Zero-waste garment adopting T-shaped plane structure

A technology of plane structure and clothing, applied in the field of clothing, can solve the problems of difficult to use, complex shape, garment production and high labor cost, and achieve the effect of zero waste, changeable shape, simple and convenient cutting and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

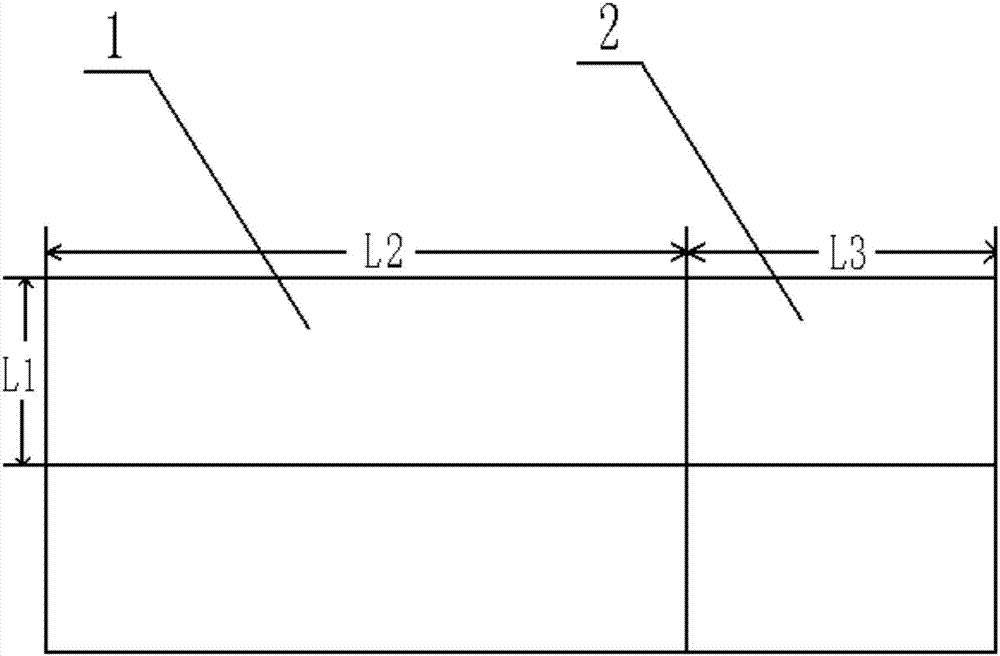

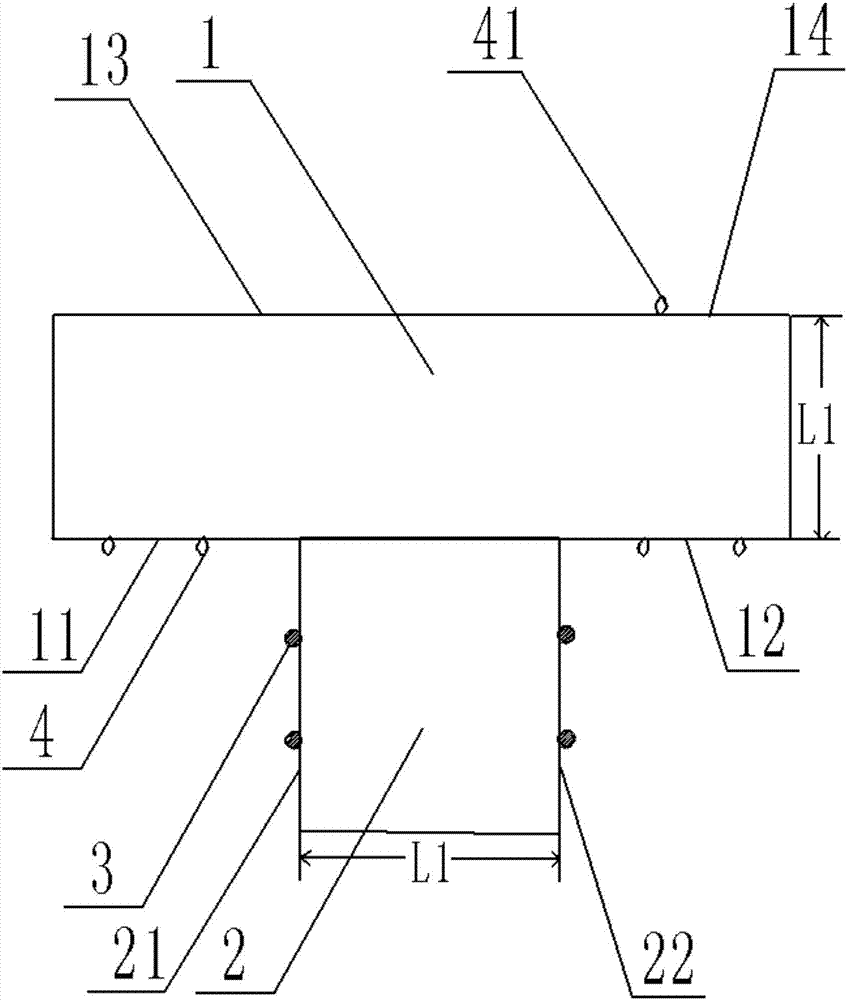

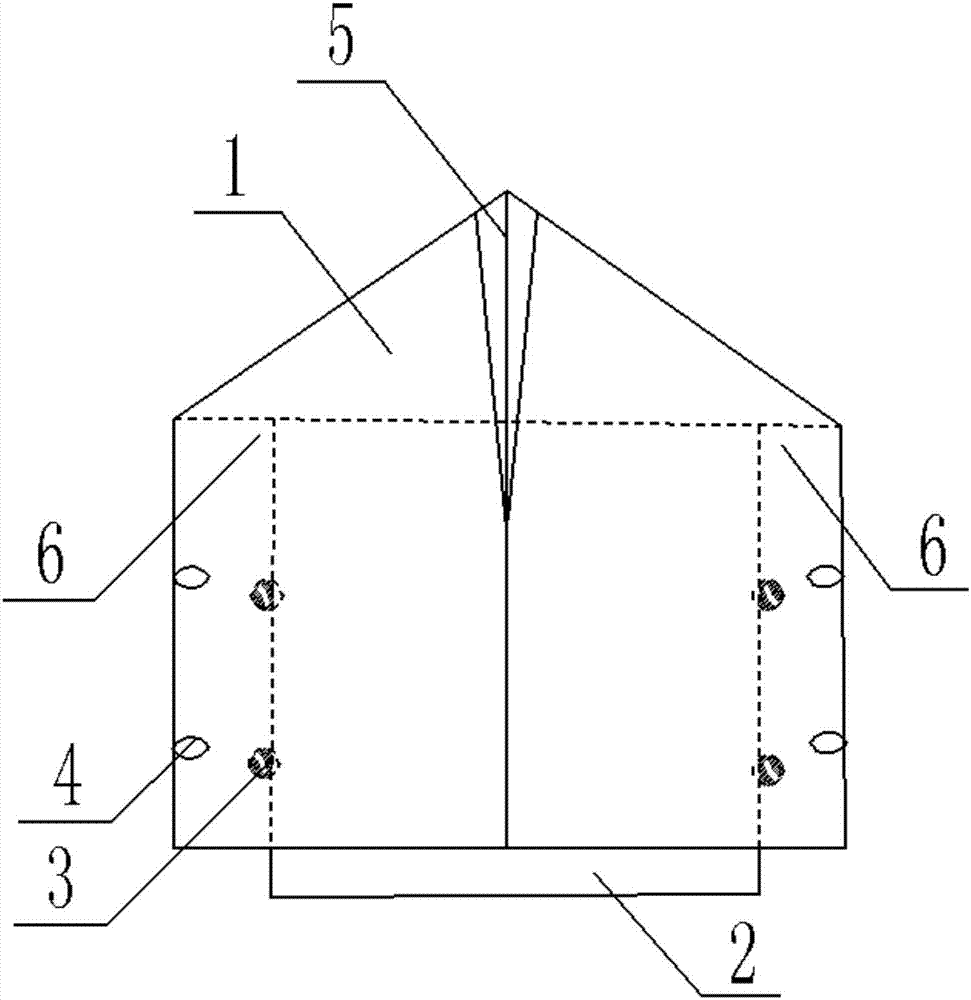

[0043] Present embodiment adopts the cloth of 1.2 meters wide, as figure 1 As shown, it is the layout diagram of this embodiment 1. The fabric width is 1.2 meters. Cut the fabric into two sections along the width direction according to the lengths of L2 and L3, and then cut the fabric evenly in the direction perpendicular to the width. , to obtain two sets of the first rectangular garment part 1 and the second rectangular garment part 2, each set of the first rectangular garment part and the second rectangular garment part can make a set of clothes of the present invention, in this embodiment, L1 is 0.6 m, L2 is 1 m, L3 is 0.7 m, such as figure 2 As shown, the narrow side of the second rectangular garment part 2 is sewn below the first rectangular garment part 1. In this embodiment, the length of the lower side of the first rectangular garment part 1 is L2, and the length of the first rectangular garment part 1 is The width is L1, the length of the upper side of the second r...

Embodiment 2

[0048] Present embodiment adopts the cloth of 1.5 meters wide, as Figure 5 As shown, it is the layout diagram of Example 2. The cloth is cut into two sections along the width direction according to the lengths of L2 and L3, and the cloth is evenly cut into three sections in the direction perpendicular to the width to obtain three sets of A rectangular garment part 1 and the second rectangular garment part 2, each set of the first rectangular garment part and the second rectangular garment part can make a set of clothes of the present invention, in the present embodiment, L1 is 0.5 meters, and L2 is 1 m, L3 is 0.5 m, such as Figure 6 As shown, the long side of the second rectangular garment part 2 is sewn below the first rectangular garment part 1. In this embodiment, the length of the lower side of the first rectangular garment part 1 is L2 and the width is L1. The length of the upper side of the garment part 2 is L3, the length of the left side and the right side is L1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com