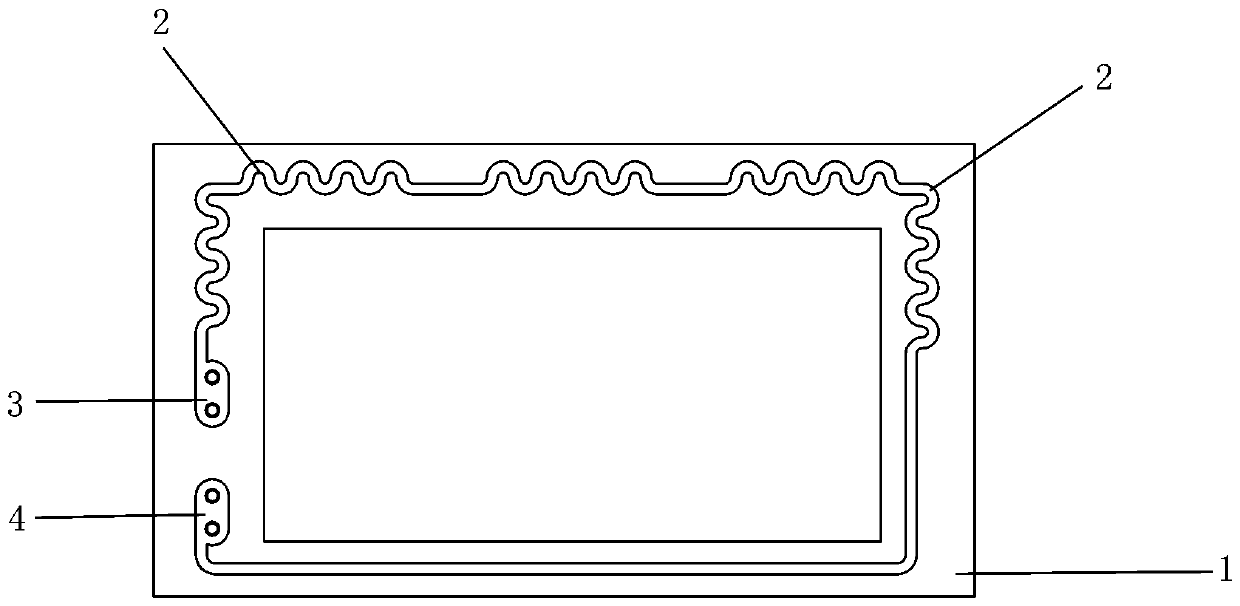

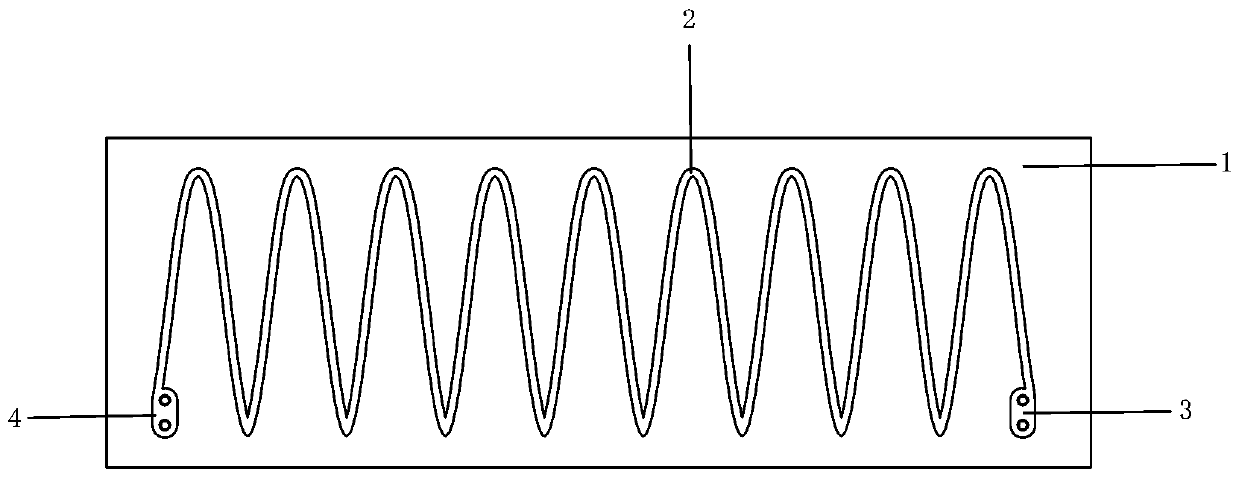

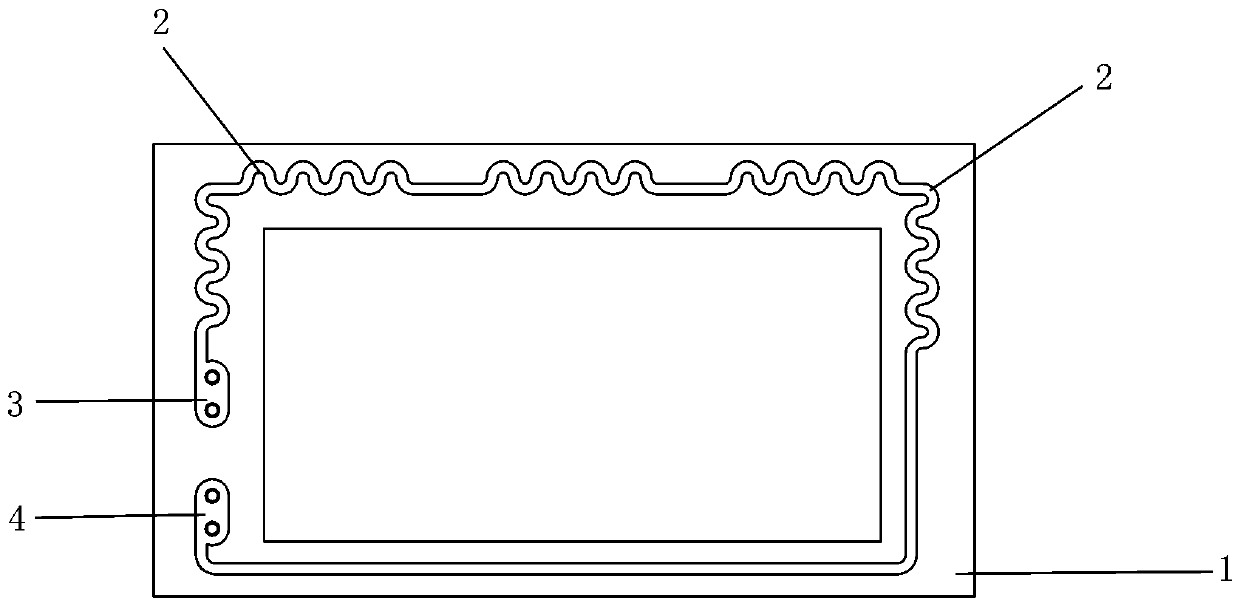

Polyester thin film heating sheet and preparation method therefor

A technology of polyester film and heating sheet is applied in the field of polyester film heating sheet and its preparation, which can solve the problems of short service life, inability to meet energy-saving thermal efficiency, uneven heating density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of polyester film heating sheet provided by the invention, its steps are as follows:

[0028] A. Prepare carbon slurry. The formula of carbon slurry includes the following mass parts and is composed as follows: 20 parts of carbon powder, 20 parts of graphite, 70 parts of organic vehicle, 10 parts of anti-aging agent, 5 parts of dispersant, 5 parts of accelerator, and the above composition Mix and add a water container to fully stir to make it mix, and the stirring time is 3-4 hours;

[0029] B. prepare silver paste, the formula of silver paste includes the composition of following mass ratio: 70 parts of silver powder, 70 parts of organic vehicle, 5 parts of accelerator, 5 parts of anti-aging agent, 5 parts of dispersant, mix above composition and pour into The water container is fully stirred to make it mix, and the stirring time is 4 hours;

[0030] C. Dry the fully stirred silver paste mixture and carbon paste mixture anaerobically, and ...

Embodiment 2

[0042] A kind of preparation method of polyester film heating sheet provided by the invention, its steps are as follows:

[0043] A. Prepare carbon slurry. The formula of carbon slurry includes the following mass parts and is composed as follows: 15 parts of carbon powder, 15 parts of graphite, 50 parts of organic vehicle, 5 parts of anti-aging agent, 1 part of dispersant, 1 part of accelerator, and the above components Mix and add a water container to fully stir to make it mix, and the stirring time is 4 hours;

[0044] B. Preparation of silver paste, the formula of silver paste includes the following mass parts and is composed as follows: 70 parts of silver powder, 70 parts of organic vehicle, 3 parts of accelerator, 3 parts of anti-aging agent, 3 parts of dispersant, mix the above components and pour them into water The container is fully stirred to make it mix, and the stirring time is 3 hours;

[0045] C. Dry the fully stirred silver paste mixture and carbon paste mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com