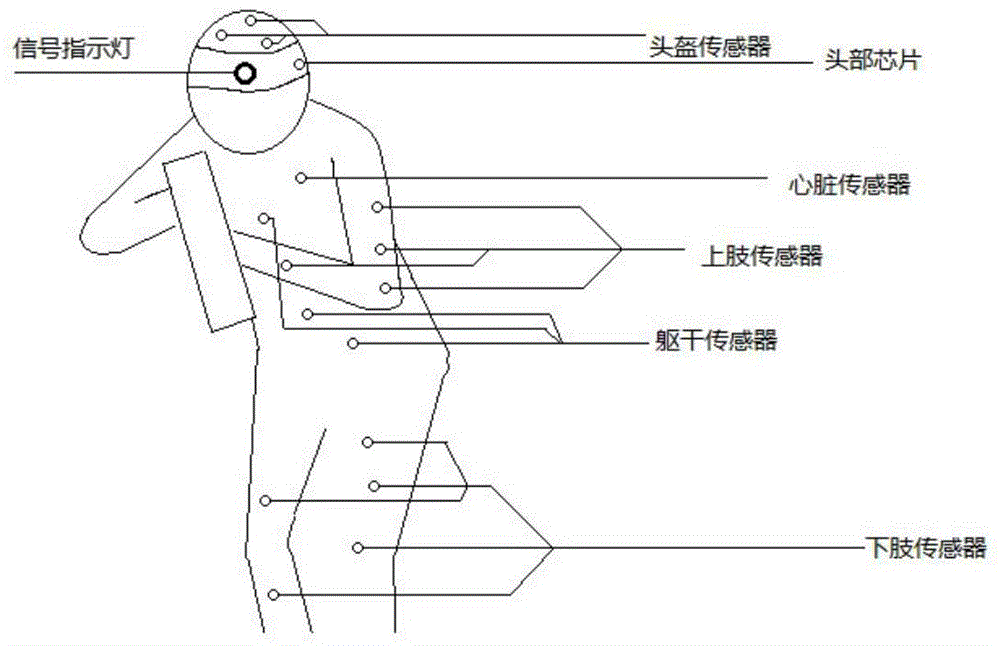

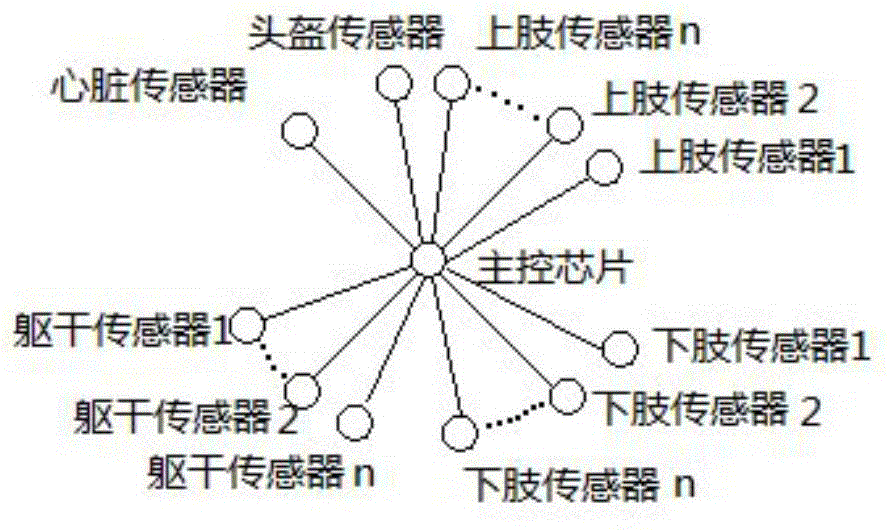

Intelligent CS (counter strike) game costume system

The invention relates to an intelligent CS (counter strike) game costume system. The intelligent CS game costume system comprises a helmet part, an upper limb part, a body part and a lower limb part. An indicator lamp used for indicating vital signs of a player is arranged on the outer side of the front of the helmet part, a master control chip is arranged on the rear inner side of the helmet part, seven flexible head sensors are arranged on the rear outer side of the helmet part, the left side and the right side are provided with one respectively, two are arranged in the front, two are arranged in the rear, and one is at the top. Six flexible upper limb sensors are distributed uniformly on the arms of the upper limb part, the front side and the rear side of a knee shank and the front side, the outer side and the rear side of thigh of the lower limb are provided with one flexible lower limb sensor respectively. Two flexible lower limb sensors are arranged on the butt of the lower limb part, a heart sensor is arranged at the heart position of the body part, the body part is provided with a flexible body sensor, and a master control chip is connected with the sensors by the wireless network. The intelligent CS game costume system is light and CS game is more real.

Owner:DONGHUA UNIV

Gliclazide oral instant membrane and preparation method thereof

InactiveCN107595821AFully swollenEasy to useMetabolism disorderSulfonylurea active ingredientsDrug release rateFiller Excipient

The invention belongs to the field of pharmaceutical preparations, and in particular relates to a prescription of a gliclazide oral instant membrane and a preparation method of the gliclazide oral instant membrane. The gliclazide oral instant membrane is prepared from the following components: gliclazide, a surface active agent, a film-forming material, a corrective, a plasticizer, and a necessaryand pharmaceutically acceptable filling agent; a coloring agent and the like also can be added into the gliclazide oral instant membrane according to the need. The gliclazide oral instant membrane prepared by the method can be rapidly dissolved in the oral cavity without needing drinking water, is rapid in drug release rate and better in taste, and can help to improve the medication compliance ofpatients, especially elderly patients. Furthermore, the product has the characteristics of being accurate in dose, quick in response and high in bioavailability.

Owner:HENAN TIANSHENG TAIFENG PHARM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com