Polymer lithium ion battery and preparation method thereof

A lithium-ion battery and polymer technology, which is applied in the manufacture of electrolyte batteries, batteries, battery electrodes, etc., can solve the problems of fixed battery shape, increase battery thickness, and inability to design batteries, achieve good electrical conductivity, avoid internal short circuits, and prepare simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

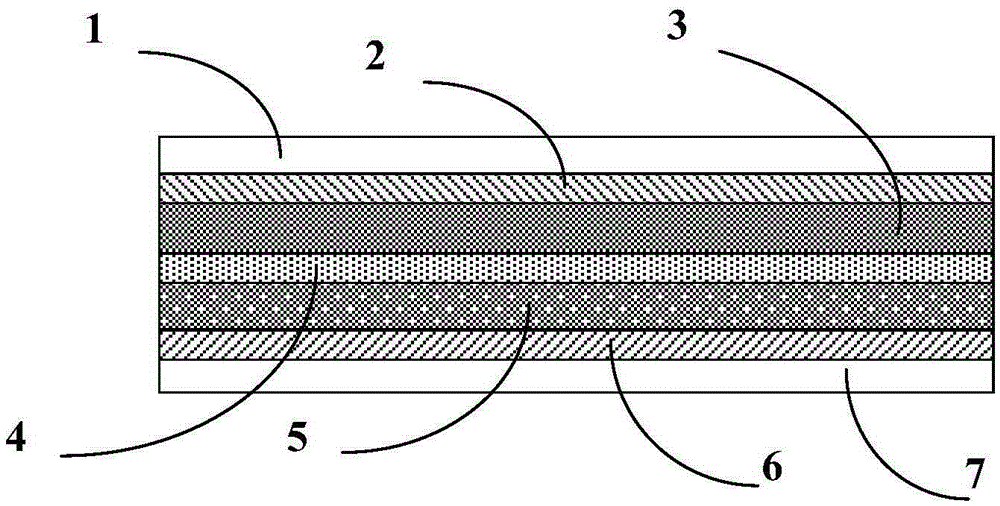

Image

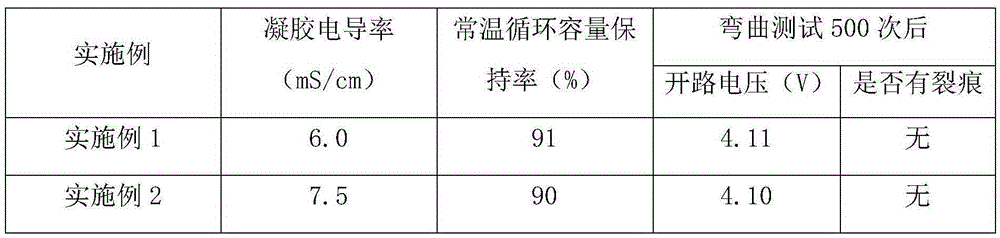

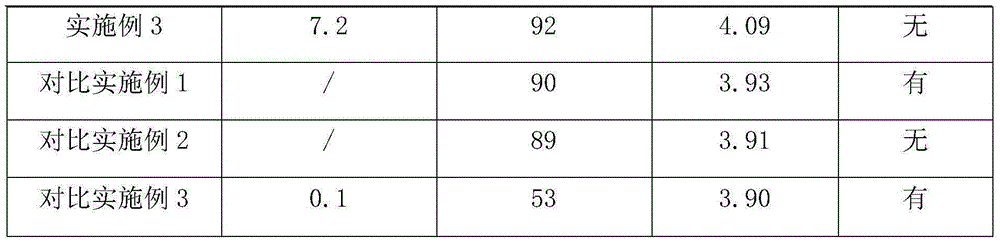

Examples

Embodiment 1

[0053] (1) Preparation of positive electrode layer

[0054] Polyester (PET) is selected as the base material, and the positive electrode current collector slurry formula is prepared according to the following mass ratio: carbon powder: polyvinylidene fluoride (PVDF) = 97:3, NMP is the solvent, the solid content is 50%, and the mixture is uniformly stirred at high speed , Vacuum or static degassing to make a slurry-like positive electrode current collector slurry, use a 230-mesh screen printing plate to print the current collector slurry on the PET substrate, and dry.

[0055] The positive electrode material slurry formula is prepared according to the following mass ratio: lithium cobaltate: PVDF: conductive carbon black (SP) = 94:3:3, NMP is the solvent, the solid content is 70%, high-speed stirring is uniform, vacuum or static degassing Finally, a paste-like positive electrode material slurry was prepared, and a 110-mesh screen printing plate was used to print the positive el...

Embodiment 2

[0064] (1) Preparation of positive electrode layer

[0065] Polypropylene (PP) is selected as the base material, and the positive electrode current collector slurry formula is prepared according to the following mass ratio: silver powder: polyvinylidene fluoride (PVDF) = 97:3, NMP is the solvent, the solid content is 65%, and the high-speed stirring is uniform, Vacuum or static degassing to make slurry-like positive electrode current collector slurry, use a 110-mesh screen printing plate to print the current collector slurry on the PP substrate, and dry.

[0066] The positive electrode material slurry formula is prepared according to the following mass ratio: lithium nickel cobalt aluminate: PVDF: conductive carbon black (SP) = 94:3:3, NMP is the solvent, the solid content is 70%, high-speed stirring is uniform, vacuum or standing After degassing, a slurry-like positive electrode material slurry was prepared, and a 110-mesh screen printing plate was used to print the positive ...

Embodiment 3

[0075] (1) Preparation of positive electrode layer

[0076] The aluminum-plastic composite film is selected as the base material, and the positive electrode current collector slurry formula is prepared according to the following mass ratio: graphene: polyvinylidene fluoride (PVDF) = 96:4, NMP is the solvent, the solid content is 55%, and the high-speed stirring is uniform, Vacuum or static degassing to make slurry positive electrode current collector slurry, use 230 mesh screen printing plate to print the current collector slurry on the aluminum-plastic composite film substrate, and dry.

[0077] The positive electrode material slurry formula is prepared according to the following mass ratio: nickel cobalt lithium manganate: PVDF: conductive carbon black (SP) = 94:3:3, NMP is the solvent, the solid content is 70%, high-speed stirring is uniform, vacuum or standing After degassing, a slurry-like positive electrode material slurry was prepared, and a 110-mesh screen printing pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com